Elna XQUISIT 2 User Manual

INSTRUCTION MANUAL

09.04 – English Elna International Corp. SA

Printed in JAPAN

www.elna.com

SAVE THESE INSTRUCTIONS

FOR USA ONLY -

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any

way.

Use only foot control YC-700 (UL, CSA) with your Xquisit II.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be

observed, including the following:

Your Elna Xquisit II computerized sewing/embroidery machine is designed and

constructed for HOUSEHOLD use only. Read all instructions before using this

machine.

DANGER- To reduce the risk of electrical shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance from the

electric outlet immediately after using and before cleaning.

2. Always unplug before relamping. Replace bulb with same type rated 3 Watts.

W ARNING

- To reduce the risk of burns, fire, electric shock or injury to

persons:

1. Do not allow to be used as a toy. Close attention is necessary when this machine is used by or near

children.

2.

Use this appliance only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as described in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or service

center for examination, repair, electrical or mechanical adjustment.

4. Never operate the machine with any air openings blocked. Keep ventilation openings of the sewing machine

and foot controller free from accumulation of lint, dust and fibers.

5. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

6. Always use the proper needle plate. The wrong plate can cause the needle to break.

7.

Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

9. Switch the sewing machine off (“0”) when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot and the like.

10.

Always unplug sewing machine from the electrical outlet when removing covers, lubricating or when

making any other servicing adjustments mentioned in the instruction manual.

11. Never drop or insert any object into any opening.

12.

Do not use outdoors.

13. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

14. To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

2

SECTION I

Machine Parts and Functions

Machine Parts.....................................................................4

Standard Accessories .........................................................5

Auxiliary Bed/Accessory Box and Free Arm .......................6

Additional Presser Foot Clearance......................................6

Attach and Remove Presser Feet.......................................6

Presser Foot Definitions ..................................................7-8

Presser Foot Storage..........................................................8

Attach and Remove Foot Holder ........................................9

Adjusting Foot Pressure......................................................9

Seam Allowance Lines........................................................9

Knee Lifter.........................................................................10

How to Lower Feed Dog ..................................................10

Controlling Sewing Speed.................................................10

Machine Operation Keys...................................................11

SECTION II

Getting Ready to Sew

Selecting Correct Needle and Thread...............................12

Needle Definitions .......................................................12-13

Changing Needles.............................................................13

For Your Safety .................................................................14

Connecting Machine to Power Supply .............................15

Welcome Screen ..............................................................15

LCD Screen Brightness Control........................................16

Index ............................................................................16-17

First Screen.......................................................................18

Operation Keys .................................................................18

LCD Keys ..........................................................................19

Removing Bobbin from Bobbin Case................................20

Winding Bobbin from Top Spool..................................20-22

Inserting the Bobbin..........................................................22

Automatic Top Threading..................................................23

Manual Top Threading .................................................24-25

Automatic Needle Threader – Manual

Operation.....................................................................26

Drawing Up the Bobbin Thread ........................................27

Test Sewing......................................................................28

How to Access Utility, Heirloom and

Quilting Groups and Folders...................................28-29

How to Select a Stitch......................................................30

Starting to Sew............................................................30-31

Thread Tension .................................................................32

Stitch Width and Length...................................................33

Stitch Width/Needle Position Key.....................................33

Stitch Length Key..............................................................34

Scissors Key and Lock/Reverse Key............................35-36

SECTION III

On-Screen Manual

Sewing Instruction Screens..............................................37

Machine Usage Screens..............................................38-39

Version and Update Data..................................................39

Personalized Machine Settings....................................40-41

SECTION IV

Sewing Techniques

Utility

Straight Stitch..............................................................42

Changing Sewing Direction.........................................42

Sewing on Heavy Fabrics............................................43

Gathering/Shirring........................................................44

Flat Fell Seam..............................................................45

Zippers, Lapped......................................................46-47

Zippers, Centered...................................................48-49

Zippers, Exposed.........................................................50

Invisible Zipper ............................................................51

Rolled Hem..................................................................52

Twin Needle Hem .......................................................53

Basting Stitch..............................................................54

Triple Seam .................................................................54

Saddle Stitch ...............................................................54

Zigzag Stitch................................................................55

Zigzag, Center – Overcast...........................................55

Multi-Cord Foot

Gathering Over a Cord...........................................55

Zigzag, Center – Satin Stitch Applique........................56

Zigzag Left...................................................................57

Zigzag Right.................................................................57

3-Step Zigzag Stitch.....................................................57

Serpentine Stitch.........................................................58

Applying Elastic...........................................................58

Blind Hem Stitch .........................................................59

Stretch Seam...............................................................60

Lingerie Stitch .............................................................60

Super Overlock Stitch..................................................60

Overlock Stitch............................................................61

Super Stretch Stitch....................................................61

Double Overlock Stitch ...............................................61

Tricot Stitch.................................................................62

Shell Tuck....................................................................62

Rickrack.......................................................................63

Eyelets.........................................................................63

Arrowtack....................................................................63

Bartack ........................................................................64

Darning Stitches..........................................................65

Directional Sewing, Straight Stitch..............................65

Directional Sewing, Zigzag Stitch................................65

Buttonholes............................................................66-68

Buttonholes, 4-Step ...............................................69-70

Bound Buttonholes .....................................................71

Corded Buttonholes ....................................................72

Sewing on Buttons......................................................73

Heirloom

Pintucks.......................................................................74

Whip and Roll Hem .....................................................75

Hemstitches................................................................75

Drawn Work and Fringing ...........................................76

Bridging (Fagoting) ......................................................77

Quilting

Patchwork ...................................................................78

Quilt Guide ..................................................................78

Walking Foot ...............................................................79

Quilt Stitch...................................................................79

Buttonhole Appliqué....................................................80

Stippling Stitches.........................................................81

T ABLE OF CONTENTS

3

SECTION V

Decorative Sewing

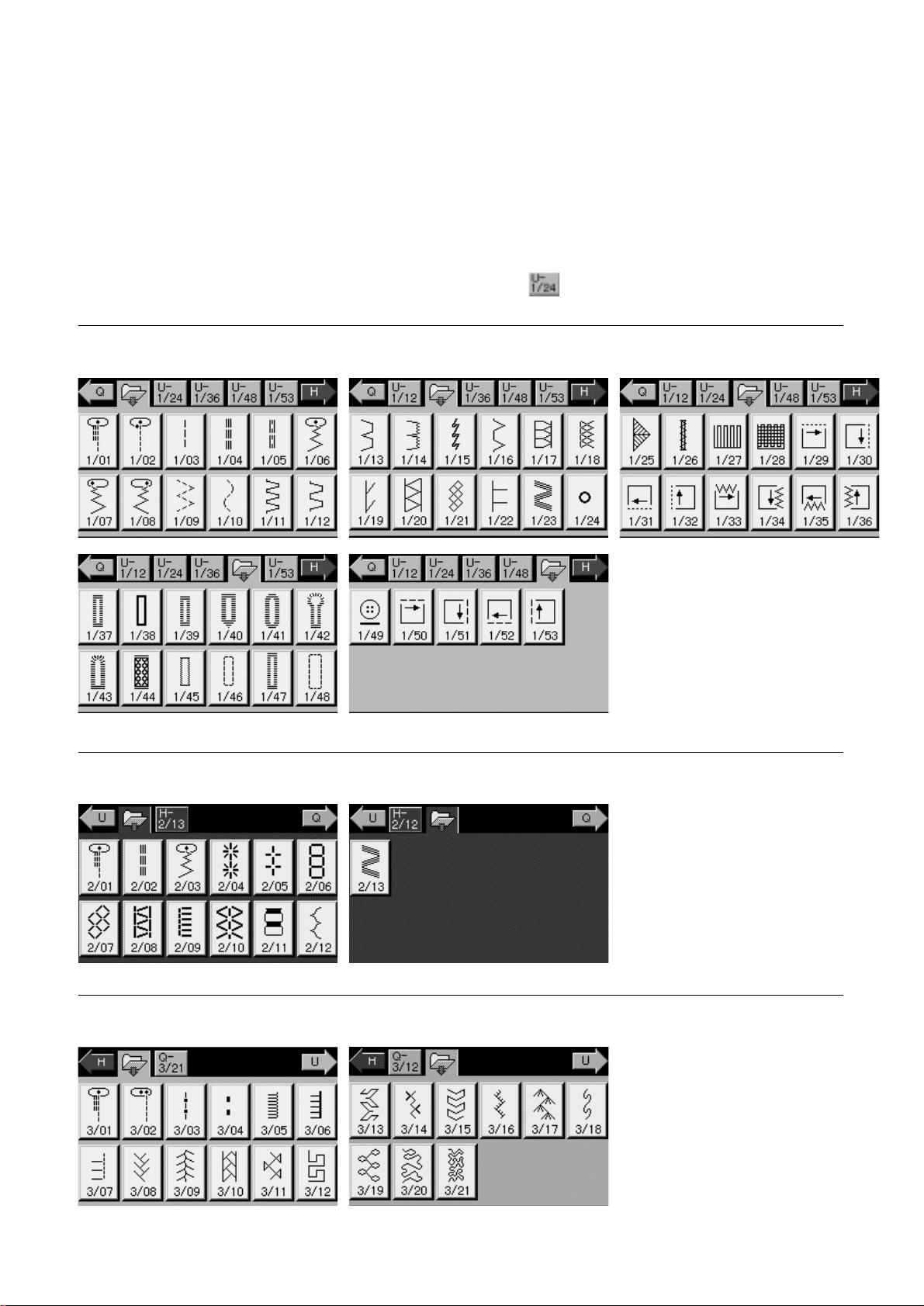

Access Stitches Using the Key............................82-87

LCD Keys .....................................................................88-89

Test Sewing......................................................................90

How to Program Decorative Patterns...............................91

Single Pattern....................................................................91

Scallop Edges....................................................................92

Twin Needle Decorative Patterns.....................................92

Combining Patterns ..........................................................93

Scissors and Lock/Reverse Keys......................................93

Reset Key..........................................................................93

Elongation Key ..................................................................94

Two Color..........................................................................94

Size Key.............................................................................95

Mirror Image and Face to Face.........................................95

Cascade Key .....................................................................95

Circular Sewing.................................................................96

Alphabets and Editing.......................................................97

Alphabets and Saving Memory.........................................98

Overwriting Memory.........................................................99

Recalling Memory...........................................................100

Deleting Memory............................................................100

Inserting a Second Color.................................................101

SECTION VI

Getting Ready to Embroider...............................102

Attaching Embroidery Foot J ..........................................103

Inserting Embroidery Needle..........................................103

Installing Embroidery Unit...............................................103

Removing Embroidery Unit.............................................103

Welcome Screen ............................................................104

First Screen.....................................................................104

How to Access Alphabets and Designs ..................104-107

Embroidery Cards (Optional)...........................................108

Operation Keys ...............................................................108

LCD Keys.................................................................108-109

Automatic Bobbin Winding......................................110-113

Threading the Machine...................................................113

Preparing the Fabric........................................................113

Embroidery Frames.........................................................114

Securing Fabric in Frame/Hoop.......................................114

Attaching Frame/Hoop....................................................115

Removing Frame/Hoop...................................................115

Embroidering Small Areas...............................................115

SECTION VII

Embroidering

Embroidering a Single Design..................................116-121

Embroidering More Than One Letter ......................122-123

Embroidering Multiple Lines of Letters and

Adding/Editing a Design.....................................124-129

Temp Embroidery Memory.............................................130

Permanent Memory.................................................131-133

Multiple Hoop Embroidery - Characters...................134-140

Multiple Hoop Embroidery with Designs.................141-146

Continuous Embroidery Frame................................146-147

Repositioning Frame After

Embroidery Begins.............................................148-149

SECTION VIII

On-Screen Manual

Machine Usage Screens.................................................150

Personalized Machine Settings................................150-152

Download from Xpressive Software (optional)...............153

SECTION IX

Maintenance

Cleaning the Bobbin Area ...............................................154

Cleaning the Hook Area and Feed Dog...........................154

Cleaning Auto Bobbin Thread Winder.............................155

Changing the Light Bulbs................................................156

Troubleshooting.............................................157-158

Specification Table....................................................158

Index................................................................159-160

Thread Color Conversion Chart..........................

161

NOTE: Information found in this instruction

manual is current at the time of printing. Elna

reserves the right to change and update

specifications and information as needed.

