Page 1

Product Bulletin

846 Transducer

D102127X012

March 2015

Fisherr 846 Electro-Pneumatic Transducer

62.1:846

The Fisher 846 electro-pneumatic transducer is a

rugged, field-mountable transducer that accepts an

electrical input signal and converts it to a pneumatic

output signal. Typically, the 4 to 20 mA is converted to

0.2 to 1.0 bar (3 to 15 psi). In the most common

application, the transducer converts an electrical

output signal from a controller to a pneumatic signal

necessary to operate a control valve actuator or

pneumatic positioner.

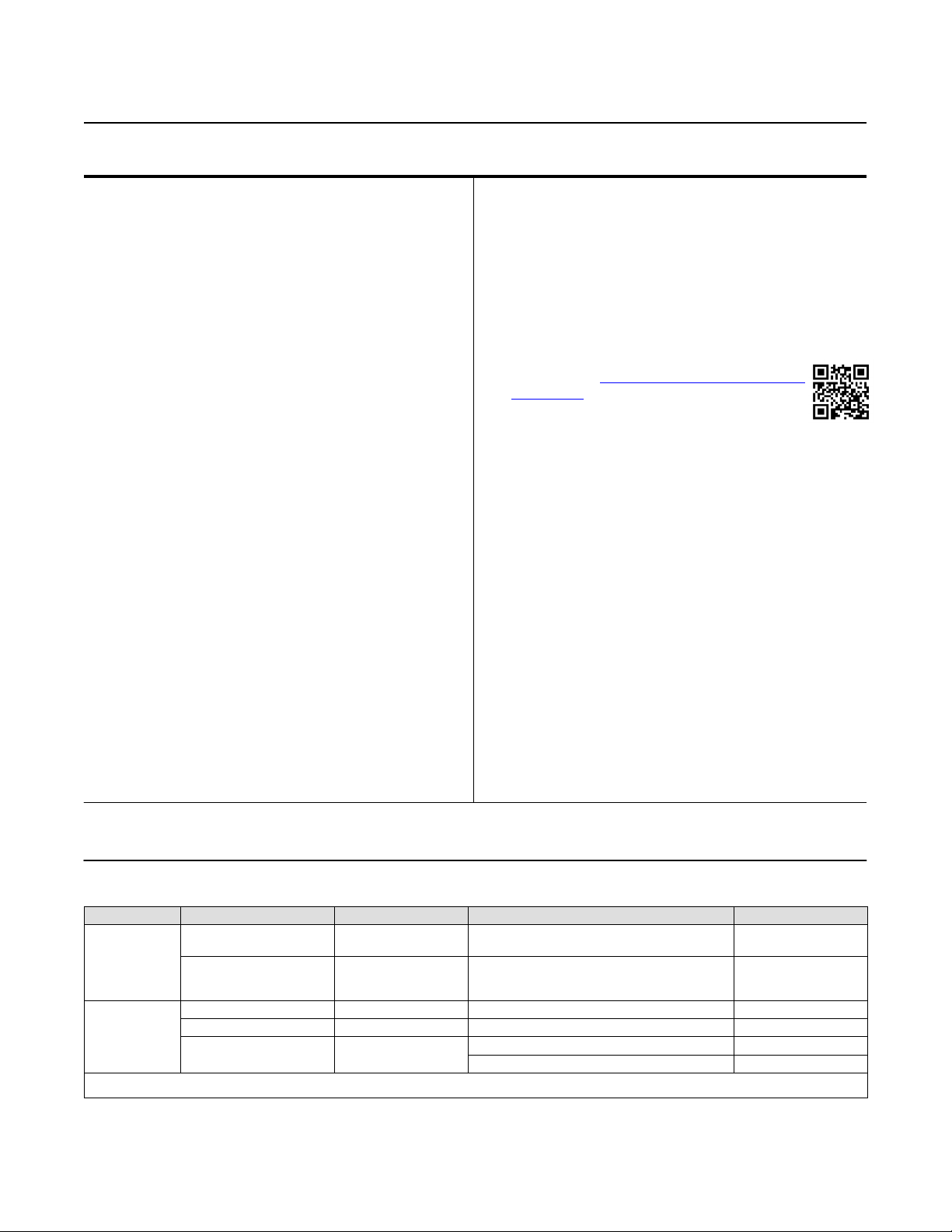

The transducer includes a deflector/nozzle design

(figure 1) that consists of two nozzles positioned so

that the constant air flow exiting the supply nozzle is

directed at the entrance of the receiver nozzle. Each

nozzle has a large bore of 0.41 mm (0.016 inches),

which provides good resistance to plugging. The input

current signal positions a deflector bar within the

nozzle's flow stream. As the input signal changes, the

deflector bar moves to alter the flow stream to the

receiver nozzle, establishing a pilot pressure at the

receiver nozzle. The pilot pressure, in turn, controls the

booster stage and output of the transducer.

An electronic feedback control network constantly

compares the value of the pneumatic output signal

with the input current signal. A solid-state pressure

sensor is part of the electronics package monitoring

the pneumatic output (figure 3). A comparator circuit

in the control network detects input-output deviations

and adjusts the output by moving the deflector in the

pilot stage to a corrected position. Because of this

feedback network, the transducer can correct for

error-producing effects such as variations in supply

pressure and downstream leakage.

X0234

www.Fisher.com

FISHER 846 ELECTRO-

PNEUMATIC TRANSDUCER

W6307-1

