fanuc 21 B, 210 B Parameter Manual

GE Fanuc Automation

Computer Numerical Control Products

Series 21 / 210 – Model B

Parameter Manual

GFZ-62710EN/03 September 1997

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

PowerMotion is a trademark of GE Fanuc Automation North America, Inc.

©Copyright 1997 GE Fanuc Automation North America, Inc.

All Rights Reserved.

B–62710EN/03

PREFACE

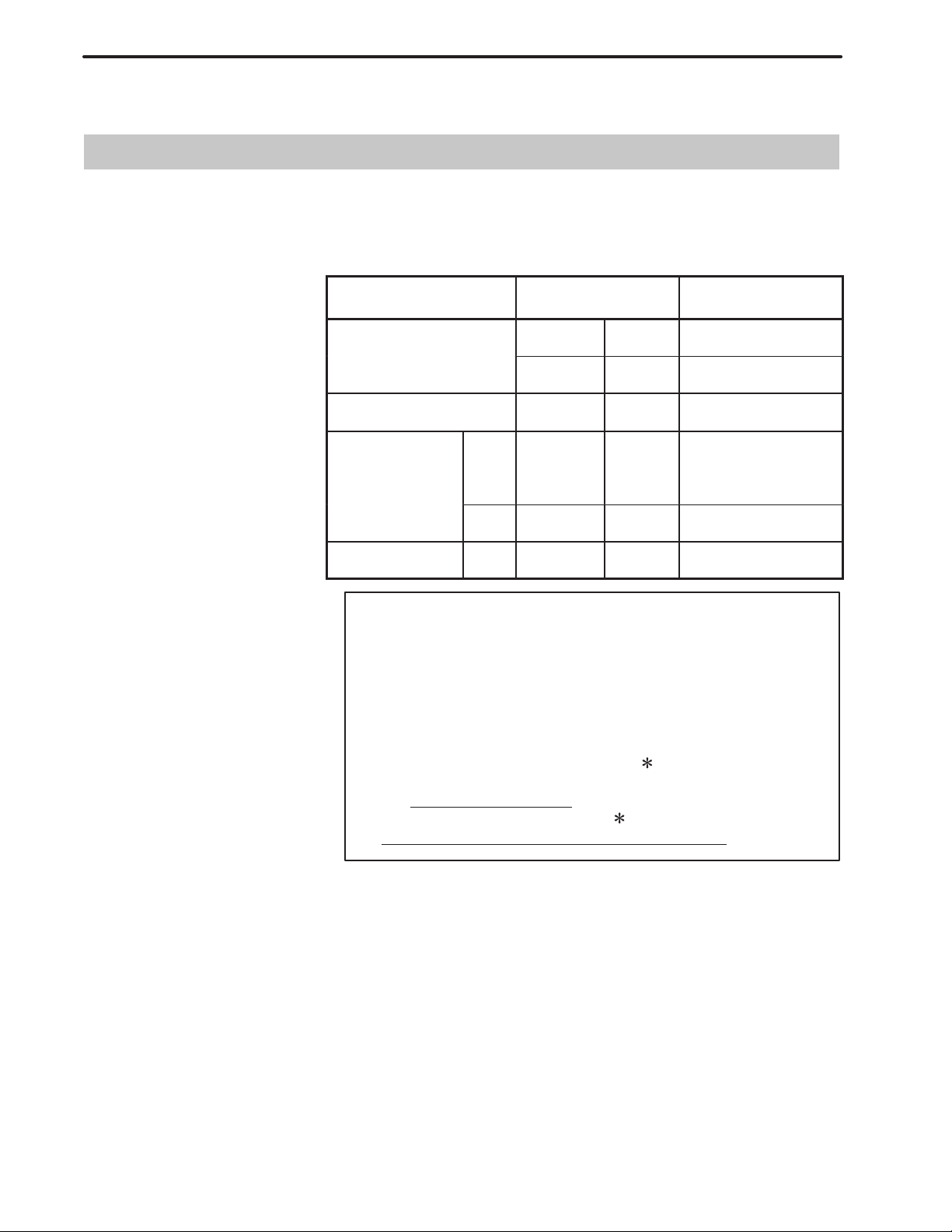

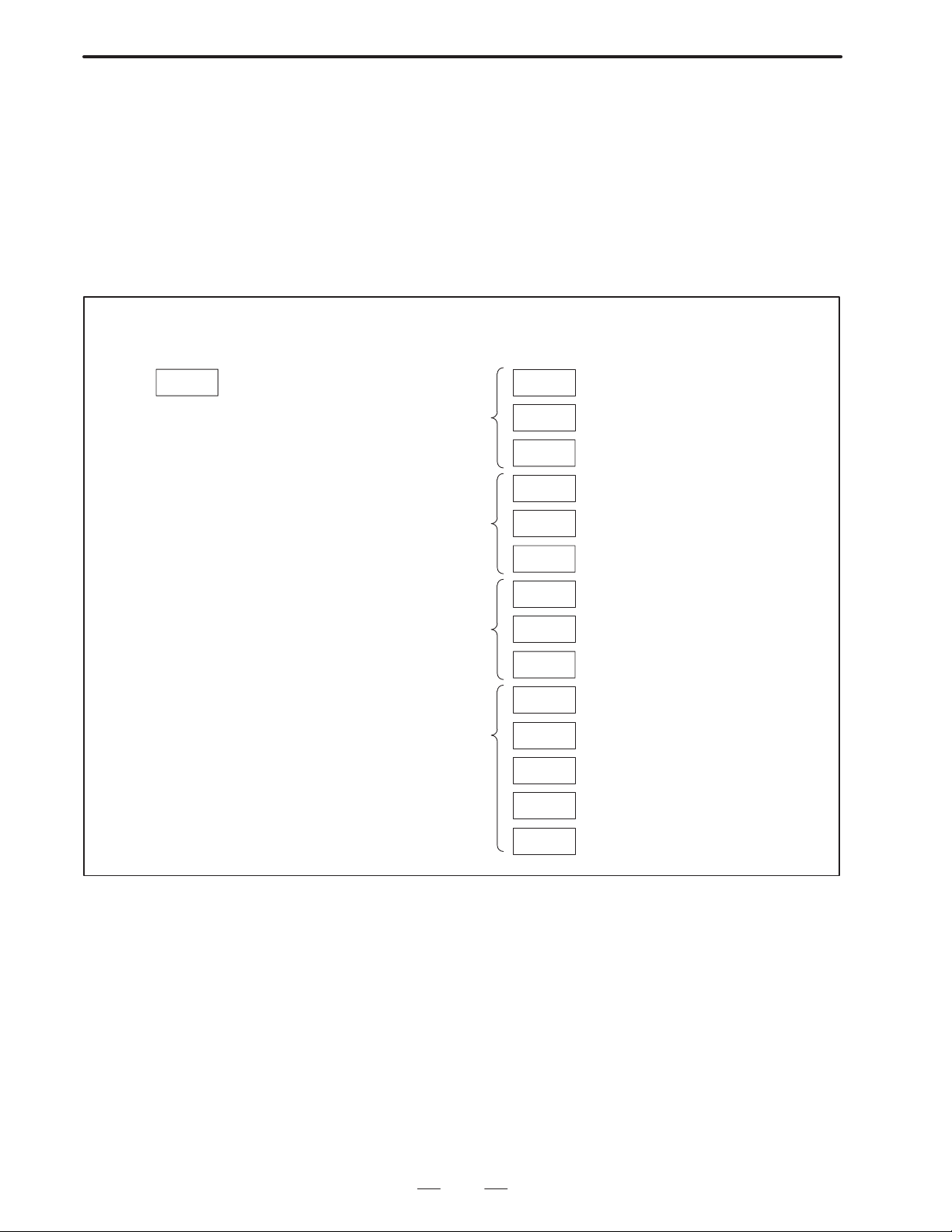

The mode covered by this manual, and their abbreviations are :

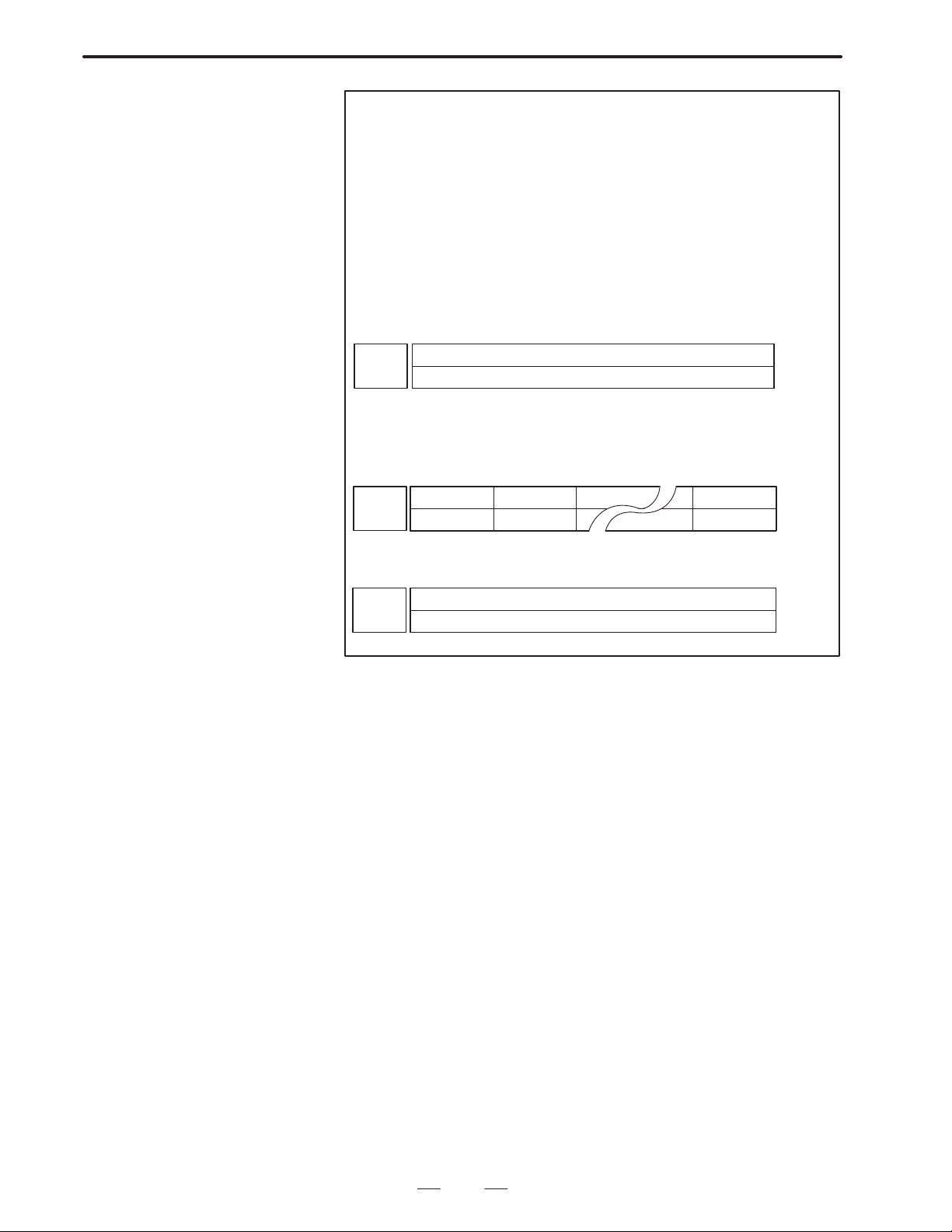

Product Name Abbreviations

FANUC Series 21–MB 21–MB Series 21 D201

21–MB Series 21 DDA1

FANUC Series 210–MB 210–MB Series 210 DDA1

FANUC Series 21–TB Control

unit A

Control

unit B

FANUC Series 210–TB Control

unit B

21–TB

(Control unit A)

21–TB

(Control unit B)

210–TB Series 210 DEA1

Series 21 DE01

Series 21 DEA1

Software Series

(Specification Number)

(A02B–0179–H800#D201)

(A02B–0218–H501#DDA1)

(A02B–0218–H501#DDA1)

(A02B–0210–H501#DE01)

DE02

(A02B–0210–H501#DE02)

(A02B–0219–H501#DEA1)

(A02B–0219–H501#DEA1)

NOTE

1 For convenience, the models may be classified into the

following series:

T series: 21–TB/210–TB

M series: 21–MB/210–MB

2 Some parameters described in this manual cannot be used

depending on the model or series. For details, refer to the

Specifications (B–62702EN).

Those parameters marked ( M) in Chapter 4,

”DESCRIPTION OF PARAMETERS” cannot be used with

the 21–MB (D201 series)

.

