Page 1

Troubleshooting Guide

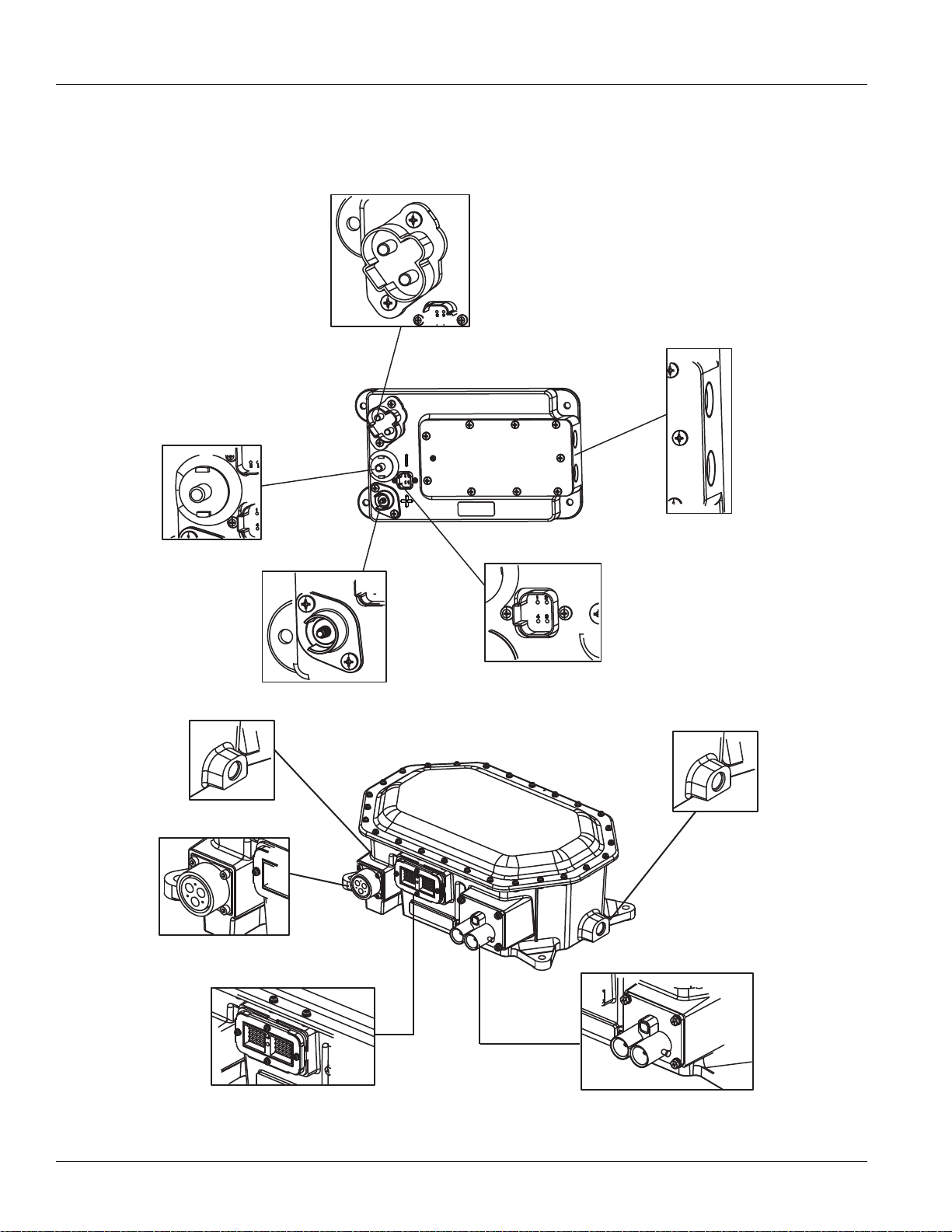

MY09 PEC

MY09 Inverter

MY09 Motor Generator

with Connectors

1

2

1

2

3

6

5

4

Eaton Hybrid Drive Systems MY09

TRTS2000 EN-US

October 2015

MY09 PEC Models

EH-8E406A-U/P

EH-8E406A-UP

EH-8E406A-UPG

EH-8E406A-CD

EH-8E406A-CDG

EH-8E406A-CDR

EH-8E406A-T

EH-6E706B - CD

EH-6E706B- P

EH-6E706B -UPG

Page 2

Page 3

TRTS2000 T able of Contents |

General Information

Warnings & Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . 1

High-Voltage Warnings & Cautions . . . . . . . . . . . . 2

Insulated Rubber Glove Test and High-Voltage Work

Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Insulated Rubber Glove Test. . . . . . . . . . . . . . . . . . 3

High-Voltage Work Area Requirements . . . . . . . . . 3

High-Voltage Service Shutdown and Power-Up

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

High-Voltage Service Shutdown Procedure . . . . . . 5

High-Voltage Service Power-Up Procedure . . . . . . 5

Diagnostic Tools and Service Publications. . . . . . . . . . 6

Eaton Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SPX/OTC To ols . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service Publications. . . . . . . . . . . . . . . . . . . . . . . . 7

Hybrid Diagnostic Procedure . . . . . . . . . . . . . . . . . . . . 8

Hybrid Component and Connector Locations. . . . . . . . 9

Transmission Wiring Connections . . . . . . . . . . . . . 9

Component Wiring Connections. . . . . . . . . . . . . . 11

Fault Code Retrieval and Clearing. . . . . . . . . . . . . . . . 13

View Active and Inactive Faults. . . . . . . . . . . . . . . 13

Clear Inactive Faults . . . . . . . . . . . . . . . . . . . . . . . 13

Fault Code Isolation Procedure Index. . . . . . . . . . . . . 14

Symptom-Driven Diagnostics Index. . . . . . . . . . . . . . 17

Product Diagnostic Mode (PDM). . . . . . . . . . . . . . . . 18

PDM will only work with the following Inactive

codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hybrid Light and Gear Display Descriptions. . . . . . . . 19

Red “Service” Light . . . . . . . . . . . . . . . . . . . . . . . 19

Amber “Check Hybrid” Light . . . . . . . . . . . . . . . . 19

Red “Stop Hybrid” Light. . . . . . . . . . . . . . . . . . . . 19

Blinking Amber “Check Hybrid” Light. . . . . . . . . . 19

“ST” in Gear Display. . . . . . . . . . . . . . . . . . . . . . . 19

“PD” in Gear Display . . . . . . . . . . . . . . . . . . . . . . 19

“CA” in Gear Display. . . . . . . . . . . . . . . . . . . . . . . 20

“OS” in Gear Display . . . . . . . . . . . . . . . . . . . . . . 20

“F” in Gear Display . . . . . . . . . . . . . . . . . . . . . . . . 20

Dash “-” in Gear Display. . . . . . . . . . . . . . . . . . . . 20

Stars “**” in Gear Display . . . . . . . . . . . . . . . . . . 20

Two Dashes “- -” in Gear Display . . . . . . . . . . . . . 20

Blank Gear Display . . . . . . . . . . . . . . . . . . . . . . . . 20

Pretest Procedure

Power-Up Sequence Test. . . . . . . . . . . . . . . . . . . . . . 21

Electrical Pretest . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hybrid Electrical Pretest. . . . . . . . . . . . . . . . . . . . . . . 28

Fault Isolation Procedure

Fault Code 1 - Motor/Generator Current Sensor. . . . . 33

Fault Code 2 - Motor/Generator Temperature Sensor. 38

Fault Code 3 - Motor/Generator Temperature. . . . . . . 42

Fault Code 4 - Motor/Generator Rotation Speed

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Fault Code 5 - Motor/Generator AC Cable. . . . . . . . . . 54

Fault Code 6 - No HCM Operation . . . . . . . . . . . . . . . 60

Fault Code 7 - Improper HCM Configuration . . . . . . . 63

Fault Code 8 - Loss of Switched Ignition Power

Fault (HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Fault Code 9 - Weak Battery Voltage . . . . . . . . . . . . . 70

Fault Code 10 - Low Battery Voltage (HCM). . . . . . . . 73

Fault Code 11 - No TECU Operation . . . . . . . . . . . . . . 76

Fault Code 12 - Improper ECU Configuration (TECU). 79

Fault Code 14 - Invalid Shifter Range. . . . . . . . . . . . . 82

Fault Code 16 - High Integrity Link (HIL) . . . . . . . . . . 87

Fault Code 17 - Start Enable Relay. . . . . . . . . . . . . . . 93

Fault Code 18 - ECA Communication Fault. . . . . . . . . 98

Fault Code 19 - CAN ECA Message Fault (HCM). . . . 101

Fault Code 22 - J1939 ABS Message Fault (HCM) . . 107

Fault Code 24 - J1939 HCM Message Fault (TECU) . 110

Fault Code 26 - Clutch Slip Fault . . . . . . . . . . . . . . . 114

Fault Code 27 - Clutch Disengagement Fault . . . . . . 117

Fault Code 32 - Loss of Switched Ignition

Power Fault (TECU) . . . . . . . . . . . . . . . . . . . . . . . . . 121

Fault Code 33 - Low Battery Voltage Fault (TECU) . . 124

Fault Code 34 - Weak Battery Voltage Fault (TECU) . 127

Fault Code 35 - J1939 Communication Link Fault

(TECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Fault Code 36 - J1939 Engine Message Faults. . . . . 135

Fault Code 37 - Power Supply Fault (TECU). . . . . . . 138

Fault Code 38 - Battery Fan Relay Fault . . . . . . . . . . 142

Fault Code 39 - Heat Exchanger Relay Fault. . . . . . . 148

Fault Code 40 - Cooling Pump Relay Fault. . . . . . . . 153

Fault Code 48 - J1939 Transmission Message

Fault (HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Fault Code 49 - J1939 Engine Message Fault (HCM) 162

