Page 1

Open CNC

Basic Operation Package 1

Operator's Manual

B-62994EN/02

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

Warnings and notices for

GFLE-003

this publication

Warning

In this manual we have tried as much as possible to describe all the various

matters. However, we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this

manual should be regarded as “impossible”.

Notice

This document is based on information available at the time of its publication. While efforts have

been made to be accurate, the information contained herein does not purport to cover all details or

variations in hardware or software, nor to provide every contingency in connection with

installation, operation, or maintenance. Features may be described herein which are not present in

all hardware and software systems. FANUC CNC assumes no obligation of notice to

holders of this document with respect to changes subsequently made.

FANUC CNC makes no representation or warranty, expressed, implied, or statutory with

respect to, and assumes no responsibility for accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall

apply.

The following are Registered Trademarks of FANUC CNC

CIMPLICITY® Genius®

The following are Trademarks of FANUC CNC

Alarm Master

CIMSTAR

Field Control

Genet

Helpmate

LogicMaster

Modelmaster

PowerMotion

ProLoop

PROMACRO

Series Five

Series 90

Series One

Series Six

Series Three

VuMaster

Workmaster

© Copyright 1998 FANUC Ltd.

Authorized Reproduction FANUC CNC Europe S.A.

All Rights Reserved

No part of this manual may be reproduced in any form.

All specifications and designs are subject to change without notice.

Page 4

Page 5

SAFETY PRECAUTIONS

This manual includes safety precautions for protecting the user and preventing damage to

the machine. Precautions are classified into Warnings and Cautions according to their

bearing on safety. Also, supplementary information is described as Notes. Read the

Warnings, Cautions, and Notes thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there

is a danger of both the user being injured and the equipment being

damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

Notes is used to indicate supplementary information other than

Warnings and Cautions.

¡ Read this manual carefully, and store it in a safe place.

s-1

Page 6

SAFETY PRECAUTIONS B-62994EN/02

General Warnings and Cautions

WARNING

1. Never attempt to machine a workpiece without first checking the

operation of the machine. Before starting a production run, ensure

that the machine is operating correctly by performing a trial run

using, for example, the single block, feedrate override, or machine

lock function, or by operating the machine with neither a tool nor

workpiece mounted. Failure to confirm the correct operation of the

machine may result in the machine behaving unexpectedly,

possibly causing damage to the workpiece and/or machine itself,

or injury to the user.

2. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in

the machine behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

3. Ensure that the specified feedrate is appropriate for the intended

operation. Generally, for each machine, there is a maximum

allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the

machine to determine the maximum allowable feedrate. If a

machine is run at other than the correct speed, it may behave

unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

4. When using a tool compensation function, thoroughly check the

direction and amount of compensation.

Operating the machine with incorrectly specified data may result in

the machine behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

5. The parameters for the CNC and PMC are factory-set. Usually,

there is no need to change them. When, however, there is no

alternative other than to change a parameter, ensure that you fully

understand the function of the parameter before making any

change.

Failure to set a parameter correctly may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece

and/or machine itself, or injury to the user.

s-2

Page 7

B-62994EN/02 SAFETY PRECAUTIONS

CAUTION

1. The operator's manual for Basic Operation Package 1 describes all

the basic functions of the CNC unit, including the optional

functions. The selected optional functions vary with the machine.

Some functions described in the manual may not, therefore, be

supported by your machine. Check the machine specifications

before using Basic Operation Package 1.

2. Some machine operations and screen functions are implemented

by the machine tool builder. For an explanation of their usage and

related notes, refer to the manual provided by the machine tool

builder.

For example:

l On some machines, executing a tool function causes the tool

change unit to operate. When executing a tool function on such

a machine, stand well clear of the tool change unit. Otherwise,

there is a danger of injury to the operator.

l Many auxiliary functions trigger physical operations, such as

rotation of the spindle. Before attempting to use an auxiliary

function, therefore, ensure that you are fully aware of the

operation to be triggered by that function.

NOTE

l Command programs, parameters, and variables are stored in

nonvolatile memory in the CNC. Generally, the contents of memory

are not lost by a power on/off operation. However, the contents of

memory may be erased by mistake, or important data in nonvolatile

memory may have to be erased upon recovering from a failure.

To enable the restoration of data as soon as possible if such a

situation arises, always make a backup of the data in advance.

s-3

Page 8

SAFETY PRECAUTIONS B-62994EN/02

Warnings and Cautions Relating to Basic

Operation Package 1

Warnings and cautions relating to Basic Operation Package 1 are explained in

this manual. Before using the function, read this manual thoroughly to

become familiar with the provided Warnings, Cautions, and Notes.

On the next page, the points to be noted when Basic Operation Package 1 is

used are summarized. These points are not explained in Chapter 1 and the

subsequent chapters of this manual. Read this part before attempting to use

the function.

s-4

Page 9

B-62994EN/02 SAFETY PRECAUTIONS

Important Notice

The following summarizes the points to be noted when Basic Operation

Package 1 is used. Before attempting to use Basic Operation Package 1, read

the following:

CAUTION

l This manual does not explain in detail those operations and

parameters that vary from one CNC model to another and which vary

with options. For an explanation of such operations and parameters,

refer to the relevant CNC manual and the manual supplied by the

machine tool builder.

l This manual describes as many reasonable variations in usage as

possible. It cannot address every combination of features, options,

and commands that should not be attempted. If a particular

combination of operations is not described, it should not be

attempted.

s-5

Page 10

B-62994EN/02

CONTENTS

SAFETY PRECAUTIONS......................................................................................................................... s-1

General Warnings and Cautions

Warnings and Cautions Relating to Basic Operation Package 1

Important Notice

PREFACE...............................................................................................................................................................p-1

Basic Operation Package 1 Features and Restrictions

Contents of the Product Package

Organization of This Manual

Notation Conventions

CONTENTS...........................................................................................................................................................c-1

1. SETUP................................................................................................................................................................. 1

1.1 Operating Environment..........................................................................................................................2

1.2 Installing Basic Operation Package 1 .................................................................................................. 4

1.3 Uninstalling Basic Operation Package 1.............................................................................................7

2. BASIC KNOWLEDGE.......................................................................................................................... 9

2.1 Starting and Terminating Basic Operation Package 1.....................................................................10

2.1.1 Starting Basic Operation Package 1...............................................................................................10

2.1.2 Terminating Basic Operation Package 1........................................................................................11

2.2 Window Names and Functions...........................................................................................................13

2.3 Selecting and Positioning Windows...................................................................................................21

2.3.1 Selecting a window........................................................................................................................21

2.3.2 Positioning a window.....................................................................................................................22

2.4 Selecting a Path..................................................................................................................................... 24

2.5 Displaying Version Information......................................................................................................... 25

3. SETTING THE PARAMETERS REQUIRED

TO USE BASIC OPERATION PACKAGE 1......................................................................26

3.1 Setting the CNC Parameters................................................................................................................27

3.2 Specifying a Node................................................................................................................................. 29

4. POSITION DISPLAY............................................................................................................................30

4.1 Overall Position Display......................................................................................................................31

4.2 Displaying the Relative Position ........................................................................................................ 33

4.2.1 Resetting relative coordinates........................................................................................................35

4.2.2 Presetting relative coordinates.......................................................................................................36

c-1

Page 11

CONTENTS B-62994EN/02

4.2.3 Setting the machine position to the floating reference position......................................................38

4.2.4 Presetting the workpiece coordinate system...................................................................................39

4.3 Displaying the Absolute Position.......................................................................................................42

4.4 Displaying the Machine Position........................................................................................................ 44

4.5 Displaying the Distance to Go............................................................................................................45

4.6 Displaying the Amount of Handle Interruption................................................................................ 46

4.6.1 Canceling the amount of handle interruption.................................................................................47

4.7 Displaying the Operating Monitor......................................................................................................49

4.8 Displaying the Machining Time and Machined Parts Count ......................................................... 50

5. NC PROGRAM..........................................................................................................................................52

5.1 Editing a NC Program.......................................................................................................................... 53

5.1.1 Getting a program from the NC ..................................................................................................... 56

