Electrolux EI30GF45QS User Manual

SERVICE DATA SHEET

GAS RANGES WITH MODULAR OVEN CONTROLS

NOTICE: This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the appliance repair trade. The manufacturer cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of this data sheet.

IMPORTANT NOTE: This unit includes an EOC (electronic oven control). This board is not field-repairable.

Safe Servicing Practices

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be observed. The following are some, but not all, examples of safe practices.

1.Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe and satisfactory manner.

2.Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit breaker to Off, or remove fuse.

3.Never interfere with the proper installation of any safety device.

4.Use only replacement parts specified for this appliance. Substitutions may not comply with safety standards set for home appliances.

5.Grounding: The standard color coding for safety ground wires is green or green with yellow stripes. Ground leads are not to be used as current carrying conductors. It is extremely important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so will create a potential hazard.

6.Prior to returning the product to service, ensure that:

•All electric connections are correct and secure.

•All electrical leads are properly dressed and secured away from sharp edges, high-temperature components, and moving parts.

•All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all metal parts and panels.

•All safety grounds (both internal and external) are correctly and securely reassembled.

•All panels are properly and securely reassembled.

Temperature Adjustment

1.While in a non-cooking mode, press and hold the Bake key for 3 seconds until UPO appears in the display.

2.Use the number keys (0-9) to enter the desired adjustments (-35° to 35° F).

3.Press the Self Clean key to change the sign of the adjustment to a (-), if necessary. A positive adjustment will not display a sign.

4.Once the desired adjustment (-35° to 35° F) has been entered, press START to accept the change or the STOP key to reject the change.

Note: Changing calibration affects all baking modes. The adjustments made will not change the self-cleaning temperature.

