Page 1

FANUC Series 30+-MODEL B

FANUC Series 31+-MODEL B

FANUC Series 32+-MODEL B

DESCRIPTIONS

B-64482EN/03

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export of Series 30i-B, Series 31i-B5 from Japan is subject to an

export license by the government of Japan. Other models in this manual may also be

subject to export controls.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

Page 3

B-64482EN/03 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units.

It is essential that these precautions be observed by users to ensure the safe operation of machines

equipped with a CNC unit (all descriptions in this section assume this configuration). Note that some

precautions are related only to specific functions, and thus may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual

supplied by the machine tool builder. Before attempting to operate the machine or create a program to

control the operation of the machine, the operator must become fully familiar with the contents of this

manual and relevant manual supplied by the machine tool builder.

CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE.........................................................................s-1

GENERAL WARNINGS AND CAUTIONS ............................................................................................ s-2

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING.......................................................s-3

WARNINGS AND CAUTIONS RELATED TO HANDLING ................................................................s-5

WARNINGS RELATED TO DAILY MAINTENANCE .........................................................................s-7

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

SAFETY PRECAUTIONS B-64482EN/03

GENERAL WARNINGS AND CAUTIONS

WARNING

1 Never attempt to machine a workpiece without first checking the operation of the

machine. Before starting a production run, ensure that the machine is operating

correctly by performing a trial run using, for example, the single block, feedrate

override, or machine lock function or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct operation of the machine

may result in the machine behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

2 Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

3 Ensure that the specified feedrate is appropriate for the intended operation.

Generally, for each machine, there is a maximum allowable feedrate.

The appropriate feedrate varies with the intended operation. Refer to the manual

provided with the machine to determine the maximum allowable feedrate.

If a machine is run at other than the correct speed, it may behave unexpectedly,

possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

4 When using a tool compensation function, thoroughly check the direction and

amount of compensation.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

5 The parameters for the CNC and PMC are factory-set. Usually, there is not need

to change them. When, however, there is not alternative other than to change a

parameter, ensure that you fully understand the function of the parameter before

making any change.

Failure to set a parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself,

or injury to the user.

6 Immediately after switching on the power, do not touch any of the keys on the

MDI panel until the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other

special operations. Pressing any of these keys may place the CNC unit in other

than its normal state. Starting the machine in this state may cause it to behave

unexpectedly.

7 The Operator’s Manual and Programming Manual supplied with a CNC unit

provide an overall description of the machine's functions, including any optional

functions. Note that the optional functions will vary from one machine model to

another. Therefore, some functions described in the manuals may not actually

be available for a particular model. Check the specification of the machine if in

doubt.

8 Some functions may have been implemented at the request of the machine-tool

builder. When using such functions, refer to the manual supplied by the

machine-tool builder for details of their use and any related cautions.

s-2

Page 5

B-64482EN/03 SAFETY PRECAUTIONS

CAUTION

The liquid-crystal display is manufactured with very precise fabrication

technology. Some pixels may not be turned on or may remain on. This

phenomenon is a common attribute of LCDs and is not a defect.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in

the CNC unit. Usually, they are retained even if the power is turned off.

Such data may be deleted inadvertently, however, or it may prove necessary to

delete all data from nonvolatile memory as part of error recovery.

To guard against the occurrence of the above, and assure quick restoration of

deleted data, backup all vital data, and keep the backup copy in a safe place.

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to perform

programming, read the supplied Operator’s Manual carefully such that you are fully familiar with their

contents.

WARNING

1

Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave

unexpectedly as a result of the program issuing an otherwise valid move

command. Such an unexpected operation may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

2

Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear

movement between the start and end points), the tool path must be carefully

confirmed before performing programming. Positioning involves rapid traverse. If

the tool collides with the workpiece, it may damage the tool, the machine itself,

the workpiece, or cause injury to the user.

3

Function involving a rotation axis

When programming polar coordinate interpolation or normal-direction

(perpendicular) control, pay careful attention to the speed of the rotation axis.

Incorrect programming may result in the rotation axis speed becoming

excessively high, such that centrifugal force causes the chuck to lose its grip on

the workpiece if the latter is not mounted securely. Such mishap is likely to

damage the tool, the machine itself, the workpiece, or cause injury to the user.

4

Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement

units of data such as the workpiece origin offset, parameter, and current

position. Before starting the machine, therefore, determine which measurement

units are being used. Attempting to perform an operation with invalid data

specified may damage the tool, the machine itself, the workpiece, or cause injury

to the user.

s-3

Page 6

SAFETY PRECAUTIONS B-64482EN/03

WARNING

5

Constant surface speed control

When an axis subject to constant surface speed control approaches the origin of

the workpiece coordinate system, the spindle speed may become excessively

high. Therefore, it is necessary to specify a maximum allowable speed.

Specifying the maximum allowable speed incorrectly may damage the tool, the

machine itself, the workpiece, or cause injury to the user.

6

Stroke check

After switching on the power, perform a manual reference position return as

required. Stroke check is not possible before manual reference position return is

performed. Note that when stroke check is disabled, an alarm is not issued even

if a stroke limit is exceeded, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the user.

7

Tool post interference check

A tool post interference check is performed based on the tool data specified

during automatic operation. If the tool specification does not match the tool

actually being used, the interference check cannot be made correctly, possibly

damaging the tool or the machine itself, or causing injury to the user. After

switching on the power, or after selecting a tool post manually, always start

automatic operation and specify the tool number of the tool to be used.

8

Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice

versa, the machine may behave unexpectedly.

9

Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or

a canned cycle, the machine may behave unexpectedly. Refer to the

descriptions of the respective functions for details.

10

Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip

is specified without the torque limit actually being applied, a move command will

be executed without performing a skip.

WARNING

11

Programmable mirror image

Note that programmed operations vary considerably when a programmable

mirror image is enabled.

12

Compensation function

If a command based on the machine coordinate system or a reference position

return command is issued in compensation function mode, compensation is

temporarily canceled, resulting in the unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel

compensation function mode.

s-4

Page 7

B-64482EN/03 SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting to

operate your machine, read the supplied Operator’s Manual carefully, such that you are fully familiar

with their contents.

WARNING

1

Manual operation

When operating the machine manually, determine the current position of the tool

and workpiece, and ensure that the movement axis, direction, and feedrate have

been specified correctly. Incorrect operation of the machine may damage the

tool, the machine itself, the workpiece, or cause injury to the operator.

2

Manual reference position return

After switching on the power, perform manual reference position return as

required.

If the machine is operated without first performing manual reference position

return, it may behave unexpectedly. Stroke check is not possible before manual

reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

3

Manual numeric command

When issuing a manual numeric command, determine the current position of the

tool and workpiece, and ensure that the movement axis, direction, and command

have been specified correctly, and that the entered values are valid.

Attempting to operate the machine with an invalid command specified may

damage the tool, the machine itself, the workpiece, or cause injury to the

operator.

4

Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such as 100,

applied causes the tool and table to move rapidly. Careless handling may

damage the tool and/or machine, or cause injury to the user.

5

Disabled override

If override is disabled (according to the specification in a macro variable) during

threading, rigid tapping, or other tapping, the speed cannot be predicted,

possibly damaging the tool, the machine itself, the workpiece, or causing injury

to the operator.

6

Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is

operating under the control of a program. Otherwise, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the tool, or causing

injury to the user.

7

Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece

coordinate system. Before attempting to operate the machine under the control

of a program, confirm the coordinate system carefully.

If the machine is operated under the control of a program without making

allowances for any shift in the workpiece coordinate system, the machine may

behave unexpectedly, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the operator.

s-5

Page 8

SAFETY PRECAUTIONS B-64482EN/03

WARNING

8

Software operator's panel and menu switches

Using the software operator's panel and menu switches, in combination with the

MDI panel, it is possible to specify operations not supported by the machine

operator's panel, such as mode change, override value change, and jog feed

commands.