Those parameters marked ( T) cannot be used with

21–TB control unit A (DE01 and DE02 series)

.

p–1

PREFACE

B–62710EN/03

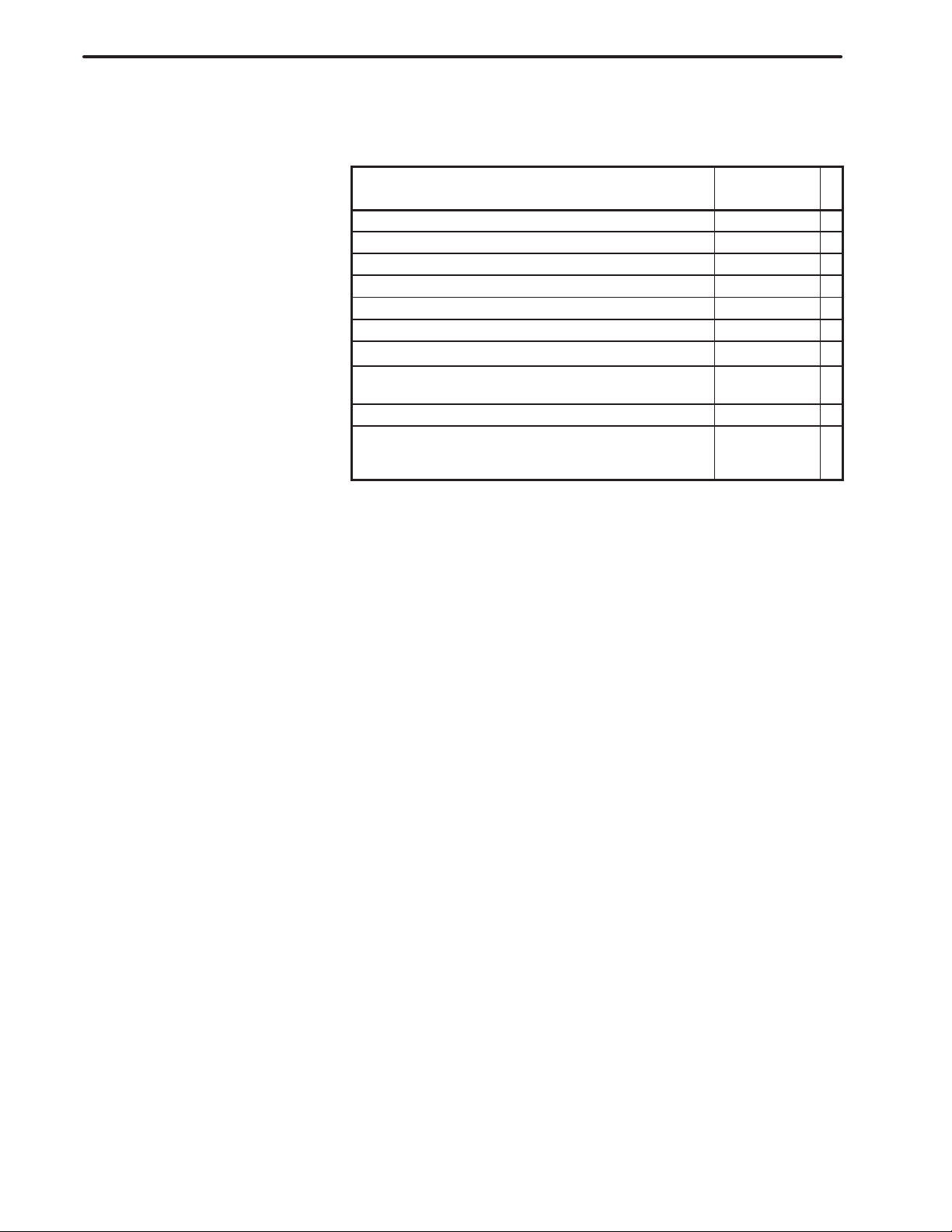

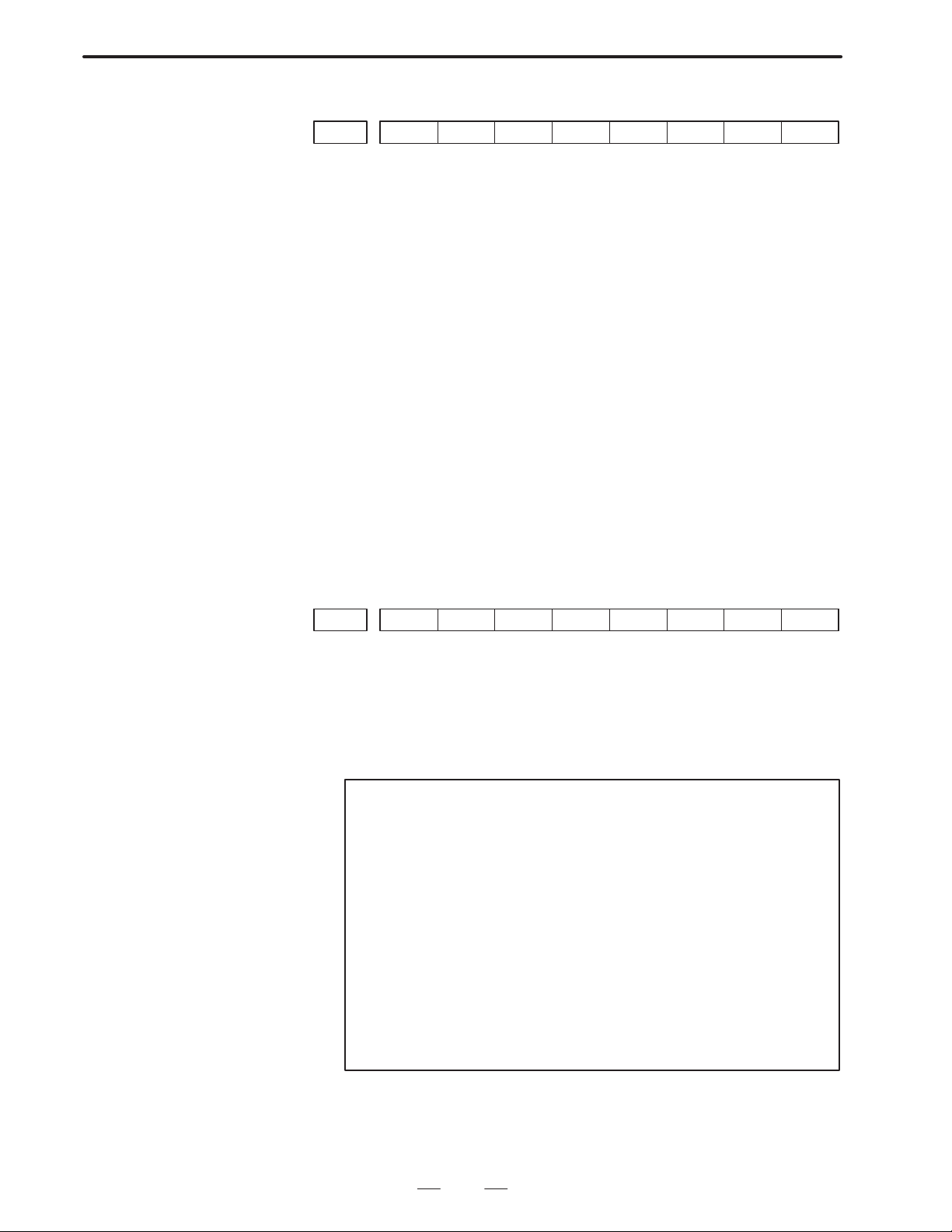

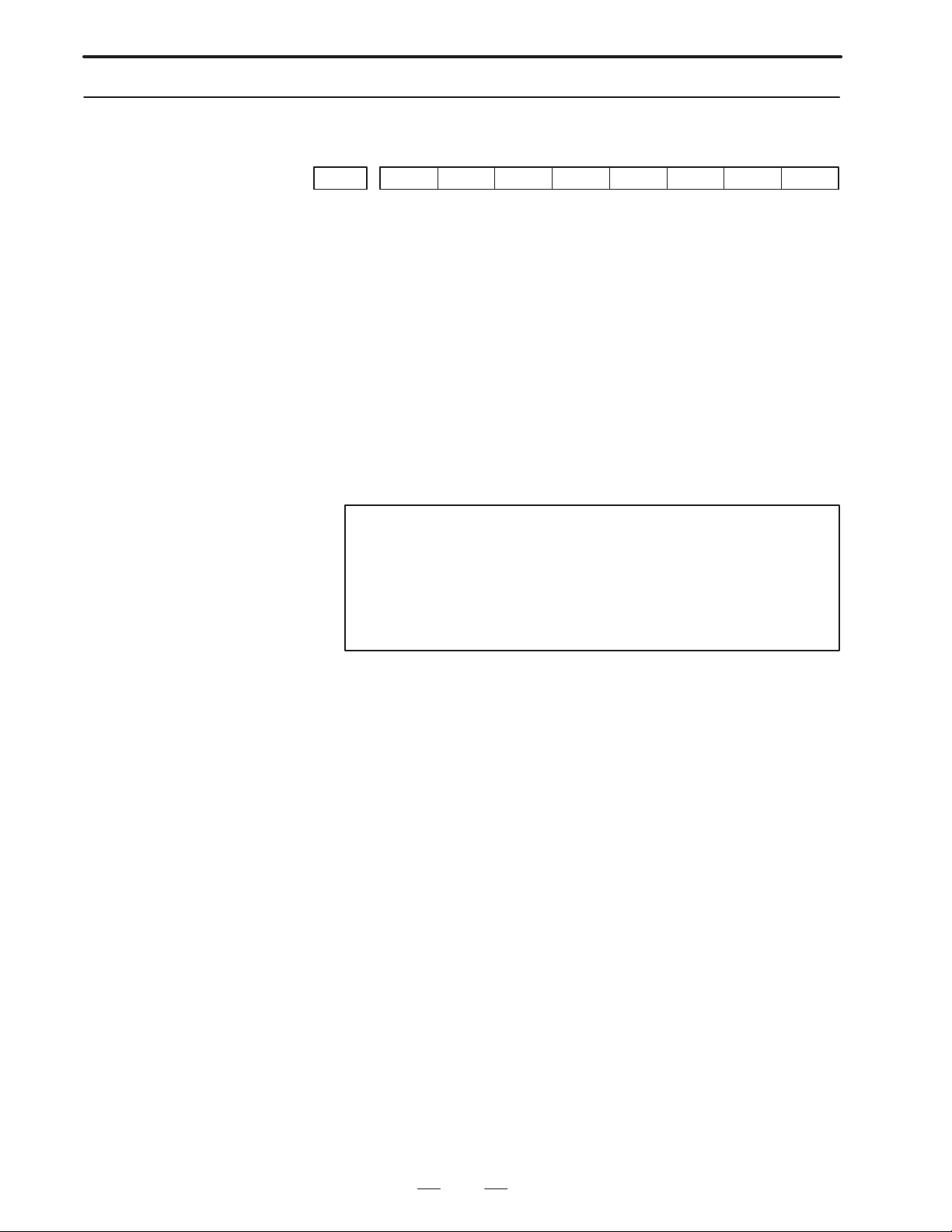

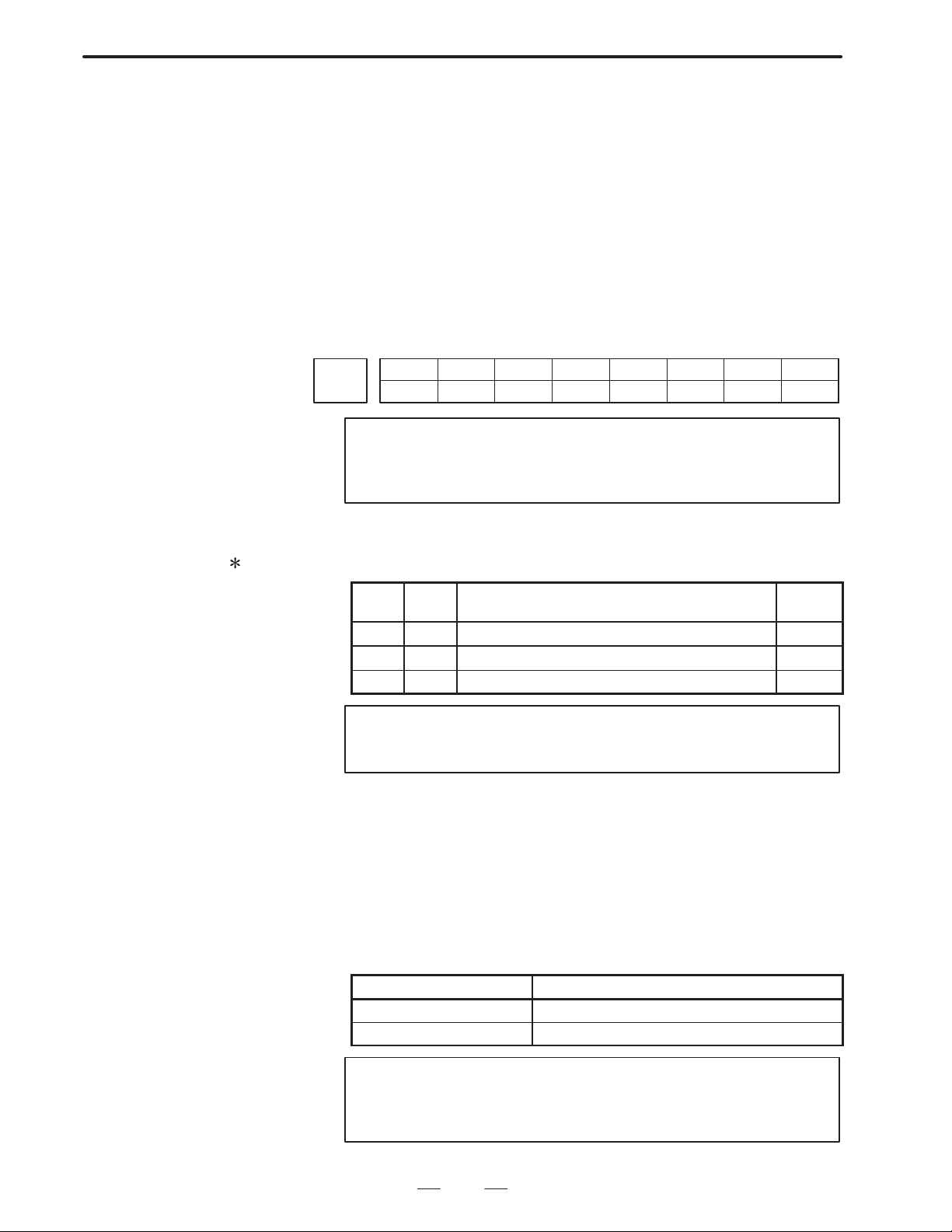

The table below lists manuals related to MODEL B of Series 21, Series

210. In the table, this manual is maked with an asterisk (*).

T able 1 Related manuals

Manual name

DESCRIPTIONS B–62702EN

CONNECTION MANUAL (Hardware) B–62703EN

CONNECTION MANUAL (Function) B–62703EN–1

OPERATOR’S MANUAL FOR LATHE B–62534E

OPERATOR’S MANUAL FOR MACHINING CENTER B–62704EN

MAINTENANCE MANUAL B–62705EN

PARAMETER MANUAL B–62710EN

PROGRAMMING MANUAL

(Macro Compiler/Macro Executor)