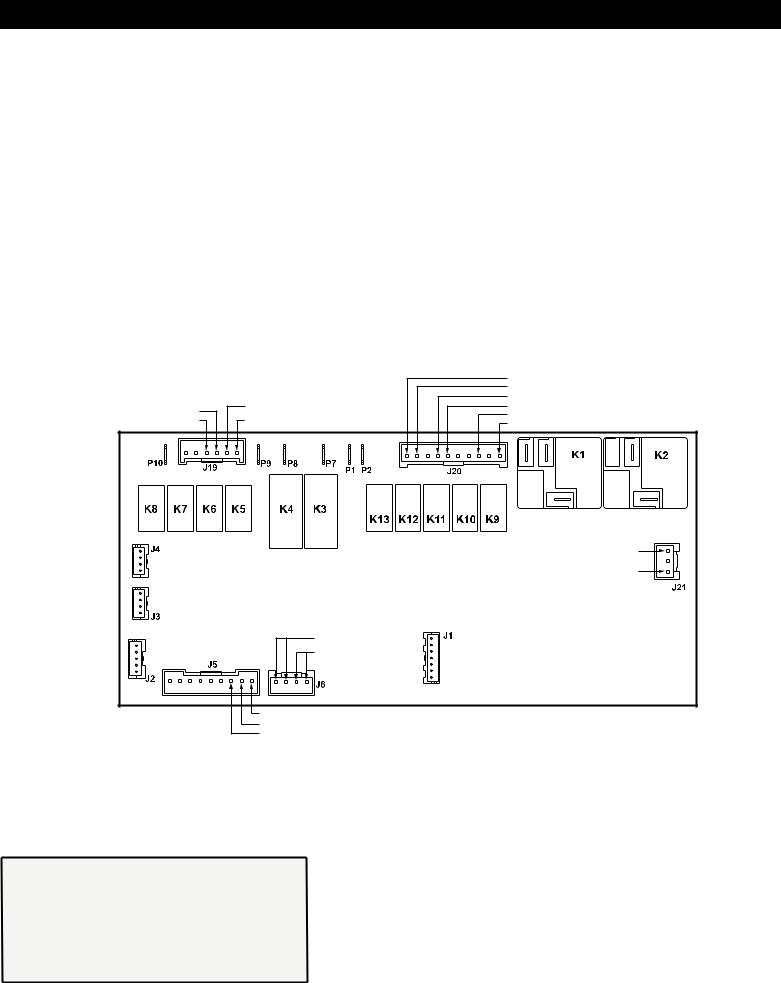

LATCH MOTOR

CONVECTION FAN

|

|

|

COOLING FAN |

|

BAKE IGNITER |

BROIL IGNITER |

OVEN LIGHT |

||

L1 & THERMAL |

L1 |

|||

CONVECTION ELEMENT |

||||

NEUTRAL |

||||

CIRCUIT BREAKER |

||||

|

|

1 |

1 |

|

|

CONV |

BAKE BROIL |

|

|

|

|

|

1 |

|

1 |

|

|

L1 |

|

|

J3 OR J4 |

NEUTRAL |

||

|

TO USER INTERFACE BOARD |

|

||

1 |

MARS BOARD |

|

||

1 |

|

MEAT PROBE |

|

|

|

TEMPERATURE PROBE |

|

||

|

|

PROGRAMMING HEADER |

||

|

|

|

||

|

|

|

1 |

|

|

1 |

1 |

|

|

MOTOR DOOR LATCH SWITCH

COMMON

DOOR SWITCH

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

p/n A00980640 Rev B (1710)

|

|

|

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS |

||

|

|

|

|

||

Fault |

Description of Error Code |

Suggested Corrective Action |

|

||

Code |

|

|

|

|

|

|

|

|

|||

F001 |

Touch panel failure |

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the touch panel. |

|||

F002 |

|

|

|

|

|

F004 |

|

|

|

|

|

F005 |

|

|

|

|

|

|

|

|

|||

F003 |

The oven user interface board is incorrectly |

Replace the oven user interface board. Make sure you install the latest revision available for this model. |

|||

|

configured. |

|

|

|

|

|

|

|

|

||

F010 |

Oven temperature runaway: the cavity |

1. |

If oven is overheating, disconnect power. Check oven temperature probe (RTD) and replace if necessary. |

||

|

temperature has been detected in excess |

2. |

If the oven temperature probe is good and if oven continues to overheat when power is reapplied, replace the oven relay board. |

||

|

of the maximum safe operating temperature. |

|

|

|

|

|

|

|

|

||

F011 |

Stuck key: a key has been detected has |

1. |

If a key was pressed inadvertently for a long time this error code will be displayed. Make sure there is nothing (water, utensils) in contact with the |

||

|

pressed continuously for 30 seconds or |

|

keyboard. The fault code should go away once the key is released and the Stop key is pressed. If the F011 error comes back when a key is pressed it |

||

|

more. |

|

means the error condition is still there. If the F011 error does not come back it means the error condition is gone and the oven can be used. |

||

|

|

2. |

If the fault code cannot be cleared, test the wiring harness between oven user interface board (connector I2C1 or I2C2) and touch panel (connector I2C1 |

||

|

|

|

or I2C2). |

|

|

|

|

3. |

If the fault code cannot be cleared and the wiring is good, the touch panel is most likely defective: replace the touch panel. |

||

|

|

4. |

If changing the touch panel did not fix the problem replace the oven user interface board. |

||

F012 |

Keyboard configuration alarm: the oven |

1. |

Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog. |

||

|

user interface board received from the touch |

2. |

Replace the oven user interface board. |

|

|

|

panel a key code that does not match the |

3. |

If the problem persists replace the touch panel. |

|

|

|

key map. |

|

|

|

|

|

|

|

|||

F013 |

Data written to non-volatile memory has |

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the oven user interface. |

|||

|

failed verification |

|

|

|

|

|

|

|

|||

F015 |

Keyboard error |

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the touch panel. |

|||

|

|

|

|

||

F017 |

The oven user interface board is unable to |

1. |

Disconnect power to the unit, wait 30 seconds, then reapply power. |

||

|

configure the touch panel. |

2. |

If fault returns, verify harness going to I2C1 or I2C2 connector of the touch panel. |

||

|

|

3. |

Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog. |

||

|

|

4. |

If fault persists, replace the oven user interface. |

|

|

|

|

5. |

If fault persists, replace the touch panel. |

|

|

|

|

|

|

||

F018 |

Oven relay board failure (wiggler) |

Replace the oven relay board. |

|

||

|

|

|

|

||

F019 |

The oven user interface board is unable to |

1. |

Disconnect power to the unit, wait 30 seconds, then reapply power. |

||

|

configure the oven relay board |

2. |

If fault returns, verify connection between the oven user interface board (MACS1 or MACS2 connector) and the oven relay board (connector J3 or J4). |

