Page 1

New Brunswick Benchtop Incubator Shakers

Excella® E-24/24R

Operating Manual

M1352-0050

Revision D

Page 2

2

COPYRIGHT:

Copyright © 2012 Eppendorf AG, Hamburg. No part of this publication may be reproduced

without the prior permission of the copyright owner.

The company reserves the right to change information in this document

without notice. Updates to information in this document reflect our commitment to

continuing product development and improvement.

TRADEMARKS:

Eppendorf

Logo™ are trademarks of Eppendorf AG, Hamburg, Germany.

Excella

Germany.

Trademarks are not marked in all cases with ™ or ® in this manual.

Eppendorf has attempted to identify the ownership of all trademarks from public records. Any

omissions or errors are unintentional.

®

is a registered trademark, and New Brunswick™ and the New Brunswick

®

and Innova® are trademarks owned and registered by Eppendorf AG, Hamburg,

April10, 2012

Revision D

M1352-0050

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 3

3

CAUTION!

This equipment must be operated as described in this manual. If

operational guidelines are not followed, equipment damage and personal

injury can occur.

Please read the entire operating manual before attempting to use this unit.

Do not use this equipment in a hazardous atmosphere or with hazardous

materials for which the equipment was not designed.

Eppendorf is not responsible for any

damage to this equipment that may result from the use of an accessory

not manufactured by Eppendorf.

New Brunswick Operating Manual

Page 4

4

TABLE OF CONTENTS

1 OVERVIEW.......................................................................................................................... 6

2 INSPECTION & UNPACKING OF EQUIPMENT ......................................................... 8

2.1 I

NSPECTION OF BOXES .....................................................................................................8

2.2 PACKING LIST VERIFICATION .......................................................................................... 8

2.3 UNPACKING OF EQUIPMENT............................................................................................. 8

2.4 OUT OF BOX CONCERNS .................................................................................................. 9

2.5 WARRANTY REGISTRATION............................................................................................. 9

3 PREPARING THE LOCATION....................................................................................... 10

3.1 PHYSICAL LOCATION ..................................................................................................... 10

3.2 ENVIRONMENT............................................................................................................... 10

3.3 ELECTRICAL REQUIREMENTS......................................................................................... 10

3.4 SPACE REQUIREMENTS .................................................................................................. 11

4 INSTALLATION................................................................................................................ 12

4.1 INSTALLATION OF PLATFORM ........................................................................................ 12

4.2 FLASK CLAMP INSTALLATION........................................................................................ 13

4.3 ELECTRICAL CONNECTIONS........................................................................................... 14

5 FEATURES......................................................................................................................... 15

5.1 CONTROL PANEL............................................................................................................ 15

5.1.1 Keypad .................................................................................................................. 15

5.1.2 User Interface Keys .............................................................................................. 16

5.1.3 LED Display.......................................................................................................... 16

5.1.4 Status Indicators................................................................................................... 17

5.1.5 Function Indicators............................................................................................... 17

6 OPERATION ...................................................................................................................... 19

6.1 ELECTRICAL CONNECTIONS........................................................................................... 19

6.2 S

TARTING THE SHAKER.................................................................................................. 19

6.3 CONTINUOUS (UNTIMED) RUN....................................................................................... 20

6.4 C

HECKING ANY SETPOINT ............................................................................................. 20

6.5 TIMED FUNCTIONS......................................................................................................... 20

6.6 A

6.7 T

LARM FUNCTIONS........................................................................................................ 21

EMPERATURE SETPOINT............................................................................................... 21

6.8 TEMPERATURE OFFSET CALIBRATION ........................................................................... 22

6.9 P

6.10 S

OWER FAILURE ............................................................................................................ 23

PEED CALIBRATION...................................................................................................... 23

7 MAINTENANCE................................................................................................................ 24

7.1 R

7.2 C

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

OUTINE MAINTENANCE ............................................................................................... 24

LEANING EXTERNAL & INTERNAL SURFACES.............................................................. 24

Page 5

5

7.3 BIOHAZARD DECONTAMINATION................................................................................... 24

8 SERVICE.............................................................................................................................26

8.1 T

8.2 P

ROUBLESHOOTING ....................................................................................................... 26

RODUCT RETURNS........................................................................................................ 27

8.3 OPENING THE SERVICE COMPARTMENT......................................................................... 27

8.4 FUSE REPLACEMENT...................................................................................................... 28

8.5 BELT REPLACEMENT OR ADJUSTMENT .......................................................................... 30

8.6 REPLACEMENT PARTS.................................................................................................... 32

9 ACCESSORIES .................................................................................................................. 33

9.1.1 Platforms............................................................................................................... 33

9.1.2 Flask Clamps for Universal Platforms................................................................. 33

9.1.3 Replacement Clamp Hardware Kits ..................................................................... 34

9.1.4 Test Tube Racks & Other Accessories.................................................................. 34

10 DRAWINGS & TABLES............................................................................................... 36

10.1 SCHEMATICS.................................................................................................................. 36

10.2 LIST OF DRAWINGS........................................................................................................ 39

10.3 LIST OF TABLES ............................................................................................................. 40

11 SPECIFICATIONS......................................................................................................... 41

11.1 CERTIFICATIONS ............................................................................................................ 42

12 APPENDIX: PRODUCT RETURNS...........................................................................44

12.1 RETURN PROCEDURE ..................................................................................................... 44

12.2 RETURN AUTHORIZATION AND DECONTAMINATION CERTIFICATE ................................ 44

13 INDEX.............................................................................................................................. 46

New Brunswick Operating Manual

Page 6

6

11

The Excella® E-24/24R Benchtop Incubator Shakers use a UniCentric™ counter-balanced drive

mechanism. They provide horizontal plane rotary motion in a ¾-inch (1.9 cm) diameter circular

orbit. A Proportional/Integral (PI) microprocessor controls the speed and temperature over the

entire range.

The incubated and refrigerated E-24R operates from 15ºC below ambient (with a minimum

setpoint of 4ºC) to 60C, and the incubated E-24 from 7ºC above ambient to 60ºC. Both these

ranges depend on relative humidity and other ambient factors. Ambient temperature is measured

one meter from the front of the unit.

Erlenmeyer flasks, 2.8-liter Fernbach flasks, and a wide variety of tubes and plates can be

accommodated using the New Brunswick shaker accessories described in Section 9.

The E-24/24R may be operated in the following ways:

Continuously: at a set speed and temperature, until user intervention.

In a timed mode: run at a set speed, time and temperature for a period of up to 99.9

hours, after which the shaker automatically shuts off, while the temperature is maintained

at its setpoint.

For safe operation, the E-24/24R shakers are designed with a safety switch that automatically

stops the shaker mechanism when the lid is opened.

Both the E-24 and the E-24R are equipped with visual and audible alarms that alert the user to

the following conditions:

The end of a timed run

Deviations from speed setpoint (5 minutes after lid is closed)

Deviations from temperature setpoint (5 minutes after lid is closed)

Power failure

Lid open

To accommodate customer needs, a wide variety of platforms can be used with the Excella

E-24/24R:

Universal platforms are the most flexible, providing hole patterns for flask clamps,

test tube racks and other accessories.

Dedicated platforms are supplied with flask clamps attached; they are designed solely

and expressly for this purpose.

O

VVEERRVVIIEEW

O

W

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 7

7

Test tube racks, microplate holders, and test tube rack holders are also available (a

universal platform is needed for all test tube racks and holders).

For further information on these accessories, see Section 9.

New Brunswick Operating Manual

Page 8

8

22

I

NNSSPPEECCTTIIOONN

I

&

&

U

NNPPAACCKKIINNGG OOFF

U

E

QQUUIIPPMMEENNT

E

2.1 Inspection of Boxes

After you receive your order, inspect the boxes carefully for any damage that may have

occurred during shipping. Report any damage immediately to the carrier and to your

local sales representative.

2.2 Packing List Verification

Verify against your packing list that you have received all of the correct materials.

2.3 Unpacking of Equipment

WARNING!

Do not attempt to lift the Excella E-24/24R by yourself. Always ask for

assistance or use a lifter or other suitable equipment when raising or

handling the unit.

CRUSH WARNING!

It is preferable to lift the Excella E-24/24R from the sides of the unit,

but if you lift it from the front and back, be sure to use the finger holes

in the back lip (toward the bottom of the unit). If these finger holes are

not used, the back lip can pinch fingers and hands.

Upon unpacking the unit, inspect it carefully for any damage that may have occurred

during transit. Report any apparent damage to the carrier and to your sales

representative. Save the crate and packing materials.

T

NOTE:

Use of the Excella E-24/24R Shakers requires a platform, which is a separate

item. See the Available Platforms list in Section 9.1.1.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 9

9

2.4 Out of Box Concerns

If any part of your order was damaged during shipping, is missing pieces, or fails to

operate properly, please contact your sales representative and also fill out Customer

Satisfaction Form 6300, included with your equipment, and return it by fax.

2.5 Warranty Registration

Please complete and return your warranty card or register electronically at our Website:

www.nbsc.com

New Brunswick Operating Manual

Page 10

10

33

3.1 Physical Location

WARNING!

Do not attempt to lift the Excella E-24/24R by yourself. Always ask for

assistance or use a lifter or other suitable equipment when raising or

handling the unit.

CRUSH WARNING!

It is preferable to lift the Excella E-24/24R from the sides of the unit,

but if you lift it from the front and back, be sure to use the finger holes

in the back lip (toward the bottom of the unit). If these finger holes are

not used, the back lip can pinch fingers and hands.

The surface where you place the E-24/24R should be smooth, level and sturdy, and must

be able to accommodate 200 pounds.

P

RREEPPAARRIINNGG TTHHEE

P

L

OOCCAATTIIOON

L

N

3.2 Environment

The shaker is designed to operate optimally in the following ambient conditions:

10º to 35°C

20 to 80% Relative Humidity (non-condensing)

3.3 Electrical Requirements

The E-24/24R can be equipped to run on:

100 Volts, 50/60 Hz, 1500 VA maximum

120 Volts, 60 Hz, 1500 VA maximum

230 Volts, 50 Hz, 1500 VA maximum

In all cases, voltage variations must not exceed ±10%.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 11

11

3.4 Space Requirements

It is essential that the shaker be situated in an area where there is sufficient space for the

unit and its service lines (see Figure 1).

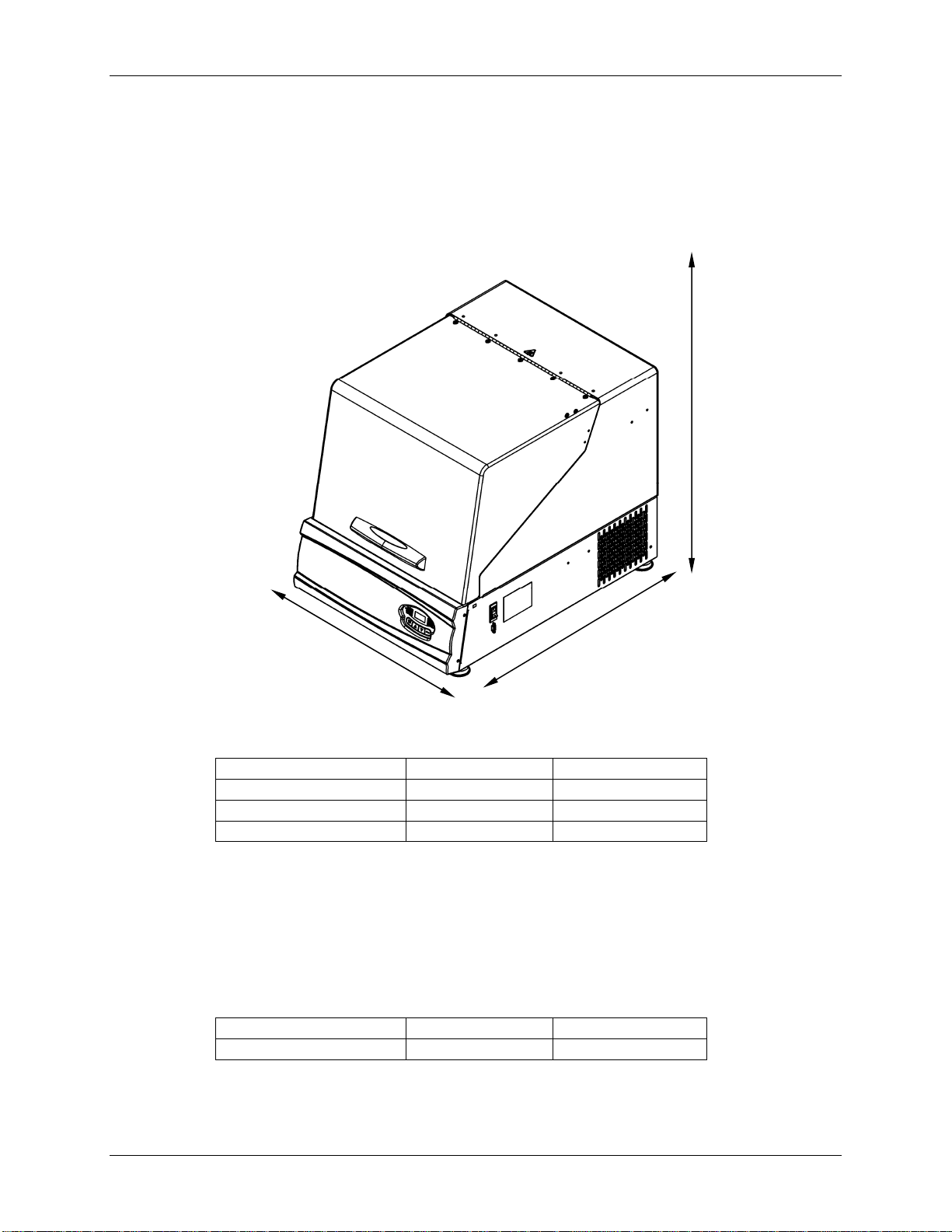

Figure 1: Space Requirements

Allow 42 inches of

height to provide

clearance (for

opening the lid)

Allow 27 inches

of width

to provide clearance

Allow 33 inches of depth

to provide clearance

The dimensions of the Excella E-24/24R are:

Width

Depth

Height

Height with lid open

22 inches 55.8 cm

30 inches 76.2 cm

24 1/16 inches 61.1 cm

40½ inches 101.9 cm

NOTE:

Be sure to allow at least three inches (7.6 cm) around shaker for ventilation,

access to power cord (rear panel), and access to power switch and RS-232

port (right side).

