Page 1

nualck CO2 Back-up System

EN) manual

New Brunswick™

CO2 Back-up System

Operating manual

Page 2

Copyright

Copyright © 2014 Eppendorf AG, Germany. No part of this publication may be reproduced without the

prior permission of the copyright owner.

The company reserves the right to change information in this document without notice. Updates to

information in this document reflect our commitment to continuing product development and

improvement.

Trademarks

®

Eppendorf

New Brunswick™ and the New Brunswick

Innova

Trademarks are not marked in all cases with ™ or

and the Eppendorf logo are registered trademarks of Eppendorf AG, Germany.

™

Logo are trademarks of Eppendorf AG, Germany.

®

is a registered trademark of Eppendorf, Inc., USA.

®

in this manual.

Eppendorf has attempted to identify the ownership of all trademarks from public records. Any omissions or

errors are unintentional.

M1288-0055-M/012014

Page 3

Table of contents

New Brunswick CO2 Back-up System

English (EN)

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Hazard icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Degrees of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 Personal injury and damage to device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 Incorrect handling of accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3

3 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Scope of manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 CO

Back-up System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2

5.3 Product versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Unpacking the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Temperature sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4.1 Temperature sensor installation for upright freezers . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.4.2 Temperature sensor installation for chest freezers. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5 Manifold-to-solenoid valve transfer line assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5.1 Manifold-to-solenoid valve transfer line assembly for upright freezers (including Model

U101)17

6.5.2 Manifold-to-solenoid valve transfer line assembly for chest freezers. . . . . . . . . . . . . . 17

6.6 Solenoid valve to freezer installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.6.1 Solenoid valve installation for upright freezers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.6.2 Solenoid valve installation for chest freezers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.7 Installing more 0.6 m (2 ft) transfer lines to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.7.1 Installing 0.6 m (2 ft) transfer line to manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.8 CO

gas supply installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

6.9 Test for gas leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.10 Door switch installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.11 Installing cables to back of control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 4

Table of contents

New Brunswick CO2 Back-up System

4

English (EN)

7 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1 Turning the control unit on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 Testing the solenoid valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.3 Testing door switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4 Testing back-up system operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.5 Battery back-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.6 Alarm system monitoring socket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1.1 Cleaning the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1.2 Cleaning the surrounding area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 CO

bottle maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2

8.3 Electrical connection maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.4 Battery maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.5 Transfer line and manifold maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.6 Maintenance forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.7 CO

/LN2 back-up system service checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2

9 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.1 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2 Weight/dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2.1 Device dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.2.2 Device weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.3 Cable and transfer line lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.4 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.5 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9.6 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.6.1 Device operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.7 Gas Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.8 CO

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2

9.9 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.10 Circuit Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 5

Operating instructions

New Brunswick CO2 Back-up System

English (EN)

1 Operating instructions

1.1 Using this manual

Carefully read this operating manual before using the device for the first time.

Also observe the operating manual enclosed with the accessories.

This operating manual should be considered part of the product and stored in a location that is easily

accessible.

Include this operating manual when forwarding the device to third parties.

If this manual is lost, please request another one. The latest version can be found on our website

www.eppendorf.com (international) or www.eppendorfna.com (North America).

1.2 Danger symbols and danger levels

1.2.1 Hazard icons

5

Material damage Freezer burn

Hazard point Electric shock

1.2.2 Degrees of danger

The following danger levels are used in safety messages throughout this manual.

DANGER Will lead to severe injuries or death.

WARNING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

1.3 Symbols used

Depiction Meaning

You are requested to perform an action.

1.

2.

• List

Text Terms and labels of the graphic user interface.

Perform these actions in the sequence described.

References useful information.

Page 6

Operating instructions

New Brunswick CO2 Back-up System

6

English (EN)

Page 7

Safety

New Brunswick CO2 Back-up System

English (EN)

2 Safety

2.1 Intended use

The CO2 Back-up System is exclusively intended for indoor use and for and to maintain inside temperature

of all Innova and Premium freezers in case of power failure.

2.2 User profile

The device may only be operated by trained lab personnel who have carefully read this operating manual

and are familiar with the device functions.

2.3 Information on product liability

In the following cases, the designated protection of the device may be compromised.

7

The liability for the function of the device passes to the operator if:

• The device is not used in accordance with this operating manual.

• The device is used outside of the range of application described in the succeding chapters.

• The device is used with accessories or consumables that were not approved by Eppendorf.

• Service or maintenance is completed on the device by people who are not authorized by Eppendorf.

• The owner has made unauthorized modifications to the device.

2.4 Warnings for intended use

Before using the device, read this operating manual and observe the following general safety instructions.

2.4.1 Personal injury and damage to device

WARNING! Electric shock due to damage to the device or power cable

Only switch on the device if the device and power cable are undamaged.

Only use devices that have been properly installed or repaired.

WARNING! Danger due to incorrect power supply

Only connect the device to voltage sources that meet the requirements on the name plate.

Only use sockets with a protective earth (PE) conductor and suitable power cable.

WARNING! Direct contact with cold contents inside the freezer can burn unprotected skin

Use freezer gloves at all times when loading or unloading equipment.

Page 8

Safety

New Brunswick CO2 Back-up System

8

English (EN)

2.4.2 Incorrect handling of accessories

CAUTION! Lack of safety due to incorrect accessories or spare parts

Accessories and spare parts that are not recommended by Eppendorf compromise the safety,

function and precision of the device. Eppendorf cannot be held liable or accept any liability for

damage resulting from the use of non-recommended accessories and spare parts.

