fanuc 0i A Maintenance Manual

MAINTENANCE MANUAL

B-63505EN/02

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS, CAUTIONS, AND NOTES RELATED TO CHECK OPERATION s–3.

3. WARNINGS AND NOTES RELATED TO REPLACEMENT s–4. . . . . . . . . . . . . . . . .

4. WARNINGS AND NOTES RELATED TO PARAMETERS s–5. . . . . . . . . . . . . . . . . . .

5. WARNINGS RELATED TO DAILY MAINTENANCE s–6. . . . . . . . . . . . . . . . . . . . . . . .

s–1

1

SAFETY PRECAUTIONS

B–63505EN/02

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–2

B–63505EN/02

2

SAFETY PRECAUTIONS

W ARNINGS, CAUTIONS, AND NOTES RELATED TO CHECK OPERA TION

WARNING

1. When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2. When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3. Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

5. Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

mark). Never

6. When using a tool compensation function, thoroughly check the direction and amount of

compensation. Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or machine itself, or

injury to the user.

s–3

3

SAFETY PRECAUTIONS

B–63505EN/02

W ARNINGS AND NOTES RELATED TO REPLACEMENT

WARNING

1. Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2. When a heavy unit is to be replaced, the task must be undertaken by two persons. If the

replacement is attempted by only one person, the replacement unit could slip and fall, possibly

causing injury.

3. After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4. When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury.

s–4

B–63505EN/02

4

SAFETY PRECAUTIONS

W ARNINGS AND NOTES RELATED TO PARAMETERS

WARNING

1. When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally, the machine may move unpredictably, possibly damaging the machine or workpiece,

and presenting a risk of injury.

2. The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

s–5

SAFETY PRECAUTIONS

W ARNINGS RELATED TO DAILY MAINTENANCE

5

WARNING

1. Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

B–63505EN/02

and

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.6 of this manual.

s–6

B–63505EN/02

2. Absolute pulse coder battery replacement

SAFETY PRECAUTIONS

WARNING

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Section 2.6 of this manual.

and

s–7

SAFETY PRECAUTIONS

WARNING

3. Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

B–63505EN/02

s–8

B–63505EN/02

PREFACE

PREFACE

Description of

this manual

This manual consists of following chapters.

1.DISPLAY AND OPERATION

This chapter covers those items, displayed on the screen, that are related

to maintenance. A list of all supported operations is also provided at the

end of this chapter.

2.HARDWARE

This chapter covers hardware–related items, including the hardware

configuration, connection, and NC status indicated on printed circuit

boards. A list of all units is also provided as well as an explanation of how

to replace each unit.

3.INPUT AND OUTPUT OF DATA

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, as well as the input/output

procedures for conversational data.

4.INTERFACE BETWEEN NC AND PMC

This chapter describes the PMC specifications, the system configuration,

and the signals used by the PMC.

5.DIGITAL SERVO

This chapter describes the servo tuning screen and how to adjust the

reference position return position.

6.AC SPINDLE

These chapters describe the spindle amplifier checkpoints, as well as the

spindle tuning screen.

7.TROUBLESHOOTING

This chapter describes the procedures to be followed in the event of

certain problems occurring, for example, if the power cannot be turned on

or if manual operation cannot be performed. Countermeasures to be

applied in the event of alarms being output are also described.

APPENDIX

A. ALARM LIST

B. LIST OF MAINTENANCE PARTS

C. BOOT SYSTEM

D. MEMORY CARD INTERFACE

E. MAINTENANCE OF OPEN CNC (BOOT–UP AND IPL)

This manual does not provide a parameter list. If necessary, refer to the

separate PARAMETER MANUAL (B–63510EN) .

p–1

PREFACE

B–63505EN/02

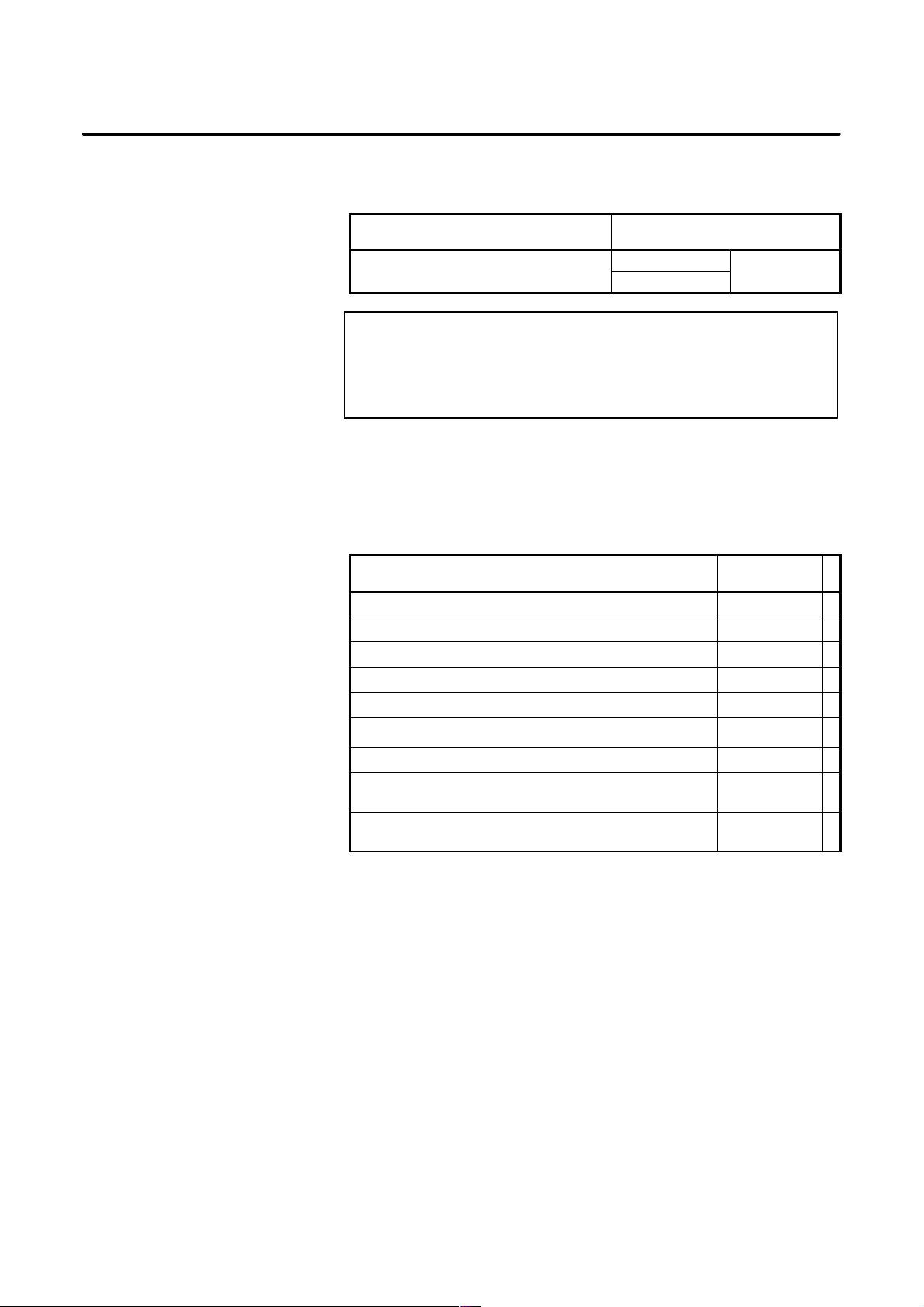

Applicable models

Related manuals

This manual can be used with the following models. The abbreviated

names may be used.

Product Name Abbreviations

FANUC Series 0i–MODEL A

0i–TA

0i–MA

Series 0i

NOTE

Some function described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS (B–63502EN).

The table below lists manuals related to Series 0i.

In the table, this manual is marked with an asterisk(*).

Table 1 Related Manuals

Manual name

DESCRIPTIONS B–63502EN

CONNECTION MANUAL (HARDWARE) B–63503EN

CONNECTION MANUAL (FUNCTION) B–63503EN–1

OPERATOR’S MANUAL FOR LATHE B–63504EN

OPERATOR’S MANUAL FOR MACHINING CENTER B–63514EN

MAINTENANCE MANUAL B–63505EN

PARAMETER MANUAL B–63510EN

MACRO COMPILER/MACRO EXECUTOR

PROGRAMMING MANUAL

FAPT MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

Specification

number

*

B–61803E–1

B–66102E

p–2

B–63505EN/02

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAY AND OPERATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Soft Keys 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER POWER IS TURNED ON 21. . . . . . . . . . . . . . . . .

1.2.1 Loading of Software 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 System Monitor Screen 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Slot Status Display 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Setting Module Screen 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Configuration Display of Software 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Display Method 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Configuration of PCBs 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Software Configuration Screen 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Module Configuration Screen 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 ALARM HISTORY SCREEN 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 General 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Screen Display 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Clearing Alarm History 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4 Alarm Display 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES RECORD 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Screen Display 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Deletion of External Operator Messages Record 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 Parameter 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 Notes 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 OPERATION HISTORY 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Parameter Setting 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Screen Display 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 Setting the Input Signal or Output Signal to be Recorded in the Operation History 33. . . . . . . . . . . . . . .

