fanuc 21 B, 210 B User Manual

GE Fanuc Automation

Computer Numerical Control Products

Series 21 / 210 – Model B

Descriptions Manual

GFZ-62702EN/03 November 1996

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1996 GE Fanuc Automation North America, Inc.

All Rights Reserved.

B–62702EN/03

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s–1

B–62702EN/03

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. LIST OF SPECIFICATIONS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. NC FUNCTION

PREFACE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. CONTROLLED AXES 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 NUMBER OF THE ALL CONTROLLED AXES 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 MACHINE CONTROLLED AXES 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Number of Controlled Paths 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Number of Basic Controlled Axes 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Number of Basic Simultaneously Controlled Axes 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Number of Controlled Axes Expanded (All) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Number of Simultaneously Controlled Axes Expanded (All) 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Axis Control by PMC 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Cs Contour Control 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 LOADER CONTROLLED AXES 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 AXIS NAMES 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 INCREMENT SYSTEM 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Input Unit (10 Times) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 MAXIMUM STROKE 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PREPARATORY FUNCTIONS 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 T SERIES 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 M SERIES 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INTERPOLATION FUNCTIONS 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 POSITIONING (G00) 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SINGLE DIRECTION POSITIONING (G60) (M series) 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 LINEAR INTERPOLATION (G01) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 CIRCULAR INTERPOLATION (G02, G03) 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 HELICAL INTERPOLATION (G02, G03) (M series) 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 POLAR COORDINATE INTERPOLATION (G12.1, G13.1) (T series) 37. . . . . . . . . . . . . . . . . . . . . . .

3.7 CYLINDRICAL INTERPOLATION (G07.1) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

T ABLE OF CONTENTS

B–62702EN/03

4. THREAD CUTTING 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 EQUAL LEAD THREAD CUTTING (G33) (WITH G CODE SYSTEM A: G32) 42. . . . . . . . . . . . . .

4.2 MULTIPLE–THREAD CUTTING (G33) (T series) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 VARIABLE LEAD THREAD CUTTING (G34) (T series) 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CONTINUOUS THREAD CUTTING(T series) 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. FEED FUNCTIONS 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 RAPID TRAVERSE 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CUTTING FEEDRATE 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Tangential Speed Constant Control 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Cutting Feedrate Clamp 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Per Minute Feed (G94) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Per Revolution Feed (G95) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 F1–digit Feed (M Series) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 OVERRIDE 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Feedrate Override 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Rapid Traverse Override 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Override Cancel 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Jog Override 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 AUTOMATIC ACCELERATION/DECELERATION 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 RAPID TRAVERSE BELL–SHAPED ACCELERATION/DECELERATION 51. . . . . . . . . . . . . . . . . .

5.6 LINEAR ACCELERATION/DECELERATION AFTER CUTTING FEED INTERPOLATION 52. . . .

5.7 BELL–SHAPED ACCELERATION/DECELERATION AFTER CUTTING FEED

INTERPOLATION 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 ERROR DETECTION (T series) 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 EXACT STOP (G09) (M series) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 EXACT STOP MODE (G61) (M series) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 CUTTING MODE (G64) (M series) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 TAPPING MODE (G63) (M series) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 AUTOMATIC CORNER OVERRIDE (G62) (M series) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 DWELL (G04) 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. REFERENCE POSITION 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 MANUAL REFERENCE POSITION RETURN 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SETTING THE REFERENCE POSITION WITHOUT DOGS 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 AUTOMATIC REFERENCE POSITION RETURN (G28, G29 (ONLY FOR M SERIES)) 59. . . . . . .

6.4 REFERENCE POSITION RETURN CHECK (G27) 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 2ND, 3RD AND 4TH REFERENCE POSITION RETURN (G30) 60. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 BUTT–TYPE REFERENCE POSITION SETTING 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. COORDINATE SYSTEMS 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 MACHINE COORDINATE SYSTEM (G53) 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 WORKPIECE COORDINATE SYSTEM 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Setting a Workpiece Coordinate System (Using G92) (with G Code System A: G50) 64. . . . . . . .

7.2.2 Automatic Coordinate System Setting 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Setting a Workpiece Coordinate System (Using G54 to G59) 67. . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–62702EN/03

7.3 LOCAL COORDINATE SYSTEM (G52) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 WORKPIECE ORIGIN OFFSET VALUE CHANGE

(PROGRAMMABLE DATA INPUT) (G10) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 ADDITIONAL WORKPIECE COORDINATE SYSTEMS (G54.1 OR G54) (M series) 70. . . . . . . . . .

7.6 WORKPIECE COORDINATE SYSTEM PRESET (G92.1) 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 WORKPIECE COORDINATE SYSTEM SHIFT (T series) 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 PLANE SELECTION (G17, G18, G19) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

8. COORDINATE VALUE AND DIMENSION 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91) 75. . . . . . . . . . . . . . . . . . . . . . . . .

8.2 POLAR COORDINATE COMMAND (G15, G16) (M series) 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 INCH/METRIC CONVERSION (G20, G21) 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 DECIMAL POINT INPUT/POCKET CALCULATOR TYPE DECIMAL POINT INPUT 77. . . . . . . .

8.5 DIAMETER AND RADIUS PROGRAMMING (T series) 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 LINEAR AXIS AND ROTATION AXIS 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 ROTATION AXIS ROLL–OVER FUNCTION 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SPINDLE FUNCTIONS 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 S CODE OUTPUT 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SPINDLE SPEED ANALOG OUTPUT (S ANALOG OUTPUT) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 SPINDLE SPEED SERIAL OUTPUT (S SERIAL OUTPUT) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 SPINDLE OUTPUT CONTROL BY THE PMC 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 CONSTANT SURFACE SPEED CONTROL 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 SPINDLE OVERRIDE 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 ACTUAL SPINDLE SPEED OUTPUT (T series) 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 SPINDLE POSITIONING (T series) 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 SPINDLE SPEED FLUCTUATION DETECTION (G25, G26) (T series) 82. . . . . . . . . . . . . . . . . . . . .

9.10 Cs CONTOUR CONTROL 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 MULTI–SPINDLE CONTROL (T series) 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12 SPINDLE SYNCHRONIZATION CONTROL 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13 SPINDLE ORIENTATION 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.14 SPINDLE OUTPUT SWITCHING 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.15 SIMPLE SPINDLE SYNCHRONOUS CONTROL 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. TOOL FUNCTIONS 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 T CODE OUTPUT 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 TOOL LIFE MANAGEMENT 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Tool Life Management 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Addition of Tool Pairs for Tool Life Management <512 Pairs> (M series) 90. . . . . . . . . . . . . . . . .

10.2.3 Extended Tool Life Management (M series) 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. MISCELLANEOUS FUNCTIONS 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 MISCELLANEOUS FUNCTIONS 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 1–BLOCK PLURAL M COMMAND 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 SECOND MISCELLANEOUS FUNCTIONS 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 HIGH–SPEED M/S/T/B INTERFACE 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

T ABLE OF CONTENTS

B–62702EN/03

12. PROGRAM CONFIGURATION 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 PROGRAM NUMBER 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 PROGRAM NAME 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 MAIN PROGRAM 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 SUB PROGRAM 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 EXTERNAL MEMORY AND SUB PROGRAM CALLING FUNCTION 98. . . . . . . . . . . . . . . . . . . . .

12.6 SEQUENCE NUMBER 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 TAPE CODES 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 BASIC ADDRESSES AND COMMAND VALUE RANGE 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9 T APE FORMAT 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.10 LABEL SKIP 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.11 CONTROL–IN/CONTROL–OUT 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.12 OPTIONAL BLOCK SKIP 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.13 ADDITIONAL OPTIONAL BLOCK SKIP 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.14 TAPE HORIZONTAL (TH) PARITY CHECK AND

TAPE VERTICAL (TV) PARITY CHECK 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. FUNCTIONS TO SIMPLIFY PROGRAMMING 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 CANNED CYCLES (G73, G74, G76, G80–G89, G98, G99) (M series) 103. . . . . . . . . . . . . . . . . . . . . .

13.2 RIGID TAP 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 EXTERNAL OPERATION FUNCTION (G81)(M series) 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 CANNED CYCLES FOR TURNING (T series) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.1 Cutting Cycle A (G77) (with G Code System A: G90) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.2 Thread Cutting Cycle (G78) (with G Code System A: G92) 113. . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4.3 Turning Cycle in Facing (G79) (with G Code System A: G94) 115. . . . . . . . . . . . . . . . . . . . . . . . .

13.5 MULTIPLE REPETITIVE CYCLES FOR TURNING (G70 – G76) (T series) 116. . . . . . . . . . . . . . . . .

13.5.1 Stock Removal in Turning (G71) 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.2 Stock Removal in Facing (G72) 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.3 Pattern Repeating (G73) 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.4 Finishing Cycle (G70) 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.5 Peck Drilling in Z–axis (G74) 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.6 Grooving in X–axis (G75) 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5.7 Thread Cutting Cycle (G76) 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 CANNED CYCLES FOR DRILLING (G80 - G89) (T series) 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 CHAMFERING AND CORNER R (T series) 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 OPTIONAL ANGLE CHAMFERING/CORNER ROUNDING (M series) 130. . . . . . . . . . . . . . . . . . . .

13.9 DIRECT DRAWING DIMENSIONS PROGRAMMING (T series) 131. . . . . . . . . . . . . . . . . . . . . . . . .

13.10 PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) (M series) 133. . . . . . . . . . . . . . . . . . . . . . . . .

13.11 MIRROR IMAGE FOR DOUBLE TURRETS (G68, G69) (T series) 134. . . . . . . . . . . . . . . . . . . . . . . .

13.12 INDEX TABLE INDEXING (M series) 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. TOOL COMPENSATION FUNCTION 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOOL OFFSET (T series) 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 Tool Offset (T Code) 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.2 Tool Geometry Compensation and Tool Wear Compensation 138. . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.3 Y Axis Offset 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

B–62702EN/03

14.2 TOOL NOSE RADIUS COMPENSATION (G40, G41, G42) (T series) 139. . . . . . . . . . . . . . . . . . . . . .

14.3 TOOL LENGTH COMPENSATION (G43, G44, G49) (M series) 142. . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 TOOL OFFSET (G45, G46, G47, G48) (M series) 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 CUTTER COMPENSATION C (G40 TO G42) (M series) 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 CORNER CIRCULAR INTERPOLATION FUNCTION (G39) (M series) 146. . . . . . . . . . . . . . . . . . . .

14.7 TOOL COMPENSATION MEMORY 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7.1 Tool Compensation Memory (M Series) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7.2 Tool Offset Amount Memory (T Series) 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8 NUMBER OF TOOL OFFSETS 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.1 Number of Tool Offsets (M Series) 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.2 Number of Tool Offsets (T Series) 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.9 CHANGING OF TOOL OFFSET AMOUNT (PROGRAMMABLE DATA INPUT) (G10) 151. . . . . .

