Page 1

GE

Measurement & Control

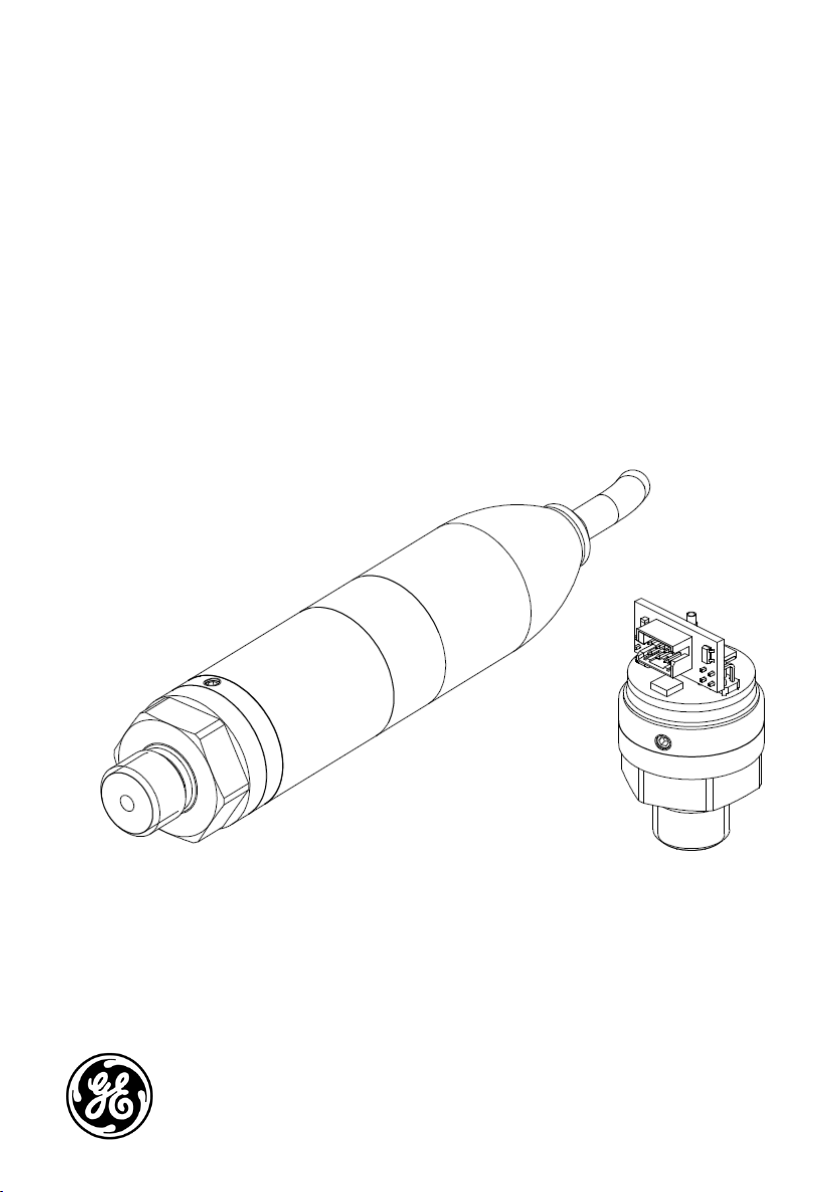

DPS 5000 Series Sensors

I2C-bus Pressure Transducer

User Manual – K0582

English

Page 2

Druck Ltd., Fir Tree Lane, Groby. Leicester, LE6 0FH, UK.

Tel: +44 (0)116 231 7100; Fax +44 (0)116 231 7103

© 2015 General Electric Company. All rights reserved

Page 3

1

Safety

The manufacturer has designed this sensor to be safe when operated using the procedures

detailed in this manual. Do not use this sensor for any other purpose than that stated.

This manual contains operating and safety instructions that must be followed for safe

operation and to maintain the sensor in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage.

Use qualified personnel and good engineering practice for all procedures in this manual.

Qualified personnel must have the necessary technical knowledge, documentation, special

test equipment and tools to carry out required work on this sensor.

Pressure Do not apply pressure greater than the maximum safe working pressure

to the sensor.

Toxic materials There are no known toxic materials used in the sensor.

Maintenance The sensor must be maintained using the manufacturer’s procedures

and these should be carried out by authorised service agents or the

manufacturer’s service departments.

Technical advice For technical advice contact the manufacturer.

EC Directives This sensor complies with the requirements of the Pressure Equipment

Directive 97/23/EEC and the EMC directive 2004/108/EC1.

For further details refer to the Sales Data Sheet or the customer

specification drawing.

A full conformity certificate is available from the manufacturer.

Contact GE Measurement & Control www.gemeasurement.com

The EMC directive is only applicable to the external variant (model E503D)

K0582 Revision B May 2015 i

Page 4

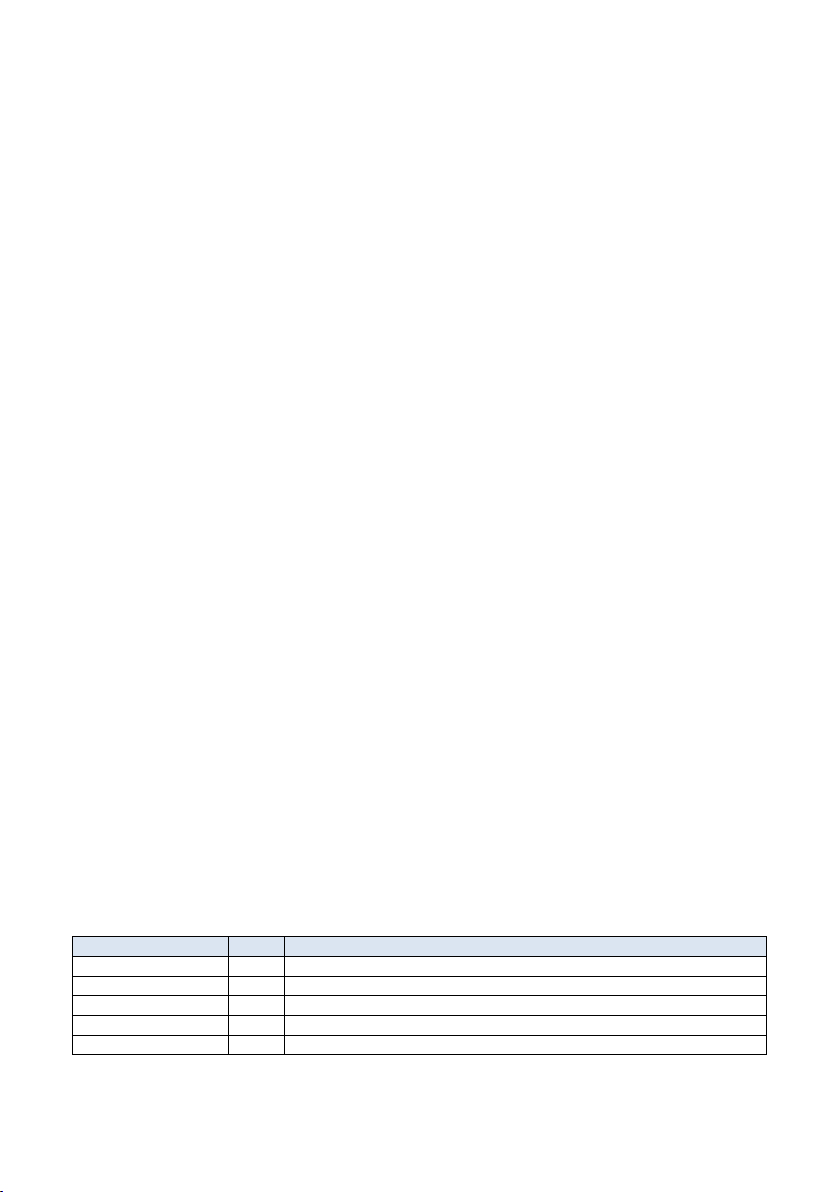

Type

Bits

Range

Unsigned byte

8

0x00 (0) to 0xFF (255)

Unsigned integer

16

0x0000 (0) to 0xFFFF (65535)

Unsigned word

32

0x00000000 (0) to 0xFFFFFFFF (4294967295)

Float

32

0xFF7FFFFF (-3.4028E-38) to 0x7F7FFFFF (+3.4028E+38)

NOTE 1

Extended ASCII

8

0x00 (NULL) to 0xFF (ÿ)

NOTE 2

Abbreviations

The following abbreviations are used in this manual.

