Page 1

nual

E

Register your instrument!

www.eppendorf.com/myeppendorf

N)

manual

FemtoJet

Operating manual

4i

®

Page 2

Copyright © 2014 Eppendorf AG, Hamburg. All rights reserved, including graphics and

images. No part of this publication may be reproduced without the prior permission of the

copyright owner.

Eppendorf

®

and the Eppendorf logo are registered trademarks of Eppendorf AG,

Hamburg, Germany.

FemtoJet®, Femtotips®, TransferMan® and InjectMan® are registered trademarks of

Eppendorf AG, Hamburg, Germany.

Registered trademarks and protected trademarks are not marked in all cases with

®

or ™

in this manual.

5252 900.014-00/012014

Page 3

Table of contents

FemtoJet

®

4i

English (EN)

Table of contents

1 Operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Delivery package – Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

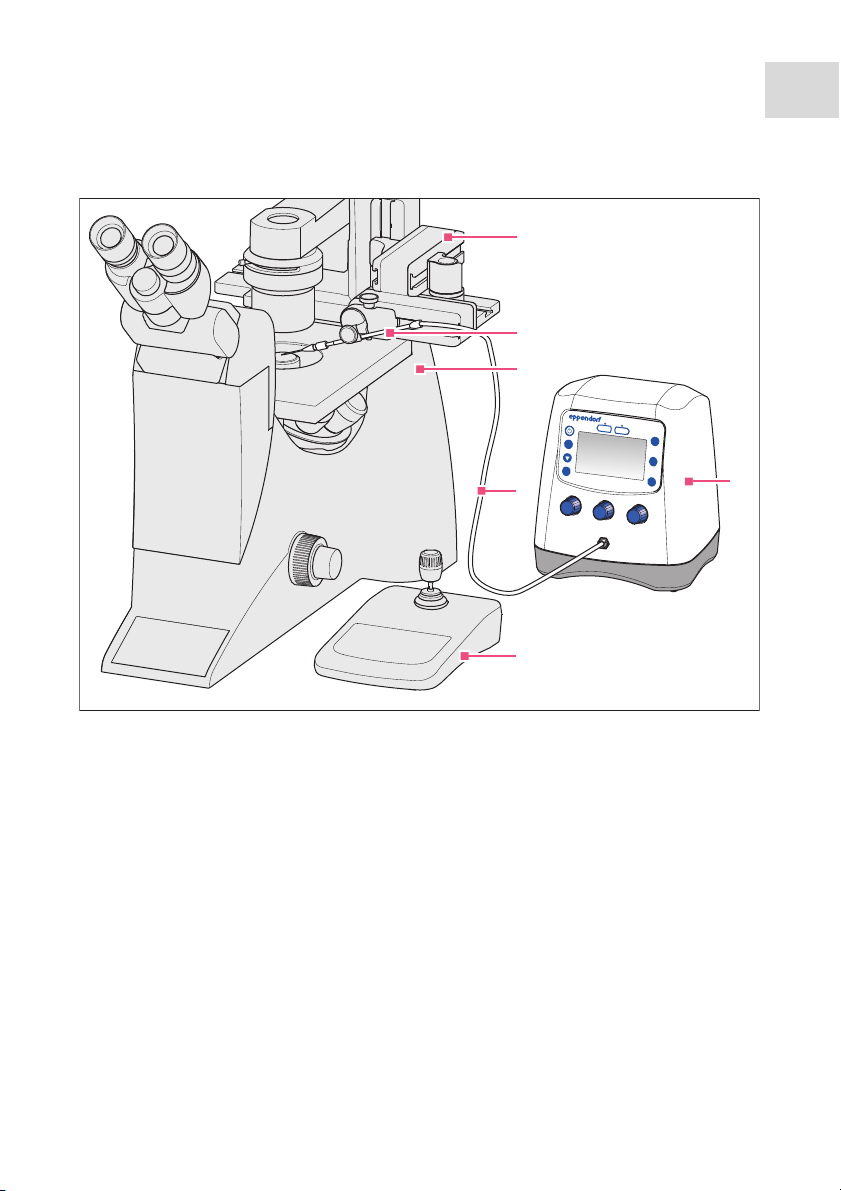

2.3 Exemplary set-up of a microinjection system . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4.1 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Name plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 Rotary knobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.8 Foot control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.9 Hand control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.10 Pressure parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.10.1 Compensation pressure p

2.10.2 Injection pressure p

2.10.3 Injection time t

2.10.4 Rinsing pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

i

2.10.5 Operating pressure p

2.11 Self-calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

c

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

w

2.12 Universal capillary holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Warning signs on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Preparing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.1 Complaints about damages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.2 Incomplete delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Connecting the Microinjector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 4

Table of con tents

FemtoJet

4

®

4i

English (EN)

4.4 Connecting an external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.1 Connecting a micromanipulator . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.2 Connecting the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4.3 Connecting two devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Connecting accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.1 Connecting a foot control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.2 Connecting a hand control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Main screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Navigating the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Selecting the menu and navigating . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 Exiting the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.3 Selecting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.4 Changing a parameter value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1 Switching on or off the Microinjector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.1 Switching on the Microinjector . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.2 Switching off the Microinjector . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Switching on or off the standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1 Switching on the standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.2 Switching off the standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Determining the injection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.1 Filling the capillaries with fluorescence dye . . . . . . . . . . . . . . . . . 27

6.3.2 Carrying out a test injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.3 Possible sources of error - cell inflates or bursts . . . . . . . . . . . . . 28

6.3.4 Possible sources of error - capillary is clogged. . . . . . . . . . . . . . . 28

6.3.5 Possible sources of error - liquid is not being injected . . . . . . . . . 28

6.3.6 Possible sources of error - capillary does not reach the cell. . . . . 28

6.3.7 Result – the injection parameters have been determined . . . . . . . 28

6.4 Setting the compensation pressure p

6.5 Setting the injection pressure p

6.6 Setting the injection time t

6.7 Setting the injection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

c

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

i

6.7.1 Setting the automatic injection mode . . . . . . . . . . . . . . . . . . . . . . 30

6.7.2 Setting the manual injection mode . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8 Injecting liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8.1 Automatically injecting liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8.2 Manually injecting liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.9 Replacing the capillary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.10 Rinsing the capillary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.11 Setting the injection counter to zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 5

Table of contents

FemtoJet

®

English (EN)

6.12 Calling up saved injection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.12.1 Calling up saved injection parameters . . . . . . . . . . . . . . . . . . . . . 32

6.13 Saving or changing the injection parameters . . . . . . . . . . . . . . . . . . . . . . . . 32

6.13.1 Saving injection parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.13.2 Changing the saved injection parameters . . . . . . . . . . . . . . . . . . . 33

6.14 Adjusting the device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.14.1 Change capillary function – Changing the capillary . . . . . . . . . . . 33

6.14.2 Pressure unit function – Selecting the pressure unit . . . . . . . . . . 33

6.14.3 Beeper function – Switching on/off the signal tone . . . . . . . . . . . 33

6.14.4 Contrast function – Setting the display contrast . . . . . . . . . . . . . . 33

6.14.5 Illumination function – Switching on/off the

display illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.14.6 Continuous flow function – Setting the constant

operating pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.14.7 Drain pressure supply function – Draining the

pressure reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.15 Inserting the capillary into the capillary holder . . . . . . . . . . . . . . . . . . . . . . 35

