Page 1

Troubleshooting Guide

Fuller Automated Transmissions

TRTS0050 EN-US

November 2015

RTAO-11710B-AC

RTAO-11710C-AC

RTAO-12710B-AC

RTAO-12710C-AC

RTAO-13710B-AC

RTAO-13710C-AC

RTAO-14710B-AC

RTAO-14710B-AS

RTAO-14710C-AC

RTAO-14710C-AS

RTAO-15710B-AC

RTAO-15710C-AC

RTAO-16710B-AC

RTAO-16710B-AS

RTAO-16710C-AC

RTAO-16710C-AS

RTLO-14918B-AS

RTLO-16918B-AS

RTLO-18918B-AS

RTLO-20918B-AS

Page 2

Warnings and Cautions

WARNING

CAUTION

WARNING

CAUTION

Warnings and Cautions

Follow the specified procedures in the indicated order to avoid personal injury.

Follow the specified procedures in the indicated order to avoid equipment malfunction or damage.

Note: Additional relevant information not covered in the service procedure.

Before starting a vehicle:

1. Sit in the driver's seat

2. Place shift lever in neutral

3. Set the parking brake

Before working on a vehicle or leaving the cab with engine running:

4. Place shift lever in neutral

5. Set the parking brake

6. Block the wheels

When parking the vehicle or leaving the cab:

7. Place shift lever in neutral

8. Set the parking brake

Do not release the parking brake or attempt to select a gear until the air pressure is at the correct level.

To avoid damage to the transmission during towing:

9. Place shift lever in neutral

10. Lift the drive wheels off of the ground or disconnect the driveling

Do not operate vehicle if alternator lamp is lit or if gauges indicate low voltage.

Page 3

Warnings and Cautions

Service Procedure

2-1

Page 4

Table of Contents

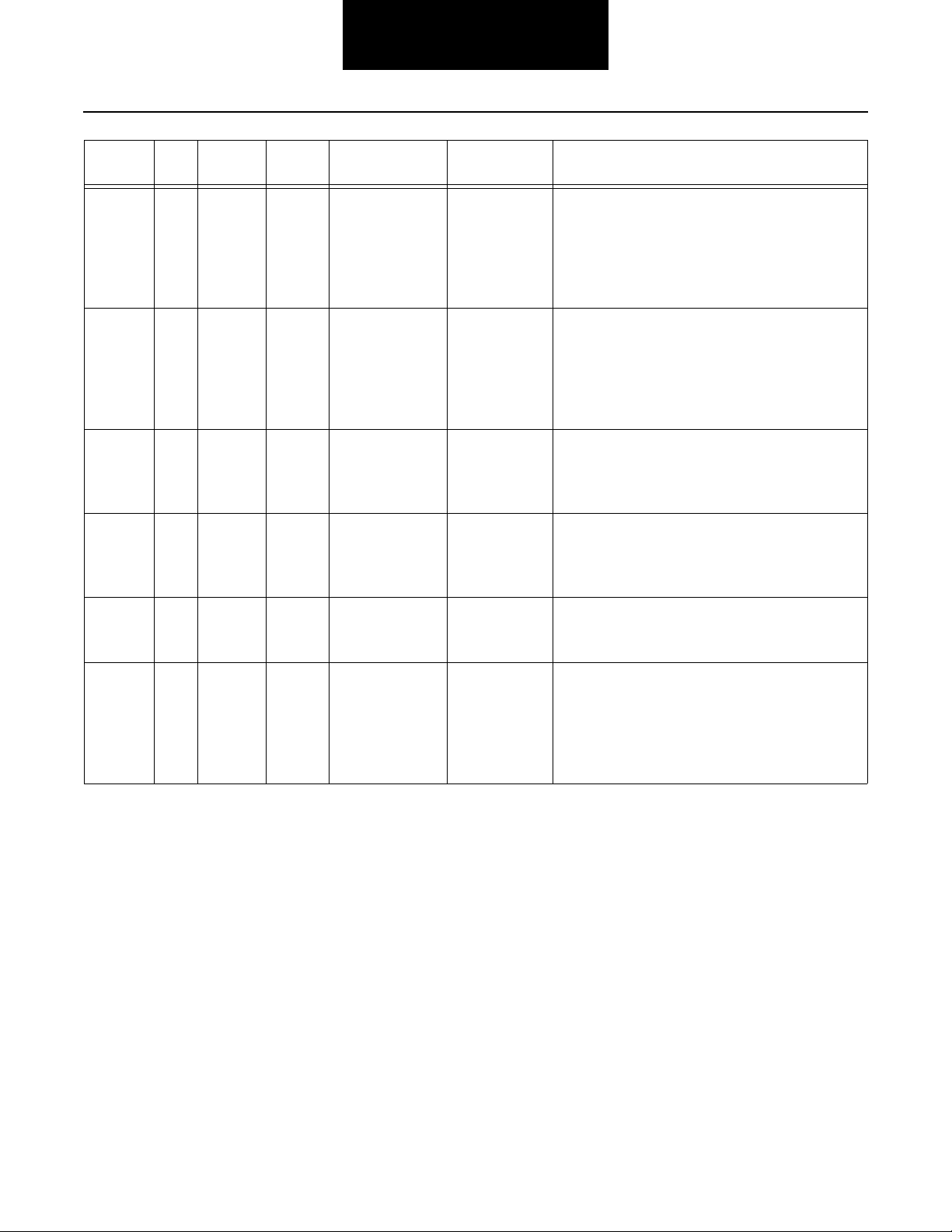

Section 1: General Information

Suggested Tools ................................ ......................1-1

Transmission Models Included ................................1-2

Diagnostic Procedure ...............................................1-3

Fault Code Retrieval/Clearing ...................................1-4

Driving Techniques ..................................................1-6

Fault Code Isolation Procedure Index .....................1-10

Symptom Driven Diagnostics Index .......................1-11

Section 2: Fault Isolation Procedures

Electrical System Pretest ..........................................2-1

Power-Up Sequence Pretest ....................................2-3

Air Pretest ................................................................2-9

Component Code: 11 (SID 254, FMI 2,12)

System Manager .............................................2-13

Code 11 (SID 254, FMI 2,12),

System Controller Test ...................................2-14

Component Code: 12 (SID 233, FMI 12)

Transmission ECU ..........................................2-15

Code 12 (SID 233, FMI 12),Transmission

ECU Test ...... ...................................................2-16

Component Code: 13 (SID 236, FMI 4,5)

Power Connect Relay Coil ............................... 2-17

Code 13 (SID 236, FMI 4,5),

Power Connect Relay Coil Test .......................2-18

Component Code: 14 (SID 18, FMI 12)

Shift Lever ......................................................2-21

Code 14 (SID 18, FMI 12), Shift Lever Test ............2-22

Component Code: 15 (SID 57, FMI 2)

Shift Lever Data Link .......................................2-25

Code 15 (SID 57, FMI 2),

Shift Lever Data Link Test ...............................2-26

Component Code: 16 (SID 248, FMI 2)

Eaton Proprietary Link (EPL) ..........................2-31

Code 16 (SID 248, FMI 2),

Eaton Proprietary Link (EPL) Test ...................2-32

Component Code: 17 (SID 237, FMI 4)

Start Enable Relay Coil ....................................2-43

Code 17(SID 237,FMI 4),

Start Enable Relay Coil Test ............................2-44

Component Code: 31 (PID 62, FMI 3,4)

Engine Brake Relay Coil ..................................2-47

Code 31 (PID 62, FMI 3,4),

Engine Brake Relay Coil Test ...........................2-48

Component Code: 33 (PID 168, FMI 4)

Battery Voltage Supply ....................................2-51

Code 33 (PID 168, FMI 4),

Battery Voltage Supply Test ...........................2-52

System Code: 35 (SID 231, FMI 2,7)

Engine Control Failure ....................................2-55

Code 35 (SID 231, FMI 2,7),

Engine Control Failure Test .............................2-56

System Code: 41 (SID 56, FMI 7)

Range Failed to Engage ..................................2-63

Code 41 (SID 56, FMI 7)

, Range Failed to Engage Test .........................2-64

System Code: 42 (SID 61, FMI 7)

Splitter Failed to Engage ................................. 2-67

Code 42 (SID 6,1, FMI 7),

Splitter Failed to Engage Test .........................2-68

Component Code: 43 (SID 35,36, FMI 3,4,5)

Range Solenoid Valve .....................................2-71

Code 43 (SID 35,36, FMI 3,4,5),

Range Solenoid Valve Test .............................2-72

Component Code: 44 (PID 54, FMI 3,4,5)

In

ertia Brake Solenoid Coil ............................. 2-77

Code 44 (PID 54, FMI 3,4,5),

ertia Brake Solenoid Coil Test ...................... 2-78

In

Component Code: 46 (SID 37,38, FMI 4,5)

Splitter Solenoid Valve ...................................2-83

Code 46 (SID 37,38, FMI 4,5),

Splitter Solenoid Valve Test ............................ 2-84

Component Code: 51 (PID 60, FMI 2)