Fault Code 50 - J1939 Body Controller Message

Fault (HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Fault Code 51 - Rail Position Sensor Fault. . . . . . . . 168

2015.10.20

© 2013 Eaton. All rights reserved

i

Page 4

| Table of Contents TRTS2000

Fault Code 52 - Gear Position Sensor Fault . . . . . . . 173

Fault Code 53 - DC/DC Converter Fault . . . . . . . . . . 178

Fault Code 54 - DC/DC Converter Output Voltage

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Fault Code 56 - Input Shaft Speed Sensor Fault. . . . 186

Fault Code 58 - Output Shaft Speed Sensor Fault . . 190

Fault Code 59 - J1939 Communication Link Fault

(HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Fault Code 60 - CAN Communication Link Fault . . . 199

Fault Code 61: Rail Motor Circuit Fault . . . . . . . . . . 203

Fault Code 63: Gear Motor Circuit Fault. . . . . . . . . . 215

Fault Code 64 - ECA Fault . . . . . . . . . . . . . . . . . . . . 227

Fault Code 65 - ECA Speed Sensor Fault . . . . . . . . . 231

Fault Code 66 - ECA Battery Voltage Fault . . . . . . . . 235

Fault Code 67 - ECA Ignition Voltage Fault. . . . . . . . 238

Fault Code 68 - Grade Sensor Fault . . . . . . . . . . . . . 243

Fault Code 70 - Engine Failed to Respond Fault

(HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Fault Code 71 - Failed to Disengage a Gear . . . . . . . 250

Fault Code 72 - Failed to Select Rail Fault . . . . . . . . 254

Fault Code 73 - Failed to Engage a Gear Fault . . . . . 258

Fault Code 74 - Engine Failed to Respond Fault

(TECU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Fault Code 75 - Power Down in Gear. . . . . . . . . . . . 265

Fault Code 76 - High Voltage Battery 1 Potential

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Fault Code 78 - High Voltage Battery 1 Current Fault 271

Fault Code 82 - High Voltage Battery 1 Temperature

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Fault Code 83 - Invalid Shift Range . . . . . . . . . . . . . 279

Fault Code 84 - Shift Control Device Not Configured

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Fault Code 85 - Shift Control Device Incompatible

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Fault Code 88 - Inverter CAN Message Fault (HCM) 294

Fault Code 89 - Battery Control Unit CAN Message

Fault (HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Fault Code 94 - Transfer Case Message Fault . . . . . 308

Fault Code 95 - 12-Volt Cranking Relay Fault. . . . . . 311

Fault Code 97 - PTO Engagement Fault . . . . . . . . . . 316

Fault Code 101 - High Voltage Battery Fault. . . . . . . 322

Fault Code 103 - Battery Control Unit (BCU)

Communication Fault. . . . . . . . . . . . . . . . . . . . . . . . 325

Fault Code 105 - Battery Control Unit Fault . . . . . . . 329

Fault Code 107 - High Voltage Battery Leak

Detection Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Fault Code 108 - Battery Control Unit Power

Supply Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

Fault Code 110 - Inverter Fault. . . . . . . . . . . . . . . . . 346

Fault Code 111 - Inverter CAN Message Fault

(HCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Fault Code 112 - Inverter Voltage Fault . . . . . . . . . . 355

Fault Code 113 - Inverter Current Fault . . . . . . . . . . 359

Fault Code 114 - Inverter Power Supply Fault . . . . . 364

Fault Code 115 - Inverter Temperature Fault . . . . . . 368

Fault Code 116 - High Voltage Relays Fault. . . . . . . 373

Fault Code 117 - Battery Control Unit Relay Cut

Request Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Fault Code 118 - Auxiliary High Voltage Relay

Control Circuit Fault. . . . . . . . . . . . . . . . . . . . . . . . . 386

Fault Code 120 - APG Unit 1 - AC Voltage Fault. . . . 395

Fault Code 122 - APG Unit 1 Output . . . . . . . . . . . . 398

Fault Code 123 - APG Unit 1 High Voltage Battery. . 403

Fault Code 125 - APG Unit 1 - Over Temperature . . 406

Fault Code 126 - APG Unit 1 Configuration . . . . . . . 409

Fault Code 127 - APG Unit 1 Ambient Air Over

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Fault Code 128 - APG Unit 1 CAN Fault . . . . . . . . . . 415

Fault Code 165 - APG Unit 1 Configuration Error. . . 419

Symptom Isolation Procedure

Front Box Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Engine Crank Test . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Hybrid Performance Test. . . . . . . . . . . . . . . . . . . . . 432

ServiceRanger Test . . . . . . . . . . . . . . . . . . . . . . . . . 436

Gear Engagement Test. . . . . . . . . . . . . . . . . . . . . . . 441

ePTO Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

ii

© 2013 Eaton. All rights reserved

2015.10.20

Page 5

TRTS2000 T able of Contents |

Appendix

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

Hybrid Tr ansmission ECU System Harness . . . . 453

Wiring Diagram with Push Button Shift

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

Connector Pin Description . . . . . . . . . . . . . . . . . . . . 456

Hybrid and Transmission Connector Pins. . . . . . 456

TECU and HCM Connectors . . . . . . . . . . . . . . . . 457

Transmission Controller 38-Way (Vehicle Interface

Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

Hybrid Controller 38-Way (Vehicle Interface

Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

Hybrid Controller 38-Way (Hybrid System Interface

Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

Push Button Shift Control Connector . . . . . . . . . 461

Push Button 30-Way Connector. . . . . . . . . . . . . 461

Inverter Connectors . . . . . . . . . . . . . . . . . . . . . . 462

Power Electronics Carrier (PEC) Connectors . . . 464

PEC High-Voltage (DC) Connector to Inverter . . 465

Electric Clutch Actuator (ECA) Connectors. . . . . 466

Motor/Generator Connectors . . . . . . . . . . . . . . . 467

Typical DC/DC Converter Circuit. . . . . . . . . . . . . 469

2015.10.20

© 2013 Eaton. All rights reserved

iii

Page 6

Warnings & Cautions | General Information TRTS2000

!

!

!

!

Warnings & Cautions

Warnings and Cautions

Throughout this service manual there are paragraphs that

are marked with a title of DANGER, WARNING, or

CAUTION. These special paragraphs contain specific safety

information and must be read, understood, and heeded

before continuing the procedure or performing the step(s).

DANGER

HAZARDOUS VOLTAGE

You will be severely injured or killed

if you do not follow the procedure.

Components marked with

DANGER High Voltage should be

avoided. Service must be

performed by qualified personnel only.

Danger: Danger indicates you will be severely injured or

killed if do not follow the indicated procedure.

Warning: Warning indicates an immediate hazard, which

could result in severe personal injury if you do not follow

the indicated procedure.

Caution: Caution indicates vehicle or property damage

could occur if you do not follow the indicated procedure.

Note: Note indicates additional detail that will aid in the

diagnosis or repair of a component/system.

Caution: Follow the specified procedures in the indicated

!

order to avoid personal injury:

1. If the high-voltage cones are around the vehicle

and the lockout is installed on the PEC, the only

person that should be allowed to start the vehicle is

the person who signed the lockout tag.

2. Before working on a vehicle or leaving the cab

while the engine is running, you should place the

Shift Lever in “N” set the parking brake, and block

the wheels.

3. For safety reasons, always engage the service

brakes prior to selecting gear positions from “N.”

4. Before starting a vehicle always be seated in the

driver's seat, select “N” on the shift control, and set

the parking brakes.

5. In vehicles with ePTO, the engine and/or

Motor/Generator can start in ePTO mode. Never

perform any maintenance or work on vehicle, while

in this mode.

6. 12-volt Battery (+) and (-) must be disconnected

prior to any welding on any Hybrid equipped

vehicle.

Caution: Follow the specified procedures in the indicated

order to avoid equipment malfunction or damage.

Caution: Do not release the parking brake or attempt to

!

select a gear until the air pressure is at the correct level.

Caution: T o avoid damage to the transmission during tow-

!

ing place the Shift Lever in “N” and lift the drive wheels off

the ground or disconnect the driveline.

1

© 2015 Eaton. All rights reserved

2015.10.20

Page 7

TRTS2000 General Information | Warnings & Cautions

DANGER

HAZARDOUS VOLTAGE

You will be severely injured or killed

if you do not follow the procedure.

Components marked with

DANGER High Voltage should be

avoided. Service must be

performed by qualified personnel only.

WARNING

To reduce risk of possible serious

injury (Shock, Burn or Death):

Components marked with High

Voltage should be avoided.

Service must be performed by

qualified personnel only.

HAZARDOUS VOLTAGE

High-Voltage Warnings & Cautions

• Use CO2 or Dry Chemical Fire Extinguishers.

• The high-voltage wiring is covered in orange

insulation or convoluted tubing and marked with

warning labels at the connectors.

• All Eaton® Hybrid Diesel/Electric vehicles will be

marked 'Hybrid' on the outside of the vehicle, along

with the shift label on the dash.

• Refer to OEM for specific location of chassis

mounted hybrid components.

• Do NOT cut into the orange high-voltage cables.

• Do NOT cut into or open the Power Electric

Carrier (PEC).

• Do NOT cut into or open the DC/DC converter.

• Do NOT cut into or open the Inverter.

A buffer zone must be set up and high-voltage insulated

rubber gloves (class 0 with leather protectors) are required

prior to working on high-voltage. Failure to follow these

instructions may result in severe personal injury or death.

The rubber-insulated gloves that must be worn while

working on the high-voltage system are class 0 with leather

protectors. The rubber gloves should be tested before every

use following the rubber insulation gloves testing

procedure (see “Insulated Rubber Glove Test” on page 3).

