Page 1

5353 900.015

MixMate®

Operating manual

Page 2

©

Copyright

2007 Eppendorf AG, Hamburg. No part of this publication may be reproduced without

the prior permission of the copyright owner.

Trademarks

eppendorf

®

and MixMate® are registered trademarks of Eppendorf AG, Hamburg, Germany.

Trademarks are not marked in all cases with ™ or

®

in this manual.

5353 900.015-11/102011

Page 3

MixMate® — Operating manual

Operating manual — MixMate®seeon p.Fig.Tab.p.

Operating manual

Table of contents

1 Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Hazard icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Degrees of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Abbreviations used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 User profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Preparing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Installing the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Overview of operating controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Inserting plates and tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.1 Insert plate in the plate holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.2 Insert the tube holder in the plate holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.3 Insert the plate in the PCR 96 tube holder . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.4 Insert tubes in the tube holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Mixing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.1 Mixing with preset parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.2 Mixing with free preset parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Vortexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.1 Touch vortex mode with 3500 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.2 Using free parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Device menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5.1 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5.2 Menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5.3 Key lock (LOCK) activation/deactivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5.4 Adjusting signal tone volume (VOL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

EN

Operating manual

3

Page 4

MixMate® — Operating manual

EN

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 Disinfection/decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 Decontamination before shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operating manual

8.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.3 Weight/dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.4 Application parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 MixMate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.2 Tubes and plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3 IsoTherm-System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1.1 Cleaning the device and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1.2 Performing a function test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4

Page 5

MixMate® — Operating manual

1 Operating instructions

1 Operating instructions

1.1 Using this manual

Please read this operating manual completely before using the device for the first time. Also

observe the instructions for use enclosed with the accessories.

Please view this operating manual as part of the product and keep it somewhere easily

accessible.

When passing the device on to third parties, be sure to include this operating manual.

If this manual is lost, please request another one. The current version can be found on our

website www.eppendorf.com

1.2 Danger symbols and danger levels

1.2.1 Hazard icons

Explosion Electric shock

Hazard point Material damage

1.2.2 Degrees of danger

The safety instructions in this operating manual indicate the following degrees of danger:

DANGER Will lead to severe injuries or death.

WARNING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

.

EN

Operating manual

NOTICE May lead to material damage.

1.3 Symbols used

Depiction Meaning

You are requested to perform an action.

1.

2.

Perform these actions in the sequence described.

• List.

Text Terms and key names from the software.

References useful information.

5

Page 6

MixMate® — Operating manual

EN

1.4 Abbreviations used

ANSI American National Standards Institute

DNA Deoxyribonucleic acid

DWP Deepwell plate

MTP Microplate

PCR Polymerase Chain Reaction

RNA Ribonucleic acid

rpm revolutions per minute

SBS Society for Biomolecular Screening

Operating manual

1.5 Glossary

Deepwell plate Plate with 48, 96 or 384 wells with a larger volume than

Incubate Includes: cultivation of cell and bacterial cultures under

Micro test plate Plates with 24, 48, 96 or 384 wells for the preparation,

Mixing load All samples to be mixed and the tubes or plates in which

Pellet Compressed material. Is, for example, created via the

Resuspending Dissolve the pellet by vortexing in a liquid. The material

Semi-skirted PCR

plate

Skirted PCR plate PCR plate with a surrounding edge.

microplates. Suitable for the preparation, mixing,

centrifuging, transporting and storing of solid and liquid

samples.

controlled ambient conditions.

mixing, centrifuging, transporting and storing of solid

and liquid samples.

the samples are located.

centrifugation of a suspension.

is distributed in the liquid. The result is a suspension.

PCR plate with surrounding half-edge.

Unskirted PCR plate PCR plate without a surrounding edge.

Vortexing Strong whirling or blending by manually pressing a tube

Well Cavity. Microplate, PCR plate or Deepwell plate tube.

6

onto the vortex mat.

Page 7

MixMate® — Operating manual

2 Product description

2 Product description

2.1 Main illustration

Abb. 1:Front and rear view

Fig. 1: Front and rear view

1 Plate holder

For holding skirted PCR plates, MTP and

DWP as well as tube holders.

3Softkeys

For selecting preset mixing parameters.

5 Operating controls

Keys for operating the MixMate (Fig. 3 on

p. 12).

7 Power connection socket

Connection for the supplied power cable.

EN

Operating manual

2Vortex mat

For direct vortexing of various tubes.

4Display

Displays the mixing frequency and the

mixing time (Fig. 4 on p. 12).

6 Mains power switch

Switch for switching the device on and off.

Switch position 0: the device is switched

off. Switch position I: the device is switched

on.