846 MOUNTED

ON FISHER 667 ACTUATOR

Page 2

Product Bulletin

62.1:846

March 2015

Specifications

Input Signal

4-20 mA DC, field adjustable split ranging.

Multirange Performance: 9.7 m

2.5 bar (35 psi) supply pressure

846 Transducer

D102127X012

3

/hr (360 scfh) at

Equivalent Circuit

See figure 4

Output Signal

Standard Performance:

J 0.2 to 1.0 bar (3 to 15 psi).

Rangeability between 0.1 to 1.2 bar (1 and 18 psi)

Multirange Performance:

J 0.4 to 2.0 bar (6 to 30 psi), and J 0 to 2.3 bar (0 to

J 0 to 1.2 bar (0 to 18 psi),

33 psi) nominal ranges. Actual rangeability available

between 0.03 to 2.3 bar (0.5 and 33 psi)

Action:

J Direct (increasing input signal increases

transducer output) (Minimum span, 6 psi) or

J Reverse (increasing input signal decreases

transducer output) (Minimum span, 11 psi)

Supply Pressure

Standard Performance: 1.2 to 1.6 bar

(18 to 24 psi)

Multirange Performance:

Minimum: 0.2 bar (3 psi) [0.14 bar (2 psi) for a 2.3 bar

(33 psi) output] greater than the maximum calibrated

output pressure.

Maximum: 2.4 bar (35 psi)

Supply Pressure Medium

Clean, dry air

Per ISA Standard 7.0.01

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended. Lubricant

content is not to exceed 1 ppm weight (w/w) or

volume (v/v) basis. Condensation in the air supply

should be minimized.

Per ISO 8573-1

Maximum particle density size: Class 7

Oil content: Class 3

Pressure Dew Point: Class 3 or at least 10°C less than

the lowest ambient temperature expected

Maximum Steady-State Air Consumption

(1)

0.3 m3/hr (12 scfh) at 1.4 bar (20 psi) supply pressure.

Output Air Capacity

(1)

Standard Performance: 6.4 m3/hr (240 scfh) at

1.4 bar (20 psi) supply pressure.

- continued -

Temperature Limits

Operating: -40 to 85_C (-40 to 185_F)

Storage: -40 to 93_C (-40 to 200_F).

Humidity Limits

0-100% condensing relative humidity.