The effective surface area required for operation is:

Width

Depth

24 inches 61 cm

30 inches 76.2 cm

New Brunswick Operating Manual

Page 12

12

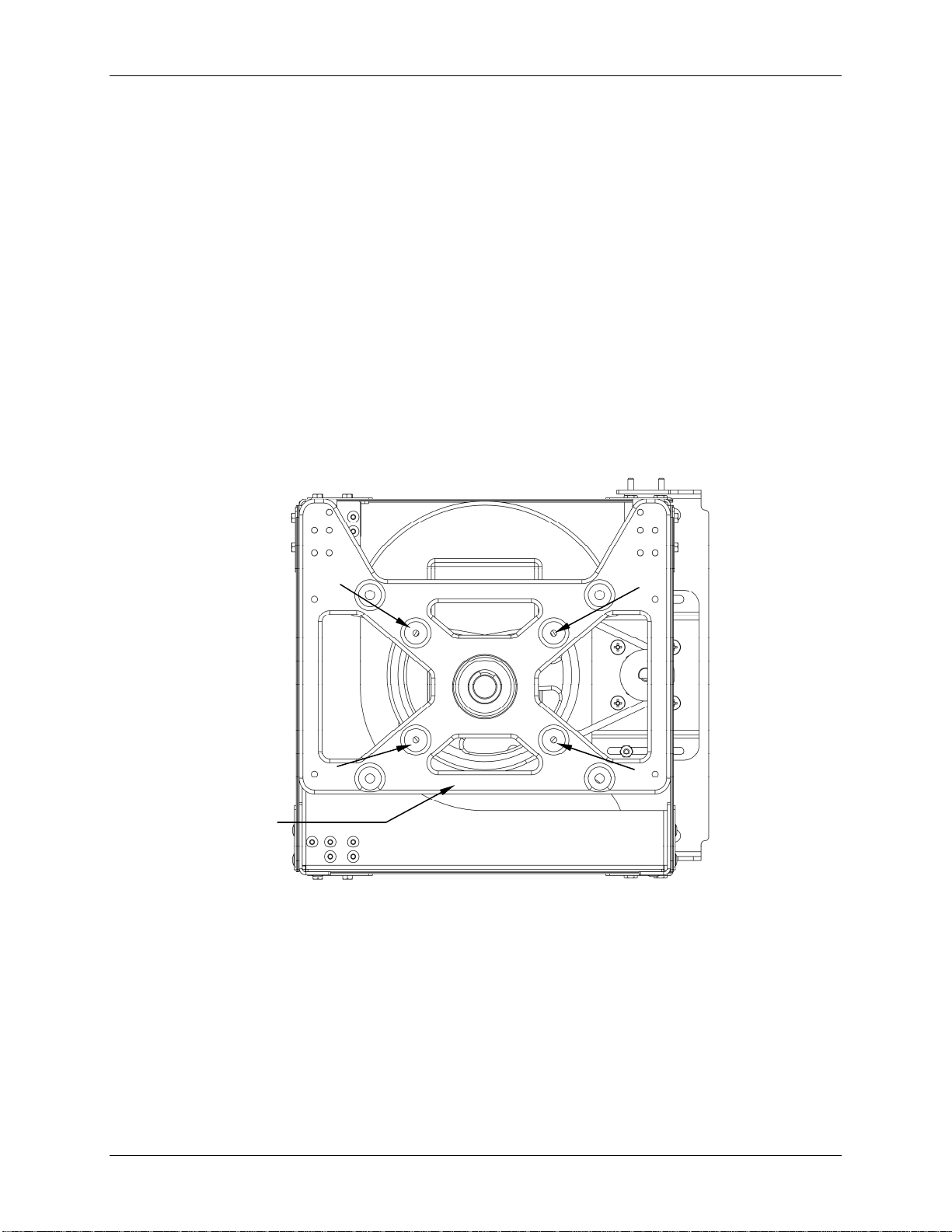

4.1 Installation of Platform

44

I

NNSSTTAALLLLAATTIIOON

I

NOTE:

There are two small plastic straps that hold the bearing housing in place for

shipping. The straps must be removed from the unit.

Prior to use, a platform must be installed on the unit. The unit is shipped with four

Allen head PLATFORM SCREWS installed in the SUBPLATFORM of the BEARING

HOUSING

installed:

. These screws must be removed and set aside for use before a platform can be

Figure 2: Platform Screw Locations

N

SUBPLATFORM

1. Using the 7/32-inch hex wrench provided, remove the four Allen head platform

screws from the subplatform. Set them aside.

2. Place the selected

platform with the platform screw locations in the subplatform.

3. Insert the four Allen head platform screws previously removed and set aside. Tighten

them with the 7/32-inch hex wrench provided to secure the platform.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

PLATFORM on the subplatform. Align the mounting holes of the

Page 13

13

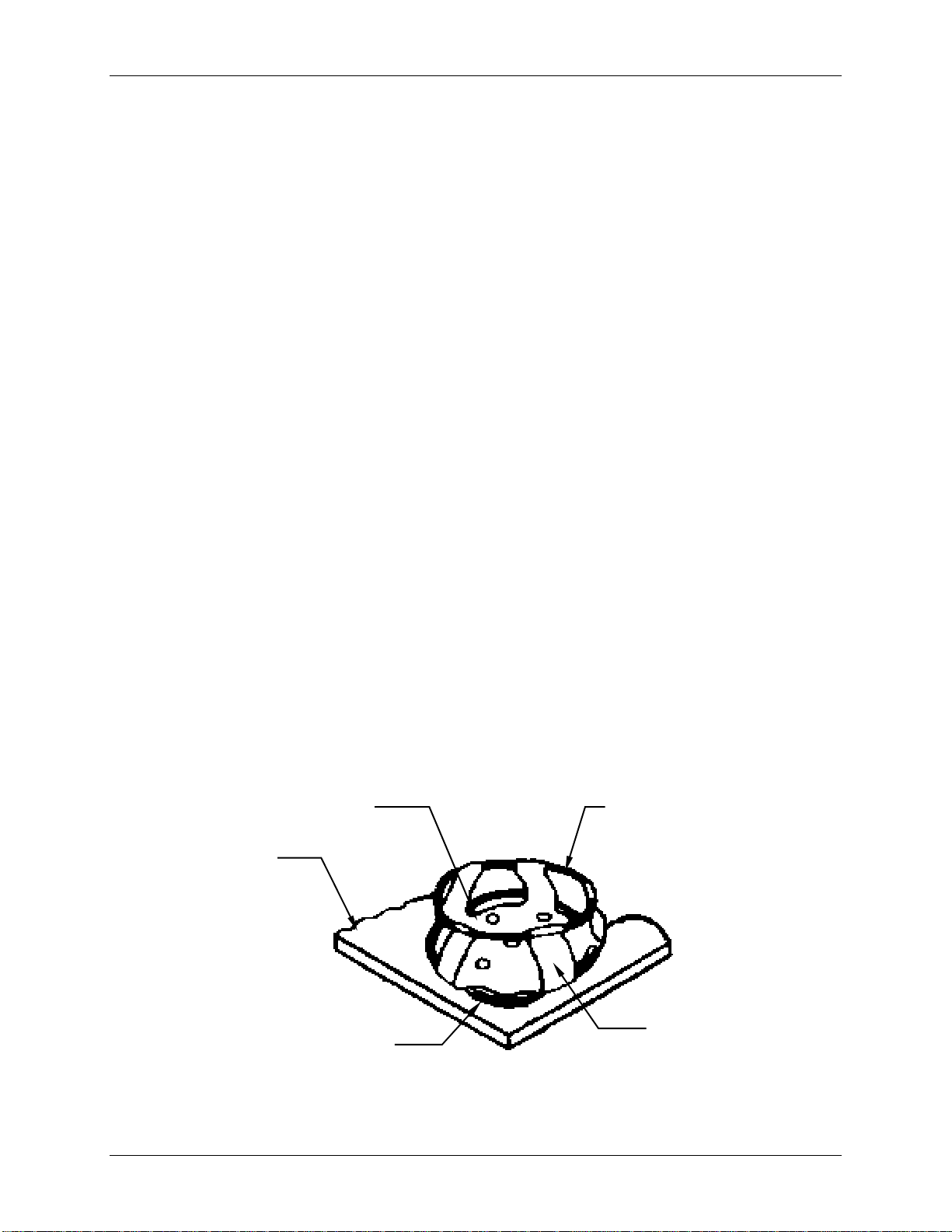

4.2 Flask Clamp Installation

Flask clamps purchased for use with universal platforms (see Section 9.1.1) require

installation. Clamps are installed by securing the base of the clamp to the platform with

the correct type and number of screws. All clamps are shipped complete with hardware.

NOTE:

The Excella E-24 and E-24R platforms require 10-24 x 5/16-inch screws,

which are the smaller Phillips head screws supplied, to fasten flask clamps.

Clamps for 2- and 2.8-liter flasks are shipped with an additional girdle to keep the flasks

in place. The girdle is an assembly of springs and sections of rubber tubing. One girdle

is already in place on the clamp, the other is packed separately. To install these double

girdle clamps:

1. Place the clamp on the platform, aligning its mounting holes with holes on the

platform. Secure the clamp in place using the flat Phillips head screws provided

(#S2116-3051, 10-24 x 5/16-inch). Use Figure 3b to help you identify the proper

screws, as three different types of screws are shipped with the clamps.

2. With the first girdle in place, as delivered, on the upper part of the clamp body (see

Figure 3a), insert an empty flask into the clamp.

3. After making sure the sections of tubing are located between the clamp legs, roll the

first girdle down the legs of the clamp as far as it can go. The tubing sections will

rest against the platform, and the springs will be under the clamp base.

4. Place the second girdle around the upper portion of clamp body (just as the first

girdle was initially). Make sure that its spring sections rest against the clamp legs,

while its rubber tubing sections sit against the flask, in between the clamp legs.

Figure 3a: Double Girdle Clamp Installation

UPPER GIRDLE

WITH GIRDLE

TUBES

PLATFORM

CLAMP

MOUNTING

HOLES (5)

LOWER

GIRDLE WITH

GIRDLE TUBES

CLAMP BODY

(LEGS AND BASE)

New Brunswick Operating Manual

Page 14

14

Figure 3b: Clamp Fastener

NOTE:

The upper girdle secures the flask within the clamp, and the bottom girdle

keeps the flask from spinning.

New Brunswick flask clamps are used on a variety of shaker platforms. Flat head

screws of different lengths and thread pitch are used to secure the clamp. With

reference to Figure 3b above, select the appropriate screws and set the others aside.

NOTE:

One-liter and larger flask clamps are fastened with 5 screws.

4.3 Electrical Connections

CAUTION!

Before making electrical connections, be sure to check the following:

1. If you have not already done so, check that the voltage and frequency of your unit are

compatible with your electric supply.

2. Remove the caution label from the rear of the unit.

3. Set the circuit breaker on the right side of the unit to the OFF position.

ONLY THEN:

4. Plug the power cord into a grounded electrical outlet.

CAUTION!

