Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 0i―Model A

Connection Manual (Hardware)

GFZ-63503EN/01 May 2000

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B–63503EN/01

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

Page 4

B–63503EN/01

PREFACE

PREFACE

This manual describes the electrical and structural specifications required

for connecting the F ANUC Series 0i CNC control unit to a machine tool.

The manual outlines the components commonly used for FANUC CNC

control units, as shown in the configuration diagram in Chapter 2, and

supplies additional information on using these components with the

Series 0i. Refer to individual manuals for the detailed specifications of

each model.

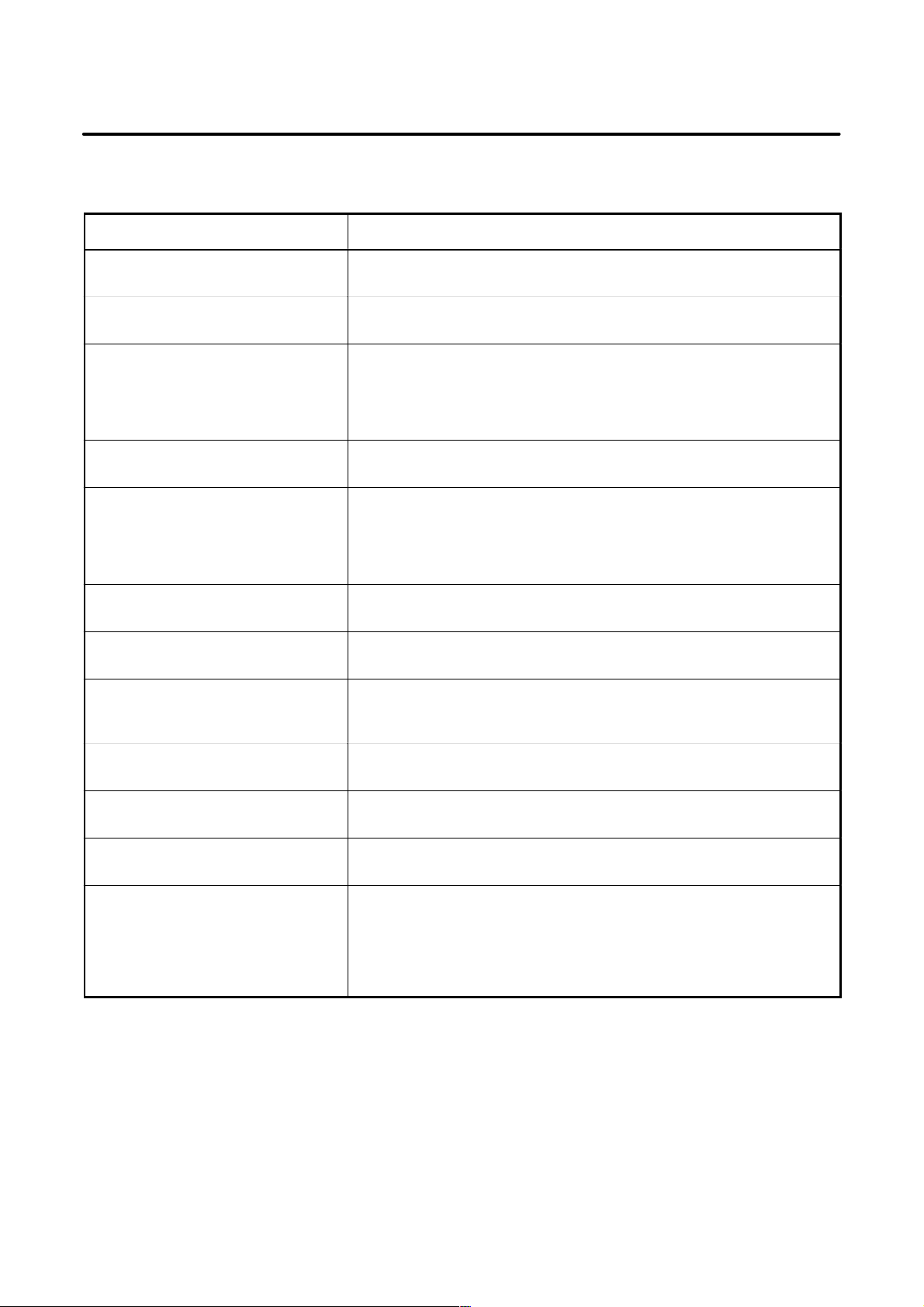

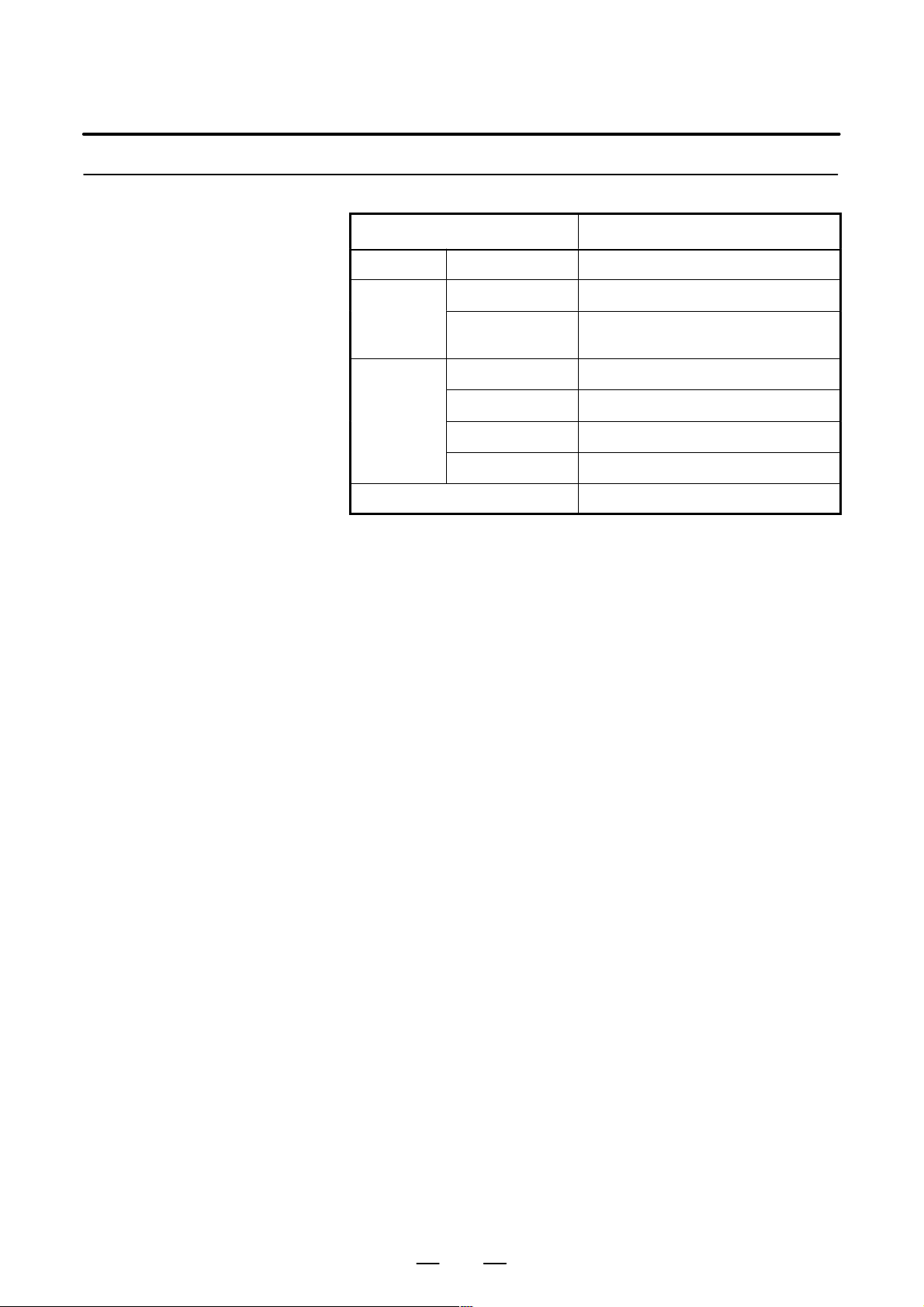

Applicable models

The models covered by this manual, and their abbreviations are:

Product name Abbreviation

FANUC Series 0i–TA 0i–TA

Series 0i

FANUC Series 0i–MA 0i–MA

p–1

Page 5

PREFACE

B–63503EN/01

Configuration of the

manual

Chapter title Description

Chapter 1

CONFIGURATION

Chapter 2

TOT AL CONNECTION DIAGRAM

Chapter 3

INSTALLATION

Chapter 4

CONNECTING THE POWER SUPPL Y

Chapter 5

CONNECTING PERIPHERAL UNITS

Chapter 6

CONNECTING THE SPINDLE UNIT

This manual consists of Chapters 1 to 15 and Appendixes.

Outlines connections for the Series 0i and guides the reader concerning additional details.

This chapter shows the total connection diagram.

This chapter describes the installation conditions for the Series 0i.

1) Required power supply

2) Heat generated

3) Connector arrangement on the control unit

4) Noise prevention

This chapter describes how to connect the power supply.

This chapter describes how to connect the following peripheral devices:

1) Display devices (CRT and LCD display)

2) MDI units

3) I/O devices (via RS232C)

4) Manual pulse generators

This chapter describes how to connect the spindle servo unit, the spindle motor.

Chapter 7

SERVO INTERF ACE

Chapter 8

CONNECTING THE MACHINE INTERFACE I/O

Chapter 9

CONNECTION TO F ANUC I/O Link

Chapter 10

EMERGENCY STOP SIGNAL

Chapter 1 1

HIGH–SPEED SERIAL BUS (HSSB)

Appendix A External dimensions of units

This chapter describes how to connect the servo unit and the servo unit.

This chapter describes the addresses and connector pins for signals transferred between the Series 0i and the machine.

Describes the built–in I/O board.

This chapter describes the use of FANUC I/O Link to expand the machine

interface I/O.

This chapter describes the handling of emergency stop signals. The user

must read this chapter before attempting to operate the CNC.

This chapter describes the high–speed serial bus (HSSB) supported by the

Series 0i.