Note, however, that if the MDI panel keys are operated inadvertently, the

machine may behave unexpectedly, possibly damaging the tool, the machine

itself, the workpiece, or causing injury to the user.

9

RESET key

Pressing the RESET key stops the currently running program. As a result, the

servo axes are stopped. However, the RESET key may fail to function for

reasons such as an MDI panel problem. So, when the motors must be stopped,

use the emergency stop button instead of the RESET key to ensure security.

10

Manual intervention

If manual intervention is performed during programmed operation of the

machine, the tool path may vary when the machine is restarted. Before restarting

the machine after manual intervention, therefore, confirm the settings of the

manual absolute switches, parameters, and absolute/incremental command

mode.

11

Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled

using custom macro system variable #3004. Be careful when operating the

machine in this case.

12

Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry

run, the machine operates at dry run speed, which differs from the

corresponding programmed feedrate. Note that the dry run speed may

sometimes be higher than the programmed feed rate.

13

Cutter and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode,

because cutter or tool nose radius compensation is not applied. When a

command is entered from the MDI to interrupt in automatic operation in cutter or

tool nose radius compensation mode, pay particular attention to the tool path

when automatic operation is subsequently resumed. Refer to the descriptions of

the corresponding functions for details.

14

Program editing

If the machine is stopped, after which the machining program is edited

(modification, insertion, or deletion), the machine may behave unexpectedly if

machining is resumed under the control of that program. Basically, do not

modify, insert, or delete commands from a machining program while it is in use.

s-6

Page 9

B-64482EN/03 SAFETY PRECAUTIONS

WARNINGS RELATED TO DAILY MAINTENANCE

WARNING

1

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

electric shock hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must

retain data such as programs, offsets, and parameters even while external

power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the contents of the CNC's memory will be lost.

Refer to the Section “Method of replacing battery” in the Operator’s Manual

(Common to Lathe System/Machining Center System) for details of the battery

replacement procedure.

WARNING

2

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked

and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

electric shock hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the absolute position data held by the pulse coder will be lost.

Refer to the FANUC SERVO MOTOR

of the battery replacement procedure.

i

series Maintenance Manual for details

α

s-7

Page 10

SAFETY PRECAUTIONS B-64482EN/03

WARNING

3

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the

cause of the blown fuse.

For this reason, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the

high-voltage circuits (marked and fitted with an insulating cover).

Touching an uncovered high-voltage circuit presents an extremely dangerous

electric shock hazard.

s-8

Page 11

B-64482EN/03 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE .............................................s-1

GENERAL WARNINGS AND CAUTIONS............................................................... s-2

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING ............................s-3