1.6.4 Inputting and Outputting the Operation History Data 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.5 Notes 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 General 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Display Method 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1 Displaying Diagnostic Page 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.2 Contents Displayed 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVE FORM DIAGNOSTIC FUNCTION 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Setting Parameters 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 Waveform Diagnostic Parameter Screen 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Graphic of Wave Diagnosis data 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Data Sampling for Storage Type Waveform Diagnosis 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.5 Outputting Waveform Diagnosis Data (Storage T ype) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.6 Notes 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11 OPERATING MONITOR 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.1 Display Method 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.2 Parameters 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Table of Contents

B–63505EN/02

1.13 WARNING SCREEN DISPLAYED WHEN AN OPTION IS CHANGED 79. . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15 POWER MATE CNC MANAGER 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.1 Parameter 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.2 Screen Display 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.3 Parameter Input/Output 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15.4 Notes 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 GENERAL OF HANDWARE 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 CONFIGURATION OF PRINTED CIRCUIT BOARD AND LED DISPLAY 94. . . . . . . . . . . . . . . . .

2.2.1 Main PCB 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 I/O Printed Circuit Board 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Power Supply Printed Circuit Board 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 HSSB Interface Board 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4.1 Parts layout 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4.2 System block diagram 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4.3 Configuration switch 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4.4 LED display 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 LIST OF UNIT AND PRINTED CIRCUIT BOARD 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 PC Board in the Control Unit 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Others 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 REPLACING THE PRINTED CIRCUIT BOARD AND MODULES 104. . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Replacing the Printed Circuit Board 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 How to Replace the Modules 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2.1 Removing 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2.2 Insertion 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 REPLACING THE FUSES 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Replacing the Fuses for Power Supply of Control Unit 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Replacing the Fuse for LCD 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 HOW TO REPLACE THE BATTERIES 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Replace the Battery for Memory Back Up 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Replacing Batteries for Separate Absolute Pulse Coder 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Replacing Batteries for Absolute Pulse Coder (α Series Servo Amplifier Module) 112. . . . . . . . . . . . . . . .

2.7 REPLACING THE FAN MOTOR 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Replacing the Fan Motor for Control Unit 1 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 ADJUSTING THE FLAT DISPLAY 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Adjusting the 8.4″ Color LCD 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Adjusting the 7.2″ Monochrome LCD 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.3 Adjusting the 10.4″ Color LCD 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 ENVIRONMENTAL REQUIREMENT 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 POWER SUPPLY 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 ACTION AGAINST NOISE 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.1 Separating Signal Lines 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.2 Ground 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.3 Connecting the Signal Ground (SG) of the Control Unit 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.4 Noise Suppressor 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.5 Cable Clamp and Shield Processing 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–63505EN/02

Table of Contents

3. INPUT AND OUTPUT OF DATA 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SETTING PARAMETERS FOR INPUT/OUTPUT 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 INPUTTING/ OUTPUTTING DATA 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Confirming the Parameters Required for Data Output 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Outputting CNC Parameters 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Outputting PMC Parameters 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Outputting Pitch Error Compensation Amount 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Outputting Custom Macro V ariable V alues 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Outputting Tool Compensation Amount 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Outputting Part Program 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Inputting CNC Parameters 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Inputting PMC Parameters 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Inputting Pitch Error Compensation Amount 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.11 Inputting Custom Macro V ariable Values 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.12 Inputting Tool Compensation Amount 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.13 Inputting Part Programs 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DATA INPUT/OUTPUT ON THE ALL IO SCREEN 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Setting Input/Output–Related Parameters 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Inputting and Outputting Programs 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Inputting and Outputting Parameters 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Inputting and Outputting Offset Data 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 Outputting Custom Macro Common Variables 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.6 Inputting and Outputting Floppy Files 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERFACE BETWEEN NC AND PMC 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL OF INTERFACE 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SPECIFICATION OF PMC 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Specification 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Address 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Built–in Debug Function 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 System Reserve Area of Internal Relay 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 Execution Period of PMC 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PMC SCREEN 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Display Method 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 PMCLAD Screen 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 PMCDGN Screen 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Memory Display (M.SRCH) 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 PMCPRM Screen 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 LIST OF SIGNALS BY EACH MODE 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 LIST OF SIGNALS 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 LIST OF ADDRESSES 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. DIGITAL SERVO 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 INITIAL SETTING SERVO PARAMETERS 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SERVO TUNING SCREEN 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Parameter Setting 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Displaying Servo Tuning Screen 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 ADJUSTING REFERENCE POSITION (DOG METHOD) 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 General 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 DOGLESS REFERENCE POSITION SETTING 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 General 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Operation 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Table of Contents

5.4.3 Associated Parameters 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63505EN/02

6. AC SPINDLE 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 AC SPINDLE (SERIAL INTERFACE) 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Outline of Spindle Control 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1.1 Method A of gear change for machining center 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1.2 Method B of gear change for machining center (PRM 3705#2=1) 221. . . . . . . . . . . . . . . . . . . . . .

6.1.1.3 For lathe 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Spindle Setting and Tuning Screen 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.1 Display method 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.2 Spindle setting screen 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.3 Spindle tuning screen 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.4 Spindle monitor screen 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.5 Correspondence between operation mode and parameters on spindle tuning screen 227. . . . . . . . .

6.1.3 Automatic Setting of Standard Parameters 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 AC SPINDLE (ANALOG INTERFACE) 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Outline of Spindle Control 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1.1 Block diagram 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1.2 Calculation of S analog voltage and related parameters 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1.3 Tuning S analog voltage (D/A converter) 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. TROUBLESHOOTING 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 CORRECTIVE ACTION FOR FAILURES 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Investigating the Conditions Under which Failure Occurred 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED 237. . . . . . . .

7.3 JOG OPERATION CANNOT BE DONE 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 HANDLE OPERATION (MPG) CANNOT BE DONE 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 AUTOMATIC OPERATION CANNOT BE DONE 246. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 CYCLE START LED SIGNAL HAS TURNED OFF 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 NO DISPLAY APPEARS AT POWER–UP 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 ALARM 85 TO 87 (READER/PUNCHER INTERFACE ALARM) 256. . . . . . . . . . . . . . . . . . . . . . . .

7.9 ALARM 90 (REFERENCE POSITION RETURN IS ABNORMAL) 261. . . . . . . . . . . . . . . . . . . . . . .

7.10 ALARM 300 (REQUEST FOR REFERENCE POSITION RETURN) 263. . . . . . . . . . . . . . . . . . . . . . .

7.11 ALARM 301 TO 305 (ABSOLUTE PULSE CODER IS FAULTY) 264. . . . . . . . . . . . . . . . . . . . . . . . .

7.12 ALARM 306 TO 308 (ABSOLUTE PULSE CODER BATTERY IS LOW) 265. . . . . . . . . . . . . . . . . .

7.13 ALARM 350 (SERIAL α PULSE CODER IS ABNORMAL) 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.14 ALARM 351 (SERIAL α PULSE CODER COMMUNICATION IS ABNORMAL) 267. . . . . . . . . . .

7.15 ALARM 400 (OVERLOAD) 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.16 ALARM 401 (*DRDY SIGNAL TURNED OFF) 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17 ALARM 404 (*DRDY SIGNAL TURNED ON) 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.18 ALARM 410 (EXCESSIVE POSITION ERROR AMOUNT DURING STOP) 272. . . . . . . . . . . . . . . .