Failure to follow these instructions may result in severe

personal injury or death.

Before inspecting or working on any high-voltage cables or

components the “High-Voltage Service Shutdown

Procedure” on page 5 should be followed. Failure to follow

these instructions may result in severe personal injury or

death.

The Lockout and Tag-out devices should only be removed

by the technician that placed the Lockout and Tag-out

devices on the vehicle. Failure to follow these instructions

may result in severe personal injury or death.

High-voltage rubber insulated gloves (class 0 with leather

protectors) must be worn when working on any

high-voltage cables. The “High-Voltage Service Shutdown

Procedure” on page 5 must be followed prior to removing

any high-voltage cables. Failure to follow these instructions

may result in severe personal injury or death.

High-voltage cables and wiring are orange and contain a

warning label at the connectors. High-voltage components

are marked with a label. High-voltage rubber insulated

gloves (class 0 with leather protectors) must be used when

working on any of these components. Failure to follow

these instructions may result in severe personal injury

or death.

2015.10.20

© 2015 Eaton. All rights reserved

2

Page 8

Insulated Rubber Glove Test and High-Voltage Work Area | General Information TRTS2000

!

Insulated Rubber Glove Test and High-Voltage Work Area

Insulated Rubber Glove Test

Warning: The rubber-insulated gloves that must be worn

while working on the high-voltage system are class 0 with

leather protectors. The rubber gloves should be tested

before EVERY use by following the procedure below. Failure

to follow these instructions may result in severe personal

injury or death.

The insulated rubber gloves that must be worn while

working on the high-voltage system are class 0 rated.

They

must be inspected before each use and must always

be worn in conjunction with the leather outer glove:

• Roll the glove up from the open end until the lower

portion of the glove begins to balloon from the

resulting air pressure. If the glove leaks any air it

must not be used. Any hole in the insulated rubber

glove is a potential entry point for high-voltage.

• The gloves should not be used if they exhibit any

signs of wear and tear.

• The leather gloves must always be worn over the

rubber insulating gloves in order to protect them.

• The rubber insulating gloves must be ASTM

Class

0 electrical insulating rubber gloves with

leather protectors.

High-Voltage Work Area Requirements

Warning: A buffer zone must be set up and ASTM Class 0

!

electrical insulating rubber gloves with leather protectors

are required prior to working on any high voltage. Failure to

follow these instructions may result in severe personal

injury or death.

The buffer zone is required only when working on the

high-voltage DC or AC systems and is called out both in the

“High-Voltage Service Shutdown Procedure” on page 5 and

the individual repair procedures:

• Position the vehicle in the service bay.

• Position 4 orange cones around the corners of

the

vehicle to mark off a 1m (3 ft.) perimeter

around the vehicle.

• Do not allow any unauthorized personnel into

the

buffer zone during repairs involving high

voltage. Only personnel trained for service on

the

high-voltage system are permitted in the

buffer

zone.

3

© 2015 Eaton. All rights reserved

2015.10.20

Page 9

High-Voltage Service Shutdown and Power-Up Procedure | General Information TRTS2000

WARNING

To reduce risk of possible serious

injury (Shock, Burn or Death):

Components marked with High

Voltage should be avoided.

Service must be performed by

qualified personnel only.

HAZARDOUS VOLTAGE

DANGER

HAZARDOUS VOLTAGE

You will be severely injured or killed

if you do not follow the procedure.

Components marked with

DANGER High Voltage should be

avoided. Service must be

performed by qualified personnel only.

High-Voltage Service Shutdown and Power-Up Procedure

A buffer zone must be set up and ASTM Class 0 electrical

insulating rubber gloves with leather protectors are

required prior to working on high-voltage. Failure to follow

these instructions may result in severe personal injury

or

death.

The rubber-insulated gloves that must be worn while

working on the high-voltage system are class 0 with leather

protectors. The rubber gloves should be tested before use

following the rubber insulation gloves testing procedure

(see

“Insulated Rubber Glove Test” on page 3). Failure to

follow these instructions may result in severe personal

injury or

death.

Before inspecting or working on any high-voltage cables or

components the

“High-Voltage Service Shutdown

Procedure” on page 5 should be followed. Failure to follow

these instructions may result in severe personal injury or

death.

The lockout and T ag-out devices should only be removed by

the technician that placed the Lockout Tag-out devices on

the vehicle. Failure to follow these instructions may result in

severe personal injury or death.

ASTM Class 0 electrical insulating rubber gloves with

leather protectors must be worn when working on any highvoltage cables. The

“High-Voltage Service Shutdown

Procedure” on page 5 must be followed prior to removing

any high-voltage cables. Failure to follow these instructions

may result in severe personal injury or death.

High-voltage cables and wiring are orange and contain a

warning label at the connectors. High-voltage components

are marked with a label. ASTM Class 0 electrical insulating

rubber gloves with leather protectors must be used when

working on any of these components. Failure to follow

these instructions may result in severe personal injury

or

death.

4

© 2015 Eaton. All rights reserved

2015.10.20

Page 10

High-Voltage Service Shutdown and Power-Up Procedure | General Information TRTS2000

High-Voltage Service Shutdown

Procedure

1. Follow “High-Voltage Work Area” procedure (see

“High-Voltage Work Area Requirements” on

page 3).

2. Locate the red Power Electric Carrier (PEC)

service

switch on the front of the PEC and push

to

the Off position.

3. Remove the service switch cover and install the

Lockout Bracket (J48506).

4. Fasten tag to the Lockout Bracket.

5. Ensure the PEC service switch cannot move from

the Off position.

6. Allow the system to set for a minimum of

5

minutes to discharge high-voltage.

7. Connect ServiceRanger and view the Data Monitor

PID 116 “High-Voltage Battery Potential.” Use SPN

520323 for J1939 connection “Battery Voltage RB”

(Relay Box).

8. The voltage should be 30 volts or less. If

the

voltage is above 30 volts, do not work

on

the vehicle and contact Eaton® at

1-800-826-HELP

9. Turn ignition key off and proceed to repair or

troubleshooting step.

Note: The voltage drops to 0 when the key is

turned

off.

(4357).

High-Voltage Service Power-Up

Procedure

1. Install all high-voltage connectors back into their

locked positions.

2. Remove the Lockout Bracket and tag ONLY IF

YOU

ARE THE PERSON WHO IS WORKING ON

THE

VEHICLE.

3. Reinstall the protection bracket over the

service

switch.

4. Pull the service switch out and let vehicle set for

2

minutes.

5. Start vehicle when appropriate.

5

© 2015 Eaton. All rights reserved

2015.10.20

Page 11

Diagnostic Tools and Service Publications | General Information TRTS2000

Diagnostic Tools and Ser vice Publications

Eaton Tools

• Visit Roadranger.com

Tool Description

ServiceRanger version 3 ServiceRanger PC-based Diagnostic Tool

ServiceRanger version 4 ServiceRanger PC-based Diagnostic Tool

SPX/OTC Tools

• Contact SPX / OTC at (800) 328-6657

Tool Description

J49818 Eaton Hybrid Tool Safety Kit - Basic PPE (Items listed below can be ordered separately)

J48603 ASTM Class 0 electrical insulating rubber gloves with leather protectors (1000 volt)

J48605 Hybrid Safety Cones (set of 4)

J48506 Lockout Switch Plate

J48906 Lockout Tags (per 25)

Tool Description

J49819 Eaton Hybrid Tool Safety Kit - Basic Plus PPE (Items listed below can be ordered separately)

J48603 ASTM Class 0 electrical insulating rubber gloves with leather protectors (1000 volt)

J48605 Hybrid Safety Cones (set of 4)

J48506 Lockout Switch Plate

J48906 Lockout Tags (per 25)

J48907 Orange Magnetic Sign

J48608 Hybrid Non-Conductive Safety Pole

J48908 Glove Bag

6

© 2015 Eaton. All rights reserved

2015.10.20

Page 12

Diagnostic Tools and Service Publications | General Information TRTS2000

Tool Description

Misc. Service Tools Items listed below are ordered separately

J48624 Nexiq USB-Link Communication Adapter

J43318-A* Pin Adapter Kit - Interface Harness Diagnostics

J48735* Alignment Pins - Hybrid Motor/Gen to Transmission Main Case

AMB-45* Digital Megohmmeter - High-Voltage Leakage Detection

J49111* Clutch Alignment Tool

J46708* Fluke Digital Multimeter

J48505 Input Shaft Turning Socket

J48507 Lifting Fixture - Power Electronics Carrier

J48502 Jack Adapter Plate - Hybrid Drive Unit

5019 Transmission Jack - Low Lift

5078 Transmission Jack - High Lift

J48577 Engine/Transmission Stand Adapter Plate - Hybrid Drive Unit

J29109-A Engine/Transmission Stand - 6000 lb. Rating

Tool Description

J48893 Hybrid PPE/Service Tool Kit (includes J49819 kit and items from Miscellaneous Service Tools

highlighted with *)

Service Publications

1. Visit Roadranger.com

TRSM2000 Service Manual (covers external components on transmission and hybrid components)

TRSM0110 Service Manual (covers internal transmission repairs only)

TRTS2000 Troubleshooting Guide

TRTS2001 Troubleshooting Guide for Alternative PEC and Alternative APG

TRDR1000 Drivers Instructions

TRDR1110 First Responder Guide

CLMT-0365 Eaton 365 mm Clutch Installation Procedure

7

© 2015 Eaton. All rights reserved

2015.10.20

Page 13

Hybrid Diagnostic Procedure | General Information TRTS2000

Key ON

Retrieve Active Faults

with ServiceRanger

Active Codes?

Yes

Go to "Fault Code Isolation Procedure

Index" (page 17)

No

Does Gear Display

Show an "N”?

Does Engine Crank?

