Page 1

r

< Series 30+-MODEL A/B

< Series 31+-MODEL A/B

< Series 32+-MODEL A/B

< Series 35+-MODEL B

< Power Motion +-MODEL A

< Series 0+-MODEL F

Fast Ethernet

Fast Data Serve

OPERATOR'S MANUAL

B-64014EN/07

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual contain software controlled based on Japan’s “Foreign

Exchange and Foreign Trade Law”.

For this reason, the export of these products is subject to an export license based on that

law.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B-64014EN/07 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

"SAFETY PRECAUTIONS" describes the safety precautions related to the use of CNC units, to ensure safe

operation of machines fitted with FANUC CNC units. Read this section carefully before attempting to use

any function described in this manual.

Users should also read the relevant descriptions in the Operator’s Manual of the CNC to become fully

familiar with the functions to be used.

Contents

DEFINITION OF WARNING, CAUTION, AND NOTE.........................................................................s-1

GENERAL WARNINGS AND CAUTIONS............................................................................................s-2

GENERAL WARNINGS FOR CNC APPLICATION DEVELOPMENT ...............................................s-3

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warnings and Cautions according to their bearing on safety. Also,

supplementary information is described as Notes. Read the Warnings, Cautions, and Notes thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger

of both the user being injured and the equipment being damaged if the approved

procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved

procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

SAFETY PRECAUTIONS B-64014EN/07

GENERAL WARNINGS AND CAUTIONS

WARNING

1 Before operating the machine, thoroughly check the entered data. Operating the

machine with incorrectly specified data may result in the machine behaving

unexpectedly, possibly causing damage to the tool, machine, and/or workpiece, or

injury to the user.

2 Never attempt to machine a workpiece without first checking the programmed

value, compensation value, current position, and external signal settings. Also,

never attempt to machine a workpiece without first checking the operation of the

machine. Before starting a production run, ensure that the machine is operating

correctly by performing a trial run using, for example, the single block, feedrate

override, or machine lock function, or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct operation of the machine

may result in the machine behaving unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

3 Ensure that the specified feedrate is appropriate for the intended operation.

Generally, for each machine, there is a maximum allowable feedrate. The

appropriate feedrate varies with the intended operation. Refer to the manual

provided with the machine to determine the maximum allowable feedrate. If a

machine is turn at other than the correct speed, unexpected load may be applied

to the machine, possibly causing damage to the tool, machine, and/or workpiece,

or injury to the user.

4 When using a tool compensation function, thoroughly check the direction and

amount of compensation.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the tool, machine, and/or

workpiece, or injury to the user.

5 The parameters for the CNC and PMC are factory-set. Usually, there is no need to

change them. When, however, there is no alternative other than to change a

parameter, ensure that you fully understand the function of the parameter before

making any change.

A failure to set a parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the tool, machine, and/or workpiece, or

injury to the user.

CAUTION

1 Immediately after switching on the power, do not touch any of the keys on the MDI

unit until the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other special

operations. Pressing any of these keys may place the CNC unit in other than its

normal state. Starting the machine in this state may cause it to behave

unexpectedly.

2 The operator's manual for the CNC describes all the basic functions of the CNC,

including the optional functions. The selected optional functions vary with the

machine. Some functions described in this manual may not, therefore, be

supported by your machine. Check the machine specifications before using the

optional functions.

s-2

Page 5

B-64014EN/07 SAFETY PRECAUTIONS

CAUTION

3 Some machine operations and screen functions are implemented by the machine

tool builder. For an explanation of their usage and related notes, refer to the

manual provided by the machine tool builder.

For example:

On some machines, executing a tool function causes the tool change unit to

•

operate. When executing a tool function on such a machine, stand well clear of

the tool change unit. Otherwise, there is a danger of injury to the operator.

Many auxiliary functions trigger physical operations, such as rotation of the

•

spindle. Before attempting to use an auxiliary function, therefore, ensure that

you are fully aware of the operation to be triggered by that function.

NOTE

Command programs, parameters, and variables are stored in nonvolatile memory

in the CNC. Generally, the contents of memory are not lost by a power on/off

operation. However, the contents of memory may be erased by mistake, or

important data in nonvolatile memory may have to be erased upon recovering

from a failure.

To enable the restoration of data as soon as possible if such a situation arises,

always make a backup of the data in advance.

GENERAL WARNINGS FOR CNC APPLICATION DEVELOPMENT

WARNING

Be careful enough for the following warnings when you develop two or more

applications or use networks.

If you neglect them, there is a danger of the user being injured or there is a danger

of both the user being injured and the equipment being damaged.

1 Be careful enough if you write an identical CNC data, an identical PMC data or

a series of related data set by two or more above applications including

network functions. Because they are executed based on each individual cycles

(in other words, asynchronous cycles), there is a possibility that the data will be

written in an unexpected order.

Therefore, do NOT write above data in the following cases.

- Applications and network functions

- Two or more applications

- Two or more network functions

Data, applications and network functions of interest are listed in below.

However, all may not be listed completely because new features will be added

in the future.

2 Be careful enough that you must prevent PMC signals in the same byte from

being written by the following two or more applications including network

functions. While an application reads and writes one byte of PMC signals, other

applications may write the same byte.

3 Be careful enough if you process a PMC signal set that is related to a CNC

function by using the following two or more applications including network

functions. Because they are executed based on each individual cycles (in other

words, asynchronous cycles), there is a possibility that the CNC may receive

the PMC signal set in an unexpected order.

s-3

Page 6

SAFETY PRECAUTIONS B-64014EN/07

WARNING

4 Generally, when multi-byte data are read or written at once among the

following two or more applications including network functions, the coherency

of the read multi-byte data (in other words, reading all latest data at once) is not

guaranteed. To ensure the coherency of the multi-byte data, prepare flags to

notify the completion of reading or writing process that is separated from the

entity of the data and make the handshaking process to access the data by

using the flags.

Data List Table

Category Data

Parameter, Tool compensation value and related data,

Work zero offset value and related data,

Workpiece coordinate system shift value and related data,

General data for CNC

PMC data PMC signal, PMC parameter

Data for Laser,

Punch press or Wire cut

Other data Parameters for Data Server, Parameters for network setting

Macro variable, P-CODE variable, Program and related data,

Tool management function data, Tool life management data,

Error compensation related data ,

Overtravel check (Interference check) related data ,

Software operator’s panel related data

Tool data for punch press and related data, Safety zone data and related data,

Laser cutting condition data and related data, Laser oscillator setting data and

related data, Wire consumption compensation data, Guide position

compensation data, Workpiece leveling data

List Table of Applications and Network Functions

Category Functions

Applications

Network functions

5 CNC has functions that read or write PMC signals in other than the G/F

PMC Ladder, Macro Executor, C Language Executor, FANUC PICTURE,

FOCAS2

FL-net, EtherNet/IP, PROFINET, Modbus/TCP, PROFIBUS-DP, DeviceNet,

CC-Link

address. Be careful enough if the above mentioned applications and network

read or write PMC signals used by these functions. When reading or writing the

same PMC signal, applications or CNC functions may work in an unexpected

manner.

For the relevant CNC functions, refer to "LIST OF FUNCTIONS USING PMC

SIGNALS OTHER THAN G/F ADDRESS " in Appendix in the CONNECTION

MANUAL (FUNCTION) of the relevant CNC.

s-4

Page 7

B-64014EN/07 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE.............................................s-1

GENERAL WARNINGS AND CAUTIONS...............................................................s-2

GENERAL WARNINGS FOR CNC APPLICATION DEVELOPMENT.....................s-3

I. GENERAL

1 GENERAL...............................................................................................3

1.1 ORGANIZATION ...........................................................................................3

1.2 APPLICABLE MODELS.................................................................................3

1.3 RELATED MANUALS....................................................................................4

II. SPECIFICATION

1 PREFACE................................................................................................9

1.1 HARDWARE ON WHICH Ethernet OPERATES ...........................................9

1.2 COMMUNICATION FUNCTIONS OPERATING ON HARDWARE

OPTIONS ....................................................................................................10

1.3 Series 30i/31i/32i/35i-B, Power Motion i-A AND Series 0i-F.......................11

1.3.1 RELATED NC PARAMETERS............................................................................11

1.3.2 Checking the Selected Hardware Option ...............................................................13

1.3.3 Screen Layout.........................................................................................................13

