Duke DPAH 2-HF, DPAH 4HF Operators Manual

FOODWARMERS

INSTALLATION

&

OPERATIONS

MANUAL

Duke Manufacturing Co.

2305 N. Broadway St. Louis, MO 63201

800.735.3853 314.231.1130 314.231.5074 fax

www.dukemfg.com

219736 Page 1 of 32 9/4/08

TABLE OF CONTENTS

Receiving and Inspection of Equipment

Concealed Damage 4

Filing a Claim 4

Warning 4

General Troubleshooting . 4

Safety Precautions

Gas Foodwarmers 5

Electric Foodwarmers 5

General Information

Operation Instructions 5

Cleaning Instructions 5

Assembly Instructions for Aerohot Foodwarmers 6

Foodwarmer “Quick Base” Pictorial 7

Foodwarmer “Carving Board” Pictorial 8

Installation Instructions

Aerohot Foodwarmers and Heritage Buffet Hot Food Units 9

Operating

Aerohot Foodservice and Thurmaduke Foodwarmer 10

Installation of the Aerohot Sealed Wells Hot Food Units 11

Maintenance of the Aerohot Foodservice and Thurmaduke Foodwarmers

Cleaning 12

Trouble Shooting Guide 12

Wiring Diagram for Aerohot Sealed Well Units 13

Parts Diagram and List for Wells 14

Gas Water Bath Hot Food Units

Clearances 15

Gas Connections 15

Preheat Instructions 16

Lighting Instructions 16

Pilot Light Adjustment 16

Main Burner Adjustment 16

"ADI, "ASI" Installation Instructions 17

BM80 - Bottom Mount Hot Food Wells. 18

Gas Food Warmers (G, S-SR, T & TD, ASI, B-SR, CC-SR & 300 Series) – General Information 19

Operating Instructions – Gas Food Warmers 20 20

Stainless Steel Equipment Care and Cleaning 21

Cleaning Procedures for Polyethylene or ABS Rubber Composition Table Tops or Cutting Boards 24

Electric Parts List 25

Aerohot Foodservice Electric Parts Diagram 27

Heritage Buffet Unit Electric Parts Diagram 28

Thurmaduke Foodwarmer Electric Parts Diagram 29

Gas Parts List 30

Aerohot Foodservice Gas Parts Diagram 31

Thurmaduke Foodwarmer Gas Parts Diagram 32

Page

219736 Page 3 of 32 9/4/08

RECEIVING AND INSPECTION OF THE EQUIPMENT

Even though most equipment is shipped boxed or crated, care should be taken during unloading so the

equipment is not damaged while being moved into the building.

Carefully check for any visible signs of damage to the cartons or containers. If evidence of damage exists, the

package should be opened immediately and a joint inventory and examination of the contents should be made

by you and the driver.

C

ONCEALED DAMAGE

If a concealed loss or damage is discovered after you have given the carrier a clear delivery receipt, notify the

carrier in writing immediately or within ten (10) days from the delivery date. If you phone the carrier, you must

follow up the call in writing to protect your rights. You can only improve your position as a claimant by

promptly reporting such loss or damage. You should also retain all cartons or containers, including packing

material, until an inspection has been made or waived.

F

ILING A CLAIM

Notation of loss or damage does not constitute the filing of a claim. You should file your claim in writing with

the carrier immediately!

Carriers will furnish the necessary form upon request. You should also request an inspection. If a claim is filed

by phone, always follow up immediately in writing.

WARNING

Installation of this equipment should be done only by persons qualified or licensed to install electrical

equipment.

Adjustments and service work should be performed only by a qualified service technician. Service is available

through Duke Authorized Parts & Service Distributors throughout the United States. For a complete listing of

these, consult your distributor listing or write to Duke for the name of the nearest distributor.

This equipment is intended for commercial use only. Not for household use.

GENERAL TROUBLESHOOTING

Always ask and check:

1. Is the unit connected to a live power source?

2. Check circuit breaker.

3. Is power switch on and pilot light glowing?

4. Check rating label. Are you operating the unit on the proper voltage?

219736 Page 4 of 32 9/4/08

G

AS FOODWARMERS

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing this equipment.

NOTICE

Due to the availability of parts, this foodwarmer may not have the ability

to adjust the gas valve as described in the operations manual. All valves

are factory pre-set to provide proper flame height with the type of gas

listed on the nameplate.