Note: Abbreviations are the same in the singular and plural

ADC Analogue to digital converter

Addr Address

ASCII American standard code for information interchange

atm atmosphere

ESD Electro-static discharge

ftH2O Feet of water

hPa HectoPascal

Hz Hertz

I2C Inter-integrated circuit

IEEE Institute of Electrical and Electronic Engineers

inHg Inch of Mercury

inH2O Inch of water

kbit/s Kilobits per second

kbyte Kilobytes (1024 bytes)

kgf/cm2 Kilogram-force per square centimetre

kPa KiloPascal

LSB Least significant bit/byte

mbar Millibar

mH2O Metre of water

mmHg Millimetre of Mercury

mmH2O Millimetre of water

MPa MegaPascal

ms Millisecond

MSB Most significant bit/byte

PCB Printed circuit board

psi Pound per square inch

s Second

SNR Signal to noise ratio

°C Degrees Celsius

Nomenclature

The following number notations are used in this document.

0bn..n Binary number notation, e.g. 0b10

0xn..n Hexadecimal number notation, e.g. 0x3BF0

The following data types are used in this document.

NOTE 1: Data type float to IEEE 754. NOTE 2: Data type Extended ASCII to ISO 8859-1

ii May 2015 K0582 Revision B

Page 5

References

Reference 1 I2C-bus specification and user manual, NPX Semiconductor UM10204 Rev. 6