Only use accessories and original spare parts recommended by Eppendorf.

Page 9

3 Product description

3.1 Main illustration

Product description

New Brunswick CO2 Back-up System

English (EN)

9

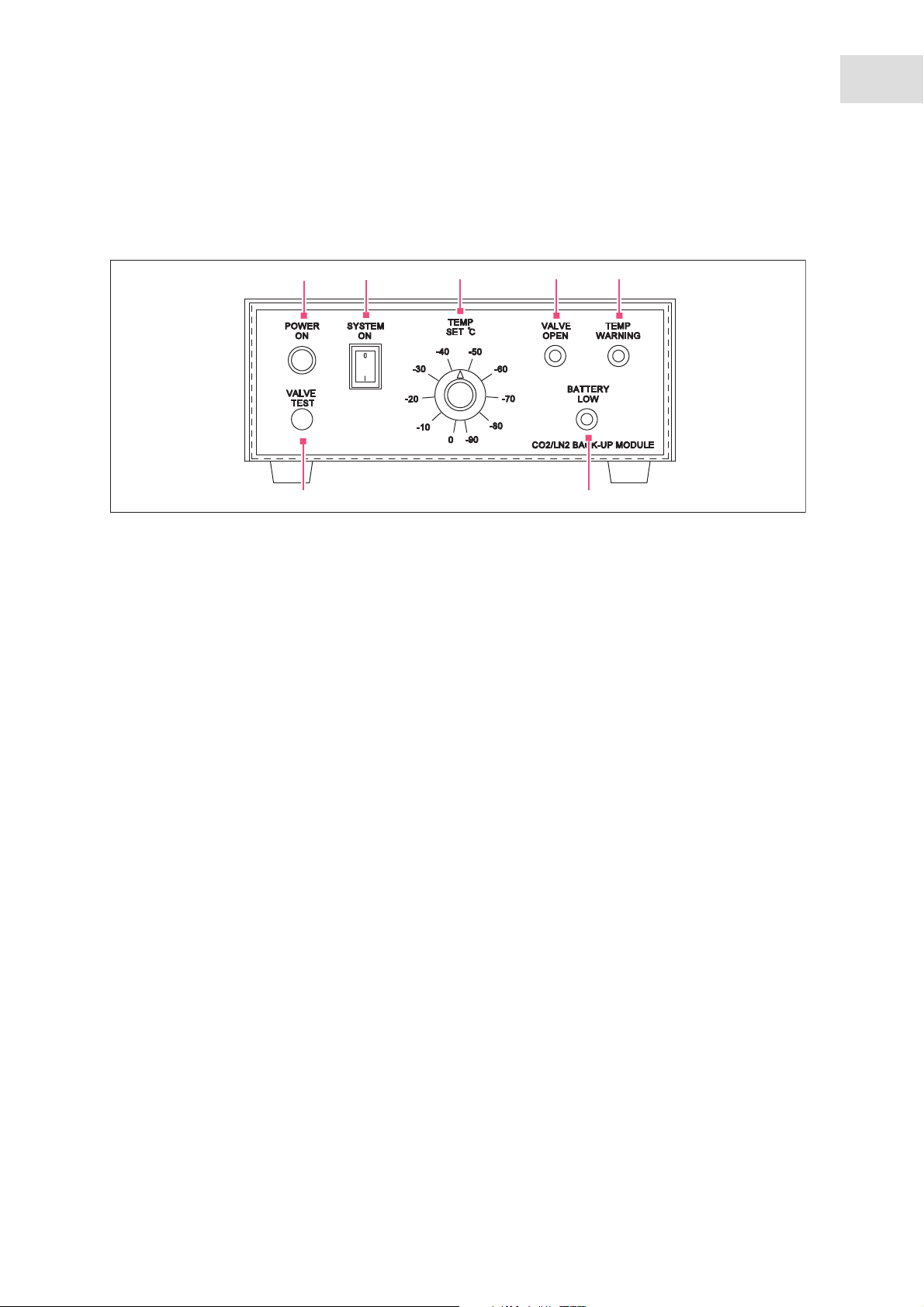

Abb. 3-1: Front view of the CO2 Back-up System

1

2

6

Fig. 3-1: Front view of the CO2 Back-up System

1 Power On LED

Illuminates when device is plugged into the

mains

2 System On Switch

Turns the device on or off

3 Temp Set Dial

Sets the back-up temperature in case of power

failure

3

4 5

7

5 Temp Warning LED

Illuminates when internal freezer temp drops

below set temperature on the Temp Set Knob

6 Valve Test Button

Button to push to test CO

injection

2

7 Battery Low LED

Illuminates when back-up battery inside device is

low

4 Valve Open LED

Illuminates when CO

valve is open

2

Page 10

10

Product description

New Brunswick CO2 Back-up System

English (EN)

Abb. 3-2: Back view of the CO2 Back-up System

8

13

Fig. 3-2: Back view of the CO2 Back-up System

8 Power Input Socket

Insertion point for power cord

9 Alarm Socket

10 Solenoid Valve Socket

5P DIN

9

10

11

11 Door Switch Socket

4P DIN

12 PT100 Probe Socket

3P DIN

13 Main Fuses

12

Page 11

Transport, storage and disposal

New Brunswick CO2 Back-up System

English (EN)

4 Transport, storage and disposal

4.1 Transport

NOTICE! Improper transportation

Only transport product in its original packaging

4.2 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European Community:

11

Within the European Community, the disposal of electrical devices is regulated by national regulations

based on EU Directive 2002/96/EC pertaining to waste electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in the business-to-business

sphere, to which this product is assigned, may no longer be disposed of in municipal or domestic waste. To

document this, they have been marked with the following identification:

Because disposal regulations may differ from one country to another within the EU, please contact your

supplier if necessary.

