Page 1

Product Bulletin

8510/8510B Valve

D100066X012

51.6:edisc (EMA)

February 2013

Fisherr 8510 and 8510B Eccentric Disc Control

Valves (EMA)

Fisher 8510 and 8510B eccentric disc valves feature an

eccentrically mounted disc and a PTFE or 316 stainless

steel seal ring. The pressure-assisted seal ring provides

excellent shutoff against pressure applied in either

direction. The 8510B is a multi-class rated valve,

available in NPS 2 through 12, and PN10 through

PN100 compatible (compatibility varies with size and

class, see table 1).

The 8510 is rated for CL150, available in NPS 14

through24,andPN10andPN16compatible

(compatibility varies with size and class, see table 1).

These valves combine with a variety of power and

manual actuators to form reliable, high-performance

control valves suited for many liquid and gas

applications requiring extremely low leakage.

Constructions are available for temperatures up to

538C (1000F).

W4739-2

Eccentric Disc C ontrol Valve with Fisher 1052 Actuator

and 3610J Positioner

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

Features

Sour Service Capability–Materials are available for

applications involving sour service. These materials

comply with the requirements of NACE

MR0175-2002.

Excellent Flow Control–The eccentrically mounted

disc design provides an approximately linear flow

characteristic and can be used for on/off or

throttling control applications through 90 degrees

of disc rotation. Optional disc stop on 8510B

provides seal protection.

(continued on page 3)

W9264-1

Fisher 8510B with Alternate Double D Shaft and

1035/El-O-Matic Actuator

www.Fisher.com

Page 2

Product Bulletin

51.6:edisc (EMA)

February 2013

Specifications

8510/8510B Valve

D100066X012

Valve Sizes and End Connection Style

8510B: NPS

J 2, J 4, J 6andJ 8(PN10through

PN100) - CL150, 300 or 600 ASME flange

compatibility,

J 10 and J 12 (PN10 through PN40) -

CL150 ASME flange compatibility

8510 flangeless valves: NPS

J 16 (PN16), J 18, J 20 (PN16) and J 24 (PN16) -

J 14 (PN10 and PN16),

CL150 ASME flange compatibility for NPS 14 through

24

Also see table 1.

Maximum Inlet Pressures

(1)

Flow Direction

Standard (forward flow) is with the seal retainer

facing upstream; reverse flow is permissible within

specified limitations

Flow Coefficients

See table 1

Flow Coefficient Ratio

100 to 1

Noise Levels

See Catalog 12 for sound pressure level prediction

Disc Rotation

WCC Steel, CF3M Stainless Steel (316L SST), and

CN7M (Alloy 20) Valve Bodies: Consistent with

applicable pressure-temperature ratings in table 2,

unless limited by pressure drop/temperature

Clockwise to close (when viewed from actuator side

of valve) through 90 degrees of disc rotation

Actuator Valve Action

capabilitiesintables6,7,8,9and10ortemperature

capabilities in table 11

M35-1ValveBodies:As shown in table 2, unless

further limited by pressure drop/temperature

capabilities in table 10 or temperature capabilities in

table 11

Maximum Pressure Drops

(1)

Steel Valve Bodies (8510 and 8510B): See table 6 or 7

CF8M Stainless Steel Valve Bodies (8510): See tables

8and9

Alloy Valve Bodies (8510B): See table 10

Shutoff Classifications per ANSI/FCI 70-2andIEC

60534-4

PTFE Seal Ring: Bidirectional shutoff to Class VI is

standard

316 Stainless Steel Seal Ring: 0.001% of maximum

valve capacity (one tenth of Class IV)

Construction Materials

See tables 3, 4, and 5

Material Temperature Capabilities

(1)

With diaphragm or piston rotary actuator,

field-reversible between

(extending actuator rod opens valve) and

push-down-to-close (extending actuator rod closes

valve)

With 1035 Rack and Pinion actuator with spring

return or double acting action, field-reversible

between

Valve Classification

J Face-to-face dimensions of NPS 3 through 6 in

CL150 and 300, and face-to-face dimensions of NPS 8

through 24 in CL150, meet API 609 standards for

face-to-face dimensions of narrow flangeless and

single-flange valves

J DIN face-to-face dimensions for all sizes meet DIN

3202 Part 3/K2, and

J JIS B2210 standard face-to-face dimensions are

available on request.

Mating Flange Capabilities

All size compatible with welding-neck and slip-on

flanges (schedule 80 or lighter for 8510B NPS 2

through 12; schedule 40 or lighter for 8510 NPS 14

through 24)

Shaft Diameters and Approximate Weights

See table 11

Flow Characteristic

Approximately linear

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation should not be exceeded.

2. Ratio of maximum flow coefficientto minimum useable flow coefficient.

See figures 7 and 8

Options

J Line flange bolting, J FGMlineflangegaskets

(2)

J push-down-to-open

J

J fail-to-open and J fail-to-close

2

Page 3

8510/8510B Valve

D100066X012

ENVIRO-SEAL Packing System Specifications

Product Bulletin

51.6:edisc (EMA)

February 2013

Available Packing

J ENVIRO-SEAL PTFE Packing System

J ENVIRO-SEAL Graphite Packing System

Maximum Temperature/Pressure Limits

(1)

Maximum Application Temperature/Pressure Limits

to meet EPA Fugitive Emission Standard of 100

(2):

ppm

For ENVIRO-SEAL PTFE Packing Systems: Up to 232C

(450F) at the ASME class rating of the valve.

For ENVIRO

-

SEAL Graphite Packing Systems: Up to

316C(600F) at the ASME class rating of the valve

Material Temperature Range:

-

For ENVIRO

SEAL PTFE Packing Material:

-46 to 232C(-50to450F)

Construction Materials

PTFE Packing Systems:

Packing Rings: PTFE V-ring

Male and Female Adaptor Rings:Carbon-filled PTFE

V-ring

Anti

-

Extrusion Rings: High strength polymer

Packing Box Rings: S31600 (316 SST)

Graphite Packing Systems:

Packing Rings: Graphite

Anti

-

Extrusion Rings: Carbon

Packing Box Rings: S31600 (316 SST)

Spring Pack Components:

O

-

Ring: Nitrile. The O-ring serves as an assembly

conveniencetoholdthespringsinpositiononthe

follower.

Packing Follower: S31600withcarbon-filled PTFE liner

Springs: N07718

Packing Flange: S31600 (316 SST)

Packing Box Studs: Strain-hardened S31600,

-

For ENVIRO

Up to 316C(600F)

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation for valve should not be exceeded.

2. The EnvironmentalProtection Agency (EPA)has set a limit of 100 parts permillion (ppm) for fugitive emissions from a valve.

3. For other materials of construction, see table 3.

4. In vacuumservice it isnot necessary toreverse the ENVIRO-SEALPTFE packing rings.

SEAL Graphite Packing Material:

SA-193-B8M

Packing Box Nuts: S31600 SA-194-8M

(3)

(4)

Features (continued)

Improved Environmental Capabilities–The optional

ENVIRO-SEALt packing systems, shown in figure 6,

are designed with very smooth stem surfaces, and

live loading provides improved sealing, guiding, and

loading force transmission. The seal of the

ENVIRO-SEAL system can control emissions to

below the EPA (Environmental Protection Agency)

limit of 100 ppm (parts per million) for valves.

Lost Motion Minimized–For 8510, the taper pin/disc

connection and the splined valve shaft with

clamped lever and single pivot linkage reduce lost

motion between the actuator and valve. For 8510B,

the taper key/disc connection and the splined valve

shaft with clamped lever and single pivot linkage

reduce lost motion between the actuator and valve.

Greater Capacities and Lower Operating

Torques–The contoured disc increases flow

capacity and reduces operating torque at peak

angles of disc opening.

3

Page 4

Product Bulletin

51.6:edisc (EMA)

February 2013

8510/8510B Valve

D100066X012

Construction Features

Field-Reversible Valve Action–The actuator/valve

assembly action can be converted from

push-down-to-open to push-down-to-close, or vice

versa, without additional parts.

Integral Shaft-to-Body Bonding–Standard valve

construction includes conductive packing to

provide electrical bonding for hazardous area

applications.