6.16 Inserting Femtotips into the capillary holder . . . . . . . . . . . . . . . . . . . . . . . . 35

7 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.1 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.1 Error 01 – 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.2 Error 11 – 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.3 Error 19 – 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.4 Error 39 – 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4i

5

8 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Replacing the sealings in the grip head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.1 Removing the sealing washer and o-rings . . . . . . . . . . . . . . . . . . 41

8.1.2 Inserting the o-rings and the sealing washer . . . . . . . . . . . . . . . . 42

8.2 Replacing the sealing in the adapter for Femtotips . . . . . . . . . . . . . . . . . . . 42

8.2.1 Replacing the o-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3 Replacing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.5 Hints with regard to service intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.6 Service and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.7 Disinfection/decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 6

Table of con tents

FemtoJet

6

®

4i

English (EN)

9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Weight/dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4.1 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.4.2 RS 232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.5 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.2 Decontamination before shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11 Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.1 FemtoJet 4i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.3 Universal capillary holder and accessories. . . . . . . . . . . . . . . . . . . . . . . . . . 50

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 7

Operating instructions

FemtoJet

English (EN)

®

4i

1 Operating instructions

1.1 Using this manual

Read this operating manual completely before using the device for the first time. Also

observe the instructions for use of the accessories.

This operating manual is part of the product. Thus, it must always be easily accessible.

Enclose this operating manual when transferring the device to third parties.

You will find the current version of the operating manual for all available languages on

our webpage under www.eppendorf.com

1.2 Danger symbols and danger levels

The safety instructions of this operating manual indicate the following danger symbols

and danger levels:

1.2.1 Danger symbols

Electric shock Hazard point

Cuts Material damage

Biohazard

.

7

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WAR NIN G May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

1.3 Symbols used

Depiction Meaning

1.

2.

Actions in the specified order

Actions without a specified order

• List

Text Display text or software text

Direction of movement

Additional information

Page 8

Product description

FemtoJet

8

®

4i

English (EN)

2 Product description

2.1 Delivery package

Number Description

1 FemtoJet 4i

1Mains/power cord

1Injection tube

1 Operating manual

2.1.1 Delivery package – Accessories

Number Description

1 Universal capillary holder

1 Grip head 0 for capillary (outer diameter 1.0 mm to 1.1 mm)

1 Adapter for Femtotips

1 Foot control

2.2 Features

The Microinjector can be used to inject very small amounts of fluid into cells. The

parameters for pressure and time are set on the device and controlled by the software. It

is possible to trigger the injection on the Microinjector or on a connected

micromanipulator by Eppendorf. The semiautomatic injection movement is controlled by

the Microinjector or the micromanipulator. The required pressure is generated by a

soundproof internal compressor.

Page 9

2.3 Exemplary set-up of a microinjection system

FemtoJet

inject

prog 1

prog 2

count

clean

menu

enter

auto

man

2

1

3

6

5

4

Abb. 2-1:Microinjection system with FemtoJet 4i

Product description

FemtoJet

®

4i

English (EN)

9

Fig. 2-1: Microinjection system with FemtoJet 4i

1 Micromanipulator InjectMan 4

2 Universal capillary holder with

capillary

3Inverse microscope

4 Injection tube

5Control board InjectMan 4

6 Microinjector FemtoJet 4i

Page 10

Product description

menu

enter

auto

man

inject

clean

count

prog 1

prog 2

FemtoJet

1

2

4

5 763

FemtoJet

10

®

4i

English (EN)

2.4 Main illustration

Abb. 2-2:Front and rear side

Fig. 2-2: Front and rear side

1Display

2 Control panel

3 Port for injection tube

4 Rotary knobs for injection parameters

5 Name plate

Lower side of device

6Interfaces

7Venting

Lower side of device

Page 11

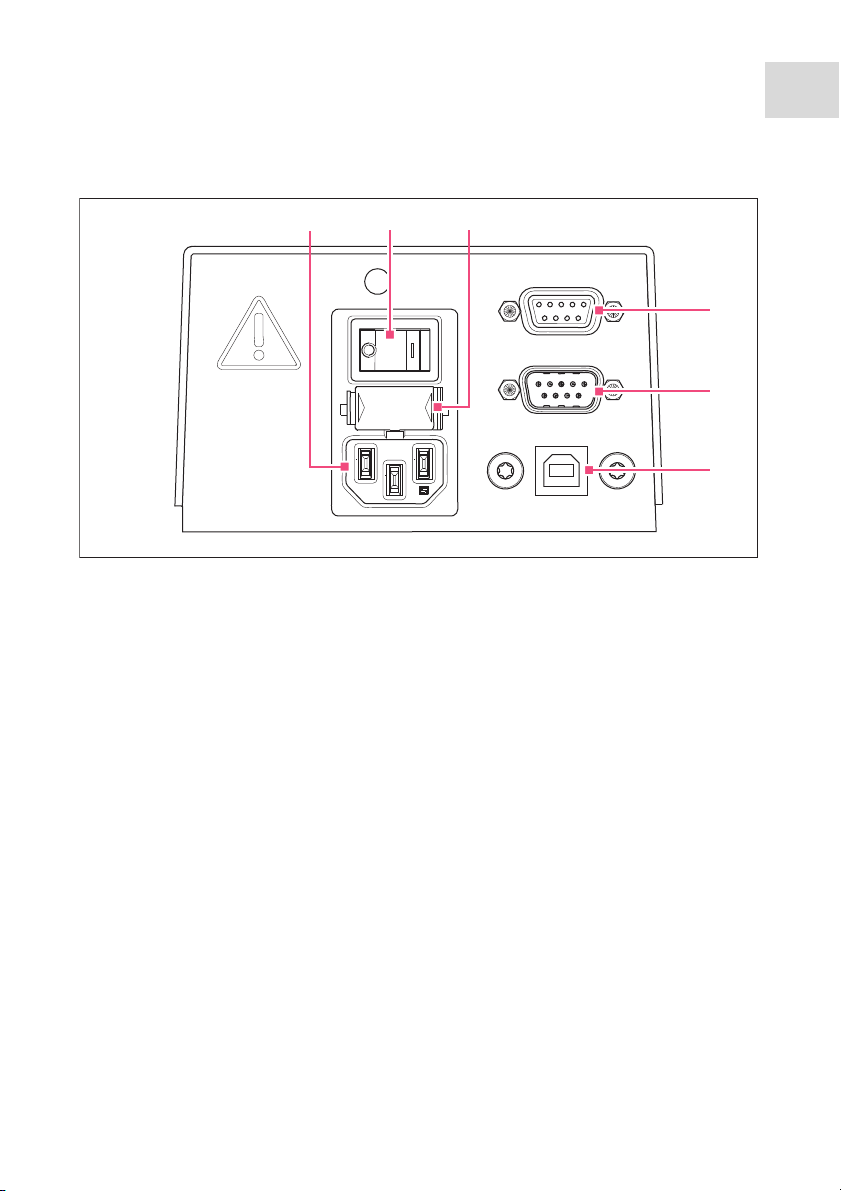

2.4.1 Interfaces

MANIPULATOR

FOOT SWITCH

SERVICE

4

5

6

213

Abb. 2-3:Interfaces

Fig. 2-3: Interfaces

Product description

FemtoJet

®

4i

English (EN)