4

SECTION I

Machine Parts and Functions

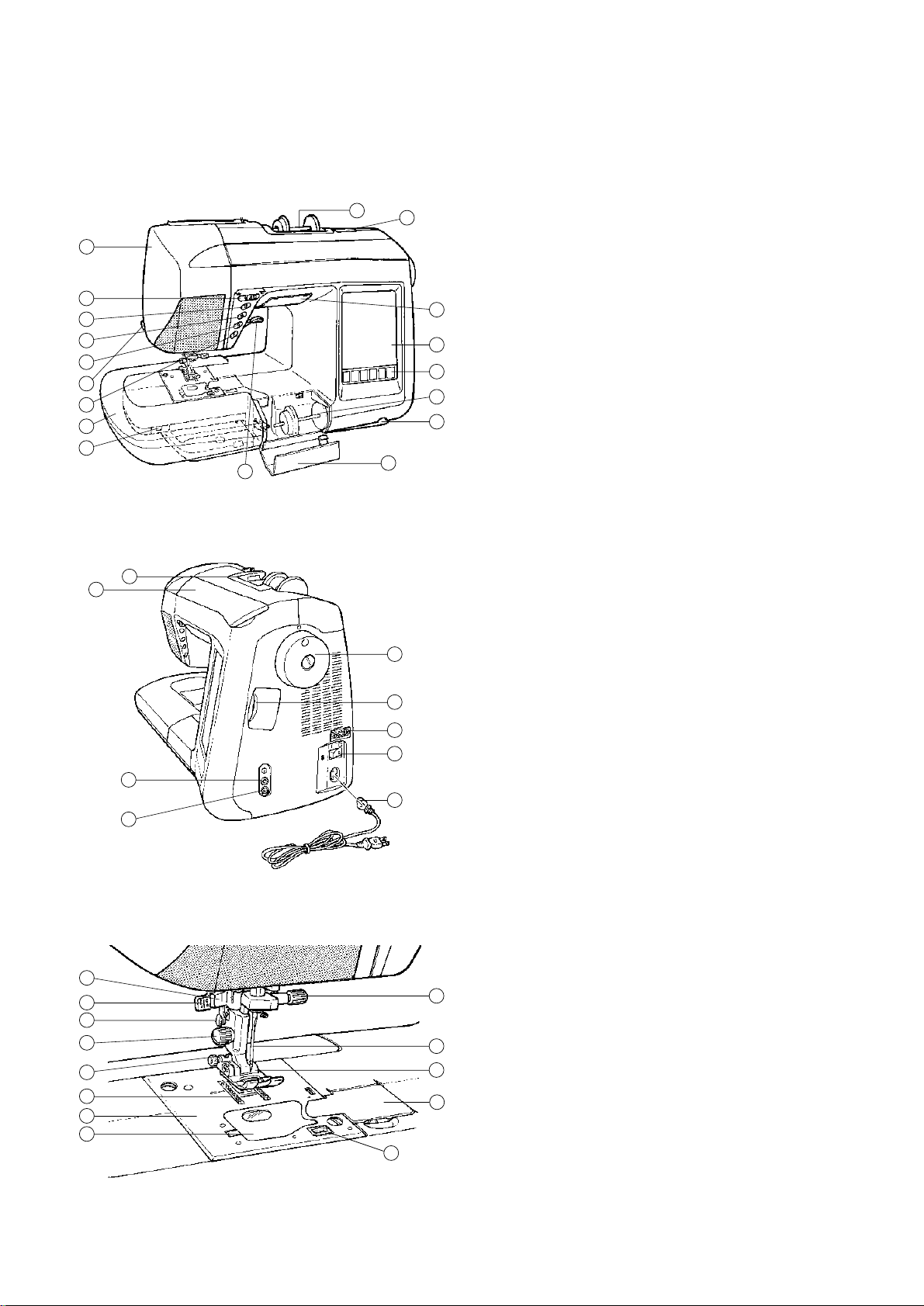

Machine Parts

1. Presser foot lifter

2. Drop feed lever

3. Auxiliary bed/accessory box

4. Start/stop key

5. Thread cutter

6. Reverse/backtack key

7. Thread cutter key

8. Up/down Needle key

9. Sewing speed lever

10. Face plate cover

11. Spool pin holder

12. Bobbin winding shaft cover

13. Light

14. LCD screen

15. Operation keys

16. Bottom spool pin for bobbin winding

17. Knee lifter insert

18. Bottom spool pin cover

19. Handle

20. Top accessory storage

21. Handwheel (always turn towards you)

22. Embroidery card insert slot

23. Serial port

24. Power/light switch

25. LCD brightness control

26. Foot control socket

27. Electrical cord and power plug

28. Bobbin case cover button

29. Bobbin case cover

30. Needle plate

31. Feed dog

32. Presser foot holder

33. Presser foot holder screw

34. Presser foot release button

35. Buttonhole lever

36. Automatic needle threader

37. Needle clamp screw

38. Needle

39. Presser foot

40. Automatic bobbin winder cover

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

21

22

23

24

27

25

26

36

28

40

39

38

37

35

34

33

32

31

30

29

5

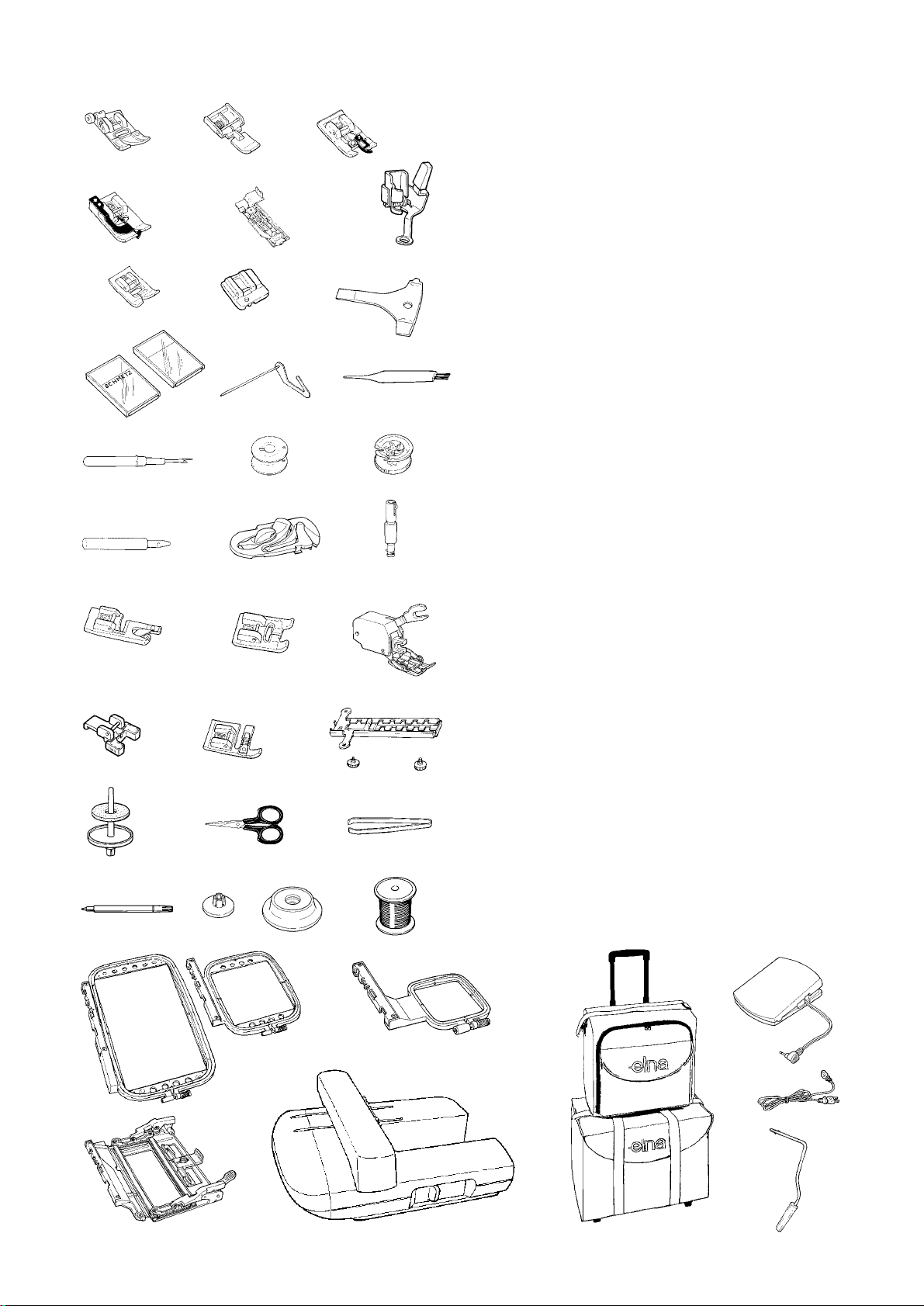

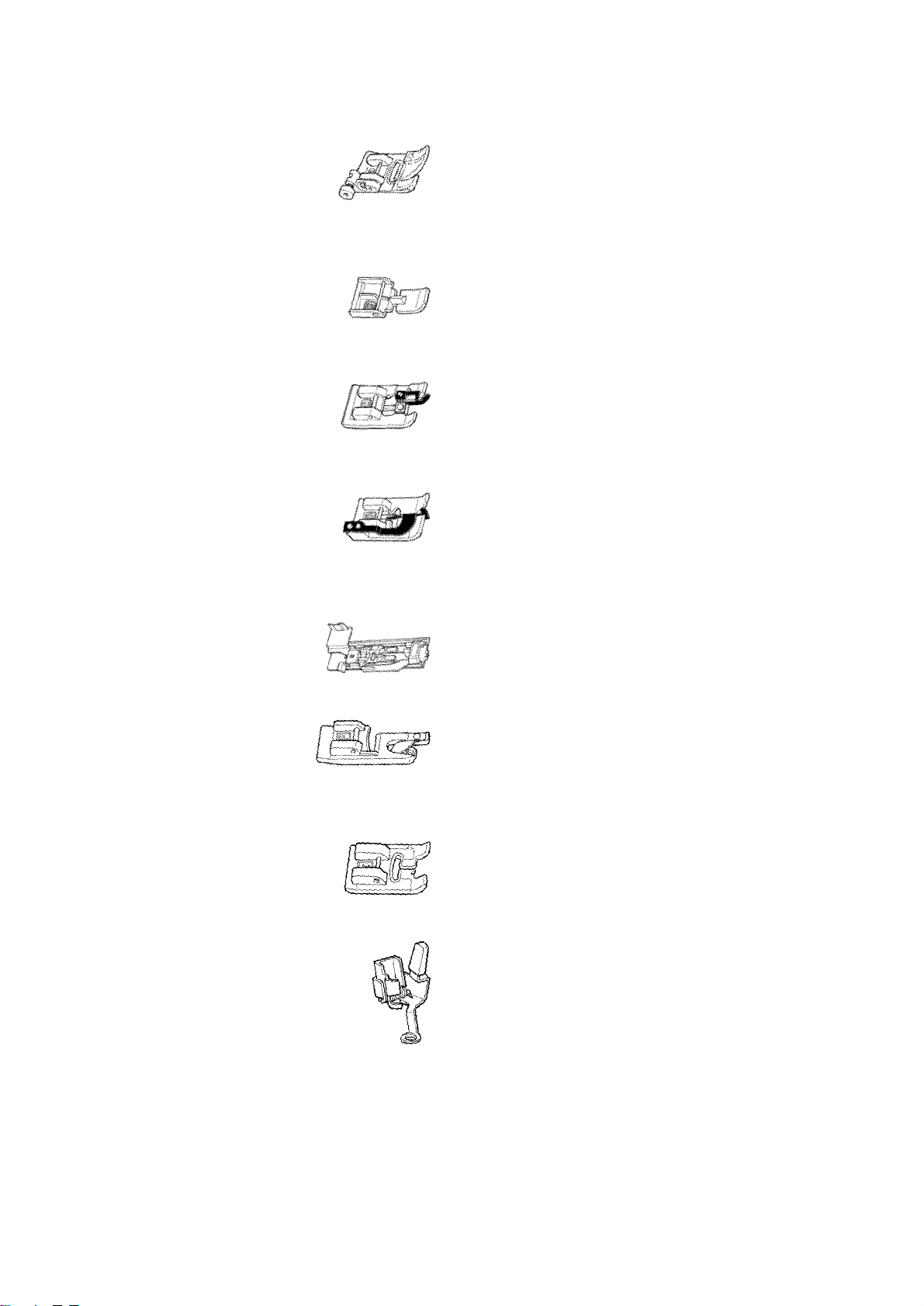

Standard Accessories

1. A:Standard metal foot

2. B:Zipper foot

3. C:Overlock foot

4. D:Blind hem foot

5. E: Automatic buttonhole foot and plate

6. J: Embroidery foot

7. T: Teflon foot

8. G: Invisible zipper foot

9. Screwdriver

10. Needles

11. Quilt guide

12. Lint brush

13. Seam ripper

14. Top winding bobbins (3)

15. Auto winding bobbins (2)

16. Eyelet punch

17. Bobbin winder guide for bottom spool

18. Bobbin winding shaft

19. F: Hemmer foot

20. I: Satin stitch foot

21. Walking foot

22. Sewing on button foot

23. H: Multi-cord foot

24. Circular sewing attachment

25. Additional spool pin and felt

26. Scissors

27. Tweezers

28. Fabric marker

29. Spool cap (1 small)

30. Spool caps (2 large)

31. Elna bobbin thread for embroidery

32. Large embroidery frame

33. Medium embroidery frame

34. Small embroidery frame

35. Continuous frame

36. Embroidery unit

37. Embroidery accessory bag/wheeled bag

38. Foot control

39. Power supply cord

40. Knee lifter

36.

38.

37.

34.

35.

39.

40.

33.

32.

30. 31.

29.

28.

27.

26.

25.

24.

23.

22.

21.

11.

20.

19.

18.

16.

15.

13.

12.

9.

8.

6.

1.

2.

3.

4.

5.

7.

10.

14.

17.