T ABLE OF CONTENTS

15. ACCURACY COMPENSATION FUNCTION 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 STORED PITCH ERROR COMPENSATION 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 BACKLASH COMPENSATION 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 BACKLASH COMPENSATION SPECIFIC TO RAPID TRAVERSE AND CUTTING FEED 155. . .

15.4 PROGRAMMABLE PARAMETER ENTRY (G10, G11) 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16. COORDINATE SYSTEM CONVERSION 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 COORDINATE SYSTEM ROTATION (G68, G69) (M Series) 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 SCALING (G50, G51) (M series) 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17. MEASUREMENT FUNCTIONS 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 SKIP FUNCTION (G31) 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 MULTI–STEP SKIP FUNCTION (G31 P1 – G31 P4) (T series) 163. . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 TORQUE LIMIT SKIP (G31 P99, G31 P98) (T series) 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 TOOL LENGTH AUTOMATIC MEASUREMENT (G37) (M series) 164. . . . . . . . . . . . . . . . . . . . . . .

17.5 AUTOMATIC TOOL OFFSET (G36, G37) (T series) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.6 TOOL LENGTH MEASUREMENT (M series) 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.7 DIRECT INPUT OF TOOL COMPENSATION MEASURED VALUE/

DIRECT INPUT OF WORKPIECE COORDINATE SYSTEM SHIFT AMOUNT (T series) 167. . . . .

17.8 TOOL COMPENSATION VALUE MEASURED VALUE DIRECT INPUT B (T series) 168. . . . . . . .

17.9 COUNT INPUT OF TOOL OFFSET VALUES (T series) 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.10 DIRECT INPUT OF WORKPIECE ZERO POINT OFFSET VALUE MEASURED 171. . . . . . . . . . . .

18. CUSTOM MACRO 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 CUSTOM MACRO 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 INCREASED CUSTOM MACRO COMMON VARIABLES 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 INTERRUPTION TYPE CUSTOM MACRO 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.4 PATTERN DATA INPUT 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.5 MACRO EXECUTER FUNCTION 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19. Series 10/11 TAPE FORMAT 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

T ABLE OF CONTENTS

B–62702EN/03

20. FUNCTIONS FOR HIGH SPEED CUTTING 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.1 FEEDRATE CLAMP BY CIRCULAR RADIUS (M series) 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2 ADVANCED PREVIEW CONTROL (G08) (M series) 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3 REMOTE BUFFER 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.1 Remote Buffer 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.2 High–speed Remote Buffer A (G05) 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.3 High–speed Remote Buffer B (G05) (M series) 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. AXES CONTROL 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1 FOLLOW UP FUNCTION 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2 MECHANICAL HANDLE FEED 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.3 SERVO OFF 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.4 MIRROR IMAGE 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.5 CONTROL AXIS DETACH 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.6 SIMPLE SYNCHRONOUS CONTROL 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.7 NORMAL DIRECTION CONTROL (G40.1, G41.1, G42.1) (M series) 193. . . . . . . . . . . . . . . . . . . . . .

21.8 POLYGONAL TURNING (G50.2, G51.2) (T series) 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.9 AXIS CONTROL WITH PMC 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.10 SLANTED AXIS CONTROL (T series) 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.11 B–AXIS CONTROL (T series) 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. MANUAL OPERATION 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.1 MANUAL FEED 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.2 INCREMENTAL FEED 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.3 MANUAL HANDLE FEED (1ST) 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.4 MANUAL HANDLE FEED (2ND, 3RD) (T SERIES: 2ND) 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.5 HANDLE FEED IN THE SAME MODE AS FOR JOGGING 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.6 MANUAL PER–ROTATION FEED (T series) 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22.7 MANUAL ABSOLUTE ON/OFF 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. AUTOMATIC OPERATION 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1 OPERATION MODE 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1.1 DNC Operation 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1.2 Memory Operation 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.1.3 MDI Operation 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2 SELECTION OF EXECUTION PROGRAMS 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2.1 Program Number Search 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2.2 Sequence Number Search 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2.3 Rewind 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2.4 External Workpiece Number Search 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.3 ACTIVATION OF AUTOMATIC OPERATION 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.3.1 Cycle Start 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.4 EXECUTION OF AUTOMATIC OPERATION 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.4.1 Buf fer Register 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

B–62702EN/03

23.5 AUTOMATIC OPERATION STOP 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.1 Program Stop (M00, M01) 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.2 Program End (M02, M30) 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.3 Sequence Number Comparison and Stop 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.4 Feed Hold 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.5 Thread Cutting Cycle Retract (T Series) 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.5.6 Reset 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.6 RESTART OF AUTOMATIC OPERATION 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.6.1 Program Restart 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.6.2 Manual Intervention and Return 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.7 MANUAL INTERRUPTION DURING AUTOMATIC OPERATION 207. . . . . . . . . . . . . . . . . . . . . . .

23.7.1 Handle Interruption 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.8 SCHEDULING FUNCTION 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

24. PROGRAM TEST FUNCTIONS 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.1 ALL–AXES MACHINE LOCK 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.2 MACHINE LOCK ON EACH AXIS 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.3 AUXILIARY FUNCTION LOCK 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.4 DRY RUN 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24.5 SINGLE BLOCK 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25. SETTING AND DISPLAY UNIT 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1 SETTING AND DISPLAY UNIT 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.1 9″ Monochrome CRT/MDI (Small Size) 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.2 9″ Monochrome CRT (Separate Type) 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.3 9″ Monochrome PDP (Separate Type) 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.4 7.2″ STN Monochrome LCD (Separate Type) 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.5 9.5″ STN Monochrome LCD (Separate Type) 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.6 8.4″ TFT Color LCD (Separate Type) 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.7 Separate MDI (Small Size) (For 9″ CRT, 9″ PDP, 7.2″ LCD, and 8.4″ LCD) 215. . . . . . . . . . . . . .

25.1.8 Separate MDI (Full–key Size) (For 9″ CRT, 9″ PDP, 7.2″ LCD, and 8.4″ LCD) 215. . . . . . . . . . .

25.1.9 Separate MDI (Full–key Size, Horizontal Type) (For 9.5″ LCD) 216. . . . . . . . . . . . . . . . . . . . . . .

25.1.10 Separate MDI (Full–key Size, Vertical Type) (For 9.5″ LCD) 216. . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.11 9.5″ Color TFT/MDI (Horizontal Type) 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.12 9.5″ Color TFT/MDI (Vertical Type) 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.13 14″ Color CRT/MDI (Horizontal Type) 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.14 14″ Color CRT/MDI (Vertical Type) 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.1.15 Intelligent Terminal (9.5″ STN Monochrome LCD (Separate Type))

(9.5″ TFT Color LCD (Separate Type)) (10.4″ TFT Color LCD (Separate Type)) 219. . . . . . . . . .

25.2 MDI KEY ARRANGEMENT 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.2.1 Small MDI Key 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.2.2 Standard MDI Key (For 9″ CRT, 9″ PDP, 7.2″ LCD, 8.4″ LCD, and 9.5″ LCD) 221. . . . . . . . . . . .

25.2.3 Standard MDI Key (For 9.5″ Color TFT/MDI (Horizontal Type)) 222. . . . . . . . . . . . . . . . . . . . . .

25.2.4 Standard MDI Key (For 14″ Color CRT/MDI (Horizontal Type)) 223. . . . . . . . . . . . . . . . . . . . . . .

25.2.5 Standard MDI Key (For 9.5″ Color TFT/MDI (Vertical Type)

and 14″ Color CRT/MDI (Vertical Type)) 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.3 EXPLANATION OF THE KEYBOARD 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.3.1 Explanation of the Function Keys 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25.3.2 Explanation of the Soft Keys 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

T ABLE OF CONTENTS

B–62702EN/03

26. DISPLAYING AND SETTING DATA 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.1 DISPLA Y 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.2 LANGUAGE SELECTION 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.3 CLOCK FUNCTION 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.4 RUN TIME & PARTS NUMBER DISPLAY 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.5 SOFTWARE OPERATOR’S PANEL 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.6 DIRECTORY DISPLAY OF FLOPPY CASSETTE 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.7 GRAPHIC DISPLAY FUNCTION 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.7.1 Graphic Display Function 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.7.2 Dynamic Graphic Display (M series) 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.8 SERVO WAVEFORM FUNCTION 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9 SCREENS FOR SERVO DATA AND SPINDLE DATA 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9.1 Servo Setting Screen 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9.2 Servo Adjustment Screen 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9.3 Spindle Setting Screen 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9.4 Spindle Adjustment Screen 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.9.5 Spindle Monitor Screen 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.10 SYSTEM CONFIGURATION DISPLAY FUNCTION 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.11 HELP FUNCTION 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.12 DATA PROTECTION KEY 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.13 DISPLAYING OPERATION HIST ORY 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.14 REMOTE DIAGNOSIS 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26.15 DIRECTORY DISPLAY AND PUNCH FOR A SPECIFIED GROUP 250. . . . . . . . . . . . . . . . . . . . . . .

26.16 CLEARING THE SCREEN 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. PART PROGRAM STORAGE AND EDITING 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.1 FOREGROUND EDITING 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.2 BACKGROUND EDITING 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.3 EXPANDED PART PROGRAM EDITING 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.4 NUMBER OF REGISTERED PROGRAMS 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.5 PART PROGRAM STORAGE LENGTH 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.6 PLAY BACK 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.7 EXTERNAL CONTROL OF I/O DEVICE 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27.8 PASSWORD FUNCTION 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28. DIAGNOSIS FUNCTIONS 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28.1 SELF DIAGNOSIS FUNCTIONS 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29. DATA INPUT/OUTPUT 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.1 READER/PUNCH INTERFACES 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.2 INPUT/OUTPUT DEVICES 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.2.1 FANUC FLOPPY CASSETTE 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.2.2 FANUC PROGRAM FILE MATE 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.2.3 FANUC Handy File 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.3 EXTERNAL PROGRAM INPUT 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.4 MEMOR Y CARD INTERFACE 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29.5 DATA INPUT/OUTPUT FUNCTION BASED ON THE I/O LINK

AND DATA INPUT/OUTPUT FUNCTION B BASED ON THE I/O LINK 259. . . . . . . . . . . . . . . . . .