5.1.2 Writing a NC program back to the NC .......................................................................................... 58

5.1.3 Inserting a NC program from a disk............................................................................................... 59

5.1.4 Writing a NC program to a disk.....................................................................................................60

5.1.5 Finding a character string in a NC program................................................................................... 61

5.1.6 Replacing a character string in a NC program ............................................................................... 62

5.1.7 Selecting character strings in a NC program..................................................................................63

5.1.8 Cutting character strings from a NC program................................................................................64

5.1.9 Copying character strings from a NC program .............................................................................. 66

5.1.10 Pasting character strings into a NC program..................................................................................67

5.1.11 Inserting sequence numbers into a NC program ............................................................................ 68

5.1.12 Entering a coordinate value into a NC program.............................................................................71

5.1.13 Displaying the top of a NC program.............................................................................................. 73

5.1.14 Displaying the end of a NC program..............................................................................................74

5.1.15 Stamping the machining time.........................................................................................................75

5.2 Editing an MDI Program......................................................................................................................77

5.2.1 Finding a character string in an MDI program...............................................................................79

5.2.2 Replacing a character string in an MDI program........................................................................... 80

5.2.3 Selecting character strings in an MDI program.............................................................................. 81

5.2.4 Cutting character strings from an MDI program............................................................................ 82

5.2.5 Copying character strings from an MDI program..........................................................................84

5.2.6 Pasting character strings into an MDI program.............................................................................. 85

5.2.7 Inserting sequence numbers into an MDI program........................................................................86

5.2.8 Displaying the top of an MDI program..........................................................................................88

5.2.9 Displaying the end of an MDI program ......................................................................................... 89

5.3 Displaying the NC Program Directory...............................................................................................90

5.3.1 Copying a NC program.................................................................................................................. 92

5.3.2 Deleting a NC program.................................................................................................................. 94

5.3.3 Selecting a NC program to be executed......................................................................................... 95

5.3.4 Changing a NC program comment................................................................................................. 97

5.3.5 Changing the NC program directory contents................................................................................98

c-2

Page 12

B-62994EN/02 CONTENTS

5.4 Checking the Program Currently Being Executed.........................................................................100

5.4.1 Rewinding the tape to the beginning of the NC program............................................................. 101

5.4.2 Searching for a sequence number.................................................................................................103

5.5 Displaying the Current and Next Blocks of the NC Program Being Executed ......................... 105

5.6 Restarting a NC Program................................................................................................................... 106

5.6.1 Setting the axis order of movement to the program restart position............................................. 108

5.6.2 Searching for a sequence/block number....................................................................................... 109

5.7 Displaying the Machining Times......................................................................................................112

5.8 Displaying the B-Axis Operating Status..........................................................................................114

6. SETTING...................................................................................................................................................... 116

6.1 Setting Data..........................................................................................................................................117

6.2 Operating Time, Parts Count, and Timer Settings......................................................................... 121

6.3 Tool Offset Settings............................................................................................................................ 124

6.3.1 Entering a relative coordinate value as the tool offset data..........................................................127

6.3.2 Entering a measured value as the tool offset data ........................................................................ 129

6.3.3 Clearing all tool offset data..........................................................................................................130

6.4 Custom Macro Variable Settings...................................................................................................... 132

6.4.1 Displaying local variables............................................................................................................134

6.4.2 Common variable 1 settings.........................................................................................................136

6.4.3 Common variable 2 settings.........................................................................................................137

6.4.4 Entering a relative coordinate value as a macro variable............................................................. 139

6.4.5 Clearing all custom macro variables............................................................................................140

6.4.6 Setting a blank in a macro variable.............................................................................................. 142

6.5 Workpiece Origin Offset Settings....................................................................................................143

6.5.1 Entering a measured value as workpiece origin offset data..........................................................145

6.6 Tool Life Management Data Settings.............................................................................................. 147

6.6.1 Adding a tool to a tool group included in the tool life management data..................................... 151

6.6.2 Changing the life status of a tool included in the tool life management data

(for machining center systems) .................................................................................................... 154

6.6.3 Changing the life status of a tool included in the tool life management data

(for lathe systems)........................................................................................................................157

6.6.4 Setting the life counter data included in the tool life management data

(for machining center systems) .................................................................................................... 159

6.6.5 Setting the life counter data included in the tool life management data (for lathe systems)......... 161

6.6.6 Deleting a tool from a tool group included in the tool life management data

(for machining center systems) .................................................................................................... 163

6.6.7 Deleting a tool from a tool group included in the tool life management data

(for lathe systems)........................................................................................................................165

6.7 Software Operator's Panel Settings..................................................................................................167

6.8 Workpiece Coordinate System Shift Settings................................................................................. 169

6.9 P-Code Macro Variable Settings......................................................................................................172

6.9.1 Displaying local variables............................................................................................................174

6.9.2 Common variable 1 settings.........................................................................................................175

c-3

Page 13

CONTENTS B-62994EN/02

6.9.3 Common variable 2 settings.........................................................................................................176

6.9.4 P-code variable 1 settings ............................................................................................................ 177

6.9.5 P-code variable 2 settings ............................................................................................................ 178

6.9.6 Setting a blank in a P-code macro variable.................................................................................. 179

6.10 Chopping Data Settings ..................................................................................................................... 180

6.11 Chuck and Tailstock Barrier Settings ..............................................................................................182

6.12 B-Axis Tool Offset Settings..............................................................................................................186

6.13 Tool Post Interference Check Settings.............................................................................................189

6.14 2-Path Interference Check Settings .................................................................................................. 192

7. SYSTEM........................................................................................................................................................ 195

7.1 Setting Parameters .............................................................................................................................. 196

7.2 Displaying the Diagnosis Screen...................................................................................................... 198

7.3 Displaying the System Configuration.............................................................................................. 200

7.3.1 Outputting the system configuration data to a file........................................................................201

7.4 Data Input/Output ............................................................................................................................... 203

7.4.1 Setting parameters for input/output..............................................................................................204

7.4.2 Displaying lists of various data files ............................................................................................ 208

7.4.3 Entering different types of data....................................................................................................210

7.4.4 Outputting different types of data ................................................................................................ 220

7.4.5 Deleting data files........................................................................................................................229

7.4.6 Renaming different types of data files..........................................................................................231

7.5 Setting Pitch Error Compensation Data........................................................................................... 233

7.6 Setting Servo Setting Data................................................................................................................. 235

7.7 Setting Servo Tuning Data ................................................................................................................237

7.8 Setting Spindle Setting Data .............................................................................................................239

7.9 Setting Spindle Tuning Data.............................................................................................................241

7.10 Collecting Waveform Diagnosis Data .............................................................................................243

7.10.1 Setting data for waveform diagnosis............................................................................................ 245

7.10.2 Collecting waveform diagnosis sampling data............................................................................. 250

7.11 Displaying Waveform Diagnosis Graphs........................................................................................252

7.11.1 Selecting the waveform diagnosis data to be displayed ............................................................... 257

7.11.2 Saving waveform diagnosis data into a file.................................................................................. 259

7.12 Displaying the PMC Status Screen .................................................................................................. 260

7.13 Displaying the PMC Alarm Screen.................................................................................................. 262

7.14 Setting the PMC Counter................................................................................................................... 263

7.15 Setting the PMC Timer ......................................................................................................................265

7.16 Setting the PMC Keep Relay ............................................................................................................ 267

7.17 Setting PMC Data ............................................................................................................................... 269

7.17.1 Setting the data table of PMC data............................................................................................... 271

7.17.2 Setting the group data of PMC data............................................................................................. 273

7.17.3 Deleting and initializing all PMC data.........................................................................................278

7.18 Displaying the Operation History..................................................................................................... 280

7.18.1 Clearing the operation history information .................................................................................. 282

c-4

Page 14

B-62994EN/02 CONTENTS

7.18.2 Setting I/O signals for the operation history.................................................................................284

8. MESSAGES................................................................................................................................................286

8.1 Displaying Alarm Messages.............................................................................................................. 287

8.2 Displaying Operator Messages......................................................................................................... 288