Rail Select Sensor ....................................... ...2-89

Code 51 (PID 60, FMI 2),

Rail Select Sensor Test ..................................2-90

Component Code: 52 (PID 59, FMI 2)

Gear Select Sensor .........................................2-99

Code 52 (PID 59, FMI 2),

Gear Select Sensor Test ..............................2-100

Component Code: 53 (SID 34, FMI 2)

Reverse Ball Switch ...................................... 2-109

Code 53 (SID 34, FMI 2),

Reverse Ball Switch Test ............................. 2-110

Component Code: 56 (PID 161, FMI 2)

Input Shaft Speed Sensor .............................2-115

Code 56 (PID 161, FMI 2),

Input Shaft Speed Sensor Test .................... 2-116

Component Code: 57 (PID 160, FMI 2)

Main Shaft Speed Sensor .............................2-119

Code 57 (PID 160, FMI 2),

Main Shaft Speed Sensor Test .....................2-120

Component Code: 58 (PID 191, FMI 2)

Output Shaft Speed Sensor ..........................2-123

Code 58 (PID 191, FMI 2),

Output Shaft Speed Sensor Test ...................2-124

Component Code: 61 (SID 39, FMI 5,6)

Rail Select Motor ..........................................2-127

Code 61 (SID 39, FMI 5,6),

Rail Select Motor Test ..................................2-128

Component Code: 63 (SID 40, FMI 5,6)

Gear Select Motor .........................................2-133

Page 5

Table of Contents

Table of Contents

Code 63 (SID 40, FMI 5,6),

Gear Select Motor Test .................................2-134

Component Code: 65 (SID 251, FMI 4)

Low Motor Voltage .......................................2-139

Code 65 (SID 251, FMI 4),

Low Motor Voltage Test ...............................2-140

System Code: 71 (SID 60, FMI 7)

Stuck Engaged .............................................. 2-143

Code 71 (SID 60, FMI 7), Stuck Engaged Test .....2-144

System Code: 72 (SID 59, FMI 7)

Failed to Select Rail .......................................2 -149

Code 72 (SID 59, FMI 7),

Failed to Select Rail Test ...............................2-150

System Code: 73 (SID 58, FMI 7)

Failed to Engage Gear ...................................2-153

Code 73 (SID 58, FMI 7),

Failed to Engage Gear Test ...........................2-154

System Code: 74 (SID 54, FMI 7)

Failed to Sync Initial Engagement .................2-157

Code 74 (SID 54, FMI 7),

Failed to Sync Initial Engagement Test ..........2-158

Component Code: 83 (SID 18, FMI 14)

Shift Lever Missing .......................................2-161

Code 83 (SID 18, FMI 14),

Shift Lever Missing Test ...............................2-162

Appendix

Current Style Wiring Harness AutoSelect ................A-1

Current Style Wiring Harness AutoShift ...................A-3

Old Style Wiring Harness AutoSelect .......................A-5

Old Style Wiring Harness AutoShift .........................A-7

Check for Proper Clutch Operation ..........................A-9

Confirm Proper Clutch Adjustment ........................ A-10

Section 3: Symptom Isolation Procedures

Electrical System ......................................................3-1

Electrical System Test ..............................................3-2

Front Box Control ...................................................3-17

Front Box Control Test ...........................................3-18

Gear Display Power Supply ....................................3-29

Gear Display Power Supply Test ............................3-30

Start Enable Relay Contact .....................................3-37

Start Enable Relay Contact Test .............................3-38

AutoShift/AutoSelect Will Not Engage a Gear .........3-41

AutoShift/AutoSelect Will Not Engage a Gear Test .3-42

J-1587 Data Link ....................................................3-49

J-1587 Data Link Test ............................................3-50

Range System ........................................................3-57

Range System Test ................................................3-58

Splitter System ........................................... ... .........3-61

Splitter System Test ...............................................3-62

Up/Down Button ............................................ ... ......3-65

Up/Down Button Test .............................................3-66

AutoShift/AutoSelect Shift Complaint ..................... 3-67

AutoShift/AutoSelect Shift Complaint Test .............3-68

Transmission Air Leak ........................................... .3-73

Transmission Air Leak Test ....................................3-74

Neutral Lock Input ..................................................3-79

Neutral Lock Input Test ..........................................3-80

Page 6

Suggested Tools

Air Gauges

• 2 (0-100) PSI Air Gauges

Volt/Ohm Meter

• SPX / Kent-Moore 1 (800) 328-6657

• P/N 5505027

PC-based Service Tool “ServiceRanger”

• Contact your OEM

Data Link Tester

• Eaton Service Parts 1 (800) 826-HELP (826-4357)

General Information

• P/N MF-KIT-04

Download Harness Kit

• Eaton Service Parts 1 (800) 826-HELP (826-4357)

• K-3481

Test Adapter Kit

• SPX / Kent-Moore 1 (800) 328-6657

• Eaton Test Adapter Kit P/N J-43318

• Serial Link Adapter Kit P/N J-38351-B

For more information call 1-800-826-HELP (826-4357)

1-1

Page 7

General Information

Transmission Models Included

18-Speed

General Information

10-Speed

1-2

Page 8

General Information

Diagnostic Procedure

Follow the flow cart below for all AutoSelect/AutoShift failures. Perform tests and procedures as directed by the flowchart.

Key on.

Retrieve active codes. Note: Scan tool

or P.C. may be required if service light

is not avialable.

• Perform Electrical System Pretest

Active codes?

YES

NO

• Refer to the Fault Code Isolation

Procedure Index to select a Fault

Code Isolation Procedure

Observe Gear Display

Can a solid "N"

be observed in

Gear Display ?

YES

Retrieve Inactive Codes.

Inactive Codes?

NO

NO

YES

Will engine crank ?

YES

• Perform Gear Display Test

• Record and clear codes

• Perform Driving Technique to reproduce

the inactive fault code

• Perform Electrical System Pretest

• Perform Air Pretest

• Refer to the Fault Code Isolation

Procedure Index to select

a fault code isolation procedure

• Perform Power-Up Sequence Pretest

• Perform Front Box Control Test

NO

1-3

Symptom?

NO

Test complete.

YES

• Perform Electrical System Pretest

• Perform Air Pretest

• Perform Power-Up Sequence Pretest

• Refer to Symptom-Driven Diagnostics

Table to select a symptom isolation procedure

Page 9

General Information

General Information

SERVICE

1 Flash

Short

pause

(1/2 sec)

Short

pause

(1/2 sec)

Long Pause

(3-4 sec)

3 Flashes

2 Flashes

Code 13 Code 21

SERVICE

SERVICE

SERVICE SERVICE

SERVICE

1 Flash

SERVICE

Fault Code Retrieval/Clearing

Retrieving Fault Codes

Retrieve fault codes by enabling the system’s self-diagnostic mode.

Note: You can also use a PC- based service tool, such as the ServiceRanger to retrieve fault codes.

1. Place the shift lever in neutral.

2. Set the parking brake.

3. Turn the ignition key on but do not start the engine. If the engine already running, you may still retrieve codes, however,

do not engage the starter if the engine stalls.

4. To Retrieve Active Codes: Start with the key in the on position. Turn the key off and on two times within five seconds

ending with the key in the on position. After five seconds, the service lamp begins flashing two-digit fault codes. If no

faults are active, the service light will not flash.

2 times

off

on

5. To Retrieve Inactive Codes: Start with the key in the on position. Turn the key off and on four times within five seconds

ending with the key in the on position. After five seconds, the service lamp begins flashing two-digit fault codes. If there

are no inactive faults, the service light will not flash.

6. Observe the sequence of flashes on the indicator lamp and record the codes. A one to two second pause separates each

stored code, and the sequence automatically repeats after all codes have been flashed.

off

4 times

on

1-4

Page 10

General Information

Clearing Fault Codes

The following procedure clears all inactive fault codes from the ECU’s memory. Active fault codes are automatically cleared when

the fault has been corrected.

Note: You may use a PC-based Service Tool, such as ServiceRanger, to clear fault codes.

1. Place the shift lever in neutral.

2. Set the parking brake.

3. Turn the ignition key on but do not start the engine.

4. Start with the key in the on position. Turn the key off and on six times within five seconds ending with the key in the on

position.

6 times

off

Note: If the codes have been successfully cleared, the service lamp will come on and stay on for five seconds.

5. Turn key off and allow the system to power down.

on

1-5

Page 11

General Information

Driving Techniques

General Information

Fault

Codes

11 254 2,12 System Control-

12 233 12 Transmission

13 236 4,5 Power Connect

14 18 12 Shift Lever Component Key on. If the fault is present, the system should

PID SID FMI Description Type of Code Driving Technique

Component Key on. If the fault is present, the system should

ler

Component Key on. If the fault is present, the system should

Controller

Component Key on. If the fault is present, the system should

Relay Coil

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat, vibration and selecting different shift lever positions.