c–8

B–62702EN/03

T ABLE OF CONTENTS

30. SAFETY FUNCTIONS 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.1 EMERGENCY STOP 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2 OVER TRAVEL FUNCTIONS 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.1 Overtravel 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.2 Stored Stroke Check 1 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.3 Stored Stroke Check 2 (G22, G23) (M Series) 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.4 Stored Stroke Checks 2 and 3 (T series) 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.5 Externally Setting the Stroke Limit (M series) 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.2.6 Chuck/Tail Stock Barrier (T Series) 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3 INTERLOCK 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3.1 Interlock for Each Axis 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3.2 All Axes Interlock 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3.3 Interlock for Each Axis Direction 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.3.4 Start Lock (T series) 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.4 EXTERNAL DECELERATION 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30.5 ABNORMAL LOAD DETECTION 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. STATUS OUTPUT 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.1 NC READY SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.2 SERVO READY SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.3 REWINDING SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.4 ALARM SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.5 DISTRIBUTION END SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.6 AUTOMATIC OPERATION SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.7 AUTOMATIC OPERATION START SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.8 FEED HOLD SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.9 RESET SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.10 IN–POSITION SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.11 MOVE SIGNAL 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.12 AXIS MOVE DIRECTION SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.13 RAPID TRAVERSING SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.14 TAPPING SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.15 THREAD CUTTING SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.16 CONSTANT SURFACE SPEED CONTROL SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.17 INCH INPUT SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.18 DI STATUS OUTPUT SIGNAL 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31.19 POSITION SWITCH FUNCTION 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32. EXTERNAL DATA INPUT 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.1 EXTERNAL TOOL COMPENSATION 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.2 EXTERNAL PROGRAM NUMBER SEARCH 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.3 EXTERNAL WORKPIECE COORDINATE SYSTEM SHIFT 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.4 EXTERNAL MACHINE ZERO POINT SHIFT 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.5 EXTERNAL ALARM MESSAGE 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.6 EXTERNAL OPERATOR’S MESSAGE 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32.7 SUBSTITUTION OF THE NUMBER OF REQUIRED PARTS

AND NUMBER OF MACHINED PARTS 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

T ABLE OF CONTENTS

B–62702EN/03

33. KEY INPUT FROM PMC (EXTERNAL KEY INPUT) 275. . . . . . . . . . . . . . . . . . . . . . . . . . .

34. MMC (MAN MACHINE CONTROL) 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.1 MMC–IV 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.2 HIGH–SPEED SERIAL BUS 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.3 INTELLIGENT TERMINAL 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34.4 ENABLING THE MMC–IV FUNCTION WITH A CONVENTIONAL PERSONAL

COMPUTER 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. AUTOMATIC PROGRAMMING FUNCTION

1. CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION

FOR MACHINING CENTERS 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 MACHINING MENU 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 TYPES OF SCREENS 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Conversational Programming Function Parameter Setting Screen 283. . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Cutting Condition Data Screen 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Pre–tool List Screen 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Tool File Data Setting and Display Screen 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Program Menu Screen 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Initial Setting Screen 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Machining Menu Screen 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.8 Detailed Machining Menu Screen 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.9 Process Data Screen 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.10 Contour Data Input Screen 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.11 Check Drawing Screen 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 OTHER OPTIONAL FUNCTIONS 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. RANGE OF COMMAND VALUE 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 T SERIES 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 M SERIES 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. FUNCTIONS AND TAPE FORMAT LIST 300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 T SERIES 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 M SERIES 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. LIST OF TAPE CODE 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. EXTERNAL DIMENSIONS OF EACH UNIT 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

I. GENERAL

B–62702EN/03

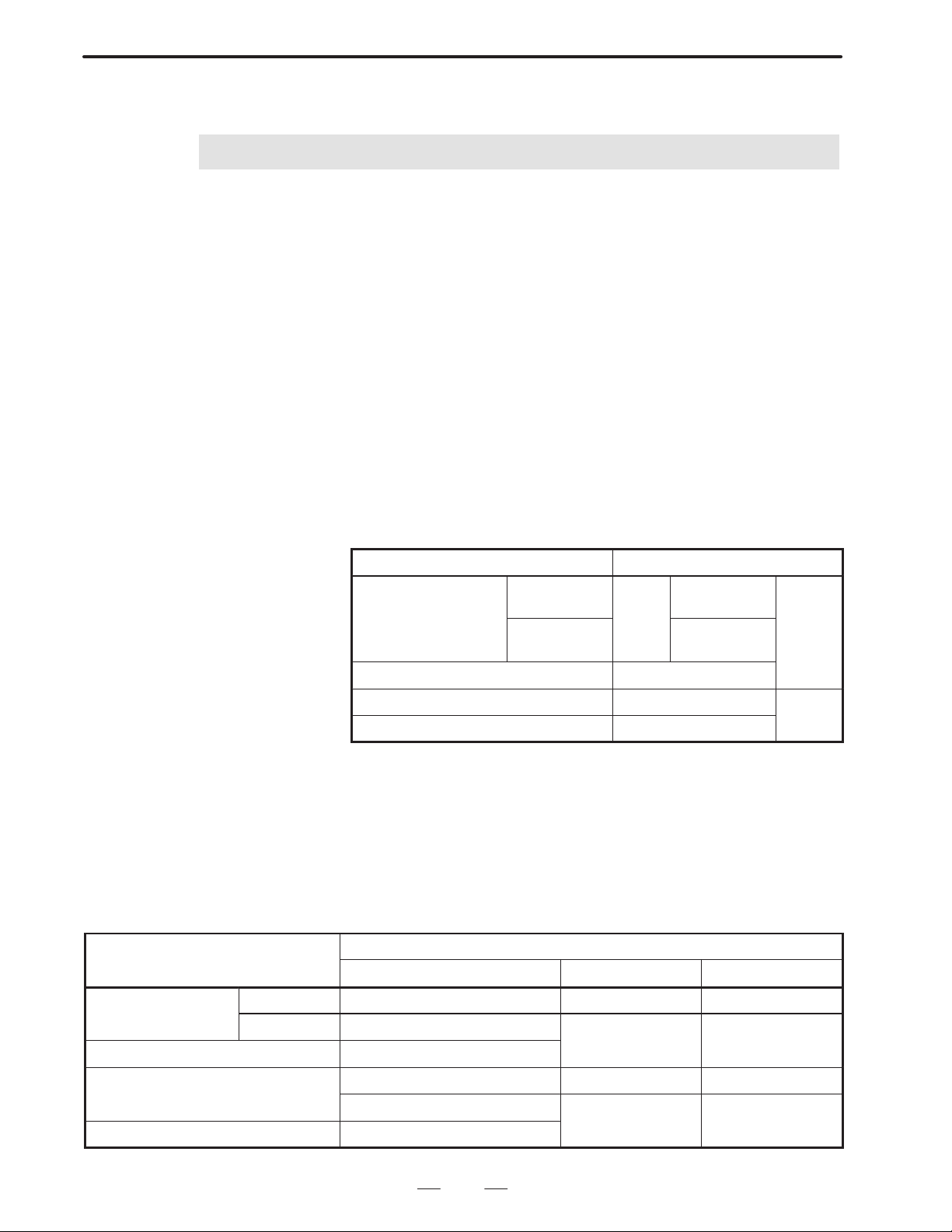

FANUC Series 21–TB

21–TB

M series

Model

FANUC Series 21–TB

DEA1

04 or later

FANUC Series 21–MB

DDA1

05 or later

1

GENERAL

GENERAL

1. GENERAL

This compact CNC provides carefully selected functions best suited for

controlling small machine tools. It is intended for use in low–end

machine tools, but equipped with advanced microprocessor and servo

control technologies. It supports high–speed, high–accuracy,

high–efficiency operations for machining. Moreover, this CNC can be

incorporated with the personal computer functions compatible with the

IBM PC (*) in order to differentiate it from other CNCs and to enhance

the machine tool functions. The personal computer functions, in

conjunction with the conversational automatic programming function for

machining center, will contribute to the production of easy–to–use

machine tools.

* IBM is a registered trademark of International Business Machines

Corporation.

Applicable software

series

The models covered by this manual, and their abbreviations are :

Product name Abbreviation

Controller A

–

Controller B

FANUC Series 210–TB 210–TB

FANUC Series 21–MB 21–MB

FANUC Series 210–MB 210–MB

*1

–

*1

21–TB

(Controller A)

21–TB

(Controller B)

T series

*1 For the FANUC Series 21–TB, two models are available: Controller

A and Controller B.

This manual describes the F ANUC Series 21/210 functions, supported by

the system software of the following series and editions. Some of the

functions described in this manual may not, therefore, be supported by

other series or editions. Some specifications may differ from those

described in this manual, depending on the series and edition of the

system software.