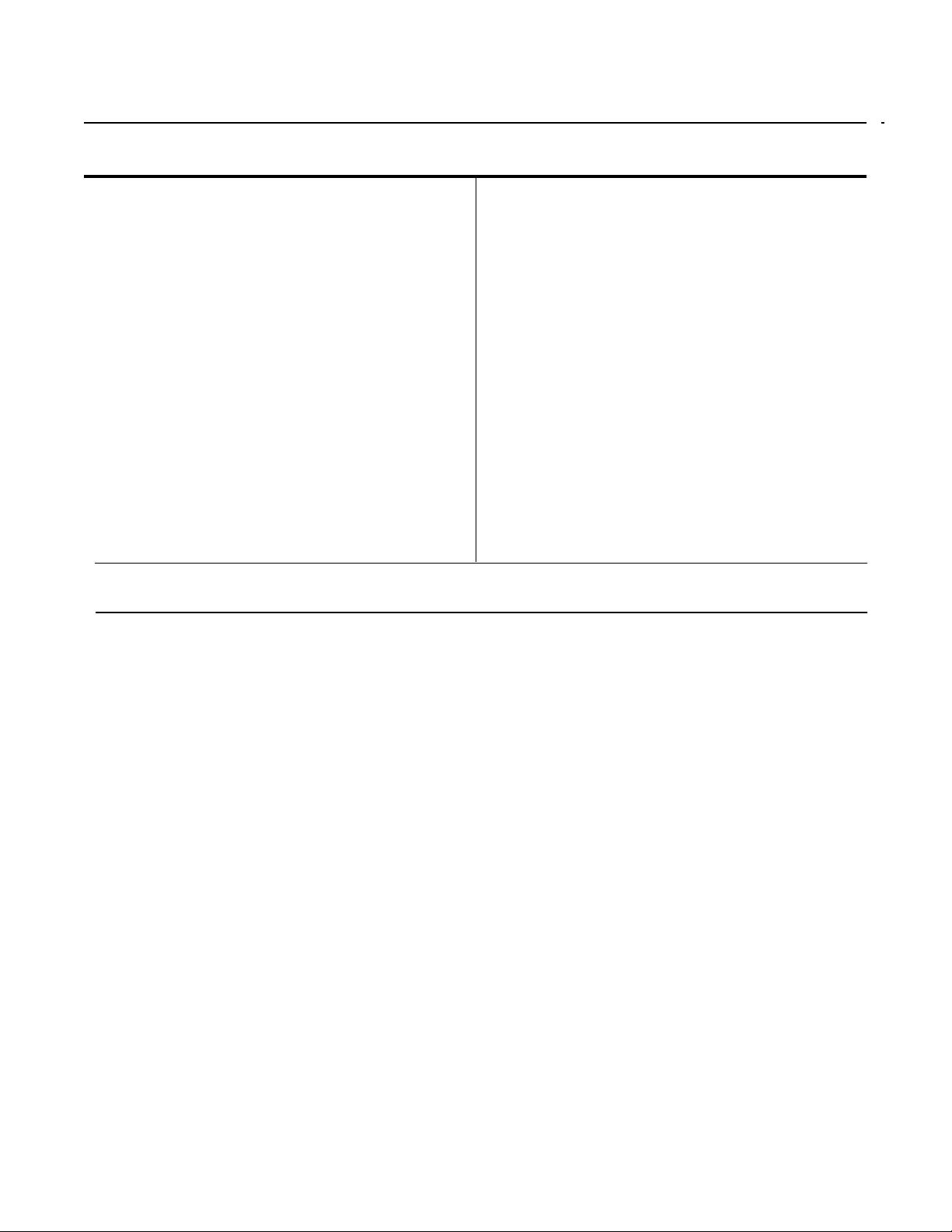

Easy Installation–Centering holes (figures 1, 2 and

3) engage the line flange bolts to simplify

installation and provide for centering of the valve in

the pipeline.

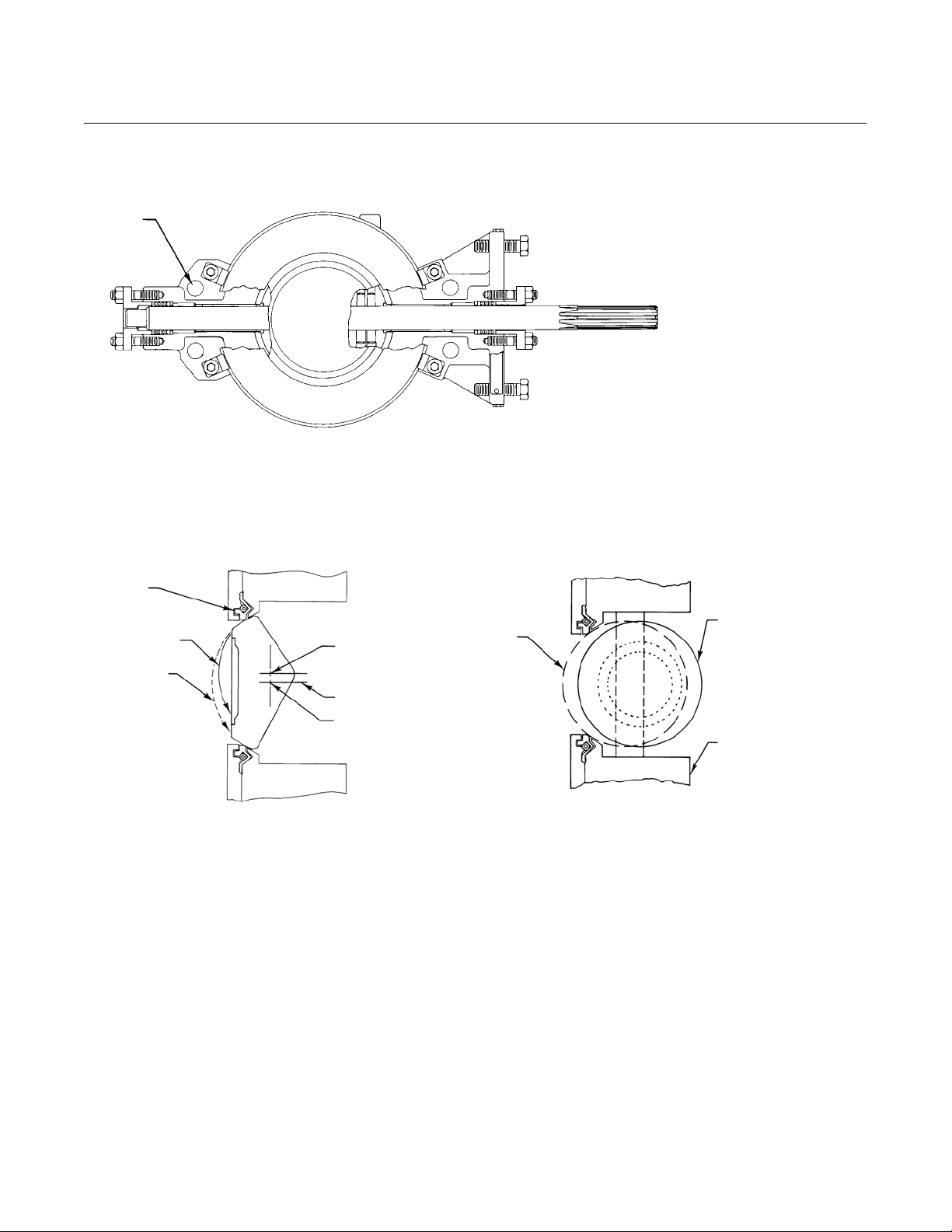

Long Seal Life–The opening and closing path of the

eccentric disc (figure 4) minimizes disc contact with

the seal ring, thereby reducing seal wear, undue

friction, and seating torque requirements.

Exceptional Shutoff at High Pressure Drops–Both

the 316 stainless steel seal ring and the bidirectional

PTFE seal ring with pressure-assisting sealing action

(figure 5) are designed to provide shutoff regardless

of flow direction.

Reliable Flange Gasketing Surface–The seal retainer

cap screws or retention clips are outside the gasket

surface of the seal retainer, and spiral wound or flat

sheet gaskets can be installed between the

uninterrupted seal retainer face and the pipeline

flange.

Self-Flushing Action–With standard right-hand

actuator mounting, the bottom edge of the disc

opens downstream away from the seal, and the flow

stream flushes sediment from the seal.

Double D Shaft–8510B valves in NPS 2 through 12

are available with double D shaft end designedto

accept the 1035 Rack and Pinion Actuator and other

quarter-turn actuators.

Shaft Retention–Redundant shaft protection is

provided with 8510B valves with the double D drive

shaft. The packing follower and stepped shaft

interact to provide the redundant shaft retention.

