Page 1

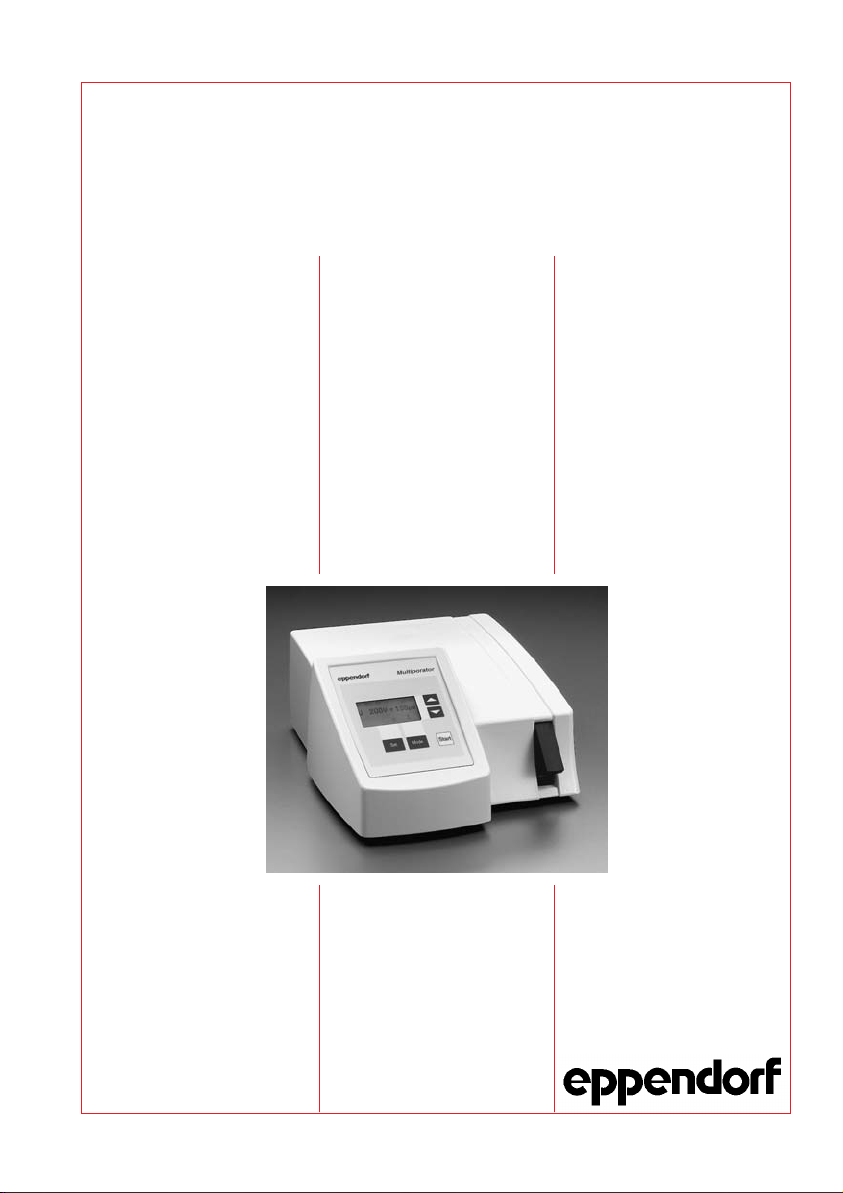

Multiporator

Bedienungsanleitung

Operating Manual

Mode d'emploi

Istruzioni d'impiego

Manual de Instrucciones

Page 2

Page 3

Bedienungsanleitung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Mode d’emploi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Istruzioni d'impiego . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Manual de Instrucciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

EG-Konformitätserklärung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

EC Conformity Declaration

Déclaration de conformité

Dichiarazione di conformità CE

Declaración de conformidad CEE

Nachdruck und Vervielfältigung – auch auszugsweise – nur mit Genehmigung.

No part of this publication may be reproduced without the prior permission of

the copyright owner.

Toute reproduction, complète ou partielle et quel que soit le proèdè est

interdiete, sauf autorisation expresse de notre part.

Ristampa e riproduzione – anche di estratti – solo con autorizzazione.

Reimpresión y copia – incluso parciales – sólo con autorización.

Copyright

©

2006 by Eppendorf AG, Hamburg

B 4308 900.016-10/0606

3

Page 4

Contents

1 General information

2 Area of application

3 Safety precautions

4 Device description

4.1 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3 Cuvette insert. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4 Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.5 Keys and key combinations . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7 Electroporation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.1 Cuvettes and cuvette insert . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.2 Electroporation buffer for eukaryotic cells . . . . . . . . . . . . . . . 59

4.8 Cell fusion (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.8.1 Micro fusion chamber (Electrode gap width 0.2 mm). . . . . . . 60

4.8.2 Micro fusion chamber (Electrode gap width 0.5 mm). . . . . . . 61

4.8.3 Cleaning the Micro fusion chamber . . . . . . . . . . . . . . . . . . . . 61

4.8.4 Helix fusion chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.8.5 Filling the Helix fusion chamber . . . . . . . . . . . . . . . . . . . . . . 63

4.8.6 Fusion and cell suspension extraction . . . . . . . . . . . . . . . . . . 64

4.8.7 Cleaning and disinfecting the Helix fusion chamber . . . . . . . 65

4.8.8 Electrofusion buffer for eukaryotic cells . . . . . . . . . . . . . . . . . 65

4.9 Insert (electroporation / electrofusion) for connecting

external electrodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.10 Printer connection / printer (optional). . . . . . . . . . . . . . . . . . . 67

5 Mode of operation

5.1 Mode for electroporation of eukaryotic cells . . . . . . . . . . . . . 71

5.2 Mode for electroporation of bacteria and yeast (optional) . . . 73

5.3 Mode for cell fusion (optional) . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.1 Function: Cell alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3.2 Procedure for cell fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6 Error messages

7 Maintenance and servicing

7.1 Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8 Technical data

9 Ordering information

9a Ordering information for North America

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . 87

46

Page 5

1 General information

The Multiporator

With the aid of optional modules, it is also possible to perform

electroporation on bacteria and yeast as well as fusion of cells. This

manual contains information on all possible uses of the Multiporator

The outstanding feature of the Multiporator is that the parameters

entered for the electroporation of eukaryotic cells and for cell fusion are

maintained exactly by means of internal calculation of the discharge

curve.

is designed for the electroporation of eukaryotic cells.

.

47

Page 6

2 Area of application

Device safety regulations and industrial standards stipulate the following

conditions:

Use the device for experiments in the field of cell technology

–

only

The range of application covers the electroporation of yeast and

bacteria and eukaryotic cells as well as cell fusion.

–

Please use only original accessories from Eppendorf

Original accessories only may be used. They are designed

specifically to ensure optimum functioning of the Multiporator

Additional devices may be used only if recommended by the

manufacturer. Eppendorf does not honor any warranty or accept

any responsibility for damage resulting from the use of incorrect

or non-recommended equipment.

– The device may only be used for research purposes, not for

medical and diagnostic applications

.

48

Page 7

3 Safety precautions

For reasons of personal safety, it is essential to observe the following!

●

Observe the instructions contained in the operating manual

It is essential to comply with the information given in the manual!

● Only use the device with a power supply which has a grounding

contact!

● Before starting up the Multiporator

supply used corresponds to the voltage specifications on the

identification plate!

● Do not use the device if it is damaged, especially if the mains cable is

damaged.

● The unit may be opened only by authorized service personnel! Before

opening the device, switch it off and remove the power supply plug.

Potentially lethal voltage inside the unit.

● Do not operate the device in an explosive environment!

● Do not allow any liquid to enter into the Multiporator

● The device should be used for in vitro applications only!

● Use the device only for the purpose for which it is intended.

Do not place parts, devices, tools or other objects into the cuvette

insert which have not been recommended by Eppendorf AG.

High voltage!

● Use the listed accessories only.

Other accessories may only be used if they are accompanied by a

safety certificate from Eppendorf AG confirming their suitability for

use!

● Electrical connection to devices which are not mentioned in this

operating manual is only permitted with the prior consent of the

manufacturer!

● The Helix fusion chamber must be handled with care.

Loose or damaged electrodes adversely affect operating procedures.

In such cases, the Helix fusion chamber must not be used!

Do not open the Helix fusion chamber until fusion has finished!

● The Micro fusion chamber must be handled with care.

Ta ke care when filling with cell suspension. Do not touch or move the

electrodes with the pipette tip! This may cause damage.

During cell alignment/fusion, avoid direct contact with the electrodes!

, please ensure that the power

or the inserts!

49

Page 8

3 Safety precautions

● Cell alignment/fusion may be performed only when the Micro fusion

chamber is connected.

The cable is designed for connection to the Micro fusion chamber only.

No other connections are permitted! Do not place the plug into liquid!

● The owner or operator of the device is liable for the functioning of the

device when the device is serviced or maintained by persons who are

not members of the Eppendorf service personnel or when the device

is not operated in accordance with the given regulations and

precautions. Eppendorf AG accepts no liability for damage resulting

from such action. Warranty and liability stipulations which form part of

the terms of sale and delivery of Eppendorf AG are not affected by the

above-mentioned conditions.

● This operating manual or parts of this operating manual may not be

reproduced in any form without the prior written permission of

Eppendorf AG!

● Eppendorf AG reserves the right to make technical alterations to this

product!

●

Transfer

If the device is passed on to someone else, please include the

instruction manual.

●

Disposal

In case the product is to be disposed of, the relevant legal regulations

are to be observed.

●

Information on the disposal of electrical and electronic devices in

the European Community

The disposal of electrical devices is regulated within the European

Community by national regulations based on EU Directive 2002/96/EC

on waste electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after 13.08.05 in

the business-to-business sphere, to which this product is assigned,

may no longer be disposed of in municipal or domestic waste. They

are marked with the following symbol to indicate this.