System software

Specification (basic) Applicable series Applicable edition

FANUC Series 210–TB A02B–0219–H501#DEA1

FANUC Series 210–MB A02B–0218–H501#DDA1

–

Controller A A02B–0210–H501#DE01 DE01 10 or later

Controller B A02B–0219–H501#DEA1

A02B–0179–H800#D201 D201 12 or later

–

A02B–0218–H501#DDA1

3

1. GENERAL

GENERAL

B–62702EN/03

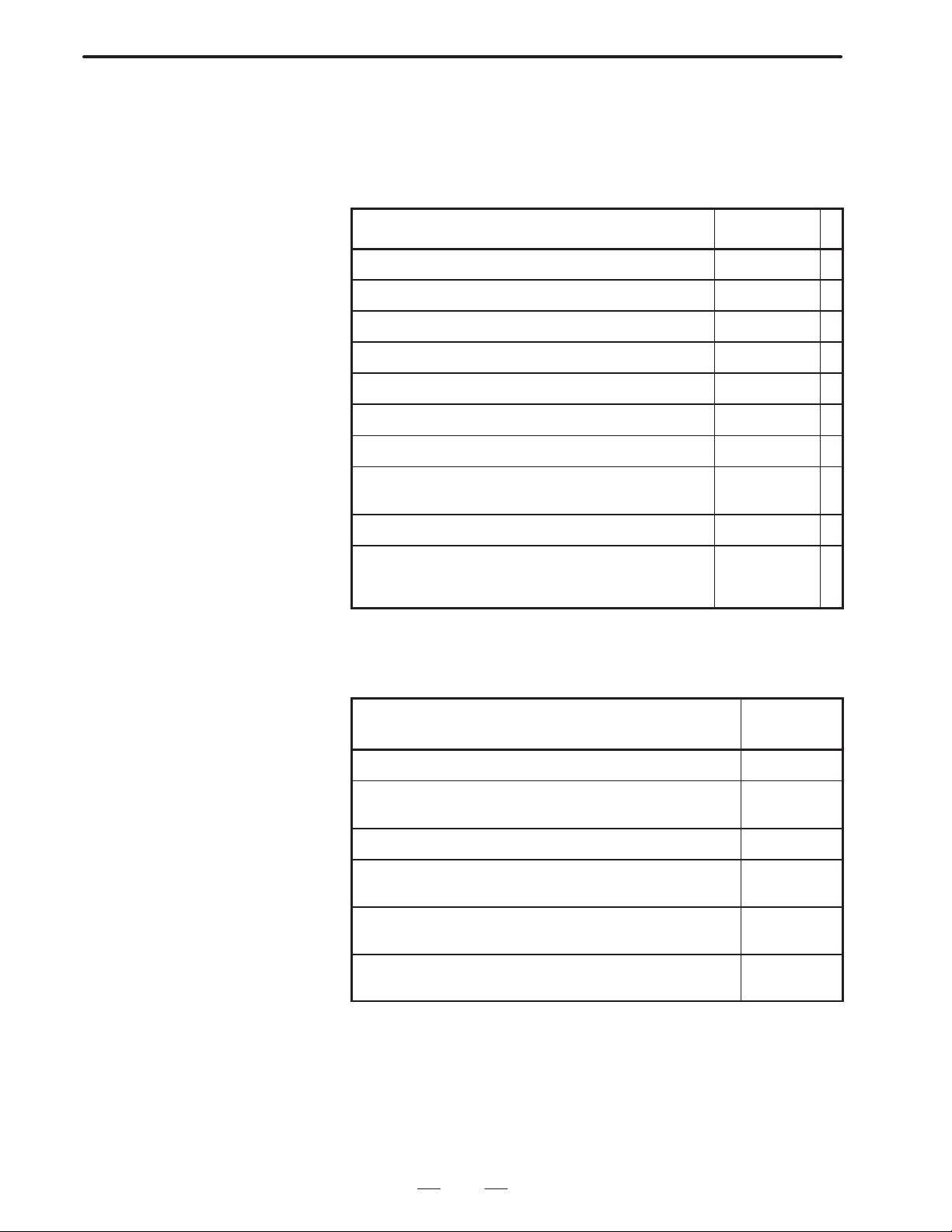

Manuals related to

Series 21/210–MODEL B

The table below lists manuals related to the FANUC Series

21/210–MODEL B. In the table, this manual is marked with an asterisk

(*).

Manuals Related to the Series 21/210–B

Manual name

DESCRIPTIONS B–62702EN *

CONNECTION MANUAL (HARDWARE) B–62703EN

CONNECTION MANUAL (FUNCTION) B–62703EN–1

OPERATOR’S MANUAL (FOR LATHE) B–62534E

OPERATOR’S MANUAL (FOR MACHINING CENTER) B–62704EN

MAINTENANCE MANUAL B–62705EN

PARAMETER MANUAL B–62710EN

PROGRAMMING MANUAL

(Macro Compiler / Macro Executer)

FAPT MACRO COMPILER PROGRAMMING MANUAL B–66102E

Specification

number

B–61803E–1

Manuals related to servo

motor α series

CONVERSATIONAL AUTOMATIC PROGRAMMING

FUNCTION FOR MACHINING CENTER OPERATOR’S

MANUAL

B–61874E–1

Manuals related to servo motor α series

Manual name

FANUC AC SERVO MOTOR α series DESCRIPTIONS B–65142E

FANUC AC SERVO MOTOR α series PARAMETER

MANUAL

FANUC AC SPINDLE MOTOR α series DESCRIPTIONS B–65152E

FANUC AC SPINDLE MOTOR α series PARAMETER

MANUAL

FANUC CONTROL MOTOR AMPLIFIER α series

DESCRIPTIONS

FANUC CONTROL MOTOR α series MAINTENANCE

MANUAL

Specification

number

B–65150E

B–65160E

B–65162E

B–65165E

4

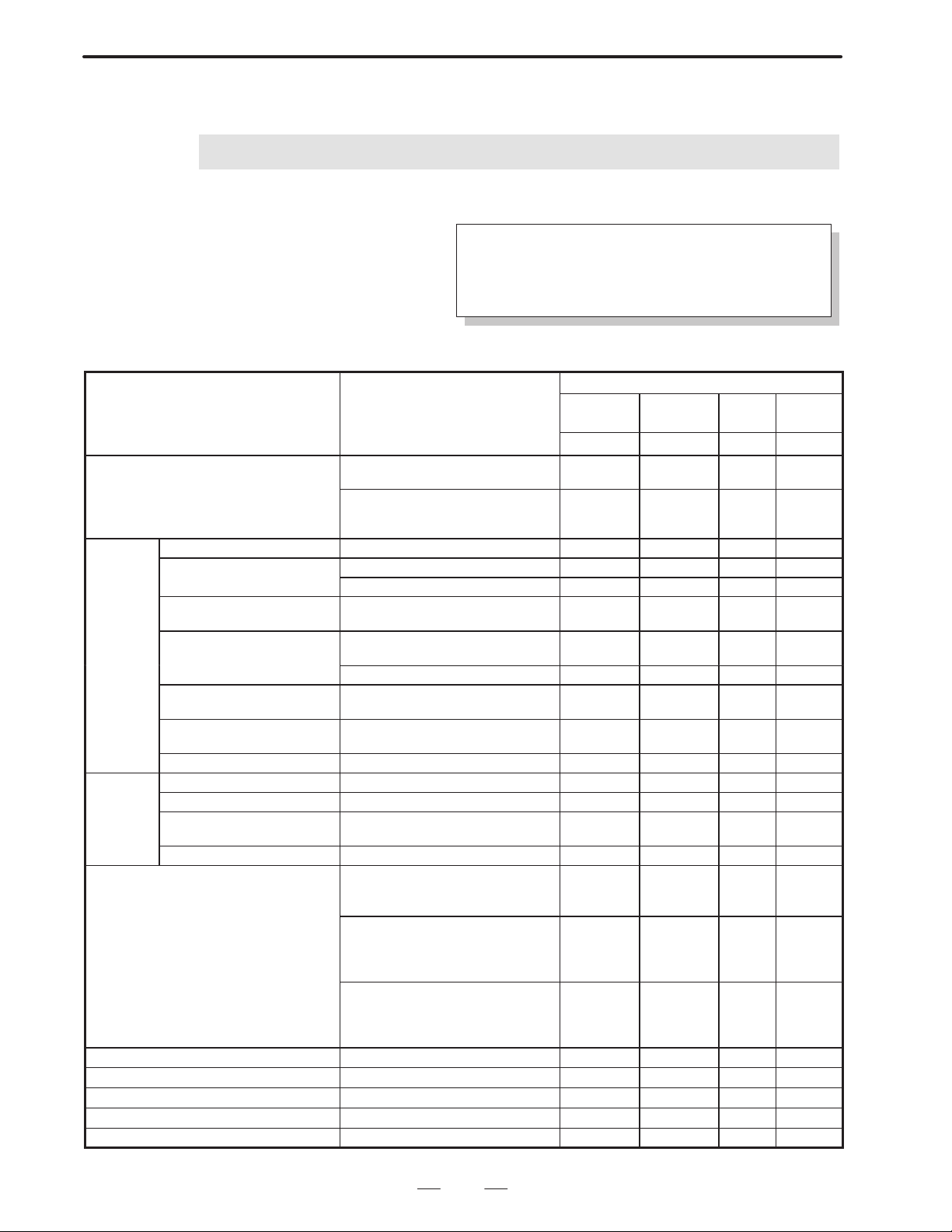

B–62702EN/03

(

Controlled axes

expansion (total)