7.19 ALRAM 411 (EXECESSIVE POSITION ERROR DURING MOVE) 273. . . . . . . . . . . . . . . . . . . . . . .

7.20 ALARM 414 (DIGITAL SERVO SYSTEM IS ABNORMAL) 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.21 ALRAM 416 (DISCONNECTION ALARM) 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.22 ALARM 417 (DIGITAL SERVO SYSTEM IS ABNORMAL) 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.23 ALARM 704 (SPINDLE SPEED FLUCTUATION DETECTION ALARM) 278. . . . . . . . . . . . . . . . . .

c–4

B–63505EN/02

7.24 ALARM 749 (SERIAL SPINDLE COMMUNICATION ERROR) 279. . . . . . . . . . . . . . . . . . . . . . . . . .

7.25 ALARM 750 (SPINDLE SERIAL LINK CANNOT BE STARTED) 280. . . . . . . . . . . . . . . . . . . . . . . .

7.26 ALARM 751 (SPINDLE ALARM) 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.27 ALARM 700 (OVERHEAT AT CONTROL SIDE) 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.28 ALARM 900 (ROM PARITY ERROR) 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.29 ALARM 910 AND 911 (DRAM PARITY ERROR) 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.30 ALARM 912 AND 913 (SRAM PARITY ERROR) 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.31 ALARM 920 AND 921 (WATCH DOG OR RAM PARITY) 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.32 ALARM 924 (SERVO MODULE MOUNTING ERROR) 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.33 ALARM 930 (CPU ERROR) 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.34 ALARM 950 (PMC SYSTEM ALARM) 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.35 ALARM 960 (ABNORMAL 24 V INPUT POWER) 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.36 ALARM 970 (NMI ALARM IN PMC CONTROL MODULE) 293. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.37 ALARM 971 (NMI ALARM IN SLC) 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.38 ALARM 973 (NMI ALARM BY UNKNOWN CAUSE) 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

Table of Contents

A. ALARM LIST 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ALARM CODES 300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 LIST OF ALARMS (PMC) 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 ALARMS (SERIAL SPINDLE) 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 ERROR CODES (SERIAL SPINDLE) 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. LIST OF MAINTENANCE PARTS 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. BOOT SYSTEM 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 OUTLINE 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.1 Starting the BOOT SYSTEM 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1.2 System File and User File 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 OPERATION AND CORRESPONDING SCREENS 333. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.1 System Data Loading Screen 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.2 System Data Check Screen 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.3 System Data Delete Screen 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.4 System Data Save Screen 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.5 SRAM Data Backup Screen 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.6 Memory Card File Delete Screen 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.7 Memory Card Format Function 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.8 End of Boot System 346. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 ERROR MESSAGES AND REQUIRED ACTIONS 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. MEMORY CARD INTERFACE 350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 OUTLINE 351. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 USABLE CARDS 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2.1 SRAM Memory Card 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2.2 Flash Memory Card 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2.3 Flash AT A Card 353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Table of Contents

D.2.4 Memory Card Capacity 354. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63505EN/02

D.3 BOOT SYSTEM FUNCTIONS USABLE WITH MEMORY CARDS 355. . . . . . . . . . . . . . . . . . . . . . .

D.4 HANDLING OF FLASH MEMORY CARDS 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.1 Notes on Formatting a Flash Memory Card with CardPro 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.2 When Flash Memory Cards Formatted by the Boot System Are Used with the Systems of

D.4.3 When Flash Memory Cards Formatted by the Systems of Some Manufacturers Are Used

Some Manufacturers 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with the Boot System 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.5 EXTERNAL DIMENSIONS FOR MEMORY CARD 358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.5.1 Names and Function of Memory Components 358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.6 OPERATING OF MEMORY CARD 359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.6.1 Connection of Memory Card 359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.6.2 Disconnection of Memory Card 359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.7 BATTERY CHANGE 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.7.1 Battery 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.7.2 Battery Life 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.7.3 Procedure of Battery Change 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. MAINTENANCE OF OPEN CNC (BOOT–UP AND IPL) 361. . . . . . . . . . . . . . . . . . . . .

E.1 OVERVIEW 362. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.2 CHANGING START SEQUENCES 363. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3 EXPLANATION OF SCREENS 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1 Boot Screen 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.1 System data manipulation 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.2 SRAM operation 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.1.3 File operation 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.2 IPL Screen 368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.3.2.1 Functions on the IPL screen 369. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4 OTHER SCREENS 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.1 CNC System Alarm Screen 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.2 Status Screen 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.4.3 Option Setting Screen 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

B–63505EN/02

1

1. DISPLAY AND OPERATION

DISPLAY AND OPERATION

This chapter describes how to display various screens by the function

keys. The screens used for maintenance are respectively displayed.

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . .

1.2 SCREEN DISPLAYED IMMEDIATELY AFTER

POWER IS TURNED ON 21. . . . . . . . . . . . . . . . . . . . . .

1.3 SYSTEM CONFIGURATION SCREEN 24. . . . . . . . . .

1.4 ALARM HISTORY SCREEN 26. . . . . . . . . . . . . . . . . . .

1.5 EXTERNAL OPERATOR MESSAGES RECORD 27. .

1.6 OPERATION HISTORY 29. . . . . . . . . . . . . . . . . . . . . . .

1.7 HELP FUNCTION 42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DISPLAYING DIAGNOSTIC PAGE 44. . . . . . . . . . . . .

1.9 CNC STATE DISPLAY 54. . . . . . . . . . . . . . . . . . . . . . . .

1.10 WAVE FORM DIAGNOSTIC FUNCTION 56. . . . . . . .

1.11 OPERATING MONITOR 68. . . . . . . . . . . . . . . . . . . . . .

1.12 LIST OF OPERATIONS 70. . . . . . . . . . . . . . . . . . . . . . .

1.13 WARNING SCREEN DISPLAYED WHEN

AN OPTION IS CHANGED 79. . . . . . . . . . . . . . . . . . . .

1.14 WARNING SCREEN DISPLAYED

WHEN SYSTEM SOFTWARE IS REPLACED

(SYSTEM LABEL CHECK ERROR) 81. . . . . . . . . . . . .

1.15 POWER MATE CNC MANAGER 82. . . . . . . . . . . . . . .

1

1. DISPLAY AND OPERATION

B–63505EN/02

1.1

FUNCTION KEYS AND SOFT KEYS

1.1.1

Soft Keys

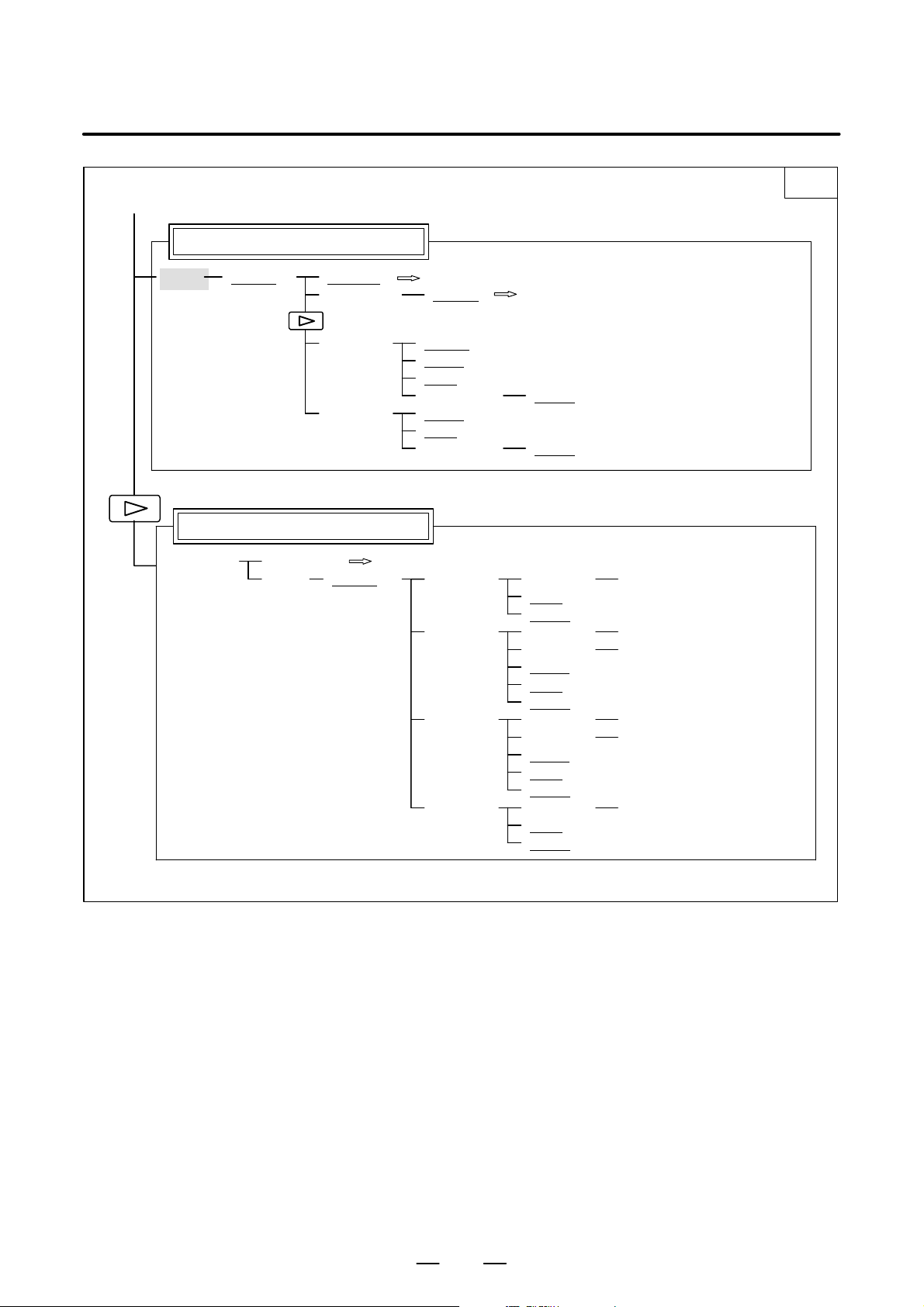

Operations and soft key display staturs for each function key are described

below:

T o display a more detailed screen, press a function key followed by a soft

key. Soft keys are also used for actual operations.