WARNINGS AND CAUTIONS RELATED TO HANDLING...................................... s-5

WARNINGS RELATED TO DAILY MAINTENANCE............................................... s-7

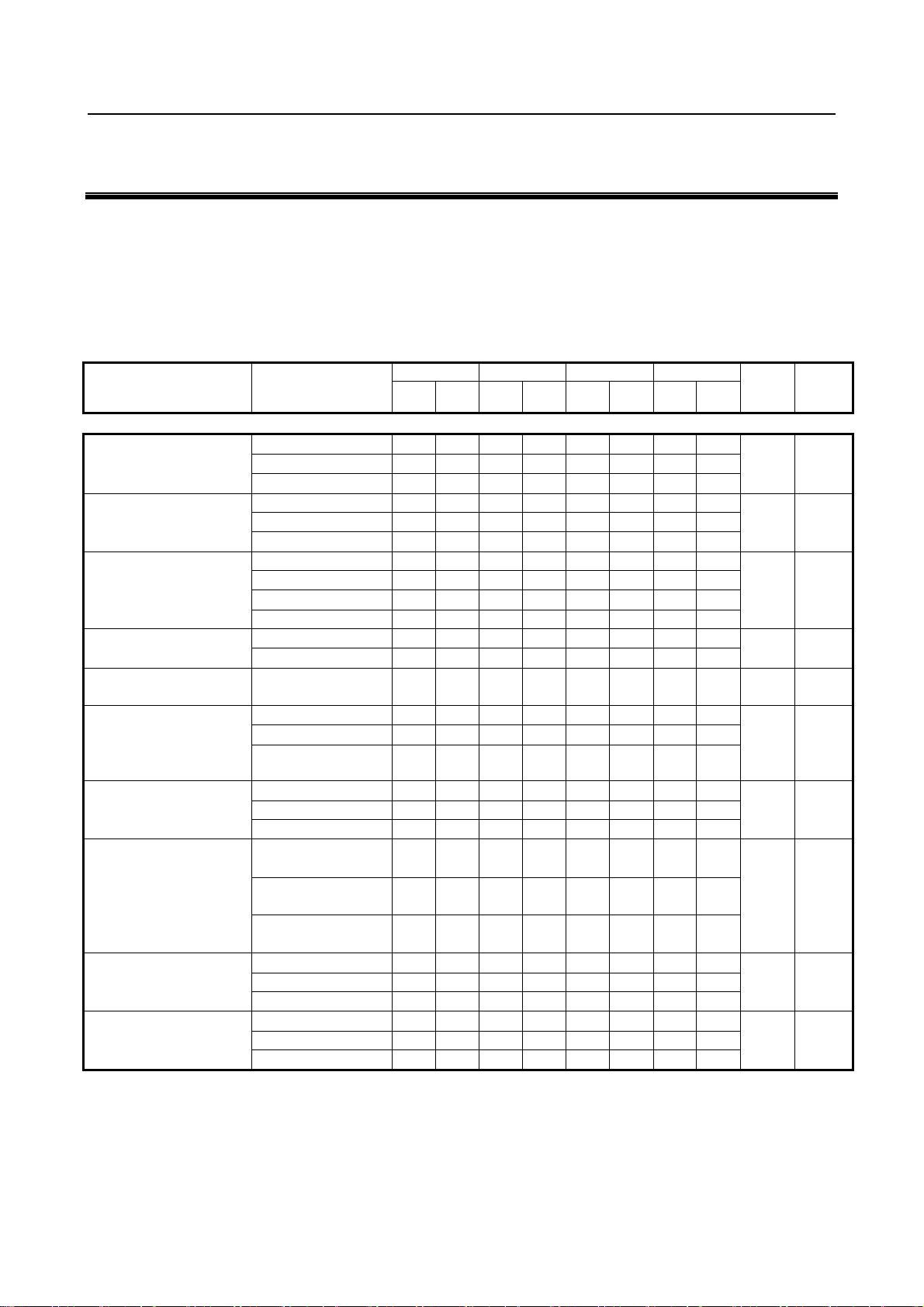

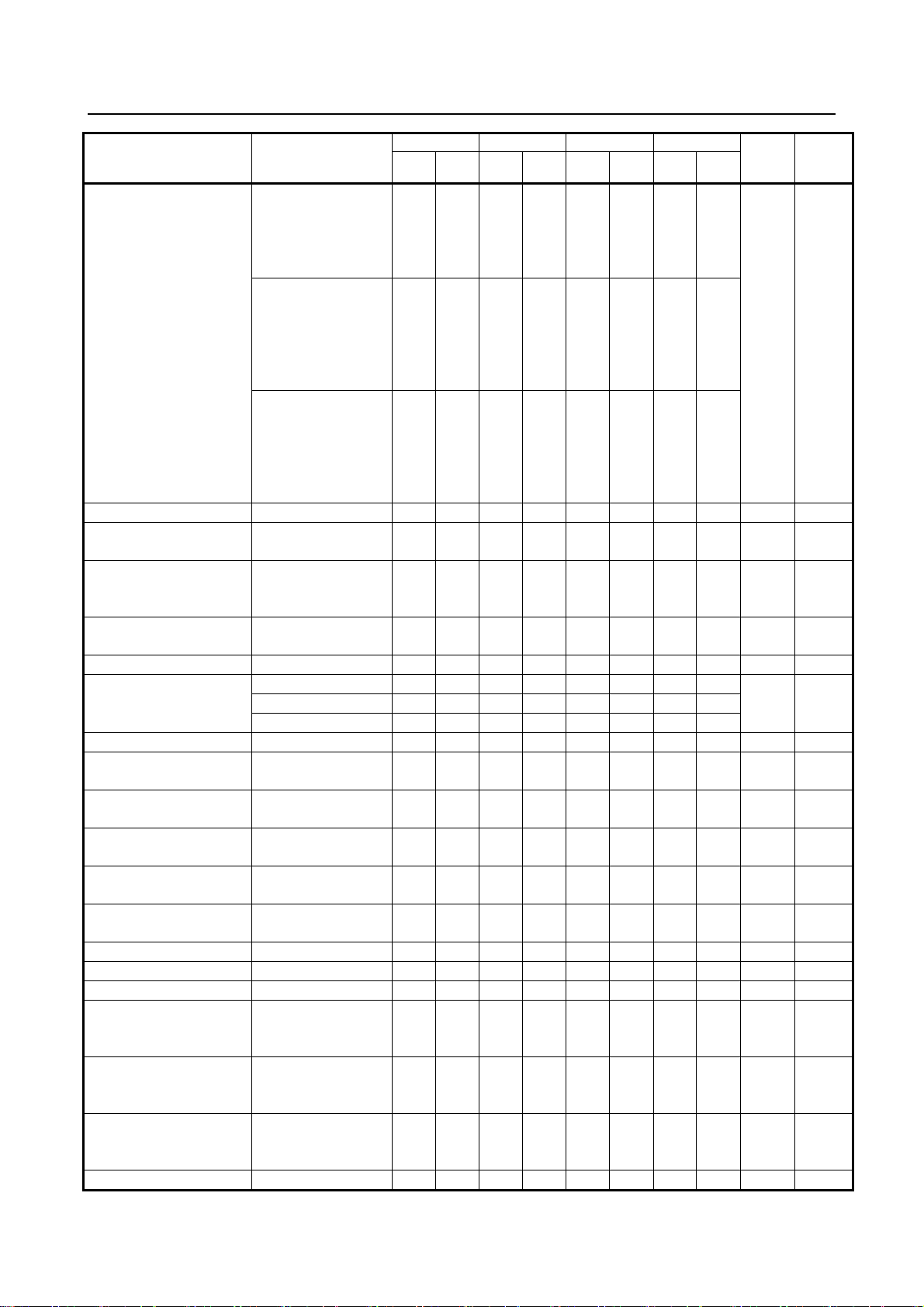

I. GENERAL

1 GENERAL ...............................................................................................3

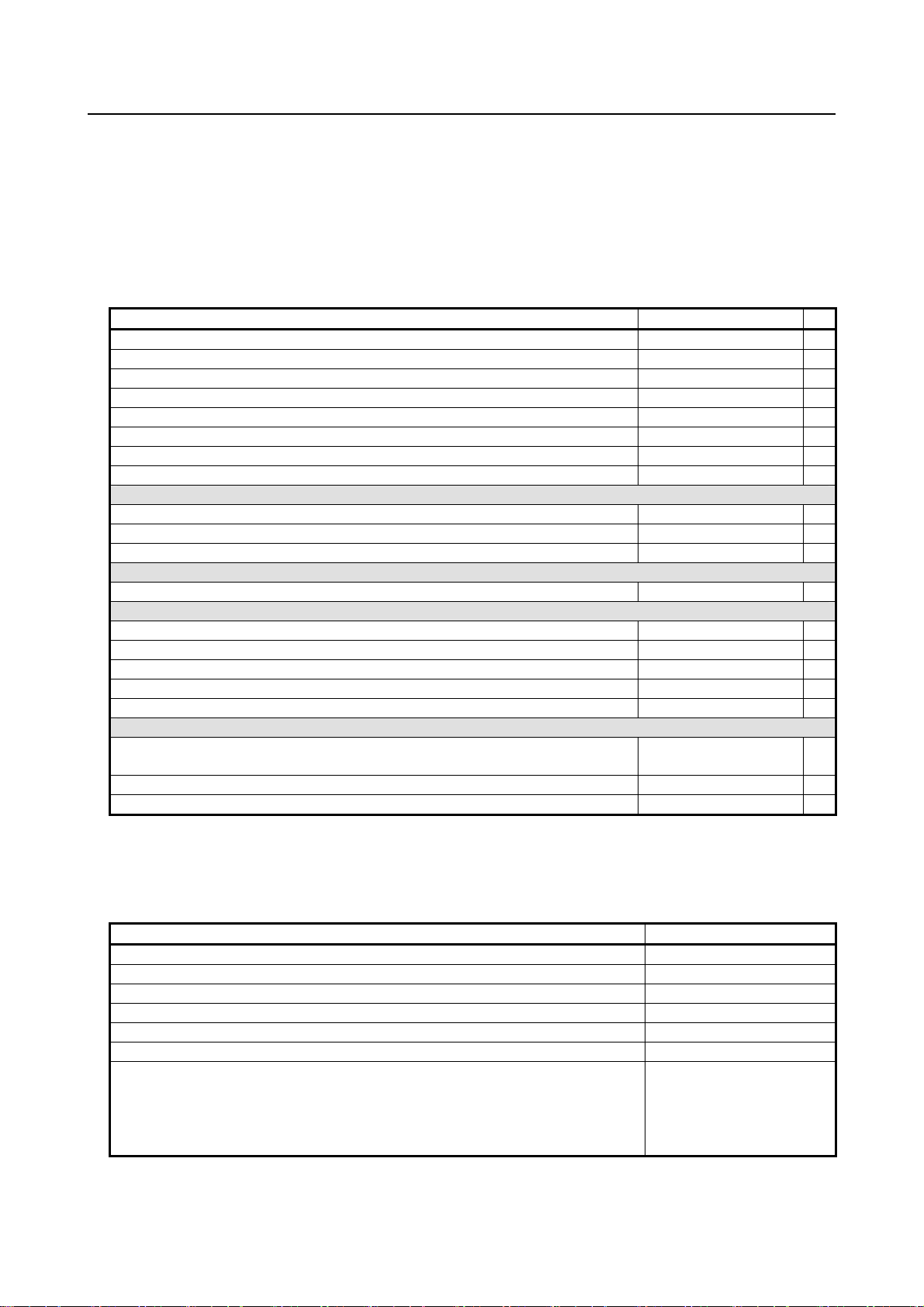

2 LIST OF SPECIFICATION ......................................................................6

II. NC FUNCTION

1 CONTROLLED AXIS ............................................................................41

1.1 NUMBER OF MAXIMUM CONTROLLED AXES......................................... 42

1.2 NUMBER OF MACHINE GROUPS ............................................................. 42

1.3 NUMBER OF CONTROLLED PATHS......................................................... 43

1.3.1 Multi-path Control..................................................................................................43

1.4 NUMBER OF CONTROLLED AXES / NUMBER OF CONTROLLED

SPINDLE AXES...........................................................................................43

1.5 AXIS CONTROL BY PMC ........................................................................... 44

1.6 Cs CONTOURING CONTROL ....................................................................44

1.7 NAMES OF AXES .......................................................................................44

1.7.1 Names of Axes .......................................................................................................44

1.7.2 Axis Name Expansion ............................................................................................45

1.8 ARBITRARY AXIS NAME SETTING ........................................................... 46

1.8.1 Arbitrary Axis Name ..............................................................................................46