15 57 2 Shift Lever Data

16 248 2 Eaton

17 237 4 Start Enable

Link

Proprietary Link

(EPL)

Relay Coil

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

1-6

Page 12

General Information

Fault

Codes

31 62 3,4 Engine Brake Re-

33 168 4 Battery Voltage

35 231 2,7 Engine Control

41 56 7 Range Failed to

PID SID FMI Description Type of Code Driving Technique

lay Coil

Supply

Failure

Engage

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

System Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat, vibration and varying levels

of throttle demand.

System Operate the vehicle and perform several range up-

shifts and downshifts. The failure is detected after

5 consecutive attempts to complete the same type

of range shift. Several shifts (ten or more) may be

necessary before the ECU confirms the failure.

42 61 7 Splitter Failed to

Engage

43 35 or 36 3,4,5 Range Solenoid

Valve

44 54 3,4,5 Interia Brake So-

lenoid Coil

46 37 or 38 4,5 Splitter Solenoid

Valve

System Operate the vehicle and perform several range up-

shifts and downshifts. The failure is detected after

5 consecutive attempts to complete the same type

of range shift. Several shifts (ten or more) may be

necessary before the ECU confirms the failure.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

1-7

Page 13

General Information

General Information

Fault

Codes

51 60 2 Rail Select Sen-

52 59 2 Gear Select Sen-

53 34 2 Reverse Ball

56 161 2 Input Shaft

57 160 2 Main Shaft

PID SID FMI Description Type of Code Driving Technique

sor

sor

Switch

Speed Sensor

Speed Sensor

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Select a reverse gear (repeatedly).

Component Select a forward gear and drive at a steady speed

no slower than 10 m.p.h. It may be necessary to

operate the vehicle for a prolonged period of time

if the cause of failure is related to heat and vibration.

Component Select a forward gear and drive at a steady speed

no slower than 10 m.p.h. It may be necessary to

operate the vehicle for a prolonged period of time

if the cause of failure is related to heat and vibration.

58 191 2 Output Shaft

61 39 5,6 Rail Select Motor Component Key on. If the fault is present, the system should

63 40 5,6 Gear Select Mo-

Speed Sensor

tor

Component Select a forward gear and drive at a steady speed

no slower than 10 m.p.h. It may be necessary to

operate the vehicle for a prolonged period of time

if the cause of failure is related to heat and vibration.

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

1-8

Page 14

General Information

Fault

Codes

65 251 4 Low Motor Volt-

71 60 7 Stuck Engaged System Engage LO gear and allow the vehicle to slowly

72 59 7 Failed to Select

73 58 7 Failed to Engage

PID SID FMI Description Type of Code Driving Technique

Component Key on. If the fault is present, the system should

age

System Complete several shifts while the vehicle is in mo-

Rail

System Complete several shifts while the vehicle is in mo-

Gear

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

move forward. While the vehicle is in motion,

move the shift lever to Reverse LO and slowly

bring the vehicle to a stop. The vehicle will shift

into Reverse LO. Several shifts (ten or more) may

be necessary before the ECU confirms the failure.

tion, including selections from neutral. Allow the

transmission to complete several automatic

shifts.

tion, including selections from neutral. Allow the

transmission to complete several automatic

shifts.

74 54 7 Failed to Syn Ini-

tial Engagement

83 18 14 Shift Lever Miss-

ing

System With vehicle stopped, select a drive gear and fully

depress the clutch pedal. Return transmission to

neutral. Repeat several times.

Component Key on. If the fault is present, the system should

automatically detect the problem and set the code.

If the fault is not present at key on, operate the vehicle and attempt to duplicate the driving conditions that triggered the fault code. Possible

triggers include heat and vibration.