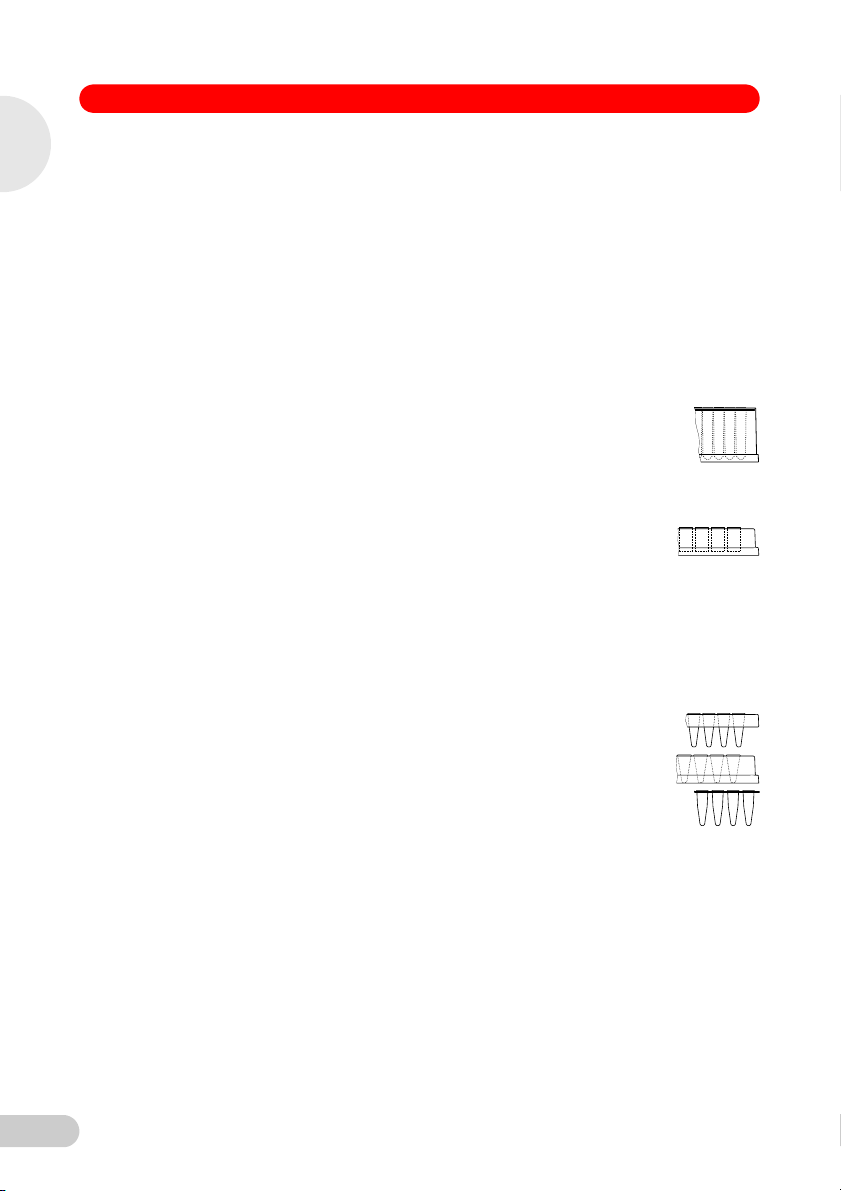

Abb. 2:Tube holder for the MixMate

Fig. 2: Tube holder for the MixMate

1 PCR 96 tube holder

For one PCR plate (96-well, semi-skirted or

unskirted) or a max. of 96 tubes (0.2 mL).

3 1.5/2.0 mL tube holder

For max. 24 tubes (1.5 and 2.0 mL).

2 0.5 mL tube holder

For max. 24 tubes (0.5 mL).

7

Page 8

MixMate® — Operating manual

EN

2.2 Delivery package

Quantity Order No.

1

or

1

1

Operating manual

1

1- - Power cable

1 5353 900.015

1 5353 900.023 Short Instructions MixMate

2.3 Features

The MixMate allows aqueous solutions and suspensions to be mixed and vortexed effectively in

a wide range of micro test tubes or plates. The MixMate supports from 0.2 mL PCR tubes to 2.0

mL micro test tubes as well as PCR, MTP and DWP plates up to 384 wells at a maximum mixing

frequency of up to 3000 rpm.

The direct select buttons facilitate rapid access to selected mixing parameters (see p. 15).

Potential applications include:

• controlled mixing of PCR, restriction or other enzyme reactions.

• controlled incubation of absorption, blocking or reaction preparations.

• resuspension of DNA, RNA, protein or cell pellets in tubes and in plates.

• vortexing in micro test tubes and in 15 mL/50 mL screw-top tubes.

(International)

5353 000.014

5353 000.022

5353 040.113

5353 040.121

5353 040.130

Order No.

(North

America)

022674226

022674200

022674005

022674021

022674048

Description

MixMate

230 V

120 V

Tube Holder

PCR 96

0.5 mL

1.5/2.0 mL

Operating Manual MixMate

multi-lingual

3 Safety

3Safety

3.1 Intended use

Exclusively intended for use indoors, the MixMate is used for mixing aqueous solutions and

suspensions in closed tubes and closed plates.

Only use Eppendorf accessories or accessories recommended by Eppendorf.

3.2 User profile

This device may only be operated by trained and skilled personnel.

Before using the device, read the operating manual carefully and familiarize yourself with the

device's mode of operation.

8

Page 9

MixMate® — Operating manual

3.3 Information on product liability

In the following cases, the designated protection of the device may be compromised. Liability for

material damage and personal injury is transferred to the operator:

• The device is not used in accordance with the operating manual.

• The device is used outside of its intended use.

• The device is used with accessories or consumables not recommended by Eppendorf.

• The device is maintained or repaired by persons not authorized by Eppendorf.

• The user makes unauthorized changes to the device.

3.4 Warnings for intended use

Read the operating instructions and observe the following general safety information before

using the MixMate.

DANGER! Danger of explosion!

Do not operate the device in areas where work is completed with explosive

DANGER!

substances.

Do not use this device to process any explosive or highly reactive substances.

Do not use this device to process any substances which could create an explosive

atmosphere.

WARNING! Electric shock due to damage to device or mains cable.

Only switch on the device if the device and mains cable are undamaged.

WARNING!

Only use devices that have been properly installed or repaired.

In case of danger, disconnect the device from the mains supply.

WARNING! Lethal voltages inside the device.

Ensure that the housing is always closed and undamaged so that no parts inside

WARNING!

the device can be contacted by accident.

Do not remove the housing of the device.

Do not allow any liquids to penetrate the inside of the housing.

Do not allow the device to be opened by anyone except service personnel who have

been specifically authorized by Eppendorf.

EN

Operating manual

WARNING! Device fire due to penetration of liquid

Penetration of liquid can cause a fire due to a short-circuit in the device.

WARNING!

Do not allow any liquids to penetrate the inside of the housing.

Only mix in closed tubes and closed plates.

If liquid has penetrated the inside of the housing: switch off the device, pull the

power plug and have the device cleaned by service personnel authorized by

Eppendorf.

9

Page 10

MixMate® — Operating manual

EN

WARNING!

Operating manual

WARNING!

WARNING!

WARNING! Injury from flying tubes and plates.

If the maximum permitted total weight of the mixing load is exceeded, plates or tubes

may become detached from the device.

Always ensure that tubes, plates and tube holder are well seated. The dimensions

of the plates used must comply with the ANSI/SBS standards for microplates

Mix the DWP and the tube holders 0.5 mL, 1.5/2.0 mL and PCR 96 with max. 2000

rpm.

Only mix mixing loads with a total weight of up to 80 g at maximum speed.

Only mix mixing loads with a total weight of 80 to 300g at speed of max. 2000 rpm.

WARNING! Injury from sample material being thrown out.

Sample material can be thrown out of open, improperly sealed or unstable tubes and

plates.

Only mix in closed tubes and closed plates.

Observe the nationally prescribed safety environment when working with

hazardous, toxic and pathogenic samples. Pay particular attention to the personal

protective equipment (gloves, clothing, goggles etc.), extraction, and the safety

class of the lab.

WARNING! Injury from improper vortex action.

Improper vortex action can destroy tubes or cause their content to be lost.

Only vortex intact and sealed tubes.

Never vortex tubes made of glass or other fragile material.