6

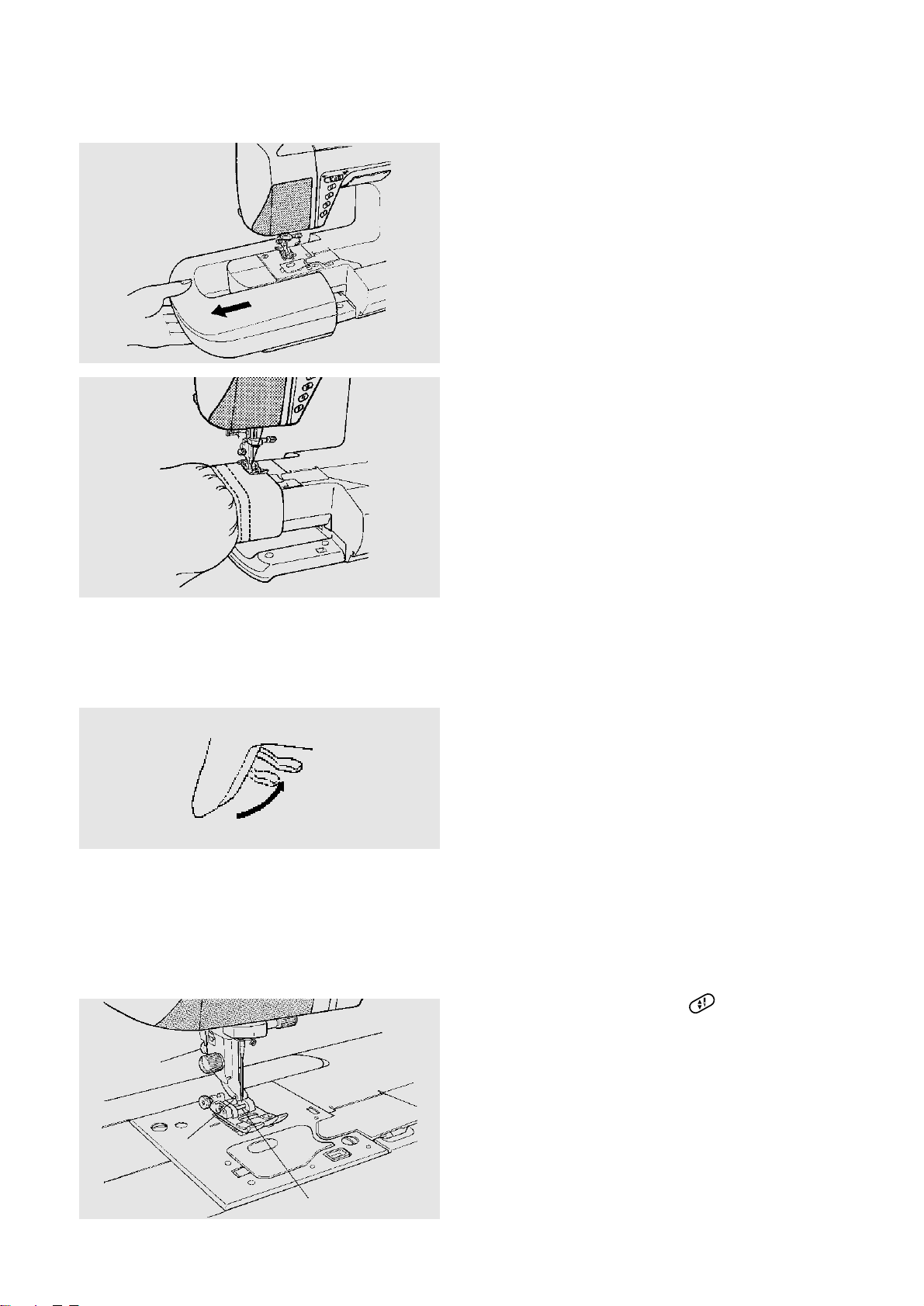

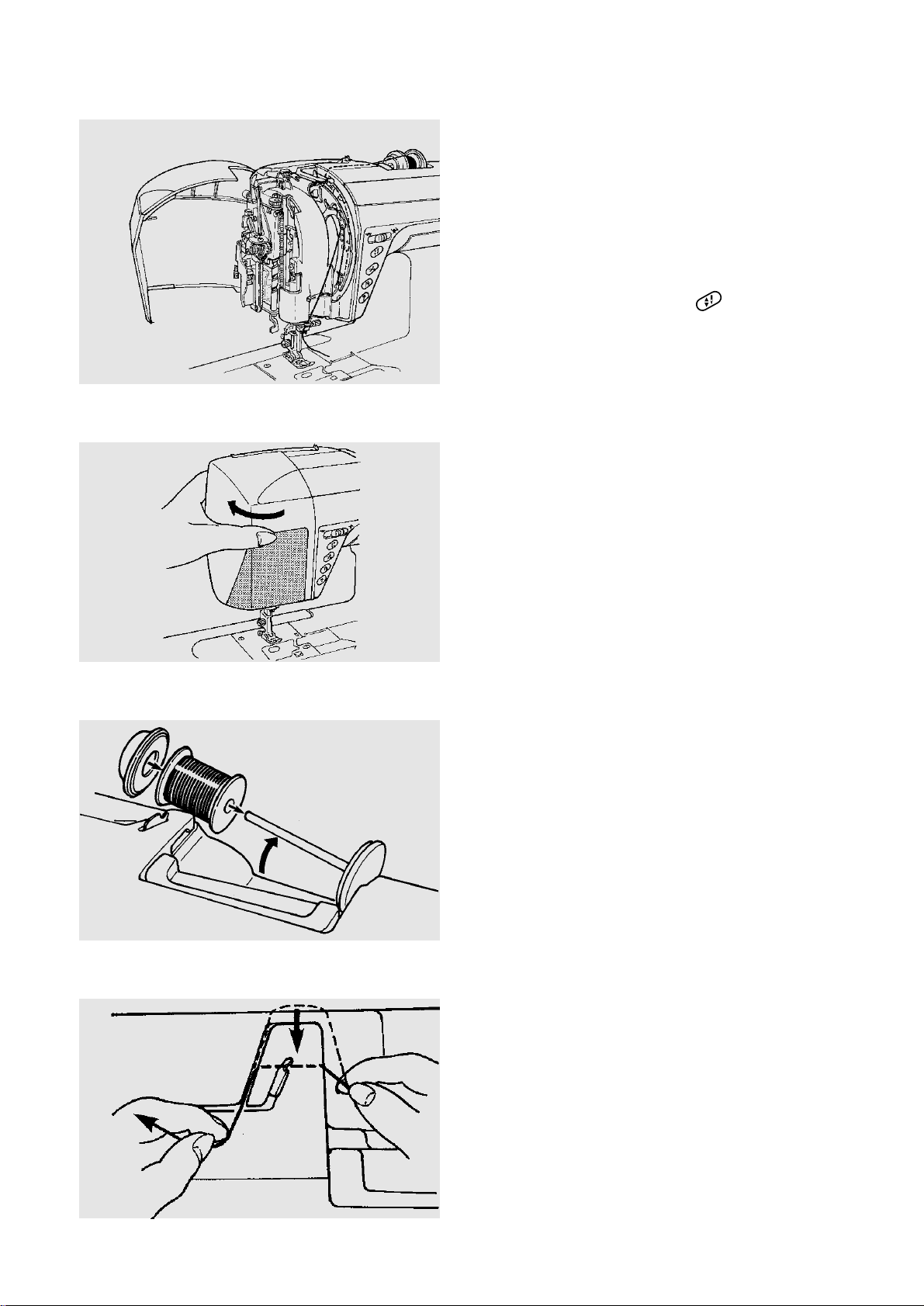

Auxiliary Bed/Accessory Box and Free

Arm

Pull the auxiliary bed/accessory box away from the

machine to expose the free arm.

Advantages of free arm sewing:

• For stitching sleeves, waistbands, pant legs or

any circular garment area.

• For darning socks or mending knees, elbows or

worn areas on children’s clothing.

Attach the auxiliary bed/accessory box for a large

sewing surface.

Additional Presser Foot Clearance

You can raise the presser foot about 6.5 mm (1/4")

higher than the normal up position for easy removal

of presser feet, for placement of heavy fabrics under

the presser foot or for attaching/ removing

embroidery frame.

NOTE: Machine will not sew with the presser

foot raised (up).

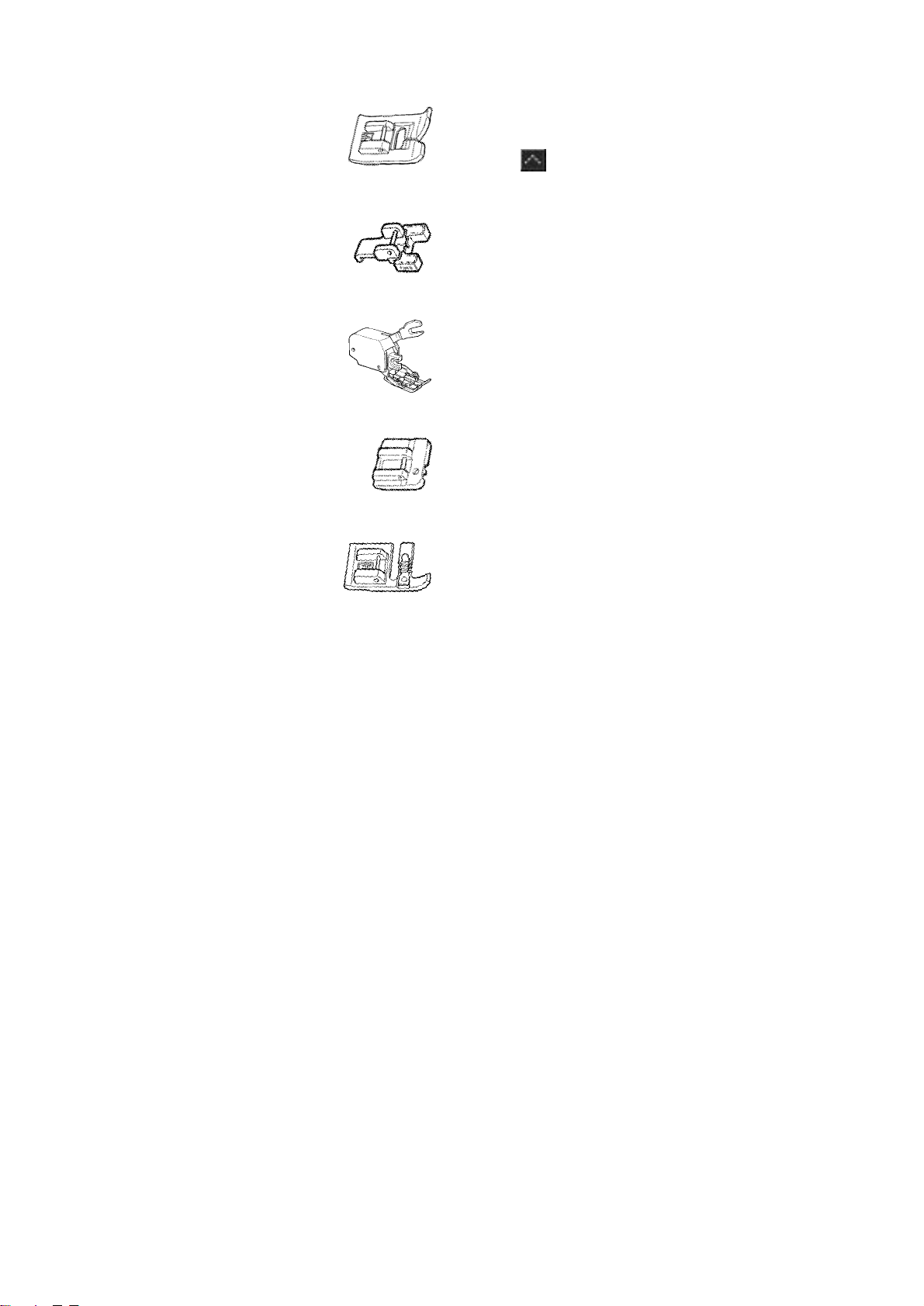

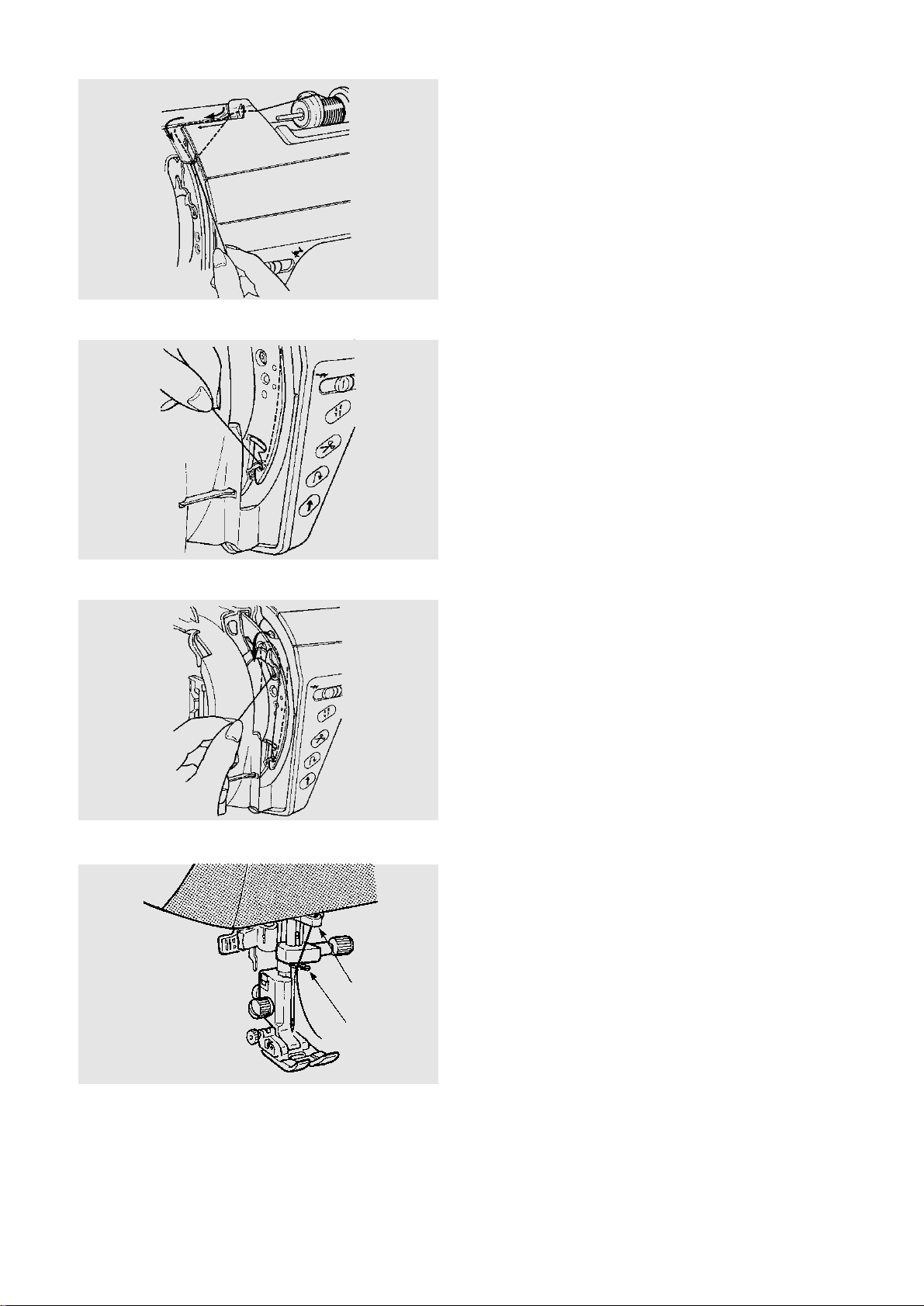

Attaching and Removing Presser Foot

Turn handwheel or press the key until needle is

raised. Raise presser foot.