The following illustrates how soft key displays are changed by pressing

each function key.

The symbols in the following figures mean as shown below :

: Indicates screens

[]

()

[ ]

: Indicates a screen that can be displayed by pressing a

: Indicates a soft key(*2)

: Indicates input from the MDI panel.

: Indicates a soft key displayed in green (or highlighted).

: Indicates the continuous menu key (rightmost soft key).

function key(*1)

*1 Press function keys to switch between screens that are used frequently.

*2 Some soft keys are not displayed depending on the option configuration.

2

B–63505EN/02

1. DISPLAY AND OPERATION

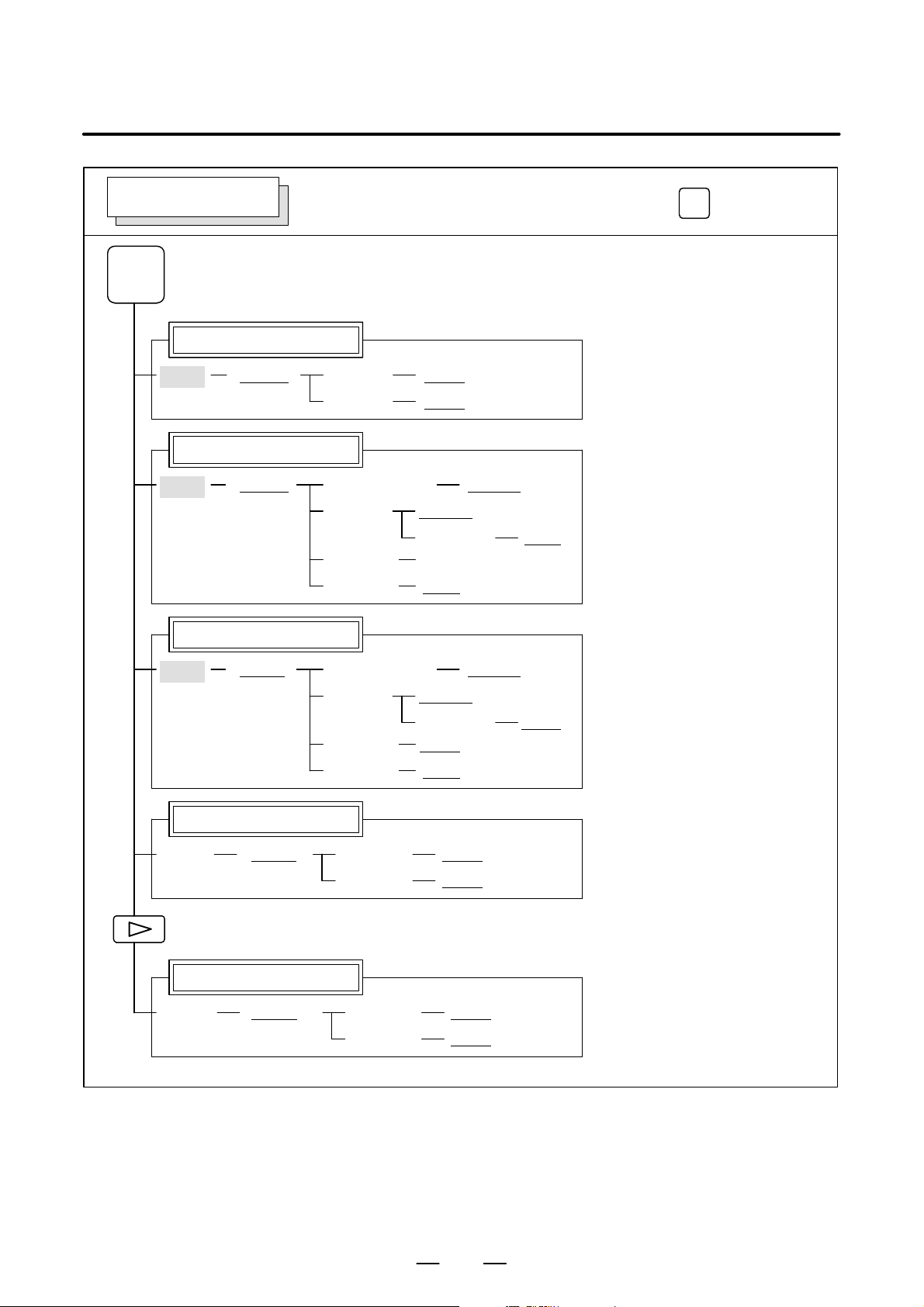

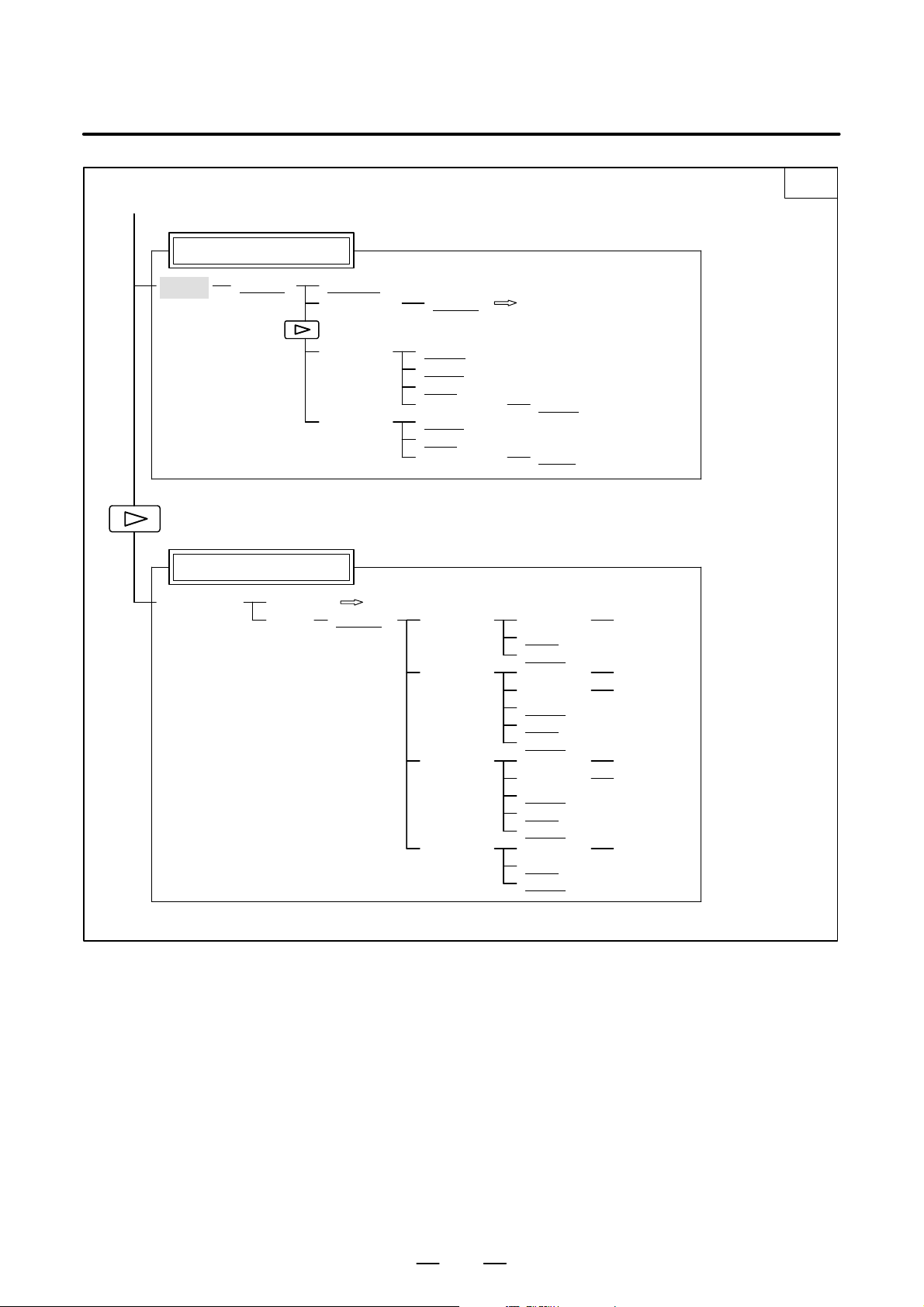

POSITION SCREEN

POS

Absolute coordinate display

[ABS]

Relative coordinate display

Current position display

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)][REL]

Soft key transition triggered by the function key

[RUNPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

(Axis name) [EXEC]

[PRESET]

POS

1.

