Page 1

E

ualh MultiCon

N)manual

epBlue™ with MultiCon

Software manual

Software-Version 40.1

Page 2

Copyright

©

2013 Eppendorf AG, Hamburg. No part of this publication may be reproduced without the prior

permission of the copyright owner.

Trademarks

®

Eppendorf

Excel

, the Eppendorf logo, epMotion®, and epT.I.P.S.® are registered trademarks of Eppendorf AG.

®

and Windows® are registered trademarks of Microsoft Corporation in the United States and other

countries.

®

Registered trademarks are not marked in all cases with

or ™ in this manual.

The software of the device (firmware) contains open source software. License information is available on

request from Eppendorf AG.

Only for epMotion M5073 and 5075m: Limited Use Label License NOTICE TO PURCHASER; LIMITED

LICENSE FOR RESEARCH USE ONLY.

This product and its use may be covered by one or more patents owned by Gen-Probe Incorporated. The

purchase price for this product includes only limited, nontransferable rights under certain claims of certain

patents owned by Gen-Probe Incorporated to use this product for research purposes only. No other rights

are conveyed. Purchaser is not granted any rights under patents of Gen-Probe Incorporated to use this

product for any commercial use. Further information regarding purchasing a license under patents of

Gen-Probe Incorporated to use this product for any other purposes, including, without limitation, for

commercial use, may be obtained by contacting Gen-Probe Incorporated, Attn: Business Development

Department, 10210 Genetic Center Drive, San Diego, California 92121-4362, U.S.A.

5075 900.866-01/122013

Page 3

Table of contents

epBlue™ with MultiCon

English (EN)

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 Danger symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 Danger levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.1 epBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.2 Assistants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Starting and exiting epBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 Starting epBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 Starting epBlue for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.3 Logging in as User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.4 Logging off as a user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.5 Exiting epBlue and switching off MultiCon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Initial steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 Using the touch screen and mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.2 Using the screen key pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.3 File menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.4 Status area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3

4 epBlue Application Runner - Carrying out the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Opening an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Preparing the application run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 Selecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 Entering the sample quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.3 Setting the HEPA air filter and the UV lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.4 Placing the labware on the epMotion worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

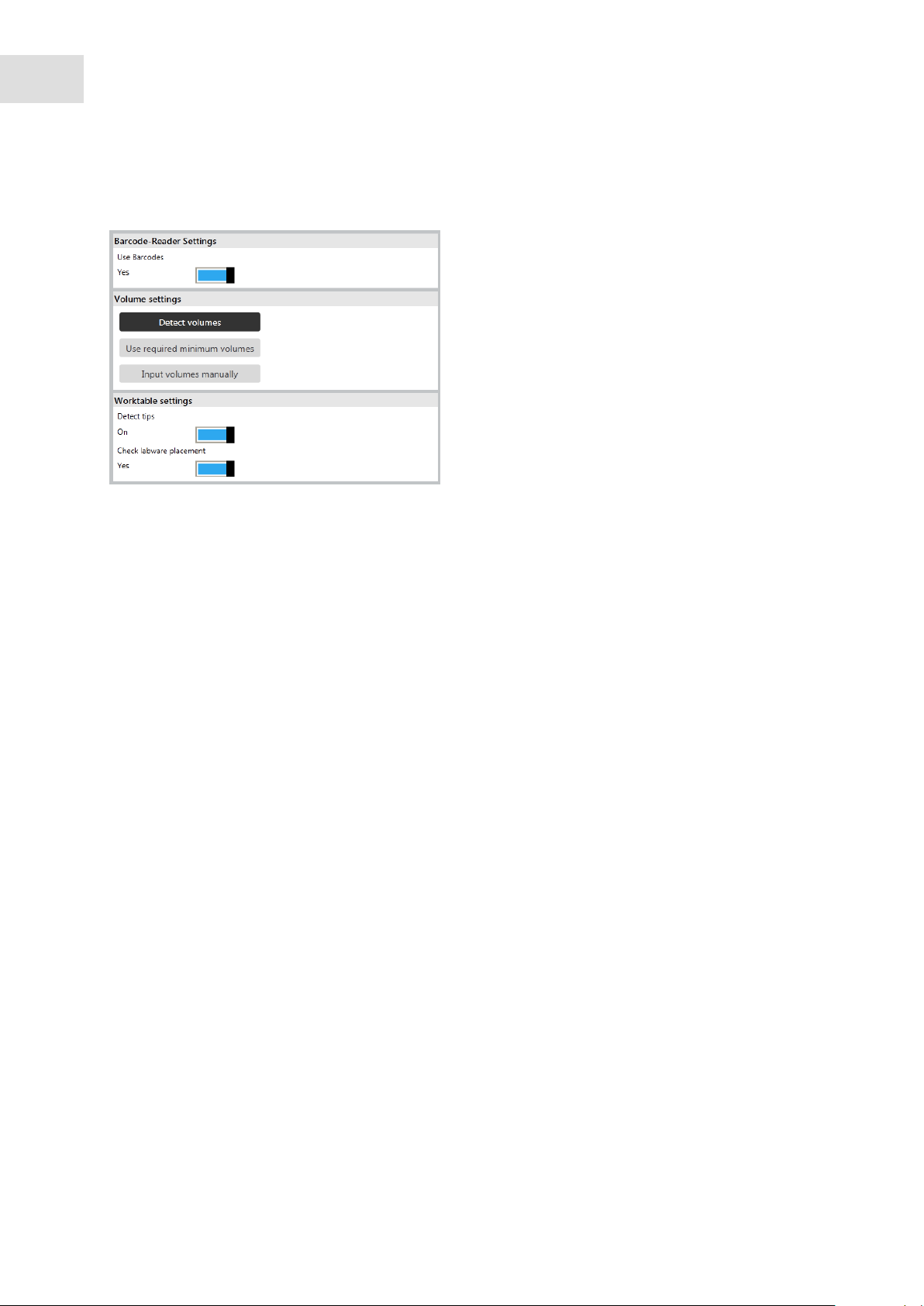

4.2.5 Setting the run parameters for the optical sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.6 Setting the ID tracking parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.7 Entering the filling level of the labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Starting the application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Controlling the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5 Ending the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 epBlue LogViewer - Managing logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Displaying protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.2 Saving the protocol as a PDF file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Page 4

Table of contents

epBlue™ with MultiCon

4

English (EN)

6 epBlue Application Editor - Creating and editing applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2 Creating an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.1 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.2 Creating an empty application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.3 Copying applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.4 Saving an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.5 Positioning labware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.6 Defining the application parameters of the labware . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2.7 Activating ID tracking of the labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2.8 Defining procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2.9 Checking an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3.1 Sample transfer command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.2 Reagent transfer command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3.3 Dilute command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3.4 Pool command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.5 Pool one destination command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.6 Comment command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.3.7 Exchange command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.8 Magnetic separation command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3.9 Mix command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3.10 Number of samples command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.3.11 Temperature command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.3.12 Thermomixer command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.3.13 Vacuum command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.14 Transport command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.3.15 User intervention command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.16 Wait command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.17 Importing commands from a CSV file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.4 Pattern. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4.1 Menu bar in the Edit Pattern window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.2 Defining regular patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4.3 Defining irregular patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.5 Optical sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.5.1 Detect volumes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.5.2 Detect tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.5.3 Check labware placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7 epBlue Application Editor - Managing applications and folders. . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.1 Menu bar and start screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.2 Copying and deleting applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.2.1 Copying applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.2.2 Deleting an application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.3 Changing the labware properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.4 Importing and exporting applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.1 Importing applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.2 Exporting applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.5 Saving an application as a PDF file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Page 5

Table of contents

epBlue™ with MultiCon

English (EN)