Turn off power/light switch.

Press the button 1 on back of the holder. The

presser foot will drop off. Place the selected presser

foot so the pin 3 on the foot lies just under the

groove 2 of the holder. Lower the presser bar to

attach the foot.

1

2

3

7

Presser Foot Definitions

A: Standard metal foot

This foot comes attached to the machine and is

mainly used for straight stitches and zigzag stitches

longer than 1.0. The button locks the foot in a

horizontal position helping to sew over multiple

layered seams.

B: Zipper foot

Attach this foot either to the left or right of the

needle to sew each side of the zipper.

C: Overlock foot

Sew the edge of the fabric next to the guide while

overcasting with the zigzag stitch set wider than 5.0.

The metal extension helps the stitch lie flatter.

D: Blind hem foot

The guide on the foot helps ensure that the needle

catches only one or two fibers of the hem, resulting

in an invisible hemline.

E: Automatic buttonhole foot

Place button in foot to determine the buttonhole

size. The machine will automatically sew the

corresponding buttonhole. Also used for bartacks

and darning.

F: Hemmer foot

Insert the fabric into the spiral on this foot. The spiral

rolls the fabric, creating a rolled hem.

I: Satin stitch foot

The cutout on the underside of the foot is designed

to accommodate dense stitch formation. Ideal for

satin and decorative stitches that are 7 mm or less,

with no directional feed.

J: Embroidery foot

Use for automatic embroidery or free motion

embroidery. As the needle lowers into the fabric, the

spring-loaded foot lowers to hold the fabric down. As

needle rises, foot rises and fabric can be moved.

8

T: Decorative stitch foot

The lightweight composition of the foot and the flat

underside are requirements for successful

directional sewing (sideways feeding). Must be used

with key and any pattern wider than 7 mm.

Sewing on button foot

Holds button in place so machine can sew on

button.

Walking foot

Fabric is between an upper and lower feed dog,

preventing fabric from slipping or puckering. Great

for keeping quilt layers from shifting when sewing.

G: Invisible zipper foot

Using left needle position, the grooves on the

underside of the foot allow the stitching to be close

to the zipper teeth.

H: Multi-cord foot

Couching is simplified because the foot is designed

to hold 1 – 3 cords, creating braids and trims.

Presser Foot Storage

Store presser feet in one of three places.

• Auxiliary bed/accessory box

• Top accessory storage – designed for storing

A, B, D, I presser feet and foot holder for

quick access

• Plastic pouch

9

Attaching and Removing the Foot Holder

Turn handwheel or press the key until needle is

raised. Raise presser foot. Turn off power/light

switch.

Turn the screw 1 counterclockwise with the

screwdriver and remove foot holder.

To attach:

A. Place foot holder on needle bar and turn screw

clockwise to tighten. OR

B. Match the hole in the holder 2 with the hole in

the presser bar 3. Put screw into hole. Turn

screw clockwise to tighten.

Adjusting Foot Pressure

There are three settings available for pressure. The

weight and characteristics of your fabrics may

require less pressure than the standard “3”

pressure.

1. Turn off power/light switch.

2. Open face cover.

3. Insert screwdriver.

4. Turn screw counterclockwise only to adjust

foot pressure.

5. Remove screwdriver.

6. Close face cover.

7. Turn on power/light switch.

Seam Allowance Lines

The lines on the needle plate help you measure

seam width.

• The number indicates the distance between the

center needle position and the seam allowance

line.

Angle lines provide accurate measurements for

aligning small fabric pieces when quilting.

1 Millimeters

2 Inches

3 Angle lines

2

3

2

3

120

o

90

o

60

o

45

o

3/8 3/4

7/8

1 Inch

mm

1/2

5/8

10

20

25

15

1

1

1

A

B

10

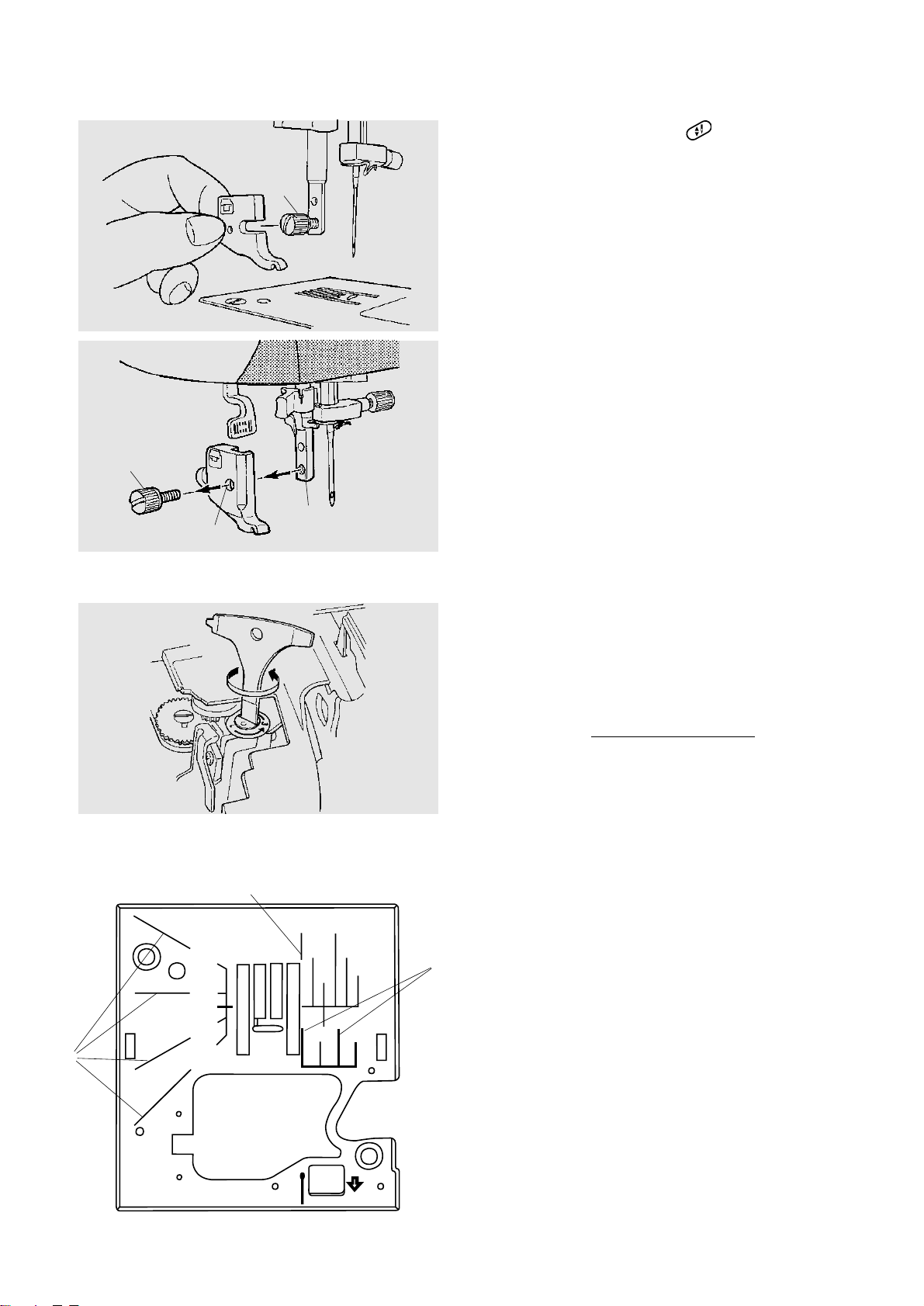

Knee Lifter

The knee lifter allows you to raise or lower the

presser foot without using your hands. This is

especially beneficial when pivoting corners or

sewing patchwork pieces.

Insert knee lifter. The presser foot rises equal to the

amount of pressure applied to the knee lifter. Move

the knee lifter to the right to raise the presser foot.

Release the knee lifter to lower the presser foot.

How to Lower the Feed Dog

The feed dog should be lowered out of position for

special sewing techniques, such as free motion

embroidery.

The feed dog must always be up for normal sewing.

Locate the feed dog lever on the front of the free

arm. Slide the lever either to the right (down) 1 or

the left (up) 2. To bring up the feed dog, press

key after sliding lever to the left.

Controlling Sewing Speed

Foot Control

Sewing speed can be varied with the foot control 1.

The harder you press on the foot control, the faster

the machine runs.

Speed Control Lever

The sewing speed can also be varied by sliding the

speed control lever 2. For a faster speed 1, slide it

to the right; for a slower speed 4, slide it to the left.

1

2

3

4

1

2

11

Machine Operation Keys

NOTE: The presser foot must be lowered before

pressing any of these keys.

1. Up/Down Needle Key

If the needle is up when you press this key, the

needle will go down to its lowest position.

If the needle is down when you press this

key, the needle will go to its highest position.

Press the key twice to sew a single stitch.

2. Thread Cutter Key

After sewing is stopped, press this key to cut

needle and bobbin threads.

CAUTION: Use the thread cutter A on the

side of the machine for heavy or decorative

threads.

3. Reverse/Backtack Key

Press and hold this key while sewing stitches

1/01, 2/01 and 3/01 and machine sews reverse

straight stitches at a slower speed. Release the

key and machine stops.

Press and hold this key while sewing all other

stitches and machine lockstitches (backtacks).

Release the key and machine stops.

See pages 35-36 for information on how this key

operates when using the and keys on

the LCD.

4. Start/Stop Key

Operates the machine when winding bobbin and

if the foot control is not connected. (If the foot

control is connected, this key acts as a Stop key

only.) Press this key and machine sews a few

stitches slowly and then continues to sew at the

speed set with the speed control lever. Press

key again to stop machine.

Key changes color to show operating status.

Green: Machine ready to sew or sewing

Red: Machine is not ready

Orange: Machine is winding bobbin

A

1

2

3

4

12

SECTION II

Getting Ready to Sew

Selecting the Correct Needle and Thread

There are many kinds of fabrics, threads and

needles. It is important to use the correct ones

together.

Always purchase good quality thread. It should be

strong, smooth and even in thickness. Use the same

thread for needle and bobbin. Always test thread and

needle size on a scrap piece of fabric.

In general, fine threads (the larger the number, the

finer the thread) and needles (smaller the number,

finer the needle) are used for sewing lightweight

fabrics and heavier threads and larger needles are

used for sewing heavyweight fabrics. There are

many specialty needles available from your sewing

machine dealer.

Check your needles frequently for rough or blunt

tips. Snags and runs in knits, fine silks and silk-like

fabrics are permanent and are often caused by

damaged needles.

Needle Definitions

Elna recommends Schmetz® needle system

130/705H.

Universal – an all-purpose needle that handles most

woven and knit fabrics. A universal needle size 14/90

comes inserted in your machine.

Ball point – the point spreads the fibers,

preventing tears and is especially suited for loose

knits and interlock knits. Not recommended for

embroidery.

Denim – the sharp tip effectively pierces densely

woven fabrics such as denim and canvas.

Stretch – specially designed to prevent skipped

stitches in synthetic suedes and elasticized knits

(swimwear).

Leather – the cutting point creates small holes in

leather and suede. Holes remain after stitching is

removed.

Quilt – The tapered point easily penetrates through

multiple layers and crossed seams.

WEIGHT

TYPE

SIZE

Very

Light

Chiffon, Fine Lace,

Organdy

Universal

Ball Point

9/65

10/70

Batiste, Lawn,

Crepe de Chine,

Challis,

Handkerchief Linen,

Crepe, Taffeta,

Satin

Ball Point

Universal

11/75

11/75

12/80

Single Knits, Jersey,

Swimwear, Tricot

Stretch

Ball Point

11/75

11/75

Light

Leather, Suede Leather 12/80

Flannel, Velour,

Velvet, Velveteen,

Corduroy, Linen,

Gabardine, Wool,

Terry, Burlap

Universal 14/90

Double Knits,

Stretch Velour,

Stretch Terry,

Sweater Knits

Ball Point 14/90

Leather, Vinyl,

Suede

Leather 14/90

Denim, Sailcloth,

Ticking

Denim 16/100

Coating, Polar

Fleece, Drapery and

Upholstery Fabrics

Universal 16/100

Heavy

Leather, Suede Leather 16/100

Canvas, Duck,

Upholstery Fabrics

Universal 18/110Very

Heavy

Topstitching for

Special Finish

Topstitching12/80

14/90

NEEDLE

FABRIC

Medium

NEEDLE

13

Topstitching – the extra sharp tip penetrates layers

of fabrics; extra large eye and large groove

accommodate heavyweight topstitching thread.

Machine embroidery – specially suited for rayon,

acrylic or other high-sheen threads used in machine

embroidery. Two common sizes: 75/11 (suitable for

most projects) and 90/14 (recommended for multilayered projects).

Twin/Double – 2 needles are joined on a crossbar

and share a single shaft. Sews two parallel rows of

stitching. Available in universal and ballpoint.

Hemstitch/Wing – wider than a universal needle, it

separates fibers and creates holes for beautiful

heirloom stitches.

Changing Needles

1. Lower the presser foot. Press the key until

needle is raised. Turn off the power/light switch.

Turn the needle clamp screw A

counterclockwise to loosen. Remove the needle

from the clamp.

2. Insert the new needle into needle clamp B with

flat side to the back. When inserting the needle

into the clamp, push it up as far as it will go and

tighten the needle clamp screw firmly.

CAUTION: If needle is not pushed up as far as

it will go, the automatic needle threader will

not function properly.

3. To determine if the needle is defective, place

the flat side of the needle on something flat (a

needle plate, glass, etc.). The gap between the

needle and flat surface should be consistent.

Never use a bent or blunt needle as it may cause

skipped stitches or thread breakage. Defective

needles can ruin fabric. Always purchase good

quality needles. Change needles often.

B

1

2

3

A

14

For Your Safety

Before connecting the power cord, make sure the voltage and frequency shown on the machine are identical to

your electrical power. USA only – Item: Rated Voltage/Power Consumption, Specification: 120V/0.9A

60Hz.