[ALL]

[(OPRT)]

Handle interruption

[HNDL]

Monitor screen

[MONI]

[(OPRT)] [PTSPRE] [EXEC]

[(OPRT)] [PTSPRE] [EXEC]

(Axis or numeral)

[ORIGIN]

[PTSPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[RUNPRE] [EXEC]

[ALLEXE]

(Axis name) [EXEC]

[PRESET]

3

1. DISPLAY AND OPERATION

B–63505EN/02

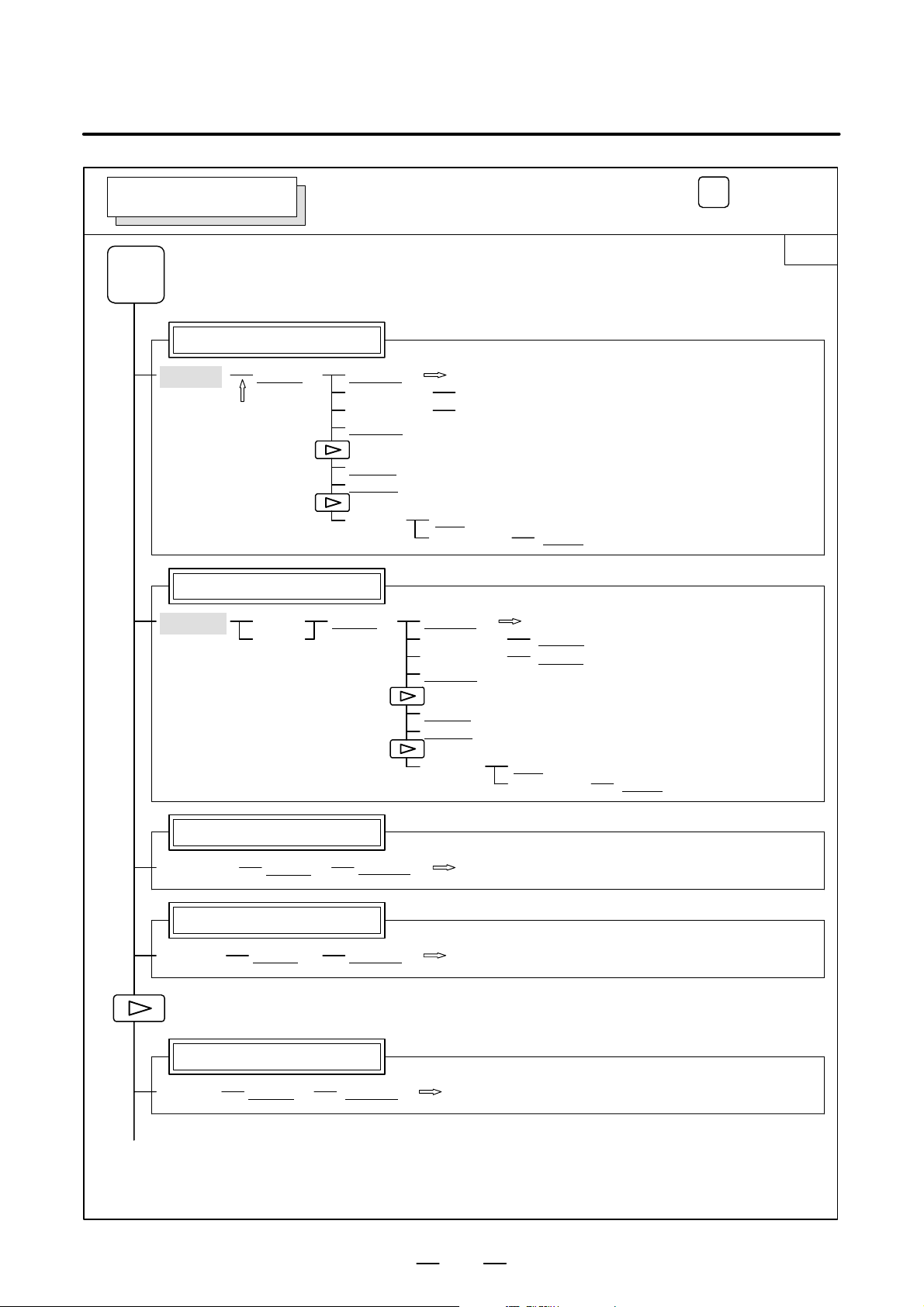

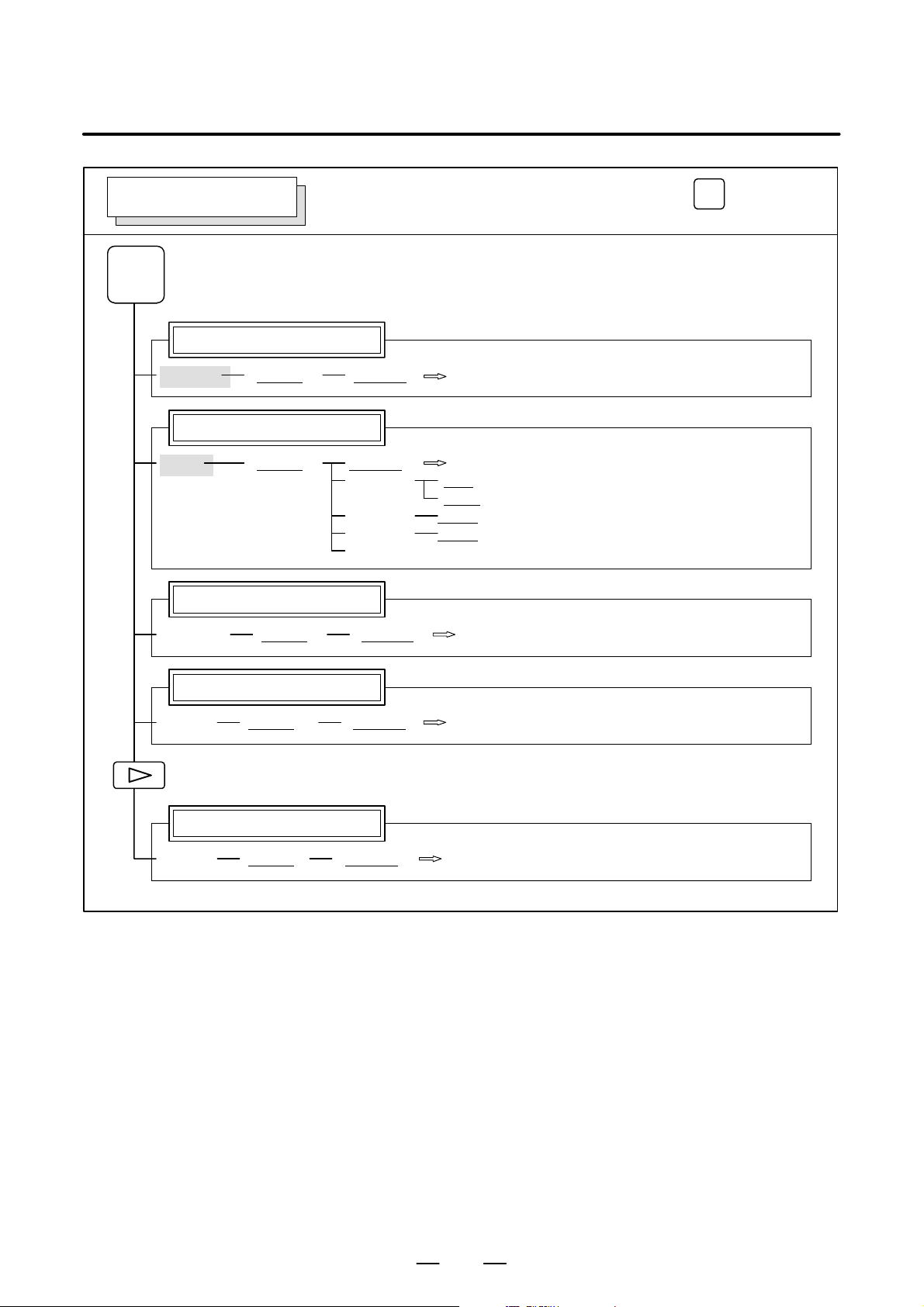

PROGRAM SCREEN

PROG

Program display screen

[PRGRM]

(1)

Program check display screen

Soft key transition triggered by the function key

in the MEM mode

2.

