Page 1

Repair Instructions for Babytherm 8000

Table of contents:

1. Mechanical system........................................................................................................... 3

1.1 Trolley ........................................................................................................................... 3

1.2 Column with electrical height adjustment...................................................................... 5

1.3 Base plate for resting surface and accessory rails........................................................ 7

1.4 Socket strip ................................................................................................................... 7

1.5 Resting surface............................................................................................................. 8

1.6 Accessories................................................................................................................. 14

2. Pneumatic system .......................................................................................................... 14

2.1 Extraction.................................................................................................................... 14

3. Heating panel with sensors ............................................................................................ 15

3.1 General information .................................................................................................... 15

3.2 Heating-panel assembly ............................................................................................. 16

3.3 Testing ........................................................................................................................ 18

3.4 Replacement in repair situation .................................................................................. 18

3.5 Testing after replacement ........................................................................................... 19

3.6 Repair information and modification statuses............................................................. 20

4. Mattress heating electronics........................................................................................... 22

4.1 Removal and installation of electronics and components........................................... 22

4.2 Electronics, complete.................................................................................................. 27

4.3 Controller PCB............................................................................................................ 34

4.4 Power PCB ................................................................................................................. 39

4.5 Display PCB................................................................................................................ 52

4.6 Mains switch ............................................................................................................... 55

4.7 Transformer ................................................................................................................ 56

4.8 Keypad........................................................................................................................ 58

4.9 Mains input ................................................................................................................. 64

4.10 Heating and sensor adapters .................................................................................. 66

5. Mattress heating software .............................................................................................. 68

5.1 Software versions ....................................................................................................... 68

5.2 Testing after replacement ........................................................................................... 68

6. Troubleshooting - mattress heating................................................................................ 69

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 1 of 115

Page 2

6.1 General information .................................................................................................... 69

6.2 Usage instructions for DS mode ................................................................................. 70

6.3 Diagnosis mode .......................................................................................................... 72

6.4 Troubleshooting and error list ..................................................................................... 82

6.5 10-minute test ........................................................................................................... 106

7. Radiant heater 600W ................................................................................................... 106

8. List of test equipment and tools.................................................................................... 107

8.1 Primarily for work on electrical components.............................................................. 107

8.2 Primarily for work on mechanical components.......................................................... 107

8.3 Equipment for functional tests .................................................................................. 108

9. File for repair information and unit modification............................................................ 108

9.1 New software version 1.02 (07.94) ......................................................................... 108

9.2 Mounting the mechanics of the resting-surface tilt-mechanism (09.94)................... 109

9.3 Alteration of class type B to BF (12.94) ................................................................... 109

9.4 Additional height adjustment extra high (02.95)....................................................... 115

9.5 Castors of non-height-adjustable units (03.95)........................................................ 115

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 2 of 115

Page 3

1. Mechanical system

1.1 Trolley

The Babytherm 8000 is available with various trolleys:

- Units with no electrical height adjustment:

o Small base plate for heated cot

o Large base plate for intensive-care model or reanimation unit. This

version permits installation of a radiant heater.

- Units with electrical height adjustment

o Small trolley for heated cot

o Large trolley for intensive-care module or reanimation unit. This

version permits installation of a radiant heater.

1.1.1 Trolley for units without height adjustment

The trolley consists of a trolley plate small or large which is keyed to the metal

casing of the column.

This trolley has the following castors:

2 x castor 2M 21 048

2 x locking castor 2M 21 050

The metal ends and the castor attachment points are secured in each case with

caps 2M 20 989.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 3 of 115

Page 4

1.1.1.1 Removal and installation of castors

- Pull off cap 2M 20 989 upwards.

- Jack up trolley at castor to be removed.

- Attention: Units manufactured in 1995

(ARJx-xxxx) may be equipped with

castors which are additional secured

by a hexagon socket-head screw M6.

In this case, remove screw.

- Knock out castor with hammer (approx.

0.2 - 0.5 kg) and pin punch

- Install in reverse order. Make sure that

circlip is fitted on pin of castor (part of

scope of delivery of castors).

- In the case the castor was secured by a

hexagon socket-head screw, this screw

must be affixed using Loctite 221

(order no. 79 01 966).

- Fit cap

1.1.2 Trolley for units with height adjustment

There are two possibilities:

- Large trolley 2M 21 036

- Short trolley 2M 21 038

These trolleys have the following height adjustments:

- Height adjustment 230V 2M 20 940

- Height adjustment 230V (extra high) 2M 21 174

(must nor be used on the Heated Cot with

the short trolley 2M 21 038)

- Height adjustment 115V 2M 20 946

- Height adjustment 110V (extra high) 2M 21 175

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 4 of 115

Page 5

(must nor be used on the Heated Cot with

the short trolley 2M 21 038)

In each case with the control unit:

o Foot pedals, complete 2M 20 290

These trolleys have the following castors:

- 2 x castor 2M 20 792

- 2 x locking castor 2M 20 794

- The castors are held in position 2M 20 348.

in each case by the caps

1.1.2.1 Removing and installing castors

The castor pins are held in position in the tubular section by the orange caps

2M 20 348, see Fig. from drawing 2M 21 036. The castors can be pressed out of

the tubular section using two screwdrivers.

Important: Do not apply leverage to plastic parts of castors.

Should this not prove possible, cut off orange cap 2M 20 348 at end of tubular

section and press out castor pin from inside.

1.1.3 Replacement in repair situation

Replacement parts are available in line with the spare parts list.

1.2 Column with electrical height adjustment

These trolleys feature the following height adjustments:

- Height adjustment 230V 2M 20 940

- Height adjustment 230V (extra high) 2M 21 174

(must nor be used on the Heated Cot with

the short trolley 2M 21 038)

- Height adjustment 115V 2M 20 946

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 5 of 115

Page 6

- Height adjustment 110V (extra high) 2M 21 175

(must nor be used on the Heated Cot with

the short trolley 2M 21 038)

In each case with the control unit:

o Foot pedals, complete 2M 20 290

1.2.1 Height-adjustment technical data

Height adjustment 230V:

- Dynamic force: 750 N

- Stroke: 295 mm

- Speed: 12 - 15 mm/s

- Voltage: 220 - 240 V / 50/60 Hz

- Current consumption: 2.5A

- Leakage current: < 0.1 mA

- Fuses:

o Temperature switch (self-resetting)

o 2 x fuse DIN 41662 T3.15A 18 15 148

Height adjustment 115V:

- Dynamic force: 750 N

- Stroke: 295 mm

- Speed: 12 - 15 mm/s

- Voltage: 100 - 127 V / 50/60 Hz

- Current consumption: 5 A

- Leakage current: < 0.1 mA

- Fuses:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 6 of 115

Page 7

o Temperature switch (self-resetting)

o 2 x fuses DIN 41662 T6.3A 18 15 172

1.2.2 Foot pedals, complete 2M 20 290

The height adjustment is controlled by the foot pedal assembly 2M 20 290.

- Foot pedals, complete 2M 20 290

- Connection diagram 2M 20 370

- Wiring harness 2M 20 213

1.2.3 Replacement in repair situation

Replacement parts are available in line with the spare parts list.

1.3 Base plate for resting surface and accessory rails

The resting surface is attached to the base plate. The Babytherm 8000 comes

with various base plates:

- Small base plate and small trolley for heated cot

o Base plate, small (with handles 2M 20 860) 2M 21 148

- Large base plate and large trolley for intensive-care module or reanimation

unit. This version permits installation of a radiant heater.

o Base plate, large (with handles 2M 20 862) 2M 21 146

Caution: Large base plate is never to be installed on small trolley!

1.3.1 Replacement in repair situation

Replacement parts are available in line with the spare list.

1.4 Socket strip

Caution: The 3x earthing-contact socket strip beneath the base plate of the

resting surface is only intended for:

- Babytherm mattress heating

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 7 of 115

Page 8

- Dräger radiant heater RH 600 (not in the USA and Canada)

- Babytherm height adjustment

Other loads are not permitted!

Important: The radiant heater envisaged at the factory is provided with an

inlet connector for non-heating appliances. The appropriate connecting cable

is pulled through the rail on the back.

Important: Retrofitted loads are not to be connected to the socket strip as

otherwise the data on the rating plate will no longer be correct!

Electrical safety is tested by way of the common power cord.

1.4.1 Replacement in repair situation

Replacement parts are available in line with the spare parts list.

