Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 0i-Model B

Series 0i-Mate Model B

Connection Manual (Function)

GFZ-63833EN-1/02 August 28, 2002

Volume 1 of 2

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2002 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 4

B–63833EN–1/02

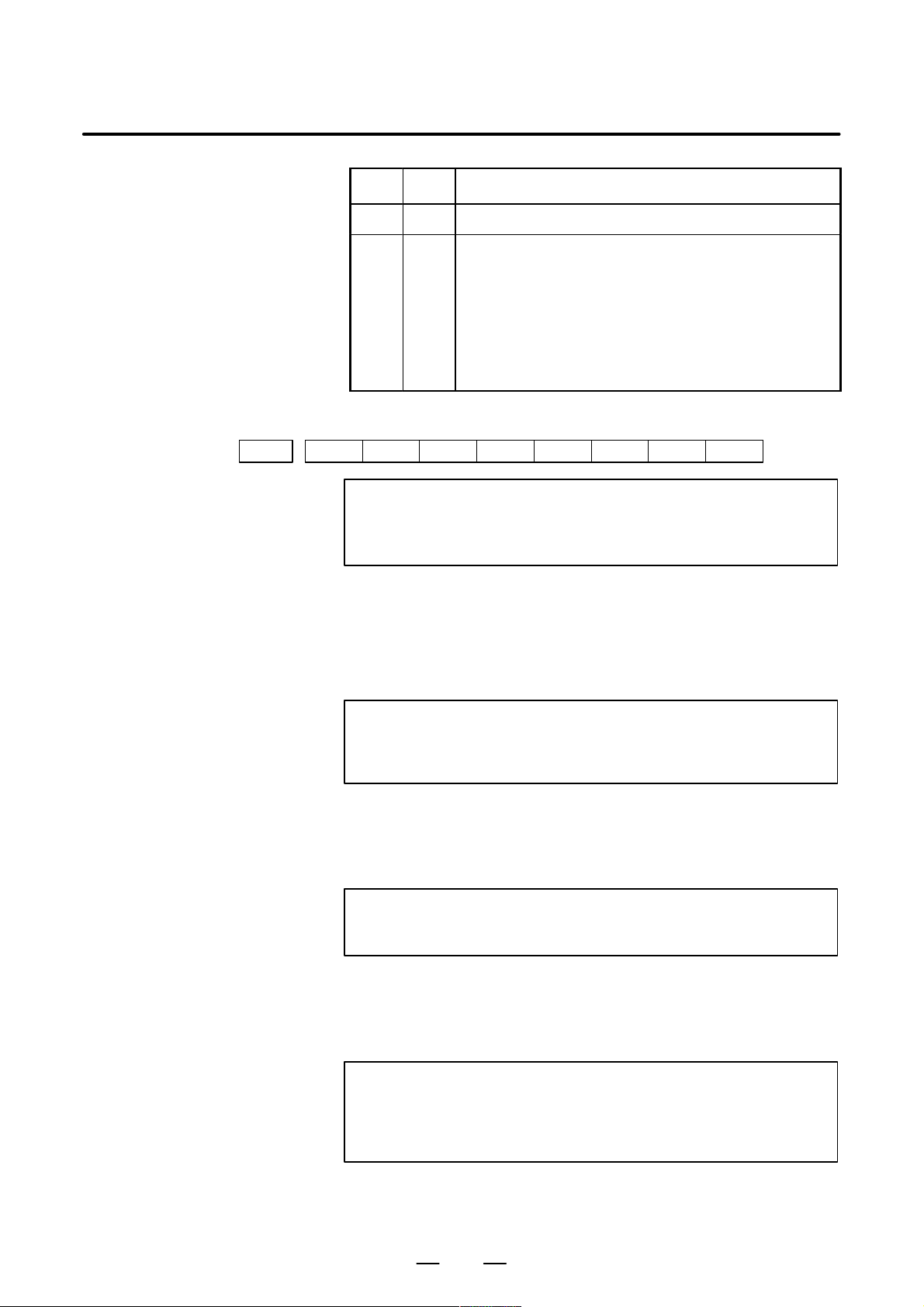

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

Page 5

Page 6

B–63833EN–1/02

PREFACE

PREFACE

This manual describes all the NC functions required to enable machine

tool builders to design their CNC machine tools. The following items are

explained for each function.

1. General

Describes feature of the function. Refer to Operator’s manual as

requied.

2. Signals

Describes names, functions, output conditions and addresses of the

signals required to realize a function.

3. Parameters

Describes parameters related with a function.

4. Alarms and messages

Lists the alarms and messages related with a function in a table.

5. Reference item

List the related items of the related manuals in a table.

A list of addresses of all signals and a list of signals are described in the

appendix of this manual. Refer to it as required.