1-9

Page 15

General Information

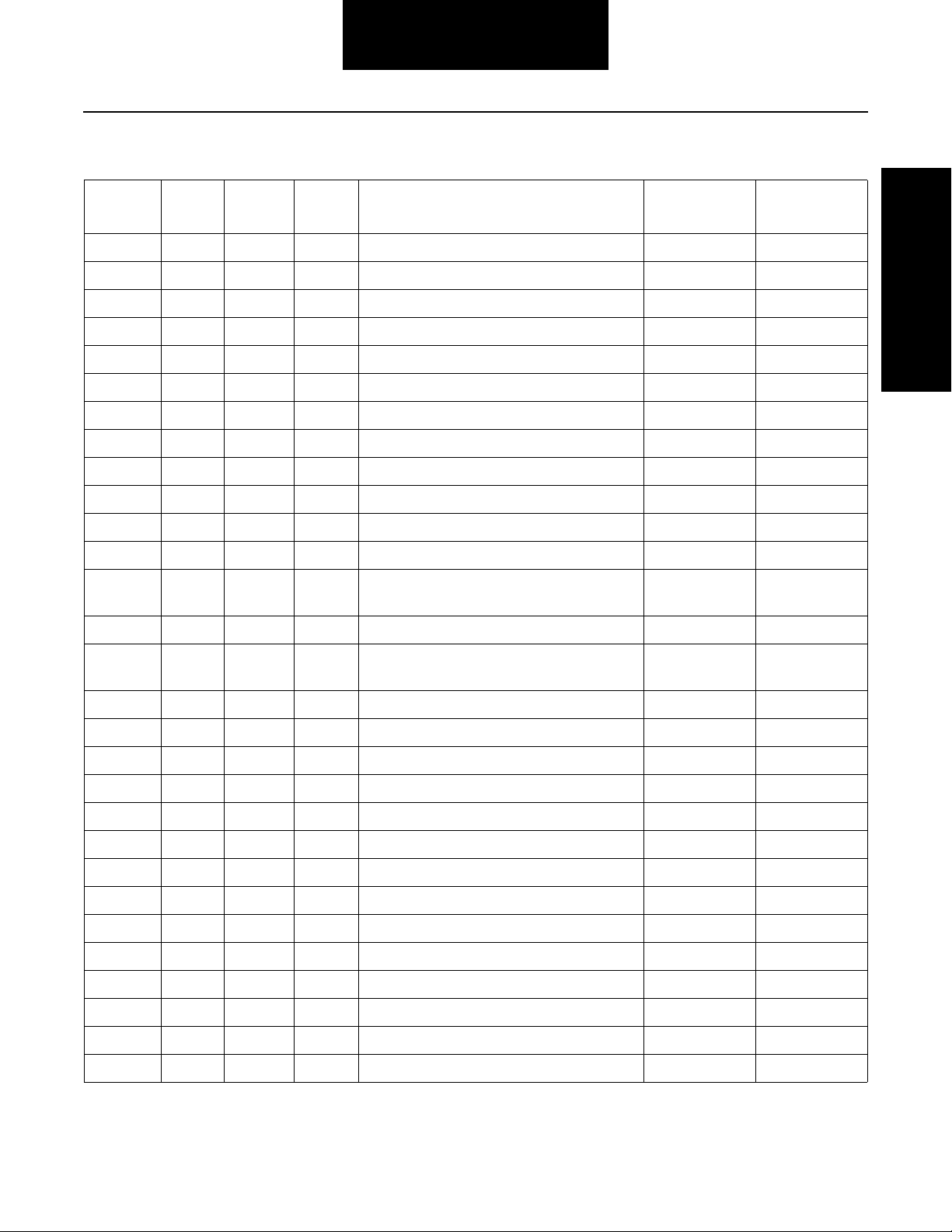

Fault Code Isolation Procedure Index

General Information

Fault

Codes

11 254 2,12 System Controller Component 2-13

12 233 12 Transmission Controller Component 2-15

13 236 4, 5 Power Connect Relay Coil Component 2-17

14 18 12 Shift Lever Component 2-21

15 57 2 Shift Lever Data Link Component 2-25

16 248 2 Eaton Proprietary Link Component 2-31

17 237 4 Start Enable Relay Coil Component 2-43

31 62 3,4 Engine Brake Relay Coil Component 2-47

33 168 4 Battery Voltage Supply Component 2-51

35 231 2,7 Engine Control Failure System 2-55

41 56 7 Range Failed to Engage System 2-63

42 61 7 Splitter Failed to Engage System 2-67

43 35 or

44 54 3,4,5 Inertia Brake Solenoid Coil Component 2-77

S I D P I D FM I

3,4,5 Range Solenoid Valve Component 2-71

36

Description Type of Code Page Number

46 37 or

38

51 60 2 Rail Select Sensor Component 2-89

52 59 2 Gear Select Sensor Component 2-99

53 34 2 Reverse Ball Switch Component 2-109

56 161 2 Input Shaft Speed Sensor Component 2-115

57 160 2 Main Shaft Speed Sensor Component 2-119

58 191 2 Output Shaft Speed Sensor Component 2-123

61 39 5,6 Rail Select Motor Component 2-127

63 40 5,6 Gear Select Motor Component 2-133

65 251 4 Low Motor Voltage Component 2-139

71 60 7 Stuck Engaged System 2-143

72 59 7 Failed to Select Rail System 2-149

73 58 7 Failed to Engage Gear System 2-153

74 54 7 Failed to Sync Initial Engagement System 2-157

83 18 14 Shift Lever Missing Component 2-161

4,5 Splitter Solenoid Valve Component 2-83

1-10

Page 16

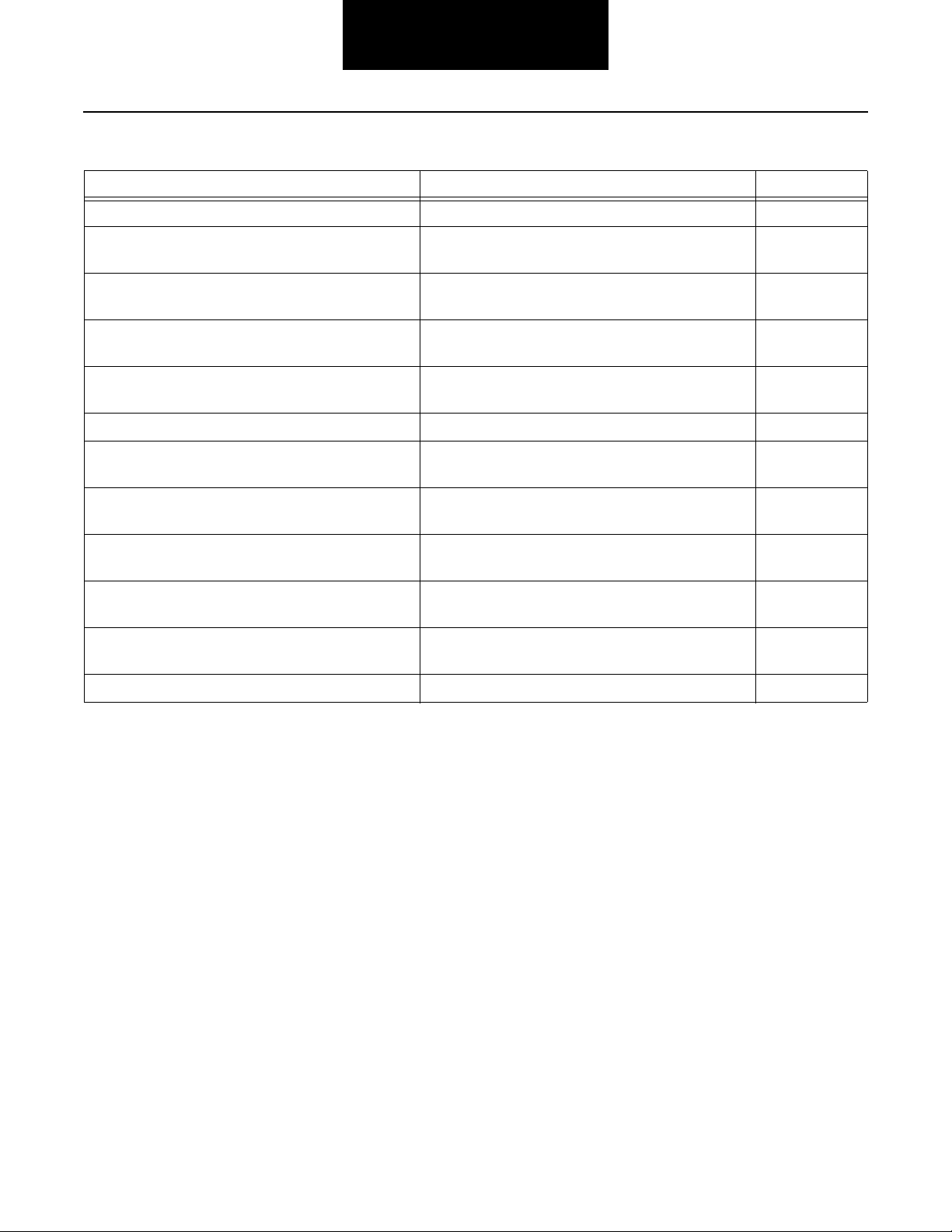

General Information

Symptom Driven Diagnostics Index

Symptom Isolation Procedure Page Number

Electrical System Test Electrical System Test 3-1

If "-" is displayed on the Gear Display, and there are no

active or inactive codes

If the Gear Display is not working, and there are no ac-

tive or inactive codes

If the engine does not start with the Shift Lever is in

neutral, and there are no active or inactive codes

If the transmission does not engage a gear, and there

are no active or inactive codes

If the PC-based Service Tool does not work J-1587 Data Link Test 3-49

If the transmission does not perform range shifts, and

there are no active or inactive fault codes

If the transmission does not perform Splitter Shifts,

and there are no active or inactive fault codes

If unable to shift the transmission with the Up/Down

Buttons, and there are no Active or Inactive codes

If a shift complaint exists and there are no Active or

Inactive codes

If the transmission has an air leak and there are no

Active or Inactive fault codes

If the Auto Neutral feature is not working Neutral Lock Input Test 3-79

Front Box Control Test 3-17

Gear Display Power Supply Test 3-29

Start Enable Relay Contact Test 3-37

AutoShift/AutoSelect will not Engage a Gear Test 3-41

Range System Test 3-57

Splitter System Test 3-61

Up/Down Button Test 3-65

AutoShift/AutoSelect Shift Complaint Test 3-67

Transmission Air Leak Test 3-73

1-11

Page 17

General Information

General Information

This page left blank intentionally.

1-12

Page 18

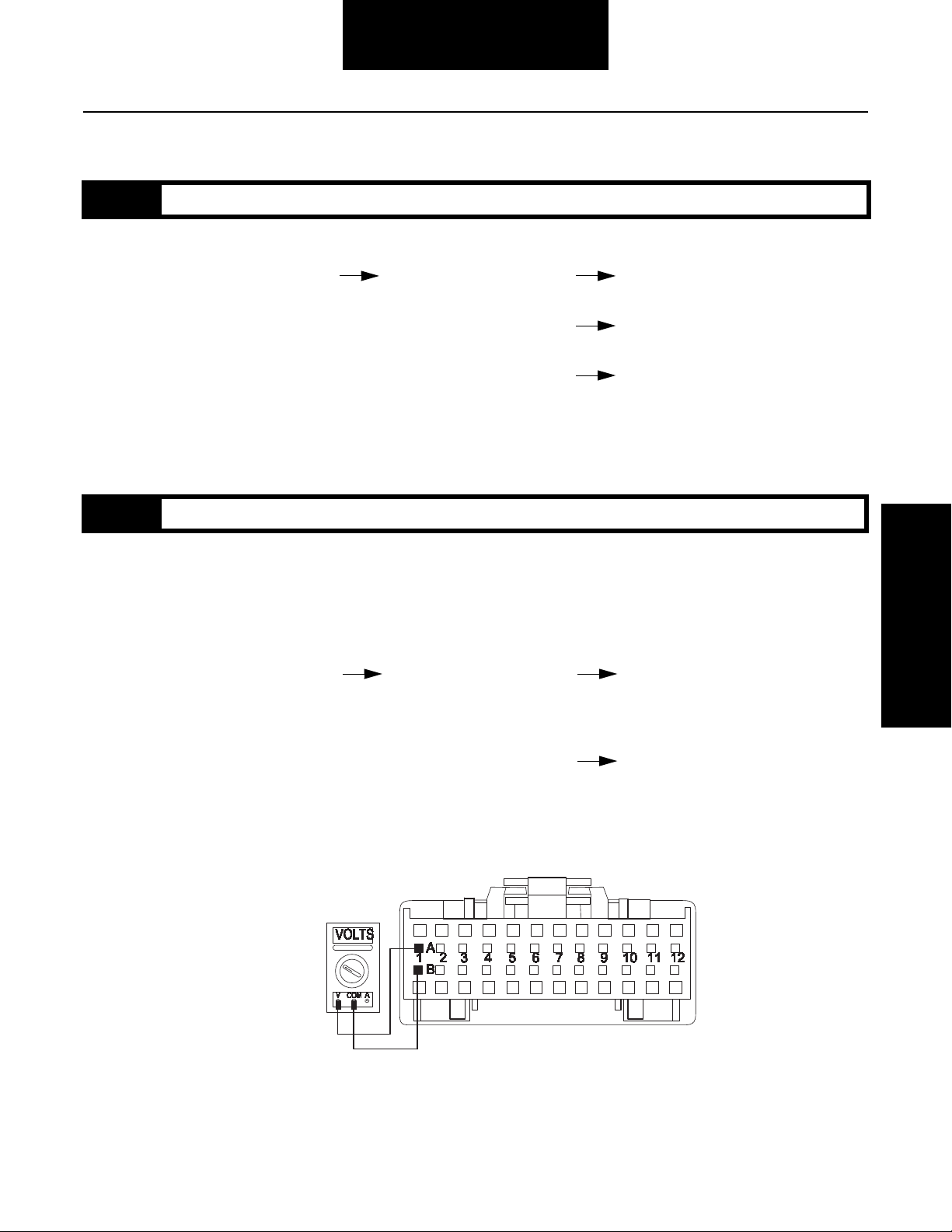

Electrical System Pretest

Fault Isolation Procedures

Overview

The test does not relate to any specific fault code, but must be

completed before performi ng Fault Code Isolati on Table procedures. The pretest verifies the batteries are fully charged.

Detection

There is no detection process specifically for the basic electrical supply. However, failures of this type are generally detected

by the transmission or driver as some other type of fault code

or symptom.