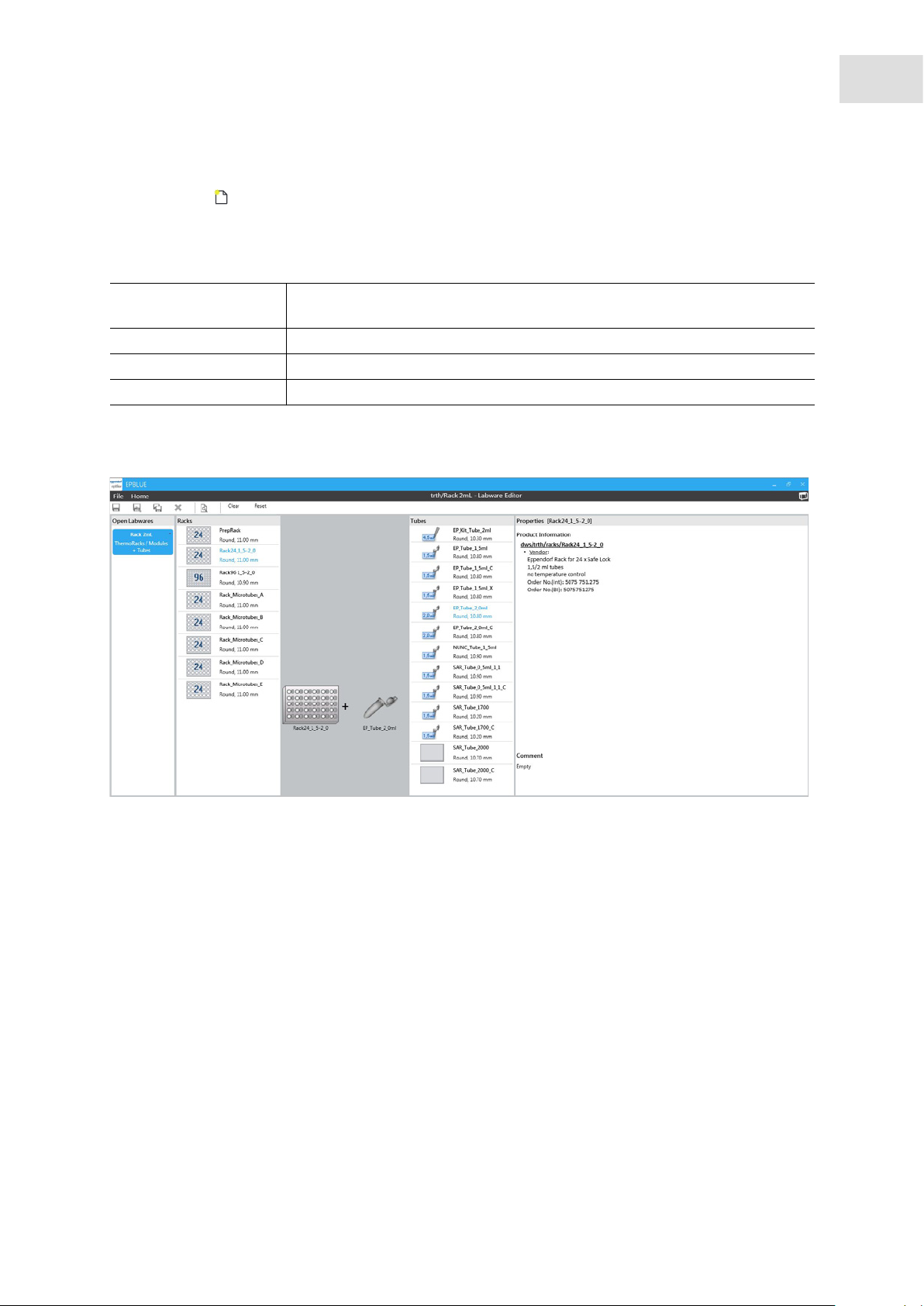

8 epBlue Labware Editor - Creating and managing labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.1 Overview of labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.2 Managing labware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.1 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2.2 Deactivating and activating labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.2.3 Delete labware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.2.4 Import labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8.2.5 Export labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.2.6 Viewing the properties of the labware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.2.7 Setting the bottom tolerance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.3 Creating labware combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.3.1 Creating a labware combination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.3.2 Creating a labware combination based on existing labware . . . . . . . . . . . . . . . . . . . 100

8.3.3 Equipping the racks, thermoracks and Reservoir Rack modules with individual

vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.3.4 Equipping the Reservoir Rack with reservoirs and Reservoir Rack modules . . . . . . . 103

8.4 Labware library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.4.1 Loading labware definitions from the Eppendorf webpage . . . . . . . . . . . . . . . . . . . . 104

8.4.2 Requesting labware definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.4.3 Adding a labware definition to the labware library. . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5 Labware types in epBlue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5.1 Reaction vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5.2 epT.I.P.S. Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5.3 MTP plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.5.4 PCR plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.5 Filter plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.6 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.7 Rack 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.8 Rack LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.9 ReservoirRack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.5.10 Reservoir Rack Module TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.5.11 Thermoracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.5.12 Tip Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.5.13 Thermoadapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.5.14 Thermoblocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5

9 epBlue simulation - Simulating applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.1 Simulating the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.1.1 Starting a simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.1.2 Controlling the simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Page 6

Table of contents

epBlue™ with MultiCon

6

English (EN)

10 epBlue ID - Working with ID tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.1 ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.1.2 Input lists and result lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.2 Commands for working with IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.3 Reading IDs into epBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.4 Managing ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.4.1 Displaying ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.4.2 Filtering and sorting ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.4.3 Import ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.4.4 Export ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.4.5 Delete ID lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.5 Making the basic settings for the epBlue ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.5.1 Making the basic settings for the epBlue ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11 epBlue settings - Checking components and making the basic settings . . . . . . . . . . . . . . . . . . . . 119

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.2 Levelsensor options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

11.3 Tool interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.3.1 Lock the tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

11.3.2 Unlocking the tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

11.4 Dosing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

11.4.1 Reading out the tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

11.5 Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11.5.1 Moving the gripper arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11.6 Temperature control unit X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11.7 Thermomixer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11.7.1 Checking the mixing function of the thermomixer. . . . . . . . . . . . . . . . . . . . . . . . . . . 124

11.7.2 Checking the temperature control of the thermomixer . . . . . . . . . . . . . . . . . . . . . . . 125

11.8 Magnetic separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

11.9 UV lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

11.9.1 Decontaminating the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

11.10 HEPA air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.10.1 Switching on the HEPA air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

11.10.2 Switching off the HEPA air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

11.11 Setting the barcode reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

12 epBlue settings - Creating and managing users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.1 Managing the user accounts as an administrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.1.1 Logging in as administrator in epBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.1.2 epBlue user groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

12.1.3 User accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

12.1.4 Assigning a new password for a user account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

12.2 Managing your own user account. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

12.2.1 Signing into and out of the user account . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

12.2.2 Changing the password of your own user account. . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Page 7

Table of contents

epBlue™ with MultiCon

English (EN)

13 epBlue Settings - Saving data and creating print templates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

13.1 Data backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

13.1.1 Securing the database. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

13.1.2 Creating an automatic backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

13.1.3 Restoring the database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

13.2 Changing the device name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

13.3 Print templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

13.3.1 Create print templates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13.3.2 Saving print templates as default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13.3.3 Delete print templates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

14 epBlue - Software error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

15 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

15.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

7

Page 8

Table of contents

epBlue™ with MultiCon

8

English (EN)

Page 9

Operating instructions

epBlue™ with MultiCon

English (EN)

1 Operating instructions

1.1 Using this manual

Your epMotion operating manual consists of hardware instructions and software instructions. Short

instructions are available for optional software enhancements.

The operating manual is part of the product.

9

The current version of the operating manual can be found on our webpage:

Read the operating manual in full before using the device.

Store the operating manual at an easily accessible location.

The device may only be transferred with the operating manual.

If the operating manual is lost, replace it immediately. Please contact Eppendorf AG for further details.

www.eppendorf.com.

1.2 Danger symbols and danger levels

The safety precautions in these instructions have the following danger symbols and danger levels:

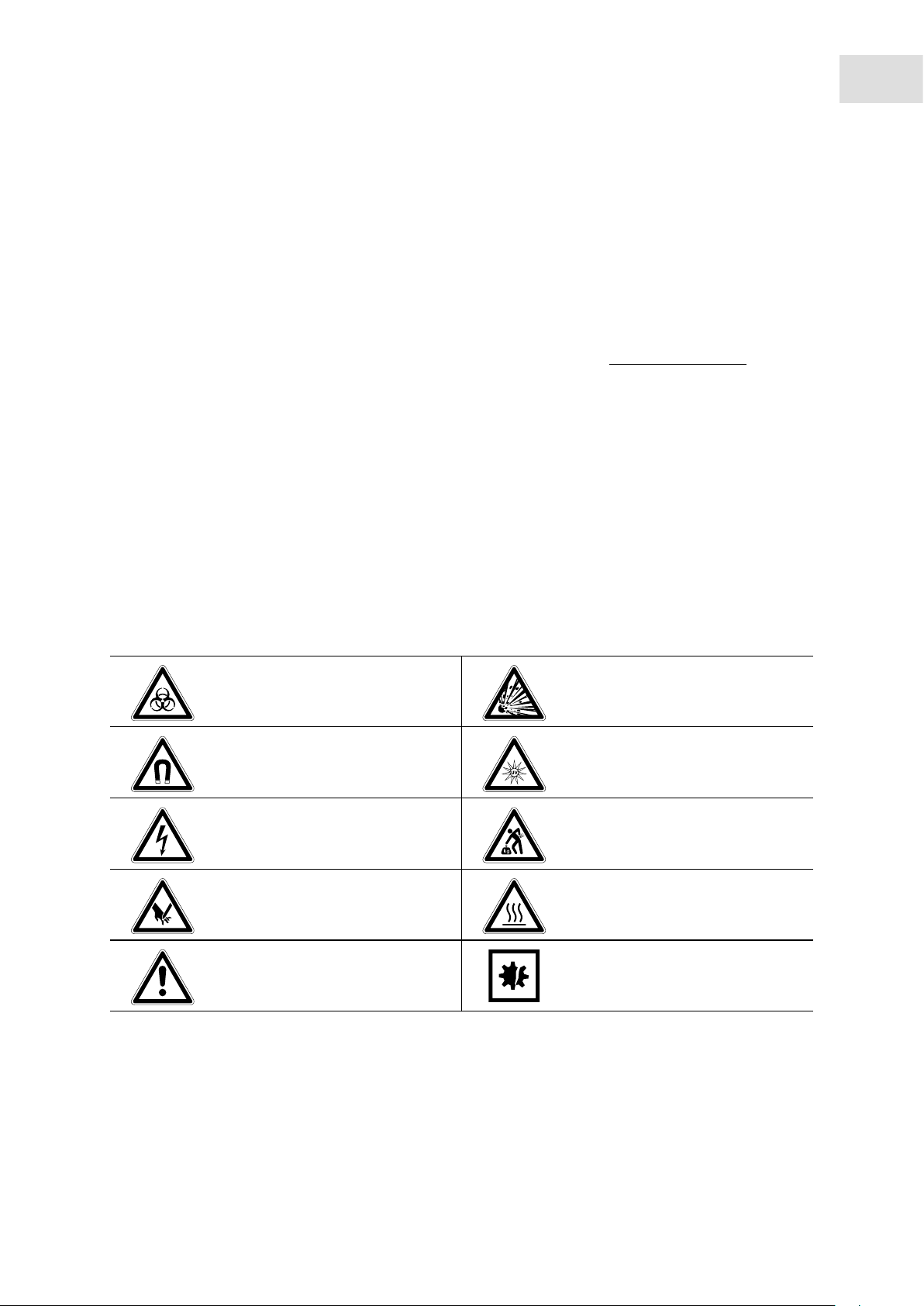

1.2.1 Danger symbols

Biohazard Explosion

Strong magnetic field UV radiation

Electric shock Heavy loads

Cuts Hot surface

Hazard point Material damage

Page 10

10

Operating instructions

epBlue™ with MultiCon

English (EN)