available from www.nxp.com

K0582 Revision B May 2015 iii

Page 6

Contents

1 Introduction 1

General 1 1.1

Configuration 1 1.2

2 Installation 2

General 2 2.1

Mounting and orientation 2 2.2

Connecting to the pressure source 2 2.3

Electrical connections 3 2.4

3 Functional description 4

Sensor communication 4 3.1

Memory map 5

3.2

Register descriptions 5 3.3

Register bit table legend 5 3.3.1

Address 0 - STATUS 6 3.3.2

Address 1 – COMP_PRES 7 3.3.3

Address 2 – COMP_TEMP 8 3.3.4

Address 3 – ADC_PRES 8 3.3.5

Address 4 – ADC_TEMP 9 3.3.6

Address 5 – ACCESS 9 3.3.7

Address 6 – MVOLT_PRES 9 3.3.8

Address 7 – MVOLT_TEMP 10 3.3.9

Address 66 – I2C_ADDR 10 3.3.10

Address 67 – COEF_FIT 11

3.3.11

Address 68 – GAIN_ADJ 11 3.3.12

Address 69 – OFFSET_ADJ 12 3.3.13

Address 70 – MAX_RANGE 12 3.3.14

Address 71 – MIN_RANGE 12 3.3.15

Address 72 – CAL_DATE 13 3.3.16

Address 73 – MAX_ADC_PRES 13 3.3.17

Address 74 – MIN_ADC_PRES 14 3.3.18

Address 75 – MAX_ADC_TEMP 14 3.3.19

Address 76 – MIN_ADC_TEMP 14 3.3.20

Address 77 – SERIAL 15 3.3.21

Address 78 – CONFIG 15 3.3.22

Address 79 – VERSION 16

3.3.23

Address 82 – AVERAGE 16 3.3.24

Address 83 – PRES_CONV 17 3.3.25

Address 84 – PRES_UNIT 17 3.3.26

Address 85 – DELAY 18 3.3.27

Address 86 - SPEC_DWG 19 3.3.28

Address 87 – TARE_VALUE 19 3.3.29

Addresses 128-157 - Pressure coefficients 19 3.3.30

Addresses 158-187 - Temperature coefficients 20 3.3.31

iv May 2015 K0582 Revision B

Page 7

4 Operational description 20

Operational states 20

4.1

Reading the pressure and temperature 21 4.2

Updating the pressure and temperature 21 4.3

Manual update 21 4.3.1

Automatic update 22 4.3.2

Updating the sensor configuration data registers 22 4.4

User modifiable registers 22 4.4.1

Modifying the I

2

C-bus address 23 4.4.2

Changing the auto-update period 23 4.4.3

Changing the unit of pressure 24 4.4.4

Reading relative pressure 24 4.4.5

Pressure and temperature SNR 25 4.4.6

Maximising the update rate 26

4.4.7

Pressure re-calibration 26 4.4.8

5 Maintenance 27

Cleaning 27 5.1

Adjustment 28 5.2

Repair 28 5.3

Disposal 28 5.4

Annex A Unit of pressure conversion factors 29

List of figures

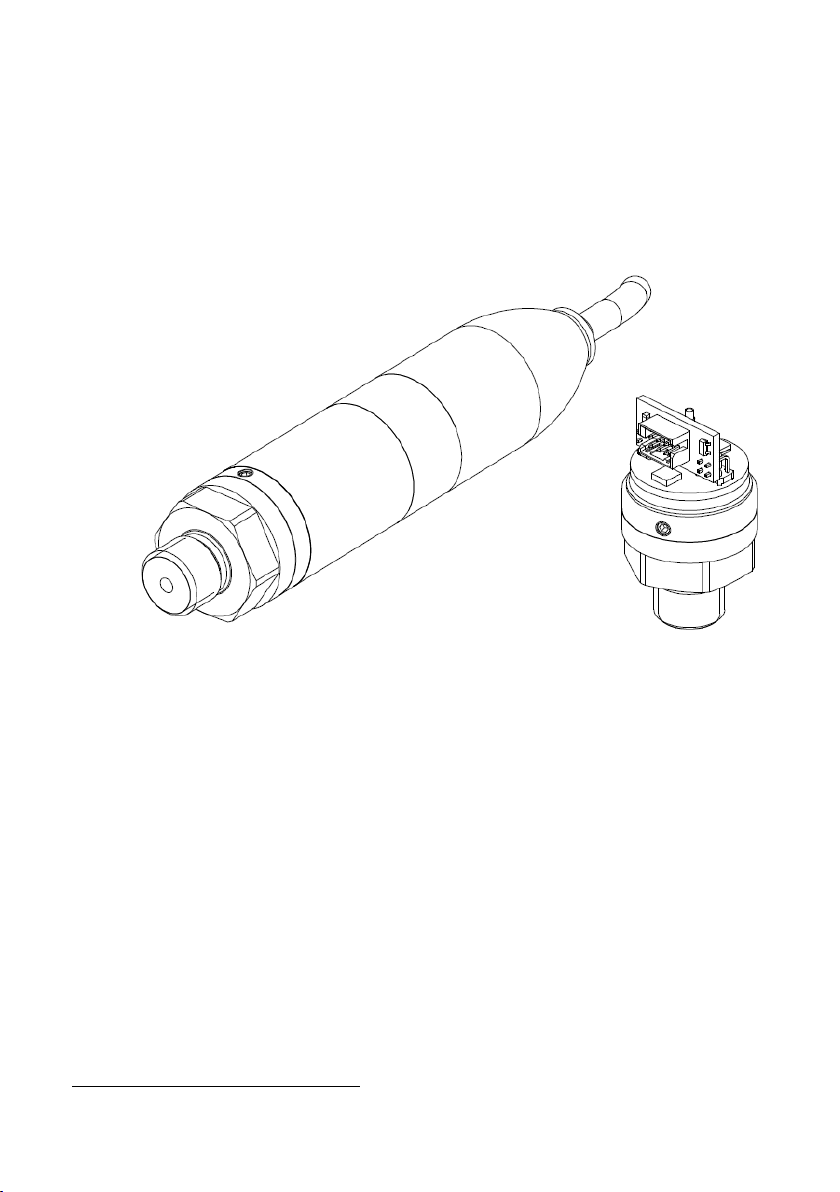

Figure 1 External and internal DPS 5000 sensors – General view 1

Figure 2 Pressure connection 3

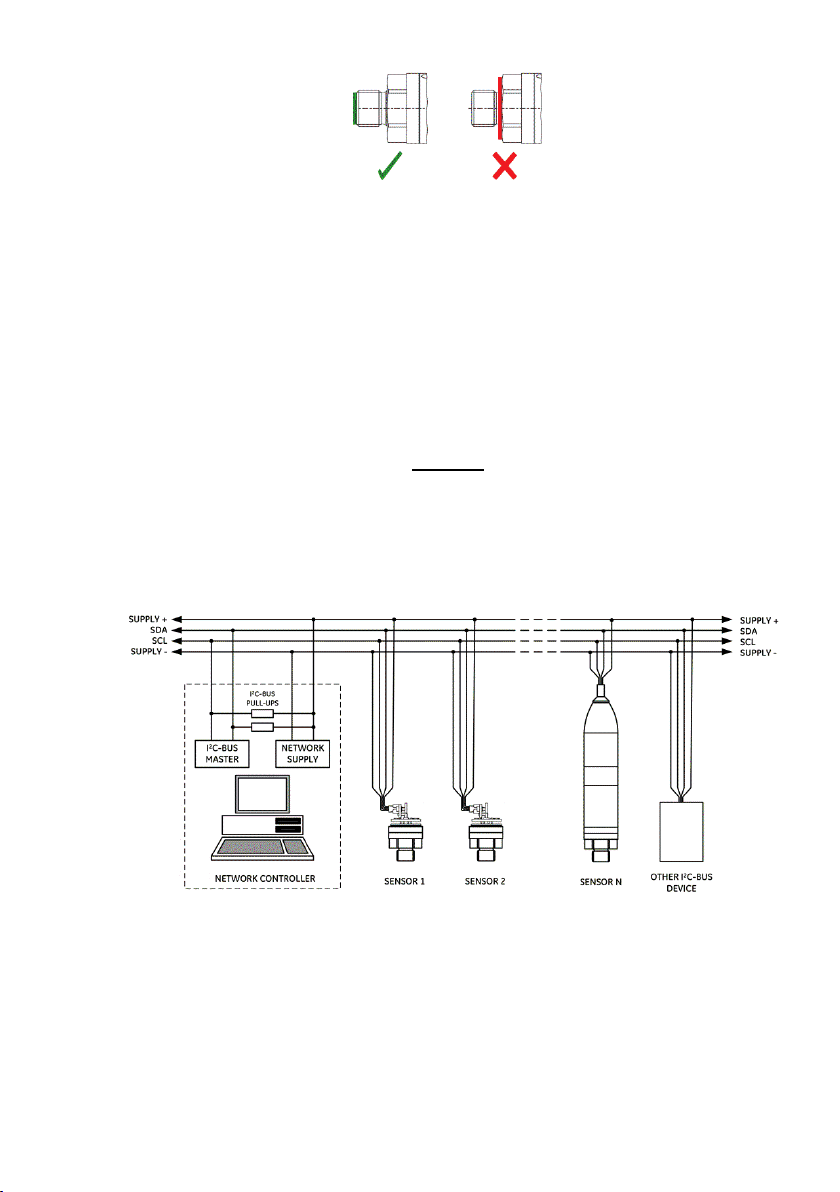

Figure 3 Typical I2C-bus network 3

Figure 4 Typical I2C-bus data transfers 4

Figure 5 Bit table legend 6

Figure 6 Operational states 20

Figure 7 Interaction legend 21

Figure 8 Noise level correction factors 25

List of tables

Table 1 Electrical connections 4

Table 2 I2C-bus feature support 4

Table 3 Memory map 5

Table 4 User modifiable registers 22

K0582 Revision B May 2015 v

Page 8

Page left intentionally blank

vi May 2015 K0582 Revision B

Page 9

2

2

1 Introduction

General 1.1

The DPS 5000 series sensor is a microcontroller based smart pressure transducer

that provides a digital output through an I2C-bus interface. The sensor is available

as either an external or internal variant. The external variant is a sealed device with

the electrical connections made via an integral cable. The internal variant is an

open frame device with electrical connections made via an integral plug.

Figure 1 External and internal DPS 5000 sensors – General view

The DPS 5000 series sensors are low powered devices offering a high level of

accuracy over a wide temperature range. The I2C-bus interface provides

compensated pressure and temperature readings and allows the sensor operation

to be software controlled.

Configuration 1.2

The following options are available at the time of ordering:

a) External or internal sensor variant

b) Pressure range

c) Pressure connector

Each sensor is supplied with the following documentation:

d) Hazardous area installation instructions

:

Document K0546 for the external sensor variant

Document K0547 for the internal sensor variant

e) Calibration certificate

Only supplied with hazardous area certified sensors

K0582 Revision B May 2015 1

Page 10

2 Installation

General 2.1

Before installing the DPS 5000 series sensor:

Ensure that the sensor is the correct type for the application and will not be

subject to pressures or media outside those specified on the applicable

datasheet or specification drawing.

If the sensor is being installed in a hazardous area observe the installation

instructions given in the supplied document K0546 or K0547.

Read all relevant instructions and procedures in the applicable system

installation manual.

To prevent contamination prior to installation, keep the sensor in the original

packaging with all the supplied covers fitted.

When installing the internal variant, to prevent possible damage, avoid touching or

applying excessive force to the exposed PCB assemblies.

WARNING

Do not interchange sensors between an oil system and a system that uses fuel or

gas. This can cause an explosion resulting in death or injury and/or damage to

equipment.

High pressures and extremes of temperature are dangerous. De-pressurize and

allow components to attain an acceptable temperature in systems where high

pressures and high or low temperatures are present.

CAUTION

The sensor contains ESD sensitive devices. Whilst the sensor incorporates

protection against ESD, caution should be taken to observe proper ESD handling

procedures when installing the internal variant.

Mounting and orientation 2.2

The DPS 5000 series sensors are designed to be mounted in any orientation.

However, the sensor is a harsh media isolated product and the isolation is achieved

by hermetically sealing the sensor chip within an oil filled chamber. The weight of

the oil gives a g-sensitivity as a pressure offset error that may be noticeable at the

lowest pressure ranges.

Ensure the sensor is mounted in a manner that avoids unwanted mechanical or

thermal stress such as vibration, shock or excessive or rapid temperatures

excursions.

Connecting to the pressure source 2.3

When connecting the pressure source to the sensor, ensure the mating surfaces are

correctly sealed. Failure to properly seal may affect the sensor performance or

calibration accuracy.

Male parallel threaded pressure connectors must not be sealed or constrained

against the face at the base of the thread. The forward flat face should be used as

shown in Figure 2.

2 May 2015 K0582 Revision B

Page 11

Figure 2 Pressure connection

Torque tighten the sensor in accordance with the system installation manual.

Electrical connections 2.4

The DPS 5000 series sensors employ a 4 wire I2C-bus user electrical interface:

Supply +

Serial data (SDA)

Serial clock (SCL)

Supply –

The sensor may be used standalone or as part of a network of compatible I2C-bus

devices.

CAUTION

The DPS 5000 is intended for use within networks operated from a single supply

at a voltage within the range 2.7 V to 3.6 V. Operation outside these limits is not

guaranteed and may damage the sensor.

The sensor interface includes 2 reserved signals. These should be left open circuit

as connecting to these signals may result in incorrect sensor operation.

Figure 3 Typical I

2

C-bus network

The electrical connections to the sensors are colour coded as shown in Table 1.

K0582 Revision B May 2015 3

Page 12

Signal

External variant

Internal variant

Plug pin

NOTE 1

Supply +

Red

Red 1 Serial data

Orange

Yellow

2

Serial clock

Black

Green

3

Supply -

White

Blue

4

Reserved

Yellow & Blue

Orange & Black

5 & 6

Case

Screen

-

-

Feature

Applicability

Feature

Applicability

Standard mode

Supported

10 bit addressing

Not supported

Fast mode

Not supported

General call address

Not supported

Fast mode plus

Not supported

Clock stretching

Supported

High speed mode

Not supported

Software reset

Not supported

7 bit address

Supported

Device ID

Not supported

NOTE 1: The mating connector for the internal variant plug is a Molex Milli-GridTM connector system

6 pin crimp housing part number 0511100660 with crimp terminals part number 0503948051

or 0503948100.

Table 1 Electrical connections

3 Functional description

Sensor communication 3.1

The DPS 5000 series sensors appear on the I2C-bus as a slave device containing a

number of memory mapped registers that are used to control the operation of the

sensor and to provide information about the sensor and its environment. Table 2

summarizes the features of the I2C-bus specification, Reference 1, that are

supported by the DPS 5000 series sensors.

Table 2 I2C-bus feature support

Each slave device on an I2C-bus network must have a unique address. The default

address for the DPS 5000 series sensors is 2, but may be changed over the bus as

required to any value within the range 1 to 127.

The DPS 5000 series sensors support the I2C-bus standard mode to permit data

transfers to or from the sensor up to 100 kbit/s under the control of the network I2C-

bus master. Data transfers may use any of the 3 I2C-bus data transfer formats to

achieve the sensor register read and write protocols shown in Figure 4.

When reading from or writing to the sensor, the master first performs a 1 byte data

write to send the required register address to the sensor. The master then performs

either an n byte data read or write to transfer the data, LSB first, from or to the

4 May 2015 K0582 Revision B

Figure 4 Typical I

2

C-bus data transfers

Page 13

Volatile data

Configuration data

Coefficient data

Addr

Register

Addr

Register

Addr

Register

0

STATUS

64

Reserved

128

Up to 30

pressure

coefficient

registers

1

COMP_PRES

65

Reserved

. 2 COMP_TEMP

66

I2C_ADDR

. 3 ADC_PRES

67

COEF_FIT

. 4 ADC_TEMP

68

GAIN_ADJ

.

5

ACCESS

69

OFFSET_ADJ

.