10

WARNING! Risk from incorrect supply voltage

Only connect the device to power supplies which correspond with the electrical

WARNING!

requirements on the nameplate.

Only use sockets with a protective earth (PE) conductor and a suitable mains cable.

NOTICE! Damage to the display due to mechanical pressure.

Do not exert mechanical pressure on the display.

NOTICE!

NOTICE! Caution! Strong vibration.

When mixing at high speeds, items located near the device may be moved by the

NOTICE!

vibrations of the work surface and, e.g., fall off the work table.

Do not place easily movable items near the mixer or secure them adequately.

NOTICE! Damage to electronic components from spilled liquids.

Make sure that the vortex mat and the cover caps are fitted properly. If the vortex

NOTICE!

mat is not fitted properly, contact your Eppendorf partner or the authorized

Technical Service.

If liquid has been spilt: Switch off the device, disconnect the power plug and

arrange for it to be cleaned by service personnel authorized by Eppendorf.

Page 11

MixMate® — Operating manual

NOTICE! Damage to electronic components due to condensation.

After the device has been moved from a cool to a warmer environment, condensation

NOTICE!

may form inside the device.

Wait at least three hours before connecting it to the power supply.

NOTICE! Damage from the use of aggressive chemicals.

Do not use any aggressive chemicals on the device or its accessories, such as

NOTICE!

4 Installation

4 Installation

4.1 Preparing installation

Hint!

Use the details on the scope of delivery (see Delivery package on p. 8) to check that delivery

is complete.

Check all parts for any transport damage.

strong and weak bases, strong acids, acetone, formaldehyde, halogenated

hydrocarbons or phenol.

If the device becomes contaminated with aggressive chemicals, clean it

immediately with a mild cleaning agent.

Keep the transport carton and the packing material for subsequent safe transport or

storage.

EN

Operating manual

4.2 Selecting the location

Select a location for the MixMate in accordance with the following criteria:

• Mains power connection (230 V/120 V) as per device identification plate. This is located on

the rear side of the device.

• At least 10 cm away from adjacent devices and walls.

• Solid bench with stable, horizontal and even work surface.

4.3 Installing the instrument

1. Place theMixMate on a suitable work surface so that the air slots on the underside of the

device are not blocked.

2. Connect the device to the mains power supply via the mains power socket 7 (see Fig. 1 on

p. 7) using the mains cable supplied.

3. Switch on the device with the mains power switch 6 (see Fig. 1 on p. 7).

4. Carry out a test run at maximum speed (3000 rpm) to ensure that the grip between the

device and the surface is sufficient. The MixMate must not move from its position.

11

Page 12

MixMate® — Operating manual

EN

5Operation

5 Operation

5.1 Overview of operating controls

Familiarize yourself with the operating controls and the display of the MixMate before using it for

the first time.

Abb. 3:Operator control elements and displ ay

Operating manual

Fig. 3: Operator control elements and display

1 Soft key for MTP (384-well) 2 Soft key for PCR plates (384-well)

3 Soft key for MTP (96-well) 4 Soft key for PCR plates (96-well) and

5 Softkey for micro test tubes (1.5 and

2.0 mL)

7 Display 8 Start/stop mixing run

9 Set the mixing frequency (speed) 10 Set the mixing duration (time)

11 Navigate in the menu 12 Call up and select menu parameters

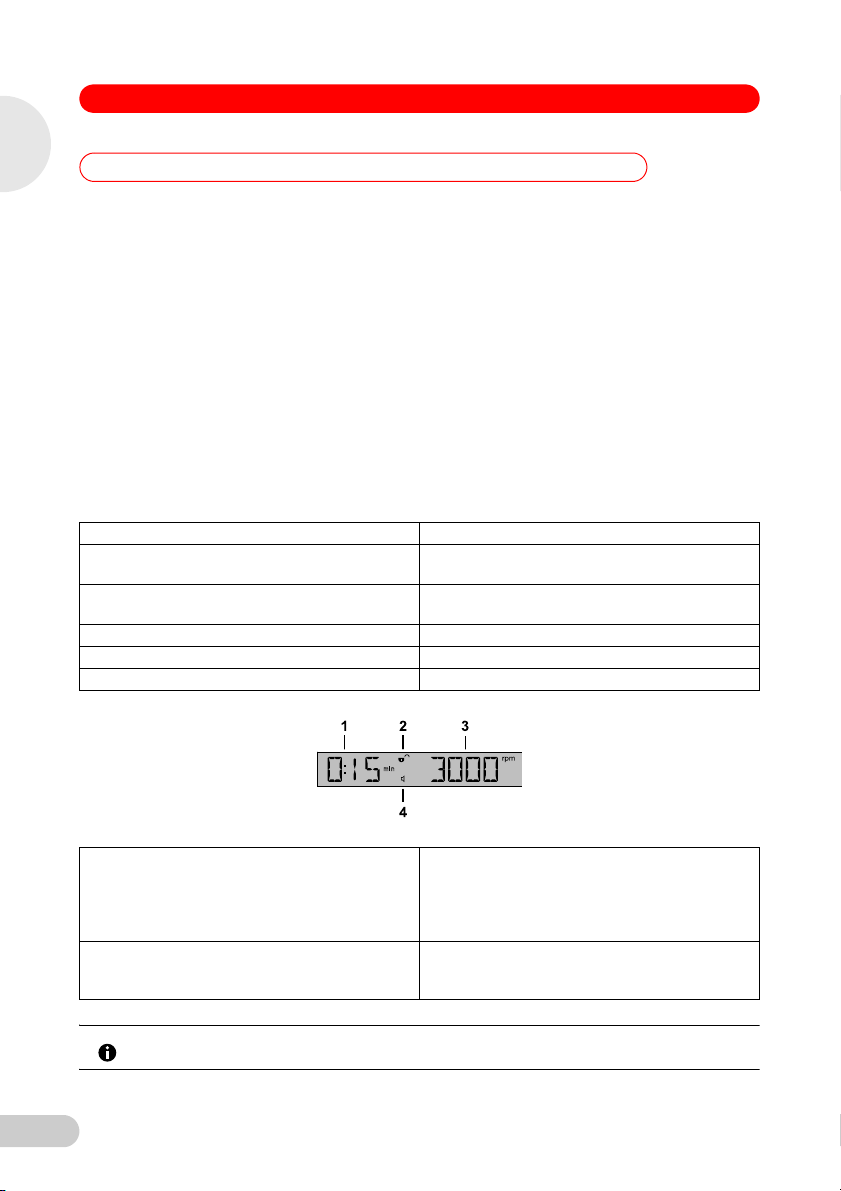

Abb. 4:Display

micro test tubes (0.2 and 0.5 mL)

6 Control LED to display the selected

softkey

Fig. 4: Display

1 Mixing time

Setting: up to 19:45 min. in 15 s

increments, from 20 min. to 59 min. in 1

min. increments, from 1.0 h to 99.5 h in 0.5

h increments, 'oo': unlimited mixing time.

