Page 1

I²C Sensor Communication Overview

21 Feb 2014 Issue A

1 INTRODUCTION

1.1 OVERVIEW

The DPS 5000 sensor is a smart pressure transducer with I²C output. This

document provides a brief overview of the communication sub-system of this

sensor. It is designed to accompany pre-release samples and not to be full

documentation.

2 COMMUNICATING WITH THE SENSOR

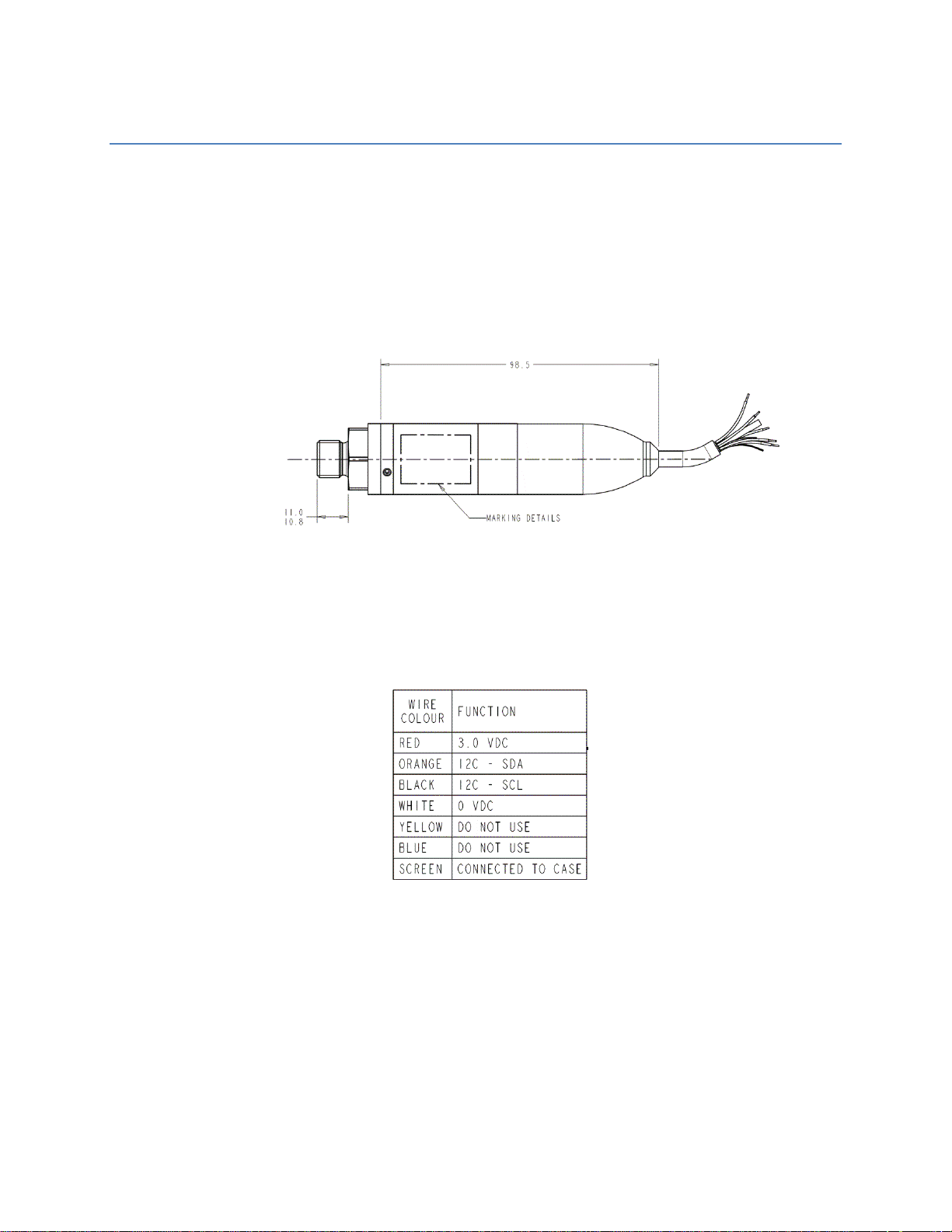

The sensor communicates over an I²C interface at speeds of up to 100 kHz. It

appears on the bus as a slave device with a number of memory addresses

containing information about the device and its environment. The electrical

connections to the sensor are shown in the table below:

The memory map is split into three groups: The volatile information,

configuration parameters and a Flash memory block. The full layout of the

memory is described in the table in section 3.

The I²C address of the supplied sensor has been pre-set to 2. This can be

changed over the bus if required.

2.1 READING FROM THE DEVICE

In order to read from the device the host must first send the address of the

sensor to read, followed by the single byte address of the location to read

Page 2

from the sensor’s memory. The host should then read the four bytes from that

location.

For example, to read the status register from sensor 2 the host should follow

the steps below.

Write 0 (location of the status word) to I2C device 2.

Read four bytes. This will return the 32 bit integer status register, LSB first. The

contents of this register are explained in section 0.

2.2 WRITING TO THE DEVICE

In order to access the device the host must first address the sensor and then

send the address of the location it wants to access followed by the data to be

written to the location.

For example, to write to the access word (location 5) of sensor 2 the host

should follow the steps below.

Write 5 to I2C device 2.

Write the four byte integer, LSB first, to the sensor.