1.4.2 Repair information and modification statuses

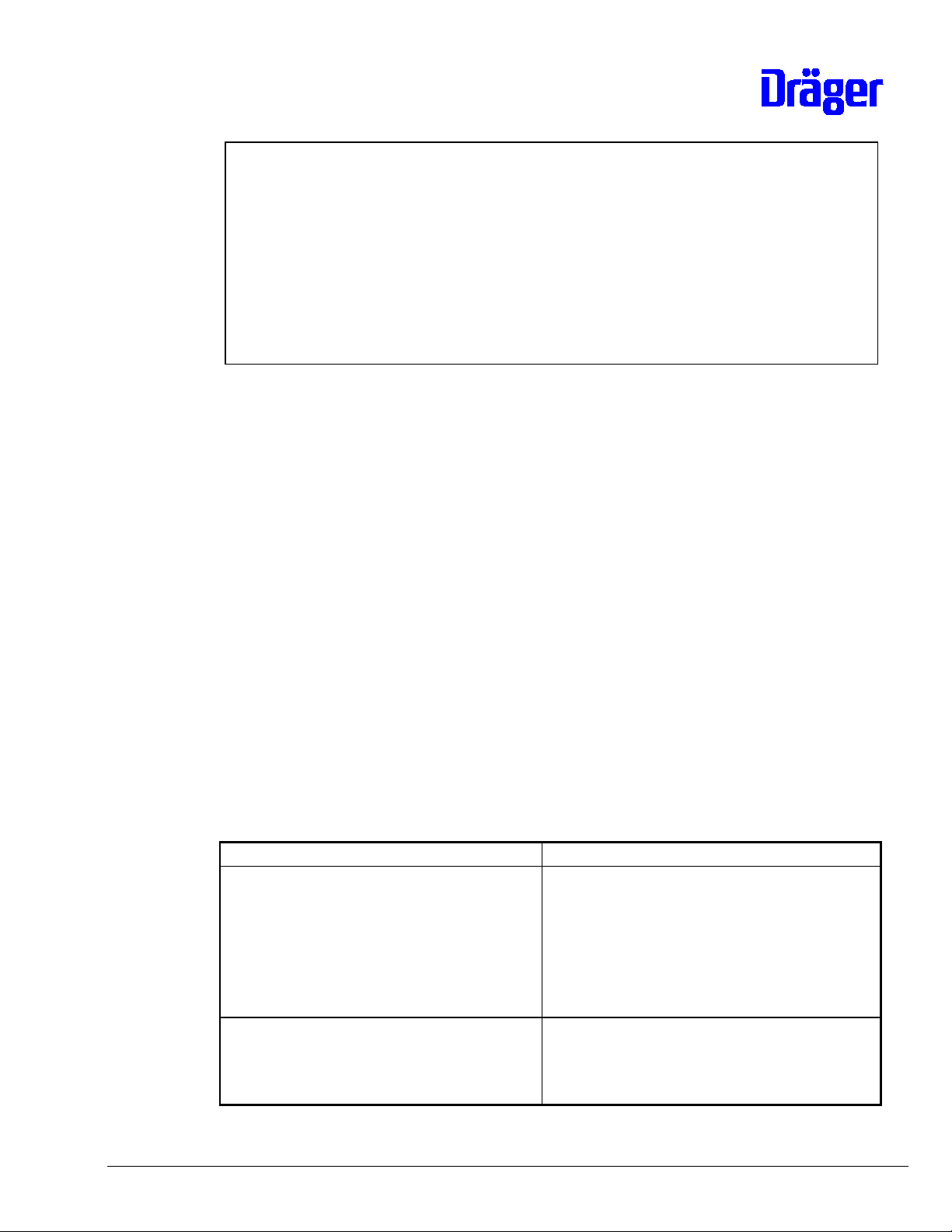

1.4.2.1 Alteration of class type B to BF (12.94)

The future Standard for mattress heating IEC 601-2-35 (as at 12.94) prescribes

that the resting surface is no longer to be earthed and that class type BF (Body

Floating) must be used. The units are currently being supplied as type B (Body) i.e.

with earthed resting surface. Production of the Babytherm 8000 with mattress

heating is to be switched as of the start of 1995 to class type Typ BF; prior to this

date roughly 300 units will be delivered with the old class type B.

Subsequent alteration from type B to BF is not envisaged.

Power cord for mattress heating control:

This refers to the short internal mains lead 2M 21 220 between the triple socket in

the Babytherm and the mattress heating control.

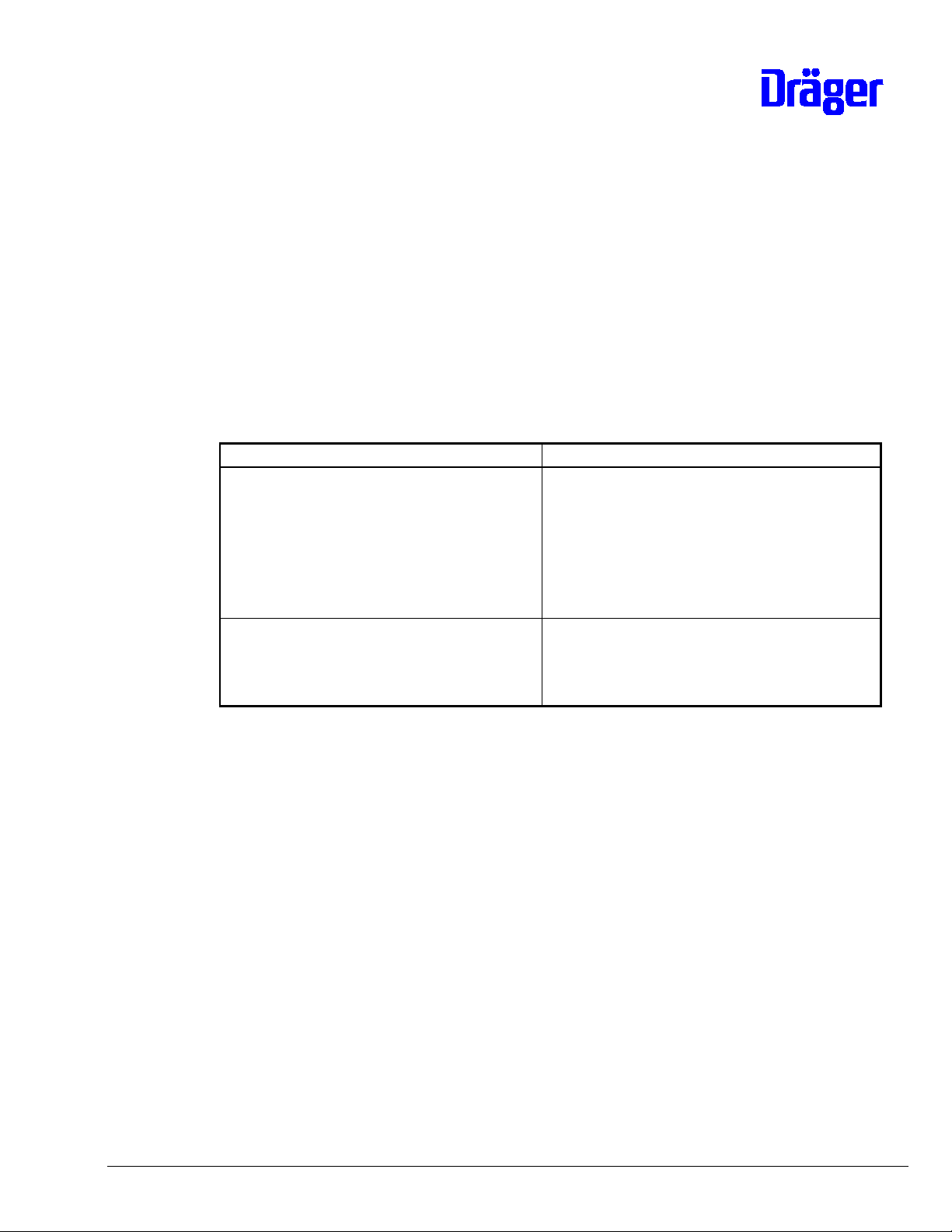

Type B Type BF

Ferrite 18 34 967 required on cable No longer ferrite on cable. If already

fitted, ferrite need not be removed

Important: A summary of class alteration from type B to BF is given in

Section 9.3. Consult this Section in the event of doubt.

1.5 Resting surface

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 8 of 115

Page 9

1.5.1 General information

The resting-surface assembly consists of the following:

- Resting surface

- Bottom-section tilt mechanism, bolted to base plate

- Mechanical system of tilt mechanism

- 4 corners for holding glass panels

Various side panels can be attached to the resting surface:

- Tall side panels for heated cot or

- Deep side panels for reanimation unit

The resting surface comes with (heated cot) and without (reanimation unit)

mattress heating:

With mattress heating:

- Gel mattress 2M 20 827

The mattress heating panel is only intended for the gel mattress 2M 20 827!

Danger:

The gel mattress 2M 20 827 may only be used in the Babytherm

8000 in conjunction with the resting-surface heater!

The gel mattress 2M 20 827 is not to be used in the Babytherm

4200 and in other heated cots with a heating-panel temperature in

excess of 40 °C ⇒ danger of burns!

Keep sharp objects away from gel mattress ⇒ danger of damage!

Without mattress heating:

- Foam mattress 2M 21 012

- Babytherm 8000 dummy panel 2M 21 067

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 9 of 115

Page 10

(for electronics opening)

- 4 Dummy plugs 14.3 mm 83 02 977

- 2 Dummy plugs 38 mm 2M 21 341

1.5.2 Testing and adjusting resting-surface tilt mechanism

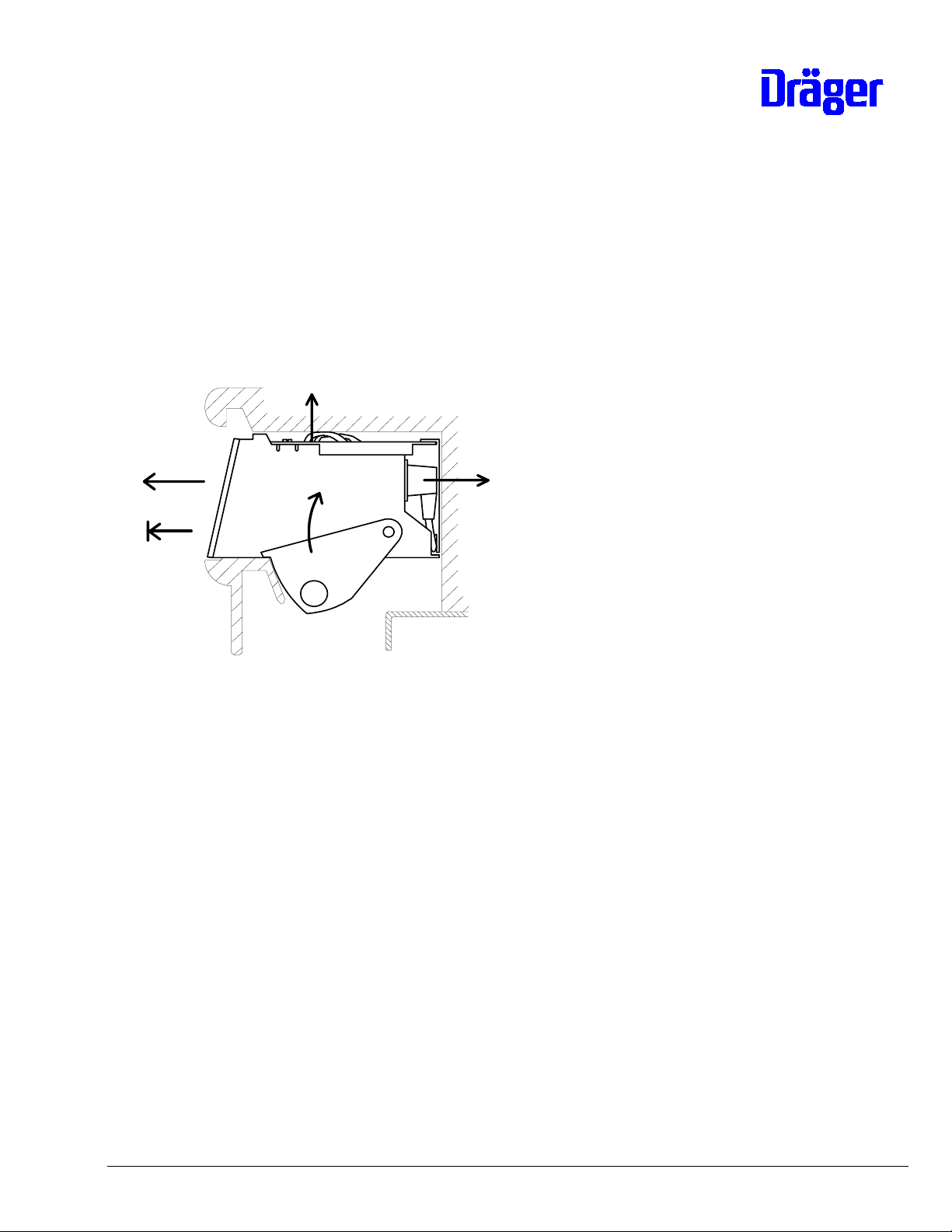

1.5.2.1 Function

The bottom section of the resting-surface tilt mechanism is connected to the base