FAPT MACRO COMPILER PROGRAMMING MANUAL B–66102E

CONVERSATIONAL AUTOMATIC PROGRAMMING

FUNCTION FOR MACHINING CENTER

OPERATOR’S MANUAL

Specification

Number

B–61803E–1

B–61874E–1

*

p–2

B–62710EN/03

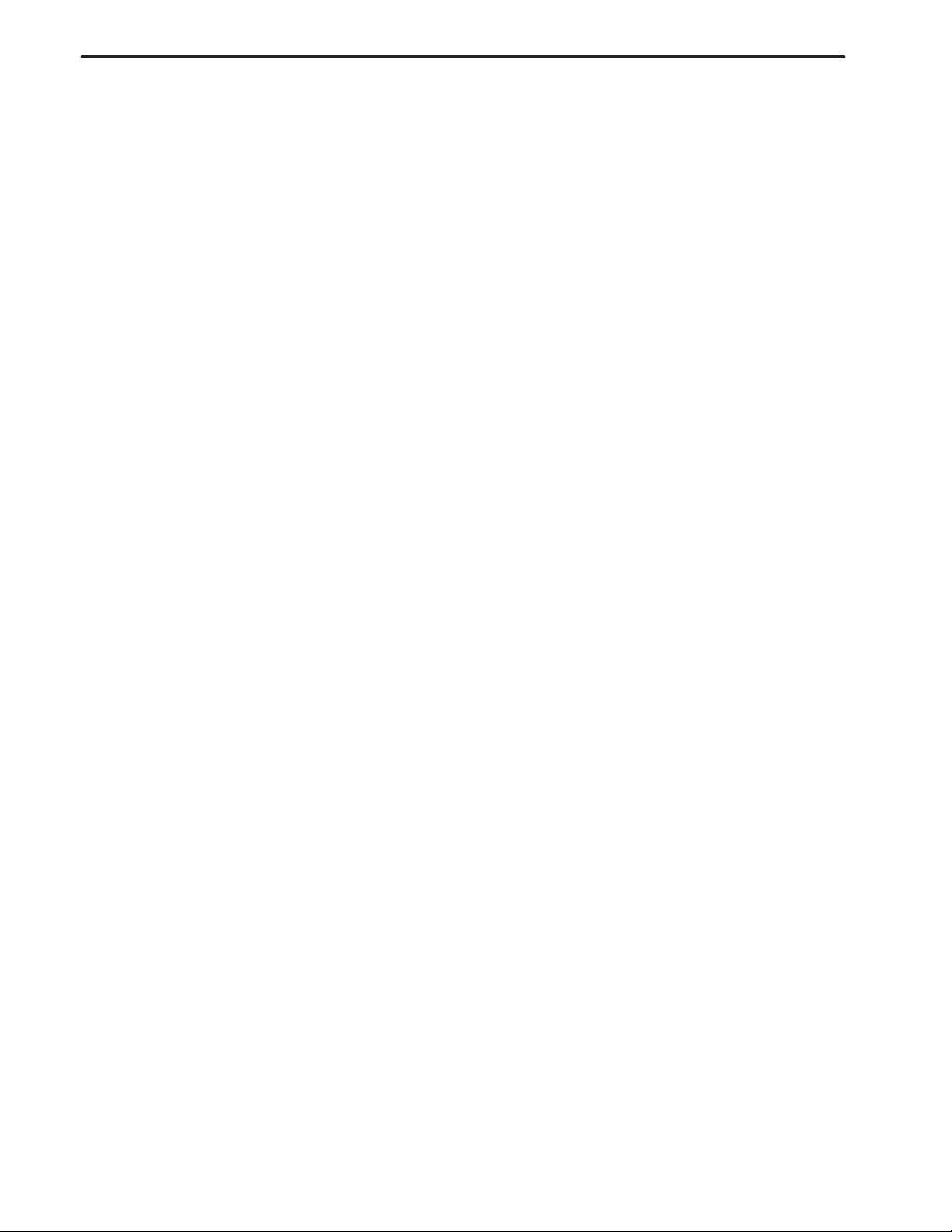

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAYING PARAMETERS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SETTING PARAMETERS FROM MDI 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERF ACE 5. . . . . . . . .

3.2 INPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERF ACE 6. . . . . . . . . . .

4. DESCRIPTION OF PARAMETERS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PARAMETERS OF SETTING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 PARAMETERS OF READER/PUNCHER INTERFACE, REMOTE BUFFER INTERFACE 12. . . . .

4.2.1 Parameters Common to All Channels 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Parameters of Channel 1 (I/O CHANNEL=0) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Parameters of Channel 1 (I/O CHANNEL=1) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Parameters of Channel 2 (I/O CHANNEL=2) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 Parameters of Channel 3 (I/O CHANNEL=3) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PARAMETERS OF DNC1/DNC2 INTERFACE 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PARAMETERS OF POWER MOTION MANAGER 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM 22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 PARAMETERS OF COORDINATES 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 PARAMETERS OF STROKE CHECK 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 PARAMETERS OF THE CHUCK AND TAILSTOCK BARRIER (T SERIES) 40. . . . . . . . . . . . . . . .

4.9 PARAMETERS OF FEEDRATE 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 PARAMETERS OF ACCELERATION/ DECELERATION CONTROL 54. . . . . . . . . . . . . . . . . . . . . .

4.11 PARAMETERS OF SERVO 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 PARAMETERS OF DI/DO 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 PARAMETERS OF MDI, DISPLAY, AND EDIT 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 PARAMETERS OF PROGRAMS 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 PARAMETERS OF PITCH ERROR COMPENSATION 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 PARAMETERS OF SPINDLE CONTROL 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 PARAMETERS OF TOOL COMPENSATION 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18 PARAMETERS OF CANNED CYCLES 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18.1 Parameter of canned Cycle for Drilling 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18.2 Parameter of Thread Cutting Cycle 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18.3 Parameter of Multiple Repetitive Canned Cycle 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18.4 Parameters of Peck Drilling Cycle of a Small Diameter 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 PARAMETERS OF RIGID TAPPING 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.20 PARAMETERS OF SCALING/COORDINATE ROTATION 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 PARAMETERS OF UNI–DIRECTIONAL POSITIONING 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.22 PARAMETERS OF POLAR COORDINATE INTERPOLATION 181. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 PARAMETERS OF NORMAL DIRECTION CONTROL 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.24 PARAMETERS OF INDEXING INDEX TABLE 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.25 PARAMETERS OF CUSTOM MACROS 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Table of Contents

4.26 PARAMETERS OF PATTERN DATA INPUT 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.27 PARAMETERS OF SKIP FUNCTION 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 PARAMETERS OF AUTOMATIC TOOL COMPENSATION (T SERIES) AND

AUTOMATIC TOOL LENGTH COMPENSATION (M SERIES) 196. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.29 PARAMETERS OF EXTERNAL DATA INPUT/OUTPUT 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30 PARAMETERS OF GRAPHIC DISPLAY 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30.1 Parameters of Graphic Display/Dynamic Graphic Display 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.31 PARAMETERS OF DISPLAYING OPERATION TIME AND NUMBER OF PARTS 200. . . . . . . . . . .

4.32 PARAMETERS OF TOOL LIFE MANAGEMENT 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.33 PARAMETERS OF POSITION SWITCH FUNCTIONS 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.34 PARAMETERS OF MANUAL OPERATIONAND AUTOMATIC OPERATION 210. . . . . . . . . . . . . .

4.35 PARAMETERS OF MANUAL HANDLE FEED, HANDLE INTERRUPTION AND

HANDLE FEED IN TOOL AXIAL DIRECTION 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.36 PARAMETERS OF REFERENCE POSITION SETTING

WITH MECHANICAL STOPPER 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.37 PARAMETERS OF SOFTWARE OPERATOR’S PANEL 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.38 PARAMETERS OF PROGRAM RESTART 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.39 PARAMETERS OF HIGH–SPEED MACHINING

(HIGH–SPEED CYCLE MACHINING/HIGH–SPEED REMOTE BUFFER) 220. . . . . . . . . . . . . . . . .

4.40 PARAMETERS OF POLYGON TURNING 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.41 PARAMETERS OF AXIS CONTROL BY PMC 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.42 PARAMETERS OF ANGULAR AXIS CONTROL 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.43 PARAMETERS OF B–AXIS CONTROL 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.44 PARAMETERS OF SIMPLE SYNCHRONOUS CONTROL 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45 PARAMETERS OF CHECK TERMINATION 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.46 OTHER PARAMETERS 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.47 PARAMETERS OF MAINTENANCE 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62710EN/03

APPENDIX

A. CHARACTER CODE LIST 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–62710EN/03

1

1. DISPLA YING PARAMETERS

DISPLAYING PARAMETERS

Follow the procedure below to display parameters.

(1) Press the SYSTEM function key on the MDI as many times as

required, or alternatively , press the SYSTEM function key once, then

the PARAM section display soft key. The parameter screen is then

selected.

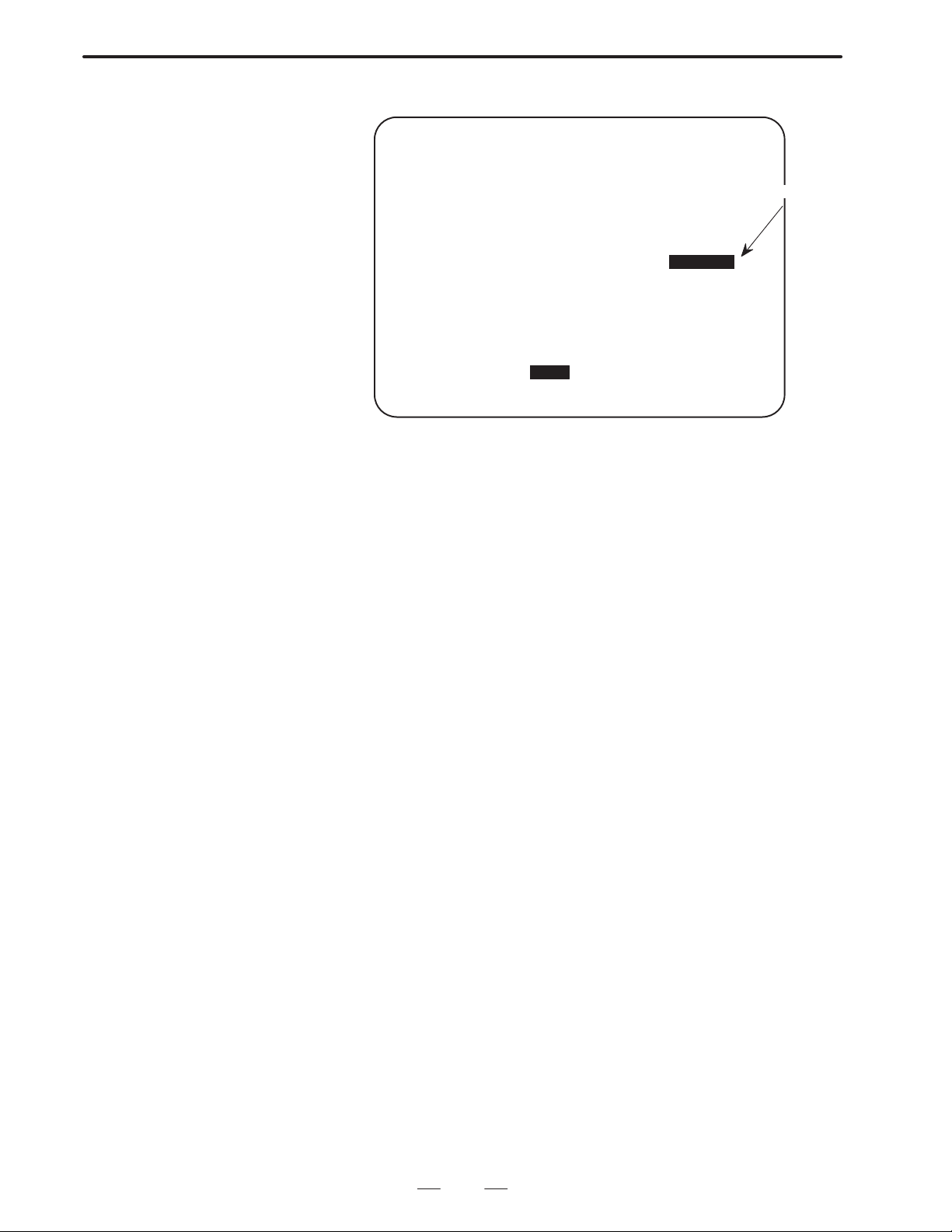

PARAMETER (FEEDRATE) O0001 N12345

1401 RDR JZR RF0 LRP RPD

0 0 0 0 0 0 0 0

1402 DLF HFC

0 0 0 0 0 0 0 0

1410 DRY RUN FEEDRATE 10000

1411 INIT.CUTTING F 0

1420 RAPID FEEDRATE X 15000

Y 15000

Z 15000

>

MEM STRT MTN FIN *** 10:02:35

[PARAM] [DGNOS] [ PMC ] [SYSTEM] [(OPRT)]