4

Page 5

8510/8510B Valve

D100066X012

Figure 1. Typical Fisher 8510B Construction Detail

RETAINER CLIP

Product Bulletin

51.6:edisc (EMA)

February 2013

CENTERING HOLE

BEARING

SPACER

41B6064-A

41B6101-A

B2303*

TAPER

KEY

VIEW A

SEE VIEW A

SEAL

RING

ASSEMBLY

Figure 2. Typical Fisher 8510B Construction Detail with Double D Shaft

TAPER KEY

CENTERING HOLE

PTFE SEAL

SEAL

RETAINER

SEAL

RING

DISC

SPRING

VALVE

BODY

316 STAINLESS

STEEL SEAL

REDUNDANT SHAFT

RETENTION DEVICE

39b8285-A

E0781

BEARING

SPACER

5

Page 6

Product Bulletin

51.6:edisc (EMA)

February 2013

Figure 3. Construction of Fisher 8510

CENTERING

HOLE

48A5626-A

B1691-3

8510/8510B Valve

D100066X012

Figure 4. Comparison of Disc Action

SEAL RING (PTFE

CONSTRUCTION

SHOWN)

ECCENTRIC

DISK PATH

OF ROTATION

CONVENTIONAL

DISK PATH

OF ROTATION

SIDE VIEW – DISK FULLY CLOSED

A2867-2

ECCENTRIC

DISK CENTER

OF ROTATION

CENTERLINE OF

VALVE BODY

CONVENTIONAL

DISK CENTER

OF ROTATION

CONVENTIONAL

DISK

BOTTOM VIEW – DISK FULLY OPENED

ECCENTRIC

DISK

VALVE BODY

6

Page 7

8510/8510B Valve

D100066X012

Figure 5. Action of Bidirectional PTFE Seal RIng (Top) and Metal Seat Ring (Bottom)

VALVE BODY

SEAL RING

SEAL

RETAINER

SPRING

Product Bulletin

51.6:edisc (EMA)

February 2013

STANDARD

FLOW DIRECTION

DISC

VALVE BODY

SEAL RING

SEAL

RETAINER

STANDARD

FLOW DIRECTION

DISC

DISC CLOSING OR OPENING AND NOT

IN CONTACT WITH SEAL RING

B1558-3

Note:

Arrow indicates disc position with no pressure.

1

DISC CLOSED AND IN

CONTACT WITH SEAL RING

DIRECTION OF

PRESSURE

DIRECTION

OF PRESSURE

ACTION OF SEAL RING WITH PRESSURE

APPLIED FROM BOTH DIRECTIONS

7

Page 8

Product Bulletin

51.6:edisc (EMA)

February 2013

Table 1. Flow Coefficients and ASME Rating and Flange Compatibility

ASME RATING

VALVE BODY

SIZE, NPS

2 91.7

3 232

4 459

6 907

8 1740

10 3570

12 4880

14 7040

16 9650 PN16

18 12,100 --20 14,500 PN16

24 21,800 PN16

1. M35-1 valve bodies arenot included in ASMEB16.34. See table 2 forpressure/temperature information for M35-1 valve bodies. The designations C L150, 300, and 600for these valve bodies

areusedonlytoindicaterelativepressure-retaining capabilities and are not ASME pressure/temperature rating class designations.

2. Consult your Emerson Process Management salesoffice for pressure/temperature ratingsof these valves.

CvWITH NORMAL FLOW AND

DISC WIDEOPEN

(90 DEGREES ROTATION)

COMPATIBILITY–

STEEL, STAINLESS

STEEL, AND ALLOY

20 VALVE BODIES

8510B

CL150, 300, and 600 CL150/300/ 600

CL150

CL300

CL150

CL300

8510

CL150 --- CL150

VALVE

DESIGNATION–

M35-1

CL150

CL300

CL150

CL300

(1)

ASME FLANGE

COMPATIBILITY

CL150, 300, and

600

CL150

CL300

CL150

CL300

8510/8510B Valve

D100066X012

PN FLANGE

COMPATIBILITY

PN10, PN16, PN25, PN40,PN63

and PN100

PN10 and PN16

PN25 and PN40

PN10 and PN16

PN25 and PN40

PN10 and PN16

(2)

(2)

(2)

(2)

300

41.3

36.5

34.1

33.1

33.0

600

530

495

480

478

(1)

(1)

M35-1

(1)

(1)

600

82.7

72.7

68.2

65.8

65.7

1200

1055

990

955

953

Table 2. Maximum Allowable Inlet Pressures for M35-1ValveBodies

TEMPERATURE

C Bar

-46 to 38

93

149

204

232

F Psig

-50 to 100

200

300

400

450

1. This material is not listed in ASMEB16.34. Also see the installation information.The designations CL150, 300, and 600 areused only to indicate relative pressure-retaining capabilities

and are not ASME pressure-temperature rating class designations.

150

15.8

13.8

13.1

12.7

12.3

230

200

190

185

178

(1)

8

Page 9

8510/8510B Valve

D100066X012

Table 3. Standard Construction Materials

Part Material

8510: WCC Steel, CG8M (316 stainless steel), M35-1

8510B: WCCSteel, CF3M(316L SST), M35-1

steel, or 1.4581 stainlesssteel

8510: WCCSteel (A216),S31603 (316L stainless steel) (both with

chrome-plated seatingsurfaces), M35-1, or alloy 20 CN-7M

8510B: WCC Steel (A216), M35-1, CN7M (alloy 20), S31603(316L SST), or Cr

PI S31603(Cr Pl 316L SST)

PTFE with 316 stainless steel, N04400, or alloy 20 spring

316 stainless steel seal and backup rings with graphite gaskets bonded to

them

8510: PTFE

w/S31600 (316SST) jacket, S44004 (440C SST), alloy 6B, silver-plated alloy

6B, filled PTFE

8510B: PTFE

S31603 jacket, filled PTFE

(3)

/composition lined w/SST jacket, PTFE

(4)

w/N04400 jacket, or filled PTFE

(3)

/composition lining with S31603 (316L SST),PTFE

jacket

(4)

with N04400jacket, and filled PTFE

N08020 (alloy20) jacket

S17400 (17-4PH), S20910, N05500, N08020 (alloy 20),

or S31603 (316L SST)

PTFE/S31603 (316L SST), S17700 (17-7 PH SST), alloy 6B, PTFE/N04400, and

PTFE/N08020 (alloy 20)

8510: S20910

8510B: S20910 SST, N05500, N10276 (alloy 276),

or N08020 (alloy 20)

Standard packing is available with PTFE packing V-rings with one carbon-filled

PTFE conductive ring, PTFE-composition rings with one graphited conductive

ring, a nd preformed graphite ribbon rings. ENVIRO-SEAL packing system is

available with PTFE V-rings with one carbon-filled PTFE conductive ring or with

graphite packing rings.

(5)

, S31600, CF8M, N04400, or alloy 20

Disc

Seal

(1)

(1)

(1)

Lined

Bearings

Valve Body

(1)

All-metal 440C stainless steel,alloy 6B, or silver-plated alloy 6B

8510: Valve shaft

(1)

and bearing spacers S17400 (17-4PHSST), S20910, N04400, or alloy 20

8510B: Valve Shaft

(1)(6)

8510B: Bearing Spacers

8510: Taper Pins

8510B: Taper Keys

S17400 (17-4PH) and

S20910 shafts

Alloy shafts Same material as shaft

8510: Bearingstops (for

metal bearings and

non-alloy valve bodies only)

Steel valve bodies S17400

CF8M steelvalve bodies S31600 (316stainless steel)

8510B: Bearings stops (for metal bearings and non-alloyvalves only) S31600 (316SST)

Seal retainer Same material as valve body

Packing arrangements

Packing followers and packing box rings S31600, N04400,or alloy 20

Packing flanges, studs and nuts Plated steel, S31603

1. See table 4 f or acceptable trim materialcombinations.

2. This is not anASME B16.34 or ASMEcode-approved material. Also see the Installation section.

3. Reinforced PTFE in phenolic resin, Emerson Process Managementdesignation is FMS 30B4.

4. PTFE with selected fillers. Emerson Process Management designationis FMS 30B5.

5. S31603 is available for 8510B only

6. 8510B valve shafts with Double D end are available onlyin 17-4PH SST, 316L SSTor S20910.