plate with 4 hexagon socket-head bolts. This section contains the resting surface

with support being provided on one side by rollers and on the other side by teflon

strips as anti-friction bearings. The resting surface is fixed by way of a gear

mechanism in the bottom section and the latch for the mechanical system of the

resting-surface tilt mechanism.

A

H

C

Pulling the lever A presses the latch B downwards out of the gear mechanism C

and the resting surface D can be swivelled out of its basic position by +15° to -20°.

The lever is pulled back again in each case by two springs and the resting surface

thus fixed in position.

1.5.2.1 Checking function in situ

- Presence of and check on the two return springs 83 00 445

⇒ The spring force must be sufficient to reliably return the lever to its

initial position

- Pull out lever A approximately half way (20 mm):

⇒ Resting surface remains fixed in every position

B

D

H

- Pull out lever A to 3/4 of overall distance (30 mm):

⇒ Resting surface can be silently adjusted

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 10 of 115

Page 11

Important: Refer to 1.5.2.2 if resting surface is released too soon or not soon

enough or if it does not reliably engage in every position.

1.5.2.2 Testing and adjustment following removal

- Remove complete resting surface. To do so interrupt mains connection to

electronics assembly or remove the electronics module and screw out the

four hexagon socket-head bolts H.

A

B

H

D

H

C

E

- Visually inspect gear mechanism C in resting-surface section; there must

not be any signs of wear.

- Visually inspect gear mechanism B of latch 2M 20 855 of mechanical

system of resting-surface tilt mechanism. To do so un screw out bolts E and

F. There must not be any signs of wear. Reattach latch. Important: The

bolts E and F are secured with epoxy hardening glue (UHU Plus).

- Visually inspect tilt mechanism: All moveable parts must be greased with

Molykote 55M order no.15 54 093.

G

F

- The 4 teflon sliders must not be greased.

- Presence of and check on the two return springs 83 00 445

⇒ Spring force must be sufficient to reliably return lever to initial

position.

- Pull out lever A approximately half way (20 mm):

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 11 of 115

Page 12

⇒ Resting surface remains fixed in every position.

- Pull out lever A 3/4 of the total distance (30 mm):

⇒ Resting surface can be silently adjusted

- The disengaging/engaging travel of the latch can be adjusted by way of the

screw G at the latch:

o Resting surface is released too early:

Loosen the screw G a few turns. Unscrew the bolts E and F and

apply epoxy hardening glue (UHU Plus, order no. 11 95 255) on their

threads. Screw in the bolts E and F and re-tighten them. Repeat the

test.

o Resting surface is not released too late or is not released properly:

Remove the bolts E and F and screw-in the screw G a few turns.

Apply epoxy hardening glue (UHU Plus, order no. 11 95 255) on the

threads of the bolts E and F. Screw in the bolts E and F and retighten them. Repeat the test.

- Reattach resting surface

- Electrical safety check

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 12 of 115

Page 13

1.5.3 Corners and side panels

1.5.3.1 Testing

The corners and side panels must be checked for reliable closure. If this is not the

case or if there are visible signs of wear, the panel hinges or housing corners are

to be renewed.

1.5.3.1 Removing and installing corners

Knock corners upwards with plastic hammer. Installation involves reverse

procedure.

1.5.3.2 Side-panel hinges

The hinges of the side panels can be renewed; this requires use of the following

spare parts:

- S-set for hinge, left 2M 21 084

- S-set for hinge, right 2M 21 082

A 2 mm bit and a drill are needed for assembly.

1.5.4 Replacement in repair situation

Replacement parts are available in line with the spare parts list.

1.5.5 Testing after replacement

- Check reliable locking of panels

- Visually inspect correct installation of all parts

- Check resting-surface tilt mechanism (see 1.5.2.1)

- If heating or electronics assembly has been removed:

o Electrical safety check

o Functional check (Test time at least 20 minutes)

• Heating function

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 13 of 115

Page 14

• Mains failure alarm

• Data storage with mains failure alarm

• Function of keys

• Function of display elements

• No error messages

1.5.6 Repair information and modification statuses

1.5.6.1 Mounting the mechanics of the resting-surface (9.94) tilt-mechanism

With immediate effect, the mechanics of the resting-surface tilt-mechanism must

be mounted with 4 Spax screws (order no. 12 75 593). Devices already in service

must be retrofitted with this type of screws, see IDM no. 1 and conversion

instructions under "U", Chapter 2.1. The two cylinder head screws of the latch

2M 20 855 and the screw on the control lever must be secured with epoxy

hardening glue (UHU-Plus, order no. 11 95 255).

1.6 Accessories

1.6.1 Cabinet

- Cabinet mount, complete 2M 20 868

- Swivel cabinet 2M 20 638

1.6.2 Rail for resting-surface

- Modification kit rail 2M 21 468

2. Pneumatic system

2.1 Extraction

The extraction is not part of this documentation.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 14 of 115

Page 15

3. Heating panel with sensors

3.1 General information

The heating panel consists of an aluminium backing plate (6 mm) to which a

heating foil 24V / 120W is bonded and two twin temperature sensors are bolted.

Transformer

Partition of prim./ sec. voltage

HHT Gel Mattress

Aluminium plate 6mm

Heating foil

Temp. Sensors(2x2 NTCs)

Control unit

Power cord

To distinguish between type B and BF the mattress heating control and heating

panel have different plugs for the heating connection:

Type B (old) - 3-pin connector for heating cable,

one cable for protective conductor

Type BF (new) - 2-pin connector for heating cable

As not all parts of the mattress heating are interchangeable, the modified

components have new order numbers. Always pay attention to repair information

when performing repairs.

The heating panel is only intended for the gel mattress 2M 20 827

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 15 of 115

Page 16

Danger:

The gel mattress 2M 20 827 may only be used in the Babytherm 8000 in

conjunction with the resting-surface heater!

The gel mattress 2M 20 827 is not to be used in the Babytherm 4200 and in

other heated cots with a heating-panel temperature in excess of 40 °C ⇒

danger of burns!

Keep sharp objects away from the gel mattress ⇒ danger of damage!

3.2 Heating-panel assembly

The heating panel consists of the following components:

- Backing plate 2M 20 878

- All-round seal for backing plate 2M 20 882

- Foil heating 24V/120W bonded on for type BF 2M 21 509

- Twin temperature sensor 2M 20 859

The sensors are fitted with thermal

conduction paste at the backing-plate

contact surfaces.

The heating panel is secured in position in the cot from underneath with four bolts.

The heating panels for types B and BF have different order numbers.

The following heating-panel parts differ:

Heating panel 2M 20 877 for type B Heating panel 2M 21 510 for type BF

Double temp. sensor 2M 20 859 with

shield connected to sensors.

Identification: No yellow and blue

shrink-down tubing at sensors.

Sensor cannot be converted to type

BF.

Foil heating 2M 20 876 with 3-pin

connector:

- 2 x heating

- Protective conductor

Double temp. sensor 2M 20 859 with

insulated shield on sensor end,

distinguished by sensors with blue and

yellow shrink-down tubing. This sensor

can also be used in type B. Alteration

has already been made on some units

of type B.

Foil heating 2M 21 509 with 2-pin

connector:

- 2 x heating

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 16 of 115

Page 17

Important: In future only the new heating panel 2M 21 510 will be available. The

new heating panel 2M 21 510 for type BF will then have to be converted to type B

in the event of repair. This will involve taking over the protective-conductor cable

connection and 3-pin heating connector from the defective heating panel

2M 20 877. In this case the protective conductor connection is to be laid separately

from the heating cables. To remove the connector, use can be made of the tool

"Extractor for crimp socket 2.6 mm" with the order no. 79 01 120; another

possibility is to make use of ballpoint-pen refills (with metal tube) with a tube ID of

approx. 2.6 mm.