Return menu key Soft key Continuous menu key

PROG

SYSTEM MESSAGE GRAPH

Cursor

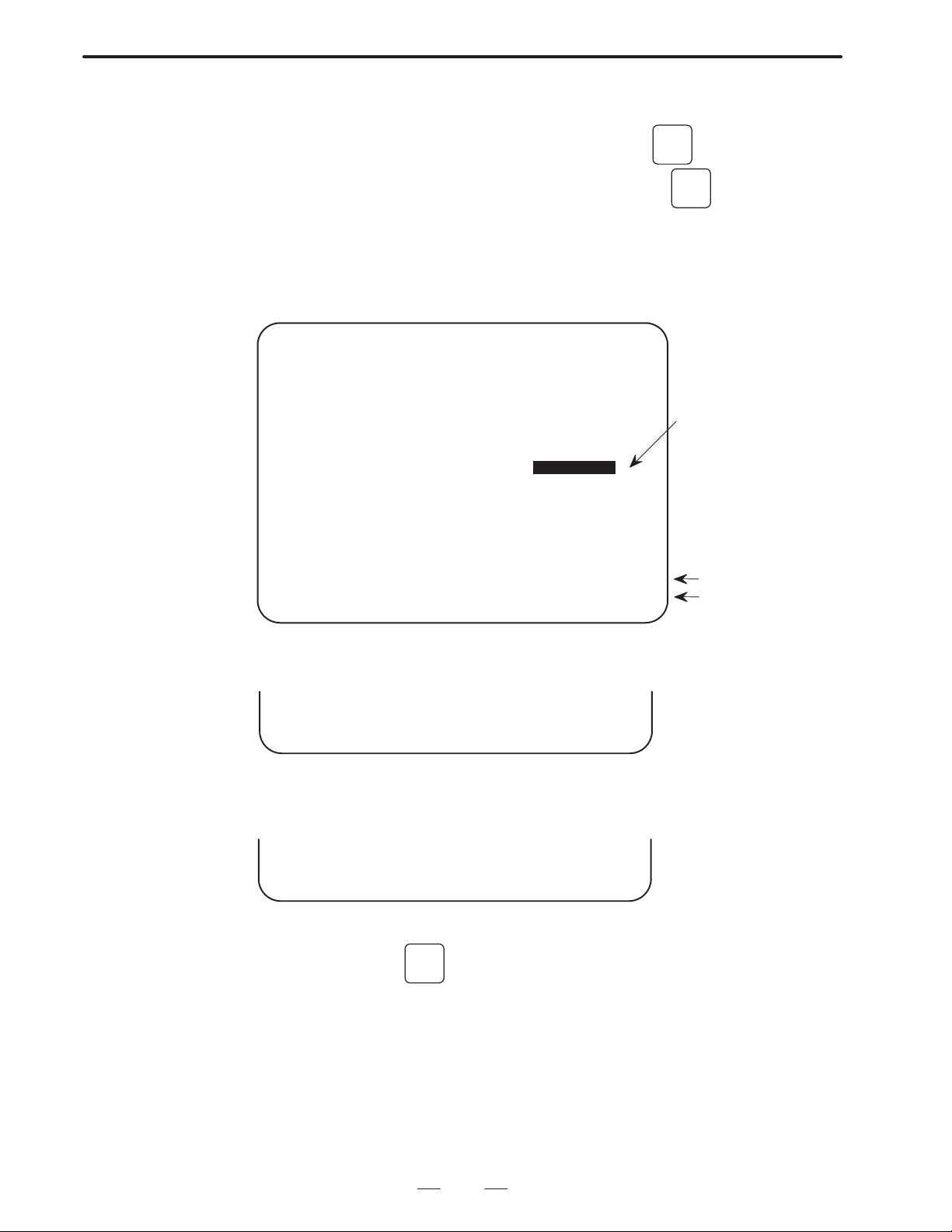

(2 ) The parameter screen consists of multiple pages. Use step (a) or (b)

to display the page that contains the parameter you want to display.

(a) Use the page select key or the cursor move keys to display the de-

sired page.

(b) Enter the data number of the parameter you want to display from

the keyboard, then press the [NO.SRH] soft key . The parameter

page containing the specified data number appears with the cursor positioned at the data number. (The data is displayed in reverse video.)

Function key

Soft key display

(section select)

OFFSET

SETTING

CUSTOM

NOTE

If key entry is started with the section select soft keys

displayed, they are replaced automatically by operation

select soft keys including [NO.SRH]. Pressing the [(OPRT)]

soft key can also cause the operation select keys to be

displayed.

>

MEM STRT MTN FIN *** 10:02:34

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT ]

1

Data entered from

←

the keyboard

Soft key display

←

(section select)

2. SETTING PARAMETERS FROM MDI

SETTING PARAMETERS FROM MDI

2

Follow the procedure below to set parameters.

(1) Place the NC in the MDI mode or the emergency stop state.

(2) Follow the substeps below to enable writing of parameters.

1. To display the setting screen, press the

B–62710EN/03

OFFSET

function key as

SETTING

many times as required, or alternatively press the

key once, then the [SETTING] section select soft key . The first

page of the setting screen appears.

2. Position the cursor on “PARAMETER WRITE” using the cursor

move keys.

SETTING (HANDY) O0001 N00010

PARAMETER WRITE = (0:DISABLE 1:ENABLE)

TV CHECK = 0 (0:OFF 1:ON)

PUNCH CODE = 0 (0:EIA 1:ISO)

INPUT UNIT = 0 (0:MM 1:INCH)

I/O CHANNEL = 0 (0–3:CHANNEL NO.)

0

3. Press the [(OPR T)] soft key to display operation select soft keys.

>

MDI STOP *** *** *** 10:03:02

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

4. T o set “PARAMETER WRITE=” to 1, press the [ON:1] soft key ,

or alternatively enter 1 and press the [INPUT] soft key. From

now on, the parameters can be set. At the same time an alarm

condition (P/S100 PARAMETER WRITE ENABLE) occurs in

the CNC.

OFFSET

function

SETTING

← Soft key display

(section select)

(3) To display the parameter screen, press the

many times as required, or alternatively press the

SYSTEM function key as

SYSTEM function key

once, then the [PARAM] section select soft key.

(See “1. Displaying Parameters.”)

(4) Display the page containing the parameter you want to set, and

position the cursor on the parameter. (See “1. Displaying

Parameters.”)

(5) Enter data, then press the [INPUT] soft key. The parameter indicated

by the cursor is set to the entered data.

2

B–62710EN/03

2. SETTING PARAMETERS FROM MDI

[Example] 12000 [INPUT]

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

00000000

1402 JRV

00000000

1410 DRY RUN FEEDRATE

1412 0

1420 RAPID FEEDRATEX 15000

Y 15000

Z 15000

>

MDI STOP *** *** ALM 10:03:10

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

12000

Cursor

Data can be entered continuously for parameters, starting at the selected

parameter, by separating each data item with a semicolon (;).

[Example] Entering 10;20;30;40 and pressing the [INPUT] key assigns values 10,

20, 30, and 40 to parameters in order starting at the parameter indicatedby

the cursor.

(6) Repeat steps (4) and (5) as required.

(7) If parameter setting is complete, set “PARAMETER WRITE=” to 0

on the setting screen to disable further parameter setting.

(8) Reset the NC to release the alarm condition (P/S100).

If an alarm condition (P/S000 PLEASE TURN OFF POWER) occurs

in the NC, turn it off before continuing operation.

3

3. INPUTTING AND OUTPUTTING P ARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE

3

This section explains the parameter input/output procedures for

input/output devices connected to the reader/puncher interface.

The following description assumes the input/output devices are ready for

input/output. It also assumes parameters peculiar to the input/output

devices, such as the baud rate and the number of stop bits, have been set

in advance.

B–62710EN/03

4

B–62710EN/03

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

3.1

OUTPUTTING

PARAMETERS

THROUGH THE

READER/PUNCHER

INTERFACE

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

1404 DLF HFC

1410 DRY RUN FEEDRATE

1411 INIT. CUTTING F 0

1420 RAPID FEEDRATEX 15000

(1)Select the EDIT mode or set to Emergency stop.

(2) To select the parameter screen, press the

times as required, or alternatively press the

SYSTEM function key as many

SYSTEM function key once,

then the [PARAM] section select soft key.

(3) Press the [(OPRT)] soft key to display operation select soft keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select keys including

[PUNCH].

00000000

00000000

12000

Y 15000

Z 15000

Cursor

>

MDI STOP *** *** ALM 10:03:10

[ ] [ READ ] [PUNCH] [ ] [ ]

(4) Pressing the [PUNCH] soft key changes the soft key display as

shown below:

>

EDIT STOP *** *** *** 10:35:03

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(5) Press the [EXEC] soft key to start parameter output. When

parameters are being output, “OUTPUT” blinks in the state display

field on the lower part of the screen.

>

EDIT STOP *** *** *** 10:35:04 OUTPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(6) When parameter output terminates, “OUTPUT” stops blinking. Press

the

RESET key to interrupt parameter output.

State display

Soft key display

(operation select)

← OUTPUT blinking

5

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

B–62710EN/03

3.2

INPUTTING

PARAMETERS

THROUGH THE

READER/PUNCHER

INTERFACE

(1)Place the NC in the emergency stop state.

(2) Enable parameter writing.

1. To display the setting screen, press the

many times as required, or alternatively press the

OFFSET

function key as

SETTING

OFFSET

SETTING

function

key once, then the [SETTING] section select soft key . The first

page of the setting screen appears.

2. Position the cursor on “PARAMETER WRITE” using the cursor

move keys.

3. Press the [(OPR T)] soft key to display operation select soft keys.

4. T o set “P ARAMETER WRITE=” to 1, press the [ON:1] soft key ,

or alternatively enter 1, then press the [INPUT] soft key. From

now on, parameters can be set. At the same time an alarm condition (P/S100 PARAMETER WRITE ENABLE) occurs in the

NC.

(3) To select the parameter screen, press the

SYSTEM function key as many

times as required, or alternatively press the SYSTEM key once, then

[PARAM] soft key.

(4) Press the [(OPRT)] soft key to display operation select keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select soft keys including

[READ].

>

EDIT STOP ALM 10:37:30

[ ] [ READ ] [PUNCH] [ ] [ ]

–EMS– ALM

(5) Pressing the [READ] soft key changes the soft key display as shown

below:

>

EDIT STOP ALM 10:37:30

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMS– ALM

(6) Press the [EXEC] soft key to start inputting parameters from the

input/output device. When parameters are being input, “INPUT”

blinks in the state display field on the lower part of the screen.

>

EDIT STOP ALM 10:37:30 INPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMS– ALM

(7) When parameter input terminates, “INPUT” stops blinking. Press the

RESET key to interrupt parameter input.

(8) When parameter read terminates, “INPUT” stops blinking, and an

alarm condition (P/S000) occurs in the NC. Turn it off before

continuing operation.

← State display

← Soft key display

← INPUT blinking

6

B–62710EN/03

0 or 1

,g

,g

99999999 to 99999999

4

4. DESCRIPTION OF P ARAMETERS

DESCRIPTION OF PARAMETERS

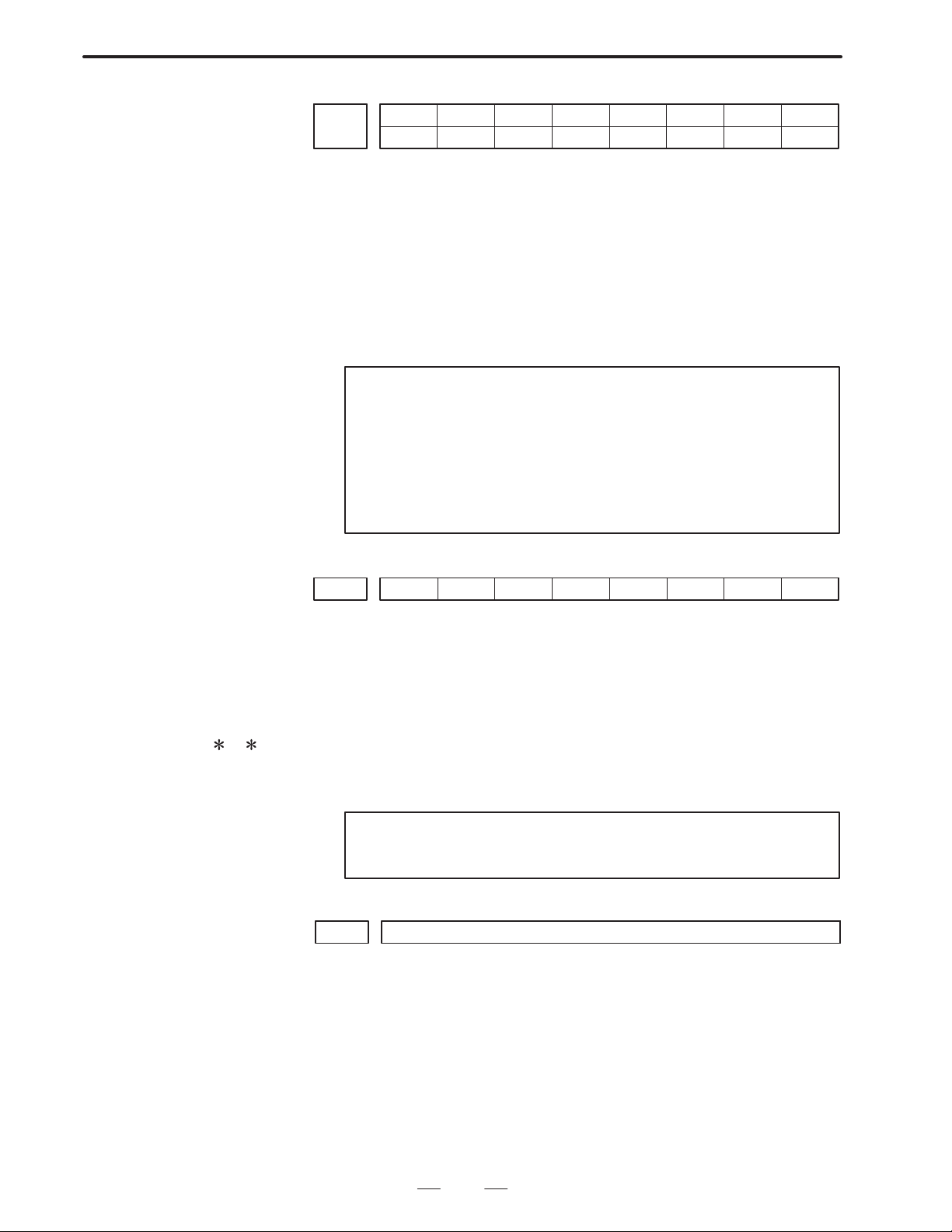

Parameters are classified by data type as follows:

Table 4 Data Types and Valid Data Ranges of Parameters

Data type

Bit

Bit axis

Byte

Byte axis

Word

Word axis

2–word

2–word axis

Valid data range Remarks

–128 to 127 In some parameters, signs are

0 to 255

–32768 to 32767 In some parameters, signs are

0 to 65535

–

ignored.

ignored.