2 DATA SERVER FUNCTIONS...............................................................14

2.1 DATA SERVER FILE MANAGEMENT........................................................15

2.1.1 File Names of CNC File Management...................................................................15

2.1.2 Number of Files Which Can Be Registered on a Data Server................................16

2.1.3 Text Files and Binary Files ....................................................................................16

2.2 DATA SERVER MODES.............................................................................17

2.3 DETAILS OF THE BUFFER MODE.............................................................19

2.4 OPERATION FROM A DATA SERVER ......................................................22

2.4.1 Subprogram Search during Memory Operation .....................................................23

2.5 NC PROGRAM FORMAT............................................................................23

2.6 LIST FILE FORMAT ....................................................................................25

2.7 DATASERVER Explorer CONNECTION.....................................................27

2.8 ISO CODE INPUT/OUTPUT FUNCTION....................................................28

3 FOCAS2/Ethernet FUNCTIONS...........................................................31

4 DNS/DHCP CLIENT FUNCTIONS........................................................32

5 MACHINE REMOTE DIAGNOSIS FUNCTIONS...................................33

6 UNSOLICITED MESSAGING FUNCTION............................................34

7 FTP FILE TRANSFER FUNCTION.......................................................36

c-1

Page 8

TABLE OF CONTENTS B-64014EN/07

III. SETTING

1 SETTING THE COMMUNICATION FUNCTION ...................................39

1.1 BACKING UP/RESTORING COMMUNICATION PARAMETERS...............39

1.1.1 Related NC Parameters...........................................................................................42

2 SETTING THE DATA SERVER FUNCTIONS.......................................43

2.1 OPERATING THE DATA SERVER SETTING SCREEN.............................44

2.2 RELATED NC PARAMETERS ....................................................................51

2.3 EXAMPLE OF SETTING THE DATA SERVER FUNCTIONS.....................59

3 SETTING THE FOCAS2/Ethernet FUNCTIONS..................................60

3.1 OPERATING THE FOCAS2/Ethernet SETTING SCREEN .........................60

3.2 RELATED NC PARAMETERS ....................................................................62

3.3 EXAMPLE OF SETTING THE FOCAS2/Ethernet FUNCTIONS..................63

4 SETTING THE DNS/DHCP FUNCTION................................................64

4.1 SETTING OF DNS.......................................................................................64

4.2 SETTING OF DHCP....................................................................................65

4.3 RELATED NC PARAMETERS ....................................................................67

4.4 EXAMPLE OF SETTING DNS/DHCP..........................................................67

4.4.1 When DNS/DHCP is Used with the Data Server...................................................68

4.4.2 When DHCP is Used with the FTP Server Function of the Data Server ...............69

4.4.3 When DHCP is Used with the FOCAS2/Ethernet Function ..................................70

5 SETTING THE MACHINE REMOTE DIAGNOSIS FUNCTIONS..........72

5.1 OPERATING THE MACHINE REMOTE DIAGNOSIS SETTING SCREEN.72

5.2 RELATED NC PARAMETERS ....................................................................76

5.3 CONTROLLING THE MACHINE REMOTE DIAGNOSIS FUNCTIONS

FROM THE PMC.........................................................................................77

5.3.1 Signals....................................................................................................................77

5.3.2 Signal Timing Charts..............................................................................................79

5.3.2.1 When the start of machine remote diagnosis is accepted...................................80

5.3.2.2 When the start of machine remote diagnosis is rejected....................................80

5.3.2.3 When machine remote diagnosis is forcibly terminated....................................81

5.4 EXAMPLE OF SETTING THE MACHINE REMOTE DIAGNOSIS

FUNCTIONS................................................................................................81

6 SETTING THE UNSOLICITED MESSAGING FUNCTION.................83

6.1 SETTING THE UNSOLICITED MESSAGING FUNCTION..........................83

6.1.1 Selection of Mode ..................................................................................................86

6.1.2 Setting Method by CNC Screen.............................................................................87

6.1.3 Setting Method by Personal Computer...................................................................91

6.2 EXECUTING THE UNSOLICITED MESSAGING FUNCTION.....................92

6.2.1 When Using a PMC Address for Control (Response Notice method) ...................92

6.2.2 When Using a PMC Address for Control (Simple Method) ..................................94

6.2.3 When Using a Macro Variable for Control (Simple Method)................................95

6.3 RELATED NC PARAMETERS ....................................................................98

7 SETTING THE FTP FILE TRANSFER FUNCTION...............................99

7.1 SETTING THE FTP FILE TRANSFER FUNCTION...................................100

c-2

Page 9

B-64014EN/07 TABLE OF CONTENTS

7.2 RELATED NC PARAMETERS ..................................................................102

8 ERROR MESSAGES DISPLAYED DURING PARAMETER SETTING

.............................................................................................................106

IV. OPERATION

1 OPERATING THE DATA SERVER FUNCTIONS...............................109

1.1 DEVICE CHANGE ON THE PROGRAM FOLDER SCREEN....................109

1.2 OPERATING THE DATA SERVER FILE LIST SCREEN ..........................110

1.2.1 Displaying and Operating the File List ................................................................114

1.2.2 File Transfer Operation ........................................................................................120

1.2.3 Preparations for File Operation and Editing.........................................................121

1.2.4 File Operation between the Data Server and USB Memory.................................122

1.3 OPERATING THE DATA SERVER HOST FILE LIST SCREEN ...............125

1.3.1 Displaying and Operating the File List ................................................................127

1.3.2 File Transfer Operation ........................................................................................129

1.3.3 Preparations for File Operation............................................................................131

1.4 M198-BASED SUBPROGRAM CALL........................................................132

1.5 DNC OPERATION.....................................................................................133

1.6 NC PROGRAM INPUT..............................................................................134

1.7 NC PROGRAM OUTPUT ..........................................................................134

1.8 FTP SERVER FUNCTIONS ......................................................................136

2 OPERATING THE MACHINE REMOTE DIAGNOSIS FUNCTIONS ..137

2.1 OPERATING THE MACHINE REMOTE DIAGNOSIS SCREEN...............137

2.1.1 Selecting an Inquiry Destination..........................................................................138

2.1.2 Starting Diagnosis ................................................................................................138

2.1.2.1 Diagnosis status............................................................................................... 138

2.1.2.2 Error numbers and error messages...................................................................139

2.1.3 Forcibly Terminating Diagnosis...........................................................................140

3 OPERATING THE FTP FILE TRANSFER FUNCTION.......................141

3.1 DEVICE CHANGE ON THE PROGRAM FOLDER SCREEN....................142

3.2 OPERATING THE FTP TRANSFER HOST FILE LIST SCREEN..............143

3.2.1 Displaying and Operating the File List ................................................................144

3.3 NC PROGRAM INPUT..............................................................................147

3.4 NC PROGRAM OUTPUT ..........................................................................147

V. CONNECTION

1 SETTING.............................................................................................151

1.1 Series 30i/31i/32i-A...................................................................................151

1.1.1 Specifications .......................................................................................................151

1.1.2 Installation............................................................................................................151

1.1.2.1 Installation on an LCD-mounted type unit......................................................151

1.1.2.2 Installation on a stand-alone type unit............................................................. 152

1.1.2.3 Total connection diagram................................................................................153

1.1.2.4 Installing a memory card.................................................................................153

1.2 Series 30i/31i/32i/35i-B, Power Motion i-A AND Series 0i-F.....................155

1.2.1 Specifications .......................................................................................................155

1.2.2 Installation............................................................................................................156

c-3

Page 10

TABLE OF CONTENTS B-64014EN/07

1.2.2.1 Installation on an LCD-mounted type unit......................................................156

1.2.2.2 Installation on a stand-alone type unit............................................................. 157

1.2.2.3 Total connection diagram................................................................................158

1.2.2.4 Installing a memory card.................................................................................158

2 CABLE CONNECTION .......................................................................160

2.1 CONNECTING TO Ethernet......................................................................160

2.2 LEADING OUT THE Ethernet CABLE.......................................................161

2.3 RJ-45 CONNECTOR PIN ASSIGNMENTS...............................................162

2.4 TWISTED-PAIR CABLE SPECIFICATION................................................163

2.4.1 Cable Connection.................................................................................................163

2.4.2 Cable Materials.....................................................................................................163