No

Yes

No

Yes

If equipped, does

vehicle operate

normal in ePTO mode?

No

Go to "ePTO Test”

(page 187)

Yes

If a mode other than neutral is selected does

transmission engage a gear?

NOTE: Service Brake must be applied

prior to selecting a gear.

No

Yes

Is vehicle acceleration

performance acceptable?

No

Yes

Clear faults and

operate vehicle

based on customers

concern

Inactive Faults = Go

to “Product

Diagnostic Mode (PDM)”

(page 19)

Active Faults = Go to

“Fault Code Isolation

Procedure Index”

(page 17)

No Fault = Test

Complete

Is Red "Stop Hybrid" or

Amber “Check Hybrid”

lamp blinking?

Yes

No

Go to “Hybrid Light and

Gear Display Descriptions”

(page 20)

Go to “Hybrid Light and

Gear Display Descriptions”

(page 20)

Go to “Gear Engagement

Test” (page 183)

Will vehicle move

from a stop?

Yes

No

Note: If ServiceRanger fails

to communicate, go to

“ServiceRanger Test”

(page 178)

Go to “Engine Crank

Test” (page 171)

Go to "Hybrid

Performance Test"

(page 175)

Go to "Gear Engagement Test”

if solid “N” is displayed

(page 183)

Go to “Front Box Test” if

flashing gear number is

displayed (page 167)

Hybrid Diagnostic Procedure

8

© 2015 Eaton. All rights reserved

2015.10.20

Page 14

Hybrid Component and Connector Locations | General Information TRTS2000

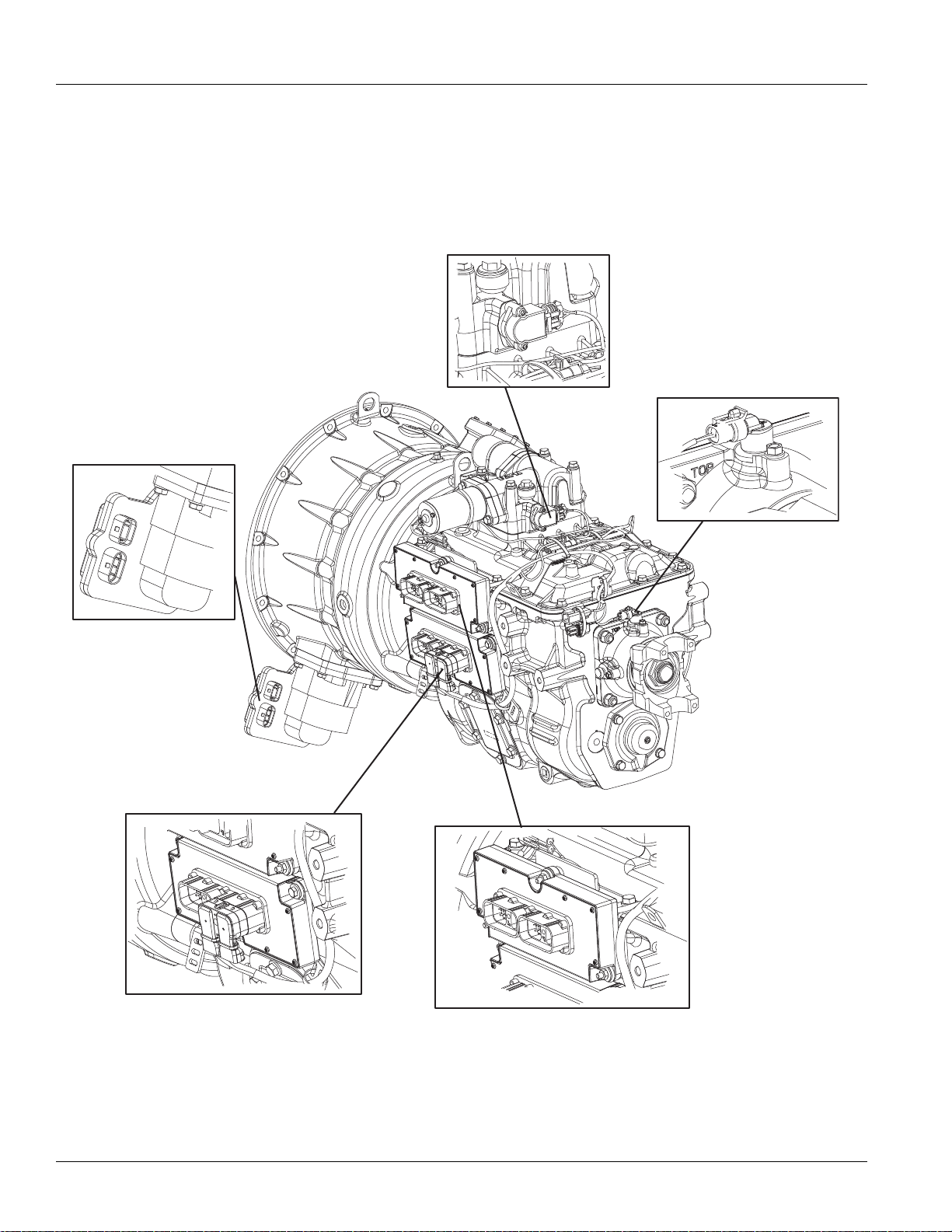

Hybrid Component and Connector Locations

Transmission Wiring Connections

Rail Position Sensor

Output Shaft Speed Sensor

Electronic Clutch Actuator

Top: 3-Way Connector

Bottom: 8-Way Connector

Transmission Electronic Control Unit (TECU)

Left: 38-Way Vehicle Connector

Right: 38-Way System Connector

Hybrid Control Module (HCM)

Left: 38-Way System Connector

Right: 38-Way Vehicle Connector

9

© 2015 Eaton. All rights reserved

2015.10.20

Page 15

TRTS2000 General Information | Hybrid Component and Connector Locations

XY Shifter

High-Voltage 3-Way AC Connector

Motor/Generator

Resolver Connector

Motor/Generator

Temperature Connector

Input Shaft Speed Sensor

Transmission Diagnostic Port

2015.10.20

© 2015 Eaton. All rights reserved

10

Page 16

Hybrid Component and Connector Locations | General Information TRTS2000

12V DC(-)

High Voltage DC Connector

Top: DC(-)

Bottom: (DC(+)

OEM Connection

DC/DC Converter

Coolant Ports

12V DC(+)

(-)

(+)

HIgh Voltage 3-Way AC Connector

Low Voltage 40-Way Connector

High-Voltage DC Connector to PEC

Inverter

Coolant Port Inlet

Coolant Port Outlet

Component Wiring Connections

11

© 2015 Eaton. All rights reserved

2015.10.20

Page 17

TRTS2000 General Information | Hybrid Component and Connector Locations

Red Service Switch with Cover

DC Connector to

DC/DC Converter

DC Connector to

APG (Optional)

Air Exhaust

(not shown)

19-Pin Low-Voltage Connector

Air Intake

Power Electronics Carrier (PEC)

DC Connector

to Inverter

2015.10.20

© 2015 Eaton. All rights reserved

12

Page 18

Fault Code Retrieval and Clearing | General Information TRTS2000

Fault Code Retrieval and Clearing

All Eaton® Hybrid systems require the use of

ServiceRanger for all diagnostics. To view fault codes

or

clear them, follow the procedures below.

View Active and Inactive Faults

1. Connect ServiceRanger to the 9-Way

Diagnostic

2. Go to the Tools menu and select the

“Communication” tab.

3. Select the appropriate communication device for

J1587 and J1939.

4. Select “Connect” on the main page.

5. Select the “View Fault Codes” tab.

Note: Initial use requires all steps; however,

subsequent uses require only steps 4 and 5.

Connector.

Clear Inactive Faults

1. Connect ServiceRanger to the 9-Way

Diagnostic

2. Go to the Tools menu and select the

“Communication” tab.

3. Select the appropriate communication device

for

J1587 and J1939.

4. Select “Connect” on the main page.

5. Select the “View Fault Codes” tab.

6. Select the “Clear Faults” button.

Note: Initial use requires all steps, however

subsequent uses require only steps 4 and 5.

Connector.

