Druck RPS8100, DPS 8100 Operating Manual

Pressure measurement

for research & industry

Druck Limited

Fir Tree Lane

Leicester LE6 0FH

England

Tel: 0116 231 7100

Trench Etched

Resonant Pressure Sensor

TERPS 8000 Series

User Manual

Groby

K0473

Druck Limited 2013

This document is the property of Druck Limited and may not, either in part or whole, be copied or otherwise

reproduced, communicated in any way to third parties, nor stored in any data processing system, without the express

written authority of Druck Limited.

Page 1 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

mendment Record

A

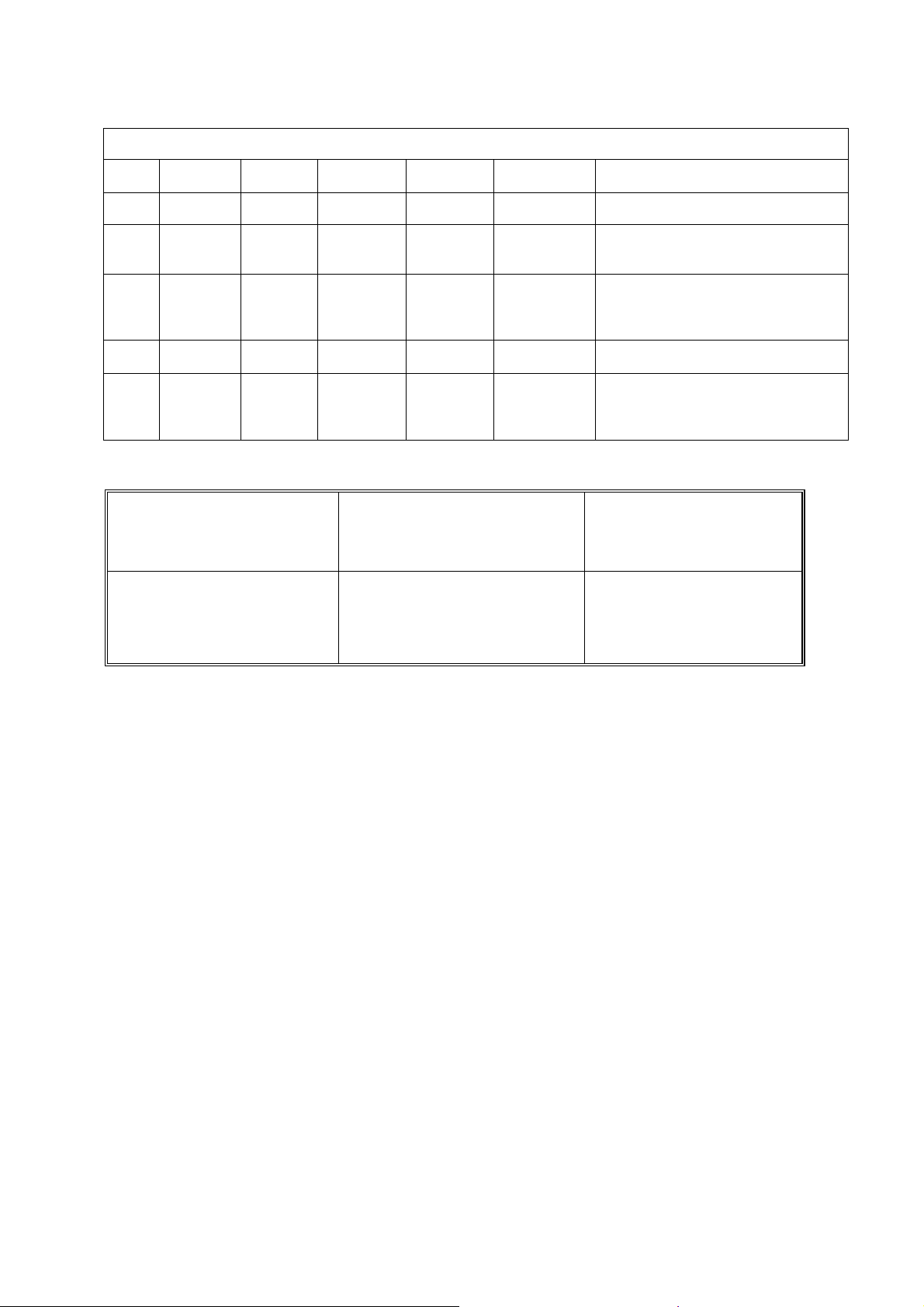

Iss No Date C/N No Originator Typed

1 20/12/10 N/A Robert Lee Robert Lee 156219 New document

2 24/06/11 26758 Robert Lee Robert Lee 165022

3 26/10/11

4 30/01/12 27572 Robert Lee Robert Lee 176971

5 08/11/12

Approvals

Engineering

Technical and operational accuracy

M COLE

Marketing

Customer/market suitability

I ABBOTT

27245

27300

28898

29134

Glenn Roles Glenn Roles 171244

Robert Lee Robert Lee 192333

Technical Communications

Compliance with style guidance and

presentation

G ROLES

Workflow

No.