p–1

Page 7

PREFACE

B–63833EN–1/02

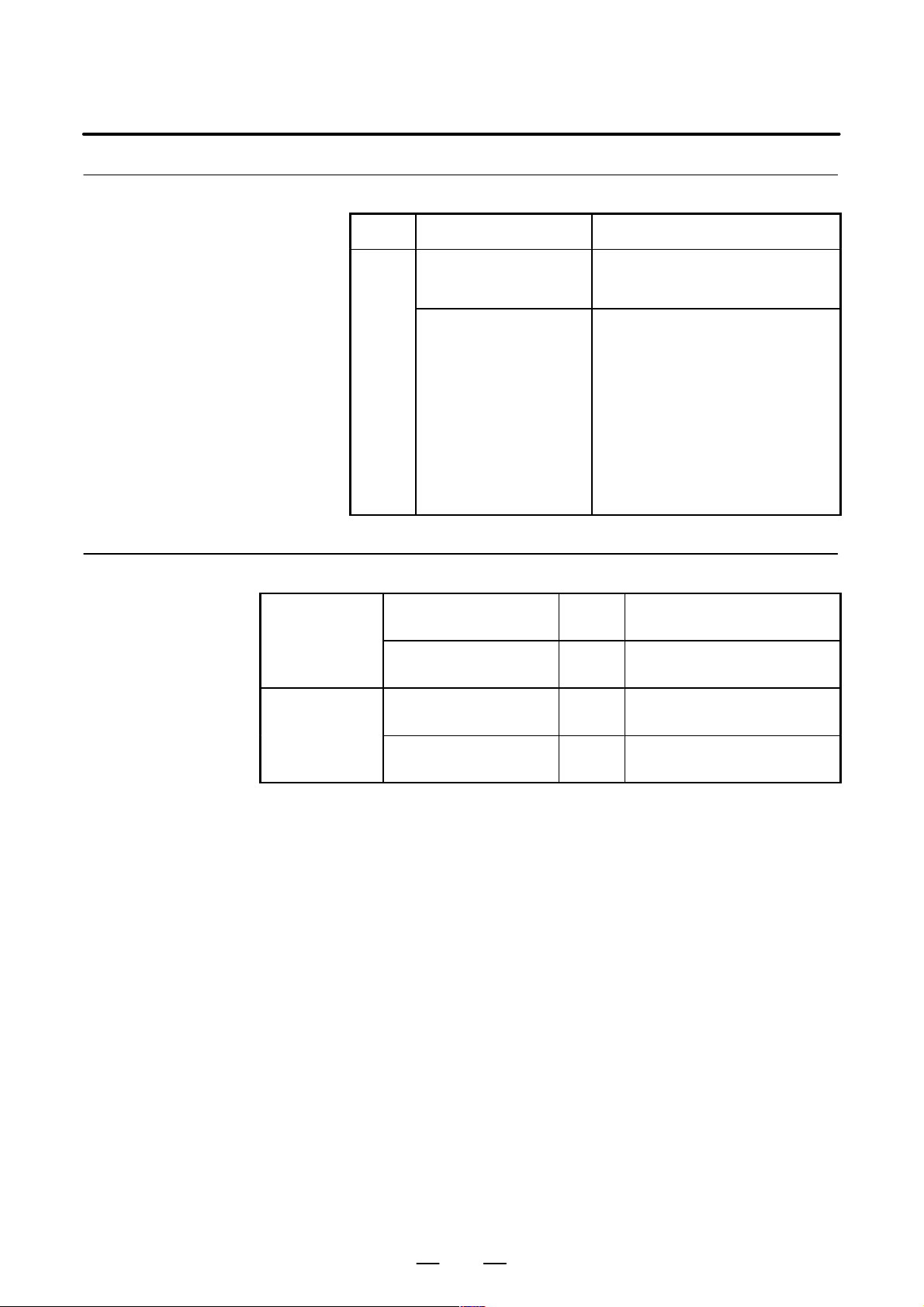

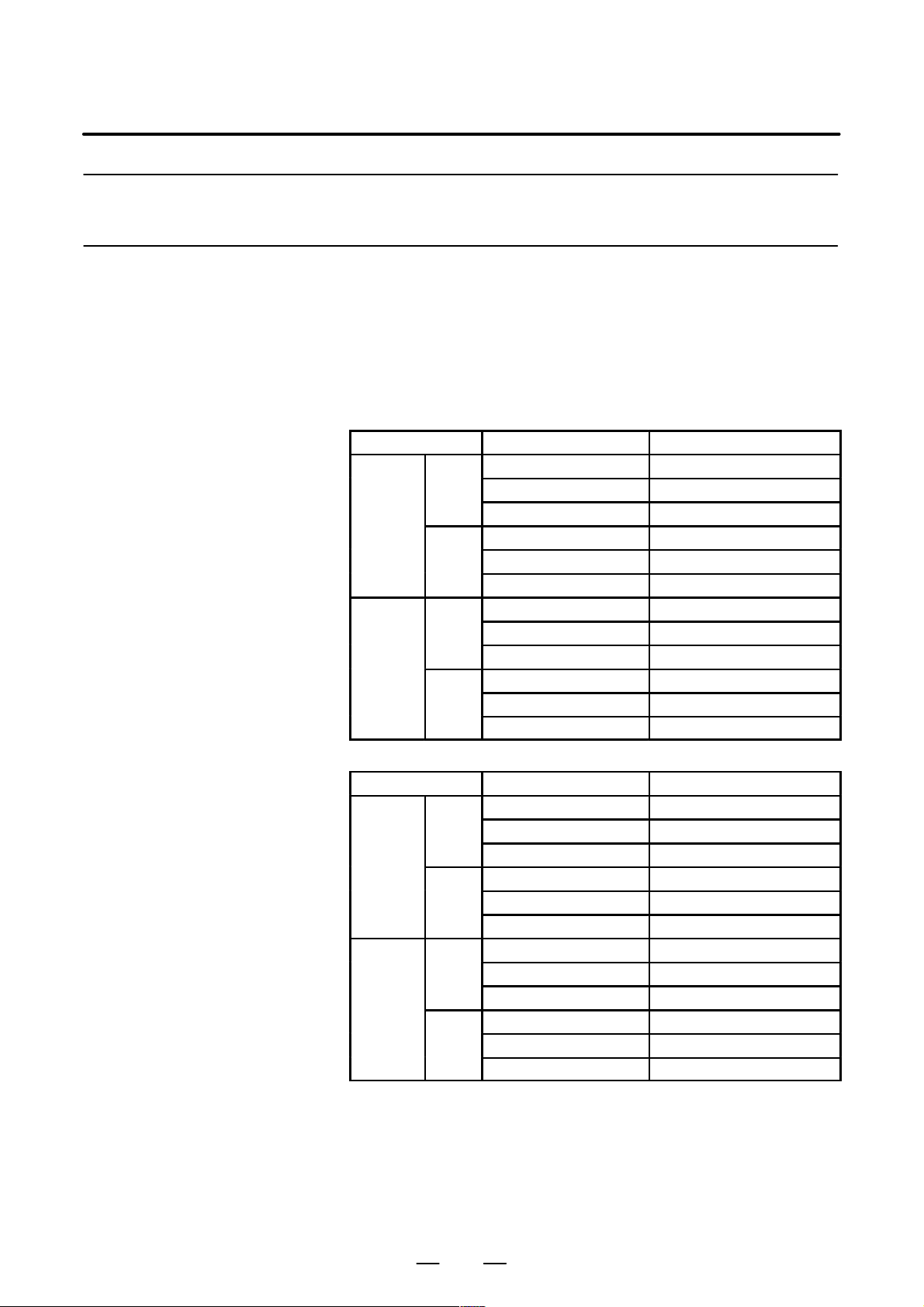

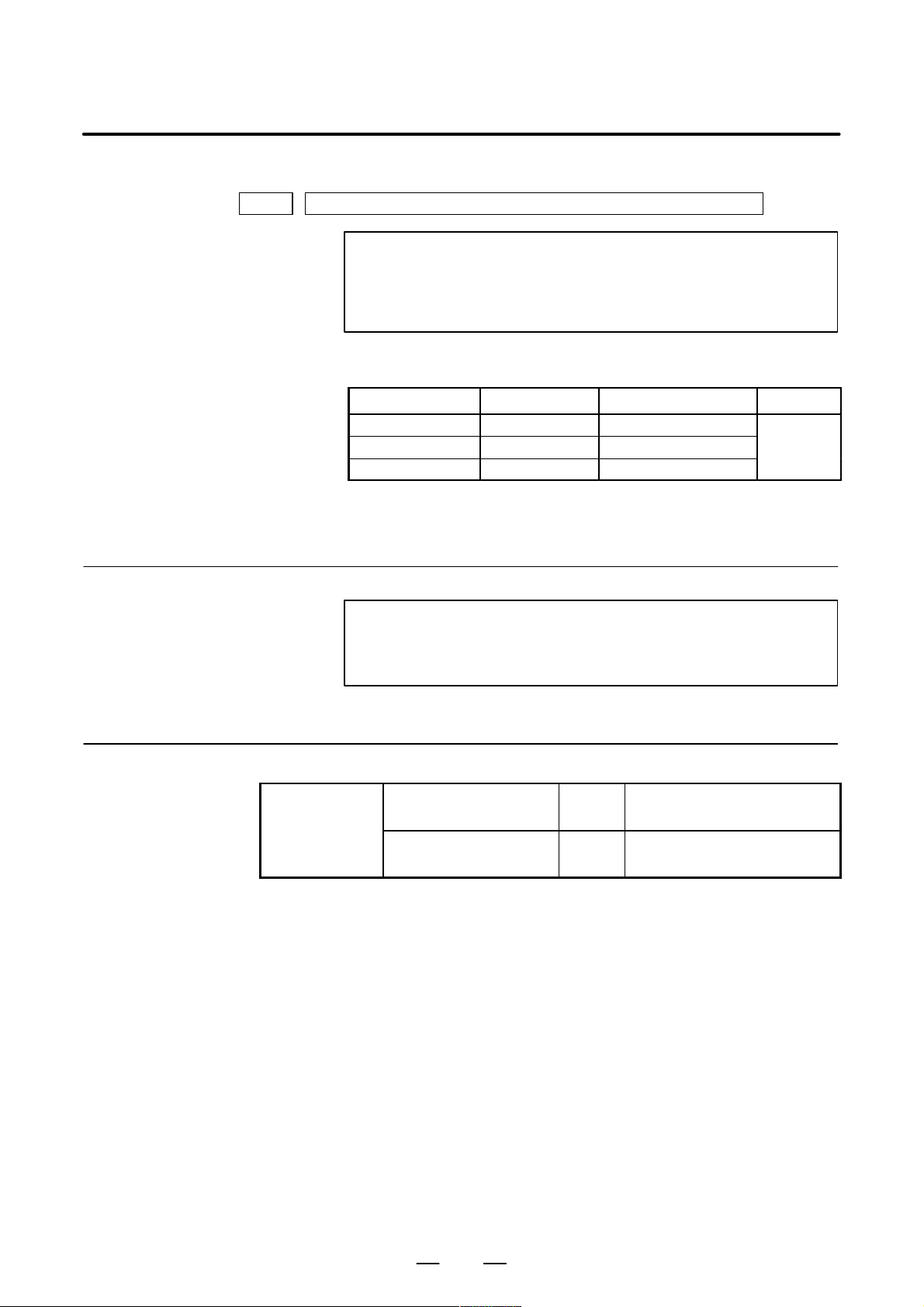

Applicable models

Signal description

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 0i–TB 0i–TB

Series 0i–B 0i

FANUC Series 0i–MB 0i–MB

FANUC Series 0i Mate–TB 0i Mate–TB

Series 0i Mate–B 0i Mate

FANUC Series 0i Mate–MB 0i Mate–MB

NOTE

Some functions described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS manual

(B–63832EN).

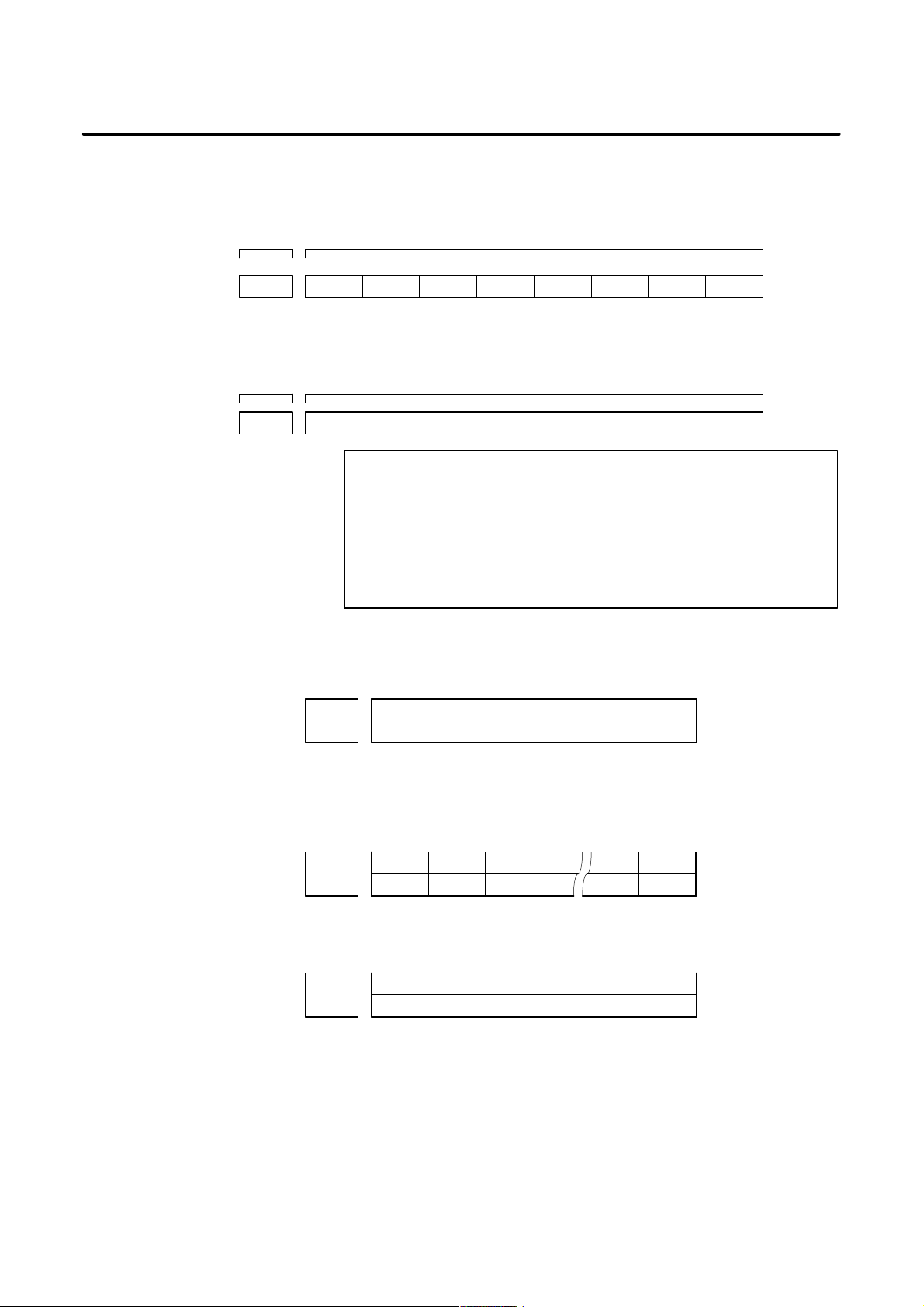

Relation of interface signals among the CNC, the PMC and the machine

tool is shown below:

D Expression of signals

G000–

CNC PMC

F000–

X000–

Y000–

Machine

tool

NOTE

For the signals, a single data number is assigned to 8 bits.

Each bit has a different meaning.

One address accommodates eight signals.

Symbol (#0 to #7 indicates bit position)Address

#7 #6 #5 #4 #3 #2 #1 #0

OPF000 SA STL SPL RWD

In an item where both T series and M series are described, some signals

are covered with shade ( ) in the signal address figure as shown

below. This means either T series or M series does not have this signal.

Upper part is for T series and lower part is for M series.

[Example 1]

Signal EXLM, ST is a common signal, STLK is for T series only and

RLSOT and RVS are for M series only.