As disposal regulations within the EU may vary from country to

country, please contact your supplier if necessary.

50

Page 9

4 Device description

The device has four different modification levels: the basic device is used

for the electroporation of eukaryotic cells. It can then be developed for the

electroporation of bacteria and yeast, with an additional level offering the

opportunity to perform cell fusion. These two levels can be combined to

form the fourth level.

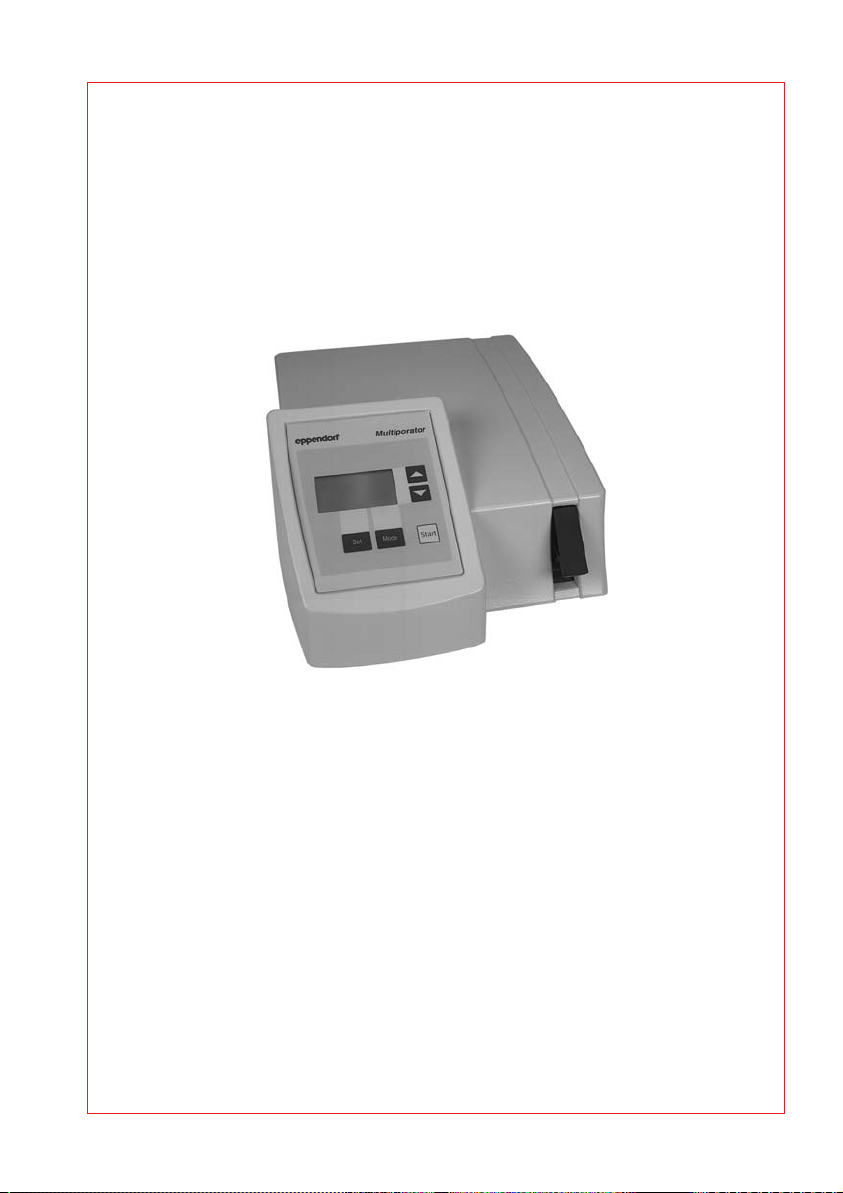

The Multiporator

The insert for the electroporation cuvette is located next to the keypad.

is operated using an easy-to-follow keypad with display.

Fig. 1: Multiporator, front view

51

Page 10

4 Device description

4.1 Delivery package

Basic device: Multiporator for the electroporation of eukaryotic

cells; with mains cable

Insert for electroporation cuvettes

Electroporation cuvettes

(Electrode gap width: 2 mm / 4 mm)

Hypo- and isoosmolar buffers for electroporation

Operating manual and Basic Applications Manual

"Bacteria module" optional:

"Cell fusion module" optional:

"Fusion- and bacteria module" optional:

Basic device incl. accessories

with integrated bacteria module

Additional electroporation cuvettes

(Electrode gap width: 1 mm)

Basic device incl. accessories

with integrated cell fusion module

Helix fusion chamber

(Electrode gap width: 0.2 mm)

Insert for Helix fusion chamber

Micro-fusion chamber

(Electrode gap width: 0.2 mm) with special insert

Hypo- and isoosmolar buffers for cell fusion

Basic device incl. accessories

with integrated fusion- and bacteria module.

52

Page 11

4 Device description

4.2 Startup

The Multiporator must stand completely on the stable work surface and be

safely positioned. There must be enough space that the front and rear

ventilation slits are not covered and that air for cooling can reach

underneath the device.

Space requirement: Width: 25.2 cm

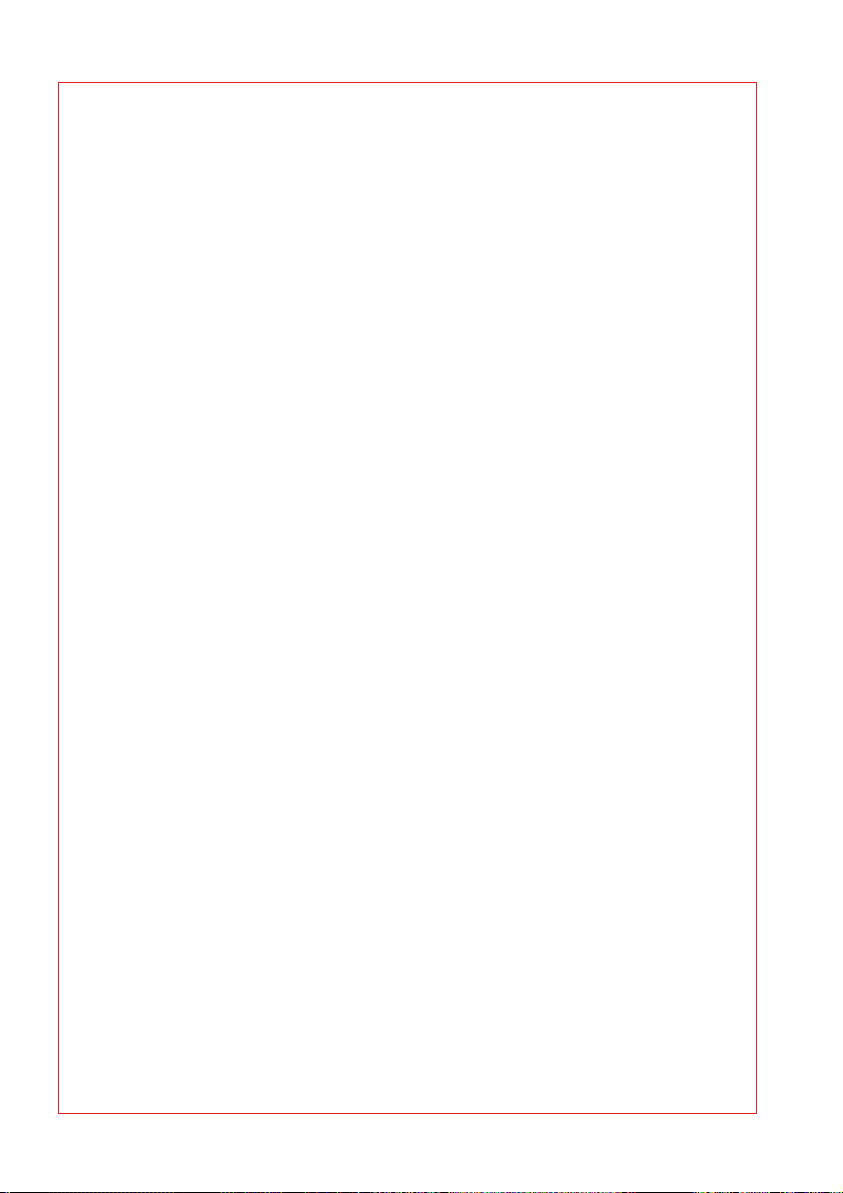

The main power socket with fuse and main power switch is located on the

rear of the Multiporator

tion on the ID plate. To start the device, insert the power cable into the

main power socket and connect it up to the main power supply. Turn on or

off the device by pressing the main power switch.

Depth: 34.2 cm

Height: 12.0 cm

. The mains power must agree with the informa-

Fig. 2: Multiporator, rear view

Power connection (left)

Printer connection (right)

The delivery carton should be kept in order to be able to safely send back

the device in case repairs are necessary.

4.3 Cuvette insert

The insert for the electroporation cuvette is next to the keypad at the

front of the device. To remove the cuvette, pull out the cuvette insert.

When inserting a new cuvette, ensure that the nose of the cuvette fits into

the rear slot. Push the cuvette insert containing the cuvette into the device

up to the stop. A sensor in the device detects whether the cuvette insert

contains a cuvette.

Note:

When transporting the device, please ensure that the insert

contains an empty cuvette. Alternatively, transport the cuvette insert

separately.

Different inserts are used for the modification level "cell fusion".

53

Page 12

4 Device description

4.4 Keypad

The keypad is used to enter the electroporation or the electrofusion

modes, to select the parameters and to start the application. Depending

on the modification level, 1 to 3 modes can be selected. Key combinations

can be used to set the date and time as well as the volume of the acoustic

signal.