Amendments

Delete two 80xx pressure ranges,

change power supply voltage from 5 to

6 Vdc.

Change Pascal to hector-Pascal, -

0.2mV/°C to -2mV/°C. Equations

changed on page 5. Pressure range

changed on page 4 25 to 40khz.

Page 11, 7.9b, add 5% of span after

`An applied pressure’.

Add Hastelloy versions and up-date

RS232/RS485.

Add section 6.5 Stored Coefficients and

appendix A

Page 2 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Print Instructions

Finished Size: A5

•

• Print in colour on white throughout (covers + text), saddle stitched.

• Cover to 285 gsm, content to 100 gsm.

Translate into French, German, Italian, Spanish, Portuguese Brazilian, Simplified Chinese and Russian.

THIS HARDCOPY IS NOT TO BE USED AS CAMERA COPY.

Page 3 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Page 4 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

GE

Measurement & Control

Trench Etched Resonant Pressure Sensor

8000 Series

User Manual - K0473

© 2013 General Electric Company. All rights reserved.

Safety • The manufacturer has designed this sensor to be safe when

operated using the procedures detailed in this manual. Do not

use this sensor for any other purpose than that stated.

• This publication contains operating and safety instructions

that must be followed for safe operation and to maintain the

sensor in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the

equipment from injury or damage.

• Use qualified* personnel and good engineering practice for all

procedures in this publication.

Pressure WARNING:

Do not apply pressure greater the maximum safe working

pressure to the sensor.

Toxic Materials There are no known toxic materials used in this sensor.

Maintenance The sensor must be maintained using the manufacturer’s

procedures and these should be carried out by authorised service

agents or the manufacturer’s service departments.

Technical Advice For technical advice contact the manufacturer.

* A qualified technician must have the necessary technical

knowledge, documentation, special test equipment and tools

to carry out the required work on this equipment.

EC Directives This equipment complies with:

BS EN 61000-6-1:2007

BS EN 61000-6-2:2005

BS EN 61000-6-3:2007

BS EN 61000-6-4:2007

BS EN 61326-1:2006

This equipment complies with the requirement of the Pressure

Equipment Directive 97/23/EEC.

For further details see the Sales Data Sheet.

A full conformity certificate is available from the manufacturer.

Contact GE Measurement & Control:

www.ge-mcs.com

i K0473 Issue 5 - [EN] English

Abbreviations

The following abbreviations are used in this manual.

Note: Abbreviations are the same in the singular and plural.

aAbsolute

ASCII American Standard Code for Information Interchange

atm Atmosphere

bps Bits per second

cmHg Centimetre of mercury

CR Carriage return

DC Direct current

EEPROM Electrically Erasable Programmable Read Only Memory

FS Full-scale

ftH

OFeet of water

2

hPa Hecto Pascal

inHg Inch of mercury

inH2OInches of water

kg Kilogram

2

kg/cm

kg/m

Kilogram per centimetre squared

2

Kilogram per metre squared

kPa Kilo Pascal

lb/ft2 Pounds per foot squared

LF Line feed

mA Milli Ampere

mbar Millibar

mbar a Millibar absolute

mHg Metre of mercury

mH

OMetres of water

2

mm Millimetre

mmHg Millimetre of mercury

mmH2O Millimetres of water

MW Mega ohm

MPa Megapascal

n/a Not applicable

[EN] English - K0473 Issue 5 ii

Abbreviations (continued)

Pa Pascal

pc Personal computer

PIN Personal identification number

ppm Parts per million

psi Pound per square inch

RS232 Serial data communication standard

RS485 Serial data communication standard

TERPS Trench etched resonant pressure sensor

VVolt

VA Volt amp

°C Degrees centigrade

iii K0473 Issue 5 - [EN] English

[EN] English - K0473 Issue 5 iv

1Introduction

1.1 General The 8000 Series uses TERPS (trench etched resonant sensor)

technology. The RPS 8000 produces a frequency and diode voltage

output. The DPS 8000 includes a microprocessor to produce a serial

digital output.