3 Mixing frequency

Setting: 300 to 3000 rpm in 50 rpm

increments.

After switching on, the display shows the values of the last run.

Hint!

12

2 Symbol for key lock

4 Symbol for signal tone setting

Page 13

MixMate® — Operating manual

5.2 Inserting plates and tubes

WARNING! Injury from flying tubes and plates.

If the maximum permitted total weight of the mixing load is exceeded, plates or tubes

WARNING!

may become detached from the device.

Always ensure that tubes, plates and tube holder are well seated. The dimensions

of the plates used must comply with the ANSI/SBS standards for microplates

Mix the DWP and the tube holders 0.5 mL, 1.5/2.0 mL and PCR 96 with max. 2000

rpm.

Only mix mixing loads with a total weight of up to 80 g at maximum speed.

Only mix mixing loads with a total weight of 80 to 300g at speed of max. 2000 rpm.

Tab. 1: Select a suitable holder

Plate / tube

PCR plate, skirted +

PCR plate, semi-skirted +

PCR plate, unskirted +

MTP +

(2)

DWP

PCR tubes 0.2 mL +

Plate holder

(1)

+

PCR 96 0.5 mL 1.5/2.0 mL

Tube holder

EN

Operating manual

(2)

PCR and tubes 0.5 mL +

Tubes 0.5 mL +

Tubes 1.5 mL +

Tubes 2.0 mL +

(1) To ensure that the plates are positioned securely in the plate holder, they must correspond

with the ANSI/SBS Standard for microplates.

(2) The maximum permissible mixing frequency for tube holders and DWP is 2000 rpm.

5.2.1 Insert plate in the plate holder

1. Place the plate up against the back of the plate holder 1 first.

13

Page 14

MixMate® — Operating manual

EN

2. Then press the plate into the plate holder. In doing so, ensure that it is properly engaged.

Operating manual

5.2.2 Insert the tube holder in the plate holder

1. Select a suitable tube holder (see Tab. on p. 13).

2. Hold the tube holder up against the back edge of the plate holder so that the stop pins fit in

the holes:

3. Engage the tube holder by pressing gently on the front.

Remove the tube holder by pressing gently on the unlatching Push key to release the latch.

14

Page 15

MixMate® — Operating manual

5.2.3 Insert the plate in the PCR 96 tube holder

1. Insert the PCR 96 tube holder in the plate holder (see Insert the tube holder in the plate

holder on p. 14).

2. Push semi-skirted or unskirted PCR plates into the bores of the tube holder. In doing so,

ensure they are evenly engaged.

5.2.4 Insert tubes in the tube holders

1. Select the suitable tube holder (Tab. on p. 13).

2. Insert it into the plate holder (see Insert the tube holder in the plate holder on p. 14).

3. Push the tubes fully into the bores of the tube holder.

5.3 Mixing

WARNING! Injury from sample material being thrown out.

Sample material can be thrown out of open, improperly sealed or unstable tubes and

WARNING!

plates.

Only mix in closed tubes and closed plates.

Observe the nationally prescribed safety environment when working with

hazardous, toxic and pathogenic samples. Pay particular attention to the personal

protective equipment (gloves, clothing, goggles etc.), extraction, and the safety

class of the lab.

WARNING! Device fire due to penetration of liquid

Penetration of liquid can cause a fire due to a short-circuit in the device.

WARNING!

Do not allow any liquids to penetrate the inside of the housing.

Only mix in closed tubes and closed plates.

If liquid has penetrated the inside of the housing: switch off the device, pull the

power plug and have the device cleaned by service personnel authorized by

Eppendorf.

EN

Operating manual

Note the following rule when setting the mixing frequency: only mix at a load above 80 g

Hint!

with a maximum mixing frequency of 2000 rpm.

The MixMate comes with an automatic protection against overloading. If the selected

speed for the mixing load is too high or the mixing load is not securely placed on the

plate holder a signal tone sounds. The MixMate reduces the mixing frequency

automatically to 1400 rpm. In the display the messages TOO FA S T and 1400 rpm

appear alternately.

Press start/stop to end the mixing process. Press again start/stop to deactivate the

error message.

5.3.1 Mixing with preset parameters

With the softkey you can select the following preset parameters (mixing frequency and mixing

duration). These permit a controlled and effective mixing of samples without wetting the tube lids

or plate sealings. The softkey cannot be programmed.

15

Page 16

MixMate® — Operating manual

EN

Tab. 2: Softkeys for preset, optimized mixing parameters

Softkey Parameter Tube/ plate Fill level

Operating manual

* Amount of maximum filling volume. Follow the manufacturer instructions.

Hint!

1. Select the appropriate parameters from the table (see Tab. on p. 16).

2. Select the respective softkey.

3. If necessary change the preset mixing duration and mixing frequency with the arrow keys

time and speed.

If you change the parameter settings the indicator lamp of the softkey goes out.

4. Press start/stop to start the mixing process.

At the end of the mixing process a signal tone sounds.

Changed parameters are not saved. At the end of the mixing process the original parameters

are reassigned to the softkeys.

5.3.2 Mixing with free preset parameters

*

15 s/2000 rpm MTP and DWP (384 well) 10 to 60 %

15 s/2600 rpm PCR plates (384 well) 10 to 50 %

30 s/1000 rpm MTP (96 well) 5 to 60 %

30 s/1650 rpm PCR plates and DWP (96

well), PCR tubes (0.2 mL) and

micro test tubes (0.5 mL)

1 min/1400 rpm Micro test tubes (1.5 and 2.0

mL)

The parameters of the softkeys do not cover all known or possible of tube or plate

geometry as well as sample properties.

For some applications these parameters can possibly be optimized. For example, the

mixing frequency can be too low or the mixing duration can be too short. As a result the

samples are not optimally mixed. Or the mixing frequency is too high which leads to the

wetting of the lid. In that case you can adjust the preset parameters before stating the

mixing procedure to your requirements.

5 to 50 %

5 to 80 %

After switching on the device, the parameters of the last run are shown on the display.

Hint!

1. Set the with the mixing time using the time arrow keys.

For continuous operation set oo below 0:15 min or above 99.5 h.