13

© 2015 Eaton. All rights reserved

2015.10.20

Page 19

Fault Code Isolation Procedure Index | General Information TRTS2000

Fault Code Isolation Procedure Index

Fault Code SPN FMI Description Page Number

1 520225 0, 6, 15 Motor/Generator Current Sensor page 33

2 520226 3 Motor/Generator Temperature Sensor page 38

3 520227 0 Motor/Generator Temperature page 42

4 520228 0, 2, 21–27 Motor/Generator Rotation Speed Sensor page 48

5 520229 21–29 Motor/Generator AC Cable page 54

6 629 13 No ECU Operation (HCM) page 60

7 629 13 Improper ECU Configuration (HCM) page 63

8 158 4 Loss of Switched Ignition Power Fault (HCM) page 66

9 168 14 Weak Battery Voltage (HCM) page 70

10 168 4 Low Battery Voltage (HCM) page 73

11 629 12 No ECU Operation (TECU) page 76

12 629 13 Improper ECU Configuration (TECU) page 79

14 751 2, 3, 4 Invalid Shifter Range page 82

16 625 2 High Integrity Link (HIL) page 87

17 626 3, 4 Start Enable Relay page 93

18 520200 2, 9 ECA Communication page 98

19 520273 2, 9 CAN ECA Message page 101

22 563 2, 9, 14 J1939 ABS Message (HCM) page 107

24 525 9 J1939 HCM Message (TECU) page 110

26 522 10 Clutch Slip page 114

27 788 7, 14 Clutch Disengagement page 117

32 43 2 Loss of Switched Ignition Power (TECU) page 121

33 168 4 Low Battery Voltage (TECU) page 124

34 168 14 Weak Battery Voltage (TECU) page 127

35 639 2 J1939 Communication Link page 130

36 639 14 J1939 Engine Message (TECU) page 135

37 610 5 Power Supply (TECU) page 138

38 520243 3, 4, 5, 14 Battery Fan Relay page 142

39 520247 3, 4, 5 Heat Exchanger Relay page 148

40 520248 3, 4, 5, 14 Cooling Pump Relay page 153

48 523 2, 9 J1939 Transmission Message (HCM) page 159

49 190 2, 9 J1939 Engine Message (HCM) page 162

50 701 2, 9 J1939 Body Controller Message (HCM) page 165

51 60 2, 3, 4, 10 Rail Position Sensor page 168

52 59 2, 3, 4 Gear Position Sensor page 173

53 520244 12, 14 DC/DC Converter page 178

54 520245 2, 4 DC/DC Converter Ou tput Voltage page 181

14

© 2015 Eaton. All rights reserved

2015.10.20

Page 20

Fault Code Isolation Procedure Index | General Information TRTS2000

Fault Code SPN FMI Description Page Number

56 161 2, 3, 4, 5, 10Input Shaft Speed Sensor page 186

58 191 2, 3, 4, 5 Output Shaft Speed Sensor page 190

59 639 2, 9 J1939 Communication Link (HCM) page 194

60 625 2, 9 CAN Communication Link (HCM) page 199

61 772 5, 6 Rail Select Motor page 203

63 773 5, 6 Gear Select Motor page 215

64 788, 520198,

520199, 524035

0, 12, 13,

21–28

ECA page 227

65 520203 2, 5 ECA Speed Sensor page 231

66 520271 3, 4, 14 ECA Battery Voltage page 235

67 520274 3, 4, 5 ECA Ignition Voltage page 238

68 520231 12, 13, 14 Grade Sensor page 243

70 188, 518, 539, 544 0, 1, 2, 7 Engine Failed to Respond (HCM) page 247

71 520275 7 Failed to Disengage Gear page 250

72 520277 7 Failed to Select Rail page 254

73 520278 7 Failed to Engage Gear page 258

74 93, 190 7 Engine Failed to Respond (TECU) page 262

75* 520276 14 Power Down In Gear page 265

76 520250 3, 4, 16, 18 High-Voltage Battery 1 Potential Voltage page 268

78 520232 6 High-Voltage Battery 1 Current page 271

82 520233 0, 16 High-Voltage Battery 1 Temperature page 274

83 751 12, 13 Invalid Shifter Range page 279

84 751 13 Shift Control Device Not Configured page 284

85 639 12 Shift Control Device Incompatible page 290

88 520223 2, 9 Inverter CAN Message (HCM) page 294

89 520234 2, 9 PEC CAN Message (HCM) page 300

94 520237 9 Transfer Case Message page 308

95 520249 3, 4 12-volt Cranking Relay page 311

97 3460 3, 4, 5, 7, 14PTO Engagement page 316

101 520238 0, 22–31 High-Voltage Battery page 322

103 520265 22–26 Battery Control Unit Communication page 325

105 520240 22–30 Battery Control Unit page 329

107 520242 1 High-Voltage Battery Leak Detection page 332

108 520268 3, 4 Battery Cont rol Unit Power Supply page 342

110 520220 21–29 Inverter page 346

111 520260 12–28 Inverter Communication page 349

112 520221 3, 4 Inverter Voltage page 355

15

© 2015 Eaton. All rights reserved

2015.10.20

Page 21

TRTS2000 General Information | Fault Code Isolation Procedure Index

Fault Code SPN FMI Descriptio n Page Number

113 520222 6, 14 Inverter Current page 359

114 520261 3, 4 Inverter Power Supply page 364

115 520223 0 Inverter Temperature page 368

116 521210, 521211,

3, 4, 5 High-Voltage Relays page 373

521212

116 520224 10, 14, 20 High-Voltage Relays page 373

117 520251 3, 14, 29 PEC Relay Cut Request page 382

118 520252 3, 4, 5 Auxiliary High-Voltage Relay Control Circuit page 386

120 520275 3, 4 APG Unit 1 - AC Voltage page 395

122 520277 6, 14, 15 APG Unit 1 - Output page 398

123 520278 3, 4 APG Unit 1 - High Voltage Battery page 403

125 520280 0 APG Unit 1 - Over Temperature page 406

126 520281 25, 26, 27 APG Unit - Configuration page 409

127 520282 0 APG Unit 1 - Ambient Air Over Temperature page 412

128 520283 9 APG Unit 1 - CAN page 415

165 520320 2 APG Unit 1 -Configuration Error page 419

2015.10.20

© 2015 Eaton. All rights reserved

16

Page 22

Symptom-Driven Diagnostics Index | General Information TRTS2000

Symptom-Driven Diagnostics Index

Symptom Isolation Procedure Page Number

Power-up no crank and gear display shows a dash “-” Front Box Test page 423

Power-up no crank and gear display shows a “N” Engine Crank T est page 428

Power-up no crank and gear display shows double

dash “--”, double stars “**” or blank

Power-up vehicle cranks and gear display shows “--”,

“**” or blank

Vehicle acceleration performance is not acceptable Hybrid Performance Test page 432

Transmission will not engage a gear from neutral and

warning tone sounds (solid N in gear display)

Transmission will not move from a stop (solid gear

number in gear display)

Transmission will not engage a gear from neutral

(flashing gear number in gear display).

Red Service light on the Push Button Shift Control is

on/blinking

Amber “Check Hybrid” light on the dash is on Fault Code Retrieval and Clearing page 13

Red “Stop Hybrid” light on the dash is on Fault Code Retrieval and Clearing page 13

ePTO mode does not operate as expected ePTO Test page 445

Power Up Sequence T est page 21

Refer to OEM for gear display issue N/A

Gear Engagement Test page 441

Gear Engagement Test page 441

Front Box T est page 423

Fault Code Retrieval and Clearing page 13

17

© 2015 Eaton. All rights reserved

2015.10.20

Page 23

Product Diagnostic Mode (PDM) | General Information TRTS2000

Product Diagnostic Mode (PDM)

Product Diagnostic Mode (PDM) is used to help diagnose

Inactive codes that may have been set during normal

driving. This diagnostic mode increases the sensitivity of

the fault sensing capabilities.

This procedure tests loose, degraded and intermittent

connections.

page 14. Use the Index as a guide to the wiring and

connectors that are associated with the Inactive fault codes.

Flex the wiring harness and connectors and attempt to

recreate the fault after activating PDM.

PDM is only to be used by a trained service technician in an

authorized dealer.

To enter PDM mode:

Note: The vehicle will not start in Product Diagnostic Mode

1. Vehicle must be stationary, engine must not be

2. Connect ServiceRanger to the 9-Way

3. Select the “View Fault Codes” screen.

See “Fault Code Isolation Procedure Index” on

(PDM). Turn vehicle key “OFF” and allow the system

to power down to exit PDM.

running, vehicle parking brake must be set.

Diagnostic

Connector.

PDM will only work with the following

Inactive codes

9, 10, 14, 16, 17, 18, 19, 22, 24, 32, 33, 34, 35, 36, 38, 39,

40, 48, 49, 50, 51, 52, 56, 58, 59, 60, 61, 63, 76, 87, 88, 89,

95, 118

4. Perform two key clicks of the ignition switch

starting with the key on, and ending with the

key

on.

Note: An "88" may show up in the dash at key on,

which is a normal power-up test of the display.

5. The gear display will flash a solid “PD” (Product

Diagnostic Mode) and the mode will be activated.

6. Flex the wiring harness and connectors and

attempt to recreate the fault.

7. If a fault becomes Active during PDM,

ServiceRanger will display the fault with a status

of

Active.

8. If a fault is detected, exit PDM mode and perform

the corresponding fault code troubleshooting

procedure.

Index” on page 14.

Note: Active codes set during PDM mode will not be

stored as Inactive.

9. To exit PDM mode, power the system down by

turning the key off.

See “Fault Code Isolation Procedure

18

© 2015 Eaton. All rights reserved

2015.10.20

Page 24

Hybrid Light and Gear Display Descriptions | General Information TRTS2000

Hybrid Light and Gear Display Descriptions

All Eaton® hybrid systems use a combination of 3 lights to

indicate failures of different operating systems and the

ability of the vehicle to drive. These lights include the red

“Service” light, amber “Check Hybrid” light, and the red

“Stop Hybrid” light.

Red “Service” Light

• Light is located on the Push Button Shift Control

and reads “Service”.

• Light is turned on and off by the Transmission

Electronic Control Unit (TECU) for automated

transmissions faults over the High Integrity

Link

(HIL).

• Light also comes on momentarily at key on as part

of the TECU self-test.

Amber “Check Hybrid” Light

• Light is located near the middle of the dash. It is

amber and reads “Check Hybrid.”

• Light is turned on and off indirectly by the Hybrid

Control Module (HCM) and directly by the Body

Controller over J1939.

• Light is turned on when a hybrid system fault

is

Active.

• When the amber light is on, the vehicle can still be

driven; however, the vehicle may operate without

hybrid electric assist.

Red “Stop Hybrid” Light

Blinking Amber “Check Hybrid” Light

The majority of vehicles have a red Stop Switch on the front

of the Power Electric Carrier (PEC). If this switch is pushed

in, the amber “Check Hybrid” light will blink.

• To reset, pull switch out and turn key off for 2

minutes. Continue to the diagnostic test for the

fault that is currently Active.

• If the light remains on, go to “Hybrid Diagnostic

Procedure” on page 8 and start with step 3

“Retrieve Active Faults with ServiceRanger.”

• There should be an Active Fault Code 76 FMI 4, or

Fault Code 116, FMI 10.