11

1 Mains/power connection

2Mains/power switch On/Off

3Micro fuse

4 Port for micromanipulator or

computer

5 Connection for foot or hand control

6 Service connection

Page 12

Product description

1

2

3

4

5

6

7

8

10

9

FemtoJet

12

English (EN)

®

4i

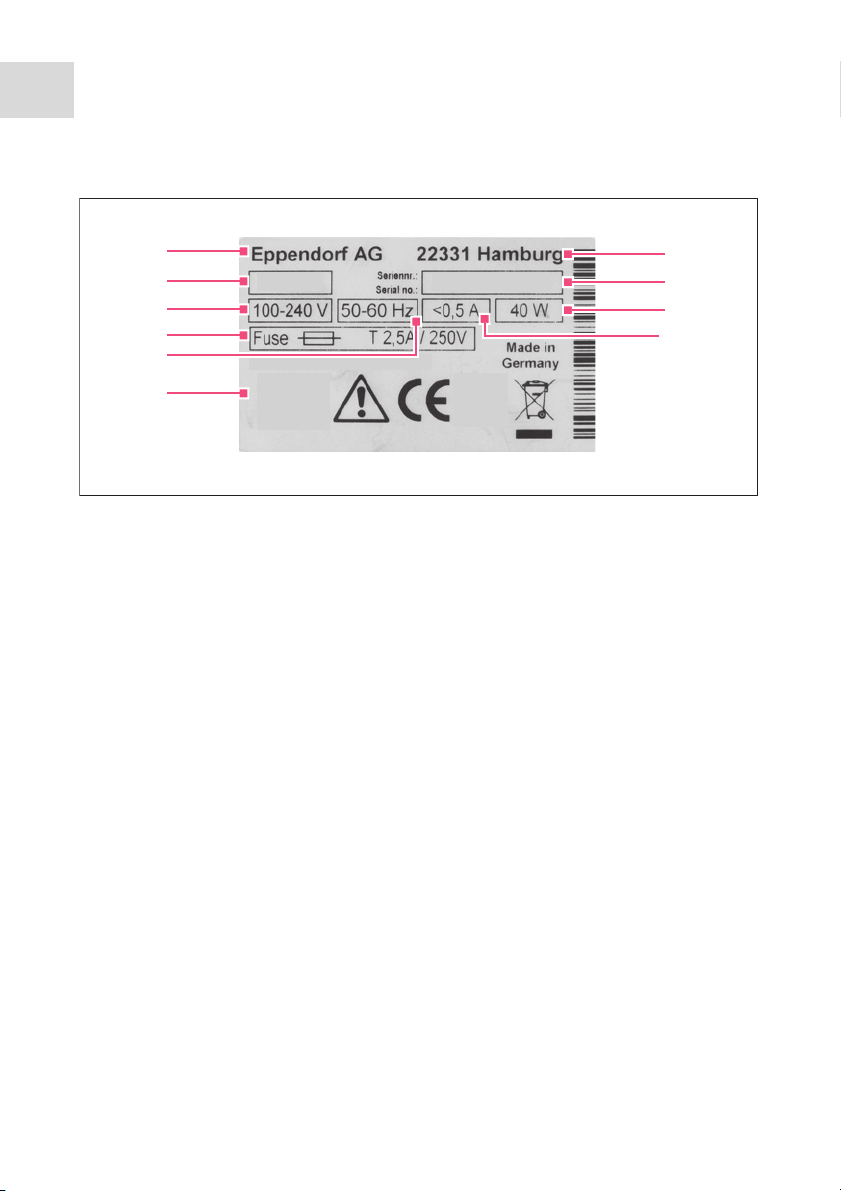

2.5 Name plate

Abb. 2-4:Name plate

Fig. 2-4: Name plate

1 Manufacturer

2Product number

3Voltage

4Micro fuse

5Frequency

6Labelings

7Address of manufacturer

8 Serial number

9Output

10 Current consumption

Page 13

Product description

countcountcount

clean

prog 1

5 6

7

8

9

4

3

2

1

FemtoJet

English (EN)

2.6 Control panel

The keys of the control panel are used to switch on the Microinjector, to perform

functions, to select programs and to navigate through the menu.

Abb. 2-5:Control panel

®

4i

13

Fig. 2-5: Control panel

1 standby key

Activate/deactivate standby mode

2 menu enter key

Open the menu

3Arrow key

Navigate the menu

4 auto man key

Toggle between automatic and manual

6 prog 2 key

Select or save parameter set 2

7 inject key

Perform an injection

8 clean key

Clean the capillary

9 count key

Set the counter to zero

injection

5 prog 1 key

Select or save parameter set 1

Page 14

Product description

enter

FemtoJet

14

®

4i

English (EN)

2.7 Rotary knobs

The rotary knobs are used to set the injection parameters as injection time, injection

pressure and compensation pressure.

Abb. 2-6:Rotary knobs

cleanclean

auto

man

Fig. 2-6: Rotary knobs

1 Rotary knob

Set the injection pressure p

2 Rotary knob

Set the injection time t

countcountcountcount

321

3Rotary knob

i

i

Set the compensation pressure p

c

Page 15

2.8 Foot control

You can connect the foot control to the Microinjector.

The foot control corresponds to the following key on the Microinjector:

• Foot control – inject key

Product description

FemtoJet

®

4i

English (EN)

15

Abb. 2-7:Foot control with plug

Fig. 2-7: Foot control with plug

2.9 Hand control

The hand control is not included in the delivery package and must be ordered

separately.

You can connect the hand control to the Microinjector.

The hand controls correspond to the following keys on the Microinjector:

• Left hand control – inject key

• Right hand control – clean key

The inject and clean keys remain active when the hand control is connected.

2.10 Pressure parameters

The parameters are used to define the pressure and time for the injection and the

cleaning of the capillary.

The pressure parameters include the following parameters:

The inject key remains active when the foot control is connected.

• Compensation pressure – p

• Injection pressure – p

• Injection time – t

i

c

i

• Operating pressure

• Rinsing pressure

Page 16

Product description

3

4

5

1

2

FemtoJet

16

®

English (EN)

4i

2.10.1 Compensation pressure p

c

The compensation pressure prevents the liquid from rising from the Petri dish into the

capillary due to the capillary action. Due to the compensation pressure, some liquid will

leak constantly from the capillary tip. This prevents the injection material from clumping

together.

Abb. 2-8:Pressure ratios in the capillary

Fig. 2-8: Pressure ratios in the capillary

1Capillary

2 Liquid with injection material

3 Compensation pressure p

c

4Hydrostatic pressure

5 Capillary action

2.10.2 Injection pressure p

i

The injection pressure defines the pressure used for injecting liquid into the cell. During

the injection process, the injection pressure is applied as long as the injection time is

running. To inject liquid into a cell, the injection pressure must be higher than the inside

pressure of the cell.

2.10.3 Injection time t

i

The injection time defines the time period for injecting the liquid. The start of the

injection time depends on the presettings of the micromanipulator. The injection time

begins either when triggering the injection function or when reaching the lower safety

limit. The injection pressure is applied as long as the injection time is running.