E

LECTRIC FOODWARMERS

CAUTION

To protect from possible severe electrical shock, this appliance is designed

to be connected to a properly grounded electrical circuit.

For a cord connected appliance: In order to provide proper grounding, it is

essential that the grounding prong of the plug be inserted into a properly

grounded receptacle. If you do not know whether a receptacle is properly

grounded, consult a licensed electrician.

NEVER

or if the plug has been altered or damaged.

insert the plug into a receptacle if the cord is frayed or damaged

GENERAL INFORMATION

1. Always clean equipment thoroughly before first use. (See general cleaning instructions.)

2. Check rating label for your model designation & electrical rating.

3. For best results, use stainless steel countertops.

GENERAL OPERATION INSTRUCTIONS

1. All foodservice equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT".

3. Where applicable: Never pour cold water into dry heated units.

4. Where applicable: Do not cook, warm or hold food directly in liner pans (well pans). Always use

steam table pans/insets, etc.

5. Never hold food below 150°F.

GENERAL CLEANING INSTRUCTIONS

1. NEVER clean any electrical unit by immersing it in water. Turn unit off before surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily, except where noted on

charts: Use warm, soapy water. Mild cleansers and PLASTIC scouring pads may be used to

remove baked-on food and water scale.

3. Turn off electrical units before cleaning or servicin

219736 Page 5 of 32 9/4/08

g.