1.8.2 AXNUM Function..................................................................................................46

1.9 SPINDLE NAME EXPANSION .................................................................... 47

1.10 SYNCHRONOUS / COMPOSITE CONTROL.............................................. 48

1.11 SUPERIMPOSED CONTROL .....................................................................50

1.12 AXIS SYNCHRONOUS CONTROL............................................................. 51

1.13 ANGULAR AXIS CONTROL........................................................................ 51

1.14 INCLINED ROTARY AXIS CONTROL ........................................................52

1.15 TANDEM CONTROL ................................................................................... 54

1.16 TANDEM DISTURBANCE ELIMINATION CONTROL................................. 54

1.17 TORQUE CONTROL................................................................................... 55

1.18 POLE POSITION DETECTION FUNCTION................................................ 55

1.19 CONTROL AXIS DETACH ..........................................................................55

1.20 CHOPPING FUNCTION .............................................................................. 55

1.21 INCREMENT SYSTEM................................................................................ 56

1.22 FLEXIBLE FEED GEAR ..............................................................................57

1.23 ARBITRARY COMMAND MULTIPLY.......................................................... 57

c-1

Page 12

TABLE OF CONTENTS B-64482EN/03

1.24 DUAL POSITION FEEDBACK.....................................................................57

1.25 HRV CONTROL........................................................................................... 58

1.26 INCH/METRIC CONVERSION .................................................................... 59

1.27 INTERLOCK ................................................................................................ 59

1.27.1 Start Lock ...............................................................................................................59

1.27.2 All-axis Interlock....................................................................................................59

1.27.3 Each-axis Interlock.................................................................................................59

1.27.4 Each-axis Direction Interlock.................................................................................59

1.27.5 Block Start Interlock ..............................................................................................60

1.27.6 Cutting Block Start Interlock .................................................................................60

1.28 MACHINE LOCK .........................................................................................60

1.28.1 All-axis Machine Lock...........................................................................................60

1.28.2 Each-axis Machine Lock ........................................................................................60

1.29 EMERGENCY STOP................................................................................... 60

1.30 OVERTRAVEL............................................................................................. 60

1.31 STORED STROKE CHECK 1...................................................................... 61

1.32 STORED STROKE CHECK 1 AREA EXPANSION ..................................... 61

1.33 STROKE LIMIT EXTERNAL SETTING ....................................................... 61

1.34 STORED STROKE CHECK 2 (G22, G23)................................................... 61

1.35 STORED STROKE CHECK 3...................................................................... 62

1.36 STROKE LIMIT CHECK BEFORE MOVE ................................................... 62

1.37 CHUCK AND TAIL STOCK BARRIER......................................................... 62

1.38 CHECKING THE STORED STROKE DURING THE TIME FROM

POWER–ON TO THE REFERENCE POSITION ESTABLISHMENT.......... 64

1.39 STROKE LIMIT AREA CHANGING FUNCTION .........................................64

1.40 ROTATION AREA INTERFERENCE CHECK ............................................. 64

1.41 MIRROR IMAGE.......................................................................................... 65

1.42 FOLLOW-UP ............................................................................................... 66

1.43 SERVO OFF / MECHANICAL HANDLE FEED............................................ 66

1.44 CHAMFERING ON/OFF .............................................................................. 66

1.45 INTERFERENCE CHECK FOR EACH PATH .............................................66

1.46 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION ........67

1.47 ROTARY AXIS CONTROL .......................................................................... 68

1.48 POSITION SWITCH ....................................................................................68

1.49 HIGH-SPEED POSITION SWITCH ............................................................. 68

1.50 DIRECTION-DEPENDENT TYPE HIGH-SPEED POSITION SWITCH ....... 68

1.51 LINEAR SCALE WITH ABSOLUTE ADDRESS REFERENCE MARK ........ 69

1.51.1 Linear Scale Interface with Absolute Address Reference Mark ............................69

1.51.2 Linear Scale with Absolute Address Reference Mark Expansion..........................69

1.52 LINEAR SCALE WITH DISTANCE-CODED REFERENCE MARKS

(SERIAL) .....................................................................................................69

1.53 ABSOLUTE POSITION DETECTION.......................................................... 69

1.54 TEMPORARY ABSOLUTE COORDINATE SETTING................................. 70

1.55 DUAL CHECK SAFETY............................................................................... 70

1.56 FUNCTION OF DECELERATION STOP IN CASE OF POWER FAILURE. 71

1.57 CORRESPONDENCE OF ROTARY SCALE WITHOUT ROTARY DATA... 71

1.58 FLEXIBLE SYNCHRONIZATION CONTROL.............................................. 71

1.58.1 Flexible Synchronization Control ..........................................................................71

c-2

Page 13

B-64482EN/03 TABLE OF CONTENTS

1.58.2 Automatic Phase Synchronization for Flexible Synchronous Control...................72

1.58.3 Inter-path Flexible Synchronous Control ...............................................................72

1.58.4 Chopping Function by Flexible Synchronous Control...........................................74

1.58.5 Skip Function for Flexible Synchronous Control...................................................74

1.59 AXIS IMMEDIATE STOP FUNCTION .........................................................74

1.60 PIVOT AXIS CONTROL .............................................................................. 74

1.61 FLEXIBLE PATH AXIS ASSIGNMENT........................................................ 75

1.62 BUILT-IN 3D INTERFERENCE CHECK...................................................... 77

1.63 HIGH PRECISION OSCILLATION FUNCTION........................................... 79

2 OPERATION .........................................................................................81

2.1 OPERATION MODE.................................................................................... 82

2.1.1 Automatic Operation (Memory Operation) ............................................................82

2.1.2 MDI Operation .......................................................................................................82

2.1.3 DNC Operation.......................................................................................................82

2.1.4 DNC Operation with Memory Card .......................................................................82

2.1.5 Schedule Operation ................................................................................................82

2.2 PROGRAM SEARCH .................................................................................. 82

2.3 SEQUENCE NUMBER SEARCH ................................................................ 82

2.4 SEQUENCE NUMBER COMPARISON AND STOP ...................................82

2.5 PROGRAM RESTART ................................................................................82

2.5.1 Auxiliary Function Output in Program Restart Function .......................................83

2.6 QUICK PROGRAM RESTART .................................................................... 83

2.7 TOOL RETRACT AND RECOVER.............................................................. 83

2.7.1 TOOL RETRACT AND RECOVER .....................................................................83

2.7.2 Improvement of Tool compensation for Tool Retract and Recover.......................85

2.8 MANUAL INTERVENTION AND RETURN.................................................. 85

2.9 RETRACE.................................................................................................... 85

2.10 ACTIVE BLOCK CANCEL FUNCTION........................................................ 85

2.11 MALFUNCTION PREVENT FUNCTIONS ................................................... 85

2.12 WRONG OPERATION PREVENTION FUNCTION..................................... 86

2.13 RETRACTION FOR RIGID TAPPING ......................................................... 86

2.13.1 Retraction for Rigid Tapping by Using the G30 Command...................................87

2.14 BUFFER REGISTER ................................................................................... 87

2.15 DRY RUN .................................................................................................... 87

2.16 SINGLE BLOCK ..........................................................................................87

2.17 HIGH SPEED PROGRAM CHECK FUNCTION .......................................... 87

2.18 JOG FEED................................................................................................... 87

2.19 MANUAL REFERENCE POSITION RETURN............................................. 88

2.20 REFERENCE POSITION SETTING WITHOUT DOG ................................. 88

2.21 REFERENCE POSITION SETTING WITH MECHANICAL STOPPER ....... 88

2.22 REFERENCE POSITION SETTING WITH MECHANICAL STOPPER FOR

AXIS SYNCHRONOUS CONTROL............................................................. 89

2.23 REFERENCE POSITION SETTING WITH MECHANICAL STOPPER BY

GRID METHOD ........................................................................................... 89

2.24 REFERENCE POSITION RETURN FEEDRATE SETTING ........................ 89

2.25 REFERENCE POSITION SHIFT ................................................................. 89

2.26 MANUAL HANDLE FEED............................................................................90

2.26.1 Manual Handle Feed (1 Unit).................................................................................90

c-3

Page 14

TABLE OF CONTENTS B-64482EN/03

2.26.2 Manual Handle Feed (2/3 Units) ............................................................................90

2.26.3 Manual Handle Feed (4/5 Units) ............................................................................90

2.26.4 Manual Handle Feed Magnification.......................................................................90

2.26.5 Manual Handle Feed Multiple 10 Million..............................................................90

2.27 3-DIMENSIONAL MANUAL FEED ..............................................................90

2.27.1 Tool Axis Direction Handle Feed / Tool Axis Direction Jog Feed / Tool Axis

Direction Incremental Feed ....................................................................................91