[(OPRT)] [BG–EDT]

(O number)

(N number)

[REWIND]

[P TYPE]

[Q TYPE]

[F SRH]

[ABS]

[REL]

[(OPRT)][CHECK]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

[CAN]

(N number)

[BG–EDT]

(O number)

(N number)

[REWIND]

[EXEC]

See “When the soft key [BG–EDT] is pressed”

[O SRH]

[N SRH]

PROG

1/2

Current block display screen

[(OPRT)]

Next block display screen

[(OPRT)] [BG–EDT][NEXT]

Program restart display screen

[(OPRT)] [BG–EDT][RSTR]

(2)(Continued on the next page)

[P TYPE]

[Q TYPE]

[F SRH]

[BG–EDT][CURRNT]

See “When the soft key [BG–EDT] is pressed”

[CAN]

(N number) [EXEC]

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

4

B–63505EN/02

1. DISPLAY AND OPERATION

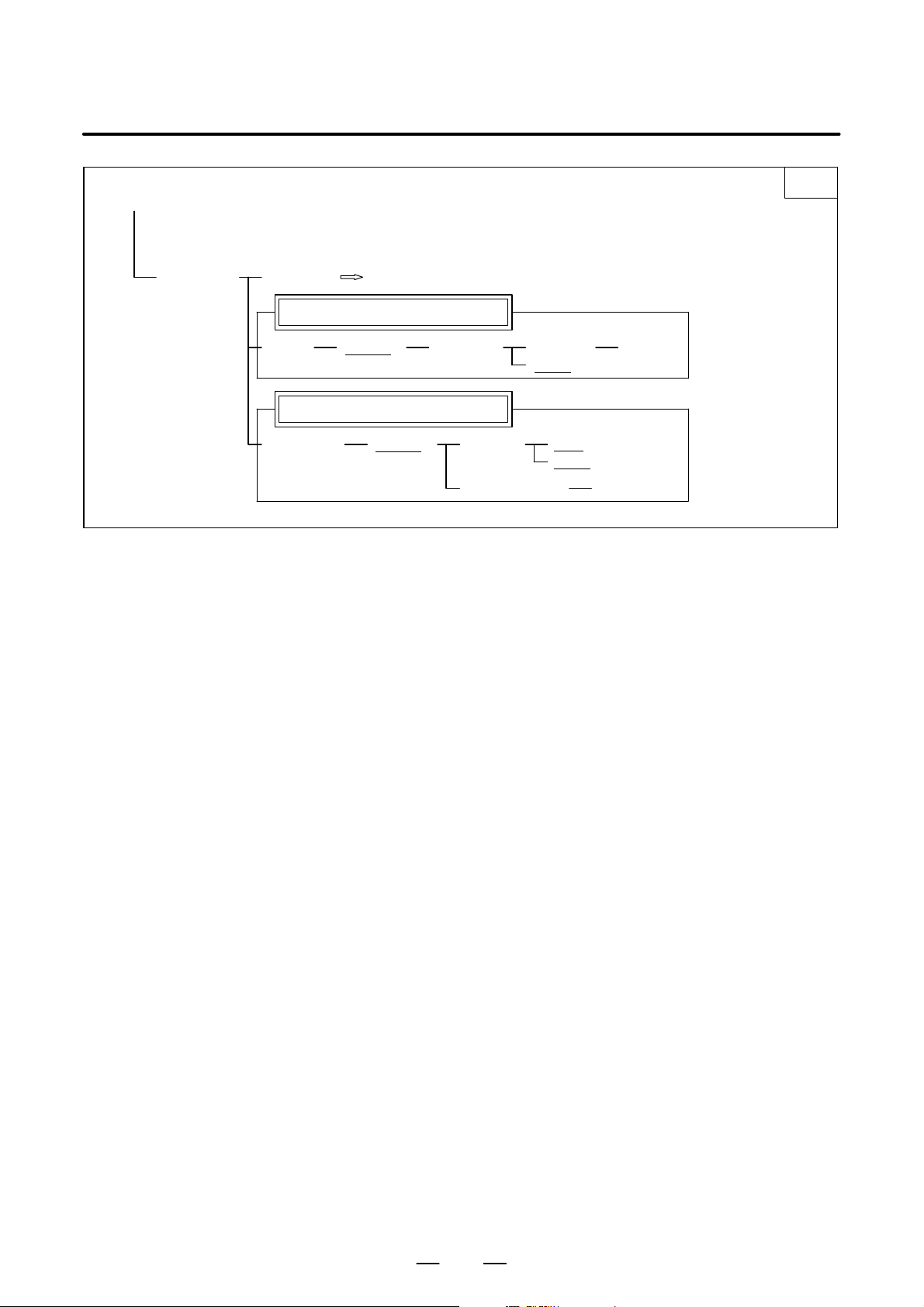

(2)

[FL.SDL] [PRGRM]

Return to (1) (Program display)

File directory display screen

[(OPRT)][DIR] [SELECT]

Schedule operation display screen

[SCHDUL] [CLEAR]

[(OPRT)]

(Schedule data)

2/2

(File No. ) [F SET]

[EXEC]

[CAN]

[EXEC]

[INPUT]

5

1. DISPLAY AND OPERATION

B–63505EN/02

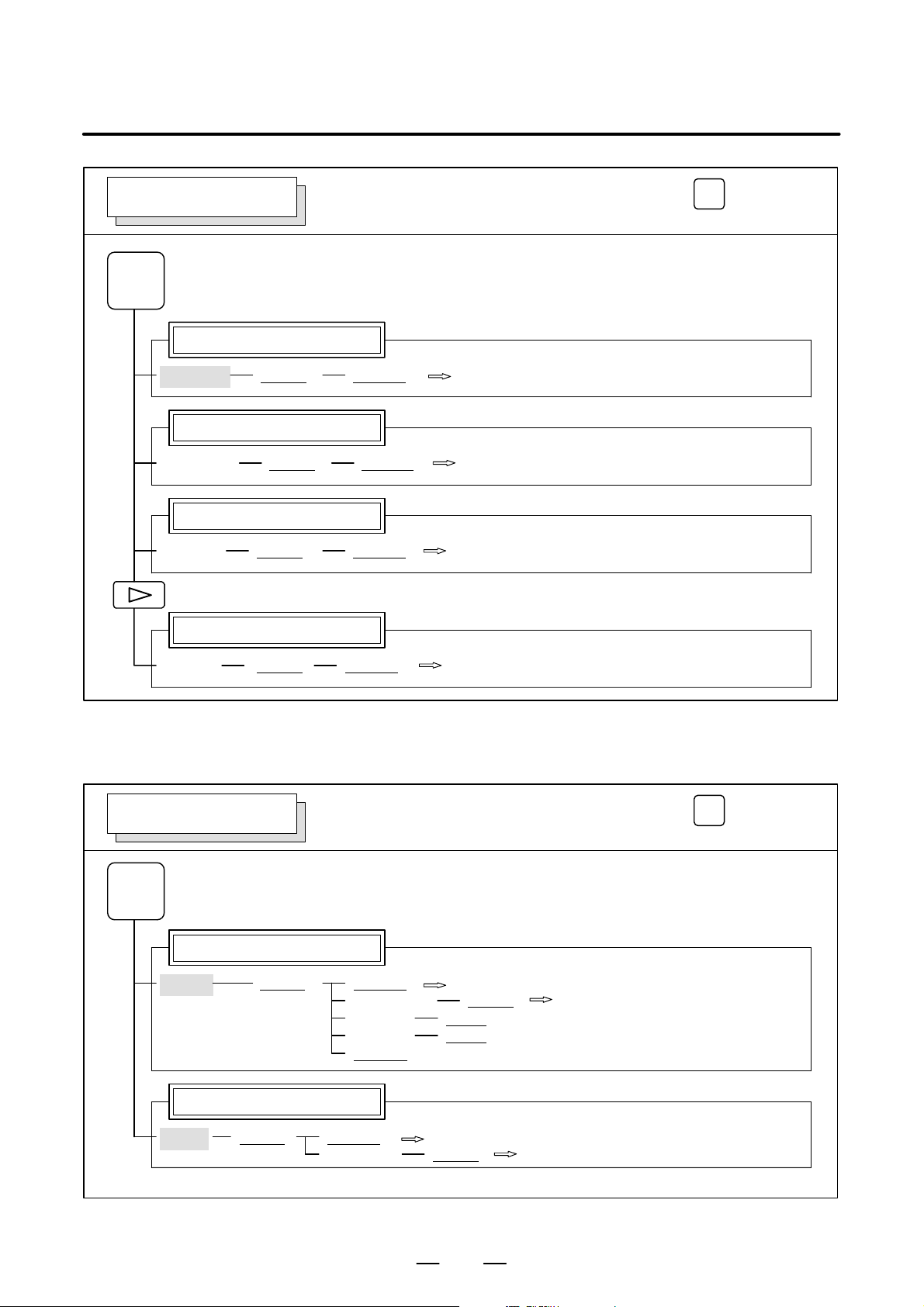

PROGRAM SCREEN

PROG

Program display

[PRGRM]

Soft key transition triggered by the function key

in the EDIT mode

3.

[(OPRT)] [BG–EDT]

(O number) [O SRH]

(Address) [SRH↓]

(Address) [SRH↑]

[REWIND]

[F SRH] [CAN]

[READ] [CHAIN]

[PUNCH] [STOP]

[DELETE] [CAN]

[EX–EDT] [COPY] [CRSR∼]

PROG

See “When the soft key [BG–EDT] is pressed”

(N number) [EXEC]

(The cursor moves to the end of a program.)

