Page 1

Service Manual

Fuller Medium Heavy Transmissions

TRSM0202

October 2007

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Service

Manual

·Operation

•

Lubrication

·Maintenance

·Repair

T-955

©Eaton

Corporation

Transmission

Div.

-1973

Series

Fuller®

Twin

Transmissions

Countershaft

Eaton

Transmission

Kalamazoo,

Corporation

Michigan

Division

Page 5

l+MH·+•...__

_______________________

_

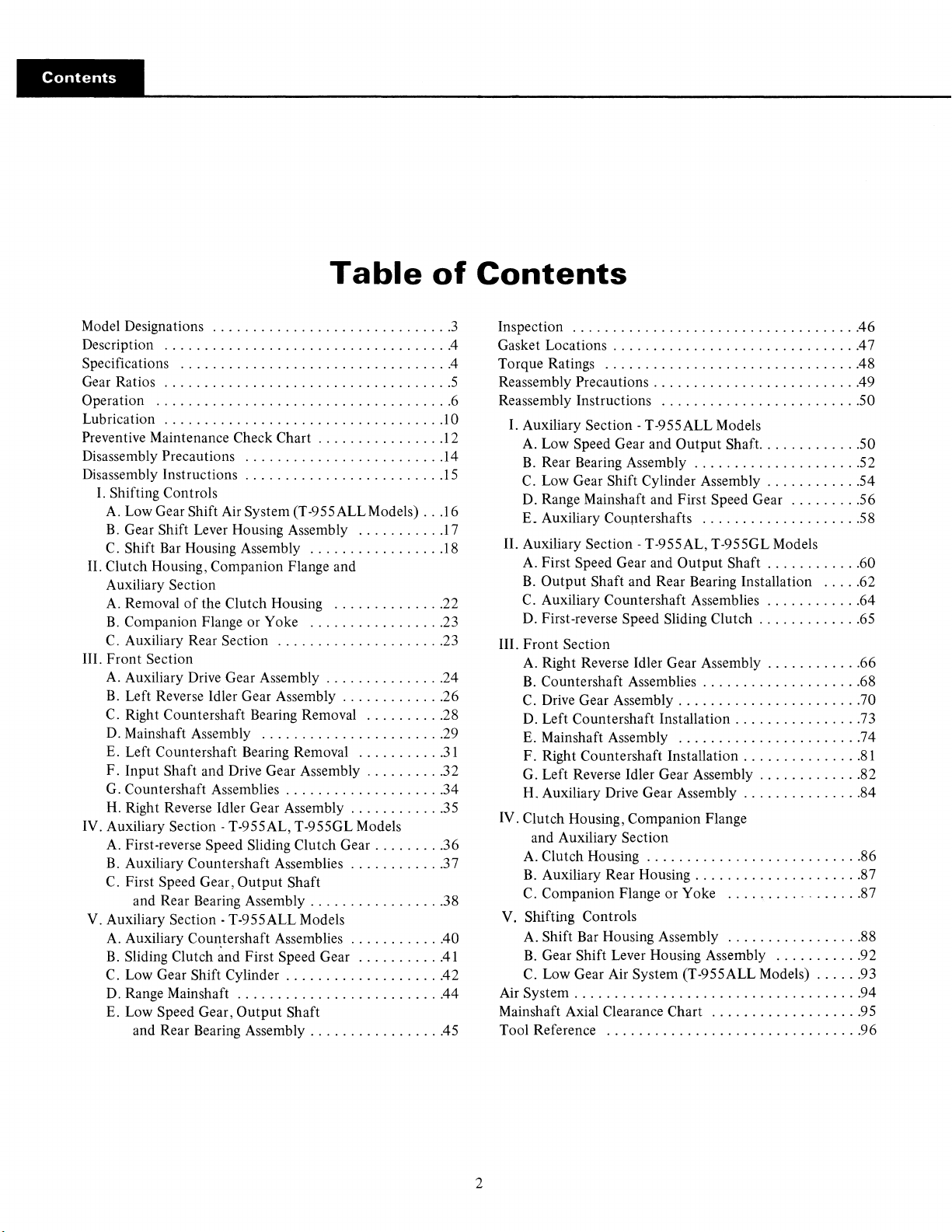

Table

Model Designations

Description

Specifications

Gear Ratios

Operation

Lubrication

Preventive

Disassembly Precautions

Disassembly Instructions

I.

Shifting Controls

A. Low Gear Shift Air System (T-955ALLModels)

B.

C. Shift Bar Housing Assembly

II.

Clutch Housing, Companion Flange and

Auxiliary Section

A. Removal

B.

C.

Front

III.

A. Auxiliary Drive Gear Assembly

B.

C. Right Countershaft Bearing Removal

D. Mainshaft Assembly

E. Left

F.

G.

H. Right Reverse Idler Gear Assembly

IV. Auxiliary

A. First-reverse

B.

C. First Speed Gear,

V. Auxiliary

A. Auxiliary

B.

C. Low Gear Shift Cylinder

D. Range Mainshaft

E. Low Speed Gear,

....................................

...................................

.....................................

...................................

Maintenance Check Chart

Gear Shift Lever Housing Assembly

Companion Flange or Yoke

Auxiliary Rear Section

Section

Left Reverse Idler Gear Assembly

Countershaft Bearing Removal

Input

Shaft and Drive Gear Assembly

Countershaft Assemblies

Auxiliary Countershaft Assemblies

and Rear Bearing Assembly

Sliding Clutch and First Speed Gear

and Rear Bearing Assembly

.............................

.................................

................

........................

.........................

..........

................

of

the Clutch Housing

.....................

.......................

...................

Section - T-955AL, T-955GL Models

Speed Sliding Clutch Gear

Output

Section - T-955ALL Models

Cou~tershaft

..........................

Output

Shaft

Assemblies

...................

Shaft

..............

.................

...............

.............

..........

............

...........

................

............

..........

.................

..........

.........

.........

of

10

12

.14

15

..

.16

.17

.18

22

23

23

24

26

28

29

.31

.32

.34

35

36

.37

.38

40

.41

.42

44

45

Contents

.3

4

.4

.5

6

Inspection

Gasket Locations

Torque Ratings

Reassembly Precautions

Reassembly Instructions

I.

Auxiliary Section - T-9 55 ALL Models

A. Low

B.

Rear Bearing Assembly

C. Low Gear Shift Cylinder Assembly

D. Range Mainshaft and First

E_

Auxiliary Coup.tershafts

II. Auxiliary

A. First

B.

Output

C.

Auxiliary Countershaft Assemblies

D. First-reverse Speed Sliding Clutch

III.

Front

A. Right Reverse Idler Gear Assembly

B.

Countershaft Assemblies

C. Drive Gear Assembly

D. Left Countershaft Installation

E. Mainshaft Assembly

F. Right

G. Left Reverse Idler Gear Assembly

H.

Auxiliary Drive Gear Assembly

IV. Clutch Housing, Companion Flange

and Auxiliary

A. Clutch Housing

B.

Auxiliary Rear Housing

C. Companion Flange

Shifting Controls

V.

A. Shift Bar Housing Assembly

B.

Gear Shift Lever Housing Assembly

C. Low Gear Air System (T-955ALL Models)

Air

System

Mainshaft Axial Clearance Chart

Tool Reference

...................................

..............................

...............................

..........................

........................

Speed Gear and

Section -T-955AL, T-955GL Models

Speed Gear and

Shaft and Rear Bearing Installation

Section

Countershaft Installation

Section

....................................

................................

Output

Output

.......................

.......................

...........................

or

Shaft.

....................

Speed Gear

...................

Shaft

....................

................

...............

...............

.....................

Yoke

.................

.................

...................

.............

.............

...........

...........

.........

............

............

............

...........

.....

......

.46

.4

.48

49

.50

.50

.52

.54

56

.58

60

62

64

65

66

68

70

73

74

81

82

84

86

87

87

88

92

93

94

9 5

96

7

2

Page 6

Model

Designations

T-955AL

T0-955AL

T-955G L T-955ALL -Seven

T0-955ALL-

Unless stated otherwise, this manual applies to all models in the T-955 series which

includes: T-955AL, T0-955AL, T-955ALL, T0-955ALL, T-955GL

- Six speed,

- Six speed, overdrive.

Six speed, gathered ratios.

Seven

direct

speed,

direct

speed, overdrive.

drive.

drive.

NOTE

Illustrated

parts

lists

with parts numbers are available upon request.

3

Page 7

Description

These

950

lb.-ft. torque capacity units are designed to take

advantage

gines and to

vehicles.

The T-955AL and T0-955AL six speed models have ratios

for construction vehicles, especially dump truck operation.

The 11.17 low gear provides ample reduction for starting

heavy loads, yet can

ping vehicle. The two reverse ratios, progressively shifted,

provide fast backing speeds plus deep reduction for job-site

spotting. The T0-955AL overdrive model

drive ratio where heavy duty drive axles are needed and

ratio choices are limited.

of

the power curve

give

the ratio spread necessary for construction

be

of

the high torque

shifted progressively without stop-

gives

rise

en-

a .65 over-

Specifications

Speeds

T-955AL, GL: 6 forward speeds, 2 reverse

T-955ALL: 7 forward speeds, 3 reverse

The T-955ALL and T0-955ALL seven speed models,

cially suited for

the reduction for extremely adverse conditions, also ratios

for curbing and paving. Three reverse ratios

stockpiling,

T0-955ALL overdrive model

speeds when heavy duty axle ratio choice

The T-955GL model has special

vehicles operating primarily on highway.

Torque

Clutch

both

job-site

Rating

Housing

dump and mixer operations, provide

give

work and load spotting. The

is

available to obtain highway

is

limited.

"gathered" ratios for

950 lb.-ft.

Size

SAE

No. 1, 2 aluminum

espe-

a range for

Power

PTO

Take-Off

Right Side: regular duty, 6-bolt type

45

tooth

PTO gear

Bottom: heavy duty, 8-bolt type

4 7

tooth

PTO gear

Gear

Relative

T-955AL: .533, right side and

T-955GL: .700, right side and

T0-955AL: .820, right side and

T-955ALL: .533, right side and

T0-955ALL: .820, right side and

Speed

to

Input

bottom

bottom

bottom

bottom

bottom

R.P.M.

Length

splines

(from

on

T-955AL, GL: 30

T-955ALL: 34

face

tailshaft)

Weight

T-955AL, GL: 580 lbs.

T-955ALL: 646 lbs.

