Druck DPI 610, DPI 615 IS Specifications

GE

Sensing

DPI 610/615 Series is a Druck

product. Druck has joined other

GE high–technology sensing

businesses under a new

name—GE Sensing.

g

• Ranges -14.7 to 10,000 psi

• Accuracy from 0.025% full scale (FS)

• Integral combined pressure/vacuum pump

• Dual readout: input and output

• 4 to 20 mA loop test: auto step and ramp

• Intrinsically safe (IS) version

• RS232 interface and fully documenting version

• Remote pressure sensors

Features

Druck Portable

Pressure Calibrators

DPI 610/615 Series

The technically advanced Druck DPI 610 and DPI 615

portable calibrators are the culmination of many years of

field experience with the company’s DPI 600 series.

These self-contained, battery powered packages contain

a pressure generator, fine pressure control, device

energizing (not IS version) and output measurement

capabilities, as well as facilities for 4 to 20 mA loop

testing and data storage. The rugged weatherproof

design is styled such that the pressure pump can be

operated and test leads connected without

compromising the visibility of the large dual parameter

display. The mA step and ramp outputs and a built-in

continuity tester extend the capabilities to include the

commissioning and maintenance of control loops.

Setting the Standard for Portable

Pressure Calibrators

A highly accurate and easy to use calibrator is only part

of the solution for improving overall data quality and

working efficiency. The DPI 610 and DPI 615, with data

storage and RS232 interface, reduce calibration times

and eliminate data recording errors. The DPI 615 also

provides error analysis for field reporting of calibration

errors and pass/fail status. In addition, procedures

downloaded from a PC automatically configure the

DPI 615 to pre-defined calibration and test routines.

Improved performance

The DPI 610/615 Series combine practical design with

state-of-the-art performance, summarized as follows:

Accuracy 0.025% FS for ranges 2.5 to 10,000 psi

Ranges 1 psi to 10,000 psi including gauge, absolute and

differential versions

Integral Pneumatic –22 inHg to 300 psi

Pressure Source

Integral Hydraulic 0 to 6000 psi

Pressure Source

Measure Pressure, mA, V, switch state (open/closed) and

ambient temperature

Output: Pressure, mA step, mA ramp, mA value

Energizing Supplies 10 and 24 VDC (not IS version)

Data Storage 92 Kbytes

Documenting (DPI 615 only) Error analysis with pass/fail status and graphs.

Two-way PC communication for transferring

procedures and results

Remote pressure sensors Up to 10 digitally characterized sensors per

calibrator

Simplified Operation

GE’s knowledge of customer needs, combined with

innovative design, results in high performance,

multi-functional calibrators that are simple to use. The

key to simple operation is the Task Menu. Specific

operating modes such as P-I, switch test and leak test

are configured at the touch of a button by menu

selection.

Featuring highly reliable pneumatic and hydraulic

assemblies and self-test routines, the DPI 610/615 Series

can be relied upon time and time again for field

calibration in the most extreme conditions.

The DPI 610 and DPI 615 have been designed for ease of

use while meeting a wide range of application needs

including calibration, maintenance and commissioning.

The Intrinsically Safe versions, certified to European and

North American standards for use in hazardous areas,

reduce response times to breakdowns and emergencies

by removing the need for ’Hot Permits‘ and gas detection

equipment. This gives peace of mind to all those

responsible for safety within hazardous areas.

The dual parameter display shows the Input and Output

values in large clear digits. A unique built-in handle

provides a secure grip for on-site use in addition to a

shoulder strap which is also designed to allow the

instrument to be suspended for hands-free operation.

Any technician can use these calibrators without formal

training, such as a novice on an emergency call out, or

those familiar with the DPI 601. By selecting basic mode

the calibrator is configured to source pressure and

measure mA or V, with all non-essential keys disabled.