2. Set the with the mixing frequency using the speed arrow keys.

3. Press start/stop to start the mixing process.

16

Page 17

MixMate® — Operating manual

The remaining mixing duration and the current mixing frequency are displayed. At continuous

operation the current mixing duration is displayed alternating with oo, after 99.5 h only oo is

displayed.

You can also change the parameters during a mixing process by pressing the time and

speed arrow keys.To do so, the key lock may not be active (see Key lock (LOCK) activation/

deactivation on p. 20). The mixing procedure is then continued with the changed parameters.

The softkeys are not available during a mixing procedure.

At the end of the mixing process a signal tone sounds. The MixMate stops.

4. In order to stop the mixing process, if applicable, prematurely press start/stop again.

5.4 Vortexing

During the vortexing process, press different tubes (e.g., 1.5 mL tubes or 50 mL screw cap tubes)

on the vortex mat of the MixMate to mix them individually.

WARNING! Injury from improper vortex action.

Improper vortex action can destroy tubes or cause their content to be lost.

WARNING!

Only vortex intact and sealed tubes.

Never vortex tubes made of glass or other fragile material.

NOTICE! Damage to vortex mat caused by improper vortexing.

Only vortex tubes in the depression in the middle of the vortex mat.

NOTICE!

5.4.1 Touch vortex mode with 3500 rpm

With the touch vortex mode, vortexing is carried out at a fixed frequency of 3500 rpm.

1. Push the tube into the depression in the vortex mat to start the touch vortex mode.

In the display, the VORTX mode is shown, along with the elapsed time:

• Up to 1 min in second increments.

• Up to 19:59 h in minute increments.

• The time display then changes to oo.

2. Remove the load from the vortex mat in order to end the touch vortex mode.

The MixMate continues to run for approx. another 2 s.

EN

Operating manual

Ergonomic vortexing: A post-run facility in touch vortex mode prevents the MixMate

Hint!

braking immediately after the load is removed from the vortex mat. This post-run

facilitates both vortexing with 15 and 50 mL screw cap tubes and vortexing several

tubes consecutively.

17

Page 18

MixMate® — Operating manual

EN

5.4.2 Using free parameters

You can also vortex on the vortex mat of the MixMate using free parameters. Vortexing time can

be set variably from 15 s to infinite, vortexing frequency from 300 to 2000 rpm.

Hint!

Operating manual

1. Set the mixing time using the time arrow keys.

For continuous operation set oo below 0:15 min or above 99.5 h.

2. Set the with the mixing frequency using the speed arrow keys.

3. Press start/stop to start the vortexing process.

4. Hold the tube on the vortex mat.

The remaining vortexing time and the current vortexing frequency are displayed. During

continuous operation, the current vortexing time appears alternately with oo, after 99.5 h only

oo is displayed.

You can also change the parameters during the vortexing process with the arrow keys time

and speed.To do so, the key lock may not be active (see Key lock (LOCK) activation/

deactivation on p. 20). The vortexing process is then continued with the changed

parameters.

The touch vortex mode is not active during the vortexing process.

A signal tone is generated at the end of the vortexing process. The MixMate stops.

5. In order to cancel the vortexing process prematurely, press start/stop again.

5.5 Device menu

In the MixMate menu, you can activate the key lock (LOCK) and set the volume of the signal

tone (VOL) .

In this Vortex mode, the TOO FAST message may be issued at frequencies > 2000

rpm. The MixMate automatically reduces the frequency to 1400 rpm. In the display the

messages TOO FA S T and 1400 rpm appear alternately.

Press the start/stop button to end the vortexing process. Press again start/stop to

deactivate the error message.

The touch vortex mode is inactive as long as the MixMate is running.

18

Page 19

MixMate® — Operating manual

5.5.1 Menu structure

Abb. 5:Menu structure

EN

Operating manual

Fig. 5: Menu structure

5.5.2 Menu navigation

With the menu/enter button, you can switch between the menu levels or confirm the

changed parameters.

You can select the parameters with the arrow key 11.

When M – 1 BACK or M – 2 BACK is displayed, press the menu/enter button to exit the

menu level without saving changes.

19

Page 20

MixMate® — Operating manual

EN

5.5.3 Key lock (LOCK) activation/deactivation

The key lock prevents set parameters being modified inadvertently during a mixing operation.

1. Press the menu/enter button to call up the menu.

2. Press the menu arrow key once.

3. Press the menu/enter button to open the key lock menu.

4. Select sub-item M – 2 ON with the menu arrow key to activate the key lock, or M – 2 OFF to

deactivate the key lock.

5. Press the menu/enter button to confirm the selected setting.

You will then exit menu level 2.

Operating manual

Press the menu/enter button again to exit the menu completely.

With key lock activated, all keys apart from menu/enter are inactive during the mixing operation.

When the mixer is at rest, all the keys are released.

You can tell from the symbol in the display that key lock is active and from the symbol that

key lock is deactivated.

5.5.4 Adjusting signal tone volume (VOL)

The MixMate announces that a mixing operation is complete by means of a signal tone. You can

set the volume of this signal tone in the device menu as follows -

1. Press the menu/enter button to call up the menu.

2. Press the menu arrow key twice.

3. Press the menu/enter button to open the menu for the signal tone volume.

4. Use the menu arrow key to select the desired setting from OFF, VOL1 to VOL3. With OFF

the signal tone is switched off, with VOL3 the signal tone sounds with maximum volume.

The selected volume is played.

5. Press the menu/enter button to confirm the selected setting.

You will then exit menu level 2.

Press the menu/enter button again to exit the menu completely.

6. Press M – 2 BACK to leave this menu level.

6 Troubleshooting

6 Troubleshooting

6.1 General errors

If the suggested troubleshooting measures fail repeatedly, please contact your Eppendorf

partner. You can find the contact addresses on the Internet at www.eppendorf.com/worldwide

Symptom/

message

No display Power supply is interrupted.

Too fast Mixing load is too heavy for the

20

Cause Remedy

Check the mains connection

and the power supply to the

lab.

Reduce the mixing frequency

selected mixing frequency.

or the weight of the mixing load.

.

Page 21

MixMate® — Operating manual

Symptom/

message

Too fast Mixing load not properly positioned

Too fast Continuous vortexing at

ERR00 - ERR03 /

ERR06 - ERR11

ERR04 - ERR05 Device overheats.

ERR12 Incorrect power supply

ERR13 Software error

ERR15 and ERR16 Hardware error

Cause Remedy

in the plate holder.

frequencies > 2000 rpm.

Electronics error

The ventilation slots on the

underside of the device are

blocked.