GENERAL

2. LIST OF SPECIFICATIONS

LIST OF SPECIFICATIONS

2

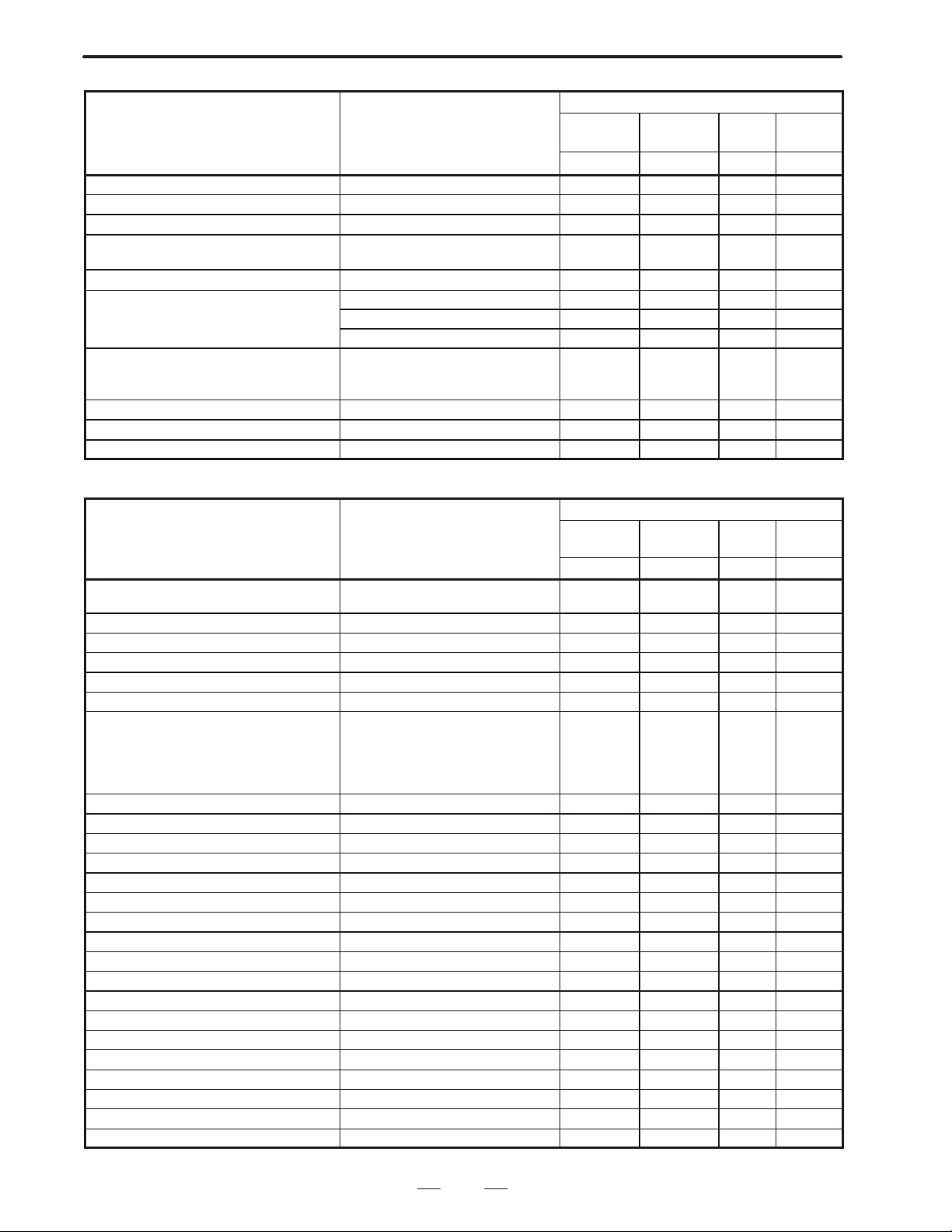

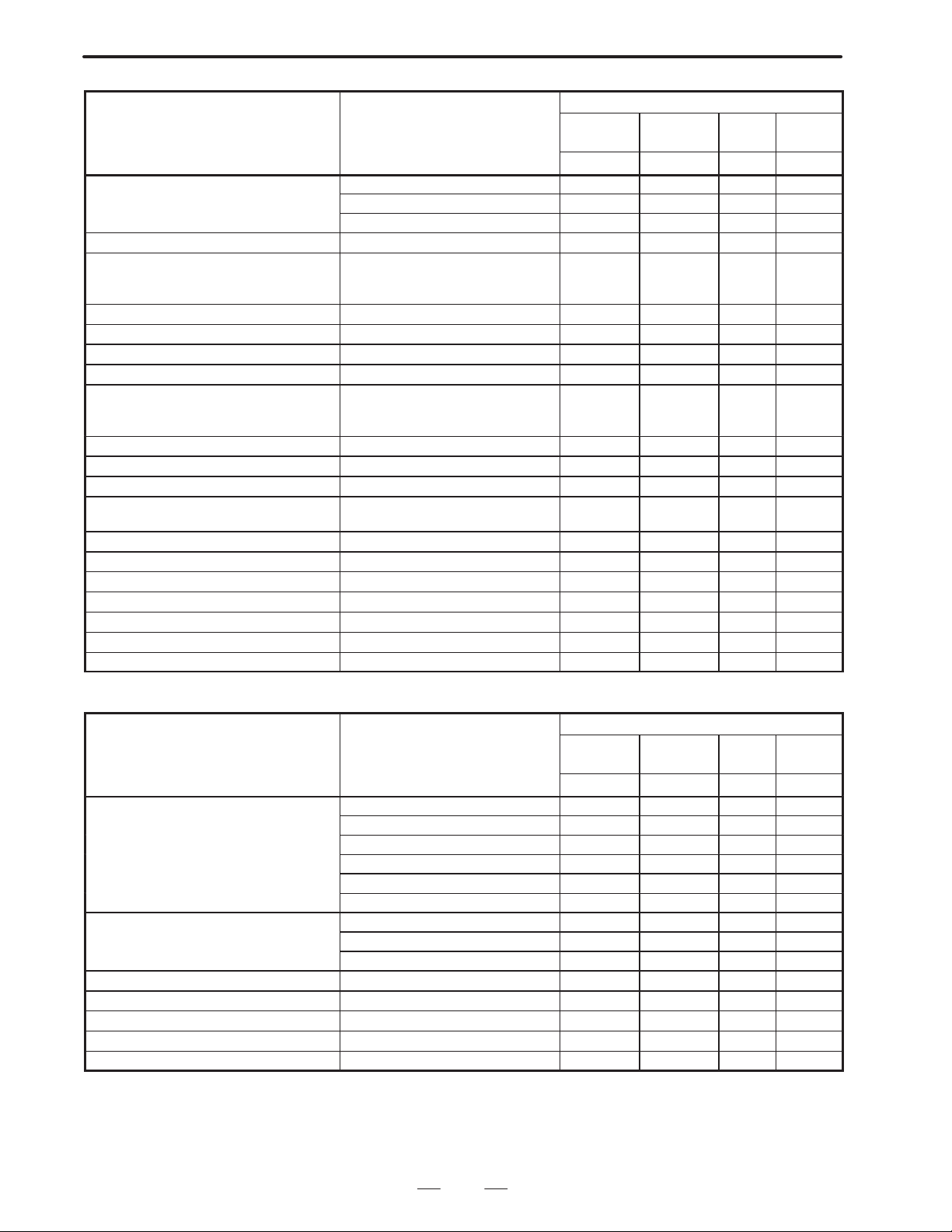

f : Standard F : Standard option l : Option

: : Function included in another option

21–TB(*A) : 21–TB (control unit A)

21–TB(*B) : 21–TB (control unit B)

Axis control

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

Max. controlled axes

(Machine controlled axes + Loader

controlled axes)

(Machine controlled axes are including

Cs axes)

Controllable path 1–path f f f f

Simultaneous controllable

axes

Machine

controlled

axes

Loader

controlled

axes

Axis name

Simple synchronous control 1 pair – l – l

Angular axis control – l – –

B axis control function – l – –

Controlled axis detach – l – l

Least input increment 0.001mm, 0.001deg, 0.0001inch f f f f

Controllable axes

p

Simultaneous controllable

axes expansion (total)

Axis control by PMC

Cs contouring control 1 axis – l l l

Controllable path 1–path – l – –

Controlled axes Max. 4 axes – l – –

Simultaneous controllable

axes

Axis control by PMC Max. 4 axes – l – –

4 axes (Machine 4 axes) l l l l

8 axes (Machine 4 axes +

Loader 4 axes)

2 axes f f – –

3 axes – – f f

Simultaneous 2 axes f f f f

Max. 4 axes

(CNC 2 axes + PMC 2 axis)

Max. 4 axes (including Cs axis) – l l l

Max. 4 axes – l l l

Max. simultaneous 4 axes per

path (Not available on Cs axis)