Page 17

2.10.4 Rinsing pressure

1 2 3 4

6 7

5

The rinsing pressure is used to clean the capillary.

Product description

FemtoJet

®

4i

English (EN)

17

2.10.5 Operating pressure p

w

The operating pressure subsumes the injection pressure, compensation pressure and

rinsing pressure.

2.11 Self-calibration

The Microinjector performs a calibration every two hours. During the calibration, the

ventilation valve opens and the collected condensation water is discharged.

2.12 Universal capillary holder

You can insert a capillary or a Femtotip into the universal capillary holder.

Abb. 2-9:Universal capillary holder

Fig. 2-9: Universal capillary holder

1Capillary

2Grip head

3Knurled screw

5 Connection for injection tube

6Femtotips

7 Adapter for Femtotips

4 Universal capillary holder

Page 18

Safety

FemtoJet

18

English (EN)

®

4i

3Safety

3.1 Intended use

The FemtoJet 4i Microinjector is designed and manufactured for the exclusive use within

the context of biologial, chemical and physical research.

Together with the micromanipulator and the capillary, the Microinjector forms a

microinjection system. The Microinjector is used for the precise and reproducible

injection of extremely small amounts of fluid (femto liter to micro liter range) in biological

cells or nuclei.

The Microinjector is intended exclusively for indoor use and for operation by qualified

staff.

3.2 Warnings for intended use

WARNING! Risk of injury due to flying capillaries and glass splinters.

If exposed to high pressures, capillaries may detach themselves from the grip

heads and become projectiles.

Capillaries can crack as a result of incorrect handling.

Wear protective goggles.

Never aim capillaries at people.

Use capillaries with an outer diameter that matches the grip head

specifications.

Always mount / dismount capillaries when they are depressurized.

Mount the capillary correctly in the grip head.

Do not touch the capillary with the Petri dish or other objects.

CAUTION! Risk of cuts from broken capillaries.

Capillaries are made of glass and are very fragile.

Wear your personal protective equipment (PPE).

Always mount capillaries depressurized.

Never aim capillaries at people.

Handle the capillaries very carefully.

Page 19

Safety

FemtoJet

English (EN)

WARNING! Damage to health due to infectious liquids and pathogenic

germs.

®

4i

When handling infectious liquids and pathogenic germs, observe the national

regulations, the biological security level of your laboratory, the material safety

data sheets, and the manufacturer's application notes.

Wear personal protective equipment.

For full instructions regarding the handling of germs or biological material of

risk group II or higher, please refer to the "Laboratory Biosafety Manual"

(Source: World Health Organization, current edition of the Laboratory

Biosafety Manual).

3.3 Warning signs on the device

Warning symbol Meaning

Read the operating manual

3.4 User profile

The device and accessories may only be operated by trained and skilled personnel.

Before using the device, read the operating manual carefully and familiarize yourself with

the device's mode of operation.

19

3.5 Information on product liability

In the following cases, the designated protection of the device may be compromised.

Liability for any resulting property damage or personal injury is then transferred to the

operator:

• The device is not used in accordance with the operating manual.

• The device is used outside of its intended use.

• The device is used with accessories or consumables which are not recommended by

Eppendorf.

• The device is maintained or repaired by people not authorized by Eppendorf.

• The user makes unauthorized changes to the device.

Page 20

Installation

FemtoJet

20

English (EN)

®

4i

4 Installation

4.1 Preparing installation

Store the packaging for later transport or storage.

In case of visible damages on the Microinjector or the packaging, do not

commission the Microinjector.

1. Check the packaging for damage.

2. Check that everything is included in the delivery.

3. Check the Microinjector and the accessories for damages.

4.1.1 Complaints about damages

Contact your local Eppendorf distribution partner.

4.1.2 Incomplete delivery

Contact your local Eppendorf distribution partner.

4.2 Selecting the location

Please select the location for the Microinjector according to the following criteria:

• Suitable mains/power connection in accordance with the name plate.

• A bench with a horizontal and even work surface which is designed to support the

weight of the Microinjector.

The mains/power switch and cutting unit of the mains/power line must be easily

accessible during operation (e.g., residual current circuit breaker).

4.3 Connecting the Microinjector

Prerequisites

• Electrical connection data according to the name plate.

• The Microinjector is switched off.

Connect the power cable.

4.4 Connecting an external device

The following devices can be connected to the Microinjector:

• Micromanipulator (InjectMan 4, TransferMan 4r or InjectMan NI 2)

•Computer

Page 21

4.4.1 Connecting a micromanipulator

Prerequisites

• Y-cable FJ4 is available.

• The Microinjector is switched off.

• The micromanipulator is switched off.

The operation is described in the manual for the micromanipulator.

1. Connect the Y-cable to the MANIPULATOR port.

2. Connect the micromanipulator to the Y-cable.

3. Switch on the Microinjector.

The initialization phase starts.

After completion of the initialization phase, the main screen appears.

4.4.2 Connecting the PC

Prerequisites

• Y-cable FJ4 is available.

• Devices are switched off.

Control with a PC is described in the Cell Technology · PC Control manual.

1. Connect the Y-cable to the MANIPULATOR port.

2. Connect the computer to the Y-cable.

3. Switch on the Microinjector.

The initialization phase starts.

After completion of the initialization phase, the main screen appears.

Installation

FemtoJet

®

4i

English (EN)

21

Page 22

Installation

FemtoJet

22

English (EN)

®

4i

4.4.3 Connecting two devices

Prerequisites

• Y-cable FJ4 is available.

• Devices are switched off.

Two devices can be connected with the Y-cable FJ4.

The following combinations are possible:

•Computer

• Micromanipulator

Control with a PC is described in the Cell Technology · PC Control manual.

The operation is described in the manual for the micromanipulator.

1. Connect the Y-cable to the MANIPULATOR port.

2. Connect the computer to the Y-cable.

3. Connect the micromanipulator to the Y-cable.

4. Switch on the Microinjector.

The initialization phase starts.

After completion of the initialization phase, the main screen appears.

4.5 Connecting accessories

It is possible to connect the following accessories to the Microinjector:

• Foot control or

•Hand control

4.5.1 Connecting a foot control

Prerequisites

• The Microinjector is switched off.

1. Connect the foot control to the FOOT SWITCH port.

4.5.2 Connecting a hand control

Prerequisites

• The Microinjector is switched off.

• No foot control has been connected.

The hand control is not included in the delivery package and must be ordered

separately.

Connect the hand control to the FOOT SWITCH port.

Page 23

Software

6

7

3

4 5

1

2

FemtoJet

®

4i

English (EN)

5 Software

5.1 Main screen

The main screen displays all injection parameters, the selected pressure unit, the injection

mode and the number of injections.

Abb. 5-1:Main screen splitting

Fig. 5-1: Main screen splitting

23

1Injection mode

Automatic or manual injection

2 Injection counter

3 Parameter for injection pressure p

Pressure unit in hPa or PSI

4 Parameter for injection time t

Time in seconds

i

5 Parameter for compensation pressure

p

c

Pressure unit in hPa or PSI

6 Line with set values

i

7 Line with actual values

Page 24

24

Software

FemtoJet

®

4i

English (EN)

5.2 Main menu

Abb. 5-2:Main menu

Fig. 5-2: Main menu

Menu Parameter

Change capillary Replace the capillary

Pressure unit Set the unit for pressure (hPa or PSI)

Beeper Switch on/off the signal tone

Contrast Set the display contrast

Illumination Switch on/off the display illumination

Continuous flow Set a fixed value for a continuous pressure

Drain pressure supply Open the venting for a short time and discharge the

condensation water

5.3 Navigating the menu

5.3.1 Selecting the menu and navigating

5.3.2 Exiting the menu

1. Select the submenu Back.

2. Press the menu enter key.

The main screen appears.