2.4.3 Connector Specification .......................................................................................165

2.5 ELECTRICAL NOISE COUNTERMEASURES..........................................165

2.5.1 Separating Signal Lines........................................................................................165

2.5.2 Clamping and Shielding Cables ...........................................................................165

2.5.3 Grounding the Network........................................................................................168

2.6 CHECK ITEMS AT INSTALLATION..........................................................170

VI. MAINTENANCE

1 HARDWARE MAINTENANCE INFORMATION..................................175

1.1 Series 30i/31i/32i-A...................................................................................175

1.1.1 Component Layout...............................................................................................175

1.1.2 LED Indications and Meanings............................................................................176

1.2 Series 30i/31i/32i/35i-B, Power Motion i-A, AND Series 0i-F....................178

1.2.1 Component Layout...............................................................................................178

1.2.2 LED Indications and Meanings............................................................................179

2 SOFTWARE MAINTENANCE INFORMATION...................................182

2.1 Ethernet LOG ............................................................................................182

2.2 ETHERNET CONNECTION CONFIRMATION..........................................187

2.3 COMMUNICATION STATE CONFIRMATION...........................................189

2.4 COMMUNICATION SOFTWARE CONFIRMATION..................................190

2.5 FTP SERVER MAINTENANCE.................................................................191

2.6 ALARM AND DIAGNOSIS DATA ..............................................................194

2.7 COMMUNICATION RETRY MONITORING FUNCTION...........................195

APPENDIX

A TROUBLESHOOTING ........................................................................199

A.1 CHECKING COMMUNICATION WITH A HUB..........................................199

A.2 CHECKING SETTINGS.............................................................................199

A.3 CHECKING COMMUNICATION................................................................200

B EXAMPLE OF FTP SERVER SETUP.................................................203

B.1 SETTING UP FTP SERVER OF Windows 2000 Professional (FOR

INTERNET INFORMATION SERVICE).....................................................203

B.2 SETTING UP FTP SERVER OF Windows XP Professional (FOR

INTERNET INFORMATION SERVICE).....................................................214

c-4

Page 11

B-64014EN/07 TABLE OF CONTENTS

B.3 SETTING UP FTP SERVER OF Windows Vista (FOR INTERNET

INFORMATION SERVICE)........................................................................233

B.4 SETTING UP FTP SERVER OF Windows 7 (FOR INTERNET

INFORMATION SERVICE)........................................................................250

B.5 SETTING UP FTP SERVER OF Windows 8 Pro (FOR INTERNET

INFORMATION SERVICE)........................................................................271

C EXAMPLE OF SETTING UP DNS/DHCP ...........................................295

C.1 EXAMPLE OF SETTING UP DHCP SERVER OF Windows 2000 Server.296

C.2 EXAMPLE OF SETTING UP DHCP SERVER OF Windows Server 2012302

C.3 EXAMPLE OF SETTING UP DNS SERVER OF Windows 2000 Server...308

C.4 EXAMPLE OF SETTING UP DNS SERVER OF Windows Server 2012...313

D FTP CLIENT OPERATION..................................................................317

D.1 OPERATION USING THE FTP COMMAND..............................................317

D.2 OPERATION USING THE Explorer...........................................................319

D.2.1 Displaying the File List........................................................................................319

D.2.2 File Operation and File Transfer ..........................................................................332

D.3 SECURITY UNBLOCKING IN Windows XP (Service Pack 2) / Vista........335

c-5

Page 12

Page 13

I. GENERAL

Page 14

Page 15

B-64014EN/07 GENERAL 1.GENERAL

1 GENERAL

This chapter explains the organization of this manual and how to read this manual.

1.1 ORGANIZATION

This manual consists of the following parts:

SAFETY PRECAUTIONS

This section describes the precautions to be observed when reading this manual.

I. GENERAL

This part describes the chapter organization, applicable models, and related manuals.

II. SPECIFICATION

This part describes the specifications of the functions that operate on the Fast Ethernet/Fast Data

Server.

III. SETTING

This part describes the method of setting.

IV. OPERATION

This part describes the method of operating the Data Server functions, machine remote diagnosis

functions, and FTP file transfer function.

V. CONNECTION

This part describes the method of connection and provides notes.

VI. MAINTENANCE

This part describes hardware and software maintenance information.

APPENDIX

These appendixes describe additional information such as that related to troubleshooting, the

operation of the FTP client, and how to set up the FTP server.

1.2 APPLICABLE MODELS

This Operator's Manual covers the following models.

The abbreviations in the following table are sometimes used in text descriptions.

Model name Abbreviation

FANUC Series 30i-MODEL A Series 30i-A

FANUC Series 31i-MODEL A

FANUC Series 31i-MODEL A5

FANUC Series 32i-MODEL A Series 32i-A

FANUC Series 30i-MODEL B Series 30i-B

FANUC Series 31i-MODEL B

FANUC Series 31i-MODEL B5

FANUC Series 32i-MODEL B Series 32i-B

FANUC Series 35i-MODEL B Series 35i-B Series 35i-B

FANUC Power Motion i-MODEL A Power Motion i-A Power Motion i-A PMi-A

FANUC Series 0i-MODEL F Series 0i-F Series 0i-F Series 0i-F 0i-F

Series 31i-A

Series 31i-B

Series 30i/31i/32i-A

Series

30i/31i/32i-B

Series

30i/31i/32i/35i-B

or

30i/31i/32i/35i-B

30i/31i/32i-A/B,

Series

35i-B, PMi-A

- 3 -

Page 16

1.GENERAL GENERAL B-64014EN/07

1.3 RELATED MANUALS

The table below lists manuals related to this manual.

Refer to these manuals when you use this manual. This manual is indicated by an asterisk(*).

Manual name

Related to Series 30i/31i/32i-A

DESCRIPTIONS B-63942EN

CONNECTION MANUAL (HARDWARE) B-63943EN

CONNECTION MANUAL (FUNCTION) B-63943EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-63944EN

OPERATOR’S MANUAL (For Lathe System) B-63944EN-1

OPERATOR’S MANUAL (For Machining Center System) B-63944EN-2

MAINTENANCE MANUAL B-63945EN

PARAMETER MANUAL B-65950EN

Related to Series 30i/31i/32i-B

DESCRIPTIONS B-64482EN

CONNECTION MANUAL (HARDWARE) B-64483EN

CONNECTION MANUAL (FUNCTION) B-64483EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64484EN

OPERATOR’S MANUAL (For Lathe System) B-64484EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64484EN-2

MAINTENANCE MANUAL B-64485EN

PARAMETER MANUAL B-64490EN

Related to Series 35i-B

DESCRIPTIONS B-64522EN

CONNECTION MANUAL (HARDWARE) B-64523EN

CONNECTION MANUAL (FUNCTION) B-64523EN-1

OPERATOR’S MANUAL B-64524EN

MAINTENANCE MANUAL B-64525EN

PARAMETER MANUAL B-64530EN

Related to Power Motion i-A

DESCRIPTIONS B-64572EN

CONNECTION MANUAL (HARDWARE) B-64573EN

CONNECTION MANUAL (FUNCTION) B-64573EN-1

OPERATOR’S MANUAL B-64574EN

MAINTENANCE MANUAL B-64575EN

PARAMETER MANUAL B-64580EN

Related to Series 0i-F

DESCRIPTIONS B-64602EN

CONNECTION MANUAL (HARDWARE) B-64603EN

CONNECTION MANUAL (FUNCTION) B-64603EN-1

CONNECTION MANUAL (Series 0i-PF FUNCTION)

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64604EN

OPERATOR’S MANUAL (Series 0i-PF)

OPERATOR’S MANUAL (For Lathe System) B-64604EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64604EN-2

MAINTENANCE MANUAL B-64605EN

PARAMETER MANUAL B-64610EN

PARAMETER MANUAL (Series 0i-PF)

PMC

PMC PROGRAMMING MANUAL (Series 30i/31i/32i-A)

Specification

number

B-64623EN

B-64624EN

B-64630EN

B-63983EN

- 4 -

Page 17

B-64014EN/07 GENERAL 1.GENERAL

Manual name

PMC PROGRAMMING MANUAL (Series 30i/31i/32i/35i-B, Power Motion i-A, Series

0i-F)

Network

PROFIBUS-DP Board CONNECTION MANUAL B-63993EN

Industrial Ethernet CONNECTION MANUAL B-64013EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64014EN *

DeviceNet Board CONNECTION MANUAL B-64043EN

FL-net Board CONNECTION MANUAL B-64163EN

CC-Link Board CONNECTION MANUAL B-64463EN

Machine Remote Diagnosis

Machine Remote Diagnosis Package OPERATOR’S MANUAL B-63734EN

PC Tool

FANUC PROGRAM TRANSFER TOOL OPERATOR’S MANUAL B-64344EN

Specification

number

B-64513EN

- 5 -

Page 18

Page 19

II. SPECIFICATION

Page 20

Page 21

B-64014EN/07 SPECIFICATION 1.PREFACE

1 PREFACE

WARNING

Fully understand the instructions described in this manual before starting

operation. If you start operation before fully understanding them, the machine

may behave unexpectedly, possibly causing damage to the tool, machine, and/or

workpiece, or injury to the user.