G007

#7

#6

EXLM

p–2

#2

ST

#1

STLKRLSOT

#0

RVS

T series

M series

Page 8

B–63833EN–1/02

–128 to 127

In some parameters, signs are ig-

–32768 to 32767

–99999999 to

PREFACE

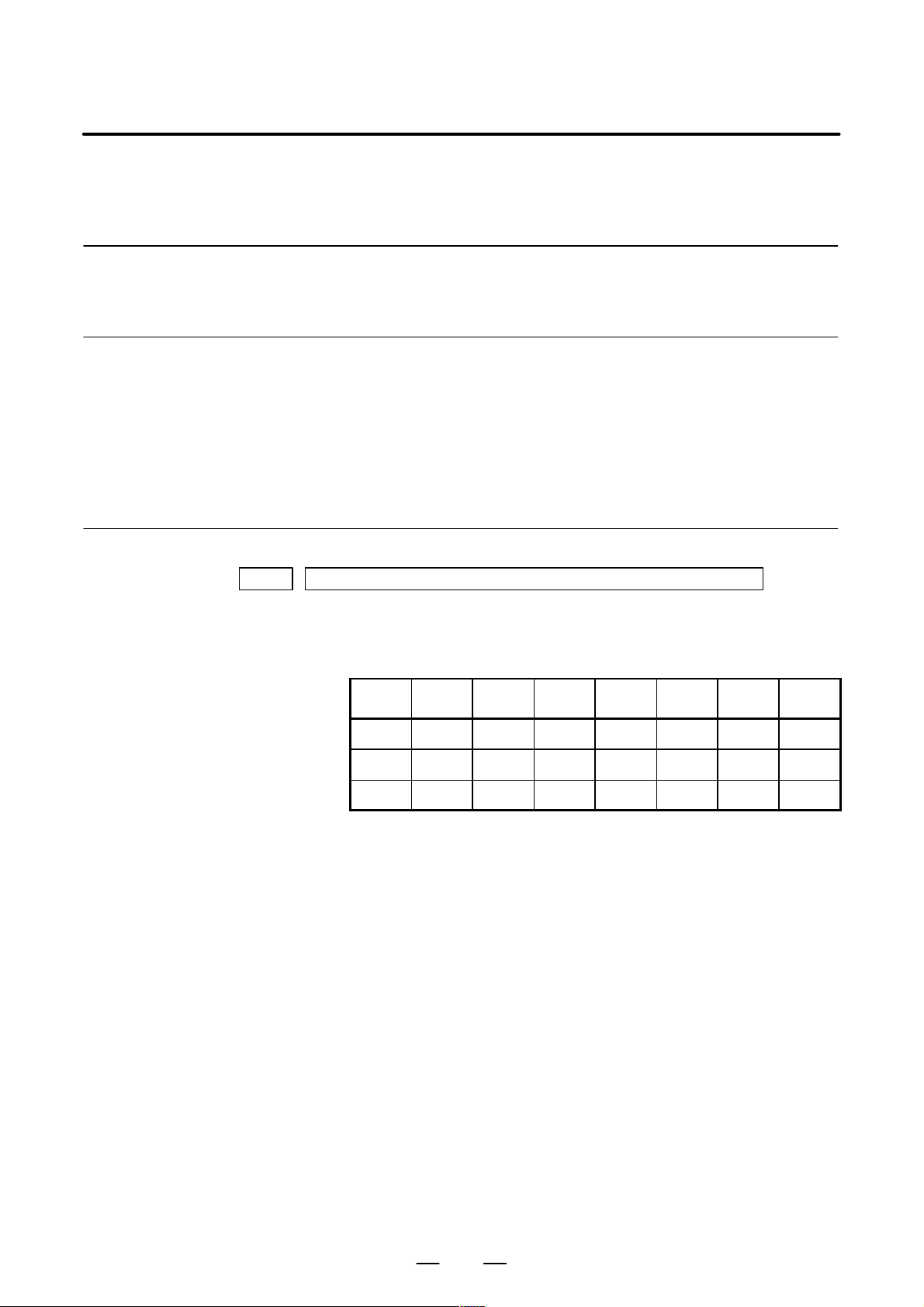

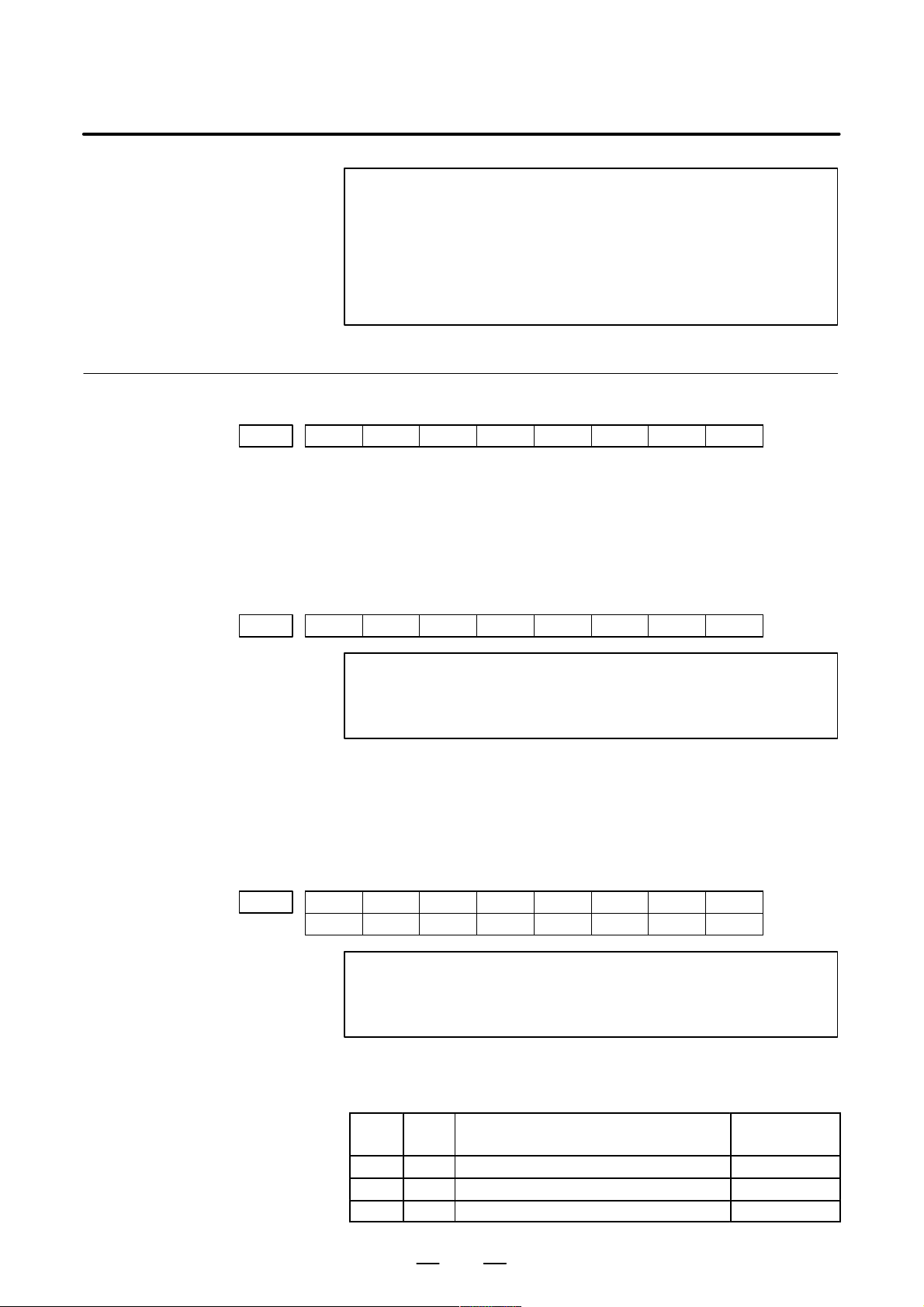

Parameter description

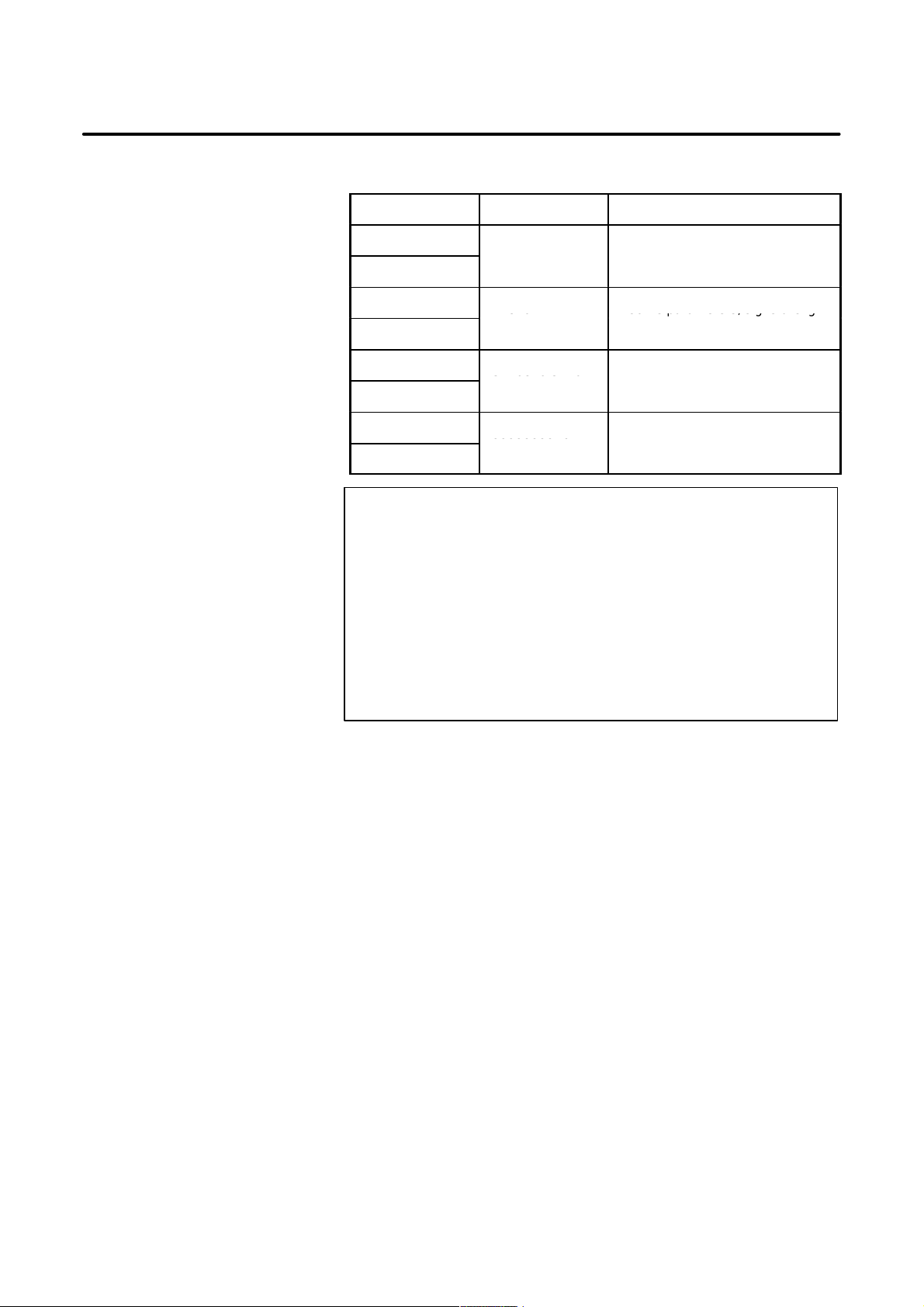

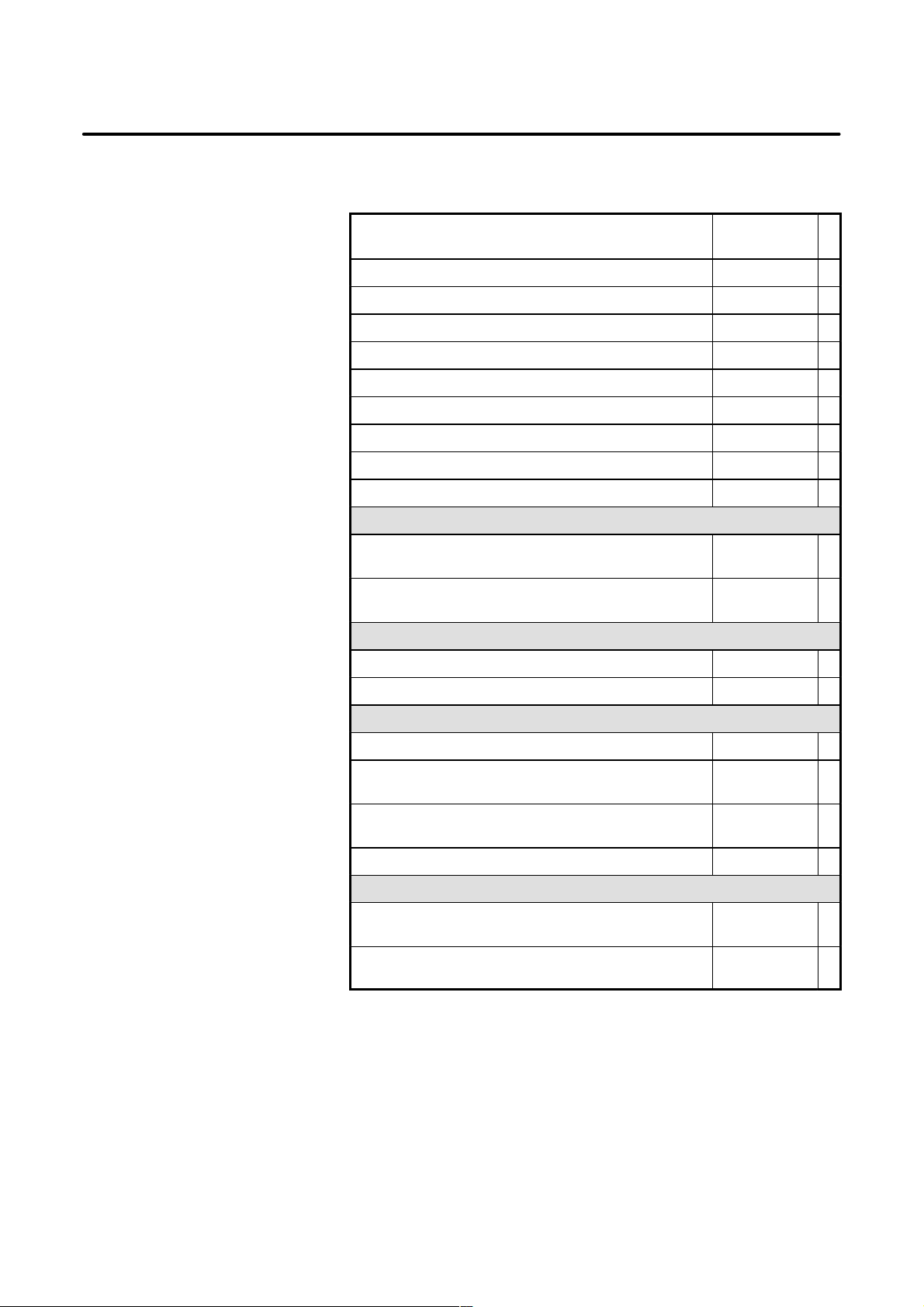

Parameters are classified by data type as follows :

Dta type Valid data range Remarks

Bit

0 or 1

Bit axis

Byte

Byte axis

Word

Word axis

2–word

2–word axis

–128 to 127 In some parameters, signs are ig-

0 to 255

–32768 to 32767

0 to 65535

–99999999 to

99999999

nored.