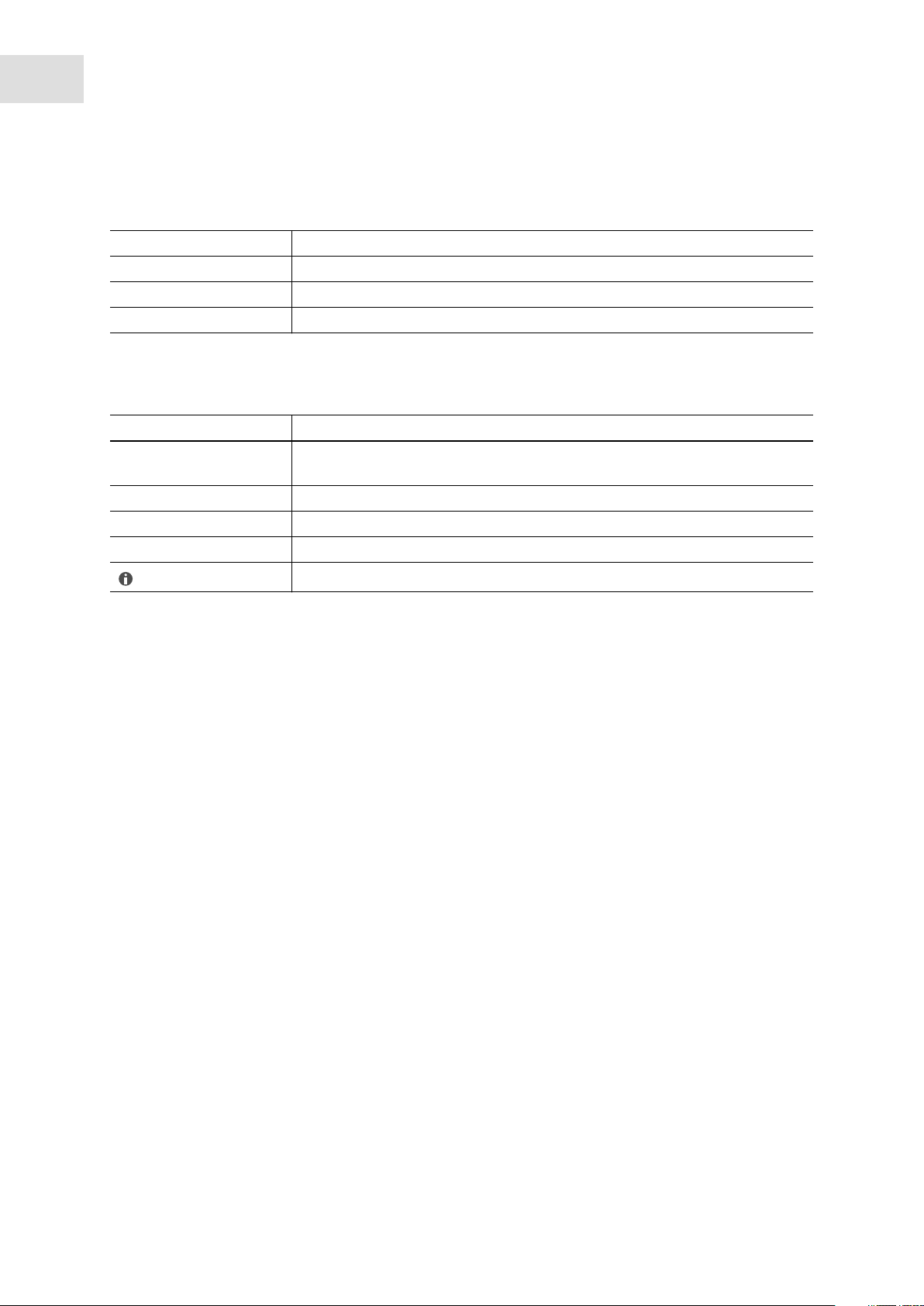

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WARNING Can lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

1.3 Symbols used

Depiction Meaning

1.

2.

Actions without a specified order

• List

Text Display text or software text

Actions in the specified order

Additional information

Page 11

1.4 Abbreviations used

BCR

Bar code reader

CSV

Comma Separated Value

DNA

Deoxyribonucleic acid

DWP

Deepwell plate

epT.I.P.S.

eppendorf Totally Integrated Pipetting System

Operating instructions

epBlue™ with MultiCon

English (EN)

11

HEPA

High Efficiency Particulate Air (filter)

LH

Liquid Handling

LIMS

Laboratory Information Management System

MTP

Microplate

PCR

Polymerase chain reaction

PDF

Portable Document Format

TMX

Thermomixer

USB

Universal serial bus

UV

Ultraviolet radiation

VAC

Vacuum unit

Page 12

12

Operating instructions

epBlue™ with MultiCon

English (EN)

1.5 Glossary

A

Administrator

User who has the rights to administrate epBlue.

Application

Program for a specific application. An application includes the procedure and the equipping of the

worktable.

B

Bar code reader

Device for scanning a barcode.

Blow-out

Movement of the piston. The liquid in the pipette tip will be dispensed after the pipetting step.

C

CleanCap

Optional epMotion equipment. The CleanCap includes a HEPA air filter and at least one UV lamp.

Command

A step in a procedure. Various parameters can be set for commands. Each command triggers an action,

e.g., the transport of liquids.

CSV file

Text file for exchanging structured information.

D

Destination labware

Rack or plate with destination positions.

Destination location

Labware that liquid is dispensed into exclusively during the application.

Dispensing tool

Tool that aspirates and dispenses liquid. Single-channel dispensing tools and eight-channel dispensing

tools are available for various volume ranges.

E

Entry list

ID list assigned to a labware at the start of the application. The ID list contains the name of the labware, IDs

for the positions of the labware and descriptions. epBlue imports and exports the IDs of the labware by

means of entry lists. epBlue can process entry lists in the formats CSV and XML.

Page 13

Operating instructions

epBlue™ with MultiCon

English (EN)

epBlue

Software for creating and administering applications and labware. The epMotion is controlled using the

software. The software includes a user administration system. Modular extension of epBlue is possible.

With the epBlue ID module you can track samples during the application. The labware is labeled with IDs

for this purpose. The sample tracking is documented automatically.

epT.I.P.S. Motion

epMotion pipette tips. Only epT.I.P.S.® Motion can be used on the epMotion. epT.I.P.S.® Motions are

available with or without a filter.

F

Filling volume

Maximum liquid volume of a labware. The epMotion uses the gripper to transport the labware up to the

filling volume. The epMotion aspirates liquid from the labware up to the filling volume. The filling volume is

higher than the working volume.

13

G

Gripper

Tool that transports labware.

H

Height adapter

Adapter for low labware. The height differences among the labware will be offset to decrease the tool

holder paths, thereby decreasing the run time of the application as well.

HEPA air filter

Air filter. The air filter prevents particles such as dust and germs from the environment entering the

epMotion work room.

I

ID

Character string which is used by the epBlue ID module to identify the labware.

Input list

ID list with information on source labware. The input list contains the IDs of the source positions. epBlue

creates an input list for each source labware for which ID tracking is active.

Intermediate labware

Rack or plate with intermediate positions.

Intermediate location

Position in the labware that is both source and destination of liquid transfers.

Page 14

14

Operating instructions

epBlue™ with MultiCon

English (EN)

L

Lab administrator

User who has the rights to administrate applications and labware.

Labware

Racks, plates, tips, etc. which are placed on the worktable.

Location

Area where labware is placed on the worktable.

M

MagSep

System consisting of the magnetic finger module, thermomixer and PrepRack and reagents for nucleic acid

preparation with the epMotion.

MultiCon

epMotion operator panel. You can control your epMotion using the control unit and the epBlue software.

P

Pattern

Pattern in which liquid is aspirated and dispensed. Patterns are defined in a transfer command. Patterns are

defined as regular patterns and irregular patterns. Patterns are independent in x-direction and y-direction.

Procedure

Sequence of commands that are executed one after the other. Part of an application.

R

Rack

Mount for tubes or pipette tips.

Remaining volume

Volume that cannot be aspirated from a vessel. The distance from the pipette tip to the vessel base, defined

in the software, and the defined immersion depth of the pipette tip in the liquid, must be observed.

Therefore, the pipette tip cannot aspirate the volume. The remaining volume depends on the vessel

geometry.

Reservoir

Reservoirs are used to hold reagents. Reservoirs are hung in a ReservoirRack or placed directly on the

worktable.

Result list

ID list with information on destination labware and intermediate labware. The result list contains the IDs of

destination positions and intermediate positions. epBlue creates a result list for each destination labware

and intermediate labware for which ID tracking is active.

Page 15

Operating instructions

epBlue™ with MultiCon

English (EN)

S

SafeRack

Rack with ep.T.I.P.S. Motion pipette tips. The SafeRack features a partition that prevents the contamination

of adjacent tips. Use the SafeRacks if you would like to use tips several times.

Source labware

Rack or plate with source positions.

Source location

Position in the labware that liquid is aspirated from exclusively during the application.

T

Thermal module

Thermal module for labware that is integrated in the worktable.

15

Thermoadapter

Heat-conductive adapter for holding plates.

Thermoblock

Thermoadapter that is permanently connected to a PCR plate or PCR vessel.

Thermorack

Temperable rack for smaller vessels, e.g., Safe-Lock tubes for 0.5 mL, 1.5 mL or 2 mL.

V

Vacuum unit

The vacuum unit uses a vacuum to suck liquid from a filter plate. The vacuum unit consists of a vacuum

manifold, vacuum pump and Vac Frame.

Vessel

Tube or single well of a plate.

W

Working volume

Liquid volume for a labware. The epMotion fills a vessel with low levels of contamination up to the working

volume. The working volume is less than the filling volume.

Worktable

epMotion work surface where labware and tools are placed. In the software, the epMotion worktable is

shown as the epBlue worktable.

Page 16

16

Operating instructions

epBlue™ with MultiCon

English (EN)

Page 17

Product description

epBlue™ with MultiCon

English (EN)

2 Product description

2.1 Features

The epBlue software is used to control the epMotion. epBlue consists of several components.

Which modules are available depends on the features of your epMotion and the specification of the

software.

2.1.1 epBlue

Module Description Operating manual

Application Editor • Create applications.

• Manage applications.

Application Runner • Execute applications. (see epBlue Application Runner - Carrying

Application Simulator • Simulate applications. (see epBlue simulation - Simulating

ID list management • Manage ID lists. (see epBlue ID - Working with ID tracking

Labware Editor • Manage labware. (see epBlue Labware Editor - Creating and

Log Viewer • Display and print logs. (see epBlue LogViewer - Managing logs on

Settings • Check components of the device.

• Perform basic settings.

• User administration.

• Backup database.

• Perform basic settings for ID

tracking.

(see epBlue Application Editor - Creating

and editing applications on p. 39)

(see epBlue Application Editor - Managing

applications and folders on p. 85)

out the application on p. 25)

applications on p. 109)

on p. 111)

managing labware on p. 91)

p. 37)

(see epBlue settings - Checking

components and making the basic settings

on p. 119)

(see epBlue settings - Creating and

managing users on p. 131)

(see epBlue Settings - Saving data and

creating print templates on p. 139)

(see epBlue ID - Working with ID tracking

on p. 111)

17

Page 18

18

Product description

epBlue™ with MultiCon

English (EN)

2.1.2 Assistants

Assistants are programs for a specific application. Assistants are optionally available and described in

separate operating manuals. The following assistants are available for epBlue:

Prep Assistant

• Nucleic acid preparation with Eppendorf MagSep kits. After that, a PCR setup can be performed.