3.2.1 Heating and sensor connections

- Heating for type B:

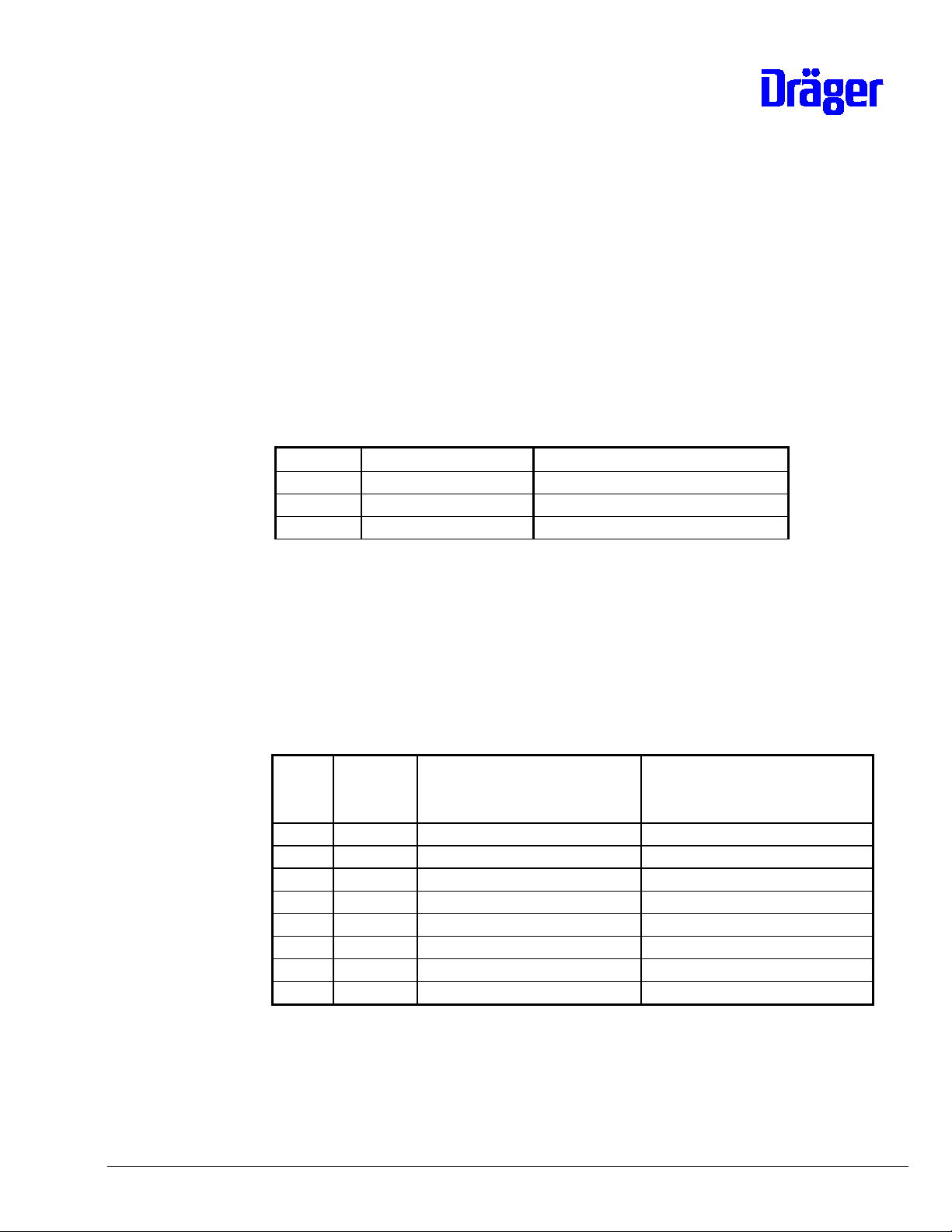

Pin Color Significance

1 not yellow/green Heating

2 not yellow/green Heating

3 yellow/green Protective conductor

- Heating for type BF:

2 x Heating

- Twin temperature sensor (2 x 2 sensors):

Refer also to drawing, wiring harness, twin temperature sensor 2M 20 875

under "S".

Pin Color Significance Temperature module

1 blue Sensor 1, first half Module 1

2 red Sensor 1, first half Module 1

6 black Sensor 2, first half Module 2

7 white Sensor 2, first half Module 2

4 blue Sensor 1, second half Module 3

5 red Sensor 1, second half Module 3

9 black Sensor 2, second half Module 4

10 white Sensor 2, second half Module 4

There is no preferential position for the two halves on the backing plate.

assignment on

controller PCB

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 17 of 115

Page 18

3.3 Testing

Refer to 3.5

If there is any doupt as to the accuracy of the temperature on the resting surface

perform the following test at a room temperature of 20 to 30 °C:

- Adjust setpoint to 36.0 °C

- Place the point of the fluid temperature probe of the temperature and

humidity set 79 01 148 on the centerof the heating plate such that the point

touches the plate.

- Cover the plate with the gel mattress 2M 20 827

- Cover the gel mattress with the foam mattress 2M 21 102

- If possible cocer the resting surface with the hood 2M 21 030

- Allow the unit to warm up at least 2 hours

- Important: Do not use any additional radiant heater!

- Test value of the reference temperature instrument:

Reading = 36,0 ± 1,0 °C

3.4 Replacement in repair situation

The following spare parts are available for repairs:

For type B:

- Heating-panel assembly 2M 20 877

o Twin temperature sensor 2M 20 859

o Backing-plate seal 2M 20 882

For type BF:

- Heating-panel assembly 2M 21 510

o Twin temperature sensor 2M 20 859

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 18 of 115

Page 19

o Backing-plate seal 2M 20 882

The following heating-panel parts differ:

Heating panel 2M 20 877 for type B Heating panel 2M 21 510 for type BF

Double temp. sensor 2M 20 859 with

shield connected to sensors.

Identification: No yellow and blue

shrink-down tubing at sensors.

Sensor cannot be converted to type

BF.

Foil heating 2M 20 876 with 3-pin

connector:

- 2 x heating

- Protective conductor

Important: In future only the new heating panel 2M 21 510 will be available. The

new heating panel 2M 21 510 for type BF will then have to be converted to type B

in the event of repair. This will involve taking over the protective-conductor cable

connection and 3-pin heating connector from the defective heating panel

2M 20 877. In this case the protective conductor connection is to be laid separately

from the heating cables. To remove the connector, use can be made of the tool

"Extractor for crimp socket 2.6 mm" with the order no. 79 01 120; another

possibility is to make use of ballpoint-pen refills (with metal tube) with a tube ID of

approx. 2.6 mm.

Double temp. sensor 2M 20 859 with

insulated shield on sensor end,

distinguished by sensors with blue and

yellow shrink-down tubing. This sensor

can also be used in type B. Alteration

has already been made on some units

of type B.

Foil heating 2M 21 509 with 2-pin

connector:

- 2 x heating

3.5 Testing after replacement

Assemble unit ready for operation.

- Visual inspection:

o Correct installation of heating panel and seal

o Proper connection of heating to electronics assembly

o Correct installation of electronics assembly

- Functional check (Test duration at least 30 minutes):

o Adjust setpoint to 37.0 °C.

o If setpoint higher than actual value:

⇒ Heating LED flashes

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 19 of 115

Page 20

o Adjust setpoint to 38.0 °C.

o Interrupt mains connection:

⇒ Visual and acoustic mains failure alarm

o Re-establish mains connection:

⇒ Unit continues to operate with setpoint of 38 °C

- Testing in DS mode, see 6.2 if actual value greater than 37 °C:

o Read out all four temperature values in each case in DS mode 6.2.1 -

6.2.4; the permitted deviation between the minimum and maximum

temperature value is 0.4 °C. Important: The displayed value in DS

mode is 1.0 °C higher than the value normally displayed in operation.

- Electrical safety check

3.6 Repair information and modification statuses

3.6.1 Alteration of class type B to BF (12.94)

The future Standard for mattress heating IEC 601-2-35 (as at 12.94) prescribes

that the resting surface is no longer to be earthed and that class type BF (Body

Floating) must be used. The units are currently being supplied as type B (Body) i.e.

with earthed resting surface. Production of the Babytherm 8000 with mattress

heating is to be switched as of the start of 1995 to class type Typ BF; prior to this

date roughly 300 units will be delivered with the old class type B.

Subsequent alteration from type B to BF is not envisaged.

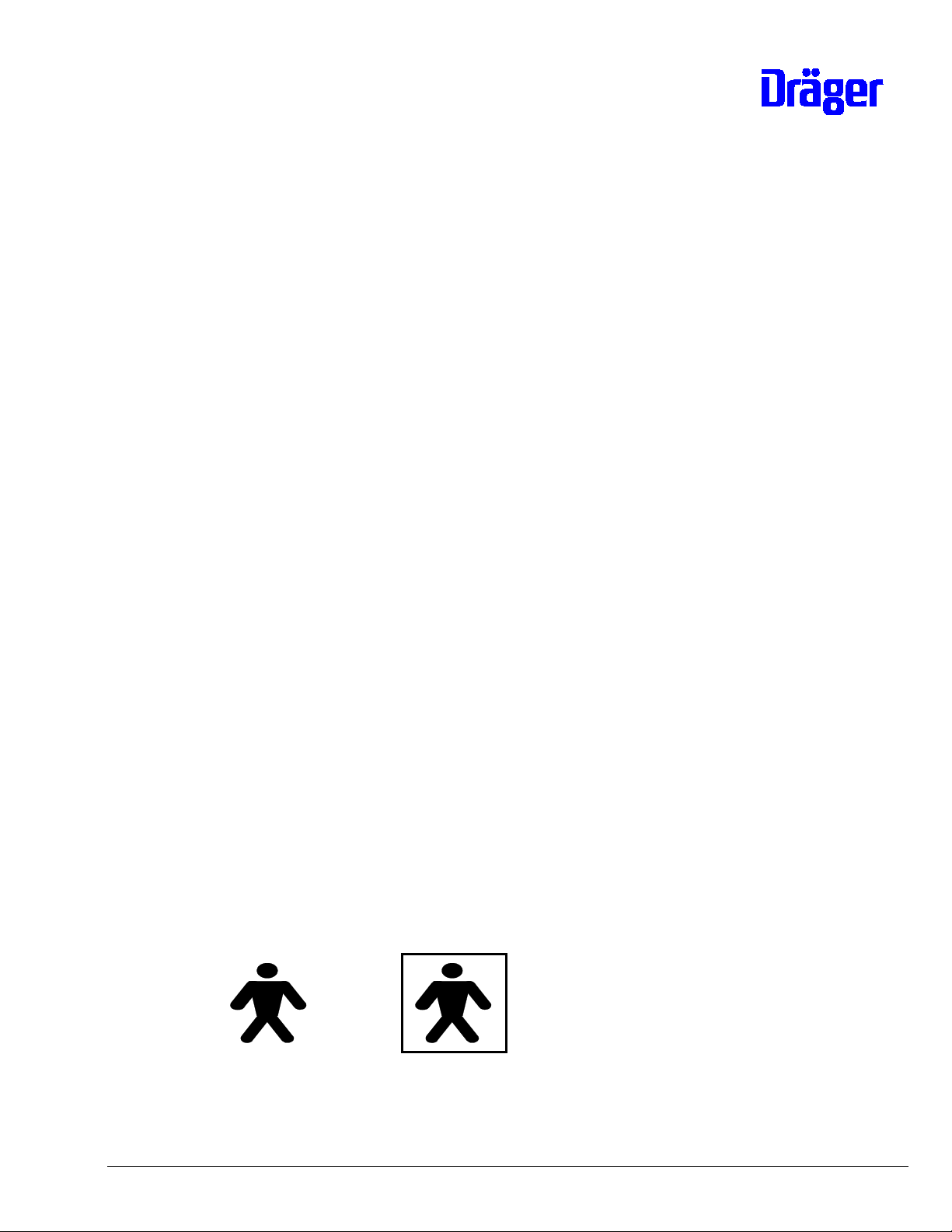

The difference can be seen from the stamp next to the rating plate of the

Babytherm:

Type B: Type BF:

(Figure with no box) (Figure in box)

To distinguish between type B and BF the mattress heating control and heating

panel have different plugs for the heating connection:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 20 of 115

Page 21

Type B (old) - 3-pin connector for heating cable,

one cable for protective conductor

Type BF (new) - 2-pin connector for heating cable

As not all parts of the mattress heating are interchangeable, the modified

components have new order numbers. Always pay attention to repair information

when performing repairs.