||

|

|

3. |

Verify the unit has the proper oven user interface board and oven relay board, based on the model number and parts catalog. |

||

|

|

4. |

If fault persists, replace oven user interface board. |

|

|

|

|

5. |

If fault persists, replace the relay board. |

|

|

F022 |

Communication failure between the oven |

1. |

Disconnect power, wait 30 seconds and reapply power. Check if error condition is still there. |

||

|

user interface board and the oven relay |

2. |

Test wiring harness between oven user interface board (connector MACS1 or MACS2) and oven relay board (connector J3 or J4). |

||

|

board |

3. |

If wiring harness is good replace oven relay board. |

|

|

|

|

4. |

If the problem persists replace the oven user interface. |

|

|

|

|

|

|

||

F023 |

Communication failure between the oven |

1. |

Disconnect power, wait 30 seconds and reapply power. Check if error condition is still there. |

||

|

user interface board and the glass touch |

2. |

Test wiring harness between oven user interface board (connector I2C1 or I2C2) and touch panel (connector I2C1 or I2C2). |

||

|

panel |

3. |

If wiring harness is good replace touch panel. |

|

|

|

|

4. |

If the problem persists replace the oven user interface. |

|

|

F025 |

The communication between the over user |

1. |

Disconnect power to the unit, wait 30 seconds, then reapply power. |

||

F027 |

interface and the oven relay board cannot |

2. |

If fault returns, verify connection between the oven user interface board (MACS1 or MACS2 connector) and the oven relay board (connector J3 or J4). |

||

|

be initiated. |

3. |

Verify the unit has the proper oven user interface board and oven relay board, based on the model number and parts catalog. |

||

|

|

4. |

If fault persists, replace relay board. |

|

|

|

|

5. |

If fault persists, replace the oven user interface board. |

|

|

F028 |

The communication between the over user |

1. |

Disconnect power to the unit, wait 30 seconds, then reapply power. |

||

F029 |

interface and the touch panel cannot be |

2. |

If fault returns, verify touch panel is connected (verify harness going to I2C1 or I2C2 connector) and is getting power from the oven user interface. |

||

|

initiated. |

3. |

Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog. |

||

|

|

4. |

If fault persists, replace the touch panel. |

|

|

|

|

5. |

If fault persists, replace the oven user interface. |

|

|

|

|

|

|

||

F030 |

Open oven temperature sensor (RTD) |

1. |

Check probe circuit wiring for possible open or short condition. |

||

|

|

2. |

Verify RTD resistance at room temperature (compare to probe resistance chart). If resistance does not match the chart, replace the RTD probe. |

||

F031 |

Shorted oven temperature probe (RTD) |

||||

3. |

If the problem persists replace the oven relay board. |

|

|||

|

|

|

|

||

F033 |

Meat probe temperature sensor shorted |

1. |

The error is triggered if the meat probe sees a temperature in excess of 392°F. Make sure the meat probe was not used in such way that it could have |

||

|

or too hot |

|

seen such temperature. If the tip of the probe is not inserted in the meat it will see the cavity temperature, which can be higher than 392°F (depending on |

||

|

|

|

the setpoint) and trigger the alarm. |

|

|

|

|

2. |

When the meat probe is connected to the socket inside the oven cavity, if the meat probe is not fully inserted into the socket it may short the contacts and |

||

|

|

|

cause the error. Make sure the probe is inserted as much as it can. |

||

|

|

3. |

Verify meat probe resistance at room temperature. Compare to meat probe resistance chart. If the meat probe does not match the chart, replace it. |

||

|

|

4. |

If the above steps failed to correct the problem, replace the oven relay board. |

||

F050 |

A/D Out of Range: the oven relay board is |

1. |

Check to ensure that the connections between the door switch, MDL and temp probes are properly connected. This includes all splices and junctions. |

||

|

unable to read the status of the switches |

2. |

If the above step failed to correct the problem, replace the oven relay board. |

||

|

(door, MDL) |

|

|

|

|

|

|

|

|

||

F090 |

Motor Door Lock mechanism failure. The |

1. |

Disconnect power to the unit, wait 30 seconds, then reapply power. Try again to make the door lock or unlock (ex: initiate a Lockout or a Clean cycle). |

