Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 0i-Model B

Series 0i-Mate Model B

Maintenance Manual

GFZ-63835EN/03 July 2003

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2003 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS RELATED TO CHECK OPERATION s–3. . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS RELATED TO REPLACEMENT s–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. WARNINGS RELATED TO PARAMETERS s–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE s–7. . . . . . . . . . . .

s–1

Page 4

1

SAFETY PRECAUTIONS

B–63835EN/03

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–2

Page 5

B–63835EN/03

2

SAFETY PRECAUTIONS

W ARNINGS RELA TED TO CHECK OPERATION

WARNING

1. When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2. When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3. Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

mark). Never

s–3

Page 6

SAFETY PRECAUTIONS

B–63835EN/03

WARNING

5. Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

6. When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

s–4

Page 7

B–63835EN/03

3

SAFETY PRECAUTIONS

W ARNINGS RELATED TO REPLACEMENT

WARNING

1. Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2. When a heavy unit is to be replaced, the task must be undertaken by two persons or more. If

the replacement is attempted by only one person, the replacement unit could slip and fall,

possibly causing injury.

3. After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4. When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury.

s–5

Page 8

4

SAFETY PRECAUTIONS

B–63835EN/03

W ARNINGS RELATED TO PARAMETERS

WARNING

1. When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally, the machine may move unpredictably, possibly damaging the machine or workpiece,

and presenting a risk of injury.

2. The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

s–6

Page 9

B–63835EN/03

5

1. Memory backup battery replacement

SAFETY PRECAUTIONS

W ARNINGS AND NOTES RELATED TO DAILY MAINTENANCE

WARNING

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.10 of this manual.

s–7

Page 10

SAFETY PRECAUTIONS

B–63835EN/03

WARNING

2. Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Servo Motor αi series Maintenance Manual

(B–65285EN)

and

s–8

Page 11

B–63835EN/03

3. Fuse replacement

SAFETY PRECAUTIONS

WARNING

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–9

Page 12

Page 13

B–63835EN/03

PREFACE

PREFACE

Description of

this manual

1.Display and operation

This chapter covers those items, displayed on the screen, that are related

to maintenance. A list of all supported operations is also provided at the

end of this chapter.

2.Hardware

This chapter describes the configuration of the hardware, lists the

hardware units, and explains how to replace printed–circuit boards.

3.Data input/output

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, aswell as the input/output

procedures for conversational data.

4.Interface between the CNC and PMC

This chapter describes the PMC specifications, the system configuration,

and the signals used by the PMC.

5.Digital servo

This chapter describes the servo tuning screen and how to adjust the

reference position return position.

6.AC spindles

These chapters describe the spindle amplifier checkpoints, as well as the

spindle tuning screen.

7.Trouble shooting

This chapter describes the procedures to be followed in the event of

certain problems occurring.

Appendix

A. Alarm list

B. List of maintenance parts

C. Boot system

D. LED display and maintenance of stand–alone type unit

E. Maintenance of open CNC (boot–up and IPL)

F. FSSB start–up procedure/materials

G. Notation of MDI keys

This manual does not provide a parameter list. If necessary, refer to the

separate PARAMETER MANUAL.