In Germany, this is mandatory from March 23, 2006. From this date, the manufacturer has to offer a

suitable method of return for all devices supplied after August 13, 2005. For all devices supplied before

August 13, 2005, the last user is responsible for the correct disposal.

Page 12

12

Transport, storage and disposal

New Brunswick CO2 Back-up System

English (EN)

Page 13

Introduction

New Brunswick CO2 Back-up System

English (EN)

5 Introduction

5.1 Scope of manual

This manual provides the user with the necessary information for the installation and operation of the CO2

®

Back-up System for New Brunswick Scientific’s Innova

and Premium -45 and -86 ranges of Ultra Low

Temperature Freezers.

5.2 CO2 Back-up System

The CO2 Back-up System system is designed to provide a means of maintaining the contents of a New

Brunswick Scientific Ultra Low Temperature Freezer at a preset temperature should the power or the

refrigeration system fail.

The freezer is fitted with a platinum resistance thermometer (referred to as a temperature sensor or probe)

to measure the internal temperature, a solenoid valve and a door switch.

13

A freestanding control unit and cables are provided. Transfer lines and connectors are supplied to connect

between the solenoid valve and the CO

NOTICE! Liquid CO

Liquid CO

is required, NOT gas. Bottles containing liquid CO2 fitted with full-length dip

2

bottle. Bottles are not provided.

2

required

2

tubes must be used.

The back-up system is plugged into the power supply and a temperature selected between 0 °C and -70 °C

on the Temp Set dial. When the temperature within the freezer rises above the selected back-up

temperature, the injector switches on. CO

gas is released in pulses of approximately two-second bursts,

2

then a fifteen-second delay.

The solenoid valve continues to inject gas until the temperature within the freezer drops below the preset

value selected on the Temp Set dial. If a power failure occurs, a battery within the back-up unit will

continue to operate the back-up system for up to 48 hours.

When the door or lid of the freezer is opened, the door switch is activated to prevent additional gas

injections while the freezer is open. This prevents the freezer user from being burned by the extremely cold

gas stream.

Page 14

14

Introduction

New Brunswick CO2 Back-up System

English (EN)

5.3 Product versions

There are four versions of the product:

Back-up Systems

Freezer type Part number

Innova 115 V / 220 V 60 Hz CGA Bottle Fitting U9043-0002

Innova 230 V 50 Hz BS341 Bottle Fitting U9043-0004

Premium 115 V / 220 V 60 Hz CGA Bottle Fitting U9043-0006

Premium 230 V 50 Hz BS341 Bottle Fitting U9043-0008

Page 15

Installation

New Brunswick CO2 Back-up System

English (EN)

6 Installation

6.1 Before installation

DANGER! Damage to device

Empty freezer before installation of device.

Open the door or lid of freezer and let reach ambient temperature.

The back-up unit cannot be fitted to a freezer that is operating!

Before installation, empty the freezer, switch it off, and disconnect it from the power outlet. Open the door

or lid and let the whole freezer reach ambient temperature.

15

6.2 Selecting the location

Select the location according to the following criteria:

• Position the control unit such that the disconnect device - the mains/power plug is easily accessible.

• Suitable mains power connection according to the ID plate

• Stable, level base

• Well ventilated area

• Ambient temperature of 5 °C to 32 °C

• Ambient humidity of 80 % at 31 °C

• Ambient humidity of 50 % at 40 °C

• Up to 2000 m

6.3 Unpacking the device

NOTICE! Damage due to incorrect usage

Only use the device for the intended use described in the operating manual.

Ensure adequate material resistance when using chemical substances.

If in doubt, contact Eppendorf.

Keep the packing material and transport securing device for later transport or storage.

Carefully unwrap the back-up unit and retain the packing materials for possible future use.

Check that all the items listed on the packing shipping list are present. Inspect all items for damage that

may have occurred during delivery. Report any damage or deficiencies to your local Eppendorf sales

representative.

Page 16

16

Installation

New Brunswick CO2 Back-up System

English (EN)

6.4 Temperature sensor installation

The temperature sensor is fitted to the freezer through the port fitted with a nylon plug. The hole is located

on either (a) the top panel, in the rear right-hand corner on upright models (except for the Model U101: see

note below), or (b) inside the compressor compartment on chest models.

On the U101 Innova freezer, the temperature sensor port is located on the left-hand side wall.

6.4.1 Temperature sensor installation for upright freezers

1. The temperature sensor is fitted through one of the two plugged ports.

2. Remove the plug that is not surrounded by four screws.

3. Insert the temperature sensor through the hole in the black blanking plug provided, pressing the

grommet on the sensor cable into the hole to seal.

4. Insert the temperature sensor through one of the insulation tubes provided and push the sensor and

insulation tube into the cabinet port.

5. Press the nylon plug into the hole.

6. Inside the freezer cabinet, position the temperature sensor next to the existing freezer temperature

sensor. The existing freezer temperature sensor is located halfway into the cabinet. (For the model U101

freezer, the temperature sensor cable should be secured to the left side of the internal cabinet and pass

under the fixed shelf. Position the CO

sensor).

7. Secure the CO

temperature sensor to the freezer temperature sensor using one of the plastic cable ties

2

provided.