||

|

oven control does not see the Motor Door |

2. |

Check if the Lock Motor is running or not. If it is not running, test the wiring between the Lock Motor and the oven relay board. If the wiring is good, check |

||

|

Lock running. |

|

if there is 120VAC at the motor when it is expected to run |

to see if the failure originates from a bad motor (120VAC present but not turning) or a problem |

|

|

|

|

with the relay board (J20 pin 10 on the oven relay board |

is the output to the Lock Motor). The Lock Motor can also be tested by applying 120VAC directly |

|

|

|

|

to the motor (unplug it from the relay board first). If the Lock Motor does not run when 120VAC is applied replace the Lock Motor Assembly. If it is the |

||

|

|

|

relay board that does not provide 120VAC to the Lock Motor replace the oven relay board. |

||

|

|

3. |

If the Lock Motor is running but the oven control cannot find the locked or unlocked position (ex: motor turns continuously until F90 fault code is gener- |

||

|

|

|

ated) the Lock Switch needs to be verified. Check wiring between Lock Switch and oven relay board. Verify with ohmmeter if the switch makes contact |

||

|

|

|

properly (verify continuity with ohmmeter when the switch is pressed). If the Lock Switch is defective replace the Motor Lock Assembly. |

||

|

|

4. |

If all above steps failed to correct the situation, replace the oven relay board. |

||

F095 |

Motor Door Lock mechanism failure. The |

1. |

The problem can be caused by a faulty Lock Switch or by a defective oven relay board. If the Motor Door Lock is always running (as if the relay con- |

||

|

Motor Door Lock does not stop running or |

|

trolling it is stuck closed) replace the oven relay board. |

|

|

|

the Lock Switch sends an invalid signal. |

2. |

If the motor is not always running replace the Motor Lock Assembly. |

||

F096 |

The oven door has been detected open |

1. |

This error occurs if the door switch has lost its contact during a Self Clean cycle. Make sure the oven door closes well and fully presses on the door |

||

|

during a Self Clean cycle. |

|

switch plunger when the door is locked, and no one attempted to pull on the oven door during the Self Clean cycle. |

||

|

|

2. |

Test continuity of wiring between the door switch and the oven relay board, make sure the door switch is well connected. With an ohmmeter, verify the |

||

|

|

|

switch is closed when the plunger is pressed. If the door switch is found to be defective replace the door switch. |

||

|

|

3. |

If the switch and wiring are good and the problem persists, replace the oven relay board. |

||

SERVICE DATA SHEET

GAS RANGES WITH MODULAR OVEN CONTROLS

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Fault Code |

Description of Error Code |

Suggested Corrective Action |

|

|

|

|

|

SPr |

This device detects voltage from spark ignitor |

If SPr continues: |

|

|

harness. If voltage is detected at the AC detect |

1. |

Start a self-clean. |

|

board this will signal to the oven control that |

2. |

Turn any burner ignitor to the LITE position. |

|

the spark module is trying to light a burner. |

3. |

Verify that the self-clean cycle has been cancelled and “Spr” is displayed in the oven display. |

|

The oven control will only look for the signal |

If this does not happen, proceed with the following troubleshooting steps. |

|

|

from the AC detect board when self-clean cycle |

||

|

is started or running. Detection of the signal |

1. |

Verify the AC harness is connected to J1 of the AC detect board. |

|

will cause clean to be cancelled and “SPR” |

2. |

Verify the DC harness is connected to J2 of the AC detect board. |

|

(which means spark detected) will appear in |

3. |

Multi-meter set to AC volts. |

|

the display. The cooktop should not be used |

4. |

Verify 0 VAC at J1 pins 1 and 3 of the AC detect board, when the spark ignitor is turned OFF. |

|

during a self-clean cycle. On some models, |

5. |

Verify 120 VAC at J1 pins 1 and 3 of the AC detect board, when the spark ignitor is turned ON. |

|

turning on any cooktop surface burner will |

6. |

Multi-meter set to DC volts. |

|

cause the clean cycle to cancel. If the clean |

7. |

Verify 4 - 5 VDC at J3 pins 2 and 3 of the AC detect board or J5 pins 5 and 6 of the OVC board, when the spark |