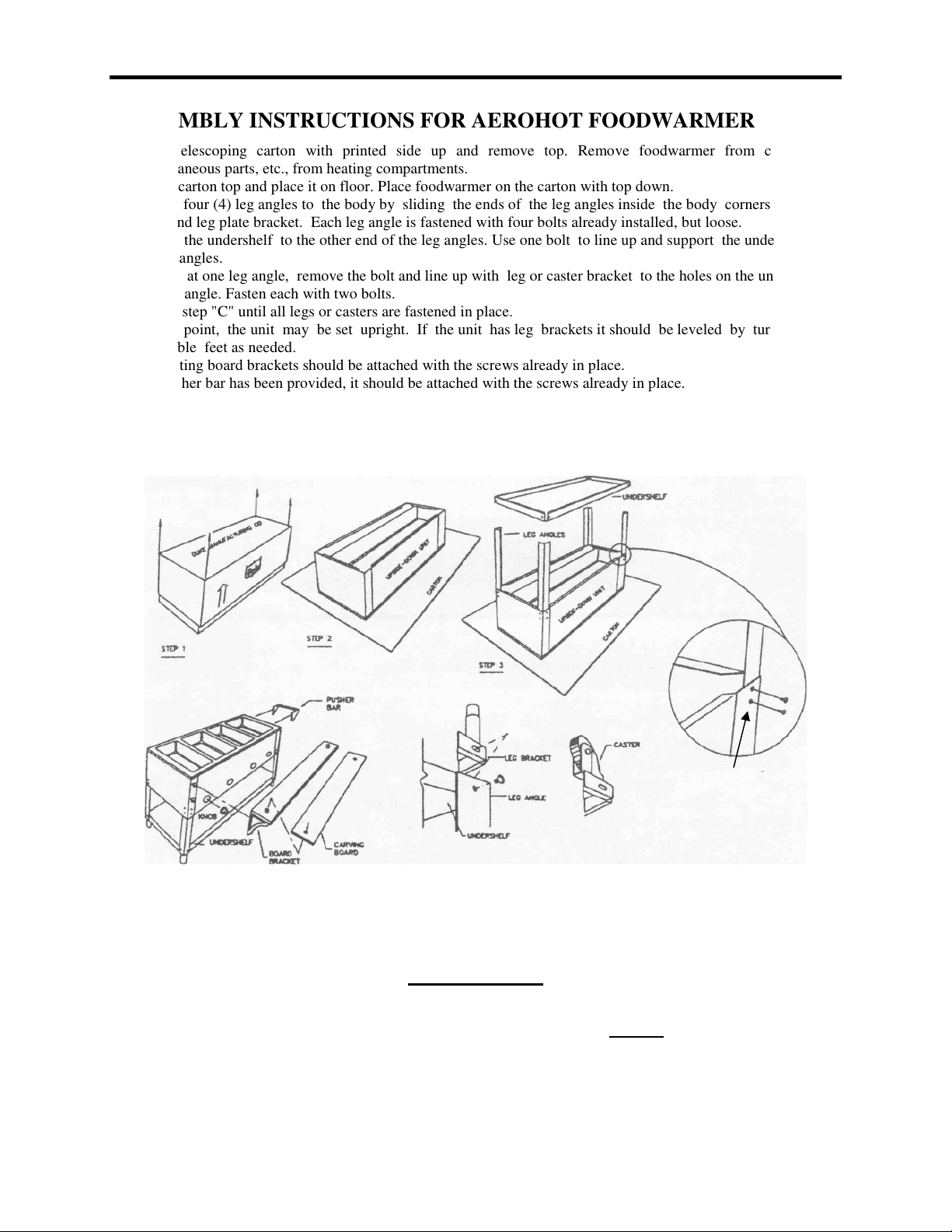

ASSEMBLY INSTRUCTIONS FOR AEROHOT FOODWARMER UNITS

1. Place telescoping carton with printed side up and remove top. Remove foodwarmer from carton, and

miscellaneous parts, etc., from heating compartments.

2. Flatten carton top and place it on floor. Place foodwarmer on the carton with top down.

3a. Attach four (4) leg angles to the body by sliding the ends of the leg angles inside the body corners between

body and leg plate bracket. Each leg angle is fastened with four bolts already installed, but loose.

b. Attach the undershelf to the other end of the leg angles. Use one bolt to line up and support the undershelf to

the leg angles.

c. Starting at one leg angle, remove the bolt and line up with leg or caster bracket to the holes on the undershelf

and leg angle. Fasten each with two bolts.

d. Repeat step "C" until all legs or casters are fastened in place.

e. At this point, the unit may be set upright. If the unit has leg brackets it should be leveled by turning the

adjustable feet as needed.

f. The cutting board brackets should be attached with the screws already in place.

g. If a pusher bar has been provided, it should be attached with the screws already in place.

h. Push all knobs onto control stems.

AEROHOT & THURMADUKE

[ S

EE FOODWARMER

Q

UICK BASE PICTORIAL

ON PAGE 7

]

[ S

EE CARVING

B

OARD PICTORIAL

ON PAGE 8

]

S

CREWS SHIPPED

INSTALLED

BE SURE ALL FASTENERS ARE TIGHTENED AS SECURELY AS POSSIBLE.

Your foodwarmer is now ready to be installed. Please read following Installation Instructions.