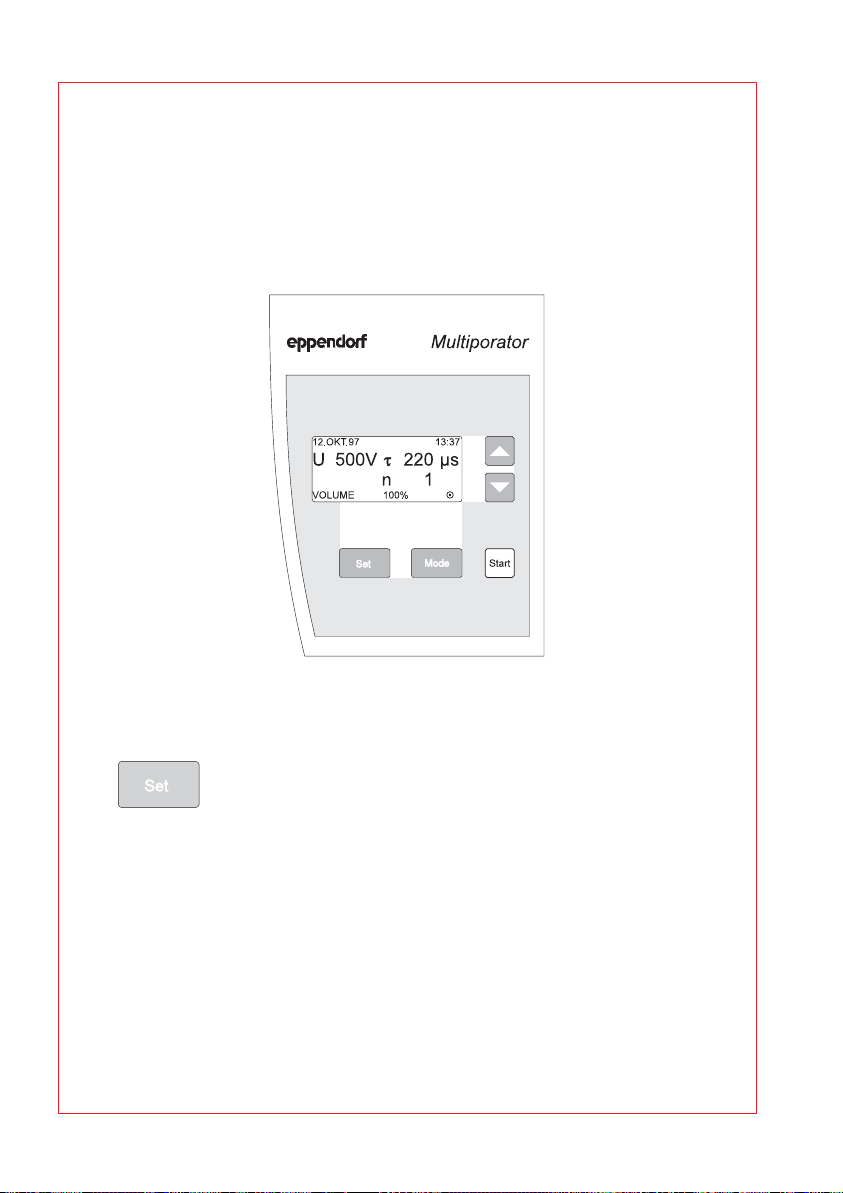

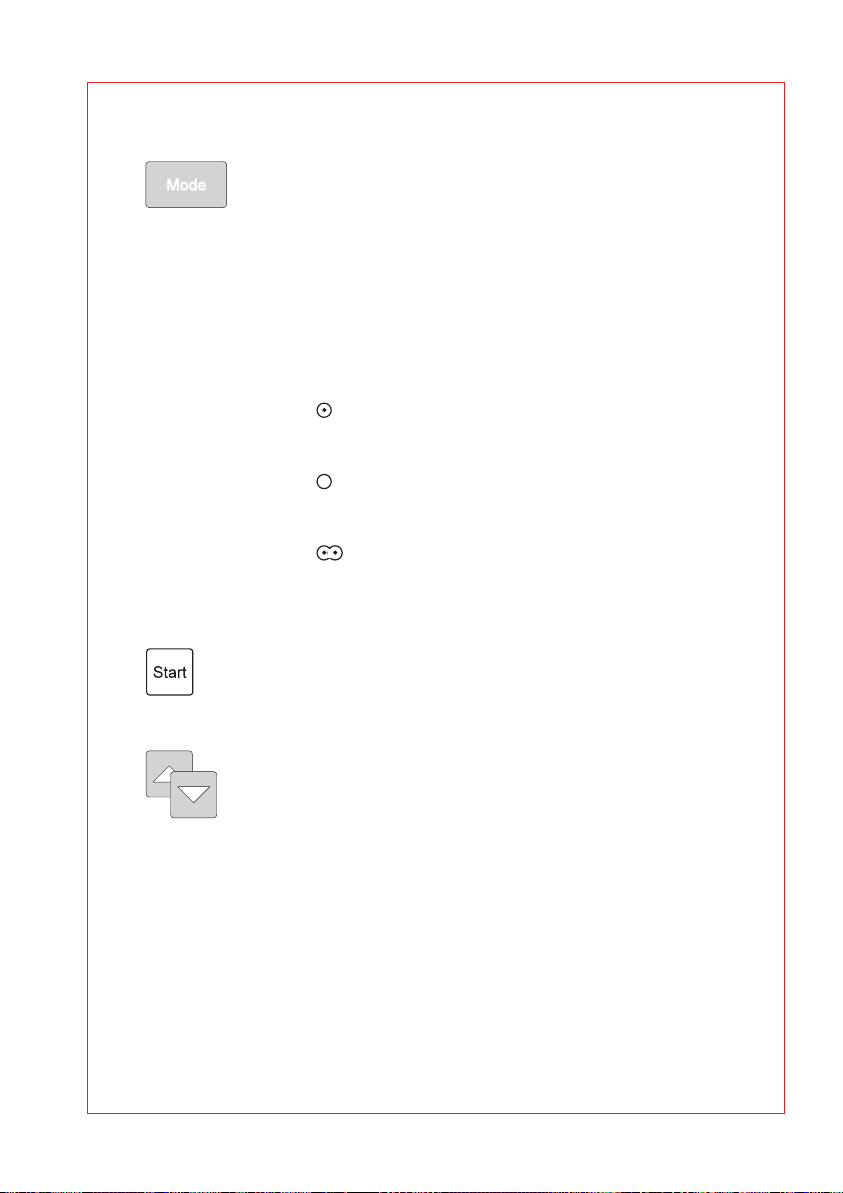

Fig. 3: Control panel with keys and display

4.5 Keys and key combinations

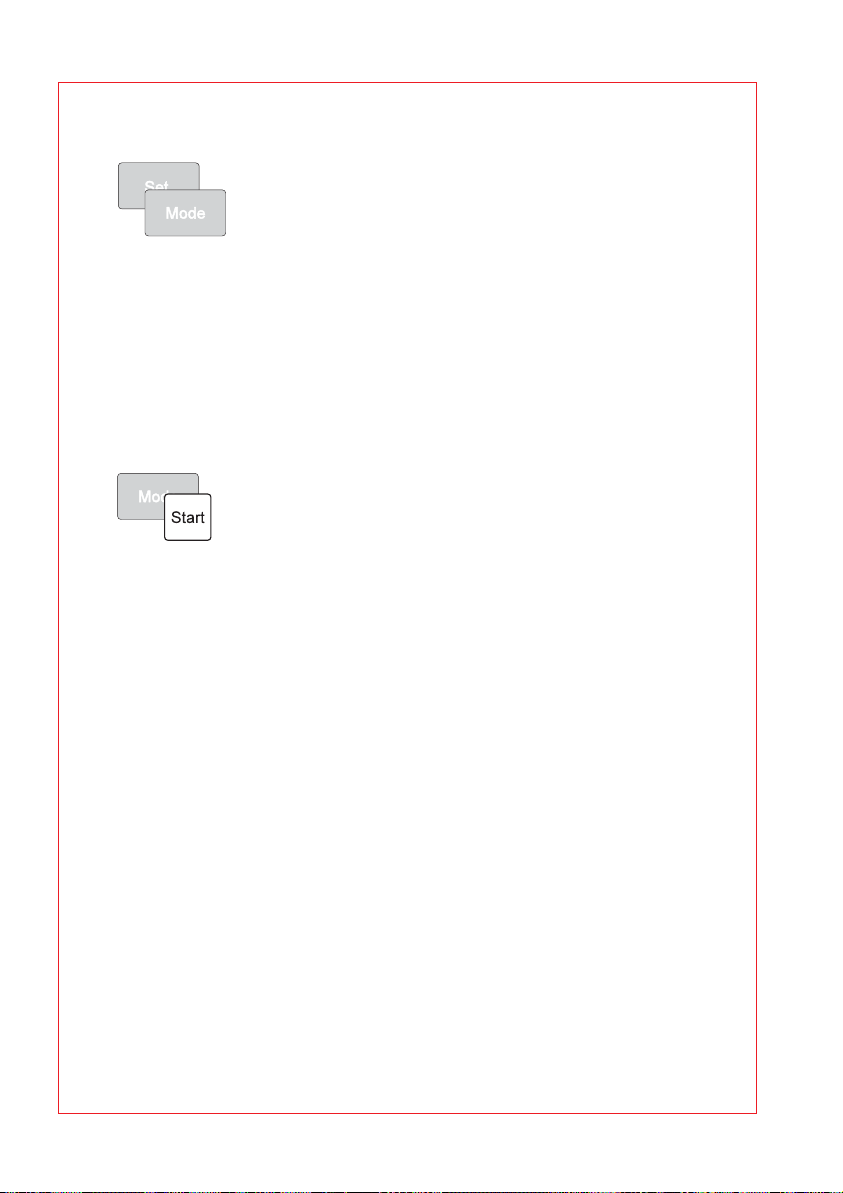

SET

The SET key is used to select the desired parameter. This

parameter is underlined in the display. Further parameters

are selected by pressing the SET key an appropriate

number of times. A SET sequence is ended either by

pressing the SET key repeatedly until the underlining

disappears or by pressing the MODE or START key.