1. Press the menu enter key.

The menu appears.

2. To select a menu entry, press the arrow

key.

The menu entry is shown with a black

bar.

Page 25

5.3.3 Selecting parameters

Prerequisites

•A submenu with parameters is selected.

1. To select a parameter, press the arrow

2. Confirm with the menu enter key.

5.3.4 Changing a parameter value

Prerequisites

• A submenu with parameter values is selected.

Software

FemtoJet

®

English (EN)

key.

The selected parameter is marked with a

check mark.

The main screen appears.

4i

25

1. For changing a value, use the rotary knob.

2. Confirm with the menu enter key.

The main screen appears.

Page 26

Operation

FemtoJet

26

English (EN)

®

4i

6Operation

6.1 Switching on or off the Microinjector

WARNING! Electric shock due to damage to device or mains cable.

Only switch on the device if the device and mains cable are undamaged.

Only use devices that have been properly installed or repaired.

In case of danger, disconnect the device from the mains supply by pulling the

power plug from the device or the mains socket or, by using the isolating

device intended for this purpose (e.g., emergency stop switch in the

laboratory).

6.1.1 Switching on the Microinjector

1. Take off the injection tube.

2. Switch on the Microinjector with the mains/power switch.

The Microinjector performs a self test.

The operating pressure is built up.

The main screen appears.

6.1.2 Switching off the Microinjector

1. Keep the standby key pressed.

The message Hold Standby to exhaust appears.

The pressure reservoir is emptied.

2. Switch off the Microinjector with the mains/power switch.

6.2 Switching on or off the standby mode

For short intermissions, you can use the standby mode. The Microinjector remains ready

for operation.

6.2.1 Switching on the standby mode

1. Press the standby key.

2. Take off the injection tube.

The display shows STANDBY.

The operating controls are deactivated.

The pressure in the pressure reservoir is maintained.

Page 27

Operation

FemtoJet

English (EN)

6.2.2 Switching off the standby mode

Prerequisites

• The display shows STANDBY.

1. Take off the injection tube.

2. Press the standby key.

The Microinjector performs a short self test.

The display shows the main screen.

6.3 Determining the injection parameters

To determine the correct injection parameters, you can carry out a test injection with

fluorescence dye.

6.3.1 Filling the capillaries with fluorescence dye

Prerequisites

• Use a capillary with an opening of 0.5 μm.

• The injection tube is mounted to the universal capillary holder.

• Pipette with Microloader by Eppendorf is available.

1. Fill the Microloader with fluorescing liquid.

2. Equip the capillary with the Microloader.

3. Insert the capillary into the universal capillary holder.

®

4i

27

6.3.2 Carrying out a test injection

Prerequisites

• The Microinjector and the micromanipulator are connected and ready for operation.

• The universal capillary holder is prepared with a capillary and fluorescence dye.

• The universal capillary holder is clamped in the Eppendorf micromanipulator.

• The Petri dish with adherent cells is prepared.

1. Connect the injection tube to the Microinjector.

2. Define the lower safety limit on the micromanipulator.

3. Position the capillary above the cell.

4. Press the prog 1 key.

5. Press the inject key.

6. Check the injection visually.

Page 28

28

Operation

FemtoJet

®

4i

English (EN)

6.3.3 Possible sources of error - cell inflates or bursts

The injected volume is too large.

A volume increase of about 10 % is an appropriate guide value for adherent

cells.

1. Decrease the injection pressure or the injection time.

2. Repeat the test injection.

6.3.4 Possible sources of error - capillary is clogged

The injection material has clumped together or an old capillary was used.

1. Press the clean key.

2. Repeat the test injection.

3. Replace the capillary if it is not possible to clean it by rinsing.

6.3.5 Possible sources of error - liquid is not being injected

The interior cell pressure is higher than the injection pressure.

1. Increase the injection pressure.

2. Repeat the test injection.

6.3.6 Possible sources of error - capillary does not reach the cell

The cell is below the lower safety limit (Z-axis Limit) of the micromanipulator.

1. Adjust the lower safety limit on the micromanipulator.

2. Repeat the test injection.

6.3.7 Result – the injection parameters have been determined

If the correct injection parameters for the current test set-up have been determined, you

can continue by performing the injection or you can save the parameter set.

• Saving the injection parameters – (see Saving or changing the injection parameters on

p. 32)

• Performing the injection – (see Injecting liquid on p. 30)

Page 29

Operation

FemtoJet

®

4i

English (EN)

6.4 Setting the compensation pressure pc

The compensation pressure depends on the surface tension, the viscosity of the injection

liquid and the diameter of the capillary opening. The setting of the compensation pressure

must provide for a continuous slight leak of liquid at the capillary tip.

Prerequisites

• The injection parameters are known.

• Use a capillary with an opening of 0.5 μm.

Set the compensation pressure p

The actual value is shown below the set value.

with the rotary knob.

c

The set value is displayed.

6.5 Setting the injection pressure pi

The set injection pressure must be higher than the inside pressure of the cell. The

injection pressure is built up from the start of the injection time.

Prerequisites

• The injection parameters are known.

• Use a capillary with an opening of 0.5 μm.

Guide values for the injection pressure are 50 hPa to 500 hPa (0.73 PSI to 7.20

PSI).

Set the injection pressure p

with the rotary knob.

i

29

6.6 Setting the injection time ti

The injection time and the injection pressure determine the injected volume. The moment

from which the injection time is counted depends on the set synchronization mode on the

connected micromanipulator.

Beginning of time measurement during synchronization mode:

• IMMEDIATE – directly after triggering the injection

• LIMIT – when the lower safety limit is reached

Prerequisites

• The injection parameters are known.

Guide values for the injection time are 0.3 – 1.5 seconds.

Set the injection time t

with the rotary knob.

i

Page 30

Operation

FemtoJet

30

English (EN)

®

4i

6.7 Setting the injection mode

6.7.1 Setting the automatic injection mode

During the automatic injection mode, the set injection time is used. During the injection,

the time elapses in reverse and the injection stops at zero.

Press the auto man key.

The Auto injection mode is displayed.

The injection time is displayed.

6.7.2 Setting the manual injection mode

During the manual injection mode, no preset injection time is used. The injection only

stops when releasing the inject key.

Press the auto man key.

The Manual injection mode is displayed.

The injection time only is displayed

when pressing the inject key.

6.8 Injecting liquid

You can trigger an injection with the inject key, the foot control or the hand control.

6.8.1 Automatically injecting liquid

Prerequisites

• The display shows Auto.

• The injection parameters are set.

• The micromanipulator is connected.

• For the synchronization, IMMEDIATE is set on the micromanipulator.

Page 31

Press the inject key.

The injection movement is triggered on the micromanipulator.

The inject key is disabled during the injection.