2.27.2 Tool Axis Right-Angle Direction Handle Feed / Tool Axis Right-Angle

Direction Jog Feed / Tool Axis Right-Angle Direction Incremental Feed.............92

2.27.3 Tool Tip Center Rotation Handle Feed / Tool Tip Center Rotation Jog Feed /

Tool Tip Center Rotation Incremental Feed...........................................................92

2.27.4 Table Vertical Direction Handle Feed / Table Vertical Direction Jog Feed /

Table Vertical Direction Incremental Feed ............................................................93

2.27.5 Table Horizontal Direction Handle Feed / Table Horizontal Direction Jog Feed /

Table Horizontal Direction Incremental Feed........................................................94

2.28 MANUAL HANDLE INTERRUPTION .......................................................... 94

2.28.1 Manual Interruption of 3-dimensional Coordinate System Conversion.................94

2.29 MANUAL LINEAR/CIRCULAR INTERPOLATION....................................... 95

2.30 HANDLE-SYNCHRONOUS FEED .............................................................. 95

2.31 FANUC SERVO MOTOR β Series (I/O OPTION) MANUAL HANDLE

INTERFACE ................................................................................................97

2.32 INCREMENTAL FEED ................................................................................97

2.33 JOG AND HANDLE SIMULTANEOUS MODE ............................................97

2.34 MANUAL NUMERICAL COMMAND............................................................ 97

2.35 REFERENCE POSITION SIGNAL OUTPUT FUNCTION ........................... 98

2.36 MANUAL HANDLE RETRACE .................................................................... 98

2.37 AUXILIARY FUNCTION OUTPUT BLOCK REVERSE MOVEMENT FOR

MANUAL HANDLE RETRACE .................................................................... 98

2.38 MANUAL HANDLE RETRACE FUNCTION FOR MULTI-PATH.................. 98

2.39 EXTENSION OF THE MANUAL HANDLE RETRACE FUNCTION ............. 98

2.40 PULSE SUPERIMPOSED FUNCTION........................................................ 98

2.41 RETRACTION FOR 3-DIMENSIONAL RIGID TAPPING ............................99

2.42 MANUAL 2ND/3RD/4TH REFERENCE POSITION RETURN FUNCTION .99

3 INTERPOLATION FUNCTION ............................................................101

3.1 NANO INTERPOLATION .......................................................................... 101

3.2 POSITIONING ........................................................................................... 102

3.3 SINGLE DIRECTION POSITIONING ........................................................102

3.4 EXACT STOP MODE ................................................................................ 103

3.5 TAPPING MODE ....................................................................................... 103

3.6 CUTTING MODE....................................................................................... 103

3.7 EXACT STOP............................................................................................ 104

3.8 IN-POSITION CHECK SIGNAL ................................................................. 104

3.9 LINEAR INTERPOLATION........................................................................ 104

3.10 CIRCULAR INTERPOLATION................................................................... 105

3.11 EXPONENTIAL INTERPOLATION............................................................ 106

3.12 DWELL ...................................................................................................... 107

3.13 POLAR COORDINATE INTERPOLATION................................................ 108

3.14 CYLINDRICAL INTERPOLATION ............................................................. 110

c-4

Page 15

B-64482EN/03 TABLE OF CONTENTS

3.14.1 Cylindrical Interpolation ......................................................................................110

3.14.2 Cylindrical Interpolation by Plane Distance Command .......................................111

3.15 HELICAL INTERPOLATION...................................................................... 112

3.16 HELICAL INTERPOLATION B................................................................... 113

3.17 INVOLUTE INTERPOLATION................................................................... 113

3.18 HYPOTHETICAL AXIS INTERPOLATION ................................................ 115

3.19 SPIRAL INTERPOLATION, CONICAL INTERPOLATION ........................ 116

3.20 SMOOTH INTERPOLATION ..................................................................... 119

3.21 NANO SMOOTHING ................................................................................. 119

3.22 NANO SMOOTHING 2 .............................................................................. 120

3.23 THREAD CUTTING, SYNCHRONOUS CUTTING .................................... 121

3.24 MULTIPLE THREADING ........................................................................... 122

3.25 THREADING RETRACT............................................................................ 123

3.25.1 Threading Retract (Canned Cycle).......................................................................123

3.25.2 Threading Retract (Multiple Repetitive Cycle) ....................................................123

3.26 CONTINUOUS THREADING..................................................................... 124

3.27 VARIABLE LEAD THREADING................................................................. 124

3.28 CIRCULAR THREAD CUTTING................................................................ 125

3.29 CIRCULAR THREAD CUTTING B ............................................................125

3.30 ARBITRARY SPEED THREADING ........................................................... 127

3.30.1 Arbitrary Speed Threading...................................................................................127

3.30.2 Re-machining Thread ...........................................................................................128

3.31 POLYGON TURNING................................................................................ 128

3.32 POLYGON TURNING WITH TWO SPINDLES.......................................... 129

3.33 SKIP FUNCTION ....................................................................................... 130

3.33.1 Skip Function .......................................................................................................130

3.33.2 Multi-step Skip.....................................................................................................131

3.33.3 High-speed Skip ...................................................................................................131

3.33.4 Continuous High-speed Skip Function.................................................................132

3.33.5 Torque Limit Skip ................................................................................................132