|

cycle is canceled, the oven control display will |

8. |

ignitor is turned OFF. (Pin 3 is GND on the AC detect board and GND is pin 6 on the OVC board) |

|

show “SPr" for 5 seconds. The oven door will |

Verify 0 – 1 VDC at J3 pins 2 and 3 of the AC detect board or J5 pins 5 and 6 of the OVC board, when the spark |

|

|

remain locked until the oven has cooled down |

9. |

ignitor is turned ON. (Pin 3 is GND on the AC detect board and GND is pin 6 on the OVC board) |

|

below cleaning temperature. If the oven is |

If steps 7 and 8 check, replace OVC board |

|

|

below cleaning temperature, the user can start |

|

|

|

another clean cycle immediately. If the oven is |

|

|

|

in cleaning temperature range, another self- |

|

|

|

clean cycle can be set once the door unlocks |

|

|

|

(up to 4 hours). |

|

|

FICHE DE RÉPARATION

CUISINIÈRE GAZ AVEC RÉGULATEUR ÉLECTRONIQUE DE FOUR MODULAR

AVIS: Cette feuille de données d’entretien est destinée aux personnes ayant reçu une formation en électricité et en mécanique, et qui possèdent un niveau de connaissance jugé acceptable dans l’industrie de réparation des appareils électroménagers. Le fabricant ne peut être tenu responsable, ni assumer aucune responsabilité, pour toute blessure ou dommage de quelque nature que ce soit pouvant résulter de l’utilisation de cette feuille de données.

NOTEs IMPORTANTES: Cet appareil inclut un contrôleur de four électronique. Le tableau de contrôle n’est pas réparable sur place.

Pratiques d’entretien Sécuritaires

Pour éviter tout risque de blessure et/ou dommage matériel, il est important que des pratiques d’entretien sécuritaires soient suivies. Voici quelques exemples de pratiques sécuritaires.

1.N’essayez jamais de réparer un appareil si vous ne croyez pas avoir les compétences nécessaires pour le faire de manière satisfaisante et sécuritaire.

2.Avant de procéder au service d’entretien ou de déplacer tout appareil ménager, débranchez le cordon d’alimentation de la prise électrique, réglez le disjoncteur de circuit à OFF, ou enlevez le fusible et fermez le robinet d’alimentation en gaz.

3.N’entravez jamais l’installation adéquate de tout dispositif de sécurité.

4.Utilisez que les pièces de remplacement énumérées dans le catalogue pour cet appareil. La moindre substitution risque de ne pas être conforme aux normes de sécurité établies pour les appareils électroménagers.

5.Mise à la Terre: La couleur de codage standard des conducteurs de mise à la terre de sécurité est verte ou verte à barres jaunes. Les conducteurs de mise à la terre ne doivent pas être utilisés comme conducteurs de courant. Il est d’une importance

capitale que le technicien d’entretien complète toutes les mises à la terre de sécurité avant de terminer le service. Si cette recommandation n’est pas suivie à la lettre, il en résultera des risques pour les personnes et les biens.

6.Avant de retourner le produit au service de réparation ou d’entretien, assurez-vous que:

•Toutes les connexions électriques sont correctes et sécuritaires.

•Tous les conducteurs électriques sont correctement préparés et à l’abri des bords tranchants, des composants à température élevée, et des parties mobiles.

•Toutes les bornes électriques, connecteurs, réchauffeurs, etc. dénudés sont espacés convenablement loin de toute pièce en métal et des panneaux.

•Toutes les mises à la terre de sécurité (interne et externe) sont correctement ré-assemblées de façon sécuritaire.

•Tous les panneaux sont correctement et fermement remontés.

Réglage de la Température

1.Assurez-vous de ne sélectionner aucun mode de cuisson, puis appuyez sur la touche BAKE (cuisson au four) et maintenez-la enfoncée pendant 3 secondes.

2.Utilisez les touches numériques (0 à 9) pour entrer l’ajustement désiré (jusqu’à 35 ºF/19 ºC).

3.Appuyez sur la touche SELF CLEAN (autonettoyage) pour ajouter le symbole à (-) à l’ajustement, si nécessaire. Aucun signe n’apparaît si l’ajustement est positif.

4.Lorsque vous avez fait le réglage désiré (-35 à 35 ºF / -18 à 18 ºC), appuyez sur la touche Start (mise en marche) pour confirmer le choix ou STOP (annuler) pour l’annuler.