NOTE

1 For the bit type and bit axis type parameters, a single data

number is assigned to 8 bits. Each bit has a different

meaning.

2 The axis type allows data to be set separately for each

control axis.

3 The valid data range for each data type indicates a general

range. The range varies according to the parameters. For

the valid data range of a specific parameter, see the

explanation of the parameter.

[Example]

0000

Data No.

1023 Servo axis number of a specific axis

Data No.

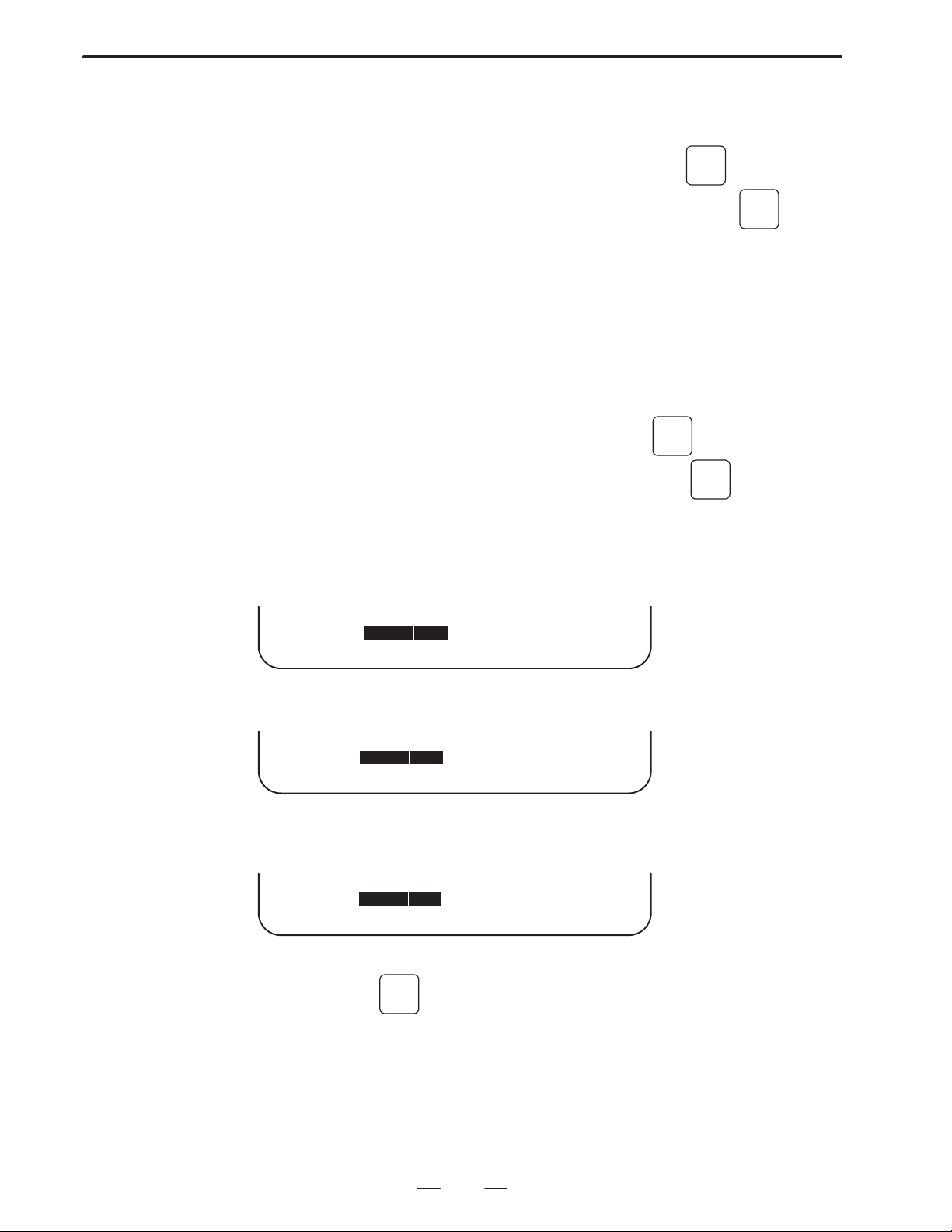

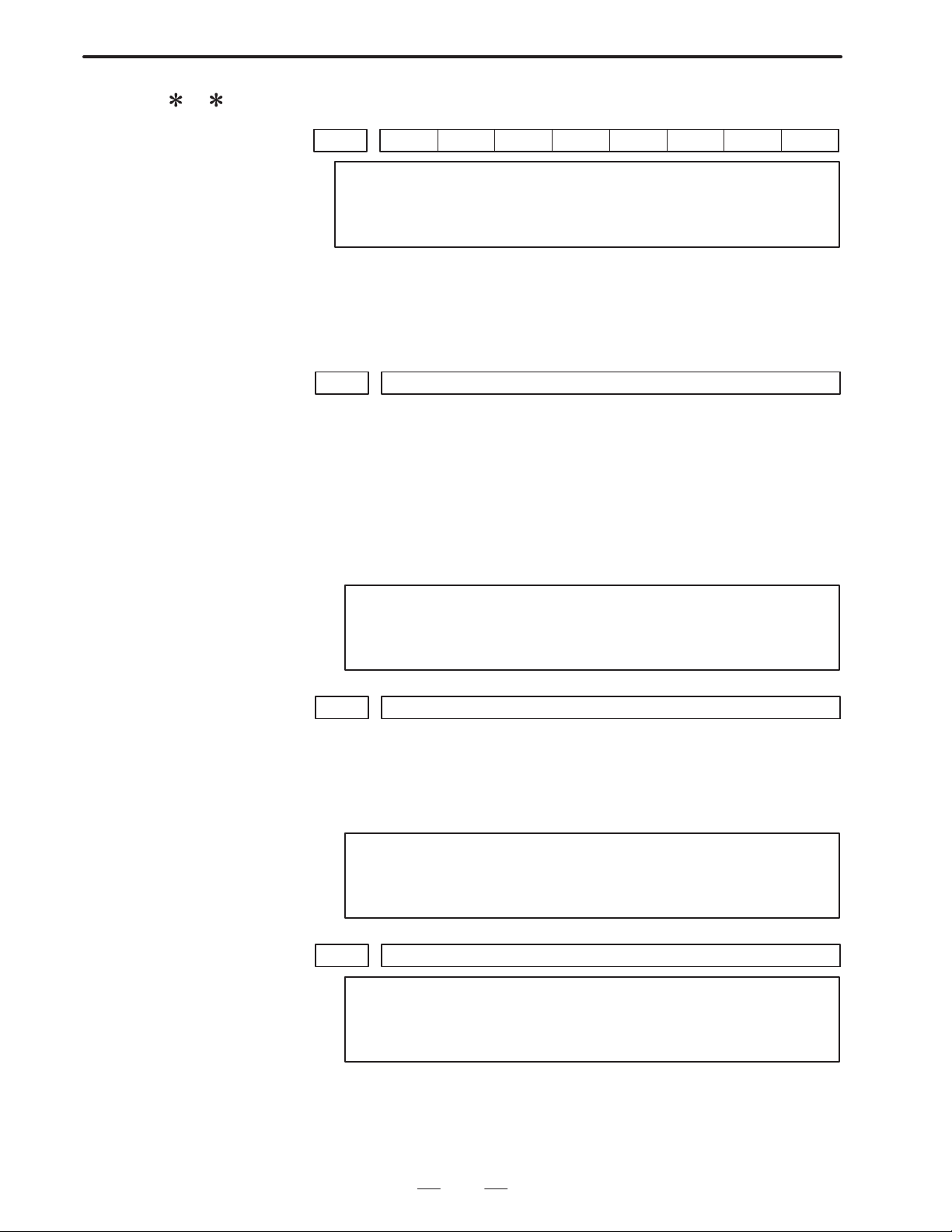

(1) Notation of bit type and bit axis type parameters

#7

#6 #5

SEQ

#4 #3 #2

Data #0 to #7 are bit positions.

INI

#1

ISO

(2) Notation of parameters other than bit type and bit axis type

Data.

7

#0

TVC

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

NOTE

1 The bits left blank in 4. DESCRIPTION OF PARAMETERS

and parameter numbers that appear on the display but are

not found in the parameter list are reserved for future

expansion. They must always be 0.

2 Parameters having different meanings between the T series

and M series and parameters that are valid only for the T or

M series are indicated in two levels as shown below.

Parameters left blank are unavailable.

Example1

Parameter 5010 has different meanings for the T series

and M series.

5010

Tool nose radius compensation ...

Tool compensation C ...

Example2

DPI is a parameter common to the M and T series, but

GSB and GSC are parameters valid only for the T series.

#7 #6 #0

3401

GSC GSB DPI

DPI

Example3

The following parameter is provided only for the M series.

1451

F1 digit feed ...

T series

M series

T series

M series

T series

M series

8

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

4.1

PARAMETERS OF

SETTING

[Data type] Bit

#7

0000

#6 #5

SEQ

#4 #3 #2

Setting entry is acceptable.

TVC TV check

0 : Not performed

1 : Performed

ISO Code used for data output

0 : EIA code

1 : ISO code

INI Unit of input

0 : In mm

1 : In inches

SEQ Automatic insertion of sequence numbers

0 : Not performed

1 : Performed

When a program is prepared by using MDI keys in the part program

storage and edit mode, a sequence number can automatically be assigned

to each block in set increments. Set the increment to parameter 3216.

INI

#1

ISO

#0

TVC

0001

Setting entry is acceptable.

[Data type] Bit

FCV Tape format

0 : Series 16 standard format

1 : Series 15 format

#7

#6 #5 #4 #3 #2 #1

FCV

#0

NOTE

1 Programs created in the Series 10/11 tape format can be

used for operation on the following functions:

1) Subprogram call M98

2) Thread cutting with equal leads G32 (T series)

3) Canned cycle G90, G92, G94 (T series)

4) Multiple repetitive canned cycle G71 to G76 (T series)

5) Drilling canned cycle G73, G74, G76, G80 to G89 (M

series)

6) Cutter compensation C (M series)

2 When the tape format used in the Series 10/11 is used for

this CNC, some limits may add. Refer to the Series

21/210–MODEL B OPERATOR’S MANUAL .

9

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

0002

Setting entry is acceptable.

[Data type] Bit

SJZ Manual reference position si performed as follows:

0 : When no reference position has been set, reference position return is

1 : Reference position return is performed using deceleration dogs at all

#7

SJZ

#6 #5 #4 #3 #2 #1 #0

performed using deceleration dogs. When a reference position is

already set, reference position return is performed using rapid traverse

and deceleration dogs are ignored.

times.

NOTE

SJZ is enabled when bit 3 (HJZ) of parameter No.1005 is set

to 1. When a reference position is set without a dog, (i.e.

when bit 1 (DLZ) of parameter No.1002 is set to 1 or bit 1

(DLZx) of parameter No.1005 is set to 1) reference position

return after reference position setting is performed using

rapid traverse at all times, regardless of the setting of SJZ.

#7

RMVx0012

#6 #5 #4 #3 #2 #1 #0

Setting entry is acceptable.

[Data type] Bit axis

MIRx Mirror image for each axis

0 : Mirror image is off.

1 : Mirror image is on.

(

T, M) RMVx Releasing the assignment of the control axis for each axis

0 : Not released

1 : Released

NOTE

RMVx is valid when RMBx in parameter 1005#7 is 1.

0020 I/O CHANNEL: Selection of an input/output device

Setting entry is acceptable.