Your machine may come equipped with a polarized plug (one prong wider than the other). A polarized plug

reduces the risk of electrical shock. This plug is intended to fit into a polarized outlet. If the plug does not fit fully

into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do

not modify the plug in any way.

Do not use extension cords or plug adapters.

Do not touch plug with wet hands.

Always turn off the power/light switch first and then unplug from the electrical outlet. Examples:

• when leaving the machine unattended

• during an electrical storm or power failure

• when cleaning the machine

Always turn off the power/light switch:

• when attaching or removing parts such as needle, presser foot, needle plate or embroidery unit

• when manually threading needle or bobbin

• when changing foot pressure

Do not place anything on the foot control.

Do not place heavy items on cords. Do not subject cords to heat. Do not use damaged cords. Have the cord

repaired immediately.

While the machine is in operation, always keep your eye on the sewing area and do not touch any moving parts

such as the thread take-up lever, handwheel or needle.

15

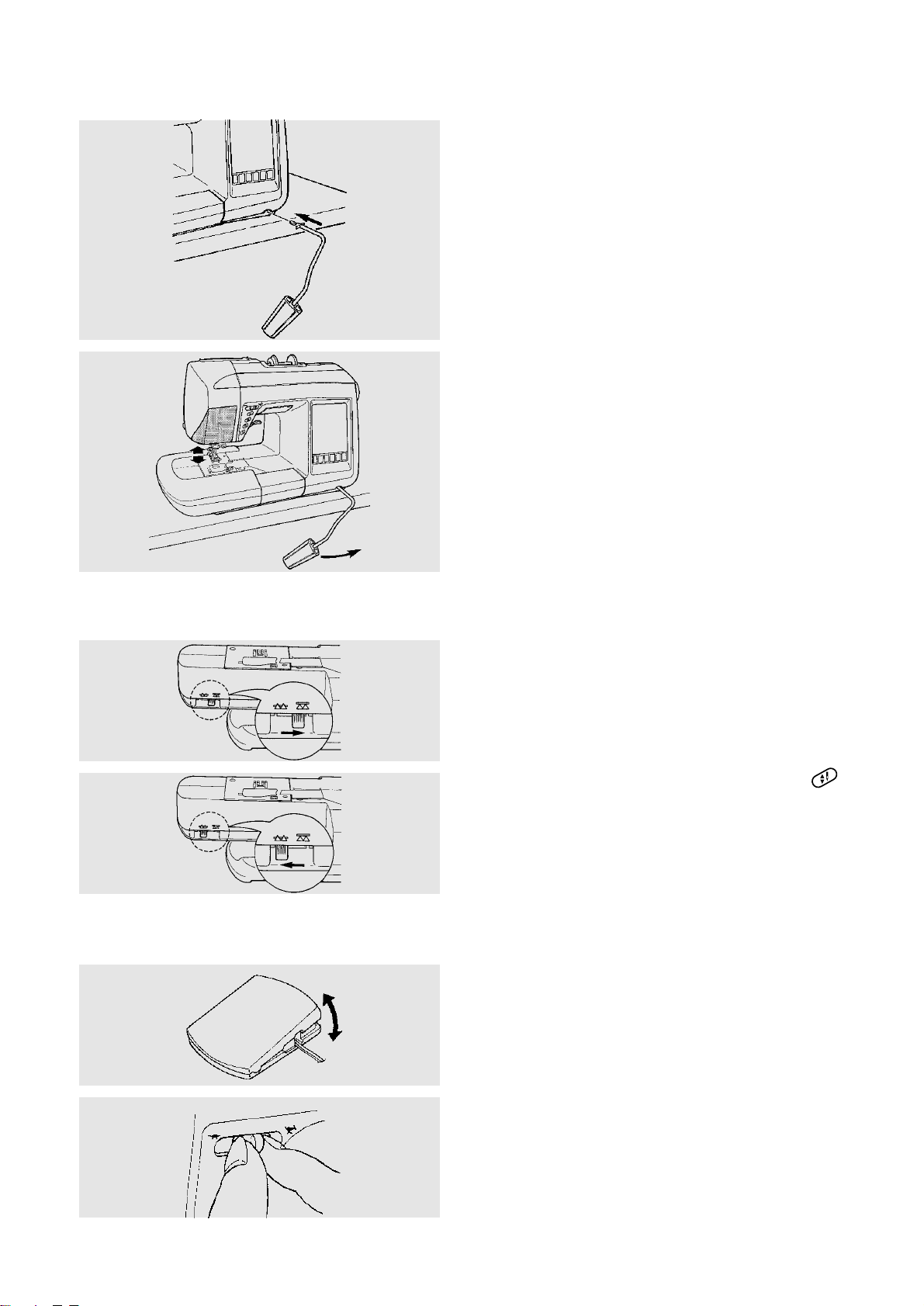

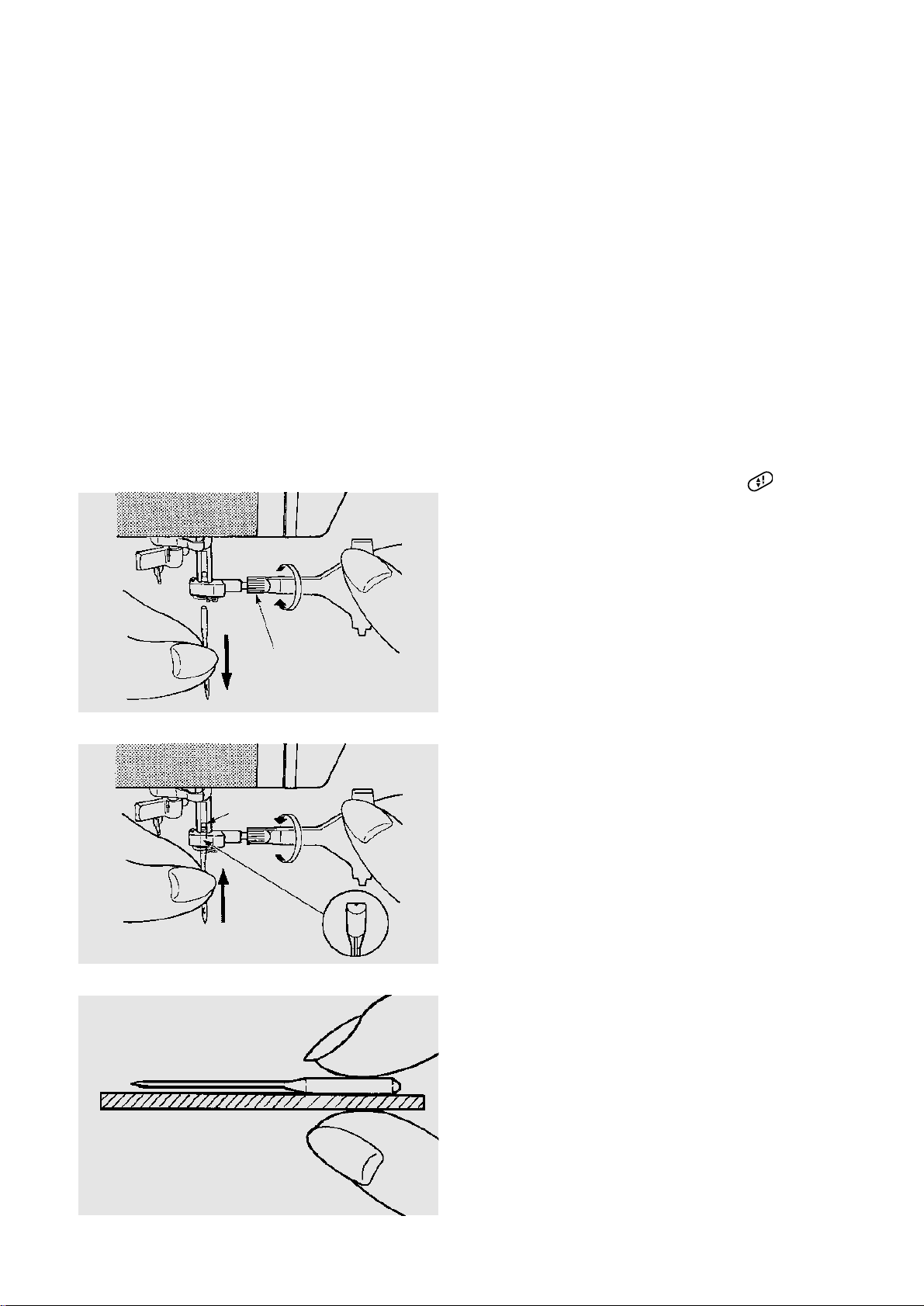

Connecting Machine to Power Supply

NOTE: Your machine should be operated at a

room temperature of 5 - 38˚C (40˚ - 100˚ F).

Extremes of temperature may affect sewing

speed.

Your machine is equipped with a detachable power

cord. First insert machine plug into machine and

then power supply plug into electrical outlet.

Optional – connect the foot control. Pull out the cord

(not past red marking) and plug into machine. When

storing the foot control, pull the cord out about 5 cm

(2") and release it to rewind.

When the foot control is connected, the key

can be used only to stop the machine or wind

bobbin.

NOTE: Machine can be operated using only

the key without connecting the foot control.

NOTE: Use only foot control YC-700 (UL, CSA)

with your Xquisit II(9010).

Welcome Screen

NOTE: Only a light touch is required when

making a selection on the LCD screen. Do not

touch the surface of the screen with any hard or

sharp object, such as pencils, pens, screwdrivers,

etc.

Press power/light switch to turn machine on.

Welcome screen will appear.

Lightly touch Welcome screen to open first screen.

Touch key to directly access index for sewing

instruction screens.

INDEX

16

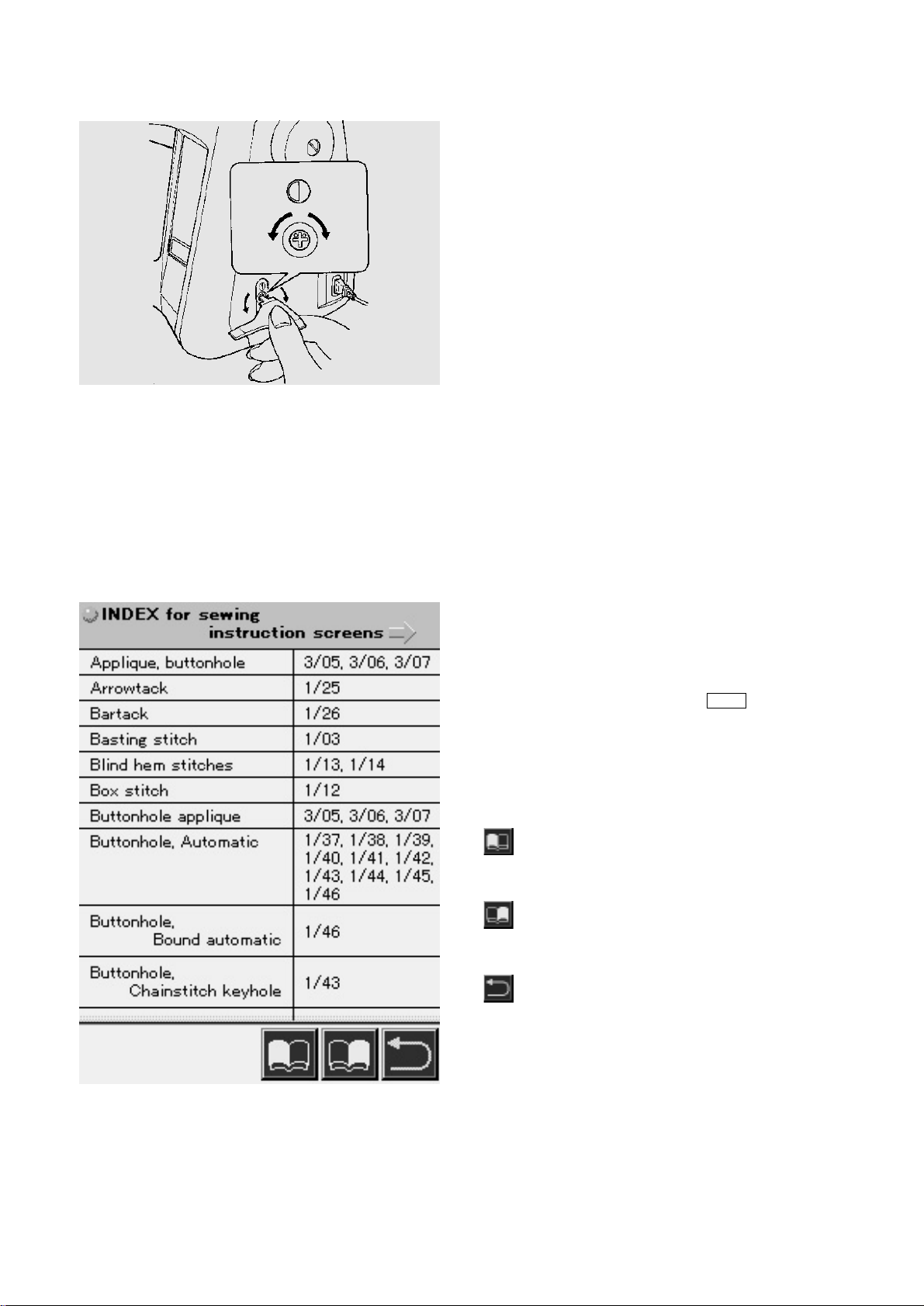

LCD Screen Brightness Control

Insert the narrow end of the screwdriver into the

LCD brightness control located on the right side of

the machine 1. Turn clockwise 2 to increase

brightness; turn counterclockwise 3 to decrease

brightness.

NOTE: Environmental changes might cause the

screen to become lighter or darker.

NOTE: When the machine has been turned off for

an extended period of time, the screen may

appear lighter when first turned on because of

the LCD backlight. The screen will adjust to the

brightness control setting.

NOTE: For best viewing of LCD screen, be sure to

sit directly in front of machine.