Product Bulletin

51.6:edisc (EMA)

February 2013

(2)

,orCN-7M (alloy 20)

(2)

, CN7M(alloy 20),1.0619

(3)

composition lined

(4)

w/N08020 (alloy20)

(4)

(4)

with

with

9

Page 10

Product Bulletin

51.6:edisc (EMA)

February 2013

Table 4. Trim Combinations with Standard Construction Materials

Disc Material Shaft Material Bearing Material Seal Material

8510: WCC steel

with

chrome-plated

seating surfaces

8510B: WCC steel

with

chrome-plated

seating surface or

S31603 (316L

(1)

SST)

8510: S31603

(316L SST)with

chrome-plated

seating surfaces

8510B: S31603

(316L SST)with

chrome-plated

seating surfaces or

S31603 (316LSST)

without plating

with PTFE seal only

M35-1 N05500 Filled PTFE

Alloy 20 CN7M Alloy 20

1. Steel disc not available in the NPS2 and 3 valves.

2. PTFE with selected fillers. Emerson Process Management designationis FMS 30B5.

3. This trim not available in the 8510NPS 14 through 24valves.

4. This trim not available with the DoubleD shaft version of the 8510B.

S17400 (17-4PHstainless

steel)

S17400

S20910

PTFE/composition-lined, w/SST

S44004 (440CSST) 316 stainless steel 9

PTFE/composition-lined w/SST

PTFE/composition-lined

S31600 (316SST) jacket

S44004 316 stainless steel Steel 10

Silver-plated alloy 6B 316 stainless steel

Alloy 6B 316 stainless steel

PTFE/composition-lined with

S31600 jacket

Silver-plated alloy 6B 316 stainless steel 11

Alloy 6B 316 stainless steel 13

(2)

Filled PTFE

(2)

20) jacket

jacket

jacket

w/ N04400 jacket PTFE M35-1orsteel 15

w/ N08020(alloy

PTFE

316 stainless steel 5

PTFE

316 stainless steel 6

PTFE

316 stainless steel 8

PTFE

316 stainless steel 7

PTFE Alloy 20 CN-7M 17

8510/8510B Valve

D100066X012

Acceptable Valve Body

Material

Steel

Steel

8510: Steel or CF8M

8510B: Steel or CF3M

(316 SST)

8510: Steelor, CF8M

8510B: Steel or CF3M

(316 SST)

8510: Steel or CF8M

8510B: Steel or CF3M

(316 SST)

Trim

Number

1

2

4

12

14

3

(3)

(3)(4)

Table 5. Trim NT3 Part Materials for Compliance with NACE MR0175-2002 (Sour Service) Specifications

Packing

Valve Body Disc Seal Bearings Valve Shaft Taper Pins Packing

8510: CG8M

(317 stainless

steel) with

8510: Steel or

CF8M (316

stainless steel)

8510B: Steel or

CF3M (316LSST)

10

chrome-

plated seating

surfaces

8510B:

S31603 (316

SST) with

chrome-plated

seating

surfaces or

S31603 (316L

SST)

PTFE seal

with

N05500

spring

8510: Filled PTFE

w/ S31600(316

SST) jacket

8510B: PTFE/

compositionlined S31603

(316L SST)

S20910 S20910

PTFE V-ring

with one

carbon-filled

conductive

packing ring

PTFE

Followers

and Packing

Box Rings

8510: S31600

(316 stainless

steel)

8510B: S31600

(316 SST)or

S31603 (316L

SST)

Packing

Flanges

8510: steel

8510B:

S31600 (316

SST) or

S31603

(316L SST)

Packing

Flange

Bolting

Grade B7

steel studs

and Grade

2H steel

nuts

Page 11

8510/8510B Valve

D100066X012

Figure 6. Typical ENVIRO-SEAL Packing Arrangements for Rotary Valves

Product Bulletin

51.6:edisc (EMA)

February 2013

PACKING

BOX STUD

ACTUATOR

MOUNTING

YOKE

VALVE

SHAFT

YOKE

BEARING

PACKING

FLANGE

PACKING

FOLLOWER

W5806-1

SPRINGS

VALVE

BODY

PTFE

PACKING

V-RINGS

SHOWN

ANTIEXTRUSION

RINGS

PACKING

BOX RING

VALVE

SHAFT

SPRINGS

W6125-1

PACKING

FLANGE

PACKING

FOLLOWER

SINGLE PTFE PACKING GRAPHITE PACKING

PACKING

BOX

RING

GRAPHITE

PACKING

SET

11

Page 12

Product Bulletin

51.6:edisc (EMA)

February 2013

8510/8510B Valve

D100066X012

Table 6. Maximum Allowable Shutoff Pressure Drops

TABLE 4

OR 5 TRIM

NUMBER

(2)

1

,2,3,4,

NT3

(2)

5

,6,7,8

(2)

9

,10

11

12

13

14

15

1. Based on valve body assembly material strengths only–actuator torque not considered.

2. This trim not available in the NPS 2, 3, and 4 valves.

3.Forhotwaterorsteamservice,limitmaximumtemperatureto207C.

4. Reverse pressure drop is limited to 6.9bar.

FLOW

DIRECTION

TEMP. C

2 3 4 6 8 10 12 14 16 18 20 24

-29 to 49

66

93

Forward or

reverse

121

149

191

204

232

Forward -29to 232

Reverse -29 to 232

-29 to 149 19.7

204 18.2

Forward or

reverse

260 17.3

316 16.8

371 15.9

427 15.0

-29 to 93 19.7

149 17.1

Forward or

reverse

204 15.0

260 14.6

316 13.9

371 13.3

427 12.6

-46 to 149 19.7

204 18.2

Forward or

reverse

260 17.3

316 16.8

371 15.9

427 15.0

-29 to 149 12.3

204 12.3

Forward or

reverse

260 12.3

316 12.3

371 12.3

427 12.3

(3)

56.2

56.2

48.5

38.6

28.7

13.8

10.3

64.5

58.5

48.5

38.6

28.7

13.8

10.3

53.8

53.8

48.5

38.6

28.7

13.8

10.3

3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

(3)

51.0 51.0 51.0 51.0 31.0 17.2 17.2 10.3 10.3 10.3 10.3 10.3

(3)

6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

31.5

29.9

28.9

28.3

27.3

26.3

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

11.0

11.0

11.0

11.0

11.0

11.0

(4)

28.8

(4)

27.4

(4)

26.5

(4)

26.0

(4)

25.1

(4)

24.2

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

18.5

(4)

9.2

(4)

9.2

(4)

9.2

(4)

9.2

(4)

9.2

(4)

9.2

Forward -29 to 427 12.3 11.0 9.2 8.5 7.3 4.6 4.6 3.5 3.7 2.8 3.0 3.3

Reverse -29 to 427 6.9 6.9 6.9 6.9 6.9 4.6 4.6 3.5 3.7 2.8 3.0 3.3

Forward or

reverse

-29 to 49

66

93

121

149

191

204

232

52.4

52.4

43.0

38.6

28.7

13.8

10.3

3.4

60.4

58.5

43.0

38.6

28.7

13.8

10.3

3.4

50.3

50.3

43.0

38.6

28.7

13.8

10.3

(1)

in Bar for Steel Valve Body Material

MAX ALLOWABLE SHUTOFF P

(PER VALVE BODY SIZE, NPS)

8510B 8510

57.9

54.6

37.7

41.4

19.7

41.4

19.0

41.4

17.9

38.6

16.9

28.7

15.5

13.8

13.8

10.3

10.3

(4)

9.0

8.5

8.2

8.1

7.7

7.4

9.0

8.1

7.4

7.2

7.0

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

5.3 10.0

4.9 9.5

4.7 9.2

4.6 9.0

4.3 8.8

4.1 8.4

5.2 7.4

4.6 7.4

4.1 7.4

3.9 7.4

3.8 7.4

6.8 3.7 7.4

6.6 3.4 7.4

(4)

9.0

8.5

8.2

8.1

7.7

7.4

(4)

(4)

(4)

(4)

(4)

5.3 7.4

4.9 7.4

4.7 7.4

4.6 7.4

4.3 7.4

4.1 7.4

33.8

33.8

33.8

33.8

28.7

13.8

10.3

3.4

3.4

57.9

54.6

48.5

38.6

28.7

13.8

10.3

51.4

51.4

43.0

38.6

28.7

13.8

10.3

3.4

37.7

37.7

37.7

28.7

13.8

10.3

(4)

(4)

13.4

(4)

(4)

12.8

(4)

(4)

12.3

(4)

(4)

12.1

(4)

(4)

11.7

(4)

(4)

11.2

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

(4)

9.1

(4)

4.6 4.6 3.5 3.7 2.8 3.0 3.3

(4)

4.6 4.6 3.5 3.7 2.8 2.8 3.3

(4)

4.6 4.6 3.5 3.7 2.8 2.8 3.3

(4)

4.6 4.6 3.5 3.7 2.8 2.6 3.3

(4)