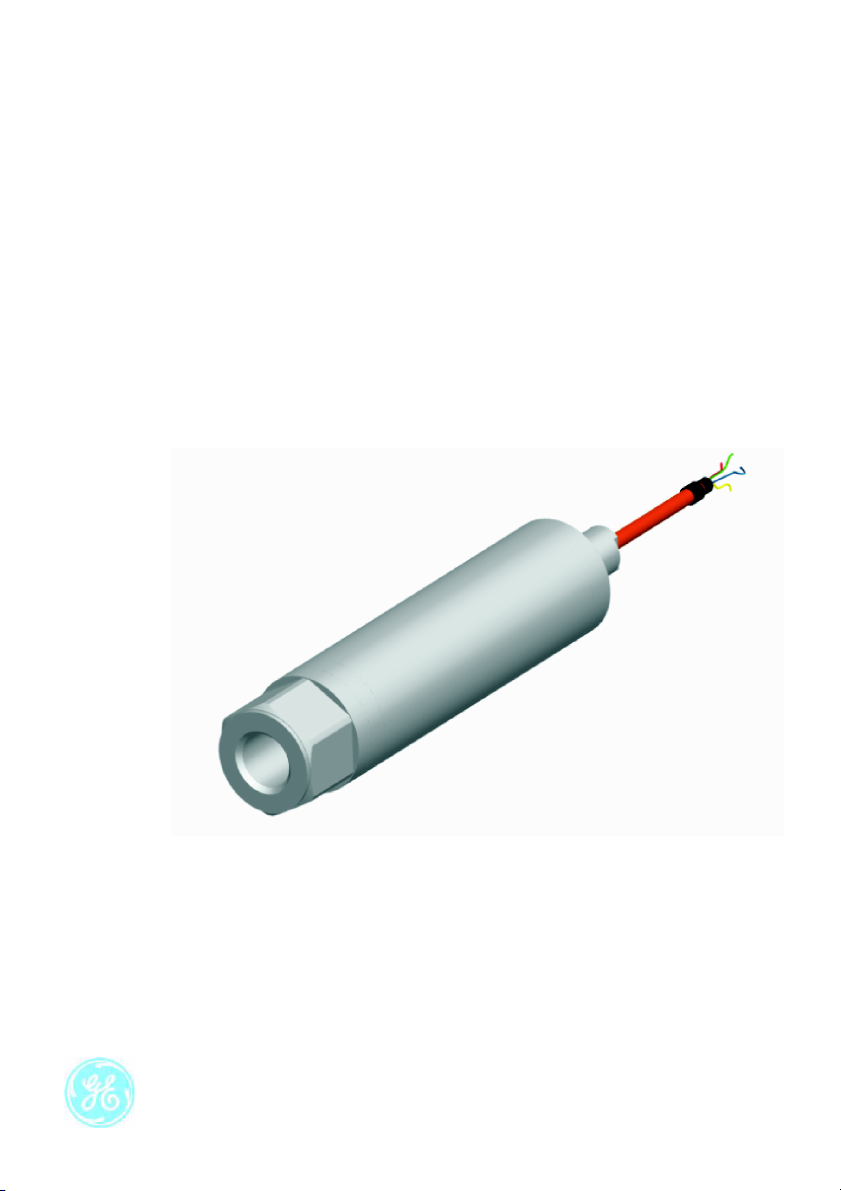

Figure 1 TERPS General view

1.2 Configuration The following variables are specified at the time of ordering.

a. Pressure range

b. Pressure connector

c. Cable length

d. Option A - Increased accuracy

e. Accessories

i. User Manual (this publication)

ii. Calibration certificate.

1 K0473 Issue 5 - [EN] English

2 Installation TERPS 8XXX is a harsh media isolated product. Isolation is achieved

by hermetically sealing the sensor chip in an oil filled chamber. The

weight of this oil gives a g-sensitivity as a pressure offset error.

To calibrate the TERPS 8XXX, the unit is mounted vertically with the

pressure port at the lowest point. Orientation other than this

produces a pressure offset error as specified in the datasheet. The

error is most noticeable at lower pressure ranges.

: The g-sensitivity will also create an error in a high vibration

Note

environment and the unit should be mounted accordingly.

TERPS 81XX is not a harsh media isolated product. There is

negligible change in offset due to mounting position and vibration.

Because the pressure media comes directly into contact with the

sensor chip, care must be taken to ensure the pressure media does

not damage the sensing chip.