8.3 Displaying the Alarm Message History........................................................................................... 289

8.3.1 Deleting the entire alarm message history.................................................................................... 290

9. MILLING ANIMATION FUNCTION (OPTION)........................................................ 292

9.1 Setting Tools for Machining-in-Progress Drawing........................................................................ 293

9.1.1 Registering tools for machining-in-progress drawing .................................................................. 294

9.1.2 Modifying tool data for machining-in-progress drawing..............................................................296

9.1.3 Deleting tools for machining-in-progress drawing.......................................................................297

9.1.4 Saving tool data for machining-in-progress drawing into a file ................................................... 299

9.1.5 Reading tool data for machining-in-progress drawing from a file................................................300

9.2 Performing Machining-in-Progress Drawing.................................................................................. 302

9.2.1 Settings for machining-in-progress drawing ................................................................................303

9.2.2 Starting machining-in-progress drawing ...................................................................................... 310

10. CUSTOM...................................................................................................................................................... 313

10.1 Displaying the OLE Object Screen .................................................................................................. 314

10.1.1 Example for inserting an OLE object........................................................................................... 316

11. CUSTOMIZATION.............................................................................................................................. 322

11.1 Customizing General Settings for Basic Operation Package 1 .................................................... 323

11.1.1 Setting general options for Basic Operation Package 1 ............................................................... 325

11.1.2 Setting soft keys........................................................................................................................... 327

11.1.3 Setting screen colors....................................................................................................................330

11.1.4 Setting the path number output option.........................................................................................332

11.2 Customizing Screens ..........................................................................................................................333

11.2.1 Creating custom screens............................................................................................................... 334

11.2.2 Changing the order in which screens appear................................................................................341

11.2.3 Deleting screens........................................................................................................................... 342

11.2.4 Showing or hiding chapters.......................................................................................................... 343

11.2.5 Setting soft keys as empty............................................................................................................345

11.3 Customizing Screen Objects ............................................................................................................. 347

11.3.1 Creating custom screen objects....................................................................................................349

11.3.2 Changing settings of screen objects ............................................................................................. 355

11.3.3 Deleting screen objects................................................................................................................356

11.4 Customizing Message Languages.....................................................................................................358

11.4.1 Installing message languages ....................................................................................................... 359

11.4.2 Switching the message language.................................................................................................. 360

11.4.3 Changing the order in which message languages are listed.......................................................... 362

c-5

Page 15

CONTENTS B-62994EN/02

11.4.4 Uninstalling message languages................................................................................................... 363

11.5 Customizing Alarm Messages...........................................................................................................364

11.6 Integrating DNC Operation Management Package........................................................................367

APPENDIX 1 REQUIRED NC SETTING FOR EACH BASIC OPERATION

PACKAGE 1 SCREEN.............................................................................................. 371

APPENDIX 2 BACKING UP THE SETTING FILE...........................................................419

APPENDIX 3 CREATING AN ActiveX CONTROL........................................................... 420

APPENDIX 4 SWITCHING THE MESSAGE LANGUAGE........................................430

APPENDIX 5 MESSAGE FILE GENERATOR...................................................................... 434

c-6

Page 16

B-62994EN/02 PREFACE

PREFACE

Thank you for purchasing the FANUC Basic Operation Package 1.

FANUC Basic Operation Package 1 (called Basic Operation Package 1

hereinafter) allows the user to perform basic CNC and PMC operations in an

Open CNC environment.

Basic Operation Package 1 is supported by Microsoft Windows. This

manual does not explain the basic common operations of Windows.

Users who are using Windows for the first time should read the manuals on

Windows first to become familiar with the basic operation of Windows.

Read this manual thoroughly to ensure the correct use of Basic Operation

Package 1.

NOTE

The purchased software product can be copied within the plant, as

required. The machine tool builder should ship machines together with

a backup copy of the software product.

FANUC holds the copyright on this software product. Redistributing the

entire software product, or part of it, to a third party to develop an

application is not allowed.

Microsoft, Windows, and Visual Basic are registered trademarks of

Microsoft Corporation. ActiveX and OLE are trademarks of

Microsoft Corporation.

Basic Operation Package 1 Features and Restrictions

Basic Operation Package 1 has the following features:

Features

l Implements the basic CNC and PMC operations under Windows, thus

providing a more user-friendly operating environment.

l Offers operability such that current users of FANUC CNCs can quickly

become familiar with the system.

l Allows customization to improve operability, such as modifying the

screen settings or adding or deleting a screen.

p-1

Page 17

PREFACE B-62994EN/02

l Provides each screen as an ActiveX component, such that it can be

embedded into a program developed with Visual Basic 4.0/5.0.

The following restrictions are imposed on Basic Operation Package 1:

Restrictions

l This software is designed to be used with a personal computer connected

to High Speed Serial Bus Type 2, the FS160i/180i/210i having personal

computer functions, a personal computer in which the NC Board has

been installed, or Intelligent Terminal Type 2. It cannot be used with the

MMC-IV, a personal computer connected to High Speed Serial Bus Type

1, or Intelligent Terminal Type 1.

l This software supports the following CNCs:

FS150-MB/TB/TTB (systems having up to 15 axes)

FS160-MB/TB/MMB/TTB, FS180-MB/TB/TTB, FS210-MB/TB

FS160-MC/TC/MMC/TTC, FS180-MC/TC/TTC

FS160i-MA/TA, FS180i-MA/TA, FS210i-MA/TA

Power Mate-D/H, Power Mate i-D/H

•• Following CNCs connected to a commercial personal computer via

High Speed Serial Bus Type 2

FS15-MB/TB/TTB (systems having up to 15 axes)

FS16-MB/TB/MMB/TTB, FS18-MB/TB/TTB, FS21-MB/TB

FS16-MC/TC/MMC/TTC, FS18-MC/TC/TTC

FS16i-MA/TA, FS18i-MA/TA, FS21i-MA/TA

Power Mate-D/H, Power Mate i-D/H

•• FA160i-MA/TA, FS180i-MA/TA, and FS210i-MA/TA having

personal computer functions

•• NC Board M/T

l This software cannot be used to develop or debug ladder programs. To

develop or debug ladder programs, obtain the following options:

•• When using a CNC other than the Power Mate-D/H: Ladder Editing

Package

•• When using the Power Mate-D/H: FAPT LADDER II

p-2

Page 18

B-62994EN/02 PREFACE

Contents of the Product Package

This product package consists of the following:

lFloppy disks

FANUC Basic Operation Package 1 (A02B-0207-K750#ZZ07)

NOTE

Read the Release Note (README.TXT), provided on the first floppy

disk of the product package. It provides detailed information on this

product package and information not described in the operator's

manual.

Organization of This Manual

This manual is organized as follows:

SAFETY PRECAUTIONS

Explains the general precautions which must be observed to ensure safety

when using Basic Operation Package 1.

PREFACE

Briefly explains the features of Basic Operation Package 1. Also explains

how to use information on the usage of Basic Operation Package 1,

including this manual.

1. SETUP

Explains how to set up the environment for using Basic Operation

Package 1 and how to prepare Basic Operation Package 1 for use.

2. BASIC KNOWLEDGE

Provides basic information with which the user should be familiar before

attempting to use Basic Operation Package 1.

3. SETTING THE PARAMETERS REQUIRED TO USE BASIC OPERATION

PACKAGE 1

Explains how to set the parameters required to display the screens of

Basic Operation Package 1.

4. POSITION DISPLAY

Explains how to display positions, such as the current position, for the

program that is currently being executed.

5. NC PROGRAM

Explains how to display, edit, and check NC programs.

6. SETTING

Explains how to set data.

p-3

Page 19

PREFACE B-62994EN/02

7. SYSTEM

Explains how to display and set system-related information, and how to

input and output different types of data.

8. MESSAGES

Explains how to display alarms and other messages.

9. MILLING ANIMATION FUNCTION (OPTION)

Explains how to perform machining-in-progress drawing when a milling

machine tool is used.

10.CUSTOM

Explains how to insert an OLE object.

11.CUSTOMIZATION

Explains how to customize Basic Operation Package 1.