6

MVOLT_PRES

70

MAX_RANGE

. 7 MVOLT_TEMP

71

MIN_RANGE

. 8 Reserved

72

CAL_DATE

157 . .

73

MAX_ADC_PRES

158

Up to 30

temperature

coefficient

registers

. . 74

MIN_ADC_PRES

. . .

75

MAX_ADC_TEMP

. . .

76

MIN_ADC_TEMP

. . .

77

SERIAL . . . 78

CONFIG

.

. . 79

VERSION

.

. . 80

Reserved

. . .

81

Reserved

. . .

82

AVERAGE

187 . .

83

PRES_CONV

188

Unused

. . 84

PRES_UNIT

. . . . 85

DELAY

. . . . 86

SPEC_DWG

. . . . 87

TARE_VALUE

. . . . 88

Reserved

. . . . . . .

.

. . . . .

.

. . . . . . 63

Reserved

127

Reserved

255

Unused

addressed register. As the sensor registers are 32 bits wide, the read and write

transfers are generally 4 bytes long. However, 1, 2 or 3 byte transfers are allowed.

Memory map 3.2

The DPS 5000 sensor registers are mapped within a 1 kbyte memory space. As each

register is 4 bytes wide, the register addresses range from 0 to 255. Not all the

address space is available to the user, some addresses are reserved whilst others

are unused. The reserved addresses cannot be written to and read as 0x00000000.

Unused addresses cannot be written to and read as 0xFFFFFFFF.

The registers are grouped into 3 blocks: volatile data, configuration data and

coefficient data as shown in Table 3.

Register descriptions 3.3

Register bit table legend 3.3.1

The legend used for the bit tables within this section is shown in Figure 5.

K0582 Revision B May 2015 5

Table 3 Memory map

Page 14

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

R-0

R-0

R-0

R-0

R-0

R-0

R-0

R-0

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

R-0

R-0

R-0

R-0

R-0

R-0

R-0

R-0

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

RESET [1..0]

CLRQERR

TARE

SET_TARE

QERR

INTRDG

AUTO

W-0

W-0

W-0

R/W-0

W-0

R-0

RW-0

R/W-0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reserved

Reserved

WRITE

ADC_ON

WENB

VALID [1..0]

CONV

R-0

R-0

W-0

R-X

R-0

R-X

R-X

R/W-X

Figure 5 Bit table legend

Not all bits within a register are available to the user. Reserved bits always read as

0b0 and writes have no effect. Unused bits are readable and writable but have no

effect on the sensor operation.

Address 0 - STATUS 3.3.2

Bit 31–16 Reserved, read as 0

Bit 15–14 RESET [1..0]: Write only - performs a sensor reset equivalent to cycling the

sensor power.

0b00 No action

0b01 No action

0b10 Reset

0b11 No action

Bit 13 CLRQERR: Write only - used to clear the QERR (bit 10) and the CONV (bit 0) flags.

0b0 No action

0b1 Clear flags

Bit 12 TARE: Read/write – used to enable the sensor tare mode. When enabled, the

COMP_PRES register (address 1) is set to the actual compensated pressure

minus the current value of the TARE_VALUE register (address 87).

0b0 Disabled

0b1 Enabled

Bit 11 SET_TARE: Write only – used to copy the current value of the COMP_PRES

register (address 1) to the TARE_VALUE register (address 87).

0b0 No action

0b1 Copy data

Bit 10 QERR: Read only - set when an internal queue error is detected whilst AUTO

(bit 8) is set. Reset using CLRQERR (bit 13).

6 May 2015 K0582 Revision B

Page 15

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

COMP_PRES [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

COMP_PRES [23..16]

R-X

0b0 No error

0b1 Error

Bit 9 INTRDG: Read/write – used to enable the sensor interleave mode. ADC_ON (bit

4) is always set when enabled, and alternate pressure and temperature ADC

values are used to generate the updated pressure and temperature readings.

0b0 Disabled

0b1 Enabled

Bit 8 AUTO: Read/write – used to enable the sensor auto-update mode. When

enabled pressure and temperature readings are updated automatically at a

rate determined by the value of the DELAY register (address 85).

0b0 Disabled

0b1 Enabled

Bit 7–6 Reserved, read as 0

Bit 5 WRITE: Write only – used to transfer the current values of the configuration

data registers to non-volatile memory when WENB (bit 3) is set.

0b0 No action

0b1 Transfer data

Bit 4 ADC_ON: Read only – indicates when the sensor ADC and bridge are active.

0b0 Inactive

0b1 Active

Bit 3 WENB: Read only – indicates the write status of the configuration data

resisters. It is set and cleared by writing to the ACCESS register (address 5).

0b0 Not writable

0b1 Writable

Bit 2–1 VALID[1..0]: Read only – used to indicate the status of the current values held

in the COMP_PRES and COMP_TEMP registers (addresses 1 and 2).

Automatically cleared by reading the COMP_PRES, COMP_TEMP, ADC_PRES,

ADC_TEMP, MVOLT_PRES or MVOLT_TEMP register (addresses 1, 2, 3, 4, 6 and 7

respectively) whilst the sensor is in the auto-update mode.

0b00 Error – invalid pressure and temperature ADC values detected

0b01 Error – invalid temperature ADC value detected

0b10 Error – invalid pressure ADC value detected

0b11 Data valid

Bit 0 CONV: Read/write – used to trigger an update of the COMP_PRES and

COMP_TEMP registers (addresses 1 and 2) and to indicate when the registers

have been updated. Cleared by writing 0b0, using CLRQERR (bit 13) or by

reading the COMP_PRES, COMP_TEMP, ADC_PRES, ADC_TEMP, MVOLT_PRES or

MVOLT_TEMP register (addresses 1, 2, 3, 4, 6 and 7 respectively) whilst the

sensor is in the auto-update mode.

0b0 Read = data not updated / Write = clear bit

0b1 Read = data updated / Write = request update

Address 1 – COMP_PRES 3.3.3

K0582 Revision B May 2015 7

Page 16

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

COMP_PRES [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

COMP_PRES [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

COMP_TEMP [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

COMP_TEMP [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

COMP_TEMP [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

COMP_TEMP [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

ADC_PRES [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

ADC_PRES [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

ADC_PRES [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

ADC_PRES [7..0]

R-X

Bit 31–0 COMP_PRES [31..0]: Read only – the most recently updated compensated

pressure value in the pressure units defined by the PRES_UNIT register

(address 84). Reading this register whilst the sensor is in the auto-update

mode will clear the CONV (bit 0) flag of the STATUS register (address 0).

0xn..n Number type float

Address 2 – COMP_TEMP 3.3.4

Bit 31–0 COMP_TEMP [31..0]: Read only – the most recently updated compensated

temperature value in °C. Reading this register whilst the sensor is in the auto-

update mode will clear the CONV (bit 0) flag of the STATUS register (address 0).

0xn..n Number type float

Address 3 – ADC_PRES 3.3.5

Bit 31–0 ADC_PRES [31..0]: Read only – the most recently updated pressure ADC value.

This value is used to calculate the value held in the MVOLT_PRES register

(address 6). Reading this register whilst the sensor is in the auto-update mode

will clear the CONV (bit 0) flag of the STATUS register (address 0).

0xn..n Number type unsigned word

8 May 2015 K0582 Revision B

Page 17

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

ADC_TEMP [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

ADC_TEMP [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

ADC_TEMP [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

ADC_TEMP [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

ACCESS [31..24]

W-0

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

ACCESS [23..16]

W-0

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

ACCESS [15..8]

W-0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

ACCESS [7..0]

W-0

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MVOLT _PRES [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MVOLT _PRES [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MVOLT _PRES [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MVOLT _PRES [7..0]

R-X

Address 4 – ADC_TEMP 3.3.6

Bit 31–0 ADC_TEMP [31..0]: Read only – the most recently updated temperature ADC

value. This value is used to calculate the value held in the MVOLT_TEMP

register (address 7). Reading this register whilst the sensor is in the auto-

update mode will clear the CONV (bit 0) flag of the STATUS register (address 0).

0xn..n Number type unsigned word

Address 5 – ACCESS 3.3.7

Bit 31–0 ACCESS [31..0]: Write only – used to clear or set WENB (bit 3) of the STATUS

register (address 0).

0xn..n Number type unsigned word

0 Clear WENB

4118 Set WENB

Address 6 – MVOLT_PRES 3.3.8

K0582 Revision B May 2015 9

Page 18

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MVOLT _TEMP [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MVOLT _TEMP [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MVOLT _TEMP [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MVOLT _TEMP [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

ADDR[7..0]

R/W-X

4

3

Bit 31–0 MVOLT _PRES [31..0]: Read only – the most recently updated pressure sensing

element output voltage. This value is used in conjunction with the pressure

and temperature coefficient registers to calculate the values held in the

COMP_PRES and COMP_TEMP registers (addresses 1 and 2). Reading this

register whilst the sensor is in the auto-update mode will clear the CONV (bit 0)

flag of the STATUS register (address 0).