Oil

Capacity

T-955AL, GL:

T-955ALL: 28

(pints)

of

25

clutch

7/8"

1/16"

housing

to

end

of

4

Page 8

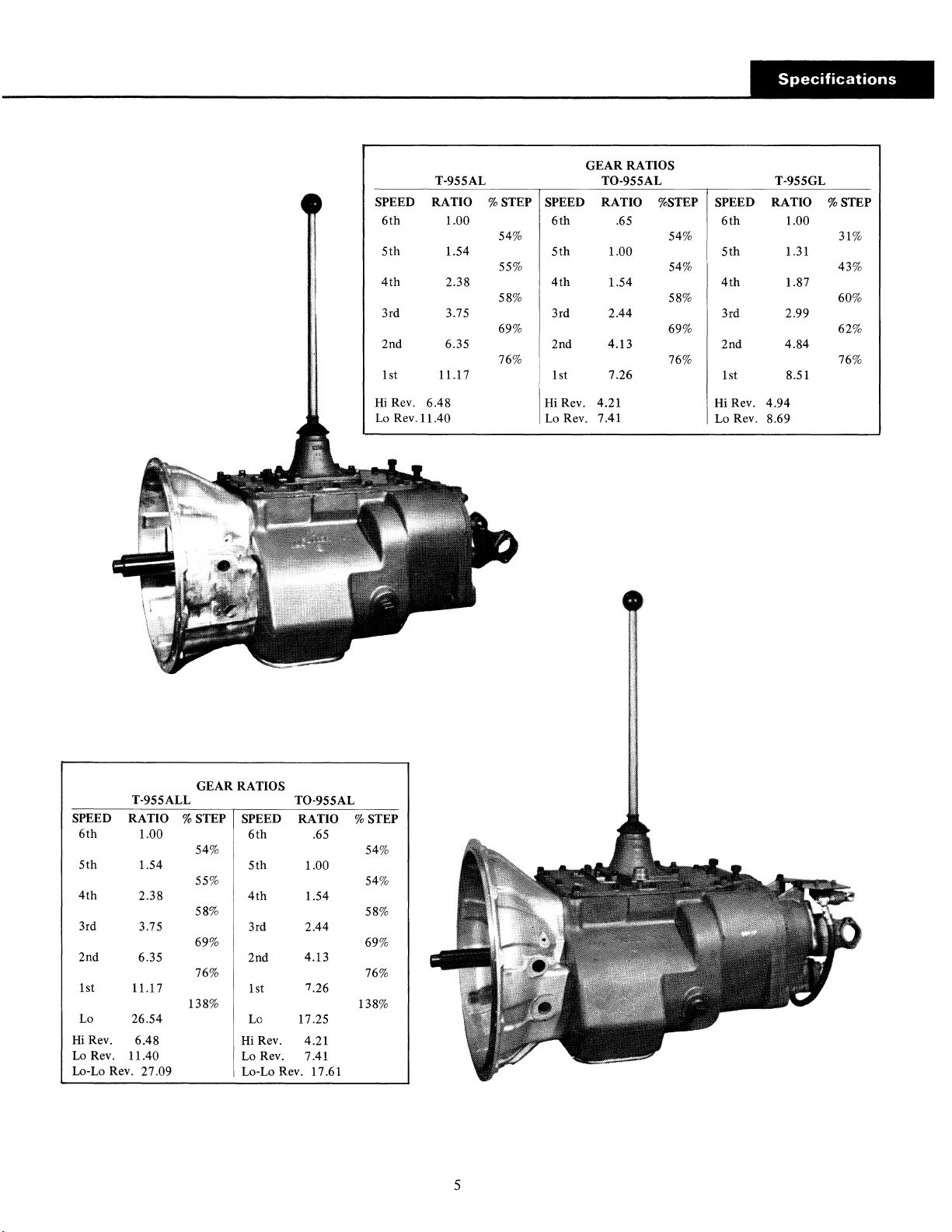

T-955AL

SPEED RATIO %STEP

6th

1.00

SPEED RATIO %STEP SPEED RATIO %STEP

6th

T0-955AL

54% 54%

GEAR RATIOS

5th

1.54

5th

1.00

55% 54% 43%

4th

2.38

4th

1.54

58% 58%

3rd

3.75

3rd 2.44 3rd 2.99

69% 69% 62%

2nd 6.35

2nd

4.13

76%

1st 11.17 1st 7.26

Hi

Rev.

Lo

Rev. 11.40

6.48

Hi

Rev. 4.21

Lo

Rev. 7.41

.65

T-955GL

6th

1.00

31%

5th

4th

1.31

1.87

60%

2nd 4.84

76% 76%

1st 8.51

Hi

Rev.

Rev.

4.94

8.69

Lo

T-955ALL

SPEED RATIO

6th

5th

4th

3rd

2nd

1st

Lo

Hi

Rev.

Lo

Rev.

Lo-Lo Rev.

1.00

1.54

2.38

3.75

6.35

11.17 1st

26.54

6.48

11.40

27

.09

RATIOS

GEAR

T0-9SSAL

%STEP SPEED RATIO

6th

54%

5th

1.00

%STEP

.65

54%

55% 54%

58%

4th

3rd

69%

2nd

76%

1.54

58%

2.44

69%

4.13

76%

7.26

138% 138%

Lo

Hi

Lo

Rev.

Rev.

17.25

4.21

7.41

Lo-LoRev. 17.61

5

Page 9

Operation

In the following instructions it is assumed that the driver

coordinate the necessary movement

of

the shift lever and clutch pedal

either direction, up or down.

Six

Speed Models

T-955AL, T-955GL & T0-955AL Models

To shift from neutral to:

1st

- shift thru 2nd.

Reverse

T0-955AL

lo-

the

shift thru reverse-hi

On overdrive model

5th & 6th

speed positions are reversed

1.

Start engine with gear shift lever in the neutral position.

2. To start vehicle moving, shift into the 1st speed position.

This

is

done by moving the gear shift lever through the

gear

2nd speed

may be necessary to feather clutch

2nd).

Move

position with the clutch disengaged (it

to

move lever into

lever through the 2nd speed gear position to

the extreme left, then push lever forward into 1st gear.

NOTE:

the neutral position between

neutral position

While

moving the lever into first

can

be used

2nd

and 1st

at

stop lights, etc.

you

may feel

gears.

This

is

familiar with motor trucks and tractors, and that he can

to

make progressive and selective gear engagements in

3. After vehicle has gained sufficient speed in 1st gear, shift

lever into the 2nd speed position.

4. Shift from 2nd to 3rd

by

moving lever from the extreme

right in the second speed gear position into the 3rd

speed position.

NOTE: A spring and plunger will move the gear shift

lever to the extreme right

When

shifting from 1st to

in

the

2nd

speed

gear

2nd

the gear shift lever will be

position.

moved to the extreme right position; when shifting from

2nd

to 1st, operator must move lever to the extreme left

in

position while

2nd gear position against the spring

pressure.

5. Shift on upward through

pattern.

On

overdrive models, the

4th,

5th

and 6th in the shift

5th

and 6th speed gear

positions are reversed.

Reverse and

To

shift into reverse, move the gear shift lever into the

Lo

Reverse

reverse gear position.

To

shift into Lo reverse; first shift into reverse, then move

lever to the extreme left and forward into the lo reverse

position (it may be necessary

to

feather clutch to move

lever into reverse.)

6

Page 10

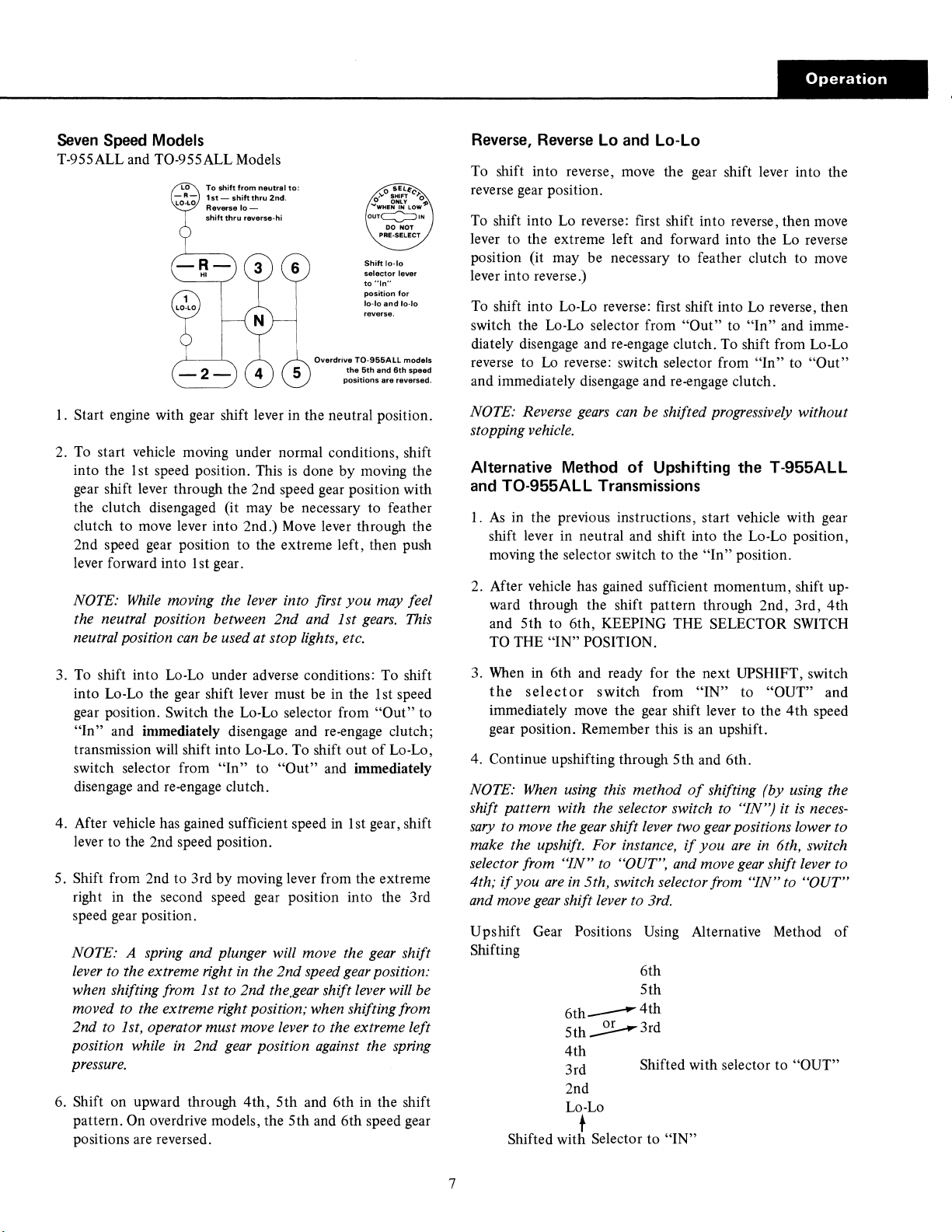

Seven

Speed

Models

T-955ALL and T0-955ALL Models

To shift

from

- shift thru

neutral

2nd.

1st

to:

Overdrive

T0-955ALL

the

5th

positions are reversed.

Shift

lo-lo

selector lever

to

"In"

position for

lo-lo

and

lo-lo

reverse.

models

and

6th

speed

Reverse,

To

Reverse

Lo

and

Lo-Lo

shift into reverse, move the gear shift lever into the

reverse gear position.

To

shift into Lo reverse: first shift into reverse, then move

lever to the extreme left and forward into the Lo reverse

position (it may be necessary to feather clutch to move

lever into reverse.)

Lo

To shift into Lo-Lo reverse: first shift into

switch the Lo-Lo selector from

diately disengage and re-engage clutch.

reverse to

Lo

reverse: switch selector from

"Out"

To

reverse, then

to

"In"

and imme-

shift from Lo-Lo

"In"

to

"Out"

and immediately disengage and re-engage clutch.

1.

Start engine with gear shift lever in the neutral position.

To

start vehicle moving under normal conditions, shift

2.

is

into the 1st speed position. This

done by moving the

gear shift lever through the 2nd speed gear position with

the clutch disengaged (it may be necessary to feather

clutch to

move

lever into 2nd.)