CAUTION

1 If connecting to communication devices made by other companies, thoroughly

read the manuals supplied with the communication devices made by the other

companies and sufficiently conduct connection tests beforehand.

2 Be sure to read through this part, "SPECIFICATION".

1.1 HARDWARE ON WHICH Ethernet OPERATES

In a CNC system, Ethernet operates on the following hardware components.

This manual covers the hardware options listed below.

Embedded Ethernet

Embedded Ethernet is a built-in Ethernet circuit mounted on the main board or stand-alone type LCD unit

supporting Windows CE.

(Connector name: CD38A or CD38S)

Hardware option

A hardware option is an Ethernet hardware component prepared as a CNC option.

There are the following two types of hardware options.

Kind Description

Fast Ethernet circuit mounted on the main board of the LCD-mounted type Series

Multi-function Ethernet

Fast Ethernet board

30i/31i/32i/35i-B or LCD-mounted type Power Motion i-A

(Connector name: CD38B)

Multi-function Ethernet may be referred to as "Fast Ethernet".

Option board mounted in an optional slot (slots 1 to 4)

(Connector name: CD38R)

An option board on which an ATA Flash card or Compact Flash Card (referred to

as a memory card below) is mounted to enable the Data Server functions to

operate may be referred to as "Fast Data Server" or "Fast Data Server board".

An option board on which no memory card is mounted may be referred to as "Fast

Ethernet" or "Fast Ethernet board".

- 9 -

Page 22

1.PREFACEPREFACE SPECIFICATION B-64014EN/07

NOTE

Note the following restrictions on hardware options:

- The maximum number of hardware options that can be mounted is 3,

including Multi-function Ethernet and/or Fast Ethernet boards. For the

stand-alone type Series 35i-B, the stand-alone type Power Motion i-A and

Series 0i-F, however, the maximum number of hardware options that can be

mounted is 2.

- The Data Server function cannot be used on Multi-function Ethernet.

- The Data Server function cannot be used on the Series 35i-B or Power

Motion i-A.

- Multi-function Ethernet cannot be used on a stand-alone type CNC or Series

0i-F.

1.2 COMMUNICATION FUNCTIONS OPERATING ON

HARDWARE OPTIONS

The following communication functions can be operated on hardware options.

Communication function Detailed in Embedded Ethernet

Data Server functions (Note 1) Chapter 2 in this Part Unavailable

FOCAS2/Ethernet functions (Note 2) Chapter 3 in this Part Available

Ethernet function

/ Data Server

function

Industrial

Ethernet

(Note 4)

NOTE

1 To use the Data Server functions, the Data Server function option (S737) is

required.

The string in the parentheses following the function option name indicates the

last four digits of the ordering number of the function option. The same applies to

the following description.

2 To use the FOCAS2/Ethernet functions, machine remote diagnosis functions,

unsolicited messaging function, and FTP file transfer function, the Ethernet

function option (S707) is required.

3 To use the DNS/DHCP functions, either of the Ethernet function option (S707)

and Data Server function option (S737) is required.

4 To use Industrial Ethernet, refer to the relevant connection manual.

DNS/DHCP functions (Note 3) Chapter 4 in this Part Available

Machine remote diagnosis functions

(Note 2)

Unsolicited messaging function (Note 2) Chapter 6 in this Part Available

FTP file transfer function (Note 2) Chapter 7 in this Part Available

FL-net functions

EtherNet/IP functions Unavailable

Modbus/TCP functions Available

PROFINET functions

Chapter 5 in this Part Available (Note 6)

FL-net Connection

Manual (B-64163EN)

Industrial Ethernet

Connection Manual

(B-64013EN)

Unavailable

Unavailable

- 10 -

Page 23

B-64014EN/07 SPECIFICATION 1.PREFACE

NOTE

5 For detailed information of the use of the embedded Ethernet, refer to the

chapter titled "EMBEDDED Ethernet FUNCTION" in the relevant CNC

maintenance manual. Note the following points:

- The number of FOCAS2/Ethernet clients that can be connected concurrently

with the embedded Ethernet is smaller than that with the hardware option.

Number of clients that can be connected concurrently Up to 20 Up to 5

Number of PCs that can be connected concurrently Up to 20 1 (recommended)

Hardware option Embedded Ethernet

- To use the unsolicited messaging function on the embedded Ethernet in the

Series 30i/31i/32i-A, the Enhanced Embedded Ethernet function option

(R952) is required.

- Since communication using embedded Ethernet is processed by the CPU in

the CNC, the CNC operation status may affect the communication

performance of embedded Ethernet and communication using embedded

Ethernet may also affect CNC processing.

For example, since embedded Ethernet operates with priority lower than that

given to automatic or manual operation performed for each axis, the

communication rate may be slower during automatic operation or operation

with many controlled axes.

Meanwhile, since embedded Ethernet operates with priority higher than that

given to the CNC screen display processing, C Language Executor (other

than high-level tasks), and other processing, communication using embedded

Ethernet may reduce the performance of the processing.

- Carefully connect embedded Ethernet to an intracompany network handling

much broadcast data because broadcast data processing takes time, which

may affect the performance of the CNC screen display processing and

others.

6 The machine remote diagnosis function cannot be used on the embedded

Ethernet in the Series 30i/31i/32i-A.

1.3 Series 30i/31i/32i/35i-B, Power Motion i-A AND Series 0i-F

With the Series 30i/31i/32i/35i-B and Power Motion i-A, Multi-function Ethernet or the Fast Ethernet

board can be selected as the hardware option using NC parameters.

With the Series 0i-F, the Fast Ethernet board can be selected as the hardware option using NC parameters.

1.3.1 RELATED NC PARAMETERS

0970 Select hardware option that operates Ethernet or Data Server function

[Input type] Parameter input

[Data type] Byte

[Valid data range] -1 to 6

Hardware option that operates each function is selected.

Value Hardware option

-1 Not used

0 Unsetting (initial value) (NOTE 1)

1 Multi-function Ethernet (NOTE 2)

- 11 -

Page 24

1.PREFACE SPECIFICATION B-64014EN/07

Value Hardware option

2 (reserved)

3 Fast Ethernet board mounted (slot1)

4 Fast Ethernet board mounted (slot2)

5 Fast Ethernet board mounted (slot3)

6 Fast Ethernet board mounted (slot4)

NOTE

1 When only one hardware option is mounted and no function option

related to Industrial Ethernet is specified, parameter No. 970 need

not be changed from 0 (initial value).

2 The Data Server function cannot be used on Multi-function

Ethernet.

If the Data Server function option (S737) is specified, do not set 1

(Multi-function Ethernet) to parameter No. 970.

With a stand-alone type CNC or Series 0i-F, do not set 1

(Multi-function Ethernet) to parameter No. 970.

3 The Ethernet functions and Data Server functions cannot be used

on different hardware options.

4 After changing parameter No. 970, turn the power off.

When parameter No. 970 is changed and the power is turned off,

then on again, alarm PW0050, "POWER MUST BE OFF

(INITIALIZED COMMUNICATION)" or alarm SR2038 "WRONG

COMMUNICATION COMBINATION" may be issued.

If alarm PW0050 is issued, turn the power to the CNC off, then on

again.

If alarm SR2038 is issued, see Section 2.6, "ALARM AND

DIAGNOSIS INFORMATION" in Part VI, "MAINTENANCE" and

review the setting.

- 12 -

Page 25

B-64014EN/07 SPECIFICATION 1.PREFACE

1.3.2 Checking the Selected Hardware Option

With the Series 30i/31i/32i/35i-B, Power Motion i-A and Series 0i-F, the selected hardware option can be

confirmed in the title bar of the setting, maintenance, or log screen of each communication function.

In the example below, [MULTI-FUNC ETHER] is selected as the hardware option.

Title Description

[MUTI-FUNC ETHER]

[BOARD(SLOT1)] Fast Ethernet board mounted in the optional slot 1

[BOARD(SLOT2)] Fast Ethernet board mounted in the optional slot 2

[BOARD(SLOT3)] Fast Ethernet board mounted in the optional slot 3

[BOARD(SLOT4)] Fast Ethernet board mounted in the optional slot 4

Fast Ethernet circuit mounted on the main board of the LCD-mounted type Series

30i/31i/32i/35i-B and LCD-mounted type Power Motion i-A

1.3.3 Screen Layout

In this manual, each screen has described mainly the example of the screen of Series 30i/31i/32i-A.