APPENDIX

Provides supplementary information to be read as required, such as how

to back up the setting file.

Notation Conventions

The following explains the notation conventions used in this manual:

lMenu, command, and screen notations

Example Explanation

[File] menu Menu names are enclosed in brackets [ ].

[Setting...] Command names are enclosed in brackets [ ].

[Program Edit] screen Screen names (displayed on the title bars) are

<OK> button Command buttons on the display are enclosed

lKey notations and operation

Example Explanation

[Enter] key Key names are enclosed in brackets [ ].

[Ctrl]+[Tab] keys When keys are to be pressed and held down

Direction keys The [→], [←], [↑], and [↓] keys are

enclosed in brackets [ ].

in angle brackets < >.

sequentially, the keys are indicated by

connecting them with +, as shown on the left.

collectively called the direction keys.

p-4

Page 20

B-62994EN/02 PREFACE

lMouse operations

Example Explanation

Click Press a mouse button, then release it

immediately.

Double-click Click a mouse button twice in quick

succession.

Drag Move the mouse while holding down a mouse

button, then release the button at a desired

location.

lFolders

This manual refers to directories and folders collectively as folders.

lSample screens

The screens shown in this manual are examples of the standard system

supplied by FANUC. Note that the screen layouts and displayed file names

may vary with the equipment being used and according to customization.

Soft keys or screens are not displayed if the equipment being used does not

support the corresponding functions (for example, some functions are

supported only by machining center systems) or if the CNC options for the

corresponding functions are not installed.

lCNC units

Unless otherwise specified, FS16/18/21 refers to the FS16/18/21MB/TB/MMB/TTB, FS16/18-MC/TC/MMC/TTC, FS160/180/210MB/TB/MMB/TTB, FS160/180-MC/TC/MMC/TTC, FS16i/18i/21i-

MA/TA, and FS160i/180i/210i-MA/TA. FS15 also refers to the FS15MB/TB/TTB and FS150-MB/TB/TTB, while Power Mate refers to the

Power Mate-D/H and Power Mate i-D/H.

p-5

Page 21

B-62994EN/02 1. SETUP

1 SETUP

This chapter explains how to set up the environment for operating Basic

Operation Package 1 and how to prepare Basic Operation Package 1 for use.

-1-

Page 22

1. SETUP B-62994EN/02

1.1 Operating Environment

The software operating environment for Basic Operation Package 1 is

described below.

u Computer

A personal computer connected to High Speed Serial Bus Type 2, the

FS160i/180i/210i having personal computer functions, a personal computer

in which the NC Board has been installed, or Intelligent Terminal Type 2

l Environmental requirements

Windows 95/Windows 98

WIN32 version

• Pentium processor with clock frequency of 75 MHz or higher

• At least 16MB of memory

WIN16 version

• i486DX2 or better CPU with clock frequency of 50 MHz or higher

• At least 12MB of memory

Windows NT 4.0

WIN32 version

• Pentium processor with clock frequency of 120 MHz or higher

• At least 32MB of memory

WIN16 version

Not supported

Windows 3.1

WIN32 version

Not supported

WIN16 version

• i486DX2 or better CPU with clock frequency of 50 MHz or higher

• At least 20MB of memory

l Recommended operating environment

Windows 95/Windows 98

WIN32 version

• Pentium processor with clock frequency of 120 MHz or higher

• At least 32MB of memory

WIN16 version

• i486DX2 or better CPU with clock frequency of 75 MHz or higher

• At least 24MB of memory

-2-

Page 23

B-62994EN/02 1. SETUP

Windows NT 4.0

WIN32 version

• Pentium processor with clock frequency of 150 MHz or higher

• At least 64MB of memory

WIN16 version

Not supported

Windows 3.1

WIN32 version

Not supported

WIN16 version

• i486DX2 or better CPU with clock frequency of 75 MHz or higher

• At least 24MB of memory

l Required free space on hard disk

At least 20MB

NOTE

FANUC recommends that Basic Operation Package 1 be operated

under Windows 95/Windows 98 or Windows NT 4.0.

-3-

Page 24

1. SETUP B-62994EN/02

1.2 Installing Basic Operation Package 1

This section describes how to install Basic Operation Package 1.

NOTE

Before Basic Operation Package 1 can be installed, operations such as

driver installation and setting must be performed according to the

operating environment. For details, refer to the following documents:

l Personal computer connected to High Speed Serial Bus Type 2, the

FS160i/180i/210i having personal computer functions, or Intelligent

Terminal Type 2

•• Release Note (README.TXT) on the driver library floppy disk

(A02B-0207-K730#ZZ07-1)

or

•• Release Note (README.TXT) on the driver disk (A02B-0207K791#ZZ07-1)

l NC Board

•• Lathe system

Release Note (README.TXT) on Disk 1 of the setup disks (A02B0234-H500)

•• Machining center system

Release Note (README.TXT) on Disk 1 of the setup disks (A02B0235-H500)

Procedure

ll WIN32 version

•• Installing Basic Operation Package 1

1. Insert the disk (A02B-0207-K750#ZZ07-2) into the floppy disk

drive.

2. Click the [Start] button.

3. Select [Run].

4. Enter <drive-name>:SETUP, then click the <OK> button. (<drive-

name> is the name of the 3.5-inch floppy disk drive.)

5. Perform installation according to the displayed messages.

6. Upon the completion of installation, restart the personal computer.

The setup program of Basic Operation Package 1 installs the English

version by default. To display non-English messages (Japanese,

German, French, Italian, or Spanish), subsequently install the nonEnglish message environment, as follows.

-4-

Page 25

B-62994EN/02 1. SETUP

NOTE

Before installing the Japanese message environment, start and

terminate Basic Operation Package 1 at least once. For an

explanation of how to start and terminate Basic Operation

Package 1, see Section 2.1, "Starting and Terminating Basic

Operation Package 1."

Non-English messages can be displayed only under Windows of

the target language version. For example, Japanese messages

can be displayed only under Japanese Windows and German

messages can be displayed only under German Windows.

•• Installing the non-English message environment

1. Insert the disk (A02B-0207-K750#ZZ07-5) into the floppy disk

drive.

2. Click the [Start] button.

3. Select [Run].

4. Enter the data corresponding tohe target language as listed below,

then click the <OK> button.

Japanese <drive-name> : \JPN\ADDLANG

German <drive-name> : \GER\ADDLANG

French <drive-name> : \FRE\ADDLANG

Italian <drive-name> : \ITA\ADDLANG

Spanish <drive-name> : \SPA\ADDLANG

<drive-name> is the name of the 3.5-inch floppy disk drive.

5. Perform installation according to the displayed messages.

ll WIN16 version

•• Installing Basic Operation Package 1

1. Insert the disk (A02B-0207-K750#ZZ07-8) into the floppy disk

drive.

2. Click the [Start] button.

(For Windows 3.1, select [File].)

3. Select [Run].

4. Enter <drive-name>:SETUP, then click the <OK> button. (<drive-

name> is the name of the 3.5-inch floppy disk drive.)

5. Perform installation according to the displayed messages.

6. Upon the completion of installation, restart the personal computer.

The setup program of Basic Operation Package 1 installs the English

version by default. To display non-English messages (Japanese,

German, French, Italian, or Spanish), subsequently install the nonEnglish message environment, as follows.

-5-

Page 26

1. SETUP B-62994EN/02

NOTE

Before installing the non-English message environment, start

and terminate Basic Operation Package 1 at least once. For an

explanation of how to start and terminate Basic Operation

Package 1, see Section 2.1, "Starting and Terminating Basic

Operation Package 1."

•• Installing the non-English message environment

1. Insert the disk (A02B-0207-K750#ZZ07-9) into the floppy disk

drive.

2. Click the [Start] button.

(For Windows 3.1, select [File].)

3. Select [Run].

4. Enter the data corresponding to the target language as listed below,

then click the <OK> button.

Japanese <drive-name> : \JPN\ADDLANG

German <drive-name> : \GER\ADDLANG

French <drive-name> : \FRE\ADDLANG

Italian <drive-name> : \ITA\ADDLANG

Spanish <drive-name> : \SPA\ADDLANG

<drive-name> is the name of the 3.5-inch floppy disk drive.