Move

lever through the

2nd speed gear position to the extreme left, then push

lever forward into 1st gear.

NOTE:

the neutral position between 2nd and 1st

neutral position

3.

To

While

moving the lever into first

you

may feel

gears.

can

be used at stop lights, etc.

shift into Lo-Lo under adverse conditions: To shift

into Lo-Lo the gear shift lever must be in the 1st speed

gear position.

"In"

and immediately disengage and re-engage clutch;

transmission will shift into Lo-Lo. To shift out

switch selector from

Switch the Lo-Lo selector from

"In"

to

"Out"

and immediately

"Out"

of

disengage and re-engage clutch.

in

4. After vehicle has gained sufficient speed

1st gear, shift

lever to the 2nd speed position.

5.

Shift from 2nd to 3rd by moving lever from the extreme

right in the second speed gear position into the 3rd

speed gear position.

NOTE: A spring and plunger will move the

lever to the extreme right

in

the 2nd speed

gear

gear

position:

when shifting from 1st to 2nd the.gear shift lever will be

moved to the extreme right position; when shifting from

2nd to 1st, operator must move lever to the extreme left

position while

in

2nd

gear

position against the spring

pressure.

6.

Shift on upward through

pattern.

On overdrive models, the

4th,

5th

and 6th in the shift

5th

and 6th speed gear

positions are reversed.

This

to

Lo-Lo,

shift

NOTE: Reverse

gears

can

be shifted progressively without

stopping vehicle.

Alternative Method

and

T0-955ALL

1.

As

in the previous instructions, start vehicle with gear

of

Upshifting the

Transmissions

T-955ALL

shift lever in neutral and shift into the Lo-Lo position,

moving the selector switch to the

"In"

position.

2. After vehicle has gained sufficient momentum, shift upward through the shift pattern through 2nd, 3rd,

and

5th

to 6th, KEEPING THE SELECTOR

TO

THE

"IN"

POSITION.

4th

SWITCH

3. When in 6th and ready for the next UPSHIFT, switch

the

selector

immediately move the gear shift lever

gear position. Remember this

4. Continue upshifting through

NOTE:

When

shift pattern with the selector switch to "JN")

sary

to move the

make the upshift. For instance,

selector from

4th;

if

you

are

and move

gear

U pshift Gear Positions Using Alternative Method

switch from

is

5th

using this method

gear

shift lever two gear positions lower to

if

"IN"

to "OUT", and move

in

5th, switch selector from

shift lever to 3rd.

"IN"

to

"OUT" and

to

the

4th

an upshift.

and 6th.

of

shifting (by using the

it

is

you

are

in

6th, switch

gear

shift lever to

"IN"

to "OUT"

speed

neces-

of

Shifting

6th

5th

6th

__

5th

_2!.--3rd

4th

4th

3rd

Shifted with selector to "OUT"

2nd

Lo-Lo

t

Shifted

with Selector to

"IN"

7

Page 11

To

Convert

From

T-955AL

To

T0-955AL,

To convert from an T-955AL or T-955ALL to

drive

model T0-955AL or T0-955ALL the fifth speed gear

on the mainshaft and mating gears, one on each countershaft, are interchanged with the main drive gear and mating

countershift drive gears.

The transmission front section must be completely

assembled to make the change

as

the drive gear on each

INTERCHANGE THESE TWO SETS OF GEARS.

or

T-955ALL

an

over-

dis-

(3 Gears

To

T0-955ALL

countershaft must be removed. When reassembling make

sure gear hubs are in the right position

detailed reassembly section

Extra parts, other than gaskets, are not needed to make

the conversion. A new drive gear bearing nut may be

needed

in

each set)

as

this part may be damaged during removal.

of

this manual.

as

described

in

the

FRONT SECTION OF T-955AL

8

AND

T-955ALL

Page 12

Special

Procedure

For

Changing

In some cases in field repair it may be necessary to

place only the input shaft due to clutch wear on the splines.

In these instances the input shaft can be removed

out disassembling the transmission other than removing the

shifting bar housing. Removal

tional. Following

is

the detailed procedure:

of

the clutch housing

Clutch

re-

with-

is

op-

Disassembly

1.

Remove gear shift lever housing and shift bar housing

from transmission.

2. Remove the front bearing cover.

3. Engage the mainshaft sliding clutches in two gears and

remove the drive gear bearing nut.

4.

Move

the drive gear assembly

and remove the drive gear bearing.

5. Remove the washer from input shaft.

6.

From the front, remove the snap ring from

gear.

7.

Pull the input shaft forward and from splines

gear.

as

far forward

as

ID

possible

of

drive

of

drive

(Input)

Shaft

Reassembly

1.

Install new input shaft into splines

enough to expose snap ring groove in

of

2. Install snap ring in ID

3. Install washer on shaft.

IMPORTANT

4.

contact end

between rear

speed gear. When installing bearing this will hold input

shaft in position

5. Install drive gear bearing on shaft and into case bore,

making sure blocking remains in place.

6. Remove blocking from mainshaft and install the drive

gear

bearing nut, left-hand thread.

threads

7.

Peen nut into milled slots in shaft.

8. Re-install front bearing cover, shifting bar housing and

gear shift lever housing.

NOTE:

input shaft only.

disassembly

-

Move

of

input shaft in hub

of

to

of

nut and shaft.

The above instructions

of

the front section must be

drive gear.

the sliding clutch gear forward to

sliding clutch and front

seat the bearing properly.

To

change the drive

of

drive gear just far

ID

of

drive gear.

of

drive gear. Block

of

Use

Loctite sealant on

are

for changing the

gear,

made.

the fifth

complete

9

Page 13

Ei.!j1ffo.l,I

___________________________

_

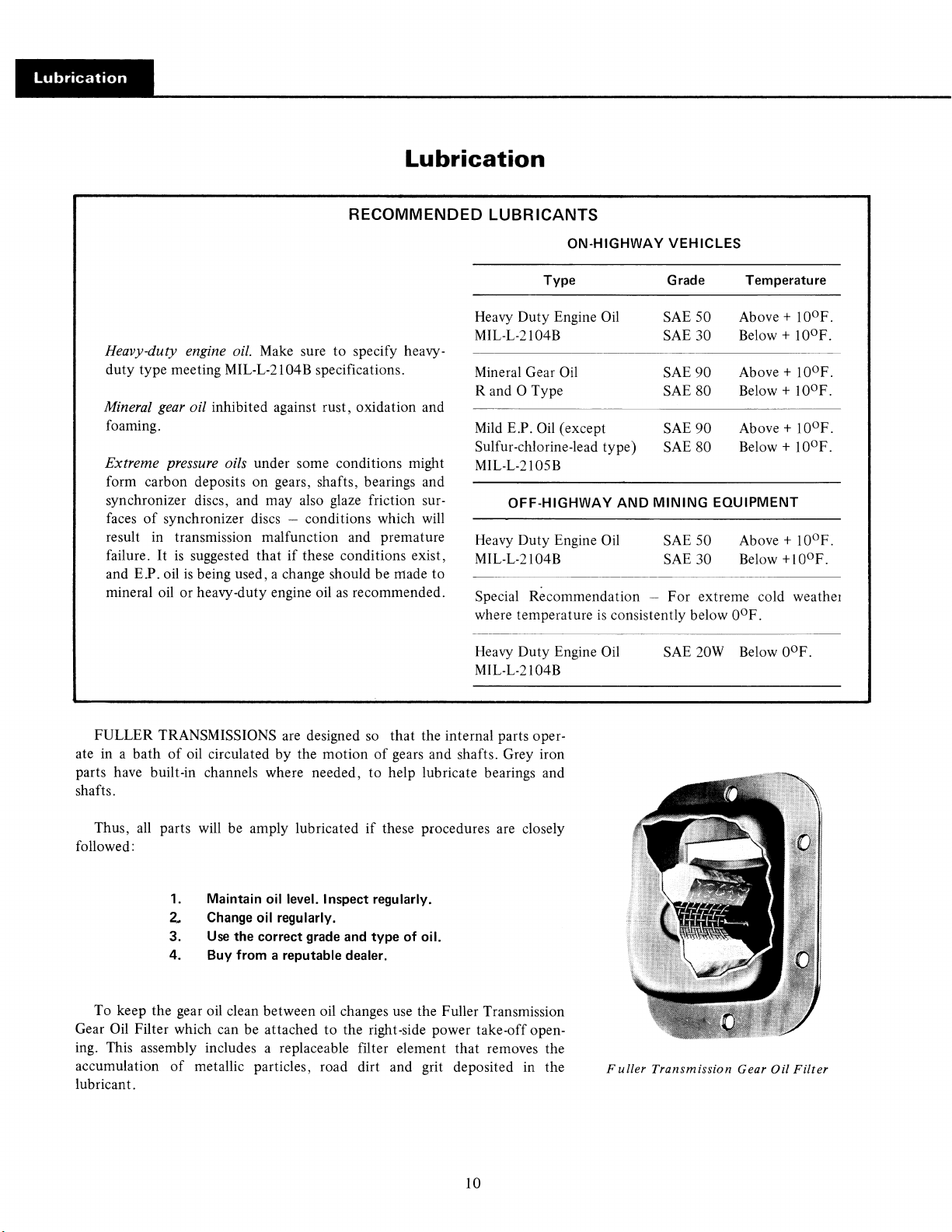

Lubrication

RECOMMENDED LUBRICANTS

Heavy-duty engine oil. Make sure to specify heavyduty type meeting MIL-L-2104B specifications.

Mineral gear oil inhibited against rust, oxidation and

foaming.

Extreme pressure oils under some conditions might

form carbon deposits on gears, shafts, bearings and

synchronizer discs, and may also glaze friction

faces

of

synchronizer discs - conditions which will

result in transmission malfunction and premature

failure.

and E.P. oil

mineral oil or heavy-duty engine oil

It

is

suggested that

is

being used, a change should be made to

if

these conditions exist,

as

recommended.

sur-

ON-HIGHWAY

Type

Heavy Duty Engine

MIL-L-2104B

Mineral Gear Oil

Rand

0 Type

Mild

E.P.

Oil

Sulfur-chlorine-lead type)

MIL-L-2105B

OFF-HIGHWAY

Heavy Duty Engine Oil

MIL-L-2104B

Special Recommendation - For extreme cold weathe1

where temperature

Heavy Duty Engine Oil

MIL-L-2104B

(except

is

Oil

AND

consistently below

VEHICLES

Grade Temperature

SAE 50 Above + 1

SAE

SAE90

SAE

SAE90

SAE

MINING

SAE 50

SAE30

SAE

Below + 1 ooF.

30

Above +

80

Below + 1

Above + 1

80 Below + 1

EQUIPMENT

Above + 1

Below + 1

o°F.

20W

Below ooF.

o°F.

I0°F.

o°F.

o°F.

o°F.

o°F.

o°F.

FULLER TRANSMISSIONS

ate in a bath

parts have built-in channels where needed, to help lubricate bearings and

shafts.

Thus,

followed:

To keep the gear oil clean between oil changes use the Fuller Transmission

Gear

Oil Filter which can be attached to the right-side power take-off opening. This assembly includes a replaceable filter element that removes the

accumulation

lubricant.

of

oil circulated by the motion

all

parts will be amply lubricated

1. Maintain oil level. Inspect regularly.

2.

Change

3.