p–1

Page 14

PREFACE

B–63835EN/03

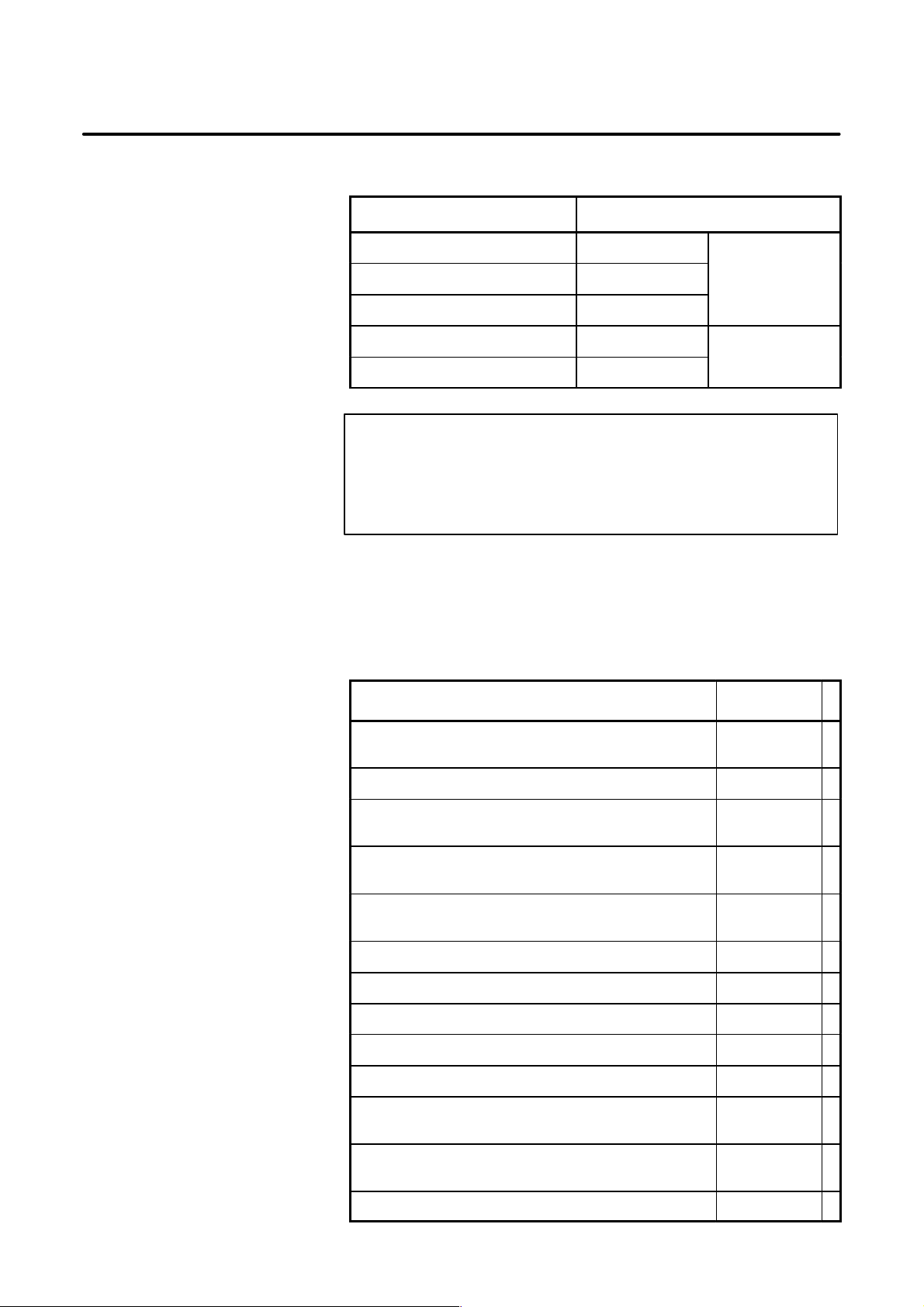

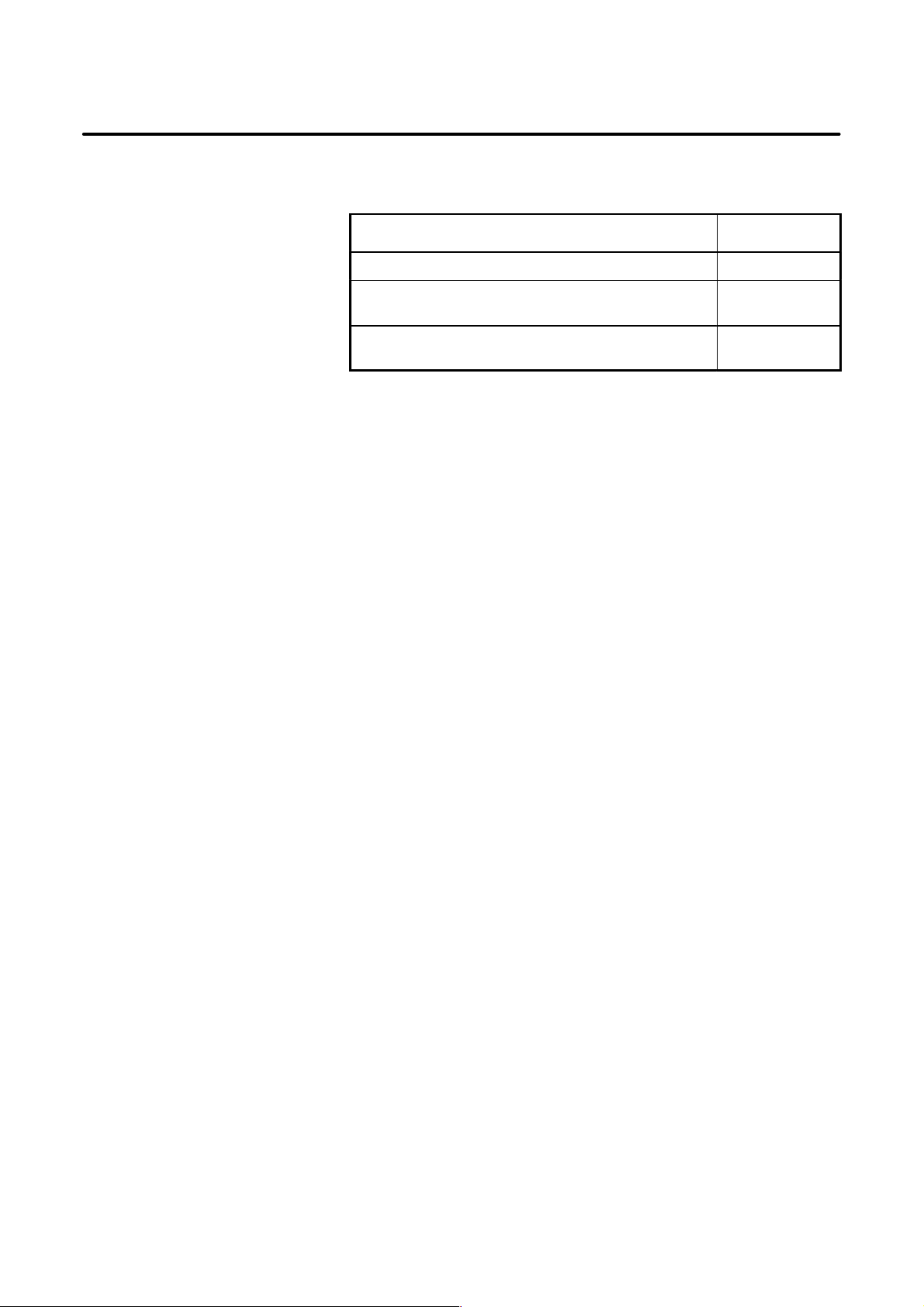

Applicable models

Related manuals of

Series 0i–B/0i Mate–B

The models covered by this manual, and their abbreviations are:

Product name Abbreviation

FANUC Series 0i–TB 0i–TB

FANUC Series 0i–MB 0i–MB

FANUC Series 0i–PB 0i–PB

FANUC Series 0i Mate–TB 0i–Mate TB

FANUC Series 0i Mate–MB 0i–Mate TB

Series 0i

Series 0i Mate

NOTE

Some function described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS manual

(B–63832EN)

The following table lists the manuals related to Series 0i–B, Series 0i

Mate–B.

This manual is indicated by an asterisk(*).

Manual name

FANUC Series 0i–MODEL B/0i Mate–MODEL B

DESCRIPTIONS

FANUC Series 0i–PB DESCRIPTIONS B–63972EN

FANUC Series 0i–MODEL B/0i Mate–MODEL B

CONNECTION MANUAL (HARDWARE)

FANUC Series 0i–MODEL B/0i Mate–MODEL B

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–PB

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–TB OPERATOR’S MANUAL B–63834EN