Performance

(2)

Linearity, Hysteresis, and Repeatability: $0.3% of

span

Temperature Effect (total effect including zero and

span): $0.07%/_C (0.045%/_F) of span

Vibration Effect: $0.3% of span per g during the

following conditions:

5-15 Hz at 4 mm constant displacement

15-150 Hz at 2 g. 150-2000 Hz at 1 g.

per SAMA Standard PMC 31.1, Sec. 5.3, Condition 3,

Steady State.

Shock Effect: $0.5% of span, when tested per SAMA

Standard PMC 31.1, Sec. 5.4.

Supply Pressure Effect: Negligible

Electromagnetic Interference (EMI): Tested per IEC

61326-1 (Edition 1.1). Meets emission levels for Class

A equipment (industrial locations) and Class B

equipment (domestic locations). Meets immunity

requirements for industrial locations (Table A.1).

Immunity performance is shown in table 1.

Leak Sensitivity: Less than 1.0% of span for up to

3

4.8 m

/hr (180 scfh) downstream leakage.

Overpressure Effect: Less than 0.25% of span for

misapplication of up to 7.0 bar (100 psi) supply

pressure for less than 5 minutes to the input port.

Reverse Polarity Protection: No damage occurs from

reversal of normal supply current (4-20 mA) or from

misapplication of up to 100 mA.

Connections

Supply and Output Pressure: 1/4-18 NPT internal

connection.

Electrical: 1/2-14 NPT internal conduit connection.

2

Page 3

846 Transducer

D102127X012

Specifications (Continued)

Product Bulletin

62.1:846

March 2015

Adjustments

Zero and Span: Screwdriver adjustments located in

terminal compartment.

Other Classifications/Certifications

CUTR— Customs Union Technical Regulations

(Russian, Kazakhstan, and Belarus)

INMETRO—National Institute of Metrology, Quality,

Remote Pressure Reading (optional)

ON or OFF; jumper selectable

Frequency Range: 0-10,000 Hz

Amplitude: 0.4-1.0 V

p-p

and Technology (Brazil)

KGS—Korea Gas Safety Corporation (South Korea)

NEPSI— National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

Required Operating Voltage

Min. 6.0 V (at 4 mA)

Max. 7.2 V (at 20 mA)

Contact your Emerson Process Management

sales office for classification/certification

specific information

with Remote Pressure Reading ON

Min. 6.4 V (at 4 mA)

Max. 8.2 V (at 20 mA)

Electrical Classification

Hazardous Area

(3)

Construction Materials

Housing: J Low-copper aluminum with polyurethane

paint, or

J CF8M

O-Rings: Nitrile, except silicone for sensor O-rings.

(see Bulletin 9.2:001, D103222X012)

CSA C/US—Intrinsically Safe, Explosion-proof,

Mounting

Non-Incendive

FM—Intrinsically Safe, Explosion-proof,

J Actuator, J pipestand, or J surface

Non-Incendive

ATEX—Intrinsically Safe, Flameproof, Type n

IECEx—Intrinsically Safe, Flameproof

Electrical Housing

Weight

Aluminum: 2.9 kg (6.5 lb) excluding options

Stainless Steel: 6.7 kg (14.8 lb) excluding options

Tropicalization (Fungus test per MIL-STD-810)

CSA C/US—Type 4X

FM—Type 4X

ATEX—IP66

IECEx—IP66

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology

1. Normal m

2. Performance values are obtained using a transducer with a 4 to 20 mA dc input signal, a 3 to 15 psig output, and 20 psig supply pressure.

3. Refer to tables 2, 3, 4, and 5 for additional information.

4. ATEX and IECEx Flameproof — IP66 per CSA Letter of Attestation.

(4)

(4)

3

/hr: normal cubic meters per hour (m3/hr, 0_C and 1.01325 bar, absolute). Scfm: standard cubic feet per minute (ft3/min, 60_F and 14.7 psig).