Use

the correct

4. Buy from a reputable dealer.

of

metallic particles, road dirt and grit deposited in the

are designed

oil regularly.

grade

so

that the internal parts oper-

of

gears and shafts. Grey iron

if

these procedures are closely

and

type of oil.

10

Fuller

Transmission Gear

Oil

Filter

Page 14

Draining Oil

Inspection

To

drain the transmission remove the drain plug at

the bottom

of

the front case. Drain oil when transmission

is

warm. After the transmission has been drained and before it

is

refilled, the

clean flushing oil or kerosene.

pound

if

pressure lubrication pumps unless pump

unit

case

should be thoroughly flushed with a

Do

not

use

flushing com-

is

equipped with side or front mounted

is

removed and

opening covered with plate. Clean both drain plugs before

reinstalling.

Refilling

In order to assure complete filling

of

the transmission

with oil, the following two methods may be used:

1)

At any inclination: Plug the fill hole in the front

case

and add entire quantity through opening in shift bar

housing. The transmission must be

completely drained

before using this method in order to avoid overfilling.

At

upgrade inclinations from 0 through 3 degrees:

2)

Add sufficient quantities through the fill hole to level

the oil at the

bottom

of

the fill hole.

Gear oil

opening at all times.

Highway

Off-highway Service

Gear Oil Change

Change the gear oil on

is

to be kept even with the level

Check at the following intervals:

Service

.....................

....................

all

new equipment after the first

of

the filler

.1,000 miles

.40 hours

3000 to 5000 miles (on-highway), or first 40 hours (off-

highway); thereafter, make oil changes

Highway Service

Off-highway

.....................

Service

Logging and associated operations

as

follows:

......

25

,000 miles

1,000 hours

Dirt moving, mining and

associated operations

............

250 to 500 hours,

as indicated by operation and contamination

lubricant.

of

Do

not overfill. Overfilling will cause the oil to be

forced out

Adding Oil

intermixed because

made through the fill hole

the fill hole with the transmission at a 0

of

the

case

through the mainshaft openings.

It

is

recommended that types and brands

of

possible incompatibility.

Additions

of

oil during servicing operations should be

to

level the oil at the

of

oil not be

bottom

to

3 degree

of

upgrade angle.

Operating Temperature

It

is

imperative that the operating temperature

transmission does not exceed

250°F.

Extensive operation at temperatures exceeding

will result in rapid breakdown

of

the oil and shorten trans-

of

the

250°F.

mission life.

Transmissions used in stationary equipment, or in

vehicles operating at slow road speeds, may have to be

so

equipped with external coolers

ture

is

not exceeded.

that the

250°F.

tempera-

Special Recommendation

The above oil inspection and change periods are based

on the average

tions listed.

make a periodic lab analysis

contamination based on the individual's own operating

use

and operating conditions for the applica-

It

is

recommended that the individual owner

of

the lubricant to determine

conditions. After this has been determined, the individual

owner can then set his own inspection and oil change

periods.

Clutch Release Bearing

Follow

vehicle manufacturer's chassis lubrication

recommendations.

Oil Filter

If

so

equipped, replace filter element at each oil

change; clean filter element housing.

11

Page 15

'i'fjij.iiijf

1

f

M

. l!IW'Sl!t?t''W'l''Sii.

------

12

Page 16

Preventive

Maintenance

Check

Chart

Preventive

Maintenance

CHECKS WITHOUT PARTIAL

DISASSEMBLY OF

CHASSIS OR

1.

Air

System

a.

Check for leaks, worn air lines, loose connections and

capscrews,

2. Clutch

a.

Check

looseness.

all

3. Clutch

a.

Remove hand hole cover and check radial and axial

clearances in release bearing.

b.

Check relative position

ing

with thrust sleeve on push type clutches.

4.

Clutch

a. Pry upward on shafts to check wear.

If

excessive movement

b.

mechanism and check bushings in bores and wear on

shafts.

5.

Gear

a.

Change at specified service intervals.

b.

Use

only gear oils

tion.

6.

Filler

a.

Remove filler plug and check level

fied intervals. Tighten filler and drain plugs securely.

and

Connections

See

Air Systems, page 94.

Housing

capscrews in bolt circle

Release

Pedal

Mounting

Bearing

of

Shaft

is

Lubricant

as

recommended.

and

Drain

Plugs

CAB

(T-955ALL)

of

clutch housing for

thrust surface

and

Bores

found, remove clutch release

of

release bear-

See

Lubrication

of

lubricant at speci-

sec-

Check

8.

Gear

Shift

a.

Remove the gear shift lever housing assembly from

transmission.

b.

Check tension spring and washer for set and wear.

c.

Check the gear shift lever pivot pin and pivot pin slot for

wear.

d.

Check

bottom

of

slot

contact points with shift lever.

yokes and blocks in shift bar housing for wear

CHECKS WITH

Chart

Lever

Housing

end

of

gear shift lever for wear and check

Assembly

DRIVE

LINE

DROPPED

Universal

9.

a.

Check for tightness. Tighten

CHECKS WITH UNIVERSAL

Joint

Companion

to

recommended torque.

Flange

JOINT

Nut

COMPANION FLANGE REMOVED

10. Output Shaft

a.

Check splines for wear from movement and chucking

action

of

the universal joint companion flange.

Pry upward against output shaft to check radial clear-

b.

ance in mainshaft rear bearing.

11. Mainshaft

a. Check oil seal for wear.

Rear

Bearing

Cover

at

7.

Gear

Shift

Lever

a.

Check for looseness and free play in housing.

loose in housing, proceed with Check No. 8.

If

lever

is

13

Page 17

General

Precautions

IMPORTANT: Read this section before starting

the

detailed disassembly procedures

It

is

assumed in the detailed disassembly instructions

that the lubricant has been drained from the transmission,

the necessary linkage and air lines removed and the transmission has been removed from the chassis. Removal

gear shift lever housing assembly

instructions; however, this assembly must also be removed

from transmission before removing unit from vehicle.

is

included in the detailed

of

the

for

Disassembly

ASSEMBLIES - When disassembling the various assem-

2.

blies, such

bar housing, lay

sequence

assembly and reduce the possibility oflosing parts.

as

the mainshaft, countershafts and shifting

all

parts on a clean bench in the same

as

removed. This procedure will simplify re-

The two control

the

transmission before removing unit from vehicle.

(T-955ALL)

Follow each procedure closely in each section, making

use

of

both

the text and pictures.

1.

BEARINGS - Carefully wash and relubricate

ings

as

removed and protectively wrap until ready for

use. Remove bearings with pullers designed for this

purpose.

REMOVED

CHISEL,

OUTER

BEARING

WITH

DAMAGED

RACE.

valve

air lines must be disconnected at

BEARING

REMOVED WITH

DAMAGED

PUNCH,

SHIELD.

all

bear-

oo

3. SNAP RINGS - Remove snap rings with pliers designed

for this purpose. Rings removed in this manner can be

reused.

INPUT SHAFT - The clutch or input shaft can be re-

4.

moved without removing the countershafts, mainshaft

drive gear.

5.

CLEANLINESS - Provide a clean place

important that no dirt or foreign material enters the unit

during repairs. The outside

fully cleaned before starting the disassembly. Dirt

abrasive and can damage bearings.

WHEN

6.

etc., with restraint. Movement

ed.

solidly.

work.

DRIVING - Apply force to shafts, housings,

Do

not apply force after the part being driven stops

Use

soft hammers and bars for

of

the unit should be care-

of

some parts

to

work.

is

all

disassembly

or

It

restrict-

is

is

14

Page 18

DISASSEMBLY

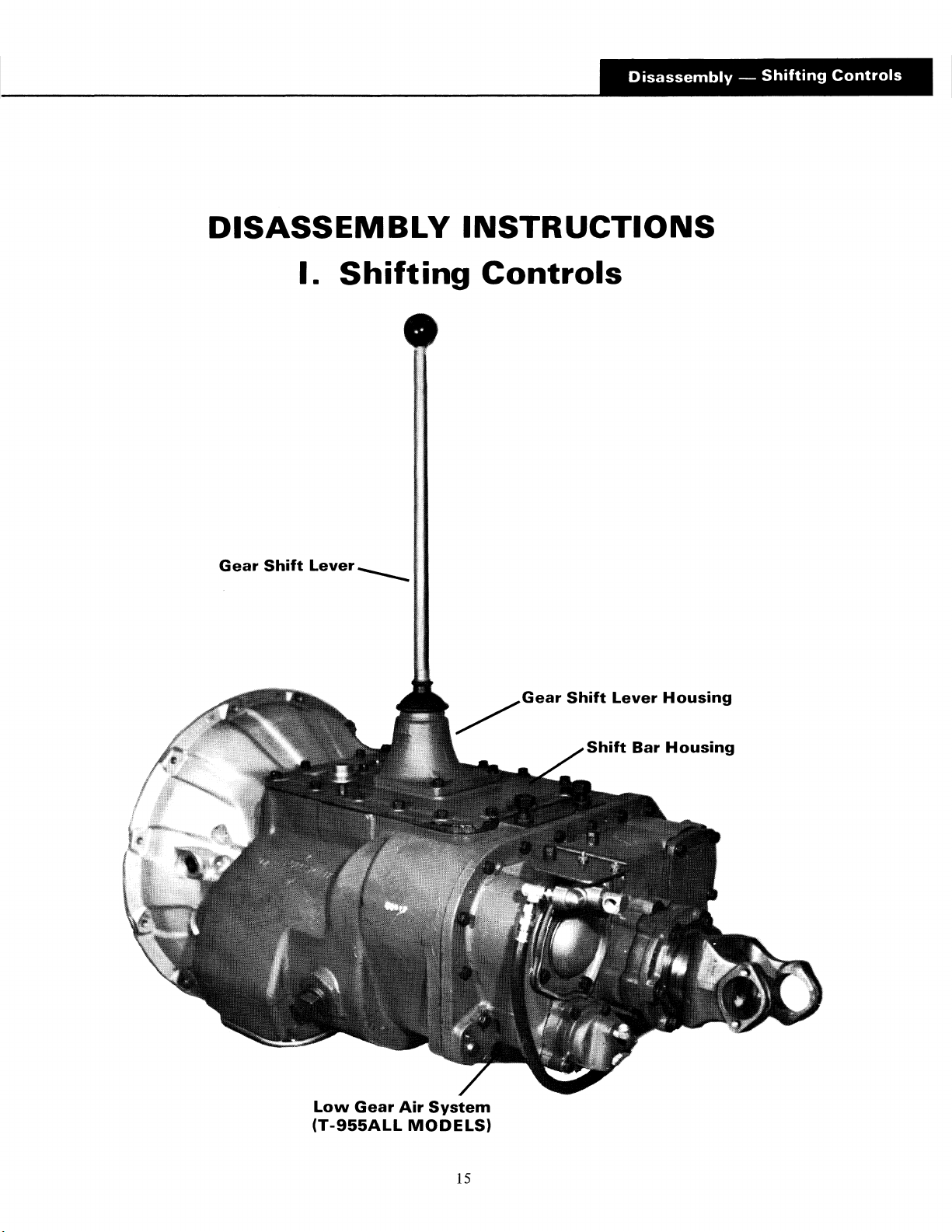

I.