Dedicated Task Menu

The dedicated task key gives direct access to the task

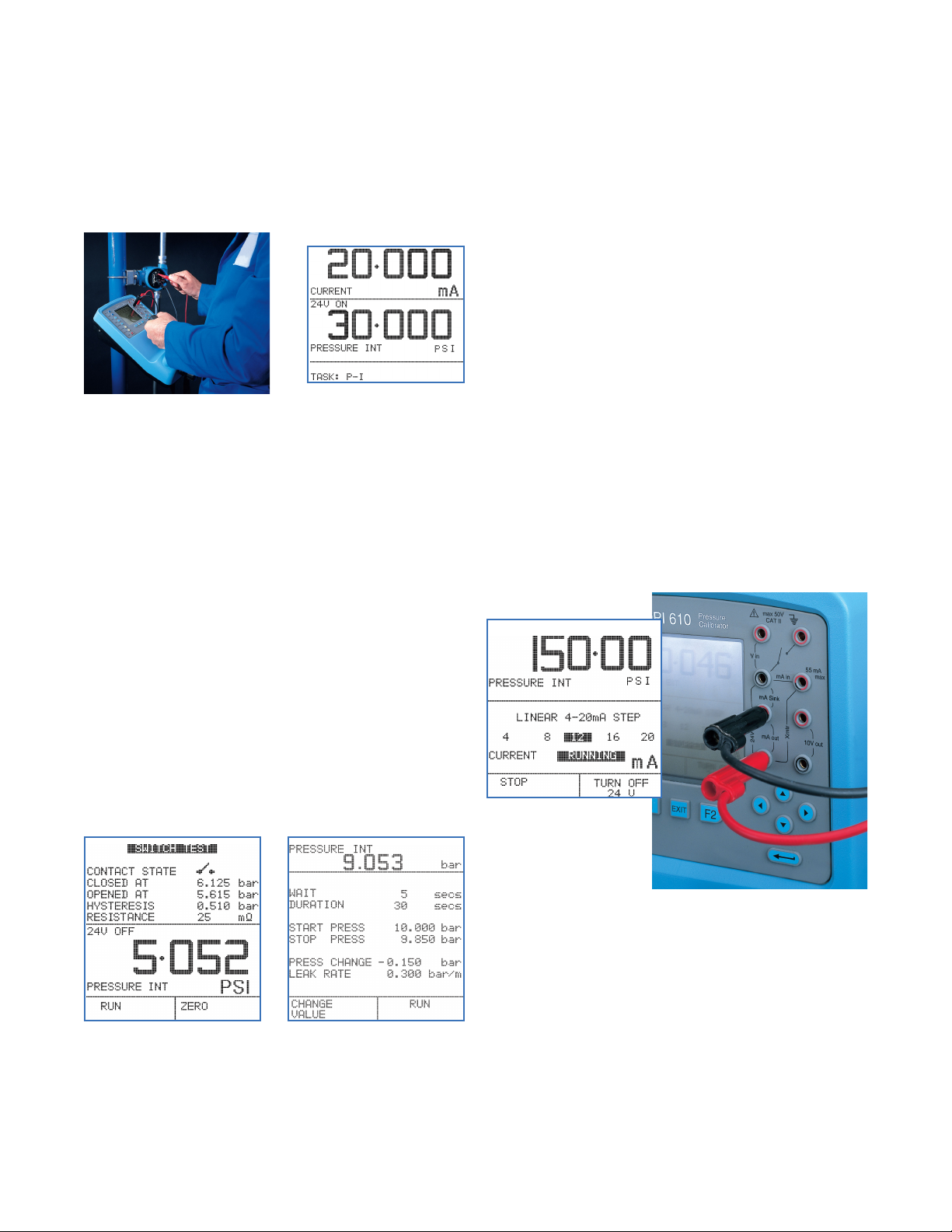

menu. Select the required test, for example P-I for a

pressure transmitter, and with a single key press, the

calibrator is ready.

Use the advanced mode for custom tasks and add to the

user task menu for future use.

Some of the Capabilities

P mA V 10 V* 24 V* Switch °F

Measure

__

Source

_

__

P = Pressure

F = Local ambient temperature

* = Not IS

Pressure Transmitter Calibration

The P-I task configures the DPI 610/615 Series to

simultaneously display the output pressure and the input

current. The pressure unit can be chosen to suit the

transmitter and a 24 V supply is available for

loop-power (not IS version).

For process transmitters reading in percentage, use %

span to scale the pressure accordingly.

The DPI 610/615 Series pneumatic calibrator hand-pump

can generate pressure from -12 to 300 psi. The volume

adjuster gives fine pressure setting and the release valve

also allows gradual venting for falling calibration points.

GE

Sensing

Reduce the burden imposed by quality systems such as

ISO 9000, simply store results in memory and leave both

pen and calibration sheet back at the office.

Pressure Switch Testing and Leak

Testing

For switch set-up and fault finding, the display shows the

output pressure and switch state open or closed.

Continuity is declared by an audible signal.

Verify pressure switch performance using the automatic

procedure. The DPI 610/615 Series displays the switch

points and the contact hysteresis.

Leak test will check for pressure leaks prior to

calibration or during routine maintenance. Define the test

times or use the defaults and wait. The DPI 610/615

Series will report the start and stop pressures, the

pressure change and the leak rate.

Take a ‘snapshot’ of the working display; all details are

stored in a numbered location for later recall.

Loop Testing and Fault Finding

The DPI 610/615 Series can generate a continuous mA

step or mA ramp output, allowing a single technician to

commission control loops.

Feed the loop using mA step or mA ramp and at the

control room, check the instrumentation.

Use mA value for alarm and trip circuit tests. Any mA

output can be set and adjusted from the keypad.

Comprehensive process features aid flow and level

measurement and help with troubleshooting. Select tare,

maximum/minimum, filter, flow or %span and the

function will be applied to the input parameter.

Save time in fault finding, by leaving the DPI 610/615

Series to monitor system parameters. Use periodic data

log or the maximum/minimum process function to

capture intermittent events.

Remote Pressure Sensors

By adding up to 10 external sensors (one at a time) the

working ranges of the DPI 610 and DPI 615 can be

extended. Modules from 1 inH2O to 10,000 psi are

available to suit most applications.

As a leading manufacturer of pressure sensors GE has

applied the latest silicon technology and digital

compensation techniques to develop these sensors.

GE

Sensing

Loading...

Loading...