Options

J Fisher 67CFR filter regulator, J supply and output

gauges,

J remote pressure reading, or J stainless

steel mounting bracket

Table 1. EMC Immunity Performance Criteria

Port Phenomenon Basic Standard Test Level Performance Criteria

Electrostatic discharge

(ESD)

Enclosure

I/O signal/control

Specification limit = ±1% of span

1. A = No degradation during testing. B = Temporary degradation during testing, but is self-recovering.

Radiated EM field IEC 61000-4-3

Burst (fast transients) IEC 61000-4-4 1 kV A

Surge IEC 61000-4-5 1 kV (line to ground only, each) B

Conducted RF IEC 61000-4-6

IEC 61000-4-2

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1kHz AM at 80%

150 kHz to 8 MHz at 3 Vrms B

8 MHz to 80 MHz at 3 Vrms A

(1)

A

A

3

Page 4

Product Bulletin

62.1:846

March 2015

846 Transducer

D102127X012

Features

n Vibration Resistant—The low-mass pilot stage,

mechanically damped deflector bar, and rugged

construction provide stable performance in

vibration.

n Large Diameter Nozzles—Large diameter nozzles,

free-flow pilot stage design, and large internal

pneumatic supply passages provide excellent

tolerance to reducing the effects of contaminant

buildup and erosion.

n Increased Accuracy, Reduced Sensitivity to Supply

Pressure Variations and Downstream Leakage—The

electronic feedback control network monitors the

pneumatic output signal, detects any input-output

deviations and corrects them. This provides very

high accuracy and allows the transducer to sense

changes in the final element condition and rapidly

optimize its air delivery.

n Easy Maintenance—Major mechanical and electrical

components are incorporated into a single

field-replaceable “master module” (figure 2). The

transducer does not have to be removed from its

mounting to facilitate troubleshooting or service. A

separate field wiring compartment eases

installation and maintenance.

Figure 1.

W6287

Detail of Deflector/Nozzle Pilot Stage

Installation

The transducer may be actuator, wall, panel, or

pipestand mounted. Dimensions are shown in

figures 6, 7, and 8.

n Quick Diagnostic Checks and Remote Performance

Monitoring—With Stroke Port, a constant bleed from

the pilot stage vents through a hole in the module

cover. Covering the hole increases the transducer

output to confirm the proper operation of the pilot

and booster stages and stroke the actuator. With

optional Remote Pressure Reading, a frequency

directly proportional to the output pressure is

superimposed on the input signal wires.

Using a frequency counter, an operator can monitor

the 846 output pressure.

4

Ordering Information

To determine what ordering information is required,

refer to the specification table. Carefully review the

description of each specification. Specify the desired

choice whenever there is a selection available.

When ordering mounting parts, specify actuator,

surface, or pipestand mounting. For actuator

mounting, specify the actuator type, size, travel, and

diaphragm pressure range. For all 657 and 667

actuators except size 80, specify whether actuator

yoke or actuator casing mounting is desired (yoke

mounting only is available on size 80 actuators).

Page 5

846 Transducer

D102127X012

Figure 2. Master Module Construction

TERMINAL COVER

TRANSDUCER HOUSING

A6326

Product Bulletin

62.1:846

March 2015

MASTER MODULE

MODULE COVER

Figure 3. Functional Block Diagram

4 TO 20 mA

INPUT

ELECTRONIC CIRCUIT

MAGNETIC ACTUATOR

PILOT STAGE

BOOSTER STAGE

3 TO 15 PSI

OUTPUT, TYPICAL

A6324

STROKE PORT

SOLID-STATE

PRESSURE

SENSOR

Figure 4. Equivalent Circuit

846 TRANSDUCER

6 VDC

50

OHMS

POWER

SUPPLY

Note:

The 846 is not a constant resistor in series with an inductor. It is better

modeled in the loop as a 50 ohm resistor in series with a 6 volt DC voltage drop

with negligible inductance.