FANUC Series 0i–MB OPERATOR’S MANUAL B–63844EN

FANUC Series 0i Mate–TB OPERATOR’S MANUAL B–63854EN

FANUC Series 0i Mate–MB OPERATOR’S MANUAL B–63864EN

FANUC Series 0i–PB OPERATOR’S MANUAL B–63974EN

FANUC Series 0i–MODEL B/0i Mate–MODEL B

MAINTENANCE MANUAL

Specification

number

B–63832EN

B–63833EN

B–63833EN–1

B–63973EN

B–63835EN *

FANUC Series 0i–MODEL B/0i Mate–MODEL B

P ARAMETER MANUAL

FANUC Series 0i–PB PARAMETER MANUAL B–63980EN

B–63840EN

p–2

Page 15

B–63835EN/03

PREFACE

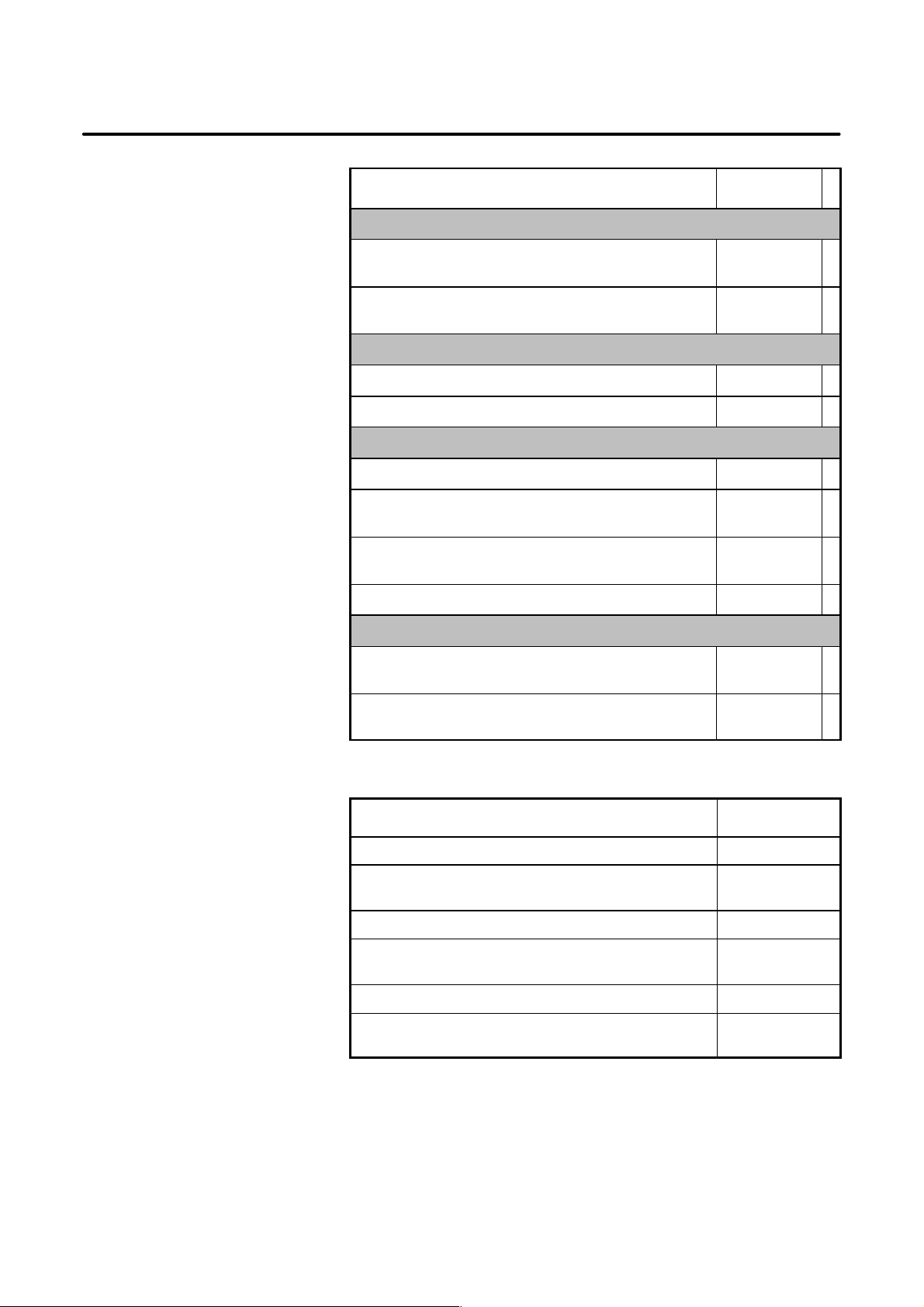

Manual name

PROGRAMMING MANUAL

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

FANUC MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUA B–61863E–1

Network

PROFIBUS–DP Board OPERA T OR’S MANUAL B–62924EN

Ethernet Board/DA T A SERVER Board

OPERATOR’S MANUAL

AST Ethernet Board/FAST DATA SERVER

OPERATOR’S MANUAL

DeviceNet Board OPERA T OR’S MANUAL B–63404EN

Specification

number

B–61803E–1

B–66102E

B–63354EN

B–63644EN

Related manuals of

SERVO MOTOR ai series

OPEN CNC

FANUC OPEN CNC OPERATOR’S MANUAL

Basic Operation Package 1 (For Windows 95/NT)

FANUC OPEN CNC OPERATOR’S MANUAL

(DNC Operation Management Package)

B–62994EN

B–63214EN

The following table lists the manuals related to SER VO MOTOR αi series

Manual name

FANUC AC SER VO MOTOR αi series DESCRIPTIONS B–65262EN

FANUC AC SER VO MOTOR αi series

P ARAMETER MANUAL

FANUC AC SPINDLE MOT OR αi series DESCRIPTIONS B–65272EN

FANUC AC SPINDLE MOT OR αi series

P ARAMETER MANUAL

FANUC SER VO AMPLIFIER αi series DESCRIPTIONS B–65282EN

FANUC SER VO MOT OR αi series

MAINTENANCE MANUAL

Specification

number

B–65270EN

B–65280EN

B–65285EN

p–3

Page 16

PREFACE

B–63835EN/03

Related manuals of

SERVO MOTOR β series

The following table lists the manuals related to SER VO MOT OR β series

Manual name

FANUC SER VO MOT OR β series DESCRIPTIONS B–65232EN

FANUC SER VO MOT OR β series MAINTENANCE

MANUAL

FANUC SER VO MOT OR β series (I/O Link Option)

MAINTENANCE MANUAL

Specification

number

B–65235EN

B–65245EN

p–4

Page 17

B–63835EN/03

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAY AND OPERATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Soft Keys 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER POWER IS TURNED ON 23. . . . . . . . . . . . . . . . .

1.2.1 Slot Status Display 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Setting Module Screen 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Configuration Display of Software 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Display Method 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Configuration of PCBs 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Software Configuration Screen 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Module Configuration Screen 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 ID Information Screen (αi Servo Information Screen/αi Spindle Information Screen) 27. . . . . . . . . . . . .

1.4 ALARM HISTORY SCREEN 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Alarm History Screen 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.1 General 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.2 Screen display 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.3 Clearing alarm history 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1.4 Alarm display 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 System Alarm History 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.1 General 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.2 System alarm history screen (history list screen) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.3 System alarm history screen (detail screen) 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2.4 Parameter 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES RECORD 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Screen Display 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Deletion of External Operator Messages Record 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 Parameter 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 Notes 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OPERATION HISTORY 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Parameter Setting 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Screen Display 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 Setting the Input Signal or Output Signal to be Recorded in the Operation History 46. . . . . . . . . . . . . . .

1.6.4 Inputting and Outputting the Operation History Data 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.5 Notes 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 General 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Display Method 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1 Displaying Diagnostic Page 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Contents Displayed 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVEFORM DIAGNOSTIC FUNCTION 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Setting Parameters 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 W aveform Diagnostic Parameter Screen 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Graphic of W ave Diagnosis Data 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Data Sampling for Storage T ype W aveform Diagnosis 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 18

Table of Contents

1.10.5 Outputting Waveform Diagnosis Data (Storage T ype) 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.6 Notes 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63835EN/03

1.11 OPERATING MONITOR 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.1 Display Method 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.2 Parameters 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13 WARNING SCREEN DISPLAYED WHEN AN OPTION IS CHANGED 108. . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15 MAINTENANCE INFORMATION SCREEN 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.1 Screen Display and Operation 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.2 Maintenance Information Input/Output 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16 COLOR SETTING SCREEN (10.4″ COLOR LCD) 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.1 Screen Display 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.2 Color Setting 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.3 Parameters 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.4 Notes 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.17 CONTRAST ADJUSTMENT 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18 POWER MATE CNC MANAGER 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.1 Parameter 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.2 Screen Display 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.3 Parameter Input/Output 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.18.4 Notes 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19 PERIODIC MAINTENANCE SCREENS 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.1 Overview 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.2 Screen Display and Setting 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.3 Status Screen Display and Setting 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.4 Setting Screen Display and Setting 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.5 Registered Data Input/Output 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.19.6 F ANUC T wo–Byte Character Code T able 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 HARDWARE CONFIGURATION 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 HARDWARE OVERVIEW 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TOTAL CONNECTION DIAGRAMS 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 CONNECTOR AND CARD CONFIGURATIONS OF PRINTED CIRCUIT BOARDS 152. . . . . . . . .

2.4.1 Main CPU Board 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Built–in I/O Board 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Serial Communication Board 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 HSSB Interface Board 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Fast Ethernet Board 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 DeviceNet Board 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.7 PROFIBUS Master Board 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.8 PROFIBUS Slave Board 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.9 FL–net Board 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.10 Main CPU Board of CNC Display Unit with PC Functions and P ANEL i 172. . . . . . . . . . . . . . . . . . . . . .