Max. 4 axes – l – –

Basic axes : X, Y, Z

Additional axes : Optional from U,

V, W, A, B, C

In the case of G code system A

Basic axes : X, Z

Additional axes : Optional from Y,

A, B, C

In the case of G code system B/C

Basic axes : X, Z

Additional axes : Optional from Y,

U, V, W, A, B, C

– l – –

l – – –

l l l l

– – f f

f f – –

* * – –

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

5

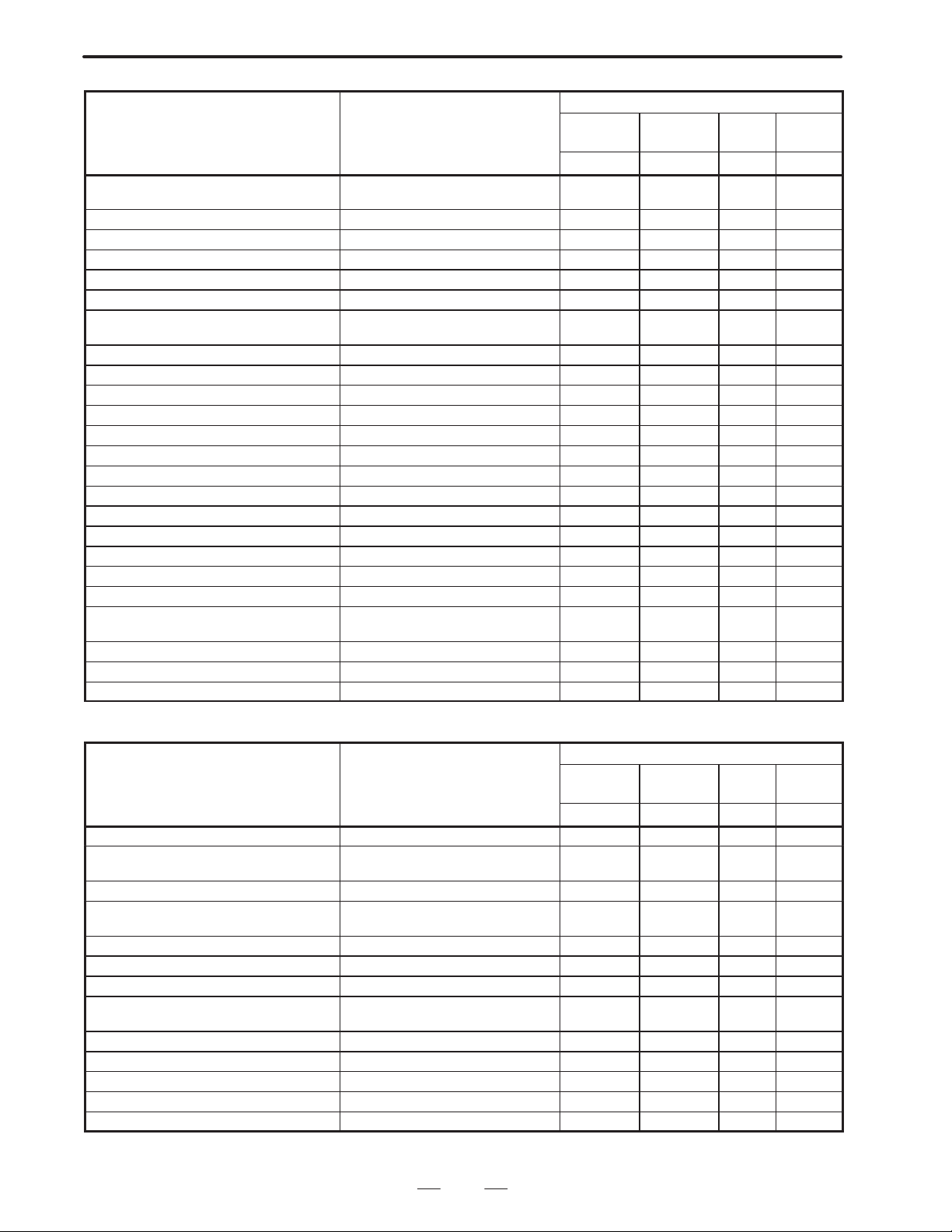

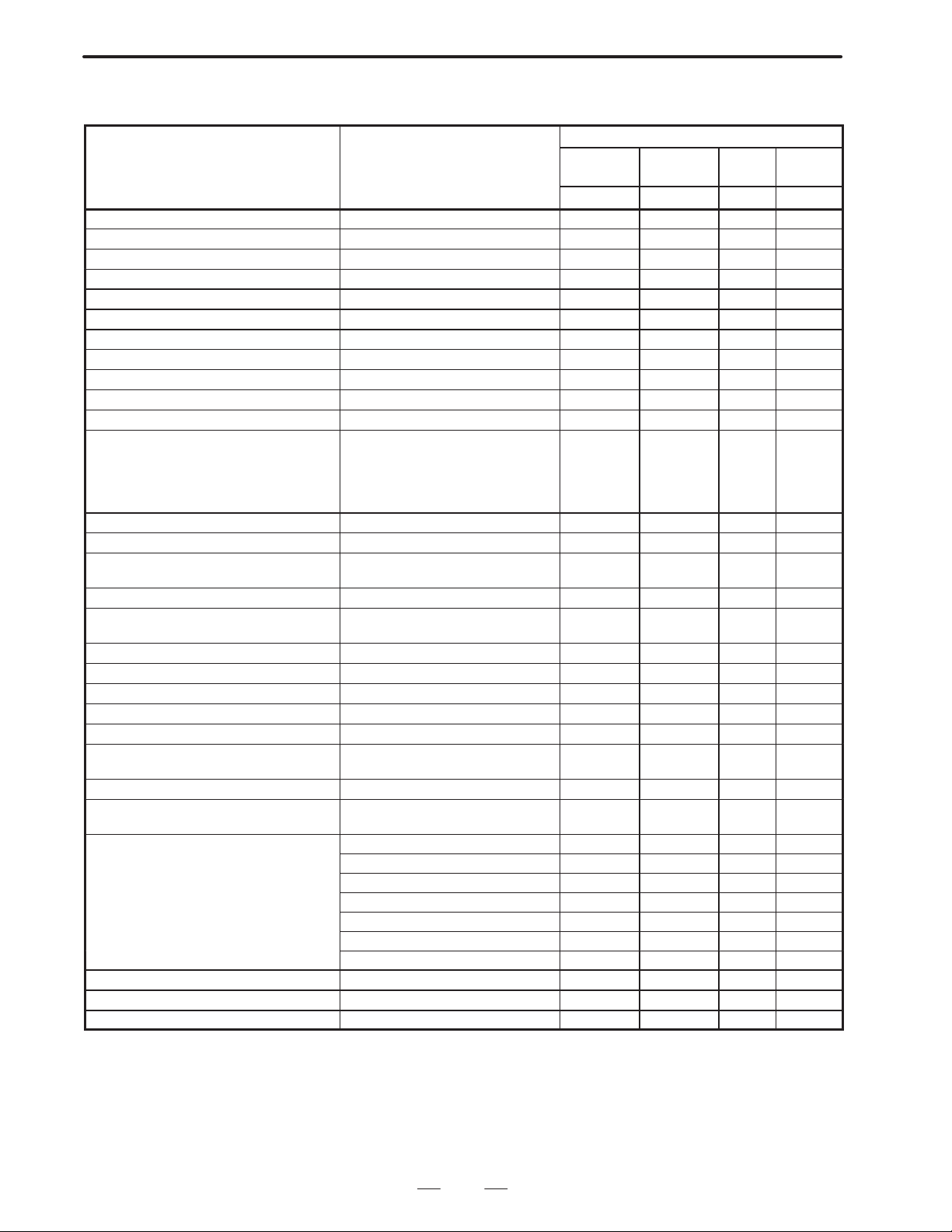

2. LIST OF SPECIFICATIONS

Item

Item

Increment system 1/10

Flexible feed gear Optional DMR f f f f

Dual position feedback – l – l

Fine Acc & Dec control – f – f

HRV control – f – f

Inch/metric conversion f f l l

Interlock

Machine lock All axes / each axis f f f f

Emergency stop f f f f

Overtravel f f f f

Stored stroke check 1 f f f f

Stroke limit external setting – – – l

Stored stroke check 2 – – l l

Stored stroke check 2, 3 l l – –

Chuck & tail stock barrier – l – –

Mirror image Each axis f f f f

Follow–up f f f f

Servo–off / mechanical handle feed f f f f

Chamfering on/off f f – –

Backlash compensation f f f f

Backlash compensation for each rapid

traverse and cutting feed

Stored pitch error compensation l l l l

Position switch l l – l

Abnormal load detection l l l l

0.0001mm, 0.0001deg,

0.00001inch

All axes / each axis / cutting block

start

GENERAL

SpecificationsItem

Specifications

Model and software series

21–TB(*A)Specifications

l l – l

f f f f

f f f f

21–TB(*B)

210–TB

21–MB

B–62702EN/03

21–MB

210–MB

DDA1D201DEA1DE01

Operation

Model and software series

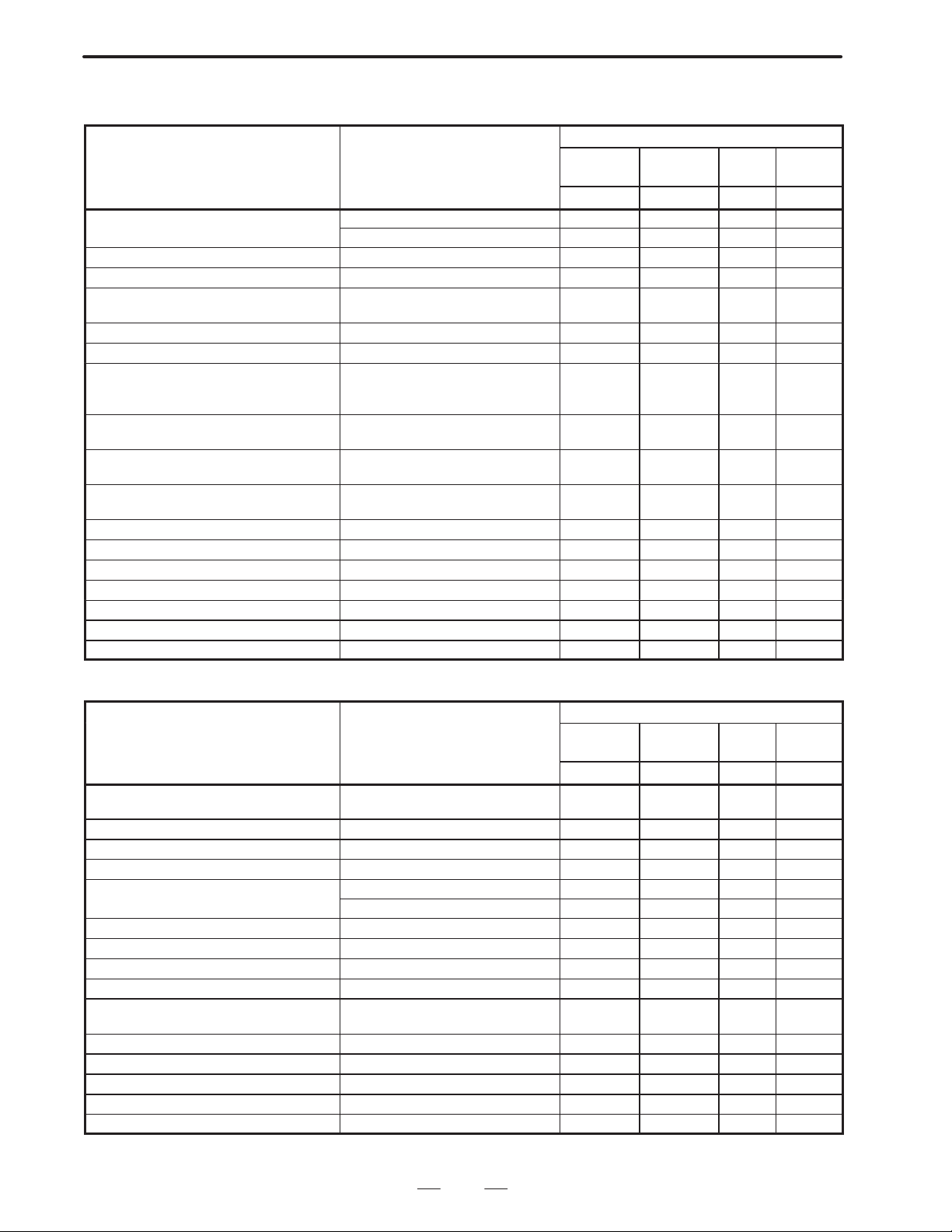

Item Specifications

Automatic operation (memory) f f f f

DNC operation

MDI operation f f f f

Scheduling function

Program number search f f f f

Sequence number search f f f f

External workpiece number search 31 f f f f

Sequence number comparison and

stop

Program restart – l l l

Retreat and retry function f f f f

Rigid tapping return – – – l

Buffer register f f f f

Dry run f f f f

Reader/puncher interface is

required.

Floppy cassette directory is

required.

21–TB(*A)

DE01 DEA1 D201 DDA1

* * * *

* * * *

– l – l

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

6

B–62702EN/03

Item

Item

Single block f f f f

JOG feed f f f f

Manual reference position return f f f f

Reference position setting without

DOG

Butt–type reference position setting – l – l

1 unit l l l l

Manual handle feed

Manual handle feed rate

Manual handle interruption l l l l

Incremental feed ×1, ×10, ×100, ×1000 f f f f

Jog and handle simultaneous mode f f f f

2 units l l – –

2 units / 3 units – – l l

×1, ×10, ×m, ×n

m : 0 to 127, n : 0 to 1000

Included in manual handle feed

GENERAL

SpecificationsItem

Specifications

21–TB(*A)Specifications

2. LIST OF SPECIFICATIONS

Model and software series

21–TB(*B)