NOTE

1 For the bit type and bit axis type parameters, a single data

number is assigned to 8 bits. Each bit has a different

meaning.

2 The axis type allows data to be set separately for each

control axis.

3 The valid data range for each data type indicates a general

range. The range varies according to the parameters. For

the valid data range of a specific parameter, see the

explanation of the parameter.

p–3

Page 9

PREFACE

D Notation of bit type and

bit axis type parameters

0000 SEQ INI ISO TVC

D Notation of parameters

other than bit type and

bit axis type

1023 Servo axis number of a specific axis

B–63833EN–1/02

Data (#0 to #7 indicates bit position)Data No.

#7 #6 #5 #4 #3 #2 #1 #0

DataData No.

NOTE

In an item where both T series and M series are described,

parameters having different meanings between the T series

and M series and parameters that are valid only for the T or

M series are indicated in two levels as shown below.

Parameters left blank are unavaliable.

[Example 1]

5010

[Example 2]

3401

[Example 3]

1450

Parameter 5010 has different meanigs for the T series and M series.

T ool nose radius compensation . . .

Cutter compensation C . . .

T series

M series

DPI is a parameter common to the M and T series, but GSB and GSC

are parameters valid only for the T series.

#7

GSC

#6

GSB

#0

DPI

DPI

T series

M series

The following parameter is provided only for the M series.

T series

F1 digit feed . . .

M series

p–4

Page 10

B–63833EN–1/02

PREFACE

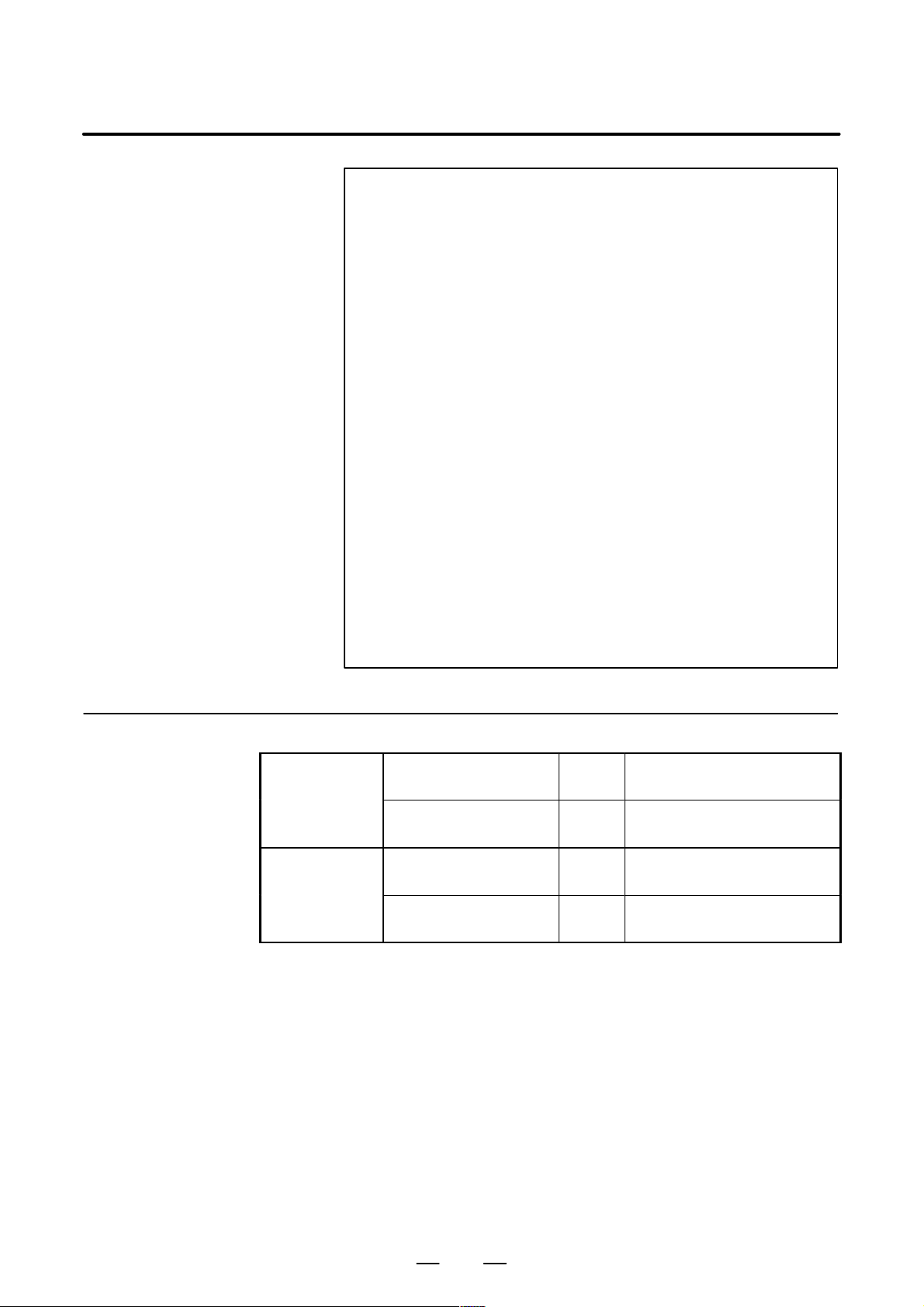

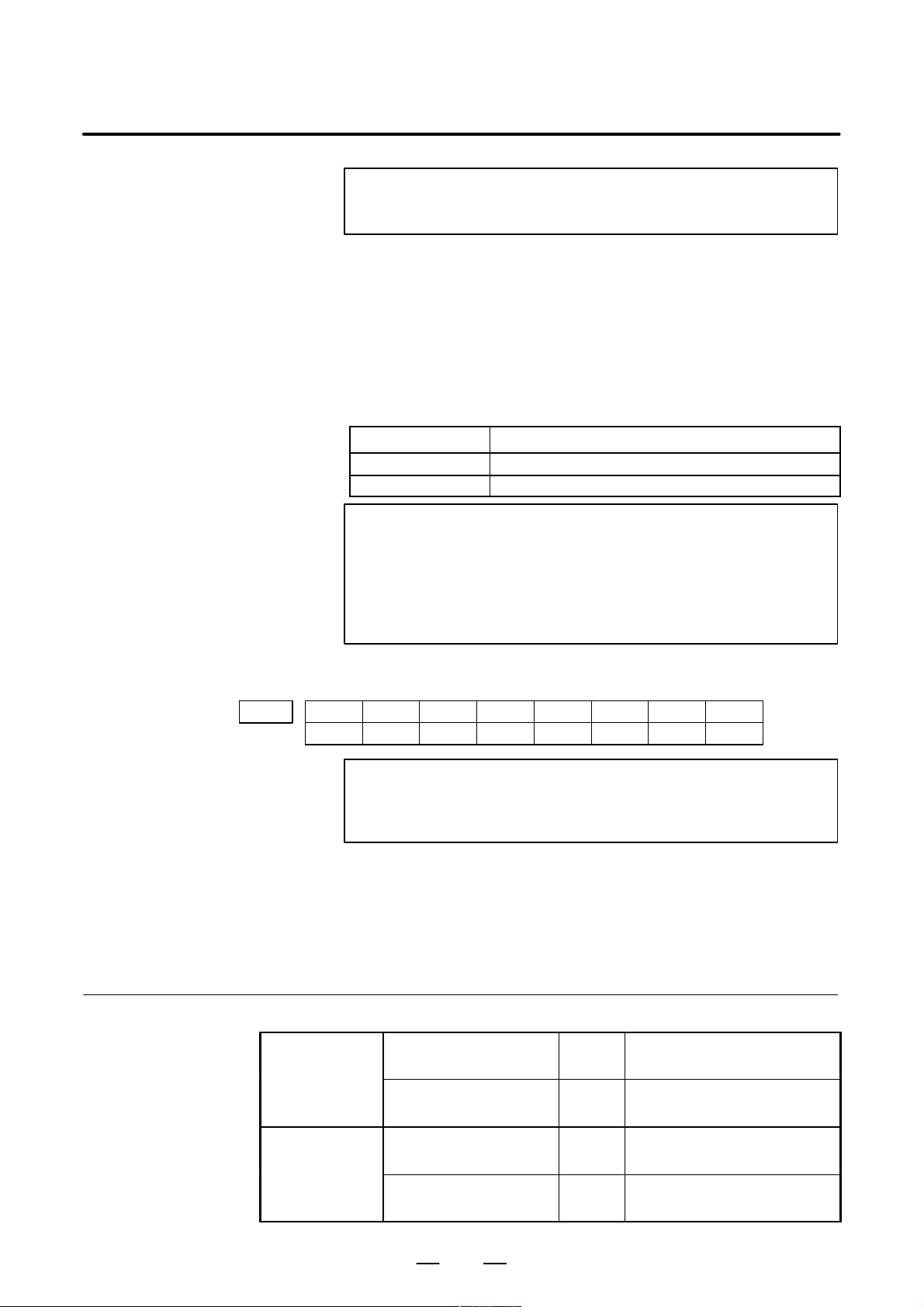

Related manuals of

Series 0i–B/0i Mate–B

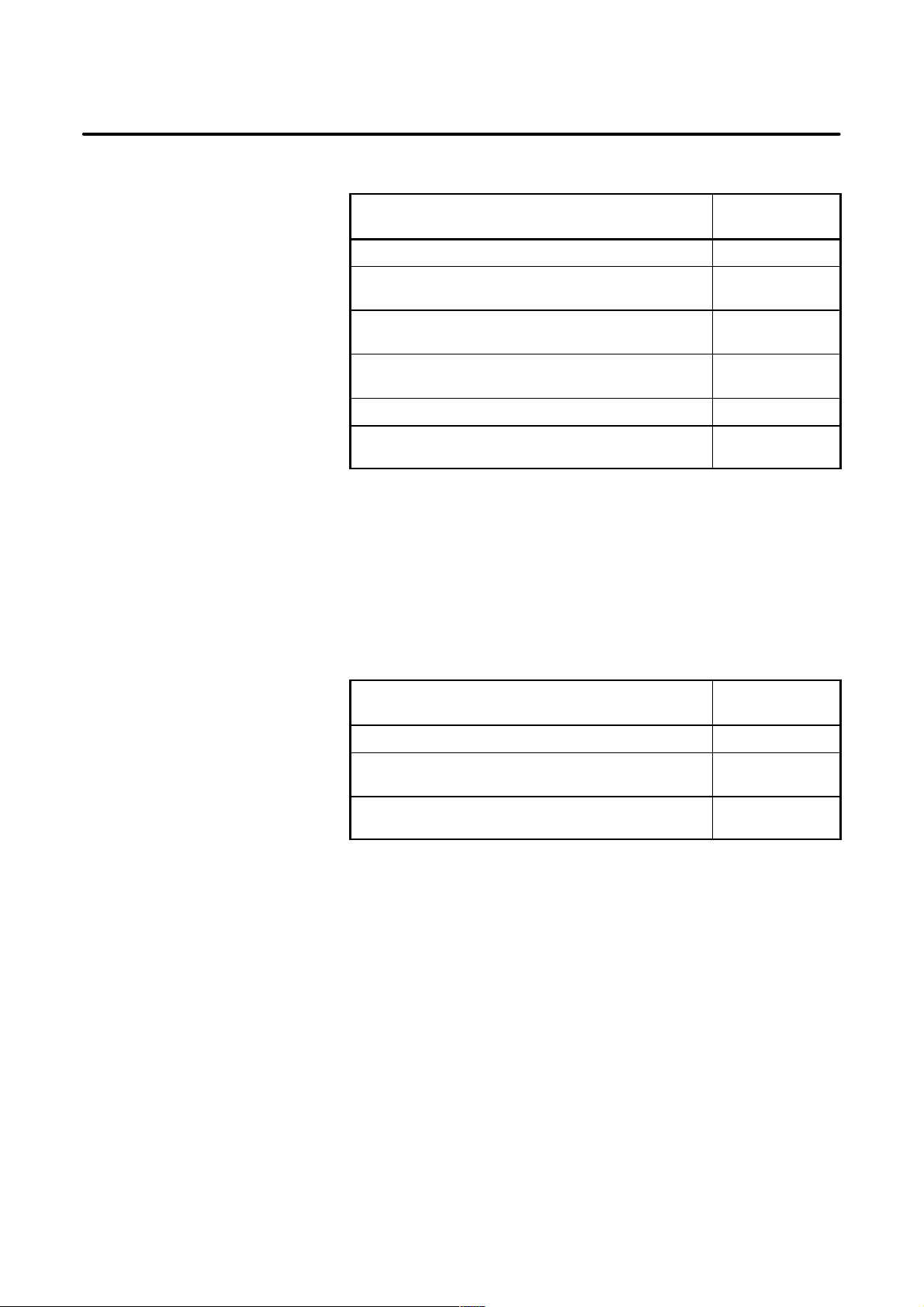

The following table lists the manuals related to Series 0i–B and 0i

Mate–B. This manual is indicated by an asterisk(*).