IMPORTANT

UNIT IS SHIPPED UNASSEMBLED. TO MEET NATIONAL SANITATION

FOUNDATION STANDARDS, THE INSTALLER MUST USE A NSFAPPROVED SILICONE SEALANT TO SEAL THE SEAMS BETWEEN THE

UNIT AND ASSEMBLED PARTS

219736 Page 6 of 32 9/4/08

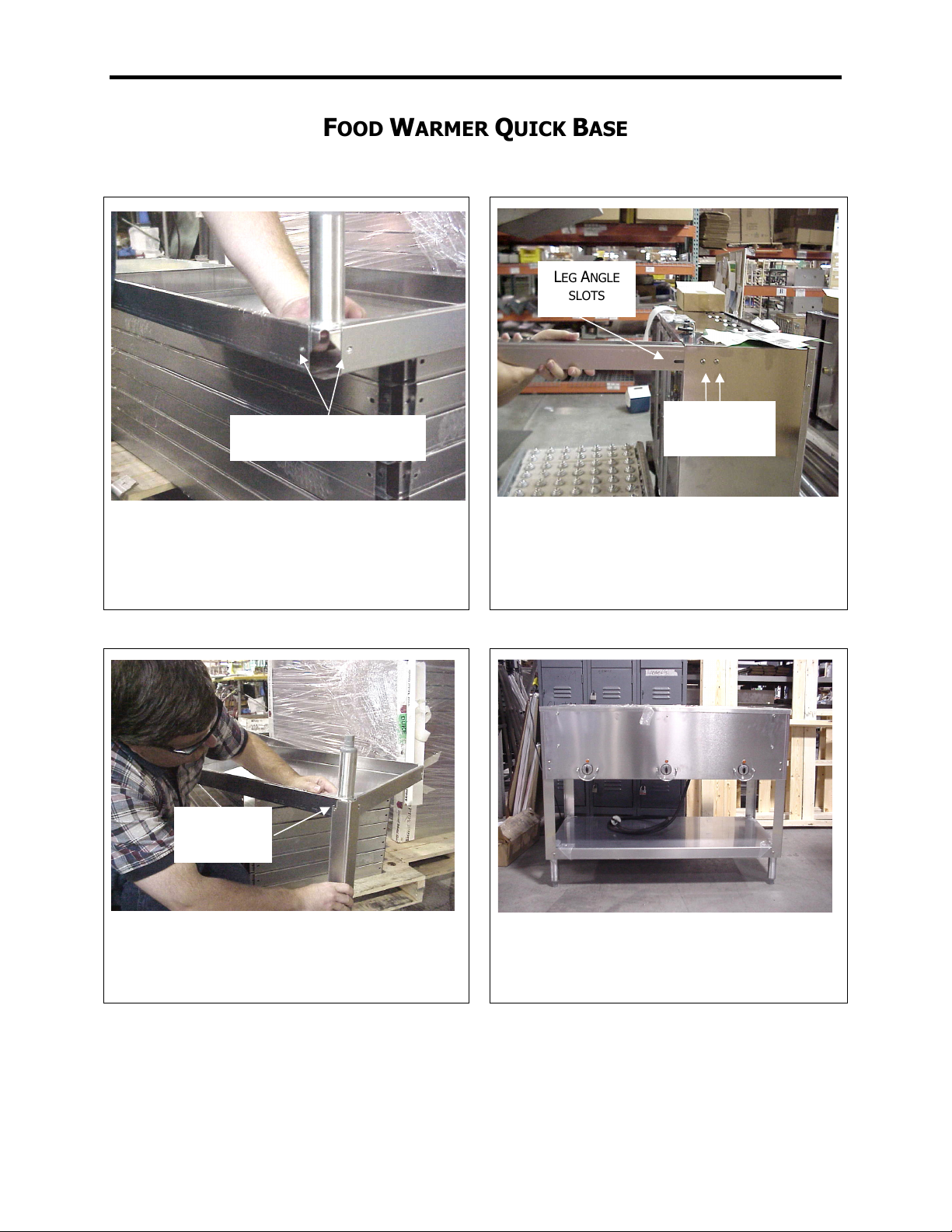

GUSSETS

F

OOD WARMER QUICK BASE

S

CREWS FOR MOUNTING LEG

L

EG ANGLE

SLOTS

L

EG ANGLE

S

CREWS

1. Mount leg gussets to bottom shelf leaving

screws loose.

L

EG ANGLE

SLOTS

3. Slide bottom shelf over leg angle so

that loose screws seat into leg angle

slots. Tighten all screws.

2. Leg angle screws will be shipped in stalled in the body unit but left loose

for easy leg angle insertion. Insert

leg between unit and bracket.

4. Unit is ready to be turned right side

up.