210–TB

f f f f

* * * *

21–MB

21–MB

210–MB

DDA1D201DEA1DE01

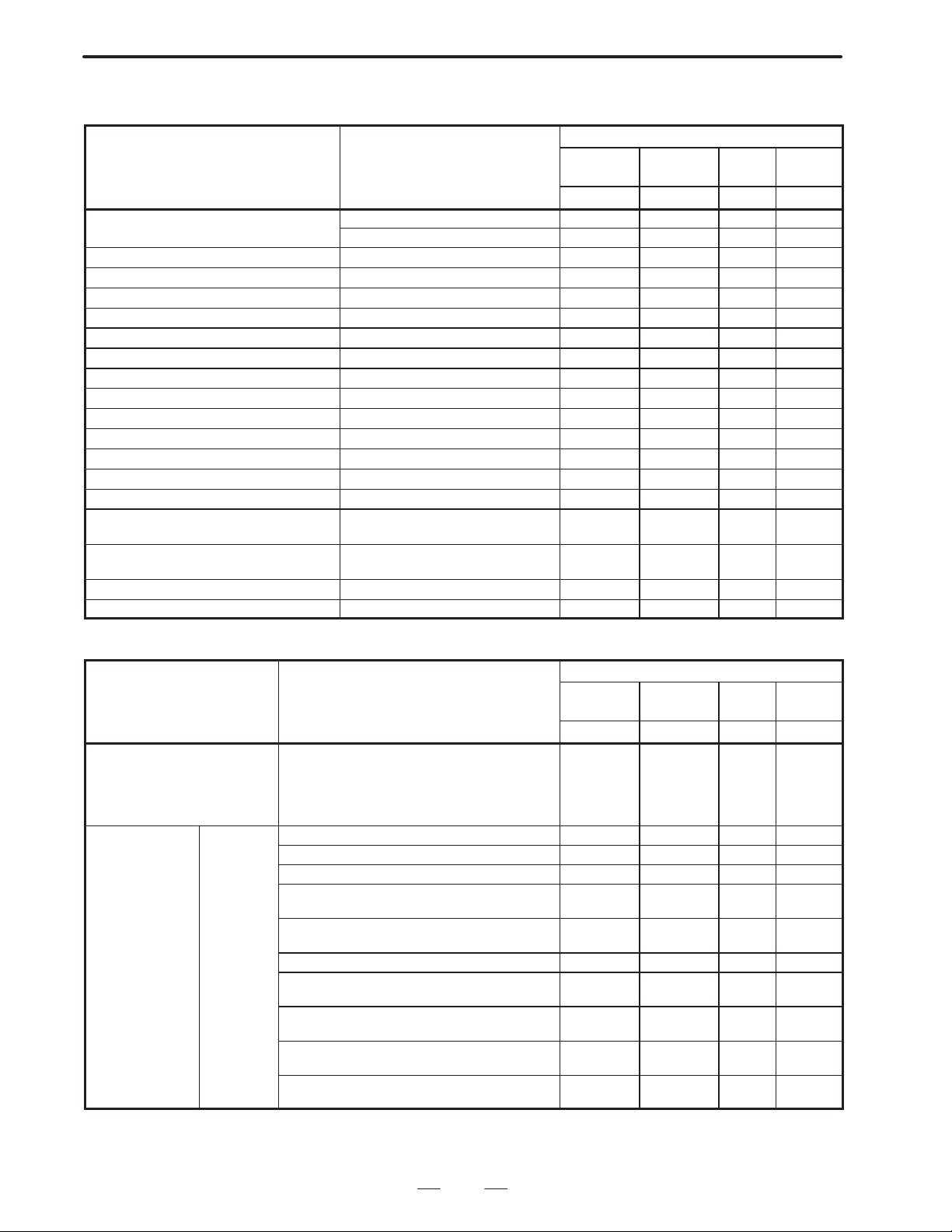

Interpolation

Model and software series

Item Specifications

Positioning

Single direction positioning G60 – – l l

Exact stop mode G61 – – f f

Exact stop G09 – – f f

Linear interpolation f f f f

Circular interpolation Multi–quadrant is possible f f f f

Dwell

Polar coordinate interpolation – l – –

Cylindrical interpolation – l – l

Helical interpolation – – l l

Thread cutting, synchronous cutting f f – l

Thread cutting retract l l – –

Continuous thread cutting l l – –

V ariable lead thread cutting – l – –

Multiple threading f f – –

Polygon turning – l – –

Skip G31 f f f f

Multi–step skip – l – –

Torque limit skip f f – –

Reference position return G28 f f f f

Reference position return check G27 f f f f

2nd reference position return f f f f

3rd/4th reference position return – l – l

Normal direction control – – – l

Index table indexing – – – l

G00 (Linear interpolation type

positioning is possible)

Dwell in seconds and dwell in

revolution (In case of dwell in

revolution for M series, thread

cutting, synchronous cutting

option is required)

21–TB(*A)

DE01 DEA1 D201 DDA1

f f f f

f f f f

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

7

2. LIST OF SPECIFICATIONS

Ra id traverse

O tional block ski

GENERAL

B–62702EN/03

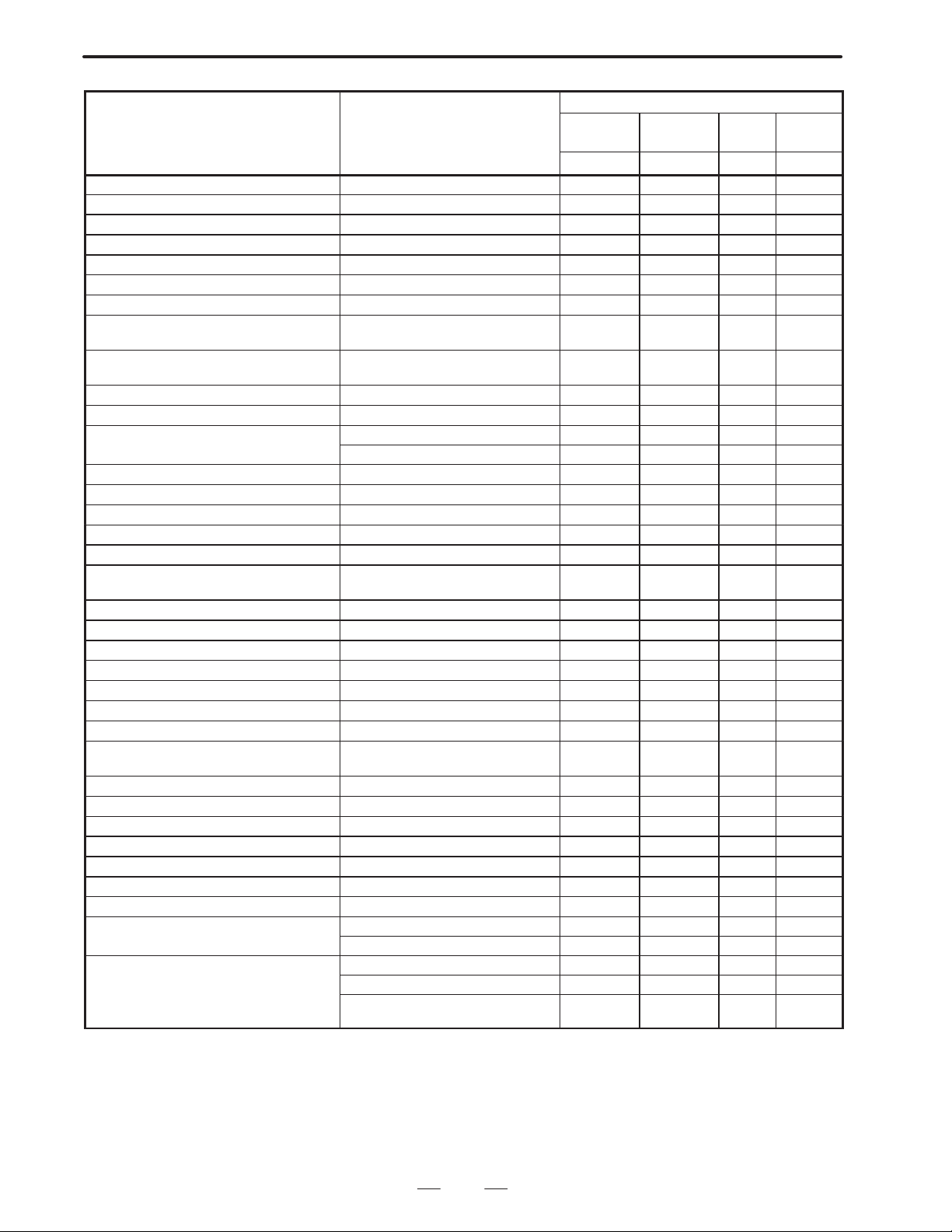

Feed function

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

p

Rapid traverse override Fo,25,50,100% f f f f

Feed per minute f f f f

Feed per revolution

Tangential speed constant control f f f f

Cutting feedrate clamp f f f f

Automatic acceleration/deceleration

Rapid traverse bell–shaped

acceleration/deceleration

Linear acceleration/deceleration after

cutting feed interpolation

Bell–shaped acceleration/deceleration

after cutting feed interpolation

Feedrate override 0 to 254% f f f f

F1–digit feed – – – l

Jog override 0 to 655.34% f f f f

Override cancel f f f f

Manual feed per revolution f f – –

External deceleration – l – l

Advanced preview control – – – l

Max. 240m/min (1µm) f f f f

Max. 100m/min (0.1µm) * * – *

Thread cutting and Synchronous

feed are required in M series.

Rapid traverse : linear

Cutting feed : exponential

function

f f – *

f f f f

l l – l

l l l l

l l – l

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

Program input

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

Tape code

Label skip f f f f

Parity check Horizontal and vertical parity f f f f

Control in/out f f f f

p

Max. programmable dimension ±8–digit f f f f

Program number O4–digit f f f f

Sequence number N5–digit f f f f

Absolute/incremental programming Combined use in the same block f f f f

Decimal point input/pocket calculator

type decimal point input

Input unit 10 time multiply f f f f

Diameter/radius programming (X axis) f f – –

Plane selection G17,G18,G19 f f f f

Rotary axis designation f f f f

Rotary axis roll over f f f f

p

EIA RS244, ISO840 automatic

recognition

1 f f f f

9 l l – l

f f f f

f f f f

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

8

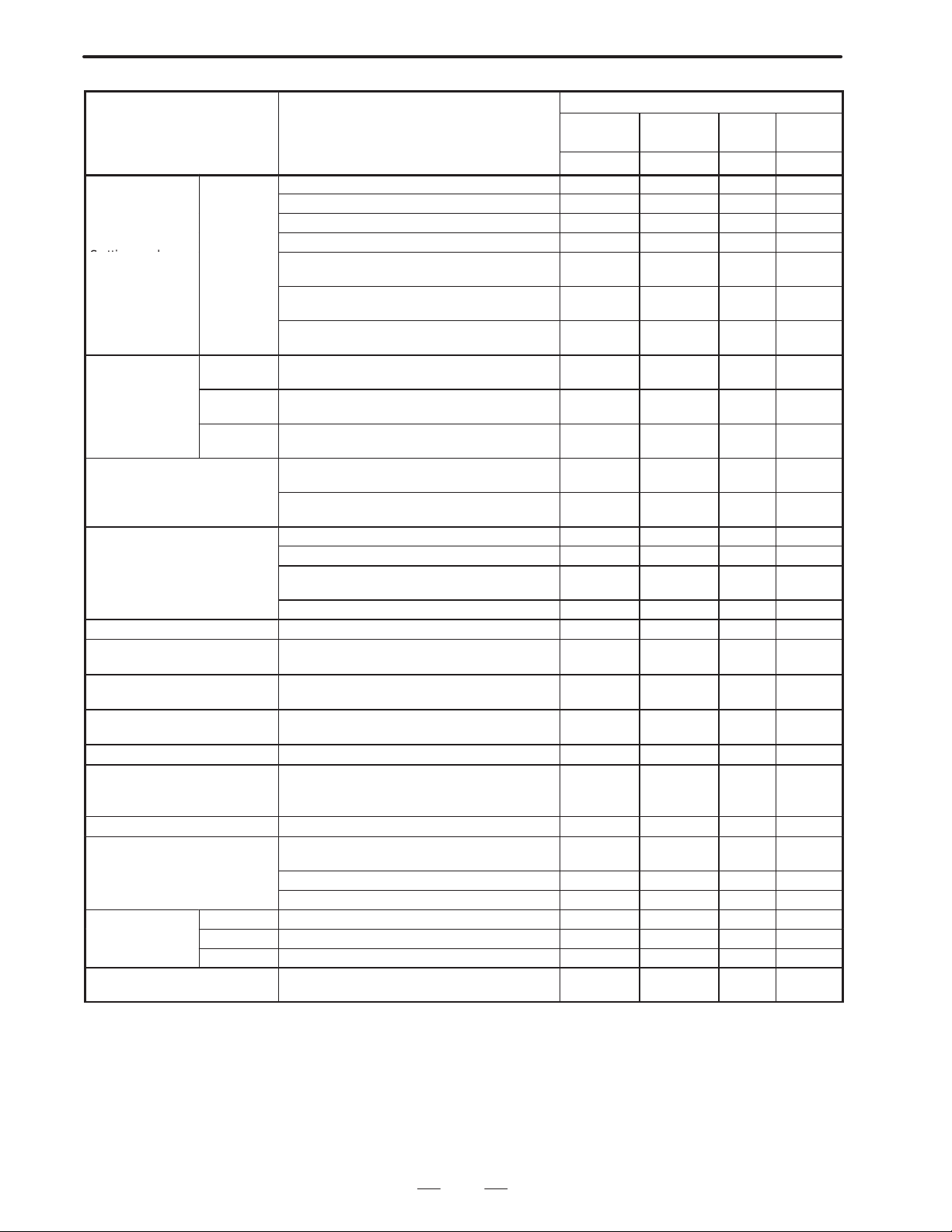

B–62702EN/03

G code system

Macro executer

MMC IV (Series 210 only)