The basic content is the same though a detailed layout might be different from that of the Series

30i/31i/32i/35i-B, Power Motion i-A or Series 0i-F.

- 13 -

Page 26

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

2 DATA SERVER FUNCTIONS

The Data Server functions use a memory card built into a board for storing files and can transfer files and

perform DNC operation using FTP.

A Data Server can operate on both FTP client and FTP server.

When you use a CNC to transfer files, the Data Server operates as an FTP client and communicates with

the FTP server on the host computer.

When you use the host computer to transfer files, the Data Server operates as an FTP server and

communicates with the FTP client on the host computer.

WARNING

1 To input or output data, the use of the ISO code input/output function is

recommended.

Parity information is not contained with data input/output using the ASCII code.

So, the use of the ASCII code is dangerous since any data corrupted during

input/output operation with the CNC is not detected.

During DNC operation using a Data Server, data input using the ASCII code is

also dangerous since parity information is not contained and any corrupted data

in a read program is not detected.

If data corruption occurs, the machine may behave unexpectedly, possibly

causing damage to the tool, machine, and/or workpiece, or injury to the user.

For details of the ISO code input/output function, see Section 2.8, "ISO CODE

INPUT/OUTPUT FUNCTION".

With the Series 30i/31i/32i-A, the ISO code input/output function cannot be

used.

2 The memory card used for a Data Server can be deteriorated by writing data too

many times. If a deteriorated memory card is used, the operation performance

may be affected because it takes time to read data, or the machine may behave

unexpectedly because correct data cannot be read, possibly causing damage to

the tool, machine, and/or workpiece, or injury to the user.

For this reason, avoid operation involved with frequent rewriting.

3 The Program Transfer Tool is available as a PC tool for transferring NC

programs between the CNC and personal computer. (drawing number:

A08B-9510-J515) This tool allows NC programs to be transferred between a

personal computer and CNC memory or Data Server memory card through a

simple operation on the personal computer side. The transfer of NC programs

between a personal computer and CNC memory requires the FOCAS2/Ethernet

functions, and that between a PC and Data Server memory card requires the

Data Server functions.

NOTE

1 Before communicating with the host computer using the Data Server functions,

completely confirm that there is no problem with the entire system including

communication with the personal computer because the personal computer

environment may affect communication operation.

2 When the host computer operates as an FTP server, FTP server software must

be run on the host computer. When the host computer operates as an FTP

client, FTP client software must be run on the host computer.

- 14 -

Page 27

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.1 DATA SERVER FILE MANAGEMENT

With the Data Server functions, you can format the built-in memory card in the CNC file management

mode to manage NC programs.

CNC file management

For NC programs managed in the CNC file management mode, memory operation such as custom macro

commands and M98-based subprogram calling are available. Operate the NC programs using the

PROGRAM FOLDER screen in the same way as for NC programs in the CNC memory.

As a CNC external input/output device, DNC operation and M198-based subprogram calling are available.

In this case, operate NC programs using the DATA SERVER FILE LIST screen.

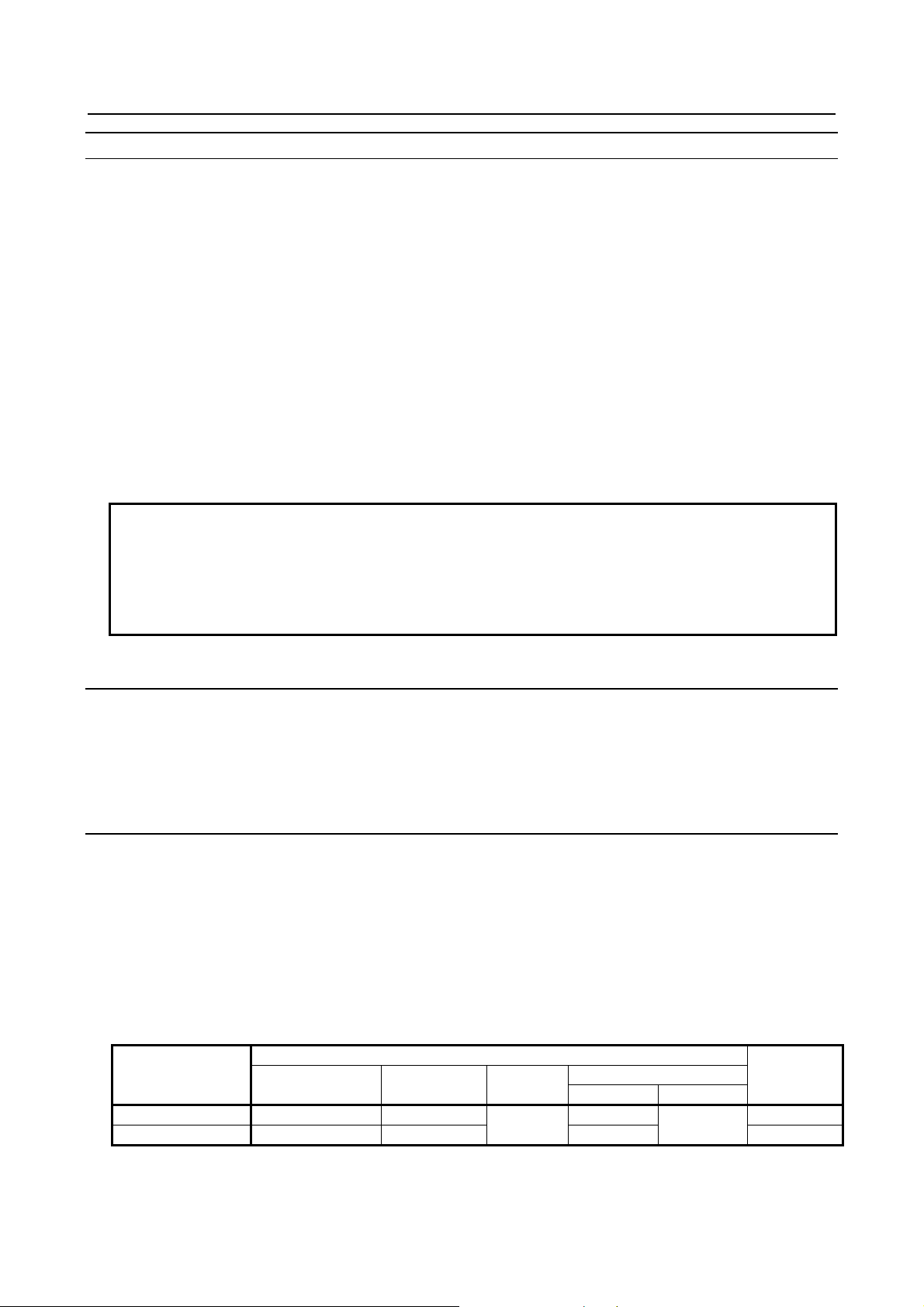

PROGRAM FOLDER screen

Edit operation

DATA SERVER FILE LIST

screen

CNC file management

(DNC operation is also available.)

File transfer operation

Memory operation

NOTE

1 The Data Server for the Series 30i/31i/32i-A/B and Series 0i-F allows editing

and memory operation of NC programs stored on the memory card, so the

method of managing files on the memory card differs from the file management

method of Data Servers for the Series 16i-B and so on. Note that, therefore, the

memory card of the 30i-A is not compatible with the memory cards of Data

Servers for the Series 16i-B and so on.

2 For operation and details of the PROGRAM FOLDER screen, refer to Chapter,

"PROGRAM MANAGEMENT" in the "OPERATOR’S MANUAL" of the relevant

CNC.

3 For operation and details of the DATA SERVER FILE LIST screen, refer to

Chapter 1, "OPERATING THE DATA SERVER FUNCTIONS," in Part IV,

"OPERATION."

2.1.1 File Names of CNC File Management

You can assign a file name and folder name to a file managed in the CNC file management mode in the

same way as for CNC memory.

• Up to 32 characters

• Alphabetic characters (in upper and lower cases), numeric characters, and four symbols (+, -, _,

and .)

NOTE

1 File names are case-sensitive.

2 Any file name or folder name cannot begin with a period (.).

3 It is impossible to assign the same name to a file and a folder.

4 Up to six levels of folders can be created.

- 15 -

Page 28

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

File names and program numbers

When a file name assigned to a file consists of uppercase O and a numeric value, the file name is treated

as a program number.