0xn..n Number type float

Address 7 – MVOLT_TEMP 3.3.9

Bit 31–0 MVOLT _TEMP [31..0]: Read only – the most recently updated temperature

sensing element output voltage. This value is used in conjunction with the

pressure and temperature coefficient registers to calculate the values held in

the COMP_PRES and COMP_TEMP registers (addresses 1 and 2). Reading this

register whilst the sensor is in the auto-update mode will clear the CONV (bit 0)

flag of the STATUS register (address 0).

0xn..n Number type float

Address 66 – I2C_ADDR 3.3.10

Bit 31–7 Unused, read/write

Bit 7–0 ADDR[7..0]: Read/write – the sensors current/new I2C-bus address3.

0xn..n Number type unsigned byte

0 Invalid address

A change of the sensor I2C bus address does not take effect until the I2C_ADDR register has been

modified, written to non-volatile memory and the sensor reset via the STATUS register or the sensor

power is cycled.

10 May 2015 K0582 Revision B

Page 19

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

TT_FIT(7..0]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

TP_FITF(7..0]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

PT_FIT(7..0]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

PP_FIT(7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

GAIN_ADJ [31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

GAIN_ADJ [23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

GAIN_ADJ [15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

GAIN_ADJ [7..0]

R/W-X

4

1 Valid address

2 Valid address- default value

⁞ ⁞

127 Valid address

128 Invalid address

4

⁞ ⁞

255 Invalid address

4

Address 67 – COEF_FIT 3.3.11

Bit 31–24 TT_FIT[7..0]: Read only – the number of temperature-related temperature

coefficients equal this value + 1.

0xn..n Number type unsigned byte

Bit 23–16 TP_FIT[7..0]: Read only – the number of pressure-related temperature

coefficients equal this value + 1.

0xn..n Number type unsigned byte

Bit 15–8 PT_FIT[7..0]: Read only – the number of temperature-related pressure

coefficients equal this value + 1.

0xn..n Number type unsigned byte

Bit 7–0 PP_FIT[7..0]: Read only – the number of pressure-related pressure coefficients

equal this value + 1.

0xn..n Number type unsigned byte

Address 68 – GAIN_ADJ 3.3.12

Invalid addresses default to 2 when the sensor is reset.

K0582 Revision B May 2015 11

Page 20

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

OFFSET _ADJ [31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

OFFSET _ADJ [23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

OFFSET _ADJ [15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

OFFSET _ADJ [7..0]

R/W-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MAX_RANGE [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MAX_RANGE [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MAX_RANGE [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MAX_RANGE [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MIN_RANGE [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MIN_RANGE [23..16]

R-X

Bit 31–0 GAIN_ADJ [31..0]: Read/write – the value of this register is used to modify the

value of the COMP_PRES register (address 1). It is used in conjunction with the

OFFSET_ADJ register (address 69) during user re-calibration of the sensor.

0xn..n Number type float

1.0 Default value

Address 69 – OFFSET_ADJ 3.3.13

Bit 31–0 OFFSET_ADJ [31..0]: Read/write – the value of this register is used to modify

the value of the COMP_PRES register (address 1). It is used in conjunction with

the GAIN_ADJ register (address 68) during user re-calibration of the sensor.

0xn..n Number type float

0.0 Default value

Address 70 – MAX_RANGE 3.3.14

Bit 31–0 MAX_RANGE [31..0]: Read only – the upper limit of the sensor pressure range in

the pressure units defined by the PRES_UNIT register (address 84).

0xn..n Number type float

Address 71 – MIN_RANGE 3.3.15

12 May 2015 K0582 Revision B

Page 21

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MIN_RANGE [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MIN_RANGE [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

YEAR [15..8]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

YEAR [7..0]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MONTH [7..0]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

DAY [7..0]

R/W-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MAX_ADC_PRES [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MAX_ADC_PRES [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MAX_ADC_PRES [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MAX_ADC_PRES [7..0]

R-X

5

Bit 31–0 MIN_RANGE [31..0]: Read only – the lower limit of the sensor pressure range in

the pressure units defined by the PRES_UNIT register (address 84).

0xn..n Number type float

Address 72 – CAL_DATE 3.3.16

Bit 31–16 YEAR [15..0]: Read/write – the year in which the sensor was calibrated. This

value may be updated by the user following re-calibration of the sensor.

0xn..n Number type unsigned integer5

Bit 15–8 MONTH [7..0]: Read/write – the month in which the sensor was calibrated. This

value may be updated by the user following re-calibration of the sensor.

0xn..n Number type unsigned byte

5

Bit 7–0 DAY [7..0]: Read/write – the day on which the sensor was calibrated. This value

may be updated by the user following re-calibration of the sensor.

0xn..n Number type unsigned byte

5

Address 73 – MAX_ADC_PRES 3.3.17

All values of the specified number type are supported which may result in nonsensical date values.

K0582 Revision B May 2015 13

Page 22

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MIN _ADC_PRES [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MIN _ADC_PRES [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MIN _ADC_PRES [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MIN _ADC_PRES [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MAX_ADC_TEMP [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MAX_ADC_TEMP [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MAX_ADC_TEMP [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MAX_ADC_TEMP [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

MIN _ADC_TEMP [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

MIN _ADC_TEMP [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

MIN _ADC_TEMP [15..8]

R-X

Bit 31–0 MAX_ADC_PRES [31..0]: Read only – if the current value of the ADC_PRES

register (address 3) exceeds this value, VALID[0] (bit 1) of the STATUS register

(address 0) will be cleared.

0xn..n Number type unsigned word

Address 74 – MIN_ADC_PRES 3.3.18

Bit 31–0 MIN_ADC_PRES [31..0]: Read only – if the current value of the ADC_PRES

register (address 3) is less than this value, VALID[0] (bit 1) of the STATUS

register (address 0) will be cleared.

0xn..n Number type unsigned word

Address 75 – MAX_ADC_TEMP 3.3.19

Bit 31–0 MAX_ADC_TEMP [31..0]: Read only – if the current value of the ADC_TEMP

register (address 4) exceeds this value, VALID[1] (bit 2) of the STATUS register

(address 0) will be cleared.

0xn..n Number type unsigned word

Address 76 – MIN_ADC_TEMP 3.3.20

14 May 2015 K0582 Revision B

Page 23

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

MIN _ADC_TEMP [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

SERIAL [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

SERIAL [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

SERIAL [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

SERIAL [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

R-0

R-0

R-0

R-0

R-0

R-0

R-0

R-0

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

R-0

R-0

R-0

R-0

R-0

R-0

R-0

R-0

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

ASYNC

STANDBY

TRIGGER

Reserved

Reserved

Reserved

Reserved

Reserved

R-X

R-X

R-X

R-0

R-0

R-0

R-0

R-0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

TYPE[7..0]

R-X

Bit 31–0 MIN_ADC_TEMP [31..0]: Read only – if the current value of the ADC_TEMP

register (address 4) is less than this value, VALID[1] (bit 2) of the STATUS

register (address 0) will be cleared.

0xn..n Number type unsigned word

Address 77 – SERIAL 3.3.21

Bit 31–0 SERIAL [31..0]: Read only – the sensor manufacturer’s serial number.

0xn..n Number type unsigned word

Address 78 – CONFIG 3.3.22

Bit 31–16 Reserved, read only

Bit 15 ASYNC: Read only – optional asynchronous serial communication capability.

0b0 Available

0b1 Not available

Bit 14 STANDBY: Read only – low power stand-by mode capability.

0b0 Available

0b1 Not available

Bit 13 TRIGGER: Read only – external wake-up trigger capability.

0b0 Not available

0b1 Available

Bit 12–8 Reserved, read only

Bit 7–0 TYPE [7..0]: Read only – ASCII character defining the sensor type.

K0582 Revision B May 2015 15

Page 24

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

FIELD_1 [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

FIELD_2 [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

FIELD_3 [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

FIELD_4 [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

P_AVE[7..0]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

T_AVE[7..0]

R/W-X

0xn..n Number type extended ASCII

A Absolute

D Differential

G Gauge

Address 79 – VERSION 3.3.23

Bit 31–24 FIELD_1 [7..0]: Read only – first software version field.

0xn..n Number type unsigned byte

Bit 23–16 FIELD_2 [7..0]: Read only – second software version field.

0xn..n Number type unsigned byte

Bit 15–8 FIELD_3 [7..0]: Read only – third software version field.

0xn..n Number type unsigned byte

Bit 7–0 FIELD_4 [7..0]: Read only – fourth software version field.