Shifting

Gear

Shift

Lever

----

INSTRUCTIONS

Controls

Low

Gear

(T-955ALL

/Gear

Air

System

MODELS)

Shift

Shift

Lever

Bar

Housing

Housing

15

Page 19

l·HfHH,,'MW

_________________

_

A. Removal of the Low Gear Shift

LowGearShift

Coo"ol

V•"'•--

~

u-

11

i i

•

Y."

l.D.

Air

\___

Lines IF'

Air

System

+·

Tee

. . I

(T-955ALL

Cap screw

(2)

Reducer Bushing

Fitting

-o-u-Rmn-

\

Models)

~

'

l u U-BoU

'--

- -

--

----

Filter

-Air

Bracket

Filter

-.

Y." I .D.

Air

Line

1.

Disconnect

of

the

the

air line between

air filter and

the

the

low gear shift cylinder.

L~

G~'

tee

fitting forward

Shrr.

Cyllod"

~'\''

c~"~

Turn

out

2.

bracket assembly.

the

the

filter, refer

'icj

two

capscrews and remove

For

disassembly and maintenance

to

page 94.

the

air filter and

of

16

Page 20

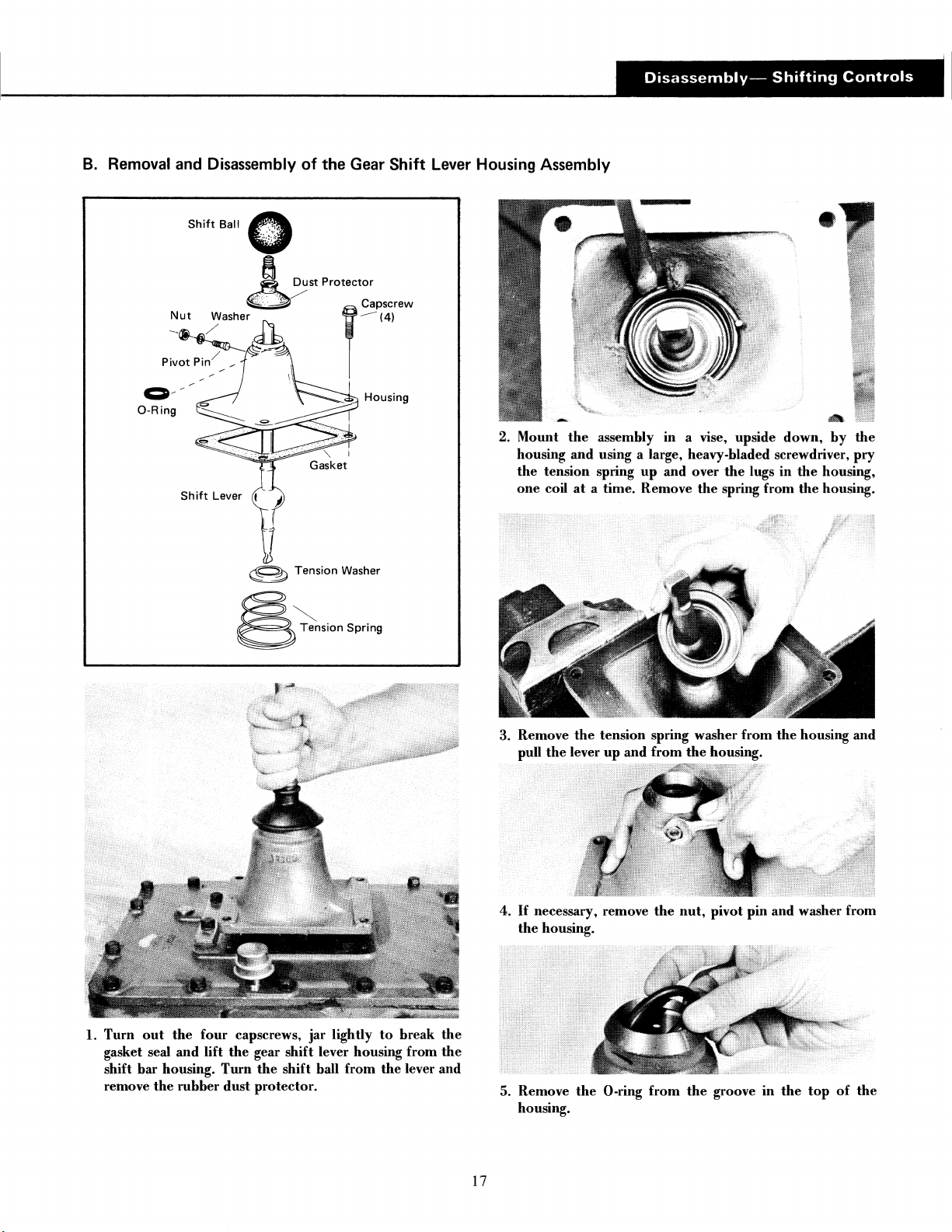

B.

Removal and Disassembly

of

the Gear

Shift

Lever Housing Assembly

ca

Tension Washer

~

';:;;,,;o"

Spd,_

2. Mount

housing and using a large, heavy-bladed screwdriver, pry

the

one

3. Remove

pull

the

assembly in a vise, upside down,

tension spring

coil

at

a time. Remove

the

tension spring washer

the

lever

up

and

up

and over

from

the

the

housing.

the

lugs

in

spring from

from

the

by

the

housing,

the

housing.

housing and

the

1.

Turn

out

the

gasket seal and lift

shift bar housing.

remove

the

rubber

four

capscrews, jar lightly

the

gear shift lever housing from

Turn

the

shift hall from

dust

protector.

to

the

break

the

the

lever and

4.

5. Remove

17

If

necessary, remove

the

housing.

the

0-ring

housing.

the

from

nut,

pivot pin and washer from

the

groove

in

the

top

of

the

Page 21

C. Removal and Disassembly

--

Capscrews

- Tensions Spring Cover

of

the

Shift

Bar Housing Assembly

Plug

@

GasketO

'

00

1

/e

Reverse~

Light

Pin

Capscrew

(161

/

I

11

/ Tension Balls

I/

00

Tension Springs

@Plug

(41

(41

Shift

/

Bar Housing

Gasket

1st

Low

Reverse Block,

Reverse

Shift

Bar

And

Yoke

2nd

Speed~~

Bar and

Yoke

3rd -4th

Bar and

Speed

Yoke

~/

'

~

18

Shift

Lockscrew

\

----~~

lunger

-Spring

\

--Plug

Page 22

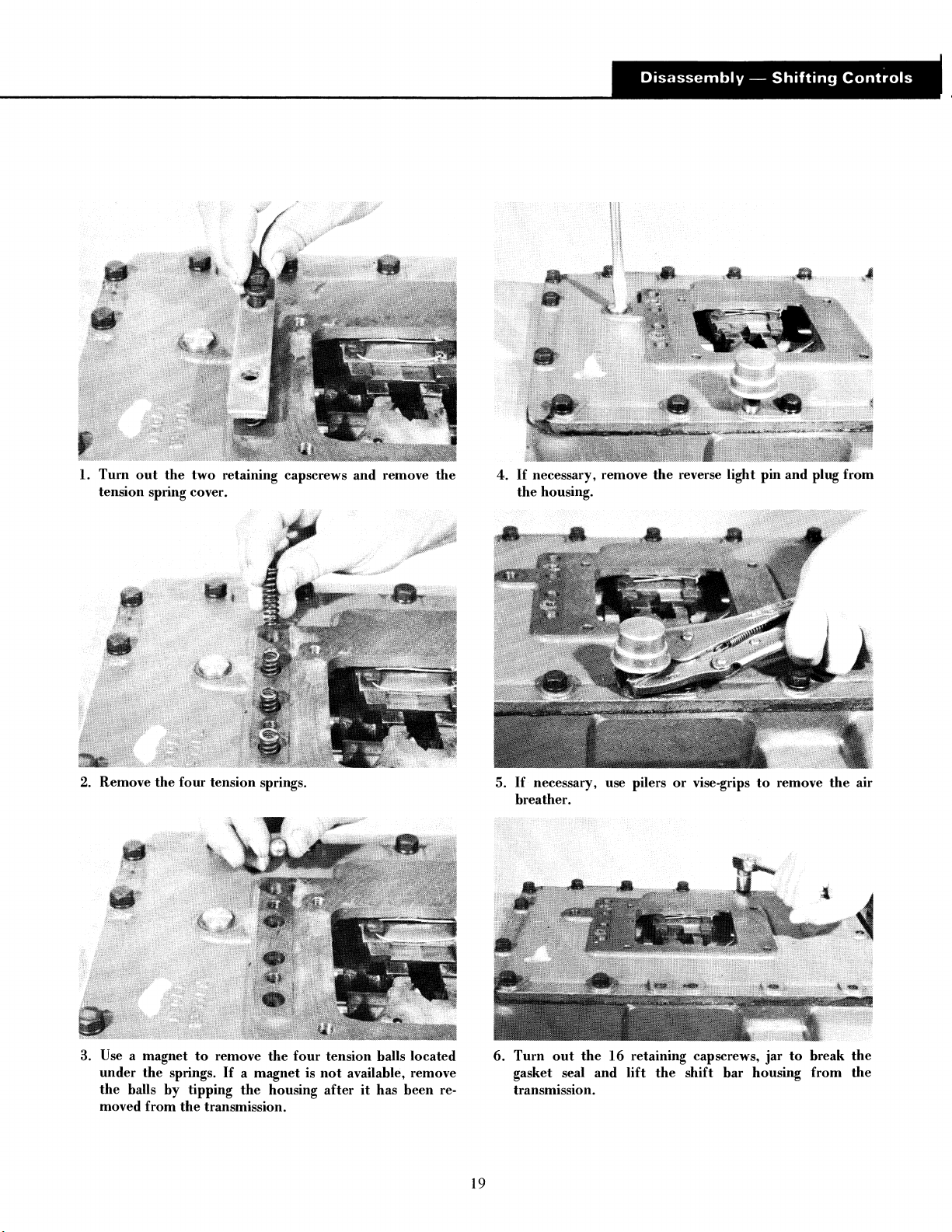

1.

Tum

out

the

tension spring cover.

two

retaining capscrews

and

remove

the

4.

If

necessary, remove

the

housing.

the

reverse light pin

and

plug

from

2. Remove

Use a magnet

3.

under

the

the

halls

moved

the

by

from

four

tension springs.

to

remove

springs.

tipping

the

transmission.

the

If

a magnet is

the

housing

four

tension balls located

not

available, remove

after

it

has

been

re-

5.

6.

19

If

necessary, use pilers

breather.

Tum

out

the

16

gasket seal

transmission.

and

or

vise-grips

retaining capscrews,

lift

the

shift

bar

to

remove

jar

to

housing

the

break

from

air

the

the

Page 23

C.

Removal and Disassembly

of

the

Shift

Bar Housing Assembly - continued

NOTE:

place all parts in their

bench, placing

each bar. Bars

neutral position

preventing removal.

