Page 1

Operating manual

—

Innova® -86 C Freezers see

on p.Fig.Tab.p

Op

l

.

erating manua

September 20, 2011

New Brunswick -86 °C Freezers

Innova®

Operating manual

M1288-0052

Revision T

Page 2

Copyright

©

Copyright

2011 New Brunswick Scientific Co., Inc., USA. No part of this publication may be reproduced without the prior

permission of the copyright owner.

New Brunswick Scientific reserves the right to change information in this document without notice. Updates to information

in this document reflect our commitment to continuing product development and improvement.

Trademarks

Eppendorf

BioCommand

Innova

®

is a registered trademark of Eppendorf AG, Germany.

®

is a registered trademark of New Brunswick Scientific Co., Inc., USA.

®

is a registered trademark of New Brunswick Scientific Co., Inc., USA.

New Brunswick™ and the New Brunswick Logo™ are trademarks of Eppendorf AG, Germany.

S.M.A.R.T. Plus™ is a pending trademark of New Brunswick Scientific Co., Inc., USA.

Trademarks are not marked in all cases with ™ or

®

in this manual.

New Brunswick Scientific has attempted to identify the ownership of all trademarks from public records. Any omissions or

errors are unintentional.

September 20, 2011

Revision T

M1288-0052

Page 3

Innova® -86 °C Freezers — Operating manual

Table of contents

1 Table of contents

1

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Hazard symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Degrees of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Manual conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 Health and safety at work act 1974. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Main illustration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Inspection of boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Packing list verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Product versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5.1 Warranty registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5.2 Extended warranty option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table of contents

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Preparing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Installing the shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Lockable freezer handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Operating controls and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Controls and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.1 Plug in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.2 Turning the freezer On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.3 Alarm/battery activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1.4 Testing the alarm monitoring socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.5 Vacuum Effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Programming the freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.1 Setting operating temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.2 Setting high alarm setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Setting low alarm setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.4 Checking temperature and alarm setpoint settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.5 Setting the alarm delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.6 Changing lock codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2.7 Setting the temperature offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 Battery backup switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3

Page 4

Innova® -86 °C Freezers — Operating manual

1

6.4 Alarm monitoring socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 Voltage stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table of contents

7.2 Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.3 After a mains/power failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.4 Interior warming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.1 Painted surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.2 Panels and shelves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.3 Air intake grille and filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.4 Heated vent port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.5 Door or lid seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.1 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.2 Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.3 Removing the inner doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.4 Replacing the inner door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.2.5 Electrical components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.1 Upright freezers specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.1.2 Chest freezers specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.1 A2 independent temperature monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.2 Auto-dialers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.3 Temperature probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.4 Validation packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.5 External voltage stabilizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.6 Padlock adapter kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.7 CO

10.1.8 Inventory racking systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.9 Chart recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1.10 New Brunswick BioCommand SFI datalogging software (RS-485 interface) . . . . . . . . . . . . . . . . . . 37

11 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1 Shut down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

and LN2 back-up systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4

Page 5

Innova® -86 °C Freezers — Operating manual

1 Operating instructions

1 Operating instructions

1.1 Using this manual

Carefully read this operating manual before using the device for the first time.

Also observe the operating manual enclosed with the accessories.

The operating manual should be considered as part of the product and stored in a location

that is easily accessible.

When passing the device on to third parties, be sure to include this operating manual.

If this manual is lost, please request another one. The current version can be found on our

website http://www.nbsc.com

1.2 Danger symbols and danger levels

1.2.1 Hazard symbols

Hazard point Burns

Electric shock Material damage

.

1

Operating instructions

Crush

1.2.2 Degrees of danger

The following degree levels are used in safety messages throughout this manual. Acquaint

yourself with each item and the potential risk if you disregard the safety message.

DANGER Will lead to severe injuries or death.

WARNIN G May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

1.3 Symbols used

Example Meaning

You are requested to perform an action.

1.

2.

Perform these actions in the sequence described.

• List.

References useful information.

5

Page 6

Innova® -86 °C Freezers — Operating manual

1.4 Abbreviations used

1

Operating instructions

A Amp

CFC Chlorofluorocarbons

°C Degree Celsius

HCFC Hydrochlorofluorocarbon

HFC Hydrofluorocarbon

Hz Hertz

kg Kilogram

lb Pound

m Meter

min Minute

mm Millimeter

N/A Not applicable

rpm Revolutions per Minute (min

ULT Ultra-Low Temperature

V Volt

-1

)

6

Page 7

Innova® -86 °C Freezers — Operating manual

2 Safety

2Safety

2.1 Intended use

New Brunswick Innova freezers are designed to provide precise, ultra-low temperature

environments for cold storage of scientific or medical materials. They are designed to provide

ultra-low temperature sample storage from -50 °C to -86 °C at 32 °C maximum ambient

operating temperature.

2.2 Warnings for intended use

2.2.1 Manual conventions used

Risk of material damage

This equipment must be operated as described in this manual.

NOTICE!

Please read the entire operating manual before attempting to use this equipment. If

operational guidelines are not followed, equipment damage may occur.

Risk of personal injury

Do not use this equiment in a hazardous atmosphere or with hazardous materials for which

CAUTION!

the equipment was not designed.

Please read the entire operating manual before attempting to use this equipment. If

operational guidelines are not followed, personal injury may occur.

Risk of personal injury

Crush Warning messages alert you to specific procedures or practices regarding heavy

CAUTION!

objects which, if not followed correctly, could result in serious personal injury.

Risk of personal injury

Flammable warning messages alert you to possible risks of of personal injury and equipment

WARNING!

damage: protect the system from sparks and flames.

2

Safety

2.2.2 Health and safety at work act 1974

(FOR THE UNITED KINGDOM)

New Brunswick Scientific, as manufacturers and suppliers of laboratory equipment, are obliged

under the terms of the above Act to provide our users with instructions on the safe installation,

operation and maintenance of our equipment.

Our equipment is designed to acceptable standards and does not entail any hazard if used, as

advised in the attached instructions.

The following safety precautions should be observed by all personnel using this equipment:

1. Read and understand this manual. If in doubt, contact your local New Brunswick sales office.

2. Do not remove any covers. There are no operable controls other than those referred to in this

manual. There are voltages in excess of 41.5 volts AC behind the covers.

3. Use freezer gloves at all times when loading or unloading the equipment. The temperature of

operation is such that direct contact with the cold contents or inside the equipment can burn

unprotected skin.

4. Observe good housekeeping practices, at all times keeping the equipment and the adjacent

areas clean, dry and uncluttered.

5. Should any malfunctions occur or be suspected, immediately call a qualified service engineer

to investigate.