“ST” in Gear Display

“ST” in the gear display indicates a driver triggered

Snapshot was recorded. Snapshot is a diagnostic tool

used

to capture specific data from the HCM at the time of

a

fault. Snapshot is only available on models with an Eaton

Push Button Shift Control. It is triggered through two

different means:

• Fault code triggered - Specific faults will trigger the

HCM to capture a Snapshot file for later retrieval.

This method will not display an “ST” in the gear

display.

• Driver triggered - If the driver chooses to capture a

Snapshot of an event he/she needs to decide if

he/she wants TECU or HCM data. To capture a

TECU Snapshot select, “Low” and the up button

twice. To capture a HCM Snapshot select, “Drive”

or “Low” and the up button and down button in the

following order: up, down, up, down.

• Light is located near the middle of the dash. The

light is red and reads “Stop Hybrid”.

• Light is turned on and off indirectly by the HCM and

directly by the Body Controller over J1939.

• Light is turned on when a hybrid system fault

is

Active.

• When the light is on, vehicle should not be driven.

Transport the vehicle to the OEM truck dealership.

19

“PD” in Gear Display

A “PD” in the gear display indicates the TECU and HCM are

in a special diagnostic mode called Product Diagnostic

Mode (PDM). For more details on the mode and its

operation,

page 18.

© 2015 Eaton. All rights reserved

See “Product Diagnostic Mode (PDM)” on

2015.10.20

Page 25

TRTS2000 General Information | Hybrid Light and Gear Display Descriptions

“CA” in Gear Display

“CA” in gear display indicates HCM is detecting a clutch

abuse situation.

• If the HCM detects a clutch abuse situation it will

first tone the Push Button Shift Control and flash a

“CA” in the gear display.

• If the clutch abuse situation continues, the hybrid

system will allow only an electric launch in addition

to continuing the tone and the “CA.”

• If the clutch abuse continues while driving, the

hybrid system will open the clutch when vehicle

speed is below 5mph and allow the clutch to cool.

“OS” in Gear Display

“OS” in the gear display indicates the HCM is detecting a

motor overspeed situation. The vehicle will upshift in Drive

and Low automatically; however , if the vehicle is in manual

mode, close to motor overspeed and the driver fails to

upshift, the vehicle will:

• Display an “OS” indicating the driver needs to

press the service brake pedal to slow the vehicle;

or,

Two Dashes “- -” in Gear Display

Two dashes “- -” in the gear display indicates the gear

display has power, and there is no communication present

on the data link, or the TECU isn’t communicating with the

display.

page 17.

See “Symptom-Driven Diagnostics Index” on

Blank Gear Display

A blank gear display indicates the display has lost power , or

the TECU isn’t communicating with the gear display.

“Symptom-Driven Diagnostics Index” on page 17.

See

• The HCM will either upshift the vehicle or reduce

torque to prevent the motor from going overspeed.

“F” in Gear Display

“F” in the gear display indicates the TECU has detected an

Active fault. This fault can be accessed with ServiceRanger.

See “Fault Code Isolation Procedure Index” on page 14.

Dash “-” in Gear Display

A “-” in the gear display indicates the transmission is stuck

in gear.

page 17.

See “Symptom-Driven Diagnostics Index” on

Stars “**” in Gear Display

T wo stars “**” in the gear display indicates the gear display

has power, but no communication on the data link.

“Symptom-Driven Diagnostics Index” on page 17.

See

2015.10.20

© 2015 Eaton. All rights reserved

20

Page 26

TRTS2000 Electrical Pretest Procedures | Power-Up Sequence Test

Power-Up Sequence Test

Overview

This test must be performed only when experiencing a

“vehicle won’t crank” with a double dash “- -”, double star

“**”, or blank gear display. The Electrical Pretest must be

performed prior to this procedure.

Detection

The power-up self-check is performed automatically at each

key on. Turn key on and watch the “Service” light. If power

up stops with the “Service” light constantly on, or it never

comes on, self-check has failed.

Fallback

There is no fallback for this test and the vehicle will not

crank if the Tr ansmission Electronic Co ntrol Unit (TECU)

or power supply harness has failed.

Possible Causes

This may be caused by any of the following:

• TECU power supply

•TECU

Additional Tools

• Basic hand tools

• Battery load tester

• Eaton® Test Adapter Kit J43318

• Digital volt/ohm meter J46708

2015.10.20

© 2015 Eaton. All rights reserved

21

Page 27

TRTS2000 Electrical Pretest Procedures | Power -Up Sequence Test

Component Identification

See “Wiring Diagrams” on page 453.

2015.10.20

© 2015 Eaton. All rights reserved

22

Page 28

Power-Up Sequence Test | Electrical Pretest Procedures TRTS2000

Power-Up Sequence Test

Purpose: Perform Electrical Pretest

A

1. Perform the “Electrical Pretest” on page 24.

2. Is problem still present after the Electrical Pretest?

• Yes, replace the Transmission Electronic

Control Unit (TECU). Return to the “Hybrid

Diagnostic Procedure” on page 8.

• No, test is complete. Return to the “Hybrid

Diagnostic Procedure” on page 8.

23

© 2015 Eaton. All rights reserved

2015.10.20

Page 29

TRTS2000 Electrical Pretest Procedures | Electrical Pretest

Electrical Pretest

Overview

This test must be performed prior to diagnosing certain

specific hybrid faults. This test verifies the quality of the

standard battery system and the main power and ground

supplies to the Hybrid Control Module (HCM), T ransmission

Electronic Control Unit (TECU), and Electronic Clutch

Actuator (ECA).

Note: This test is called out in the procedures when it

is required.

Detection

The power-up self-check is performed automatically each

time the key is turned on. Turn the key on and watch the

“Service” light. If power-up stops with the “Service” light

constantly on, or it never comes on, self-check has failed.

Fallback

A weak power supply can cause many issues such as shift

performance, power-up or failure to crank.

Possible Causes

Low-voltage can be caused by the following:

• Low batteries

• Charging system

• Power harness connections or fuses to TECU, HCM

or ECA

Additional Tools

• Basic hand tools

• Battery load tester

• Eaton® Test Adapter kit J43318

• Digital volt/ohm meter J46708

• ServiceRanger

2015.10.20

© 2015 Eaton. All rights reserved

24

Page 30

Electrical Pretest | Electrical Pretest Procedures TRTS2000

A

B

C

ECA - 3-Way Connector

H

Battery

38

Plus (+)

B

HCM

HCM Power (Vehicle)

36

ECA

ECA Power

C

ECA Ground

Neg (-)

Clutch Ignition (System)

Front View

(HCM - Vehicle Interface Connector)

37

38

35

36

1

6

7

12

13

22

23

28

29

34

ECA -Pack 8-Way Connector

E

A

B

C

D

H

G

F

NOTE: Refer to the Eaton Hybrid Component and Connector Location page for connector locations

HCM Ground (Vehicle)

TECU

TECU Ground

36

35

38

TECU Ignition

TECU Power

13

Front View

(TECU - Vehicle Interface Connector)

37

38

35

36

1

6

12

13

22

23

28

29

34

7

35

HCM Ignition (Vehicle)

Ignition Relay

87

Component Identification

25

© 2015 Eaton. All rights reserved

2015.10.20

Page 31

TRTS2000 Electrical Pretest Procedures | Electrical Pretest

Electrical Pretest

Purpose: Verify chassis battery voltage.

A

1. Key off.

2. Inspect starter, battery and in line fuse holder

connections on Electric Clutch Actuator (ECA),

Hybrid Control Module (HCM), and Transmission

Electronic Control Unit (TECU) for integrity.

Note: ECA, HCM and TECU use a 30-amp fuse.

Refer to OEM for locations.

3. Measure voltage across batteries.

• If voltage is between 11–13 volts on a 12-volt

system, proceed with battery load test. Repair

or replace batteries as required, go to Step B.

• If voltage is outside of range, repair or replace

batteries and charging system as required.

Repeat this step.

Connection Measurement

Starter Battery to ECA

Starter Battery to HCM

Starter Battery to TECU

Purpose: Verify ECA battery voltage and ignition

B

status.

1. Key on.

2. Connect ServiceRanger to 9-Way Diagnostic

Connector in the cab.

3. Select the “Data Monitor” option and view the

following parameters under the hybrid (clutch

actuator) list:

- PID 132 “Clutch Actuator Battery Voltage.”

- PID 160 “Clutch Actuator Ignition Switch Status.”

Note: If the clutch parameters can not be viewed on

ServiceRanger you must check the power

supply to the ECA with a voltmeter.

• If PID 132 is within 0.6 volts of battery voltage

and PID 160 reads "1", go to Step C.

• If either voltage is out of range, repair main

power or ignition supply to the ECA. Repeat

this step.

Parameter Reading

PID 132 Clutch Actuator

Battery Voltage

PID 160 Clutch Actuator

Ignition Switch Status

2015.10.20

© 2015 Eaton. All rights reserved

26

Page 32

Electrical Pretest | Electrical Pretest Procedures TRTS2000

Purpose: Verify HCM battery voltage and ignition

C

status.

1. Select the “Data Monitor” option and view the

following parameters under the Hybrid Control

Module list:

- PID 165 Battery Potential Voltage

- PID 166 Ignition Switch Status

Note: If the Battery Potential Voltage or Ignition

Switch Status can not be viewed on

ServiceRanger, you must check the power

supply to the HCM with a voltmeter.

• If PID 165 is within 0.6 volts of battery voltage

and PID 166 reads "1", go to Step D.

• If either voltage is out of range, repair the main

power or ignition supply to the HCM. Repeat

this step.

Parameter Reading

PID 165 Battery Potential

Voltage

PID 166 Ignition Switch

Status

Purpose: Verify TECU battery and switched

D

voltage.