Manual name

DESCRIPTIONS B–63832EN

CONNECTION MANUAL (HARDWARE) B–63833EN

CONNECTION MANUAL (FUNCTION) B–63833EN–1 *

Series 0i–TB OPERATOR’S MANUAL B–63834EN

Series 0i–MB OPERA T OR’S MANUAL B–63844EN

Series 0i Mate–TB OPERATOR’S MANUAL B–63854EN

Series 0i Mate–MB OPERA T OR’S MANUAL B–63864EN

MAINTENANCE MANUAL B–63835EN

P ARAMETER MANUAL B–63840EN

Programming

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

FANUC MACRO COMPILER

(For Personal Computer)PROGRAMMING MANUAL

Specification

number

B–61803E–1

B–66102E

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUAL B–61863E–1

Network

PROFIBUS–DP Board OPERA T OR’S MANUAL B–62924EN

Ethernet Board/DA T A SERVER Board

OPERA T OR’S MANUAL

FAST Ethernet Board/FAST DAT A SER VER

OPERA T OR’S MANUAL

DeviceNet Board OPERA T OR’S MANUAL B–63404EN

OPEN CNC

FANUC OPEN CNC OPERATOR’S MANUAL

Basic Operation Package 1 (For Windows 95/NT)

FANUC OPEN CNC OPERATOR’S MANUAL

(DNC Operation Management Package)

B–63354EN

B–63644EN

B–62994EN

B–63214EN

p–5

Page 11

PREFACE

B–63833EN–1/02

Related manuals of

Servo Motor ai series

The following table lists the manuals related to Servo Motor ai series

Manual name

FANUC AC SER VO MOTOR ai series DESCRIPTIONS B–65262EN

FANUC AC SER VO MOTOR ai series

P ARAMETER MANUAL

FANUC AC SPINDLE MOT OR ai series

DESCRIPTIONS

FANUC AC SPINDLE MOT OR ai series

P ARAMETER MANUAL

FANUC SER VO AMPLIFIER ai series DESCRIPTIONS B–65282EN

FANUC SER VO MOT OR ai series

MAINTENANCE MANUAL

Specification

number

B–65270EN

B–65272EN

B–65280EN

B–65285EN

Either of the following servo motors and the corresponding spindle can

be connected to the CNC covered in this manual.

D FANUC SERVO MOTOR αi series

This manual mainly assumes that the FANUC SER VO MOT OR αi series

of servo motor is used. For servo motor and spindle information, refer to

the manuals for the servo motor and spindle that are actually connected.

Related manuals of

Servo Motor b series

The following table lists the manuals related to Servo Motor b series

Manual name

FANUC SER VO MOT OR b series DESCRIPTIONS B–65232EN

FANUC SER VO MOT OR b series

MAINTENANCE MANUAL

FANUC SER VO MOT OR b series (I/O Link Option)

DESCRIPTIONS

Specification

number

B–65235EN

B–65245EN

p–6

Page 12

B–63833EN–1/02

Table of Contents

Volume 1

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. AXIS CONTROL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 CONTROLLED AXES 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SETTING EACH AXIS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Name of Axes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Increment System 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Specifying the Rotation Axis 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Outputting the Movement State of an Axis 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Mirror Image 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Follow–up 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Servo Off (Mechanical Handle) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.8 Position Switch 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 ERROR COMPENSATION 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Stored Pitch Error Compensation 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Backlash Compensation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 SETTINGS RELATED TO SERVO–CONTROLLED AXES 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Parameters Related to Servo 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Absolute Position Detection 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 FSSB Setting 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 SETTINGS RELATED WITH COORDINATE SYSTEMS 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Machine Coordinate System 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Workpiece Coordinate System/Addition of Workpiece Coordinate System Pair 66. . . . . . . . . . .

1.5.3 Rotary Axis Roll Over 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 SIMPLE SYNCHRONOUS CONTROL 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 ANGULAR AXIS CONTROL 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PREPARATIONS FOR OPERATION 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 EMERGENCY STOP 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 CNC READY SIGNAL 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 OVERTRAVEL CHECK 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Overtravel Signal 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Stored Stroke Check 1 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Stored Stroke Check 2, 3 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Chuck/Tailstock Barrier (T series) 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 ALARM SIGNAL 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 START LOCK/INTERLOCK 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 MODE SELECTION 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 STATUS OUTPUT SIGNAL 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 VRDY OFF ALARM IGNORE SIGNAL 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 ABNORMAL LOAD DETECTION 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 13

TABLE OF CONTENTS

2.10 SERVO/SPINDLE MOTOR SPEED DETECTION 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63833EN–1/02

3. MANUAL OPERATION 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 JOG FEED/INCREMENTAL FEED 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 MANUAL HANDLE FEED 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 MANUAL HANDLE INTERRUPTION 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. REFERENCE POSITION ESTABLISHMENT 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 MANUAL REFERENCE POSITION RETURN 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SETTING THE REFERENCE POSITION WITHOUT DOGS 188. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 REFERENCE POSITION SHIFT 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 REFERENCE POSITION RETURN 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 2ND REFERENCE POSITION RETURN/3RD, 4TH REFERENCE POSITION RETURN 200. . . . .

4.6 BUTT–TYPE REFERENCE POSITION SETTING 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. AUTOMATIC OPERATION 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CYCLE START/FEED HOLD 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 RESET AND REWIND 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 TESTING A PROGRAM 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Machine Lock 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Dry Run 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Single Block 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 MANUAL ABSOLUTE ON/OFF 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 OPTIONAL BLOCK SKIP/ADDITION OF OPTIONAL BLOCK SKIP 233. . . . . . . . . . . . . . . . . . . .

5.6 SEQUENCE NUMBER COMPARISON AND STOP 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 PROGRAM RESTART 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 EXACT STOP/EXACT STOP MODE/TAPPING MODE/CUTTING MODE (M SERIES) 241. . . . . .

5.9 DNC OPERATION 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 MANUAL INTERVENTION AND RETURN 246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 RETRACTION FOR RIGID TAPPING (M SERIES) 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. INTERPOLATION FUNCTION 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 POSITIONING 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 LINEAR INTERPOLATION 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 CIRCULAR INTERPOLATION 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 THREAD CUTTING 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Thread Cutting 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Thread Cutting Cycle Retract (T series) 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 SINGLE DIRECTION POSITIONING 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 HELICAL INTERPOLATION 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 POLAR COORDINATE INTERPOLATION 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 CYLINDRICAL INTERPOLATION 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 POLYGONAL TURNING (T SERIES) 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.1 Polygonal Turning 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 NORMAL DIRECTION CONTROL (M SERIES) 296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 LINEAR INTERPOLATION (G28, G30, G53) 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 14

B–63833EN–1/02

TABLE OF CONTENTS

7. FEEDRATE CONTROL/ACCELERATION AND DECELERATION CONTROL 304. . . . .

7.1 FEEDRATE CONTROL 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Rapid Traverse Rate 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Cutting Feedrate Clamp 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Feed Per Minute 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Feed Per Revolution/Manual Feed Per Revolution 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 F1-digit Feed (M series) 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6 Override 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6.1 Rapid traverse override 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6.2 Feedrate override 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6.3 Override cancel 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.7 Automatic Corner Override (M series) 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.8 External Deceleration 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.9 Feedrate Clamping by Arc Radius (M series) 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.10 Automatic Corner Deceleration 333. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.11 Advanced Preview Control 341. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.12 AI Advanced Control (M Series) 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 ACCELERATION/DECELERATION CONTROL 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Automatic Acceleration/Deceleration 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.1 Automatic acceleration/deceleration 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1.2 Rapid traverse block overlap 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Rapid Traverse Bell–shaped Acceleration/Deceleration 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Linear Acceleration/Deceleration after Cutting Feed Interpolation 390. . . . . . . . . . . . . . . . . . . .

7.2.4 Corner Control 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4.1 In–position check 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4.2 In–position check independently of feed/rapid traverse 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4.3 Error detect (T series) 397. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.5 Feed Forward in Rapid Traverse 399. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. AUXILIARY FUNCTION 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 MISCELLANEOUS FUNCTION/2ND AUXILIARY FUNCTION 401. . . . . . . . . . . . . . . . . . . . . . . . .

8.2 AUXILIARY FUNCTION LOCK 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 MULTIPLE M COMMANDS IN A SINGLE BLOCK 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 HIGH–SPEED M/S/T/B INTERFACE 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SPINDLE SPEED FUNCTION 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 SPINDLE SPEED FUNCTION (S CODE OUTPUT) 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SPINDLE SERIAL OUTPUT/SPINDLE ANALOG OUTPUT 425. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 SPINDLE SPEED CONTROL 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 CONSTANT SURFACE SPEED CONTROL 462. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 SPINDLE SPEED FLUCTUATION DETECTION 468. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 ACTUAL SPINDLE SPEED OUTPUT (T SERIES) 473. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 SPINDLE POSITIONING (T SERIES) 474. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 Cs CONTOUR CONTROL 495. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 MULTI–SPINDLE CONTROL 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10 RIGID TAPPING 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 15

TABLE OF CONTENTS

9.10.1 General 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.2 Connection Among Spindle, Spindle Motor, and Position Coder 527. . . . . . . . . . . . . . . . . . . . . .

9.10.3 Rigid Tapping Specification 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.4 Display Data on the Diagnosis Screen 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.5 Command Format 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6 Signal 541. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.1 Signals for the rigid tapping function 541. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.2 Signals related to S code output 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.3 Signals related to gear switching 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.4 Signals related to second spindle rigid tapping 545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.5 Signal addresses 547. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.6.6 Notes on interface with the PMC 547. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.7 Timing Charts for Rigid Tapping Specification 550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.7.1 When M29 is specified before G84 (G74) 551. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.7.2 M29 and G84 (G74) are specified in the same block 555. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.7.3 Specifying G84 (G74) for rigid tapping by parameters 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.7.4 Timing to cancel rigid tapping mode 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.8 Parameter 565. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.9 Alarm and Message 588. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.10 Notes 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 SPINDLE SYNCHRONOUS CONTROL 594. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12 SPINDLE ORIENTATION 598. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13 SPINDLE OUTPUT SWITCHING 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63833EN–1/02

Volume 2

10. TOOL FUNCTIONS 603. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 TOOL FUNCTION 604. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 TOOL COMPENSATION VALUE/T OOL COMPENSATION NUMBER/

TOOL COMPENSATION MEMORY 607. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Tool Compensation Value/Tool Compensation Number/Tool Compensation Memory 607. . . . . .

10.3 TOOL LIFE MANAGEMENT 614. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 Tool life management 614. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.2 Tool Life Arrival Notice Signal (M Series) 623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 CUTTER COMPENSATION 624. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 Cutter Compensation C (M Series) 624. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 Tool Nose Radius Compensation (T Series) 629. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. PROGRAM COMMAND 633. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 DECIMAL POINT PROGRAMMING/

POCKET CALCULATOR TYPE DECIMAL POINT PROGRAMMING 634. . . . . . . . . . . . . . . . . . . .