4.6 4.6 3.5 3.7 2.8 2.6 3.3

(4)

4.6 4.6 3.4 3.7 2.8 2.3 3.3

33.4

33.4

33.4

33.4

28.7

13.8

10.3

3.4

48.5

38.6

28.7

13.8

10.3

(4)

(4)

20.2

20.2

19.6

19.2

18.6

17.9

17.0

17.0

17.0

17.0

17.0

16.8

16.3

17.0

17.0

17.0

17.0

17.0

17.0

8.5

8.5

8.5

8.5

8.5

8.5

24.3

(4)

24.3

(4)

24.3

(4)

24.0

(4)

23.3

(4)

22.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

14.6

(4)

7.3

(4)

7.3

(4)

7.3

(4)

7.3

(4)

7.3

(4)

7.3

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

57.9

57.9

43.0

38.6

28.7

13.8

10.3

3.4

19.7

19.0

17.9

16.9

15.5

13.8

10.3

19.7

19.0

17.9

16.9

15.5

13.8

10.3

(4)

6.4 3.8 7.9

(4)

6.1 3.5 7.5

(4)

5.8 3.3 7.3

(4)

5.7 3.2 7.2

(4)

5.4 3.0 7.0

(4)

5.2 2.8 6.7

(4)

5.7 3.7 6.7

(4)

5.7 3.2 6.7

(4)

5.2 2.8 6.7

(4)

5.1 2.8 6.6

(4)

4.9 2.6 6.4

(4)

4.8 2.6 6.3

(4)

4.6 2.3 6.1

(4)

5.7 3.8 6.7

(4)

5.7 3.5 6.7

(4)

5.7 3.3 6.7

(4)

5.7 3.2 6.7

(4)

5.4 3.0 6.7

(4)

5.2 2.8 6.7

---

19.7

19.0

17.9

16.9

15.5

13.8

10.3

19.7

19.0

17.9

16.9

15.5

13.8

10.3

(4)

(4)

(4)

(4)

(4)

(4)

12

Page 13

8510/8510B Valve

D100066X012

Product Bulletin

51.6:edisc (EMA)

February 2013

Table 7. Maximum Allowable Shutoff Pressure Drops

TABLE 4

OR 5 TRIM

NUMBER

(2)

1

,2,3,4,

NT3

(2)

5

,6,7,8

(2)

9

,10

11

12

13

14

15

1. Based on valve body assembly material strengths only–actuator torque not considered.

2. This trim not available in the NPS 2 and 3 valves.

3.Forhotwaterorsteamservice,limitmaximumtemperatureto405F.

4. Reverse pressure drop is limited to 100psi.

FLOW

DIRECTION

TEMP. F

2 3 4 6 8 10 12 14 16 18 20 24

-20 to 120

150

200

Forward or

reverse

250

300

375

400

450

Forward -20 to 450

Reverse -20 to 450

-20 to 300 285

400 264

Forward or

reverse

500 251

600 244

700 231

800 218

-20 to 200 285

300 248

Forward or

reverse

400 218

500 212

600 201

700 193

800 183

-20 to 300 285

400 264

Forward or

reverse

500 251

600 244

700 231

800 218

-20 to 300 178

400 178

Forward or

reverse

500 178

600 178

700 178

800 178

(3)

816

816

704

560

416

200

150

935

848

704

560

416

200

150

50 50 50 50 50 50 50 50 50 50 50 50

(3)

740 740 740 740 450 250 250 150 150 150 150 150

(3)

100 100 100 100 100 100 100 100 100 100 100 100

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

457

434

419

411

396

381

318

318

318

318

318

318

318

318

318

318

318

318

318

159

159

159

159

159

159

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

Forward -20 to 800 178 159 134 123 106 66 67 51 53 41 44 48

Reverse -20 to 800 100 100 100 100 100 66 67 51 53 41 44 48

Forward or

reverse

-20 to 120

150

200

250

300

375

400

450

760

760

704

560

416

200

150

50

876

848

704

560

416

200

150

50

(1)

in Psi for Steel Valve Body Material

MAX ALLOWABLE SHUTOFF P

(PER VALVE BODY SIZE, NPS)

8510B 8510

780

840

792

547

600

780

704

560

416

200

150

417

397

384

377

364

351

268

268

268

268

268

268

268

268

268

268

268

268

268

134

134

134

134

134

134

730

730

704

560

416

200

150

50

840

792

704

560

416

200

150

746

746

704

560

416

200

150

50

547

547

547

416

200

150

(4)

(4)

194

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

131

(4)

185

124

(4)

179

119

(4)

175

117

(4)

169

112

(4)

163

107

(4)

132

130

(4)

132

118

(4)

132

107

(4)

132

105

(4)

132

102

(4)

132

(4)

132

(4)

132

131

(4)

132

124

(4)

132

119

(4)

132

117

(4)

132

112

(4)

132

107

66 67 51 53 41 44 48

66 67 51 53 41 41 48

66 67 51 53 41 40 48

66 67 51 53 41 38 48

66 67 51 53 41 37 48

66 67 50 53 41 34 48

484

484

484

484

416

200

150

50

704

560

416

200

150

(4)

(4)

307

293

284

279

270

260

246

246

246

246

246

246

236

246

246

246

246

246

246

123

123

123

123

123

123

353

(4)

353

(4)

353

(4)

348

(4)

338

(4)

328

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

212

(4)

106

(4)

106

(4)

106

(4)

106

(4)

106

(4)

106

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

840

840

704

560

416

200

150

50

285

600

275

600

260

560

245

416

230

200

200

150

150

(4)

77 145

(4)

71 138

(4)

68 133

(4)

66 131

(4)

62 127

(4)

59 122

(4)

76 107

(4)

67 107

(4)

59 107

(4)

57 107

(4)

55 107

99 53 107

95 50 107

(4)

77 107

(4)

71 107

(4)

68 107

(4)

66 107

(4)

62 107

(4)

59 107

490

490

490

490

416

200

150

50

285

275

260

245

230

200

150

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

285

285

275

275

260

260

245

245

230

230

200

200

150

150

93 55 115

88 51 109

84 48 106

83 47 104

79 44 101

78 41 97

82 54 97

82 47 97

75 41 97

74 40 96

71 38 93

69 37 91

66 34 88

82 55 97

82 51 97

82 48 97

82 47 97

79 44 97

75 41 97

---

285

275

260

245

230

200

150

(4)

(4)

(4)

(4)

(4)

(4)

13

Page 14

Product Bulletin

51.6:edisc (EMA)

February 2013

8510/8510B Valve

D100066X012

Table 8. Maximum Allowable Shutoff Pressure Drops

TABLE 4

OR 5

TRIM

NUMBER

3, 4,

NT3

7

8

(3)

11x7.4

12

13

14

1. Based on valve body assembly material strengths only–actuator torque not considered.

2.Forhotwaterorsteamservice,limitmaximumtemperatureto207C.

3. Reverse pressure drop is limited to 6.9bar.

FLOW

DIRECTION

TEMP. C

2 3 4 6 8 10 12 14 16 18 20 24

-46 to 49

66

93

Forward or

reverse

121

149

191

204

232

Forward -46 to 232

Reverse -46 to 232

Forward -46 to 232

Reverse -46 to 232

-46 to 93 19.7

149 17.1

204 15.0

Forward or

reverse

260 14.6

316 13.9

371 13.3

427 12.6

482 11.9

438 11.1

-46 to 149 19.7

204 18.2

Forward or

reverse

260 17.3

316 16.8

371 15.9

427 15.0

-46 to 149 12.3

204 12.3

260 12.3

Forward or

reverse

316 12.3

371 12.3

427 12.3

482 11.9

538 11.1

(2)

56.2

56.2

48.5

38.6

28.7

13.8

10.3

64.5

58.5

48.5

38.6

28.7

13.8

10.3

3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4 3.4

(2)

51.0 51.0 51.0 51.0 31.0 17.2 17.2 10.3 10.3 10.3 10.3 10.3

(2)

6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

(2)

51.0 51.0 51.0 51.0 31.0 17.2 17.2 10.3 10.3 10.3 10.3 10.3

(2)

6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9 6.9

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

21.9

11.0

11.0

11.0

11.0

11.0

11.0

11.0

11.0

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

18.5

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

Forward -46 to371 12.3 11.0 9.2 8.5 7.3 4.6 4.6 3.5 3.7 2.8 3.0 3.3

Reverse -46 to 371 6.9 6.9 6.9 6.9 6.9 4.6 4.6 3.5 3.7 2.8 3.0 3.3

(1)

in Bar for Stainless Steel Valve Body Material

MAX ALLOWABLE SHUTOFF P

(PER VALVE BODY SIZE, NPS)