A grounded electrical outlet is necessary for the safe operation of this

instrument.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 15

15

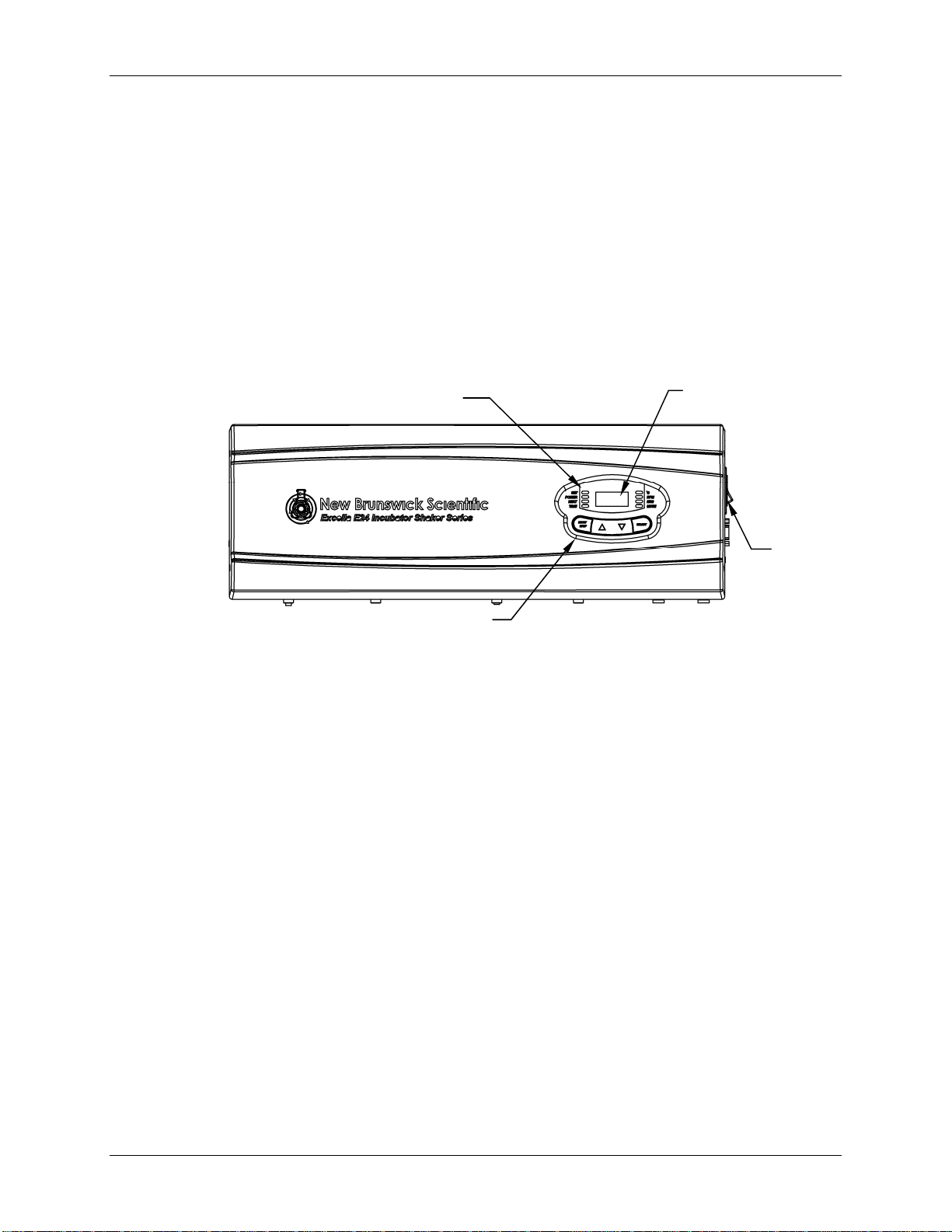

5.1 Control Panel

The front panel (see Figure 4) of the Excella E-24/24R shakers provides easy access to

the control panel, which consists of the keypad, display and indicator lights. The ON/OFF

switch is conveniently located on the right side of the unit, as you face the controls.

Figure 4: Control Panel

INDICATORS (see Sections 5.1.4 & 5.1.5)

55

F

EEAATTUURREES

F

LED DISPLAY

(see Section 5.1.3 )

S

ON/OFF

SWITCH

KEYPAD (see Sections 5.1.1 & 5.1.2)

5.1.1 Keypad

The keypad (see close-up in Figure 4a on the following page) is the operator’s

command center for the shaker. In one convenient location are grouped the user

interface keys, the LED display, the status indicator lights and the function

indicator lights.

New Brunswick Operating Manual

Page 16

16

INDICATORS

STATUS

Figure 4a: Keypad

LED

DISPLAY

FUNCTION

INDICATORS

USER INTERFACE

KEYS

5.1.2 User Interface Keys

START/STOP

This key is used to start or stop the shaker. It will

also activate or stop the timer when a timed run is

desired.

SELECT

This key is used to change the displayed parameter.

(UP), (DOWN)

These keys are used to adjust the setpoint of a

displayed parameter up or down. They also allow

the user to enter the

changes.

5.1.3 LED Display

The digital display on the control panel is a three-digit LED DISPLAY. During

normal shaker operation, the display will indicate:

Shaker status (On/Off)

Shaking speed

Chamber temperature

Setpoints

Hours remaining (in a timed run)

Lid open (“LID”)

SET MODE for setpoint

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 17

17

5.1.4 Status Indicators

Four status indicator lights are located to the left of the LED DISPLAY. They are:

SET

Indicates that the shaker is in the

SET MODE,

when setpoints are being displayed and can be

altered. This is activated by the

SELECT key

or by pressing the (UP) or (DOWN) KEY.

POWER

Illuminates and blinks during power up or if

power is interrupted during a run. Press the

SELECT key and change to another function to

turn off this indicator.

HEAT

Illuminates to indicate that the heater is on.

TIME

Indicates that the timer is in operation. The

shaker can be programmed to run for a preset

time from 0.1 to 99.9 hours. The timer can be

disengaged without stopping an ongoing run.

5.1.5 Function Indicators

Four function indicator lights are located to the right of the LED DISPLAY. They indicate

the current parameter(s) being displayed:

C

Interior chamber temperature. Can be set from

4°C to 60°C, when in SET MODE, using the

(UP) or (DOWN) KEY. It indexes at 0.1°C

increments unless the key is pressed for 4

seconds, after which it indexes more rapidly.

RPM

Revolutions per minute. When in SET MODE,

use the (UP) or (DOWN) KEY to change the

speed. It indexes at 1 RPM increments unless

the key is pressed for 4 seconds, after which it

indexes more rapidly.

New Brunswick Operating Manual

Page 18

18

HRS

Time remaining in a timed run. Can be set

from 0.1 to 99.9 hours, in 0.1 increments or, if

the (UP) or (DOWN) KEY is pressed for 4

seconds, the time indexes more rapidly.

The countdown begins when the START/STOP

key is pressed. If the START/STOP key is

pressed, the shaking stops (but temperature is

maintained) and the timer pauses until the

START/STOP key is pressed again.

When a timed run ends, the HRS indicator will

blink. Press the SELECT key and change to

another function to turn off this indicator.

MUTE

This feature is controlled by the SELECT key.

When activated, the audible alarm is muted,

and remains so until is is reactivated. If MUTE

is activated when the shaker is turned off using

the ON/OFF switch, it will remain engaged

when the machine is powered up again. To

activate (or deactivate) the MUTE function,

press the SELECT key until the MUTE indicator

illuminates; press the (UP) or (DOWN) KEY

to display ON or OFF, as desired; then press

SELECT.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 19

19

6.1 Electrical Connections

Before making electrical connections, verify that the power source voltage matches the

voltage on the ELECTRICAL SPECIFICATION PLATE and that the ON/OFF SWITCH is on the

OFF position. The ELECTRICAL SPECIFICATION PLATE is located on the rear panel of the

unit near the

CONNECTOR

end to a suitable, grounded receptacle.

6.2 Starting the Shaker

To initially start the shaker, close the lid and turn the ON/OFF SWITCH on the right side

panel of shaker to the ON position. During start-up, the LED DISPLAY will indicate the

model of your shaker. When the shaker begins to operate, the LED DISPLAY will track the

speed as it accelerates to the last entered setpoint. The shaking action may be started or

stopped by pressing the START/STOP KEY on the KEYPAD.

POWER CONNECTOR. Connect the POWER CORD to the POWER

(Universal Voltage Input Module) on the rear panel, then connect the other

Figure 5: ON/OFF Switch Location

66

O

PPEERRAATTIIOON

O

N

LID

HANDLE

KEYPAD

ON/OFF SWITCH

NOTE:

The shaker will not operate if the lid is open.

New Brunswick Operating Manual

Page 20

20

6.3 Continuous (Untimed) Run

1. Press SELECT until the RPM INDICATOR is illuminated.

2. If the display indicates that the shaker is OFF, press the START/STOP KEY.

3. Press either the

(UP) or (DOWN) KEY to enter SET MODE (the SET INDICATOR will

illuminate).

4. Set the speed by using the

(UP) or (DOWN) KEY until the desired setpoint is

displayed. Continued pressure the (UP) or (DOWN) KEY will cause the setting to

change more rapidly.

NOTE:

The setpoint may be changed during a run without stopping the shaker by

following steps 2-4 above. During speed changes, a visual alarm (flashing

RPM INDICATOR) will flash and an audible alarm will sound until the speed

returns to within 5 rpm of the setpoint.

6.4 Checking Any Setpoint

1. Press SELECT until the desired indicator is illuminated.

2. Briefly press either the (UP) or (DOWN) KEY to enter the SET MODE and display

the current setpoint.

CAUTION!

Holding the the (UP) or (DOWN) KEY for more than 0.5 seconds causes the

speed setpoint to change. Should this occur, resetting will be necessary.

6.5 Timed Functions

The shaker may be programmed to automatically stop after a preset time period of 0.1 to

99.9 hours. There must be power to the shaker in order to set the timer, although a timed

run can be initiated while the unit is either stopped or operating.

To set the timer:

1. Press the SELECT KEY until the HRS INDICATOR is illuminated.

2. Press either the (UP) or (DOWN) KEY to enter the SET MODE and set the desired

run time, between 0.1 and 99.9 hours.

If the shaker is stopped, skip to Step 5 below. If the shaker is already running:

3. Press the START/STOP KEY. The shaker will stop and the display will read OFF.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 21

21

4. Press the START/STOP KEY again; the TIME INDICATOR will light and the shaker will

start the timed run.

If the shaker is stopped:

5. Press the START/STOP KEY. The shaker will start in untimed mode.

6. Press the START/STOP KEY again. The shaker will stop and the display will read

OFF.

7. Press the START/STOP KEY a third time; the TIME INDICATOR will light and the

shaker will start the timed run.

To disable the visual alarm (flashing TIME INDICATOR), press the SELECT KEY and

change to any other function.

To cancel the timer without stopping the shaker:

Repeat steps 1 and 2 above, then immediately press the START/STOP KEY. The TIME

INDICATOR

will cease to flash and the display will read OFF.

6.6 Alarm Functions

In addition to the visual alarm mentioned above, the Excella E-24/24R shakers have an

audible alarm that is activated at predetermined times, as explained in Section 1

(Overview). It can be deactivated by using the MUTE function:

1. Press the SELECT key until the MUTE indicator illuminates.

2. Press the (UP) or (DOWN) KEY to display ON, then press the SELECT KEY.

To reactivate the audible alarm:

1. Press the

2. Press the

SELECT key until the MUTE indicator illuminates.

(UP) or (DOWN) KEY to display OFF, then press the SELECT KEY.

6.7 Temperature Setpoint

Press the SELECT KEY until the function C INDICATOR illuminates. The temperature can

be set from 5C above ambient temperature to 60C (non-refrigerated units) or from 4C

to 60C (refrigerated units). Increasing or decreasing the setpoint is accomplished with

(UP) or (DOWN) KEY.

the

During operation, if the temperature of the chamber is more than 1.0C higher or lower

than the temperature setpoint, an alarm is triggered. This alarm consists of a flashing C

New Brunswick Operating Manual

Page 22

22

INDICATOR and audible beep. The alarm will automatically deactivate as the unit

achieves the set temperature.

6.8 Temperature Offset Calibration

The temperature probe and the temperature controller are calibrated together at the

factory. The temperature probe measures the temperature of the air at the probe’s

location, near the heat exchanger return vent. The controller uses the probe input to

adjust air temperature, up or down, to match the temperature setpoint.

Depending on various conditions within the chamber, such as flask placement and size,

the heat produced by growing organisms, heat losses due to liquid evaporation from

flasks, etc., the display temperature may differ from temperatures within the flasks

themselves.

If you wish to have the temperature display (“Indicated Temperature”) match the

temperature at a given point, or match the average of a series of points within the

chamber (“Actual Temperature”), proceed as follows:

1. Let the unit equilibrate at or near the desired temperature. Record the Indicated

Temperature.