219736 Page 7 of 32 9/4/08

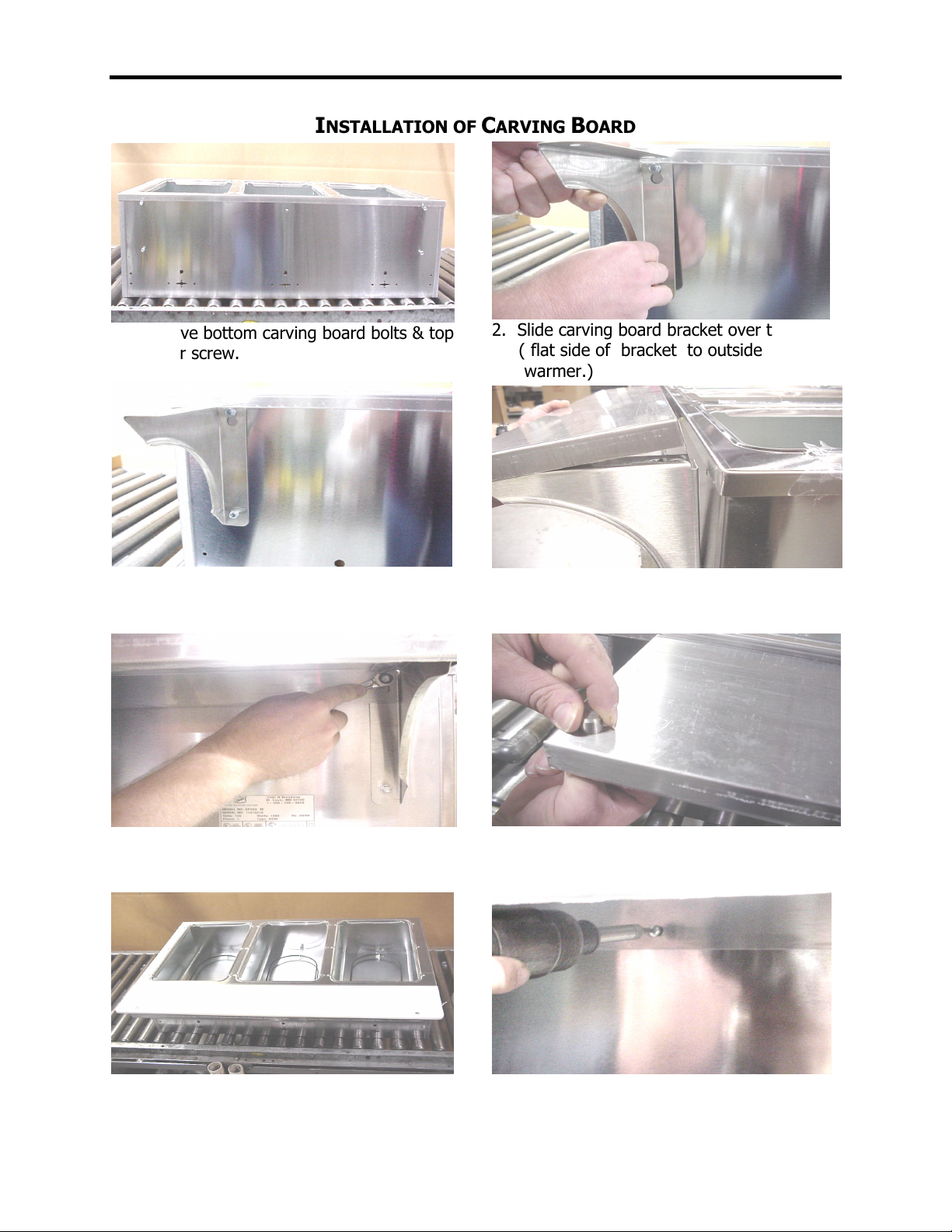

I

NSTALLATION OF CARVING BOARD

1. Remove bottom carving board bolts & top

center screw.

3. Replace bottom carving board bolt and

tighten. Repeat step 2 & 3 on opposite

end of warmer.

2. Slide carving board bracket over top bolt

( flat side of bracket to outside edge of

warmer.)

4. Remove top bolts from Foodwarmer

brackets. Place carving board into

bracket slots.

5. Replace top bolts through brackets and

carving board and into foodwarmer.

Tighten.

7. Place polyboard over position pens.

6. Insert position pen into corners of carving

board and hole of bracket. Secure with nut

8. Replace center screw through carving

board into warmer. Tighten.

219736 Page 8 of 32 9/4/08

INSTALLATION INSTRUCTIONS FOR

ELECTRIC AEROHOT FOODWARMERS &

HERITAGE BUFFET HOT FOOD UNITS

GENERAL

This foodwarmer is designed for installation as an independent heavy-duty appliance.

For Heritage Buffet Units: Do not use alcohol or mineral spirits, or products with a high concentration

of these solvents, to clean the body panels.

INSTALLATION

Operating temperatures permit safe installation of this foodwarmer within 1" of a combustible wall or

partition.

Unit should be set adjusted to desired height, or to align with other equipment before it is permanently connected to electrical supply. For leveling the foodwarmer on an uneven floor or to

eliminate rocking, turn the feet of the legs in the proper direction until the desired results are obtained.

ELECTRICAL CONNECTIONS

The voltage and wattage ratings of this foodwarmer are given on the device nameplate. Connect the

foodwarmer to a circuit having a voltage and type of current (AC or DC) similar to that stamped on

the device nameplate. For movable equipment a proper cord and cap are included for connection to

the matching power supply outlet.

For permanent installations, connections to supply line may be made through conduit or armored

cable. For supply connections use No. 12 AWG or larger wires suitable for at least 90°C (194°F). Use

copper wire for power supply or suitable copper to aluminum wire connector.

Supply connections are made through a knockout in the junction box. The device leads extend into

the junction box for making easy connections. After making and taping connections, push excess wire

back into junction box and replace cover.