11.2 G CODE SYSTEM (T SERIES) 636. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 PROGRAM CONFIGURATION 642. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 INCH/METRIC CONVERSION 645. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 CUSTOM MACRO 649. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 16

B–63833EN–1/02

11.5.1 Custom Macro 649. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.2 Interruption Type Custom Macro 659. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 CANNED CYCLE (M SERIES)/CANNED CYCLE FOR DRILLING (T SERIES) 663. . . . . . . . . . .

11.7 EXTERNAL MOTION FUNCTION (M SERIES) 674. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8 CANNED CYCLE (T SERIES)/MULTIPLE REPETITIVE CANNED CYCLE (T SERIES) 676. . . .

11.9 INDEX TABLE INDEXING FUNCTION (M SERIES) 684. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.10 SCALING (M SERIES) 693. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.11 COORDINATE SYSTEM ROTATION 697. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.12 MACRO COMPILER/ EXECUTER 700. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.13 SMALL HOLE PECK DRILLING CYCLE (M SERIES) 701. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

12. DISPLAY/SET/EDIT 708. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 DISPLAY/SET 709. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.1 Clock Function 709. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.2 Displaying Operation History 710. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.3 Help Function 715. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.4 Displaying Alarm History 716. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.5 Servo Tuning Screen 717. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.6 Spindle Setting and Tuning Screen 717. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.7 Waveform Diagnosis Display 718. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.8 Self–diagnosis 720. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.9 Display of Hardware and Software Configuration 721. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.10 Position Display Neglect 722. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.11 Run Hour and Parts Count Display 723. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.12 Graphic Display/Dynamic Graphic Display 729. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.13 Displaying Operating Monitor 735. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.14 Software Operator ’s Panel 737. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.15 Multi–language Display 747. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.16 Remote Diagnosis 748. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.17 External Operator Message Logging and Display 750. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.18 Erase Screen Display/Automatic Erase Screen Display 751. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.19 Touch Panel 754. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.20 Periodic Maintenance Screen 758. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.21 Actual Speed Display 767. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1.22 Other Functions 768. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 EDIT 769. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.1 Part Program Storage Length 769. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.2 No. of Registered Programs 770. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.3 Memory Protection Key 770. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.4 Password Function 772. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.5 Background Editing 774. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.6 Playback 775. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.7 Conversational Programming with Graphic Function 776. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. INPUT/OUTPUT OF DATA 777. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 READER/PUNCHER INTERFACE 778. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 DNC2 INTERFACE 789. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 17

TABLE OF CONTENTS

13.3 EXTERNAL I/O DEVICE CONTROL 790. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 EXTERNAL PROGRAM INPUT 797. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 DATA INPUT/OUTPUT FUNCTIONS BASED ON THE I/O Link 802. . . . . . . . . . . . . . . . . . . . . . . .

B–63833EN–1/02

14. MEASUREMENT 827. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOOL LENGTH MEASUREMENT (M SERIES) 828. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 AUTOMATIC TOOL LENGTH MEASUREMENT (M SERIES)/

AUTOMATIC TOOL OFFSET (T SERIES) 829. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 SKIP FUNCTION 836. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.1 Skip Function 836. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.2 High–speed Skip Signal 839. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.3 Multi–step Skip 842. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.4 Torque Limit Skip 847. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 ENTERING COMPENSATION VALUES 850. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.1 Input of Offset Value Measured A (T series) 850. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.2 Input of Tool Offset Value Measured B (T series) 852. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.3 Input of Measured Workpiece Origin Offsets 871. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15. PMC CONTROL FUNCTION 872. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 PMC AXIS CONTROL 873. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1.1 PMC Axis Control 873. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1.2 PMC Axis Control Expansion 920. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 EXTERNAL DATA INPUT 925. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 EXTERNAL WORKPIECE NUMBER SEARCH 937. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3.1 External Workpiece Number Search 937. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3.2 Expanded External Workpiece Number Search 940. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 SPINDLE OUTPUT CONTROL BY THE PMC 942. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 EXTERNAL KEY INPUT 949. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6 DIRECT OPERATION BY PMC OR OPEN CNC 955. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.1 DNC Operation by the PMC or OPEN CNC (PC with HSSB Connection) 955. . . . . . . . . . . . . . .

16. INTERFACE WITH THE POWER MATE CNC 956. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 FANUC SERVO MOTOR b SERIES I/O LINK OPTION

MANUAL HANDLE INTERFACE (PERIPHERAL DEVICE CONTROL) 957. . . . . . . . . . . . . . . . . .

17. PCMCIA ETHERNET FUNCTION 961. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 PCMCIA ETHERNET 962. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 SETTING THE PCMCIA ETHERNET FUNCTION 963. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.1 Ethernet Parameter Setting Screen 963. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2.2 Communication Parameter Input Method 966. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 PCMCIA ETHERNET ERROR MESSAGE SCREEN 968. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.4 PCMCIA ETHERNET MAINTENANCE SCREEN 970. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 TROUBLESHOOTING 975. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5.1 Check Items Related to Connection 975. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5.2 Checking the Setting of Each Parameter 975. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5.3 Checking Communication 976. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 18

B–63833EN–1/02

17.6 ERROR MESSAGES 979. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.6.1 EMB_ETH MASTER CTRL LOG Screen 979. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.6.2 EMB_ETH FOCAS1/ETHER LOG Screen 980. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.7 GLOSSARY FOR ETHERNET 981. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

APPENDIX

A. INTERFACE BETWEEN CNC AND PMC 985. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ADDRESSES 986. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.1 Series 0i/0i Mate Address List 986. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 SIGNAL SUMMARY 1014. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1 Signal Summary (In Order of Functions) 1014. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 List of Signals (In Order of Symbols) 1030. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.3 List of Signals (In Order of Addresses) 1045. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 19

Page 20

B–63833EN–1/02

1

1. AXIS CONTROL

AXIS CONTROL

1

Page 21

1. AXIS CONTROL

1.1

CONTROLLED AXES

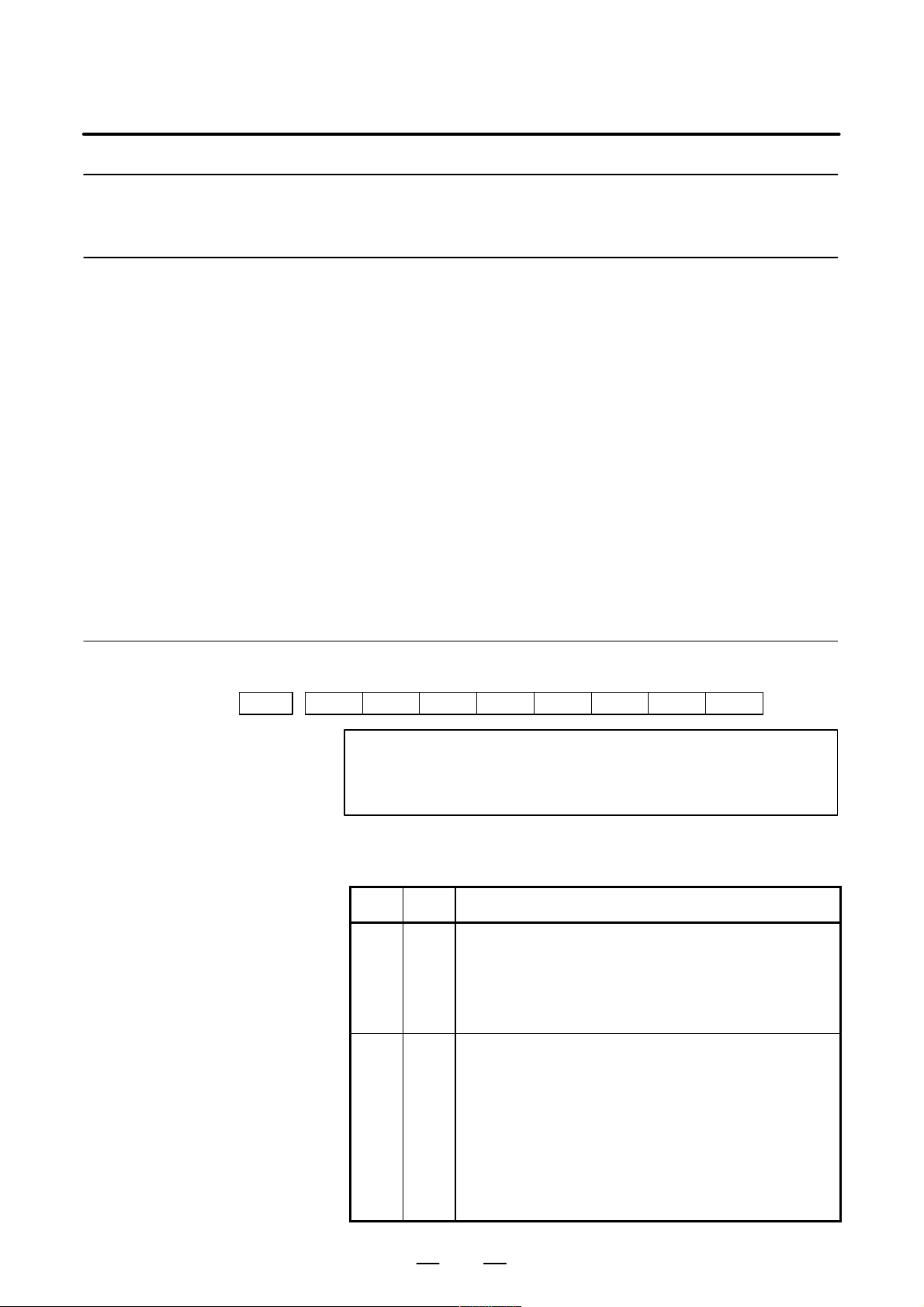

General

B–63833EN–1/02

Series 0i–B

Series 0i Mate–B

Item M series T series

Controlled path 1 path 1 path

Controlled axes 4 axes 2 axes

Simultaneously

controlled axes

Axis control by PMC Max. simultaneous 4

Cs contouring control 1 axis 1 axis

Item M series T series

Controlled path 1 path 1 path

Controlled axes 3 axes 2 axes

Simultaneously

controlled axes

Axis control by PMC – –

Cs contouring control – –

Max. 4 axes Max. 4 axes

Max. simultaneous 4

axes (Not available on

Cs axis)

Max. 3 axes Max. 2 axes

axes (Not available on

Cs axis)

Parameter

1010 Number of CNC–controlled axes

NOTE

After setting this parameter, turn the power of f then on again

so that the setting will take effect.

[Data type] Byte

[Valid data range] 1, 2, 3, ..., the number of controlled axes

Set the maximum number of axes that can be controlled by the CNC.

[Example] Suppose that the first axis is the X axis, and the second and subsequent

axes are the Y, Z, and A axes in that order, and that they are controlled as

follows:

X, Y, and Z axes: Controlled by the CNC and PMC

A axis: Controlled by the PMC (cannot be controlled directly by the

CNC)

Then set this parameter to 3 (total 3: X, Y, and Z)

2

Page 22

B–63833EN–1/02

Alarm and message

1. AXIS CONTROL

Number Message Description

Reference item

Series 0i–B

Series 0i Mate–B

015

TOO MANY AXES COMMANDED

TOO MANY AXES

COMMANDED

OPERATOR’S MANUAL

(M series) (B–63844EN)

OPERATOR’S MANUAL

(T series) (B–63834EN)

OPERATOR’S MANUAL

(M series) (B–63864EN)

OPERATOR’S MANUAL

(T series) (B–63854EN)

The number of the commanded axes

(M series)

(T series)

exceeded that of simultaneously controlled axes. Correct the program.

An attempt was made to move the machine along the axes, but the number of

the axes exceeded the specified number of axes controlled simultaneously.

Alternatively, in a block where the skip

function activated by the torque–limit

reached signal (G31 P99/P98) was

specified, either moving the machine

along an axis was not specified, or

moving the machine along multiple

axes was specified. Specify movement

only along one axis.