A6325

5

Page 6

Product Bulletin

62.1:846

March 2015

Figure 5. Dimensions

67

COVER REMOVAL

(2.62)

CLEARANCE

(2.31)

78

(3.08)

59

68

(2.69)

846 Transducer

D102127X012

1/4-18 NPT

SUPPLY CONN

156

(6.15)

29

(1.13)

137

MODULE COVER

(5.38)

REMOVAL CLEARANCE

1/4-18 NPT

OUTLET CONN

PLUGGED WHEN

GAUGE NOT

FURNISHED

5/16-18

3 PLACES

129

(5.07)

119

(4.68)

168

(6.60)

1/2-14 NPT

CONDUIT CONN

6

14B7364-C

5.43

(138)

1/4-18 NPT

OUTLET CONN

mm

(INCH)

Page 7

846 Transducer

D102127X012

Figure 6. Dimensions with Optional Fisher 67CFR Filter-Regulator (Yoke Mounted)

67

(2.62)

COVER REMOVAL

CLEARANCE

13

(0.50)

Product Bulletin

62.1:846

March 2015

78

(3.08)

CENTERLINE OF ACTUATOR

6

(0.25)

YOKE MOUNTED

191

(7.51)

FOR PROPER MOISTURE

DRAINAGE THIS END

MUST BE UP

MODULE

COVER

REMOVAL

CLEARANCE

137

(5.38)

1

Note:

1 The mounting positions shown allow any moisture buildup in the terminal compartment to drain to the signal wire conduit

entrance. Do not mount the transducer with the terminal compartment cover on the bottom; moisture may accumulate in the

terminal compartment or pilot stage, preventing proper transducer operation. The vertical mount is most effective for moisture

drainage in wet applications.

14B7361-D

mm

(INCH)

7

Page 8

Product Bulletin

62.1:846

March 2015

Figure 7. Dimensions with Optional Fisher 67CFR Filter-Regulator (Surface/Wall Mounted)

67

(2.62)

(0.50)

COVER REMOVAL

CLEARANCE

89

(3.50)

19

(0.76)

13

89

(3.50)

846 Transducer

D102127X012

222

(8.76)

FOR PROPER MOISTURE

DRAINAGE THIS END

MUST BE UP

1

61

(2.39)

10/0.38∅

MOUNTING

HOLE

4 PLACES

SURFACE/WALL MOUNTED

Note:

1 The mounting positions shown allow any moisture buildup in the terminal compartment to drain to the signal wire conduit

entrance. Do not mount the transducer with the terminal compartment cover on the bottom; moisture may accumulate in the

terminal compartment or pilot stage, preventing proper transducer operation. The vertical mount is most effective for moisture

drainage in wet applications.

14B7332-D

MODULE COVER

REMOVAL

CLEARANCE

137

(5.38)

mm

(INCH)

8

Page 9

846 Transducer

D102127X012

Figure 8. Dimensions with Optional Fisher 67CFR Filter-Regulator (Pipe Stand Mounted)

(8.27)

148

67

(2.62)

COVER REMOVAL

CLEARANCE

(5.82)

Product Bulletin

62.1:846

March 2015

210

1/2-14 NPT

CONDUIT CONN

54

(2.51)

13

(0.50)

60

(2.38)

FOR PROPER MOISTURE

DRAINAGE THIS END

MUST BE UP

262

(10.31)

PIPE STAND MOUNTED

1

2

156

(6.15)

67CFR

1/4-18 NPT

SUPPLY CONN

137

(5.38)

1/2-14 NPT

OUTLET CONN

PLUGGED WHEN

GAUGE NOT

FINISHED

MODULE

COVER

REMOVAL

CLEARANCE

1/2-14 NPT

CONDUIT CONN

mm

(INCH)

Notes:

1 The mounting positions shown allow any moisture buildup in the terminal compartment to drain to the signal wire conduit

entrance. Do not mount the transducer with the terminal compartment cover on the bottom; moisture may accumulate in the

terminal compartment or pilot stage, preventing proper transducer operation. The vertical mount is most effective for moisture

drainage in wet applications.