Remarque: La modification de la calibration affecte tous les modes de cuisson. Les ajustements n’influent pas sur la température du cycle d’autonettoyage.

CIRCUIT |

|

|

|

|

|

|

Door |

|

|

ANALYSIS |

|

|

|

|

|

|

|

||

|

|

|

Door |

|

Conv. |

Switch |

Cooling |

||

MATRIX |

|

|

|

|

|||||

Bake |

Broil |

Conv. |

Motor |

Light |

Fan |

J5-7, |

Fan |

||

|

|||||||||

|

J19-3 |

J19-2 |

J19-4 |

J20-10 |

J20-6 |

J20-9 |

J5-8 |

J20-7 |

|

Bake |

X |

|

X |

|

|

X |

|

X |

|

Broil |

|

X |

|

|

|

|

|

X |

|

Conv. Bake |

X |

|

X |

|

|

X |

|

X |

|

Conv. Roast |

X |

|

X |

|

|

X |

|

X |

|

Clean |

X |

|

|

|

|

|

|

X |

|

Locking |

|

|

|

X |

|

|

|

|

|

Unlocking |

|

|

|

X |

|

|

|

|

|

Light |

|

|

|

|

X |

|

|

|

|

Door Open |

|

|

|

|

X |

|

|

|

|

Door Closed |

|

|

|

|

|

|

X |

|

RTD SCALE

|

Temperature °F (°C) |

|

Resistance (ohms) |

32 ± 1.9 (0 ± 1.0) |

1000 ± 4.0 |

||

|

|

|

|

75 ± 2.5 (24 ± 1.3) |

1091 ± 5.3 |

||

|

|

|

|

250 ± 4.4 (121 ± 2.4) |

1453 ± 8.9 |

||

|

|

|

|

350 ± 5.4 (177 ± 3.0) |

1654 ± 10.8 |

||

|

|

|

|

450 ± 6.9 (232 ± 3.8) |

1852 ± 13.5 |

||

|

|

|

|

550 ± 8.2 (288 ± 4.5) |

2047 ± 15.8 |

||

|

|

|

|

650 ± 9.6 (343 ± 5.3) |

2237 ± 18.5 |

||

|

|

|

|

900 ± 13.6 (482 ±7.5) |

2697 ± 24.4 |

||

|

|

|

|

|

Probe circuit to case ground |

|

Open circuit/infinite resistance |

|

|

|

|

|

MEAT PROBE TEMPERATURE VS RESISTANCE |