Values ranging from 1 to 9999 can be used (values ranging from 1 to 99999999 can be used according to

the parameter setting).

A value beyond this range cannot be used for a file name in the program number format.

Example)

File names that can be used as program numbers

“O0123” Program number 123

“O0001” Program number 1

“O3000” Program number 3000

“O9999” Program number 9999

File names that cannot be used as program numbers

“ABC” (Does not have the format "O plus a numeric value")

“o123” (Does not begin with uppercase letter "O")

“O123.4” (Uses a character other than numeric characters)

NOTE

When files on a Data Server are managed by program number, their program

numbers always consist of "O" plus a 4-digit number ("O" plus a 8-digit number).

So, even if there are files managed with different file names such as "O1" and

"O01" on a personal computer, their program numbers are regarded as the

same when these files are transferred to the Data Server.

2.1.2 Number of Files Which Can Be Registered on a Data Server

In the initial status, the maximum number of files which can be registered on a memory card on a Data

Server is 2047 and the maximum file size is 512 MB. Each folder is counted as one file.

The maximum number of files and the maximum file size can be changed using parameter No. 930.

For details, see Section 2.2, "RELATED NC PARAMETERS," in Part III, "SETTING."

2.1.3 Text Files and Binary Files

You can store the following two types of files on a memory card on a Data Server: text files and binary

files.

Whether a program on a Data Server is a text or binary file can be checked by pressing soft key [DETAIL

ON] in the DATA SERVER FILE LIST screen. When a program is a binary file, "R/B" is displayed.

For a text file, memory operation and edit operation as well as DNC operation can be performed by

selecting it as a main program.

For binary files, only DNC operation is available, but programs for high-speed binary operation can be

handled.

The following table lists differences between text files and binary files.

Operation

Attribute of file

Text file Available Available Available Available

Binary file Unavailable Unavailable

Selected as a

main program

Memory

operation

DNC

operation

Available

Subprogram calling

M98 M198

Unavailable

Available

Editing

Unavailable

- 16 -

Page 29

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

Follow the procedures below to specify a text or binary file:

(1) When registering a file from the CNC

In the DATA SERVER HOST FILE LIST screen, to register a file as a text file, use [GET], or to

register it as a text file, use [BGET].

(2) When registering a file from the host computer

A parameter is available to set whether to register a file as a text or binary file. For details, see

Section 2.2, "RELATED NC PARAMETERS" in Part III, "SETTING".

If NC data other than an NC program is not handled as a binary file, it may not be able to be input or

output correctly. NC data output and stored on a memory card on a Data Server from the CNC is

automatically handled as a binary file. A file to be transferred from a personal computer to a memory card

on a Data Server must be specified explicitly as a binary file.

NOTE

1 An NC program stored as a text file is converted to an editable file format so that

the file can be edited on the CNC. For this reason, when a text file is read from

the host computer to the memory card on the Data Server, then the file is

transferred to the host computer, binary compatibility can no longer be

maintained.

2 The file name of a text file and the O number or arbitrary file name in the

program are always the same. See Section 2.5, “NC PROGRAM FORMAT” for

details

2.2 DATA SERVER MODES

Each Data Server mode determines the input or output destination when a Data Server is operated as a

CNC external input/output device. You can select one of the following three modes.

NOTE

1 Data Server modes are valid only when the Data Server is operated as an

external storage device of the CNC. In case of main program operation for

editing and a memory operation and an M98-based subprogram call, programs

on the memory card of the Data Server are selected regardless of the Data

Server mode.

2 When a file is input to or output from the Data Server board with the FTP server

function by operating an FTP client on the host computer, there is no difference

in operation among Data Server modes.

Storage mode

The memory card built into the Data Server is selected as the external input/output device.

For example, when DNC operation or M198-based subprogram calling is executed, the relevant NC

program is called from the memory card built into the Data Server.

When input operation is executed for the Data Server, the relevant NC program is read from the memory

card built into the Data Server.

Conversely, when NC program output operation is executed for the Data Server, the output NC program

is written on the memory card built into the Data Server.

- 17 -

Page 30

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

Data Server

Memory card

Input

CNC memory

Output

DNC operation

FTP mode

The host computer connected to the Data Server is selected as the external input/output device.

For example, when DNC operation or M198-based subprogram calling is executed, the relevant NC

program is called from the host computer.

When input operation is executed for the Data Server, the relevant NC program is read from the host

computer connected to the Data Server.

Conversely, when NC program output operation is executed for the Data Server, the output NC program

is directly written on the host computer.

Host computer

Data Server

Input

Output

CNC memory

DNC operation

CAUTION

1 In the FTP mode, an NC program is transferred from the host computer to the

CNC. For this reason, if the line is disconnected during communication for some

reason such as noise on the network, the disconnection directly affects the CNC

operation as compared with the storage mode. Before DNC operation in the FTP

mode, surely take measures to prevent noise and make sure that good

communication conditions are present.

2 When feed hold is performed during DNC operation in the FTP mode,

communication with the host computer may be stopped. In this case, the host

computer may disconnect the communication. Perform feed hold during a trial

run and completely confirm that the communication with the host computer is not

disconnected.

This symptom is generally caused because the CNC data read speed is slow

and the host computer causes a timeout. Depending on the machining program,

the host computer may cause a timeout even when communication is not

stopped by feed hold. If this symptom occurs, use DNC operation in the FTP

mode while being careful not to cause a timeout, or use DNC operation in the

storage mode, and not in the FTP mode.

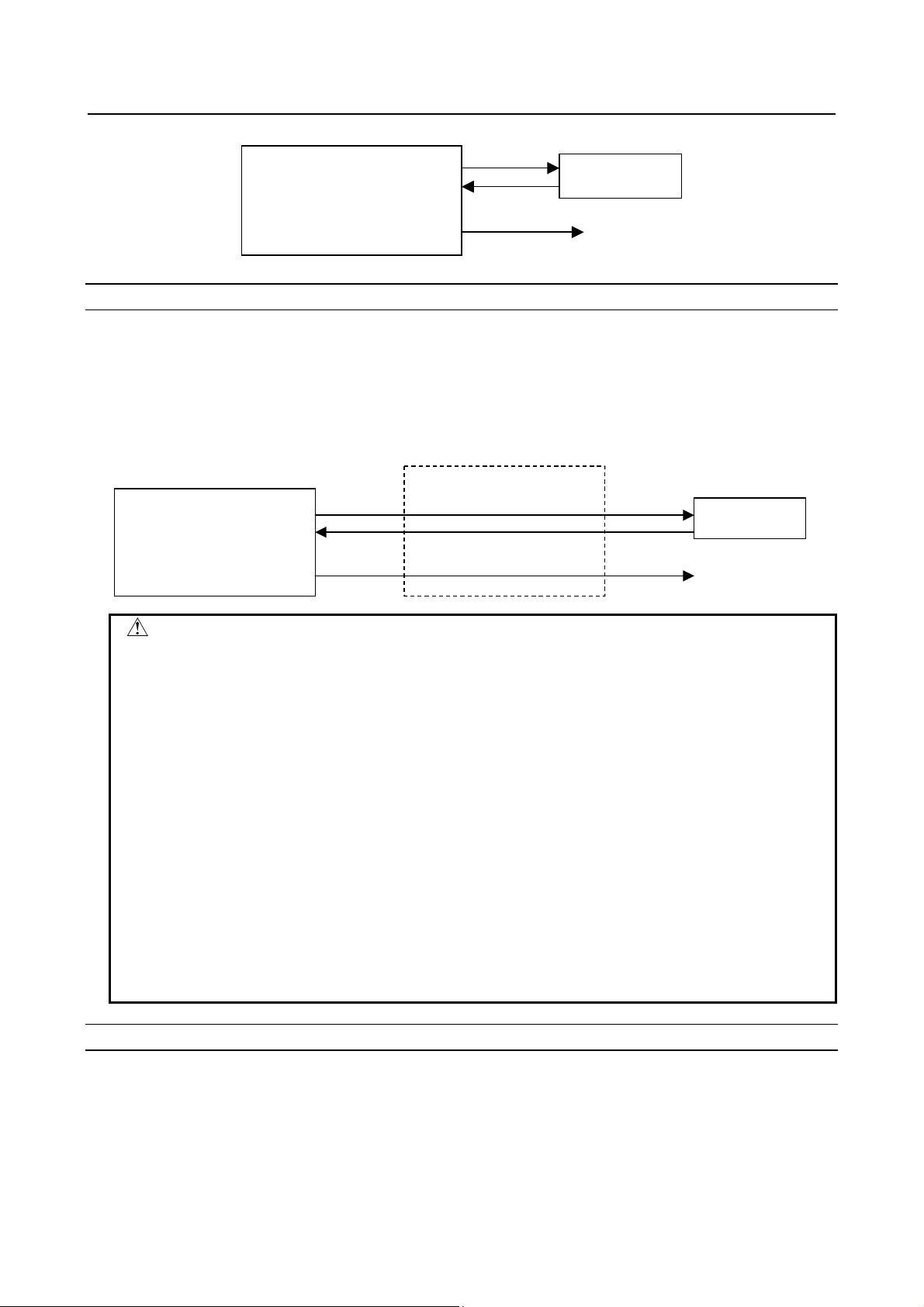

Buffer mode

The host computer connected to the Data Server is selected as the external input device.