Fallback

There is no fallback for the electrical pretest, however, it may

effect other systems.

Required Tools

• Basic Hand Tools

• Eaton Test Adapter Kit

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• Battery Load Tester

Possible Causes

This pretest can be used for any of the following:

• Low Batteries

• Starter/Battery connections

2-1

VOLTS

V

COM

–

A

–

+

+

Page 19

Fault Isolation Procedures

Electrical System Pretest

Step A Procedure Condition Action

1. Key off.

2. Inspect starter/battery

connections for integrity.

3. Measure voltage

across battery.

If voltage is 11 to 13 volts on a 12

volt system or

22 to 26 on a 24 volt

system

If voltage is outside of

range

Go to Step V.

Repair or replace battery/s and

charging system as required.

Repeat this step.

Fault Isolation Procedures

Step V Procedure Condition Action

1. Key off.

2. Load Test the Battery/

s.

If the battery/s maintain

the specified load

If the battery/s fail the

load test

Test Complete.

Replace the damaged battery/s and

repeat this step.

2-2

Page 20

Power-Up Sequence Pretest

Fault Isolation Procedures

Overview

A failure during the self-check indicates a failure of the Shift

Control.

Detection

The power-up self-check is performed automatically each time

the key is turned on. Turn the key on and watch the service

lamp. If power-up stops with the service lamp constantly on,

or it never comes on, self-check has failed.

Fallback

If self-check fails, the product cannot perform any operations.

Required Tools

• Basic Hand Tools

• Eaton Test Adapter Kit

• Digital Volt/Ohm Meter

• Troubleshooting Guide

Possible Causes

This test can be used for the following:

• Shift Control

• Vehicle Harness

2-3

Page 21

Fault Isolation Procedures

Power-Up Sequence Pretest

Step A Procedure Condition Action

1. Key on.

2. Observe service

lamp.

If service lamp lights for

one second and goes off

If service lamp never

comes on

If service lamp is on

steady

Test complete.

Go to Step B.

Replace Eaton supplied shift tower

containing system manager and

shift lever. If vehicle has the

System Manager ECU mounted in a

separate location from the Shift

Lever, go to Step C.

Step B Procedure Condition Action

1. Key off.

2. Disconnect shift lever 24-way

connector.

3. Key on.

4. Measure voltage

between shift lever

24-way connector

pins A1 and B1.

If voltage is within 1 volt

of battery voltage

Replace shift lever. Go to Step A.

Fault Isolation Procedures

If voltage is outside of

range

Repair or replace tower harness.

Go to Step A.

2-4

Page 22

Fault Isolation Procedures

Power-Up Sequence Pretest , continued

Step C Procedure Condition Action

1. Key on.

2. Connect hand-held diagnostic

tool to transmission diagnostic

port.

3. Select monitor data and view

"TRANS_RNG_SEL".

4. Disconnect shift lever 24-way

5. Place a jumper

between shift lever

24-way connector

pins:

• A1 and B3

• B1 and B4

If TRANS_RNG_SEL

reads "HI"

If hand-held diagnostic

tool does not read

TRANS_RNG_SEL "HI"

Go to Step D.

Go to Step E.

2-5

Page 23

Fault Isolation Procedures

Power-Up Sequence Pretest , continued

Step D Procedure Condition Action

1. Key on.

2. Remove jumpers.

3. Place a jumper

between shift lever

24-way connector

pins:

• B1 and B3

• A1 and B4

If TRANS_RNG_SEL

reads "LO"

If hand-held diagnostic

tool does not read

TRANS_RNG_SEL "LO"

Replace shift lever. Go to Step A.

Go to Step E.

Fault Isolation Procedures

2-6

Page 24

Fault Isolation Procedures

Power-Up Sequence Pretest , continued

Step V Procedure Condition Action

1. Disconnect system manager 32way connector.

2. Measure resistance

between system

manager 32-way

connector pins and shift lever

24-way connector pins:

• 32-way D8 and 24-way B8

• 32-way C8 and 24-way B7

• 32-way D9 and 24-way B6

• 32-way C9 and 24-way B5

• 32-way C13 and 24-way B4

• 32-way D13 and 24-way B3

If resistance for each

measurement is 0 to .3

ohms

If any measurement is

outside of range

Replace system manager ECU. Go

to Step A.

Repair or replace tower har ness as

required. Go to Step A.

2-7

Page 25

Fault Isolation Procedures

Power-Up Sequence Pretest , continued

Fault Isolation Procedures

This page left blank intentionally.

2-8

Page 26

Air Pretest

r

Fault Isolation Procedures

Overview

The pretest does not relate to any specific fault code, but must

be completed before performing Fault Code Isolation Table

procedures. The pretest verifies that the basic air input is OK

before testing individual system functions.

Detection

There is no detection process specifically for the basic air supply. However, failures of this type are generally detected by the

transmission or driver as some other type of fault code or

symptom.

Fallback

There is no fallback mode for air pretest, however, it may effect

other systems.

Required Tools

• Basic Hand Tools

• 0-100 PSI Air Pressure Gauge

• Troubleshooting Guide

Possible Causes

This pretest can be used for any of the following:

• Low Air Pressure

• Contaminated Air

• Air Filter / Regulator

2-9

Air filter/regulato

Page 27

Fault Isolation Procedures

Air Pretest

Step A Procedure Condition Action

1. Key off.

2. Install a 0 to 100 PSI air gauge

in the requlated test port of the

air filter/regulator.

3. Start engine and

allow air pressure to

build to governor cutoff.

If air pressure cuts off at

90 to 120 PSI

If air pressure is outside

of range

Go to Step B.

Repair vehicle air system as

required. Repeat this step.

Fault Isolation Procedures

Step B Procedure Condition Action

1. Key off.

2. Monitor air pressure. If vehicle maintains air

pressure

If vehicle loses air

pressure

Go to Step C.

Repair vehicle air system as

required. Repeat this step.

2-10

Page 28

Fault Isolation Procedures

Air Pretest, continued

Step C Procedure Condition Action

1. Read air pressure

gauge installed at the

requlated port.

If air pressure is 55 to 65

PSI

If air pressure is outside

of range

Test Complete.

Repair vehicle air system as

required. Repeat this Step V.

Step V Procedure Condition Action

1. Remove air supply

line to the air filter/

regulator and check

air flow.

If air flows from the

supply line

If air does not flow from

the supply line

Replace air filter/regulator. Go to

Step C.

Repair vehicle air supply to the

regulator. Go to Step C.

2-11

Page 29

Air Pretest, continued

Fault Isolation Procedures

Fault Isolation Procedures

This page left blank intentionally.

2-12

Page 30

Component Code: 11

(SID 254, FMI 2,12)

System Manager

Fault Isolation Procedures

Overview

This fault code indicates an internal failure of the System Manager ECU.

Detection

The System Manager checks the program memory every time

the key is turned on. If the System Manager ECU is able to detect a failure within its own memory, it sets this fault code.

Fallback

This fault causes an In Place fallback while moving and a selfcheck failure if it occurs during power-up.

Required Tools

• Basic Hand Tools

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Improper configuration software

• Fault System Manager ECU

2-13

Page 31

Fault Isolation Procedures

Code 11 (SID 254, FMI 2,12), System Controller Test

Step A Procedure Condition Action

1. Key on.

2. Retrieve code (see

page 1-4)

If code 11 is active Replace System Manager.

If code 11 is inactive Test complete.

Fault Isolation Procedures

2-14

Page 32

Component Code: 12

(SID 233, FMI 12)

Transmission ECU

Fault Isolation Procedures

Overview

The code indicates an internal failure of the Transmission ECU.

Detection

The Transmission ECU checks the program memory every

time the key is turned on. If the transmission is able to detect

a failure within its own memory, it sets this fault code.

Fallback

This fault causes an In Place fallback while moving and a failure during system initialization.

Required Tools

• Basic Hand Tools

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Improper configuration software

• Faulty Transmission ECU

2-15

Page 33

Fault Isolation Procedures

Code 12 (SID 233, FMI 12),Transmission ECU Test

Step A Procedure Condition Action

1. Key on.

2. Retrieve codes (see

page 1-4)

If code 12 is active Replace Transmission ECU.

If code 12 is inactive Test complete.

Fault Isolation Procedures

2-16

Page 34

Component Code: 13

(SID 236, FMI 4,5)

Power Connect Relay Coil

Fault Isolation Procedures

Overview

This code indicates an electrical failure of the relay used to distribute power throughout the transmission system.

Detection

The System Manager checks the integrity of the Power Connect Relay Coil. If it detects a short to ground or open it sets a

fault.

Fallback

This fault causes and In Place fallback while moving and a failure during system initialization.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• System manager ECU

• Tower harness

• Power connect relay

2-17

Page 35

Fault Isolation Procedures

Code 13 (SID 236, FMI 4,5), Power Connect Relay Coil Test

Step A Procedure Condition Action

1. Key off.

2. Disconnect system manager 24way connector.

3. Measure resistance

between system

manager 24-way

connector pins A6 and B4.