8. Secure the temperature sensor cable to the two attachment points (plastic clips) attached to the cabinet.

temperature sensor next to the existing freezer temperature

2

6.4.2 Temperature sensor installation for chest freezers

1. Remove the right side cover of the frezer to expose the compressor compartment.

2. Looking into the compressor compartment, at the top left-hand corner, the existing freezer temperature

sensor can be seen passing into the freezer cabinet. The CO

through the same port.

3. Create a hole through the insulation next to the freezer temperature sensor by inserting a length of 1/

4-inch or ~6mm metal rod or tube through the insulation to create a passage for the probe (keeping the

rod or tube perpendicular to the cabinet wall when inserting through the insulation).

4. After creating the new hole, push the CO

temperature sensor through the hole and pull enough

2

temperature sensor cable through the hole to reach the freezer temperature sensor, located

approximately halfway down the front right corner, inside the freezer cabinet.

5. Remove freezer temperature sensor cover and position the two sensors side-by-side.

6. Fasten the two sensors with the plastic cable ties provided.

7. Replace the temperature sensor cover.

temperature sensor should be fitted

2

Page 17

Installation

New Brunswick CO2 Back-up System

English (EN)

6.5 Manifold-to-solenoid valve transfer line assembly

The manifold-to-solenoid valve transfer line assembly consists of the brass, six position block manifold, the

2.0 m (6.6 ft) transfer line, and the solenoid valve.

6.5.1 Manifold-to-solenoid valve transfer line assembly for upright freezers (including

Model U101)

1. Insert the free end of the 2.0 m (6.6 ft) transfer line into the solenoid valve assembly.

2. Rotate the fitting clockwise to tighten.

6.5.2 Manifold-to-solenoid valve transfer line assembly for chest freezers

1. Remove the compressor housing panel.

2. Remove the 2-inch blanking plug from the rear panel of the freezer.

3. Insert the free end of the 2.0 m (6.6 ft)transfer line into the solenoid valve. Pull enough hose through to

reach the solenoid valve.

4. Rotate fitting clockwise to tighten.

17

6.6 Solenoid valve to freezer installation

The solenoid valve is fitted to the freezer through the port fitted with a nylon plug and surrounded by a ring

of four screws. The port is located (a) on the top panel, in the rear right-hand corner on Upright models

(except for the Model U101: see NOTE below), or (b) inside the compressor compartment on Chest models.

NOTE: On the U101 Innova freezer, the injector port is located on the left-hand side wall.

6.6.1 Solenoid valve installation for upright freezers

1. Remove the nylon plug and the 4 screws surrounding the plug. Retain the screws for reuse.

2. Remove the protective cap from the end of the solenoid valve injector pipe.

3. Slide the square attachment plate with the central hole over the copper solenoid valve pipe.

4. Slide the insulation tube over the solenoid valve injection pipe.

5. Push the solenoid valve injector pipe with insulation tube into the exposed port in the freezer cabinet.

6. Slide the U-shaped bracket onto the slot of the solenoid valve body.

7. Secure the two plates to the body with the 4 screws that were set aside for reuse.

8. Tighten screws evenly to lock the solenoid valve into position.

6.6.2 Solenoid valve installation for chest freezers

1. Locate the port for the solenoid assembly on the upper right-hand side of the compressor compartment.

2. Remove the protective cap from the end of the solenoid valve injector pipe.

3. Slide the square attachment plate with the central hole over the solenoid valve injector pipe.

Page 18

18

Installation

New Brunswick CO2 Back-up System

English (EN)

4. Slide the insulation tube over the copper solenoid valve pipe.

5. Push the solenoid valve injector pipe with insulation tube into the exposed port in the freezer cabinet.

6. Slide the U-shaped bracket onto the slot of the solenoid valve body.

7. Secure the two plates to the body with the 4 screws that were set aside for reuse.

8. Tighten screws evenly to lock the injector and solenoid valve into position.

6.7 Installing more 0.6 m (2 ft) transfer lines to manifold

The kit is supplied with two 0.6 m (2 ft) transfer lines. These these transfer lines are attached from the CO2

bottles to the brass manifold. One 0.6 m (2 ft) transfer line is pre-attached to the end of the manifold. If

more than two CO

port on brass manifold), additional transfer lines can be purchased if required. If only one bottle is to be

used, the second supplied hose can be kept as a spare. CO

bottles will be used (up to five transfer lines and bottles can be connected; one for each

2

bottles are not supplied.

2

6.7.1 Installing 0.6 m (2 ft) transfer line to manifold

1. Remove the banking plug on one of the ports of the brass manifold with a hex key.

2. Place the Dowty seal over the threaded end of the 0.6 m (2 ft) transfer line.

3. Screw the 0.6 m (2 ft) transfer line into the threaded port on the brass manifold.

6.8 CO2 gas supply installation

1. Position the CO2 bottle(s) within 2m (6.6 ft) of the freezer. Secure them to the wall or place them in a

safety bottle rack to make sure they cannot fall or cause injury.

2. Attach the 0.6 m (2 ft) transfer line(s) to the CO

attached to each hose to make a proper seal to the CO

washer be used each time a CO

bottle is changed). Do not overtighten the fitting as the plastic washer

2

bottle(s) using the supplied plastic sealing washer

2

bottle fitting (it is recommended that a new

2

can be crushed and gas will leak.

6.9 Test for gas leaks

Before continuing with installation, ensure there are no gas leaks with the following procedure:

WARNING! Leaking gas

Regularly check device parts for leaks

Replace plastic seal after each CO

1. Ensure all fittings are tight before testing.

2. Apply liquid soap solution on each joint.

3. Turn CO

on.