The heating panels for types B and BF have different order numbers.

The following heating-panel parts differ:

Heating panel 2M 20 877 for type B Heating panel 2M 21 510 for type BF

Double temp. sensor 2M 20 859 with

shield connected to sensors.

Identification: No yellow and blue

shrink-down tubing at sensors.

Sensor cannot be converted to type

BF.

Double temp. sensor 2M 20 859 with

insulated shield on sensor end,

distinguished by sensors with blue and

yellow shrink-down tubing. This sensor

can also be used in type B. Alteration

has already been made on some units

of type B.

Foil heating 2M 20 876 with 3-pin

connector:

- 2 x heating

Foil heating 2M 21 509 with 2-pin

connector:

- 2 x heating

- Protective conductor

Important: In future only the new heating panel 2M 21 510 will be available. The

new heating panel 2M 21 510 for type BF will then have to be converted to type B

in the event of repair. This will involve taking over the protective-conductor cable

connection and 3-pin heating connector from the defective heating panel

2M 20 877. In this case the protective conductor connection is to be laid separately

from the heating cables. To remove the connector, use can be made of the tool

"Extractor for crimp socket 2.6 mm" with the order no. 79 01 120; another

possibility is to make use of ballpoint-pen refills (with metal tube) with a tube ID of

approx. 2.6 mm.

Important: A summary of class alteration from type B to BF is given in

Section 9.3. Consult this Section in the event of doubt.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 21 of 115

Page 22

4. Mattress heating electronics

4.1 Removal and installation of electronics and components

4.1.1 Removing and installing electronics assembly

Important: Components can be effected by static electricity!

- Interrupt mains connection to Babytherm

5.

2.

4.

1. (2x)

- 1. Swing up the two side catches on the

electronics assembly

3.

- 2. Pull electronics assembly slightly out

of Babytherm

- 3. Detach mains connection

- 4. Detach sensor and heating connecting

cable

- 5. Pull out electronics assembly

- Install in reverse order

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 22 of 115

Page 23

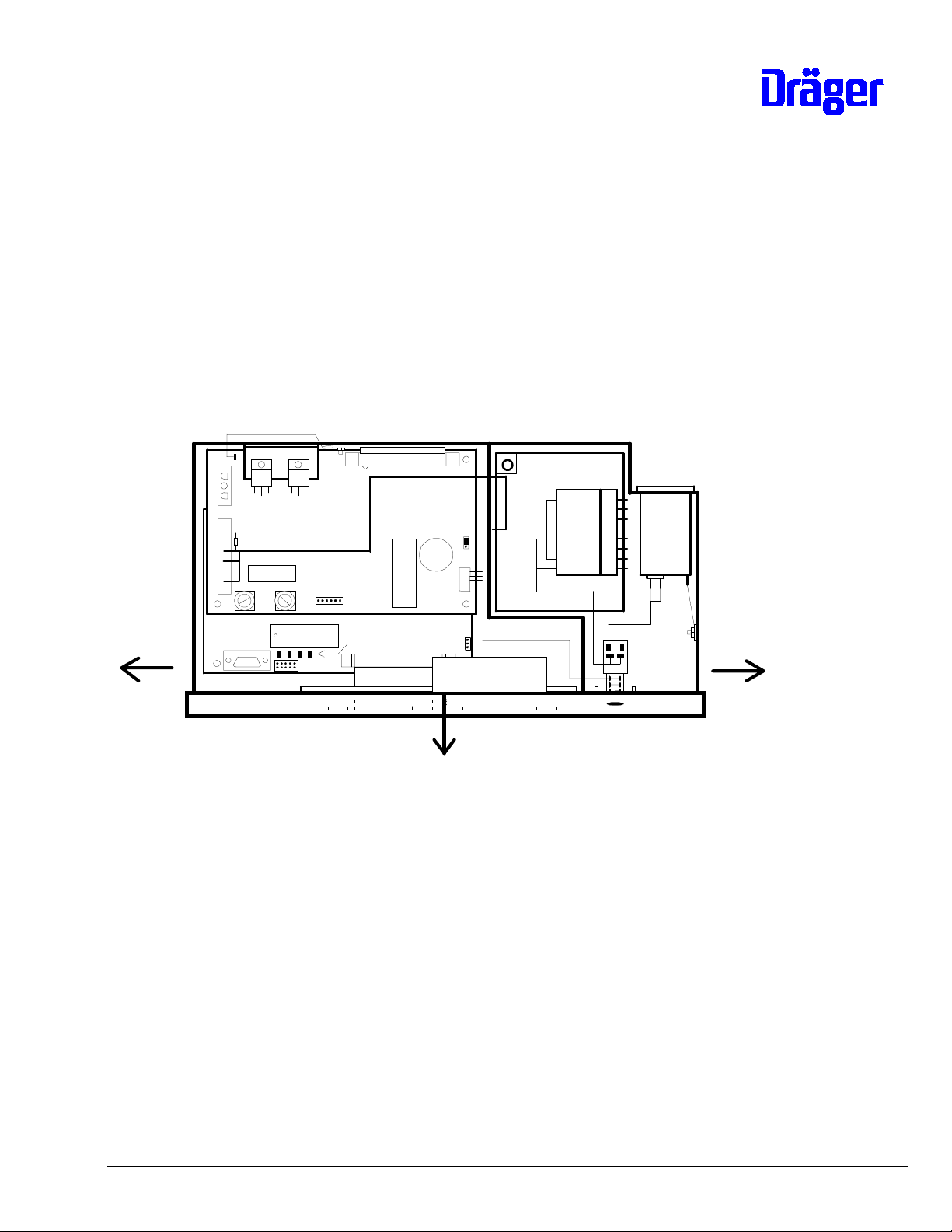

4.1.2 Opening electronics assembly

Important: Components can be effected by static electricity!

- Loosen both screws in the cover of the electronics assembly (do not screw

out); push cover forwards and remove upwards.

- Detach cable connections from connectors in cover to printed circuit cards.

- Bend housing apart on side (1.) and tilt keypad with display PCB forwards

(2.).

Transformer

PCB Power

PCB Controller

1.

1.

Keyboard

2.

- Install in reverse order.

PCB Display

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 23 of 115

Page 24

4.1.3 Wiring diagram

V2 V11

Connection

heating

R22

Relay

Fuses

F2 F1

Connection protective

conductorr PCB Power

+ PCB Controller

Connection

Sensors

RS232

PCB Power

Test points

PCB Controller

EPROM

4 Service-LEDs

Gold Cap

Horn

Mains input with fuses

Transformer

Keyboard

PCB Display

Switch

Important: 100 - 127 V units feature a voltage adapter from the accessory set:

voltage conversion 2M 21 176 between mains switch and transformer.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 24 of 115

Page 25

4.1.4 Display PCB, keypad and mains switch

Important: Components can be effected by static electricity!

- Remove electronics assembly (see 4.1.1)

- Open electronics assembly (see 4.1.2)

- Detach cable connections to keypad and display PCB (see 4.1.3 wiring

diagram)

- Display PCB is attached to keypad with three nuts

- Mains switch with wiring harness is attached to keypad

- Perform installation in reverse order

4.1.5 Power PCB and controller PCB

Important: Components can be effected by static electricity!

- Remove electronics assembly (see 4.1.1)

- Open electronics assembly (see 4.1.2)

- Detach cable connections to keypad and display PCB, (see 4.1.3 wiring

diagram)

- Power PCB is attached with three snap fasteners and a screw connection

(at the heat sink) whereas controller PCB is secured in position with four

snap fasteners.

o Loosen screw connection for power PCB

o Squeeze snap fastener 1

together and raise printed

circuit card 2; snap fastener

engages again on installation.

o Important: There are two

replacement snap fasteners at

the dividing wall in the

electronics assembly.

1.

2.

o Removal of the controller PCB may involve removal of the snap

fasteners for the power PCB. To do so, squeeze snap fasteners

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 25 of 115

Page 26

together at bottom with pointed pliers and press out fasteners

upwards.