The elapsing injection time is displayed.

6.8.2 Manually injecting liquid

Prerequisites

• The injection parameters are set.

• The micromanipulator is connected.

• For the synchronization, IMMEDIATE is set on the micromanipulator.

1. Press the auto man key.

The display shows Manual.

2. Keep the inject key pressed.

The injection of the liquid continues until the inject key is released.

The progress of the injection time is displayed.

6.9 Replacing the capillary

1. Press the menu enter key.

2. Select the Change capillary menu.

3. Confirm with the menu enter key.

The message Capillary may be changed now is displayed.

The valve on the injection tube is closed.

4. Replace the capillary on the micromanipulator.

5. Press the menu enter key.

The main screen appears.

Operation

FemtoJet

English (EN)

®

4i

31

6.10 Rinsing the capillary

You can rinse a clogged capillary using the cleaning function.

1. Keep the clean key pressed.

The rinsing of the capillary continues until you release the clean key.

The capillary is rinsed at maximum pressure.

The pressure build-up is shown in a chart.

6.11 Setting the injection counter to zero

For each injection performed, the counter is increased by one. You can reset the counter

to zero.

1. Press the count key.

The Count display is reset to zero.

Page 32

32

Operation

FemtoJet

®

4i

English (EN)

6.12 Calling up saved injection parameters

The program keys are predefined with exemplary parameter sets for standard

applications. One parameter set consists of injection pressure, injection time,

compensation pressure and injection mode.

The parameter sets are suited for the following standard applications:

• prog 1 – For adherent cell injection with a capillary diameter of approx. 0.5 μm.

• prog 2 – For pronucleus injection with a capillary diameter of approx. 0.5 μm.

Parameter set Injection pressure

p

i

Injection time

t

i

Compensation

pressure

p

c

Injection mode

prog 1 150 hPa 0.30 s 50 hPa Auto

2.18 PSI 0.30 s 0.73 PSI

prog 2 110 hPa – 15 hPa Manual

1.60 PSI – 0.22 PSI

6.12.1 Calling up saved injection parameters

1. Press the prog 1 or prog 2 key.

An acoustic signal will sound.

The LED above the program key is illuminated.

The selected program is active.

The parameter set is displayed.

6.13 Saving or changing the injection parameters

You can save individual injection parameters on the two program slots. One parameter set

consists of injection pressure, injection time, compensation pressure and injection mode.

6.13.1 Saving injection parameters

The current parameter set is overwritten. For the ex factory parameter sets, refer

to chapter “Calling up saved injection parameters” on page 32.

1. Set the injection parameters.

2. Select the injection mode automatically or manually.

3. Keep the prog 1 or prog 2 key pressed for approx. two seconds.

An acoustic signal will sound.

The LED above the program key is illuminated.

The injection parameters are saved.

Page 33

6.13.2 Changing the saved injection parameters

The current parameter set is overwritten. For the ex factory parameter sets, refer

to chapter “Calling up saved injection parameters” on page 32.

1. Change the injection parameters.

2. Keep the prog 1 or prog 2 key pressed for two seconds.

An acoustic signal will sound.

The LED above the program key is illuminated.

The new value is saved.

6.14 Adjusting the device settings

6.14.1 Change capillary function – Changing the capillary

1. Press the menu enter key.

2. Select the Change capillary menu.

3. Confirm with the menu enter key.

You can change the capillary.

4. Quit the menu with the menu enter key.

6.14.2 Pressure unit function – Selecting the pressure unit

1. Press the menu enter key.

2. Select the Pressure unit menu.

3. Confirm with the menu enter key.

4. Select the pressure unit.

5. Confirm with the menu enter key.

Operation

FemtoJet

English (EN)

®

4i

33

6.14.3 Beeper function – Switching on/off the signal tone

1. Press the menu enter key.

2. Select the Beeper menu.

3. Confirm with the menu enter key.

4. Select the mode.

5. Confirm with the menu enter key.

6.14.4 Contrast function – Setting the display contrast

1. Press the menu enter key.

2. Select the Contrast menu.

3. Confirm with the menu enter key.

4. Set the parameter value with a rotary knob.

5. Confirm with the menu enter key.

Page 34

34

Operation

FemtoJet

®

4i

English (EN)

6.14.5 Illumination function – Switching on/off the display illumination

1. Press the menu enter key.

2. Select the Illumination menu.

3. Confirm with the menu enter key.

4. Select the mode.

5. Confirm with the menu enter key.

6.14.6 Continuous flow function – Setting the constant operating pressure

1. Press the menu enter key.

2. Select the Continuous flow menu.

3. Confirm with the menu enter key.

The screen for Continuous flow appears.

4. Set the operating pressure p

with the rotary knob.

w

5. Confirm with the menu enter key.

6.14.7 Drain pressure supply function – Draining the pressure reservoir

1. Press the menu enter key.

2. Select the Drain pressure supply menu.

3. Press the menu enter key.

The venting opens for a short time.

The condensation water is discharged.

Page 35

6.15 Inserting the capillary into the capillary holder

WARNING! Risk of injury due to flying capillaries and glass splinters.

If exposed to high pressures, capillaries may detach themselves from the grip

heads and become projectiles.

Capillaries can crack as a result of incorrect handling.

Wear protective goggles.

Never aim capillaries at people.

Use capillaries with an outer diameter that matches the grip head

specifications.

Always mount / dismount capillaries when they are depressurized.

Mount the capillary correctly in the grip head.

Do not touch the capillary with the Petri dish or other objects.

Prerequisites

• Grip head 0

• Capillary with an outer diameter of 1.0 mm to 1.1 mm

1. Insert the capillary up to the stop.

2. Tighten the grip head.

Operation

FemtoJet

English (EN)

®

4i

35

6.16 Inserting Femtotips into the capillary holder

1. Remove the grip head.

2. Screw the adapter for Femtotips into the universal capillary holder.

3. Screw the Femtotip into the adapter and tighten.

Page 36

Troubleshooting

FemtoJet

36

English (EN)

®

4i

7 Troubleshooting

7.1 General errors

Symptom/message Cause Remedy

No liquid is injected. • Capillary is clogged.

Capillary does not

reach the injection

position.

• The lower safety limit is set

too high.

7.2 Error messages

7.2.1 Error 01 – 10

Symptom/message Cause Remedy

Error #01 • Software problem

Error #02 • Compressor control signals

an unexpected error.

Error #03 • System error

Error #04 • General electronic error in

the device.

Error #05 • Faulty hand or foot control.

Clean the capillary using the

clean function.

If the error persists, replace

the capillary.

Set the lower safety limit on

the micromanipulator.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Page 37

Troubleshooting

FemtoJet

English (EN)

Symptom/message Cause Remedy

Error #06 • The key pad is faulty. Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Error #07 • System error

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Error #08 • Injection pressure control

signals an unexpected error

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Error #09 • Pressure reservoir control

signals an unexpected error.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Error #10 • Safety monitor signals an

unexpected error.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

®

4i

37

7.2.2 Error 11 – 18

Symptom/message Cause Remedy

Error #11 • Serial interface RS232

signals an unexpected error.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Error #12 • The voltage control signals

an unexpected error.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Page 38

Troubleshooting

FemtoJet

38

English (EN)

Symptom/message Cause Remedy

Error #13 • The compressor does not

Error #14 • Pressure control is faulty.