The body of the appliance should be grounded by connecting the ground wire provided in the junction

box to a good electrical ground, such as a water pipe, a steam pipe, or a grounded supply conduit.

The foodwarmer is not fused and consequently must be connected to a fused circuit equipped with

suitable disconnect means, as required by local code authorities.

219736 Page 9 of 32 9/4/08

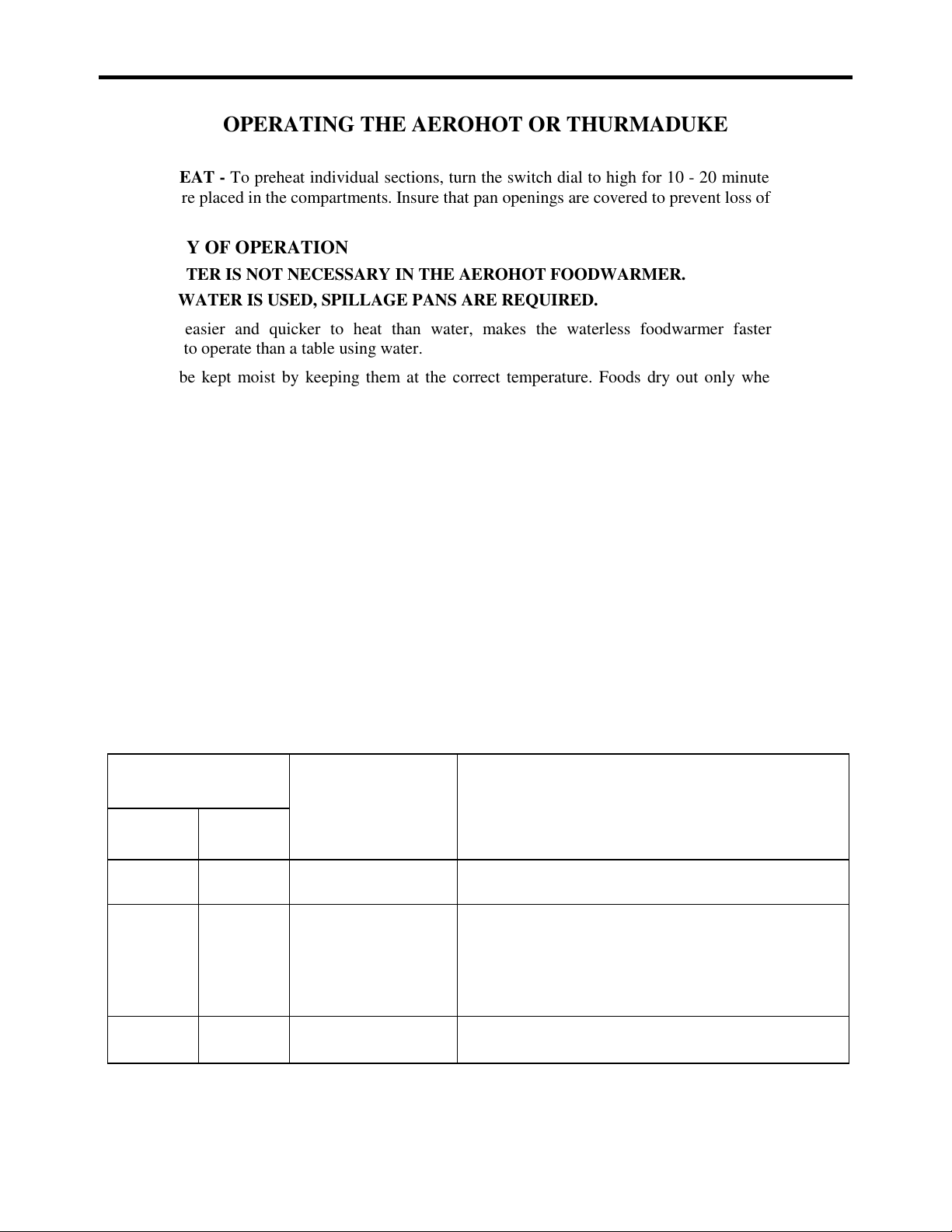

OPERATING THE AEROHOT OR THURMADUKE

PREHEAT - To preheat individual sections, turn the switch dial to high for 10 - 20 minutes before the

foods are placed in the compartments. Insure that pan openings are covered to prevent loss of heat.