(Note:

The MODE key switches to another mode if

available.) Parameters are modified using the up/down

arrow keys. When the lowest possible value has been

reached, the display then moves to the highest value.

Similarly, when the highest value has been reached, the

display then moves to the lowest value.

54

Page 13

4 Device description

MODE

The MODE key is used to activate the mode with

which electroporation or electrofusion is to be

performed. It is only possible to select modes in

accordance with the modification level of the device.

This means for the basic device, the mode for the

electroporation of eukaryotic cells is available, while

there is a choice of three modes for the maximum

expansion level.

The corresponding symbol then appears in the

display:

: Mode for eukaryotic cells

Modification level: Basic device

Pulse used: Decaying e-function

: Mode for bacteria and yeasts

Modification level: Bacteria module

Pulse used: Decaying e-function

: Mode for cell fusion

Modification level: Fusion module

Pulse used: Square-wave pulse

START

The process required is started by pressing the

START key.

Arrow keys

The arrow keys are used to modify the selected

(i.e. underlined) parameters in the desired direction.

55

Page 14

4 Device description

Setting the date

The procedure for setting the date and time can

be activated by pressing the SET and MODE keys

simultaneously. If the SET key is pressed again,

the underlining in the display for the date and time

moves from left to right. The arrow keys can thus

be used to modify the settings.

To end the process for setting the date, press the

SET key repeatedly until the underlining is no longer

visible in the display. Alternatively, the underlining

disappears from the display when the MODE or

START key is pressed.

switches to another mode if available.)

Setting the volume of the acoustic signals

The procedure for setting the volume of the acoustic

signals can be activated by pressing the MODE

and START keys simultaneously. "VOLUME" then

appears in the bottom line of the display, together

with a figure in percent. This figure indicates the

volume and the tone type and can be modified using

the arrow keys.

To end the procedure for setting the volume of the

acoustic signals, press the SET, MODE or START

key.

(Note:

mode if available.) "VOLUME" then disappears from

the display.

(Note:

The MODE key

The MODE key switches to another

56

Reset

An experiment can be terminated only by pressing

the main power switch. This switch also functions as

a reset switch.

Page 15

4 Device description

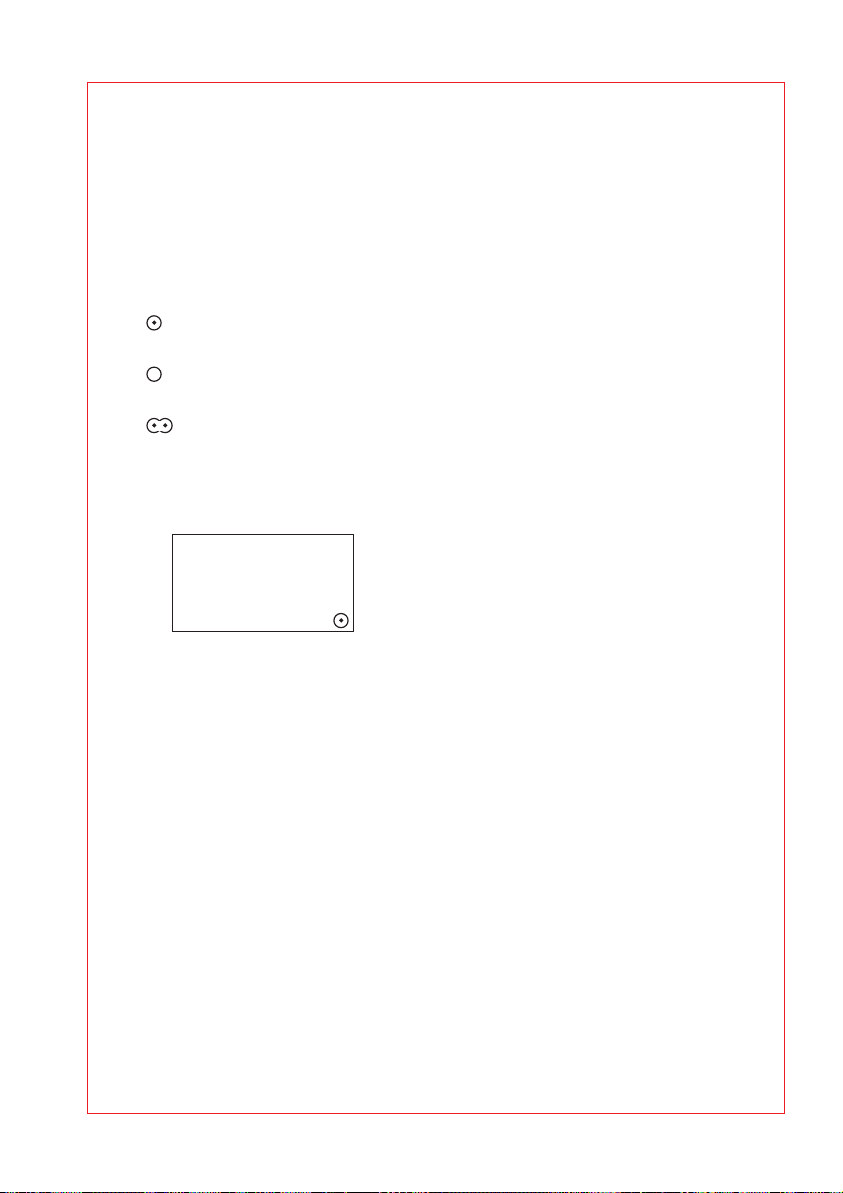

4.6 Display

The date and time of day are always displayed in the uppermost line of

the display. The parameters which are relevant for the experiment appear

in lines 2 to 4 in larger letters and in bold print. The parameters and the

number of parameters differ according to the mode which has been

selected. The mode which has been selected is always represented by a

symbol on the right of the bottom line:

: Mode for eukaryotic cells

Modification level: Basic device

: Mode for bacteria and yeasts

Modification level: Bacteria module

: Mode for cell fusion

Modification level: Fusion module

"VOLUME" or the remaining time for the experiment can also appear in

the display in this line.

n

13:37

220µs

1

Example of the display for setting

the volume of the acoustic signal

12.AUG.00

U 500V

VOLUME 100%

τ

During and after the experiment, the display changes to show the

information relevant to the stage of the experiment which has been

reached.

57

Page 16

4 Device description

4.7 Electroporation

4.7.1 Cuvettes and cuvette insert

The electroporation of eukaryotic cells, bacteria or yeasts is carried out in

disposable cuvettes. The biological material is placed in the gap between

the electrodes of the cuvette, whereby the prescribed liquid volumes of

the relevant cuvette are to be maintained. Although a supernatant above

the electrode does not drastically affect the experiment, however it

reduces the general efficiency.

A matt window allows the cuvette to be inscribed.

The plastic nose on the cuvette ensures that the cuvette is inserted

correctly into the cuvette insert. The lid seals the cuvette. However, to

safeguard against excess pressure, the cuvette is not hermetically sealed

by the lid. A filled cuvette should therefore be transported in an upright

position only in order to ensure that biological material does not leak out.

Lid

Plastic cuvette

Plastic nose

Electrodes

Gap

Fig. 4: Schematic diagram of electroporation cuvette

The cuvette insert is removed from the Multiporator

using the protruding

grip. No bubbles are present when the cuvette is filled.

When the cuvette is inserted into the inner recess of the cuvette insert,

care must be taken to ensure that the cuvette nose is positioned in the

long slit and that the cuvette is in contact with the base of the cuvette

insert. The cuvette insert, complete with cuvette, is then pushed into the

device up to the stop.

The cuvette insert may be stored in a cool place.

When transporting the device, please note that the cuvette insert may slip

out of the device if no cuvette has been inserted (see chap. 4.3).

58

Page 17

4 Device description

4.7.2 Electroporation buffer for eukaryotic cells

To achieve optimal transfection results, the original electroporation buffer

from Eppendorf, with a low electrical conductivity, should be used. These

electroporation buffers (hypo and isoosmolar) are tested for sterility and

the absence of mycoplasms and endotoxins.

The use of these buffer systems means that considerably less current

flows during electroporation, with the result that no significant damage is

sustained by the cells. Simultaneously, the use of appropriate buffer

media results in the electrically induced "pores" being much larger than

those of pulse applications in conductive solutions.

Ideally, the electroporation should be carried out in hypoosmolar buffer.

Through the hypoosmolar buffer system, the cells absorb water shortly

before the pulse and swell as a result. Due to a variety of effects, including

the lowering of the breakdown voltage, this process enables increased

permeability of the plasma membrane. The yields can thereby be

considerably increased in comparison to those under isoosmolar

conditions. In the case of cells that react sensitively to purely hypoosmolar

conditions, step-by-step addition of the isoosmolar electroporation buffer

can be used to adjust the necessary osmolarity.

The Eppendorf electroporation buffer should be used for the electroporation of eukaryotic cells (with the exception of yeasts and some

microorganisms and plants). Electroporation media with low conductivity

can be used for the electroporation of bacteria, yeasts and other

microorganisms. Detailed application protocols can be downloaded from

the Eppendorf Homepage www.eppendorf.com.

59

Page 18

4 Device description

4.8 Cell fusion (optional)

4.8.1 Micro fusion chamber (Electrode gap width 0.2 mm)

With the help of the Micro fusion chamber, the parameters for the cell

alignment and for the cell fusion can be optimized under microscopic

control.

The Micro fusion chamber consists of a housing equipped with a

transparent reservoir, into which two electrodes with a gap of 200 µm are

embedded. The connection to the Multiporator takes place through a

coaxial cable (approx. 1 m) over a special insert (see Fig. 5).