Error #15 • System error

Error #16 • System error

Error #17 • An open injection tube is

Error #18 • An open injection tube is

®

4i

work or is faulty.

connected.

connected.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Take off the injection tube.

Connect the injection tube to

the universal capillary

holder.

Connect the injection tube.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Take off the injection tube.

Connect the injection tube to

the universal capillary

holder.

Connect the injection tube.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Page 39

7.2.3 Error 19 – 38

Symptom/message Cause Remedy

Error #19 • System error

Error #20 • System error

Error #21 • System error

Error #22 • System error

Error #23 • System error

Error #24 • System error

Error #25 • System error

Error #26 • System error

Error #27 • System error

Error #28 • System error

Error #29 • System error

Error #30 • System error

Error #31 • System error

Error #32 • System error

Error #33 • System error

Error #34 • System error

Error #35 • System error

Error #36 • System error

Error #38 • System error

Warning #37 • Micromanipulator is not

connected correctly.

• Micromanipulator takes too

much time for the action to

be performed until sending

an answer.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Press the menu enter key.

Check the micromanipulator.

Check the connecting cable.

If the error persists, please

contact the authorized

service.

Troubleshooting

FemtoJet

English (EN)

®

4i

39

Page 40

Troubleshooting

FemtoJet

40

English (EN)

®

4i

7.2.4 Error 39 – 40

Symptom/message Cause Remedy

Warning #39 • Capillary is broken.

•Injection tube is not

separated from the device

when switching on.

• Injection tube connected

without equipped capillary.

• Storage pressure is too low.

•System error

Warning #40 • Capillary is broken.

•Injection tube is not

separated from the device

when switching on.

• Injection tube connected

without equipped capillary.

• Storage pressure is too low.

•System error

Insert a new capillary.

Take off the injection tube.

Wait until the initialization

phase is completed.

Connect the injection tube.

Connect an equipped

capillary.

Wait until the storage

pressure is reached.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Insert a new capillary.

Take off the injection tube.

Wait until the initialization

phase is completed.

Connect the injection tube.

Connect an equipped

capillary.

Wait until the storage

pressure is reached.

Switch the device off and

back on again.

If the error persists, please

contact the authorized

service.

Page 41

8 Maintenance

1

2

4

3

8.1 Replacing the sealings in the grip head

You must replace any damaged o-rings.

Maintenance

FemtoJet

English (EN)

®

4i

41

1 Sealing washer

2O-rings

3 Grip head with sealing washers and

o-rings

4Removal tool

8.1.1 Removing the sealing washer and o-rings

Extract the sealing washer and the o-rings with the hook of the removal tool.

1. Extract the sealing washer.

2. Extract the two o-rings consecutively.

The second sealing washer remains in

the grip head.

Page 42

Maintenance

3

1

2

FemtoJet

42

English (EN)

®

4i

8.1.2 Inserting the o-rings and the sealing washer

The sealing washer has two sides. The concave side must point to the o-ring.

1. Insert the first o-ring.

2. Press the o-ring down with the universal

capillary holder.

3. Insert the second o-ring and press it

down.

4. Insert the sealing washer and press it on

the o-ring.

8.2 Replacing the sealing in the adapter for Femtotips

You must replace any leaky sealings.

1O-ring

2Adapter

8.2.1 Replacing the o-ring

3Removal tool

1. Remove the Femtotips by turning them.

2. Extract the o-ring with the removal tool.

Page 43

Maintenance

FemtoJet

English (EN)

3. Insert a new o-ring and press it down

with the universal capillary holder.

4. Insert the Femtotips in the adapter by

turning them.

8.3 Replacing fuses

DANGER! Electric shock.

Switch off the device and disconnect the power plug before starting

maintenance or cleaning work.

The fuse holder is located between the mains connection socket and the mains power

switch. The fuses may only be replaced with the same type of fuse.

1. Disconnect the mains plug.

2. Pull the fuse holder out completely.

3. Replace the defective fuse.

4. Insert the fuse holder.

®

4i

43

8.4 Cleaning

DANGER! Electric shock as a result of penetration of liquid.

Switch off the device and disconnect the power plug before starting cleaning

or disinfection work.

Do not allow any liquids to penetrate the inside of the housing.

Do not spray clean/spray disinfect the housing.

Only plug the device back in if it is completely dry, both inside and outside.

NOTICE! Damage from the use of aggressive chemicals.

Do not use any aggressive chemicals on the device or its accessories, such as

strong and weak bases, strong acids, acetone, formaldehyde, halogenated

hydrocarbons or phenol.

If the device has been contaminated by aggressive chemicals, immediately

clean it by means of a mild cleaning agent.

Clean the device at least every 4 weeks

Page 44

Maintenance

FemtoJet

44

English (EN)

1. Wipe the painted parts and the aluminum surfaces with a cloth and mild detergent.

2. Polish with a dry cloth.

®

4i

8.5 Hints with regard to service intervals

The display shows the following message:

• Please contact local service soon – Contact the authorized service.

• Please contact local service now – Have the service performed by the authorized

service.

8.6 Service and maintenance

Application-specific service and safety inspections are not required.

The Eppendorf AG service team is available to service and certify your device.

Service provisions:

•Service

• Operational qualification (OQ) according to manufacturer's specifications

• Electrical safety testing according to country-specific regulations

•Software update

Information on the services offered can be found on our webpage: www.eppendorf.com/

epservices.

8.7 Disinfection/decontamination

Choose the disinfection method which corresponds to the legal regulations and

guidelines in place for your range of application.

If you have any questions on cleaning, disinfection, decontamination, or the

cleaning agents to be used, please contact Eppendorf AG Application Support.

The relevant contact details are provided on the back of this operating manual.

Prerequisites

• All device parts are cleaned.

• A disinfectant containing alcohol (such as isopropanol or spirit) is available.

Wipe all parts of the device with a cloth and the disinfectant.

Page 45

9 Technical data

9.1 Mode of operation

Mode of operation S1 (IEC 60034-1)

9.2 Weight/dimensions

Width 213 mm

Depth 207 mm

Height 250 mm

Weight 5 kg

9.3 Power supply

Voltage 100 V – 240 V, AC, 10 %

Frequency 50 Hz – 60 Hz

Power consumption 40 W

Protection class I

Overvoltage category II (IEC 61010-1)

Micro fuse T 2.5 A/250 V

9.4 Interfaces

9.4.1 USB

Technical data

FemtoJet

English (EN)

®

4i

45

Type Slave

Use Service

9.4.2 RS 232

Baud rate 9600

Start bit 1

Data bits 8

Parity none

Stop bit 2

Page 46

Technical data

FemtoJet

46

English (EN)

®

4i

9.4.3 Injection time t

i

Time interval 0.10 s – 99.99 s

Increment 0.01 s

9.4.4 Injection pressure p

i

Pressure range, controlled 5 hPa – 6 000 hPa

0.07 PSI – 87.0 PSI

Increment 1 hPa

0.01 PSI

Pressure, uncontrolled 0 hPa

0 PSI

Accuracy ±2.5 %

9.4.5 Compensation pressure pc/p

w

Pressure range, controlled 5 hPa – 6 000 hPa

0.07 PSI – 87.0 PSI

Increment 1 hPa

0.01 PSI

Pressure, uncontrolled 0 hPa

0 PSI

Accuracy ±2.5 %

9.4.6 Rinsing pressure

Pressure range 4 000 hPa – 6 000 hPa

58.01 PSI– 87.02 PSI

Page 47

9.4.7 Accuracy

Technical data

FemtoJet

®

4i

English (EN)

47

6000 hPa

±0.20 %

87.02 PSI

2500 hPa

±0.20 %

36.26 PSI

1000 hPa

±0.10 %

14.50 PSI

100 hPa

±0.50 %

1.45 PSI

50 hPa

±1.00 %

0.73 PSI

15 hPa

0.22 PSI

±1 hPa

±0.01 PSI

9.5 Ambient conditions

Ambience Only for use indoors.