7

Page 8

Innova® -86 °C Freezers — Operating manual

3 Product description

3 Product description

3.1 Main illustration

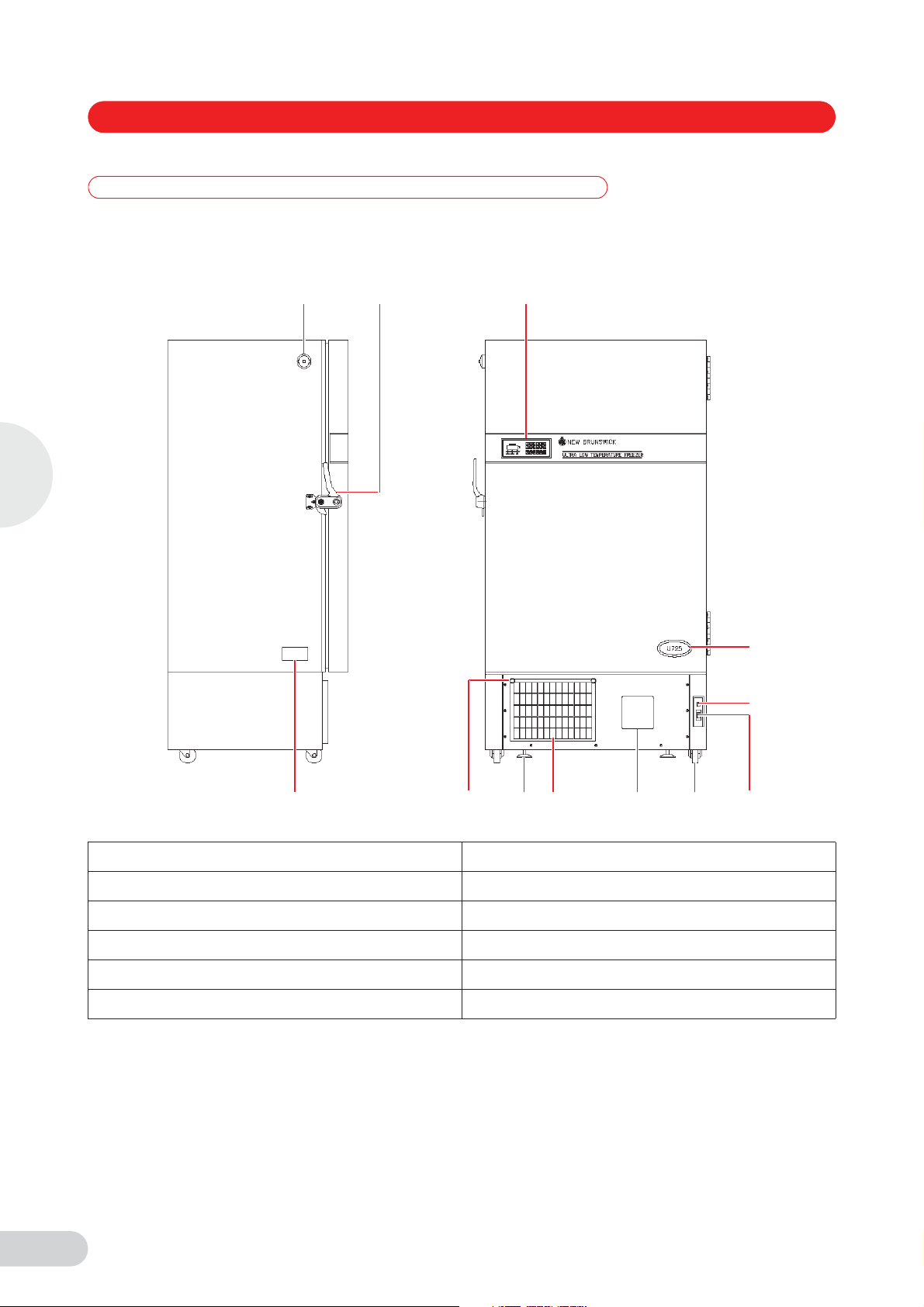

Abb. 1: Upright freezer - side and front views

3

Product description

12 3

4

5

7689101112

Fig. 1: Upright freezer - side and front views

1 Heated vent port 2 Door handle (lockable)

3 Control panel/display 4 Model label

5 Battery switch behind lockable panel 6 On/Off circuit breaker behind lockable panel

7 Transport castors 8 Chart recorder (optional)

9 Air filter grille 10 Adjustable feet

11 Quarter turn fastener 12 Specification plate

8

Page 9

Innova® -86 °C Freezers — Operating manual

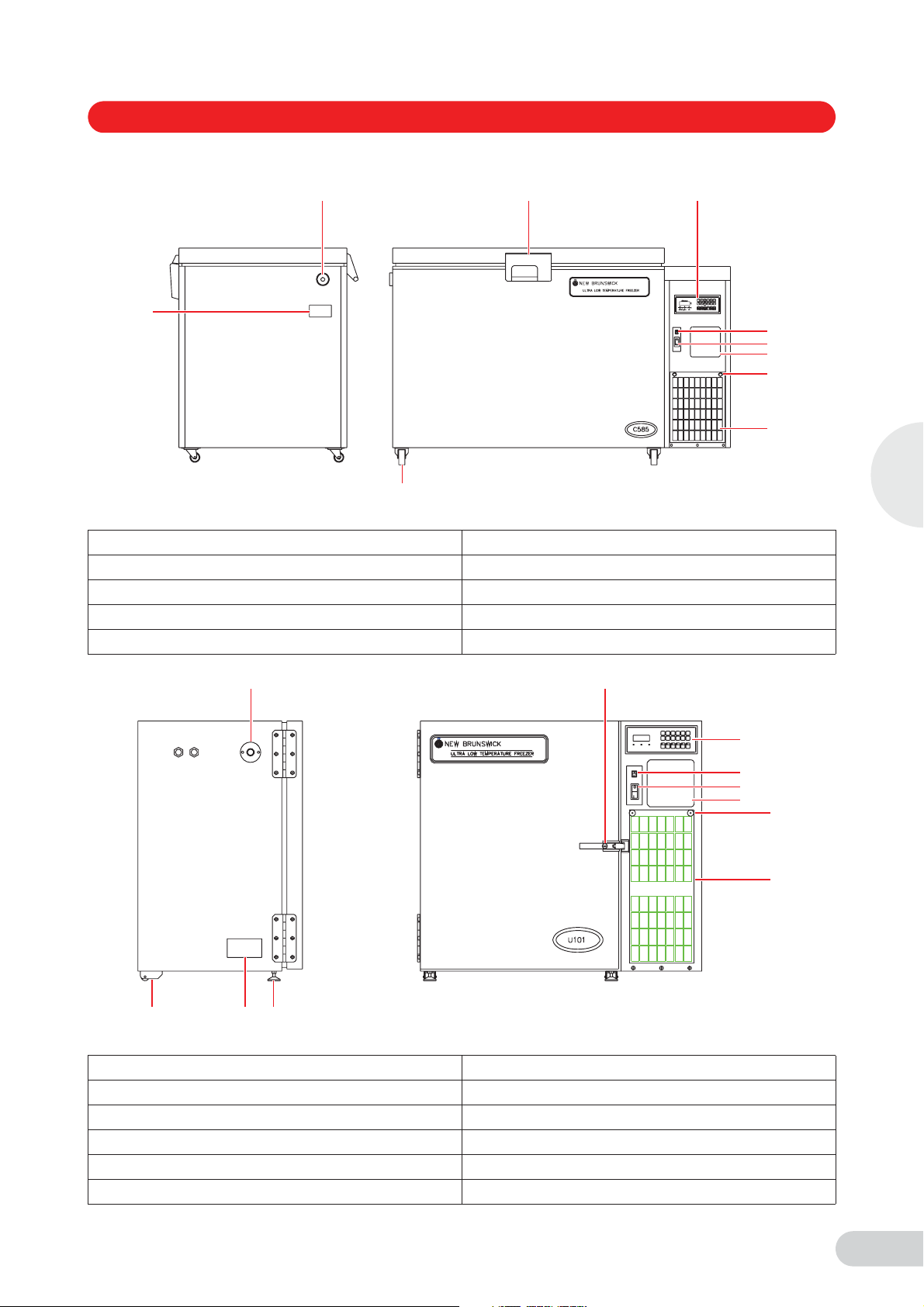

Abb. 2: Chest freeze r - side and front v iews

1

10

9

Fig. 2: Chest freezer - side and front views

1 Heated vent port 2 Lockable handle

3 Control panel/display 4 Battery switch (alarm) behind lockable panel

5 On/Off circuit breaker behind lockable panel 6 Chart recorder (optional)

7 Quarter turn fasteners 8 Air filter grille

9 Braked castors (front) 10 Specification plate

23

4

5

6

7

8

3

Product description

Abb. 3: U101 freeze r - side and front view s

12

3

4

5

6

11 10 9

Fig. 3: U101 freezer - side and front views

1 Heated vent port 2 Lockable handle

3 Control panel/display 4 Battery switch (alarm)behind lockable panel

5 On/Off circuit breaker behind lockable panel 6 Chart recorder (optional)

7 Quarter turn fasteners 8 Air filter grille

9 Adjustable feet 10 Specification plate

11 Rear rollers

7

8

9

Page 10

3

Innova® -86 °C Freezers — Operating manual

3.2 Delivery package

3.2.1 Inspection of boxes

Inspect the boxes carefully for any damage that may have occurred during shipping. Report any

damage to the carrier and to your local New Brunswick Sales Order Department immediately.

3.2.2 Packing list verification

Unpack your order, saving the packing materials for possible future use. Save the operating

manual for instruction and reference. Verify against your New Brunswick packing list that you

have received the correct materials, and that nothing is missing. If any part of your order was

damaged during shipping, is missing, or fails to operate, fill out the "Customer Feedback" form,

NOTICE!

available online at www.nbsc.com/CustomerFeedback.aspx

Risk of material damage

Vacuum insulation panels are used in the construction of these freezers. Inspect the cabinet

panels for punctures or other damage that compromises the integrity of the product.

These panels are mounted in the cavity against the steel outer wall of the freezer. Any drilling

or puncture to the outer wall could release the vacuum from the panel, resulting in impaired

freezer performance.

Any unauthorized punctures or other damage deliberately made to the cabinet walls will

invalidate the warranty.

.