B20–pin interface connectors and cables

C Connection cables

D Optical fiber cable

E Attaching a CRT protecting cover

F Machine operator’s panel

p–2

Page 6

B–63503EN/01

PREFACE

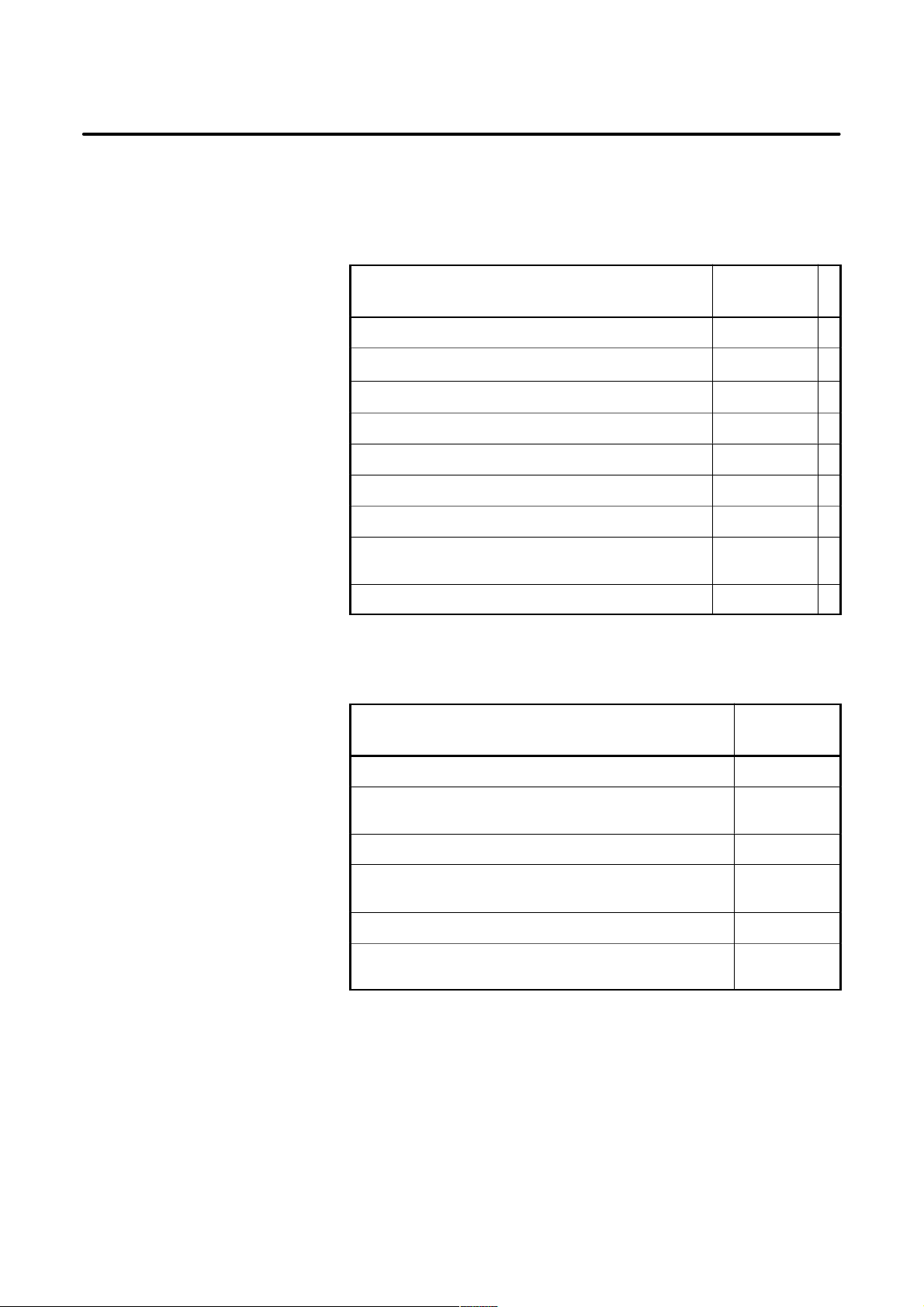

Related manuals

The table below lists manuals related to the Series 0i. In the table, this

manual is marked with an asterisk (*).

Manuals Related to the Series 0i

Manual name

DESCRIPTIONS B–62502EN

CONNECTION MANUAL (Hardware) B–62503EN

CONNECTION MANUAL (Function) B–62503EN–1

OPERATOR’S MANUAL (For Lathe) B–63504EN

OPERATOR’S MANUAL (For Machining Center) B–62514EN

MAINTENANCE MANUAL B–62505EN

P ARAMETER MANUAL B–62510EN

PROGRAMMING MANUAL

(Macro Compiler / Macro Executer)

FAPT MACRO COMPILER PROGRAMMING MANUAL B–66102E

Specification

number

*

B–61803E–1

Manuals related to

control motor a series

Manuals related to control motor a series

Manual name

FANUC AC SER VO MOTORa series DESCRIPTIONS B–65142E

FANUC AC SER VO MOTORa series P ARAMETER

MANUAL

FANUC AC SPINDLE MOT ORa series DESCRIPTIONS B–65152E

FANUC AC SPINDLE MOT ORa series PARAMETER

MANUAL

FANUC SER VO AMPLIFIERa series DESCRIPTIONS B–65162E

FANUC SER VO MOT ORa series MAINTENANCE

MANUAL

Specification

number

B–65150E

B–65160E

B–65165E

p–3

Page 7

B–63503EN/01

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. CONFIGURATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 NAME OF EACH PART OF CONTROL UNIT 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 GENERAL OF HARDWARE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. TOTAL CONNECTION DIAGRAM 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 ENVIRONMENT FOR INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Environmental Requirements Outside the Cabinet 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Installation Requirements of CNC and Servo Unit 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 POWER SUPPLY 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Power Supply for CNC Control Units 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 THERMAL DESIGN OF THE CABINET 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Temperature Rise Within the Cabinet 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Cooling by Heat Exchanger 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Heat Loss of Each Unit 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 ACTION AGAINST NOISE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Separating Signal Lines 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Ground 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Connecting the Signal Ground (SG) of the Control Unit 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Noise Suppressor 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Cable Clamp and Shield Processing 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 CONTROL UNIT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Installation of the Control Unit 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 CABLE LEAD–IN DIAGRAM 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 CONNECTOR LAYOUT DIAGRAM 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. POWER SUPPLY CONNECTION 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT 30. . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Power Supply for the Control Unit 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 +24 V Input Power Specifications 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Procedure for Turning On the Power 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Procedure for Turning Off the Power 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 BATTERY 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Battery for Memory Backup (3VDC) 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Battery for Separate Absolute Pulse Coders (6VDC) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. CONNECTION TO CNC PERIPHERALS 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CONNECTION TO THE DISPLAY UNIT 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 8

TABLE OF CONTENTS

5.1.1 Outline 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Connection to Display Unit 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 9″ CRT Display Unit Interface 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 8.4″ LCD Units Interface 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Adjusting the TFT Color LCD 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CONNECTION OF MDI UNIT 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 General 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Connection to the MDI Unit 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Connection to the Standard MDI Unit 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Varied MDI Key Switch 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 CONNECTING I/O DEVICES 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 General 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Connecting I/O Devices 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 RS–232–C Serial Port 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 RS–232–C Interface Specification 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 FANUC Handy File Connection 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CONNECTING THE MANUAL PULSE GENERATOR 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 General 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Connection to Manual Pulse Generators 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Cable Length When Only One Manual Pulse Generator is Used 62. . . . . . . . . . . . . . . . . . . . . . .

B–63503EN/01

6. SPINDLE CONNECTION 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 SERIAL SPINDLE INTERFACE 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 ANALOG SPINDLE INTERFACE 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 POSITION CODER INTERFACE 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. SERVO INTERFACE 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 OUTLINE 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Interface to the Servo Amplifier 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Separate Type Detector Interface 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Connection of Battery for Separate Type Absolute Detector 71. . . . . . . . . . . . . . . . . . . . . . . . . . .

8. CONNECTING MACHINE INTERFACE I/O 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

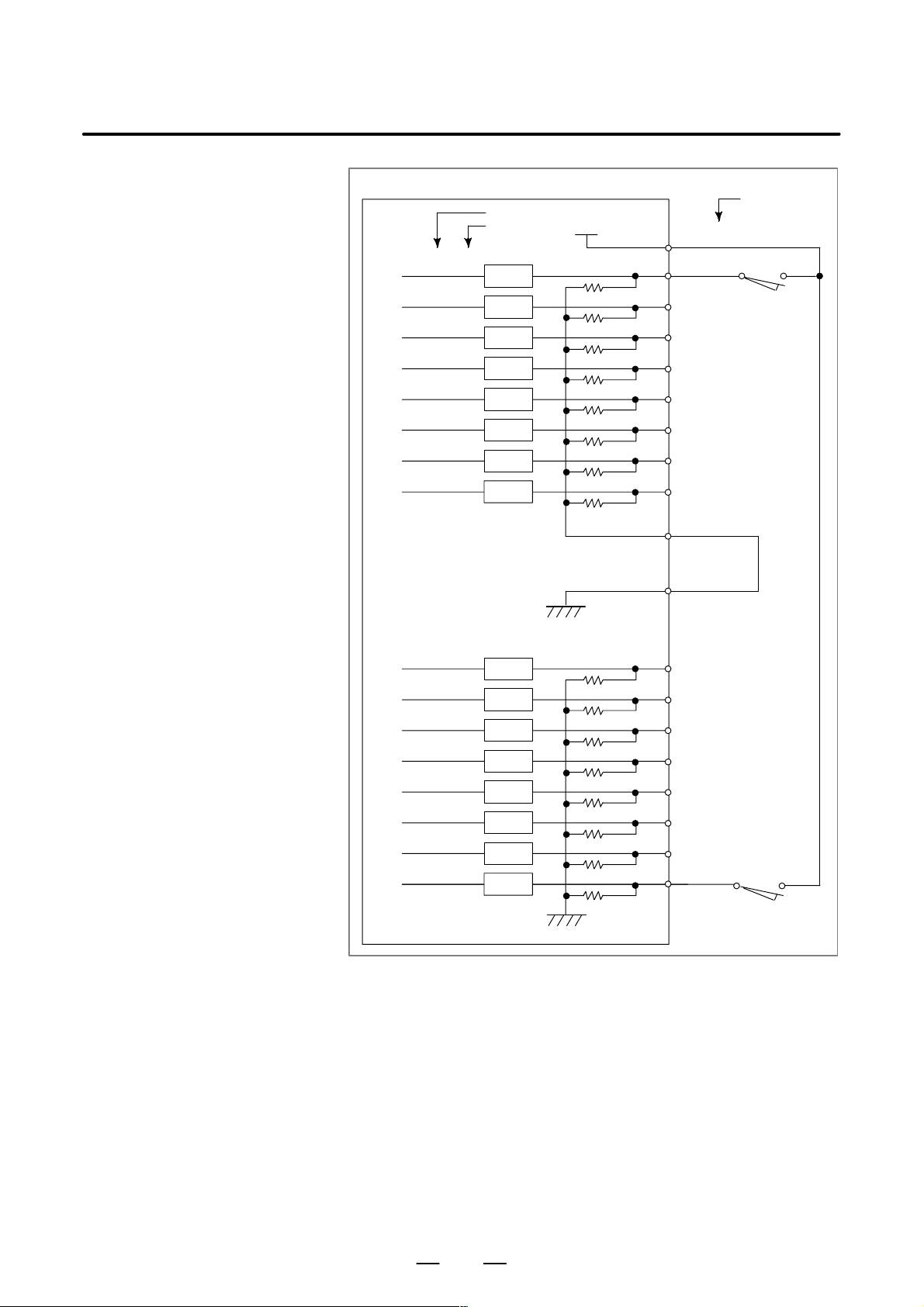

8.1 GENERAL 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 CAUTIONS 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 DI Signals and Receivers 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 DO Signals and Drivers 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 BUILT–IN I/O CARD CONNECTION 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Connector Pin Arrangement 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Connecting DI/DO 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 I/O Signal Requirements and External Power Supply for DO 93. . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 CONNECTION TO THE HIGH–SPEED SKIP (HDI) 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. CONNECTION TO FANUC I/O Link 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 GENERAL 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 CONNECTION 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 9

B–63503EN/01

9.3 UNITS THAT CAN BE CONNECTED USING FANUC I/O Link 104. . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Connection to Machine operator’s panel 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 CONNECTION OF OPERATOR’S PANEL I/O MODULE (FOR MATRIX INPUT) 127. . . . . . . . . .

9.6 CONNECTION TO THE OPERATOR’S PANEL I/O MODULE 144. . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

9.2.1 Connection of FANUC I/O Link by Electric Cable 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Overview 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Total Connection Diagram 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Connections 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.1 Pin assignment 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.2 Power supply connection 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.3 I/O link connection 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.4 Emergency stop signal connection 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.5 Power ON/OFF control signal connection 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.6 DI (input signal) connection 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.7 DO (output signal) connection 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3.8 Connector (on the cable side) specifications 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4 DI/DO Address 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4.1 Keyboard of main panel 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4.2 Override signals 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.5 DI/DO Mapping 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.6 Connector Locations of Main Panel B 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7 Specifications 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.1 Environmental requirement 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.2 Order specification 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.3 Main panel A/B specification 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.4 Sub panel B1 specification 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.5 Power supply specification 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.6 General–purpose DI signal definition 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7.7 General–purpose DO signal definition 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8 Key Symbol Indication on Machine Operator’s Panel 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8.1 Meaning of key symbols 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8.2 Detachable key top 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.9 Others 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 Overall Connection Diagram 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Power Connection 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 DI/DO Connector Pin Arrangement 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.4 DI (General–purpose Input Signal) Connection 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.5 DI (Matrix Input Signal) Connection 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.6 DO (Output Signal) Connection 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.7 External View 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.8 Specifications 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.9 Other Notes 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Overall Connection Diagram 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Power Connection 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 DI/DO Connector Pin Arrangement 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 DI (General–purpose Input Signal) Connection 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.5 DO (Output Signal) Connection 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 10

TABLE OF CONTENTS

9.6.6 External View 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.7 Specifications 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.8 Other Notes 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 CONNECTING THE FANUC SERVO UNIT β SERIES WITH I/O Link 160. . . . . . . . . . . . . . . . . . .