5. Perform installation according to the displayed messages.

-6-

Page 27

B-62994EN/02 1. SETUP

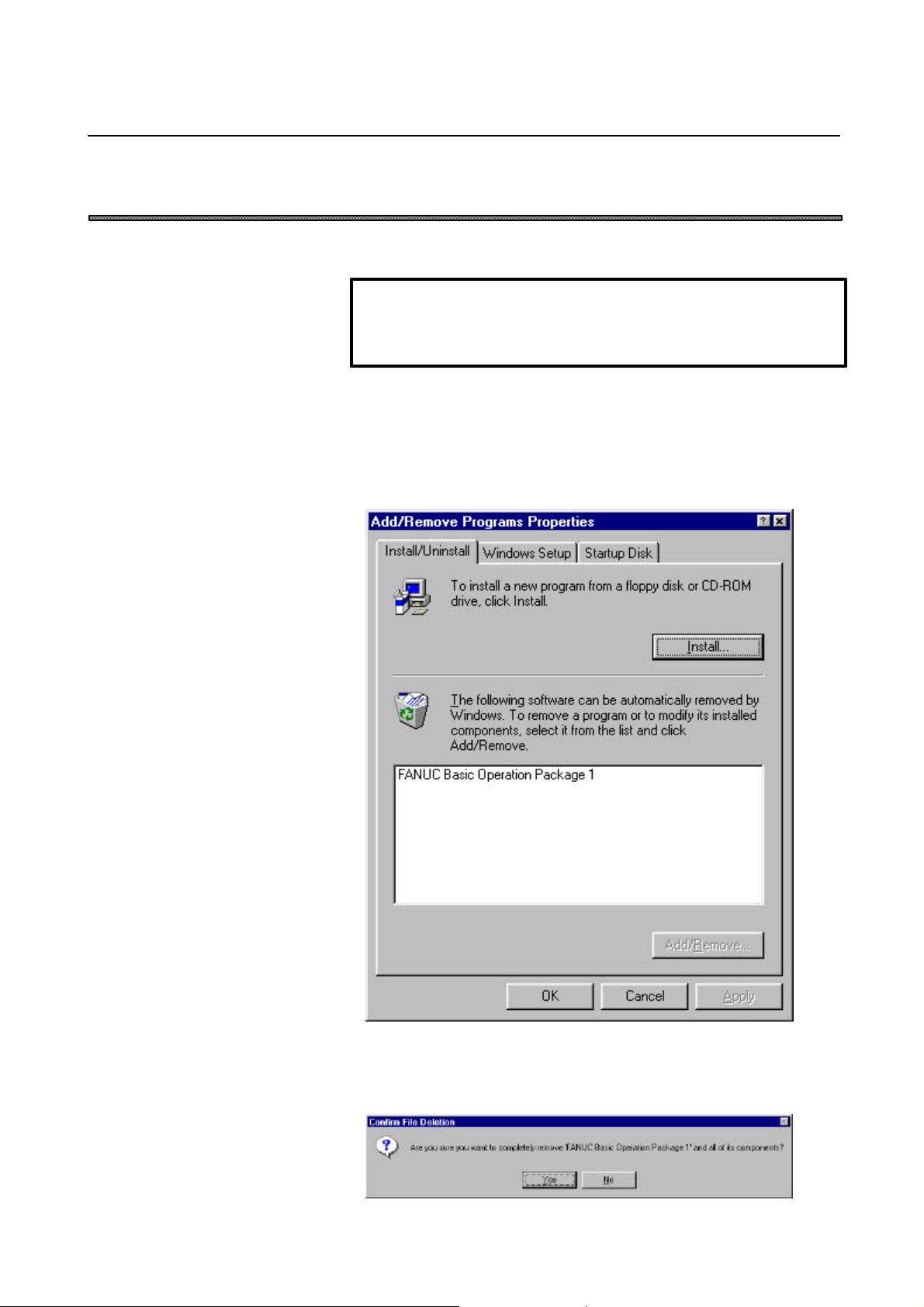

1.3 Uninstalling Basic Operation Package 1

This section describes how to uninstall Basic Operation Package 1.

NOTE

Uninstallation is supported only by the WIN32 version of Basic

Operation Package 1.

Procedure

1. Click the [Start] button.

2. Choose [Settings], then choose the [Control Panel] command.

3. Execute [Add/Remove Programs].

The [Add/Remove Programs Properties] screen appears.

4. Select Basic Operation Package 1.

5. Click the <Add/Remove> button.

The uninstall function starts, asking you whether you really want to

uninstall Basic Operation Package 1.

-7-

Page 28

1. SETUP B-62994EN/02

6. To uninstall Basic Operation Package 1, click the <Yes> button.

Subsequently, the uninstall function will ask several questions, such as

whether to delete shared files. Perform uninstallation by clicking

<Yes> or <No> as required.

When Basic Operation Package 1 has been uninstalled normally, it is

deleted from the Windows program menu.

-8-

Page 29

B-62994EN/02 2. BASIC KNOWLEDGE

2 BASIC KNOWLEDGE

This function provides basic information with which the user should be

familiar before attempting to use Basic Operation Package 1.

-9-

Page 30

2. BASIC KNOWLEDGE B-62994EN/02

2.1 Starting and Terminating Basic Operation Package 1

This section describes how to start and terminate Basic Operation Package 1

and provides notes on starting it.

2.1.1 Starting Basic Operation Package 1

This section describes how to start Basic Operation Package 1 and provides

notes on starting it.

NOTE

In an operating environment using the NC Board, the system software

for the NC Board must be loaded before Basic Operation Package 1 is

first started after power-on.

For details, click the [Start] button, then choose [NC Board]-[Guide for

English] from the program menu. (When using Windows 3.1, open

[Guide for English] from the [NC Board] group in the Program

Manager.)

Procedure

Windows 95/Windows 98

1. Click the [Start] button.

2. Select [Program].

3. Select Basic Operation Package 1.

When High Speed Serial Bus multiconnection is being used, the node

selection screen appears if a node number has not been specified for

an argument for Basic Operation Package 1.

For an explanation of how to specify the node number, see

Section 3.2, "Specifying a Node."

4. Select the CNC to be connected.

Click the <OK> button.

-10-

Page 31

B-62994EN/02 2. BASIC KNOWLEDGE

Windows 3.1

1. Start the program from the Basic Operation Package 1 group in the

Program Manager.

The Basic Operation Package 1 screen, shown below, appears.

2.1.2 Terminating Basic Operation Package 1

How to terminate Basic Operation Package 1 is described below.

Procedure

1. If the soft key is currently not displayed, press the function

selection soft key

2. Press the soft key.

If a check mark is not placed against "Enable the language switch

function" in the customization setting, the Basic Operation Package 1

screen disappears and Basic Operation Package 1 is terminated.

If a check mark is placed against "Enable the language switch function"

in the customization setting, the [Exit Basic Operation Package] screen

appears.

.

-11-

Page 32

2. BASIC KNOWLEDGE B-62994EN/02

For details of the language switch function, see Sections

11.1.1, "Setting general options for Basic Operation Package

1," and 11.4.2, "Switching the message language."

3. Select [Exit Basic Operation Package ?].

Click the <Yes> button.

The Basic Operation Package 1 screen disappears and Basic Operation

Package 1 is terminated.

If [Switch language after restart?] is selected, clicking the <Yes> button

restarts Basic Operation Package 1 using the selected language.

-12-

Page 33

B-62994EN/02 2. BASIC KNOWLEDGE

2.2 Window Names and Functions

This section describes the name and functions of each window displayed by

Basic Operation Package 1.

Basic Operation Package 1 displays a parent window which consists of one or

more child windows. Each child window contains the display items of a

conventional CNC screen.

Explanation

l Parent window

• Main window of Basic Operation Package 1

• Selecting a soft key at the bottom of the parent window displays the

corresponding child window within the parent window.

• Multiple child windows can be displayed within the parent window.