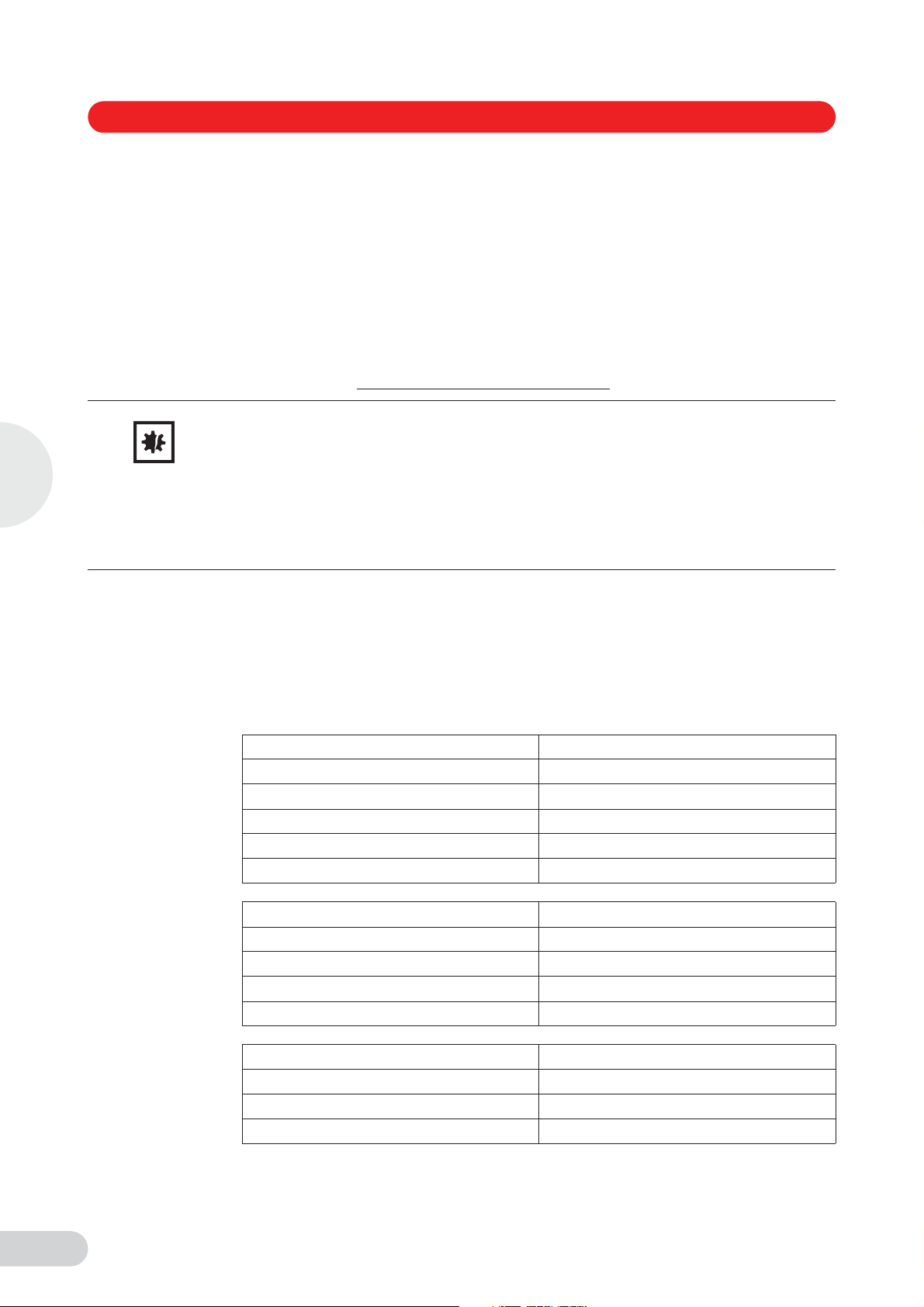

3.3 Product versions

3.3.1 Introduction

Product description

This manual provides the user with the necessary information for installation and operation of

New Brunswick's Innova

provides some preliminary user maintenance information.

This manual covers the following freezer models:

Model (230 V, 50 Hz) Capacity

Model (208 - 230 V, 60 Hz) Capacity

®

ultra-low temperature freezers with vacuum insulation panels. It also

U101 101 liters (3.6 cubic feet)

U535 535 liters (18.9 cubic feet)

U725 725 liters (25.6 cubic feet)

C585 585 liters (20.7 cubic feet)

C760 760 liters (26.9 cubic feet)

U535 535 liters (18.9 cubic feet)

U725 725 liters (25.6 cubic feet)

C585 585 liters (20.7 cubic feet)

C760 760 liters (26.9 cubic feet)

10

Model (120 V, 60 Hz) Capacity

U101 101 liters (3.6 cubic feet)

U535 535 liters (18.9 cubic feet)

C585 585 liters (20.7 cubic feet)

All freezers listed are totally free of CFCs (Chlorofluorocarbons) and HCFCs

(Hydrochlorofluorocarbons). They use HFCs (Hydrofluorocarbons) as refrigerants.

Page 11

Innova® -86 °C Freezers — Operating manual

3.4 Features

The freezers are manufactured using high quality steel and electronics for long life. The cabinets

are insulated with a combination of foamed-in-place polyurethane foam and vacuum insulation

panels. This combination ensures superior insulation properties while maintaining an extra large

internal capacity for the footprint of the freezer. The Innova freezers have many features designed

to provide ease of use and maintanence, security and reliability to your ultra-low temperature

storage needs. They are built to stringent regulatory requirements for safety and environmental

friendliness and disposability, and they are CE and UL certified.

Features include:

• Designed to be exceptionally energy efficient and eco-friendly.

• A setpoint keypad and digital temperature readout are provided on a control panel, located on

the door of the upright freezers and on the console on the right side of chest freezers.

Controls for setting the freezer temperature and alarm warning setpoints are enabled by an

electronic lock. A unique code, which is selected by the user through the keypad, sets this

lock. The code can be changed at any time, provided the current setting of the lock is known.

On delivery, the lock code is "0000" (unlocked).

• Indicator lamps on the control panel provide warnings of power loss, system failure,

exceeding High/Low temperature setpoints, low battery voltage, and filter blockage. There is

also an LED to indicate when the freezer is under remote control via the RS-485 optional

computer interface.

• Vacuum insulation panel technology reduces the cabinet wall thickness while maintaining

superb insulation characteristics to provide the largest internal volume per floor space used.

• Freezers are totally free of CFCs (Chlorofluorocarbons) and HCFCs

(Hydrochlorofluorocarbons). They use industrial grade, commercially available HFCs

(Hydrofluorocarbons) as refrigerants.

• Upright models utilize gasketed and insulated inner doors to reduce cold air loss and recovery

times, reduce internal temperature fluctuations and conserve energy. Chest models utilize

insulated covers to reduce internal temperature fluctuations and conserve energy.

• Heavy-duty commercially available compressors provide rapid temperature pull-down and

recovery after door opening.

• A heated port with ice-clearing plunger prevents vacuum formation enabling the outer door to

be easily opened at anytime.

• All interior panels and shelves are made of high grade corrosion-resistant stainless steel,

making them durable and easy to keep clean and sterilize.

• Inner doors lift off their hinges without the use of tools to simplify cleaning.

• Heavy duty castors enable easy installation and relocation (the model U101 has rear rollers

and adjustable front legs.)

• Two access ports allow easy addition of sensors, or of back-up systems that can provide

cooling protection for your samples in the case of a power outage or other system failure.

• An alarm contact is provided for connection to an external monitoring device or system.

• The freezers can be fitted with an optional 7-day circular chart recorder to provide

independent temperature recording.

• An automatic reset restarts freezers at random 15 second intervals to protect the

microprocessor controller from damage by electrical spikes caused by multiple freezers

turning on at once.

• Lockable freezer handles on outer door provide added security against unauthorized users.

• An internal voltage stabilizer (60 Hz models only, except U101) that automatically

compensates for variations in mains/power supply voltage (in case of over-voltage,

brown-outs, dips, sags and surges).

• Multiple accessories are offered, including CO

systems, external voltage stabilizer, inventory racking, and more.

/LN2 back-up systems, remote monitoring

2

3

Product description

11

Page 12

Innova® -86 °C Freezers — Operating manual

3.5 Warranty

New Brunswick Scientific equipment is protected by a comprehensive warranty. The warranty

covers faulty components and assembly, and our obligation under this warranty is limited to

repairing or replacing the instrument or part thereof, which shall prove to be defective after our

examination.

The warranty does not cover loss of time or materials, such as the loss of biological or

biochemical by-products caused by any work interruption resulting from equipment failure; it does

not extend to equipment that has been subject to misuse, neglect, accident or improper

installation or application; nor does it cover any machine that has been repaired or altered by

anyone other than an authorized factory-trained service representative, without prior written

approval from your local New Brunswick sales office or distributor.

Expendable items such as bearings and seals, lamps, probes, sensors, glass, filters, single-use

vessels, etc., are not covered.

The warranty begins on the date the equipment ships from New Brunswick Scientific or an