7. Mount

shift bar

lockscrew and pull

from

sary, use a screwdriver

the

In

the

the

shift

to

the

the

shift

spring and plunger from

following steps

order

the

correct shift yokes and blocks

not

being removed

or

interlock parts will lock

bar

housing in a vise with

top

and

the

short (5th-6th speed) shift bar

yoke

and web

to

for

of

rentoval

cut

all lockwires.

of

tum

out

the

shift yoke.

ease

of

on

must

he

the

housing.

the

plug and remove

reassembly,

a clean work-

on

kept

in

the

the

bars,

the

shortest

Tum

out

the

If

neces-

9. Turn

out

shift bar from

and block.

the

two

lockscrews and pull

the

web

of

the

housing and

the

2nd-reverse

the

shift

yoke

8. Turn

bar from

clears

the

out

the

bar.

the

lockscrew and pull

the

yoke

and web

web

the

interlock pin will fall from

of

the

3rd-4th speed shift

the

housing.

As

the

the

bore

bar

in

10. Turn

11. Three interlock balls are located

out

the

two

lockscrews and pull

verse shift bar from

shift

yoke

and block.

housing. These will fall from

bar

is

removed

web.

the

or

may have

web

20

of

the

to

the

in

web as

he

the

1st-low re-

housing and

the

web

of

the

last shift

removed from

the

the

the

Page 24

12. Mount

remove

13. Turn

spring retaining plate.

the

the

out

the

1st-low reverse shift block in a vise and

two

sets

of

lockwires.

two

lockscrews evenly and remove

the

15.

Turn

out

retaining plate.

16. Remove

from each block.

the

the

two

lockscrews and remove

two

blocks and remove

the

the

interlock pin

block

14. Remove

the

two

springs

from

the

bores.

21

Page 25

'·BiHi+"M

1

lli'NNh.iiH'·

1

·B+b'+'·m

1

1

•

iM.t.iiifiiiif

Biiii"+I..._

_________

_

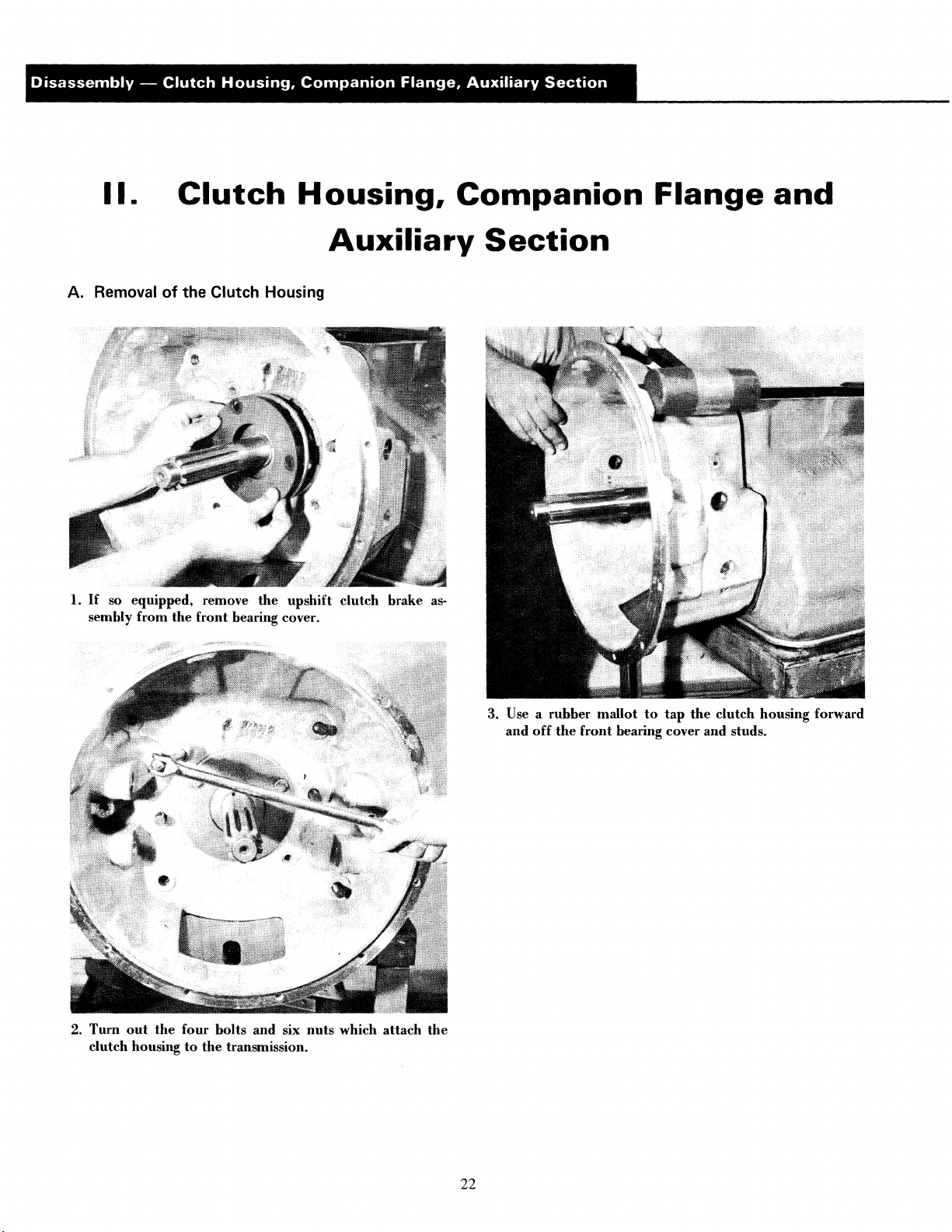

II.

A. Removal

1.

If

so equipped, remove

sembly from

Clutch

of

the Clutch Housing

the

the

front

bearing cover.

Housing,

Auxiliary

upshift clutch brake as·

Companion

Section

Flange

and

2.

Turn

out

clutch housing

the

four

bolts and six

to

the

transmission.

nuts

which

attach

the

3. Use a rubber mallot

and

off

the

front

bearing cover and studs.

to

tap the

clutch housing forward

22

Page 26

B.

1.

Turn

C.

Removal

Removal

the

elastic stop

of

the Companion Flange

nut

from

the

of

the

Auxiliary

Rear Section

Disassembly

or

output

shaft.

Yoke

-

Clutch

2. Pull

Housing,

the

the

output

or

spacer

Companion

companion flange

shaft and remove

from

the

flange

or

Flange,

or

yoke

the

yoke.

Auxiliary

from

the

speedometer drive gear

splines

Section

of

1.

Turn

out

the

19

capscrews retaining

to

the

front

case.

NOTE: With T-955AL and GL series transmissions,

may be necessary

right corner

the

top

right retaining capscrews.

2.

Insert

three

flange

of

break

the

from

the

front

imately

Y2".

the

to

remove

of

the

auxiliary section

puller screws

auxiliary section and tighten evenly

gasket seal

case. Move

and

in

move

the

the

auxiliary section

the

plate located

to

allow access

the

tapped holes in

the

rear section away

rear housing back approx·

at

the

it

top

to

the

to

3. Remove

23

the

top

the

rear housing

NOTE:

the

output

the

puller screws and

of

the

rear housing. Use a chain hoist

off

It

is

advisable

shaft

to

attach

the

front

case dowel pins.

to

re-install

avoid damage

a hanger bracket

the

elastic stop

to

the

threads.

to

move

nut

to

on

Page 27

Ill.

Front

Section

A. Removal and Disassembly

Bearing Retaining Snap Ring

of

the

Auxiliary Drive Gear Assembly

Retaining

Snap Ring

Capscrew (6)

1. Cut

retaining

case.

the

two

lockwires and

the

auxiliary drive gear assembly

turn

out

the

six capscrews

to

the

front

24

2.

Remove

mainshaft.

the

snap ring

from

the

groove

in

the

rear

of

the

Page 28

3. Insert three puller screws

retaining ring and tighten evenly

to

the

rear and

4. Remove

the

auxiliary drive gear.

from

the

snap ring from

the

case bore.

in

the

the

to

groove

tapped holes

move

the

on

the

of

the

assembly

front

of

5.

Support

use a mall and driver

the

the

assembly

hearing. This will free

in

to

a vise

drive

the

by

the

retaining ring and

the

gear

down

retaining ring.

and

from

25

Page 29

B.

Removal

of

the

Left

Reverse

Idler Gear Assembly

Bearing

Needle Bearing \

\

Inner

Race

Rear Washer

1.

Remove

the

snap ring

mainshaft reverse gear.

2. Move

against

the

reverse

sliding

the

reverse gear forward

the

1st speed gear, engaging

and

clutch

gear.

1st

speed gears

from

the

ID

on

with

of

the

the

the

the

hub

mainshaft

splines

of

splines

of

of

the

and

both

the

3. Remove

26

the

elastic

the

idler shaft.

4.

Use inside jaw pullers

tershaft

auxiliary

moved

front

countershaft

at

this

time.

stop

bearing

nut

to

from

front

and

remove

the

bearing

washer

the

left

case

from

the

end

auxiliary coun-

bore.

The

may

also be re-

of

right

Page 30

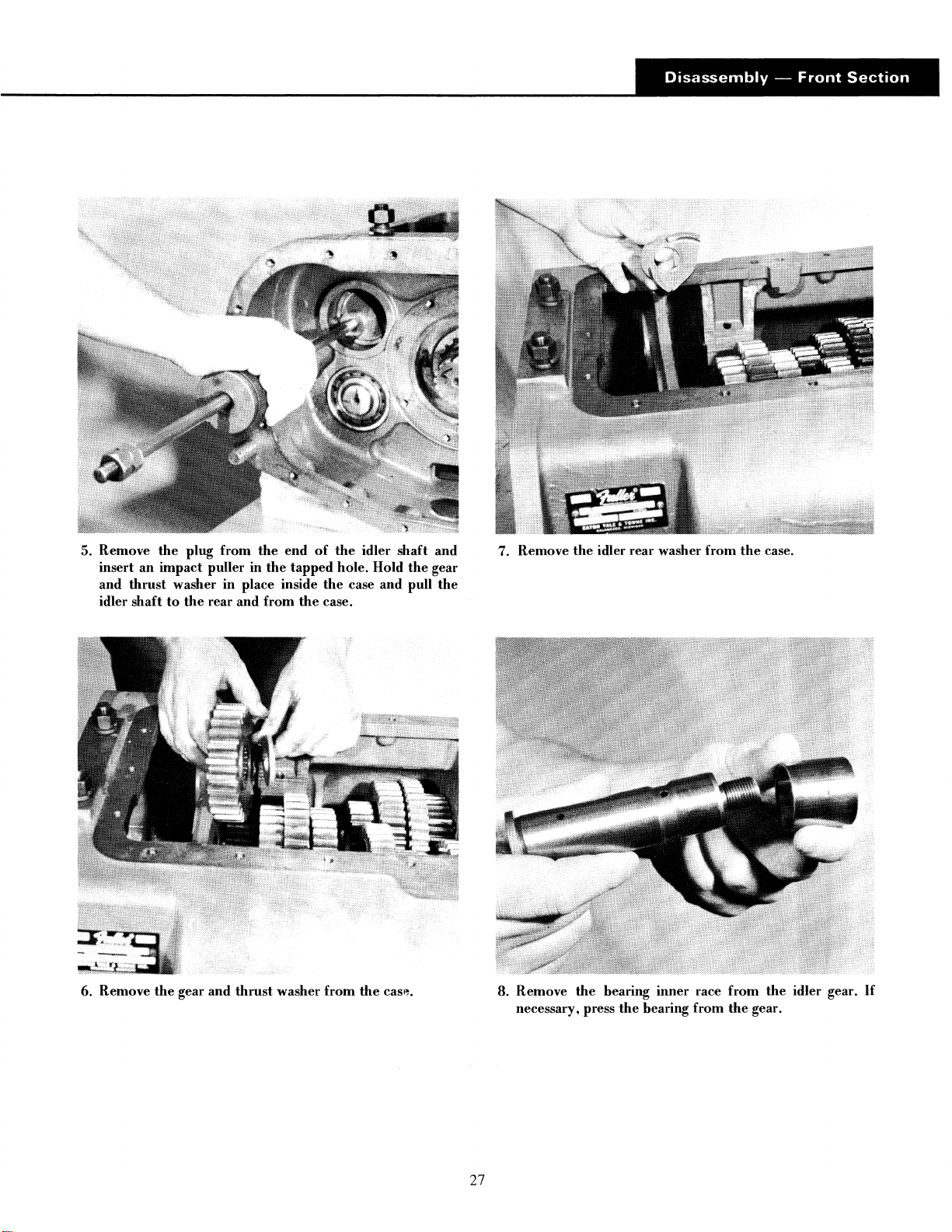

5. Remove

an

insert

and

thrust

idler shaft

the

plug from

impact puller

washer

to

in

the

rear and from

the

end

in

the

tapped

place inside

the

of

the

hole. Hold

the

case and pull

case.

idler shaft and

the

gear

the

7. Remove

the

idler rear washer

from

the

case.