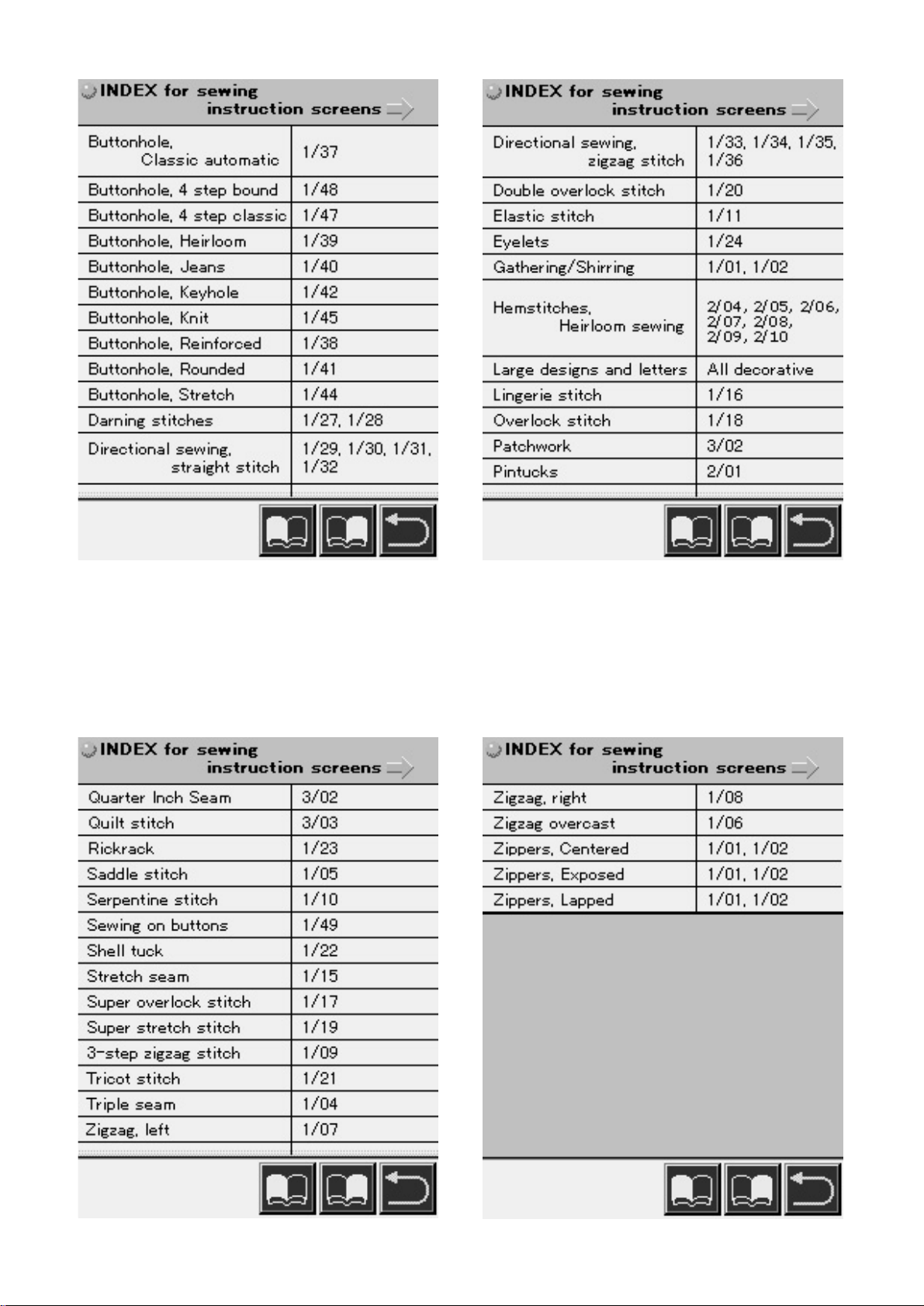

Index

This machine provides an on-screen instruction

manual for sewing and embroidery techniques and

machine usage. The Index gives you an overview of

all sewing techniques available on-screen. See page

37.

On the Welcome Screen, touch key to

directly access index for sewing instruction screens.

The index indicates under which stitch(es) you will

find a certain technique. For example, pintucks will

be found in the heirloom group (H), stitch 2/01.

Previous key – use this key to go back to

previous screen in index

Next key – use this key to go forward to

next screen in index

Return key – use this key to exit index

screens

1

23

INDEX

17

18

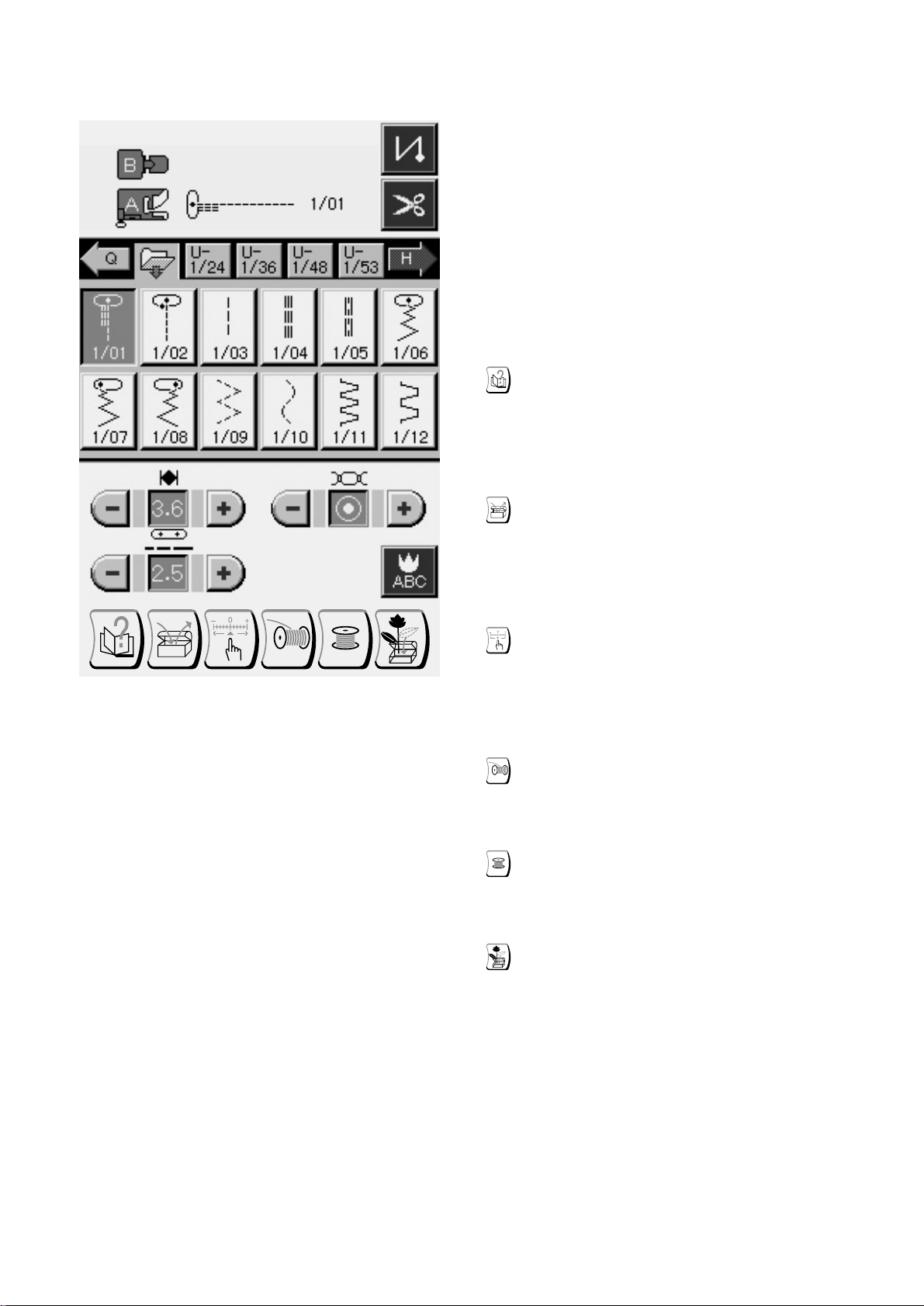

First Screen

When the first screen opens, the machine

automatically displays the first 12 stitches of the

Utility group (U) and selects 1/01 (straight stitch,

center needle position).

NOTE: If the embroidery unit is attached, the

first embroidery screen will open. See page

104.

Operation Keys

Hint Key

Accesses sewing instruction screens for

selected stitch. See page 37. When

embroidery unit is attached, accesses

machine usage screens. See page 150.

Memory Key

Saves stitch sequence to memory. See page

98-100. When embroidery unit is attached,

saves design(s) to memory. See pages 131-

133.

Adjustment Key

Changes thread tension, stitch length, stitch

width/needle position. See pages 32-34.

When embroidery unit is attached, changes

thread tension.

Auto Top Thread Key

Begins automatic top threading process.

See page 23.

Auto Bobbin Wind Key

Winds bobbin when embroidery unit is

attached. See pages 110-113.

Temp Embroidery Memory Key

Temporarily saves embroidery sewing so

machine can be turned off while sewing a

design. Embroidery can be restarted at

same position when machine is turned on.

Key only operates when embroidery unit is

attached. See page 130.

19

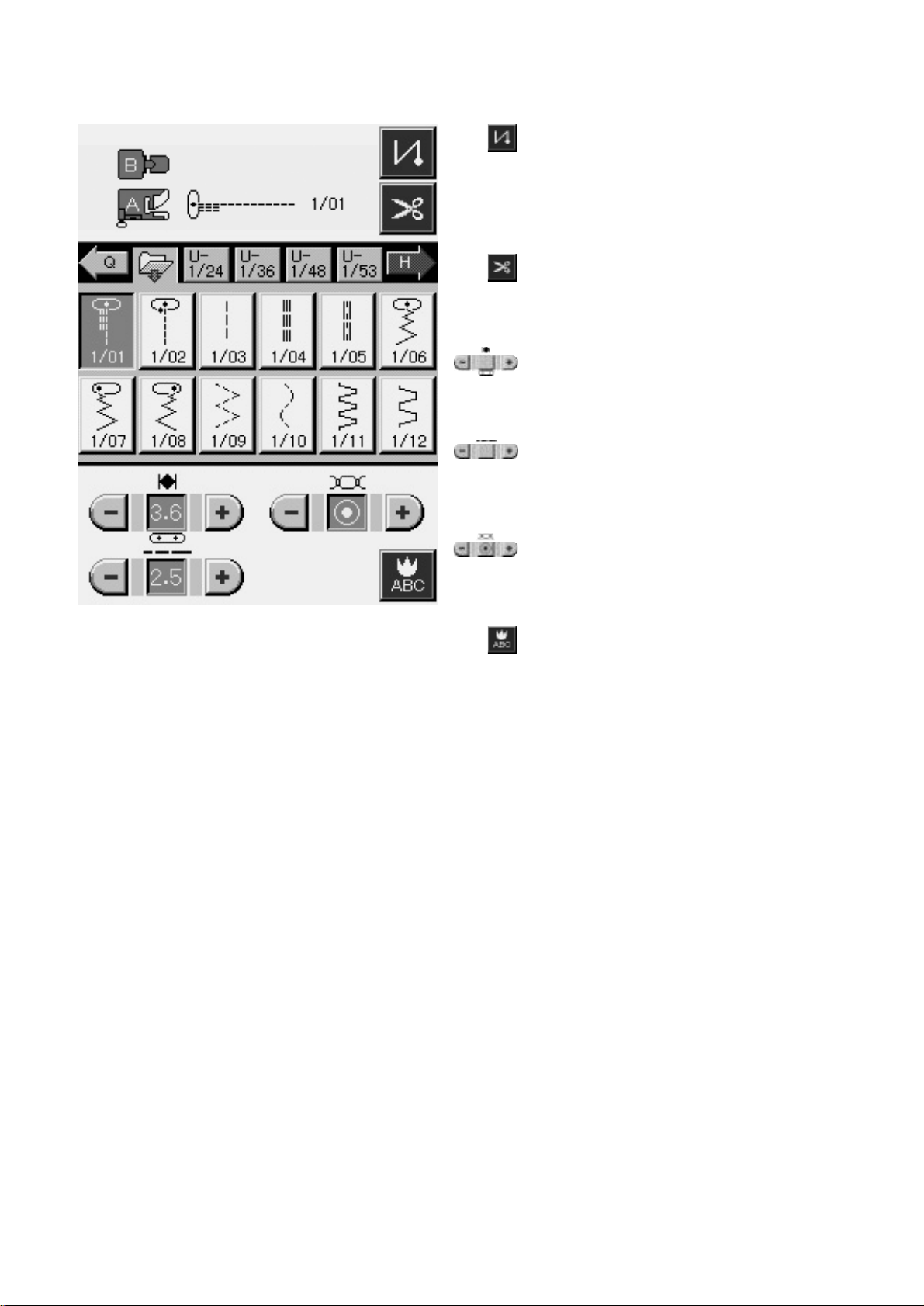

LCD Keys

Lock/Reverse Key

When highlighted yellow, sews lock or

reverse stitches (straight stitches) or stops

pattern sewing and lockstitches (other

stitches). See pages 35-36.

Scissors Key

When highlighted yellow, cuts needle and

bobbin threads. See pages 35-36.

Stitch Width/Needle Position Key

Increases or decreases stitch width or

changes needle position. See page 33.

Stitch Length Key

Increases or decreases stitch length. See

page 34.

Tension Key

Changes pre-programmed tension for

special fabrics and techniques. See page

32.

Decorative Sewing Key

Accesses decorative sewing groups. See

page 82.