2

tank exchange

2

Page 19

Installation

New Brunswick CO2 Back-up System

English (EN)

Bubbling or foaming will identify leaks.

4. Retighten the fitting or replace the seals if necessary.

6.10 Door switch installation

The magnetic door switch is composed of two separate items (magnet and magnet sensor) and is installed

on (a) the top left-hand surface of the door on Upright models (top right-hand surface of the door on the

model U101) or (b) the rear, right-hand surface of the lid on Chest models.

For Innova Freezers and the Premium U700, use the two, small metal adapter plates supplied. Install the

magnet and magnetic sensor to the adaptor plates using the attached fittings. When attaching to a

Premium freezer, the adapter plates are not used and the magnetic sensor assembly is attached directly to

the freezer cabinet and door.

19

1

5

6

1 Door switch cable

(Attached to sensor)

2 Attachment nuts

3 Magnet

4 Attachment screws

(Must be removed before installation. Retain

screws on door for attaching the magnet.)

2

4

8

3

7

5 Adapter plates

6 Freezer case

7 Freezer door

8 Installed doorswitch

Page 20

20

Installation

New Brunswick CO2 Back-up System

English (EN)

1. Remove the two screws on the lid or door of the freezer and retain for re-use.

2. Fasten the door switch magnet in place using the two screws removed above. The magnet should face

toward the case of the freezer. The magnet portion of the sensor can be identified by the lack of

electrical wires

3. Remove the screws on the case of the freezer.

CAUTION! Failure of system to operate correctly

Ensure magnetic door switch is installed correctly

4. Using the screws provided, fasten the magnet sensor that has the electrical cable attached.

5. Close the lid or door to check that the two parts of the switch do not touch. There should be a gap of no

more than 3 - 10 mm (0.12 - 0.4 inches).

6. If gap is larger than 10 mm, or less than 3 mm, loosen the screws and adjust the magnet until the gap is

corrected.

7. Tighten screws.

6.11 Installing cables to back of control unit

Note: Some kits are supplied with more than one removable power cord. Use the power cord that matches

your power receptacle. Check the voltage rating plate on the underside of the control unit to confirm that

the system is compatible with your laboratory power supply.

1. Place the control unit on top surface of upright freezer, or on compressor compartment of chest freezer.

2. Plug solenoid valve cable into appropriate socket (labelled Solenoid Valve on back of unit).

3. Plug temperature sensor cable into appropriate socket (labelled PT100 Probe).

4. Plug door switch cable into the appropriate socket (labelled Door Switch).

CAUTION! Failure of system

Ensure that the control unit's voltage rating matches you electrical supply

Do not plug in unit if you are not sure of electrical supply voltage rating

5. Choose appropriate power cord to use. Sytem is capable of operating within this voltage range: 100/

240 V 50/60 Hz

6. Insert power cord into socket on back of system.

7. Plug power cord into mains.

Only use approved power cords with the correct rating. Contact Eppendorf sales office for

replacement cords.

Page 21

Operation

New Brunswick CO2 Back-up System

English (EN)

7 Operation

7.1 Turning the control unit on

1. Plug the power cord into the mains.

The green Power On LED illuminates.

2. Turn the System On switch to the on position.

The control unit will beep. The alarm may sound if the control unit has not been switched on for some

time. In this case, the alarm will continue to sound until the battery has been charged or replaced with a

fully charged battery.

The Temp Warning light will illuminate, indicating the temperature in the freezer is warmer than the

temperature set on the Back-up Unit.

7.2 Testing the solenoid valve

1. Unplug freezer.

2. Close the door or lid of freezer.

3. Turn the System On switch on.

4. Turn CO

The Valve Open LED will pulse on and off indicating gas injection.

supply on.

2

21

WARNING! High pressure

Do not keep Valve open for more than 2 seconds at a time.

Allow 15 seconds before pushing Valve Test button again.

5. Push the Valve Test button and hold for no more than 2 seconds at a time.

The Valve Open light will illuminate and CO

the Valve Test button.

6. Release the Valve Test button.

The front panel LED's will illuminate in sequence, in a clockwise direction.

7. Confirm that gas has been flowing by determining the presence of frozen condensation around the

injector and on the freezer's shelf.

will be injected into the freezer for however long you push

2

7.3 Testing door switch

WARNING! Extremely cold gas

You may be burned by cold gas.

Open door or lid of freezer with caution

The door switch is NOT designed as a safety interlock.

1. Carefully open the door or lid of the freezer 5 cm (about 2 in).

should not be injected into freezer.

CO

2

Page 22

22

Operation

New Brunswick CO2 Back-up System

English (EN)

2. Check for frozen condensation around injector and freezer shelf. Frozen condensation indicates CO2

Back-up System is working.

3. Push Valve Test button.

Gas should not be injected into freezer.

Valve Open light should not illuminate.

7.4 Testing back-up system operation

1. Turn off CO2 Back-up System with the System On switch.

2. Turn on freezer.

3. Set freezer to to desired temperature and wait until temperature is reached.

4. Set Temp Set dial on the control unit to 10 °C higher than the freezer's temperature.

5. Flip System On switch on.

The Temperature Warning LED and Valve Open LED remain off. This is because the temperature of

freezer is lower than temperature set on Temp Set dial.

6. Change Temp Set dial to 10 °C lower than freezer's temperature .

The Temperature Warning LED will turn on indicating that the temperature in the freezer is below the

temperature set on the dial of the control unit.

The Valve Open LED will flash on and off indicating gas is being injected into the freezer.

7. Unplug CO

Back-up System from mains.