[STOP]

[CAN]

(O number)

[CAN]

(O number)

(N number)

[MOVE] [CRSR∼]

[MERGE] [∼CRSR]

[CHANGE] (Address) [BEFORE]

[EXEC]

[EXEC]

[EXEC]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼BTTM]

1/2

(1)(Continued on the next page)

(Address) [AFTER] [SKIP]

[1–EXEC]

[EXEC]

6

B–63505EN/02

1. DISPLAY AND OPERATION

(1)

Program directory display

[LIB]

[FLOPPY]

[(OPRT)] [BG–EDT]

Floppy directory display

[PRGRM]

[DIR] (Numeral)

See “When the soft key [BG–EDT] is pressed”

(O number) [O SRH]

[READ] [CHAIN]

[STOP]

[CAN]

(O number)

[PUNCH] [STOP]

[CAN]

(O number)

Return to the program

[(OPRT)]

[F SRH]

[READ]

[PUNCH]

[DELETE]

Return to the program

[EXEC]

[EXEC]

[F SET]

[CAN]

[EXEC]

(Numeral)

(Numeral)

[STOP]

[CAN]

[EXEC]

(Numeral)

(Numeral)

[STOP]

[CAN]

[EXEC]

(Numeral)

[CAN]

[EXEC]

[F SET]

[O SET]

[F SET]

[O SET]

[F SET]

2/2

7

1. DISPLAY AND OPERATION

B–63505EN/02

PROGRAM SCREEN

PROG

Program display

Program input screen

Current block display screen

[(OPRT)] [BG–EDT][PRGRM]

[(OPRT)] [BG–EDT][MDI]

[(OPRT)]

Soft key transition triggered by the function key

in the MDI mode

4.

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

[START]

(Address)

(Address)

[REWIND]

[BG–EDT][CURRNT]

[CAN]

[EXEC]

[SRH↓]

[SRH↑]

See When the soft key [BG-EDT] is pressed"

PROG

Next block display screen

[(OPRT)] [BG–EDT][NEXT]

Program restart display screen

[(OPRT)] [BG–EDT][RSTR]

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

8

B–63505EN/02

1. DISPLAY AND OPERATION

PROGRAM SCREEN

PROG

Program display

Current block display screen

Next block display screen

Program restart display screen

Soft key transition triggered by the function key

PROG

in the HNDL, JOG, or REF mode

5.

[(OPRT)] [BG–EDT][PRGRM]

[(OPRT)] [BG–EDT][CURRNT]

[(OPRT)] [BG–EDT][NEXT]

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

See “When the soft key [BG–EDT] is pressed”

PROGRAM SCREEN

PROG

Program input screen

Program directory display

[(OPRT)] [BG–EDT][RSTR]

[(OPRT)] [BG–EDT][MDI]

6.

See “When the soft key [BG–EDT] is pressed”

Soft key transition triggered by the function key

in the TJOG or THDL mode

See “When the soft key [BG–EDT] is pressed”

(O number)

(Address)

(Address)

[REWIND]

[O SRH] Return to the program

[SRH↓]

[SRH↑]

PROG

[LIB]

[(OPRT)] [BG–EDT]

(O number) [O SRH]

See “When the soft key [BG–EDT] is pressed”

Return to the program

9

1. DISPLAY AND OPERATION

B–63505EN/02

PROGRAM SCREEN

PROG

Program display

[PRGRM]

Soft key transition triggered by the function key

(When the soft key [BG–EDT] is pressed in all modes)

7.

[(OPRT)] [BG–END]

(O number) [O SRH]

(Address) [SRH↓]

(Address) [SRH↑]

[REWIND]

[F SRH] [CAN]

[READ] [CHAIN]

[PUNCH] [STOP]

[DELETE] [CAN]

[EX–EDT] [COPY] [CRSR∼]

(N number) [EXEC]

(The cursor moves to the end of a program.)

[STOP]

[CAN]

(O number)

[CAN]

(O number)

(N number)

[MOVE] [CRSR∼]

[MERGE] [∼CRSR]

[CHANGE] (Address) [BEFORE]

[EXEC]

[EXEC]

[EXEC]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼CRSR]

[∼BTTM]

[ALL]

(O number) [EXEC]

[∼BTTM]

PROG

1/2

(1)(Continued on the next page)

(Address) [AFTER] [SKIP]

[1–EXEC]

[EXEC]

10

B–63505EN/02

1. DISPLAY AND OPERATION

(1)

Program directory display

[LIB]

Floppy directory display

[FLOPPY]

[(OPRT)] [BG–EDT]

[PRGRM]

[DIR]

(O number) [O SRH]

[READ] [CHAIN]

[STOP]

[CAN]

(O number)

[PUNCH] [STOP]

[CAN]

(O number)

Return to the program

[(OPRT)]

[F SRH]

[READ]

[PUNCH]

[DELETE]

Return to the program

[EXEC]

[EXEC]

(Numeral)

[CAN]

[EXEC]

(Numeral)

(Numeral)

[STOP]

[CAN]

[EXEC]

(Numeral)

(Numeral)

[STOP]

[CAN]

[EXEC]

(Numeral)

[CAN]

[EXEC]

[F SET]

[F SET]

[O SET]

[F SET]

[O SET]

[F SET]