PCR Assistant

• Create PCR master mixes and dilution series for quantification standards, normalization of sample

concentrations, and setting up PCR reactions.

LH assistant

• Create Liquid Handling applications such as assay setup, pooling and reformatting of samples; cherry

picking.

Page 19

epBlue™ with MultiCon

3 Operation

3.1 Starting and exiting epBlue

3.1.1 Starting epBlue

Prerequisites

• The device does not show any sign of external damage.

Switch on the epMotion using the mains/power switch.

Switch on the MultiCon.

To start epBlue, double-click on the epBlue symbol on the desktop.

Alternatively, open the Windows start menu and select Programs >Eppendorf > epBlue.

epBlue is started. The login screen appears.

3.1.2 Starting epBlue for the first time

Operation

19

English (EN)

Prerequisites

• epMotion and MultiCon were installed by a service technician.

• epBlue has been started (see p. 19).

• epBlue displays the login screen.

1. Log in as an administrator (see Logging in as administrator in epBlue on p. 131).

2. Create user accounts (see Creating a user account on p. 134).

3. Log off as administrator.

4. Log on to epBlue as a user (see Logging in as User. on p. 19).

3.1.3 Logging in as User.

Prerequisites

• epBlue has been started (see p. 19).

• epBlue displays the login screen.

• The administrator has created a user account for the user.

1. Enter the name of the user account and the password.

If you have forgotten your password, please contact your administrator (see p. 136).

2. Press the Login button.

The epBlue start screen appears. The symbols that are displayed depend on your user rights and the

features of your epMotion.

Page 20

20

Operation

epBlue™ with MultiCon

English (EN)

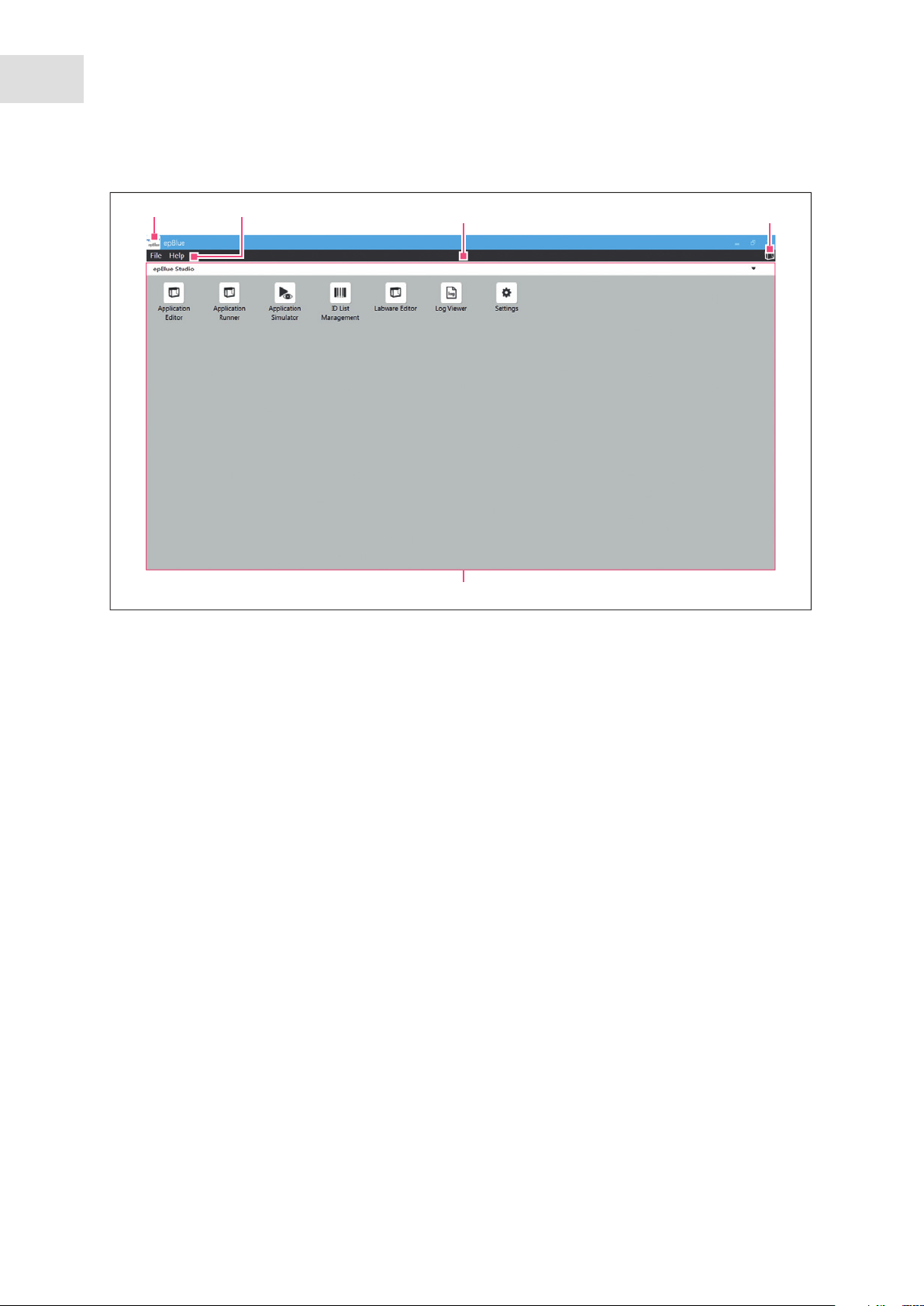

Abb. 3-1: epBlue start screen

1

2

3

4

5

Fig. 3-1: epBlue start screen

1 Eppendorf menu

Exit the program.

2 Menu bar

Contains functions that can be accessed in all

4 Status area

epMotion status.

5 Working range

Contents and applications.

applications.

3 Information area

Contains information on the open file.

3.1.4 Logging off as a user

You can only log off if all applications started from your user account have been exited. If you want to log

off before completing an application, the application has to be ended manually.

Prerequisites

• All applications have been ended and saved.

• Changes to the labware have been saved.

In the File menu, select the Log off entry.

You are logged out of your account. The login screen appears.

Page 21

Operation

epBlue™ with MultiCon

English (EN)

3.1.5 Exiting epBlue and switching off MultiCon

1. In the Eppendorf menu, select Close.

2. When the program is ended, shut down MultiCon.

3. Switch off the epMotion using the mains power switch.

3.2 Initial steps

3.2.1 Using the touch screen and mouse

You can operate the MultiCon by using the touch screen or a USB mouse.

Connect the mouse to a USB interface on the MultiCon.

Tab. 3-1: Touch screen/mouse comparison

Touch screen Mouse

Tap Click using the left mouse button

Tap and hold 2 s Click using the right mouse button

Drag Drag with the left mouse button pressed down

Tap twice Double click using the left mouse button

21

3.2.2 Using the screen key pad

Enter the numbers and letters using the screen key pad.

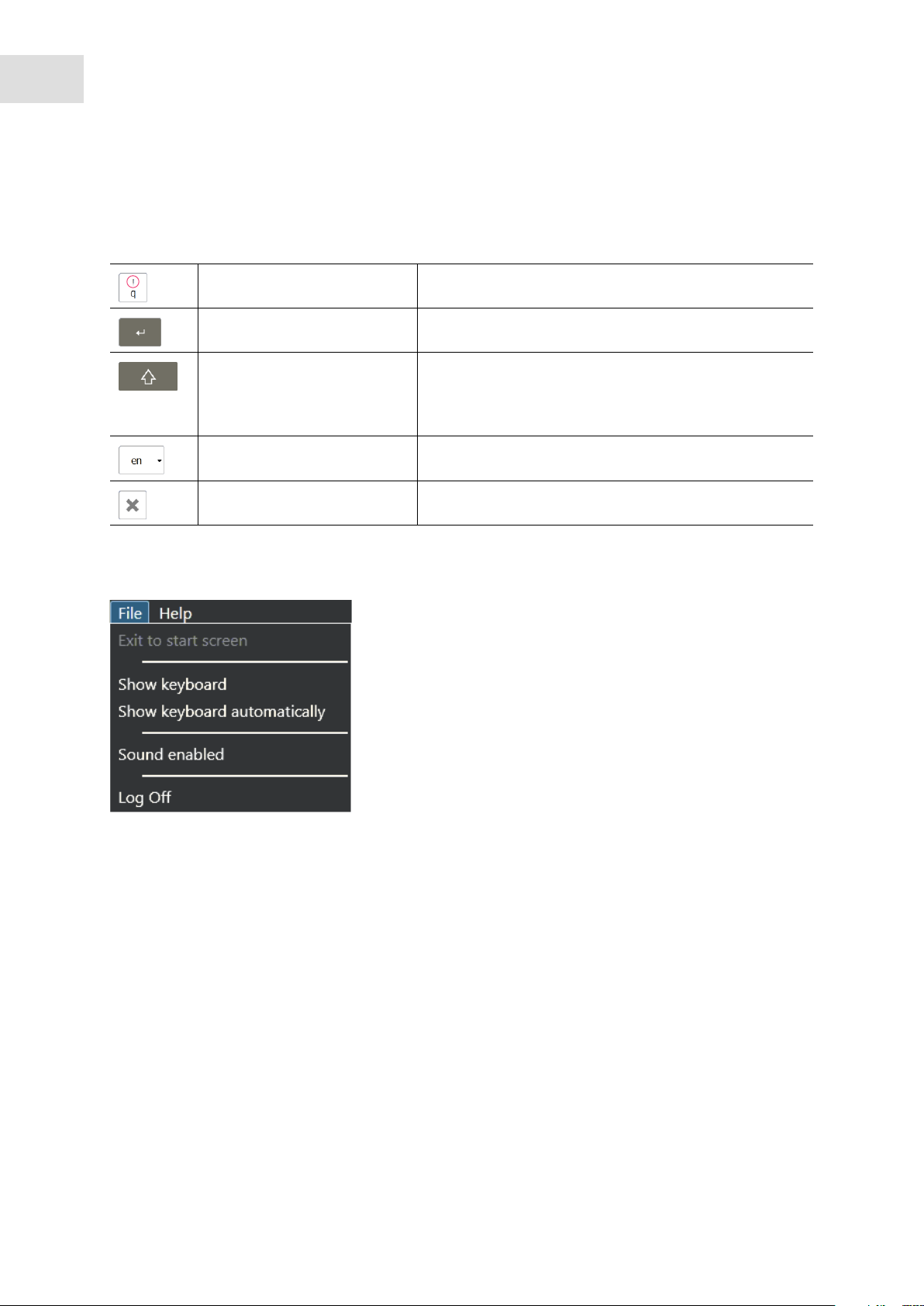

Abb. 3-2: Screen key pad

Fig. 3-2: Screen key pad

Automatically show the screen key pad.

epBlue automatically shows a key pad if you have selected an input field.