3.34 REFERENCE POSITION RETURN........................................................... 133

3.34.1 Automatic Reference Position Return ..................................................................133

3.34.2 Reference Position Return Check.........................................................................134

3.34.3 Second, Third, and Fourth Reference Position Return.........................................134

3.34.4 In-position Check Disable Reference Position Return .........................................134

3.34.5 Floating Reference Position Return......................................................................136

3.35 NORMAL DIRECTION CONTROL ............................................................ 136

3.36 NURBS INTERPOLATION ........................................................................ 138

3.36.1 NURBS Interpolation Additional Functions ........................................................139

3.37 3-DIMENSIONAL CIRCULAR INTERPOLATION...................................... 139

3.38 BALANCE CUTTING ................................................................................. 140

3.39 INDEX TABLE INDEXING ......................................................................... 141

3.40 GENERAL PURPOSE RETRACT ............................................................. 142

3.41 GROOVE CUTTING BY CONTINUOUS CIRCLE MOTION...................... 142

4 FEED FUNCTION................................................................................ 144

4.1 RAPID TRAVERSE ................................................................................... 144

4.2 RAPID TRAVERSE OVERRIDE................................................................ 145

4.3 FEED PER MINUTE .................................................................................. 145

c-5

Page 16

TABLE OF CONTENTS B-64482EN/03

4.4 FEED PER REVOLUTION......................................................................... 146

4.5 FEED PER REVOLUTION WITHOUT POSITION CODER....................... 147

4.6 CONSTANT SURFACE SPEED CONTROL WITHOUT POSITION

CODER...................................................................................................... 147

4.7 TANGENTIAL SPEED CONSTANT CONTROL ........................................ 147

4.8 CUTTING FEEDRATE CLAMP .................................................................147

4.9 AUTOMATIC ACCELERATION/DECELERATION .................................... 147

4.10 RAPID TRAVERSE BLOCK OVERLAP..................................................... 148

4.11 PROGRAMMABLE RAPID TRAVERSE OVERLAP .................................. 149

4.12 RAPID TRAVERSE BELL-SHAPED ACCELERATION/DECELERATION 149

4.13 POSITIONING BY OPTIMUM ACCELERATION....................................... 150

4.14 OPTIMUM TORQUE ACCELERATION/DECELERATION........................ 150

4.15 BELL-SHAPED ACCELERATION/DECELERATION AFTER CUTTING

FEED INTERPOLATION ........................................................................... 151

4.16 LINEAR ACCELERATION/DECELERATION BEFORE CUTTING FEED

INTERPOLATION...................................................................................... 151

4.17 FEEDRATE OVERRIDE............................................................................ 152

4.18 SECOND FEEDRATE OVERRIDE............................................................ 152

4.19 ONE-DIGIT F CODE FEED ....................................................................... 152

4.20 INVERSE TIME FEED............................................................................... 152

4.21 JOG OVERRIDE........................................................................................ 152

4.22 OVERRIDE CANCEL ................................................................................ 153

4.23 DWELL/AUXILIARY FUNCTION TIME OVERRIDE FUNCTION............... 153

4.24 MANUAL PER REVOLUTION FEED......................................................... 153

4.25 EXTERNAL DECELERATION ................................................................... 153

4.26 FEED STOP .............................................................................................. 153

4.27 SPEED CONTROL WITH ACCELERATION IN CIRCULAR

INTERPOLATION...................................................................................... 154

4.28 LINEAR ACCELERATION/DECELERATION AFTER CUTTING FEED

INTERPOLATION...................................................................................... 155

4.29 AI CONTOUR CONTROL I / AI CONTOUR CONTROL II......................... 156

4.30 HIGH-SPEED PROCESSING.................................................................... 157

4.31 LOOK-AHEAD BLOCKS EXPANSION...................................................... 157

4.32 BELL-SHAPED ACCELERATION/DECELERATION BEFORE

LOOK-AHEAD INTERPOLATION .............................................................157

4.33 JERK CONTROL ....................................................................................... 158

4.34 RIGID TAPPING BELL-SHAPED ACCELERATION/DECELERATION..... 159

4.35 SPEED COMMAND EXTENSION IN LEAST INPUT INCREMENTS C, D,

AND E........................................................................................................ 159

4.36 OPTIMUM ACCELERATION/DECELERATION FOR RIGID TAPPING .... 160

5 PROGRAM INPUT .............................................................................. 162

5.1 PROGRAM CODE.....................................................................................163

5.2 LABEL SKIP .............................................................................................. 163

5.3 PARITY CHECK ........................................................................................ 163

5.4 CONTROL-IN / CONTROL-OUT ............................................................... 164

5.5 OPTIONAL BLOCK SKIP .......................................................................... 164

c-6

Page 17

B-64482EN/03 TABLE OF CONTENTS

5.6 OPTIONAL BLOCK SKIP EXTENSION..................................................... 164

5.7 MAXIMUM COMMAND VALUES ..............................................................164

5.8 PROGRAM NAME..................................................................................... 166

5.9 SEQUENCE NUMBER .............................................................................. 166

5.10 ABSOLUTE PROGRAMMING / INCREMENTAL PROGRAMMING .........167

5.11 DECIMAL POINT PROGRAMMING / POCKET CALCULATOR TYPE

DECIMAL POINT PROGRAMMING .......................................................... 167

5.12 INPUT UNIT 10 TIME MULTIPLY.............................................................. 168

5.13 DIAMETER PROGRAMMING / RADIUS PROGRAMMING ...................... 168

5.14 DIAMETER AND RADIUS SETTING SWITCHING ................................... 169

5.15 PLANE SELECTION.................................................................................. 169

5.16 PLANE CONVERSION FUNCTION ..........................................................170

5.17 ROTARY AXIS SPECIFICATION .............................................................. 171

5.18 ROTARY AXIS ROLL-OVER..................................................................... 171

5.19 POLAR COORDINATE COMMAND.......................................................... 171

5.20 COORDINATE SYSTEM SETTING........................................................... 172

5.20.1 Machine Coordinate System.................................................................................172

5.20.2 Workpiece Coordinate System.............................................................................173

5.20.2.1 Setting a Workpiece Coordinate System ......................................................... 173

5.20.2.2 Automatic Coordinate System Setting............................................................. 174

5.20.2.3 Setting a Workpiece Coordinate System ......................................................... 174

5.20.3 Local Coordinate System .....................................................................................175

5.21 WORKPIECE COORDINATE SYSTEM PRESET ..................................... 176

5.22 EACH AXIS WORKPIECE COORDINATE SYSTEM PRESET SIGNALS. 176

5.23 ADDITION OF WORKPIECE COORDINATE SYSTEM PAIR................... 176

5.24 DIRECT INPUT OF WORKPIECE ORIGIN OFFSET VALUE

MEASURED ..............................................................................................177

5.25 MANUAL ABSOLUTE ON AND OFF......................................................... 177

5.26 DIRECT DRAWING DIMENSION PROGRAMMING ................................. 177

5.27 G CODE SYSTEM..................................................................................... 178

5.27.1 G Code for Lathe System .....................................................................................178

5.27.2 G Code System for Machining Center .................................................................182

5.28 LATHE/MACHINING CENTER G CODE SYSTEM SWITCHING

FUNCTION ................................................................................................ 185

5.29 CHAMFERING AND CORNER R .............................................................. 186

5.30 OPTIONAL CHAMFERING AND CORNER R........................................... 189

5.31 PROGRAMMABLE DATA INPUT.............................................................. 190

5.31.1 Setting the Pitch Error Compensation Data..........................................................190

5.31.2 Setting the Workpiece Origin Offset Value .........................................................191

5.31.3 Setting the Tool Compensation Offset Value.......................................................191

5.31.4 Setting the Tool Management Data......................................................................194

5.31.4.1 Registering new tool management data ........................................................... 194

5.31.4.2 Modifying tool management data .................................................................... 196

5.31.4.3 Deleting tool management data .......................................................................196

5.31.4.4 Registering new cartridge management table data .......................................... 196

5.31.4.5 Modifying the cartridge management table ..................................................... 197

5.31.4.6 Deleting cartridge management table data....................................................... 197

5.31.4.7 Naming customization data ............................................................................. 197

5.31.4.8 Naming tool life states ..................................................................................... 198

5.32 PROGRAMMABLE PARAMETER INPUT ................................................. 198

c-7

Page 18

TABLE OF CONTENTS B-64482EN/03

5.33 SUB PROGRAM CALL.............................................................................. 199

5.34 CUSTOM MACRO..................................................................................... 201

5.35 ADDITION OF CUSTOM MACRO COMMON VARIABLES ...................... 206

5.36 CUSTOM MACRO COMMON VARIABLES BETWEEN EACH PATH ...... 206

5.37 INTERRUPTION TYPE CUSTOM MACRO............................................... 206

5.38 PATTERN DATA INPUT............................................................................ 207

5.39 CANNED CYCLE....................................................................................... 208

5.39.1 Outer Diameter/Internal Diameter Cutting Cycle.................................................208

5.39.2 Threading Cycle ...................................................................................................209

5.39.3 End Face Turning Cycle.......................................................................................211

5.40 MULTIPLE REPETITIVE CYCLE ..............................................................212

5.40.1 Stock Removal in Turning ...................................................................................212

5.40.2 Stock Removal in Facing .....................................................................................214

5.40.3 Pattern Repeating .................................................................................................216

5.40.4 Finishing Cycle ....................................................................................................217

5.40.5 End Face Peck Drilling Cycle ..............................................................................218

5.40.6 Outer Diameter / Internal Diameter Drilling Cycle..............................................219

5.40.7 Multiple Threading Cycle ....................................................................................220

5.40.8 Stock Removal in Turning ...................................................................................221

5.40.9 Stock Removal in Facing .....................................................................................222

5.40.10 Pattern Repeating .................................................................................................222

5.40.11 Finishing Cycle ....................................................................................................223