If resistance is 40 to 90

ohms

If resistance is outside of

range

Replace system manager ECU

(Only if Fault Code is Active). Go

to Step V.

Go to Step B.

Fault Isolation Procedures

2-18

Page 36

Fault Isolation Procedures

M

Code 13 (SID 236, FMI 4,5), Power Connect Relay Coil Test, continued

Step B Procedure Condition Action

1. Remove power connect relay

connector from tower harness.

2. Measure resistance between

power connect relay pins 85 and

86.

If resistance is 40 to 90 ohms Repair or replace tower harness.

Go to Step V.

If resistance is outside of range Replace power connect relay. Go

to Step V.

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes (see page 1-4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault Codes (see

page 1-4)

2-19

If no codes Test complete.

If code 13 appears Return to Step A to find error in

testing.

If code other than 13 appears Go to Fault Code Isolation

Procedure Index (see page 1-10).

Page 37

Fault Isolation Procedures

Code 13 (SID 236, FMI 4,5), Power Connect Relay Coil Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-20

Page 38

Component Code: 14

(SID 18, FMI 12)

Shift Lever

Fault Isolation Procedures

Overview

This code indicates an internal failure of the shift lever.

Detection

Starting at key-on and throughout operation, the System Manager constantly measures the feedback from the Shift Lever

circuit. If the feedback is out of range, the fault is set. This type

of failure represents a short to battery, short to ground, or

open circuit.

Fallback

This fault causes a downshift only fallback.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Malfunctioning shift lever

• System Manager

• OEM harness

2-21

Page 39

Fault Isolation Procedures

Code 14 (SID 18, FMI 12), Shift Lever Test

Step A Procedure Condition Action

1. Key off.

2. Disconnect shift lever 24-way

connector.

3. Key on.

4. Measure voltage across shift

lever 24-way connector pins A1

and B1.

If voltage is within 1 volt of battery

voltage

If voltage is outside of range Repair ignition supply to shift lever.

Replace shift lever (Only if Fault

Code is Active). Go to Step V.

Go to Step V.

Fault Isolation Procedures

2-22

Page 40

Fault Isolation Procedures

Code 14 (SID 18, FMI 12), Shift Lever Test, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes (see page 1-4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault Codes (see

page 1-4)

If no codes Test complete.

If code 14 appears Return to Step A to find error in

testing.

If code other than 14 appears Go to Fault Code Isolation

Procedure Index (see page 1-10).

2-23

Page 41

Fault Isolation Procedures

Code 14 (SID 18, FMI 12), Shift Lever Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-24

Page 42

Component Code: 15

(SID 57, FMI 2)

Shift Lever Data Link

Fault Isolation Procedures

Overview

This code indicates that the system manager ECU and the shift

lever are unable to communicate.

Detection

The System Manager constantly monitors communication

with the Shift Lever and sets a fault if communication drops

out.

Fallback

There is no Fallback Mode for this fault.

Required Tools

• Basic Hand Tools

• Hand-Held Diagnostic Tool

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Damaged shift lever data link

• Malfunctioning shift lever

• Malfunctioning system manager ECU

2-25

Page 43

Fault Isolation Procedures

Code 15 (SID 57, FMI 2), Shift Lever Data Link Test

Step A Procedure Condition Action

1. Key on.

2. Retrieve Fault Codes (see

page 1-4)

If code 15 is active Replace Eaton supplied shift tower

containing system manager and

shift lever. If vehicle has the

system manager ECU mounted in a

separate location from the shift

lever, go to Step B.

If code 15 is inactive Test complete.

Step B Procedure Condition Action

1. Key off.

2. Connect hand-held diagnostic

tool to transmission diagnostic

port.

3. Select monitor data view

"TRANS_RNG_SEL".

Disconnect shift lever 24-way

connector.

Place a jumper between shift lever

24-way connector pins:

• A1 and B3

• B1 and B4

If TRANS_RNG_SEL reads "HI" Go to Step C.

Fault Isolation Procedures

If hand-held diagnostic tool does

not read TRANS_RNG_SEL "HI"

Go to Step D.

2-26

Page 44

Fault Isolation Procedures

Code 15 (SID 57, FMI 2), Shift Lever Data Link Test, continued

Step C Procedure Condition Action

1. Remove jumpers.

2. Place a jumper between shift

lever 24-way connector pins:

• B1 and B3

• A1 and B4

If TRANS_RNG_SEL reads "LO" Replace shift lever. Go to Step V.

If hand-held diagnostic tool does

not read TRANS_RNG_SEL "LO"

Go to Step D.

2-27

Page 45

Fault Isolation Procedures

Code 15 (SID 57, FMI 2), Shift Lever Data Link Test, continued

Step D Procedure Condition Action

1. Disconnect system manager 32way connector.

2. Measure resistance between

system manager 32-way

connector pins and shift lever

24-way connector pins:

• 32-way D8 and 24-way B8

• 32-way C8 and 24-way B7

• 32-way D9 and 24-way B6

• 32-way C9 and 24-way B5

• 32-way C13 and 24-way B4

• 32-way D13 and 24-way B3

If resistance for each measurement

is 0 to .3 ohms

If any measurement is outside of

range

Replace system manger ECU. Go

to Step V.

Repair or replace tower harness as

required. Go to Step V.

Fault Isolation Procedures

2-28

Page 46

Fault Isolation Procedures

Code 15 (SID 57, FMI 2), Shift Lever Data Link Test, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes. (see page 1-

4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault

Codes(see page 1-4)

If no codes Test complete.

If code 15 appears Return to Step A to find error in

testing.

If code other than 15

appears

Go to Fault Code Isolation

Procedure Index. (see page 1-10)

2-29

Page 47

Fault Isolation Procedures

Code 15 (SID 57, FMI 2), Shift Lever Data Link Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-30

Page 48

Component Code: 16

(SID 248, FMI 2)

Eaton Proprietary Link (EPL)

Fault Isolation Procedures

Overview

This code indicates that the system manager ECU and the

transmission ECU are unable to communicate.

Detection

Starting at key-on and throughout operation, the System Manager constantly monitors the communication with the Transmission ECU. If a communication fault occurs for more than

five seconds, fault code 16 is set.

Fallback

This fault causes an In Place fallback while moving and a failure during system initialization.

Required Tools

• Basic Hand Tools

• Hand-Held Diagnostic Tool

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

• Data Link Tester

Possible Causes

This fault can be caused by any of the following:

• Damaged transmission interface harness

• Damaged transmission harness

• Damaged tower or OEM harness

• Malfunctioning transmission ECU

• Malfunctioning system manager ECU

• Powers and Grounds

• Damaged PIM

2-31

Page 49

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test

Step A Procedure Condition Action

1. Key off.

2. Inspect starter/

battery,inline fuse

holder and PIM

connections for integrity.

If okay Go to Step B.

If corroded or loose Repair wiring or battery

connections. Go to Step V.

Fault Isolation Procedures

2-32

Page 50

Fault Isolation Procedures

CAUTION

CAUTION

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step B Procedure Condition Action

1. Key off.

2. Insert 15-amp fuse

into Motor Supply 2way connector.

If fuse blows immediately

Disconnect negative battery cable

before reconnecting motor supply

2-way connector. Go to Step C.

If fuse does not blow

immediately

Disconnect the battery cable

before reconnecting the motor

supply 2-way connector. Failure to

disconnect the battery negative

cable can cause the failure of the

power interface module. Replace

power interface module. Go to

Step V.

2-33

Page 51

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect transmission ECU

24-way connector.

3. Place a jumper between

transmission ECU 24-way

connector pins 2 and 14. The

procedure is providing ground

to the system manager ecu

during the test.

4. Key on.

5. Measure voltage

across transmission

ECU 24-way

connector pins 1 and 14. This

procedure is checking for

correct voltage from the power

connect relay to the

transmission controller.

If voltage is within 1 volt

of battery voltage

If voltage is outside of

range

Go to Step E.

Fault Isolation Procedures

Go to Step D.

2-34

Page 52

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step D Procedure Condition Action

1. Remove jumper.

2. Disconnect transmission

harness from transmission

interface harness.

3. Disconnect power interface

module from transmission

harness.

4. Measure resistance between

transmission ECU 24-way

connector pin 14 and power

interface module connector pin

A on transmission harness. This

procedure is checking the

resistance of the ground wire

supplied by the pim to the

transmission ecu.

5. Measure resistance

between transmission

harness 6-way

connector pin D and

transmission ECU 24-way

connector pin 1. This procedure

is checking resistance of the

power connect relay feed from

the 6-way connector to the

transmission ecu.

If both measurements

are 0 to .3 ohms

If either measurement is

outside of range

Repair or replace vehicle

interface harness or tower

harness. Go to Step V.

Repair or replace transmission

harness. Go to Step V.

2-35

Page 53

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step E Procedure Condition Action

1. Reconnect transmission ECU

24-way connector.

2. Key off. Allow transmission to

power down.

3. Disconnect system manager 32way connector.

4. Connect data link tester to

system manager 32-way

connector pins C2 and D1.

5. Key on.

6. Start EPL

Communication Test.