Manually show the screen key pad.

In the File menu, select the Show keyboard entry.

Page 22

22

Operation

epBlue™ with MultiCon

English (EN)

Switch the automatic display of the screen key pad on and off.

In the File menu, select the Show keyboard automatically entry.

Tab. 3-2: epBlue key combinations

Enter special characters.

Press the letter key for 2 s.

Confirm your entry.

Switch between lowercase

letters and capital letters.

Switch the key pad.

Show the screen key pad.

3.2.3 File menu

Abb. 3-3: File drop-down menu

Press the key once.

To enter a capital letter, press the key once. Then press

the letter.

To switch the key pad to all capital letters, press the key

twice.

To switch between the English and German key pads,

press the key once.

Press the key once.

Fig. 3-3: File drop-down menu

Exit to start screen entry

Show the epBlue start screen.

Menu – Show keyboard

Manually show the screen key pad.

Menu – Show keyboard automatically

Switch the automatic display of the screen key

pad on and off.

Sound enabled entry

Switch the system sound on or off.

Log Off entry

User is logged out. The login window appears.

Page 23

Abb. 3-4: Help drop-down menu

Fig. 3-4: Help drop-down menu

Operation

epBlue™ with MultiCon

English (EN)

23

Device manuals entry

Open the operating manual of the device.

About epBlue entry

Show the epBlue version.

Software manuals entry

Open the operating manual of the software.

3.2.4 Status area

The status area is located in the top right of the screen.

If you click on the epMotion in the status area, the following information will be displayed:

• Serial number of the epMotion

• Features of the epMotion

• Firmware version

• epMotion status

• Actual temperature of a thermal module or Thermomixer.

Example Info: C3:21°C. The thermal module in location C3 has a temperature of 21°C.

Page 24

24

Operation

epBlue™ with MultiCon

English (EN)

Page 25

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

4 epBlue Application Runner - Carrying out the application

This chapter describes how to carry out an application on the epMotion.

4.1 Opening an application

Abb. 4-1: Selecting an application

25

English (EN)

Fig. 4-1: Selecting an application

Prerequisites

• epMotion is ready for operation.

• Application Runner is started.

1. Select the application in the Select application area.

Recently used applications can be found in the Recently used area.

Open applications in the Select application area have a red padlock .

The Properties area displays the properties of the selected application.

2. Press the Next button.

The application is opened.

Page 26

26

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

4.2 Preparing the application run

4.2.1 Selecting the device

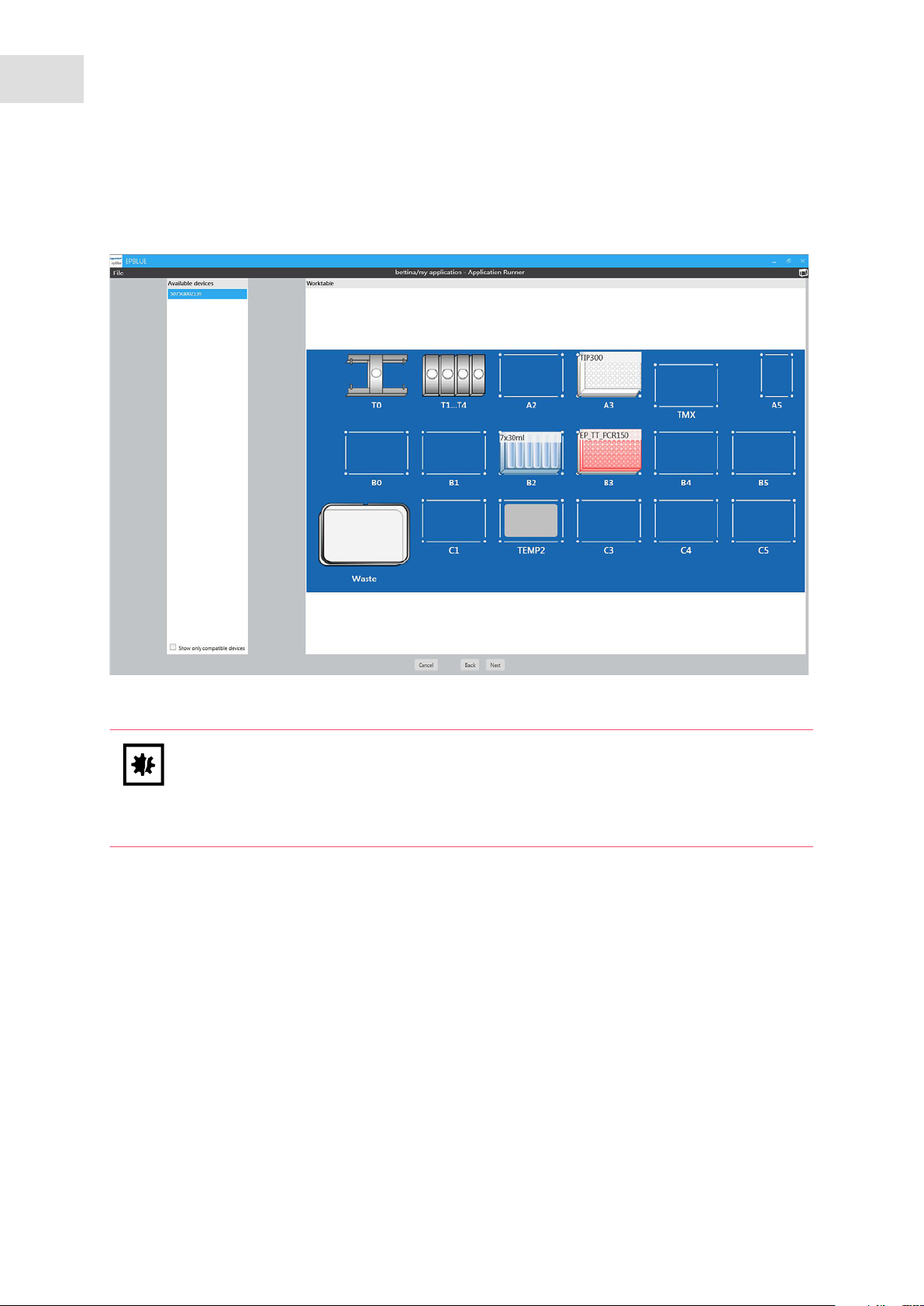

Abb. 4-2: Selection of an available device

Fig. 4-2: Selection of an available device

NOTICE! Tool collisions with incorrectly positioned labware.

Labware must be positioned on the epMotion worktable as defined in the application.

Tools and labware become damaged in a collision. A collision can lead to sample loss.

Check the positioning of the labware before starting the application.

In the Available devices area, the connected epMotion is displayed.

Prerequisites

epMotion is ready for operation.

1. Select the device for the application run.

2. Press the Next button.

Page 27

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

4.2.2 Entering the sample quantity

Abb. 4-3: Process control window

Fig. 4-3: Process control window

The window Process control appears if the sample quantity in the application is variable.

1. Enter the sample quantity for the current run.

2. Press the OK button.

27

English (EN)

4.2.3 Setting the HEPA air filter and the UV lamp

Abb. 4-4: Setting the parameters for the HEPA air filter and the UV lamp

Fig. 4-4: Setting the parameters for the HEPA air filter and the UV lamp

If your epMotion is equipped with a HEPA air filter and UV lamp, you can define the settings for the HEPA

air filter and the UV lamp.

Activate or deactivate the HEPA air filter.

Define whether a decontamination is to be carried out before the application.

The worktable may only be decontaminated if no labware or tools are present on the worktable.

Page 28

28

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

4.2.4 Placing the labware on the epMotion worktable

Position the labware on the epMotion worktable according to the application.

Additional information on positioning the labware can be found in the hardware operating manual.

4.2.5 Setting the run parameters for the optical sensor

If you have the epBlue ID module, the Use bar codes checkbox will appear in the window.

In the application, you defined the application parameters for the optical sensor. You can enter run

parameters to use other settings of the optical sensor for an individual run. The run parameters overwrite

the application parameters for this run only (see Optical sensor on p. 80).

Abb. 4-5: Setting the run parameters

Fig. 4-5: Setting the run parameters

Use Barcodes checkbox

Activate ID tracking.

Detect volumes radio button

Activate the Detect volumes function. The

parameters set in the application for the labware

are used.

Use required minimum volumes radio button

epBlue assumes that all vessels are filled with the

minimum required volume for this run. Use this

function for dry runs.

Input volumes manually radio button

Deactivate the Detect volumes function. You have

to enter the sample volume manually.

Detect tips checkbox

Activate the Detect tips function.

Check labware placement checkbox

Activate the Check labware placement function.