0xn..n Number type unsigned byte

Address 82 – AVERAGE

3.3.24

Bit 31–16 Unused, read/write

Bit 15–8 P_AVE[7..0]: Read/write – defines the number of individual pressure ADC data

samples averaged to produce each pressure and temperature reading.

0xn..n Number type unsigned byte

0 1 sample

1 2 samples

2 4 samples

⁞ ⁞

7 128 samples

16 May 2015 K0582 Revision B

Page 25

6

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

PRES_CONV [31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

PRES_CONV [23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

PRES_CONV [15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

PRES_CONV [7..0]

R/W-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

PRES_UNIT[7..0]

R/W-X

6

8 Invalid value

⁞ ⁞

255 Invalid value

6

Bit 7–0 T_AVE[7..0]: Read/write – defines the number of individual temperature ADC

data samples averaged to produce each pressure and temperature reading.

0xn..n Number type unsigned byte

0 1 sample

1 2 samples

2 4 samples

⁞ ⁞

7 128 samples

8 Invalid value6

⁞ ⁞

255 Invalid value

6

Address 83 – PRES_CONV 3.3.25

Bit 31–0 PRES_CONV [31..0]: Read/write – the value of this register is used to modify the

value of the COMP_PRES register (address 1) by the converting the value from

the manufacturer’s pressure units to the user pressure units.

0xn..n Number type float

1.0 Default value

Address 84 – PRES_UNIT 3.3.26

Values between 8 and 255 are allowed but the maximum number of samples will remain at 128.

K0582 Revision B May 2015 17

Page 26

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

DELAY[15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

DELAY[7..0]

R/W-X

8

7

8

Bit 31–8 Unused, read/write

Bit 7–0 PRES_UNIT[7..0]: Read/write – defines the manufacturer’s pressure unit for the

values in the COMP_PRES, MAX_RANGE and MIN_RANGE registers (addresses

1, 70 and 71). May be updated to define the user pressure units created using

the PRES_CONV register (address 83).

0xn..n Number type unsigned byte

0 Undefined7

1 mbar

2 bar

3 hPa

4 kPa

5 MPa

6 psi

7 mmH2O

8 inH2O

9 ftH2O

10 mH2O

11 mmHg

12 inHg

13 kgf/cm2

14 atm

15 Undefined

7

⁞ ⁞

255 Undefined

7

Address 85 – DELAY 3.3.27

Bit 31–16 Unused, read/write

Bit 15–0 DELAY[15..0]: Read/write – defines the delay in milliseconds between updates

of the pressure and temperature readings when the sensor auto-update mode

is selected by setting AUTO (bit 8) of the STATUS register (address 0).

0xn..n Number type unsigned integer

100 Default value

Values 0 and 15 to 255 are allowed but are undefined.

Any value N within the range 0 to 65535 is allowed but the delay in milliseconds will be (N mod 2000)

which restricts the maximum delay to 1999 ms.

18 May 2015 K0582 Revision B

Page 27

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

SPEC_DWG [31..24]

R-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

SPEC_DWG [23..16]

R-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

SPEC_DWG [15..8]

R-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

SPEC_DWG [7..0]

R-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

TARE_VALUE [31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

TARE_VALUE [23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

TARE_VALUE [15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

TARE_VALUE [7..0]

R/W-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

K

P(IJ)

[31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

K

P(IJ)

[23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

K

P(IJ)

[15..8]

R/W-X

Address 86 - SPEC_DWG 3.3.28

Bit 31–0 SPEC_DWG [31..0]: Read only – the 4-digit specification drawing number of the

sensor.

0xn..n Number type unsigned word

Address 87 – TARE_VALUE 3.3.29

Bit 31–0 TARE_VALUE [31..0]: Read/write – the value of this register is used to modify

the value of the COMP_PRES register (address 1) when the sensor tare mode is

selected by setting TARE (bit 12) of the STATUS register (address 0).

0xn..n Number type float

Addresses 128-157 - Pressure coefficients 3.3.30

The pressure coefficient registers contain a total of (I+1)*(J+1) contiguous pressure

coefficients where I and J represent the values of the PP_FIT(7..0] and PT_FIT[7..0] bits of

the COEF_DIM register (address 67). Each coefficient register is bit mapped as follows:

K0582 Revision B May 2015 19

Page 28

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

K

P(IJ)

[7..0]

R/W-X

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

K

T(IJ)

[31..24]

R/W-X

Bit 23

Bit 22

Bit 21

Bit 20

Bit 19

Bit 18

Bit 17

Bit 16

K

T(IJ)

[23..16]

R/W-X

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

K

T(IJ)

[15..8]

R/W-X

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

K

T(IJ)

[7..0]

R/W-X

Bit 31–0 K

[31..0]: Read only

P(IJ)

0xn..n Number type float

Addresses 158-187 - Temperature coefficients 3.3.31

The temperature coefficient registers contain a total of (I+1)*(J+1) contiguous temperature

coefficients where I and J represent the values of the TP_FIT(7..0] and TT_FIT[7..0] bits of the

COEF_DIM register (address 67). Each coefficient register is bit mapped as follows:

Bit 31–0 K

[31..0]: Read only

T(IJ)

0xn..n Number type float

4 Operational description

Operational states 4.1

The basic operational states of the DPS 5000 sensor are shown in Figure 6.

Figure 6 Operational states

When power is first applied, the sensor enters the power-up state. Whilst in this

state the sensor is unresponsive to I2C-bus activity and user interaction with the

sensor is not possible. After the power-up checks have been completed the sensor

automatically enters the acquire state in which the sensor obtains pressure and

temperature data. User interaction with the sensor is now possible but the pressure

and temperature data will not be available until after the sensor acquisition time

and the sensor enters the stand-by state. The sensor will remain in the standby

state until either:

20 May 2015 K0582 Revision B

Page 29

The sensor power is cycled and the sensor returns to the power-up state.

User interaction results in a new data request being internally generated and

the sensor re-enters the acquire state.

CAUTION

Due to the low power consumption of the DPS 5000 sensors, the I2C-bus pull-up

resistors may provide sufficient power to maintain the sensor in the standby

state when the I2C-bus SUPPLY+ line is disconnected from the sensor. To ensure

the sensor is correctly powered down, disconnect the sensor completely from the

I2C-bus or turn off the I2C-bus network power supply.

Figure 7 shows the legend used within this section to describe the user interactions

with the sensor.

Figure 7 Interaction legend

Reading the pressure and temperature 4.2

The DPS 5000 sensors directly provide compensated pressure and temperature

data via the COMP_PRES and COMP_TEMP registers avoiding the need for the user

to undertake any additional calculations. Unless modified by the user (see section

4.4.3), the unit of pressure is that used by the manufacturer during calibration of the

sensor and defined in the PRES_UNIT register. The unit of temperature is always °C.

The following steps should be used to read the pressure and temperature data:

i. Check the status of the new data available flag.

Read STATUS: CONV <0 [0]> 0b1 = new data available

ii. Check that the data is valid.

Read STATUS: VALID [1..0] <0 [2..1]> 0b11 = new data valid

iii. Get the compensated pressure data.

Read COMP_PRES: COMP_PRES [31..0] <1 [31..0]>

iv. Get the unit of pressure information (optional).

Read PRES_UNIT: PRES_UNIT [7..0] <84 [7..0]>

v. Get the compensated temperature data.

Read COMP_TEMP: COMP_TEMP [31..0] <2 [31..0]>

Updating the pressure and temperature 4.3

When the sensor enters the standby state for the first time, the new data available

flag, CONV (bit 0) of the STATUS register (address 0), will be set to indicate that

pressure and temperature data is available, This data will not be updated until a

new data request is generated, which can be achieved either manually or

automatically.

Manual update 4.3.1

A new data request is manually generated by the user:

K0582 Revision B May 2015 21

Page 30

Addr

Register

See section(s)

Addr

Register

See section(s)

66

I2C_ADDR

4.4.2

83

PRES_CONV

4.4.4, 4.4.8

68

GAIN_ADJ

4.4.8

84

PRES_UNIT

4.4.4

69

OFFSET_ADJ

4.4.8

85

DELAY

4.4.3

72

CAL_DATE

4.4.8

87

TARE_VALUE

4.4.5

82

AVERAGE

4.4.6

i. Initiate a data update.

Write 0b1 to STATUS: CONV <0 [0]>

Writing 0b1 to STATUS: CONV automatically clears the new data available flag. It is

set back to 0b1 when the updated data is available which can then be read using

the steps given in section 4.2.

Automatic update 4.3.2

The user initiates the automatic generation of new data requests at a pre-defined

interval:

i. Clear the new data available flag.

Write 0b0 to STATUS: CONV <0 [0]>

ii. Set the auto-update mode bit.