12 4

Insert of Micro fusion chamber

1 Contacts

Fig. 5: Schematic diagram of the insert and the Micro fusion chamber

Caution :

2 Earthing springs

The Micro fusion chamber must be handled with care.

3 Cable

3

Micro fusion chamber

4 Coaxial connector

3

Ta ke care when filling with cell suspension. Do not touch or move the

electrodes with the pipette tip. This may cause damage!

During cell alignment/fusion, avoid direct contact with the

electrodes. Cell alignment/fusion may be performed only when

the micro fusion chamber is connected.

– Slide the Micro fusion chamber firmly into the Multiporator

.

– Place the Micro fusion chamber (which is filled with approx. 20–50 µl

cell suspension) onto the microscope.

Note :

Pipetting the cell suspension carefully onto the area around the

electrodes can maximize the number of cells between the electrodes.

– The brackets can be used

to lock into place on the

microscope table. They

can also be used to

fasten a glass slide.

60

Page 19

4 Device description

– Connect the Micro fusion chamber with the coaxial connection of the

cable.

–Focus the electrodes and cells under the microscope.

– Run through the parameters by pressing the START key. This can be

monitored under the microscope (see chap. 5.3).

200 µm

Alignment of the cells

between the electrodes

Fig. 6: Microscopic view of the cells during the alignment and after the fusion

sequence with individual fusion products

The parameters determined to be optimal can be directly adopted for the

fusion in the Helix fusion chamber (see chap. 4.8.4).

Cells after fusion and fusion products

4.8.2 Micro fusion chamber (Electrode gap width 0.5 mm)

The non-standard accessories (see "Ordering information") contain a

Micro fusion chamber with a modified electrode interval of 500 µm. With

the help of this Micro fusion chamber, cells can be fused under

microscopic control.

General instructions for usage of a Micro fusion chamber are given in

chapter 4.8.1 and in the Basic Applications Manual for electrofusion. This

is included in the delivery package of the fusion module.

Important note:

Applications Manual for electrofusion), the modified electrode interval of

500 µm must be taken into account. Please note that the parameters

determined as optimal cannot be adopted directly for fusion in the Helix

fusion chamber.

When calculating the fusion parameters (see Basic

4.8.3 Cleaning the Micro fusion chamber

The content of the Micro fusion chamber is rinsed out using bi-distilled

water from a spray bottle. Cell residue that is particularly stubborn can be

removed by carefully cleaning the electrodes with a soft toothbrush using

vertical strokes. (The space between the electrodes must not be changed

during this process!) The drying process can be accelerated by rinsing the

chamber with 70 % non-denatured ethanol.

61

Page 20

4 Device description

4.8.4 Helix fusion chamber

The Helix fusion chamber has been specially designed for the production

of larger quantities of fusion products (hybrids). It consists of a conical

tapered core that carries the electrodes and a beaker into which the cell

suspension is added (see fig. 7).

Fig. 7: Helix fusion chamber

Diagram of Helix fusion chamber

The Helix fusion chamber (see fig. 8) consists of a cup (1) and a core with

parallel wound platinum wires, which are the electrodes (2). They are

wound around the core as a double helix. Both parts are screwed

together. The gap (4) between the cup and the core has a filling volume of

250 µl.

The Helix fusion chamber is linked to the insert (6) for cell fusion via the

coaxial connector (3).

3

1

4

2

5

Cup Core Helix fusion chamber Fusion insert

1 Thread 2 Electrodes

Fig. 8: Schematic representation of the Helix fusion chamber and the fusion insert

3 Coaxial

connector

4 Gap for cell fusion 5 Contacts

6 Coaxial connector

62

6

Page 21

4 Device description

The gap between the wound platinum electrodes is approx. 200 µm.

200 µm

Fig. 9: Microscope view of the electrodes of the Helix fusion chamber

Caution :

Loose or damaged electrodes adversely affect operating procedures.

In such cases, the Helix fusion chamber must not be used!

4.8.5 Filling the Helix fusion chamber

The Helix fusion chamber is filled with 250 µl cell suspension. It is

essential to ensure that the liquid is pipetted into the deepest possible

position in the cup. The edge and the walls must not be wetted as this has

an adverse effect on filling the Helix fusion chamber. Air bubbles may form

which reduce the effectivity of the experiment.

The core is inserted into the upright cup in the stand and carefully

screwed into place. As a result of this screwing action, the cell suspension

in the ever-decreasing gap is forced upwards.

Handle the Helix fusion chamber with care!

63

Page 22

4 Device description

When screwing the core, make sure that no air bubbles form.

Fig. 10: Filling the Helix fusion chamber (schematic representation)

Leave the closed Helix fusion chamber upside-down on the coaxial

connector until the fusion process has been completed!

4.8.6 Fusion and cell suspension extraction

– Slide the fusion insert firmly into the device.

– Place the closed Helix fusion chamber onto the coaxial connector

and lock it into place by rotating it a quarter-turn.

– Carry out the fusion with the set parameters (see chap. 5.3).

– Loosen the Helix fusion chamber carefully by rotating it a quarter-turn

and then remove it.

–To open the chamber, place it in a vertical position (e.g. in the stand).

– Unscrew the core carefully from the beaker.

– Using a small quantity of the appropriate medium, rinse off any cell

suspension that may be on the core.

– The cell suspension from the beaker is mixed with the cell suspension

that has been rinsed off and is then treated further as required.

64

Page 23

4 Device description

4.8.7 Cleaning and disinfecting the Helix fusion chamber

The beaker and core of the Helix fusion chamber should be rinsed with

distilled water directly after the experiment in order to prevent cell and

buffer residue from drying up.

If heavily contaminated, the Helix fusion chamber should be cleaned

briefly in an ultrasonic bath (possibly with a cleaning supplement, such as

Edisonite Super) or with a very soft (tooth)brush. When cleaning is carried

out using brushes, please ensure that brushing is carried out in the same

direction as the windings, since the electrodes may otherwise move out of

their correct position and thus render the Helix fusion chamber unusable.

Disinfect the parts using non-denatured 70 % ethanol. To do this, the

beaker is filled with 250 µl of ethanol and the core screwed into the

beaker. After

removed. To subsequently dry the beaker and the core place them in the

stand under sterile, dust-free conditions. After drying, the Helix fusion

chamber may be re-used.

4.8.8 Electrofusion buffer for eukaryotic cells

The electrofusion medium (fusion buffer) is of considerable importance for

the survival rate of the cells and for the successful extraction of hybrid

cells. Only a single buffer should be used for the entire electrofusion

procedure (alignment, fusion, post-alignment) in order to protect the cells

from additional stress. The fusion buffers from Eppendorf are

differentiated from the commonly used fusion media by low conductivity

and low osmolarity. The low conductivity (120 µS/cm) of the Eppendorf

buffers enables the application of relatively low field strengths (voltage)

when merging cells.

Ideally, electrofusion should be carried out in hypoosmolar buffer. As a

result of the hypoosmolar buffer system, the cells absorb water shortly

before the pulse and swell. The membrane and actin skeleton proteins are

thereby temporarily disengaged, thus easing fusion in the electrical field.

The yields of fusion products attained can thereby be considerably

increased in comparison to those under isoosmolar conditions. For cells

that react sensitively under purely hypoosmolar conditions, the necessary

osmolarity can be adjusted through step-by-step addition of the

isoosmolar buffer.

The Eppendorf fusion buffers (hypo and isoosmolar) are tested for sterility

and the absence of mycoplasma and endotoxins.

10 seconds

, the core is unscrewed and the alcohol can be

65

Page 24

4 Device description

4.9 Insert (electroporation / electrofusion)

for connecting external electrodes

Prior to using the insert for the connection of external

electrodes, the supplement sheet accompanying the insert

must be read thoroughly. The safety instructions found in the

supplement sheet must be observed.

The non-standard accessories (see "Ordering information") contain an

insert, to which it is possible to connect external electrodes. By changing

the position of a function switch ( P / F ) accordingly, the insert can be used

for electroporation (symbols ) or for cell fusion with external

electrodes (symbol ).

The electrodes are connected using two 4 mm contact-proof

laboratory plugs.

1

2

Position of the function switch for electroporation P

1

2

Position of the function switch for electrofusion F

1

Connecting socket, positive pole (red)

2

Connecting socket, ground (black)

Fig. 11: Insert for the connection of external electrodes (schematic representation)

Attention! Characteristic of electrofusion of cells with

external electrodes:

During the electrofusion, a resistance of 50 Ohm must be

connected parallel to the electrodes with the help of plug in

connections.

66

Page 25

4 Device description

When external electrodes are connected, the relevant national

safety regulations (relating to high voltage) and EMC

regulations apply and should be observed

(EMC: electro-magnetic compatibility).

The user is responsible for all equipment that has been

connected!

4.10 Printer connection / printer (optional)

The Multiporator

This protocol contains the parameters used as well as the date and time,

which are automatically retained. Additional data pertaining to the

experiment, such as buffer, concentration or cell line, can also be entered

by hand. In the event of an error occurring, the error message is also

printed out. Examples of printouts for different applications are shown

below:

18.Aug.00 16:03:04 eppendorf Multiporator 4308 V4.00

Higher Eucaryotic Cells U = 100 V,

Cuvette Gap Width 1mm 2mm 4mm

Strain / Cell Line ______________________________

Cell Density ______________________________

Tr ansfer Substance ______________________________

Concentration ______________________________

Buffer ______________________________

Temperature ______________________________

can supply a printer protocol for each experiment.