[Data type] Byte

MIRx

[Valid data range] 0 to 35

The CNC provides the following interfaces for data transfer to and from

the host computer and external input/output devices:

Input/output device interface (RS–232C serial port1, 2)

Remote buffer interface (RS–232C/RS–422)

DNC1/DNC2 interface

10

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

In addition, data can be transferred to and from the Power Mate via the

FANUC I/O Link.

This parameter selects the interface used to transfer data to and from an

input/output device.

Setting Description

0, 1 RS–232C serial port 1

2 RS–232C serial port 2

3 Remote buffer interface

4 Memory card interface

5 Data server interface

10 DNC1/DNC2 interface, OSI–Ethernet

20

21

22

34

35

|

Group 0

Group 1

Group 2

|

Group 14

Group 15

Data is transferred between the CNC and a Power

Mate in group n (n: 0 to 15) via the FANUC I/O Link.

NOTE

1 An input/output device can also be selected using the setting screen. Usually, the setting

screen is used.

2 The specifications (such as the baud rate and the number of stop bits) of the input/output

devices to be connected must be set in the corresponding parameters for each interface

beforehand. (See Section 4.2.) I/O CHANNEL = 0 and I/O CHANNEL = 1 represent

input/output devices connected to RS–232C serial port 1. Separate parameters for the baud

rate, stop bits, and other specifications are provided for each channel.

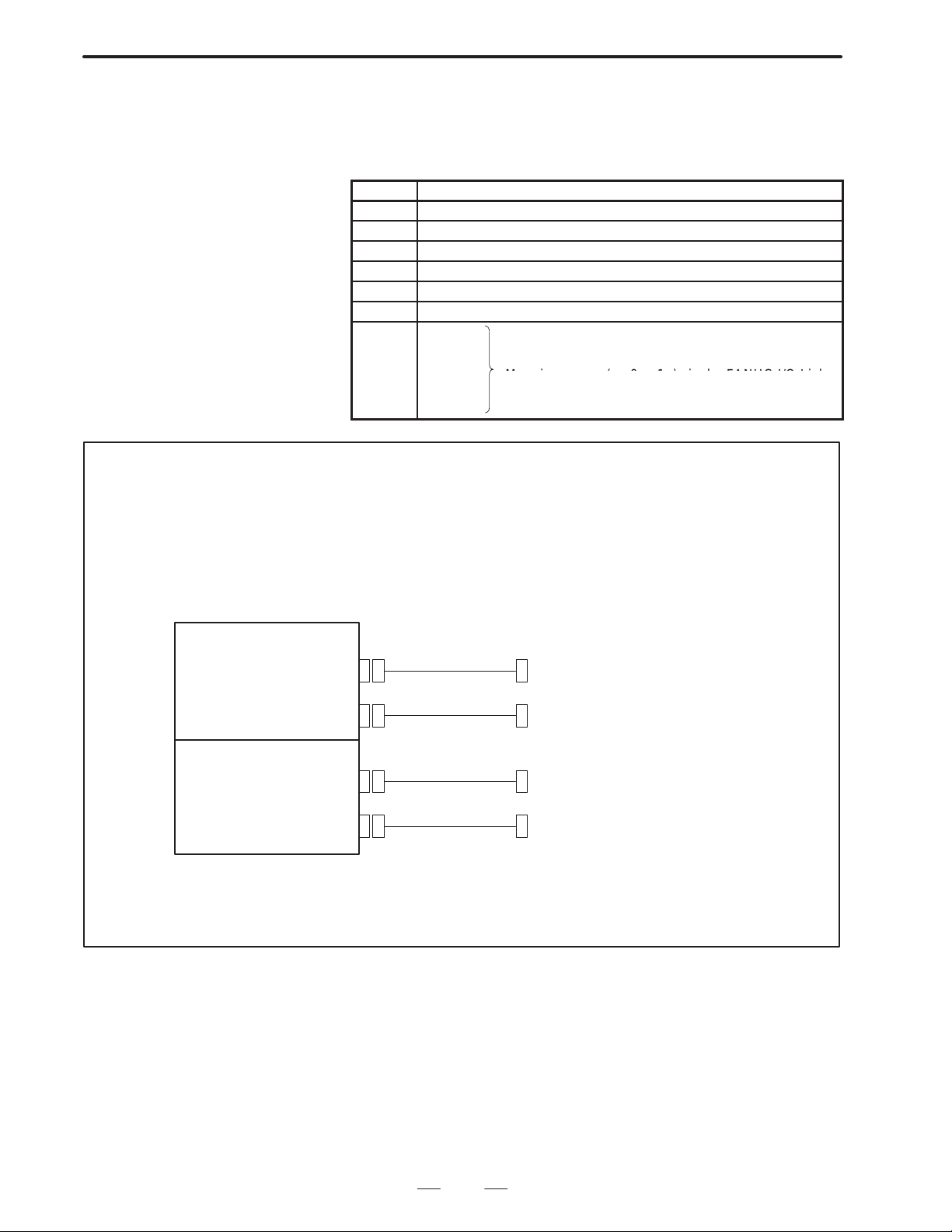

I/O board

RS–232–C serial port 1

R232–1(JD5A)

RS–232–C serial port 2

R232–2(JD5B)

Option 1 board

R232-3(JD5C)

R422-1(JD6A)

I/O CHANNEL=0, 1

(Channel 1)

I/O CHANNEL=2

(Channel 2)

I/O CHANNEL=3

(Channel 3)

I/O CHANNEL=3

(Channel 3)

RS-232-C I/O device

RS-232-C I/O device

RS-232-C I/O device

RS-422 I/O device

3 The input/output unit interface may be referred to as the reader/punch interface.

RS–232C serial port 1 and RS–232C serial port 2 are also referred to as channel 1 and channel

2, respectively. The remote buffer interface is also referred to as channel 3.

11

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

4.2

PARAMETERS OF

READER/PUNCHER

INTERFACE,

REMOTE BUFFER

INTERFACE

0020 0101

Specify a channel for an input/output device.

I/ O CHANNEL

=0 : Channel1

=1 : Channel1

=2 : Channel2

=3 : Channel3

I/O CHANNEL

This CNC has three channels of input/output device interfaces. The

input/output device to be used is specified by setting the channel

connected to that device in setting parameter I/O CHANNEL.

The specified data, such as a baud rate and the number of stop bits, of an

input/output device connected to a specific channel must be set in

parameters for that channel in advance.

For channel 1, two combinations of parameters to specify the input/output

device data are provided.