Write 0b1 to STATUS: AUTO <0 [8]>

The new data available flag is set to 0b1 when the updated data is available which

can then be read using the steps given in section 4.2. When in the auto-update

mode, reading the COMP_PRES, COMP_TEMP, ADC_PRES, ADC_TEMP, MVOLT_PRES

or MVOLT_TEMP register (addresses 1, 2, 3, 4, 6 and 7 respectively) will automatically

clear the new data available flag.

As supplied, the auto-update period is set to the default value of 100 ms but it may

be changed by the user (see section 4.4.3).

Updating the sensor configuration data registers 4.4

User modifiable registers 4.4.1

The configuration data registers provide information for the user and allow the user

to change the functionality of the sensor. Table 4 lists the configuration data

registers that can be modified by the user.

22 May 2015 K0582 Revision B

Table 4 User modifiable registers

With the exception of the I2C_ADDR and DELAY registers, any change to a register

value takes immediate effect. The changes made to a register value may be

temporary or permanent:

Temporary - the modified register value will remain valid until the either the

sensor is reset via the status register or the sensor power is cycled.

Permanent - the modified register value is written to non-volatile memory and

then remains valid even if the sensor is reset via the status register or the

sensor power is cycled.

The configuration data registers are normally locked to prevent inadvertent

changes from being made. The following steps are required unlock the registers:

i. Enable changes to the configuration data registers.

Write 4118 to ACCESS: ACCESS [31..0] <5 [31..0]>

Page 31

9

10

ii. Check the configuration data write access status (optional).

Read STATUS: WENB <0 [3]> 0b1 = configuration data write enabled

The configuration registers may then be modified by writing the new user values to

the appropriate registers. If the new user values are to be permanent, the following

step must be performed:

iii. Save the register data to non-volatile memory.

Write 0b1 to STATUS: WRITE <0 [5]>

Finally, the configuration data registers should be re-locked to prevent further

changes from being made:

iv. Disable changes to the configuration data registers.

Write 0 to ACCESS: ACCESS <5 [31..0]>

Modifying the I

2

C-bus address 4.4.2

All DPS 5000 sensors are supplied with the I2C-bus address set to the default value

of 2. The I2C-bus address may be changed by the user by writing the desired new

address to the I2C_ADDR register9. Allowable address values are 1 to 127.

For example, to change the I2C-bus address to 64:

i. Unlock the configuration data registers as described in section 4.4.1.

ii. Update the I

2

C-bus address.

Write 64 to I2C_ADDR: ADDR [7..0] <66 [7..0]>

iii. Save the new I

2

C-bus address to non-volatile memory and re-lock the

configuration data registers as described in section 4.4.1.

iv. Reset the sensor. Either power cycle the sensor or:

Write 0b10 to STATUS: RESET [1..0] <0 [15..14]>

The sensor will now respond to the new I2C-bus address.

Changing the auto-update period 4.4.3

All DPS 5000 sensors are supplied with the auto-update period set to the default

value of 100 ms. The auto-update period may be changed by the user by writing

the desired new period to the DELAY register10. The allowable period is between 1

and 1999 ms in 1 ms increments.

For example, to change the auto-update period to 1.512 s:

i. Exit the automatic update mode (if applicable).

Write 0b0 to STATUS: AUTO <0 [8]>

ii. Unlock the configuration data registers as described in section 4.4.1.

iii. Update the auto-update period.

Write 1512 to DELAY: DELAY [15..0] <85 [15..0]>

iv. Save the new auto-update period to non-volatile memory if required and re-

lock the configuration data registers as described in section 4.4.1.

A change of the sensor I2C bus address will not come into effect until the I2C_ADDR register has been

modified, copied to non-volatile memory and the sensor is reset via the status register or by cycling the

sensor power.

A change to the DELAY register will not come into effect whilst the sensor is in the auto-update

mode. Exit then re-enter the auto-update mode for the change to be applied.

K0582 Revision B May 2015 23

Page 32

v. Re-enter the automatic update mode (if applicable).

Write 0b1 to STATUS: AUTO <0 [8]>

CAUTION

The automatic update period should be chosen with care to avoid new updates

being requested before the data from the preceding request is available. The

update interval should be set to be longer than the sensor acquisition time (see

section 4.4.6). Failure to observe this precaution will result in the queue error flag

(STATUS: QERR <0 [10]>) being set and may result in invalid pressure and

temperature data.

Changing the unit of pressure 4.4.4

The DPS 5000 sensors can be supplied calibrated in a variety of pressure units. As

supplied, the pressure value given in the COMP_PRES register and the sensor upper

and lower pressure limits defined in the MAX_RANGE and MIN_RANGE registers will

all be in the calibrated unit of pressure. However, the user may change the unit of

pressure of the COMP_PRES register to an alternative unit of pressure.

For example, if the sensor is supplied calibrated in bar and the required unit of

pressure for the pressure readings is psi:

i. Unlock the configuration data registers as described in section 4.4.1.

ii. Determine the appropriate conversion factor from Annex A and update the

pressure unit conversion factor value.

Write 14.50377 to PRES_CONV: PRES_CONV [31..0] <83 [31..0]>

iii. Save the new pressure unit conversion factor value to non-volatile memory if

required and re-lock the configuration data registers as described in section

4.4.1.

The user may also change the value of the pressure unit code held in the PRES_UNIT

register to the alternative unit of pressure code

For example, if the unit of pressure for the pressure reading has been changed to

psi then add the following step between steps ii. and iii. above:

iv. Determine the appropriate unit of conversion code from Annex A and update

the unit of pressure code value.

Write 6 to PRES_UNIT: PRES_UNIT [7..0] <84 [7..0]>

CAUTION

Changing the PRES_CONV and PRES_UNIT registers has no effect on the

MAX_RANGE and MIN_RANGE register values. The unit of pressure for these

values will remain in the supplied calibrated unit of pressure.

Reading relative pressure 4.4.5

The DPS 5000 sensors can be configured to provide pressure measurements relative

to a pressure offset such that:

RELATIVE PRESSURE = TRUE PRESSURE – PRESSURE OFFSET

The relative pressure value is available via the COMP_PRES register when the sensor

tare mode is selected. The pressure offset value is held in the TARE_VALUE register.

The value can be either a user defined value or set to the current value of the

COMP_PRES register.

24 May 2015 K0582 Revision B

Page 33

11

For example, to set the pressure offset to 1.000000:

i. Unlock the configuration data registers as described in section 4.4.1.

ii. Update the pressure offset value.

Write 1.000000 to TARE_VALUE: TARE_VALUE [31..0] <87 [31..0]>

iii. Save the new pressure offset value to non-volatile memory if required and re-

lock the configuration data registers as described in section 4.4.1.

Alternatively, to set the pressure offset to the current value of the COMP_PRES

register:

iv. Copy the current COMP_PRES register value to the TARE_VALUE register.

Write 0b1 to STATUS: SET_TARE <0 [11]>

To enable reading relative pressure:

v. Enable the sensor tare mode.

Write 0b1 to STATUS: TARE <0 [12]>

Pressure and temperature SNR 4.4.6

The DPS 5000 sensors provide compensated pressure and temperature readings

with a high SNR. However, for very low noise applications, the user can modify the

contents of the AVERAGE register to increase the SNR of either or both readings at

the expense of the sensor acquisition time.

The AVERAGE register has 2 bit fields, P_AVE[7..0] and T_AVE[7..0] that can be used

to adjust the SNR of the pressure and temperature reading respectively. Typically

the sensors are supplied with P_AVE[7..0] set to 2 and T_AVE[7..0] set to 1. Modifying

these values will typically change the RMS amplitude of the corresponding reading

noise by the correction factor shown in Figure 8.

Figure 8 Noise level correction factors

If the values of the AVERAGE register P_AVE[7..0] and T_AVE[7..0] bit fields are P and

T respectively, then the typical sensor acquisition time can be found using the

formula:

tA ≈ 2.12 ( 2 P + 2 T ) + 10.60 ) ms11

This formula excludes the time taken to initiate a new data request when the sensor is used in the

manual mode as it is dependent upon the I2C-bus clock speed and the message length.

K0582 Revision B May 2015 25

Page 34

12

12

For example, if the sensor has P_AVE[7..0] set to 2 and T_AVE[7..0] set to 1 and it is

required to reduce the RMS amplitude of the pressure reading noise by a factor of 4

and the temperature reading noise by a factor of 2, then using Figure 8, the new

values for P_AVE[7..0] and T_AVE[7..0] will be 6 and 3 respectively.

i. Unlock the configuration data registers as described in section 4.4.1.

ii. Update the number of pressure samples.

Write 6 to AVERAGE: P_AVE [7..0] <82 [15..8]>

iii. Update the number of temperature samples.