In the buffer mode unlike the FTP mode, however, areas on the memory card built into the Data Server

are used as intermediate buffers. For details of the buffer mode, see Section 2.3, "DETAILS OF THE

BUFFER MODE," which is the following section.

As the external output device, the memory card built into the Data Server is selected. When NC program

output operation is performed, the operation equivalent to that in the storage mode is performed.

- 18 -

Page 31

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

A

A

Host computer

Data Server

Memory card

Intermediate

buffers

Output

Input

CNC memory

DNC operation

NOTE

1 With the Series 30i/31i-A, to use the buffer mode, the buffer mode function

option (J728) is required.

2 With the Series 32i-A, the buffer mode cannot be used.

2.3 DETAILS OF THE BUFFER MODE

In the buffer mode, two areas (areas A and B) are prepared on the memory card. While the NC program

data stored in one area is being supplied to the CNC, the subsequent NC program data is read in the other

area from the host computer using FTP transfer. When all data in the former area has been supplied to the

CNC, the data in the latter area is supplied to the CNC. In the former area, which becomes empty, the

subsequent NC program data is read from the host computer using FTP transfer.

Repeating this operation enables an NC program larger than the capacity of the memory card to be

handled. To use the buffer mode, however, the original NC program must be divided into some files on

the host computer in advance.

The size of a divided file must be smaller than half the remaining capacity of the memory card. If the size

of a divided file is too large (for example, 100 MB or more), it takes much time to read the first file from

the host computer and it also takes time until operation starts.

Using the buffer mode

In the buffer mode, a file (such as Oxxxx) called by DNC operation or M198-based subprogram calling is

a file list. The file list contains the names of files to be called in the order in which they are to be called.

In the buffer mode, the Data Server sequentially calls the files specified in the file list from the host

computer and supplies data to the CNC.

CNC Data Server Host computer

Program

call

Oxxxx

file1

file2

file3

file4

file5

Memory card

get (FTP)

rea A

rea B

Hard disk

Oxxxx

file1

file2

file3

file4

file5

Contents

of Oxxxx

file1

file2

file3

file4

file5

- 19 -

Page 32

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

Files (file1 to file5) specified in the file list on the host computer are stored on the memory card built into

the Data Server using FTP transfer and supplied to the CNC. In the buffer mode, after the CNC issues a

request to read an NC program to the Data Server, the specified file list is read from the host computer.

When the first file has been read, the Data Server starts supplying data to the CNC. For this reason, it

takes time from when the CNC issues a request to read a program to when the Data Server starts

supplying data.

While the Data Server is supplying the data in one area to the CNC, it stores data into the other area using

FTP transfer. For this reason, divide the original program data so that two consecutive files can be

contained on the memory card built into the Data Server.

Although the data in one area has been supplied to the CNC, FTP transfer may not terminate for the other

area. In this case, program calling terminates abnormally because the subsequent data cannot be supplied.

You can use a parameter not to cause the abnormal termination.

In the file list, you can specify any file name allowed by the host computer that consists of up to 255

single-byte alphanumeric characters. Be sure to specify at least one LF (0A in hexadecimal) or CR (0D in

hexadecimal) following each file name in the file list to delimit the file names.

NOTE

In the buffer mode, you can also register a new file on the memory card built into

the Data Server by the "NC program GET" or "NC program output" operation.

By this operation, however, the remaining capacity of the memory card built into

the Data Server that is required for operation in the buffer mode may be

exhausted, resulting in an error in DNC operation in the buffer mode.

For this reason, during DNC operation in the buffer mode, do not register any

new file on the memory card built into the Data Server.

Dividing an NC program into files

To perform operation in the buffer mode, divide an original NC program into several files on the host

computer and create a file list indicating the order in which the divided files are to be transferred in

advance.

- 20 -

Page 33

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

Example)

Dividing an NC program into three files

%

O1234(SAMPLE);

:

:

:

X1.Y1.Z1.;

X2.Y2.Z2.;

:

:

:

X3.Y3.Z3.;

X4.Y4.Z4.;

:

:

:

M30;

%

Dividing the

program into

three files

%

O1234(SAMPLE);

:

:

:

X1.Y1.Z1.;

X2.Y2.Z2.;

:

:

:

X3.Y3.Z3.;

X4.Y4.Z4.;

:

:

:

M30;

%

file1

file2

file3

file1

file2

file3

O1234

As shown above, divide an original NC file into three files, file1, file2, and file3. Specify the divided file

names in the file list (file name: O1234).

CAUTION

In the above example, the NC program is divided into files so that any block is

not divided. You can divide a program at a point in a block. When dividing a

program at a point in a block, be careful so that any unnecessary character is

not inserted at the end of each file.

If an unnecessary character is inserted at the end of a file, the NC program may

perform unexpected operation when executed. Be very careful when preparing

and editing an NC program on the host computer.

NOTE

1 Divide an NC program into files so that each file size is about 20 to 30 MB. If the

file size is too large, it takes time until DNC operation starts. If the file size is too

small, data transmission may stop between files and operation may stop.

2 Although you can divide an NC program at a point in a block, divide the program

in block units whenever possible and retract the tool at the end of each divided

file. This prevents data transmission from stopping at the end of a file and cutter

marking from being made.

3 Store the file list and relevant divided files in the same folder (directory) on the

same host computer.

- 21 -

Page 34

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

2.4 OPERATION FROM A DATA SERVER

NOTE

The Data Server functions produce an effect when large NC programs are

operated. Use the Data Server Functions to handle large NC programs.

Memory operation

You can perform memory operation for an NC program on the memory card built into a Data Server in

the same way as for an NC program in the CNC memory.

You can also supply an NC program simultaneously for a multipath CNC system.

NOTE

When memory operation is performed, a selected NC program on the Data

Server must be a text file. It is impossible to use a binary file for memory

operation.

M198 subprogram operation

In the storage mode, you can perform M198 calling from the memory card built into a Data Server. In the

FTP or buffer mode, you can perform M198 calling form the host computer.

On the DATA SERVER FILE LIST screen, set an M198 folder in advance. When M198 calling is

specified, the set M198 folder is searched for the target subprogram.

DNC operation

In the storage mode, you can perform DNC operation from the memory card built into a Data Server. In

the FTP or buffer mode, you can perform DNC operation from the host computer.

On the DATA SERVER FILE LIST screen, set the file name for DNC operation in advance. When DNC

operation starts, the set DNC operation file is called.

- 22 -

Page 35

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

/

2.4.1 Subprogram Search during Memory Operation

The subprogram search sequence during memory operation for an NC program on the memory card built

into a Data Server is the same during memory operation for an NC program in the CNC program

memory.

Order in which a subprogram is c alled f rom the main program on a Data Serv er (1) to (5)

Me mory card built int o

a Dat a Server

//DATA_SV

(1) Folder containi ng

the main progra m

DIR01

DIR02

Main

program

/CNC_MEM

SYSTEM

MTB1

MTB2

USER

PATH1

LIBRARY

CNC program

memory

(5) System folder

(4) MT B-dedica ted folder 1

(3) MT B-dedica ted folder 2

(2) Common program folder

NOTE

1 You can set whether to enable search (2) to (5) in the figure above with

parameter No. 3457. For details, see “Parameter Manual” of the relevant CNC.

2 On the memory card built into a Data Server, only the subprograms in the folder

containing the main program can be executed.

3 It takes time to call a program on the memory card built into a Data Server as a

subprogram as compared with the CNC memory. Be careful when calling many

small programs.