2

The Power On LED will turn off. The device is now operating on battery back-up. There should be no

change in temperature in the freezer while CO

8. Plug the CO

Back-up System back into mains.

2

Back-up System is in operation.

2

9. Reset the Temp Set dial to the desired temperature at which the device should turn on in the event of

power failure.

10.Verify that the gas supply is still on and the freezer is operating.

The Temp Warning should be off indicating that the freezer temperature is below the temperature set

on the Temp Set knob.

The Valve Open LED should be off indicating that gas is not being injected into the freezer.

The Power On LED should be on indicating that the CO

Back-up System is plugged into the mains.

2

7.5 Battery back-up

The CO2 Back-up System contains a rechargeable battery in case of power failure.

If the CO

Back-up System is plugged into the mains, and the Power On LED is illuminated, the battery is

2

being charged.

If the external power supply fails, the back-up battery will power the CO

Back-up System for up to 48

2

hours, depending upon ambient conditions. The lower the ambient temperature, the longer the back-up

battery will run.

Page 23

Operation

New Brunswick CO2 Back-up System

English (EN)

When the back-up battery's voltage drops below 11.4 volts, the Battery Low LED will illuminate and an

alarm will sound.

7.6 Alarm system monitoring socket

WARNING! Hazardous voltages

Hazardous voltages must not be connected to the remote alarm socket. Maximum rating is

24 volts, 1 amp.

The CO2 Back-up System is designed with a fixed socket at the rear labelled Alarm Socket, and a plug for

external monitoring purposes.

23

Within the control unit, the alarm socket is connected to volt-free, switching contacts rated at 24 volts, 1

amp. In normal operation, pin 1 (E) is connected to pin 2 (L) and in the alarm condition, pin 1 (E) is

connected to pin 3 (N).

NOTICE!

External device shall secure double reinforced insulation from mains voltage in accordance

with 61010-1

1 2 3

1 Freezer Socket

3 Alarm Plug (internal view)

2 Alarm Plug (external view)

The alarm plug can be used to connect to a remote alarm device or central monitoring system.

Page 24

24

Operation

New Brunswick CO2 Back-up System

English (EN)

Page 25

8 Maintenance

CAUTION!

Maintenance, service and repair work should be carried out only by qualified personnel

who have been authorized by Eppendorf.

Failure to use authorized service agents may invalidate the warranty.

8.1 Cleaning

DANGER! Electric shock

Switch the device off and pull the power plug out of the socket before beginning work.

Maintenance

New Brunswick CO2 Back-up System

English (EN)

25

NOTICE! Damage due to incorrect cleaning agent or sharp objects

Unsuitable cleaning agents can damage the display, surfaces and printing.

Never use corrosive cleaning agents, strong solvents or abrasive polishes.

Do not use acetone to clean the device.

Do not use sharp objects to clean the device.

8.1.1 Cleaning the device

Clean the accessories and all accessible surfaces of the device once a month or if they have become

significantly dirty.

Use a mild cleaning agent and a damp cloth.

8.1.2 Cleaning the surrounding area

Keep the air around the device dust-free.

Clean the area around the device on a regular basis.

8.2 CO2 bottle maintenance

We recommend that a record sheet be placed on or near the freezer, and that a routine check of the liquid

gas remaining in the bottles be allocated to a staff member. Record the measurements on the record sheet.

All gas supplies can leak away with time; the majority of CO

failures, but rather empty gas bottles due to lack of routine checks.

Back-up System failures are not equipment

2

Page 26

26

Maintenance

New Brunswick CO2 Back-up System

English (EN)

8.3 Electrical connection maintenance

All electrical cables should be checked every month. Failure to do so may result in failure of the device. If

damage is found, do not attempt to repair by yourself.

1. Turn off CO

2. Inspect the power cord, door switch cable, solenoid cable, and temperature sensor cable for cuts or

other damage.

3. If damage is found, contact a qualifed service engineer to replace the damaged parts.

Back-up System and unplug the power cord from the mains.

2

8.4 Battery maintenance

WARNING! Battery

Do not attempt to replace or repair battery by yourself.

The control unit contains mains voltage.

The CO2 Back-up System runs on a rechargeable battery during a power failure.

Contact a qualified service engineer to replace the battery every 5 years or when the Low Battery Alarm

sounds despite it being plugged into the mains.

8.5 Transfer line and manifold maintenance

A qualified service engineer should inspect the CO2 transfer lines from the gas bottles to the solenoid valve

annually.

8.6 Maintenance forms

Period Place the task Task Personnel

Weekly Near device Clean with damp rag if

necessary.

Weekly Near CO

Monthly Near device Check for cuts or

supply Weigh CO2 supplies to

2

see if they are full.

abrasions on all electrical

wires.

User

User

User

Page 27

New Brunswick CO2 Back-up System

Period Place the task Task Personnel

Inspect all hoses for cuts,

chaffing, and squashing.

Inspect hose connection

to bottle and seal

connection on the bottle.

There should be no

damage or corrosion.

Inspect manifold plugs

and seals. There should

be no mechanical

damage or corrosion.

Once every 5 years or

when battery fails

Inspect CO

connection and solenoid

valve connection. There

should be no damage or

corrosion.

Near device Replace battery. Qualified service

supply

2

engineer

Maintenance

27

English (EN)

8.7 CO2/LN2 back-up system service checklist

NOTICE!

Service should check the following points.

Refer to user manual sections as indicated.