2. Record the Actual Temperature.

3. Calculate the temperature correction value: Actual Temperature – Indicated

Temperature = Temperature Correction Value.

4. Press the SELECT KEY until the function C INDICATOR illuminates.

5. Simultaneously press the (UP) and (DOWN) KEYS. The display will indicate CAL.

6. Using the (UP) or (DOWN) KEY, enter the Temperature Correction Value

calculated in Step 3 above.

7. Simultaneously press the (UP) and (DOWN) KEYS to save the Temperature

Correction Value to memory.

NOTE:

°C light will pulse rapidly to indicate it is not operating in the factory

The

default mode.

To return to the factory calibration:

1. Press the

2. Simultaneously press the (UP) and (DOWN) KEYS. The display will indicate CAL.

3. Using the

4. Simultaneously press the

INDICATOR will stop.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

SELECT KEY until the function C INDICATOR illuminates.

(UP) or (DOWN) KEY, set the Temperature Correction Value to zero.

(UP) and (DOWN) KEYS. The rapid pulsing of the C

Page 23

23

6.9 Power Failure

In the event of a power failure, the Excella E-24/24R shakers are equipped with an

automatic restart function.

If the shaker was in operation prior to the power interruption, when power is restored the

shaker will begin to operate at its last entered setpoint. The LED DISPLAY will flash and

the audible alarm will sound, indicating that a power failure has occurred. Press any key

to cease the flashing in the display and the audible alarm.

6.10 Speed Calibration

To calibrate the shaking speed:

1. Set the shaker to a speed that can easily be measured. If you are using a strobe,

minimum speed should be 250 RPM.

2. Compare the reading on the display to the measured reading.

If an adjustment is needed:

1. Press the SELECT KEY until the RPM indicator light illuminates.

2. Press the (UP) and (DOWN) KEYS simultaneously. The display will indicate CAL.

3. Press either the (UP) or (DOWN) KEY to change the displayed value to match the

measured speed.

4. Press the (UP) and (DOWN) KEYS simultaneously to save the adjustment.

5. Turn unit OFF using the power switch, then turn it back ON.

New Brunswick Operating Manual

Page 24

24

WARNING!

When cleaning the unit, always turn off the shaker and disconnect the

power cord from the power supply.

7.1 Routine Maintenance

No routine maintenance schedule is required for the Excella E-24 and E-24R.

To ensure that your shaker retains its attractive appearance, an occasional cleaning, using

a cloth with conventional household (non-abrasive) cleaner is recommended (see Section

7.2 below for more details).

We also suggest that the area around the shaker be vacuumed or swept to remove dust

and other debris, ensuring proper air flow in and around the shaker.

77

M

AAIINNTTEENNAANNCCE

M

E

7.2 Cleaning External & Internal Surfaces

The unit may be cleaned using a damp cloth or any standard household or laboratory

cleaner to wipe down its outer surfaces. Do not use abrasive or corrosive compounds to

clean this instrument, as they may damage the unit and void the warranty.

If Biohazard decontamination is required, see Section 7.3 below.

7.3 Biohazard Decontamination

It is the responsibility of the user to carry out appropriate decontamination

procedures if hazardous material is spilled on or inside the equipment. Before

using any cleaning or decontamination method other than those suggested by the

manufacturer, users should check with Eppendorf that the proposed method would

not damage the equipment.

Commercially available household bleach solutions, when diluted at a 1:10 ratio, are

effective in routine decontamination of the instrument. The method for decontaminating

a spill depends upon the nature of the spill.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 25

25

Spills involving fresh cultures or samples known to have low concentrations of biomass

should be flooded with decontamination solution and soaked for 5 minutes before

cleanup. Spills involving samples with high concentrations of biomass, or involving

organic matter, or occurring in areas warmer than room ambient temperature, should be

exposed to decontamination solution for at least one hour before cleanup.

WARNING!

Personnel involved in the cleanup of any spill should wear gloves, safety

glasses, and a laboratory coat or gown during the cleanup process.

Respiratory protection should be considered for spills where aerosolization

is suspected.

New Brunswick Operating Manual

Page 26

26

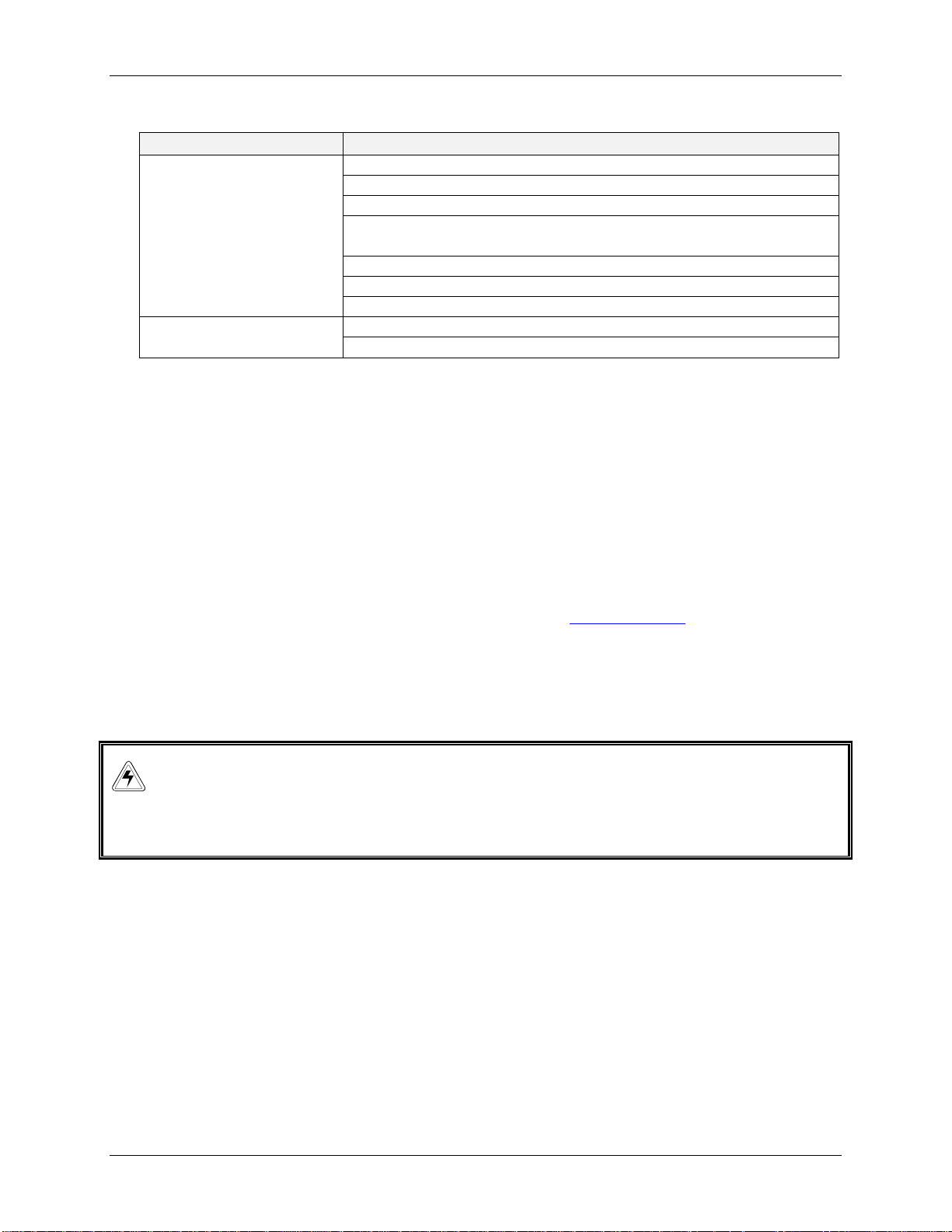

8.1 Troubleshooting

If any problems occur with your shaker, do not attempt to perform any service on the unit

other than specified in this manual. Unauthorized servicing may void the warranty.

Please contact your local Eppendorf Customer Service Department

In any correspondence with Eppendorf, please refer to the model number and serial

number of your unit. This information is on the electrical specification plate, located on

the rear panel of the unit, above the power connector.

There are some problems, however, that you can investigate and correct yourself. Refer

to the following Troubleshooting Guide:

Symptom(s) Probable Cause(s) & Solution(s)

Shaker does not run.

Shaker runs slowly

and/or no speed

indication.

Shaker does not run at

set speed.

Power cord is not plugged in and/or power switch is off: plug in

power cord (to working electric outlet), and turn on power

switch.

Lid is open and “LID” is indicated on display: close lid firmly.

On/Off switch is not working: call for service.

If you recently replaced a fuse, it may not have been seated

properly: remove and reinstall the fuse carefully.

Defective main board: call for service

Defective display controller board: call for service.

Jammed shaking mechanism: call for service

Defective motor: call for service

Drive belt out of alignment or worn: call for service.

Incorrect speed calibration: recalibrate shaking speed (see

Section 6.10).

Defective main board: call for service.

Defective motor: call for service.

Drive belt is out of alignment or worn: call for service.

Shaker is overloaded and/or you are using baffled flasks:

remove some contents & balance load.

Defective motor: call for service.

Drive belt out of alignment or worn: call for service.

Load out of balance: unload all contents, then reload. Operating noise

Loose component(s) in platform, subplatform and/or drive

assembly: call for service.

...continued...

88

S

EERRVVIICCE

S

E

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 27

27

Symptom(s) Probable Cause(s) & Solution(s)

Incubator does not

reach set temperature.

indication.

Heater fuse blown: replace.

Compressor fuse blown: replace.

Compressor over-pressure switch activated: call for service.

Ambient temperature too high or too low: cool or heat the

room as needed.

Defective heater: call for service.

Defective refrigeration system: call for service.

Incorrect temperature indication (see below).

Defective RTD assembly: call for service. Incorrect temperature

Defective main board: call for service.

8.2 Product Returns

Should you need to return your Excella E-24/24R to Eppendorf for any reason, first

contact Customer Service to obtain a Returned Material Authorization (RMA) number.

This number must appear on the outside of the shipping container, otherwise Eppendorf

Receiving will refuse to accept the shipment.

In addition, you must also certify that the instrument being returned has been thoroughly

cleaned and decontaminated. A form for this purpose is provided in Section 12 of this

manual; it can also be downloaded from our website (www.nbsc.com). A copy of this

completed Return Authorization and Decontamination Certificate must be attached to the

outside of the container, with a second copy packed inside with the instrument.

8.3 Opening the Service Compartment

WARNING!

Before opening the Service Compartment, always turn off the shaker and

disconnect the power cord from the power supply.

The Service Compartment contains the shaker’s electronic and temperature control

components. Normally, this compartment should be accessed by authorized service

technicians only. You may, from time to time, need to remove the access panel in order

to replace fuses (see Section 8.4 below).

New Brunswick Operating Manual

Page 28

28

8.4 Fuse Replacement

WARNING!

When replacing fuses, always turn off the shaker and disconnect the power

cord from the power supply.

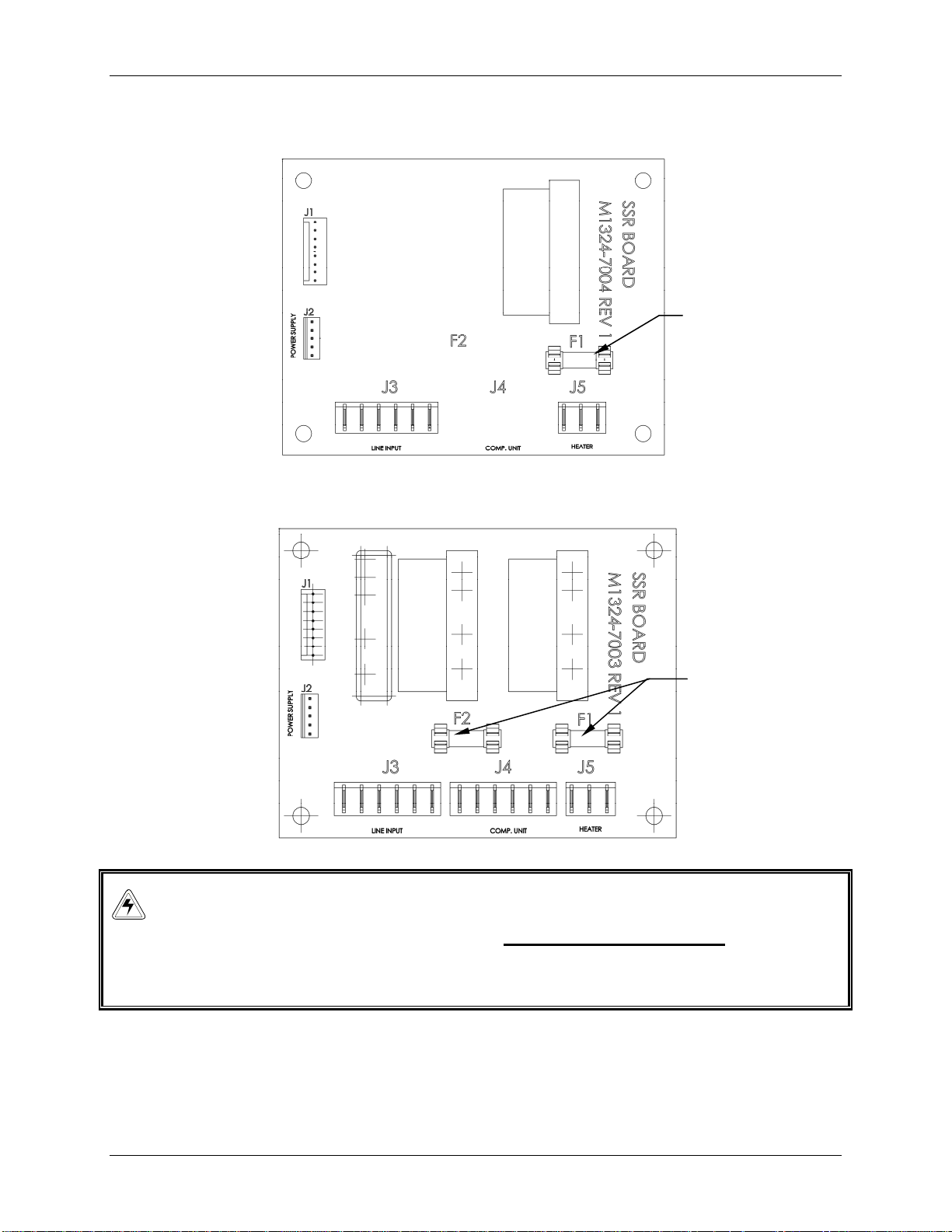

The user can replace one fuse on the Excella E-24 and two fuses on the E-24R. Fuses are

located behind the front bezel panel, on the PC board. To access the fuses:

1. Turn the power off and unplug the shaker. Open the cover of the shaker.

2. Remove the four fasteners that hold the front panel in place, setting them aside for

reuse.

3. Open the front panel, allowing it to lay flat.

4. The fuses are located on the PC board (see Figures 6,7a & 7b), which you will find

on the right side of the base weldment.

Figure 6: Accessing Fuses

FRONT PANEL REMOVED

(but not shown)

PC BOARD

(see Figures 7a & 7b)

5. Fuses are numbered (see Table 1); access the fuse you wish to replace by using a coin

or a blade screwdriver to turn and release the spring-loaded cap.

6. Replace the fuse with a new one of the same type and rating (see Table 1):

Table 1: Fuses

Fuse Holder

Number

F1 Heater 8.0 A

F2 Refrigeration (E-24R only)

Function Type Rating

Slo Blo

®

8A

8.0 A

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 29

29

Figure 7a: Fuse Replacement (Excella E-24)

FUSE

Figure 7b: Fuse Replacement (Excella E-24R)

FUSES

WARNING!

The following procedures are provided for your information only.

Do not attempt to perform these service interventions yourself unless you

are an authorized service technician.

New Brunswick Operating Manual

Page 30

30

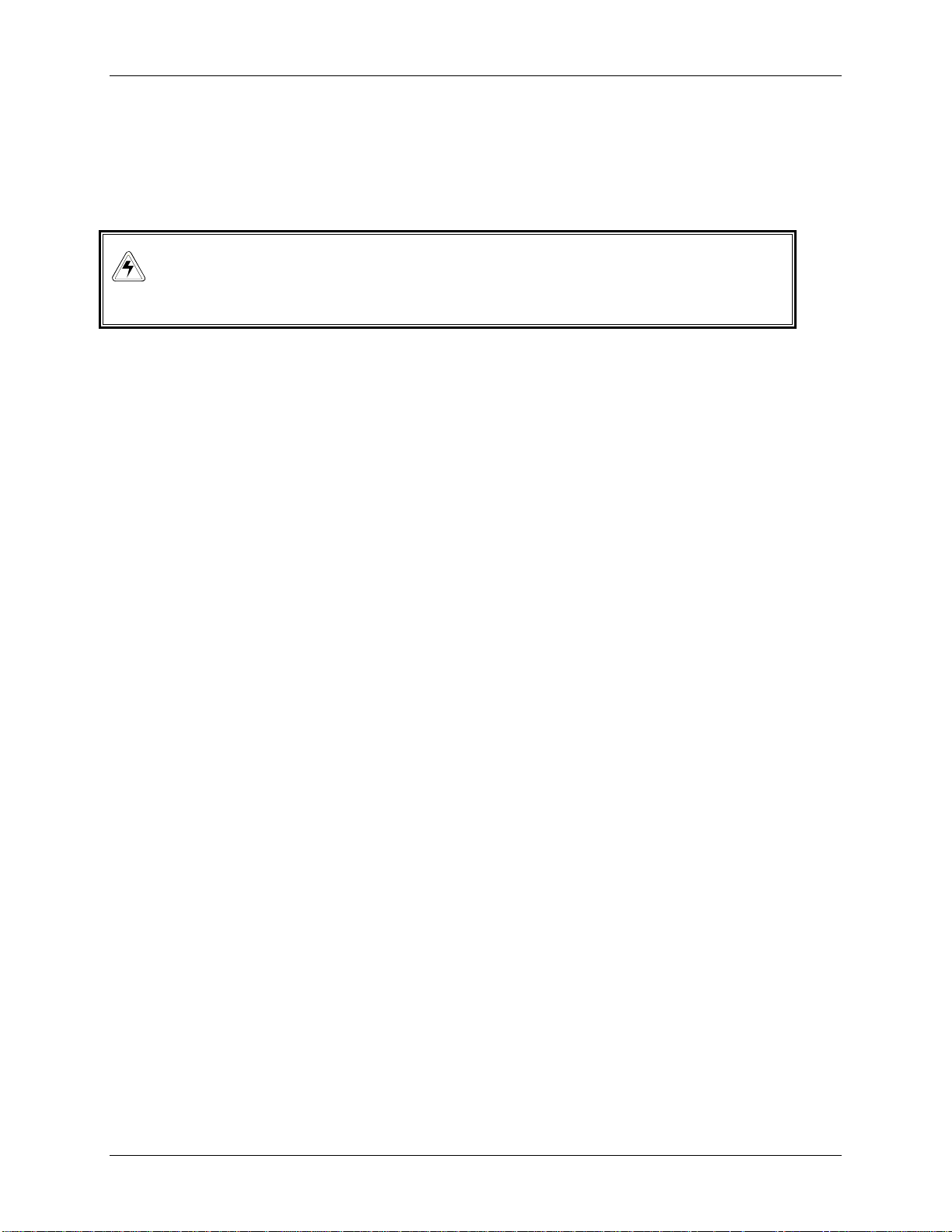

8.5 Belt Replacement or Adjustment

To gain access to the drive belt, your service technician will follow these steps with

reference to Figure 8:

WARNING!

Always keep fingers clear of the drive belt and pulley.

1. Set the ON/OFF power switch to OFF.

2. Disconnect the power cord from the electrical outlet.

3. Open the lid.

4. Using an Allen wrench, remove the four Allen head screws that hold the platform to

the bearing housing. Set the platform and its mounting screws aside for reuse.

5. Remove the E-ring that holds the upper bearing housing to the shaft.

6. Remove the four nuts (two on either side) from the bearing housing mounting plate.

These nuts hold the flexure arms in place.

7. Slide the upper bearing housing off the shaft, and set it aside.

8. Use the hex wrench to loosen the four hex nuts on the motor mounting bracket.

9. Gently slide the motor mounting bracket toward the righthand side of the shaker.

This loosens the drive belt from the motor pulley and the large counterweighted

pulley. Moving the motor mounting bracket forward will cause the belt to fall from

both belt tracks.

10. Remove the old belt.

11. With one hand, place the new belt around the motor pulley, and with the other hand

guide the belt around the large counterweighted pulley.

12. Move the motor mounting bracket back, until there is a slight resistance.

13. Verify that the drive belt has a slight pressure near the center. The recommended

deflection is 3/8 inch (9.5 mm).

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 31

31

Figure 8: Drive Belt Replacement

E-RING

UPPER

BEARING

HOUSING

FLEXURE

ARM NUTS

FLEXURE ARM

FLEXURE ARM NUTS

COUNTERWEIGHTED

MOTOR

PULLEY

PULLEY

DRIVE BELT

MOTOR MOUNTING

BRACKET

14. Use the hex wrench to tighten the four hex nuts on the motor mounting bracket.

15. Reinstall the upper bearing housing on the shaft.

16. Reattach the flexure arms to the bearing housing mounting plate with the four nuts

previously removed.

17. Reattach the E-ring to the shaft.

18. Reinstall the platform on the bearing housing with the four Allen head screws

previously removed.

19. Close the shaker lid.

20. Reconnect the power cord to the electrical outlet.

New Brunswick Operating Manual

Page 32

32

8.6 Replacement Parts

We recommend that you keep on hand one spare motor drive belt and two (each)

replacement fuses. Eppendorf offers a spare parts kit that contains commonly needed

replacement parts for your Excella E-24/24R (see Table 2 below).

Table 2: Spare Parts Kit M1352-6000

V-Belt 1

Gas springs 2

Fuse, 8-amp 4

Description Quantity

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 33

33

99

When ordering accessories, you may be asked to provide the model number and serial number of

your shaker. This information is on the electrical specification plate, located on the rear panel of

the unit.

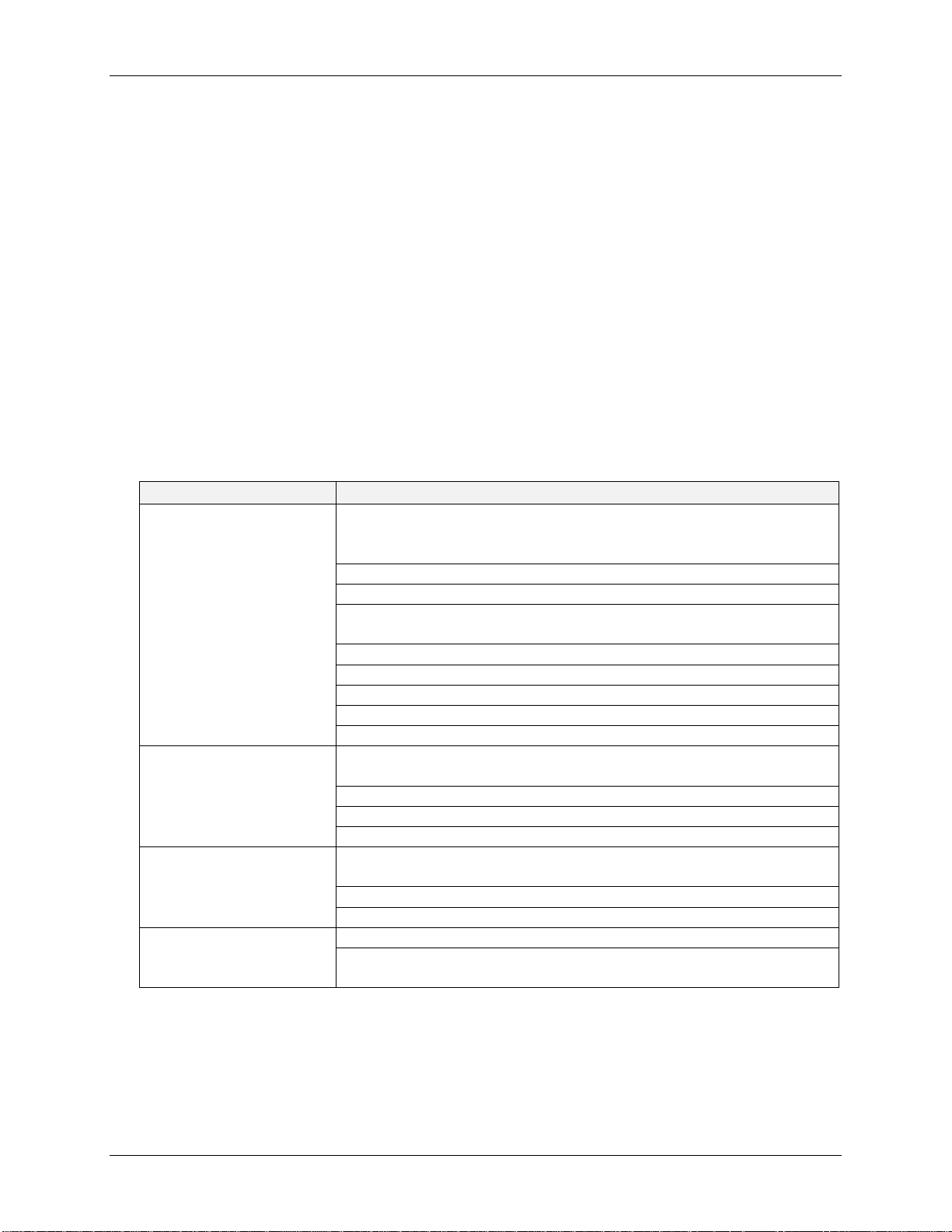

9.1.1 Platforms

Table 3: Available Platforms

Description Capacity Part No.