2.5 UNITS AND PRINTED CIRCUIT BOARDS 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Basic Units 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Printed Circuit Boards of Control Unit 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 LCD/MDI Unit 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Other Units 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 CNC Display Unit with PC Functions and P ANEL i 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 19

B–63835EN/03

2.6 MOUNTING AND REMOVING AN OPTION BOARD 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 MOUNTING AND DEMOUNTING CARD PCBS 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 MOUNTING AND DEMOUNTING DIMM MODULES 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 MOUNTING AND REMOVING THE BACK PANEL 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 REPLACING THE FUSE OF THE CONTROL UNIT 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 REPLACING THE BATTERY 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 REPLACING A FAN UNIT 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 REPLACING THE FUSE OF THE LCD UNIT 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 REPLACING THE LCD BACKLIGHT 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 HEAT LOSS OF EACH UNIT 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16 DISTRIBUTED I/O SETTING (SERIES 0i–B ONLY) 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.17 REPLACING FUSES ON VARIOUS UNITS 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CONTROL UNIT 218. . . . . . . . . . . . . . . . .

2.19 ACTION AGAINST NOISE 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20 REPLACING THE MAINTENANCE PARTS OF CNC DISPLAY UNIT FOR PC FUNCTIONS

Table of Contents

2.6.1 Mounting and Removing the Main CPU Board and a Full–Size Option Board 184. . . . . . . . . . . . . . . . . .

2.6.1.1 Removing the board 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1.2 Mounting the board 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Mounting and Removing a Mini–Slot Option Board (Except DeviceNet Board) 186. . . . . . . . . . . . . . . . .

2.6.2.1 Removing the board 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2.2 Mounting the board 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Mounting and Removing the DeviceNet Board 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3.1 Removing the board 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3.2 Mounting the board 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Demounting a Card PCB 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Mounting a Card PCB 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Demounting a DIMM Module 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Mounting a DIMM Module 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 Removing the Panel 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2 Mounting the Back Panel 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.1 Battery for Memory Backup (3VDC) 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.2 Batteries for CNC Display Unit with PC Functions (3VDC) 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.3 Battery for Separate Absolute Pulse Coders (6VDC) 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.4 Battery for Absolute Pulse Coder Built into the Motor (6VDC) 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.1 Separating Signal Lines 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.2 Ground 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.3 Connecting the Signal Ground (SG) of the Control Unit 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.4 Noise Suppressor 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19.5 Cable Clamp and Shield Processing 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AND PANEL i 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.1 Replacing the Battery 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.2 Replacing the Fuse 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.3 Replacing the Fan 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.4 Replacing the LCD Back–Light 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.5 Replacing the T ouch Panel Protection Sheet 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUT AND OUTPUT OF DATA 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SETTING PARAMETERS FOR INPUT/OUTPUT 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 INPUTTING/OUTPUTTING DATA 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Confirming the Parameters Required for Data Output 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 20

Table of Contents

3.2.2 Outputting CNC Parameters 246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Outputting PMC Parameters 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Outputting Pitch Error Compensation Amount 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Outputting Custom Macro V ariable Values 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Outputting Tool Compensation Amount 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Outputting Part Program 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Inputting CNC Parameters 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Inputting PMC Parameters 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Inputting Pitch Error Compensation Amount 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.11 Inputting Custom Macro V ariable Values 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.12 Inputting Tool Compensation Amount 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.13 Inputting Part Programs 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63835EN/03

3.3 DATA INPUT/OUTPUT ON THE ALL IO SCREEN 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Setting Input/Output–Related Parameters 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Inputting and Outputting Programs 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Inputting and Outputting Parameters 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Inputting and Outputting Offset Data 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 Outputting Custom Macro Common Variables 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.6 Inputting and Outputting Floppy Files 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 DATA INPUT/OUTPUT USING A MEMORY CARD 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERFACE BETWEEN CNC AND PMC 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL OF INTERFACE 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SPECIFICATION OF PMC 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Specification 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Address 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 System Reserve Area of Internal Relay 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Execution Period of PMC 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 I/O Module Assignment Name List 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PMC SCREEN (PMC–SA1) 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 PMC Menu Selection Procedure Using Soft Keys 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Dynamic Display of Sequence Program 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Display of PMC Diagnosis Screen 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.1 Title screen (TITLE) 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.2 Status screen (STA TUS) 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.3 Alarm screen (ALARM) 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.4 Trace screen (TRACE) 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 PMC Parameter 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.1 Input of PMC parameter from MDI 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.2 Timer screen (TIMER) 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.3 Counter screen (COUNTER) 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.4 Keep relay screen (KEEPRL) 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.5 Data table screen (DAT A) 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.6 Setting screen 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Input/Output of PMC Data 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.1 Start of the built-in type PMC programmer 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.2 Input/output method 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.3 Copy function (COPY) 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 System Parameters 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 Online Monitor Setting Screen 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PMC SCREEN (PMC–SB7) 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 PMC Menu Selection Procedure Using Soft Keys 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 21

B–63835EN/03

4.5 LIST OF SIGNALS BY EACH MODE 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 LIST OF INPUT/OUTPUT SIGNALS 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 LIST OF ADDRESSES 362. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

4.4.2 Dynamic Display of Sequence Programs 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.1 Ladder diagram display screen 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.2 Selection monitor screen 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.3 Ladder diagram editing screen 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2.4 Net editing screen 320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Display of the PMC Diagnosis Screen 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.1 Title screen 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.2 Status screen 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.3 Alarm screen 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.4 Trace function 325. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3.5 I/O Link connection check screen 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 PMC Parameters 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.1 Parameter input/output method 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.2 TIMER screen 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.3 COUNTER screen 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.4 KEEP RELAY screen 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.5 Data table screen 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4.6 Setting screens 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 PMC Data Input/Output 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5.1 Starting the built–in programmer 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5.2 Input/output method 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 System Parameters 341. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.7 Online Monitor Setting Screen 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. FOCAS1/ETHERNET PARAMETER SETTING 389. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. DIGITAL SERVO 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 INITIAL SETTING SERVO PARAMETERS 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SERVO TUNING SCREEN 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Parameter Setting 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Displaying Servo Tuning Screen 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 ADJUSTING REFERENCE POSITION (DOG METHOD) 408. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 General 408. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 DOGLESS REFERENCE POSITION SETTING 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 General 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Operation 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Associated Parameters 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 αi SERVO WARNING INTERFACE 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 αi SERVO INFORMATION SCREEN 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. AC SPINDLE (SERIAL INTERFACE) 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 AC SPINDLE (SERIAL INTERFACE) 420. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Outline of Spindle Control 420. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1.1 Method A of gear change for machining center 422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1.2 Method B of gear change for machining center (PRM 3705#2=1) 422. . . . . . . . . . . . . . . . . . . . . .

c–5

Page 22

Table of Contents

7.1.1.3 T series 422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Spindle Setting and Tuning Screen 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.1 Display method 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.2 Spindle setting screen 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.3 Spindle tuning screen 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.4 Spindle monitor screen 426. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.5 Correspondence between operation mode and parameters on spindle tuning screen 428. . . . . . . . .