20

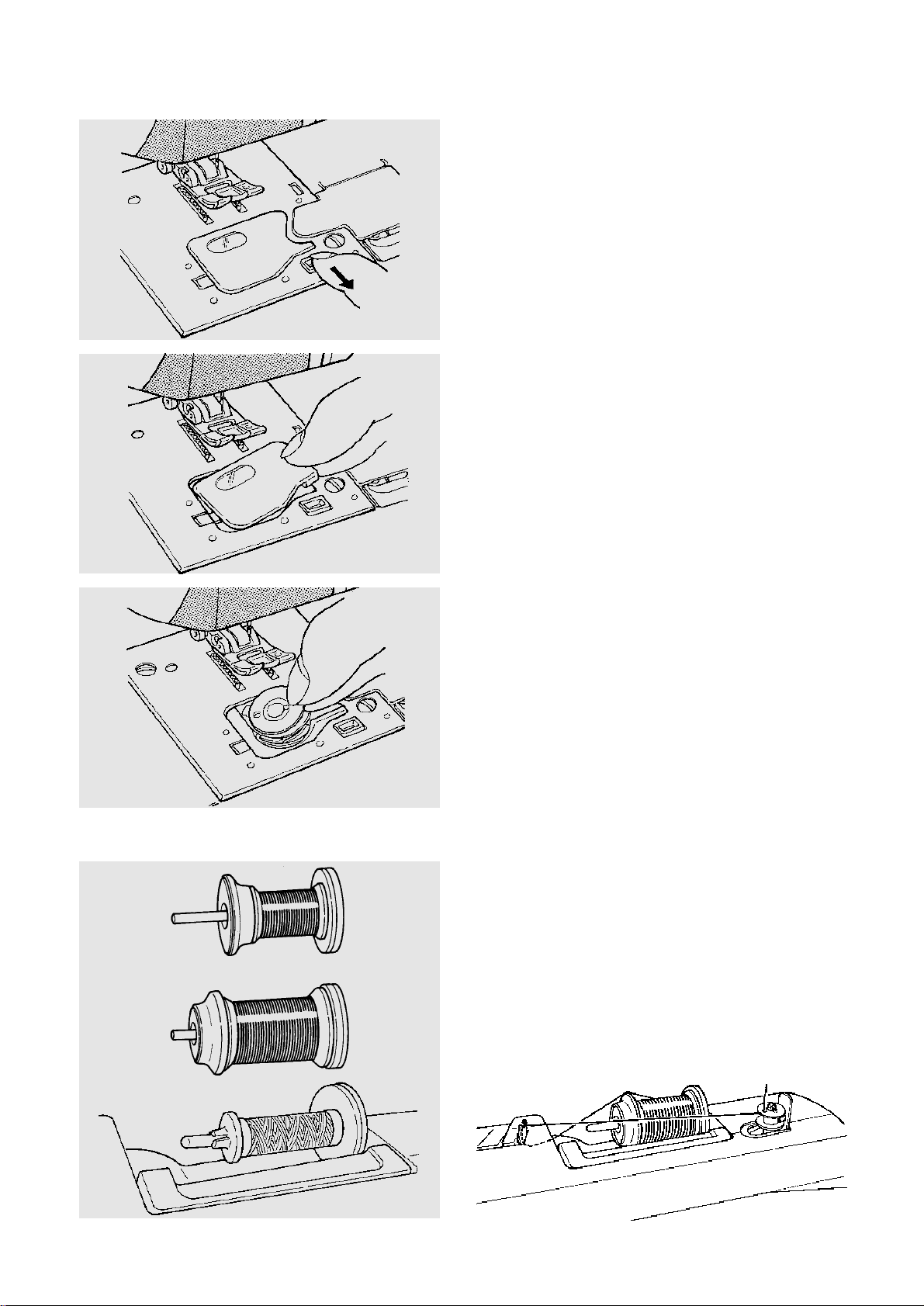

Removing Bobbin from Bobbin Case

Turn off power/light switch.

1. Raise presser foot. Slide bobbin case cover

button forward.

2. Lift away bobbin case cover.

3. Remove bobbin.

Winding Bobbin from Top Spool

Turn on power/light switch.

1. Place spool of thread on spool pin. Firmly attach

large spool cap with small end towards small

spool A or large end towards large spool B.

Some types of thread spools require the use of

the small spool cap C.

1

2

3

4

5

6

7

8

1

2

3

1

A

B

C

21

2. Using both hands, insert thread into opening.

3. Guide thread up to thread guide.

4. Open bobbin winding shaft cover.

5. Remove bobbin winding shaft from accessory

box. Place bobbin on shaft and attach shaft.

NOTE: Use top winding bobbins only.

CAUTION: Twin needle must be removed

before winding bobbin.

6. Pass the thread through the hole in the bobbin

from the inside to the outside.

2

3

4

5

6

22

7. Push bobbin to the right.

While holding the free end of the thread, start

the machine. Stop the machine when the bobbin

has made a few turns and cut thread tail close to

hole in bobbin. Continue winding bobbin and

stop machine when bobbin is full.

8. Return bobbin winding shaft to the left. Cut the

thread and remove bobbin. Remove and store

bobbin winding shaft. Close bobbin winding

shaft cover.

NOTE: Be sure to correctly wind the bobbin.

Incorrectly wound bobbins can result in

jammed threads, tension problems, etc.

Inserting the Bobbin

Turn off power/light switch.

1. Raise the presser foot. Place the bobbin in the

bobbin case with the thread running

counterclockwise.

2. Guide the thread into notch A on the front side

of the bobbin case. Hold bobbin with right hand

and pull thread to the left, through tension spring

blades. Continue pulling thread lightly until

thread slips into notch B.

Pull about 15 cm (6") of thread.

3. Replace bobbin case cover.

1

2

3

8

7

A

B

23

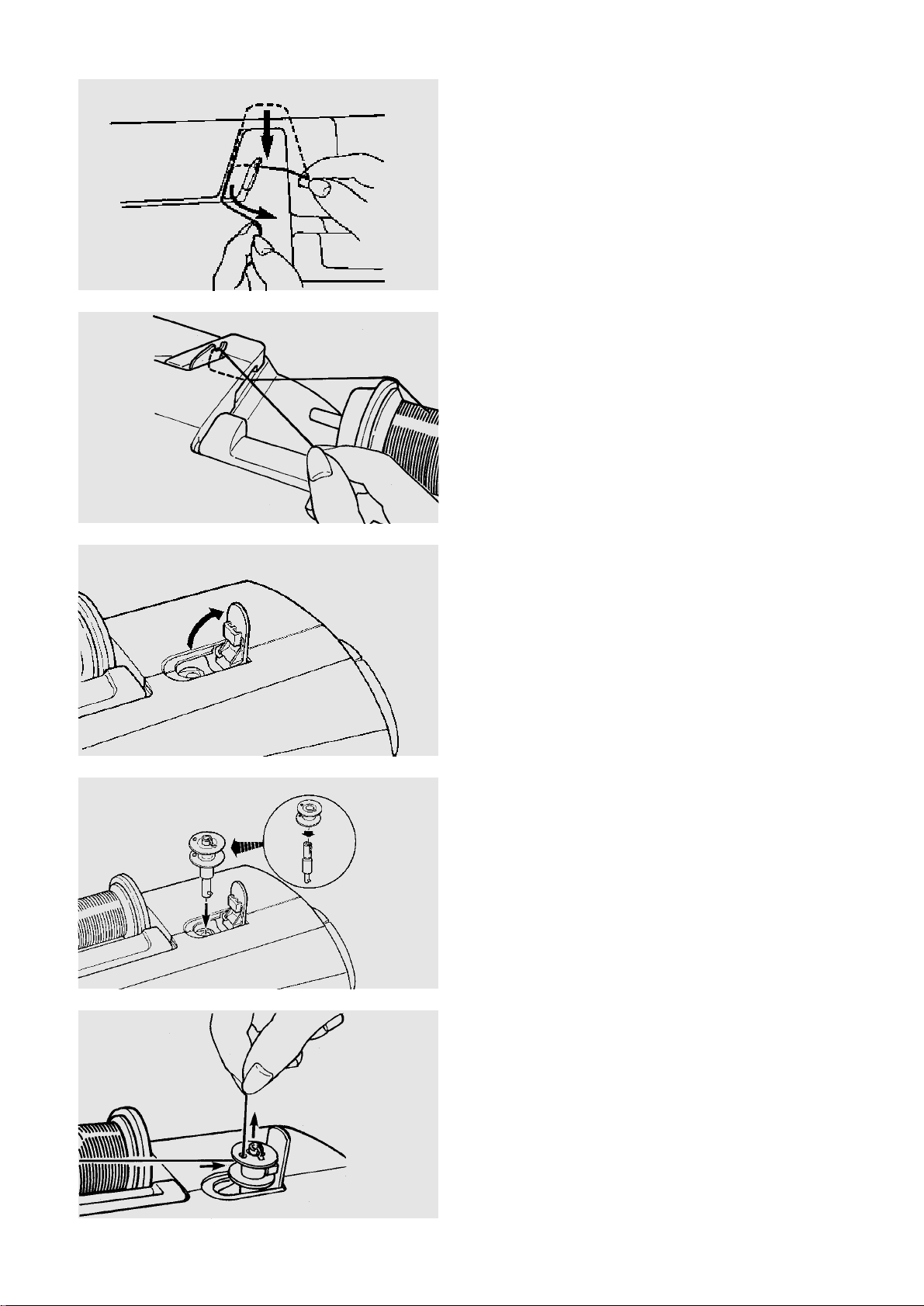

Automatic Top Threading

NOTE: Close face plate cover. Never open face

plate cover when automatic top threading is in

process.

NOTE: Check needle size. Use only size

11/75 – 16/100 (excluding twin and

hemstitch/wing needles) for automatic top

threading. Any other size needle requires manual

threading. See page 24.

NOTE: Check that needle is pushed up as far as it

will go.

NOTE: Some specialty threads will require

manual threading.

Turn on power/light switch and touch Welcome

screen.

2. Using both hands, pull thread into groove of

thread sensor guide.

1. Lower presser foot. Press the key until the

needle is raised. Place spool of thread on spool

pin and firmly attach spool cap. See page 20.

3. Hold thread with right hand while left hand pulls

thread through groove towards back of machine.

Cut using mounted top thread cutter A.

4. Touch key.

NOTE: If the thread is caught on the hook,

remove it before sewing.

1

2

3

4

A

3

2

1

1

A

24

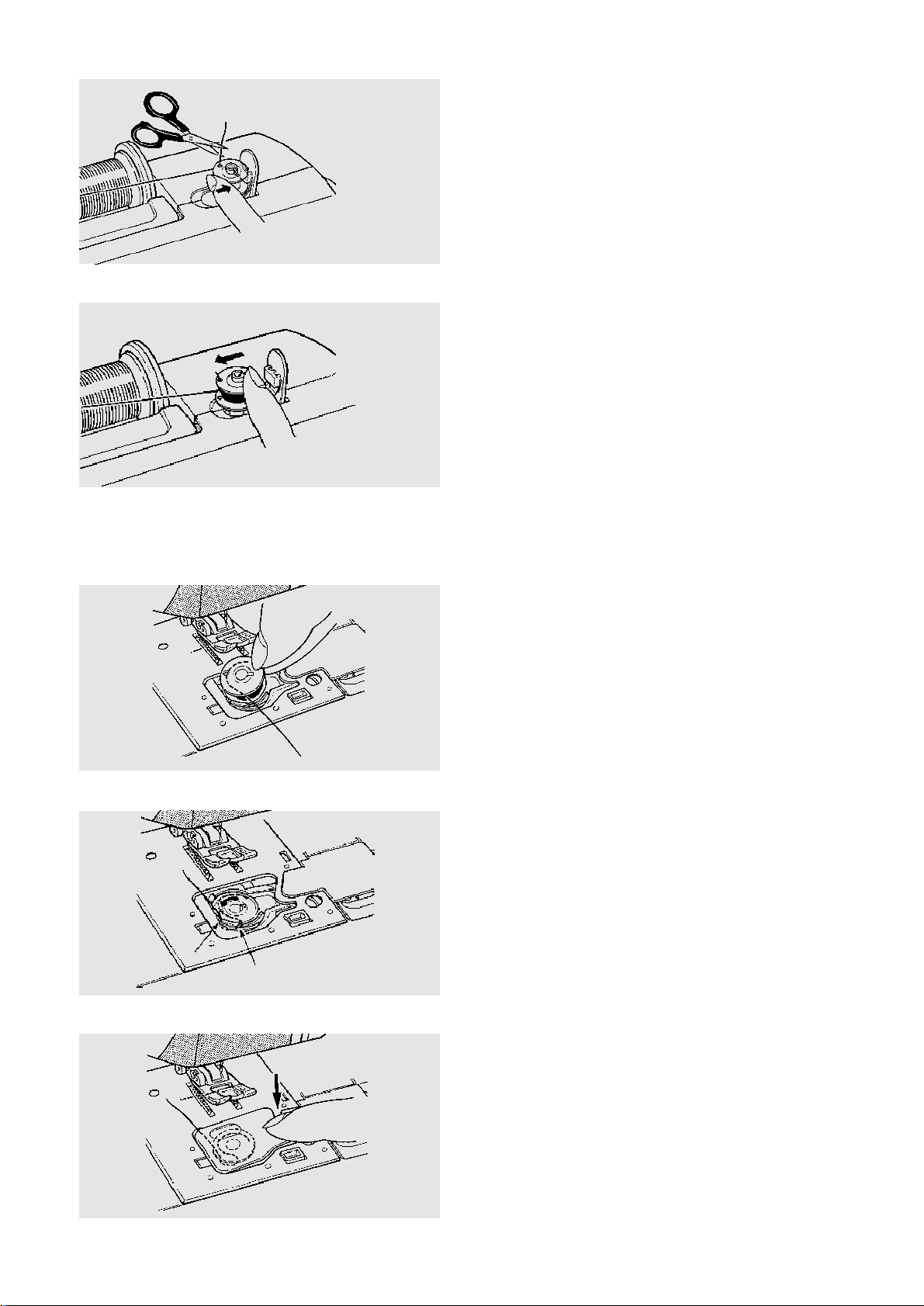

Manual Top Threading

Under certain circumstances, it may be necessary to

thread the machine manually.

• when using needles other than sizes

11/75 – 16/100

• when using specialty needles – twin,

hemstitch/wing, etc.

• when using some specialty threads

1. Lower presser foot. Press key until needle

is raised. Raise presser foot.

2. Open face plate cover.

3. Place spool of thread on spool pin and firmly

attach spool cap. See page 20.

4. Using both hands, pull thread into groove of

thread sensor guide.