8510B 8510

53.8

53.8

48.5

38.6

28.7

13.8

10.3

9.2

9.2

9.2

9.2

9.2

9.2

9.2

9.2

57.9

57.9

48.5

38.6

28.7

13.8

10.3

(3)

17.0

(3)

17.0

(3)

17.0

(3)

17.0

(3)

17.0

(3)

16.8

(3)

16.3

(3)

15.8

(3)

15.2

(3)

17.0

(3)

17.0

(3)

17.0

(3)

17.0

(3)

17.0

(3)

17.0

(3)

8.5

(3)

8.5

(3)

8.5

(3)

8.5

(3)

8.5

(3)

8.5

(3)

8.5

(3)

8.5

54.6

37.7

54.6

41.4

37.7

48.5

38.6

28.7

13.8

10.3

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

14.6

7.3

7.3

7.3

7.3

7.3

7.3

7.3

7.3

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

9.1

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

41.4

37.7

41.4

37.7

38.6

28.7

28.7

13.8

13.8

10.3

10.3

(3)

9.0

(3)

8.1

(3)

7.4

(3)

7.2

(3)

7.0

(3)

(3)

(3)

(3)

(3)

9.0

(3)

8.5

(3)

8.2

(3)

8.1

(3)

7.7

(3)

7.4

4.6 4.6 3.5 3.7 2.8 3.0 3.3

4.6 4.6 3.5 3.7 2.8 2.8 3.3

4.6 4.6 3.5 3.7 2.8 2.8 3.3

4.6 4.6 3.5 3.7 2.8 2.6 3.3

4.6 4.6 3.5 3.7 2.8 2.6 3.3

4.6 4.6 3.4 3.7 2.8 2.3 3.3

4.6 4.6 3.2 3.7 2.8 2.2 3.3

4.6 4.6 3.0 3.7 2.8 2.1 3.3

19.7

19.0

17.9

16.9

15.5

13.8

10.3

(3)

5.2 7.4

(3)

4.6 7.4

(3)

4.1 7.4

(3)

3.9 7.4

(3)

3.8 7.4

6.8 3.7 7.4

6.6 3.4 7.4

6.3 3.2 7.3

6.1 3.0 7.0

(3)

5.3 7.4

(3)

4.9 7.4

(3)

4.7 7.4

(3)

4.6 7.4

(3)

4.3 7.4

(3)

4.1 7.4

19.7

19.0

17.9

16.9

15.5

13.8

10.3

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

19.7

19.7

19.0

17.9

16.9

15.5

13.8

10.3

19.7

19.0

17.9

16.9

15.5

13.8

10.3

19.0

17.9

16.9

15.5

13.8

10.3

5.7 3.7 6.7

5.7 3.2 6.7

5.2 2.8 6.7

5.1 2.8 6.6

4.9 2.6 6.4

4.8 2.6 6.3

4.6 2.3 6.1

4.3 2.2 5.9

4.1 2.1 5.7

5.7 3.8 6.7

5.7 3.5 6.7

5.7 3.3 6.7

5.7 3.2 6.7

5.4 3.0 6.7

5.2 2.8 6.7

14

Page 15

8510/8510B Valve

D100066X012

Product Bulletin

51.6:edisc (EMA)

February 2013

Table 9. Maximum Allowable Shutoff Pressure Drops

TABLE 4

OR 5

TRIM

NUMBER

3, 4,

NT3

7

8

11

12

13

14

1. Based on valve body assembly material strengths only–actuator torque not considered.

2.Forhotwaterorsteamservice,limitmaximumtemperatureto405F.

3. Reverse pressure drop is limited to 100psi.

FLOW

DIRECTION

TEMP. F

2 3 4 6 8 10 12 14 16 18 20 24

-50 to 120

150

200

Forward or

reverse

250

300

375

400

450

Forward -50 to 450

Reverse -50 to 450

Forward -50 to 450

Reverse -50 to 450

-50 to 200 285

300 248

400 218

Forward or

reverse

500 212

600 201

700 193

800 183

900 172

1000 161

-50 to 300 285

400 264

Forward or

reverse

500 251

600 244

700 231

800 218

-50 to 300 178

400 178

500 178

Forward or

reverse

600 178

700 178

800 178

900 172

1000 161

(2)

816

816

704

560

416

200

150

935

848

704

560

416

200

150

780

780

704

560

416

200

150

50 50 50 50 50 50 50 50 50 50 50 50

(2)

740 740 740 740 450 250 250 150 150 150 150 150

(2)

100 100 100 100 100 100 100 100 100 100 100 100

(2)

740 740 740 740 450 250 250 150 150 150 150 150

(2)

100 100 100 100 100 100 100 100 100 100 100 100

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

318

318

318

318

318

318

318

318

318

318

318

318

318

318

318

159

159

159

159

159

159

159

159

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

268

(3)

134

(3)

134

(3)

134

(3)

134

(3)

134

(3)

134

(3)

134

(3)

134

Forward -50 to 800 178 159 134 123 106 66 67 51 53 41 44 48

Reverse -50 to 800 100 100 100 100 100 66 67 51 53 41 44 48

(1)

in Psi for Stainless Steel Valve Body Material

MAX ALLOWABLE SHUTOFF P

(PER VALVE BODY SIZE, NPS)

8510B 8510

840

792

840

792

704

704

560

560

416

416

200

200

150

150

(3)

(3)

246

246

246

246

246

243

236

229

221

246

246

246

246

246

246

123

123

123

123

123

123

123

123

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

212

(3)

106

(3)

106

(3)

106

(3)

106

(3)

106

(3)

106

(3)

106

(3)

106

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

547

547

547

547

416

200

150

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

132

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

600

275

600

257

600

240

560

227

416

215

200

200

150

150

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

130

118

107

105

102

(3)

(3)

(3)

(3)

76 107

67 107

59 107

57 107

55 107

99 53 107

95 50 107

91 47 106

88 44 102

(3)

131

124

119

117

112

107

(3)

(3)

(3)

(3)

(3)

77 107

71 107

68 107

66 107

62 107

59 107

66 67 51 53 41 44 48

66 67 51 53 41 41 48

66 67 51 53 41 40 48

66 67 51 53 41 38 48

66 67 51 53 41 37 48

66 67 50 53 41 34 48

66 67 47 53 41 32 48

66 67 44 53 41 30 48

275

257

240

227

215

200

150

275

257

240

227

215

200

150

(3)

82 54 97

(3)

82 54 97

(3)

75 41 97

(3)

74 40 96

(3)

71 38 93

(3)

69 37 91

(3)

66 34 88

(3)

63 32 85

(3)

60 30 82

(3)

82 55 97

(3)

82 51 97

(3)

82 48 97

(3)

82 47 97

(3)

79 44 97

(3)

75 41 97

275

257

240

227

215

200

150

275

257

240

227

215

200

150

15

Page 16

Product Bulletin

51.6:edisc (EMA)

February 2013

8510/8510B Valve

D100066X012

Table 10. Maximum Allowable Forward and Reverse Shutoff Pressure Drops

MAX ALLOWABLE SHUTOFF P

ALLOY VALVE

BODY

MATERIAL

TABLE 5

TRIM

NUMBER

TEMPERATURE

2 3 4 6 8 10 12

(PER VALVE BODY SIZE, NPS)

C F Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi Bar Psi

-46 to 49

93

M35-1 15

149

191

204

232

-46 to 49

Alloy 20

CN7M

17

66

93

149

1. Based on valve body assembly material strengths only–actuator torque not considered.

-50 to 120

200

300

375

400

450

-50 to 120

150

200

300

52.4

40.3

25.2

13.8

10.3

3.4

18.6

18.1

17.1

15.2

760

584

365

200

150

50

270

262

248

221

60.4

45.8

27.5

13.8

10.3

3.4

33.2

31.0

27.1

19.5

876

664

399

200

150

50

482

449

393

283

50.3

38.9

24.5

13.8

10.3

3.4

34.3

31.9

27.9

19.8

730

564

356

200

150

50

497

462

404

287

Table 11. Material Temperature Capabilities

VALVE BODY

MATERIAL

Steel

316 stainless

steel

M35-1 15

Alloy 20 17

1.Forhotwaterorsteamservice,limitmaximumtemperatureto207C (405F)