2 If mounted on horizontal pipe, the I/P must be on top of the pipe for proper moisture drainage.

14B7363-D

9

Page 10

Product Bulletin

62.1:846

March 2015

Table 2. Hazardous Area Classifications for Canada—cCSAus

Certification Body Certification Obtained Entity Rating Temperature Code

Vmax = 30 VDC

Imax = 100 mA

Ci = 0.016 mF

Li = 20 mH

- - - T4 (Tamb ≤ 60_C)

CSA

Ex ia Intrinsically Safe

Class I Division 1 Groups A,B,C,D T4

per drawing GE59146

XP Explosion-proof

Class I Division 1 Groups C,D

DIP Dust Ignition-proof

Class II III Division I Groups E,F,G T4

NI Non-incendive

Class I, Division 2, Groups A,B,C,D T4

Table 3. Hazardous Area Classification for United Stated—FM

Certification Body Certification Obtained Entity Rating Temperature Code

Vmax = 30 VDC

Imax = 100 mA

Pmax = 1.0 W

Ci = 0.016 mF

Li = 20 mH

- - - T4 (Tamb ≤ 60_C)

FM

IS Intrinsically Safe

Class I, II, III Division 1 Groups A,B,C,D,E,F,G

per drawing GE59147

XP Explosion-proof

Class I Division 1 Groups B,C,D

DIP Dust Ignition-proof

Class II, III Division I Groups EFG

NI Non-incendive

Class I Division 2 Groups A,B,C,D

846 Transducer

D102127X012

T4 (Tamb ≤ 60_C)

T4 (Tamb ≤ 60_C)

Table 4. Hazardous Area Classifications—ATEX

Certificate Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

ATEX

II 1 GD

Gas

Ex ia IIC T4,T5 Ga

Dust

Ex ia IIIC IP66 Da T90_C (Tamb ≤ 80_C)

Ex ia IIIC IP66 Da T50_C (Tamb ≤ 40_C)

Flameproof

II 2 G

Gas

Ex d IIB T5/T6 Gb

Type n

II 3 GD

Gas

Ex nA IIC T5/T6 Gc

Dust

Ex tc IIIC T88_C T

Ex tc IIIC T77_C T

500

500

Dc IP66

Dc IP66

Ui = 30 VDC

Ii = 100 mA

Pi = 1.0 W

Ci = 8 nF

Li = 20 mH

- - -

- - -

T4 (Tamb ≤ 80_C)

T5 (Tamb ≤ 40_C)

T5 (Tamb ≤ 80_C)

T6 (Tamb ≤ 65_C)

T5 (Tamb ≤ 85_C)

T6 (Tamb ≤ 74_C)

10

Page 11

846 Transducer

D102127X012

Table 5. Hazardous Area Classifications—IECEx

Certificate Certification Obtained Entity Rating Temperature Code

Intrinsically Safe

Gas

IECEx

Ex ia IIC T4/T5 Ga

Flameproof

Gas

Ex d IIB T5/T6 Gb

Ui = 40 VDC

Ii = 200 mA

Pi = 1.0 W

Ci = 8 nF

Li = 20 mH

- - -

Product Bulletin

62.1:846

March 2015

T4 (Tamb ≤ 80_C)

T5 (Tamb ≤ 40_C

T5 (Tamb ≤ 80_C)

T6 (Tamb ≤ 65_C)

11

Page 12

Product Bulletin

62.1:846

March 2015

846 Transducer

D102127X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1995, 2015 Fisher Controls International LLC. All rights reserved.

12

Loading...

Loading...