7.1.3 Automatic Setting of Standard Parameters 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 W arning Interface for the αi Spindle 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 αi Spindle Information Screen 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63835EN/03

7.2 AC SPINDLE (ANALOG INTERFACE) 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Outline of Spindle Control 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.1 Block diagram 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.2 Calculation of S analog voltage and related parameters 440. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.3 Tuning S analog voltage (D/A converter) 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. TROUBLESHOOTING 444. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 CORRECTIVE ACTION FOR FAILURES 446. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Investigating the Conditions Under which Failure Occurred 446. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED 448. . . . . . . .

8.3 JOG OPERATION CANNOT BE DONE 452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 HANDLE OPERATION CANNOT BE DONE 456. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 AUTOMATIC OPERATION CANNOT BE DONE 461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 CYCLE START LED SIGNAL HAS TURNED OFF 469. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 NOTHING IS DISPLAYED ON THE SCREEN WHEN THE POWER IS TURNED ON 471. . . . . . .

8.8 THE DISPLAY ON THE LCD UNIT FLASHES 474. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 INPUT FROM AND OUTPUT TO I/O DEVICES CANNOT BE PERFORMED

INPUT/OUTPUT CANNOT BE PERFORMED PROPERLY 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 IN A CONNECTOR PANEL I/O UNIT, DATA IS INPUT TO AN UNEXPECTED ADDRESS

(FOR SERIES 0i–B) 477. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 IN A CONNECTOR PANEL I/O UNIT, NO DATA IS OUTPUT TO AN EXPANSION UNIT

(FOR SERIES 0i–B) 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12 ALARM 85 TO 87 (READER/PUNCHER INTERFACE ALARM) 479. . . . . . . . . . . . . . . . . . . . . . . .

8.13 ALARM 90 (REFERENCE POSITION RETURN IS ABNORMAL) 483. . . . . . . . . . . . . . . . . . . . . . .

8.14 ALARM 300 (REQUEST FOR REFERENCE POSITION RETURN) 485. . . . . . . . . . . . . . . . . . . . . . .

8.15 ALARM 401 (V READY OFF) 486. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.16 ALARM 404 (V READY ON) 488. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.17 ALARM 462 (SEND CNC DATA FAILED)

ALARM 463 (SEND SLAVE DATA FAILED) 490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.18 ALARM 417 (DIGITAL SERVO SYSTEM IS ABNORMAL) 491. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.19 ALARM 700 (OVERHEAT: CONTROL UNIT) 492. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.20 ALARM 701 (OVERHEAT: FAN MOTOR) 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.21 ALARM 704 (SPINDLE SPEED FLUCTUATION DETECTION ALARM) 494. . . . . . . . . . . . . . . . . .

8.22 ALARM 749 (SERIAL SPINDLE COMMUNICATION ERROR) 495. . . . . . . . . . . . . . . . . . . . . . . . . .

8.23 ALARM 750 (SPINDLE SERIAL LINK STARTUP FAILURE) 496. . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 23

B–63835EN/03

8.24 ALARM 5134 (FSSB: OPEN READY TIME OUT)

8.25 ALARM 5136 (FSSB: NUMBER OF AMPS IS SMALL) 500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.26 ALARM 900 (ROM PARITY) 501. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.27 ALARMS 912 TO 919 (DRAM PARITY) 502. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.28 ALARM 920 (SERVO ALARMS) 503. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.29 ALARM 926 (FSSB ALARM) 504. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.30 ALARM 930 (CPU INTERRUPT) 508. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.31 ALARM 935 (SRAM ECC ERROR) 509. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.32 ALARM 950 (PMC SYSTEM ALARM) 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.33 ALARM 951 (PMC WATCHDOG ALARM) 514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.34 ALARM 972 (NMI ALARM ON AN OPTION BOARD) (SERIES 0i–B ONLY) 515. . . . . . . . . . . . . .

8.35 ALARM 973 (NMI ALARM WITH AN UNKNOWN CAUSE) 516. . . . . . . . . . . . . . . . . . . . . . . . . . .

8.36 ALARM 974 (F–BUS ERROR) 517. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.37 ALARM 975 (BUS ERROR) 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.38 ALARM 976 (LOCAL BUS ERROR) 519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.39 SERVO ALARMS 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.40 SPC ALARMS 524. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.41 SPINDLE ALARMS 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

ALARM 5135 (FSSB: ERROR MODE)

ALARM 5137 (FSSB: CONFIGURATION ERROR)

ALARM 5197 (FSSB: OPEN TIME OUT)

ALARM 5198 (FSSB: ID DATA NOT READ) 498. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. ALARM LIST 529. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ALARM CODES (CNC) 530. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 LIST OF ALARMS (PMC) 567. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 ALARM LIST (SERIAL SPINDLE) 592. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 ERROR CODES (SERIAL SPINDLE) 604. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. LIST OF MAINTENANCE PARTS 606. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. BOOT SYSTEM 607. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 OVERVIEW 608. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.1 Starting the Boot System 608. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.2 System Files and User Files 609. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 SCREEN CONFIGURATION AND OPERATING PROCEDURE 610. . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.1 System Data Loading Screen 611. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.2 System Data Check Screen 613. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.3 System Data Delete Screen 615. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.4 System Data Save Screen 616. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.5 SRAM Data Backup Screen 618. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.6 Memory Card File Delete Screen 621. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.7 Memory Card Format Function 622. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.8 Load Basic System Function 623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 ERROR MESSAGES AND REQUIRED ACTIONS 625. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 24

Table of Contents

B–63835EN/03

D. LED DISPLAY AND MAINTENANCE OF CONTROL UNIT 628. . . . . . . . . . . . . . . . . .

D.1 OVERVIEW 629. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 LAYOUT OF THE 7–SEGMENT LED AND SWITCHES 630. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3 OPERATION 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.1 Operation Before Power–On 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.2 Function Number 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3 Seven–Segment LED Display 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3.1 NC status display 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3.2 LED display during automatic operation 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3.3 LED display when the push switch is pressed 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3.4 LED display when a system alarm is issued 633. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.3.5 Display on the 7–segment LED at power–on 634. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.3.4 Operation of Each Function 635. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. MAINTENANCE OF OPEN CNC (BOOT–UP AND IPL) 637. . . . . . . . . . . . . . . . . . . . .

E.1 OVERVIEW 638. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.2 CHANGING START SEQUENCES (NOT APPLICABLE TO THE SERIES 0i MATE) 639. . . . . . . .

E.3 EXPLANATION OF SCREENS 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1 Boot Screen 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.1 System data manipulation 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.2 SRAM operation 642. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.3 File operation 643. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.2 IPL Screen 644. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.2.1 Functions on the IPL screen 645. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4 OTHER SCREENS 647. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.1 CNC Alarm Screen 647. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.2 Status Screen 648. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.3 Option Setting Screen 649. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. FSSB START–UP PROCEDURE/MATERIALS 650. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.1 OVERVIEW 651. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.2 SLAVE 652. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.3 AUTOMATIC SETTING 653. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .3.1 [Sample Setting 1] General Configuration (Semi–Closed Loop) 655. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .3.2 [Sample Setting 2] General Configuration (Closed Loop) 656. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .3.3 [Sample Setting 3] When the C–Axis is a Cs Axis 658. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.4 MANUAL SETTING 2 660. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.5 MANUAL SETTING 1 666. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.6 ALARMS 667. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.7 ACTIONS FOR TROUBLE ENCOUNTERED AT START–UP TIME 672. . . . . . . . . . . . . . . . . . . . . .