Item

Item

Polar coordinate command – – l l

Coordinate system setting f f f f

Automatic coordinate system setting f f f f

Coordinate system shift f f – –

Direct input of coordinate system shift f f – –

Workpiece coordinate system G52,G53,G54 to G59 – l l l

Workpiece coordinate system preset – l – l

Addition of workpiece coordinate

system pair

Direct input of workpiece zero offset

value measured

Manual absolute on/off f f f f

Direct drawing dimension programming – l – –

Chamfering / Corner R f f – –

Optional chamfering/corner R – – – l

Programmable data input G10 f f l l

Sub program call 4 folds nested f f f f

Custom macro B f f l l

Addition of custom macro common

variables

Pattern data input – l – l

Interruption type custom macro – l – l

Canned cycles f f – –

Multiple repetitive cycles l l – –

Multiple repetitive cycles II Pocket figure – l – –

Canned cycles for drilling – l l l

Peck drilling cycle for small diameter – – – l

Circular interpolation by R

programming

Mirror image for double turret l l – –

Automatic corner override – – – l

Feedrate clamp by circular radius – – – l

Scaling – – l l

Coordinate system rotation – – l l

Programmable mirror image – – – l

Tape format for F10/F11 – l – l

–

48 pairs – – – l

A f f – –

B/C l l – –

#100 to #199, #500 to #999 – l – l

Max. 128KB l – – –

Max. 1MB – l l l

Using FANUC MMC–IV – l – l

Using Intelligent Terminal – l – l

Using High–speed Serial Bus and

personal computer

GENERAL

SpecificationsItem

Specifications

21–TB(*A)Specifications

2. LIST OF SPECIFICATIONS

Model and software series

21–TB(*B)

210–TB

* * * *

f f f f

– l – l

21–MB

21–MB

210–MB

DDA1D201DEA1DE01

9

2. LIST OF SPECIFICATIONS

Tool function

GENERAL

B–62702EN/03

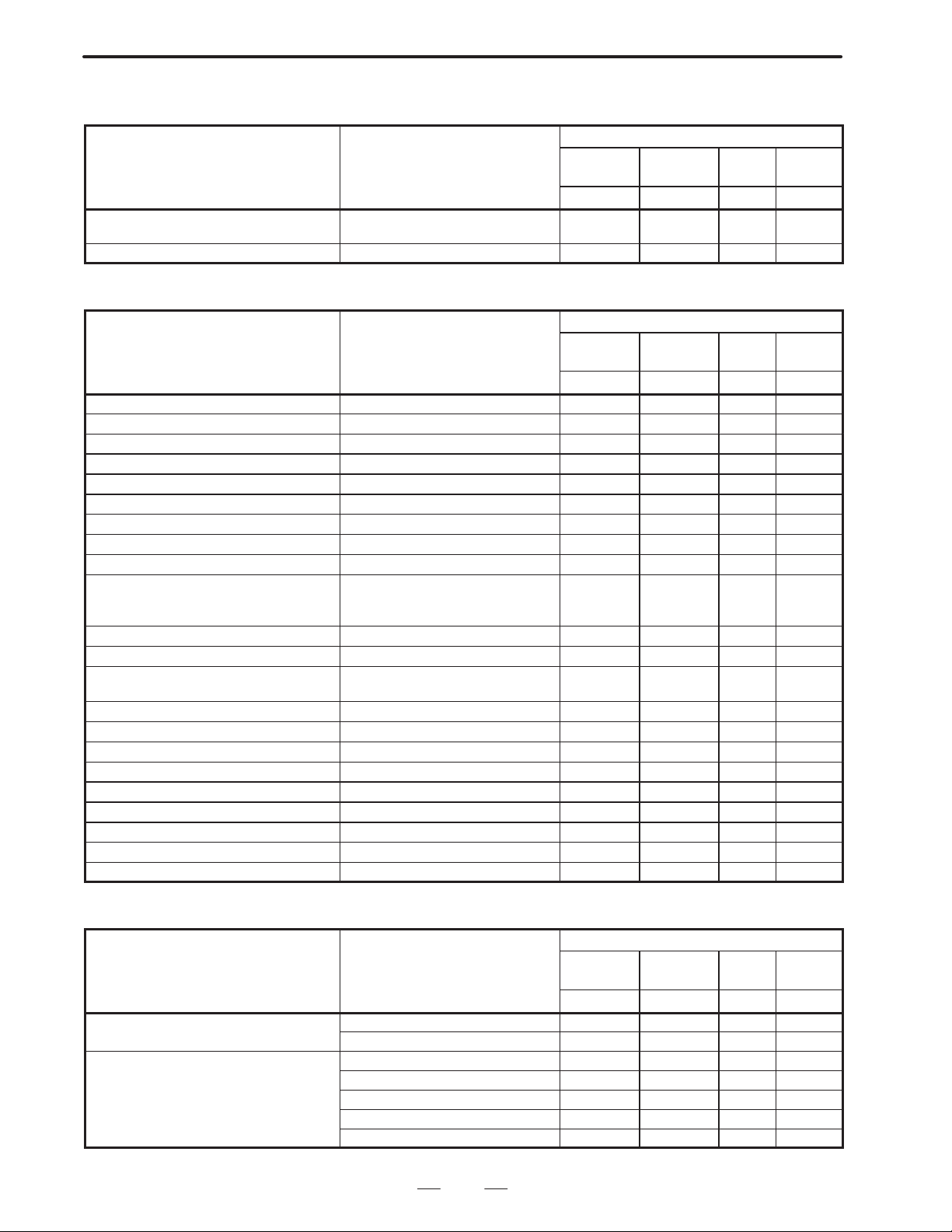

Conversational automatic programming function for machining center

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

Conversational automatic programming

function I for machining center (CAP I)

NC format output function – – l l

– – l l

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

Auxiliary / Spindle function

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

Auxiliary function M8–digit f f f f

2nd auxiliary function B8–digit l l – l

Auxiliary function lock f f f f

High speed M, S, T, B interface f f f f

Multiple command of auxiliary function 3 f f f f

Spindle function S5–digit, binary output f f f f

Spindle serial output S5–digit, serial output l l l l

Spindle analog output S5–digit, analog output l l l l

Constant surface speed control f f – l

0 to 254%

Spindle override

Actual spindle speed output – l – –

Spindle speed fluctuation detection l l – –

Spindle output control by PMC

1st spindle orientation l l l l

1st spindle output switching function l l l l

2nd spindle orientation – l l l

2nd spindle output switching function – l l l

Spindle synchronous control – l – l

Spindle simple synchronous control – l – l

Multi spindle control – l – –

Spindle positioning – l – –

Rigid tapping – l l l

Included in soindle serial output /

spindle amalog output

Included in soindle serial output /

spindle amalog output

* * * *

* * * *

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

Tool function / Tool compensation

Item Specifications 21–TB(*A)

T7+1/T6+2 f f – –

T8 digits – – f f

±6 digits 32 – – f f

±6 digits 64 – – l l

Tool offset

±6 digits 99 – – l l

±6 digits 200 – – – l

±6 digits 400 – – – l

10

Model and software series

21–TB(*B)

210–TB

DE01 DEA1 D201 DDA1

21–MB

21–MB

210–MB

B–62702EN/03

Part rogram storage length

Item

Item

±6 digits 9/16 f f – –

Tool offset

Tool offset memory B Geometry/wear memory – – – l

Tool offset memory C

Tool length compensation – – – f

Tool offset f f – l

Y–axis offset – l – –

Cutter compensation C – – l l

Corner circular interpolation

Tool nose radius compensation f f – –

Tool geometry / wear compensation f f – –

Tool life management – l – l

Addition of tool pairs for tool life

management

Extended tool life management Included in tool life management – – – *

Tool offset value counter input f f – –

Tool length measurement – – – l

Automatic tool length measurement – – – l

Automatic tool offset l l – –

Offset value measuremet direct input f f – –

Offset value measuremet direct input B l l – –

±6 digits 32 l l – –

±6 digits 64 l l – –

Distinction between geometry

and wear, or between cutter and

tool length compensation

G39

Included in cutter compensation

C

512 pairs – – – l

GENERAL

SpecificationsItem

Specifications

21–TB(*A)Specifications

2. LIST OF SPECIFICATIONS

Model and software series

21–TB(*B)

210–TB

– – – l

– – – *

21–MB

21–MB

210–MB

DDA1D201DEA1DE01

Editing operation

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

10m – – f f

20m – – l l

p

Registered programs

Part program editing f f f f

Program protect f f f f

Background editing f f l l

Extended part program editing l l – l

Playback – l l l

40m f f l l

80m l l l l

160m l l l l

320m – l – l

63 f f f f

125 – l l l

200 – l l l

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

11

2. LIST OF SPECIFICATIONS

GENERAL

B–62702EN/03

Setting and display

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

Status display f f f f

Clock function f f f f

Current position display f f f f

Program display Program name 31 characters f f f f

Parameter setting and display f f f f

Self–diagnosis function f f f f

Alarm display f f f f

Alarm history display f f f f

Operator message history display Included external message – * – *

Operation history display f f f f

Help function f f f f

Reading mounted PCB data,

reading data displayed on CNC

Remote diagnosis

Run hour and parts count display l l l l

Actual speed display f f f f

Display of actual spindle speed and T

code at all screens

Directory display of floppy cassette l l l l

Directory display and punch for each

group

Graphic display – l – l

Dynamic graphic display Only for tool path – – l l

Servo adjusting screen f f f f

Spindle adjusting screen Only for serial output * * * *

Servo waveform display Graphic display circuit is required – * – *

Display of hardware and software

configuration

Software operator’s panel l l l l

Software operator’s panel general

purpose switch

Multi–language display

Data protection key 4 types f f f f

Erase CRT screen display f f f f

Automatic erase CRT screen display – f – f

screen, and reading

internal status and alarm status,

etc.

Thread cutting and Synchronous

feed are required in M series

English f f f f

Japanese (Chinese character) f f l l

German / French l l l l

Italian l l l l

Chinese l l l l

Spanish l l l l

Korean l l l l

– * – *

f f – *

– f – f

f f f f

l l l l

21–TB(*B)

210–TB

21–MB

21–MB

210–MB

12

B–62702EN/03

Reader/ uncher interface

Series

displ

Series 21

GENERAL

2. LIST OF SPECIFICATIONS

Data input/output

Model and software series

Item Specifications 21–TB(*A)

DE01 DEA1 D201 DDA1

p

Remote buffer – l – l