2.3 READING THE COMPENSATED PRESSURE AND TEMPERATURE

When the sensor is first switched on it takes a pressure and temperature

reading. It will not take another reading until instructed to do so by the host. If

the sensor is used in an application where it is only turned on when a reading

is needed and turned off when this reading has been read, this may be

adequate, in other cases the host will need to trigger a reading when required.

To trigger a pressure reading, bit 0 of the status register should be set. The

sensor will now clear that bit and begin taking a reading. This will typically

take approximately 25ms. This host should poll the status register waiting for

bit 0 to be set again. This indicates that the reading is available now. The host

can now read locations 1 and 2 to obtain the compensated pressure and

temperature values.

For example, to trigger a new reading and get the values from sensor 2 the

host should follow the steps below.

Trigger a reading.

Write 0 to I2C device 2.

Write 1 as a four byte integer, LSB first, to the sensor.

Poll the sensor until a reading has been completed.

Write 0 to I2C device 2.

Read the four byte integer, LSB first and check bit 0. If 1, a reading has been

taken. Otherwise, poll again.

Page 3

Read the compensated pressure value.

Address

Type

Name

Volatile?

Description

0

uint32

Status

Y

Status Word. Shows various

aspects of the sensors operation

including Reading available,

pressure valid, and temperature

valid. Also used to start a new

conversion.

1

Float

Compensated

Pressure

Y

Pressure reading in bar

2

Float

Compensated

Temperature

Y

Temperature reading in ºC

5

uint32

Access Word

Y

The access word is used to enable

writing of permanent information.

66

uchar

I²C Address

-

The address of the sensor on the

bus.

77

uint32

Serial Number

-

The serial number of the sensor

79

uint32

Version

-

Software version. nn.nn.nn.nn

128

Float

K00

-

Coefficients (IEEE Float)

129

Float

K01

-

Coefficients (IEEE Float)

130

Float

K02

-

Coefficients (IEEE Float)

131

Float

K03

-

Coefficients (IEEE Float)

132

Float

K04

-

Coefficients (IEEE Float)

133

Float

K10

-

Coefficients (IEEE Float)

134

Float

K11

-

Coefficients (IEEE Float)

135

Float

K12

-

Coefficients (IEEE Float)

136

Float

K13

-

Coefficients (IEEE Float)

137

Float

K14

-

Coefficients (IEEE Float)

138

Float

K20

-

Coefficients (IEEE Float)

139

Float

K21

-

Coefficients (IEEE Float)

140

Float

K22

-

Coefficients (IEEE Float)

141

Float

K23

-

Coefficients (IEEE Float)

142

Float

K24

-

Coefficients (IEEE Float)

Write 1 to I2C device 2.

Read the four byte floating point number.

Read the compensated temperature value.

Write 2 to I2C device 2.

Read the four byte floating point number.

3 MEMORY LAYOUT

Memory Layout is described in the table below.

Page 4

143

Float

K30

-

Coefficients (IEEE Float)

144

Float

K31

-

Coefficients (IEEE Float)

145

Float

K32

-

Coefficients (IEEE Float)

146

Float

K33

-

Coefficients (IEEE Float)

147

Float

K34

-

Coefficients (IEEE Float)

7 6 5 4 3 2 1 0 0

ERASE FLASH

WRITE

ADCPWR

WENAB

TVAL

PVAL

CONV

3.1 STATUS (ADDRESS 0)

The status register represents a bit map that reports on the status of the

sensor. It is also used to trigger a new reading.

Bits 31 to 8 are unused.

3.1.1 ERASE FLASH

Erase the upper flash region of memory. This will only work when WENAB is

set.

3.1.2 WRITE

When this bit is set and WENAB is set, the current configuration will be written

to the Flash memory.

3.1.3 ADCPWR.

Read only. The ADC is powered up.

3.1.4 WENAB.

Read only. The sensor is in customer write enable mode.

3.1.5 TVAL.

Read only. The temperature reading is valid i.e. between the min and max

values of the ADC count. In addition, CONV must be 1.

3.1.6 PVAL.

Read only. The pressure reading is valid i.e. between the min and max values

of the ADC count. In addition, CONV must be 1.

3.1.7 CONV.

Read write. When read, a 1 indicates that a reading has been completed.

When 1 is written a new conversion will be started.

Page 5

3.2 COMPENSATED PRESSURE VALUE (ADDRESS 1)

The most recently requested reading of the pressure.

3.3 COMPENSATED TEMPERATURE VALUE (ADDRESS 2)

The most recently requested reading of the temperature.

3.4 ACCESS WORD (ADDRESS 5)

This word controls access permissions to the other locations in the memory

map. Writing the number 4118 to this register will enable writing of the I2C

address.

3.5 I

2

C ADDRESS (ADDRESS 66).

The address used to access the sensor. This has been pre-set as described in

section 2 above. In order to change this value, the correct value should be

written into the access word above, the new address written here and the

WRITE bit set in the status word.

3.6 SERIAL NUMBER (ADDRESS 77)

The sensor’s serial number.

3.7 VERSION (ADDRESS 79)

The version of the software within the sensor. This is held as 4 hex bytes and

gives a value of the form xx.xx.xx.

3.8 COEFFICIENTS (ADDRESSES 128+)

This section of the memory holds the coefficients/compensation data for the

sensor.

Loading...

Loading...