1. Check Back-up system components for wear and any damage.

2. Check system and gas supply installation (see CO

3. Check system connections for leaks (see Test for gas leaks on p. 18).

4. Test the injector valve operation (see Testing the solenoid valve on p. 21).

5. Test the door switch operation (see Testing door switch on p. 21).

6. Test overall system operation (see Testing back-up system operation on p. 22).

gas supply installation on p. 18).

2

Page 28

28

Maintenance

New Brunswick CO2 Back-up System

English (EN)

Safety checklist

1. Observe any warning or caution symbols or statements (see Warnings for intended use on p. 7).

2. Operating personnel should always wear the appropriate personal protective equipment (i.e. cold

insulating gloves EN511, etc.).

3. As with any equipment that uses CO

/LN2 gas, there is a likelihood of oxygen depletion in the vicinity of

2

the equipment. It is important to assess the work site to ensure there is suitable and sufficient

ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe environment

should be considered.

For information on use, safety, handling and storage of refrigerated liquids/gases refer the

manufacturers safety data sheets.

Service verification

To be completed by service engineer.

The following equipment has be serviced and checked by an approved engineer and declared safe to use.

Product:

Serial No.:

Date:

Signature:

Address, Division, Telephone:

Page 29

Technical data

New Brunswick CO2 Back-up System

English (EN)

9 Technical data

9.1 Performance

The CO2 Back-up System is capable of maintaining a freezer maximum internal temperature of -80 °C in an

ambient temperature of ±32 °C.

9.2 Weight/dimensions

9.2.1 Device dimensions

Height 86.5 mm (3.4 inch)

Width 203 mm (8.0 inch)

Depth 342 mm (13.5 inch)

29

9.2.2 Device weight

Weight of CO

Back-up System 5.6 kg (12.3 lb)

2

9.3 Cable and transfer line lengths

Power Cord 3.0 m (9.8 ft)

Temperature sensor cable 2.75 m (9 ft)

Solenoid valve cable 0.9 m (3 ft)

Door switch cable 1.2 m (4 ft)

Transfer line(s), CO

Transfer line, brass manifold to solenoid valve 2.0 m (6.6 ft)

bottle to brass manifold 0.6 m (2 ft)

2

9.4 Power supply

Single phase, 100/240 V, 50/60 Hz, 1.5 Amp

9.5 Fuses

The control unit input power socket is fitted with two fuses: Live and Neutral: Specification

2 A 250 V 20 mm (T2AH250V).

Page 30

30

Technical data

New Brunswick CO2 Back-up System

English (EN)

9.6 Ambient conditions

9.6.1 Device operating environment

Altitude Up to 2000 m

Minimum ambient temperature 5 °C

Maximum ambient temperature 32 °C

Maximum humidity at 31 °C 80 %

Maximum humidity at 40 °C 50 %

Pollution degree 2

9.7 Gas Consumption

The consumption of gas is very difficult to specify because it is dependent on the operating conditions.

Gas consumption is affected by several factors. Consumption increases with:

• An increase in ambient temperature

• Increasing age of freezer

• Increasing age of door or lid seal

• A colder temperature set on the device

• Frequent opening of door or lid

Page 31

Technical data

New Brunswick CO2 Back-up System

English (EN)

We highly recommend that the user decide, prior to full operation, what temperature conditions the

back-up unit should maintain. The user should then install the system, switch the freezer off, and record the

time it takes for the gas bottle to empty while the system maintains the desired temperature. This

precaution will enable the user to select the gas bottle size best suited to providing the degree of protection

required. As a guide, the following chart can be used to calculate consumption:

31

Consumption in kg/hr

at -50 °C at -60 °C at -70 °C

(lbs/hr):

Upright freezers

(empty)

U725 Innova 1.85 (4.07) 2.0 (4.4) 2.35 (5.17)

U535 Innova 1.45 (3.19) 1.57 (3.45) 1.65 (3.63)

U101 Innova 0.8 (1.76) 1.0 (2.2) 1.4 (3.08)

U410 Premium 1.38 (3.03) 1.5 (3.3) 1.6 (3.52)

U570 Premium 1.95 (4.3) 1.6 (3.52) 1.7 (3.74)

Chest freezers (empty)

C760 Innova 1.95 (4.3) 2.6 (5.72) 2.8 (6.16)

C585 Innova 1.7 (3.74) 2.0 (4.4) 2.7 (5.94)

C660 Premium 1.83 (4.0) 2.45 (5.39) 2.65 (5.83)

C340 Premium 1.3 (2.86) 1.45 (5.39) 1.6 (3.52)

9.8 CO2 Supplies

Consult your local gas supplier for suitable CO2 supplies. Do not include a regulator, as liquid withdrawal is

necessary for the satisfactory operation of the system in utilizing the cooling properties of the compressed

gas.

CO

2

The connection on the CO2 bottle should be (a) in Europe, British Standard BS341, No. 8, 0.851 inch 14TPI

Female, (b) in the USA, Type CGA 320.

NOTICE! Wrong CO

bottles

2

Device will not operate correctly.

Use liquid CO

Use bottles containing liquid CO

, NOT gas.

2

fitted with full-length dip tubes.

2

Page 32

32

Technical data

New Brunswick CO2 Back-up System

English (EN)

9.9 Spare parts

Parts should only be replaced/installed by a qualified service engineer.