τ

= 50 µs, n = 1

67

Page 26

4 Device description

18.Aug.00 16:42:47 eppendorf Multiporator 4308 V4.00

Bacteria and Yeast U = 1000 V, Ua = 992 V,

Cuvette Gap Width 1mm 2mm 4mm

Strain / Cell Line ______________________________

Cell Density ______________________________

Tr ansfer Substance ______________________________

Concentration ______________________________

Buffer ______________________________

Temperature ______________________________

18.Aug.00 16:17:49 eppendorf Multiporator 4308 V4.00

Cell Fusion U'

Fusion Chamber

Strain / Cell Line A ______________________________

= 8.0 V, t = 20 s

~

U

= 15 V, t = 100 µs, n = 3

U"

= 4.0 V, t = 10 s

τa = 5.0 ms

68

Cell Density A ______________________________

~

Strain / Cell Line B ______________________________

Cell Density B ______________________________

Buffer ______________________________

Temperature ______________________________

Page 27

4 Device description

18.Aug.97 15:59:08 eppendorf Multiporator 4308 V1.00

******** ERROR 07 ********

******** Short τ *********

Serial printers can be connected to the serial printer interface at the rear

of the device. It is also possible to read protocols for documentation

purposes via a PC terminal program. This requires a zero-modem cable

(9-pin socket / 9-pin socket, order no. 0013 610.525).

The following thermal printers are available from Eppendorf AG. The DIP

switch setting for an IBM-compatible printer is also described:

Order no.

Printer type

Accessories

Connecting

cable

Thermal printer DPU-414 0013 608.148

Power unit (230 V)

Power unit (115 V)

Thermal paper (10 rolls)

9-pin socket / 9-pin plug

cable guide 1:1

(for Thermal printer DPU-414)

9-pin socket / 25-pin plug

zero-modem cable

(EDP compatible

e.g. for Matrix printer

Seikosha SP 2400 (endless paper)

0013 608.172

0013 608.164

6547 001.018

0013 610.517

0013 610.533

69

Page 28

4 Device description

For Thermal printer DPU-414 e.g. for Matrix printer

Seikosha SP 2400

(endless paper)

DIP SW

settings Dip SW-1 Dip SW-1

1 (OFF) : Input = Serial

2 (ON) : Printing Speed = High

3 (ON) : Auto Loading = ON

4 (ON) : Auto LF = ON

5 (ON) : Setting Command

= Enable

6 (OFF) : Printing

7 (ON) : Density

8 (ON) : = 100 %

Dip SW-2 Dip SW-2

1 (OFF) : Printing Columns = 80

2 (ON) : User Font Back-up

= ON

3 (ON) : Character Select

= Normal

4 (OFF) : Zero = Slash

5 (ON) : International

6 (ON) : Character

7 (ON) : Set

8 (OFF) : = USA

1 (OFF) : USA

2 (OFF) : USA

3 (OFF) : USA

4 (ON) : IBM

5 (OFF) : Character Set 1

6 (ON) : 12 inches

7 (OFF) : LF only

8 (ON) : CR = CR + LF

1 (ON) : 9600 Baud

2 (ON) : 9600 Baud

3 (ON) : XON/XOFF

4 (OFF) : No Parity

5 (OFF) : No Parity

6 (OFF) : 8 bits

7 (ON) : Serial

8 (OFF) : No single sheet

70

Dip SW-3

1 (ON) : Data Length = 8 bits

2 (ON) : Parity Settings = No

3 (ON) : Parity Conditions

= Odd

4 (OFF) : Busy Control

= XON/XOFF

5 (OFF) : Baud

6 (ON) : Rate

7 (ON) : Select

8 (ON) : = 9600 bps

Page 29

5 Mode of operation

5.1 Mode for electroporation of eukaryotic cells

This mode is represented in the display by the symbol .

Instructions for the filling of the electroporation cuvettes have been

summarized in chapter 4.7.1 of the operating instructions. A detailed

description of the electroporation of eukaryotic cells can be found in the

Basic Applications Manual for electroporation, which is included in the

delivery package. This application manual can also be downloaded from

the Eppendorf Homepage www.eppendorf.com.

Step 1 – Entering / modifying parameters

– If necessary, switch

to the mode by

pressing the MODE

key.

– Press the SET key

to select the

parameter desired

(the parameter will

be underlined).

– Use the arrow keys

to modify the

parameter in the

direction required.

– If necessary, modify

other parameters

using the SET key

and the arrow keys.

–Terminate the

entering procedure.

The parameters

are effective

immediately and

do not have to be

stored.

Note:

The course of the curve is calculated internally, so that the course

of the discharge curve (e-function) is maintained according to the

parameters which have been entered.

12.AUG.00

U 500V

220µs

τ

n

Example of a display for

13:37

the electroporation of

eukaryotic cells.

2

The relevant parameters

appear in the display in

larger letters and in bold

print.

U: Voltage, in V (volt).

Can be set in

increments of 1 V in

the range 20–100 V;

in increments of 10 V

in the range

100–1,000 V;

in increments of

100 V in the range

1,000–1,200 V.

τ

: Time constant, in µs

(microseconds).

Can be set in

increments of 5 µs in

the range 15–500 µs.

n: Number of pulses

during the

experiment.

Can be set between

1 and 99. A period of

one minute elapses

between each pulse.

71

Page 30

5 Mode of operation

Step 2 – Starting electroporation

–Trigger the

electroporation

process by pressing

the START key.

– "Charge" appears in

the third line of the

display. Charging

commences.

– After the charging

procedure has

ended, discharging

occurs. This is

indicated by a flash

in the third line of

the display.

12.AUG.00

U 500V

τ

Charge

13:37

220µs

If more than one pulse

has been set, "Wait"

appears in the display,

accompanied by the

remaining waiting time.

After the experiment has

ended, a double acoustic

signal is emitted and the

initial information

appears

in the display with the

parameters which have

been used.

The time which has

elapsed since the end of

the experiment appears

in the bottom line in

minutes and seconds.

After 99 minutes or after

any key has been

pressed, this information

disappears from the

display.

12.AUG.00

U 500V

τ

Wait

0:57

12.AUG.00

U 500V

τ

n

READY SINCE 1:36

220µs

13:37

13:37

220µs

2

72

Page 31

5 Mode of operation

5.2 Mode for electroporation of bacteria and yeast (optional)

This mode is represented in the display by the symbol .

Instructions for the filling of the electroporation cuvettes have been

summarized in chapter 4.7.1 of the operating instructions. In addition,

application protocols for the electroporation of bacteria, yeasts and other

microorganisms can be downloaded from the Eppendorf Homepage

www.eppendorf.com.

Step 1 – Entering / modifying parameters

– If necessary, switch

to the mode by

pressing the MODE

key.

– Press the SET key

to select the Voltage

(U) parameter (the

parameter will be

underlined).

– Use the arrow keys

to modify the

parameter in the

direction required.

–Terminate the

entering procedure.

The parameters

are effective

immediately and

do not have to be

stored.

12.AUG.00

U 2000V

τ

5

Example of a display for

13:42

the electroporation of

ms

bacteria and yeast.

The relevant parameters

appear in the display in

larger letters and in bold

print.

U: Voltage, in V (volt).

Can be set in

increments of 10 V

in the range

200–1,000 V;

in increments of

100 V in the range

1,000–2,500 V.

τ

: Time constant,

in ms (milliseconds).

Set to 5.0 ms.

73

Page 32

5 Mode of operation

Step 2 – Starting electroporation

–Trigger the

electroporation

process by pressing

the START key.

– "Charge" appears in

the third line of the

display. Charging

commences.

– After the charging

procedure has

ended, discharging

occurs. This is

indicated by a flash

in the third line of

the display,

accompanied by a

double acoustic

signal.

12.AUG.00

U 2000V

τ 5

Charge

13:42

ms

≤

After the experiment has

ended, a double acoustic

signal is emitted and the

initial information and

the set parameters

appear in the display.

The actual parameters

U

and

τ

a

third line

of the display.

The time which has

elapsed since the end of

the experiment appears

in the bottom line in

minutes and seconds.

After 99 minutes or after

any key has been

pressed, this information

disappears from the

display.

74

appear in the

a

12.AUG.00

U 2000V

U 2003V

a

READY SINCE 1:36

τ

τ

5

5.1

a

U

13:42

: Actual measured

a

ms

ms

voltage used, in V

(volt).

τ

: Actual time constant

a

used, in ms

(milliseconds). Values

0.8 are shown as

0.8 ms.

Page 33

5 Mode of operation

5.3 Mode for cell fusion (optional)

This mode is represented in the display by the symbol .

Instructions for the usage of the Micro fusion chamber and the Helix

fusion chamber have been summarized in chapter 4.8 of the operating

instructions. A detailed description of the electrofusion of eukaryotic cells

can be found in the Basic Applications Manual for electrofusion, which is

included in the delivery package of the fusion module. This application

manual can also be downloaded from the Eppendorf Homepage

www.eppendorf.com.

5.3.1 Function: Cell alignment

The functions for alignment are indicated by the symbols U'

pulse, alignment) and U"

of the display.

Step 1 – Entering / changing parameters

– If necessary, switch

to the mode by

pressing the MODE

key.

– Press the SET key

to select the

parameter desired

(the parameter will

be underlined).

– Use the arrow keys

to modify the

parameter in the

direction required.

If a value in lines

U'

/ U"

/

~

set to "0", the

U are

function in question

is not carried out.

This enables U'

U"

to be triggered

~

individually or

consecutively

without the fusion

pulse being

activated.

(after the pulse, post-alignment) in lines 2 and 4

Example of the display for

12.AUG.00

5V t

U'

~

0V t

U

U "

0V

t

60s

15s

30s

13:42

cell alignment U'

out activation of pulse U

~

n2

and alignment U"

The relevant parameters

appear in larger letters

and in bold print.

~

~

~

U'

/ U"

~

~

Alternating voltage, in

V (volts). Can be set

to "0" and in increments of 0.1 V between 1.0 V and 10 V.

t: Duration of alignment

0–95 s, in s (seconds).