Ambient temperature 15 °C – 40 °C

Relative humidity 10 % – 75 %, non-condensing.

Atmospheric pressure 795 hPa – 1060 hPa

Use up to a height of 2000 m above sea level.

Degree of pollution 2 (IEC 664)

Page 48

Transport, storage and disposal

FemtoJet

48

®

4i

English (EN)

10 Transport, storage and disposal

10.1 Storage

Air temperature Relative humidity Atmospheric

pressure

In transport

-20 °C – 70 °C 10 % – 80 % 300 hPa – 1060 hPa

packaging

Without transport

– – –

packaging

10.2 Decontamination before shipment

If you are shipping the device to the authorized Technical Service for repairs or to your

authorized dealer for disposal please note the following:

WARNING! Risk to health from contaminated device

1. Observe the notes on the decontamination certificate. You find it as a PDF file

on our website (www.eppendorf.com/decontamination

).

2. Decontaminate all the parts you would like to dispatch.

3. Include the fully completed decontamination certificate in the package.

10.3 Transport

Air temperature Rel. humidity Atmospheric pressure

General transport -25 °C – 60 °C 10 % – 95 % 30 kPa - 106 kPa

Air freight -40 °C – 55 °C 10 % – 95 % 30 kPa - 106 kPa

Carry out the following steps before transport:

1. Pack the Microinjector in the original packaging.

2. Only use the original packaging for transporting the Microinjector.

Page 49

Transport, storage and disposal

FemtoJet

®

4i

English (EN)

10.4 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European

Community:

Within the European Community, the disposal of electrical devices is regulated by

national regulations based on EU Directive 2002/96/EC pertaining to waste electrical and

electronic equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in the

business-to-business sphere, to which this product is assigned, may no longer be

disposed of in municipal or domestic waste. To document this, they have been marked

with the following identification:

Because disposal regulations may differ from one country to another within the EU,

please contact your supplier if necessary.

In Germany, this is mandatory from March 23, 2006. From this date, the manufacturer has

to offer a suitable method of return for all devices supplied after August 13, 2005. For all

devices supplied before August 13, 2005, the last user is responsible for the correct

disposal.

49

Page 50

Ordering information

FemtoJet

50

®

4i

English (EN)

11 Ordering information

11.1 FemtoJet 4i

Order no.

(International)

Order no. (North

America)

Description

5252 000.013 5252000013 FemotJet 4i microinjector

11.2 Accessories

Order no.

(International)

Order no. (North

America)

Description

Hand control

5252 070.011 5252070011 for FemtoJet 4i/4x

Foot control

5252 070.020 5252070020 for FemtoJet 4i/4x

5192 080.004 5192080004 Y-ca ble FJ4

11.3 Universal capillary holder and accessories

Order no.

(International)

Order no. (North

America)

Description

Universal capillary holder

For holding Femtotips, Femtotips II or

grip heads

5176 190.002 920007392 Including grip head 0, adapter for

Femtotips and spare O-rings

Grip head 0

5176 210.003 920007414 For microcapillaries with an outer

diameter of 1.0 mm to 1.1 mm, set of 2

Grip head 1

5176 212.006 920007708 For microcapillaries with an outer

diameter of 1.2 mm to 1.3 mm, set of 2

Grip head 2

5176 214.009 920007716 For microcapillaries with an outer

diameter of 1.4 mm to 1.5 mm, set of 2

Grip head 3

5176 207.002 920007406 For microcapillaries with an outer

diameter of 0.7 mm to 0.9 mm, set of 2

O-ring set

5176 196.000 920005870 For grip heads 0-3 with removal tool

Service kit

For grip heads and capillary holder

5176 195.004 920005888 Consisting of O-ring set, adapter for

Femtotips

Page 51

Index

FemtoJet

®

4i

English (EN)

51

Index

A

Ambient conditions ................................ 47

C

Capillary

Cleaning ........................................... 31

Cleaning ................................................. 44

Compensation pressure

Setting .............................................. 29

Connection

Accessories....................................... 22

Computer.......................................... 21

Device combination .......................... 22

External device ................................. 20

Foot control ...................................... 22

Hand control..................................... 22

Microinjector .................................... 20

Micromanipulator............................. 21

D

Decontamination .................................... 48

Device settings

Functions .......................................... 33

Disinfectant ............................................ 44

Disposal .................................................. 49

F

Fluorescence dye

Test injection .................................... 27

Foot control ............................................ 15

Function

Beeper............................................... 33

Change capillary................................ 33

Continuous flow................................. 34

Contrast............................................. 33

Device settings ................................. 33

Drain pressure supply ....................... 34

Illumination ....................................... 34

Pressure unit ..................................... 33

H

Hand control

Accessories .......................................15

I

Injection

Liquid ................................................30

Injection counter .....................................31

Injection mode ........................................30

automatic ..........................................30

manual ..............................................30

Injection parameters

Compensation pressure ....................16

Injection pressure .............................16

Injection time ....................................16

Result ................................................28

Injection pressure

Setting ...............................................29

Injection time

Setting ...............................................29

Installation

Selecting the location........................20

Intermissions

Standby .............................................26

M

Main menu ..............................................24

Main screen.............................................23

N

Navigation

Menu .................................................24

O

O-ring ......................................................41

P

Parameter change ...................................25

Parameter selection ................................25

Parameter set

Page 52

52

Index

FemtoJet

®

4i

English (EN)

prog 1................................................ 32

prog 2................................................ 32

Possible sources of error

Capillary clogged.............................. 28

Cell bursts......................................... 28

Limit ................................................. 28

No injection ...................................... 28

Test injection .................................... 28

Pressure parameters............................... 15

Operating pressure........................... 17

Rinsing pressure............................... 17

Program key

prog 1................................................ 32

prog 2................................................ 32

S

Seal washer ............................................ 41

Selecting the location ............................. 20

Service

Safety inspections............................. 44

Service provisions ............................ 44

Service interval ....................................... 44

Setting

Compensation pressure.................... 29

Injection mode.................................. 30

Injection pressure............................. 29

Injection time ................................... 29

Standby................................................... 26

Standby mode......................................... 26

Storage ................................................... 48

Switching off .......................................... 26

Switching on........................................... 26

Synchronization

Micromanipulator............................. 29

T

Test injection

Injection parameters ........................ 27

U

Unpacking .............................................. 20

Page 53

Page 54

Page 55

Page 56

Evaluate your manual

Give us your feedback.

www.eppendorf.com/manualfeedback

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

Loading...

Loading...