2/2

11

1. DISPLAY AND OPERATION

B–63505EN/02

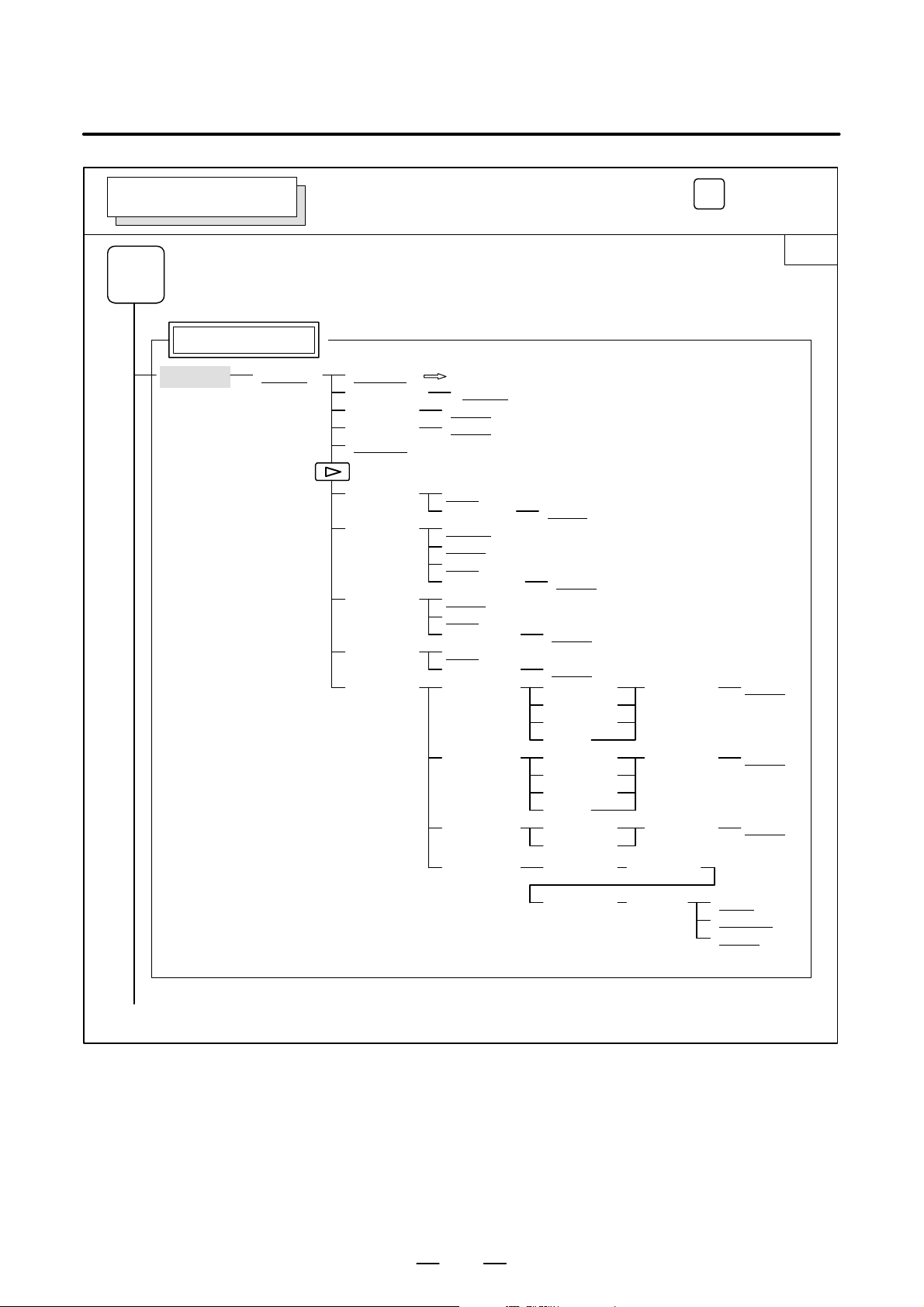

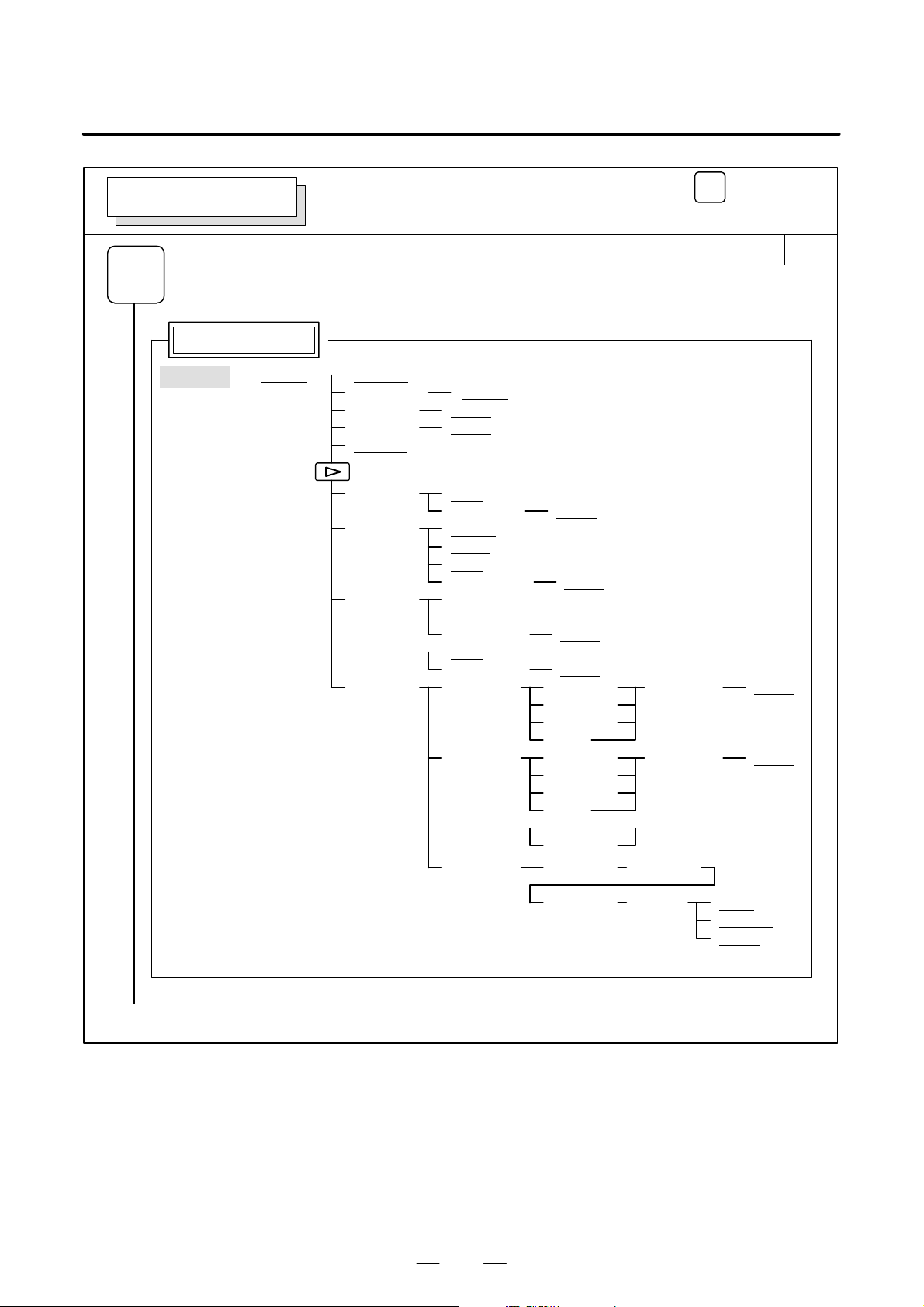

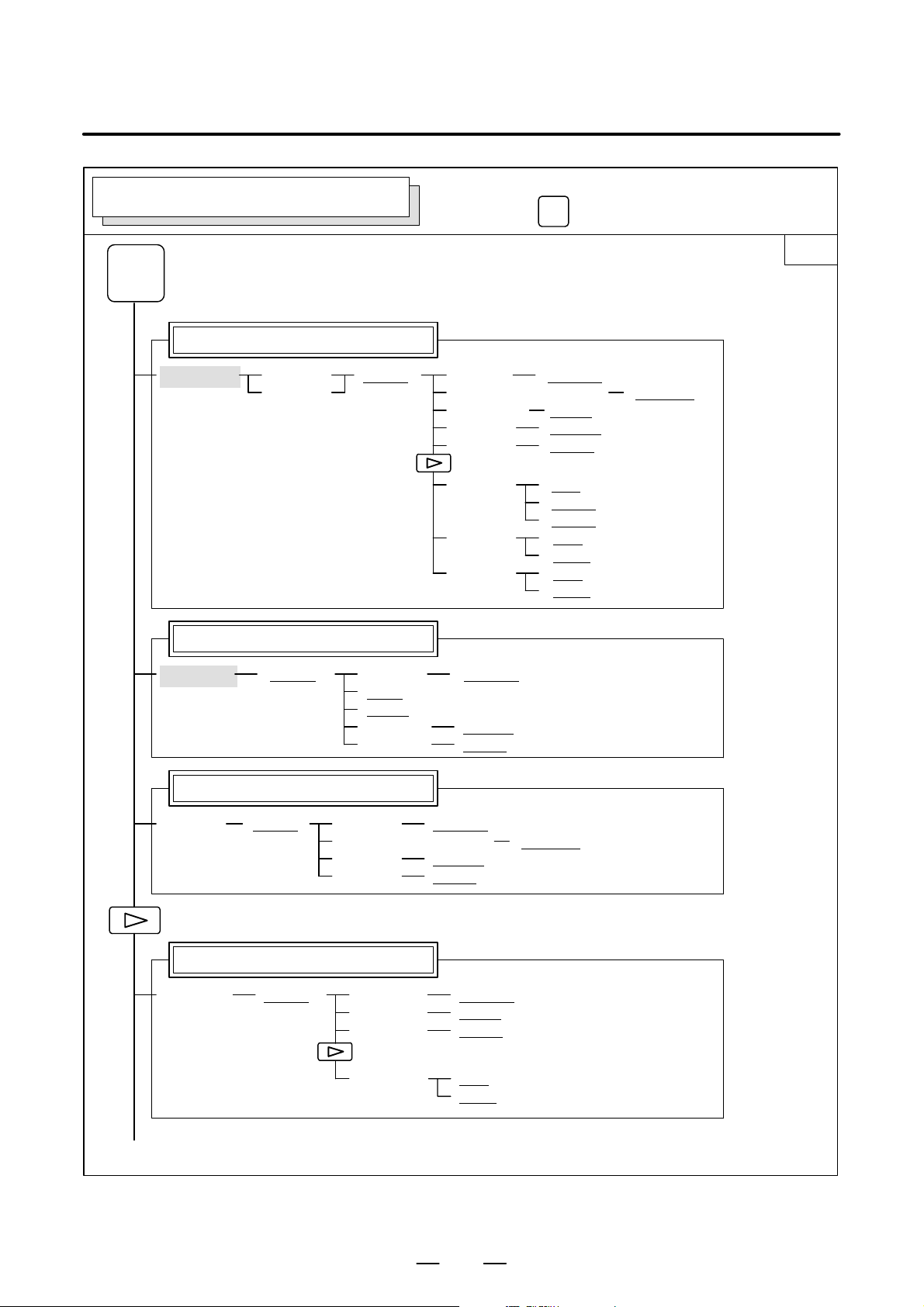

OFFSET/SETTING SCREEN (T series)

OFFSET

SETTING

Tool offset screen

8.

[WEAR]

[GEOM] (Axis name and numeral) [MEASUR]

[(OPRT)][OFFSET]

Soft key transition triggered by the

function key

(Number)

(Axis name)

(Numeral)

(Numeral)

[CLEAR] [ALL]

[READ] [CAN]

[PUNCH] [CAN]

OFFSET

SETTING

[NO SRH]

[INP.C.]

[+INPUT]

[INPUT]

[WEAR]

[GEOM]

[EXEC]

[EXEC]

1/2

Setting screen

[(OPRT)][SETING]

Workpiece coordinate system setting screen

[WORK]

Macro variables display screen

[(OPRT)]

[(OPRT)][MACRO]

(Number)

[ON:1]

[OFF:0]

(Numeral)

(Numeral)

(Number)

(Axis name and numeral) [MEASUR]

(Numeral)

(Numeral)

(Number)

(Axis name) [INP .C.]

(Numeral)

[PUNCH]

[NO SRH]

[+INPUT]

[INPUT]

[NO SRH]

[+INPUT]

[INPUT]

[NO SRH]

[INPUT]

[CAN]

[EXEC]

(1)(Continued on the next page)

12

Loading...

Loading...