ECONOMY OF OPERATION

WATER IS NOT NECESSARY IN THE AEROHOT FOODWARMER.

IF WATER IS USED, SPILLAGE PANS ARE REQUIRED.

Air. being easier and quicker to heat than water, makes the waterless foodwarmer faster and more

economical to operate than a table using water.

Foods can be kept moist by keeping them at the correct temperature. Foods dry out only when excessive

temperatures are reached, so when foods tend to dry out, REDUCE HEAT.

If only part of the foodwarmer is needed, the compartment not in use need not be heated. Insulation between

the compartments divide the unit into a series of smaller independent foodwarmers.

CARE AND CLEANING

Care should be used to prevent spilling when placing full food containers into the pan openings. Spilled

foods that are not removed will dry out and eventually burn, causing odors. The inside of the heating

compartments should be wiped out daily and thoroughly cleaned at least once each week.

SWITCH SETTINGS

The most satisfactory switch settings must be determined by experience based on the nature of the

foodservice and the type of operation as well as individual preference of the restaurant operator. The proper

switch setting necessary to keep foods at the desired temperature will vary dependent upon the frequency of

turnover, size of food containers, amount of food in each container, room temperature, location of

foodwarmer with respect to range or other heated equipment, air outlets, fans, doors and passageways

SWITCH DIAL

Covers

ON

Lo

2-3

3-4

SETTINGS

Covers

OFF

2

4-5

4-6

RECOMMENDED

TEMPERATURES

(in degrees)

140° - 150°F

150° - 170°F

170° - 200°F

FOODS OR TYPES OF FOODS

Rolls - Thick Soups

Creamed Foods - Mashed Potatoes

Roasts* - Short Ribs - Sliced Meats

Baked Ham* - Fish - Vegetables - Cutlets

Stews - Baked Beans - Croquettes

Fried Liver – Fried Potatoes

Fried Chicken Medium Gravies

Baked Potatoes - Barbecued Ribs

Dressing - Thin Gravies and Soups

.

* A low perforated rack is recommended to keep roasts and hams off the bottom of the pan. When a rack is used, keep

1" - 2" of thin gravy in the bottom of the pan.

219736 Page 10 of 32 9/4/08

INSTALLATION OF AEROHOT SEALED WELL UNITS

Check unit’s electrical rating tag to insure that electrical service is of the proper voltage and

adequately sized for this equipment.

LOCATION

Do not install the hot food unit near any combustible objects or surfaces affected by heat or moisture.

LEVELING

This unit must be level, both front and back and left to right, in order to maintain an equal water depth

throughout the wells.

UNITS WITH DRAINS

A 1/2" female pipe thread drain is supplied on all models. The installer must provide a suitable drain connection

and shut-off valve. CAUTION: Over tightening or failure to use proper tools may result in damage to the weld

where the drainpipe is connected to the well. This equipment is to be installed to comply with

applicable Federal, State or Local Plumbing Code.

ELECTRICAL CONNECTION

Connections must be made in accordance with all applicable local codes and/or the National Electrical Code. Refer to the wiring diagrams on the following pages.

OPERATION

Before the unit is used for the first time, turn the temperature knob to "10" and heat the well for 20-30

minutes. Do not be alarmed if smoke appears; this preheat should burn off any residue or dust on the

heating element.

WARNING: Steam can cause serious burns. Always wear some type of protective covering

on your hands and arms when removing lids or pans from the unit. Lift the lid or pan in a

way that will direct escaping steam away from your face and body.

Never place food directly into the well. Always use pans.

Wet operation is recommended.

Always place covers on pans when not serving to prevent food from drying out and to reduce your

operating costs.

For most efficient operation, keep empty, covered insets in each well during preheating and when the well

is not in use.

W

ET OPERATION

1. Fill food well with two (2) quarts of water. For quicker pre-heating, use hot water to till the well.

2. Turn the control to "HIGH" and pre-heat the warmer for 30 minutes.

3. After pre-heating, set the control to your desired serving temperature.

4. Never pour water into a well that has been heated dry. This may cause well to crack and leak.

Always fill well before preheating or before water level is below 1/2".

D

RY OPERATION

1. Pre-heat the well on "HIGH" for approximately 15 minutes.

2. After pre-heating, set the control to your desired serving temperature.

219736 Page 11 of 32 9/4/08

Loading...

Loading...