9.7.1 Overview 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.2 Connection 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.3 Maximum Number of Units that can be Connected 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.4 Address Assignment by Ladder 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63503EN/01

10. EMERGENCY STOP SIGNAL 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 1. HIGH–SPEED SERIAL BUS (HSSB) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 OVERVIEW 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 CAUTIONS 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 CONNECTION DIAGRAM 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 PERSONAL COMPUTER SPECIFICATION 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 INSTALLATION ENVIRONMENT 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 HANDLING PRECAUTIONS 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.7 PROCEDURE FOR INSTALLING PERSONAL COMPUTER INTERFACE BOARDS 171. . . . . . . .

11.8 RECOMMENDED CABLES 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. EXTERNAL DIMENSIONS OF EACH UNIT 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. 20–PIN INTERFACE CONNECT ORS AND CABLES 214. . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 OVERVIEW 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 BOARD–MOUNTED CONNECTORS 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 CABLE CONNECTORS 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.4 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND CABLES 218. . . . . . . . . . . .

C. CONNECTION CABLE (SUPPLIED FROM US) 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. OPTICAL FIBER CABLE 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. ATTACHING A CRT PROTECTIVE COVER 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 11

B–63503EN/01

1

1. CONFIGURATION

CONFIGURATION

1

Page 12

1. CONFIGURATION

B–63503EN/01

1.1

NAME OF EACH P ART OF CONTROL UNIT

slot

Memory back

up battery

(4.4)

I/O Link

connecter

(9)

The following figure shows the configuration of F ANUC Series 0i control

unit.

This manual describes how to connect the units illustrated in this diagram.

The numbers in parentheses shown in the diagram are section references

for this manual.

LED for display

of status/alarm

FuseMemory card

II/O device I/F

connector

(5.3)

Power supply

pilot lamp

Power supply

connector

(4.3)

Machine I/F

connector

(8.3)

Serial spindle or

position coder

connector

(6.1,6.3)

Serial spindle or

analog spindle

connector

(6.2)

Servo amp

connector

(7.1.1)

Separate type

detector

I/F connector

(7.1.2)

Separate type ABS

pulse coder battery

connector

(7.1.3)

Series 0i control unit (2–slot)

Display unit

connector

(5.1)

MDI connector

(5.2)

Manual pulse

generator

connector

(5.4)

Machine I/F

connector

(8.3)

Mini slot

High–speed serial

bus (*)

(11)

2

Page 13

B–63503EN/01

1.2

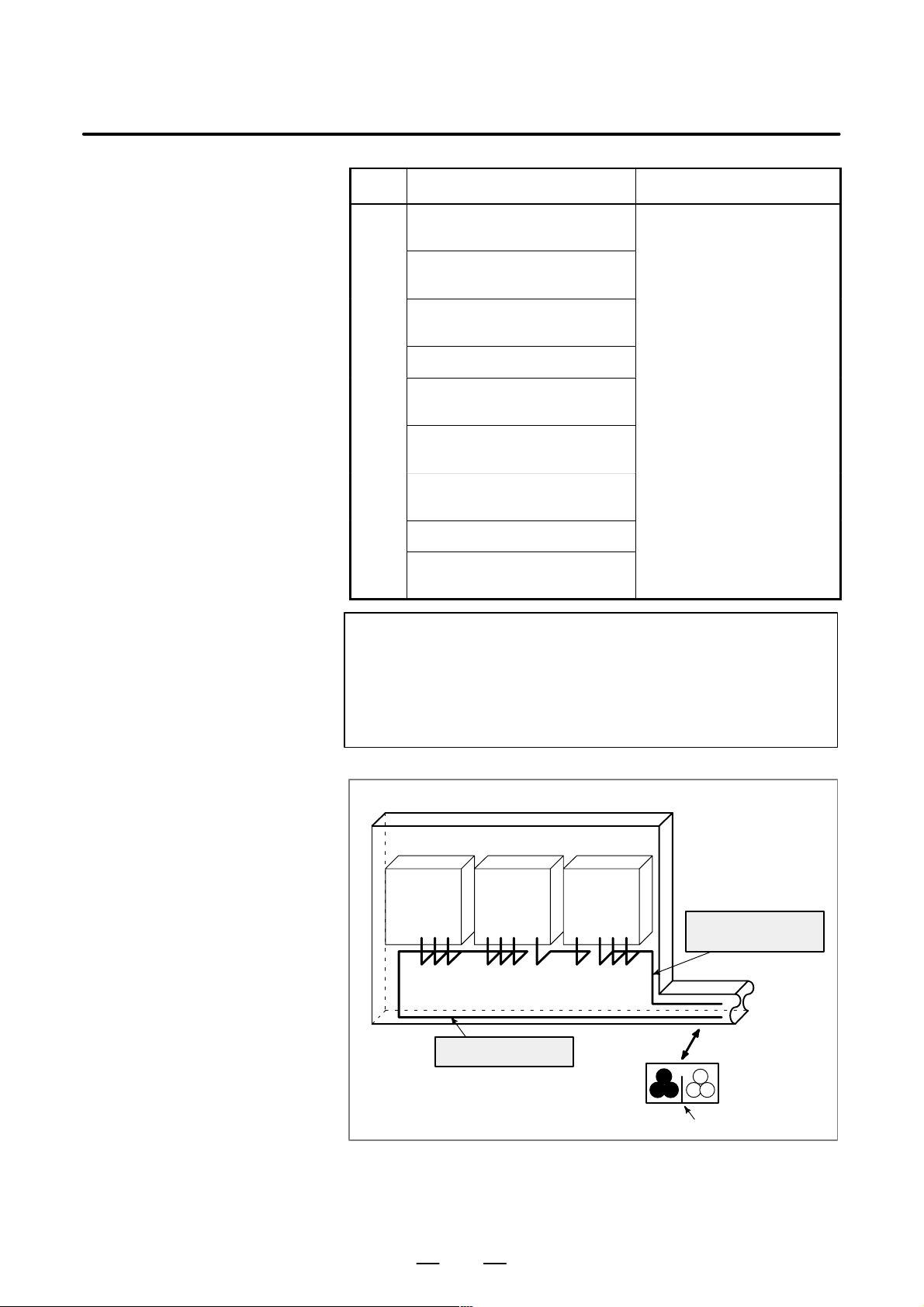

GENERAL OF HARDWARE

1. CONFIGURATION

Main board

S Main CPU

S Memory

System software,

Macro program,

Ladder program,

Parameter , and etc.

S PMC control

S I/O Link control

S Servo control

S Spindle control

S Memory card I/F

S LED display

I/O board

S Power PCB (built–in)

DC–DC converter

S DI/DO

S Reader/puncher I/F

S MDI control

S Display control

S Manual pulse generator

control

Main I/O

3

Mini slot

S HSSB board

2–slot

Page 14

2. TOTAL CONNECTION DIAGRAM

TOTAL CONNECTION DIAGRAM

2

Main board

C

o

n

t

r

o

l

u

n

i

t

B–63503EN/01

Power

supply

24VDC

Units that can be

connected with the

I/O Link

Position coder

Analog

spindle

amplifier

Serial

spindle

amplifier

Servo

amplifier

M–axis servo motor

N–axis servo motor

4th axis servo motor

Analog

spindle

Position coder

Serial

spindle

L–axis

servo motor

L–axis scale

M–axis scale

N–axis scale

4th axis scale

ABS BA TTERY for scale

NOTE

Either an analog or serial spindle can be used. For details of spindle and servo motor

connection, refer to the relevant manuals.

4

Page 15

B–63503EN/01

I/O Board D

C

o

n

t

r

o

l

u

n

i

t

I/O Board

Power supply unit

DC–IN (CP1A)

DC–OUT(CP1B)

CRT(JA1)

MDI(JA2)

2. TOTAL CONNECTION DIAGRAM

Power supply

24VDC

Display unit

(CN2)DC–IN

(CN1)CRT

(JA1)LCD

MDI unit

(CK1)MDI

R232C–1(JD5A)

R232C–2(JD5B)

RS–232–C I/O device (channel 1)

RS–232–C I/O device (channel 2)

MPG(JA3)

MPG MPG MPG

DIDO–1(CB104)

DIDO–2(CB105)

DIDO–3(CB106)

Machine side DI/DO

DIDO–4(CB107)

When the high–speed serial bus (HSSB) is used

C

High–speed serial

o

n

bus interface board

t

(installed in a mini–

r

o

slot)

l

u

n

i

t

COP7

(Two units for 0i–TA)

Personal computer

High–speed

serial bus interface board

COP7

5

Page 16

3. INSTALLATION

INSTALLATION

3

B–63503EN/01

6

Page 17

B–63503EN/01

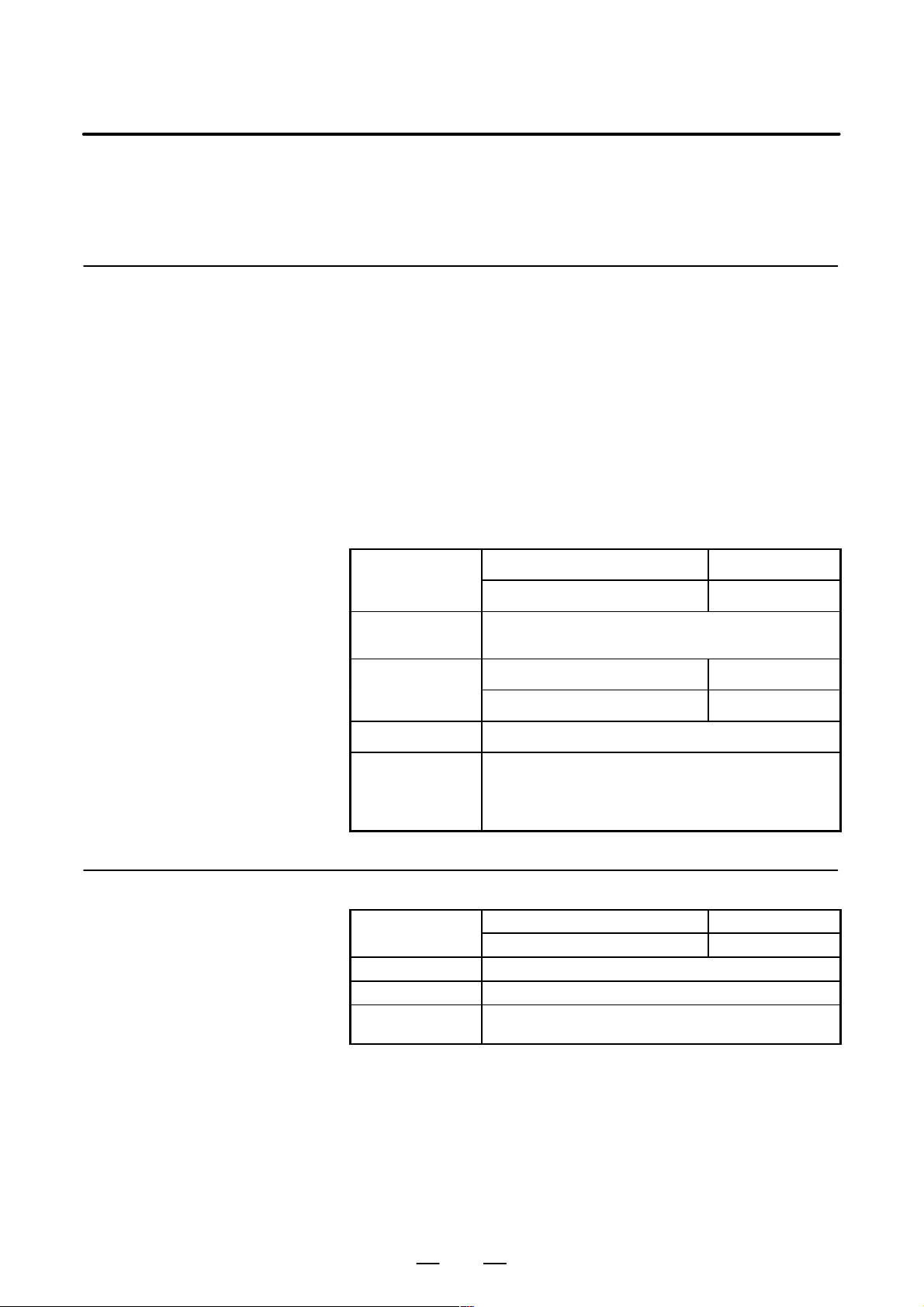

3.1

ENVIRONMENT FOR INSTALLATION

3. INSTALLATION

3.1.1

Environmental

Requirements Outside

the Cabinet

The peripheral units, such as the control unit and CRT/MDI, have been

designed on the assumption that they are housed in closed cabinets. In

this manual “cabinet” refers to the following:

(1) Cabinet manufactured by the machine tool builder for housing the

control unit or peripheral units;

(2) Cabinet for hous ing the flexible turnkey sys tem provi ded by FANUC ;

(3) Operation pendant, manufactured by the machine tool builder, for

housing the CRT/MDI unit or operator’s panel.

(4)Equivalent to the above.

The environmental conditions when installing these cabinets shall

conform to the following table. Section 3.3 describes the installation and

design conditions of a cabinet satisfying these conditions.

In operation 0°C to 45°C

Room temperature

In storage or transportation –20°C to 60°C

Change in

temperature

Relative humidity

Vibration In operation: 0.5G or less

1.1°C /minute max.

Normal 75% or less

T emporary(within 1 month) 95% or less

3.1.2

Installation

Requirements of CNC

and Servo Unit

Normal machine shop environment

Environment

Room temperature

Relative humidity 95% RH or less (no condensation)

Vibration 0.5 G or less

Environment

(The environment must be considered if the cabinets

are in a location where the density of dust, coolant, and/

or organic solvent is relatively high.)

In operation 0°C to +55°C

In storage or transportation –20°C to +60°C

The unit shall not be exposed direct to cutting oil, lubricant or cutting chips.

7

Page 18

3. INSTALLATION

"

3.2

POWER SUPPLY

B–63503EN/01

3.2.1

Power Supply for CNC

Control Units

The following units related to the CNC control unit require input power

of 24 VDC "10%.

T able 3.2.1 Power supply

Unit Power supply

0i control unit

9″ CRT/MDI unit

8.4″ TFT color unit

24 VDC"10%

momentary surges

and ripples.

voltage

3.5A (only control unit)

10% includes

0.8A

0.8A

Power supply

8

Page 19

B–63503EN/01

3. INSTALLATION

3.3

DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental conditions

described in Sec. 3.1. In addition, the magnetic interference on the CR T

screen, noise resistance, and maintenance requirements must be

considered. The cabinet design must meet the following conditions :

(1)The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne

dust,coolant,and organic solvent.

Cabinets that let in air may be desined for the servo amplifier and servo

transformer provided that they :

D Use an air filter on the air inlet ;

D Place the ventilating fan so that it does not blow air directly toward

the unit;

D Control the air flow so that no dust or coolant enters the air outlet

(2)The cabinet must be designed to maintain a difference in temperature

of 10°C or less between the air in the cabinet and the outside air when

the temperature in the cabinet increases.

See Sec. 3.4 for the details on thermal design of the cabinet.

(3) A closed cabinet must be equipped with a fan to circulate the air

within.

The fan must be adjusted so that the air moves at 0.5 m/sec along the

surface of each installed unit.

CAUTION

If the air blows directly from the fan to the unit, dust easily

abheres to the unit. This may cause the unit to fail.

(4)For the air to move easily, a clearance of 100 mm is required between

each unit and the wall of the cabinet.

(5) Packing materials must be used for the cable port and the door in

oreder to seal the cabinet.

Because the CRT unit uses a voltage of approximatery 1 1 kV, airborne

dust gathers easily. If the cabinet is insufficiently sealed, dust passes

through the gap and abheres to the unit. This may cause the insulation

of the unit to deteriorate.

(6)The display unit and other display units must be installed in a location

where coolant cannot be poured directly on it. The unit does have a

dust–proof front panel.

(7)Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts that

generate noise may be placed near noise–sensitive parts in the

magnetics cabinet.

The CNC unit is built to protect it from external noise. Cabinet design

to minimize noise generation and to prevent it from being transmitted

to the CNC unit is necessary. See Sec. 3.5 for details of noise

elimination/management.

(8)The units must be installed or arranged in the cabinet so that they are

easy to inspect and maintain.

9

Page 20

3. INSTALLATION

B–63503EN/01

(9)The CRT screen can be distorted by magnetic interference.

Arranging magnetic sources must be done with care.

If magnetic sources (such as transformers, fan motors,

electromagnetic contactors, solenoids, and relays) are located near the

CRT display, they frequently distort the display screen. To prevent

this, the CRT display and the magnetic sources generatlly must be kept

300 mm apart. If the CRT display and the magnetic sources are not

300 mm apart, the screen distortion may be suppressed by changing

the direction in which the magnetic sources are installed.

The magnetic intensity is not constant, and it is often increased by

magnetic interference from multiple magnetic sources interacting

with each other . As a result, simply keeping the CR T and the magnetic

sources 300 mm apart may not be enough to prevent the distortion.

If they cannot be kept apart, or if the CRT screen remains distorted

despite the distance, cover the screen with a magnetic shield.

10

Page 21

B–63503EN/01

3. INSTALLATION

3.4

THERMAL DESIGN OF THE CABINET

3.4.1

Temperature Rise

Within the Cabinet

The purpose of the thermal design of the cabinet is to limit the difference

in temperature between the air in the cabinet and the outside air to 10°C

or less when the temperature in the cabinet increases.

The internal air temperature of the cabinet increases when the units and

parts installed in the cabinet generate heat. Since the generated heat is

radiated from the surface of the cabinet, the temperature of the air in the

cabinet and the outside air balance at certain heat levels. If the amount

of heat generated is constant, the larger the surface area of the cabinet, the

less the internal temperature rises. The thermal design of the cabinet

refers to calculating the heat generated in the cabinet, evaluating the

surface area of the cabinet, and enlarging that surface area by installing

heat exchangers in the cabinet, if necessary. Such a design method is

described in the following subsections.

The cooling capacity of a cabinet made of sheet metal is generally 6 W/°C

per 1m

cabinet having a surface area of 1 m

cabinet rises by 1°C. In this case the surface area of the cabinet refers to

the area useful in cooling , that is, the area obtained by subtracting the area

of the cabinet touching the floor from the total surface area of the cabinet.

There are two preconditions : The air in the cabinet must be circuited by

the fun, and the temperature of the air in the cabinet must be almost

constant.

The following expression must then be satisfied to limit the difference in

temperature between the air in the cabinet and the outside air to 10°C or

less when the temperature in the cabinet rises:

For example, a cabinet having a surface area of 4m

of 24W/°C. T o limit the internal temperature increase to 10°C under these

conditions, the internal heat must not exceed 240W. If the actual internal

heat is 320W, however, the temperature in the cabinet rises by 13°C or

more. When this happens, the cooling capacity of the cabinet must be

improved using the heat exchanger described next.

2

surface area, that is, when the 6W heat source is contained in a

Internal heat loss P [W] x 6 [W/m

× 10 [°C] of rise in temperature

2

, the temperature of the air in the

2 S

@ °C ] × surface area S [m2]

2

has a cooling capacity

3.4.2

Cooling by Heat

Exchanger

If the temperature rise cannot be limited to 10°C by the cooling capacity

of the cabinet, a heat exchanger must be added. The heat exchanger

forcibly applies the air from both the inside and outside of the cabinet to

the cooling fin to obtain effective cooling. The heat exchanger enlar ges

the surface area.

11

Page 22

3. INSTALLATION

3.4.3

Heat Loss of Each Unit

B–63503EN/01

Name Heat loss

Control unit Series 0i 60W

Display unit

I/O unit

Multi–tap transformer 51W

9″CRT/MDI unit 14W

8.4″LCD/MDI

color unit

AIF01A, AIF01B 1.2W

AID32A, AID32B 1.2W+0.23W number of ON points

AID16C, AID16D 0.1W+0.21W number of ON points

AID32E, AID32F 0.1W+0.23W number of ON points

20W

12

Page 23

B–63503EN/01

3. INSTALLATION

3.5

ACTION AGAINST NOISE

3.5.1

Separating Signal

Lines

The CNC has been steadily reduced in size using surface–mount and

custom LSI technologies for electronic components. The CNC also is

designed to be protected from external noise. However, it is difficult to

measure the level and frequency of noise quantitatively, and noise has

many uncertain factors. It is important to prevent both noise from being

generated and generated noise from being introduced into the CNC. This

precaution improves the stability of the CNC machine tool system.

The CNC component units are often installed close to the parts generating

noise in the power magnetics cabinet. Possible noise sources into the

CNC are capacitive coupling, electromagnetic induction, and ground

loops.

When designing the power magnetics cabinet, guard against noise in the

machine as described in the following section.

The cables used for the CNC machine tool are classified as listed in the

following table:

Process the cables in each group as described in the action column.

Group Signal line Action

Primary AC power line

Secondary AC power line

AC/DC power lines (containing the

power lines for the servo and

A

spindle motors)

AC/DC solenoid

Bind the cables in group A separately (Note 1) from groups B

and C, or cover group A with

an electromagnetic shield

(Note 2).

See Subsec. 3.5.4 and connect spark killers or diodes with

nect spark killers or diodes with

the solenoid and relay .

AC/DC relay

DC solenoid (24VDC)

DC relay (24VDC)

DI/DO cable between the CNC and

B

power magnetics cabinet

DI/DO cable between the CNC and

machine

Connect diodes with DC solenoid and relay .

Bind the cables in group B separately from group A, or cover

group B with an electromagnetic shield.

Separate group B as far from

Group C as possible.

It is more desirable to cover

group B with the shield.

13

Page 24

3. INSTALLATION

B–63503EN/01

Group ActionSignal line

Cable between the CNC and servo

amplifier

Cable for position and velocity

feedback

Cable between the CNC and

spindle amplifier

Cable for the position coder

Cable for the manual pulse gener-

C

ator

Cable between the CNC and the

CRT/MDI

RS–232–C and RS–422 interface

cable

Cable for the battery

Other cables to be covered with the

shield

Bind the cables in group C

separately from group A, or

cover group C with an electromagnetic shield.

Separate group C as far from

Group B as possible.

Be sure to perfrom shield processing in Subsec. 3.5.5.

NOTE

1 The groups must be 10 cm or more apart from one another

when binding the cables in each group.

2 The electromagnetic shield refers to shielding between

groups with grounded steel plates.

Spindle

amp.

Cabinet

Servo

amp.

Cable of group A

Control

unit

Cable of group B, C

Duct

Section

Group A Group B, C

Cover

To operator’s

panel,

motor , etc.

14

Page 25

B–63503EN/01

3. INSTALLATION

3.5.2

Ground

The following ground systems are provided for the CNC machine tool:

(1)Signal ground system (SG)

The signal ground (SG) supplies the reference voltage (0 V) of the

electrical signal system.