Page 29

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

1. Set the functions of the optical sensor.

2. Activate ID tracking, if required.

3. Press the Run button.

4.2.6 Setting the ID tracking parameters

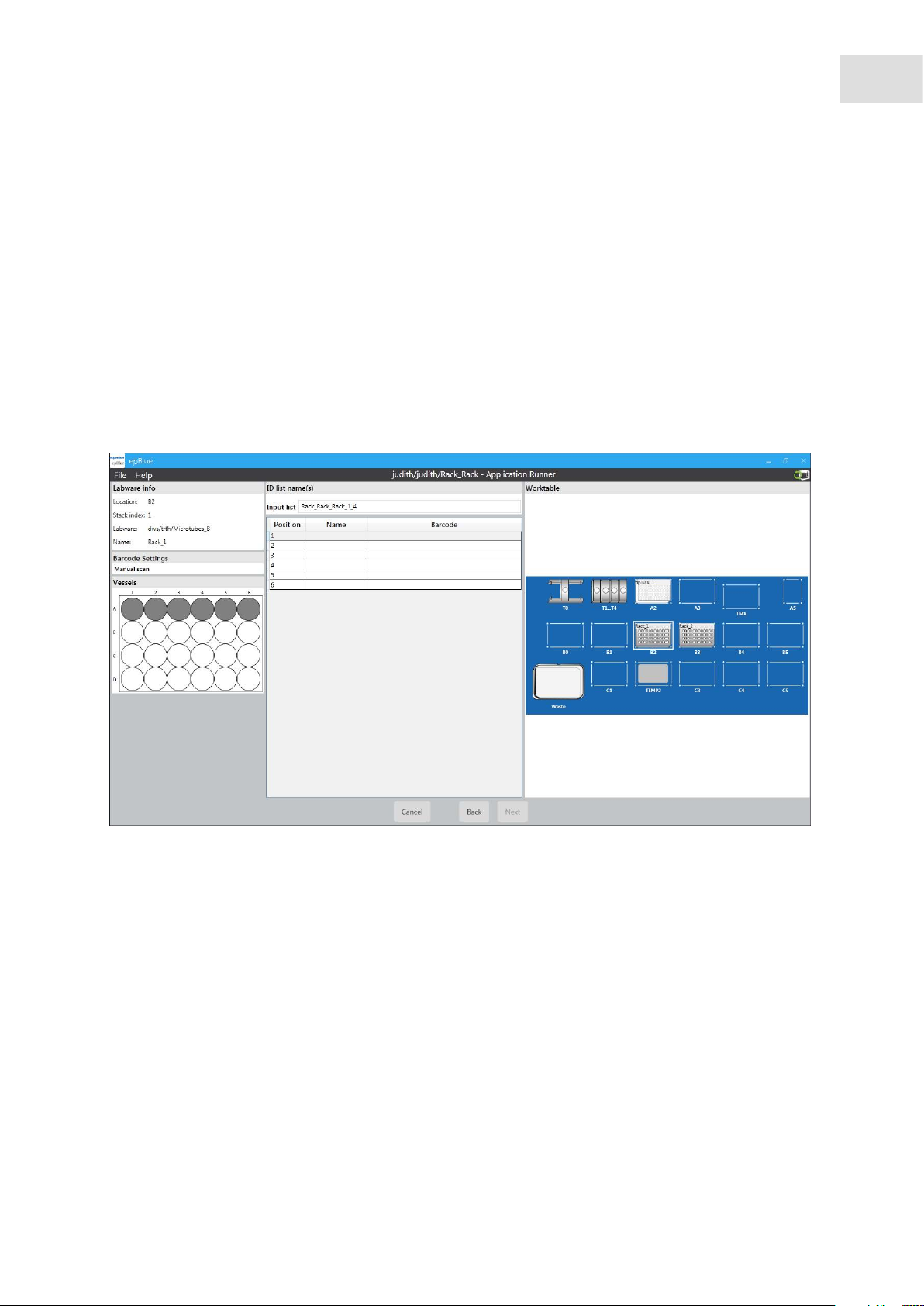

If you have the epBlue ID module and ID tracking is activated for the labware, a window appears. In the

labware settings, you defined whether the IDs are entered manually or read in via the entry list. The

window displays the corresponding option.

4.2.6.1 Entering IDs manually

Abb. 4-6: Entering IDs manually

29

Fig. 4-6: Entering IDs manually

Prerequisites

• Labware ID tracking is activated.

• The manual scan option is activated for the labware.

1. Press the Next button.

You are prompted to enter the IDs for the labware. The labware is marked with a red border.

2. Enter the name for the ID list that is created during the application for this labware in the List name

field.

3. Read the ID with the barcode reader or enter it manually.

4. If 2 IDs are to be assigned for a reagent, 2 entry fields appear. If you are using only one ID, press the

Use only one ID button.

Page 30

30

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

5. Confirm your entry with the OK button.

6. Press the Next button to enter the ID for the next labware.

7. When all IDs have been entered, the application starts.

4.2.6.2 Reading the IDs with an entry list

Prerequisites

• Labware ID tracking is activated.

• The Entry list option is activated for the labware.

1. Press the Next button.

You are prompted to enter the IDs for the labware. The labware is marked with a border.

2. Press the Select ID list button.

The Select ID list window appears.

By default, the window shows all compatible entry lists.

3. Import the entry list, if required (see p. 115)

4. Select the entry list to be imported.

5. Press the OK button.

6. Enter the ID for the selected position.

epBlue compares the entered ID with the ID of the entry list.

7. If the ID does not correspond to the ID of the entry list, an error message appears. Correct the

corresponding ID.

8. When all IDs have been entered, the application starts.

Page 31

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

4.2.7 Entering the filling level of the labware

4.2.7.1 Checking the filling level automatically

If the Detect volumes function is active, the optical sensor checks the filling level after the start.

If the following problems occur, a dialog window appears:

• Filling level too low.

• Filling level too high.

• Filling level cannot be correctly detected.

Abb. 4-7: Checking window

31

English (EN)

Fig. 4-7: Checking window

Maximum volume

Filling level of the vessel.

Minimum volume

Volume required to remove the set liquid

quantity.

Calculated volume

Volume in the vessel, calculated using vessel

data and the liquid level.

Repeat scan button

Abort button

Aborts the application.

User input button

Manual volume entry.

Accept level and continue button

Accept the displayed calculated volume.

µL input field

Manually select the volume if the User Input

button has been selected.

Repeat Detect volumes.

NOTICE! Dispensing error due to refilling of vessels.

The optical sensor only checks the level of the vessels at the specified location.

Only change the volume of the vessels at the specified location.

Do not change the volume of the vessels at other locations.

If the Calculated volume is larger than the Maximum volume, remove liquid from the vessel.

If the Calculated volume is smaller than the Minimum volume, add liquid to the vessel.

The optical sensor cannot carry out a detection if there is an air bubble in the liquid. Remove the air

bubble. Select Repeat scan to repeat the detection.

Page 32

32

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

4.2.7.2 Entering the filling level manually

If the Detect volumes function is not active, you have to enter the filling level manually after the start.

Abb. 4-8: Entering the filling level

Fig. 4-8: Entering the filling level

Labware info area

Information on the selected labware.

Liquid detection area

Optical sensor settings for the selected labware.

Off The filling level is not checked.

Random positons The filling level of the first, the

last, and of 8 randomly selected vessels is

checked.

All used positions The filling level is checked in all

used positions.

Volume column

Enter the volume for the selected labware.

Page 33

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

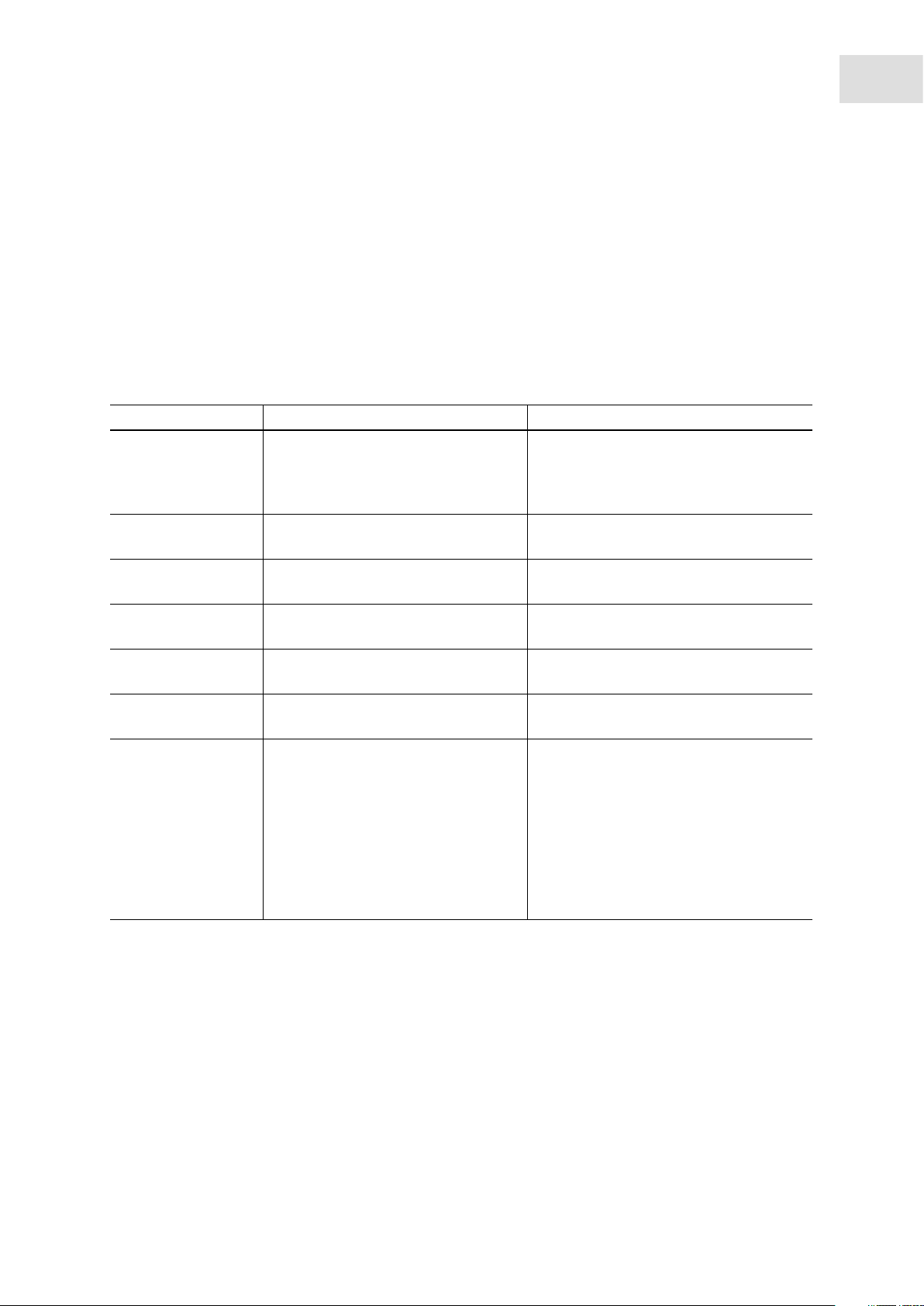

Tab. 4-1: Meaning of the columns in the Volume table

Column Meaning

Red border Entry of an invalid volume. Invalid volumes are volumes that are smaller than the

required volume or larger than the maximum volume of the labware.