- Install in reverse order

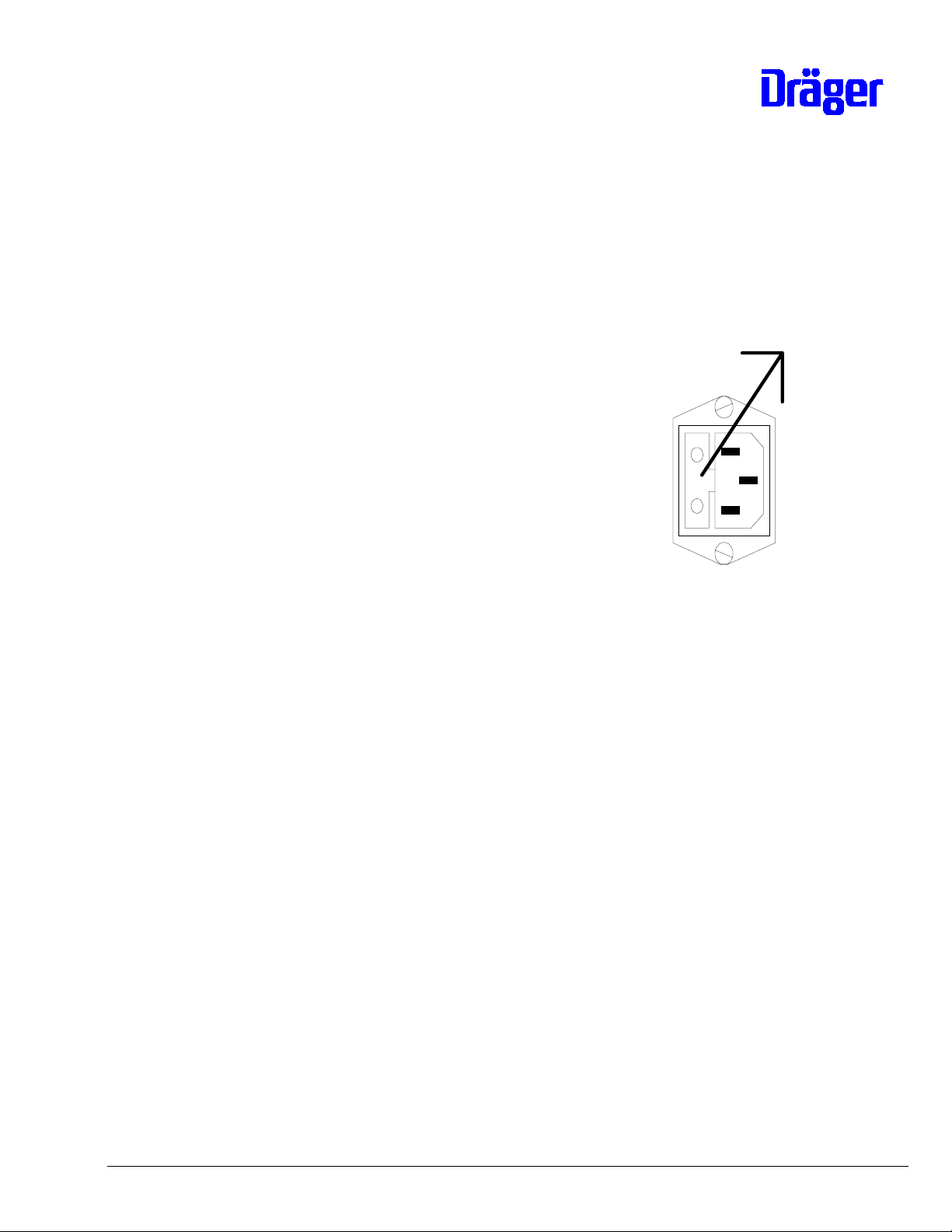

4.1.6 Mains input with mains fuses

4.1.6.1 Mains fuses

- Remove electronics assembly

(see 4.1.1)

- Pull out fuse compartment next

to mains socket.

- Following fuse ratings must be

used:

o 220/240V units:

2 x fuse DIN 41662, T800mA 18 15 075

o 100/127V units:

2 x fuse DIN 41662, T1.6A 18 15 105

- Slide fuse compartment back in again

- Re-install electronics assembly

4.1.6.2 Removing and installing mains input

Important: Components can be effected by static electricity!

- Remove electronics assembly (see 4.1.1)

- Open electronics assembly (see 4.1.2)

- Detach cable connections at mains input (see 4.1.3 wiring diagram)

- Mains input is attached to housing with two screw connections

- Install in reverse order

4.1.7 Transformer, adapter for mains voltage conversion 100 - 127 V

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 26 of 115

Page 27

Important: Components can be effected by static electricity!

- Remove electronics assembly (see 4.1.1)

- Open electronics assembly (see 4.1.2)

- Detach cable connections to transformer (see 4.1.3 wiring diagram)

- 100 - 127 V units feature the voltage adapter 83 06 462 from the accessory

set for voltage conversion 2M 21 176 between mains switch and mains input

of transformer.

- Transformer is attached to housing with four screw connections

- Install in reverse order

4.2 Electronics, complete

4.2.1 General information

The electronics module contains the entire control system for the mattress heating.

The module is made up of the following components:

- Controller PCB

- Power PCB

- Display PCB

- Mains switch

- Transformer

- Keypad

- Mains input

- Adapter for voltage conversion (100/127 V units only)

The repair information for these individual components is given in sections 4.3 -

4.9

4.2.2 Voltage conversion

As the heating is driven via the transformer, the mains voltage is no problem to

convert.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 27 of 115

Page 28

The following is required for conversion from 220/240V to 100/127V:

- Accessory set, voltage 100/127V 2M 21 176

Important: It is not possible to change the voltage for the optional height

adjustment!

4.2.3 Testing electronics, complete

Assemble unit ready for operation, but do not fix electronics assembly in position in

housing. Connector for attaching sensor cable to unit is therefore accessible.

Switch on unit:

- All displays and horn are actuated for 1.2 s

- Then:

o Setpoint display = 37.0 °C

o Measured value and label "SEt" flash up alternately on actual value

display. Important: measuring range 5 °C - 45 °C.

o Pressing one of the keys " ⇑ " or " ⇓ " setpoint produces constant

actual display.

- Without prior pressing of range expansion key setpoint can be adjusted to

between 35.0 °C and 37.0 °C.

- After prior pressing of range expansion key setpoint can be adjusted in each

case to min 30.0 °C or max. 38.5 °C.

- Adjust setpoint to 37.0 °C.

- Press "check" key:

o All displays and horn are actuated for 2 s.

o All displays and horn then off for 2 s.

o This is followed by return to original display.

- If setpoint higher than actual value:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 28 of 115

Page 29

o Heating LED flashes

- If actual value is in range between 35.5 °C and 38.0 °C, adjust setpoint in

each case to 1.1 °C higher or lower than actual value:

o Visual and acoustic alarm ± 1 °C

o Acoustic alarm can be suppressed with "horn off" key

- Adjust setpoint to 38.0 °C.

- Interrupt mains connection:

o Visual and acoustic mains failure alarm

- Re-establish mains connection:

o Unit continues to operate with setpoint of 38 °C

- Disconnect plug from sensor cable at assembly:

o Visual and acoustic sensor alarm

- Reconnect plug

- Testing in DS mode, see 6.2, if actual value greater than 37 °C:

o Read out all four temperature values in each case in DS mode 6.2.1 -

6.2.4. The permitted deviation between the minimum and

maximum temperature value is 0.4 °C. Note: The value displayed in

DS mode is 1.0 °C higher than the value normally displayed in

operation.

- Instead of sensors, connect up Babytherm 8000 test plug (35 °C + 1 °C

Offset) 79 00 965.

- Testing in DS mode, see 6.1:

o Read out all four temperature values in each case in DS mode. Test

value is always 35.0 ± 0.2 °C.

- Switch off unit and assemble ready for operation.

- Electrical safety check.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 29 of 115

Page 30

4.2.4 Replacement in repair situation

If a defective assembly cannot be repaired by replacing individual components, the

following spare parts are available:

For Type B:

- Electronics assembly 220/240V, complete 2M 20 880

o Conversion set 100/127V 2M 21 176

- Repair/replacement electronics assembly 2M 21 095

220/240V, complete

For Type BF:

- Electronics assembly 220/240V, complete 2M 21 500

o Conversion set 100/127V 2M 21 176

- Repair/replacement electronics assembly 2M 21 506

220/240V, complete

Important: The control system 2M 20 880 and the RAT (repair/replacement) control

system 2M 21 095 for type B will no longer be available in future.

Type BF controls are to be ordered as spare part for the old type B. On installation,

merely the housing cover with the two wiring harnesses (heating adapter and

sensor adapter) is to be taken over from the defective control system. The marking

on the housing of the new control system is to be changed to type B and the order

no. from 2M 21 500 to 2M 20 880.

4.2.5 Testing after replacement

The following tests are to be performed after replacement of the electronics

assembly:

- Visual checks:

o Correct mains voltage set in electronics assembly (see 4.2.3).

- Electrical safety check

- Functional test (Test duration at least 20 minutes)

o Function of heating

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 30 of 115

Page 31

o Mains failure alarm

o Data storage with mains failure alarm

o Function of keys

o Function of display elements

o No error messages

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 31 of 115

Page 32

4.2.6 Repair information and modification statuses

4.2.6.1 Alteration of class type B to BF (12.94)

The future Standard for mattress heating IEC 601-2-35 (as at 12.94) prescribes

that the resting surface is no longer to be earthed and that class type BF (Body

Floating) must be used. The units are currently being supplied as type B (Body) i.e.

with earthed resting surface. Production of the Babytherm 8000 with mattress

heating is to be switched as of the start of 1995 to class type Typ BF; prior to this

date roughly 300 units will be delivered with the old class type B.

Subsequent alteration from type B to BF is not envisaged.

The mattress heating controls 220/240V for types B and BF have different order

numbers.

Type B Type BF

Mattress heating control 2M 20 880

Distinguishing feature:

- 3-pin heating connection

RAT mattress heating control

2M 21 095

Mattress heating control 2M 21 500

Distinguishing features:

- 2-pin heating connection

- Order no. printed on

- Marked "BF"

RAT mattress heating control

2M 21 506

Important: The control system 2M 20 880 and the RAT (repair/replacement) control

system 2M 21 095 for type B will no longer be available in future.

Type BF controls are to be ordered as spare part for the old type B. On installation,

merely the housing cover with the two wiring harnesses (heating adapter and

sensor adapter) is to be taken over from the defective control system. The marking

on the housing of the new control system is to be changed to type B and the order

no. from 2M 21 500 to 2M 20 880.

Wiring diagram/wiring harnesses

There is no change to the cable connections between the PCBs. The only

alteration is to the wiring harnesses (sensor adapter and heating adapter), i.e. the

two cable connections from the cover to the PCBs.

Type B Type BF

Wiring harness

Heating adapter 2M 21 096

3-pin adapter cable without ferrite

between heating connection on

Wiring harness

Heating adapter 2M 21 507

2-pin adapter cable with ferrite

between heating connection on

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 32 of 115

Page 33

housing cover and power PCB. housing cover (2-pin) and power PCB

(3-pin).