5.40.12 End Face Peck Drilling Cycle ..............................................................................223

5.40.13 Outer Diameter / Internal Diameter Drilling Cycle..............................................223

5.40.14 Multiple Threading Cycle ....................................................................................224

5.41 IN-FEED CONTROL (FOR GRINDING MACHINE)................................... 225

5.42 CANNED GRINDING CYCLE (FOR GRINDING MACHINE)..................... 225

5.43 CANNED CYCLE FOR DRILLING............................................................. 226

5.44 IN-POSITION CHECK SWITCHING FOR DRILLING CANNED CYCLE... 227

5.45 CIRCULAR INTERPOLATION BY R PROGRAMMING ............................228

5.46 MIRROR IMAGE FOR DOUBLE TURRET................................................ 229

5.47 AUTOMATIC CORNER OVERRIDE .........................................................230

5.48 SCALING................................................................................................... 230

5.49 COORDINATE SYSTEM ROTATION........................................................ 231

5.50 3-DIMENSIONAL COORDINATE CONVERSION ..................................... 233

5.51 TILTED WORKING PLANE INDEXING..................................................... 234

5.52 TILTED WORKING PLANE INDEXING BY TOOL AXIS DIRECTION....... 235

5.53 PROGRAMMABLE MIRROR IMAGE ........................................................ 236

5.54 SYNCHRONOUS, COMPOSITE, AND SUPERIMPOSED CONTROL BY

PROGRAM COMMAND ............................................................................ 237

5.55 FIGURE COPY.......................................................................................... 238

5.56 PROGRAM FORMAT FOR FANUC Series 15 (PROGRAM FORMAT

FOR FANUC Series 10/11) ....................................................................... 240

5.57 MACRO EXECUTOR ................................................................................240

5.58 C LANGUAGE EXECUTOR ...................................................................... 241

5.59 ADDITION OF C LANGUAGE EXECUTOR SRAM ................................... 241

5.60 CUSTOM SOFTWARE SIZE..................................................................... 241

5.61 WORKPIECE COORDINATE SYSTEM SHIFT......................................... 242

5.62 EMBEDDED MACRO ................................................................................ 242

c-8

Page 19

B-64482EN/03 TABLE OF CONTENTS

5.63 SMALL-HOLE PECK DRILLING CYCLE................................................... 243

5.64 REAL TIME CUSTOM MACRO................................................................. 244

5.65 HIGH-SPEED CYCLE MACHINING .......................................................... 245

5.65.1 High-speed Cycle Machining...............................................................................245

5.65.2 High-speed Cycle Machining Retract Function ...................................................245

5.65.3 High-speed Cycle Machining Skip Function .......................................................246

5.65.4 High-speed Cycle Machining Operation Information Output Function...............246

5.65.5 Spindle Control Switching Function for High-speed Cycle Machining...............246

5.65.6 Superimposed Control for High-speed Cycle Machining ....................................248

5.66 HIGH-SPEED BINARY PROGRAM OPERATION..................................... 248

5.66.1 High-speed Binary Program Operation ................................................................248

5.66.2 High-speed Binary Program Operation Retract Function ....................................248

5.67 PATH TABLE OPERATION.......................................................................249

6 GUIDANCE FUNCTION ...................................................................... 250

6.1 MANUAL GUIDE i ................................................................................................ 250

6.1.1 Basic Function......................................................................................................250

6.1.2 Milling Cycle........................................................................................................250

6.1.3 Turning Cycle.......................................................................................................250

6.1.4 Animation.............................................................................................................250

6.1.5 Set-up Guidance Function ....................................................................................250

6.2 MANUAL GUIDE i MULTI-PATH LATHE FUNCTION ............................... 251

7 AUXILIARY FUNCTION / SPINDLE SPEED FUNCTION................... 252

7.1 AUXILIARY FUNCTION ............................................................................ 252

7.2 SECOND AUXILIARY FUNCTION ............................................................ 253

7.3 AUXILIARY FUNCTION LOCK.................................................................. 253

7.4 HIGH-SPEED M/S/T/B INTERFACE ......................................................... 253

7.5 WAITING FUNCTION................................................................................ 254

7.6 MULTIPLE COMMAND OF AUXILIARY FUNCTION ................................ 255

7.7 SPINDLE SPEED FUNCTION (S CODE OUTPUT) .................................. 256

7.8 SPINDLE SERIAL OUTPUT...................................................................... 256

7.9 SPINDLE ANALOG OUTPUT.................................................................... 256

7.10 CONSTANT SURFACE SPEED CONTROL .............................................256

7.11 SPINDLE OVERRIDE................................................................................ 257

7.12 ACTUAL SPINDLE SPEED OUTPUT ....................................................... 257

7.13 SPINDLE ORIENTATION.......................................................................... 257

7.14 SPINDLE OUTPUT SWITCHING FUNCTION...........................................257

7.15 SPINDLE SYNCHRONOUS CONTROL.................................................... 257

7.16 SPINDLE COMMAND SYNCHRONOUS CONTROL................................ 257

7.17 MULTI SPINDLE CONTROL ..................................................................... 258

7.18 SPINDLE POSITIONING........................................................................... 260

7.19 RIGID TAPPING........................................................................................ 261

7.20 RIGID TAPPING BY MANUAL HANDLE................................................... 261

7.21 ARBITRARY POSITION REFERENCE SETTING FOR Cs AXIS

FUNCTION ................................................................................................ 262

7.22 M CODE GROUP CHECK FUNCTION ..................................................... 262

7.23 M-CODE PROTECT FUNCTION............................................................... 262

7.24 SPINDLE SPEED FLUCTUATION DETECTION....................................... 262

c-9

Page 20

TABLE OF CONTENTS B-64482EN/03

7.25 Cs CONTOUR CONTROL AXIS COORDINATE ESTABLISHMENT ........ 262

7.26 SPINDLE CONTROL WITH SERVO MOTOR........................................... 263

7.26.1 Description of the servo axes for spindle use.......................................................264

7.27 SPINDLE REVOLUTION NUMBER HISTORY FUNCTION ......................265

7.28 SERVO/SPINDLE SYNCHRONOUS CONTROL ...................................... 265

7.29 HIGH-PRECISION SPINDLE SPEED CONTROL ..................................... 265

7.30 SIMPLE SPINDLE ELECTRONIC GEAR BOX.......................................... 265

7.31 SPINDLE SPEED COMMAND CLAMP ..................................................... 266

8 TOOL FUNCTION / TOOL COMPENSATION FUNCTION.................267

8.1 TOOL FUNCTION .....................................................................................267

8.2 EXTENDED TOOL SELECTION FUNCTION............................................268

8.3 TOOL OFFSET PAIRS .............................................................................. 269

8.4 TOOL COMPENSATION MEMORY.......................................................... 269

8.5 COMMON COMPENSATION MEMORY BETWEEN EACH PATH........... 271

8.6 TOOL LENGTH COMPENSATION ...........................................................271

8.7 TOOL OFFSET..........................................................................................273

8.8 TOOL CENTER POINT CONTROL........................................................... 274

8.9 HIGH-SPEED SMOOTH TCP.................................................................... 275

8.10 TOOL POSTURE CONTROL .................................................................... 277

8.11 CUTTING POINT COMMAND................................................................... 278

8.12 Y-AXIS OFFSET........................................................................................279

8.13 CUTTER OR TOOL NOSE RADIUS COMPENSATION ........................... 279

8.14 3-DIMENSIONAL TOOL COMPENSATION .............................................. 283

8.15 CUTTING POINT INTERPOLATION FOR CYLINDRICAL

INTERPOLATION...................................................................................... 284

8.16 TOOL GEOMETRY OFFSET AND TOOL WEAR OFFSET ...................... 285

8.17 SECOND GEOMETRY TOOL OFFSET .................................................... 286

8.18 TOOL MANAGEMENT FUNCTION........................................................... 286

8.18.1 Tool Management Extension Function ................................................................287

8.18.2 Tool Management Function Oversize Tools Support...........................................288

8.19 TOOL OFFSET VALUE COUNTER INPUT............................................... 288

8.20 TOOL LENGTH MEASUREMENT............................................................. 288

8.21 AUTOMATIC TOOL LENGTH MEASUREMENT / AUTOMATIC TOOL

OFFSET .................................................................................................... 289

8.21.1 Automatic Tool Length Measurement..................................................................289

8.21.2 Automatic Tool Offset..........................................................................................290