Position Position of the labware on the worktable.

Minimum volume Volume that is required for this run.

Start Volume Actual volume in the labware.

Maximal Volume Maximum volume the labware can be filled with.

Proceed as follows:

Enter the filling volume into the Start Volume column.

To enter the same volume for the entire labware, click on the title in the Volume column.

Enter the run parameters of the optical sensor in the Liquid detection area, if necessary.

Press the Run button.

33

Page 34

34

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

4.3 Starting the application

Prerequisites

• The labware is positioned on the epMotion worktable.

• epMotion is ready for operation.

• The application run was prepared. (see p. 26)

Click on the Run button.

The application starts.

4.4 Controlling the application

Abb. 4-9: Running application

Fig. 4-9: Running application

Procedure area

Carrying out the application. The epMotion executes the

application until the end.

Executing the application step-by-step. The epMotion

executes the next step and then stops.

Pause. The application stops, but it will not be aborted.

Aborting the application. If you have stopped the

application using the button, the button is now

active.

Commands. The active command is

highlighted blue.

Worktable area

Worktable.

Remaining Runtime area

Status of the application/runtime of the

application/total time for the application.

Log area

Log.

Control the application with the buttons from the Control area.

Page 35

epBlue Application Runner - Carrying out the application

4.5 Ending the application

When the application run is finished, a message appears.

epBlue™ with MultiCon

English (EN)

35

Abb. 4-10: The application is finished

Fig. 4-10: The application is finished

Abb. 4-11: The application was canceled

Fig. 4-11: The application was canceled

1. To confirm the message press the OK button.

2. In the Application Runner window, press the Next button.

The final window appears. If your epMotion is equipped with a HEPA air filter and UV lamp, you can

activate the HEPA air filter and the UV lamp.

Abb. 4-12: Final window

Fig. 4-12: Final window

3. Activate the HEPA air filter, if necessary.

Prerequisites

The worktable of the device must be cleared completely before activating the UV lamp.

4. Activate the UV lamp, if necessary.

5. Press the Exit button to end the application.

Page 36

36

epBlue Application Runner - Carrying out the application

epBlue™ with MultiCon

English (EN)

Page 37

5 epBlue LogViewer - Managing logs

The chapter also describes how to view and print application logs.

5.1 Displaying protocols

Abb. 5-1: Logs window

Fig. 5-1: Logs window

epBlue LogViewer - Managing logs

epBlue™ with MultiCon

English (EN)

37

Prerequisites

• The application was executed (see p. 34).

• The epBlue start screen is shown.

1. Click on the LogViewer symbol.

Select the folder in which the application is saved.

2. Select the log.

The log is opened.

Stored logs column

Logs saved for the selected application

Content area

Content of the opened log

Page 38

38

epBlue LogViewer - Managing logs

epBlue™ with MultiCon

English (EN)

5.2 Saving the protocol as a PDF file

Prerequisites

1. Click on the symbol.

The print preview opens.

2. Check the layout and set up the page.

3. Save or print the document as a PDF file.

4. Close the window.

Tab. 5-1: Symbols in the print preview

Search in the document. Show the first page.

Print the document Show the previous page.

Page setup. Show the next page.

Scale the document. Show the last page.

Zoom in the view. Create a PDF.

Set the zoom factor. Close the view.

Zoom out the view.

Page 39

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6 epBlue Application Editor - Creating and editing applications

This chapter describes how to create and edit applications in epBlue.

6.1 Overview

Applications are programmed processes in epBlue. An application consists of equipping the worktable and

a sequence of commands. Each command triggers a specific action.

Applications are created in a fixed order:

1. Create an empty application (see p. 40).

2. Position labware and define the application parameters of the labware (see p. 41).

3. Activate ID tracking of the labware (see p. 44).

4. Define the procedure (see p. 45).

5. Check the application (see p. 47).

6. Simulate the application (see p. 109).

39

6.2 Creating an application

6.2.1 Menu bar

Abb. 6-1: Application Editor menu bar.

Fig. 6-1: Application Editor menu bar.

Saving the application.

Saving the application for another worktable.

Saving all applications.

Closing the application.

Cutting the application.

Copying the application.

One step back.

One step forward.

CSV

Import CSV file.

Printing the application.

Checking the application.

Go to simulation.

Pasting the application.

Deleting the application.

Go to Application Runner.

Page 40

40

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.2.2 Creating an empty application

Abb. 6-2: Start screen of the Application Editor

Fig. 6-2: Start screen of the Application Editor

Prerequisites

• The Application Editor is open.

1. Select the folder in which the application is to be saved.

2. Click on the symbol in the menu bar.

The Create new application window appears. epBlue detects the connected device.

3. Enter the name and description of the application.

4. Close the window using the Create button.

You have created an empty application. The Worktable window of the application opens.

6.2.3 Copying applications

You can create new applications by copying and changing existing applications.

The Eppendorf folder contains applications defined by Eppendorf AG. These applications

cannot be executed or changed. They are used as templates and examples.

In order to use applications from the Eppendorf folder, copy the corresponding application

to your folder.

To copy an application (see p. 86).

Page 41

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.2.4 Saving an application

To save an application, click on the symbol in the toolbar.

To save an application under a new name, click on the symbol in the toolbar.

To save all open applications, click on the symbol in the toolbar.

6.2.5 Positioning labware

6.2.5.1 Positioning the labware on the epBlue worktable

Labware can only be positioned at specific locations. Information on positioning the labware can be found

in the hardware operating manual.

Abb. 6-3: Positioning the labware on the epBlue worktable

41

Fig. 6-3: Positioning the labware on the epBlue worktable

Labware Category column

Overview of all labware types.

Worktable area

epBlue worktable with positioned labware.

Switch to procedure button

To go to the Procedure window, press the

Switch to procedure button.

Labware area

Labware that can be positioned on the epBlue

worktable.

Properties area

Properties of the selected labware.

Placed Labware column

Labware positioned on the epBlue worktable.

Trash

Delete the selected labware from the epBlue

worktable.

Page 42

42

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

Prerequisites

• Labware combinations have been created for reaction vessels (see p. 92).

• The application is open (see p. 25).

• The Worktable window is open.

1. Select labware from the Labware area.

2. Draw the labware to the desired position of the epBlue worktable.

If the labware cannot be positioned at this location, the location is marked in red.

6.2.5.2 Deleting positioned labware from the epBlue worktable

There are several options to delete labware from the epBlue worktable.

Selecting the labware

Activate the checkbox for the corresponding labware in the Placed labware column.

Alternatively, select the labware with the mouse.

Deleting the labware

Drag the selected labware into the trash with the mouse.

Alternatively, click on the symbol in the menu bar.

Or click on the selected labware with the right mouse button and select the Delete function in the

context menu.

6.2.5.3 Stacking labware

The gripper stacks and transports labware. The gripper is required to stack labware or to unstack a stack

during an ongoing application.

You can stack a maximum of 5 plates on the worktable. You can stack a plate on a height adapter. The

maximum stacking height is 126 mm. Stacked labware must have the same properties, e.g. name,

geometry, and bottom tolerance.

The gripper only transports one part at a time. The gripper can stack plates or unstack a stack of plates.

Liquids cannot be transferred in a plate stack.

Functions of the optical sensor in case of stacked plates

• The Check labware placement function is available.

• The Detect volumes function is not available.

You can stack the following plates:

• EP_pDNA_96_MTP

• EP_TT_PCR_150

• EP_TT_PCR_40

• EP_DWP_1200

• EP_pDNA_96_DWP

• EP_DWP_200

Page 43

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

• EP_DWP_2000

• EP_DWP_1000

• EP_DWP_500

• EP_MTP_384

• EP_MTP_96

• EP_MTP_UV_VIS_96

On the vacuum unit, you can stack 4 labware components. Information on the vacuum unit can be found in

the hardware operating manual.

Plates that are stacked may only be filled up to the working volume.

Abb. 6-4: Stacking labware on the epBlue worktable

43

Fig. 6-4: Stacking labware on the epBlue worktable

Proceed as follows to stack labware at a location.

1. Place lower labware at one location.

2. Place upper labware at the same location.

The Placed labware column shows, which labware is placed in the epBlue worktable locations.

The number behind the designation shows how many parts have been stacked at this location. Example:

pcr384_3. Only 3 plates have been stacked.

Page 44

44

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.2.6 Defining the application parameters of the labware

You can change the properties of each labware used.

Abb. 6-5: Properties window

Fig. 6-5: Properties window

To change the properties of a labware, double click on the labware.

Alternatively, select the labware and go to the Properties menu with the right mouse button or click on

the Properties button.

The Properties window appears.

Set the properties for the filling level detection of the selected labware.

A description of the properties for the optical sensor (see Optical sensor on p. 80).

6.2.7 Activating ID tracking of the labware

In order for epBlue to create an ID list for a labware, ID tracking of the labware must be active.

ID tracking is activated separately for each labware. To track IDs activate ID tracking for source labware,

intermediate labware, and destination labware.

Prerequisites

• The application is open.

• The Worktable window is open.

Select the option for ID tracking.

The following options are available for ID tracking:

• Manual scan: Enter the ID manually or read it with the barcode reader.

• Entry list: Select ID list. To check the ID list enter the first position of the list or the list ID when starting

the application.

• None: No ID is assigned to the labware.

Page 45

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.2.8 Defining procedures

A procedure is a defined sequence of commands that epMotion executes during an application.

Commands are described in the Commands chapter (see p. 47).

The first command of each procedure is the Procedure Start command. The Procedure Start command is

created automatically and cannot be deleted. The Procedure Start command shows the epBlue worktable at

the start of the application. The Procedure Start command does not influence the application.

The software does not include a command for aspirating pipette tips. The user defines which pipette tips

will be used in one command. The user must provide for the corresponding pipette tips on the worktable.

The user defines the dispensing tool with each command. Tools are picked up according to the command

parameters.

Abb. 6-6: Creating a procedure for an application

45

Fig. 6-6: Creating a procedure for an application

Commands column

Available commands.

Procedure column

Sequence of commands. The commands are

executed in the order displayed.

Worktable

The state of the worktable during the execution of

the selected command.

Options area

Parameter of the selected command.

Page 46

46

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

Prerequisites

• The application is open (see p. 25).

• Labware is positioned on the worktable (see p. 25).

• The Procedure window is open.