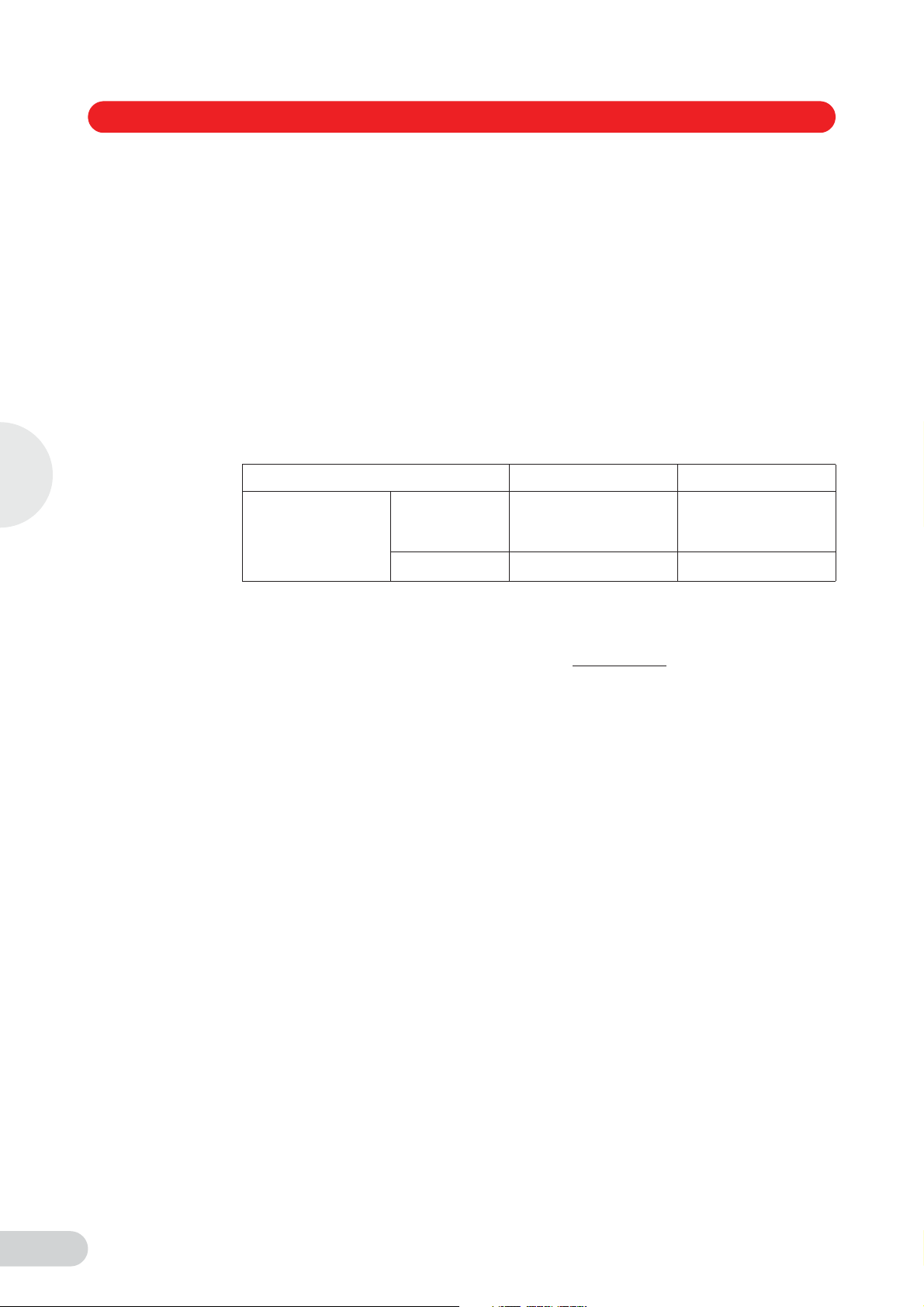

authorized distributor and extends through the period indicated in the chart below:

3

3.5.1 Warranty registration

Product description

3.5.2 Extended warranty option

Instrument Parts Warranty Labor Warranty

Freezers ULT Freezers 5 years; vacuum

insulation panels: 12

years

1

Accessories

1

Chart recorders, CO2/LN2 back-up systems, etc.

To register your warranty, complete the online form at www.nbsc.com

Help? tab.

A variety of service plans are offered to help minimize downtime from unexpected malfunctions in

equipment operation. Speak to your New Brunswick sales representative for more information.

1 year 1 year

2 years

under the How Can We

12

Page 13

Innova® -86 °C Freezers — Operating manual

4 Installation

4 Installation

4.1 Preparing installation

Risk of personal injury

DO NOT attempt to lift any freezer by hand. Preferred lifting for loading and unloading is by

WARNING!

NOTICE!

4.2 Selecting the location

mechanical lifting equipment.

Risk of material damage

Maintenance, adjustment and repair work should be carried out only by QUALIFIED,

EXPERIENCED personnel who have been AUTHORIZED to undertake such work by New

Brunswick Scientific or its authorized agents.

Failure to use authorized service agents will invalidate the warranty.

All freezers are mounted on castors for ease of movement. The U101 upright freezer has two

rear wheels. Upright freezers have feet that provide both a leveling feature and a locking feature

to stop the freezer from rolling once it is in place. Chest freezers have locking front castors; these

do not provide leveling adjustment, so the site chosen for the freezer must have a flat, level floor.

Position the freezer to allow disconnection to be made in respect to removal of the plug or

appliance coupler, also the free air entry through the intake grille in the front and free air exit from

the back. Provide a clearance of at least 150 mm (6 in) on all sides.

For efficient temperature control, the freezer should be placed in a shaded area, away from

sources of excessive heat. For maximum cooling capability, the product should be located in an

air-conditioned room.

4

Installation

4.3 Installing the shelves

Model U101 upright freezers are fitted with one fixed shelf. Model U535 and U725 upright

freezers are fitted with two adjustable shelves. These can be positioned in 12.7 mm (½ in) steps

anywhere throughout the freezer.

To effectively utilize racks within the freezer, be sure to position them so that each shelf is aligned

with the bottom of each inner door.

Perform the following steps to install the shelves:

1. Ensure that the freezer is turned off and unplugged.

2. Remove the protective plastic coating from the shelf.

3. Position the four shelf clips evenly within the freezer by squeezing the clip, then inserting it

into the shelf support within the freezer.

4. Place the shelf in the freezer, making sure all four shelf clips are supporting the weight of the

shelf.

To readjust the shelf or shelf clips, gently squeeze the shelf clip to release it from the side of the

freezer, then reposition it as needed.

4.4 Lockable freezer handle

Freezers are supplied with lockable handles.

The U101, C585, and C760 are fitted with quarter turn key locks.

The U535 and U725 upright freezer handle is fitted with barrel locks (push in and turn key to lock,

turn key to unlock; the barrel will only lock when a key is turned to the lock position). The barrel

lock may be removed from the upright freezer handle if the lock feature is not required.

An optional padlock adaptor can provide extra security by allowing the addition of a

customer-supplied padlock to secure the freezer handle.

13

Page 14

Innova® -86 °C Freezers — Operating manual

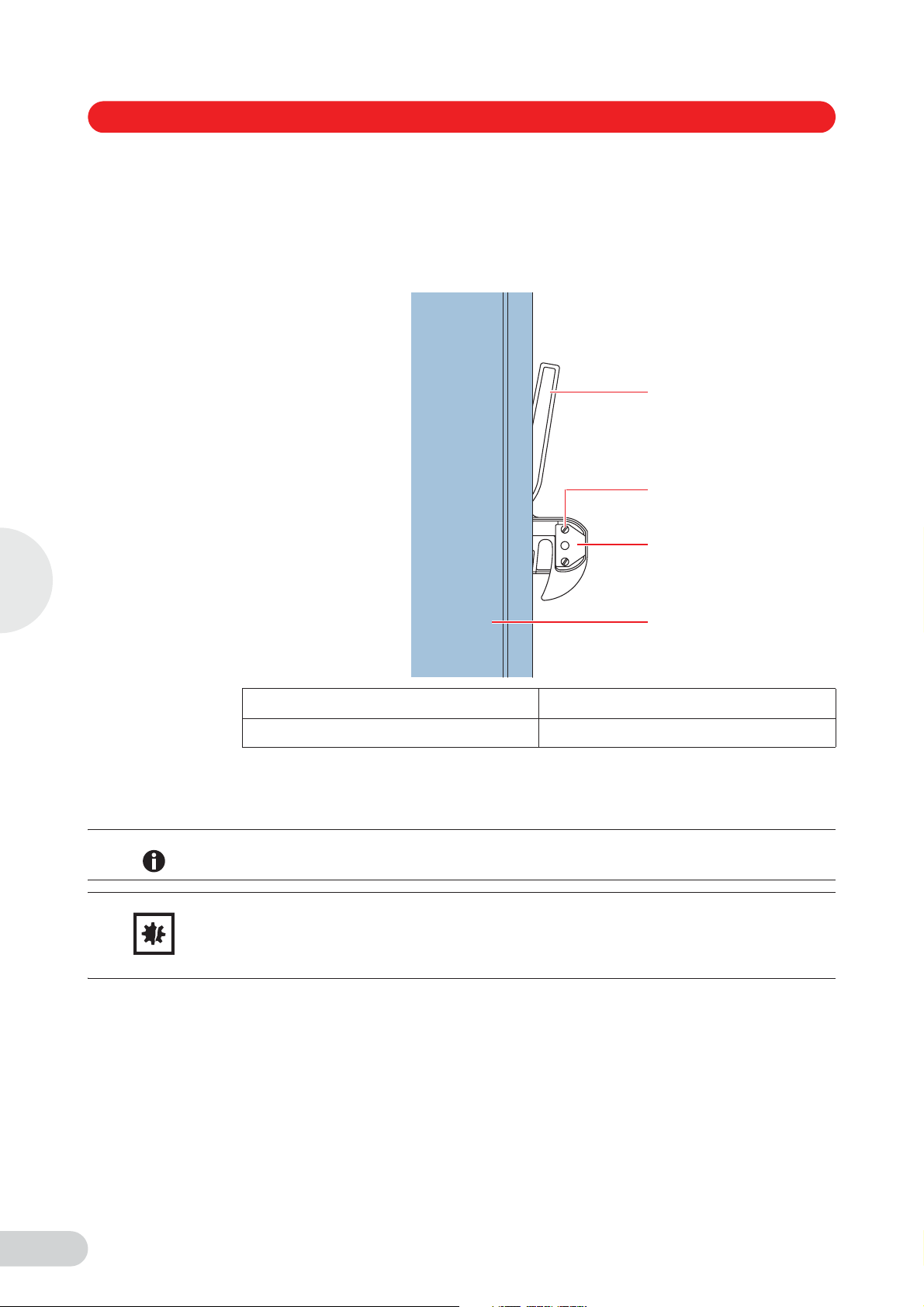

Removing the upright freezer handle barrel lock

Perform the following steps to remove the barrel lock from the upright freezer handle, if the lock

feature is not required:

1. Open the freezer door and place the freezer handle in closed position.

2. Remove the two screws from behind the lock barrel.

1

2

3

4

Installation

4

1 Freezer handle 2 Screw (1 of 2)

3 Lining plate 4 Freezer door wall

3. Remove the lining plate and lock barrel.

4. Insert the plastic blanking plug supplied.

5. Insert the lining plate and screw in the two screws.

It is important that the handle lock lining plate be installed at all times.