Universal Platform see Table 4 M1250-9902

125 mL Erlenmeyer flask Dedicated Platform* 34 M1194-9904

250 mL Erlenmeyer flask Dedicated Platform* 25 M1194-9905

500 mL Erlenmeyer flask Dedicated Platform* 16 M1194-9906

1L Erlenmeyer flask Dedicated Platform* 9 M1194-9907

2L Erlenmeyer flask Dedicated Platform* 5 M1194-9908

2.8L Fernbach flask Dedicated Platform* 4 M1194-9932

Utility carrier with cushioned crossbars -- M1194-9909

Utility tray with non-skid rubber surface -- M1194-9910

Sticky pad platform -- M1250-9903

*dedicated platforms include flask clamps

Should you decide in favor of the Universal Platform, following is a list of that

particular platform’s flask capacity, according to flask size:

Table 4: Universal Platform Flask Capacities

Flask Type Capacity*

50 ml Erlenmeyer Flasks 45

125 ml Erlenmeyer Flasks 21

250 ml Erlenmeyer Flasks 18

500 ml Erlenmeyer Flasks 14

1 L Erlenmeyer Flasks 8

2 L Erlenmeyer Flasks 5

2.8 L Fernbach Flasks 4

*Clamps for Universal Platform are sold separately.

A

CCCCEESSSSOORRIIEES

A

S

9.1.2 Flask Clamps for Universal Platforms

The following clamps, according to flask size, are available for use with the

Universal Platform:

New Brunswick Operating Manual

Page 34

34

Table 5: Flask Clamps

Clamp Size Part Number

10 ml Erlenmeyer Flask ACE-10S

25 ml Erlenmeyer Flask M1190-9004

50 ml Erlenmeyer Flask M1190-9000

125 ml Erlenmeyer Flask M1190-9001

250 ml Erlenmeyer Flask M1190-9002

500 ml Erlenmeyer Flask M1190-9003

1 L Erlenmeyer Flask ACE-1000S

2 L Erlenmeyer Flask ACE-2000S

2.8 L Fernbach Flask ACSB-2800S

9.1.3 Replacement Clamp Hardware Kits

New Brunswick flask clamps come complete with mounting screws. Additional

screws are available separately in packs of 25 (see Section 8.6).

9.1.4 Test Tube Racks & Other Accessories

Table 6: Racks & Trays

Accessory Description Part

Adjustable angle Test Tube

Rack for tubes 8 – 11 mm

diameter

Adjustable angle Test Tube

Rack for tubes 12 - 15 mm

diameter

Adjustable angle Test Tube

Rack for tubes 15 –18 mm

diameter

Adjustable angle Test Tube

Rack for tubes 18 – 21 mm

diameter

Adjustable angle Test Tube

Rack for tubes 22 – 26 mm

diameter

Adjustable angle Test Tube

Rack for tubes 26 - 30 mm

diameter

Microplate holder rack

(stacked)

Microplate holder rack

(single layer)

80 tube capacity M1289-0100 4

60 tube capacity M1289-0010 5

48 tube capacity M1289-0001 5

60 tube capacity M1289-0200 4

44 tube capacity M1289-0020 5

34 tube capacity M1289-0002 5

42 tube capacity M1289-0300 4

31 tube capacity M1289-0030 5

24 tube capacity M1289-0003 5

30 tube capacity M1289-0400 4

23 tube capacity M1289-0040 5

18 tube capacity M1289-0004 5

22 tube capacity M1289-0500 4

16 tube capacity M1289-0050 5

13 tube capacity M1289-0005 5

20 tube capacity M1289-0600 4

16 tube capacity M1289-0060 5

12 tube capacity M1289-0006 5

3 deep well or 9 standard M1289-0700 8

5 deep well or standard TTR-221 2

...continued...

Number

Platform

Capacity

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 35

35

Accessory Description Part

Number

Angled Test Tube Rack Holder* for user-supplied test tube

racks that are 4-5 in. (10-13 mm) wide and up to 15 in.

(38 mm) long.

Angled Test Tube Rack Spacer Bar* for use with TTR-210

to accommodate test tubes racks that are less than 5 in.

(13 mm) wide.

* Universal Platform Required

TTR-210

TTR-215

Platform

Capacity

2

NA

New Brunswick Operating Manual

Page 36

36

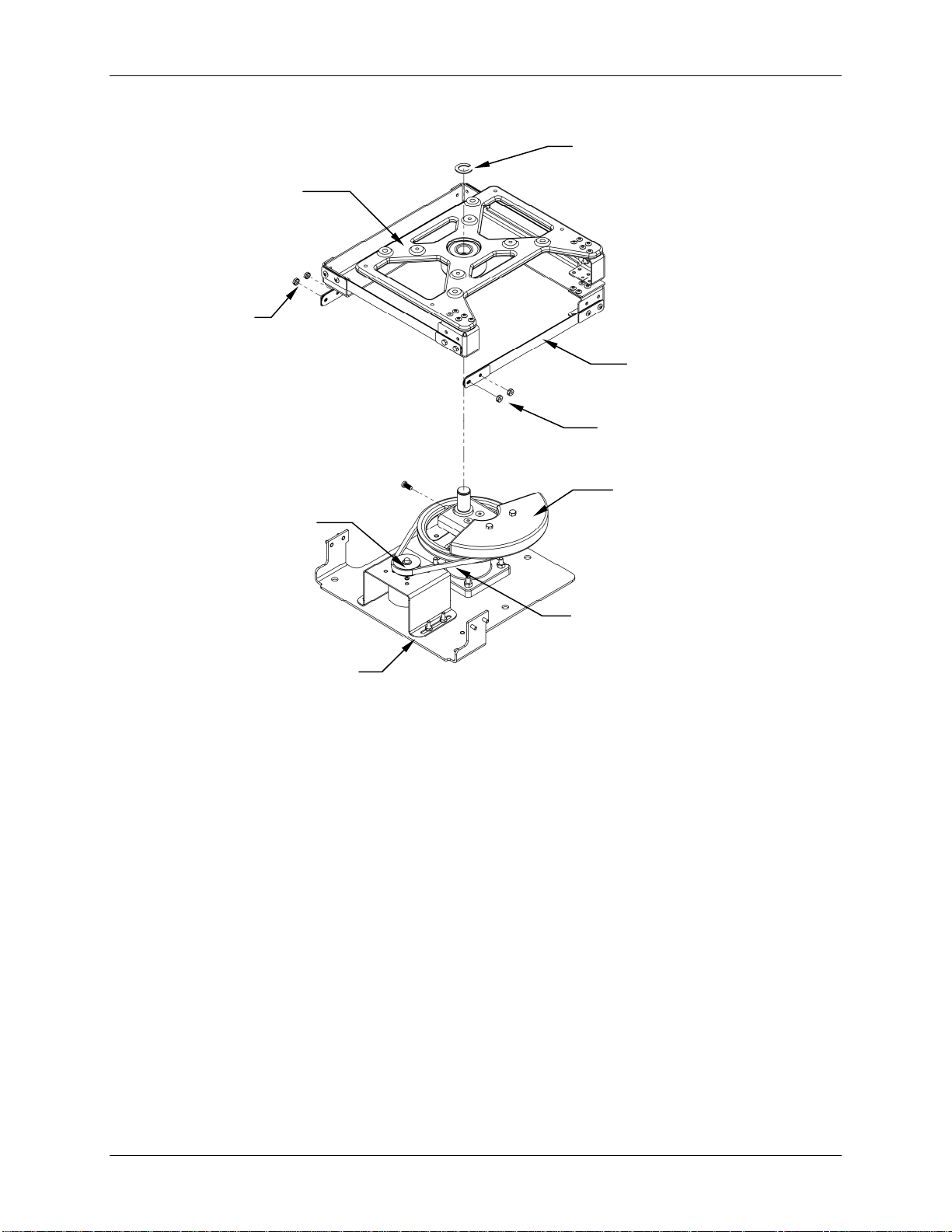

10.1 Schematics

Figure 9: Control Schematics (overview)

CB001 CB001

15 AMP

15 AMP

N

G

L

RED

BLACK

WHITE

YELLOW

RED

BLACK

WHITE

YELLOW

RED

BLACK

WHITE

YELLOW

line

THERMAL

THERMAL

THERMAL

M1324-8019

SWITCH

M1335-8018

SWITCH

M1335-8018

SWITCH

Filter

BLACK

L

2222

1212

LF1

load

M1324-8002

WHITE

L

N

TB002

TB002

TB002

1

J3

N

4

J5

3

1

WHITE

RED

RED

M1352-8003

M1324-8001

WHITE

RED

AC POWER

ENTRY

100-240 VAC 50/60Hz

HEATER 230Vac OPERATION

HEATER 120Vac OPERATION

HEATER 100Vac OPERATION

BLACK

M1299-8010

WHITE

M1299-8009

2121

1111

1100

SSR BOARD

M1324-7004

(REFRIGERATION OPTION)

(M1324-7003)

J4

21 6543

VIOLET

YELLOW

ORANGE

WHITE

BLACK

M1324-8010

DISPLAY BOARD

M1324-7002

1 2 3 4 5

1

J2

3

4123J1765

4321

76561

J2

POWER DISTRIBUTION

DISPLAY DRIVER BOARD

J5

M1352-8001

20 Cond. Ribbon Cable

J4

J2

M1352-8006

BRN

J6

M1324-7001

D

RRAAW

D

PINK

J3

84

WIINNGGSS

M1352-8005

J4

M1352-8004

1

12

2

CN2

11

3

10

M1282-8003

50 Cond. Ribbon Cable

DOOR SW.

E-24; I-24

5

3

CN1

1

POWER SUPPLY

J1

34

M1352-8009

&

T

&

R1 - 7.5 ohm/25W

PINK

BRN

M1352-8005

PINK

BRN

PINK

BRN

M1352-8005

BRN

-MGND

J6BJ6A

J6

J5

CONTROL BOARD

M1324-7000

M1352-8005

PINK

+30V

J7

3

4

5

6

7

J1

8

9

10

1

1

2

3

4

J3

AABBLLEES

T

WHITE

WHITE

PINK

BRN

BLUE

BLUE

M1299-8002

PHASE C

PHASE B

PHASE A

GND

VREF

Temp.

Sensor,RTD

M1195-8001

RS232

10 Cond.

Ribbon Cable

Port

M1299-8020

M1352-8008

SA

SB

SC

S

+

+

FAN1

FAN2

1

2

3

4

MTR

5

M001

6

7

8

(REFRIGERATION OPTION)

COMPRESSOR UNIT

M1352-8011

SEE DRAWING #2 FOR DIFFERENT VOLT OPERATION

TB001

KEY PAD

ALARM OPTION

(I24 ONLY)

NOTE:

For a larger version of this drawing, contact your sales or service

representative.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 37

37

Figure 10a: 230VAC/50 Hz Schematic

230Vac/50Hz OPERATION

POWER

TRANSFORMER

M1324-8015

N

230V

100V

120V

FROM

M1324-7003

RED

ORANGE

BLACK

WHITE

YELLOW

VIOLET

M1352-8002

J4-1

J4-3

J4-5

J4-2

J4-4

J4-6

COND. FAN

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

ORANGE

M1352-8007

BLUE

1

2

BLACK

BLACK

BLACK

VIOLET

ORANGE

WHITE

BLACK

M1352-8007

RED

TB001

Figure 10b: 100VAC/60 Hz Schematic

100Vac/60Hz OPERATION

POWER

TRANSFORMER

M1324-8015

N

230V

120V

100V

TB001

M1352-8002

COND. FAN

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

ORANGE

M1352-8007

BLUE

1

2

BLACK

BLACK

BLACK

VIOLET

WHITE

ORANGE

M1352-8007

RED

BLACK

M1324-7003

ORANGE

BLACK

RED

WHITE

YELLOW

VIOLET

FROM

J4-3

J4-5

J4-1

J4-2

J4-4

J4-6

New Brunswick Operating Manual

Page 38

38

Figure 10c: 100VAC/50 Hz Schematic

100Vac/50Hz OPERATION

POWER

TRANSFORMER

M1324-8015

N

230V

120V

100V

FROM

M1324-7003

ORANGE

RED

BLACK

WHITE

YELLOW

VIOLET

M1352-8002

COND. FAN

ORANGE

M1352-8007

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

BLUE

RED

ORANGE

WHITE

BLACK

BLACK

BLACK

M1352-8007

BLACK

1

VIOLET

2

TB001

J4-3

J4-1

J4-5

J4-2

J4-4

J4-6

Figure 10d: 120VAC/60 Hz Schematic

120Vac/60Hz OPERATION

TB001

COND. FAN

ORANGE

M1352-8007

BLUE

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

BLACK

BLACK

M1352-8002

BLACK

VIOLET

M1352-8007

1

2

FROM

M1324-7003

RED

ORANGE

BLACK

WHITE

YELLOW

VIOLET

J4-1

J4-3

J4-5

J4-2

J4-4

J4-6

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 39

39

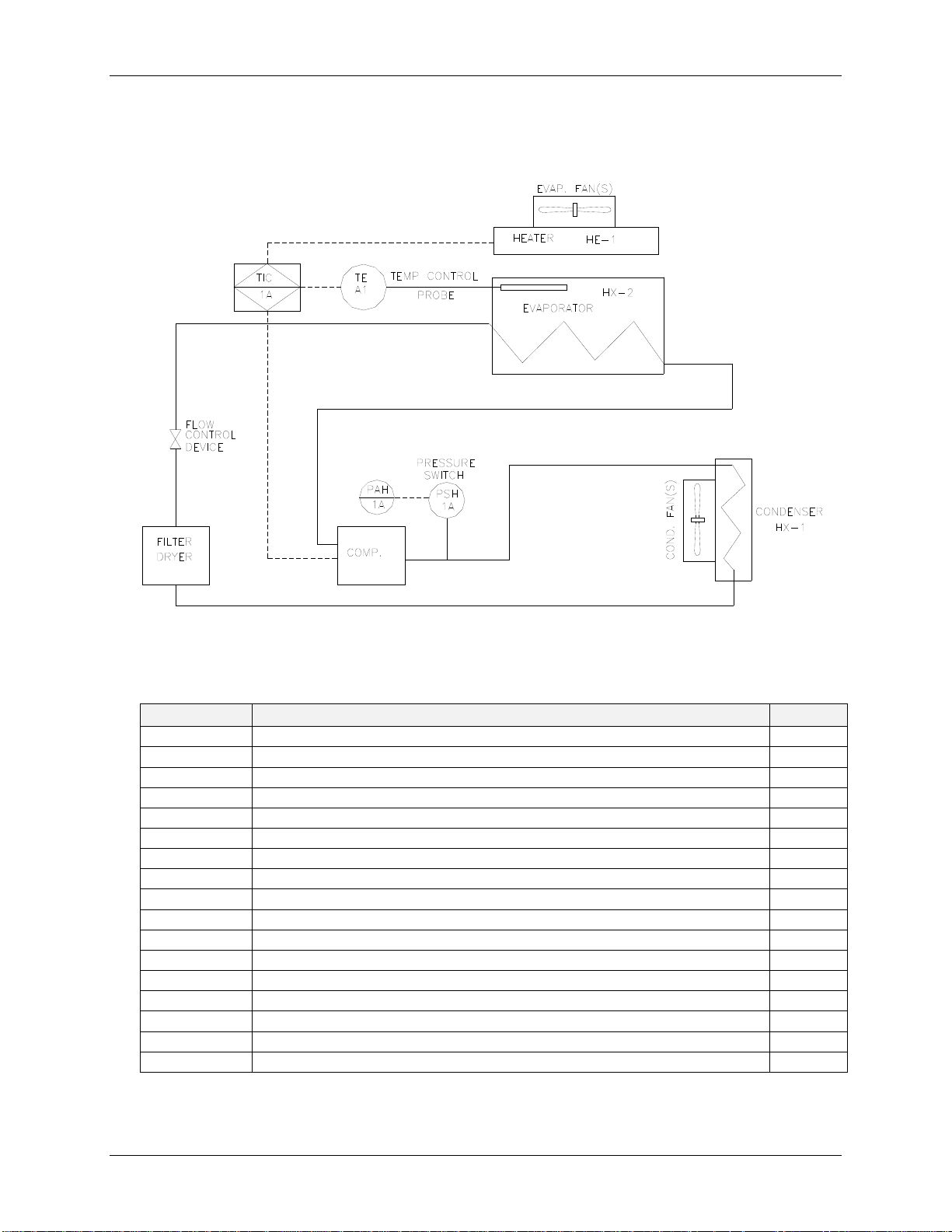

Figure 11: Refrigeration Schematic

10.2 List of Drawings

Figure Description Page

1 Space Requirements 14

2 Platform Screw Locations 15

3a Double Girdle Clamp Installation 16

3b Clamp Fastener 17

4 Control Panel 18

4a Keypad 19

5 ON/OFF Switch Location 22

6 Accessing Fuses 31

7a Fuse Replacement (Excella E-24) 32

7b Fuse Replacement (Excella E-24R) 32

8 Drive Belt Replacement 34

9 Control Schematic 39

10a 230VAC/50 Hz Schematic 40

10b 100VAC/60 Hz Schematic 40

10c 100VAC/50 Hz Schematic 41

10d 120VAC/60Hz Schematic 41

11 Refrigeration Schematic 42

New Brunswick Operating Manual

Page 40

40

10.3 List of Tables

Table Description Page

1 Fuses 31

2 Spare Parts Kit M1352-6000 35

3 Available Platforms 36

4 Universal Platform Flask Capacities 36

5 Flask Clamps 37

6 Racks & Trays 37

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 41

41

S

1111

PPEECCIIFFIICCAATTIIOONNS

S

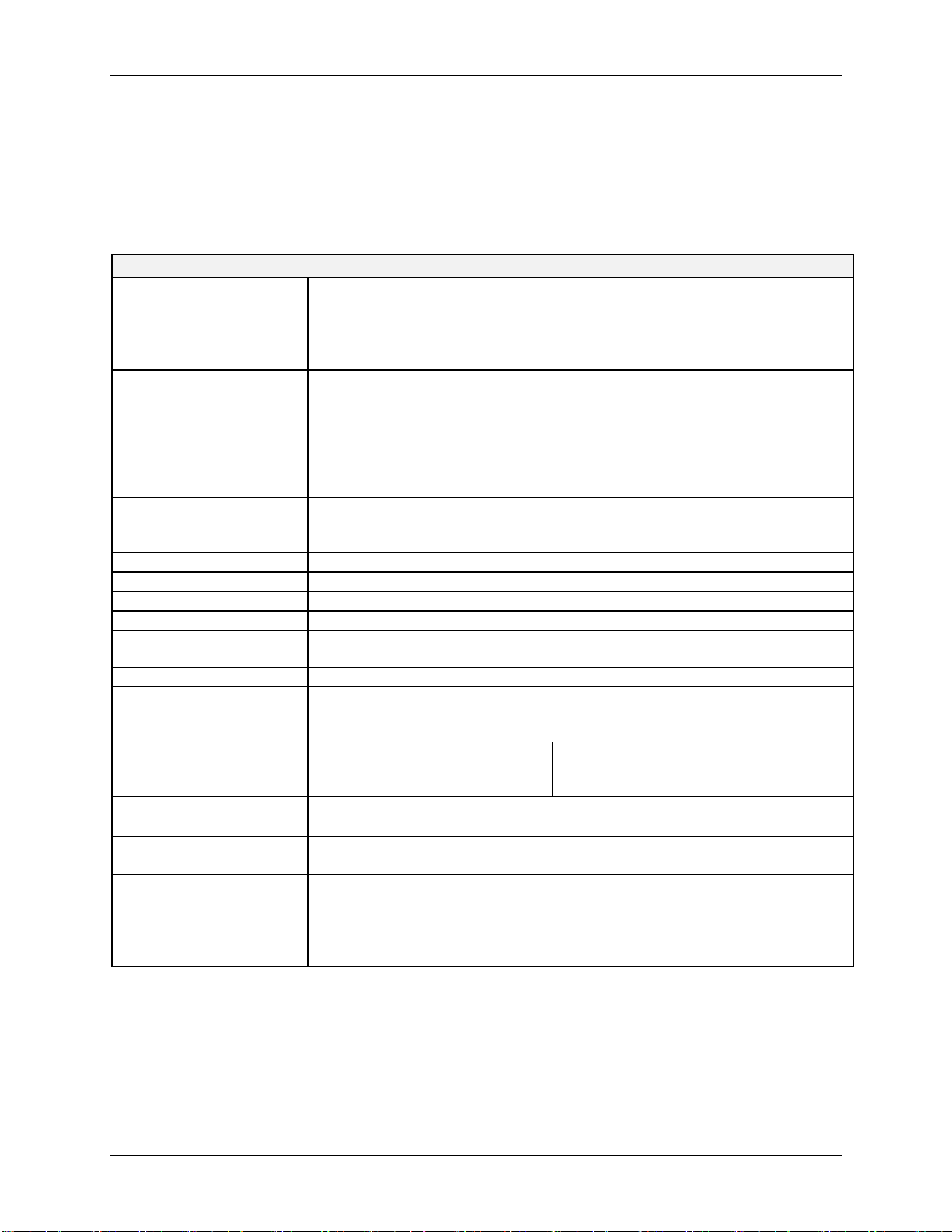

These specifications assume a maximum load of 34 pounds (15.5 kg), including platforms,

clamps, glassware and contents.

Excella E-24 & E-24R Incubator Shaker

SHAKING

Speed

Control Accuracy

Indication

Stroke/Orbit

TEMPERATURE

Range (E-24)

Range (E-24R)

Control Accuracy

Indication

Heater

ALARMS

LED DISPLAY

RS-232

SETPOINT RETENTION

AUTOMATIC RESTART

DRIVE

DRIVE MOTOR

SAFETY

ELECTRICAL

REQUIREMENTS

ETL REGULATORY

STANDARDS

CE REGULATORY

STANDARDS

DIMENSIONS

Width

Depth (Front to Back)

Height

Height with lid open

1

see first NOTE on following page

2

depending on ambient factors, such as relative humidity. Ambient temperature is measured one meter

from the front of the shaker

1

2

2

50-400 rpm

1 rpm

Displayed in 1 rpm increments

¾-inch (1.9 cm)

7ºC above ambient temperature to 60°C

15ºC below ambient temperature (minimum 4ºC) to 60°C

0.1°C at 37°C

Displayed in 0.1°C increments

Long-life, low-watt density resistance-type heater with high temperature

thermostat

Visible and audible warning indication when speed deviates more than 5

rpm or temperature more than 1°C from setpoints, and when timer has

expired. Audible alarm can be muted.

9/16-inch (1.4 cm)

Data logging

All setpoints and operating status are retained in non-volatile memory

Automatic restart after power is restored, indicated by flashing display

UniCentric™ counterbalanced drive with four permanently lubricated ball

bearings

Solid-state brushless DC motor.

Drive Interrupt shuts off power to Shaker when lid opens.

Acceleration/deceleration circuit prevents sudden starts and stops,

minimizing both splashing and mechanical damage.

100 Volts, 50/60 Hz

120 Volts, 60 Hz

230 Volts, 50 Hz

UL 61010A-1 CAN/CSA-C22.2 No. 1010.1

UL 61010A-2-010 CAN/CSA-C22.2 No. 1010.2.010

See Declaration of Conformity, Section 11.1.

24 1/16 inches (61.1 cm)

40⅛ inches (101.9 cm)

E-24: 800 VA per shaker

E-24R: 1500 VA per shaker

22 inches (55.8 cm)

30 inches (76.2 cm)

.

S

New Brunswick Operating Manual

Page 42

42

Excella E-24 & E-24R Incubator Shaker

CHAMBER

DIMENSIONS

PLATFORM

NET WEIGHT

24

24R

21 inches deep x 20⅜ inches wide x 13 9/16 inches high

(53.3 cm deep x 51.7 cm wide x 34.4 cm high) from top of platform

Aluminum, 18" X 18" (46 X 46 cm). Select universal or dedicated styles.

138 lbs (62.7 kg)

184 lbs (83.6 kg)

NOTE:

Use of baffled flasks will significantly reduce maximum speed for any shaker. We

may be able to improve this maximum speed by using an alternative motor pulley.

Contact your Eppendorf representative for more information.