TABLE 4 OR 5

TRIM NUMBER

PACKING

1, 2, 3, 4, 5, 6, 7, 8 All -29 to 232

9, 10, 11, 12, 13, 14

PTFE V-ring or PTFE composition -29 to 232 -20 to 450

Graphite ribbon -29 to 427 -20 to 800

15 All -29 to 232 -20 to 450

NT3 PTFE V-ring -29 to 232

3, 4, 8

PTFE composition or graphite ribbon

PTFE V-ring

PTFE V-ring

7

PTFE composition

Graphite ribbon

PTFE V-ring

11, 13

PTFE composition

Graphite ribbon

PTFE V-ring

12, 14

PTFE composition

Graphite ribbon

NT3 PTFE V-ring -40 to 232

PTFE V-ring

PTFE composition or graphite ribbon

PTFE V-ring

PTFE composition or graphite ribbon

(1)

for Alloy Valve Body Materials

8510B

57.9

840

51.4

746

44.1

26.8

13.8

10.3

3.4

24.0

22.8

20.8

16.8

639

388

200

150

50

348

331

302

244

39.6

24.8

13.8

10.3

3.4

32.1

29.9

26.3

19.2

575

360

200

150

50

465

434

382

278

33.4

27.2

19.6

13.8

10.3

3.4

16.8

16.5

15.9

14.7

MATERIAL

TEMPERATURE CAPABILITY

C F

(1)

(1)

-40 to 232

-46 to 232

-40 to 232

-46 to 232

-46 to 232

(1)

(1)

(1)

(1)

(1)

-40 to 232

-46 to 260

-46 to 538

-40 to 232

-46 to 260

-46 to 427

(1)

-40 to 232

-46 to 232

-40 to 149

-46 to 149

484

33.8

395

27.5

284

19.7

200

13.8

150

10.3

50

3.4

244

12.7

239

230

213

(1)

-20 to 450

-20 to 450

-40 to 450

-50 to 450

-40 to 450

-50 to 450

-50 to 450

-40 to 450

-50 to 500

-50 to 1000

-40 to 450

-50 to 500

-50 to 800

-40 to 450

-40 to 450

-50 to 450

-40 to 300

-50 to 300

490

399

285

200

150

50

184

---

---

---

---

---

---

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

16

Page 17

8510/8510B Valve

D100066X012

Product Bulletin

51.6:edisc (EMA)

February 2013

Material Selection

Guidelines

Pick the valve body, trim, and other construction

materials from tables 3, 4, and 5, according to the

recommendationsandlimitationsintables6,7,8,9,

10, and 11. Also, make sure that the

pressure/temperature limits in the specifications table

andtables1,2,6,7,8,9,10,and11arenotexceeded.

Installation

As indicated in this bulletin, M35-1 valve bodies are not

ASME B16.34 or ASME code-approved materials. Valve

bodies constructed of M35-1 will mate with ASME

flanges, but are not included in ASME

pressure-temperature ratings and must not be

installed in systems requiring conformance to ASME

standards.

An 8510 and 8510B valve may be installed in any

position.

b. Reducing or relief

2. Controlled fluid

3. Specific gravity of controlled fluid

4. Fluid temperature

5. Range of flowing inlet pressures

6. Pressure drops

a. Range of flowing pressure drops

b. Maximum at shutoff

7. Flow rates

a. Minimum controlled flow

b. Normal flow

c. Maximum flow

8. Maximum permissible noise level, if critical

9. Line size and schedule

Dimensions are shown in figure 7.

Ordering Information

When ordering, specify:

Application

1. Type of application

a. Throttling or on/off

Valve Information

Refer to the Specifications table. Review the

information under each specification and in the

referenced tables. Indicate the choice wherever there

is a selection to be made.

Actuator and Accessory Information

Specify the desired actuator type and size from the

separate actuator bulletin. Also refer to the separate

actuator and accessory bulletins for additional

ordering information.

17

Page 18

Product Bulletin

51.6:edisc (EMA)

February 2013

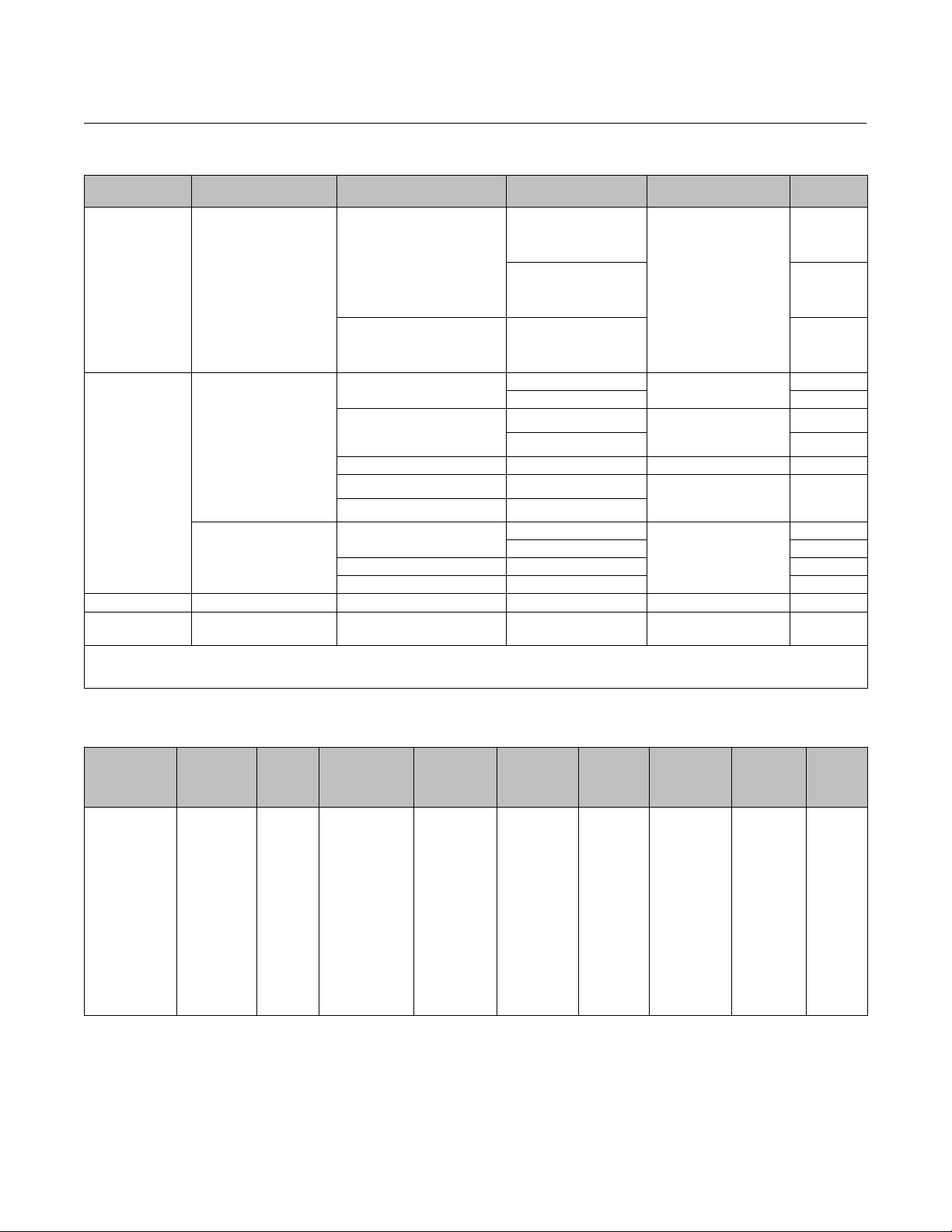

Table 12. Dimensions for Fisher 8510 and 8510B

VALVE

SIZE,

NPS

2

3

4

6

8

10

12

14

16

18

20

24

2

3

4

6

8

10

12

14

16

18

20

24

1. Valve assembly only.

A B D F G K R

45

48

56

57

64

71

83

92

102

114

127

154

1.78

1.88

2.19

2.25

2.5

2.81

3.25

3.62

4.00

4.50

5.00

6.06

59

78

102

141

191

241

286

329

376

427

470

564

2.31

3.06

4.00

5.56

7.50

9.50

11.25

12.94

14.81

16.81

18.50

22.19

187

187

214

214

208

208

208

208

356

356

356

356

7.38

7.38

8.44

8.44

8.19

8.19

8.19

8.19

14.00

14.00

14.00

14.00

141

168

197

251

317

378

438

416

473

536

589

699

5.56

6.62

7.75

9.88

12.50

14.88

17.25

16.38

18.62

21.12

23.19

27.50

138

155

198

238

289

289

348

362

409

397

464

522

5.44

6.12

7.81

9.38

11.38

11.38

13.69

14.25

16.12

15.62

18.25

20.56

8510/8510B Valve

D100066X012

S

(SHAFT

DIA)