• The top of the parent window indicates the function name

corresponding to the child window which is currently active and

statuses such as the CNC mode. The displayed statuses and their

meanings are as follows:

-13-

Page 34

2. BASIC KNOWLEDGE B-62994EN/02

FS15

(1) Automatic operation mode selection

Status Meaning

**** Not selected

MDI MDI mode

Tape TAPE mode

Mem MEMORY mode

Edit EDIT mode

Thin TEACH in mode

(2) Manual operation mode selection

Status Meaning

**** Not selected

Ref REFERENCE mode

Inc INCREMENTAL mode

Hndl HANDLE mode

Jog JOG mode

AngJ ANGULAR JOG mode

IHnd INCREMENTAL + HANDLE mode

JHnd JOG + HANDLE mode

(3) Automatic operation status

Status Meaning

Stop Stopped

Hold Halted

Strt Starting

MStr Numeric JOG mode

Rstr Restarting a block

PRsr Restarting a program

NSrc Searching for a sequence number

Rset Resetting

HPCC RISC operation

(4) Program editing status

Status Meaning

**** No editing

Edit Editing

Srch Searching

Vrfy Verifying

Cond Condensing

Read Inputting data

Pnch Outputting data

-14-

Page 35

B-62994EN/02 2. BASIC KNOWLEDGE

(5) Axial movement and dwell status

Status Meaning

**** Others

Motn Moving along an axis

Dwel Dwelling

Wait Waiting (only for 2-path lathe systems)

(6) M, S, T, and B function status

Status Meaning

Fin Waiting for processing

(7) Emergency stop status

Status Meaning

Emg Emergency stop

(8) Nonvolatile memory write status

Status Meaning

**** No write

Writ Writing

(9) Label skip status

Status Meaning

**** Label skip disabled

LSk Label skip enabled

(10) Alarm status

Status Meaning

Alam Alarm issued

(11) Warning message status

Status Meaning

Warn Warning issued

(12) Battery status

Status Meaning

Batt Battery of nonvolatile memory and absolute position

detector requires replacement

-15-

Page 36

2. BASIC KNOWLEDGE B-62994EN/02

FS160/180/210 or NC Board

(1) Automatic/manual mode selection

Status Meaning

**** Not selected

MDI MDI mode

Mem MEMORY mode

Edit EDIT mode

Hndl HANDLE mode

Jog JOG mode

TJog TEACH in JOG mode

THnd TEACH in HANDLE mode

Inc INCREMENTAL mode

Ref REFERENCE mode

Rmot SCHEDULE mode

Test TEST operation mode

(2) Automatic operation mode

Status Meaning

**** Resetting

Stop Stopped

Hold Halted

Strt Starting

MStr Returning (tool retract and return), repositioning, or

operating based on a manual numeric command

-16-

Page 37

B-62994EN/02 2. BASIC KNOWLEDGE

(3) Program editing status

Status Meaning

***** No editing

Edit Editing

Search Searching

Output Outputting data

Input Inputting data

Compare Comparing

LblSkp Label skip enabled

Restrt Restarting a program

PTRR Tool retract and return mode

HPCC RISC operation (only for machining center systems)

Revers Reverse movement during retrace (only for machining

center systems)

Retry Re-forward movement during retrace (only for

machining center systems)

RvEnd Reverse movement completed during retrace (only for

machining center systems)

Handle Handle interruption applied (only for machining center

systems)

WrkOfs Workpiece origin offset measurement mode (only for

machining center systems)

SHPCC Simple high-precision contour control applied (only for

machining center systems)

WrkSft Work shift write mode (only for lathe systems)

Offset Tool length offset measurement mode (for machining

center systems)/Tool length offset write mode (for lathe

systems)

(4) Axial movement and dwell status

Status Meaning

**** Others

Motn Moving along an axis

Dwel Dwelling

(5) M, S, T, and B function status

Status Meaning

Fin Waiting for processing

-17-

Page 38

2. BASIC KNOWLEDGE B-62994EN/02

(6) Emergency stop status

Status Meaning

Emg Emergency stop

Rset Reset

(7) Alarm status

Status Meaning

Alam Alarm issued

Batt Battery of nonvolatile memory and absolute position

detector requires replacement

For details of each status, refer to the operator's manual provided with

the CNC being used.

l Child window

• Window which implements the display items of an individual CNC screen

• Chapter and function

A collection of child windows is called a chapter.

A collection of chapters is called a function.

Basic Operation Package 1 is configured with the function and chapter

hierarchy shown below.

Functions and chapters can be selected using the soft keys at the

bottom of the parent window.

-18-

Page 39

B-62994EN/02 2. BASIC KNOWLEDGE

l Soft key

• Key-like field used to display a child window. A soft key can be

selected either by clicking the image on the screen or pressing the

corresponding key on the keyboard.

In the standard state, where no soft key customization has been

performed, the soft keys are assigned to the following keyboard keys.

The subsequent descriptions in this manual assume the standard soft

key assignment.

NOTE

The soft keys can be customized. For details, see Section 11.1.2,

"Setting soft keys."

• There are the following three types of soft key states: "Function

selection," "chapter selection," and "operation selection."

For example, the soft keys used for [Position] are switched as follows:

-19-

Page 40

2. BASIC KNOWLEDGE B-62994EN/02

• Function selection state

• Chapter selection state

• Operation selection state

The displayed soft keys are for the currently active child window.

Soft key

or

[F1] key

Soft key

or

[F1] key

Soft key

or

[F12] key

Soft key

or

[F1] key

Soft key

or

[F12] key

Soft key

or

[F12] key

NOTE

l The subsequent descriptions in this manual refer to the selection of a

soft key as simply "pressing a soft key," meaning either clicking the

soft key image on the screen or pressing the corresponding key on

the keyboard.

-20-

Page 41

B-62994EN/02 2. BASIC KNOWLEDGE

2.3 Selecting and Positioning Windows

This section describes how to select and position child windows.

NOTE

Settings may have been made so that the position and size of a

window cannot be changed. For details, see Section 11.1.1, "Setting

general options for Basic Operation Package 1."

2.3.1 Selecting a window

A child window can be selected using the mouse or keyboard.

Procedure

1. Click the window to be selected.

Alternatively, hold down the [Alt] key and press the key corresponding

to the number of the child window (indicated on the title bar).

-21-

Page 42

2. BASIC KNOWLEDGE B-62994EN/02

2.3.2 Positioning a window

The size and position of a child window can be changed as required, using the

mouse or automatic positioning function.

The changed screen display information is stored even when Basic Operation

Package 1 is terminated.

(The changed screen display information is stored in the setting file

upon the termination of Basic Operation Package 1. For details of the setting

file, see Appendix 2, "BACKING UP THE SETTING FILE.")

NOTE

l A child window can be moved only within the parent window.

l Some child windows automatically change their display format

according to the vertical/horizontal ratio of the window.

l Positioning a child window using the mouse

Dragging the title bar or an edge of a child window enables the position and

size of the child window to be changed as required.

l Positioning child windows using the automatic positioning function

This function automatically positions the child windows so that they fit in

the parent window.

-22-

Page 43

B-62994EN/02 2. BASIC KNOWLEDGE

Procedure

Vertically aligning the child windows

1. Right-click the soft key area.

Alternatively, press the [Application] key on the keyboard (such as

the Microsoft Natural keyboard or 109 keyboard).

Alternatively, press [Shift]+[F10].

The following pop-up menu appears:

2. In this case, choose [Tile Vertical].

The child windows are automatically positioned within the parent

window.

-23-

Page 44

2. BASIC KNOWLEDGE B-62994EN/02

2.4 Selecting a Path

If the CNC has multiple paths, select the path to be used as described below.

NOTE

The selection of a path is supported only by TT and MM CNCs and

CNCs having a loader.

Procedure

1. If the

selection soft key

2. Press the

The [Path Setting] screen appears.

3. Select the path to be used for operation.

Click the <OK> button.

soft key is currently not displayed, press the function

.

soft key.

-24-

Page 45

B-62994EN/02 2. BASIC KNOWLEDGE

2.5 Displaying Version Information

This section describes how to display the version information for Basic

Operation Package 1, for maintenance and other purposes.