1. Select the “Data Monitor” option and view the

following parameters under the hybrid

Transmission list:

- PID 168 Battery Potential Voltage.

- PID 158 Battery Potential Voltage Switched.

Note: If the Battery Potential Voltage or

Battery Potential Voltage Switched can

not be viewed on ServiceRanger, you must

check the power supply to the TECU with

a voltmeter.

• If PID 168 is within 0.6 volts of battery voltage

and PID 158 is within 0.6 volts of ignition

voltage, test is complete. Return to the fault

or symptom procedure that directed you to

this step.

• If either voltage is out of range, repair main

power or ignition supply to the TECU. Repeat

this step.

Parameter Reading

PID 168 Battery Potential

Voltage

PID 158 Battery Potential

Voltage Switched

27

© 2015 Eaton. All rights reserved

2015.10.20

Page 33

TRTS2000 Electrical Pretest Procedures | Hybrid Electrical Pretest

Hybrid Electrical Pretest

Overview

This test must be performed prior to diagnosing certain

specific Hybrid faults. This test verifies the power supply for

the Inverter and the Power Electric Carrier (PEC).

Note: You must perform the Electrical Pretest before

performing the Hybrid Electrical Pretest.

Note: This test is called out in the procedures where it

is required.

Detection

The power-up self-check is performed automatically each

time the key is turned on. Turn the key on and watch the

“Service” light. If power-up stops with the “Service” light

constantly on, or it never comes on, self-check has failed.

Fallback

Loss of ignition power causes the hybrid system to be

inoperable. In this situation, the vehicle will run under diesel

power only.

Possible Causes

Low-voltage can be caused by power harness connections

from Inverter or PEC.

Additional Tools

• Basic hand tools

• ASTM Class 0 electrical insulating rubber gloves

with leather protectors J48603

• Lockout bracket J48506

• Lockout tags

• Battery load tester

• Eaton Test Adapter kit J43318

• Digital volt/ohm meter J46708

• ServiceRanger

2015.10.20

© 2015 Eaton. All rights reserved

28

Page 34

Hybrid Electrical Pretest | Electrical Pretest Procedures TRTS2000

Component Identification

Deutsch 19 - Way Mating Connector View

(PEC - Low Voltage Connector)

8

7

5

123

4

14

9

10

11

12

13

17

19

18

6

16

15

10

20

30

Deutsch 40-Way Mating Connector View

(Inverter - Low Voltage Connector)

1

11

40

Inverter

Chassis Ground 1

Chassis Ground 2

Inverter Enable

Relay Box Enable

Relay Box Enable 2

GND_BC

GND-BC2

6

7

1

14

24

15

25

21

31

PEC

HCM

(Pin 2)

6

7

NOTE: Refer to the Eaton Hybrid Component and Connector Location page for Connector Locations

DC/DC

Converter

DC/DC Converter

4-Way OEM Connector

29

4

Ground

© 2015 Eaton. All rights reserved

3

4

1

2

2015.10.20

Page 35

TRTS2000 Electrical Pretest Procedures | Hybrid Elec trical Pretest

!

Hybrid Electrical Pretest

Purpose: Verify Inverter ground continuity.

A

1. Perform the Electrical Pretest, then continue to

Step 2.

2. Key off.

3. Disconnect the Inverter 40-Way Connector.

Danger: See “High-Voltage Service Shutdown and

Power-Up Procedure” on page 4. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage.

4. Measure resistance from Pin 6 to battery negative

and then from Pin 7 to battery negative:

• If resistance is 0–0.3 ohms from Pin 6 to

battery negative and from Pin 7 to battery

negative, go to Step B.

• If resistance is outside of range, repair the

Inverter Ground Harness. Repeat this step.

Connection Measurement

Purpose: Verify voltage at Inverter 40-Way

B

Connector.

1. Connect a volt/ohm meter to the Inverter 40-Way

Connector Pin 1 and Pin 6.

2. Key on.

3. Observe Volt/Ohm Meter voltage reading:

• If voltage is 11–13 volts, go to Step C.

• If voltage is outside of range, repair the

harness from the HCM. Repeat this step.

Connection Measurement

Pin 1 to Pin 6

Pin 6 to Battery Negative

Pin 7 to Battery Negative

2015.10.20

© 2015 Eaton. All rights reserved

30

Page 36

Hybrid Electrical Pretest | Electrical Pretest Procedures TRTS2000

Purpose: Verify continuity of Inverter to PEC

C

ground wire.

1. Key off.

2. Reconnect the Inverter 40-Way Connector.

3. Disconnect the Power Electric Carrier (PEC)

19-Way Connector.

4. Measure resistance from PEC Pin 7 to

battery negative.

• If resistance from Pin 7 to battery negative

is 0–0.3 ohms, go to Step D.

• If resistance is outside of range, repair the

Inverter to PEC ground wire. Repeat this step.

Connection Measurement

Pin 7 to Battery Negative

Purpose: Verify voltage at PEC 19-Way Connector.

D

1. Connect a volt/ohm to the PEC 19-Way Connector

Pin 6 and Pin 7.

2. Key on.

3. Observe volt/ohm voltage reading.

• If voltage is 11–13 volts and vehicle has ePTO

feature on Push Button, go to Step E.

• If voltage is 11–13 volts and vehicle does not

have ePTO feature, test is complete.

Reconnect PEC 19-Way Connector. Go to

“Fault Code Isolation Procedure Index” on

page 14.

• If voltage is outside of range, repair the

power supply harness from the Inverter.

Repeat this step.

Connection Measurement

Pin 6 to Pin 7

31

© 2015 Eaton. All rights reserved

2015.10.20

Page 37

TRTS2000 Electrical Pretest Procedures | Hybrid Elec trical Pretest

Purpose: Verify continuity of DC/DC Ground Wire.

E

1. Key off.

2. Reconnect PEC 19-Way Connector.

3. Disconnect DC/DC Converter 4-Way Connector.

4. Measure resistance from DC/DC Converter 4-Way

Connector Pin 4 to battery negative:

• If resistance between Pin 4 and battery

negative is 0–0.3 ohms.

• Test is complete. Reconnect the 4-Way

Connector. Go to “Fault Code Isolation

Procedure Index” on page 14.

• If resistance is outside of range, repair the

Ground Harness from the DC/DC Converter to

battery negative. Repeat this step.

Connection Measurement

Pin 4 to Battery Negative

2015.10.20

© 2015 Eaton. All rights reserved

32

Page 38

TRTS2000 Fault Isolation Procedures | Fault Code 1 - Motor/Generator Current Sensor

Fault Code 1 - Motor/Generator Current Sensor

J1939 SA 239 SPN 520225 FMI 0, 6, 15

Overview

The high-voltage motor/generator assembly is connected

to the Inverter Assembly through an AC high-voltage cable

that contains 3 separate cables. During operation, the

Inverter monitors the amperage in the AC cables through

a current sensor, mounted in side the Inverter. This

Inductive Sensor produces an output based on amperage

present in the cables.

Detection

Fault is detected when the Inverter ignition voltage is

greater than 7 volts and less than 16 volts.

Conditions to Set Fault Code Active

The following conditions may set the fault Active:

FMI 6 is set when Inverter detects current input from the

motor/generator greater than 100 amps for 150 MS.

FMI 0 is set when the Inverter detects current input from

the motor/generator greater than 200 amps for 0.3 MS.

FMI 15 is set when the sensor offset is out of range at

initial check.

Fallback

When Fault Code 1 is set, the following conditions occur:

• Amber “Check Hybrid” light illuminates.

• Fault is stored in Hybrid Control Module (HCM)

memory.

• Electric motor/generator assist and regeneration

are disabled; however, the high-voltage relays

remain powered.

• HCM continues to control the hybrid vehicle in a

diesel-only mode.

• Transmission defaults start gear to 1st.

Possible Causes

This fault code can be caused by any of the following:

• FMI 0, 6

- Inverter

- Motor/Generator

-AC Cable

• FMI 15

- Inverter

2015.10.20

© 2015 Eaton. All rights reserved

33

Page 39

TRTS2000 Fault Isolation Procedures | Fault Code 1 - Motor/Generator Current Sensor

Component Identification

High-Voltage AC Harness Connector View

(Amphenol Connector)

C

ED

A

F

B

High-Voltage AC Motor/Gen Connector View

(Amphenol Connector)

F

A

D

C

B

E

NOTE: Refer to the Eaton Hybrid Component and Connector Location page for Connector Locations

Inverter Motor/

Generator

Phase 3

Phase 2

Phase 1

C

B

A

Note: Refer to “Hybrid Component and Connector Locations” on page 9 for connector locations.

Phase 3

C

B

Phase 2

Phase 1

A

2015.10.20

© 2015 Eaton. All rights reserved

34

Page 40

Fault Code 1 - Motor/Generator Current Sensor | Fault Isolation Procedures TRTS2000

!

Fault Code 1 - Motor/Generator Current Sensor

Purpose: Check for fault code status and continuity

A

of high-voltage circuitry.

1. Review and follow the “Warnings & Cautions” on

page 1.

2. Retrieve Active fault codes and FMIs with ServiceRanger using the 9-Way Diagnostic Connector.

Verify Fault Code 1 is Active.

3. Key off.

Danger: See “High-Voltage Service Shutdown and

Power-Up Procedure” on page 4. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage.

4. Remove the AC cable from the motor/generator

and Inverter.

5. Measure resistance of each circuit in the

AC high-voltage cable; A-A, B-B, C-C:

• If resistance for each circuit is less than

1 ohm, go to Step B.

• If resistance is outside of range, replace the

AC high-voltage cable and go to Step V.

Purpose: Verify continuity of high-voltage circuitry

B

to ground.