mm kg

102

119

162

202

244

257

297

311

359

346

406

465

Inches Pounds

4.00

4.69

6.38

7.94

9.62

10.12

11.69

12.25

14.12

13.62

16.00

18.31

103

127

159

217

272

325

384

416

473

536

589

699

4.06

5.00

6.25

8.53

10.69

12.81

15.12

16.38

18.62

21.12

23.19

27.50

12.7

15.9

19.1

25.4

31.8

31.8

38.1

38.1

44.5

44.5

50.8

63.5

0.5

0.625

0.75

1

1.25

1.25

1.5

1.5

1.75

1.75

2

2.5

T U W

117

117

152

152

235

235

235

235

273

273

273

337

4.62

4.62

6.00

6.00

9.25

9.25

9.25

9.25

10.75

10.75

10.75

13.25

---

--32

32

46

46

46

46

51

51

51

76

---

---

1.25

1.25

1.81

1.81

1.81

1.81

2.00

2.00

2.00

3.00

1/2-13

1/2-13

1/2-13

1/2-13

5/8-11

5/8-11

5/8-11

5/8-11

3/4-10

3/4-10

3/4-10

7/8-9

1/2-13

1/2-13

1/2-13

1/2-13

5/8-11

5/8-11

5/8-11

5/8-11

3/4-10

3/4-10

3/4-10

7/8-9

APPROXIMATE

WEIGHT

4.3

5.9

9.1

102

136

204

277

9.5

102

158

194

225

300

450

610

(1)

19

31

46

72

88

13

20

41

69

Table 13. Dimensions for Fisher 8510 and 8510B

DIN VALVE

BODY SIZE

DN 50

DN 80

DN 100

DN 150

DN 200

DN 250

DN 300

A

FACE-TO-FACE

mm PN 10 PN 16 PN 25 PN 40-100

43

49

56

70

71

76

83

102

138

158

212

268

320

370

102

138

158

212

268

320

378

RAISED FACE

Figure 7. Dimensions for Fisher 8510 and 8510B (also see tables 12 and 13)

R

S

F

41B6064-A

B2036-1

G

B

K

D

mm

102

138

162

218

278

335

395

102

138

162

218

285

345

410

A

A

T

U

T

WW

NPS 2 AND 3 NPS 4 THROUGH 24

18

Page 19

8510/8510B Valve

D100066X012

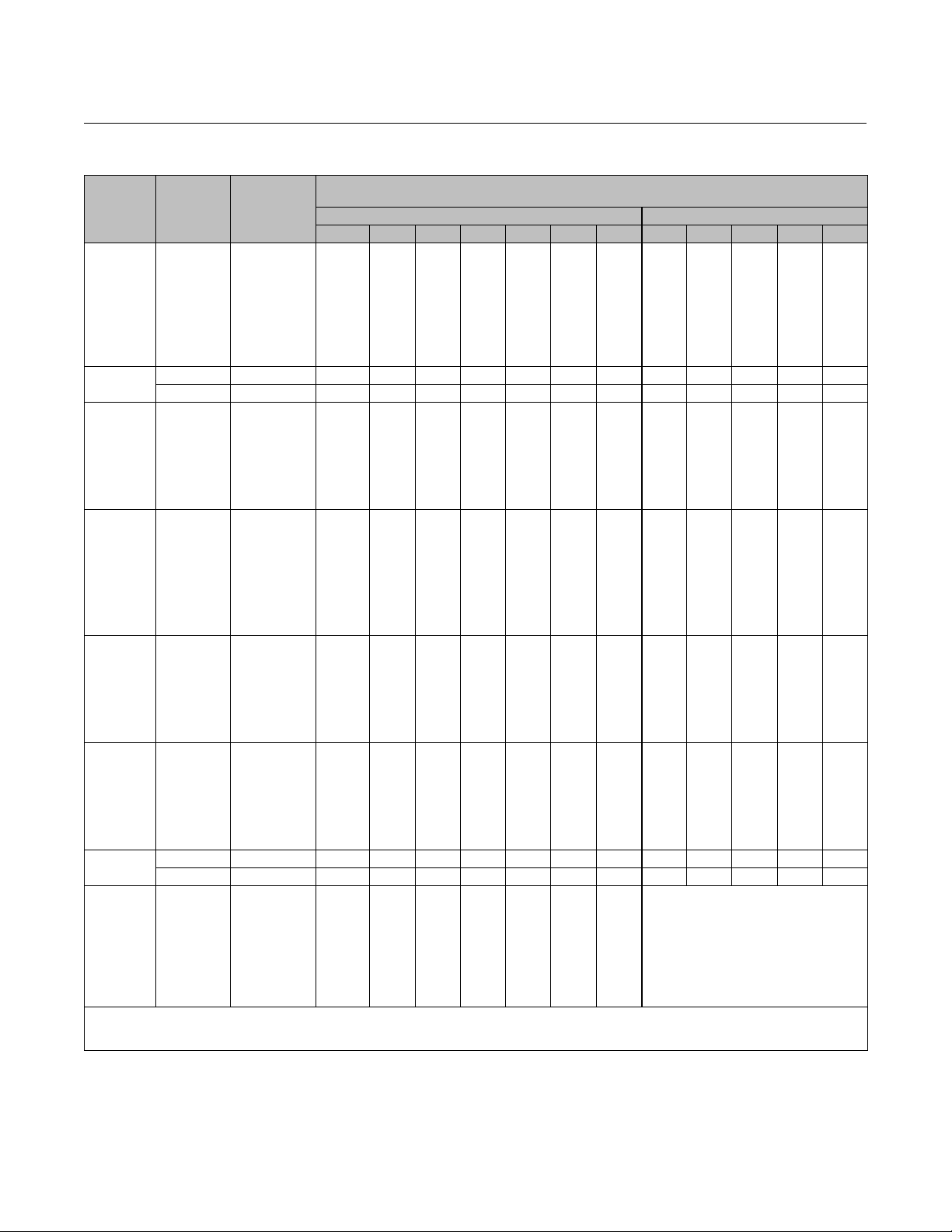

Table 14. Dimensions for Fisher 8510B with Alternate Double D Shaft

VALVE

SIZE,

NPS

2

3

4

6

8

10

12

2

3

4

6

8

10

12

1. Valve assembly only.

A B D F G K R

mm kg

45

48

54

57

64

71

83

1.78

1.88

2.12

2.25

2.50

2.81

3.19

59

78

102

141

191

241

286

2.31

3.06

4.00

5.56

7.50

9.50

11.25

--83

83

83

83

89

89

---

3.25

3.25

3.25

3.25

3.50

3.50

141

168

197

251

317

378

438

5.56

6.62

7.75

9.88

12.50

14.88

17.25

138

155

198

238

289

289

348

5.44

6.12

7.81

9.38

11.38

11.38

13.69

102

119

162

202

244

257

297

Inches Pounds

4.00

4.69

6.38

7.94

9.62

10.12

11.69

103

127

159

217

272

325

384

4.06

5.00

6.25

8.53

10.69

12.81

15.12

Figure 8. Dimensions for Fisher 8510B with Alternate Double D Shaft (also see table 14)

S

(SHAFT

DIA)

---

12.7

15.7

19.0

25.4

31.8

38.1

---

0.5

0.625

0.75

1

1.25

1.5

T U W

117

117

152

152

235

235

235

4.62

4.62

6.00

6.00

9.25

9.25

9.25

---

--32

32

46

46

46

---

---

1.25

1.25

1.81

1.81

1.81

Product Bulletin

51.6:edisc (EMA)

February 2013

APPROXIMATE

WEIGHT

1/2-13

1/2-13

1/2-13

1/2-13

5/8-11

5/8-11

5/8-11

1/2-13

1/2-13

1/2-13

1/2-13

5/8-11

5/8-11

5/8-11

4.3

5.9

9.1

19

31

46

72

9.5

13

20

41

69

102

158

(1)

39B8285-A

E0782

R

S

F

GK

B

D

19

Page 20

Product Bulletin

51.6:edisc (EMA)

February 2013

8510/8510B Valve

D100066X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility forproper selection, use,and maintenanceof any product remains solely with thepurchaser and end user.

Fisher and ENVIRO-SEAL are marks owned by one of the companies in the EmersonProcess Management business unitof Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1982, 2013 Fisher ControlsInternational LLC. All rights reserved.

20

Loading...

Loading...