Check that the mixing load is

fixed in position.

Reduce the continuous

vortexing frequency to

≤ 2000 rpm.

Switch off the device and

switch it on again after 5 s.

1. Switch off the device and leave

to cool down for 10 minutes.

2. Ensure that the ventilation slots

on the underside of the device

are clear.

3. Switch the device back on

again.

Make sure that the supply

voltage and the power

frequency are compatible with

the information given on the

device name plate. This is

located on the underside of the

device.

Switch off the device and

switch it on again after 5 s.

Contact your Eppendorf

partner.

EN

Operating manual

7 Maintenance

7 Maintenance

7.1 Cleaning

7.1.1 Cleaning the device and accessories

Clean the housing of the MixMate, the vortex mat, the plate holder and the tube holders regularly.

DANGER! Electric shock as a result of penetration of liquid.

Switch off the device and disconnect it from the power supply before starting

DANGER!

cleaning or disinfecting.

Do not allow any liquids to penetrate the inside of the housing.

Do not spray clean/spray disinfect the housing.

Wait until the device is completely dry before connecting it to the power source

again.

21

Page 22

EN

MixMate® — Operating manual

WARNING! Device fire due to penetration of liquid

Penetration of liquid can cause a fire due to a short-circuit in the device.

WARNING!

Do not allow any liquids to penetrate the inside of the housing.

Only mix in closed tubes and closed plates.

If liquid has penetrated the inside of the housing: switch off the device, pull the

power plug and have the device cleaned by service personnel authorized by

Eppendorf.

Operating manual

NOTICE! Damage from the use of aggressive chemicals.

Do not use any aggressive chemicals on the device or its accessories, such as

NOTICE!

strong and weak bases, strong acids, acetone, formaldehyde, halogenated

hydrocarbons or phenol.

If the device becomes contaminated with aggressive chemicals, clean it

immediately with a mild cleaning agent.

NOTICE! Corrosion due to aggressive cleaning agents and disinfectants.

Do not use corrosive cleaning agents, aggressive solvents or abrasive polishes.

NOTICE!

Do not incubate the accessories in aggressive cleaning agents or disinfectants for

prolonged periods.

NOTICE! Damage to electronic components from spilled liquids.

Make sure that the vortex mat and the cover caps are fitted properly. If the vortex

NOTICE!

mat is not fitted properly, contact your Eppendorf partner or the authorized

Technical Service.

If liquid has been spilt: Switch off the device, disconnect the power plug and

arrange for it to be cleaned by service personnel authorized by Eppendorf.

Required equipment

• Mild, soap-based household cleaning agent

1. Switch off the MixMate and isolate it from the power supply.

2. Clean the housing, plate holder, vortex mat and tube holder.

The housing may only be wiped with a damp cloth. Do not spray clean/spray disinfect the

housing.

3. Dry all cleaned parts.

4. Perform a function test.

7.1.2 Performing a function test

1. Use the mains cable to connect the MixMate to the power supply (see Installing the

instrument on p. 11).

2. Switch on the device, using the mains power switch.

3. Check the touch vortex function, using a suitable tube (see Vortexing on p. 17).

22

Page 23

MixMate® — Operating manual

7.2 Disinfection/decontamination

DANGER! Electric shock as a result of penetration of liquid.

Switch off the device and disconnect it from the power supply before starting

DANGER!

cleaning or disinfecting work.

Do not allow any liquids to penetrate the inside of the housing.

Do not spray clean/spray disinfect the housing.

Only connect the device to the power supply if it is fully dried inside and out.

WARNING! Device fire due to penetration of liquid

Penetration of liquid can cause a fire due to a short-circuit in the device.

WARNING!

Do not allow any liquids to penetrate the inside of the housing.

Only mix in closed tubes and closed plates.

If liquid has penetrated the inside of the housing: switch off the device, pull the

power plug and have the device cleaned by service personnel authorized by

Eppendorf.

NOTICE! Damage from UV and other high-energy radiation.

Do not use UV, beta, gamma, or any other high-energy radiation for disinfecting.

NOTICE!

Required equipment

• Alcohol (ethanol, isopropanol) or disinfectants containing alcohol

• Mild, soap-based household cleaning agent

Proceed as follows:

1. Choose the disinfection method which corresponds to the legal regulations and guidelines in

place for your range of application.

2. Switch off the device and disconnect it from the power supply.

3. Wipe down all parts of the device and accessories, including the connecting cable, with the

disinfectant.

4. Clean the device with a mild soap-based household cleaning agent (see Cleaning on p. 21).

EN

Operating manual

7.3 Decontamination before shipment

If you are shipping the device to the authorized Technical Service for repairs or to your authorized

dealer for disposal please note the following:

WARNING! Risk to health from contaminated device

WARNING!

1. Follow the instructions in the decontamination certificate. It is available in PDF

format on our homepage (www.eppendorf.com/decontamination)

2. Decontaminate all the parts you want to dispatch.

3. Enclose the fully-completed decontamination certificate for returned goods

(including the serial number of the device) with the dispatch.

.

23

Page 24

MixMate® — Operating manual

EN

8 Transport, storage and disposal

8 Transport, storage and disposal

8.1 Transport

Only transport the device in the original packaging.

General

transportation

Air freight -20 to 55 °C 10 to 95 % 30 to 106 kPa

Operating manual

8.2 Storage

in transport packaging -20 to 55 °C 10 to 95 % 70 to 106 kPa

without transport

packaging

8.3 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European

Community:

Within the European Community, the disposal of electrical devices is regulated by national

regulations based on EU Directive 2002/96/EC pertaining to waste electrical and electronic

equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in the

business-to-business sphere, to which this product is assigned, may no longer be disposed of in

municipal or domestic waste. To document this, they have been marked with the following

identification:

Air temperature Max. rel. humidity Air pressure

-20 to 60 °C 10 to 95 % 30 to 106 kPa

Air temperature Max. rel. humidity Air pressure

-5 to 45 °C 10 to 95 % 70 to 106 kPa

Because disposal regulations may differ from one country to another within the EU, please

contact your supplier if necessary.

24

Page 25

MixMate® — Operating manual

9 Technical data

9 Technical data

9.1 Power supply

Mains power connection: 220 to 240 V ±10 %, 50 to 60 Hz

110 to 120 V ±10 %, 50 to 60 Hz

Power consumption: 40 W

Overvoltage category: II

9.2 Ambient conditions

Environment: Use only indoors

Ambient temperature: 2 to 40 °C

Relative humidity: 10 to 75 %

Atmospheric pressure: Use up to an altitude of 2000 m above MSL.