(2)Frame ground system (FG)

The frame ground system (FG) is used for safety, and suppressing

external and internal noises. In the frame ground system, the frames,

cases of the units, panels, and shields for the interface cables between

the units are connected.

(3)System ground system

The system ground system is used to connect the frame ground

systems connected between devices or units with the ground.

Signal ground system

Power

magnetics

unit

Servo

amplifier

CNC

control

unit

Frame ground sysytem

System ground system

Operator’s

panel

Machine

tool

Notes on connecting the

ground systems

Power

magnetics

cabinet

Distribution board

D Connect the signal ground with the frame ground (FG) at only one

place in the CNC control unit.

D The grounding resistance of the system ground shall be 100 ohms or

less (class 3 grounding).

D The system ground cable must have enough cross–sectional area to

safely carry the accidental current flow into the system ground when

an accident such as a short circuit occurs.

(Generally, it must have the cross–sec tional area of the AC power cable

or more.)

D Use the cable containing the AC power wire and the system ground

wire so that power is supplied with the ground wire connected.

15

Page 26

3. INSTALLATION

3.5.3

Connecting the Signal

Ground (SG) of the

Control Unit

Control unit

B–63503EN/01

MAIN

STATUS

ALARM

IOL INK

JD 1A

SPDL–1

JA 7A

A–OUT

JA 8A

SERVO1

JS1A

SERVO2

JS2A

SERVO3

JS3A

SERVO4

JS4A

SCALE1

JF21

SCALE2

JF22

SCALE3

JF23

SCALE4

JF24

SC–ABS

JF25

BATTERY

MEMORY

CARD

CNMC

I/O

PSU

4

231

CPS

MPG

JA3B

FUSE75A

PIL

CP1A

CP1B

DCIN

DCOUT

24V

24V

5A

CRT

JA1

MDI

JA2

R232–1

JD5A

R232–2

JD5B

1A

R

L

R

L

RSW1

M3 terminal for

MINI

SLOT

signal ground (SG)

Ground plate

Ground cable

(upper 2mm

Frame

ground

(FG)

FANUC

FA-

NUC

2

)

= Ground plate of

the cabinet

FANUC

M3

Ground cable

System ground

Connect the 0 V line of the electronic circuit in the control unit with the

ground plate of the cabinet via the signal ground (SG) terminal.

The SG terminal is located below the main board of the control unit.

16

Page 27

B–63503EN/01

3. INSTALLATION

MDI

M4 stud

Approx. 15mm

Approx. 20 mm (for 9″ CRT/MDI unit)

Approx. 150 mm (for 8.4″ LCD/MDI unit)

CRT

9″ CRT/MDI unit

8.4″ LCD/MDI unit

17

Page 28

3. INSTALLATION

B–63503EN/01

3.5.4

Noise Suppressor

Notes on selecting the

spark killer

The AC/DC solenoid and relay are used in the power magnetics cabinet.

A high pulse voltage is caused by coil inductance when these devices are

turned on or off.

This pulse voltage induced through the cable causes the electronic circuits

to be disturbed.

D Use a spark killer consisting of a resistor and capacitor in series. This

type of spark killer is called a CR spark killer.(Use it under AC)

(A varistor is useful in clamping the peak voltage of the pulse voltage,

but cannot suppress the sudden rise of the pulse voltage. FANUC

therefore recommends a CR spark killer.)

D The reference capacitance and resistance of the spark killer shall

conform to the following based on the current (I (A)) and DC

resistance of the stationary coil:

1) Resistance (R) : Equivalent DC resistance of the coil

2) Capacitance (C) :

10

2

I

2

I

to

20

(µF)

I : Current at stationary state of the coil

RC

Equivalent circuit of the spark killer

AC

relay

Spark killer

Mount the noise eliminator near a motor or a relay coil.

Spark killer

NOTE

Use a CR–type noise eliminator. Varistor–type noise

eliminators clamp the peak pulse voltage but cannot

suppress a sharp rising edge.

Diode (used for direct–current circuits)

Diode

Use a diode which can withstand a

DC relay

voltage up to two times the applied

voltage and a current up to two times

the applied current.

Motor

18

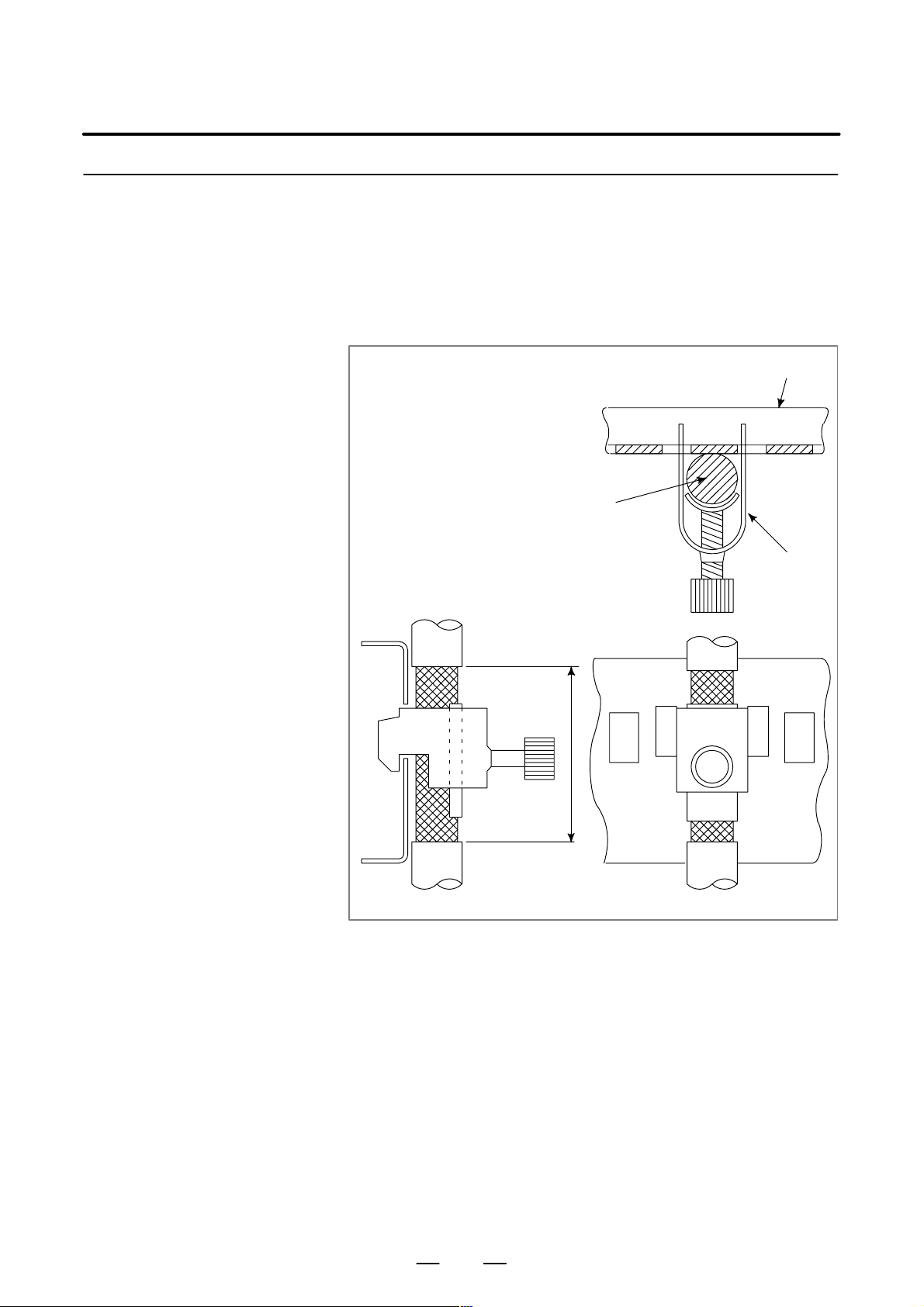

Page 29

B–63503EN/01

3. INSTALLATION

3.5.5

Cable Clamp and

Shield Processing

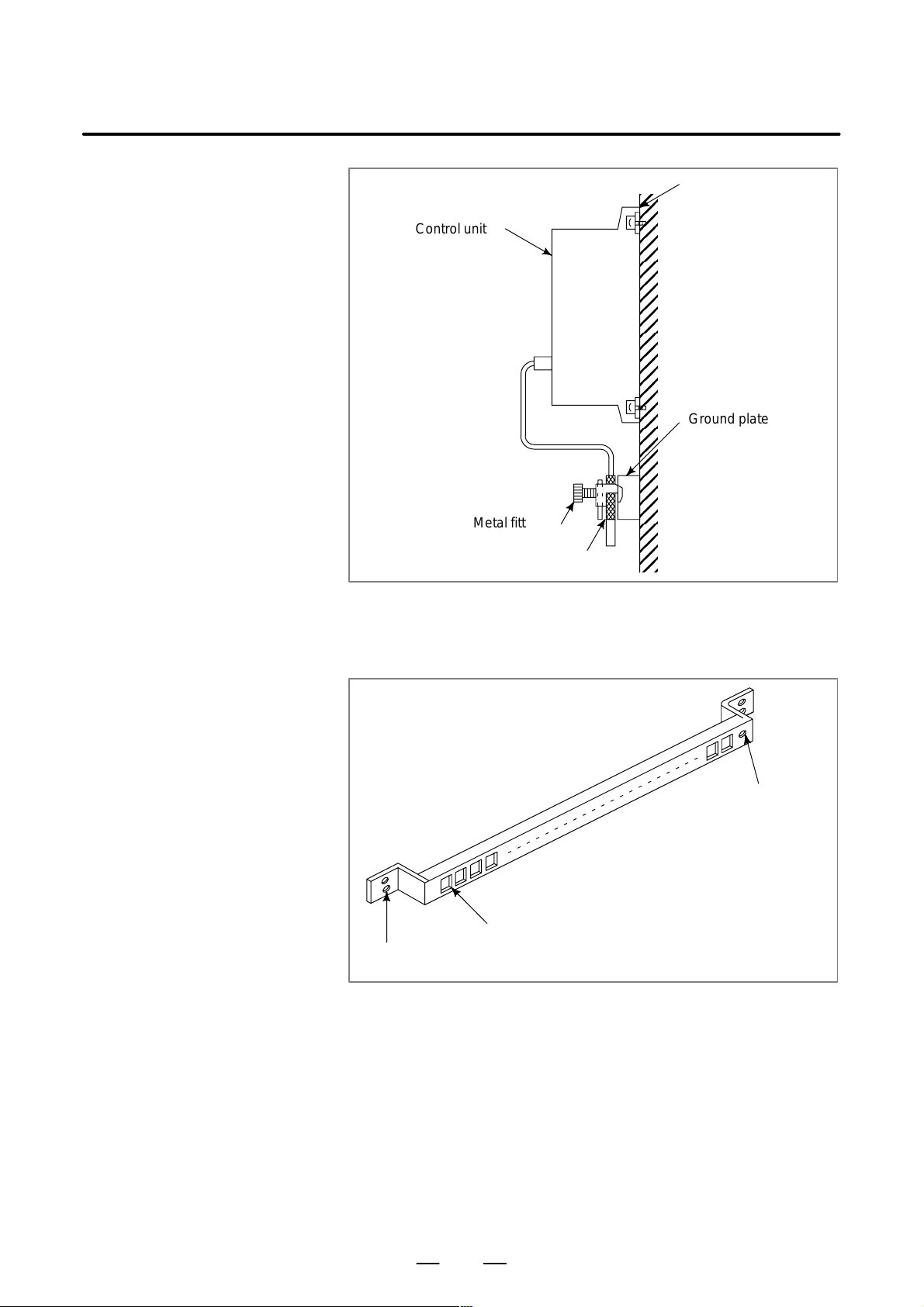

The CNC cables that require shielding should be clamped by the method

shown below. This cable clamp treatment is for both cable support and

proper grounding of the shield. To insure stable CNC system operation,

follow this cable clamp method.