F.8 FSSB DATA DISPLAY 674. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .8.1 Amplifier Setting Screen 674. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .8.2 Axis Setting Screen 675. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F .8.3 Amplifier Maintenance Screen 676. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. NOTATION OF MDI KEYS 678. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 25

B–63835EN/03

1

1. DISPLAY AND OPERATION

DISPLAY AND OPERATION

This chapter describes how to display various screens by the function

keys. The screens used for maintenance are respectively displayed.

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER

POWER IS TURNED ON 23. . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 25. . . . . . . . . .

1.4 ALARM HISTORY SCREEN 28. . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES

RECORD 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OPERATION HISTORY 37. . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 59. . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 82. . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVEFORM DIAGNOSTIC FUNCTION 84. . . . . . . . .

1.11 OPERATING MONITOR 96. . . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 98. . . . . . . . . . . . . . . . . . . . . . .

1.13 WARNING SCREEN DISPLAYED WHEN

AN OPTION IS CHANGED 108. . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED

WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 110. . . . . . . . . . . . .

1.15 MAINTENANCE INFORMATION SCREEN 111. . . . . .

1.16 COLOR SETTING SCREEN

(10.4″ COLOR LCD) 115. . . . . . . . . . . . . . . . . . . . . . . . . .

1.17 CONTRAST ADJUSTMENT 119. . . . . . . . . . . . . . . . . . .

1.18 POWER MATE CNC MANAGER 120. . . . . . . . . . . . . .

1.19 PERIODIC MAINTENANCE SCREENS 130. . . . . . . . .

1

Page 26

1. DISPLAY AND OPERATION

B–63835EN/03

1.1

FUNCTION KEYS AND SOFT KEYS

1.1.1

Soft Keys

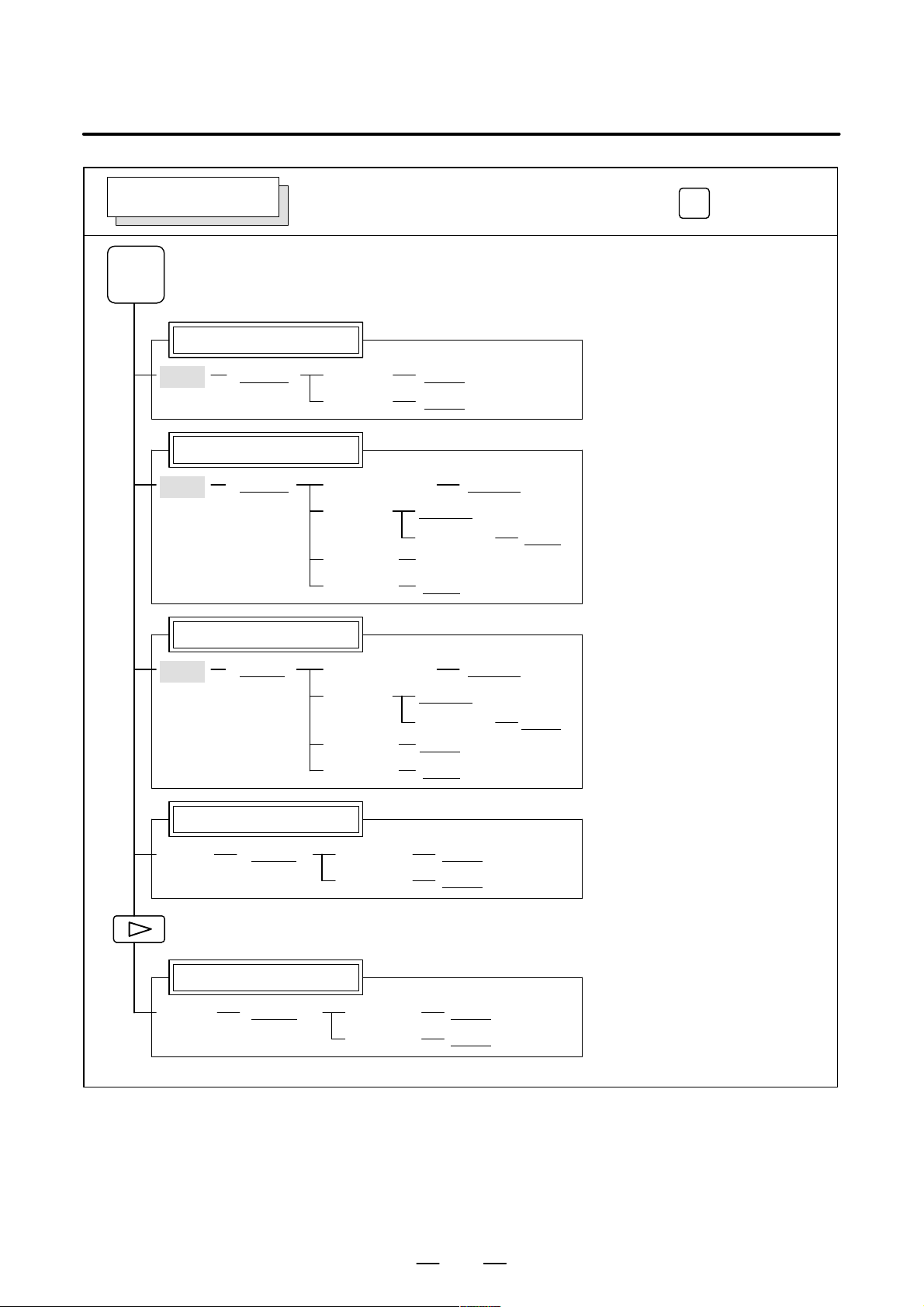

Operations and soft key display staturs for each function key are described

below:

T o display a more detailed screen, press a function key followed by a soft

key. Soft keys are also used for actual operations.

The following illustrates how soft key displays are changed by pressing

each function key.

The symbols in the following figures mean as shown below :

: Indicates screens

[]

()

[ ]

: Indicates a screen that can be displayed by pressing a

: Indicates a soft key(*2)

: Indicates input from the MDI panel.

: Indicates a soft key displayed in green (or highlighted).

: Indicates the continuous menu key (rightmost soft key)(*3).

function key(*1)

*1 Press function keys to switch between screens that are used frequently.

*2 Some soft keys are not displayed depending on the option configuration.

*3 In some cases, the continuous menu key is omitted when the 12 soft keys

type is used.