Degree of contamination: 2

9.3 Weight/dimensions

Dimensions: Width: 170 mm

Depth: 230 mm

Height: 130 mm

Weight: 4.15 kg

Noise level: < 50 dB(A)

9.4 Application parameters

EN

Operating manual

Max. load: 300 g

Mixing frequencies

with a load up to 80g: 300 to 3000 rpm, in 50 rpm increments

with a load above 80 g: 300 to 2000 rpm, in 50 rpm increments

for tube holders and DWP: up to max. 2000 rpm

Adjustable mixing time: up to 19:45 min. in 15 s increments,

from 20 min. to 59 min. in 1 min. increments,

from 1.0 h to 99.5 h in 0.5 h increments

and unlimited mixing time.

Touch vortexing frequency: 3500 rpm

Mixing and vortexing radius: 1.5 mm (3 mm mixing stroke)

25

Page 26

MixMate® — Operating manual

EN

10 Ordering Information

10 Ordering Information

CAUTION!

Operating manual

10.1 MixMate

Order No.

(International)

5353 000.014

5353 000.022

5353 040.113

5353 040.121

5353 040.130

5353 863.101 5353863101

10.2 Tubes and plates

Order No.

(International)

0030 121.023 022363611

0030 120.086 -

0030 120.094 -

0030 124.502 951010057

0030 124.332 951010006

0030 124.340 951010014

CAUTION! Poor safety due to incorrect accessories and spare parts.

The use of accessories and spare parts other than those recommended by Eppendorf

may impair the safety, function and precision of the device. Eppendorf cannot be held

liable or accept any liability for damage resulting from the use of incorrect or

non-recommended accessories and spare parts or from the improper use of such

equipment.

Only use accessories and original spare parts recommended by Eppendorf.

Order No.

(North America)

022674226

022674200

022674005

022674021

022674048

Order No.

(North America)

Description

MixMate

230 V

120 V

Tube Holder

PCR 96

0.5 mL

1.5/2.0 mL

Cover caps

set of 4

Description

Safe-Lock micro test tubes

0.5 mL per 500 pieces

colorless

Safe-Lock micro test tubes

1.5 mL per 1,000 pieces

colorless

Safe-Lock micro test tubes

2.0 mL per 1,000 pieces

colorless

PCR tubes

thin-walled with hinged lid, colorless, 500 pieces

0.5 mL

PCR Tubes

0.2 mL, colorless, 1,000 pieces

Five-tube strip for 0.2 mL PCR Tubes

colorless, pack of 125 (= 625 tubes)

26

Page 27

MixMate® — Operating manual

Order No.

(International)

0030 124.359 951010022

0030 124.200 951010006

0030 128.648

0030 128.575

0030 521.102 951031003

0030 501.101 951031801

0030 501.209 951032603

0030 501.306 951033405

All plates are also available with different border colors (red, yellow, green and blue) and purity

qualities, in large packs as well as with barcoding on request. You can find further information in

our catalog or our website www.eppendorf.com

Order No.

(North America)

951020401

951020303

Description

PCR Tube Strips

0.2 mL, colorless, 120 strips

PCR Tubes

0.2 mL per 1,000 pieces

colorless

twin.tec PCR Plate 96

Wells colorless

skirted, colorless, 25 pcs.

semi-skirted, colorless, 25 pcs.

Eppendorf Deepwell Plate 384/200 μL

40 plates, wells clear

PCR Clean, white border color

Eppendorf Deepwell Plate 96/500 μL

40 plates, wells clear

PCR Clean, white border color

Eppendorf Deepwell Plate 96/1000 μL

20 plates, wells clear

PCR Clean, white border color

Eppendorf Deepwell Plate 96/2000 μL

20 plates, wells clear

PCR Clean, white border color

.

10.3 IsoTherm-System

EN

Operating manual

Order No.

(International)

3880 001.018

3880 000.011

3881 000.015

3881 000.023

3881 000.031

Order No.

(North America)

022510053

022510002

022510509

022510541

022510525

Description

IsoTherm-System

includes IsoSafe, IsoRack, 0 °C IsoPack and -21 °C for

1.5/2.0 mL tubes

0.5 mL tubes

PCR-Cooler

Starter Set (1 x pink, 1 x blue)

Pink

Blue

27

Page 28

MixMate® — Operating manual

EN

Index

Index

Abbreviations................................................ 6

Adjusting the volume ..................................20

Application fields........................................... 8

Application parameters............................... 25

Applications ..................................................8

Operating manual

Changing the parameters.