2.1 Connecting

TERPS to

pressure source

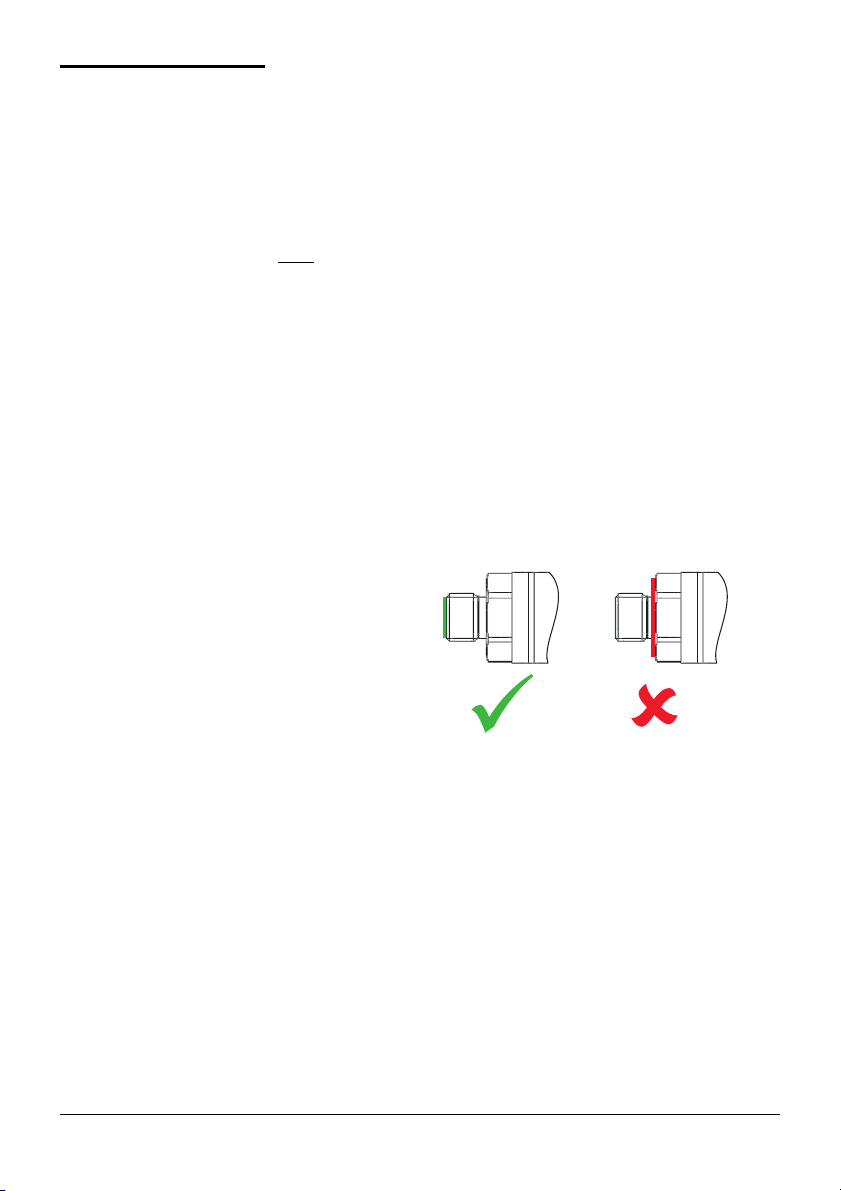

When mounting the sensor, seal the mating surfaces. Failure to

properly seal may affect performance or calibration accuracy.

Male threaded pressure connectors must not be sealed or

constrained against the face at the base of the thread. The forward

cone or flat face should always be used as indicated below.

Depth versions should not be used at hyperbaric pressures above

70 bar (approximately 700 m of water).

[EN] English - K0473 Issue 5 2

3 TERPS media

compatibility

3.1 TERPS 81XX 0 to 3.5 bar: non-condensing dry gases compatible with silicon,

silicon dioxide, RTV adhesive, stainless steel 316L and glass.

3.2 TERPS 80XX- Ranges 0 to 200 bar: Fluids compatible with Stainless Steel 316L

and Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Stainless Steel 316L and Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

3.3 TERPS 82XX- Ranges 0 to 200 bar: Fluids compatible with Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

3.4 TERPS 83XX- Ranges 0 to 200 bar: Fluids compatible with Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

4 Pressure

containment

4.1 TERPS 81XX Ranges 0 to 3.5bar 7 bar maximum.

4.2 TERPS 8XXX- Ranges up to 7 bar: 70 bar maximum.

Ranges >7 to 100 bar: 200 bar maximum.

3 K0473 Issue 5 - [EN] English

Loading...

Loading...