2

Page 27

B–63835EN/03

1. DISPLAY AND OPERATION

POSITION SCREEN

POS

Absolute coordinate display

[ABS]

Relative coordinate display

Current position display

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)][REL]

Soft key transition triggered by the function key

[RUNPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

[Axis name] [EXEC]

[PRESET]

POS

[ALL]

[(OPRT)]

Handle interruption

[HNDL]

Monitor screen

[MONI]

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)] [PTSPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

[Axis name] [EXEC]

[PRESET]

3

Page 28

1. DISPLAY AND OPERATION

B–63835EN/03

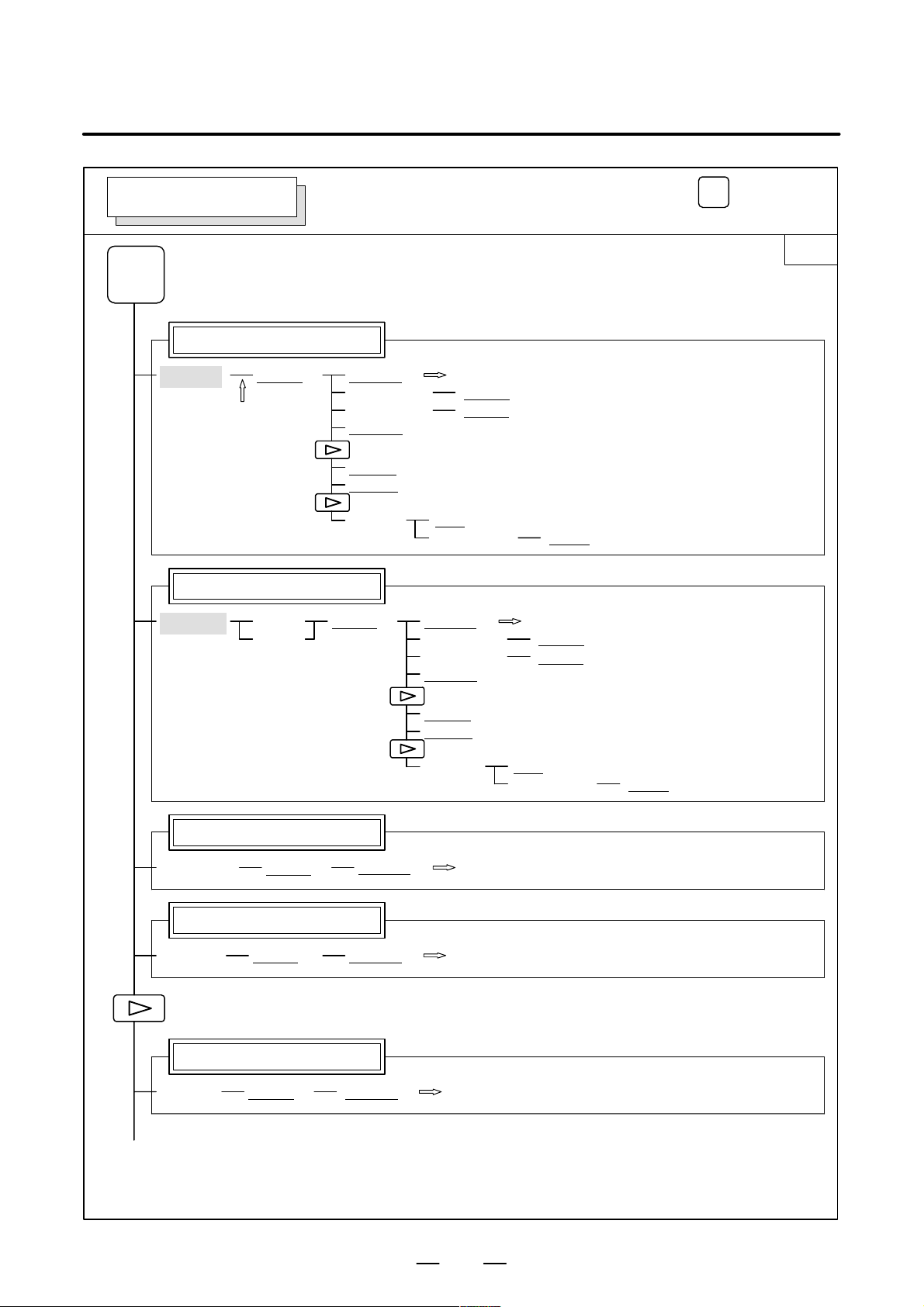

PROGRAM SCREEN

PROG

Program display screen

[PRGRM]

(1)

Program check display screen

Soft key transition triggered by the function key

in the MEM mode

[(OPRT)] [BG–EDT]

[O number]

[N number]

[REWIND]

[P TYPE]

[Q TYPE]

[F SRH]

[ABS]

[REL]

[(OPRT)][CHECK]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

[CAN]

(N number)

[BG–EDT]

[O number]

[N number]

[REWIND]

[EXEC]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

PROG

1/2

Current block display screen

[(OPRT)]

Next block display screen

[(OPRT)] [BG–EDT][NEXT]

Program restart display screen

[(OPRT)] [BG–EDT][RSTR]

(2)(Continued on the next page)

[P TYPE]

[Q TYPE]

[F SRH]

[BG–EDT][CURRNT]

See “When the soft key [BG–EDT] is pressed”

[CAN]

(N number)

[EXEC]

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

4

Page 29

B–63835EN/03

1. DISPLAY AND OPERATION

(2)

[FL.SDL] [PRGRM]

Return to (1) (Program display)

File directory display screen

[(OPRT)][DIR] [SELECT]

Schedule operation display screen

[SCHDUL] [CLEAR]

[(OPRT)]

(Schedule data)

2/2

(File No. ) [F SET]

[EXEC]

[CAN]

[EXEC]

[INPUT]