Write 3 to AVERAGE: T_AVE [7..0] <82 [7..0]>

iv. Save the new sample values to non-volatile memory if required and re-lock

the configuration data registers as described in section 4.4.1.

As a result of the above changes, the sensor acquisition time will typically increase

from 23 ms to 163 ms.

CAUTION

If the sensor automatic update mode is used (see section 4.3.2), ensure the autoupdate period (see section 4.4.3) is set to be longer than the modified acquisition

time. Failure to observe this precaution will result in the queue error flag

(STATUS: QERR <0 [10]>) being set and may result in invalid pressure and

temperature data.

Maximising the update rate 4.4.7

For applications that require the DPS 5000 sensor acquisition time to be faster than

is achievable by adjusting the sensor SNR (see section 4.4.6), the sensor provides an

interleave mode. This mode is only intended to be used when both the P_AVE[7..0]

and T_AVE[7..0] bit fields of the AVERAGE register are set to 0 and should be used

with caution. It provides a sensor acquisition time of typically 10 ms permitting a

pressure and temperature measurement refresh rate of up to 100 Hz to be

achieved.

To use the interleave mode:

i. Set the P_AVE[7..0] and T_AVE[7..0] bit fields of the AVERAGE register to 0 using

the steps described in section 4.4.6.

ii. Set the interleave mode bit.

Write 0b1 to STATUS: INTRDG <0: [9]>

Pressure re-calibration 4.4.8

The user may perform a 2 point pressure re-calibration on the DPS 5000 sensors by

adjusting the zero and span settings of the sensor. The following steps describe the

procedure:

i. Apply a known pressure, P

and record the measured pressure, P

, ideally ≤ 10% of the sensor’s full scale pressure,

A1

.

M1

PM1 = Read COMP_PRES: COMP_PRES [31..0] <1 [31..0]>

To minimise the effects of noise it is recommended that the values PM1 and PM2 used are the average

of several measurements.

26 May 2015 K0582 Revision B

Page 35

ii. Apply a second known pressure, P

pressure, and record the measured pressure, P

, ideally ≥ 90% of the sensor’s full scale

A2

12

.

M2

PM2 = Read COMP_PRES: COMP_PRES [31..0] <1 [31..0]>

iii. Read and record the current values G, O and C of the following configuration

data registers:

G = Read GAIN_ADJ: GAIN_ADJ [31..0] <68 [31..0]>

O = Read OFFSET_ADJ: OFFSET_ADJ [31..0] <69 [31..0]>

C = Read PRES_CONV: PRES_CONV [31..0] <83 [31..0]>

iv. Calculate the values S, G* and O* using the following formulae;

𝑃𝑀2− 𝑃

𝑆 =

𝐺∗=

𝑂∗=

𝑀1

𝐴1

𝑃𝐴2− 𝑃

𝐺

𝑆

𝑆 ∙ 𝑃𝐴1+ 𝑂 ∙ 𝐶 − 𝑃

𝑆 ∙ 𝐶

𝑀1

v. Unlock the configuration data registers as described in section 4.4.1.

vi. Update the following configuration registers:

Write the value of G* to GAIN_ADJ: GAIN_ADJ [31..0] <68 [31..0]>

Write the value of O* to OFFSET_ADJ: OFFSET_ADJ [31..0] <69 [31..0]>

vii. Save the new calibration zero and span factor values to non-volatile memory

if required and re-lock the configuration data registers as described in section

4.4.1.

The user may also record the date of re-calibration by modifying the date fields of

CAL_DATE register.

For example, to change the calibration date to 16th April 2015 then add the following

step between steps vi. and vii. above:

viii. Update the date field values.

Write 2015 to CAL_DATE: YEAR [15..0] <72 [31..16]>

Write 4 to CAL_DATE: MONTH [ 7..0] <72 [15..8]>

Write 16 to CAL_DATE: DAY [7..0] <72 [7..0]>

5 Maintenance

WARNING

High pressures and extremes of temperature are dangerous. Be careful when

working on components of systems where high pressures and high or low

temperatures are present. Use all applicable protection measures and observe

all safety precautions.

Cleaning 5.1

The external version of the DPS 5000 sensors may be periodically cleaned if required

using a lint free cloth and a soft brush. If necessary, use a weak detergent solution

to moisten the cloth. Allow the sensor to dry before re-use.

CAUTION

Do not use cleaning agents, solvents or high-pressure gas to remove dirt as

these may damage the sensor.

K0582 Revision B May 2015 27

Page 36

Adjustment 5.2

The DPS 5000 sensors are supplied fully calibrated by the manufacturer. When it is

necessary to re-calibrate the sensor, the procedure given in section 4.4.8 should be

followed. The minimum recommended re-calibration interval is once per year and

should be undertaken using a pressure source with a measurement accuracy of at

least ±0.01% of reading.

Note: GE can provide a calibration service that is traceable to international

standards.

Repair 5.3

The DPS 5000 sensors contain no user serviceable items. For any repairs, return the

sensor to the manufacturer or an approved service agent.

Disposal 5.4

Disposal of the DPS 5000 sensor must be in accordance with the local statutory

regulations. Do not dispose of with regular household refuse.

28 May 2015 K0582 Revision B

Page 37

Required unit of pressure

mbar

bar

hPa

kPa

Mpa

psi

mmH2O

Code 1 2 3 4 5 6

7

Calibrated unit of pressure

mbar

1 1 0.001 1 0.1

0.0001

0.01450377

10.19716

bar 2 1000 1 1000

100

0.1

14.50377

10197.16

hPa 3 1

0.001 1 0.1

0.0001

0.01450377

10.19716

kPa

4

10

0.01

10 1 0.001

0.1450377

101.9716

Mpa 5 10000

10

10000

1000

1

145.0377

101971.6

psi 6 68.94757

0.06894757

68.94757

6.894757

0.006894757

1

703.0696

mmH2O

7

0.0980665

9.80665E-05

0.0980665

0.00980665

9.80665E-06

0.001422334

1

inH2O 8 2.490889

0.002490889

2.490889

0.2490889

0.000249089

0.03612729

25.4

ftH2O

9

29.89067

0.02989067

29.89067

2.989067

0.002989067

0.4335275

304.8

mH2O

10

98.0665

0.0980665

98.0665

9.80665

0.00980665

1.422334

1000

mmHg

11

1.333224

0.001333224

1.333224

0.1333224

0.000133322

0.01933678

13.5951

inHg

12

33.86389

0.03386389

33.86389

3.386389

0.003386389

0.4911542

345.3155

kgf/cm2

13

980.665

0.980665

980.665

98.0665

0.0980665

14.22334

10000

atm

14

1013.25

1.01325

1013.25

101.325

0.101325

14.69595

10332.28

Required unit of pressure

inH2O

ftH2O

mH2O

mmHg

inHg

kgf/cm2

atm

Code 8 9

10

11

12

13

14

Calibrated unit of pressure

mbar

1

0.4014631

0.03345526

0.01019716

0.7500616

0.02952998

0.001019716

0.000986923

bar 2 401.4631

33.45526

10.19716

750.0616

29.52998

1.019716

0.9869232

hPa

3

0.4014631

0.03345526

0.01019716

0.7500616

0.02952998

0.001019716

0.000986923

kPa 4 4.014631

0.3345526

0.1019716

7.500616

0.2952998

0.01019716

0.009869232

Mpa 5 4014.631

334.5526

101.9716

7500.616

295.2998

10.19716

9.869232

psi

6

27.6799

2.306659

0.7030696

51.71492

2.036021

0.07030696

0.06804596

mmH2O

7

0.03937008

0.00328084

0.001

0.07355591

0.002895902

0.0001

9.67841E-05

inH2O

8 1 0.08333333

0.0254

1.86832

0.07355591

0.00254

0.002458316

ftH2O

9

12 1 0.3048

22.41984

0.8826709

0.03048

0.02949979

mH2O

10

39.37008

3.28084

1

73.55591

2.895902

0.1

0.0967841

mmHg

11

0.5352402

0.04460335

0.0135951

1

0.03937008

0.00135951

0.00131579

inHg

12

13.5951

1.132925

0.3453155

25.4

1

0.03453155

0.03342105

kgf/cm2

13

393.7008

32.8084

10

735.5591

28.95902

1

0.967841

atm

14

406.7825

33.89854

10.33228

760

29.92126

1.033228

1

Annex A Unit of pressure conversion factors

The following tables give the value necessary to convert from the calibrated unit of

pressure to the required unit of pressure.

The conversion factors for the units mmH2O, inH2O, ftH2O and mH2O are for water at 4°C.

The conversion factors for the units mmHg and inHg are for Mercury at 0°C.

K0582 Revision B May 2015 29

Page 38

Page 39

Page 40

Loading...

Loading...