Hint!

Risk of material damage

DO NOT SLAM THE DOOR WITH THE HANDLE IN THE CLOSED POSITION.

NOTICE!

6. Place freezer handle in open position and close freezer door.

The door handle has a cam action to pull the door closed and a reverse cam action to break the

seal so the door can be opened. When closing the outer door, ensure that the cam is engaged for

correct operation. The initial vacuum inside the cabinet may cause the door to appear closed, but

when the vacuum releases, the door will open. Always ensure the handle is properly engaged. It

is important that the heated vent port is kept clear. This will avoid putting undue stress on the

handle mechanism.

14

Page 15

Innova® -86 °C Freezers — Operating manual

5 Operating controls and function

5 Operating controls and function

5

5.1 Controls and function

Operating controls are located on a control panel mounted in the door of the upright freezers, and

on the console on the right side of chest freezers.

Every New Brunswick freezer is equipped with S.M.A.R.T. Plus™ diagnostic software, to help

identify the cause of a fault or setpoint variance.

This section describes the controls and function of the control panel, (see Fig. 4 on p. 15).

Abb. 4: Display panel & keypad

TEMPERATURE

1

12

8

Fig. 4: Display panel & keypad

REMOTE-CONTROL

TEMP-ALARM

FILTER-CLEAN BATTERY-LOW

POWER-FAIL FAULT

C

1315

1

23456

78 90EC

ALARM

SET

TEMP

LOW

ALARM

HIGH

ALARM

LOCK

CODE

CHANGE

TEST/

MUTE

10927543 6

Operating controls and function

14

11

Temperature °C Display

Item Name Function

1 TEMPERATURE °CThe digital display normally shows the current internal

temperature of the freezer. Temperature is displayed in 1°C

increments.

High alarm/low alarm

Item Name Function

2 & 8 [HIGH/LOW]

TEMP-ALARM

The TEMP-ALARM illuminates and the audible alarm sounds if

the freezer’s internal temperature is above/below the

user-selected alarm setpoints. The LED illuminates as soon as

the setpoint is passed. The high temperature audible alarm has

a programmable delay (see Setting the alarm delay on p. 23).

After the temperature returns to the normal range, the

TEMP-ALARM switches off and the audible warning stops.

The audible alarm can be silenced by pressing the ALARM TEST/MUTE KEY. If the temperature

Hint!

has not returned to normal range after the programmed time period, the audible warning will

sound again. This pattern will continue to repeat until the temperature returns to normal.

15

Page 16

Innova® -86 °C Freezers — Operating manual

5

Temp-alarm light

Power fail light

Operating controls and function

Fault light

Item Name Function

8 TEMP-ALARM Should a mains/power failure cause the temperature to surpass

the alarm setpoint, the TEMP-ALARM illuminates. (The audible

alarm will already be sounding due to the mains/power failure).

The TEMP-ALARM lamp will extinguish when the temperature

returns to normal set range. Cancel the TEMP-ALARM by

pressing the ALARM TEST/MUTE KEY.

Item Name Function

3 POWER-FAIL Illuminates if the mains/power supply fails, flashing at

approximately 10-second intervals, accompanied by an audible

alarm. When mains/power is restored, the indicator goes off

and the audible alarm stops. (The battery must be switched on

and charged for this indicator to operate.)

Item Name Function

4 FAULT Illuminates if there is a system failure within the freezer.

Interfacing with the S.M.A.R.T. Plus™ diagnostics via the

control panel, the fault can be determined (see Error messages

on p. 32). System failure is accompanied by an audible alarm.

Correction of the fault extinguishes the light and audible alarm.

Battery low light

Item Name Function

5 BATTERY-LOW With mains/power ON: illuminates if battery voltage is below 6

volts, flashes when voltage drops to 5 Volts. With mains/power

OFF: if battery voltage drop below 5.5 Volts, this fault indicator

will stop functioning.

Filter clean light

Item Name Function

6 FILTER-CLEAN Illuminates, accompanied by an audible alarm, to indicate a

blocked or dirty filter. Filter is located on the front at the bottom

of all freezers. Remove by turning the two thumbscrews on the

filter holder ¼ turn. Clean filter by washing in mildly soapy

water, then air dry. If filter warning light does not go out after

replacing the cleaned filter, contact your local New Brunswick

service representative.

16

Remote control light

Item Name Function

12 REMOTE

CONTROL

Indicates when freezer is operating under remote computer

control via the optional RS-485 interface port and New

Brunswick's BioCommand

data logging software.

®

SFI software, or other laboratory

Page 17

Innova® -86 °C Freezers — Operating manual

The keypad controls are locked when the freezer is under remote control.

Hint!

Set temp key

Operation in normal mode with LOCK lamp off.

Item Name Function

7 SET TEMP Displays current temperature setting. Used to change

temperature settings.

High alarm/low alarm keys

Operation in normal mode with LOCK lamp off.

Item Name Function

2 HIGH-ALARM Displays current high alarm temperature setting.

2 LOW-ALARM Displays current low alarm temperature setting.

Lock key

Operation in normal mode with LOCK lamp off.

5

Operating controls and function

Item Name Function

9 LOCK Locks and unlocks the control panel for programming

sequence.

Code change key

Operation in normal mode with LOCK lamp off.

Item Name Function

10 CODE CHANGE Used to change freezer lock codes. Inactive in normal mode.

Alarm test/mute key

Operation in normal mode with LOCK lamp off.

Item Name Function

11 ALARM TEST/

MUTE

Using the TEST/MUTE button does NOT cancel remote alarm monitor socket switching.

Hint!

Sounds the audible alarm. If the audible alarm is on due to a

fault condition, press this key to silence the alarm. The lamp

LED lights can also be tested by pressing this key. The lights

should all illuminate and the display should read “8888”.

"E" key

Operation in normal mode with LOCK lamp off.

Item Name Function

13 E Used to enter data when programming.

17

Page 18

Innova® -86 °C Freezers — Operating manual

5

"C" key

Operation in normal mode with LOCK lamp off.

Numerical keys

Operation in normal mode with LOCK lamp off.

Operating controls and function

Item Name Function

14 C Used to cancel data when programming.

Item Name Function

15 NUMERICAL

KEYS (1-0)

Used to input data when programming. Keys 8 and 9 are also

used to program alarm delays (see Setting the alarm delay on

p. 23).

18

Page 19

Innova® -86 °C Freezers — Operating manual

6 Operation

6 Operation

6.1 Getting started

Risk of personal injury

BEFORE connecting the freezer to the mains/electrical supply, make sure that the mains/

WARNING!

6.1.1 Plug in

power supply matches the requirements of the equipment. Check the specification plate

(located on the side of the freezer) for the electrical requirements. The equipment should be

connected to an earthed/grounded outlet socket.

Once you have verified that the mains/power supply matches the electrical requirements of the

freezer, connect the product to the mains/power supply using the mains/power cord provided.

Risk of personal injury

If the freezer’s voltage rating does not match your mains/electrical supply, or if the plug on the

WARNING!

mains/power cord does not fit the outlet, do not plug the freezer in.

Contact your laboratory supervisor, safety officer, or qualified service or electrical engineer.

Risk of material damage

Some freezers are supplied with more than one removable mains/power cord. Utilize the cord

NOTICE!

6.1.2 Turning the freezer On/Off

that matches your power receptacle. Check the voltage rating plate on the side of the freezer,

to confirm that the freezer is compatible with your laboratory mains/power supply.

6

Operation

WARNING!

Hint!

Risk of personal injury

The On/Off circuit breaker and battery switch are fitted with IP65 plastic covers, to prevent a

possible source of ignition. These covers must not be removed. If one of the covers needs to

be replaced, the replacement must be performed by a qualified and authorized person.

Failure to observe this safety warning will invalidate the warranty and could result in a

dangerous situation in the event of a failure.

The ON/OFF circuit breaker is located within the lockable panel at the bottom right-hand corner

of the upright freezer or to the left of the control panel on the chest model.

To remove the lockable panel and turn the circuit breaker and battery switch On/Off:

1. Insert and turn the key (provided) one quarter turn to the right.

The key can be removed to prevent access.

2. Remove the panel.

19

Page 20

6

Operation

Innova® -86 °C Freezers — Operating manual

3. Set the ON/OFF circuit breaker and battery switch to the I (ON) position.

The temperature display illuminates immediately.

Abb. 5: Upright fre ezers switch locat ion (except U101)

1

2

Fig. 5: Upright freezers switch location (except U101)

1 Battery switch 2 On/Off circuit breaker switch

Abb. 6: Chest freeze rs (and U101) sw itch location

1

Fig. 6: Chest freezers (and U101) switch location

1 Battery switch 2 On/Off circuit breaker switch

The compressors will not operate for approximately three minutes after connection of the mains/

Hint!

power supply, because there is an automatic delay device in the circuit. Temperature and alarm

settings can be adjusted immediately.

6.1.3 Alarm/battery activation

The equipment is delivered with the battery deactivated. The Power Fail alarm is activated by the

battery rocker switch within the lockable panel, which is located at the bottom right-hand corner.

The switch is labeled I (ON) and O (OFF)

!Invalid cross reference to: 0

and

!Invalid cross reference to: 0

.

To activate the alarm, place the battery switch in the I position.