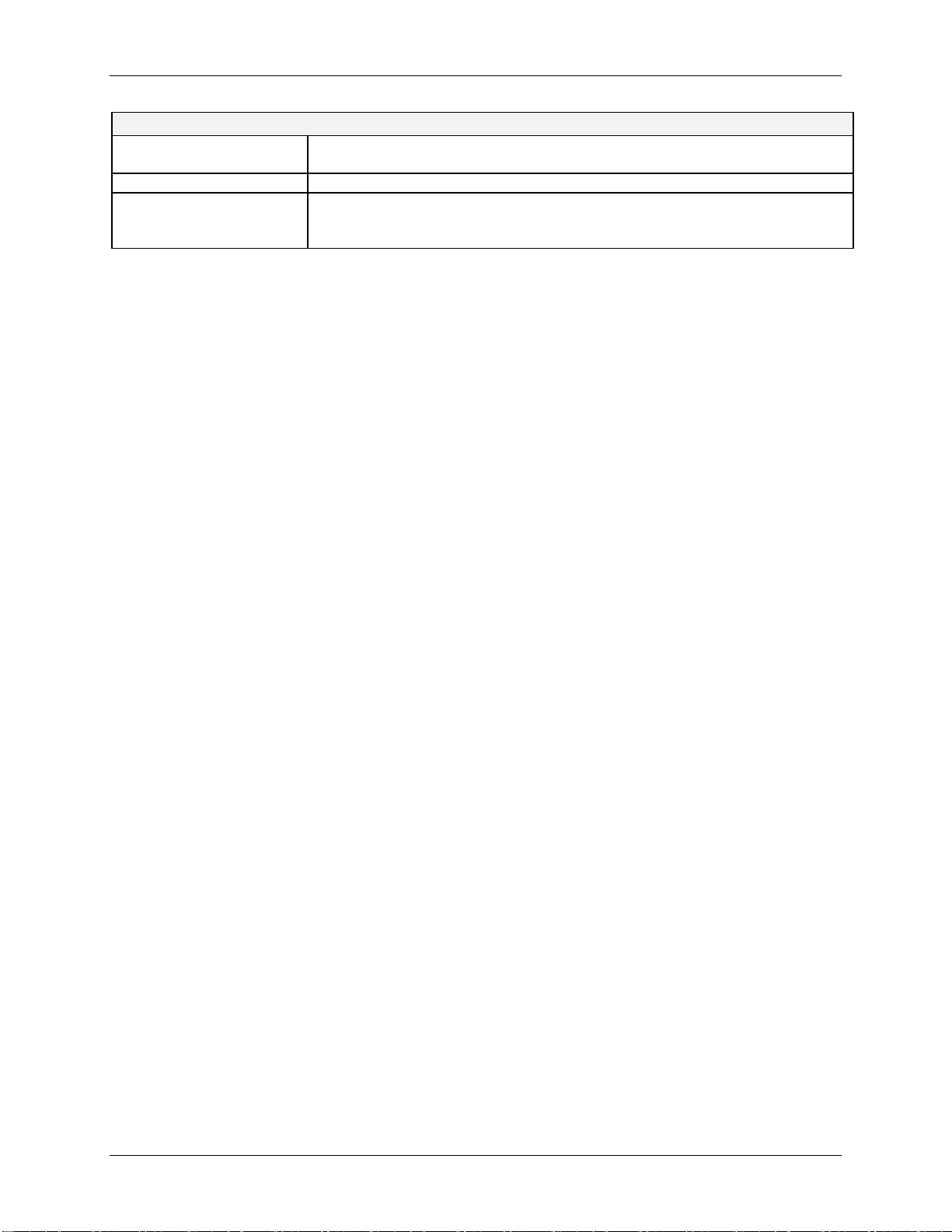

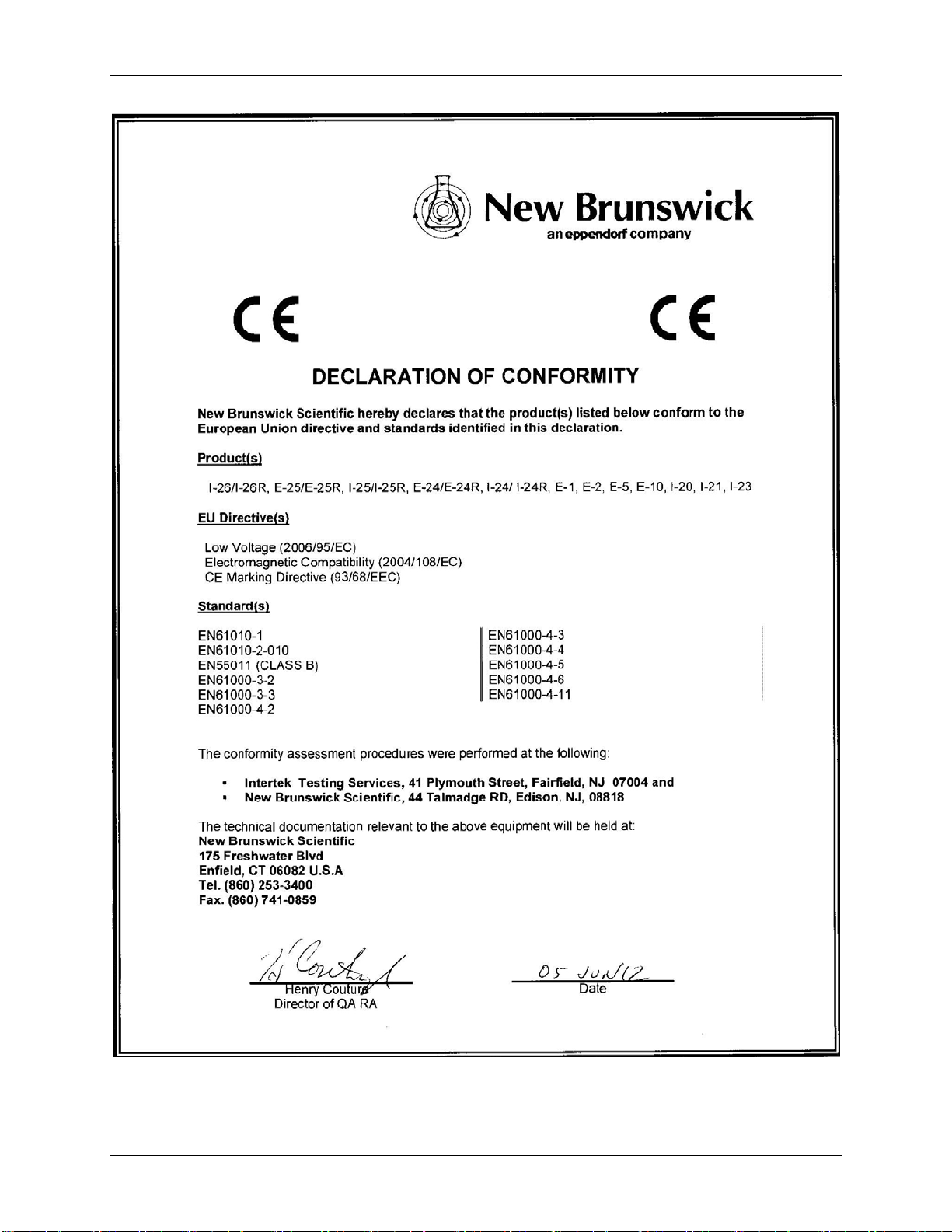

11.1 Certifications

The Excella E-24 and E-24R have been tested to ETL standards, to comply with UL and

CAN/CSA electrical safety standards (see “ETL Regulatory Standards” in the

specifications table).

As attested in the CE Declaration of Conformity reproduced on the following page, the

Excella E-24 and E-24R also conform to the appropriate CE standards (see also “CE

Regulatory Standards” in the specifications table).

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 43

43

New Brunswick Operating Manual

Page 44

44

A

1122

12.1 Return Procedure

As explained in Section 8.2, should you need to return your Excella E-24/24R to

Eppendorf for any reason, first contact Customer Service to obtain a Returned Material

Authorization (RMA) number. This number must appear on the outside of the shipping

container, otherwise Eppendorf Receiving will refuse to accept the shipment.

In addition, you must also certify that the instrument being returned has been thoroughly

cleaned and decontaminated. A form for this purpose is provided on the following page;

you can photocopy it and fill it out by hand. It can also be downloaded from our website

(www.nbsc.com

A copy of the completed Return Authorization and Decontamination Certificate must be

attached to the outside of the container, with a second copy packed inside with the

instrument.

12.2 Return Authorization and Decontamination Certificate

), if you prefer to fill it out electronically.

PPPPEENNDDIIX

A

X

:

:

P

RROODDUUCCTT

P

R

EETTUURRNNS

R

S

A sample form for you to copy and fill out is provided on the following page.

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 45

45

New Brunswick Scientific

Return Authorization and

Decontamination Certificate

Contact Eppendorf for an RMA number prior to returning any equipment, then complete this form and

attach it to the outside container of the equipment being returned to our facility. In addition, please

enclose a completed, duplicate copy of this form with the returned item.

Returned Material Authorization (RMA) Number ____________________

Equipment being returned: Model Number ______________Serial Number__________________

Reason for its return:

______________________________________________________________________________

__________________________________________________________________

This equipment (check all that apply):

New Product Biohazards

Never used Not used

_________________________

Hazardous Chemicals Radioactive Materials

Not used Not used

Used, but decontaminated with Used, but decontaminated with

_________________________ _________________________

I certify that the equipment described above has been thoroughly cleaned and

decontaminated of all chemical, biological and radioactive contaminants and also certify

that the returned unit is safe for unprotected human contact.

By: _______________________________ _________________________________

Signature Print name

Title: ______________________________ Date: ____________________________

Company: ____________________________

Address: ____________________________

____________________________

____________________________

Phone: _________________ Fax: ________________ email: ______________

Used, but decontaminated with

Form 2847

New Brunswick Operating Manual

Page 46

46

A

Accessories, 33

Racks & Trays, 34

Actual Temperature, 22

Alarm Functions, 21

Alarms, 6, 41

Audible Alarm

Disabling the, 21

Muting the, 21

Automatic Restart, 41

B

Belt Replacement, 30

Biohazards, 24

C

Calibrating Speed, 23

Certifications, 42

Checking Setpoints, 20

Clamp Hardware Kits, 34

Cleaning, 24

Continuous Operation, 6

Continuous Run, 20

Control Schematic, 36

Customer Satisfaction Form 6300, 9

D

Declaration of Conformity, 43

Decontamination, 24

Decontamination Certificate, 27, 44, 45

Dimensions

Chamber, 42

Overall, 41

Platform, 42

Double Girdle Clamps, 13

Drawings

List of, 39

Drive, 41

1133

Drive Belt

Removing the, 30

Replacing the, 30

E

Electrical Connections, 14

Electrical Requirements, 10, 41

Electrical Service, 14

Environment, 10

F

Features

Status Indicators, 17

Flask Capacities, 33

Flask Clamp Installation, 13

Flask Clamps, 33

Function Indicators, 17

Fuses, 28

H

Heater, 41

I

Incomplete Order, 9

Index of Drawings, 39

Index of Tables, 40

Indicated Temperature, 22

Inspection

of Boxes, 8

Installation Space, 11

L

LED Display, 16, 41

M

Maintenance, 24

Missing Parts, 9

Motor, 41

I

NNDDEEX

I

X

Excella E-24/24R Incubator Shakers M1352-0050 Operating Manual

Page 47

47

Mute Function, 21

N

Net Weight, 42

O

On/Off Switch

Location of, 19

Operation, 19

Operation Modes, 6

P

Packing List

Verification of, 8

Platform

Available Types, 33

Platforms, 6

Power Failure, 23

Problems, 26

Product Returns, 27, 44

Shipping Damage, 9

Space Requirements, 11

Spare Parts, 32

Specifications, 41

Speed Calibration, 23

Spills, 24

Starting the Unit, 19

Status Indicators, 17

T

Tables

List of, 40

Temperature Correction Value, 22

Temperature Offset Calibration, 22

Temperature Range, 41

Temperature Setpoint, 21

Test Tube Racks, 34

Timed Functions, 20

Timed Run, 6

Troubleshooting, 26

R

Refrigeration Schematic, 39

Replacement Parts, 32

Return Authorization, 27, 44, 45

Returned Material Authorization Number,

27, 44

RMA, 27, 44, 45

RS-232, 41

S

Safety, 41

Safety Switch, 6

Setpoint Retention, 41

Shaking Speed, 41

U

UniCentric™ Drive, 6, 41

Universal Platform, 33

Untimed Run, 20

User Interface Keys, 16

V

Visual Alarm

Disabling the, 21

W

Warranty Registration, 9

New Brunswick Operating Manual

Page 48

Evaluate your operating manual

www.eppendorf.com/manualfeedback

Your local distributor for New Brunswick products: www.nbsc.com/ContactUs

New Brunswick Scientific, 175 Freshwater Boulevard, Enfield, CT 06082-4444 USA

Eppendorf AG • 22331 Hamburg • Germany • Tel: +49 40 538 01-0 • Fax: +49 40 538 01-556 • E-mail: eppendorf@eppendorf.com

New Brunswick Scientific Europe B.V. • Nijmegen • The Netherlands • Tel: +31 (0) 24 3717 600 • E-mail: europe@nbsbv.nl

Eppendorf North America, Inc. • Hauppauge, NY • USA • Tel: +1 516 334 7500 • +1 800 645 3050 • E-mail: info@eppendorf.com

Application Support Europe, International: Tel: +49 1803 666 789 • E-mail: support@eppendorf.com

North America : Tel : +1 800 645 3050 menu option 2 • E-mail: techserv@eppendorf.com

Asia Pacific: Tel: +603 8023 6869 • E-mail: support_asiapacific@eppendorf.com

Loading...

Loading...