6. Remove

the

gear and

thrust

washer from

the

cas".

8. Remove

27

the

hearing inner race from

necessary, press

the

hearing from

the

the

gear.

idler gear.

If

Page 31

C. Removal

of

the Right Countershaft

Bearings

1. Remove

right countershaft.

the

snap ring

from

the

groove

in

the

rear

of

the

3. Cut

move

sary

the

4.

Use a

possible

the

lockwire,

the

front

to

lock

the

lockscrews.

soft

bar

to

the

tum

out

the

two

bearing retaining plate.

trnnsmission

and mall

rear.

to

drive

in

the

two

lockscrews and re-

It

may

be

neces-

speeds

countershaft

to

remove

as

far

as

2.

Use a mall and

against

to

NOTE: Removal

generally result

be

planned.

the

the

rear and

attempted

punch

or

other

inner race

from

of

the

the

case

of

the

countershaft

in

damage

unless replacement

similar

pointed

bearing

bore

to

the

to

and countershaft.

bearings and should

of

instrument

drive

the

bearing

rear bearings will

not

the

bearings is

28

Use a

5.

to

unseat

ing puller

soft

drive

bar

and mall

the

shaft as far forward as possible. This will

the

front

bearing

to

remove

the

on

the

from

bearing

rear

of

the

the

case bore. Use a bear-

from

the

countershaft

countershaft.

Page 32

0.

Removal and Disassembly

Small Splined

Spacer

Small

Washe~

Small

Sliding

Clutch

\

~';"·~

/

Small Snap Ring

5th

Speed Gear

of

the

Mainshaft Assembly

4th

Speed Gear

Key

3rd

Speed Gear

\

\

Mainshaft

Large

2nd

Speed Gear

Sliding

\

Clutch

(2)

Large

Splined Spacer (4)

"'Large

Snap Ring (4)

Reverse Gear

1. Block

and

the

front

ward

gears

shaft. Use

from

the

pull

and

on

the

right

countershaft

the

mainshaft as far

of

the

mainshaft

lift

the

mainshaft

the

mainshaft

caution

mainshaft.

as

against

up,

from

past

the

reverse gear is free and can fall

the

side

to

the

rear as possible. Tilt

move

the

the

case, working

the

gears

on

of

assembly for-

the

the

case

the

counter-

29

2. Place

reverse gear.

the

mainshaft

on

a workbench and remove

the

Page 33

D. Removal and Disassembly

of

the Mainshaft Assembly - continued

3. Remove

of

the

mainshaft.

4. Remove

clutch.

the

5th-6th speed sliding clutch from

the

key located

under

the

5th-6th speed sliding

the

front

6. Remove

mainshaft.

7. Remove

mainshaft.

the

the

5th

speed gear, spacer and washer from

4th

speed gear, spacer and washer from

the

the

5. Remove

mainshaft.

the

snap ring from

the

groove

in

the

rear

of

the

30

8.

Pull

the

the

mainshaft.

3rd-4th speed sliding clutch from

the

splines

of

Page 34

9. Use a pointed object

shaft until

the

other

to

end

push

the

extends

key

beyond

down

the

the

main-

mainshaft.

10. Pull

11. Remove

the

mainshaft.

key from

the

the

keyway.

reverse gear washer and spacer from

the

12. Pull

13. Remove

the

splines

spacers from

reverse-2nd speed sliding clutch from

of

the

mainshaft.

the

second and third speed gears, washers and

the

mainshaft.

the

E.

Removal

1. See page 28 as removal procedures for

tershaft bearings are identical.

of

the

Left

Countershaft Bearings

both

sets

of

coun-

31

Page 35

F. Removal and Disassembly

Bearing

Nut

Bearing

of

the

Input

Shaft and Drive Gear Assembly

Brass Bushing

1. Turn

out

bearing cover.

the

retaining capscrews and remove

the

front

32

2.

From

the

soft

necessary.

inside

the

snap ring can

bar and mall

case,

tap

be

removed from

to

move

the

drive gear forward so

the

the

drive gear forward if

that

bearing. Use a

Page 36

3. Move

the

drive gear assembly

working past

drive gear assembly

to

the

inside

the

countershaft assemblies. Remove

from

the

case.

of

the

case,

the

5.

Turn

the

bearing

nut

from

the

shaft (left

hand

thread.)

4. Relieve

the

bearing

nut

where

it

is

peened

into

the

shaft.

Press

6.

sary, remove

Check

place if damaged.

33

the

shaft through

the

bushing

the

snap ring from

in

the

the

bearing and gear.

the

pocket

of

the

ID

input

of

If

neces-

the

gear.

shaft; re-

Page 37

G. Removal and Disassembly

Bearing Retainer Plate

~JJ

Retainer Capscrews

of

the

Countershaft Assemblies

Key~

I

/i

Roll Pin

1

1

1. Remove

the

case.

NOTE:

gears,

the

assembled

the

right

Except

for

countershaft

in

the

same manner.

and

left

countershaft

the

number

assemblies are identical

of

assemblies

teeth

on

the

and

from

PTO

dis-

2. Press

the

6th,

PTO,

5th

and

4th

countershaft. (This will require a press

capacity; use metal shield as a safety precaution.)

34

speed gears

of

at

least 25-ton

from

the

Page 38

IMPORTANT: Never use

the

pressing as

ceptible

larger diameter

to

breakage. ·

the

PTO gear as a base for

of

this gear makes

it

sus-

3. Press

H. Removal and Disassembly

1. Refer

the

3rd

speed gear from

remove

assemblies are identical and are disassembled

manner.

the

key and roll pin from

to

page

26

as

the

right and

the

the

of

the Right

left

shaft.

If

necessary,

shaft.

Reverse

reverse idler gear

in

the

same

Idler

Gear

Assembly

35

Page 39

IV.

Auxiliary

Section

A.

Removal

of

T-955AL,

the

First-Reverse Speed Sliding Clutch Gear

T-955GL,

Models

1. Insert a large screwdriver between

the

and

and

2.

Remove

shaft.

1st speed gear and

off

the

splines

the

tension hall from

of

the

pry

output

the

shaft.

the

the

sliding clutch gear

sliding

clutch

bore

in

the

forward

output

3.

Rotate

from

the

the

bore

output

in

the

shaft until

shaft.

the

tension spring falls

36

Page 40

B. Removal

Front

of

the Auxiliary Countershaft Assemblies

Bearing

3. Remove

countershaft.

the

snap ring

from

the

rear

of

each auxiliary

1.

If

not

previously removed,

screws and remove

2.

Tum

out

the

covers.

tum

out

the

rear cover.

capscrews and remove

the

retaining cap·

the

two

rear bearing

4.

5.

37

Use a soft

ward

the

bearing inner race

and

bar

from

Use a soft bar

the

housing bores. Tap

age

to

the

bearings.

and mall

the

rear bearings.

from

to

tap the

to

the

bearings

on

the

drive

front

outer

the

countershafts for·

If

necessary, remove

of

each shaft.

to

the

rear and from

race

to

avoid dam·

Page 41

C.

Removal

of

the

First Speed Gear,

Output

Shaft and Rear Bearing Assembly

First,

Low

Reverse Speed

Sliding

Clutch

. Bearing

~

Capscrew

./"....

/

"-...~···

(191

~

~~:::1-'\~·V

~·_G·

Oil

..

Seal

~pscrew(6)

I Plug Bushing

Plug

Gasket

Rear Bearing Housing

C~.~~~.

·.

(\

C~ew

.

·:

.

....

,

...

·/

j

..

·

Gasket

(4)

~

Stop

Nut

~·

\

Stepped

Spacer

First

Speed Gear

1.

Tum

out

hearing housing.

the

housing.

the

six retaining capscrews

If

necessary, remove

-,_Q

Tension Spring Tension Ball

and

remove

the

the

oil seal

rear

from

NOTE:

removal

of

the

2. Use a

and

The

oil seal will

and

should

seal is planned.

soft

bar

and

from

the

rear bearing assembly.

not

mall

most

likely

he

damaged during

he

removed unless replacement

to

drive

the

output

shaft

forward

38

Page 42

3. Remove

the

rear bearing

cone

from

the

rear housing.

5. Place

inner spacer.

the

output

shaft

on

end and remove

the

hearing

4.

Use a

spacer

soft

from

bar

the

to

tap the

bore

in

the

two

bearing cups

rear housing.

and

outer

6. Using

the

first speed gear as a base, press

ing cone

ing, gear, washer and spacer.

from

39

the

output

the

shaft. This will free

front

the

hearhear-

Page 43

V.

Auxiliary

Section

A. Removal

of

the Auxiliary Countershafts

T-955ALL,

Models

1.

Mount

tion,

turn

two

rear hearing covers.

Remove

2.

countershaft.

the

auxiliary

out

the

the

snap

section

attaching

ring

in

a vise

in

the

upright

capscrews and remove

from

the

rear

of

posi-

the

each

3. Use a soft

ward

the

4.

Use a

the

the

40

bar

and

from

hearing

case bores.

hearings.

soft

inner

bar

and

mall

the

rear hearings.

race

from

to

tap the

Tap

on

to

hearings

the

drive

the

outer

the

countershafts

If

necessary, remove

front

of

each shaft.

to

the

race

to

avoid damage

rear

and

for-

from

to

Page 44

Disassembly

-

Auxiliary

Section

B. Removal

Sliding

\

~-----~

_

Jl!f!!!}I

Clutch

of

the Sliding Clutch and First

Ke$-·

Pin

First

Speed Gear

Speed

Gear

4.

Turn

the

gear.

the

splined washer inside

teeth

align with

the

1st

speed gear until

the

grooves in mainshaft, freeing

the

1. Pry

the

sliding clutch forward and

range mainshaft.

2.

Rotate

plunger falls from

the

mainshaft until

the

bore

off

the

~plines

the

sliding clutch retaining

in

the

shaft.

of

the

5.

Pull

the

6. Remove

1st speed gear from

the

coupler

from

the

the

splines

splines

of

of

the

mainshaft.

the

mainshaft.