Partially peel out the sheath and expose the shield. Push and clamp by

the plate metal fittings for clamp at the part. The ground plate must be

made by the machine tool builder, and set as follows :

Ground plate

Cable

Metal fittings

for clamp

40mm – 80mm

Fig.3.5.5(a) Cable clamp (1)

19

Page 30

3. INSTALLATION

B–63503EN/01

Machine side

installation

board

Control unit

Ground plate

Metal fittings

for clamp

Shield cover

Fig.3.5.5(b) Cable clamp (2)

Prepare ground plate like the following figure.

Ground terminal

(grounded)

Hole for securing metal fitting clamp

Mount screw hole

Fig.3.5.5(c) Ground plate

For the ground plate, use a metal plate of 2 mm or thicker, which surface

is plated with nickel.

20

Page 31

B–63503EN/01

3. INSTALLATION

8mm

12mm

20mm

Fig.3.5.5(d) Ground plate holes

(Reference) Outer drawings of metal fittings for clamp.

Max. 55mm

Ground

plate

6mm

Fig.3.5.5(e) Outer drawings of metal fittings for clamp

Ordering specification for metal fittings for clamp

A02B–0124–K001 (8 pieces)

28mm

17mm

21

Page 32

3. INSTALLATION

3.6

CONTROL UNIT

B–63503EN/01

3.6.1

Installation of the

Control Unit

The rack consists of a plastic box, fan motors and a backplane PCB. The

air comes into the rack from the bottom and goes out through the fan

motor, which is located on the top of the rack. Space as shown in Fig.

3.6.1 must be reserved not to disturb the air flow ((A), (B))

The backplane PCB, which is located on the rear side of the rack,

interconnects the PCBs installed in the rack. It has another connector

which appears at the left side panel of the rack. This connector is used for

testing the controller, connecting other purposes. The space for this shall

be reserved as shown in (C) of Fig. 3.6.1.

AIR FLOWAIR FLOW

Reserved

Reserved

(C)

(A)

50

(A)

250

30

(B)

Reserved

Fig.3.6.1

50

(B)

172

Unit : mm

22

Page 33

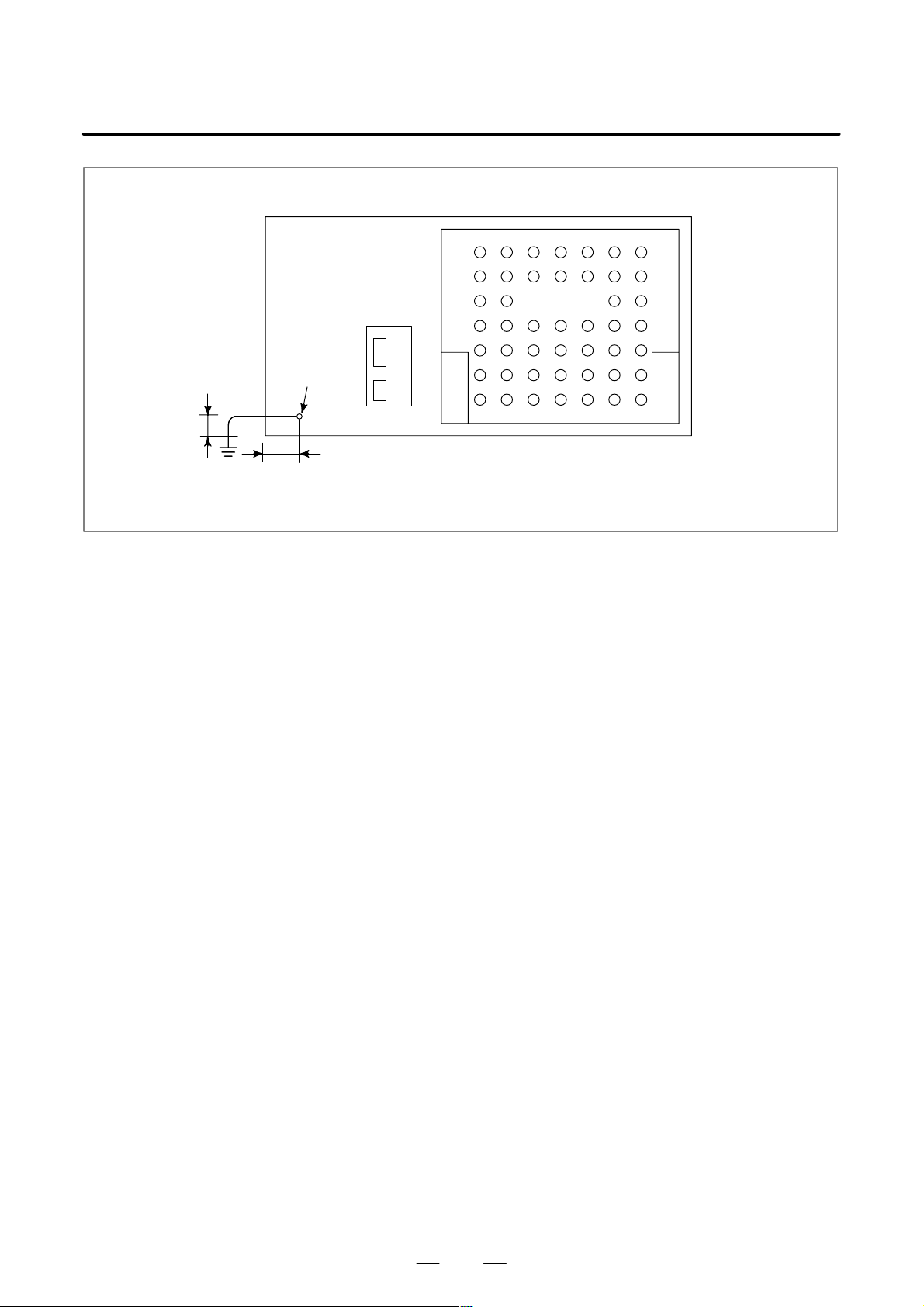

B–63503EN/01

3. INSTALLATION

3.7

CABLE LEAD–IN DIAGRAM

Fig. 3.7 (a) shows the grid of connector location.

Control board may not have all connectors as shown in Fig. 3.7 (a).

For actual connector layout of each board, please see the connector layout

diagrams in Fig. 3.8 (a) or later.

8

1732350392545 25

36

745864386086

129

35

Main board I/O board

52

1452

9

Fig.3.7 (a)

23

Page 34

3. INSTALLATION

B–63503EN/01

Memory

card

(80)

172

Unit : mm

Fig.3.7 (b)

24

Page 35

B–63503EN/01

3.8

CONNECTOR LAYOUT DIAGRAM

3. INSTALLATION

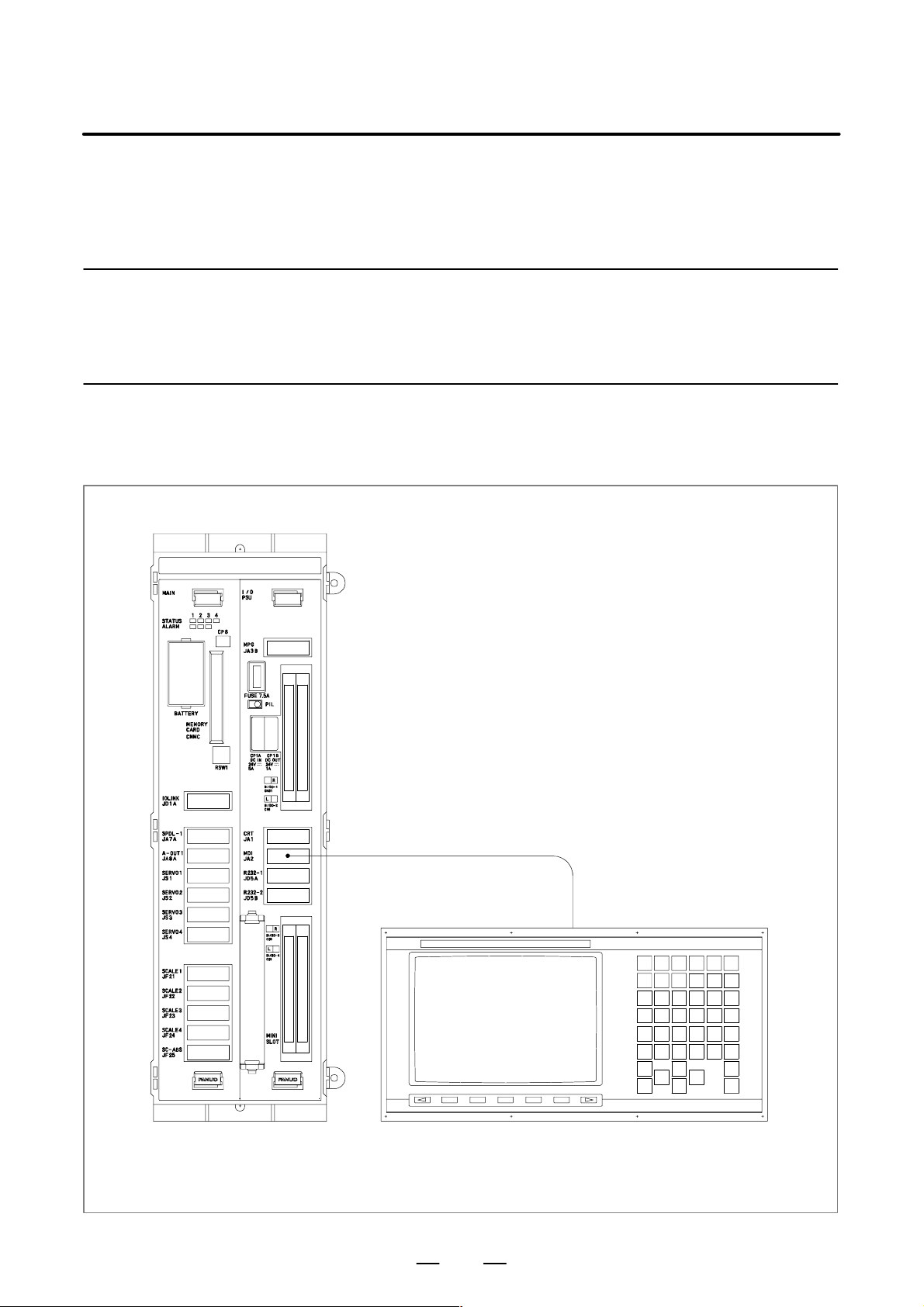

LED display Connector name and comment

Function Upper Lower

LED STATUS/ALARM

Battery for memory CPB

Battery BATTERY

Memory card MEMORY/CARD CNMC

Rotary switch RSW1

for maintenance

Serial I/O Link IOLINK JD1A

Serial spindle SPDL–1 JA7A

Analog output A–OUT1 JA8A

Servo amp.1 SERVO1 JS1A

Servo amp.2 SERVO2 JS2A

Servo amp.3 SERVO3 JS3A

Servo amp.4 SERVO4 JS4A

Linear scale1 SCALE1 JF21

Linear scale2 SCALE2 JF22

Linear scale3 SCALE3 JF23

Linear scale4 SCALE4 JF24

APC battery for SC–ABS JF25

linear scale

Fig.3.8 (a) Main board

25

Page 36

3. INSTALLATION

B–63503EN/01

Connector name and comment

Function Upper Lower

Position

1 Serial port R232–1 JD5A

2 Fuse FUSE

3

4 Pilot lamp PIL

5 24VDC output (R side) DC OUT CP1B

6 24VDC input (L side) DC IN CP1A

7 Operator’s panel I/O (R side) DI/DO–1 CB104

8 Machine side I/O (L side) DI/DO–2 CB105

R

L

9

10 CRTdisplay CRT JA1

1 1 MDI MDI JA2

12 Serial port R232–2 JD5B

13 Manual pulse generator MPG JA3

14

15 Machine side I/O (R side) DI/DO–3 CB106

16 Machine side I/O (L side) DI/DO–4 CB107

R

L

17

18

19

20

21

Fig.3.8 (b) I/O board

26

Page 37

B–63503EN/01

3. INSTALLATION

Function Comment

Mode switch

LED display

High–speed serial

bus interface

Fig.3.8 (c) High–speed serial bus interface board

SW

ST– 4 3 2 1

AL– 1 2

COP7

27

Page 38

4. POWER SUPPLY CONNECTION

POWER SUPPLY CONNECTION

4

B–63503EN/01

28

Page 39

B–63503EN/01

4. POWER SUPPLY CONNECTION

4.1

GENERAL

This section explains the connection of power supply for Series 0i control

unit.