2.5 NC PROGRAM FORMAT

NC programs prepared on the host computer must have the following format:

% TITLE ;

O0001(COMMENT) ;

⋅

⋅

⋅

M30 ;

%

An NC program starts with a start file mark (%). In the subsequent part (leader section) until EOB (;,

program start) is encountered, a comment such as a title can be inserted as necessary.

- 23 -

Page 36

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

At the beginning of the program section, be sure to specify an O number or arbitrary file name consisting

of up to 32 characters that is enclosed with “<” and “>” as the program name. This O number or file name

must be used for management on the personal computer.

If the O number or arbitrary file name in an NC program and the file name in the personal computer are

not the same, the file name in the personal computer is used basically when the program is transferred

from the personal computer to the Data Server (NOTE 2).

The semicolon ";" used at the end of each block means EOB (end of block) and actually functions as LF

(LF: 0A in hexadecimal), CR-LF (CR: 0D in hexadecimal), or LF-CR-CR.

The NC program must end with "M code ; %".

When performing binary input operation, insert data for binary input operation, enclosed with the start

code and end code of binary input operation, into the part ". . ." in the above figure.

For details of the NC program configuration and binary input operation, refer to the relevant CNC

OPERATOR’S MANUAL.

WARNING

If an NC program prepared on the host computer does not use the program

format specified by the CNC, executing the NC program can cause an

unpredictable operation. So, special care should be taken when an NC program

is prepared on the host computer.

NOTE

1 Any unrecognizable character codes in an NC program registered as a text file

on a memory card on a Data Server are ignored. Do not use any unrecognizable

character code.

A 2-byte code used for Japanese and others may be recognized as an invalid

character code when the system recognizes it on a byte-by-byte basis. Do not

use any 2-byte code used for Japanese and others.

2 The system always manages each text file on the memory card so that the file

name and the O number or arbitrary file name in the program are the same. For

this reason, if they are different, the system sets the O number or arbitrary file

name to the file name when transferring the file. The O number or arbitrary file

name in the program can also be set as the file name when the file is transferred

according to the parameter setting, however.

- 24 -

Page 37

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.6 LIST FILE FORMAT

In the LIST-GET, LIST-PUT, and LIST-DELETE functions described later, one of the following list file

formats must be used:

Format 1 Format 3

% ;

O0001(COMMENT) ;

N111 ;

N222 ;

N333 ;

:

:

N999 ;

%

Format 2 Format 4

% ;

O0001(COMMENT) ;

N111 (PC-File) ;

N222 (PC-File) ;

N333 (PC-File) ;

:

:

N999 (PC-File) ;

%

Specifications common to all formats

<1> A list file begins with a start file mark "%".

<2> In the next block, be sure to specify an O number. Assign this O number as the file name.

A comment enclosed in parentheses "(" and ")" can be inserted between the O number and EOB.

<3> In the subsequent blocks, specify files to be processed.

<4> The list file must end with "%".

Specifications of format 1

The following describes the specifications of list file format 1:

<1> This specification method applies when the file names of files to be processed have the format

"Oxxxx" (where "xxxx" denotes a 4-digit number). In this case, change "O" in file name "Oxxxx" to

"N" when specifying the file name. The 4-digit number can be zero-suppressed. The example shows

that files O0111, O0222, O0333, and so on up to O0999 are processed sequentially.

<2> The LIST-GET service transfers "Oxxxx" files stored on the built-in hard disk of the host computer

to the built-in memory card of the Fast Data Server without modifying file names "Oxxxx". The

LIST-PUT service transfers "Oxxxx" files stored on the built-in memory card of the Fast Data

Server to the built-in hard disk of the host computer without modifying file names "Oxxxx". The

LIST-DELETE service deletes "Oxxxx" files stored on the built-in memory card of the Fast Data

Server.

% ;

O0001(COMMENT) ;

(Dtsvr-File) ;

(Dtsvr-File) ;

(Dtsvr-File) ;

:

:

(Dtsvr-File) ;

%

% ;

O0001(COMMENT) ;

(Dtsvr-File, PC-File) ;

(Dtsvr-File, PC-File) ;

(Dtsvr-File, PC-File) ;

:

:

(Dtsvr-File, PC-File) ;

%

- 25 -

Page 38

2.DATA SERVER FUNCTIONS SPECIFICATION B-64014EN/07

Specifications of format 2

The following describes the specifications of list file format 2:

<1> This specification method applies when files to be processed are named "Oxxxx" (where "xxxx"

denotes a 4-digit number) on the built-in memory card of the Fast Data Server and are named

arbitrary file names on the built-in hard disk of the host computer. In this case, change "O" in file

name "Oxxxx" to "N" when specifying the file name on the Fast Data Server. The 4-digit number

can be zero-suppressed. The example shows that files O0111, O0222, O0333, and so on up to O0999

are processed sequentially.

A file name on the built-in hard disk of the host computer can be specified by enclosing it with

parentheses "(" and ")" following the corresponding "Nxxxx". The characters that can be used in file

names depend on the OS of the host computer.

<2> The LIST-GET service transfers files with arbitrary file names "PC-File" stored on the built-in hard

disk of the host computer to the built-in memory card of the Fast Data Server as "Oxxxx" files. The

LIST-PUT service transfers "Oxxxx" files stored on the built-in memory card of the Fast Data

Server to the built-in hard disk of the host computer as files with arbitrary file names "PC-File". The

LIST-DELETE service deletes "Oxxxx" files stored on the built-in memory card of the Fast Data

Server.

Specifications of format 3

The following describes the specifications of list file format 3:

<1> This specification method applies when the file names of files to be processed are arbitrary file

names. In this case, file names on the built-in memory card of the Fast Data Server and on the

built-in hard disk of the host computer are assumed to be the same. Specify an arbitrary file name

enclosed with parentheses "(" and ")". The characters that can be used in arbitrary file names are the

following 66 ASCII characters only:

Numeric characters 0 to 9

Lowercase letters a to z

Uppercase letters A to Z

Four symbols (+, -, _, .)

<2> The LIST-GET service transfers files with arbitrary file names "Dtsvr-File" stored on the built-in

hard disk of the host computer to the built-in memory card of the Fast Data Server with the file

names kept unchanged.

The LIST-PUT service transfers "Dtsvr-File" files stored on the built-in memory card of the Fast

Data Server to the built-in hard disk of the host computer with the file names "Dtsvr-File" kept

unchanged. The LIST-DELETE service deletes "Dtsvr-File" files stored on the built-in memory card

of the Fast Data Server.

Specifications of format 4

The following describes the specifications of list file format 4:

<1> This specification method applies when files to be processed have arbitrary file names. In this case,

file names on the built-in memory card of the Fast Data Server and file names on the built-in hard

disk of the host computer are assumed to be different. Specify a file name on the built-in memory

card of the Fast Data Server and a file name on the built-in hard disk of the host computer in

parentheses, separated by a comma ",".

The characters that can be used in file names on the built-in memory card of the Fast Data Server are

the following 66 ASCII characters only:

Numeric characters 0 to 9

Lowercase letters a to z

Uppercase letters A to Z

Four symbols (+, -, _, .)

The characters that can be used in arbitrary file names on the built-in hard disk of the host computer

depend on the OS of the host computer.

<2> The LIST-GET service transfers files with arbitrary file names "PC-File" stored on the built-in hard

disk of the host computer to the built-in memory card of the Fast Data Server as "Dtsvr-File" files.

- 26 -

Page 39

B-64014EN/07 SPECIFICATION 2.DATA SERVER FUNCTIONS

The LIST-PUT service transfers "Dtsvr-File" files stored on the built-in memory card of the Fast

Data Server to files with file name "PC-File" on the built-in hard disk of the host computer.

The LIST-DELETE service deletes "Dtsvr-File" files stored on the built-in memory card of the Fast

Data Server.

Limitations on file names in a list file

The following limitations apply when file names are specified in a list file:

<1> The characters that can be used in file names on the built-in memory card of the Fast Data Server are

the following 66 ASCII characters only:

Numeric characters 0 to 9

Lowercase letters a to z

Uppercase letters A to Z

Four symbols (+, -, _, .)

The characters that can be used in arbitrary file names on the built-in hard disk of the host computer

depend on the OS of the host computer.

<2> Up to 255 characters can be used as an arbitrary file name on the built-in hard disk of the host

computer. However, the number of characters that can actually be used depends on the OS of the

host computer.

Storage locations of list files

The LIST-GET, LIST-PUT, and LIST-DELETE services are useful functions for managing NC programs

in groups.