6.2.8.1 Inserting a command

1. Select a command from the Commands column.

2. Drag the command to the Procedure column.

3. In order to insert a command at the end of the application, double-click on the selected command in the

column Commands.

6.2.8.2 Copying commands

Select a command from the Procedure column.

Click on the symbol in the menu bar.

Alternatively, open the context menu with the right mouse button and select Copy.

6.2.8.3 Inserting a copied command

1. Copy the command.

2. Select the position in the Procedure column where you would like to insert the copied command.

3. Select the Paste command in the context menu.

The copied command is inserted behind the selected position.

6.2.8.4 Changing the command sequence

Select a command in the Procedure column.

Drag the command to the desired position in the procedure.

6.2.8.5 Deleting commands

Select a command in the Procedure column.

Delete the command using the symbol in the menu bar or via the context menu.

6.2.8.6 Changing command parameters

1. Select a command in the Procedure column.

The parameters of the selected command are shown in the Options area.

2. Set the parameters to suit your requirements.

Page 47

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.2.9 Checking an application

1. Click on the symbol in the menu bar.

2. Select the Check command function.

The application is checked.

Example: Pipette tips without a filter are placed on the epMotion worktable. In the application, pipette

tips with filter were selected. The screen displays an error message.

6.3 Commands

A procedure is a sequence of commands that epMotion executes during an application run. Commands are

executed one after the other and independent of each other. Each command has a specific set of

parameters.

The software does not include a command for taking up pipette tips. The user defines which pipette tips

will be used in a command. The user positions the corresponding pipette tips on the worktable.

47

The user defines the dispensing tool for each command. Tools are taken up according to the command

parameters.

The parameter set displayed in the software depends on the equipment of your epMotion.

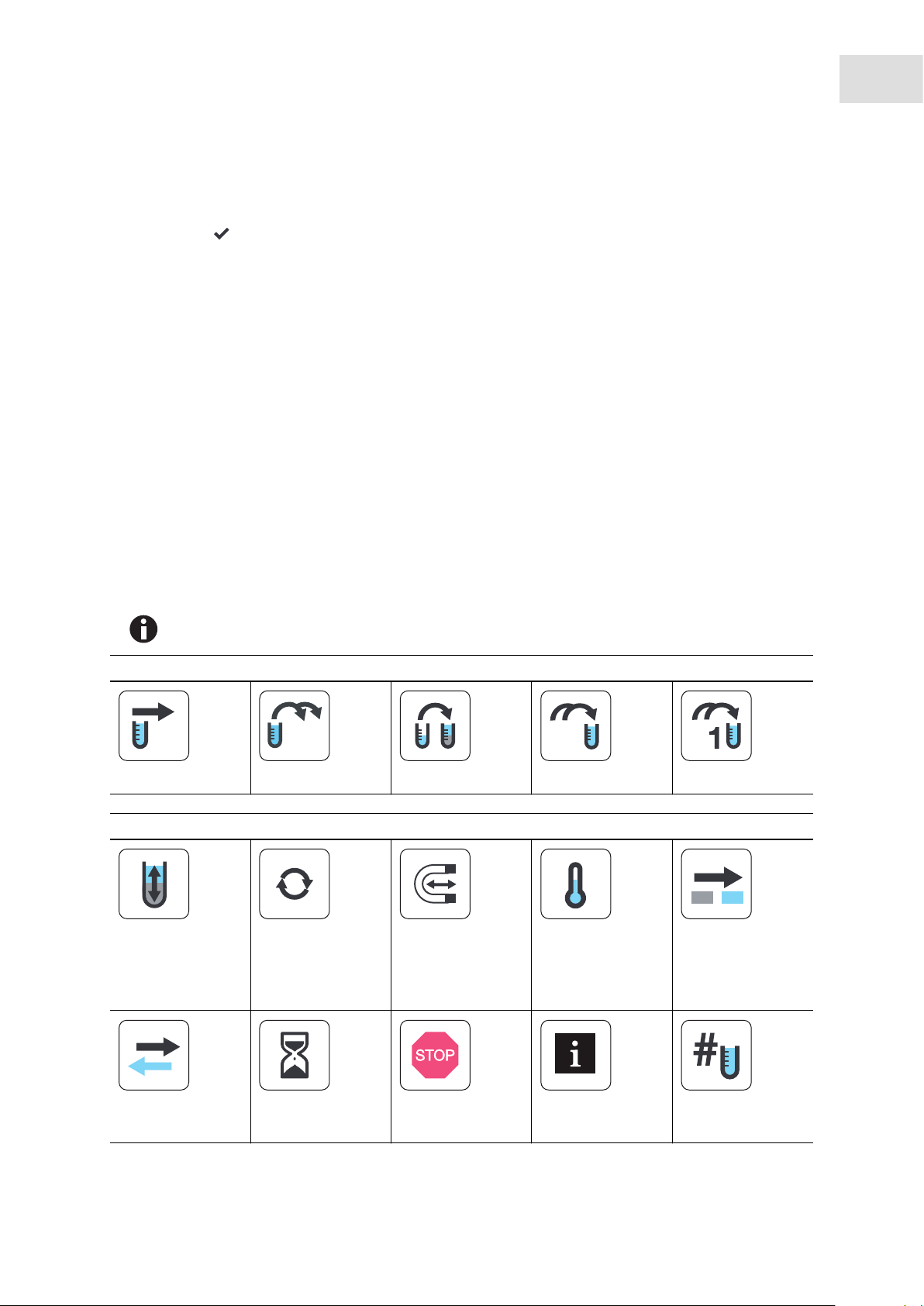

Transfer commands

Sample transfer Reagent transfer Dilute Pool Pool one destination

Additional commands

Mix Thermomixer

epMotion with

thermomixer

Magnetic separation

epMotion with

magnetic finger

module

Temperature

epMotion with

thermal module

Transport

epMotion 5075

epMotion 5073

Exchange

epMotion 5070

Wait User intervention Comment Number of samples

Page 48

48

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

Additional commands

BAR

Vacuum

epMotion with

vacuum unit.

6.3.1 Sample transfer command

Various transfer commands are available to transfer liquids. All transfer commands are derived from the

Sample transfer command.

Abb. 6-7: Principle of the Sample transfer command

Fig. 6-7: Principle of the Sample transfer command

The Sample transfer command is used to transfer liquids from various source positions to several

destination positions. The number of samples that will be aspirated from the source labware depends on

the Number of samples (see p. 64) command.

Page 49

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.3.1.1 Sample transfer > Parameter command

Abb. 6-8: Sample transfer > Parameter

Fig. 6-8: Sample transfer > Parameter

Volume Select volume in µL or nL. A decimal place is available for volumes ≤ 99.9 µL.

You can transfer a volume larger than the maximum volume of the pipette tip.

The volume to be transferred will be pipetted in several steps.

Example: The user would like to transfer 1500 µL and enters this value into the

Volume field. If a 1000 µL tip is being used, 2x 750 µL will be pipetted. If a

300 µL tip is being used, 5 x 300 µL will be pipetted.

Pipet. tool Used dispensing tool.

Pipette The volume is individually aspirated and dispensed for each liquid transfer.

Multidispense Aspirate liquid and dispense it in the destination position in defined subsets.

Multiaspirate Aspirate liquid from several source positions using one pipette tip and

dispense the liquid in one destination position. Available for Pool and Pool one

destination commands.

Use filter tips Activate when using tips with filter.

Source Select the source labware. The source labware must be placed on the

worktable. You can select 4 source labwares. If you are using more than one

source labware, the number of positions in the labware (384, 96, 24) must

match. If you dispense within one labware, the source labware and destination

labware are identical.

Destination Select the destination labware. The destination must be placed on the

worktable. You can select 4 destination labwares. If you are using more than

one destination labware, the number of positions in the labware (384, 96, 24)

must match. If you dispense within one labware, the source labware and

destination labware are identical.

Pattern Select the source positions and destination positions. Create replicates.

49

Information on the aspiration and transfer of liquids by means of the epMotion can be found in

the hardware operating manual.

Page 50

50

epBlue Application Editor - Creating and editing applications

epBlue™ with MultiCon

English (EN)

6.3.1.2 Sample transfer > Options command

Abb. 6-9: Sample transfer > Options

Fig. 6-9: Sample transfer > Options

Aspirate from bottom Aspirate liquid from the base of the vessel. When using several vessels with

different volumes, enter the lowest filling volume of these vessels (Sample

transfer > Parameter).

Elution from filter Aspirate liquids from the supernatant in filter plates. Available if in the

Parameter window the Pipette radio button is selected.

Dispense from top During liquid dispensing, position the pipette tips 3 mm – 4 mm below the

edge of the vessel. When using several vessels with different volumes, enter

the highest filling volume of these vessels (Sample transfer > Parameter).

Change Tips Defined time when the pipette tips are changed.

when command finished Eject pipette tips after the end of the command. The liquid will be aspirated

with the same tip from all source labware positions.

before asp. for next

destination well

before each aspiration Eject pipette tips prior to each aspiration. Liquid will always be aspirated with

keep tips, do not change

tips

after XX aspirations Pipette tips will be ejected after a defined number of aspirations.

Restore tips Pipette tips will be placed back into the position of the box they were removed

Eject the pipette tips before the liquid from the next source position is

aspirated. Liquid from the same source position will be aspirated with the same

tip. Liquid from the next source position will be aspirated using a new tip.

a new tip. Additional volume will be discarded in the waste container along

with the pipette tip.

Do not eject pipette tips. Liquid will be aspirated with the same tip from all

source positions. The tips are also used in the next command. If the transfer

type changes in one of the following commands, or the Mix command is used,

the tips will be ejected.

from.

Is only executed if the tips within an application are reused for the same source

vessel.

The restore tips checkbox is only available with specific settings of the Change

Tip option.

Page 51

epBlue Application Editor - Creating and editing applications

Reuse tips Returned pipette tips will be reused.

The pipette tips will be reused within an application for the same source vessel.

Is only executed if the restore tips option was selected in a previous command

and the restored tips are available.

The Reuse tips checkbox is only available with specific settings of the Change

Tip option.

Information on the aspiration and transfer of liquids can be found in the hardware operating

manual.

6.3.1.3 Sample transfer > Mix command

The Mix command is also available for mixing (see p. 63).

Abb. 6-10: Sample transfer > Mix

epBlue™ with MultiCon

English (EN)

51

Fig. 6-10: Sample transfer > Mix

Mix before aspirating Mix before each aspiration. Set the parameters following activation.