1

2

3

4

5

6

7

8

2

3

4

25

5. Pull the thread around upper thread guide.

6. Guide the thread down and around the

checkspring holder.

7. Firmly pull thread from right to left, over the

take-up lever and down into the take-up lever

eye.

8. Proceed down through lower thread guide 1.

Slide thread to the right behind needle bar

thread guide 2. Lower presser foot. Close face

plate cover.

9. Thread needle from front to back or use

automatic needle threader – manual operation.

See page 26.

5

6

7

8

1

2

26

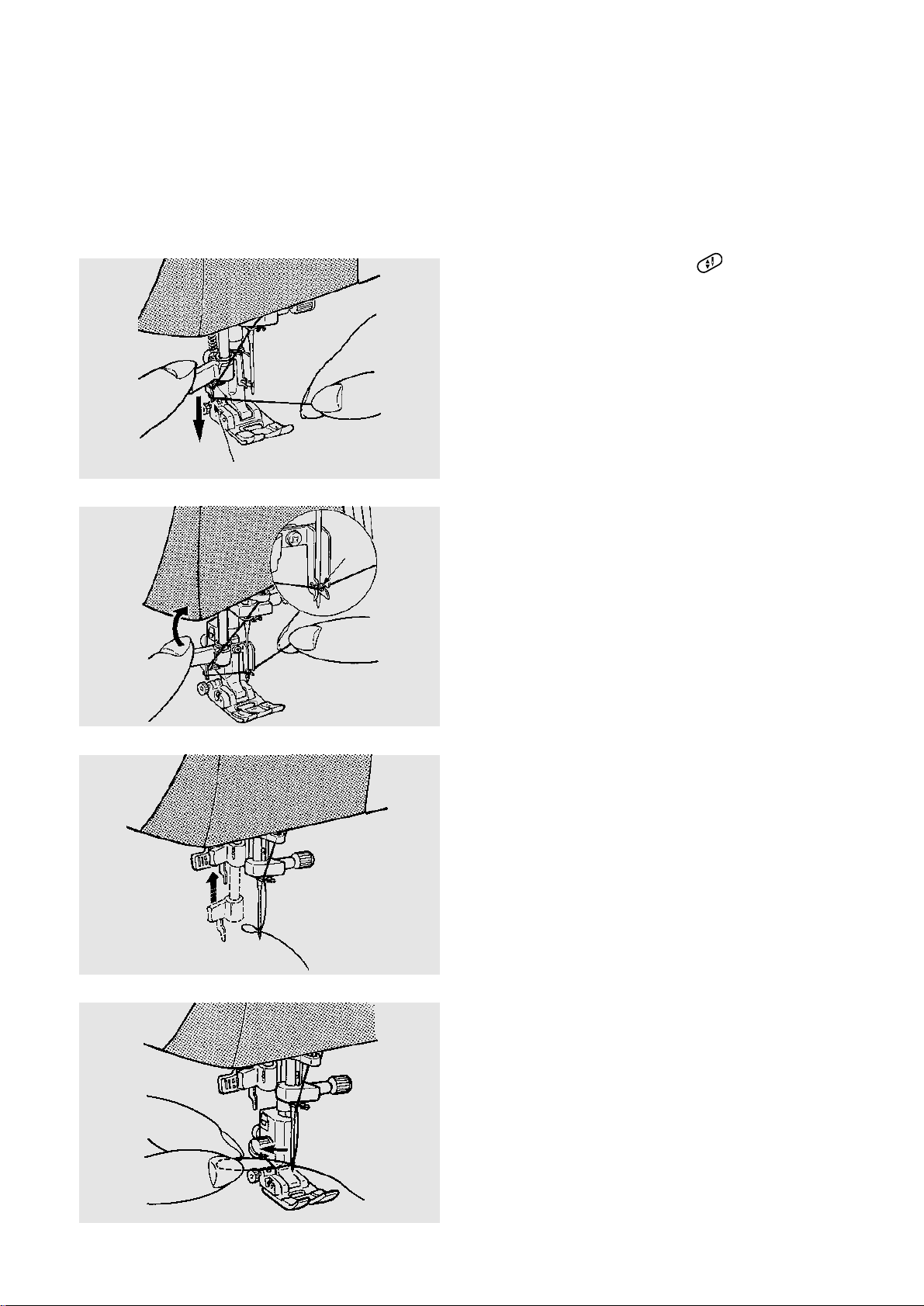

Automatic Needle Threader -

Manual

Operation

NOTE: Check needle size. Use only size 11/75 –

16/100 (excluding twin and hemstitch/wing

needles) for automatic top threading. Any other

size needle requires manual threading. See

pages 24 - 25.

4. Pull thread loop to the back to complete

threading the needle eye.

3. Release needle threader and hook will catch

thread pulling it through the needle eye.

2. Pivot needle threader as shown and hook will go

through eye of needle. Pass thread in front of

needle eye B.

1. Lower presser foot. Press key until needle

is raised. Pull needle threader down. Place

thread into hook A.

CAUTION: Do not lower needle threader

while the machine is sewing.

1

A

B

2

3

4

27

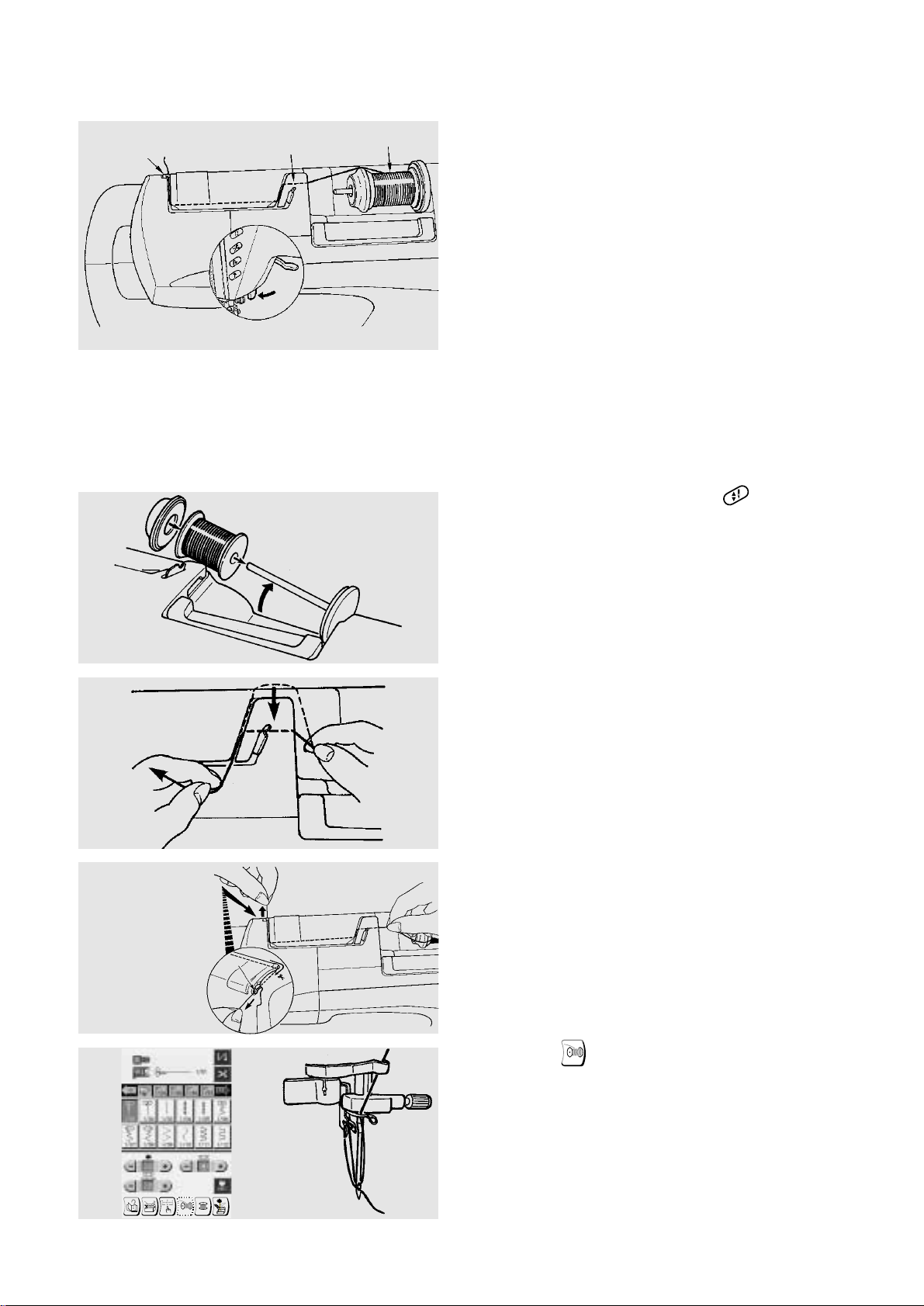

Drawing Up the Bobbin Thread

1. Hold needle thread lightly with left hand.

Press key twice to pick up bobbin thread.

2. Raise presser foot. Pull on needle thread to draw

up loop of bobbin thread.

3. Slide 10 cm (4") of both threads to the back

under presser foot.

NOTE: It is not necessary for bobbin thread

to be drawn up to the surface after using the

key.

28

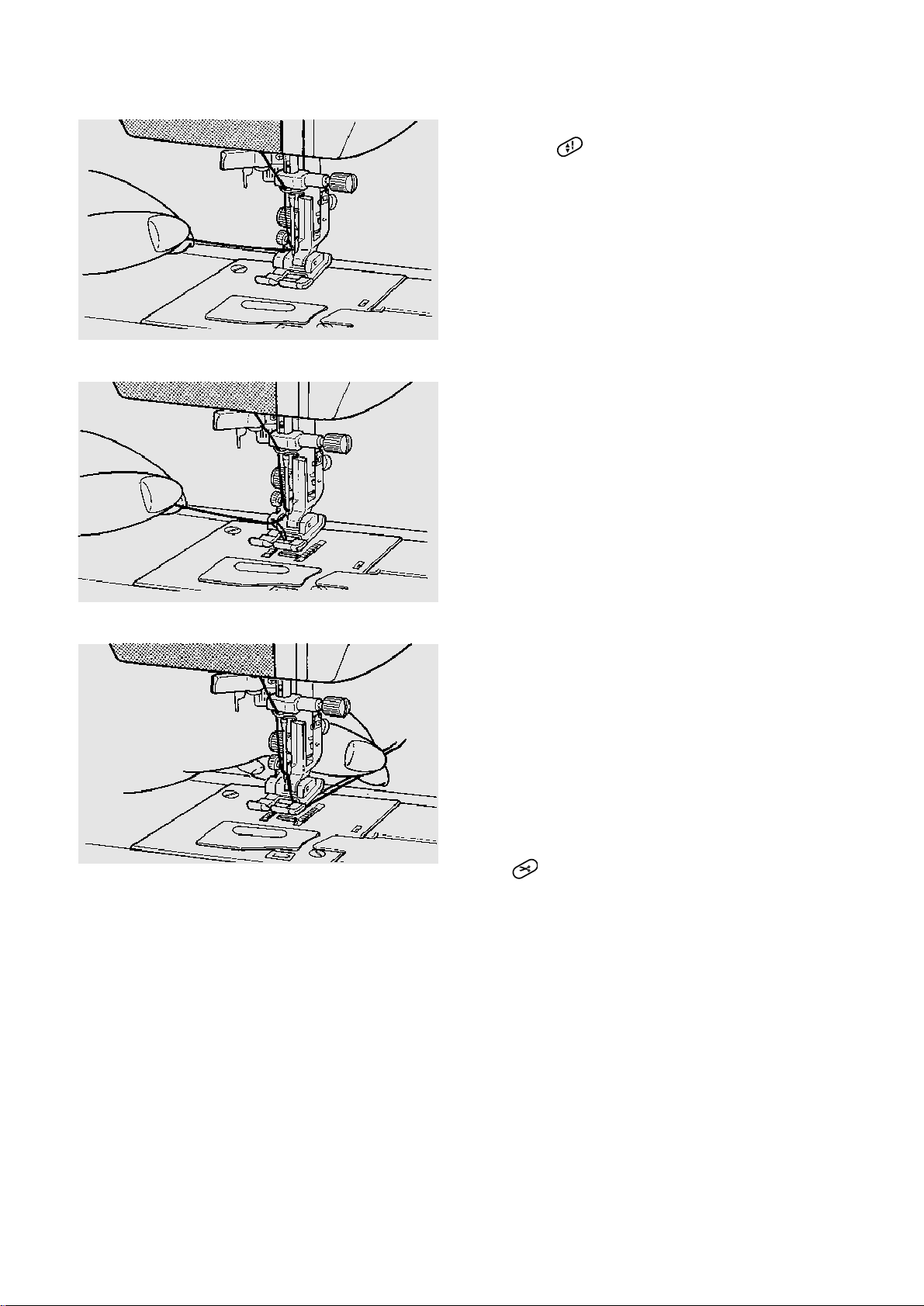

Test Sewing

Turn on power/light switch and touch the Welcome

Screen. The machine automatically sets itself to sew

1/01, a straight stitch in center needle position. This

key will be highlighted on the screen.

The stitch illustration and number will appear in the

top section of the screen, along with the

recommended foot or feet.

How to Access Utility, Heirloom and

Quilting Groups and Folders

The stitches have been grouped together according

to their characteristics.

The groups are identified by letters or

letters/numbers.

On a Utility (U) screen, touch key to access

Heirloom (H) group or key to access Quilting

(Q) group. The screens for these 3 groups provide

direct access to stitch width, length and tension. To

memorize these stitches in a sequence touch

key. See page 82.

Touch key to go quickly to 1/01 in Utility (U)

group.

H

Q

29

The groups have been arranged into folders. Each

folder is identified by a letter and group number plus

the last stitch number in that folder.

For example, the Utility group has 5 folders:

Folder 1: U-1/12

Folder 2: U-1/24

Folder 3: U-1/36

Folder 4: U-1/48

Folder 5: U-1/53

Touch key to access the folder containing

stitches 1/13 – 1/24.

Utility (U)

Heirloom (H)

Quilting (Q)

Loading...

Loading...