Procedure

1. Right-click the soft key area.

Alternatively, press the [Application] key on the keyboard (such as the

Microsoft Natural keyboard or 109 keyboard).

Alternatively, press [Shift]+[F10].

The following pop-up menu appears:

2. Choose [About Basic Operation Package...].

The [About Basic Operation Package] screen appears.

The following information is displayed:

• Version information for Basic Operation Package 1

• CNC type ("99" for the NC Board)

• CNC software series

• CNC software version

• Number of controlled axes

-25-

Page 46

3. SETTING THE PARAMETERS REQUIRED TO USE BASIC OPERATION PACKAGE 1 B-62994EN/02

3 SETTING THE PARAMETERS REQUIRED

TO USE BASIC OPERATION PACKAGE 1

This chapter describes how to set the parameters required to display the

screens of Basic Operation Package 1.

-26-

Page 47

B-62994EN/02 3. SETTING THE PARAMETERS REQUIRED TO USE BASIC OPERATION PACKAGE 1

3.1 Setting the CNC Parameters

This section describes how to set the CNC parameters required to use Basic

Operation Package 1.

NOTE

If the CNC parameters are not set, screen display and the writing of

programs and MDI commands cannot be performed normally.

NOTE

To set the parameters, first establish the following status:

l Setting data

• Parameter Write enabled

l Operation

Set either of the following statuses:

• Emergency stop

• Stopped or paused in MDI mode

For an explanation of how to specify the setting data, see Section 6.1,

"Setting Data."

To change the CNC operating mode from the software operator's panel,

see Section 6.7, "Software Operator's Panel Settings."

Procedure

1. If the

selection soft key

2. Press the

soft key is currently not displayed, press the function

.

soft key.

3. If the [Parameter] screen is currently not displayed, press the chapter

selection soft key

.

Press the

soft key.

The [Parameter] screen appears.

-27-

Page 48

3. SETTING THE PARAMETERS REQUIRED TO USE BASIC OPERATION PACKAGE 1 B-62994EN/02

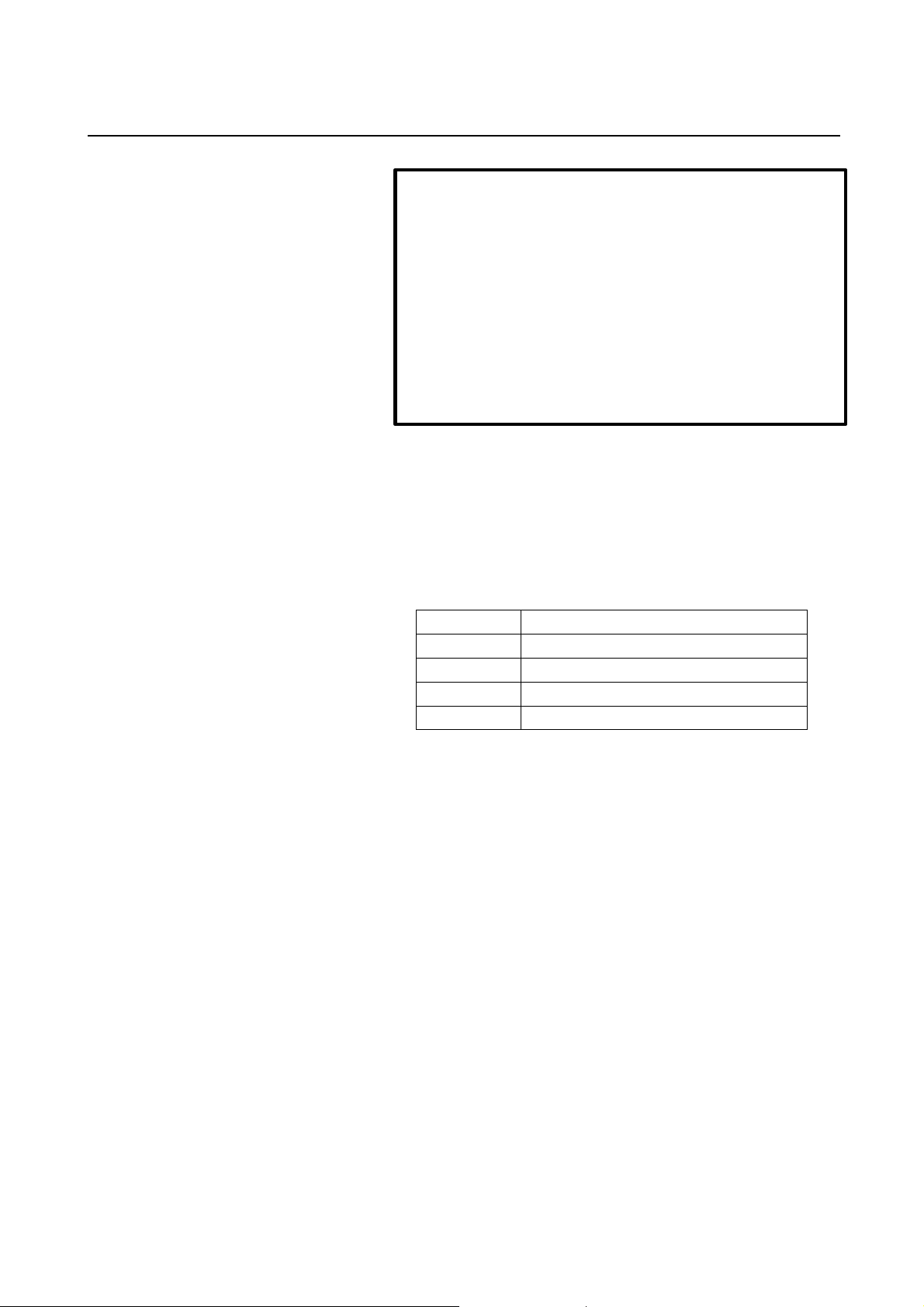

Explanation

Set the following parameters:

l FS15

Description Set value

TV check No. 0000 bit 0 → 0

Foreground input device No. 0020 → 16

Background input device No. 0022 → 16

Enable overwriting of program from outside of NC No. 2200 bit 1 → 1

Use M02 and M30 to terminate registration No. 2200 bit 3 → 1

Enable background editing No. 2201 bit 6 → 1

Use position display No. 2204 bit 1 → 1

Use dynamic data display No. 7613 bit 0 → 1

Use actual speed display No. 7613 bit 1 → 1

Use spindle speed display No. 7613 bit 2 → 1

Use program check No. 7710 bit 7 → 1

The above settings for the foreground input device and background

input device are required to use the program edit screen of Basic

Operation Package 1.

To change the setting of each input device, refer to the FS15

parameter manual.