Mixing................................................... 17

Vortexing .............................................. 18

Cleaning ..................................................... 21

Continuous operation

Mixing................................................... 16

Vortexing .............................................. 18

Decontamination......................................... 23

Deepwell plate .............................................. 6

Dimensions................................................. 25

Disinfection ................................................. 23

Display........................................................ 12

LOCK.................................................... 18

M – 2 BACK.......................................... 20

M – 2 OFF ............................................ 20

M – 2 ON.............................................. 20

VOL ...................................................... 18

Disposal...................................................... 24

DWP .............................................................6

Environmental conditions............................ 25

Error messages ..........................................20

Front view ..................................................... 7

Glossary ....................................................... 6

Hazards ........................................................9

Incubate........................................................ 6

Insert

Plates in the plate holder ..................... 13

Plates in the tube holder ...................... 15

A

C

Tube holder in the plate holder ............ 14

Tubes in the tube holder ...................... 15

Insert plate ........................................... 13, 15

Inserting

Plates and tubes .................................. 13

Inserting tubes............................................ 15

Installation

Device.................................................. 11

Preparation .......................................... 11

Select location ..................................... 11

Intended use ................................................ 8

K

Key lock activation/deactivation.................. 20

L

D

LOCK.......................................................... 18

M

Mains power switch...................................... 7

Menu structure ........................................... 19

Menu/Enter................................................. 20

Micro test plate............................................. 6

Mixing......................................................... 15

Free parameters................................... 16

Preset parameters ............................... 15

Start ..................................................... 16

Mixing frequency

Maximum permissible .......................... 13

parameter............................................. 16

E

F

G

Mixing load ................................................... 6

Mixing time

parameter............................................. 16

MTP.............................................................. 6

O

OFF ............................................................ 20

Operator control elements.......................... 12

P

H

I

PCR plate

Semi-skirted........................................... 6

PCR-Platte

Skirted.................................................... 6

Unskirted................................................ 6

28

Page 29

MixMate® — Operating manual

Pellet............................................................. 6

Performing a function test........................... 22

Plate holder................................................... 7

Power connection socket .............................. 7

Power supply .............................................. 25

Preset parameters ...................................... 16

Press start/stop

Mixing................................................... 16

Vortexing .............................................. 18

Product properties ........................................8

R

Rear view...................................................... 7

Resuspending............................................... 6

S

Safety Information......................................... 9

Select holder............................................... 13

Select location ............................................11

Semi-skirted.................................................. 6

Signal tone.................................................. 20

Skirted .......................................................... 6

Softkeys...................................................... 16

Software menu ........................................... 19

SPEED

Mixing frequency .................................. 16

Vortex frequency .................................. 18

Storage ....................................................... 24

T

Technical data

Application parameters......................... 25

Dimensions .......................................... 25

Environmental conditions ..................... 25

Power supply........................................ 25

Time

Mixing time ........................................... 16

Vortex time ........................................... 18

Transport .................................................... 24

Troubleshooting ..........................................20

tube formats.................................................. 8

Tube holder................................................... 7

Insert ....................................................14

Tubes

Select ...................................................13

U

Unskirted ...................................................... 6

V

VOL ............................................................ 18

Vortex frequency

set ........................................................ 18

Vortex mat.................................................... 7

Vortex time

set ........................................................ 18

Vortexing................................................ 6, 17

Free parameters................................... 18

Post-run facility .................................... 17

Start ..................................................... 18

Touch vortex mode............................... 17

W

Weight

Device.................................................. 25

Mixing load........................................... 13

Well .............................................................. 6

EN

Operating manual

29

Page 30

MixMate® — Operating manual

EN

Operating manual

30

Page 31

Page 32

Declaration of Conformity

The device was tested in accordance with EN ISO 5349-1 : 2001 “Mechanical vibration – measurement

and assessment of human exposure to hand-transmitted vibration – Part 1”

Product name:

MixMate 5353

Product type:

Mixer for microtest tubes and plates with integrated touch vortex function

Hand-arm-vibration assessment of MixMate 5353 in accordance with DIN ISO 5349-1:2001

Tests were performed on the MixMate operated in the “touch vortex” operation mode (3500 rpm) with 15

ml and 50 ml Falcon tubes. The total vibration value was measured, the daily vibration exposure and the

exposure points calculated from it.

The exposure action value EAV of 2.5 m/s

2

A(8) is equivalent to 100 exposure points and is the level at

and above which hand-arm-vibration management procedures must be initiated where employees are

regularly exposed to this level of vibration exposure.

The exposure limit value ELV of 5 m/s

2

A(8) is equivalent to 400 exposure points and must not be

exposure times to limit daily vibration exposure to below the ELV.

Tube

Total

vibration

value

Daily

exposure

value

1 HOUR

e

Time – single tool

use:

For not exceeding

EAV ELV

m/s2 m/s2 2.5 m/s

2

minutes

5 m/s

2

minutes

Usage patter n : Each

test consisted of a

reprensent ative usage

pattern equiv a lent to 5

successive t ouch vortex

a total of 2 minutes 30

seconds “on” and 20

seconds “off”. Tubes

were filled wit h 2/ 3 of

water.

15 ml

50 ml

5.2

9.4

1.8

3.3

54

177

111

34

444

136

Exposure Action Value (EAV)

The table indicates that the operator using 15 ml Falcon tubes in touch vortex mode (3500 rpm) with

reported usage would reach the EAV in 111 minutes and using 50 ml Falcon tubes in

34 minutes. Based on a usage pattern of 30 seconds vortex / 5 seconds gap for changing

the tube, this means that approximately 190 of the 15 ml or 58 of the 50 ml Falcon tubes could produce

exposures that reach the EAV. With a usage pattern of 15 seconds vortex / 5 seconds gap, 333 x 15 ml

tubes or 102 x 50 ml tubes may be vortexed without exceeding the EAV.

With a usage pattern of 45 seconds vortex / 5 seconds gap 133 x 15 ml tubes or 40 x 50 ml tubes may be

vortexed.

exceeded on any work day. If it is, immediate measures must be taken to control vibration levels or reduce

operations of 30 seconds

with 5 second intervals in

xposure points

Page 33

Exposure Limit Value (ELV)

The table indicates that the operator using 15 ml Falcon tubes in touch vortex mode (3500 rpm) with reported

usage would reach the ELV in 444 minutes and using 50 ml Falcon tubes in 136 minutes. Based on a usage

pattern of 30 seconds vortex / 5 seconds gap, this means that approximately 761 of the 15 ml or 233 of the 50

ml Falcon tubes could produce exposures that reach the ELV. Immediate action must thus be taken to limit

exposures to below the ELV. With a usage pattern of 15 seconds vortex / 5 seconds gap, 1332 x 15 ml tubes

or 408 x 50 ml tubes must be vortexed until the ELV is reached. With a usage pattern of 45 seconds vortex / 5

seconds gap 532 x 15 ml tubes or 163 x 50 ml tubes must be vortexed.

Number of tubes to reach

Vortex time

(5 sec gap)

EAV ELV

15 ml

EAV ELV

50 ml

15 sec

333

1332

102

408

30 sec

190

761

58

233

45 sec

133

532

40

163

Number of tubes for not exceeding

Vortex

time

EAV ELV

15 ml

EAV ELV

50 ml

15 sec

333

1332

102

408

30 sec

190

761

58

233

45 sec

133

532

40

163

(5 sec gap)

Page 34

*

*) Sample measurement for this device only.

Page 35

*

*) Sample measurement for this device only.

Page 36

*

*) Sample measurement for this device only.

Page 37

Page 38

Your local distributor: www.eppendor f.com/worldwide

Eppendorf AG · 22331 Hamburg · Germany · Tel: +49 40 53801-0 · Fax: +49 40 538 01-556 · E-mail: eppendorf@eppendorf.com

Eppendorf North America, Inc. · 102 Motor Parkway · Hauppauge, N.Y. 11788-5178 · USA

Tel: +1 516 334 7500 · Toll free phone: +1 800-645-3050 · Fax: +1 516 334 7506 · E-mail: info@eppendorf.com

Application Support Europe: Tel: +49 1803 666 789 (Preis je nach Tarif im Ausland; 9 ct/min aus dem dt. Festnetz; Mobilfunkhöchstpreis 42 ct/min)

support@eppendorf.com

North America: Tel: +1 800 645 3050 · E-mail: techserv@eppendorf.com

Asia Pacific: Tel: +60 3 8023 6869 · E-mail: support_asiapacific@eppendorf.com

Loading...

Loading...