29

Page 40

4. POWER SUPPLY CONNECTION

4.2

TURNING ON AND OFF THE POWER TO THE CONTROL UNIT

B–63503EN/01

4.2.1

Power Supply for the

Control Unit

Main

breaker

200VAC

Magnetic

contactor

Supply power (24VDC) to the control uint of Series 0i from an external

sources.

Install a power switch at (1) in Fig. 4.2.1 (a).

AC line

filter

External

24VDC

power

Servo unit

PSM

Input

3f

200VAC

For control line

1f

200VAC

(1)

SVM

ON/OFF circuit

Series 0i

control unit

24VDC

Input

24VDC

Output

9″CRT or

8.4″LCD

unit

Fig.4.2.1 (a)

30

ON OFFCOM

Page 41

B–63503EN/01

4. POWER SUPPLY CONNECTION

ON/OFF circuit (example)

G

+24V

DC INPUT

24V 4A

0V 0V

OFF COM ON

For example, “ON/OFF circuit” is as follows : (Fig.4.2.1 (b) )

Select the circuit devices, in consideration of its capacity.

G

lc3

+24V

DC OUTPUT

RY1 LC3

ry1

ry1

SERGE

ABSORBER

24V 4A

SPARK

KILLER

POWER ON/OFF SWITCH

OFF ON

Fig.4.2.1 (b)

DIODE

RELAY

COIL

B CONT ACT

FUSE

RELAY

CONTACT

A CONT ACT

31

Page 42

4. POWER SUPPLY CONNECTION

B–63503EN/01

4.2.2

+24 V Input Power

Specifications

Recommended connection and recommended power specifications

(1)Recommended connection

AC input

Regulated

power

supply

CNC

unit

(2)Recommended power specifications

(Must conform to the applicable safety standard.)

Output voltage: +24 V "10% (21.6 V to 26.4 V)

(including ripple voltage and noise. See the figure

below.)

Output current: The continuous load current must be larger than

the current consumption of the CNC (at the

maximum allowable temperature in the power

magnetics cabinet in which the power supply is

located).

Output retention time in the event of an instantaneous input

interruption:

10 mS (in the event of a drop by 100%)

20 mS (in the event of a drop by 50%)

AC input voltage

26.4V

Output voltage

21.6V

Output current

0A

Instantaneous

interruption

(–100%)

10mS 20mS

Fig. Examples of ripple voltage and noise due to switching power supply

Instantaneous

interruption

(–50%)

Abrupt

load

change

Noise

Ripple

voltage

Noise

Fig.4.2.2 Timing Chart

32

Page 43

B–63503EN/01

4. POWER SUPPLY CONNECTION

D Circuit configurations

Circuit configurations such as those shown below are not recommended.

a) Circuit examples in which the output voltage cannot be retained in the

event of an instantaneous interruption (the voltage decreases to 21.6

V or below)

Example 1

AC input

circuit

Rectifying

CNC unit

Example 2

AC input

circuit

Rectifying

CNC unit

b) Circuit examples that exceed the output voltage specification (21.6 V

to 26.4 V) due to an abrupt load change

Example 1

AC input

Example 2

AC input

Regulated

power

supply

Regulated

power

supply

CNC unit

Unit with

considerable load

fluctuations

CNC unit

Unit with

large rush

current

33

Page 44

4. POWER SUPPLY CONNECTION

B–63503EN/01

4.2.3

Procedure for Turning

On the Power

Turn on the power to each unit in the following order or all at the same

time.

1. Power supplies (200 VAC) for the entire machine

2. Power supplies (24 VDC) for slave I/O devices connected

using the FANUC I/O Link

3. Power supplies (24 VDC) for the control unit and CRT unit

Do not disconnect the battery for memory backup (3 VDC) or the battery

for the separate absolute pulse coders (6 VDC) regardless of whether the

power to the control unit is on or off. If batteries are disconnected when

the power to the control unit is turned off, current data stored in the control

unit for the pulse coders, parameters, programs etc, are lost.

Make sure that the power to the control unit is on when replacing batteries.

See Section 4.4.1 for how to replace the batteries for memory backup.

CAUTION

The maintenance rotary switch must be always set to 0 (set

to 0 at shipping from factory).

Changing this setting may cause the contents of memory to

be lost.

4.2.4

Procedure for Turning

Off the Power

Turn off the power to each unit in the following order or all at the same

time.

1. Power supplies (24 VDC) for slave I/O devices connected

using the FANUC I/O Link

2. Power supplies (24 VDC) for the control unit and CRT unit

3. Power supplies (200 VAC) for the entire machine

Motors cannot be controlled when the power is turned off or momentarily

interrupted. Take appropriate action on the machine side when necessary .

For example, when the tool is moved along a gravity axis, apply brakes

to prevent the axis from falling. Apply a brake that clamps the motor

when the servo is not operating or the motor is not rotating. Release the

clamp only when the motor is rotating. When the servo axis cannot be

controlled when the power is turned off or momentarily interrupted,

clamp the servo motor . In this case, the axis may fall before the relay for

clamping starts operating. The designer should make sure if the distance

results in trouble.

34

Page 45

B–63503EN/01

4. POWER SUPPLY CONNECTION

4.3

CABLE FOR POWER SUPPLY TO CONTROL UNIT

Supply power to the control unit from external resouce.

Series 0i control unit

CP1A

13+24V

2

Cable

CP1A

AMP Japan

1–178288–3 (housing)

1–175218–5 (Contact)

Recommended cable : A02B–0124–K830 (5m)

(Crimp terminal of size M3 is available on the external power side)

0V

+24V (1)

0v (2)

External power

24VDC stabilized

power

24VDC "10%

External power

Select a source that

meets the external

power terminal.

35

Page 46

4. POWER SUPPLY CONNECTION

4.4

BATTERY

B–63503EN/01

4.4.1

Battery for Memory

Backup (3VDC)

Part programs, offset data, and system parameters are stored in CMOS

memory in the control unit. The power to the CMOS memory is backed

up by a lithium battery mounted on the front panel of the control unit. The

above data is not lost even when the main battery goes dead. The backup

battery is mounted on the control unit at shipping. This battery can

maintain the contents of memory for about a year.

When the voltage of the battery becomes low, alarm message “BAT”

blinks on the CRT display and the battery alarm signal is output to the

PMC. When this alarm is displayed, replace the battery as soon as

possible. In general, the battery can be replaced within two or three

weeks, however, this depends on the system configuration.

If the voltage of the battery becomes any lower, memory can no longer

be backed up. T urning on the power to the control unit in this state causes

system alarm 910 (SRAM parity alarm) to occur because the contents of

memory are lost. Clear the entire memory and reenter data after replacing

the battery.The power to the control unit must be turned on when the

battery is replaced. If the battery is disconnected when the power is turned

off, the contents of memory are lost.

Observe the following precautions for lithium batteries:

WARNING

If an unspecified battery is used, it may explode.

Replace the battery only with the specified battery

(A02B–0177–K106.)

Replacing the battery

Dispose of batteries used in accordance with the applicable laws of your

country or the applicable laws or regulations of your local self–governing

body. Before disposal, insulate the terminals with tape or something

similar to prevent them from being short–circuited.

1 Use a litium battery (ordering drawing number :

A02B–0177–K106)

2 Turn on the Series 0i.

3 Remove the battery case from the front panel of the power supply unit.

The case can be removed easily by holding the top and bottom of it and

pulling.

36

Page 47

B–63503EN/01

4. POWER SUPPLY CONNECTION

Front panel of control

unit main board

MAIN

STATUS

ALARM

Battery case

BATTERY

Battery (Ordering drawing

number A02B–0177–K106)

Fig.4.4.1(a) Replacing the battery(1)

4 Remove the connector from the battery.

Front panel of control

unit main board

CP8

231

MEMORY

CARD

CNMC

4

CP8

Battery connector

RSW1

Battery connector

BATTERY

MEMORY

CARD

CNMC

Fig.4.4.1(b) Replacing the battery(2)

5 Replace the battery and reconnect the connector.

6 Install the battery case.

7 Turn off the Series 0i.

37

Battery

Page 48

4. POWER SUPPLY CONNECTION

B–63503EN/01

4.4.2

Battery for Separate

Absolute Pulse Coders

(6VDC)

One battery unit can maintain current position data for six absolute pulse

coders for a year.

When the voltage of the battery becomes low , APC alarms 3n6 to 3n8 (n:

axis number) are displayed on the CRT display. When APC alarm 3n7

is displayed, replace the battery as soon as possible. In general, the battery

should be replaced within two or three weeks, however, this depends on

the number of pulse coders used.

If the voltage of the battery becomes any lower , the current positions for

the pulse coders can no longer be maintained. Turning on the power to

the control unit in this state causes APC alarm 3n0 (reference position

return request alarm) to occur. Return the tool to the reference position

after replacing the battery .See Subsec. 7.1.3 for connecting the battery for

separate absolute pulse coders.

38

Page 49

B–63503EN/01

5

5. CONNECTION TO CNC PERIPHERALS

CONNECTION TO CNC PERIPHERALS

39

Page 50

5. CONNECTION TO CNC PERIPHERALS

5.1

CONNECTION T O THE DISPLAY UNIT

B–63503EN/01

5.1.1

Outline

The display unit is used for displaying the programs, parameters etc, and

supporting the machine operation.

The Series 0i supports the following display units: 9″ CRT and 8.4″ LCD.

40

Page 51

B–63503EN/01

5.1.2

Connection to Display

Unit

Connection to Series 0i

Control unit

5. CONNECTION TO CNC PERIPHERALS

CP1B

DC OUT

Power supply cable

CRT

JA1

Video cable

CN2 (CRT)

CP5 (LCD)

CRT/MDI, LCD/MDI unit

CN1 (CTR)

JA1 (LCD)

41

Page 52

5. CONNECTION TO CNC PERIPHERALS

5.1.3

9″ CRT Display Unit

Interface

Series 0i CRT unit

B–63503EN/01

JA1

(PCR–EV20MDT)

VDR

01

0V

02

03

VDG

04

0V

05

VDB

06

0V

07

08

09

10

CP1B

Cable side

JAPAN AMP

2–178288–3 (Housing)

1–175218–5 (contact)

Connection of

VIDEO Signal Cable

JA1

HIROSE FI40A–20S–CV5 (Connector)

11

12

13

14

15

16

17

18

19

20

1

2

3

VSYNC

0V

0V

HSYNC

+24V

0V

CN1

(MR–20RM)

1

VDR

2

HSYNC

3

VSYNC

4

VDG

5

VDB

6

7

1

2

3

(0V)

4

0V

5

+24V

6

(+24V)

0V

8

0V

9

0V

10

0V

11

0V

12

13

CN2

Cable side

JAPAN FCI

SMS6PN–5 (Housing)

RC16M–23TB or RC16M

(contact)

CN1

HONDA MR20pins/female

14

15

16

17

18

19

20

(0V)

(0V)

VDR (01)

0V (02)

VDG (03)

0V (04)

VDB (05)

0V (06)

HSYNC (18)

0V (16)

VSYNC (12)

0V (14)

RECOMMENDED CABLE MA TERIAL

A66L–0001–0371 COAXIAL CABLE (MAX : 50m)