Can be set in increments of 5 seconds.

/

~

U: Voltage,

(square-wave pulse)

unit V (volts).

Can be set to "0" and

in increments of 1 V

between 5 V and

100 V, and in

increments of 10 V

between 100 V and

300 V.

(before the

~

:

~

with-

.

75

Page 34

5 Mode of operation

–Terminate the

entering procedure.

The parameters

are effective

immediately and

do not have to be

stored.

Step 2 – Starting cell alignment

–Trigger alignment

U'

by pressing

~

the START key.

– The information

At the end of the

experiment, an acoustic

signal is emitted and an

initial display appears

with the parameters that

have been set and used.

In addition, the time that

has elapsed (in minutes

and seconds) since the

end of the experiment is

shown in the bottom line.

This display disappears

after 99 minutes or when

any key is pressed.

appears in

the fourth line of the

display; alternating

voltage is applied

for the duration

selected.

12.AUG.00

5V t

U'

~

0V t

U

0V

U "

t

60s

15s

30s

: Duration of pulse,

t

Unit µs

(microseconds).

Can be set in

increments of 5 µs

between 0 and

15 µs–300 µs.

n: Number of pulses

0–99. Can be set in

one-pulse increments.

13:42

~

n2

76

Page 35

5 Mode of operation

5.3.2 Procedure for cell fusion

Step 1 – Entering / modifying parameters

– Press the SET

key to select the

parameters desired

(the parameter will

be underlined).

12.AUG.00

U'

~

U

U "

5V t

t

30V

t

5V

30s

15µs

30s

Example of a display of

13:42

electrofusion with activated alignments U'

~

n2

/ U"

.

~

~

– Use the arrow

keys to modify the

parameter in the

direction required.

According to the

parameters selected

for U'

~

and U"

can be carried out

without alignment or

in combination with

one or both

alignment functions

as required.

–Terminate the

entering procedure.

The parameters

are effective

immediately and

do not have to be

stored.

, fusion

~

12.AUG.00

0V t

U'

~

U

30V

U "

5V

t

t

30s

15µs

30s

Example of the display

13:42

for carrying out electrofusion with inactiva-

~

n2

ted alignment U'

The relevant parameters

appear in the display in

larger letters and in bold

print.

U'

/ U"

~

~

Alternating voltage, in

V (volt).

Can be set to "0" and

in increments of 0.1 V

in the range 1.0–10 V.

t: Duration of alignment

0–95 s, in

s (seconds). Can be

set in increments of

5 seconds.

U: Voltage, in V (volt).

Can be set to "0" and

in increments of 1 V

between 5 V and

100 V, and in increments of 10 V between 100 V and

300 V.

: Duration of pulse,

t

in µs (microseconds).

Can be set in

increments of 5 µs

between 0 and

15 µs–300 µs.

n: Number of pulses

0–99.

Can be set in onepulse increments.

:

.

~

77

Page 36

5 Mode of operation

Step 2 – Starting cell fusion

–Trigger the cell

fusion process

by Pressing the

START key.

– "Charge" appears

briefly in the fourth

line of the display.

Charging

commences.

– During the charging

procedure,

alternating voltage

U'

is applied for the

~

selected duration.

The alternating

voltage is

represented by the

symbol

~

oscillation).

– Discharge occurs

after the precounted alignment

time (0–95

seconds). This is

indicated by a flash

in the fourth line of

the display.

If the number n

which has been

entered is n >1,

a further discharge

occurs each time

after one second.

(sine-wave

12.AUG.00

U'

~

U

12.AUG.00

U'

~

U

5V t

t

30V

Charge

5V t

30V

t

30s

15µs

30s

15µs

0:23

13:42

13:42

n2

n2

78

Page 37

5 Mode of operation

– After the discharging

procedure has

ended, the

alternating voltage

U"

is applied for

~

the set duration

(0–95 seconds).

The overall time

remaining for the

experiment is

constantly visible

on the bottom line

of the display.

After the experiment has

ended, a double acoustic

signal is emitted and the

initial menu appears in

the display with the

parameters which have

used.

The time which has

elapsed since the end of

the experiment appears

in the bottom line in

minutes and seconds.

After 9 minutes or after

any key has been

pressed, this information

disappears from the

display.

12.AUG.00

5V t

'

~

U

U "

t

30V

t

5V

READY SINCE 1:36

30s

15µs

30s

13:42

n2

U

~

79

Page 38

6 Error messages

In the event of an error, the Multiporator

error message appears in the display or via the printer (optional). These

error messages refer to device errors or to applicational errors. Errors 1–4

and 9 may occur in the mode for bacteria, errors 1–7 in the mode for

eukaryotic cells and errors 1–8 in the mode for cell fusion.

Error

Error message Cause Solution

no.

emits an acoustic signal and an

01 No Display Display is not

02 No RTC /

NVRAM

03 High Current The current was

04 No Cuvette Cuvette has not

05 Timeout Charge The capacitor was

06 Timeout Charge During repeated

controlled.

Electronic module

for the internal

clock is defective.

too high during

the discharging

process (pulse).

been inserted.

unable to be

charged in within

the allotted period

of time.

pulsing, the

capacitor was

unable to be

charged within the

period between the

individual pulses.

Contact SERVICE.

Contact SERVICE.

Reduce the conductivity

of the solution used.

Check whether the

correct cuvette type has

been inserted.

Insert a cuvette.

Restart the device.

Push cuvette insert fully

into the device.

Contact SERVICE.

Reduce the conductivity

of the solution used.

Check whether the

correct cuvette type has

been inserted.

80

Page 39

6 Error messages

Error

Error message Cause Solution

no.

07 Short

τ

The capacitor

was completely

emptied; it is

uncertain whether

the

has been

τ

executed. The

limiting element

was the capacitor

and not the pulse

regulator.

Reduce the conductivity

of the solution used.

Check whether the

correct cuvette type has

been inserted.

08 Low Resistance The current in the

09 Timeout

Measuring

Bacteria

module

= 0.8 ms,

τ

a

U

is

a

considerably

lower than the

parameter U

which has been

set.

cuvette is too high

and the alternating

voltage cannot be

maintained.

Timeout for the

measurement of

τ

the bacteria

module.

– Sparks in the

– The current

–Technical error.

τ

cuvette.

during

discharge

(pulse) was too

high.

Reduce the conductivity

of the solution used.

-

Contact SERVICE.

– Use a cuvette which

has a greater

distance between the

electrodes.

– Reduce the

conductivity of the

solution.

– Contact SERVICE.

81

Page 40

7 Maintenance and servicing

Warranties and servicing are the responsibility of the distributor.

7.1 Disinfection

Before disinfecting the Multiporator

, disconnect the device from the main

power supply.

All parts of the Multiporator

, including the accessories and the

connecting cable, must undergo wipe disinfection.

The cuvette insert can also undergo spray disinfection.

However, it is not advisable to carry out spray disinfection on the entire

device, as disinfectant may enter the device.

7.2 Cleaning

Before cleaning the Multiporator

Ensure that no fluids enter the Multiporator

, disconnect the plug.

, as this could cause short-

circuits in the electrical installation as well as corrosion.

Wipe painted parts and aluminum surfaces using a cloth and mild

detergent and then wipe with a dry cloth.

Warning:

Do not use any corrosive, solvent or abrasive detergents or

polishes.

82

Page 41

8 Technical data

Voltage/frequency: 100–240 V ±10 %, 50–60 Hz

Fuses: T0, 1.0 A – 5 x 20 mm (2 pcs.)

Power consumption: 60 W

Excess-voltage category:

Protection class:

Degree of contamination: 2

Voltage range

for the following modules:

Eukaryotic cells: 20– 100 V, in increments of 1 V

Cell fusion: 0, 5– 100 V, in increments of 1 V

Alternating voltage: 0,

Bacteria: 200–1,000 V, in increments of 10 V

Capacitor: 10 µF, 2,500 V impulse discharge

Resistance: 600 Ω parallel

Charging time: <30 seconds

No. of pulses (n): 0–99

Time constant

Eukaryotic cells: 15–500 µs, in increments of 5 µs,

Bacteria: Nominal 5 ms,

Duration of alignment: 0–95 s, in increments of 5 s

Duration t of pulse:

Cell fusion: 0, 15 µs–300 µs, in increments of 5 µs,

RS 232 interface: 9,600 baud, 8 bits, no parity,

Ambient temperature: max. 40 °C

Relative ambient humidity: max. 80 %

τ

of discharge:

II

I

100–1,000 V, in increments of 10 V

1,000–1,200 V, in increments of 100 V

Interval between pulses: 1 minute

100– 300 V, in increments of 10 V

Interval between pulses: 1 second

1.0– 10 V, in increments of 0.1 V

1,000–2,500 V, in increments of 100 V

No multiple pulse

56 Ω series

fading e-function

with an impedance of the sample of 3.3 k Ω

Measurement and display from 0.8–6.0 ms

2 stop bits, XON/XOFF

square-wave pulse

83

Page 42

8 Technical data

Weight: max. 5.5 kg (according to modification level)

Dimensions: Width: 25.2 cm

Depth: 34.2 cm

Height: 12.0 cm

The device is -approved and has UL and CSA authorization

(cUL: E 158089).

U.S. Pat. No. 6,008,038.

Technical specifications subject to change!

84

Page 43

9 Ordering information

Order no.

4308 000.015 Multiporator

,

basic version, for eukaryotic cells,

100–240 V, 50–60 Hz

4308 000.023 Multiporator

, eukaryotic cells,

and modification level "bacteria mode"

4308 000.031 Multiporator

, eukaryotic cells

and modification level "cell fusion"

4308 000.040 Multiporator

, eukaryotic cells and modification

level "bacteria mode" and "cell fusion"

Accessories

Buffer

4308 070.501 Hypoosmolar buffer for electroporation (PH), 100 ml

4308 070.510 Isoosmolar buffer for electroporation (PI), 100 ml

4308 070.528 Hypoosmolar buffer for cell fusion (FH), 100 ml

4308 070.536 Isoosmolar buffer for cell fusion (FI), 100 ml

Electroporation cuvettes

4307 000.569 1 mm gap width, aluminum, sterile, 50 pcs.

