Page 1

GE

Measurement & Control

The PRECISE

DPS2000 Series

Digital Pressure Transmitter

The PRECISE DPS2000 Series digital pressure

transmitter is an ultra high accuracy digital

pressure and temperature sensor designed for high

pressure measurement in critical applications in

harsh environments where accuracy and stability

of the data are key to system performance.

Features and Benefi ts

• Pressure ranges up to 1480 bar/21,000 psi

• Total accuracy < ±0.01% FS

• Long-term stability < ±0.01% FS/year

• Resolution < 2 ppm

• Shock and vibration resistant

• High overpressure capability

• Low current consumption

• RS-232 and RS-485 communication

Applications Areas

Oceanographic Applications:

• Vertical depth measurement

• AUVs and Submarines

• ROVs, towed arrays, bathymetry

• Tsunami detection

• Dynamic subsea positioning

High Pressure Calibration:

• Rugged high pressure transfer standard

• Laboratory reference

• Portable calibration equipment

• Pressure controllers

• Leak detection

Page 2

Advanced Sensing

Unique Pressure

Technology

At the core of the PRECISE sensor is PRESENS’ patented

tubular sensing element, well

proven in subsea oil and gas

applications for many years.

Our piezoresistivesensors are

distinguished for their reliability,

robustness, long-term stability

and high fi eld accuracy. This is

due to the unique features of

the sensing element:

Silicon (Si) single crystal

structure:

• Minimizes errors due to thermal and mechanical

hysteresis

• Prevents long-term drift due to ”creep”

Tubular design:

• Mechanical decoupling of sensing area eliminates

error due to mounting stress

Operation in compressive stress:

• Extreme tolerance to over-pressure and pressure

spikes

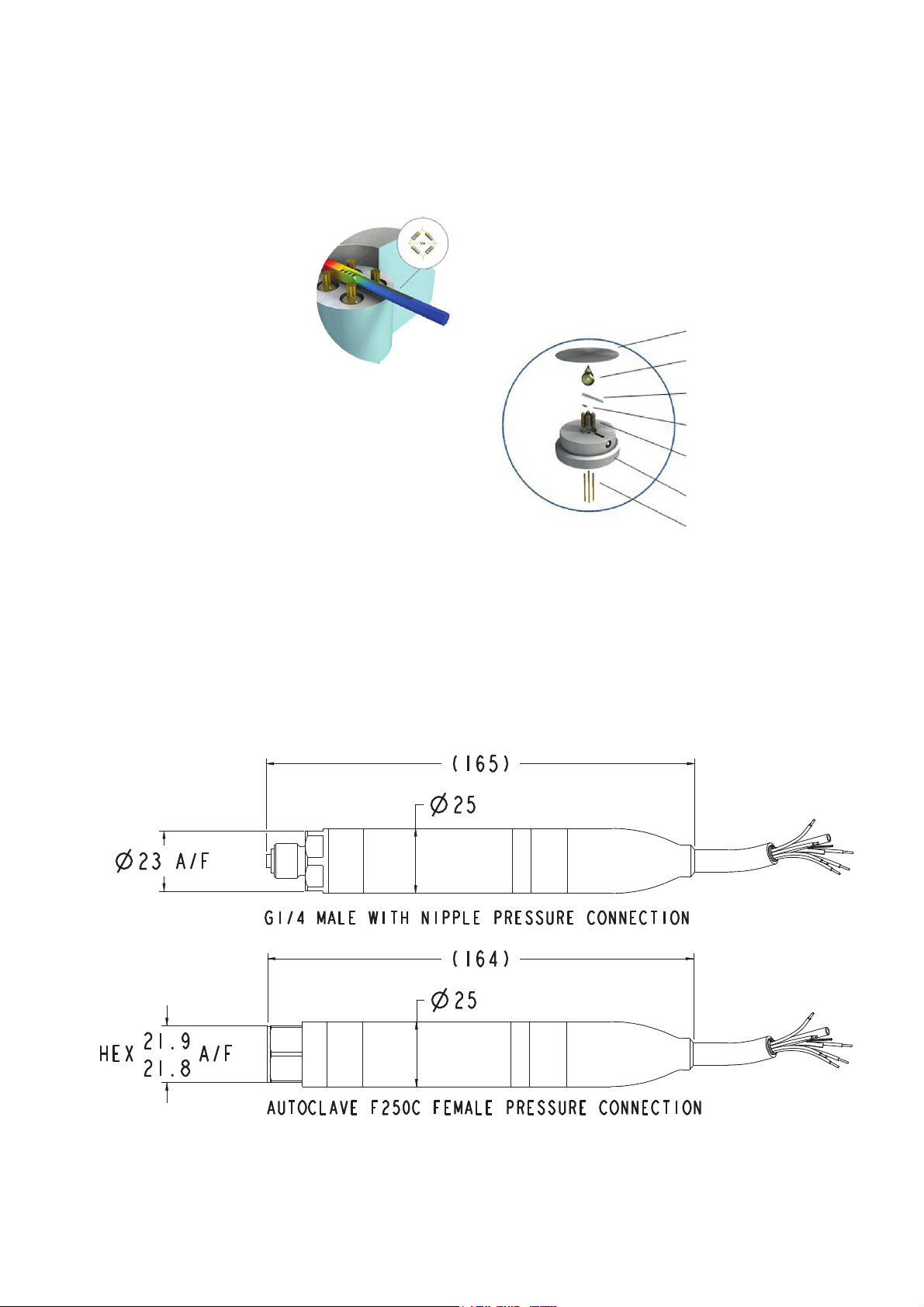

Module Design

• A thick isolation diaphragm improves protection

against harsh environments

• A reduced oil volume decreases thermal errors

• A reduced oil volume improves protection against

damage caused by transient step changes in pressure

Protective diaphragm

Hydraulic oil

Sensing element

Die attach

Glass feed throughs

Sensor housing

Gold plated pins

Piezoresistive resistor bridge:

• Extremely stable

• Pressure and temperature measured simultaneously

Dimensional Drawing (all dimensions in mm)

Page 3

PRECISE Specifi cations

Pressure Measurement

Pressure Ranges

Min. range: 0 to 50 bar

Max. range: 0 to 1480 bar

Pressure Reference

Absolute

Overpressure

1.5 x FS ranges listed above equals the

maximum pressure that can be applied to a transducer

without damage or change in performance beyond the

specifi ed tolerance.

Pressure Containment (Burst Pressure)

2 x FS ranges listed above

Pressure Scales

bar, psi, mH2O, MPa, dbar

Temperature Measurement

Temperature range:

±0.6°C over the compensated temperature range

Electrical

Power Supply Voltage

8.5-30 Vdc

Current Consumption

Typ 4.8 mA, 24 V, receive mode

Pulse Power Excitation

Switch on to sample time in less than 1 second

Output Signal and Protocol

RS-232, and RS-485 programmable pressure signal

output, Modbus Remote Terminal Unit (RTU)

Programmable Lowpass Filter

User defi nable down to 30 mHz

EMC/RFI Certifi cation

IEC 61326, basic immunity test requirements

Electrical Insulation

Greater than 1 GΩ at 100 Vdc

Physical

Pressure Performance

Accuracy

For each specifi cation, better than

A1 ±0.04% FS

A2 ±0.02% FS

A3 ±0.01% FS

Defi ned as pressure hysteresis, temperature hysteresis,

temperature effects, repeatability, non-linearity, zero

offset and uncertainty of calibration equipment over the

compensated temperature range.

Compensated Temperature Range:

-5 to 35°C (23 to 95°F)

Long Term Stability (drift):

0.01% FS/year max. at reference conditions

Resolution

<2 ppm FS

Acceleration (positional) Sensitivity

Less than 1 mbar/g

Shock

IEC 60068-2-27: 30 g, 11 ms half-sine,

3x4 bidirectional shocks

Operating within requirements

Pressure Connection

Autoclave F250C 9/16”, G 1/4” Male

Pressure Equipment Directive (PED)

97/23/EC - SEP

Operating Temperature Range

-40 to 85°C (-40 to 185°F)

Storage Temperature Range

-50 to 100°C (-58 to 212°F)

Material

Wetted Parts: Inconel 625

Non Wetted Parts: Inconel 625 or AISI316

Electrical Connection

1 metre shielded cable

CE Approval

Designed for electromagnetic compatibility

Calibration Certifi cate

Each unit is supplied with a calibration certifi cate stating

conformity to pressure performance specifi cations

across calibrated pressure and temperature envelope.

The specifi cations are traceable to international

standards.

Vibration

IEC 60068-2-6: Sinusoidal 5-1000 Hz, 20 g, 10 ct/min

IEC 60068-2-64: Random 20-2000 Hz, 6 grms, 2 hours

Operating within requirements

Page 4

PRECISE Part Number

1. Specify Part String

Model

DPS Digital Pressure Transmitter

Series

2 High Precision

Build

0 Non-Hyperbaric

Electrical Connection

2 1 m Polyurethane Screened Cable (Depth) IP68

Output

B RS-232/RS-485 Modbus

Compensated Temperature Range

TA -5 to 35 °C

Accuracy

A1 Industrial 0.04%

A2 Improved 0.02% (200 bar and above )

A3 Premium 0.01% (400 bar and above)

Calibration

CC Full Thermal Calibration

Hazardous area approval

H0 None

Pressure Connection

P1 G1/4 Male w/nipple, pressure ranges to 700 bar

P2 9/16-18UNF F250C Female

2. Specify Pressure Range

0 to (50 to 1480 bar)

3. Specify Pressure Units

bar

psi

mH

0

2

MPa

dbar

Examples: DPS202B-TA-A3-CC-H0-P1 0 to 450 bar

DPS202B-TA-A2-CC-H0-P2 0 to 30 MPa

www.gemeasurement.com

© 2016 General Electric Company. All Rights Reserved. Specifi cations are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affi liated with GE.

920-667A

Loading...

Loading...