RECOMMENDED CABLE MA TERIAL

A02B–0120–K819 CRT VIDEO SIGNAL CABLE (5m)

(01) VDR

(08) 0V

(04) VDG

(1 1) 0V

(05) VDB

(12) 0V

(02) HSYNC

(09) 0V

(03) VSYNC

(10) 0V

42

Page 53

B–63503EN/01

5.1.4

8.4″ LCD Units

Interface

Series 0i LCD unit

5. CONNECTION TO CNC PERIPHERALS

JA1

(PCR–HV20MDT)

01

VDR

02

0V

03

VDG

04

0V

05

VDB

06

0V

07

08

09

10

CP1B

Cable side

Housing: JAPAN AMP 2–178288–3

Contact : JAPAN AMP 1–175218–5

Connection of

VIDEO Signal Cable

JA1

HIROSE FI40A–20S–CV5 (Connector)

11

12

13

14

15

16

17

18

19

20

1

2

3

VSYNC

0V

0V

HSYNC

(+24V)

(0V)

JA1

(PCR–HV20MDT)

01

02

03

04

05

06

07

08

09

10

1

2

3

VDR

0V

VDG

0V

VDB

0V

(+24V)

(0V)

11

12

13

14

15

16

17

18

19

20

CP5

Cable side

Housing: JAPAN AMP 2–178288–3

Contact : JAPAN AMP 1–173218–5

VSYNC

0V

0V

HSYNC

JA1

HIROSE FI40A–20S–CV5

(Connector)

VDR (01)

0V (02)

VDG (03)

0V (04)

VDB (05)

0V (06)

HSYNC (18)

0V (14)

VSYNC (12)

0V (16)

RECOMMENDED CABLE MA TERIAL

A66L–0001–0371 COAXIAL CABLE (MAX : 50m)

RECOMMENDED CABLE MA TERIAL

A02B–0120–K818 LCD/VIDEO SIGNAL CABLE (5m)

(01) VDR

(02) 0V

(03) VDG

(04) 0V

(05) VDB

(06) 0V

(18) HSYNC

(16) 0V

(12) VSYNC

(14) 0V

43

Page 54

5. CONNECTION TO CNC PERIPHERALS

B–63503EN/01

5.1.5

Adjusting the TFT

Color LCD

(1)Applied unit

Name Specification number

8.4″ color LCD/MDI unit A02B–0279–C081#TA

A02B–0279–C081#MA

(2)Adjustment point (as viewed from the rear of the display unit

TM1

SW1

(3)Adjustment method

(a)Display horizontal setting

D The horizontal position of the display is set as described below ,

using SW1. Rotating SW1 one notch in the positive (+)

direction shifts the display one dot to the right. Rotating SW1

one notch in the negative (–) direction shifts the display one dot

to the left.

D Set SW1 such that the entire display is visible. There is only one

optimum setting position.

(b)Flickering adjustment

Flickering is eliminated by setting jumper pin TM1. One side of

TM1 is marked A, while the other side is marked B. TM1 is

factory–set to the B position. If the screen flickers, set TM1 to the

A position.

44

Page 55

B–63503EN/01

5.2

CONNECTION OF MDI UNIT

5. CONNECTION TO CNC PERIPHERALS

5.2.1

General

5.2.2

Connection to the MDI

Unit

Control unit

Manual data input devices for the Series 0i are called MDI units. MDI

units are keyboards used to enter data such as CNC programs and

parameters into the CNC.

MDI

JA2

MDI CABLE

Connection to the MDI

CK1

CRT/MDI unit

LCD/MDI unit

45

Page 56

5. CONNECTION TO CNC PERIPHERALS

5.2.3

Connection to the

Standard MDI Unit

B–63503EN/01

MDI unitSeries 0i control unit

JA2

:KEY01

:KEY00

01

02

:KEY02

03

:KEY04

04

:KEY06

05

:COM00

06

:COM02

:COM04

07

08

:COM06

09

:COM08

10

:COM10

Cable

JA2

Honda PCR connector

11

:KEY03

12

:KEY05

13

:KEY07

14

:COM01

15

:COM03

16

:COM05

17

18

:COM07

:COM09

19

:COM11

20

:KEY00 (01)

:KEY02 (02)

:KEY04 (03)

:KEY06 (04)

:COM00 (05)

:COM02 (06)

:COM04 (07)

:COM06 (08)

:COM08 (09)

:COM10 (10)

:KEY01 (1 1)

:KEY03 (12)

:KEY05 (13)

:KEY07 (14)

:COM01 (15)

:COM03 (16)

:COM05 (17)

:COM07 (18)

:COM09 (19)

:COM1 1 (20)

CK1

:KEY01

:KEY00

01

02

:KEY02

03

:KEY04

04

:KEY06

05

:COM00

06

:COM02

:COM04

07

08

:COM06

09

:COM08

10

:COM10

CK1

Honda PCR connector

(01) :KEY00

(02) :KEY02

(03) :KEY04

(04) :KEY06

(05) :COM00

(06) :COM02

(07) :COM04

(08) :COM06

(09) :COM08

(10) :COM10

(11) :KEY01

(12) :KEY03

(13) :KEY05

(14) :KEY07

(15) :COM01

(16) :COM03

(17) :COM05

(18) :COM07

(19) :COM09

(20) :COM11

11

:KEY03

12

:KEY05

13

:KEY07

14

:COM01

15

:COM03

16

:COM05

17

:COM07

18

:COM09

19

:COM11

20

GROUND

PLATE

RECOMMENDED CABLE SPECIFICA TION : A02B–0120–K810 (5m)

RECOMMENDED CABLE MA TERIAL : A66L–0001–0284#10P (#28AWG 10pair)

SHIELD

46

Page 57

B–63503EN/01

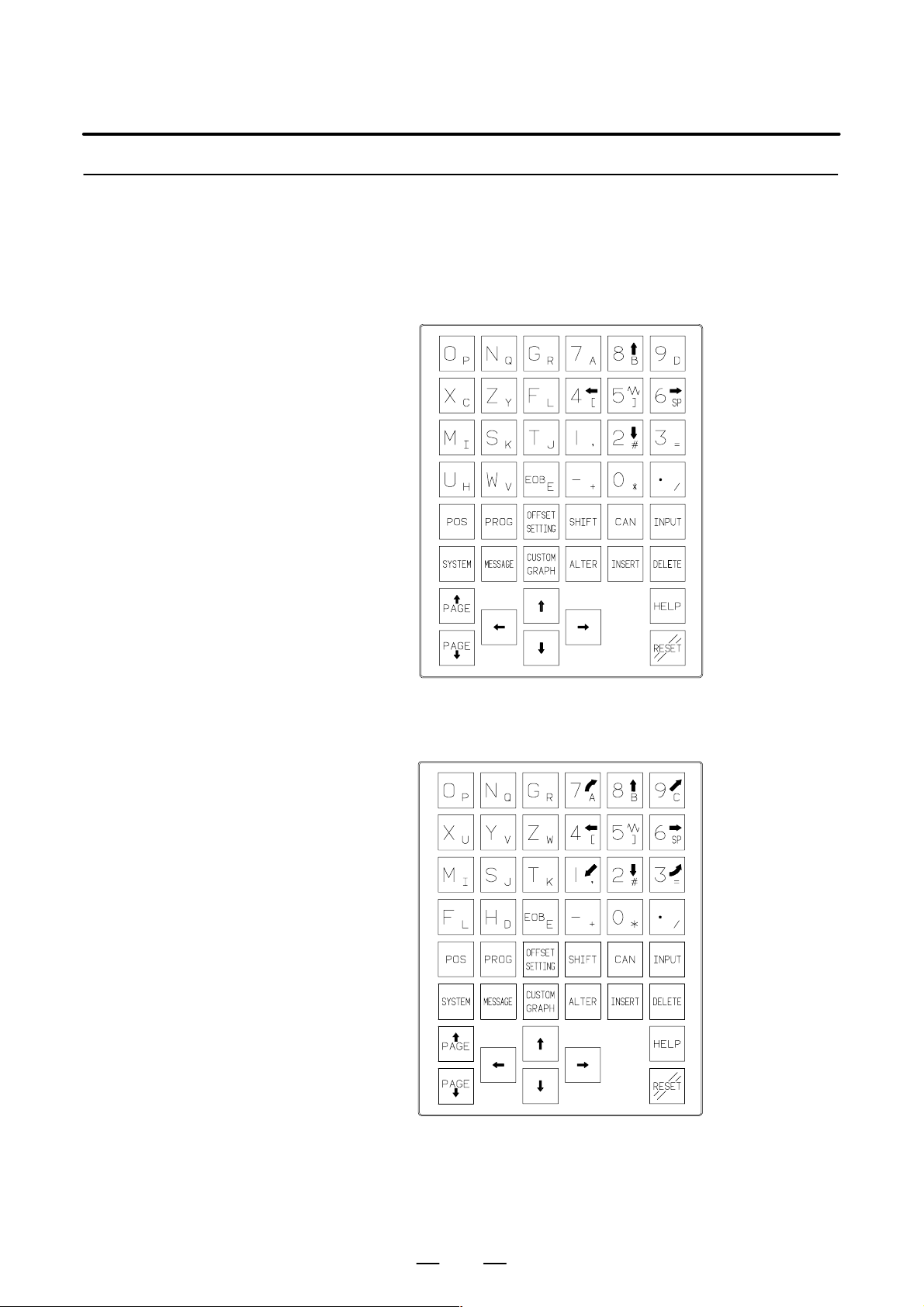

5.2.4

V aried MDI Key Switch

D 9″ CRT/MDI unit and

8.4″ LCD/MDI unit for

Series 0i–TA

English display

5. CONNECTION TO CNC PERIPHERALS

D 9″ CRT/MDI unit and

8.4″ LCD/MDI unit for

Series 0i–MA

English display

47

Page 58

5. CONNECTION TO CNC PERIPHERALS

5.3

CONNECTING I/O DEVICES

B–63503EN/01

5.3.1

General

I/O devices are used for inputting various data such as CNC programs and

parameters from external devices to the CNC or outputting data from the

CNC to external devices.

The Handy File is one of the I/O devices for the Series 0i. The interface

for I/O devices complies with RS–232–C. The Series 0i can therefore be

connected to devices which have an RS–232–C interface.

48

Page 59

B–63503EN/01

5.3.2

Connecting I/O Devices

Control unit

5. CONNECTION TO CNC PERIPHERALS

Punch panel

R232–1

JD5A

R232–2

JD5B

Handy File

49

Page 60

5. CONNECTION TO CNC PERIPHERALS

5.3.3

RS–232–C Serial Port

CNC

JD5A, JD5B

(PCR–EV20MDT)

RD

1

0V

2

DR

3

0V

4

CS

5

0V

6

CD

7

0V

8

9

+24V

10

11

12

13

14

15

16

17

18

19

20

SD

0V

ER

0V

RS

0V

+24V

B–63503EN/01

RELA YING CONNECTOR

(DBM–25S)

FG

10

11

12

13

1

2

SD

RD

3

RS

4

5

CS

DR

6

SG

7

8

CD

9

14

15

16

17

18

19

20

21

22

23

24

25

ER

+24V

CABLE WIRING

1

RD

2

0V

3

DR

4

0V

5

CS

6

0V

7

CD

8

0V

9

10

+24V

11

SD

12

0V

13

ER

14

0V

15

RS

16

0V

17

18

19

+24V

20

SHIELD

GROUND PLA TE

RECOMMENDED CABLE MA TERIAL

A66L–0001–0284#10P(#28AWG 10–pair)

RECOMMENDED CABLE SPECIFICA TION (PUNCH P ANEL)

<Narrow width type>

A02B–0120–C191 (1m)

A02B–0120–C192 (2m)

A02B–0120–C193 (5m)

<Wide width type>

A02B–0120–C181 (1m)

A02B–0120–C182 (2m)

A02B–0120–C183 (5m)

20

25

GND

3

6

5

8

2

4

7

1

RD