5

Page 30

1. DISPLAY AND OPERATION

B–63835EN/03

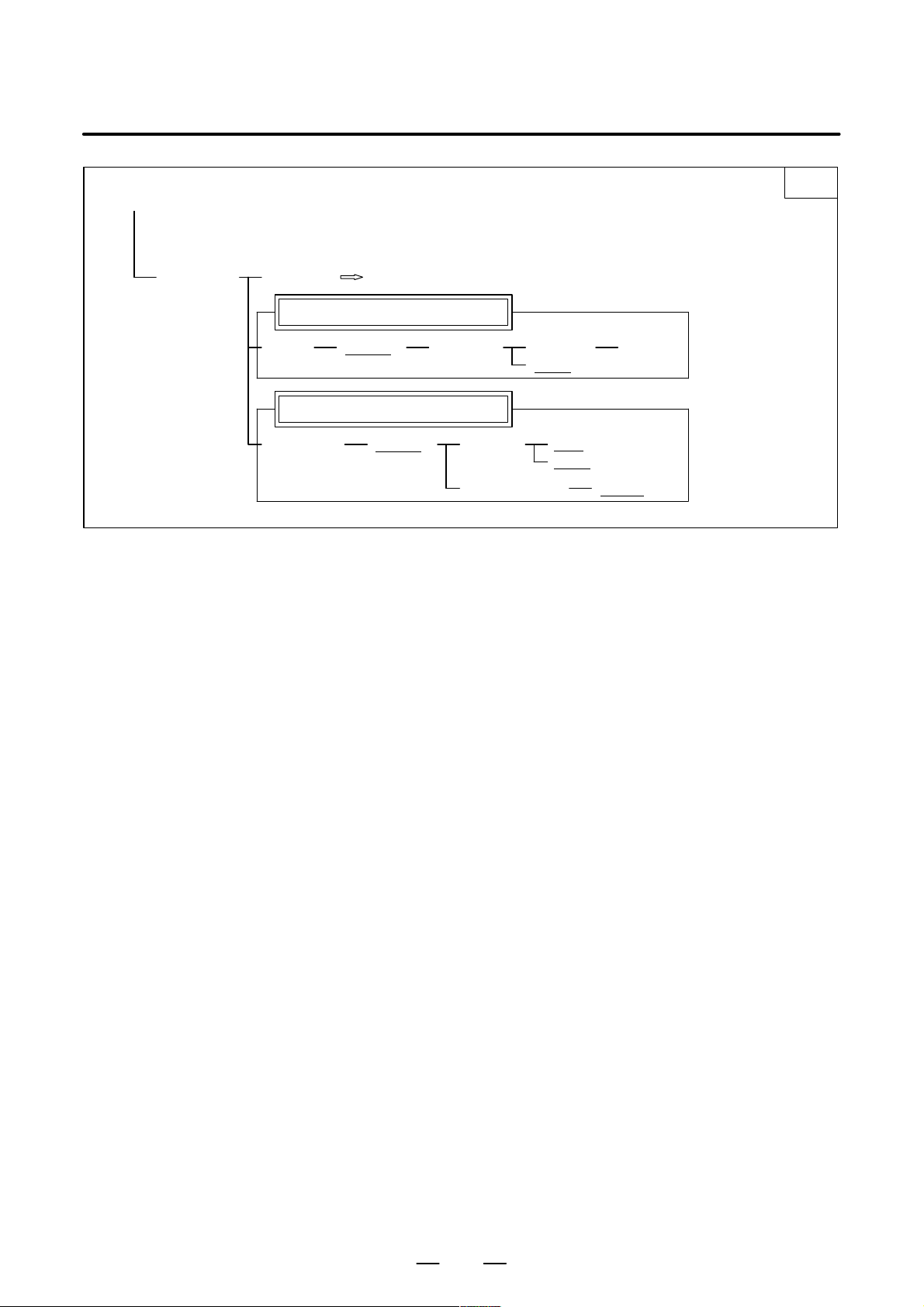

PROGRAM SCREEN

PROG

Program display

[PRGRM]

Soft key transition triggered by the function key

in the EDIT mode

[(OPRT)] [BG–EDT]

(O number) [O SRH]

(Address) [SRH↓]

(Address) [SRH↑]

[REWIND]

[F SRH] [CAN]

[READ] [CHAIN]

[PUNCH] [STOP]

[DELETE] [CAN]

[EX–EDT] [COPY] [CRSR∼]

PROG

See “When the soft key [BG–EDT] is pressed”

(N number) [EXEC]

(The cursor moves to the end of a program.)

[STOP]

[CAN]

(O number)

[CAN]

(O number)

(N number)

[MOVE] [CRSR∼]

[MERGE] [∼CRSR]

[CHANGE] (Address) [BEFORE]

[EXEC]

[EXEC]

[EXEC]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼BTTM]

1/2

(1)(Continued on the next page)

(Address) [AFTER] [SKIP]

[1–EXEC]

[EXEC]

6

Page 31

B–63835EN/03

1. DISPLAY AND OPERATION

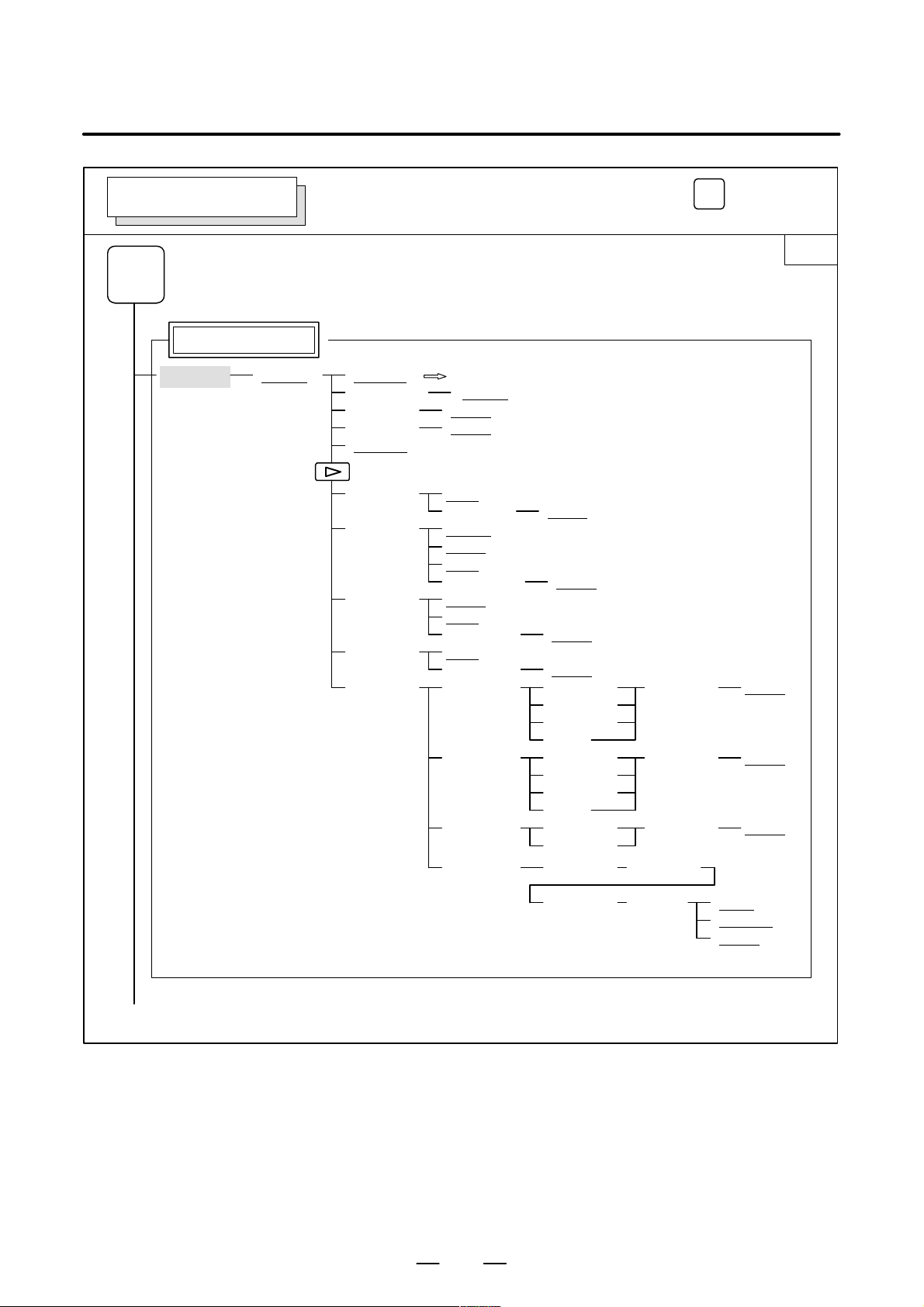

(1)

Program directory display

[LIB]

Graphic Conversational Programming (T series)

[C.A.P.]

[(OPRT)] [BG–EDT]

(O number) [O SRH]

[READ] [CHAIN]

[PUNCH] [STOP]

[PRGRM]

[G.MENU]

(G number) [BLOCK] (Data)

When a G number is omitted,

the standard screen appears.

Return to the program

See “When the soft key [BG–EDT] is pressed”

Return to the program

[STOP]

[CAN]

(O number)

[CAN]

(O number)

[EXEC]

[EXEC]

[LINE]

[CHAMF]

[CNR.R]

[INPUT]

2/2

Graphic Conversational Programming (M series)

[C.A.P.]

Floppy directory display

[FLOPPY]

[PRGRM]

[G.MENU]

[(OPRT)] [INPUT]

(G number) [BLOCK] (Data) [INPUT]

When a G number is omitted, the standard screen appears.

[PRGRM]

[DIR] (Numeral)

Return to the program

Return to the program

[(OPRT)]

[F SRH]

[READ]

[PUNCH]