Description Part Number

Control unit, CO

2

Power Supply, 18 V, 45-Watt P0625-0500

Battery 12 V 7Ah - Control unit K0480-0220

Fuse 20 mm 2 A - Control K0380-0610

PT100 Temperature Sensor Assembly P0625-1410

Magnetic Door Switch Sensor Assembly P0625-1420

Door Switch Magnet K0400-0631

Magnetic Door Switch Adapter Plates, Innova and Premium U700 only P0625-0320

Square Clamping Plate for Solenoid Valve K0160-1530

Alarm Plug, 3P-connector K0380-0451

Black Plastic Blanking Plug, (pack of 2) K0740-0330

Insulation Tube (2×25 mm) P0625-0300

Tie wrap fasteners (pack of 5) K0700-0140

6-position Manifold K0240-0240

Manifold blanking plugs (pack of 5) K0240-0186

Manifold fitting seal (Dowty Seal) (pack of 5) K0280-0060

P0625-0310

Transfer Line Assembly BS341 No.8 P0625-0201

Transfer Line Assembly CGA320 P0625-0200

Transfer Line, Manifold to Injector 3M K0740-0340

CO

Solenoid Valve Injector Assembly, Premium only P0625-1433

2

Solenoid Valve Injector Assembly, Innova only P0625-1432

CO

2

CO2 Solenoid Valve Injector Tube, Premium only P0625-0341

CO2 Solenoid Valve Injector Tube, Innova only P0625-0340

Power Cord, 230 V, 50 Hz, UK 3-pin P0625-0193

Power Cord, 230 V, 50 Hz , Schuko P0625-0192

Power Cord, 115 V, 60 Hz P0625-0191

Power Cord, 208-220 V, 60 Hz P0625-0560

Sealing washers for CO

Supply to Manifold BS341 (bag of 5) P0625-0480

2

Page 33

New Brunswick CO2 Back-up System

Description Part Number

Sealing washers for CO2 Supply to Manifold CGA320 (bag of 5) P0625-0490

9.10 Circuit Schematics

Technical data

33

English (EN)

Page 34

34

Technical data

New Brunswick CO2 Back-up System

English (EN)

Page 35

10 Declaration of conformity

Declaration of Conformity

The products named below fulfill the requirements of directives and standards listed. In the case of

unauthorized modifications to the product or an unintended use this declaration becomes invalid.

Product name:

CO2 Back Up System

LN2 Back Up System

Declaration of conformity

New Brunswick CO2 Back-up System

English (EN)

35

Product type:

U9043-0002, U9043-0004, U9043-0006 & U9043-0008

Relevant directives / st andards:

2006/95/EC: EN 61010-1,

UL 61010-1, CSA C22.2 No. 61010-1 (US Voltage 60 Hz Models)

2004/108/EC: EN 61326-1

FCC Part 15 Class B (US Voltage 60 Hz Models)

2011/65/EU

2012/19/EU

Date: November 25, 2013

tnemeganaM oiloftroPdraoB tnemeganaM

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com

Eppendorf® and the Eppendorf Logo are registered trademarks of Eppendorf AG Hamburg/Germany.

All rights reserved incl. graphics and pictures. Copyright 2013 © by Eppendorf AG.

www.eppendorf.com

ISO 9001

Certified

ISO 13485

Certified

ISO 14001

Certified

U9043-9999-00

Page 36

36

Declaration of conformity

New Brunswick CO2 Back-up System

English (EN)

WARNING!

Any modification or changes made to this device, unless explicitly approved by Eppendorf,

will invalidate the authorization of this device. Operation of an unauthorized device is

prohibited under Section 302 of the Communications Act of 1934, as amended, and

Subpart 1 of Part 2 of Chapter 47 of the Code of Federal Regulations.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Page 37

Index

New Brunswick CO2 Back-up System

English (EN)

37

Index

A

Alarm monitoring socket.......................................23

Altitude limit..........................................................30

Ambient conditions ...............................................30

B

Battery .............................................................13, 22

Alarm................................................................23

Charging ..........................................................22

Replacement ....................................................26

C

Certificate of conformity........................................35

Circuit schematics .................................................33

Copyright.................................................................2

Door switch ..................................................... 19

Location........................................................... 20

Selecting the location ...................................... 15

Solenoid valve.................................................. 17

Temperature sensor......................................... 16

Unpacking device ............................................ 15

Intended use .......................................................... 7

M

Maintenance

Cleaning........................................................... 25

CO2 Bottles...................................................... 25

Transfer lines................................................... 26

Manual conventions................................................ 5

P

Power on............................................................... 21

Product liability....................................................... 7

Product versions ................................................... 14

D

Danger level ............................................................5

CAUTION ...........................................................5

DANGER.............................................................5

NOTICE ..............................................................5

WARNING ..........................................................5

Device overview

Back view .........................................................10

Front view ..........................................................9

Disposal .................................................................11

Door switch ...........................................................13

Dowty seal .............................................................18

E

Electrical connection.............................................26

I

Installation

0.6 m (2 ft) Transfer line ..................................18

2.0 m (6.6 ft) Transfer line ...............................17

CO2 Bottles ......................................................18

Control unit ......................................................21

S

Solenoid valve injector pipe.................................. 17

Spare parts............................................................ 32

Specifications

Fuses ............................................................... 29

Performance .................................................... 29

Power supply ................................................... 29

System on ............................................................. 21

T

Temp dial .............................................................. 13

Temp Warning ......................................................21

Temperature sensor .............................................. 16

Testing

Door switch ..................................................... 21

Leaks ............................................................... 18

Solenoid valve.................................................. 21

Testing the system........................................... 22

Trademarks............................................................. 2

Page 38

38

Index

New Brunswick CO2 Back-up System

English (EN)

U

User requirement ....................................................7

Page 39

Page 40

Evaluate your manual

Give us your feedback.

www.eppendorf.com/manualfeedback

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

Loading...

Loading...