2

20

Failure to turn on the battery switch may lead to a discharged battery, low battery alarm

Hint!

indication, and/or a disabled alarm system.

After activating the alarm, test its operation by pressing the ALARM TEST/MUTE key on the

display.

The audible alarm should sound.

Page 21

Innova® -86 °C Freezers — Operating manual

The ALARM TEST/MUTE key also tests the LED lamps. All of the LEDs should light up together

when the button is pressed.

Pull down time to -86 °C will be dependent on the freezer size and model (see Specifications on

Hint!

6.1.4 Testing the alarm monitoring socket

6.1.5 Vacuum Effect

p. 34). The alarm will sound every 30 minutes until the temperature setpoint is reached. Use the

ALARM TEST/MUTE key to mute the alarm during this initial pull-down period.

If the freezer is turned off during the initial pull-down period, the alarm will activate 30 minutes

after switching it back on.

The factory-set temperature is -80°C.

The freezer is fitted with a remote alarm socket for testing power-fail and low battery alarms, and

for connection to an external building monitoring system or optional auto-dialer, (see Alarm

monitoring socket on p. 25). To test the alarm monitoring socket.

Tur n o ff (O) the ON/OFF circuit breaker.

This will test the POWER FAIL and ALARM output at the same time.

The battery must be switched on to test the POWER FAIL. The remote alarm facility provides

voltage-free contacts rated at 1 amp, 24 volts maximum.

6

Operation

After closing the freezer door following access to the contents, a vacuum may be created. Before

the door can be opened again, it may be necessary to wait two or three minutes for the vacuum

to be released by the vent port. Do not try to force the door. During the release of the vacuum,

a slight hissing may be heard. In order to minimize vacuum formation, the vent heater assembly

has a spring-loaded plunger to clear ice from the inside of the vent.

Be careful not to place a rack directly against the vent, as this will inhibit the plunger’s ability to

Hint!

operate correctly (see Heated vent port on p. 28).

6.2 Programming the freezer

Set the freezer to any temperature within the range from -50 °C to -86 °C.

All temperature setpoints are automatically negative °C.

Hint!

6.2.1 Setting operating temperature

To set the operating temperature for the freezer:

1. Press the LOCK key.

The LOCK lamp will flash if a lock code (password protection) is required, (see Changing lock

Hint!

codes on p. 24).

The LOCK lamp will illuminate, indicating the system is unlocked and parameters can be

changed.

2. Press the SET TEMP key.

Its indicator will flash and the display will indicate 0.

3. Using the numerical keys, enter a new temperature (from -50 °C to -86 °C).

The temperature selected will appear in the TEMPERATURE display.

4. When the correct temperature is displayed, press the E key to enter the data. To set the high

alarm setpoint skip to (see Setting high alarm setpoint on p. 22), step 2.

The SET TEMP lamp will go off.

21

Page 22

6

Innova® -86 °C Freezers — Operating manual

5. Press the LOCK key to exit programming.

The LOCK lamp will go off and the freezer will return to normal mode.

Press the C key to clear the display during programming.

Hint!

6.2.2 Setting high alarm setpoint

The high alarm setpoint may not be warmer than -10 °C and may not be less than within +5° of

the operating temperature. The default setting is +5° from the temperature setpoint.

1. Press the LOCK key.

Operation

6.2.3 Setting low alarm setpoint

The LOCK lamp will flash if a lock code (password protection) is required, (see Changing lock

Hint!

codes on p. 24).

The LOCK lamp will illuminate, indicating the system is unlocked and parameters can be

changed.

2. Press the HIGH ALARM key.

Its indicator will flash and the display will indicate 0.

3. Using the numerical keys, enter a new alarm setpoint temperature.

The selected temperature will appear in the TEMPERATURE display.

4. When the correct temperature is displayed, press the E (Enter) key to enter the data. To set

the low alarm setpoint skip to (see Setting low alarm setpoint on p. 22), step 2.

The HIGH ALARM indicator will turn off.

5. Press the LOCK key to exit programming.

The LOCK lamp will go off and the freezer will return to normal mode.

Press the C key to clear the display during programming.

Hint!

The low alarm setpoint may not be colder than -91 °C and may not be more than within -5° of the

operating temperature. The default setting is -5 °C from the temperature setpoint.

1. Press the LOCK key.

22

The LOCK lamp will flash if a lock code (password protection) is required, (see Changing lock

Hint!

codes on p. 24).

The LOCK lamp will illuminate, indicating the system is unlocked and parameters can be

changed.

2. Press the LOW ALARM key.

Its indicator will flash and the display will indicate 0.

3. Using the numerical keys, enter a new alarm setpoint temperature.

The selected temperature will appear in the TEMPERATURE display.

4. When the correct temperature is displayed, press the E (Enter) key to enter the data.

The LOW ALARM indicator will turn off.

5. Press the LOCK key to exit programming.

The LOCK lamp will go off and the freezer will return to normal mode.

Page 23

Innova® -86 °C Freezers — Operating manual

Press the C key to clear the display during programming.

Hint!

6.2.4 Checking temperature and alarm setpoint settings

To view the currently set operating temperature, high alarm setpoint, or low alarm setpoint for the

freezer.

Press the SET TEMP key, HIGH ALARM key, or the LOW ALARM key and read the display.

If you press the SET TEMP, HIGH ALARM or LOW ALARM key while the LOCK key lamp is

Hint!

6.2.5 Setting the alarm delay

Hint!

flashing, the display will read ---- , which indicates that the freezer is locked.

The HIGH ALARM audible alarm and the REMOTE ALARM monitoring socket can be

programmed to a time delay set between 0 and 40 minutes.

The default time delay is 30 minutes. If the time delay is set to 0 minutes, the system will program

it as 15 seconds.

Press KEY 8 to display the High Temperature audible alarm delay, and press KEY 9 to display

the Remote Alarm Socket switching delay.

To set the audible HIGH ALARM delay (KEY 8):

1. Press the LOCK key.

The LOCK lamp illuminates, indicating the system is unlocked and parameters can be

changed.

2. Press keypad button 8.

pp flashes on the display.

3. Enter the desired value (e.g., press keypad buttons 1 and 0 to designate 10 minutes).

4. Press the E (Enter) key.

The LOCK lamp goes out.

To set the REMOTE ALARM socket time delay (KEY 9):

1. Press the LOCK key.

The LOCK lamp illuminate, indicating the system is unlocked and parameters can be

changed.

2. Press keypad button 9.

pp flashes on the display.

3. Enter the desired value (e.g., press keypad button 5 to designate 5 minutes).

4. Press the E (Enter) key.

The LOCK lamp goes out.

If the number entered is valid, --- flashes on the display, the value has been stored, and the

LOCK lamp goes out. (This is a one-shot operation.)

If the number entered is out of range, –EE– shows on the display and the operation will need to

be repeated using a valid number.

6

Operation

23

Page 24

6

Operation

Innova® -86 °C Freezers — Operating manual

6.2.6 Changing lock codes

If you enter a lock code when there is none, or if you replace an existing lock code with a new

Hint!

one, take note of the new code before you enter it.

If the code is forgotten, you will need to contact Customer Service to regain access to the

programming mode of the freezer.

The freezer is delivered unlocked. To change the code, the freezer must be unlocked. If a lock

code has already been set (indicated by the LOCK lamp flashing when the LOCK key is

pressed), that same code must be entered to unlock the freezer. When the freezer is unlocked,

the LOCK lamp is on (not flashing).

Once the freezer is unlocked, follow these steps to set a new lock code:

1. Press the CODE CHANGE key.

The lamp will flash and the display will go blank.

2. Using the numerical keys, enter the new four-digit number. Check it on the display.

3. Press the C key to cancel the entry if the display shows it to be incorrect, then enter the

correct number.

4. When the number is correct, record the new number somewhere secure. Then press the E

(Enter) key.

The CODE CHANGE indicator will turn off.

5. Press the LOCK key.

Its indicator lamp will turn off.

The freezer now has a new lock code. If at any time you wish to change this code, you will have

to enter this code to unlock the system before you can enter a new code.

Setting the lock code to 0000 disables the lock completely. With the 0000 code, you would need

only press the LOCK key to reprogram the freezer.

6.2.7 Setting the temperature offset

The temperature offset function enables to add a temperature offset to the factory defined

temperature settings.

1. Press the LOCK Key.

2. Press the C key to access the offset function.

3. Press 0, 1, 2, 3, or 4 key to set the offset in degrees.

4. Press the ENTER key to confirm selection.

Set temperature offset to "0" for no offset.

Hint!

6.3 Battery backup switch

This is a rocker switch labeled I/O behind the locked front panel. In the O position, the battery is

disconnected. This position should only be used while in transit, in storage, or to change the

battery.

At all other times the switch should be kept in the I position for the battery to be charged, and for

the alarm function to be available in the event of mains/power failure. (Failure to set the switch

may result in impaired battery life, and the alarm will not trigger if the mains/power fails.)

With the battery switch on, during a mains/power failure, the internal freezer temperature will be

displayed at ten-second intervals, and the audio alarm will also sound. The audible alarm may be

muted by pressing the ALARM TEST/MUTE key on the control panel, but will sound again after

30 minutes if the fault has not been corrected. Pressing the same button again will mute the

alarm for an additional 30 minutes; the pattern will continue to repeat until the initial problem is

corrected.