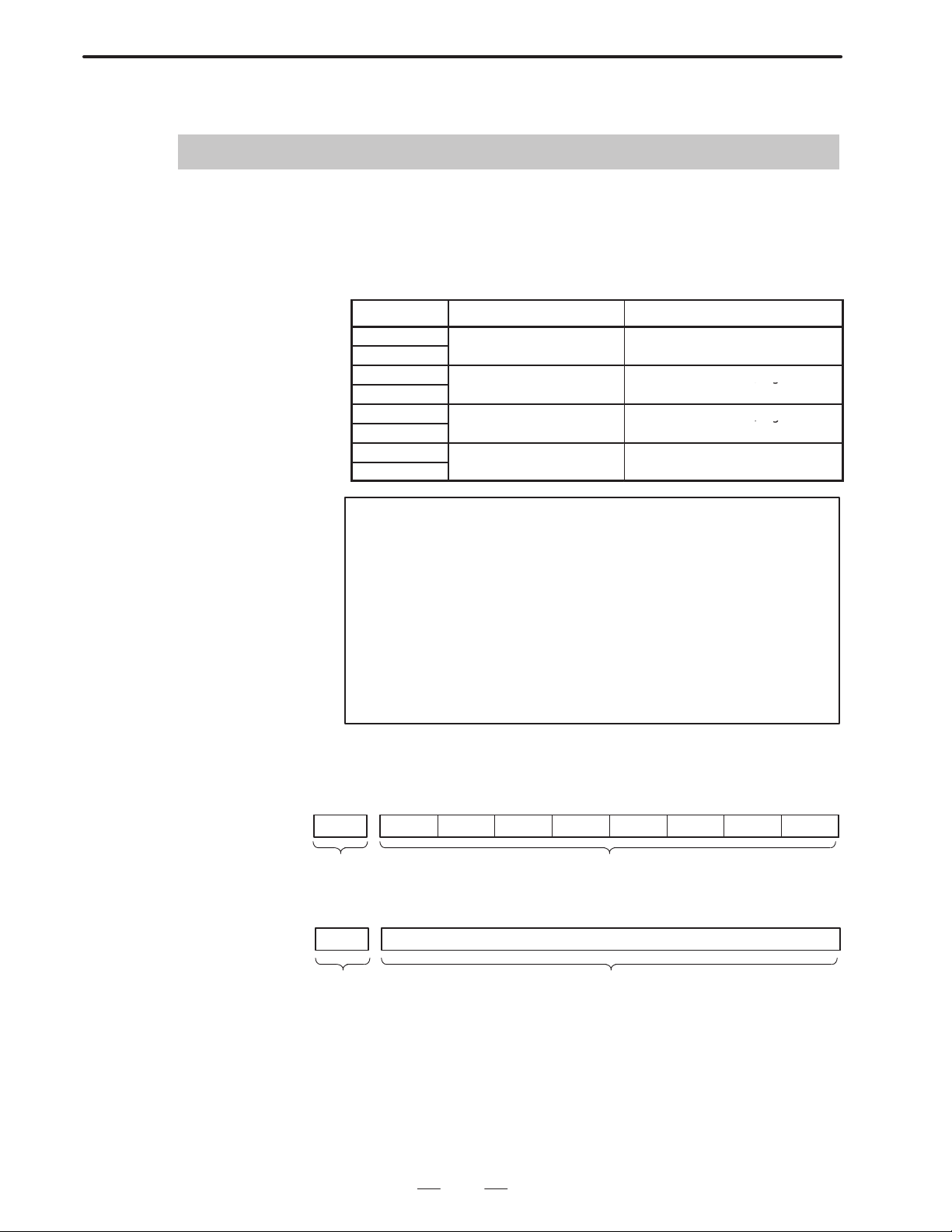

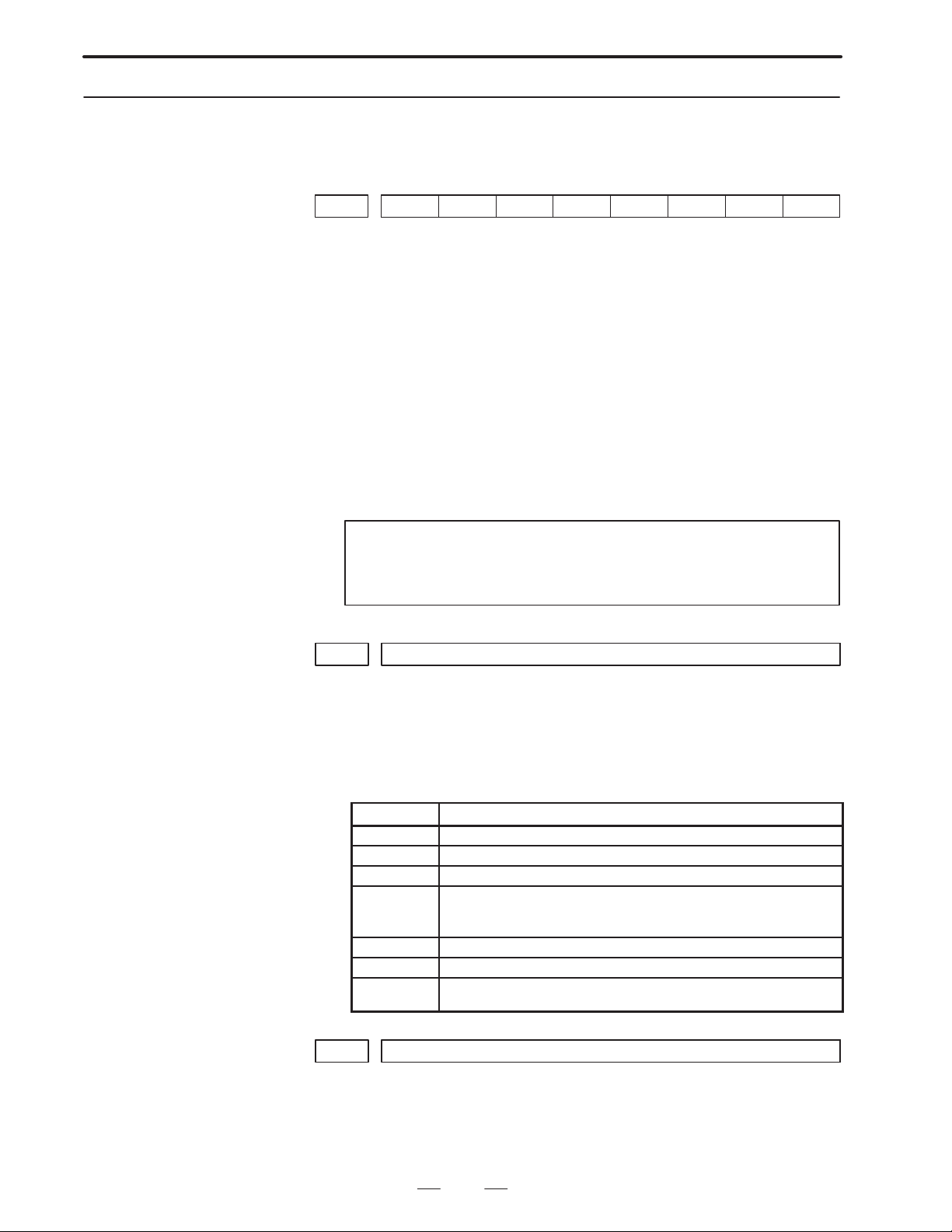

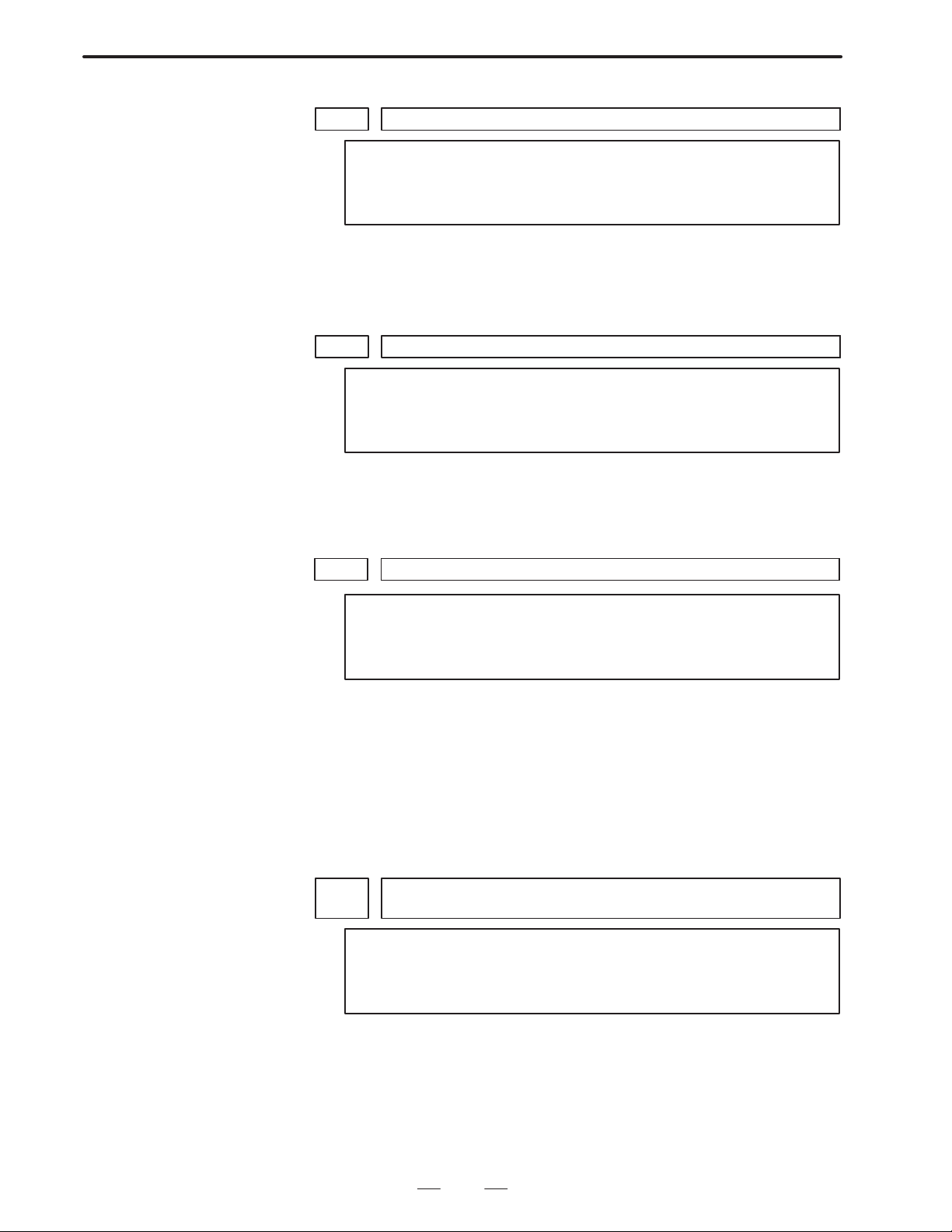

The following shows the interrelation between the input/output device

interface parameters for the channels.

Input/output channel number (parameter No.0020)

↓

Stop bit and other data

I/O CHANNEL=0

(channel 1)

I/O CHANNEL=1

(channel 1)

0102

0103

01 11

01 12

01 13

Number specified for the input/

output device

Baud rate

Stop bit and other data

Number specified for the input/

output device

Baud rate

0121

I/O CHANNEL=2

(channel 2)

I/O CHANNEL=3

(channel 3)

Fig. 4.2 I/O device interface settings

0122

0123

0131

0132

0133

0134

0135

Stop bit and other data

Number specified for the input/

output device

Baud rate

Stop bit and other data

Number specified for the input/

output device

Baud rate

Selection of protocol

Selection of RS–422 or

RS–232C, and other data

12

B–62710EN/03

4.2.1

Parameters Common

to All Channels

[Data type] Bit

4. DESCRIPTION OF P ARAMETERS

#7

ENS0100

#6

IOP

#5

ND3

#4 #3

NCR

#2 #1

CTV

#0

Setting entry is acceptable.

CTV Character counting for TV check in the comment section of a program.

0 : Performed

1 : Not performed

NCR Output of the end of block (EOB) in ISO code

0 : LF, CR, CR are output.

1 : Only LF is output.

ND3 In DNC operation, a program is:

0 : Read block by block. (A DC3 code is output for each block.)

1 : Read continuously until the buffer becomes full. (A DC3 code is

output when the buffer becomes full.)

NOTE

In general, reading is performed more efficiently when ND3

set to 1. This specification reduces the number of buffering

interruptions caused by reading of a series of blocks

specifying short movements. This in turn reduces the

effective cycle time.

IOP Specifies how to stop program input/output operations.

0 : An NC reset can stop program input/output operations.

1 : Only the [STOP] soft key can stop program input/output operations.

(An reset cannot stop program input/output operations.)

ENS Action taken when a NULL code is found during read of EIA code

0 : An alarm is generated.

1 : The NULL code is ignored.

13

4. DESCRIPTION OF P ARAMETERS

4.2.2

Parameters of

Channel 1

(I/O CHANNEL=0)

[Data type] Bit type

SB2 The number of stop bits

ASI Code used at data input

NFD Feed before and after the data at data output

#7

NFD0101

#6 #5 #4 #3

ASI

0 : 1

1 : 2

0 : EIA or ISO code (automatically distinguished)

1 : ASCII code

0 : Output

1 : Not output

B–62710EN/03

#2 #1 #0

SB2

NOTE

0102 Number specified for the input/output device (when the I/O CHANNEL is set to 0)

[Data type] Byte

Set the number specified for the input/output device used when the I/O

CHANNEL is set to 0, with one of the set values listed in T able 4.2.2 (a).

Set value

When input/output devices other than the FANUC PPR are

used, set NFD to 1.

Table 4.2.2 (a) Set value and input/output device

Input/output device

0 RS–232–C (Used control codes DC1 to DC4)

1 FANUC CASSETTE ADAPT OR 1 (FANUC CASSETTE B1/ B2)

2 FANUC CASSETTE ADAPTOR 3 (FANUC CASSETTE F1)

3 FANUC PROGRAM FILE Mate, FANUC FA Card Adaptor

FANUC FLOPPY CASSETTE ADAPTOR, FANUC Handy File

FANUC SYSTEM P-MODEL H

4 RS–232–C (Not used control codes DC1 to DC4)

5 Portable tape reader

6 FANUC PPR

FANUC SYSTEM P-MODEL G, FANUC SYSTEM P-MODEL H

0103 Baud rate (when the I/O CHANNEL is set to 0)

[Data type] Byte

Set baud rate of the input/output device used when the I/O CHANNEL is

set to 0, with a set value in Table 4.2.2 (b).

14

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

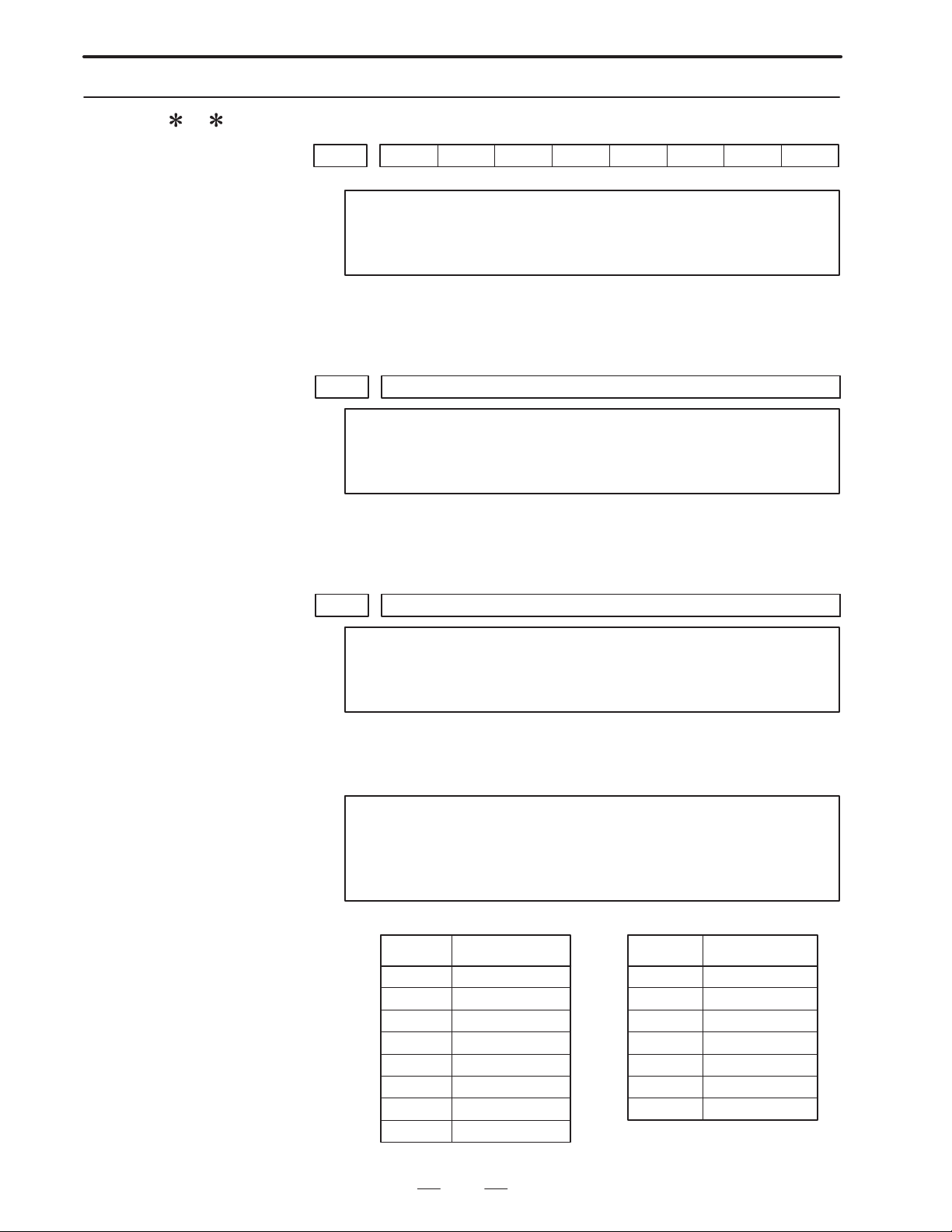

Table 4.2.2 (b)

4.2.3

Parameters of

Channel 1

(I/O CHANNEL=1)

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 1. The meanings

of the bits are the same as for parameter 0101.

0112 Number specified for the input/output device (when I/O CHANNEL is set to 1)

[Data type] Byte

Set the number specified for the input/output device used when the I/O

CHANNEL is set to 1, with one of the set values listed in T able 4.2.2 (a).

Set value Baud rate (bps)

1

2

3

4

5

6

#7

NFD0111

50

100

110

150

200

300

#6 #5 #4 #3

Set value Baud rate (bps)

7

8

9

10

11

12

#2 #1 #0

ASI

600

1200

2400

4800

9600

19200

SB2

4.2.4

Parameters of

Channel 2

(I/O CHANNEL=2)

0113 Baud rate (when I/O CHNNEL is set to 1)

[Data type] Byte

Set the baud rate of the input/output device used when I/O CHANNEL is

set to 1, with a value in Table 4.2.2 (b).

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 2. The meanings

of the bits are the same as for parameter 0101.

0122 Number specified for the input/output device (when I/O CHANNEL is set to 2)

[Data type] Byte

Set the number specified for the input/output device used when I/O

CHANNEL is set to 2, with a value in Table 4.2.2 (a).

0123 Baud rate (when the I/O CHANNEL is set to 2)

#7

NFD0121

#6 #5 #4 #3

ASI

#2 #1 #0

SB2

[Data type] Byte

Set the baud rate of the input/output device used when I/O CHANNEL is

set to 2, with a value in Table 4.2.2 (b).

15

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

4.2.5

( T, M)

Parameters of

Channel 3

(I/O CHANNEL=3)

NOTE

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 3. The meanings

of the bits are the same as for parameter 0101.

0132 Number specified for the input/output device (when I/O CHANNEL is set to 3)

NOTE

[Data type] Byte

Set the number specified for the input/output device used when I/O

CHANNEL is set to 3, with a number in Table 4.2.2 (a).

#7

NFD0131

#6 #5 #4 #3

ASI

#2 #1 #0

SB2

When this parameter is set, the power must be turned off

before operation is continued.

When this parameter is set, the power must be turned off

before operation is continued.

0133 Baud rate (when the I/O CHANNEL is set to 3)

NOTE

[Data type] Byte

Set the baud rate of the input/output device used when the I/O CHANNEL

is set to 3 according to the table 4.2.5.

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

Valid data range: 1 to 15 (up to a baud rate of 86400 bps)

for the RS–422 interface or 1 to 12 (up to a baud rate of

19200 bps) for the RS–232C interface.