Wiring harness

Sensor adapter 2M 21 094

Wiring harness with ferrite 18 31 577

between sensor connection on

housing cover and controller PCB.

Wiring harness

Sensor adapter 2M 21 508

Wiring harness without ferrite

between sensor connection on

housing cover and controller PCB

This cable can also be used in type

BF.

Controller PCB

Use in the type BF requires additional capacitors in the measurement input which

cannot be retrofitted in the field. Retrofitting has already been performed if the

modification number after the order no. is ³ 1.1, i.e. the PCB is marked with

82 90 688 - 1.1 or a higher modification number. Some units of type B already

feature this modification.

Controller PCB 82 90 688 ≤≤≤≤ 1.0 Controller PCB 82 90 688 ≥≥≥≥ 1.1

Only for use in type B. Use in type

Can be used in types B and BF

BF could result in destruction of

measurement input caused by the

influence of voltage peaks

Important: A summary of class alteration from type B to BF is given in

Section 9.3. Consult this Section in the event of doubt.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 33 of 115

Page 34

4.3 Controller PCB

4.3.1 General information

Important: Components can be effected by static electricity!

Position in electronics system:

Connection protective

ground PCB Power + PCB Controller

V2 V11

Connection heating

PCB Power

R22

Relay

Fuses

F2 F1

Test points

Gold Cap

Horn

Transformer

Mains input with fuses

Connection

Sensors

Keyboard

EPROM

PCB Controller

4 Service-LEDs

Switch

PCB Display

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 34 of 115

Page 35

4.3.2 Controller PCB 82 90 668

Layout:

X2

X12

1

X1

X3

Connection

M1

M2

M3

M4

M5

M6

D2 EPROM

RS232

T1

D1

PCB Controller

4 Service-LEDs

X11

Sensors

Components and jumpers:

Item Component/function

X1 Connection to display PCB

X2 Connection to power PCB

X3 Connection to sensors of heating panel; refer to 3.2.1

for wiring diagram

X11 RS232 (not active)

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 35 of 115

Page 36

Item Component/function

X12 Call-up of service mode without keys

Position in operation without jumper or jumper in park

position 2-3:

X12

1

X1

Call-up of service mode. Short circuit for max.

30 seconds between 1-2:

X12

1

X1

T1 Connection to housing (protective conductor)

D1 Microcontroller 68332 18 37 109

D2 EPROM, see 5. Repair information, software

M1 - M4 Temperature module 83 50 082

M5, M6 Not used

Service LEDs

during switch-on test after swich-on test

EPROM defective

RAM defective

PCB Display INOP

Processor ok

no key pressed = V1 to V3 off

1 key pressed = 1 LED flashes

2 keys pressed = 2 LEDs flash

3 keys pressed = 3 LEDs flash

Processor ok

V1 V2 V3 V4

Important: There are no components on the controller PCB which have to be

replaced at service intervals.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 36 of 115

Page 37

4.3.3 Testing controller PCB

4.3.3.1 Processor system

Following switch-on no INOP error message; LED V4 must light; refer to table in

4.3.2.

4.3.3.2 Measured value acquisition and heating control

Refer to 4.2.3 Testing of electronics, complete.

4.3.4 Replacement in repair situation

The following spare parts are available for repairs:

- Controller PCB (Babytherm) 82 90 668

o EPROM See 5.

Use in the type BF requires additional capacitors in the measurement input which

cannot be retrofitted in the field. Retrofitting has already been performed if the

modification number after the order no. is ³ 1.1, i.e. the PCB is marked with

82 90 688 - 1.1 or a higher modification number. Some units of type B already

feature this modification.

Controller PCB 82 90 688 ≤≤≤≤ 1.0 Controller PCB 82 90 688 ≥≥≥≥ 1.1

Only for use in type B. Use in type

BF could result in destruction of

measurement input caused by the

influence of voltage peaks

Can be used in types B and BF

4.3.5 Testing after replacement

Refer to 4.2.3 Testing electronics, complete

4.3.6 Repair information and modification statuses

4.3.6.1 Alteration of class type B to BF (12.94)

The future Standard for mattress heating IEC 601-2-35 (as at 12.94) prescribes

that the resting surface is no longer to be earthed and that class type BF (Body

Floating) must be used. The units are currently being supplied as type B (Body) i.e.

with earthed resting surface. Production of the Babytherm 8000 with mattress

heating is to be switched as of the start of 1995 to class type Typ BF; prior to this

date roughly 300 units will be delivered with the old class type B.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 37 of 115

Page 38

Subsequent alteration from type B to BF is not envisaged.

Use in the type BF requires additional capacitors in the measurement input which

cannot be retrofitted in the field. Retrofitting has already been performed if the

modification number after the order no. is 1.1, i.e. the PCB is marked with

82 90 668 - 1.1 or a higher modification number. Some units of type B already

feature this modification.

Controller PCB 82 90 668 ≤≤≤≤ 1.0 Controller PCB 82 90 668 ≥≥≥≥ 1.1

Only for use in type B. Use in type

BF could result in destruction of

measurement input caused by the

influence of voltage peaks

Important: A summary of class alteration from type B to BF is given in

Section 9.3. Consult this Section in the event of doubt.

Can be used in types B and BF

4.3.6.2 New EEPROM on Controller PCB 04.01

A new EEPROM on the Controller PCB P/N 8290668 requires the new software

version 1.04. If a new Controller PCB is used with the previous software version

error code 15 will be generated.

When replacing the Controller PCB P/N 8290668, software version 1.04 (P/N

2M22467) must be installed.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 38 of 115

Page 39

4.4 Power PCB

4.4.1 General information

Important: Components can be effected by static electricity!

Position in electronics system:

Connection protective

ground PCB Power + PCB Controller

V2 V11

Connection heating

PCB Power

R22

Horn

Relay

Fuses

F2 F1

Test points

Gold Cap

Transformer

Mains input with fuses

Connection

Sensors

Keyboard

EPROM

PCB Controller

4 Service-LEDs

Switch

PCB Display

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 39 of 115

Page 40

4.4.2 Power PCB 82 90 641

Layout:

T1

X7

1

V2 V11

13

2

13

2

X1

PCB Power

R22

Horn

X2

Relay K1

1

Fuses

F2 F1

Test points

X6

1

C25

+

Components and jumpers:

Item Component/function

X1 Connection to controller PCB

X2 Connection to transformer

X5 Connection to auxiliary contacts in mains

switch

X6 Test points:

1 = GND digital

2 = + 5 V digital

3 = Voltage, gold cap (battery)

4 = not used

5 = not used

6 = not used

X7 Connection, heating:

1 and 2 = Heating

3 = Protective conductor, heating panel

X8

+

X5

1

1

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 40 of 115

Page 41

Item Component/function

X8 Operating position: jumper 3-2

Horn

C25

Test points

X6

1

+

Position without jumper or jumper 1-2 for

"horn off" for service only (absolutely

prohibited in operation!):

Horn

C25

Test points

X6

1

+

X8

1

+

X5

+

X5

X8

1

1

1

T1 Connection to housing (protective conductor)

F1 Fuse T 800 mA DIN 41662 18 15 075

F2 Fuse T 6.3 A DIN 41662 18 15 172

K1 Relay 5V / 8A 18 30 732

V2 Triac 600V / 8A 18 13 951

V11 Voltage regulator 5V 18 09 245

C25 Gold cap 3.3F 18 36 986

Horn Buzzer 18 24 880

Important: There are no components on the power PCB which have to be

replaced at service intervals.

4.4.3 Testing power PCB

4.4.3.1 Supply voltages

Preparation for testing:

1 = In

2 = GNDD

3 = Out

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 41 of 115

Page 42

- Interrupt mains connection to Babytherm

- Remove electronics assembly or pull it out of Babytherm

- Remove cover from electronics assembly

- Heating and sensors do not have to be connected

- Establish mains connection

Caution:

Parts under current (e. g. mains switch) may

be touched by coincidance, therefore use

insulation transformer.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 42 of 115

Page 43

Test set-up and measurement points:

V2 V11

PCB Power

R22

Transformer

24 V AC

Fuses

F2 F1

EPROM

1

Test points

R0

9 V AC

Fuses

F2

PCB Controller

4 Service-LEDs

PCB Display

F1 = Fuse for 24 V AC - Voltage

F2 = Fuse for 5 V - Voltages

F1

Test points

1

PCB Power

GND digital

+ 5 V digital

Batt.-Volt.

Testing:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 43 of 115

Page 44

- Switch on unit

What How Test value Possible faults

+ 5 V digital Measure with

multimeter between

test points 2 and 1

(GNDD)

Battery

voltage

Battery

voltage

Measure with

multimeter between

test points 3 and 1

(GNDD) with mains

connection

Measure with

multimeter between

test points 3 and 1

(GNDD) without mains

connection, however

with device switched on

+ 5.0 ± 0.2 VDC

≥ 3.5 VDC

≥ 3.5 VDC

- Mains fuses defective

- Fuse F2 defective

- Voltage regulator defective

- 9 VAC from transformer

defective

- Gold cap C25 defective

- Gold cap C25 not charged

(charging time approx. 15

min), because + 5V

defective

- Charging circuit for gold cap

C25 defective

- Gold cap C25 defective, if

previous test with voltage

supply OK

4.4.3.2 Testing heating actuation, safety relay and heating feedback

Preparation for testing:

- Interrupt mains connection to Babytherm.

- Remove electronics assembly and heating panel with sensors from

Babytherm.

- Remove cover from electronics assembly.

- Interrupt ribbon cable connection between power PCB and controller PCB;

this involves disconnecting power PCB.

- Connect up Uni test board, complete 79 00 610 with 40-pin ribbon cable to

power PCB.

- Connect up heating on power PCB.

- Establish mains connection:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 44 of 115

Page 45

Test set-up and measurement points:

V2

V11

13

2

Connection

heating

PCB Power

R22

Relay

Horn

F2 F1

EPROM

Test points

2

LP Controller

4 Service-LEDs

IN

3

PCB Display

20

13

Dräger Testboard Uni 79 00 620

OUT

free

40

36

1

5 VD

Heating on

GNDD

Relay on

Feedback heating

39

V

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 45 of 115

Page 46

Testing:

- Connect up multimeter on test board between TP 20 (heating feedback) and

TP 1 (GNDD).