4307 000.593 2 mm gap width, aluminum, sterile, 50 pcs.

4307 000.623 4 mm gap width, aluminum, sterile, 50 pcs.

4308 078.006 Cuvette stand for 16 electroporation cuvettes

4308 070.072 Insert for electroporation cuvettes

4308 021.004 Insert (electroporation / electrofusion)

for connecting external electrodes

4308 012.005 Insert for Helix fusion chambers

4308 014.008 Helix fusion chamber

(Electrode gap width: 0.2 mm)

4308 030.003 Micro fusion chamber

(Electrode gap width: 0.2 mm)

4308 031.000 Micro fusion chamber

(Electrode gap width: 0.5 mm)

4308 024.003 Insert for Micro fusion chamber

4308 013.001 Replacement cup for Helix fusion chamber

4308 017.007 Stand for 10 Helix fusion chambers

0013 608.148 Thermal printer DPU-414

0013 608.172 Power unit (230 V)

for thermal printer DPU-414

85

Page 44

9 Ordering information

0013 608.164 Power unit (115 V)

6547 001.018 Thermal paper (10 rolls)

0013 610.517 Connecting cable

0013 610.525 Zero-modem cable for PC connection

0013.610.533 Zero-modem cable for matrix printer

4308 010.002 Conversion kit for mode for bacteria

4308 011.009 Conversion kit for mode for cell fusion

for thermal printer DPU-414

(9-pin socket, 9-pin plug, cable guide 1:1)

(9-pin socket, 9-pin socket)

(9-pin socket / 25-pin plug)

(to be installed by SERVICE)

(to be installed by SERVICE)

86

Page 45

9a Ordering information for North America

Order no.

940000505 Multiporator,

940000602 Multiporator

940000700 Multiporator

940000807 Multiporator, eukaryotic cells and modification

940002001 Hypoosmolar buffer for electroporation (PH), 100 ml

940002109 Isoosmolar buffer for electroporation (PI), 100 ml

940002150 Hypoosmolar buffer for cell fusion (FH), 100 ml

940002206 Isoosmolar buffer for cell fusion (FI), 100 ml

basic version, for eukaryotic cells,

100–240 V, 50–60 Hz

and modification level "bacteria mode"

and modification level "cell fusion"

level "bacteria mode" and "cell fusion"

, eukaryotic cells,

, eukaryotic cells

Accessories

Buffer

940001005 1 mm gap width, aluminum, sterile, 50 pcs.

Electroporation cuvettes

940001013 2 mm gap width, aluminum, sterile, 50 pcs.

940001021 4 mm gap width, aluminum, sterile, 50 pcs.

940001102 Cuvette stand for 16 electroporation cuvettes

940004225 Insert for electroporation cuvettes

940004209 Insert (electroporation / electrofusion)

for connecting external electrodes

940004268 Insert for Helix fusion chambers

940001200 Helix fusion chamber

(Electrode gap width: 0.2 mm)

940001251 Micro fusion chamber

(Electrode gap width: 0.2 mm)

940001234 Micro fusion chamber

(Electrode gap width: 0.5 mm)

940004241 Insert for Micro fusion chamber

940004187 Replacement cup for Helix fusion chamber

940001218 Stand for 10 Helix fusion chambers

952010158 Thermal printer DPU-414

87

Page 46

9a Ordering information for North America

952010166 Power unit (230 V)

952010174 Power unit (115 V)

952010409 Thermal paper (5 rolls)

952010182 Connecting cable

940004306 Zero-modem cable for PC connection

940004322 Zero-modem cable for matrix printer

940004101 Conversion kit for mode for bacteria

940004128 Conversion kit for mode for cell fusion

for thermal printer DPU-414

for thermal printer DPU-414

(9-pin socket, 9-pin plug, cable guide 1:1)

(9-pin socket, 9-pin socket)

(9-pin socket / 25-pin plug)

(to be installed by SERVICE)

(to be installed by SERVICE)

88

Page 47

p

r

EG-Konformitätserklärung

EC Conformity Declaration

Das bezeichnete Produkt entspricht den einschlägigen grundlegenden Anforderungen der

aufgeführten EG-Richtlinien und Normen. Bei einer nicht mit uns abgestimmten Änderung des

Produktes oder einer nicht bestimmungsgemäßen Anwendung verliert diese Erklärung ihre Gültigkeit.

The product named below fulfills the relevant fundamental requirements of

the EC directives and standards listed. In the case of unauthorized modifications to the product

Produktbezeichnung, Product name:

orato

®

4308

Multi

Produkttyp, Product type:

Elektroporator / electroporator

Einschlägige EG-Richtlinien/Normen, Relevant EC directives/standards:

73/23/EWG, EN 61010-1

or an unintended use this declaration becomes invalid.

89/336/EWG, EN 55011/B, EN 61000-6-1, EN 61000-3-2, EN 61000-3-3

Vorstand, Board of Management: Projektmanagement, Project Management:

04.08.2003

Hamburg, Date:

Eppendorf AG · Barkhausenweg 1 · 22339 Hamburg · Germany

0015 033.509-02

4308 900.997-01

Page 48

Eppendorf Offices

ASEAN

Eppendorf AG

Regional Office in Malaysia

Tel. +60 3 8023 2769

Fax +60 3 8023 3720

E-Mail:

eppendorf@eppendorf.com.my

Internet: www.eppendorf.com.my

AUSTRALIA / NEW ZEALAND

Eppendorf South Pacific Pty. Ltd.

Tel. +61 2 9889 5000

Fax +61 2 9889 5111

E-mail: Info@eppendorf.com.au

Internet: www.eppendorf.com.au

AUSTRIA

Eppendorf AG

c/o Schott Austria

Tel. +43 1 29017560

Fax +43 1 290175620

E-Mail: gilch.p@eppendorf.de

Internet: www.eppendorf.com

BRAZIL

Eppendorf do Brasil Ltda.

Tel. +55 11 30 95 93 44

Fax +55 11 30 95 93 40

E-Mail:

eppendorf@eppendorf.com.br

Internet: www.eppendorf.com.br

CANADA

Eppendorf Canada Ltd.

Tel. +1 905 826 5525

Fax +1 905 826 5424

E-Mail: canada@eppendorf.com

Internet: www.eppendorf.com

CHINA

Eppendorf AG

Tel. +86 21 68760880

Fax +86 21 50815371

E-Mail:

market.info@eppendorf.cn

Internet: www.eppendorf.cn

FRANCE

EPPENDORF FRANCE S.A.R.L.

Tel. +33 1 30 15 67 40

Fax +33 1 30 15 67 45

E-Mail: eppendorf@eppendorf.fr

Internet: www.eppendorf.fr

GERMANY

Eppendorf Vertrieb

Deutschland GmbH

Tel. +49 2232 418-0

Fax +49 2232 418-155

E-Mail: vertrieb@eppendorf.de

Internet: www.eppendorf.de

INDIA

Eppendorf India Limited

Tel. +91 44 52111314

Fax +91 44 52187405

E-Mail: info@eppendorf.co.in

Internet: www.eppendorf.co.in

ITALY

Eppendorf s.r.l.

Tel. +390 2 55 404 1

Fax +390 2 58 013 438

E-Mail: eppendorf@eppendorf.it

Internet: www.eppendorf.it

JAPAN

Eppendorf Japan Co. Ltd.

Tel. +81 3 5825 2363

Fax +81 3 5825 2365

E-Mail: info@eppendorf.jp

Internet: www.eppendorf.jp

NORDIC

Eppendorf Nordic Aps

Tel. +45 70 22 2970

Fax +45 45 76 7370

E-Mail: nordic@eppendorf.dk

Internet: www.eppendorf.dk

SPAIN

Eppendorf Ibérica S.L.

Tel. +34 91 651 76 94

Fax +34 91 651 81 44

E-Mail: iberica@eppendorf.de

Internet: www.eppendorf.es

SWITZERLAND

Vaudaux-Eppendorf AG

Tel. +41 61 482 1414

Fax +41 61 482 1419

E-Mail: vaudaux@vaudaux.ch

Internet: www.eppendorf.com

UNITED KINGDOM

Eppendorf UK Limited

Tel. +44 1223 200 440

Fax +44 1223 200 441

E-Mail: sales@eppendorf.co.uk

Internet: www.eppendorf.co.uk

USA

Eppendorf North America

Tel. +1 516 334 7500

Fax +1 516 334 7506

E-Mail: info@eppendorf.com

Internet: www.eppendorfna.com

OTHER COUNTRIES

see:

www.eppendorf.com/worldwide

Page 49

Your local distributor:

www.eppendorf.com/worldwide

Eppendorf AG

22331 Hamburg · Germany

Tel. +49 40 538 01-0

Fax +49 40 538 01-556

E-Mail: eppendorf@eppendorf.com

Eppendorf North America, Inc.

One Cantiague Road, P.O. Box 1019

Westbury, N.Y. 11590-0207 USA

Tel. +1 516 334 7500

Toll free phone 800 645 3050

Fax +1 516 334 7506

E-Mail: info@eppendorf.com

Application Support

Europe, International:

Tel. +49 1803 666 789

E-Mail: support@eppendorf.com

North America:

Tel. 800 645 3050 ext. 2258

E-Mail: support_NA@eppendorf.com

Asia, Pacific:

Tel. +603 8023 2769

E-Mail:

support_Asia@eppendorf.com

eppendorf is a registered trademarkPrinted in Germany

Loading...

Loading...