24

Page 25

Innova® -86 °C Freezers — Operating manual

6.4 Alarm monitoring socket

The freezers are provided with an alarm monitoring socket at the rear of the freezer and a

matching plug for external monitoring. This plug can be connected either to a central monitoring

system such as a building management system, or to a remote alarm via an auto-dialer.

Abb. 7: Upright freezers alarm monitoring socket (except U101)

6

1

2

3

Fig. 7: Upright freezers alarm monitoring socket (except U101)

1 RS-485 connector (optional) 2 Alarm monitoring socket

3 Mains/power socket

Abb. 8: Chest (and U 101) freezers alarm monitoring socket

123

Operation

Fig. 8: Chest (and U101) freezers alarm monitoring socket

1 RS-485 connector (optional) 2 Alarm monitoring socket

3 Mains/power socket

The configuration of the socket is shown in (Fig. 9 on p. 26) and (Fig. 10 on p. 26), as viewed

from the rear of the freezer. Within the freezer, the socket is connected to voltage-free contacts

rated at 24 volts, 1 amp. In normal operation, with the mains/power on, pin 1 is connected to pin

2 (N/C), and in the alarm condition, with mains/power off, pin 1 is connected to pin 3.

The High Temperature Alarm output to the Remote Alarm Monitoring Socket can be programmed

to a set time delay (see Setting the alarm delay on p. 23).

Risk of material damage

Hazardous voltages must not be connected to the remote alarm socket. Max Rating 24 V 1 A.

NOTICE!

25

Page 26

6

Operation

Innova® -86 °C Freezers — Operating manual

Abb. 9: Remote alarm socket - upright freezer (except U101)

Fig. 9: Remote alarm socket - upright freezer (except U101)

Abb. 10: Remote alarm socket - chest an d U101 upright free zers

Fig. 10: Remote alarm socket - chest and U101 upright freezers

6.5 Voltage stabilizer

The following freezer models are equipped with a built-in voltage stabilizer:

• Innova U535, 120 V and 208 - 230 V, 60 Hz

• Innova U725, 208 - 230 V, 60 Hz

• Innova C585, 120 V and 208 - 230 V, 60 Hz

• Innova C760, 208 - 230 V, 60 Hz

The built-in voltage stabilizer automatically compensates for variations in the supply voltage (in

case of over-voltage, brown-outs, dips, sags and surges). The output is only switched if the

power disturbance is sustained for at least two seconds.

The U101 freezer has the option of an external voltage stabilizer.

The voltage stabilizer unit indication is displayed on the lower right front panel of the upright

freezers and on the front panel above the air filter on the chest freezers.

When you switch the freezer on, if the input voltage is within the specified range, the green LED

NORMAL will illuminate. If the voltage stays within the specified range, the green LED will remain

illuminated.

Sustained variations in the input power will be automatically compensated for by the stabilizer

circuit and indicated by a red LED for HIGH voltage or an amber LED for LOW voltage.

26

Page 27

Innova® -86 °C Freezers — Operating manual

Tab. 1: Voltage stabilizer specifications

208 - 230 V 120 V

Rated at 15 Amps 20 Amps

Line Voltage:

• Normal Freezer Operating Voltage 230 V ± 10 % 120 V ± 10 %

• Normal Voltage Stabilizer Operating Range (LED Green) 204 V - 242 V

± 2.5 V

• Low (Boost) Voltage Limit (LED Amber) < 204 V < 106 V

• High (Buck) Voltage Limit (LED Red) > 242 V > 123 V

106 - 123 V

± 2.5 V

6

Operation

27

Page 28

Innova® -86 °C Freezers — Operating manual

7 Maintenance

7 Maintenance

7.1 Cleaning

6

Operation

Risk of material damage

Maintenance, adjustment and repair work should be carried out only by QUALIFIED,

NOTICE!

EXPERIENCED personnel who have been AUTHORIZED to undertake such work by New

Brunswick Scientific or its authorized agents.

Failure to use authorized service agents will invalidate the warranty.

7.1.1 Painted surfaces

All exterior paint work and inner doors should be cleaned using a solution of mild detergent in

water. Do not use abrasive cleaners or solvents.

7.1.2 Panels and shelves

The interior panels and shelves are made of stainless steel. They may be cleaned and sterilized.

7.1.3 Air intake grille and filter

Risk of material damage

Serious damage to the freezer may result if the air intake is blocked. Check that there is no

NOTICE!

obstruction of the airflow to the freezer. The air intake filter must also be cleaned regularly.

Remove the filter from behind the grille by turning the thumbscrews ¼ turn and opening grille

downward. The filter should be washed in warm soapy water and left to air dry before

replacing.

The air intake grille must be cleaned regularly to keep it free from dust and debris. Under normal

conditions, clean the grille once every three months. If the area around the freezer is very dusty

or dirty, clean the grille more often.

Brush the grille with a soft brush and, if a vacuum cleaner is available, vacuum the dust from

the grille.

7.1.4 Heated vent port

Hint!

28

There is an electrically-heated vent port in the freezer which must not be allowed to become

blocked or sealed off.

Over a period of a few weeks, depending on how often the freezer is being used, a small

mushroom of ice will form around the end of the vent port. If the vent port is allowed to become

blocked, a vacuum will be created when the door is closed. It will not be possible to open the door

or lift the lid until the vacuum has leaked away through the seal, which can take up to two hours

due to the high quality of the seals.

The vent port is located on the left-hand side of the freezers.

If the door cannot be opened, clear the vent port by pressing the manual plunger on the

outside of the air vent.

Page 29

Innova® -86 °C Freezers — Operating manual

123

7

1 Plunger 2 Cover

3 Freezer outer wall

7.1.5 Door or lid seal

Be sure to treat the door or lid seal with care. Avoid damaging this seal in any way. The freezer

cannot operate properly with a defective seal.

It is advisable to wipe both the seal and the surface against which it seals with a soft dry cloth

once a month.

7.2 Routine maintenance

7.2.1 Lubrication

Every 12 months the outer door hinges and the handle mechanism should be lightly lubricated

using general-purpose oil or spray grease.

7.2.2 Defrosting

After an extended period of operation, defrosting may become necessary:

Risk of material damage

Do not attempt to chip or scrape the ice with a sharp instrument. Allow the ice to melt

NOTICE!

naturally.

Maintenance

1. De-activate the alarm by switching the battery (alarm) switch (located behind the lockable

panel on the front of the freezer) to off (O).

2. Unplug the freezer from the mains/electrical supply.

3. Leave the innner and outer doors or lids open.

4. Allow the accumulated ice to melt.

5. Mop up the resulting water.

6. Dry and decontaminate the interior of the freezer.

7. When defrosting is complete, reconnect the freezer to the mains/electrical supply.

8. Turn the mains/power switch on (I) and re-activate the battery (alarm) switch.

7.2.3 Removing the inner doors

The inner doors of the freezer can be removed for defrosting and cleaning.

1. Fully open the outer door of the freezer.

2. Fully open the inner door.

29

Page 30

7

Maintenance

Innova® -86 °C Freezers — Operating manual

3. Lift off inner door from hinges and set aside.

Abb. 11: Lift-off inner door

1

Fig. 11: Lift-off inner door

1 Inner door 2 Lift-off hinge

2

Repeat procedure for each door.

7.2.4 Replacing the inner door

1. Fully open the outer door of the freezer.

2. Fit door to hinge pins and close.

3. Check to ensure that inner door gasket is sealing against the freezer trim.

4. If required, adjust the latch retainer by loosening the screws and moving forward or

backwards.

5. Close outer door.

7.2.5 Electrical components

Risk of personal injury

During routine maintenance, care must be taken to avoid any damage to the gaskets and

WARNING!

sealing grommets of these enclosures; also check the gaskets and sealing grommets

routinely to ensure their integrity. Should any damage or deformity be detected, the gasket

and/or sealing grommet must be replaced immediately.

Failure to observe this safety warning will invalidate the warranty and could result in a

dangerous situation.

Lamps

Regularly check the indicator lamps:

Press the ALARM TEST/MUTE key.

All of the indicator lamps should illuminate, and the display should read 8888.

30

Alarms

Regularly check the alarm:

Press the ALARM TEST/MUTE key.

The TEMP indicator should illuminate and the audible alarm should sound.

Page 31

Innova® -86 °C Freezers — Operating manual

Battery replacement

Risk of material damage

There are no user controls behind any panels. The removal of any other part or panels from

NOTICE!

NOTICE!

the freezer by anyone other than a qualified, authorized Service Engineer may invalidate the

warranty.

Risk of material damage

Use only a replacement battery of the correct type and part number.

The battery must be fitted so the terminals correspond to the polarity labels on the electrical

panel.

The YUASA–NP6 V 2.8 Ah battery is mounted on the electrical panel. This is located behind the

right-hand base cover.

To replace the battery:

1. Switch off the mains/power switch and disconnect the mains/power supply.

2. Remove the side cover and the battery clamp securing the battery to the electrical panel.

3. Disconnect the battery terminals.

4. Install the new battery, fixing screws, and the side cover.

7

Maintenance

Be certain, when reconnecting the battery, to respect the correct polarity (red is + positive and

Hint!

black is – negative).

5. Reconnect the freezer to the mains/power supply and turn the mains/power switch on (I).

Fuses

Fuses must be replaced by a New Brunswick Scientific approved service engineer. Contact New

Brunswick Service.