Table 4.2.5 Baud rate settings

Set value Baud rate (bps)

1

2

3

4

5

6

7

8

50

100

110

150

200

300

600

1200

Set value Baud rate (bps)

9

10

11

12

13

14

14

2400

4800

9600

19200

38400

76800

86400

16

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

#7

0134

#6 #5

CLK#4NCD

#3 #2

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

PRY Parity bit

0: Not used

1: Used

SYN Reset/alarm in protocol B

0: Not reported to the host

1: Reported to the host with SYN and NAK codes

NCD CD (signal quality detection) of the RS–232C interface

0: Checked

1: Not checked

CLK Baud rate clock when the RS–422 interface is used

0: Internal clock

1: External clock

NOTE

When the RS–232C interface is used, set this bit to 0.

SYN

#1

PRY

#0

#7

RMS0135

#6 #5 #4 #3

R42

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

ASC Communication code except NC data

0: ISO code

1: ASCII code

ETX End code for protocol A or extended protocol A

0: CR code in ASCII/ISO

1: ETX code in ASCII/ISO

NOTE

Use of ASCII/ISO is specified by ASC.

PRA Communication protocol

0: Protocol B

1: Protocol A

R42 Interface

0: RS–232C interface

1: RS–422 interface

RMS State of remote/tape operation when protocol A is used

0: Always 0 is returned.

1: Contents of the change request of the remote/tape operation in the

SET command from the host is returned.

#2

PRA

#1

ETX

#0

ASC

17

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

4.3

( T, M)

PARAMETERS OF

DNC1/DNC2

INTERFACE

[Data type] Bit

[Data type] Byte

[Valid data range] 1 or 2

#7

0140

#6

BCC

#5 #4 #3 #2 #1 #0

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

BCC The BCC value (block check characters) for the DNC2 interface is:

0: Checked.

1: Not checked.

0141 System for connection between the CNC and host (DNC1 interface)

This parameter specifies the system for connection (DNC1 interface)

between the CNC and host.

Set value

1 : Point–to–point connection

2 : Multipoint connection

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

0142 Station address of the CNC (DNC1 interface)

[Data type] Byte

[Valid data range] 2 to 52

This parameter specifies the station address of the CNC when the CNC is

connected via the DNC1 interface using multipoint connection.

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

0143 Time limit specified for the timer monitoring a response (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Seconds

[Valid data range] 1 to 60 (The standard setting is 3.)

18

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

0144 Time limit specified for the timer monitoring the EOT signal (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Seconds

[Valid data range] 1 to 60 (The standard setting is 5.)

0145 Time required for switching RECV and SEND (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Seconds

[Valid data range] 1 to 60 (The standard setting is 1.)

0146 Number of times the system retries holding communication (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Seconds

[Valid data range] 1 to 10 (The standard setting is 3.)

Set the maximum number of times the system retries holding

communication with the remote device if the remote device uses an

invalid protocol in the data–link layer or the remote device does not

respond to the request.

0147

Number of times the system sends the message in response to the NAK signal

(DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Number of times

[Valid data range] 1 to 10 (The standard setting is 2.)

Set the maximum number of times the system retries sending the message

in response to the NAK signal.

19

4. DESCRIPTION OF P ARAMETERS

0148 Number of characters in overrun (DNC2) interface)

[Data type] Byte

[Valid data range] 10 to 225 (The standard setting is 10.)

B–62710EN/03

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

Set the number of characters the system can receive after transmission is

stopped (CS off).

0149

Number of characters in the data section of the communication packet (DNC2

interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Word

[Valid range] 80 to 256

The standard setting is 256. If the specified value is out of range, a value of

80 or 256 is used.

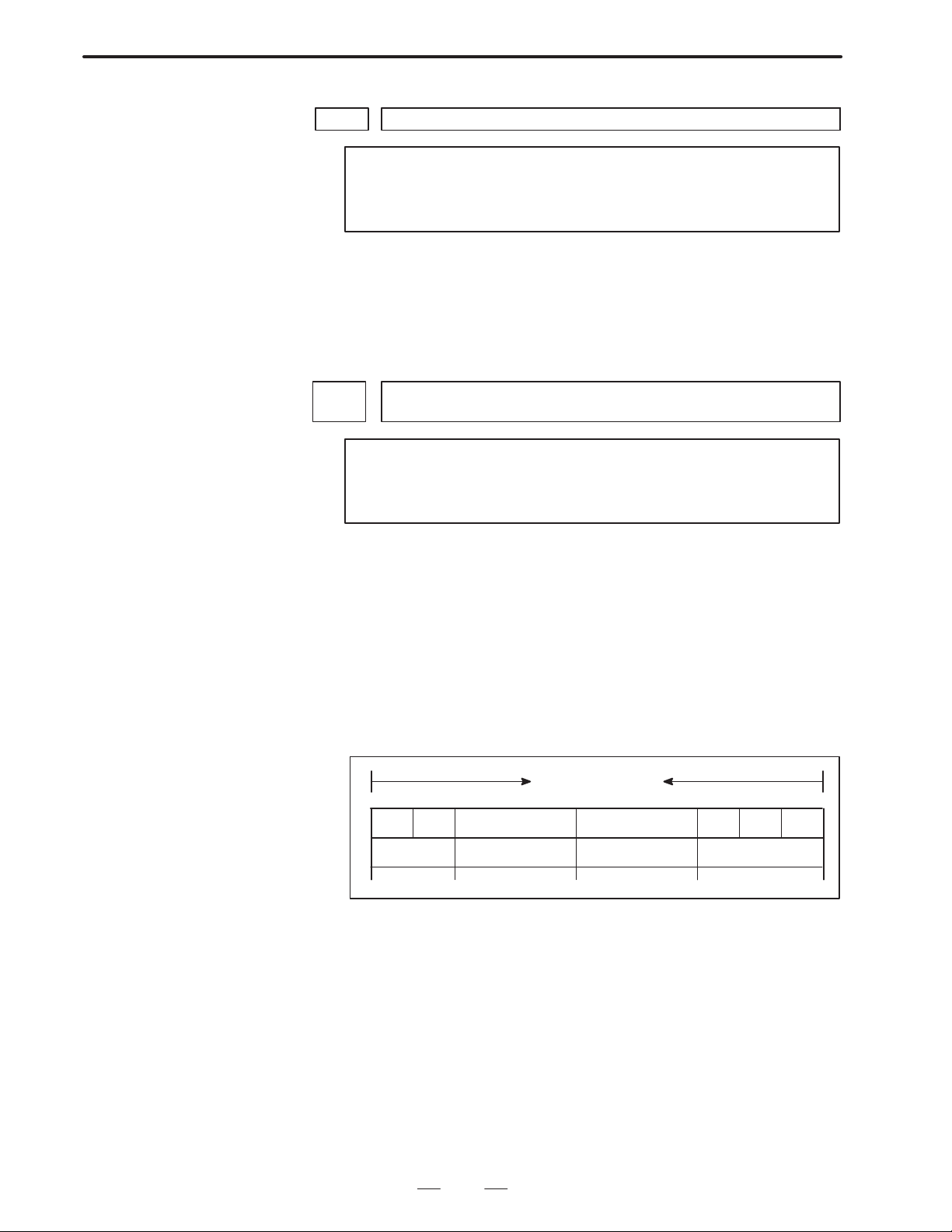

This parameter determines the maximum length of the packet used in

transmission over the DNC2 interface. Including the two characters at the

start of the packet, the four characters used for a command, and the three

characters at the end, the maximum number of characters in the packet is

nine plus the number specified in parameter No.0149.

DLE

STX

Length of the packet

Command Data section DEL ETX BCC

2 bytes 4 bytes 80 to 256 bytes 3 bytes

20

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

4.4

( M)

PARAMETERS OF

POWER MOTION

MANAGER

[Data type] Bit

MD1,MD2

#7

0960

#6 #5 #4 #3

PMN

#2

MD2#1MD1

SLV When the power motion manager is selected, the screen displays:

0 : One slave.

1 : Up to four slaves with the screen divided into four.

These parameters set a slave parameter input/output destination.

MD2 MD1 Input/output destination

0 0 Part program storage

0 1 Memory card

In either case, slave parameters are output in program format.

PMN The power motion manager function is:

0 : Enabled.

1 : Disabled. (Communication with slaves is not performed.)

#0

SLV

21

4. DESCRIPTION OF P ARAMETERS

4.5

PARAMETERS OF

AXIS CONTROL/

INCREMENT SYSTEM

1001

[Data type] Bit

INM Least command increment on the linear axis

B–62710EN/03

#7

#6 #5 #4 #3 #2 #1 #0

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

0 : In mm (metric system machine)

1 : In inches (inch system machine)

INM

1002

#7

IDG

#6 #5 #4

XIK

XIK

#3

AZR

#2 #1

DLZ

DLZ

[Data type] Bit

JAX Number of axes controlled simultaneously in manual continuous feed,

manual rapid traverse and manual reference position return

0 : 1 axis

1 : 3 axes

DLZ Function setting the reference position without dog

0 : Disabled

1 : Enabled

NOTE

This function can be specified for each axis by DLZx, bit 1

of parameter No.1005.

AZR When no reference position is set, the G28 command causes:

0: Reference position return using deceleration dogs (as during manual

reference position return) to be exected.

1: P/S alarm No.090 to be issued.

#0

JAX

JAXIDG

NOTE

When reference position return without dogs is specified,

(when bit 1 (DLZ) of parameter No.1002 is set to 1 or bit 1

(DLZx) of parameter No.1005 is set to 1) the G28 command

specified before a reference position is set causes P/S

alarm No.090 to be issued, regardless of the setting of AZR.

22

B–62710EN/03

4. DESCRIPTION OF P ARAMETERS

XIK When LRP, bit 1 of parameter No.1401, is set to 0, namely, when

positioning is performed using non–linear type positioning, if an

interlock is applied to the machine along one of axes in positioning,

0: The machine stops moving along the axis for which the interlock is

applied and continues to move along the other axes.

1: The machine stops moving along all the axes.

IDG When the reference position is set without dogs, automatic setting of the

IDGx parameter (bit 0 of parameter No.1012) to prevent the reference

position from being set again is:

0 : Not performed.

1 : Performed.

1004

#7

IPR

IPR

#6 #5 #4 #3 #2 #1

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

(

M) ISA, ISC The least input increment and least command increment are set.

ISC ISA

0 0 0.001 mm, 0.001 deg, or 0.0001 inch IS–B

0 1 0.01 mm, 0.01 deg, or 0.001 inch IS–A

1 0 0.0001 mm, 0.0001 deg, or 0.00001 inch IS–C

Least input increment and least command

increment

NOTE

IS–A cannot be used at present.

ISC

ISC

#0

ISA

Symbol

IPR Whether the least input increment for each axis is set to a value 10 times as

large as the least command increment is specified, in increment systems

of IS–B or IS–C at setting mm.

0: The least input increment is not set to a value 10 times as larg as the

least command increment.

1: The least input increment is set to a value 10 times as large as the least

command increment.

If IPR is set to 1, the least input increment is set as follows:

Input increment Least input increment

IS–B 0.01 mm, 0.01 deg, or 0.0001 inch

IS–C 0.001 mm, 0.001 deg, or 0.00001 inch

NOTE

For IS–A, the least input increment cannot be set to a value

10 times as large as the least command increment.

23

4. DESCRIPTION OF P ARAMETERS

B–62710EN/03

1005

#7

RMBx

#6

MCCx

MCCx

#5

EDMx

EDMx

#4

EDPx

EDPx#3HJZx

#2 #1

DLZx

DLZx

[Data type] Bit axis

ZRNx When a command specifying the movement except for G28 is issued in

automatic operation (MEM, RMT, or MDI) and when a return to the

reference position has not been performed since the power was turned on

0 : An alarm is generated (P/S alarm 224).

1 : An alarm is not generated.

NOTE

The state in which the reference position has not been

established refers to that state in which reference position

return has not been performed after power–on when an

absolute position detector is not being used, or that state in

which the association of the machine position with the position

detected with the absolute position detector has not been

completed (see the description of bit 4 (APZx) of parameter

No. 1815) when an absolute position detector is being used.

DLZx Function for setting the reference position without dogs

0 : Disabled

1 : Enabled

#0

ZRNx

ZRNxRMBx

NOTE

When DLZ of parameter No.1002 is 0, DLZx is enabled.

When DLZ of parameter No.1002 is 1, DLZx is disabled, and

the function for setting the reference position without dogs

is enabled for all axes.

HJZx When a reference position is already set:

0 : Manual reference position return is performed with deceleration sogs.

1 : Manual reference position return is performed using rapid traverse

without deceleration dogs, or manual reference position return is

performed with deceleration dogs, depending on the setting of bit 7

(SJZ) of parameter No.0002.

NOTE

When reference position return without dogs is specified,

(when bit 1 (DLZ) of parameter No.1002 is set to 1 or bit

(DLZx) of parameter No.1005 is set to 1) reference position

return after a reference position is set is performed using

rapid traverse, regardless of the setting of HJZ.

T, M) EDPx External deceleration signal in the positive direction for each axis

(

0 : Valid only for rapid traverse

1 : Valid for rapid traverse and cutting feed

T, M) EDMx External deceleration signal in the negative direction for each axis

(

0 : Valid only for rapid traverse

1 : Valid for rapid traverse and cutting feed

MCCx When an axis become the removal state using the controlled axis removal

signal or setting:

0: MCC is turned off

1: MCC is not turned of f. (Servo motor excitation is turned off, but the

MCC signal of the servo amplifier is not turned off.)

24

Loading...

Loading...