II.2.1 Controlled Axes

II.2.1 Controlled Axes

II.2.1 Controlled Axes

II.2.1 Controlled Axes

3

Page 23

1. AXIS CONTROL

1.2

SETTING EACH AXIS

1.2.1

Name of Axes

B–63833EN–1/02

General

Parameter

Each axis that is controlled by the CNC (including those controlled by the

PMC) must be named. Select and set names from among X, Y, Z, A, B,

C, U, V, and W (with parameter 1020).

The names of the basic axes, however, are fixed (X, Y, and Z for the M

series and X and Z for the T series). The names of additional axes can be

selected, as desired, from the names other than those for the basic axes.

The same name cannot be assigned to more than one axis.

1020 Name of the axis used for programming for each axis

[Data type] Byte axis

Set the name of the program axis for each control axis, with one of the

values listed in the following table:

Axis

name

Setting Axis

name

X 88 U 85 A 65 E 69

Y 89 V 86 B 66

Z 90 W 87 C 67

Setting Axis

name

Setting Axis

Setting

name

4

Page 24

B–63833EN–1/02

1. AXIS CONTROL

NOTE

1 With the T series, when G code system A is used, neither

U, V , nor W can be used as an axis name. Only when G code

system B or C is used, U, V, and W can be used as axis

names.

2 The same axis name cannot be assigned to more then one

axis.

3 When the secondary auxilliary function (option) is provided,

the address used by the secondary auxilliary function

(address B with the T series or, with the M series, the

address specified in parameter No.3460) cannot be used as

an axis name.

4 With the T series, when address C or A is used for direct

drawing dimension programming (when the CCR

parameter (bit 4 of parameter No.3405) is set to 1),

addresses C or A cannot be used as an axis name.

5 Only with the T series, address E can be used as an axis

name. Address E cannot be used with the M series. When

address E is used as an axis name, note the following:

– When G code system A is used, address E is always

assigned to an absolute command.

– When an equal–lead threading command (G32) is

issued in the FS10/11 tape format. Use address F to

specify the thread lead.

Reference item

Series 0i–B

Series 0i Mate–B

OPERATOR’S MANUAL

(M series) (B–63844EN)

OPERATOR’S MANUAL

(T series) (B–63834EN)

OPERATOR’S MANUAL

(M series) (B–63864EN)

OPERATOR’S MANUAL

(T series) (B–63854EN)

II.2.2 NAMES OF AXES

II.2.2 NAMES OF AXES

II.2.2 NAMES OF AXES

II.2.2 NAMES OF AXES

5

Page 25

1. AXIS CONTROL

machine

machine

machine

machine

1.2.2

Increment System

B–63833EN–1/02

General

The increment system consists of the least input increment (for input ) and

least command increment (for output). The least input increment is the

least increment for programming the travel distance. The least command

increment is the least increment for moving the tool on the machine. Both

increments are represented in mm, inches, or degrees.

The increment system is classified as either IS–B or IS–C (Tables 1.2.2(a)

and 1.2.2 (b)). Select IS–B or IS–C using bit 1 (ISC) of parameter 1004.

Table 1.2.2 (a) Increment system IS–B

Least input increment Least command increment

Metric mm 0.001mm(Diameter) 0.0005mm

system

machine

Inch mm 0.001mm(Diameter) 0.00005inch

system

machine

input

inch 0.0001inch(Diameter) 0.0005mm

input

input

inch 0.0001inch(Diameter) 0.00005inch

input

0.001mm(Radius) 0.001mm

0.001deg 0.001deg

0.0001inch(Radius) 0.001mm

0.001deg 0.001deg

0.001mm(Radius) 0.0001inch

0.001deg 0.001deg

0.0001inch(Radius) 0.0001inch

0.001deg 0.001deg

Table 1.2.2 (b) Increment system IS–C

Least input increment Least command increment

Metric mm 0.0001mm(Diameter) 0.00005mm

system

machine

Inch mm 0.0001mm(Diameter) 0.000005inch

system

machine

input

inch 0.00001inch(Diameter) 0.00005mm

input

input

inch 0.00001inch(Diameter) 0.000005inch

input

0.0001mm(Radius) 0.0001mm

0.0001deg 0.0001deg

0.00001inch(Radius) 0.0001mm

0.0001deg 0.0001deg

0.0001mm(Radius) 0.00001inch

0.0001deg 0.0001deg

0.00001inch(Radius) 0.00001inch

0.0001deg 0.0001deg

6

Page 26

B–63833EN–1/02

Parameter

1. AXIS CONTROL

NOTE

Diameter programming is used only for T series. Diameter

programming or radius programming is determined by

parameter DIAx (No. 1006#3) for each axis. Also,

parameter IPR (No. 1004#7) can make the least input

increment of IS–B and IS–C ten times the least command

increment on each axis.

#7 #6 #5 #4 #3 #2 #1 #0

0000 INI

The following parameter can be set at “Setting screen”.

[Data type] Bit

INI Unit of input

0 : In mm

1 : In inches

#7 #6 #5 #4 #3 #2 #1 #0

1001 INM

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

INM Least command increment on the linear axis

0 : In mm (metric system machine)

1 : In inches (inch system machine)

#7 #6 #5 #4 #3 #2 #1 #0

IPR1004

IPR

ISC

ISC ISA

NOTE

After setting this parameter, turn the power of f then on again

so that the setting will take effect.

[Data type] Bit

ISA, ISC The least input increment and least command increment are set.

ISC ISA Least input increment and

least command increment

0 0 0.001mm, 0.001deg, or 0.0001inch IS-B

0 1 0.01mm, 0.01deg, or 0.001inch IS-A

1 0 0.0001mm, 0.0001deg, or 0.00001inch IS-C

7

Symbol

Page 27

1. AXIS CONTROL

B–63833EN–1/02

NOTE

IS–A is not available.

IPR Whether the least input increment for each axis is set to a value 10 times as

large as the least command increment is specified, in increment systems

of IS–B and IS–C, mm input.

0 : The least input increment is not set to a value 10 times as large as the

least command increment.

1 : The least input increment is set to a value 10 times as large as the least

command increment.

If IPR is set to 1, the least input increment is set as follows:

Input increment Least input increment

IS-B 0.01 mm, 0.01 deg, or 0.0001 inch

IS-C 0.001 mm, 0.001 deg, or 0.00001 inch

NOTE

For IS–A, the least input increment cannot be set to a value

10 times as large as the least command increment.

When inch of input is specified, the least input increment

does not become 10 times as large as the least command

increment.

Reference item

#7 #6 #5 #4 #3 #2 #1 #0

1006 DIAx

NOTE

When this parameter is changed, turn off the power before

continuing operation.

[Data type] Bit axis

DIAx Either a diameter or radius is set to be used for specifying the amount of

travel on each axis.

0 : Radius

1 : Diameter

OPERATOR’S MANUAL

(M series) (B–63844EN)

Series 0i–B

OPERATOR’S MANUAL

(T series) (B–63834EN)

OPERATOR’S MANUAL

(M series) (B–63864EN)

Series 0i Mate–B

OPERATOR’S MANUAL

(T series) (B–63854EN)

II.2.3 Increment System

II.2.3 Increment System

II.2.3 Increment System

II.2.3 Increment System

8

Page 28

B–63833EN–1/02

1.2.3

Specifying the Rotation

Axis

1. AXIS CONTROL

General

Parameter

Bit 0 (ROTx) of parameter 1006 can be used to set each axis to a linear

axis or rotation axis. Bit 1 (ROSx) of parameter 1006 can be used to select

the rotation axis type, A or B, for each axis. See the explanation of the

parameters for details of types A and B.

When the roll over function is used, the values displayed for absolute

coordinates are rounded by the shift amount per rotation, as set in

parameter No. 1260. This can prevent coordinates for the rotation axis

from overflowing. Displayed values for relative coordinates are also

rounded by the angle corresponding to one rotation when bit 2 (RRLx) of

parameter No. 1008 is set to 1. The roll–over function is enabled by

setting bit 0 (ROAx) of parameter 1008 to 1.

For an absolute command, the coordinates after the tool has moved are

values rounded by the angle corresponding to one rotation set in

parameter No. 1260. The tool moves in the direction in which the final

coordinates are closest when bit 1 of parameter No. 1008 is set to 0. For

an incremental command, the tool moves the angle specified in the

command.

#7 #6 #5 #4 #3 #2 #1 #0

1006 ROSx ROTx

NOTE

After setting this parameter, turn the power of f then on again

so that the setting will take effect.

[Data type] Bit axis

ROTx, ROSx Setting linear or rotation axis.

ROSx ROTx Meaning

0 0 Linear axis

(1) Inch/metric conversion is done.

(2) All coordinate values are linear axis type.

(Not rounded in 0 to 360°)

(3) Stored pitch error compensation is linear axis type

(Refer to parameter No. 3624)

0 1 Rotation axis (A type)

(1) Inch/metric conversion is not done.

(2) Machine coordinate values are rounded in 0 to 360_. Ab-

solute coordinate values and relative coordinate values

are rounded or not rounded by parameter No. 1008#0

and #2.

(3) Stored pitch error compensation is the rotation type. (Re-

fer to parameter No. 3624)

(4) Automatic reference position return (G28, G30) is done in

the reference position return direction and the move

amount does not exceed one rotation.

9

Page 29

1. AXIS CONTROL

B–63833EN–1/02

ROSx MeaningROTx

1 0 Setting is invalid (unused)

1 1 Rotation axis (B type)

(1) Inch/metric conversion is not done.

(2) Machine coordinate values, absolute coordinate values

and relative coordinate values are linear axis type. (Is not

rounded in 0 to 360_)

(3) Stored pitch error compensation is linear axis type (Refer

to parameter No. 3624)

(4) The rotation axis roll over function and index table index-

ing function (M series) cannot be used.

#7 #6 #5 #4 #3 #2 #1 #0

1008 RRLx RABx ROAx

NOTE

After setting this parameter, turn the power of f then on again

so that the setting will take effect.

[Data type] Bit axis

ROAx The roll–over function of a rotation axis is

0 : Invalid

1 : Valid

NOTE

ROAx specifies the function only for a rotation axis (for

which ROTx, #0 of parameter No. 1006, is set to 1)

RABx In the absolute commands, the axis rotates in the direction

0 : In which the distance to the target is shorter.

1 : Specified by the sign of command value.

NOTE

RABx is valid only when ROAx is 1.

RRLx Relative coordinates are

0 : Not rounded by the amount of the shift per one rotation

1 : Rounded by the amount of the shift per one rotation

NOTE

1 RRLx is valid only when ROAx is 1.

2 Assign the amount of the shift per one rotation in parameter

No. 1260.

10

Page 30

B–63833EN–1/02

1. AXIS CONTROL

1260 Amount of a shift per one rotation of a rotation axis

NOTE

1 After setting the parameter, turn off the power once and turn

it on again to operate the machine.

2 This parameter is valid only when ROAx = 1.

[Data type] Two–word axis

[Valid data range] 1000 to 9999999

Note

Reference item

[Unit of data]

Series 0i–B

Increment system Unit of data Standard value Unit

IS–A 0.01 36000

IS–B 0.001 360000

IS–C 0.0001 3600000

deg

Set the amount of a shift per one rotation of a rotation axis.

NOTE

Rotary axis roll–over function cannot be used together with

the indexing function of the index table.

OPERATOR’S MANUAL

(M series) (B–63844EN)

OPERATOR’S MANUAL

(T series) (B–63834EN)

II.20.2 Rotary Axis Roll–over

II.18.2 Rotary Axis Roll–over

11

Page 31

1. AXIS CONTROL

1.2.4

Outputting the

Movement State of an

Axis

B–63833EN–1/02

General

Signal

Axis moving signals

MV1 – MV4 <F102>

[Classification] Output signal

[Output condition] The signals turn to “1” in the following cases:

The movement state of each axis can be output to the PMC.

[Function] These signals indicate that a control axis is moving.

The signals are provided for each control axis, and the number in the

signal name corresponds to the control axis number.

MV 1

1 ..... The 1st axis is moving.

2 ..... The 2nd axis is moving.

3 ..... The 3rd axis is moving.

::

::

. The corresponding axis has started moving.

. In manual handle feed mode, the handle feed axis of the corresponding

axis has been selected.