If LED is solid or flashing Replace system manager ECU

(Only if Fault Code is Active). Go

to Step V.

If LED is off Go to Step F.

Fault Isolation Procedures

2-36

Page 54

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step F Procedure Condition Action

1. Key off. Allow transmission to

power down.

2. Disconnect transmission ECU

32-way connector.

3. Remove EPL tester from system

manager 32-way connector.

Measure resistance

between system

manager 32-way

connector pins C2 and D1 and

from each pin to ground.

If resistance for each

measurement is more

than 10K ohms or open

circuit (OL)

If resistance of any

measurement is less than

10K ohms

Go to Step G.

Go to Step H.

2-37

Page 55

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step G Procedure Condition Action

1. Place a jumper across

transmission ECU 32-way

connector pins 29 and 30.

2. Measure resistance

between system

manager 32-way

connector pins C2 and D1.

If resistance is 0 to .3

ohms

If resistance is outside of

range

Replace transmission ECU. Go to

Step V.

Go to Step H.

Fault Isolation Procedures

2-38

Page 56

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step H Procedure Condition Action

1. Reconnect system manager 32way connector.

2. Disconnect transmission

harness 3-way connector from

transmission interface harness.

3. Remove any jumper wires

currently in place.

4. Measure resistance between

transmission harness 3-way

connector pins A and B and

from each pin to ground.

Note: Depending on

which

connector you

have, refer to either the

old style or the new style

connector illustration.

If resistance for each

measurement is more

than 10K ohms or open

circuit (OL)

If resistance of any

measurement is less than

10K ohms

Go to Step H.

Repair or replace transmission

harness.Go to Step V.

2-39

Page 57

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step I Procedure Condition Action

1. Measure resistance between

transmission ECU 32-way

connector pin 29 and

transmission harness 3-way

connector pin A.

Note: Depending on which

connector you have, refer to

either the old style or the new

style connector illustration.

2. Measure resistance

between

transmission ECU 32way connector pin 30 and

transmission harness 3-way

connector pin B.

If both measurements are

0 to .3 ohms

If either measurement is

outside of range

Repair OEM wiring from system

manager ECU to transmission. Go

to Step V.

Fault Isolation Procedures

Repair or replace transmission

harness.Go to Step V.

2-40

Page 58

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes (see page 1-4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault

Codes(see page 1-4)

If no codes Test complete.

If code 16 appears Return to Step A. to find error in

testing.

If code other than 16

appears

Go to Fault Code Isolation

Procedures Index.(see page 1-10)

2-41

Page 59

Fault Isolation Procedures

Code 16 (SID 248, FMI 2), Eaton Proprietary Link (EPL) Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-42

Page 60

Component Code: 17

(SID 237, FMI 4)

Start Enable Relay Coil

Fault Isolation Procedures

Overview

This fault code indicates an electrical failure of the relay that allows the engine to start after start-up conditions are met.

Detection

Starting at key-on and throughout operation, the System Manager constantly measures the circuit. A failure mode of short

to battery, short to ground, or open circuit is detected.

Fallback

The start enable relay has no fallback, however, if the failure occurred before the engine was started, it is possible the engine

will not start.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Relay coil open or shorted

• Damaged tower or OEM harness

• Malfunctioning system manager ECU

2-43

Page 61

Fault Isolation Procedures

Code 17 (SID 237, FMI 4), Start Enable Relay Coil Test

Step A Procedure Condition Action

1. Key off.

2. Disconnect system manager.

3. Measure resistance

between system

manager 24-way

connector pin A1 and ground.

If resistance is 40 to 120

ohms

If resistance is outside of

range

Replace system manager ECU

(Only if Fault Code is Active). Go

to Step V.

Go to Step B.

Fault Isolation Procedures

2-44

Page 62

Fault Isolation Procedures

Code 17 (SID 237, FMI 4), Start Enable Relay Coil Test, continued

Step B Procedure Condition Action

1. Remove start enable relay from

OEM dash harness.

2. Measure resistance

between start enable

relay pins 85 and 86.

If resistance is 40 to 120

ohms

If resistance is outside of

range

Repair OEM wiring from system

manager ECU to start enable relay.

Go to Step V.

Replace start enable relay. Go to

Step V.

M

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes (see page 1-4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault Codes

(see page 1-4).

2-45

If no codes Test complete

If code 17 appears Return to Step A to find error in

testing.

If code other than 17

appears

Go to Fault Code Isolation

Procedure Index. (see page 1-10)

Page 63

Fault Isolation Procedures

Code 17 (SID 237, FMI 4), Start Enable Relay Coil Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-46

Page 64

Component Code: 31

(PID 62, FMI 3,4)

Engine Brake Relay Coil

Fault Isolation Procedures

Overview

This code indicates an electrical failure of the relay used to inhibit the engine brake during shifts.

Detection

Starting at key-on and throughout operation, the System Manager constantly measures this circuit. A failure mode of a short

to battery, short to ground, or open circuit is detected.

Fallback

There is no fallback mode with this fault.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Relay coil open or shorted

• Damaged tower or OEM harness

• Malfunctioning system manager ECU

2-47

Page 65

Fault Isolation Procedures

Code 31 (PID 62, FMI 3,4), Engine Brake Relay Coil Test

Step A Procedure Condition Action

1. Key off.

2. Disconnect system manager 24way connector.

3. Measure resistance

between system

manager 24-way

connector pin A3 and ground.

If resistance is 40 to 90

ohms

If resistance is outside of

range

Replace system manager ECU

(Only if Fault Code is Active). Go

to Step V.

Go to Step B.

Fault Isolation Procedures

2-48

Page 66

Fault Isolation Procedures

Code 31 (PID 62, FMI 3,4), Engine Brake Relay Coil Test, continued

Step B Procedure Condition Action

1. Remove engine brake inhibit

relay from OEM dash harness.

2. Measure resistance

between engine brake

inhibit relay pins 85

and 86.

If resistance is 40 to 90

ohms

If resistance is outside of

range

Repair OEM wiring from system

manager ECU to engine brake

inhibit relay. Go to Step V.

Replace engine brake inhibit relay.

Go to Step V.

M

2-49

Page 67

Fault Isolation Procedures

Code 31 (PID 62, FMI 3,4), Engine Brake Relay Coil Test, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes(see page 1-4)

5. Use Driving Technique(see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault

Codes(see page 1-4)

If no codes Test complete.

If code 31 appears Return to Step A to find error in

testing.

If code other than 31

appears

Go to Fault Code Isolation

Procedure Index.(see page 1-10)

Fault Isolation Procedures

2-50

Page 68

Component Code: 33

(PID 168, FMI 4)

Battery Voltage Supply

Fault Isolation Procedures

Overview

This code indicates the system manager has detected that the

battery power supply is low.

Detection

The fault is detected immediately after power-up. This fault

causes the service lamp to flash, but cannot be retrieved via

key clicks (because turning the ignition key off at this point results in an immediate shutdown).

Fallback

This fault causes an In Place fallback.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

•

Possible Causes

This fault can be caused by any of the following:

• Battery bus fuse/circuit breaker is open

• Low batteries

• Damaged tower or OEM harness

• Damaged transmission harness

• Malfunctioning power connect relay

• Malfunctioning system manager ECU

2-51

Page 69

Fault Isolation Procedures

Code 33 (PID 168, FMI 4), Battery Voltage Supply Test

Step A Procedure Condition Action

1. Key off.

2. Inspect starter/battery,

inline fuse holder and

PIM connections for

integrity.

If okay Go to Step B.

If corroded or loose Repair wiring or battery

connections. Go to Step V.

Fault Isolation Procedures

2-52

Page 70

Fault Isolation Procedures

CAUTION

CAUTION

Code 33 (PID 168, FMI 4), Battery Voltage Supply Test, continued

Step B Procedure Condition Action

1. Key off.

2. Insert 15-amp fuse

into Motor Supply 2way connector.

If fuse blows immediately

Disconnect the negative battery

cable before reconnecting the

motor supply 2-way connector.

Failure to disconnect the battery

negative cable can cause the

failure of the power interface

module.Go to Step C.

If fuse does not blow

immediately

Disconnect the negative battery

cable before reconnecting the

motor supply 2-way connector.

Failure to disconnect the battery

negative cable can cause the

failure of the power interface

module. Replace power interface

module. Go to Step V.

2-53

Page 71

Fault Isolation Procedures

Code 33 (PID 168, FMI 4), Battery Voltage Supply Test, continued

Step C Procedure Condition Action

1. Key on.

2. Retrieve Fault Codes

(see page 1-4)

If code 33 is active Perform Electrical System Test (see

page 3-1).

If code 33 is inactive Test complete.

Fault Isolation Procedures

2-54

Page 72

System Code: 35

(SID 231, FMI 2,7)

Engine Control Failure

Fault Isolation Procedures

Overview

This code indicates the AutoShift failed to receive information

from the engine or the engine failed to properly respond to

throttle control during a shift as commanded by the engine J1939 data link.

Detection

75 seconds after key-on and throughout the operation, the

System Manager constantly monitors the communication with

the engine ECM. If a communication fault occurs for more than

five seconds, fault code 35 is set.