31

Page 32

Innova® -86 °C Freezers — Operating manual

8 Troubleshooting

8 Troubleshooting

8.1 General errors

If you are experiencing a problem with your freezer, check the following troubleshooting guides

before contacting your New Brunswick authorized Service technician.

7

Maintenance

8.2 Error messages

Symptom/

message

Door will not

open

Cause Remedy

1. The door handle is locked.

2. The heated vent port is

blocked.

1. Unlock the door handle.

2. Break up the ice in the vent port using

the plunger, (see Heated vent port on

p. 28).

If the door will not open:

Call New Brunswick Service.

FILTER-CLEAN

LED lights up

• Filter is contaminated. Clean the filter, (see Air intake grille

and filter on p. 28).

If the LED remains lit:

Call New Brunswick Service.

Your electronically-controlled New Brunswick freezer incorporates the unique Systems

Monitoring And Reporting Technology (S.M.A.R.T. Plus™) self-diagnostic software to diagnose

faults in its electronic systems, its probes and/or its refrigeration system.

This table interprets error codes that may appear in the control panel display:

Symptom/

message

E-01

E-02

E-03

E-04 Air-cooled condenser

Cause Remedy

• PT100 Probe 1 failure. This

probe, located inside the

freezer cabinet, indicates

cabinet temperature.

• Probe 2 failure. This probe

monitors the cascade

condenser.

• This probe monitors the

air-cooled condenser.

temperature too high:

1. Filter may be blocked.

2. Ambient temperature may be

too high.

If alarm continues to sound:

Call New Brunswick Service department.

Call New Brunswick Service department.

Call New Brunswick Service department.

1. Clean filter according to the instructions

(see Air intake grille and filter on p. 28).

2. Cool the room.

Call New Brunswick Service department.

• Fan may have failed.

• Water supply not turned on,

insufficient flow, regulating

valve not opening or

defective (water-cooled

version only).

32

A fan is required to cool the compressors on the water-cooled models.

Hint!

Page 33

Innova® -86 °C Freezers — Operating manual

8.3 After a mains/power failure

If mains/power is interrupted, the POWER-FAIL indicator lamp (see Fig. 4 on p. 15), Item 3, will

illuminate. In addition, the audible alarm will sound and the display will flash at approximately

10-second intervals.

When mains/power is restored, both alarm and light will automatically be cancelled.

If mains/power has been interrupted for only a short time, the internal temperature of the freezer

will not have risen above the temperature setpoint (the user-set alarm threshhold), so normal

operation will be resumed immediately.

If the interruption was long enough for the internal temperature to rise above the temperature

setpoint, the TEMP-ALARM indicator will illuminate. If the internal temperature does not fall

below the temperature setpoint within the programmed time after mains/power was restored, the

audible alarm will sound again. The TEMP-ALARM indicator will extinguish when the internal

temperature reaches the High Alarm temperature set point.

8.4 Interior warming

If the lid or door is left open long enough for the internal temperature to rise above the

temperature setpoint, the same effects will be observed as described above regarding power

failure.

To minimize the risk of this happening, the lid or door should only be opened when necessary, for

a short period of time.

The upright freezers are fitted with internal doors which latch shut, minimizing temperature rise

when the outer door is opened. Chest freezers are fitted with inner insulating lids to ensure

efficient running of the freezer. The lids should remain fitted at all times when the freezer is

running.

8

Troubleshooting

33

Page 34

Innova® -86 °C Freezers — Operating manual

9 Technical data

9 Technical data

9.1 Specifications

9.1.1 Upright freezers specifications

Part No. U9420-000X* U9430-000X* U9440-000X*

Internal Dimensions:

Height x Width x Depth

External Dimensions:

Height x Width x Depth

Capacity 101 Liters

8

Troubleshooting

Net Weight 116 kg

Lock Standard Standard Standard

No. Compartments 233

Interior Stainless steel grade 304L

Alarms High/Low temperature, power fail, battery low, filter clean, fault

Insulation Material Vacuum insulation panels and urethane foam

Remote alarm port Standard Standard Standard

RS-485 interface Optional Optional Optional

Refrigerants: High Stage Refrigerant: R404A / Low Stage Refrigerant: R508B

‡Power Consumption:

• 120 V electrical supply 265 Watts 550 Watts N/A

• 208 - 230 V electrical

supply

• 230 V electrical supply 367 Watts 550 Watts 660 Watts

Mains/Power Source and Current Rating:

120 V, 60 Hz 13 A 16.5 A N/A

208 - 230 V, 60 Hz N/A 9 A 10 A

230 V, 50 Hz 5 A 5 A 9.5 A

Pull Down Time: From +25 °C to -85 °C (freezer empty; 240 V, 50 Hz electrical supply)

Model No. U101 U535 U725

640 x 480 x 330 mm

25.2 x 18.9 x 13 in

830 x 900 x 566 mm

32.7 x 35.4 x 22.3 in

3.6 cubic feet

256 lb

N/A 550 Watts 685 Watts

3.7 hours 5.3 hours 5.6 hours

1365 x 640 x 615 mm

53.7 x 25.2 x 24.2 in

1950 x 800 x 867 mm

76.8 x 31.5 x 34.1 in

535 Liters

18.9 cubic feet

250 kg

551 lb

1365 x 865 x 615 mm

53.7 x 34.0 x 24.2 in

1950 x 1025 x 867 mm

76.8 x 40.4 x 34.1 in

725 Liters

25.6 cubic feet

315 kg

693 lb

Performance -50 °C to -86 °C at 32 °C maximum ambient operating temperature

Environmental Conditions All freezers use components tested to CE/UL specifications listed below:

• Indoor use

• Altitude up to 2000 m

• Ambient temperature range 10 °C to 32 °C

• Maximum relative humidity 80 % for temperatures up to 31 °C, decreasing linearly to

50 % relative humidity at 40 °C

• Mains/power supply voltage fluctuations not to exceed ± 10 % of the nominal voltage

• Installation category II

• Pollution degree 2

* X = 0 for 120 V, 2 for 208 - 230 V (N/A for U101), or 1 for 230 V

‡ Freezer set to -80 °C, ambient 20 - 25 °C at rated mains/electrical supply

34

Page 35

Innova® -86 °C Freezers — Operating manual

9.1.2 Chest freezers specifications

Model No. C585 C760

Part No. U9400-000X* U9410-000X*

Internal Dimensions:

Height x Width x Depth

External Dimensions:

Height x Width x Depth

Capacity 585 Liters

Net Weight 240 kg

Lock Standard Standard

No. Compartments N/A N/A

Interior Stainless steel grade 304L

Alarms High/Low temperature, power fail, battery low, filter clean, fault.

Insulation Material Vacuum insulation panels and urethane foam

Remote alarm port Standard Standard

RS-485 interface Optional Optional

Refrigerants: High Stage Refrigerant: R404A / Low Stage Refrigerant: R508B

‡Power Consumption:

• 120 V electrical supply 580 Watts N/A

• 208 - 230 V electrical

supply

• 230 V electrical supply 565 Watts 665 Watts

Mains/Power Source and Current Rating:

120 V, 60 Hz 16.5 A N/A

208 - 230 V, 60 Hz 9 A 10 A

230 V, 50 Hz 5.5 A 9.5 A

Pull Down Time: From +25 °C to -85 °C (freezer empty; 230 V, 50 Hz electrical supply)

780 x 1200 x 625 mm

30.7 x 47.2 x 24.6 in

1092 x 1690 x 785 mm

43 x 66.5 x 30.9 in

20.7 cubic feet

528 lb

580 Watts 698 Watts

4.5 hours 5.8 hours

780 x 1560 x 625 mm

30.7 x 61.4 x 24.6 in

1092 x 2050 x 785 mm

43 x 80.7 x 30.9 in

760 Liters

26.9 cubic feet

285 kg

627 lb

9

Technical data

Performance -50 °C to -86 °C at 32 °C maximum ambient operating temperature

Environmental Conditions All freezers use components tested to CE/UL specifications listed below:

• Indoor use

• Altitude up to 2000 m

• Ambient temperature range 10 °C to 32 °C

• Maximum relative humidity 80 % for temperatures up to 31 °C, decreasing linearly to

50 % relative humidity at 40 °C

• Mains/power supply voltage fluctuations not to exceed ± 10 % of the nominal voltage

• Installation category II

• Pollution degree 2

* X = 0 for 120 V, 2 for 208 - 230 V, or 1 for 230 V

‡ Freezer set to -80 °C, ambient 20 - 25 °C at rated mains/electrical supply

35

Page 36

Innova® -86 °C Freezers — Operating manual

10 Ordering Information

10 Ordering Information

10.1 Accessories

A number of accessories are available for New Brunswick's range of ultra-low temperature

freezers. Contact your local New Brunswick representative or distributor for details.

10.1.1 A2 independent temperature monitor

The A2 system is an independent temperature monitor with alarm, electronic chart recorder, and

auto-dialer that communicates via the internet for remote monitoring from anywhere in the world.

Ask your New Brunswick sales representative for availability.

10.1.2 Auto-dialers

Auto-dialers can call a set of preprogrammed telephone numbers in the event of an alarm

condition and connect right into the freezer's remote alarm port.

10.1.3 Temperature probes

Additional Temperature Probes (such as the New Brunswick A2 monitoring system) can be

installed upon request for an external alarm system or for validation.

10.1.4 Validation packages

10

10.1.5 External voltage stabilizers

10.1.6 Padlock adapter kits

10.1.7 CO

Ordering Information