||

|

Temperature °F (°C) |

|

Resistance (Kohm) |

|

|

|

|

|

77 (25) |

|

50.0 ± 7% |

|

|

|

|

|

122 (50) |

|

18.0 ± 4.9% |

|

|

|

|

|

176 (80) |

|

6.3 ± 3.3% |

|

|

|

|

|

212 (100) |

|

3.4 ± 4.6% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

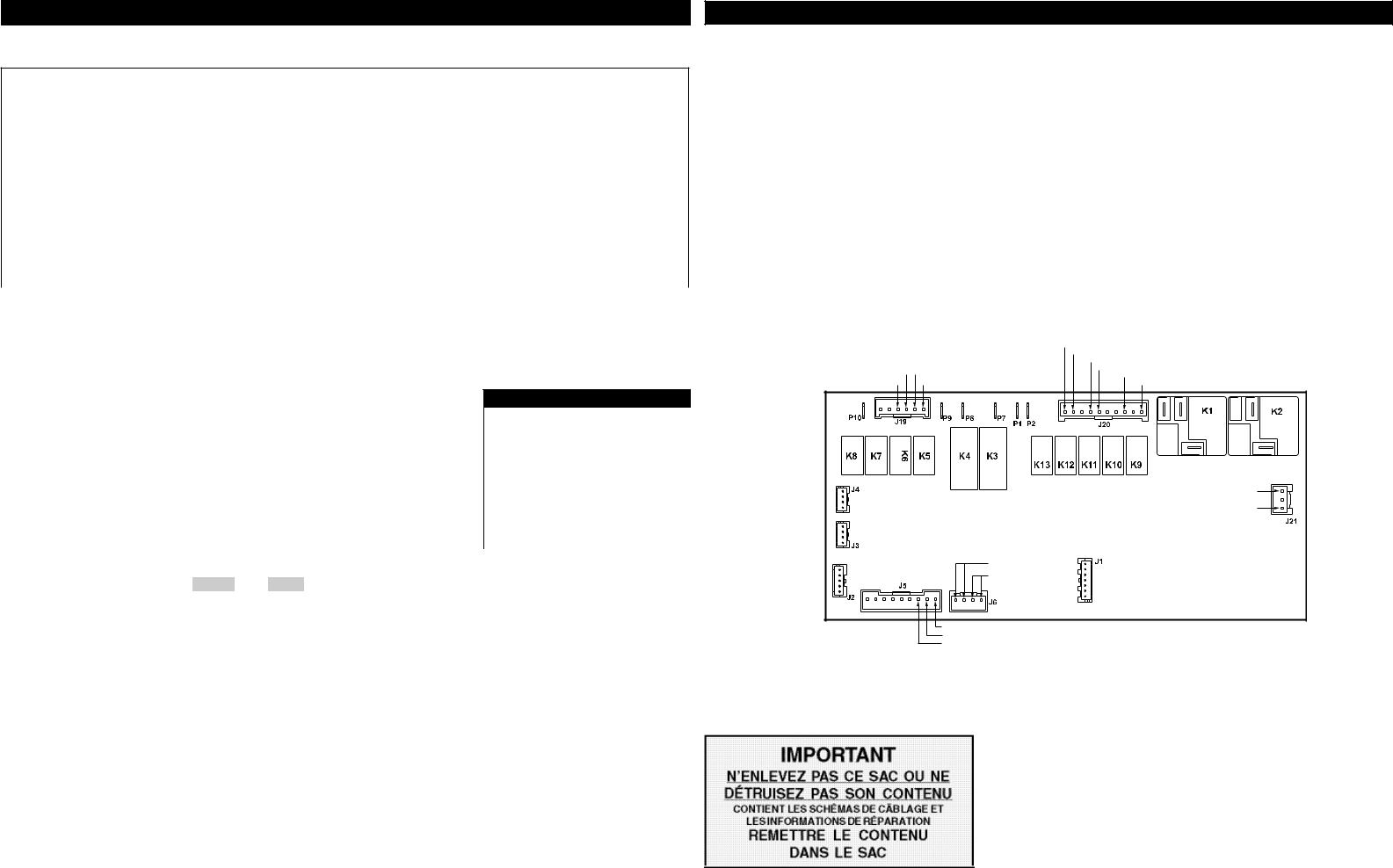

MOTEUR VERROU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VENTILATEUR DE CONVECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VENTILATEUR DE REFROIDISSEMENT |

|

|

|

|

|

|

|

ALLUMEUR DU |

|

|

|

|

|

|

||||

ALLUMEUR DU |

|

|

|

|

|

|

|

|

|

|

|

LAMPE HALOGÈNE |

|||||

|

|

|

|||||||||||||||

BRÛLEUR DE CUISSON |

|

|

|

|

|

|

BRÛLEUR DE GRILLAGE |

|

|

|

|

|

L1 |

||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|||||||||||||||

ÉLÉMENT DE CONVECTION |

|

|

|

|

|

|

L1 & DISJONCTEUR THERMIQUE |

|

|

|

|

NEUTRE |

|||||

|

|

|

|

|

|

||||||||||||

|

|

N |

1 |

|

1 |

|

|

|

|

|

|

|

CONV |

CUISSO |

GRIL |

|

|

|

|

|

|

||

|

|

|

|

|

1 |

1 |

|

|

|

|

L1 |

|

J3 OU J4 |

|

|

NEUTRE |

|

|

À PLAQUETTE D'INTERFACE DE UTILISATEUR |

|

|||

1 |

“MARS BOARD” |

|

|

|

|

1 |

|

|

|

SONDE À VIANDE |

|

|

|

|

SONDE À TEMPÉRATURE |

|

|

|

|

|

|

TÊTE DE PROGRAMMATION |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

1 |

|

|

1 |

|

INTERRUPTEUR DU MOTEUR VERROU DE LA PORTE

COMMUNE

INTERRUPTEUR DE PORTE

A00980640 Rev B (1710) FR

Loading...

Loading...