Fallback

If the fault occurs while moving, it causes a 1-speed fallback.

Once vehicle has stopped, the starting gear and reverse can be

engaged. If the failure occurs at system initialization, it causes

an AutoSelect fallback mode.

Required Tools

• Basic Hand Tools

• Hand-Held Diagnostic Tool

• Digital Volt/Ohm Meter

• AutoSelect/AutoShift Troubleshooting Guide

• Data Link Tester

Possible Causes

This fault can be caused by any of the following:

• Faulty J-1939 data link

• Faulty vehicle interface harness or connections

• Faulty engine harness or connections

• Excessive radio interference

• Faulty engine ECM

• Faulty engine fuel pump

• Faulty system manager ECU

2-55

Page 73

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test

Step A Procedure Condition Action

1. Key off.

2. Disconnect system manager 32way connector.

3. Disconnect engine ECM’s

connector which contains the J1939 data link.

4. Measure resistance

between:

• System manager

32-way connector pin C5 and

engine ECM pin # (see chart)

• System manager 32-way pin

C5 and ground

• If resistance between

pin C5 and engine ECM

pin # (see chart) is 0 to .3

ohms and

• If resistance between pin C5 and

ground is more than 10K ohms or

open circuit (OL)

If resistance is outside of

range

Go to Step B.

Fault Isolation Procedures

Repair J-1939 data link harness

between engine ECM and system

manager. Go to Step V.

2-56

Page 74

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Step B Procedure Condition Action

1. Key off.

2. Measure resistance

between:

• System manager 32way connector pin C4

and engine ECM pin # (see chart)

• System manager 32-way pin

C4 and ground

• If resistance between pin

C4 and engine ECM pin #

(see chart) is 0 to .3 ohms

and

• If resistance between pin C4 and

ground is more than 10K ohms or

open circuit (OL)

If resistance is outside of

range

• If equipped with J-1939-Lite, go

to Step D.

• If not equipped with J-1939-Lite,

go to Step C.

Repair J-1939 data link harness

between engine ECM and system

manager. Go to Step V.

2-57

Page 75

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Step C Procedure Condition Action

1. Key off.

2. Measure resistance

between system

manager 32-way

connector pin D5 and engine

ECM pin # (see chart).

If resistance between pin

D5 and engine ECM pin #

(see chart) is 0 to .3

ohms

If resistance is outside of

range

Go to Step D. (If working on a Mack

engine, go to Step E).

Repair J-1939 data link harness

between engine ECM and system

manager. Go to Step V.

Fault Isolation Procedures

2-58

Page 76

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Step D Procedure Condition Action

1. Key off.

2. Measure resistance between

system manager 32-way

connector pins C5 and C4.

Note: Make sure the

volt/ohm meter

is on the proper

scale (around

200 ohm scale).

If resistance between pin

C5 and C4 is between 50

to 70 ohms

If resistance is above 70

ohms

If resistance is less than

50 ohms

Go to Step E.

One or both of the terminating

resistors on J-1939 data link

harness are either missing or out of

range. Repair J-1939 data link

harness. Go to Step V.

Repair the J-1939 data link in

between the engine ECM and the

system manager. Go to Step V.

2-59

Page 77

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Step E Procedure Condition Action

1. Key off.

Note: Data link test is designed to

test a signal from an

individual ECU. The ECU

must be isolated from the

rest of the Data link.

2. Reconnect engine ECM

connector and system manager

32-way connector.

3. Disconnect the 3-way stub

connector, which connects the

transmission into the J-1939

data link.

4. Connect the data link tester to

the 3-way stub connector,

which connects the

transmission into the J-1939

data link.

• Red lead from data link tester

connects to the +J-1939

•Black lead from data link tester

connects to the -J-1939

Note: If vehicle does not use 3-

way stub connectors,

then do no reconnect the

engine ECM connector

and connect the data link

tester across the +/- J1939 terminals (see

chart).

5. Place the data link tester in

communication mode.

Fault Isolation Procedures

6. Key on. If LED is solid or flashing Problem exists with the engine

ECM. Repair according to

manufacturer’s recommendations.

Go to Step V.

If LED if off Replace system manager. Go to

Step V.

2-60

Page 78

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Step V Procedure Condition Action

1. Key off.

2. Key on.

3. Clear Fault Codes (see page 1-4)

4. Use Driving Technique to

attempt to reset the code (see

page 1-6)

5. Retrieve Fault Codes

(see page 1-4)

If no codes Test complete.

If code 35 appears Return to Step A to find error in

testing.

If code other than 35

appears

Go to Fault Code Isolation

Procedure Index. (see page 1-10)

2-61

Page 79

Fault Isolation Procedures

Code 35 (SID 231, FMI 2,7), Engine Control Failure Test, continued

Fault Isolation Procedures

This page left blank intentionally.

2-62

Page 80

System Code: 41

(SID 56, FMI 7)

Range Failed to Engage

Fault Isolation Procedures

Overview

This code indicates the transmission is unable to complete a

shift across the range. The range is either stuck in HI or LO, or

cannot complete engagement in HI or LO.

Detection

The transmission attempts the same range shift five consecutive times and determines the shift cannot be completed based

on the speeds across the back box.

Fallback

This fault causes a 5-speed fallback and the transmission stays

in either LO range or HI range. When the vehicle comes to a

stop, an attempt to shift into LO range is made.

Required Tools

• Basic Hand Tools

• (2) 0-100 PSI Air Pressure Gauges

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Low air pressure

• Contaminated air supply

• Air leak

• Range solenoid stuck

• Failed range synchronizer

• Failed range actuator/cylinder/piston/yoke

2-63

Page 81

Fault Isolation Procedures

Code 41 (SID 56, FMI 7), Range Failed to Engage Test

Step A Procedure Condition Action

1. Key off.

2. Install both 0 to 100 PSI air

gauges into the range valve

diagnostic ports.

3. Start vehicle and allow air

pressure to reach governor cutoff.

4. Release clutch to register input

speed in transmission.

5. Turn off engine, but leave key in

"ON" position.

6. With the shift control,

select reverse and

back to neutral.

If LO range gauge = 55 to 65 PSI

and

If HI range gauge = 0 PSI

Note: 5 minutes is

allowed for

checking the

pressure after moving the

shift lever to neutral.

If both air gauges do not

read in range

Go to Step B.

Repair or replace range valve and

range cylinder as required. Retest.

Fault Isolation Procedures

2-64

Page 82

Fault Isolation Procedures

D

Code 41 (SID 56, FMI 7), Range Failed to Engage Test, continued

Step B Procedure Condition Action

1. Move shift lever to reverse,

press upshift button, and move

lever back to neutral.

Note: If shift lever DOES

NOT have upshift

buttons, move shift

lever to reverse and place a

jumper between service port

connector pins B and D.

Remove jumper and place

shift lever in neutral.

If HI range gauge = 55 to 65 PSI and

If LO range gauge = 0 PSI

Note: 5 minutes is

allowed for

checking the

pressure after moving the

shift lever to neutral.

If both air gauges do not

read in range

H

B

Repair or replace mechanical range

system as required. Go to Step V.

Repair or replace range valve and

range cylinder as required. Go to

Step V.

G

2-65

Page 83

Fault Isolation Procedures

Code 41 (SID 56, FMI 7), Range Failed to Engage Test, continued

Step V Procedure Condition Action

1. Disconnect gauges.

2. Reconnect all connectors.

3. Key on.

4. Clear Fault Codes (see page 1-4)

5. Use Driving Technique (see

page 1-6) to attempt to reset the

code.

6. Retrieve Fault Codes

(see page 1-4)

If no codes Test complete.

If code 41 appears Return to Step A to find error in

testing.

If code other than 41

appears

Go to Fault Code Isolation

Procedure Index. (see page 1-10)

Fault Isolation Procedures

2-66

Page 84

System Code: 42

(SID 61, FMI 7)

Splitter Failed to Engage

Fault Isolation Procedures

Overview

This code indicates the transmission is unable to complete a

shift across the splitter. The splitter is either stuck in HI or LO,

or cannot complete engagement in HI or LO.

Detection

The transmission attempts the same splitter shift five consecutive times and determines the shift cannot be completed

based on the speeds across the back box.

Fallback

This fault causes a 9-speed fallback and the transmission stays

in either LO split or HI split.

Required Tools

• Basic Hand Tools

• (2) 0-100 PSI Air Pressure Gauges

• AutoSelect/AutoShift Troubleshooting Guide

Possible Causes

This fault can be caused by any of the following:

• Low air pressure

• Contaminated air supply

• Air leak

• Splitter solenoid stuck

• Failed splitter actuator/cylinder/piston/yoke

2-67

Page 85

Fault Isolation Procedures

Code 42 (SID 6,1, FMI 7), Splitter Failed to Engage Test

Step A Procedure Condition Action

1. Key off.

2. Install both 0 to 100 PSI air

gauges into the splitter valve

diagnostic ports.

3. Start vehicle and allow air

pressure to reach governor cutoff.

4. Release clutch to register input

speed in transmission.