8.22 TOOL LENGTH / WORKPIECE ZERO POINT MEASUREMENT............. 290

8.23 DIRECT INPUT OF TOOL OFFSET VALUE MEASURED / DIRECT

INPUT OF COORDINATE SYSTEM SHIFT .............................................. 290

8.24 DIRECT INPUT OF TOOL OFFSET VALUE MEASURED B..................... 291

8.25 ROTARY TABLE DYNAMIC FIXTURE OFFSET....................................... 291

8.26 WORKPIECE SETTING ERROR COMPENSATION ................................292

8.27 ACTIVE OFFSET VALUE CHANGE FUNCTION BASED ON MANUAL

FEED .........................................................................................................292

8.28 TOOL AXIS DIRECTION TOOL LENGTH COMPENSATION................... 293

8.29 3-DIMENSIONAL CUTTER COMPENSATION .........................................295

c-10

Page 21

B-64482EN/03 TABLE OF CONTENTS

8.30 GRINDING WHEEL WEAR COMPENSATION .........................................296

8.31 TOOL LIFE MANAGEMENT...................................................................... 297

8.32 SPINDLE UNIT COMPENSATION, NUTATING ROTARY HEAD TOOL

LENGTH COMPENSATION ...................................................................... 299

8.33 TOOL OFFSET FOR MILLING AND TURNING FUNCTION..................... 299

8.34 TOOL OFFSET CONVERSION FUNCTION (G44.1) ................................ 299

9 ACCURACY COMPENSASION FUNCTION ...................................... 302

9.1 BACKLASH COMPENSATION.................................................................. 302

9.2 BACKLASH COMPENSATION FOR EACH RAPID TRAVERSE AND

CUTTING FEED ........................................................................................ 302

9.3 SMOOTH BACKLASH COMPENSATION................................................. 303

9.4 STORED PITCH ERROR COMPENSATION ............................................ 304

9.5 INTERPOLATION TYPE PITCH ERROR COMPENSATION.................... 304

9.6 BI-DIRECTIONAL PITCH ERROR COMPENSATION .............................. 305

9.7 EXTENDED BI-DIRECTIONAL PITCH ERROR COMPENSATION .......... 305

9.8 PERIODICAL SECONDARY PITCH ERROR COMPENSATION.............. 306

9.9 INCLINATION COMPENSATION .............................................................. 306

9.10 LINEAR INCLINATION COMPENSATION ................................................ 307

9.11 STRAIGHTNESS COMPENSATION......................................................... 307

9.12 INTERPOLATION TYPE STRAIGHTNESS COMPENSATION................. 308

9.13 3-DIMENSIONAL ERROR COMPENSATION........................................... 308

9.14 THREE-DIMENSIONAL ROTARY ERROR COMPENSATION ................. 309

9.15 THERMAL GROWTH COMPENSATION ALONG TOOL VECTOR .......... 310

9.16 3-DIMENSIONAL MACHINE POSITION COMPENSATION ..................... 311

10 ELECTRONIC GEAR BOX ................................................................. 312

10.1 ELECTRONIC GEAR BOX........................................................................ 312

10.2 SPINDLE ELECTRONIC GEAR BOX........................................................ 313

10.3 ELECTRONIC GEAR BOX AUTOMATIC PHASE SYNCHRONIZATION .314

10.4 SKIP FUNCTION FOR EGB AXIS............................................................. 315

10.5 ELECTRONIC GEAR BOX 2 PAIR............................................................ 316

10.6 U-AXIS CONTROL .................................................................................... 317

10.7 U-AXIS CONTROL 2 PAIRS...................................................................... 317

10.8 SIGNAL-BASED SERVO EGB SYNCHRONOUS CONTROL................... 318

11 GAS CUTTING MACHINE .................................................................. 320

11.1 TORCH SWING FOR GAS CUTTING MACHINE .....................................320

11.2 TOOL OFFSET B ......................................................................................324

11.3 CORNER CONTROL BY FEED RATE...................................................... 326

11.4 IN-ACCELERATION/DECELERATION SIGNAL ....................................... 327

11.5 AUTOMATIC EXACT STOP CHECK ........................................................327

11.6 AXIS SWITCHING ..................................................................................... 328

11.7 GENTLE NORMAL DIRECTION CONTROL............................................. 329

12 EDITING OPERATION........................................................................ 330

12.1 PART PROGRAM STORAGE SIZE / NUMBER OF REGISTERABLE

PROGRAMS.............................................................................................. 330

c-11

Page 22

TABLE OF CONTENTS B-64482EN/03

12.2 PROGRAM EDITING................................................................................. 331

12.3 PROGRAM PROTECT .............................................................................. 332

12.4 KEY AND PROGRAM ENCRYPTION ....................................................... 332

12.5 EXTENDED PART PROGRAM EDITING.................................................. 333

12.6 PLAYBACK................................................................................................333

12.7 MACHINING TIME STAMP ....................................................................... 333

12.8 BACKGROUND EDITING ......................................................................... 333

12.9 MEMORY CARD PROGRAM OPERATION/EDITING ..............................333

13 SETTING AND DISPLAY ....................................................................334

13.1 STATUS DISPLAY ....................................................................................335

13.2 CLOCK FUNCTION................................................................................... 335

13.3 CURRENT POSITION DISPLAY ............................................................... 336

13.4 PROGRAM DISPLAY ................................................................................ 337

13.5 PARAMETER SETTING AND DISPLAY ................................................... 339

13.6 ALARM DISPLAY ...................................................................................... 339

13.7 ALARM HISTORY DISPLAY .....................................................................340

13.8 OPERATOR MESSAGE HISTORY DISPLAY ........................................... 340

13.9 OPERATION HISTORY DISPLAY............................................................. 340

13.10 RUN HOUR AND PARTS COUNT DISPLAY ............................................ 341

13.11 ACTUAL CUTTING FEEDRATE DISPLAY................................................ 342

13.12 DISPLAY OF SPINDLE SPEED AND T CODE AT ALL SCREENS .......... 343

13.13 DIRECTORY DISPLAY OF FLOPPY CASSETTE..................................... 343

13.14 OPTIONAL PATH NAME DISPLAY........................................................... 343

13.15 OPERATING MONITOR SCREEN............................................................344

13.16 SERVO SETTING SCREEN...................................................................... 345

13.16.1 Servo Setting Screen ............................................................................................345

13.16.2 Servo Motor Tuning Screen .................................................................................345

13.17 SPINDLE SETTING SCREEN................................................................... 346

13.17.1 Spindle Setting Screen..........................................................................................346

13.17.2 Spindle Tuning Screen .........................................................................................346

13.17.3 Spindle Monitor Screen........................................................................................347

13.18 SERVO WAVEFORM DISPLAY................................................................ 347

13.19 MAINTENANCE INFORMATION SCREEN............................................... 348

13.20 SOFTWARE OPERATOR'S PANEL.......................................................... 348

13.21 SOFTWARE OPERATOR'S PANEL GENERAL PURPOSE SWITCH ...... 349

13.22 MULTI-LANGUAGE DISPLAY...................................................................350

13.22.1 Changing the Display Language by PMC Signals ...............................................350

13.23 DATA PROTECTION KEY.........................................................................350

13.24 PROTECTION OF DATA AT EIGHT LEVELS........................................... 351

13.25 ERASE CRT SCREEN DISPLAY .............................................................. 351

13.26 PARAMETER SET SUPPORTING SCREEN ............................................ 352

13.27 MACHINING CONDITION SELECTING FUNCTION ................................ 353

13.28 MACHINING QUALITY LEVEL ADJUSTMENT......................................... 354

13.29 SYSTEM CONFIGURATION SCREEN ..................................................... 355

13.29.1 Hardware Configuration Screen...........................................................................355

13.29.2 Software Configuration Screen ............................................................................356

13.30 HELP SCREEN ......................................................................................... 357

c-12

Page 23

B-64482EN/03 TABLE OF CONTENTS

13.30.1 Initial Menu Screen ..............................................................................................357

13.30.2 Alarm Detail Screen .............................................................................................357

13.30.3 Operation Method Screen.....................................................................................358