The signals turn to “0” in the following case:

. When the move command for the corresponding axis has been

distributed (when bit 6 (MVX) of parameter 3003 is 0)

. When deceleration for the corresponding axis has been completed and

the axis is set to the in–position condition. If in–position check is not

performed, when the deceleration for the corresponding axis is

completed. (When bit 6 (MVX) of parameter 3003 is 1)

Setting 1 in bit 7 (MVG) of parameter 3003 prevents these signals from

being output during drawing in dynamic graphics mode (drawing without

movement of the machine) in the T system.

12

Page 32

B–63833EN–1/02

Axis moving direction

signals

MVD1 – MVD4 <F106>

[Classification] Output signal

[Function] These signals indicate the movement direction of control axis.

[Output condition] “1” indicates the corresponding axes are moving in the minus direction,

1. AXIS CONTROL

They are provided for each control axis, and the number in the signal name

corresponds to the control axis number.

MVD 1

1 ..... The moving direction of the 1st axis is minus.

2 ..... The moving direction of the 2nd axis is minus.

3 ..... The moving direction of the 3rd axis is minus.

::

::

and “0” indicates they are moving in the plus direction.

CAUTION

These signals maintain their condition during a stop,

indicating the direction of the axes’ movement before

stopping.

Signal address

F102 MV4 MV3 MV2 MV1

F106 MVD4 MVD3 MVD2 MVD1

Parameter

D Setting the output format

of the axis moving signal

[Data type] Bit

MVX The axis moving signal is set to 0 when:

MVG While drawing using the dynamic graphics function (with no machine

#7 #6 #5 #4 #3 #2 #1 #0

#7 #6

MVG3003 MVX

MVX

#5 #4 #3 #2 #1 #0

0 : Distribution for the axis is completed. (The signal is set to 0 in

deceleration.)

1 : Deceleration of the axis is terminated, and the current position is in the

in–position.

When the deceleration–time in–position check is suppressed by

setting bit 5 (NCI) of parameter No. 1601, the signal is set to 0 at the

end of deceleration.

movement), the axis moving signal is:

0: Output

1: Not output

13

Page 33

1. AXIS CONTROL

Caution

1.2.5

Mirror Image

B–63833EN–1/02

CAUTION

Axis moving signals and axis moving direction signals are

output in both automatic and manual operations.

General

Mirror image can be applied to each axis, either by signals or by

parameters (setting input is acceptable). All movement directions are

reversed during automatic operation along axes to which a mirror image

is applied.

X

A

0

When MI1 signal turned to “1” at point A

Mirror image (Example for T series)

B

B’

Z

However, the following directions are not reversed:

– Direction of manual operation and direction of movement, from the

intermediate position to the reference position during automatic

reference position return (for the M and T series)

– Approach direction for single direction positioning (G60) and shift

direction for boring cycles (G76 and G87) (for M series only)

Signal

Mirror image signal

MI1 – MI4 <G106>

[Classification] Input signal

Mirror image check signals indicate whether mirror image is applied to

each axis. System variable #3007 contains the same information (refer

to the operator’s manual).

[Function] Apply mirror image to the specified axes.

[Operation] Apply mirror image to those axes for which the signals are 1.

These signals are provided for the controlled axes on a one–to–one basis.

A number appended to a signal represents the controlled axis number.

14

Page 34

B–63833EN–1/02

Mirror image check

signal

MMI1 – MMI4<F108>

1. AXIS CONTROL

MI 1

1 ..... Applies mirror image to the 1st axis.

2 ..... Applies mirror image to the 2nd axis.

3 ..... Applies mirror image to the 3rd axis.

::

::

The mirror image signal can be turned to “1” in the following cases:

a) During offset cancel;

b) When the CNC is in the automatic operation stop state and not in the

feed hold state.

[Classification] Output signal

[Function] These signals indicate the mirror image condition of each axis. The mirror

image is set by taking the logical sum of the signal from the MDI panel

and the input signal of the machine tool, then relaying the information to

the machine tool.

These signals are provided for every control axis; the numeral in the signal

name indicates the relevant control axis number.

MMI 1

1 ..... Mirror image is applied to the 1st axis

2 ..... Mirror image is applied to the 2nd axis

3 ..... Mirror image is applied to the 3rd axis

::

::

[Output condition] These signals turn to “1” when:

· Mirror image signal MIn of the corresponding axis is “1”; or

· Mirror image of the corresponding axis is turned on by setting data

from the MDI panel.

These signals turn to “0” when:

· Mirror image signal (MIn) of the corresponding axis is “0” and the

setting of the mirror image in the control unit is turned off.

Signal address

#7 #6 #5 #4 #3 #2 #1 #0

G106 MI4 MI3 MI2 MI1

#7 #6 #5 #4 #3 #2 #1 #0

F108 MMI4 MMI3 MMI2 MMI1

15

Page 35

1. AXIS CONTROL

Parameter

Warning

B–63833EN–1/02

#7 #6 #5 #4 #3 #2 #1 #0

0012 MIRx

The following parameter can be set at “Setting screen.”

[Data type] Bit axis

MIRx Mirror image for each axis

0 : Mirror image is off.

1 : Mirror image is on.

WARNING

1 When programmable mirror image (M series) and ordinary

mirror image are specified at the same time, programmable

mirror image is applied first.

2 No programmable mirror image (M series) affects mirror

image check signals MMI1 to MMI4 <F108>.

Caution

Reference item

CAUTION

Series 0i–B

Series 0i Mate–B

Even when the mirror image is applied, commands which do

not actuate mirror image (such as automatic reference

position return and manual operation) do not affect mirror

image check signals MMI1 to MMI4 <F108>.

OPERATOR’S MANUAL

(M series) (B–63844EN)

OPERATOR’S MANUAL

(T series) (B–63834EN)

OPERATOR’S MANUAL

(M series) (B–63864EN)

OPERATOR’S MANUAL

(T series) (B–63854EN)

III.4.8 Mirror Image

III.4.7 Mirror Image

III.4.8 Mirror Image

III.4.7 Mirror Image

16

Page 36

B–63833EN–1/02

1.2.6

Follow–up

1. AXIS CONTROL

General

D When follow–up is not

performed for the axes

for which the servo is

turned off

D When follow–up is

performed for the axes

for which the servo is

turned off

When position control is disabled for the controlled axes (when the servo

is off, during emergency stop, or during a servo alarm), if the machine is

moved, a positional error occurs. Follow–up is a function for changing

the current position of the CNC and reseting the error counter to zero.

Assuming a command corresponding to the error has been specified.

You can select whether to perform follow–up for axes when the servo is

turned off.

Follow–up is always performed during emergency stop or a servo alarm.

When signal *FLWU is 1 or bit 0 (FUPx) of parameter 1819 is 1,

follow–up is not performed. The error is added to the error counter as a

servo error. In this case, the machine moves to compensate for the error

when the servo off signal changes to 0.

In general, follow–up is not used if the machine is mechanically clamped

when position control is disabled for the controlled axes.

When *FLWU is “0”, the follow-up function is engaged. The present

position of the CNC is changed to reset the error counter to zero. The

machine tool remains in a deviated position, but since the present position

of the CNC changes correspondingly, the machine moves to the correct

position when the absolute command is next applied.

In general, follow–up should be used when motors are driven by

mechanical handles.

Signal

Follow–up signal

*FLWU <G007#5>

[Classification] Input signal

Signal address

[Function] Select whether to perform follow–up when the servo is turned off for those

axes for which bit 0 (FUPx) of parameter 1819 is 0.

[Operation] 0: Performs follow–up.

1: Does not perform follow–up.

#7 #6 #5 #4 #3 #2 #1 #0

G007 *FLWU

17

Page 37

1. AXIS CONTROL

Parameter

B–63833EN–1/02

#7 #6 #5 #4 #3 #2 #1 #0

1819 FUPx

[Data type] Bit axis

FUPx To perform follow–up when the servo is off for each axis.

0 : The follow–up signal, *FLWU, determines whether follow–up is

performed or not.

When *FLWU is 0, follow–up is performed.

When *FLWU is 1, follow–up is not performed.

1 : Follow–up is not performed.

CAUTION

When the index table indexing function (M series) is used,

be sure to set FUPx of the 4th axis to 1.

Reference item

CONNECTION MANUAL

(This manual)

1.2.7 Servo Off (Mechanical handle)

18

Page 38

B–63833EN–1/02

1.2.7

Servo Off

(Mechanical Handle)

1. AXIS CONTROL

General

Signal

Servo off signal

SVF1 – SVF4 <G126>

[Classification] Input signal

[Function] Select whether to place each axis in the servo off state.

Place the controlled axes in the servo off state, stop the current to the servo

motor, which disables position control. However, the position detection

feature functions continuously, so the current position is not lost.

These signals are used to prevent the servo motors from overloading when

the tools on the axes are mechanically clamped under certain machining

conditions on the machine, or to move the machine by driving the motors

by mechanical handles.

These signals are provided for the controlled axes on a single axis basis.

A number appended to a signal represents a controlled axis number.

SVF 1

Signal address

1 ..... Servo off for the first axis

2 ..... Servo off for the second axis

3 ..... Servo off for the third axis

::

[Operation] These signals put the axes for which the signals are 1 in the servo off state

(the current to the servo motor is stopped). This disables position control.

However, the position detection feature continues to function, so the

current position is not lost.

#7 #6 #5 #4 #3 #2 #1 #0

G126 SVF4 SVF3 SVF2 SVF1

19

Page 39

1. AXIS CONTROL

Caution

B–63833EN–1/02

CAUTION

1 In general, interlock is applied to an axis while the servo off

signal for that axis is 1.

2 When one of these signals turns to “1”, the servo motor is

turned off. The mechanical clamp is done by using the

auxiliary function. Set the timing for the auxiliary function,

mechanical clamp and servo off signals as shown in the

diagram below. The clamp command auxiliary function

should be executed only after the distribution end signal

(DEN) turned to “1”.

Reference item

CONNECTION MANUAL

(This manual)

MF

Machine

clamp

SVF1, ...

FIN

Clamp command

Servo off state

1.2.6 Follow–up

Unclamp command

20

Page 40

B–63833EN–1/02

1.2.8

Position Switch

1. AXIS CONTROL

General

Signal

Position switch signal

PSW01 – PSW16

<F070#0 – F071#7>

[Classification] Output signal

[Function] Indicates that the machine coordinates along the controlled axes specified

[Output condition] These signals are 1 in the following case:

Position switch signals can be output to the PMC while the machine

coordinates along a controlled axes are within a specified ranges.

by parameters (6910 to 6925) are within the ranges specified by

parameters (6930 to 6945 and 6950 to 6965). Up to 16 position switch

signals can be output.

(Using 11 or more position switches requires setting the EPS parameter

(bit 1 of No. 6901.)

· When the machine coordinates along the controlled axes are within the

specified ranges.

Signal address

These signals are 0 in the following case:

· When the machine coordinates along the controlled axes are not within

the specified ranges.

#7 #6 #5 #4 #3 #2 #1 #0

PSW08F070 PSW07 PSW06 PSW05 PSW04 PSW03 PSW02 PSW01

PSW16F071 PSW15 PSW14 PSW13 PSW12 PSW11 PSW10 PSW09

21

Page 41

1. AXIS CONTROL

Parameter

D Increasing the number of

position switch signals

B–63833EN–1/02

#7

6901

[Data type] Bit

IGP During follow–up for the absolute position detector, position switch

EPS The number of position switches is:

PCM Position switch signals are output:

PSF In AI advanced preview control or advanced preview control mode,

#6 #5 #4 #3

PSF

#2

PCM#1EPS

#0

IGP

signals are:

0 : Output

1 : Not output

0 : Up to 10.

1 : Up to 16.

0 : Without considering acceleration/deceleration and servo delay.

1 : With considering acceleration/deceleration and servo delay.

position switches are:

0 : Not used.

1 : Used.

To use the position switches in any of the following modes, set this

parameter:

AI advanced preview control mode or advanced preview control mode

NOTE

The position switch signals are output considering

acceleration/deceleration after interpolation and servo

delay. Acceleration/deceleration after interpolation and

servo delay are considered even for position switch signal

output in a mode other than the AI advanced preview control

and advanced preview control modes. When this

parameter is set to 1, however, signals are output from the

position switches at different times from the specified ones.

22

Page 42

B–63833EN–1/02

D Setting the

correspondence