3. Remove

the

key from

the

groove

in

the

mainshaft.

41

Page 45

C. Removal and Disassembly of the Low Gear Shift Cylinder

Shift

Shift

Cylinder

Yoke

\

Housing

\ /

""'

~\

~

V.

Gasket

-~

\

Lock

screw

HousingO-Ring

Shift

Bar

\

Co~~

~fl

~f

\ Gasket

Shift

Bar

0-Ring

sh;ft

cvo;"'"

c~"

1. Cut

the

lockwire and

gear shift yoke.

turn

out

the

lockscrew

on

the

low

42

2. Turn

out

the

capscrews and remove

the

cylinder cover.

Page 46

3.

Pull

the

ing.

If

necessary, remove

diameter

4. Remove

If

necessary, remove

housing.

shift

bar

to

the

rear and from

of

the

bar.

the

cylinder housing from

the

the

0-ring

the

0-ring from

the

cylinder hous-

from

the

large

auxiliary housing.

the

bore

in

the

5. Remove

the

shift

yoke

from

the

sliding clutch.

43

Page 47

D. Removal

of

the

Range

Mainshaft

Tension Pin

Tension Spring

Bearing-~-©'~

-G-·~

au;u

S"•P

~~""

-~-

>

~

R;og

\

Range Mainshaft

Low

Speed Gear

\

Stepped

"'--

Output

Spacer

Stop

Shaft

Nut

1. Remove

quill.

2.

Use pry bars

ward and

the

snap ring from

or

equivalent

off

the

quill.

the

to

front

move

of

the

output

the

mainshaft for-

shaft

3. Remove

if necessary, remove

tension spring from

44

the

hearing from

the

bore

of

the

the

brass hushing, snap ring and

the

mainshaft.

mainshaft and,

Page 48

E.

Removal

of

the

Low Speed Gear,

Output

Disassembly

Shaft and Rear Bearing Assembly

-

Auxiliary

Section

1. Remove

shaft.

2.

Use a soft bar and mall

and from

the

sliding clutch from

the

rear bearing assembly.

to

drive

the

the

splines

output

of

the

output

shaft forward

4. Using

5.

the

low speed gear as a base, press

ing

cone

from

the

output

ing, gear, washer and spacer.

Turn

out

the

retaining capscrews and remove

bearing housing from

the

remove

bearing cone from

NOTE: Removal procedures will

oil seal and should

of

the

oil seal from

seal is planned.

the

the

rear housing.

not

be

.

......

the

shaft. This will free

auxiliary section.

the

housing. Remove

most

likely damage

attempted

unless replacement

front

the

the

If

necessary,

the

bear-

bear-

rear

rear

the

3. Remove

the

bearing inner spacer from

the

output

shaft.

45

6.

Use a soft

spacer from

bar

to

tap the

the

auxiliary housing bore.

two

bearing cups and

outer

Page 49

"++'ii".!.I

......

_________________________

Inspection

Before reassembling the transmission, the individual parts should be carefully checked to eliminate those damaged

from previous service. This inspection procedure should be carefully followed

rebuilt unit.

The cost

questionable part make additional repairs necessary before the next regularly scheduled overhaul.

Recommended inspection procedures are set forth in the following check list:

A.

Bearings

l.

Wash

all

bearings in clean solvent. Check balls, rolls and

races for pits and spalled areas. Replace bearings which

are

pitted or spalled.

2. Lubricate bearings which

are not spalled or pitted

and check for axial and

radial clearances. Replace

bearings

clearances.

of

a new part

with excessive

is

generally a small fraction

Spalled Bearing Extreme

Load

of

the total cost

D. Thrust

1.

Check

thrust

scored or reduced in thickness should be replaced.

E.

Reverse

1.

Check bearing sleeve for wear from action

bearings.

F. Gray Iron

to

Washers

surfaces

washers.

Gear

insure the maximum

of

downtime and labor, should the

of

all

Washers

and

Shaft

Parts

of

wear life from the

of

use

roller

of

_

a

Check fits

3.

case

turn freely in the bores,

the

replaced.

B.

Gears

1.

c«eck

faces. Gears with pitted teeth should be replaced.

Check all engaging gear teeth. Gears with teeth worn,

2.

tapered or reduced in length from clashing in shifting

should be replaced.

3.

Check axial clearances

ance

gear hub for excessive wear.

C.

Splines

1.

Check splines on

gears, companion flange or clutch hub have worn into

the sides

should be replaced.

of

bearings in

bores.

If

outer races

case

is

should

operating gear teeth for pitting on the

found, check gear snap ring, washer, spacer and

of

the splines, the shafts in this condition

be

o(

gears. Where excessive clear-

all

shafts for wear.

False Brinnelling -

Vibration Without

Rotation

If

sliding clutch

tooth

1.

Check

all

gray iron parts for cracks and breaks. Replace

or repair parts found to be

damaged. Heavy castings

may be welded or brazed

providing the cracks do

not extend into bearing

bores or bolting surfaces.

G. Clutch

1.

Check clutch release parts. Replace yokes worn at cam

surfaces and bearing carrier

worn at contact pads.

2.

Check pedal shafts. Re-

place those worn at bear-

ing surfaces.

Release

Parts

46

Page 50

H. Shifting Bar Housing Assembly

J.

Bearing

Covers

1.

Check yokes and blocks for wear at pads and lever slot.

Replace worn parts.

2.

Check

ment.

which are sprung.

3.

Check yokes for excessive

wear; replace worn yokes.

4.

Check lockscrews in yokes

and blocks. Tighten and

rewire those found loose.

5.

If

shifting bars for wear from interlock balls.

at points adjacent to the neutral notch should be

replaced.

yokes for align-

Straighten those

housing has been dismantled, check neutral notches

Bars

indented

of

1. Check covers for wear from thrust

Replace covers worn and grooved from thrust

outer race.

2.

Check bores

oversize.

Oil Return Threads

K.

1.

Check oil return threads in front bearing cover.

action

input shaft, replace the cover.

2.

Check oil seal in mainshaft rear bearing cover.

action

L.

Sliding Clutches

1.

Check

extreme wear or discoloration from heat.

of

covers for wear. Replace those worn

of

threads has been destroyed

of

lip has been destroyed, replace seal.

all

yokes and yoke slots in sliding clutches for

I. Gear Shift Lever Housing Assembly

2.

Check engaging teeth

1. Check spring tension on shift lever. Replace tension engagement pattern.

spring and washer

2.

If

housing

sponding slot in lever for wear. Replace

worn.

if

lever moves too freely.

is

dismantled, check pivot pin and corre-

both

parts

if

M.

Front Bearing Cover

1.

Check inside hub

by backing

off

of

drive gear bearing nut.

of

adjacent bearing.

of

and

Seals

If

by

contact with

If

of

sliding clutches for partial

of

front bearing cover for wear caused

bearing

sealing

sealing

Location

Seat gasket with shellac on part to be installed.

gaskets

Gaskets are located between the following parts:

T-955AL,

l.

2.

3. Reverse light plug.

4. Tension spring cover plate.

5.

6. Front bearing cover and case.

7. Rear plate and case.

throughout

GL

Gear Shift lever housing and shift bar housing.

Shift bar housing and case.

Clutch housing and case.

when reassembling transmission.

Use

new

of

Gaskets

8. Mainshaft rear bearing cover and rear plate.

9. Rear plate cover and rear plate.

10. Right aux. countershaft rear bearing cover and rear

plate.

Left aux. countershaft rear bearing cover and rear

11.

plate.

12. Large

13.

T-955ALL

To

1.

2. Low gear shift cylinder and case.

47

PTO cover and case.

Small PTO cover and case.

the above list add:

Low gear shift cylinder cover and cylinder.

Page 51

Torque

Ratings

Recommended torque ratings, location and thread sizes

Capscrew lengths are given for reference purposes

Correct torque application

is

extremely important to assure long transmission life and dependable

as

a guide for installation at proper locations.

of

capscrews and nuts are listed below.

performance. Over-tightening or under-tightening can result in a loose installation and, in many

instances, eventually cause damage

to

transmission gears, shafts or bearings.

Do

not torque capscrews

dry.

CAPSCREWS

Thread

Location

Filter Bracket 2

*PTO Cover, small 6

Low Gear

Aux. Drive Gear Retainer Ring 6

Shift Bar Housing

Gear

Front Bearing Cover 6

Countershaft Rear Bearing Covers 8

Rear Plate

Rear Plate to Case (T-955ALL only) 18

Mainshaft Rear Bearing Cover 6

PTO Cover, large 8

Outch

C/S

Shift Cylinder

(T-955ALL only)

Shift Lever Housing

to

Case (T-955AL, GL only) 18

Housing to Case

Front

Bearing Retainers

Qty.

16

Size

And

Length

3/8-16 x 3/4

3/8-16 x 3/4

4 5/16-18 x 1-7/8

3/8-16 x 1

3/8-16 x 1-1/4

4 3/8-16 x 1-1/4

3/8-16 x 1-1/4

3/8-16 x 1-1/4

3/8-16x2

1

1

2

2 1/2-13 x 3-1/2

4

3/8-16 x 1-3/4

3/8-16 x 1-1/2

3/8-16x2

3/8-16 x 2-3/4

7/16-14 x 1-1/4

1/2-13 x 1-1/2

1/2-20 x 1 50-65

Torque

Rating

Foot-Pounds

20-25

18-23

(12-15 with oil filter)

20-25

35-45

50-65

70-75

70-75

*NOTE:

away from

Reverse Idler Shafts

Outch

Drive Gear

Companion Flange

Installing

the

case with resultant oil leakage.

Housing

to

the

capscrews with more than 23 ft-lbs.

of

torque will force the corners

NUTS

Qty.

2

Case 6 5/8-18

1 2-1/8-16

or

Yoke 1

Thread

5/8-18

2-16

48

Size

of

the

Torque

Foot-Pounds

75-80

170-185

250-300

450-500

PTO cover

Rating

Page 52

General

Precautions

for

Reassembly

Make

sure that interiors

It

is

important that dirt be kept out

reassembly. Dirt

faces

of

bearings and washers.

listed below, during reassembly.

1.

GASKETS

sion

as

3.

0-RINGS - Lubricate

200 Fluid," 50,000

2.

CAPSCREWS

all

capscrews.

torque.

is

abrasive and can damage polished sur-

-

Use

it

is

being rebuilt. Make sure all gaskets are in-

- To prevent oil leakage,

See

of

new gaskets throughout the transmis-

stalled,

can result in oil leakage or

misalignment

covers.

kets" heading.

all

cs.

torque rating chart for recommended

IMPORTANT:

the

case

and housings are clean.

of

transmission during

Use

certain precautions,

as

omission

See

"Location

0-rings with "Dow Corning

use

Read this section before starting

detailed reassembly procedures.

as

of

gasket

of

bearing

of

Gas-

shellac on

7.

BEARINGS

commended for the installation

8.

UNIVERSAL

companion flange tightly into place with the mainshaft

nut, using

speedometer gear

the same width must be used. Failure to pull the yoke or

flange tightly into place will permit the shaft to move

axially with resultant damage to rear bearing.

-

Use

of

flanged-end bearing drivers

drivers apply equal force to

both

venting damage to balls and

races and maintaining correct

......

bearing alignment with shaft

and bore.

type driver

force only to inner race.

JOINT

450-500 foot-pounds

COMPANION

is