l FS16/18/21 or NC Board

Description Set value

TV check No. 0000 bit 0 → 0

Enable overwriting of program from outside of NC No. 2200 bit 1 → 1

Use M02, M30, and M99 to terminate registration No. 2200 bit 3 → 1

-28-

Page 49

B-62994EN/02 3. SETTING THE PARAMETERS REQUIRED TO USE BASIC OPERATION PACKAGE 1

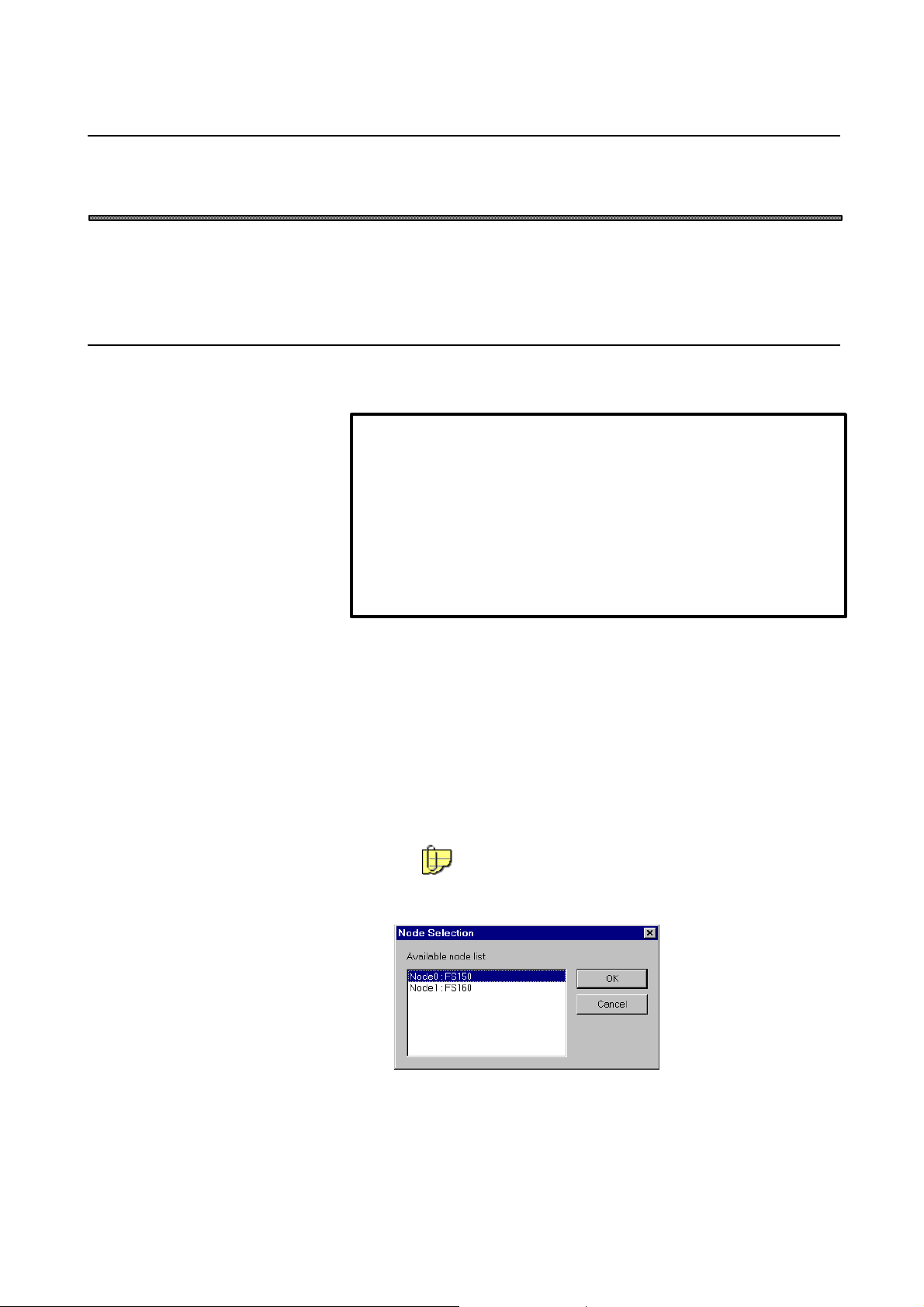

3.2 Specifying a Node

This section describes how to specify a node number for Basic Operation

Package 1.

NOTE

A node can be specified only when the WIN32 version is used with

High Speed Serial Bus multiconnection.

Explanation

A node number can be specified as an argument for Basic Operation

Package 1. The format is as follows:

WINBOP32.EXE /NODE=<node-number>

As a node number, specify the number which was set during the installation

of the High Speed Serial Bus driver.

-29-

Page 50

4. POSITION DISPLAY B-62994EN/02

4 POSITION DISPLAY

This chapter describes how to display positions, such as the current position.

-30-

Page 51

B-62994EN/02 4. POSITION DISPLAY

4.1 Overall Position Display

This section describes how to display the overall position display (including

the relative position, absolute position, machine position, and distance to go)

for the program that is currently being executed.

Procedure

1. If the

selection soft key

2. Press the soft key.

3. If the [Over All Position] screen is currently not displayed, press the

chapter selection soft key

Press the

The [Over All Position] screen appears.

soft key is currently not displayed, press the function

.

.

soft key.

-31-

Page 52

4. POSITION DISPLAY B-62994EN/02

Explanation

l Overall position display

The overall position display includes the relative position, absolute

position, machine position, and distance to go for the program that is

currently being executed.

To perform operation such as setting the origin for the relative

coordinates, press the operation selection key

.

The operation soft keys appear.

For details of each function, see the following sections:

Origin Relative Position: Section 4.2.1, "Resetting relative coordinates"

Preset Relative Position: Section 4.2.2, "Presetting relative coordinates"

Set Float Point: Section 4.2.3, "Setting the machine position

to the floating reference position"

Preset Work Coord.: Section 4.2.4, "Presetting the workpiece

coordinate system"

NOTE

When a child window other than the overall position child window

is selected, the operation soft keys do not appear.

For floating reference position setting, a CNC option is required.

When the FS16/18/21 or NC Board is used, a CNC option is

required for workpiece coordinate system presetting.

l Modal screen

Displays modal information about the program that is currently being

executed, such as G codes. No operation can be performed on this

screen.

l Actual speed screen

Displays the feedrate for the program that is currently being executed.

No operation can be performed on this screen.

-32-

Page 53

B-62994EN/02 4. POSITION DISPLAY

4.2 Displaying the Relative Position

This section describes how to display the relative position for the program

that is currently being executed.

Procedure

1. If the

selection soft key

2. Press the soft key.

3. If the [Relative Position] screen is currently not displayed, press the

chapter selection soft key

Press the

The [Relative Position] screen appears.

soft key is currently not displayed, press the function

.

.

soft key.

-33-

Page 54

4. POSITION DISPLAY B-62994EN/02

Explanation

l Relative position screen

Displays the relative position for the program that is currently being

executed.

To perform an operation such as setting the origin for the relative

coordinates, press the operation selection key

.

The operation soft keys appear.

For details of each function, see the following sections:

Origin Relative Position: Section 4.2.1, "Resetting relative coordinates"

Preset Relative Position: Section 4.2.2, "Presetting relative coordinates"

Set Float Point: Section 4.2.3, "Setting the machine position

to the floating reference position"

Preset Work Coord.: Section 4.2.4, "Presetting the workpiece

coordinate system"

NOTE

When a child window other than the overall position child window

is selected, the operation soft keys do not appear.

For floating reference position setting, a CNC option is required.

When the FS16/18/21 or NC Board is used, a CNC option is

required for workpiece coordinate system presetting.

When the Power Mate is used, floating reference position setting

and workpiece coordinate system presetting cannot be

performed.

l Actual speed screen

Displays the feedrate for the program that is currently being executed.

No operation can be performed on this screen.

-34-

Page 55

B-62994EN/02 4. POSITION DISPLAY

4.2.1 Resetting relative coordinates

The coordinates of the relative position can be reset to 0.

Procedure

1. If the [Relative Position] screen (or [Over All Position] screen) is

currently not displayed, display the [Relative Position] screen (or [Over

All Position] screen) by applying the procedure explained in Section

4.2, "Displaying the Relative Position" (or Section 4.1, " Overall

Position Display").

(Example with the [Relative Position] screen)

2. Press the

The [Position - Origin Relative Position] screen appears.

soft key.

-35-

Page 56

4. POSITION DISPLAY B-62994EN/02

3. From the list of the coordinate axes, select one or more axes for which

the relative coordinates are to be reset.

To select all the axes, click the <Set All> button.

To deselect all the axes, click the <Clear All> button.

4. Clicking the <OK> button resets the selected relative coordinates to 0.

4.2.2 Presetting relative coordinates

The coordinates of the relative position can be preset to an entered value.

Procedure

1. If the [Relative Position] screen (or [Over All Position] screen) is

currently not displayed, display the [Relative Position] screen (or [Over

All Position] screen) by applying the procedure explained in Section

4.2, "Displaying the Relative Position" (or Section 4.1, " Overall

Position Display").

-36-

Page 57

B-62994EN/02 4. POSITION DISPLAY

(Example with the [Relative Position] screen)

2. Press the

soft key.

The [Position - Preset Relative Position] screen appears.

3. Select the axis for which the relative coordinate is to be preset.

Enter the value to which the relative coordinate is to be preset.

4. Clicking the <OK> button presets the selected relative coordinate.

-37-