1. Measure resistance of each circuit to ground in the

AC high-voltage cable.

• If resistance between each circuit and ground

is 5M ohms or greater, go to Step C.

• If resistance is outside of range, replace the

AC high-voltage cable, then go to Step V.

Connection Measurement

Pin A to ground

Pin B to ground

Pin C to ground

• If FMI 15 is Active, replace the Inverter . See the

MY09 Inverter Removal and Installation

procedure in TRSM2000, go to Step V.

Connection Measurement

Pin A to Pin A

Pin B to Pin B

Pin C to Pin C

35

© 2015 Eaton. All rights reserved

2015.10.20

Page 41

TRTS2000 Fault Isolation Procedures | Fault Code 1 - Motor/Generator Current Sensor

Purpose: Verify continuity of high-voltage circuitry.

C

1. Key off.

2. Measure the resistance between the following

AC High-Voltage Cable Pins: A-A, B-B, C-C:

• If resistance of each phase is 5M or greater,

go to Step D.

• If resistance is outside of range, replace the

AC high-voltage cable, then go to Step V.

Connection Measurement

Pin A to Pin A

Pin B to Pin B

Pin C to Pin C

Purpose: Verify continuity of Motor/Generator

D

phases.

1. Measure resistance of each motor/generator

phase at the following pins: A-A, B-B, C-C:

• If resistance of each phase is less than

10 ohms, replace the Inverter. See the MY09

Inverter Removal and Installation procedure

in TRSM2000, go to Step V.

• If resistance is outside of range, replace the

motor/generator. See the MY09

Motor/Generator Removal and Installation

procedure in TRSM2000, go to Step V.

Connection Measurement

Pin A to Pin A

Pin B to Pin B

Pin C to Pin C

2015.10.20

© 2015 Eaton. All rights reserved

36

Page 42

Fault Code 1 - Motor/Generator Current Sensor | Fault Isolation Procedures TRTS2000

Purpose: Verify repair.

V

1. Key off.

2. Reconnect all connectors and the negative

battery cable.

3. Key on.

4. Clear codes. See “Fault Code Retrieval and

Clearing” on page 13.

5. Drive the vehicle and attempt to recreate the code.

6. Check for codes. See “Fault Code Retrieval and

Clearing” on page 13.

• If no codes, test is complete.

• If Fault Code 1 appears, find error in testing,

go to Step A.

• If a code other than 1 appears, go to “Fault

Code Isolation Procedure Index” on page 14.

37

© 2015 Eaton. All rights reserved

2015.10.20

Page 43

TRTS2000 Fault Isolation Procedures | Fault Code 2 - Motor/Generator Temperature Sensor

Fault Code 2 - Motor/Generator Temperature Sensor

J1939 SA 239 SPN 520226 FMI 3

Overview

The Motor/Generator Temperature Sensor is a thermistor

located inside the motor/generator. The Temperature

Sensor resistance varies based on the temperature of

the motor/generator. The Inverter supplies a 5 volt

reference voltage to the sensor and measures any volt

drop in the circuit.

When the motor/generator temperature is warm the sensor

resistance is low and the Inverter detects low voltage (0.2

volts equals 536 °F [280 °C]). When the motor/generator is

cold the sensor resistance is high and the Inverter detects

high voltage (4.1 volts equals 32 °F [0 °C]).

Detection

Fault is detected when the Inverter ignition voltage is

greater than 7 volts and less than 16 volts.

Conditions to Set Fault Code Active

The following conditions may set the fault Active:

FMI 3 is set when the sensor voltage is greater than

4.1 volts for 10 seconds, while the Inverter temperature

is over 95 °F (35 °C) or if the sensor output voltage is

less than 0.2 volts for 10 seconds.

Possible Causes

This fault code can be caused by any of the following:

•FMI 3

- Motor/generator

- Short/open Temperature Sensor wires between

the motor/generator and the Inverter

- Inverter

Fallback

When Fault Code 2 is set, the following conditions occur:

• Amber “Check Hybrid” light illuminates

• Fault is stored in Hybrid Control Module (HCM)

memory

• High-voltage motor/generator assist is available,

but at a reduced amount

2015.10.20

© 2015 Eaton. All rights reserved

38

Page 44

Fault Code 2 - Motor/Generator Temperature Sensor | Fault Isolation Procedures TRTS2000

36

37

2

1

Inverter

Motor/Generator

Temperature Sensor

TM Ground

TM

Temp Sensor

Temp Sensor

NOTE: Refer to the Eaton Hybrid Component and Connector Location page for Connector Locations

10

20

30

40

1

11

21

31

Deutsch 40-Way Mating Connector View

(Inverter - Low Voltage Connector)

Terminal Side - Harness Connector

Temperature Sensor

(Deutsch 2-pin connector)

Component Identification

Note: Refer to “Hybrid Component and Connector Loca-

tions” on page 9 for connector locations.

39

© 2015 Eaton. All rights reserved

2015.10.20

Page 45

TRTS2000 Fault Isolation Procedures | Fault Code 2 - Motor/Generator Temperature Sensor

!

Fault Code 2 - Motor/Generator Temperature Sensor

Purpose: Check for fault code status and continuity

A

of Motor/Generator Temperature Sensor circuit.

1. Review and follow the “Warnings & Cautions” on

page 1.

2. Retrieve Active fault codes and FMIs with ServiceRanger using the 9-Way Diagnostic Connector.

Verify Fault Code 2 is Active.

3. Key off.

Danger: See “High-Voltage Service Shutdown and

Power-Up Procedure” on page 4. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage.

4. Disconnect the Temperature Sensor Connector at

the motor/generator.

5. Measure resistance at the motor/generator 2-Way

Temperature Sensor Connector from Pin 1 to Pin 2:

• If resistance is 0.8K ohms–301.7K ohms,

go to Step B.

• If resistance is outside of range, replace the

Motor/Generator. See the MY09

Motor/Generator Removal and Installation

procedure in TRSM2000, go to Step V.

Purpose: Verify continuity of Inverter and

B

Motor/Generator Temperature Sensor circuit.

1. Key off.

2. Disconnect the Inverter 40-Way Connector.

3. Reconnect the motor/generator2-Way T emperature

Sensor Connector.

4. Measure resistance at the following; Inverter

40-Way Connector Pin 37 to Pin 36, Inverter

40-Way Connector Pin 37 to ground:

• If resistance is 0.8K–301.7K ohms between

Pin 37 and Pin 36 and resistance between Pin

37 and ground is 10K ohms or greater, replace

the Inverter. See the MY09 Inverter Removal

and Installation procedure in TRSM2000, go

to Step V.

• If resistance is outside of range, repair the

open or short to ground in the harness

between the Inverter 40-Way Connector and

the motor/generator 2-Way Connector, then

go to Step V.

Connection Measurement

Connection Measurement

Pin 1 to Pin 2

Pin 36 to Pin 37

Pin 37 to ground

2015.10.20

© 2015 Eaton. All rights reserved

40

Page 46

Fault Code 2 - Motor/Generator Temperature Sensor | Fault Isolation Procedures TRTS2000

Purpose: Verify repair.

V

1. Key off.

2. Reconnect all connectors and the negative

battery cable.

3. Key on.

4. Clear codes. See “Fault Code Retrieval and

Clearing” on page 13.

5. Drive the vehicle and attempt to recreate the code.

6. Check for codes. See “Fault Code Retrieval and

Clearing” on page 13.

• If no codes, test is complete.

• If Fault Code 2 appears, find error in testing.

Restart troubleshooting, then go to Step A.

• If a code other than 2 appears, go to “Fault

Code Isolation Procedure Index” on page 14.

41

© 2015 Eaton. All rights reserved

2015.10.20

Page 47

TRTS2000 Fault Isolation Procedures | Fault Code 3 - Motor/Generator Temperature

Fault Code 3 - Motor/Generator Temperature

J1939 SA 239 SPN 520227 FMI 0

Overview

The Motor/Generator temperature is measured through a

thermistor sensor, which is located internal to the unit. The

sensor changes value based on the temperature. The

Inverter supplies a 5-volt reference voltage to the sensor

and measures the volt drop in the circuit.

When the motor/generator temperature is warm the sensor

resistance is low and the Inverter detects a low-voltage (0.2

volts equals 536 °F [280 °C]). When the motor/generator is

cold, the sensor resistance is high and the Inverter detects

a high-voltage (4.1 volts equals 32 °F [0 °C]).

Detection

Fault is detected when Inverter ignition voltage is greater

than 7 volts and less than 16 volts.

Conditions to Set Fault Code Active

The following conditions may set the fault Active:

FMI 0 is set when the temperature sensor value is greater

than 365 °F (185 °C) for 1 second.

Fallback

When Fault Code 3 is set, the following conditions occur:

• Amber “Check Hybrid” light illuminates.

• Fault is stored in Hybrid Control Module

(HCM) memory.

• Electric motor/generator assist and regeneration

are disabled; however, the high-voltage relays

remain powered.

• HCM continues to control the hybrid vehicle in a

diesel only mode.

• Transmission defaults start gear to 1st.

Possible Causes

This fault code can be caused by any of the following:

•FMI 0

- Motor/generator

- Inverter

- Liquid cooling system (e.g. low coolant,

no coolant flow, coolant pump, radiator,

radiator fan, reservoir)

2015.10.20

© 2015 Eaton. All rights reserved

42

Page 48

Fault Code 3 - Motor/Generator Temperature | Fault Isolation Procedures TRTS2000

36

37

2

1

Inverter

Motor/Generator

Temperature Sensor

TM Ground

TM

Temp Sensor

Temp Sensor

NOTE: Refer to the Eaton Hybrid Component and Connector Location page for Connector Locations

10

20

30

40

1

11

21

31