- Switch on unit.

⇒ Horn on (no significance)

⇒ Test voltage V < 1 V (low level = heating off)

- Create short circuit on test board between TP 3 (+ 5 VD) and TP 13 (heating

on).

- Additionally create short circuit on test board between TP 3 (+ 5 VD) and TP

36 (relay on).

⇒ Test voltage V > 4 V (high level = heating on)

- Remove one short circuit in each case.

⇒ Test voltage always V < 1 V (low level)

4.4.3.3 Testing horn, acoustic mains failure alarm and mains-switch auxiliary contacts

Preparation for testing (as for 4.4.3.2, however heating and sensors do not have to

be connected):

- Interrupt mains connection to Babytherm.

- Remove electronics assembly from Babytherm.

- Remove cover from electronics assembly.

- Interrupt ribbon cable connection between power PCB and controller PCB;

this involves disconnecting power PCB.

- Connect up Uni test board complete 79 00 610 with 40-pin ribbon cable to

power PCB.

- Establish mains connection.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 46 of 115

Page 47

Test set-up and measurement points:

V2 V11

13

2

Connection

heating

PCBPower

R22

Relay

Fuses

Test points

1

Horn

Tastatur

V

EPROM

PCB Controller

4 Service-LEDs

IN

2

1

PCB Display

Dräger Testboard Uni 79 00 620

27

Switch

OUT

free

40

38

37

39

R

R

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 47 of 115

Page 48

Testing:

- Testing mains-switch auxiliary contacts (changeover switch):

Switch

position

Off

On R = 0 Ohms

Resistance

measurement on test

board between TP 1

(GNDD) and TP 37

R = ∞

Resistance

measurement on test

board between TP 1

(GNDD) and TP 38

R = 0 Ohms

R = ∞

- Testing mains-switch auxiliary contacts (on/off switch):

Switch

position

Voltage measurement

between TP 27 on test

Possible faults

board and TP 3 on

power PCB (X6)

Off

V > 3.5 VDC

- Switch defective

- Gold cap C25 defective

- Gold cap C25 not

charged because

+ 5V defective

- Charging circuit for

gold cap C25 defective

On

V ≈ 0 V

- Switch defective

- Testing horn and mains failure recognition:

Prerequisite: Mains-switch auxiliary contacts OK

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 48 of 115

Page 49

Test set-up and measurement points:

V2 V11

13

2

Connection

heating

PCB Power

R22

Relay

Fuses

Test points

1

Horn

EPROM

PCB Controller

4 Service-LEDs

IN

2

3

1

Switch

PCB Display

Dräger Testboard Uni 79 00 620

OUT

free

40

30

35

39

Horn on

Horn off

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 49 of 115

Page 50

- Switch on unit

⇒ Horn on

- Create short circuit on test board between TP 3 (+ 5 VD) and TP 30 (horn

off).

⇒ Horn off

- Interrupt mains connection but do not switch off unit.

⇒ Horn on (delay time due to monoflop)

- Reestablish mains connection

⇒ Horn off

- Additionally create short circuit on test board between TP 3 (+ 5 VD) and TP

35 (horn on ).

⇒ Horn on

4.4.3.4 Testing visual mains failure alarm

Prerequisite: mains-switch auxiliary contacts OK.

- Assemble unit ready for operation

- Create mains connection

- Switch on unit

- Interrupt mains connection

⇒ Visual and acoustic mains failure alarm

4.4.4 Replacement in repair situation

The following spare parts are available for repairs:

- Power PCB, complete (see TSB # 4 or IDM # 5) 82 90 771

o Relay 5V / 8A 18 37 001

o Fuse T 800 mA 18 15 075

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 50 of 115

Page 51

o Fuse T 6.3 A 18 15 172

4.4.5 Testing after replacement

The following checks are to be carried out after performing repairs on the power

PCB or after replacing the power PCB:

- Visual checks:

o Jumper fitted on X8 position 2-3 (see 4.4.2 Layout).

o Correct connection of all cables for power PCB (see 4.1.3 Wiring

diagram).

o Heat sink attached to housing by way of screw connection.

- Electrical safety check

- Functional check (Test duration at least 20 minutes)

o Function of heating

o Mains failure alarm

o Data storage with mains failure alarm

o Function of keys

o Function of display elements

o No error messages

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 51 of 115

Page 52

4.5 Display PCB

4.5.1 General information

Important: Components can be effected by static electricity!

The display PCB contains the 7-segment displays and their actuation systems.

The display PCB likewise actuates the LEDs "40°C", "±1°C", ">37°C/<35°C" and

"horn off" on the keypad in addition to reading in all keys.

4.5.2 Display PCB

Layout:

X1

1

PCB Display

1

Components:

Item Component/function

X1 Connection to controller PCB

X2 Connection to keypad

D1 Keypad and display driver 18 20 877

4.5.3 Testing display PCB

4.5.3.1 Testing read-in of keys

Following successful switch-on test, every actuation of a key is displayed by the

service LEDs on the controller PCB. Important: a jumper on the controller PCB

X12 at position 1-2 (call-up of DS mode without keys) is classed as a key being

pressed (refer also to 4.3.3).

D1

X2

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 52 of 115

Page 53

F2 F1

Keyboard

EPROM

PCB Controller

4 Service-LEDs

PCB Display

4 Service-LEDs on Controller PCB

during switch-on test after swich-on test

EPROM defective

RAM defective

PCB Display INOP

Processor ok

V1 V2 V3 V4

no key pressed = V1 to V3 off

1 key pressed = 1 LED flashes

2 keys pressed = 2 LEDs flash

3 keys pressed = 3 LEDs flash

Processor ok

Refer also to testing of keypad under 4.8.3.2.

4.5.3.2 Testing displays and LEDs in situ

Prerequisite: "Check" key OK (see 4.5.3.1).

Press "Check" key during operation:

⇒ All LEDs (and horn) are actuated for one second; "88.8" appears on the

7-segment displays.

Possible faults:

Display Possible faults

LEDs "40°C", "±1°C", ">37°C/<35°C"

and "horn off" defective (off or flash);

7-segment displays not OK

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 53 of 115

- Display PCB defective

Page 54

LED "40°C", "±1°C", ">37°C/<35°C"

and "horn off" off; 7-segment displays

OK

One - three of the LEDs "40°C", "±

1°C",

">37°C/<35°C", or "horn off" off;

7-segment displays OK

Refer also to testing of keypad LEDs "40°C", "±1°C", ">37°C/<35°C" under 4.8.3.3.

4.5.4 Replacement in repair situation

The following spare parts are available for repairs:

- Display PCB 82 90 611

- Keypad and display driver 18 20 877

4.5.5 Testing after replacement

- Display PCB defective (actuation of

LEDs)

- Keypad defective (cable break in

joint GND of these LEDs)

- Keypad defective (LED or cable

break)

The following tests are to be performed after replacing the keypad:

- Visual checks:

o Display PCB correctly installed

- Electrical safety check

- Functional check:

Test duration at least 20 minutes

o Function of keys

o Function of displays

o Mains failure alarm

o Data storage with mains failure alarm

o No error messages

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 54 of 115

Page 55

4.6 Mains switch

4.6.1 General information

The mains switch consists of four switches:

- 2 on/off switches for mains voltage

- 1 on/off switch for horn actuation in the event of mains failure

- 1 changeover switch for mains failure recognition

4.6.2 Mains switch

For connection of mains switch refer to 4.1.3 Wiring diagram.

4.6.3 Testing of mains switch

4.6.3.1 Testing of mains contacts

Testing is performed by measuring the mains voltage upstream and downstream

of the mains contacts (see 4.1.3 Wiring diagram).

4.6.3.2 Testing of auxiliary contacts

Refer to 4.4.3.3 Power PCB; Testing mains-switch auxiliary contacts

4.6.4 Replacement in repair situation

The following spare parts are available for repairs:

- Wiring harness, mains 220/240V 82 01 795

o Mains switch 83 01 781

o Knob for mains switch 83 02 369

4.6.5 Testing after replacement

The following tests are to be performed after replacing the keypad:

- Visual checks

o Mains switch correctly installed (see also 4.1.3 Wiring diagram)

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 55 of 115

Page 56

- Electrical safety check

- Functional check:

Test duration at least 20 minutes.

o Function of keys

o Function of displays

o Mains failure alarm

o Data storage with mains failure alarm

o No error messages

4.7 Transformer

4.7.1 General information

The transformer uses the mains voltage to generate the AC voltages required for

operation (9 V for electronics and 24 V for resting-surface heating). The

transformer is provided with a thermal release.

4.7.2 Technical data of transformer

- Input, primary:

o 2 x 100 V

o 2 x 120 V

- Output, secondary:

o 24 V / 6.7 A with centre tap 9 V

- Frequency:

o 50 / 60 Hz

Ambient temperature:

o max. 45 °C

Limit temperature:

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 56 of 115

Page 57

o 165 °C under overload condition

Thermo-switch:

o Efen 4257A

4.7.3 Testing of transformer

For testing of output voltages refer to 4.4.3.1 Power PCB, testing of supply

voltages.

Caution:

If the thermal release on the transformer has tripped, a check

is to be made as to whether the heating actuation on the

power PCB only switches through whole sinusoidal waves.

This means that if a sinusoidal wave is commenced with

positive voltage pass, it must be ended with the negative

voltage pass!

Testing is performed by taking measurements with an

oscilloscope instead of a multimeter as described under

4.4.3.2 "Testing triac and triac actuation"; the triac is only to

be actuated for an extremely brief period of time.

The transformer cannot be repaired.

4.7.4 Replacement in repair situation

The following spare part is available for repairs:

- Transformer 82 01 796

4.7.5 Testing after replacement

The following tests are to be performed after replacing the

keypad:

- Visual checks

o Transformer correctly installed (see also 4.1.3 Wiring diagram)

- Test output voltages of transformer

- Electrical safety check

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 57 of 115

Page 58

- Functional check(Test duration at least 20 minutes)

o Function of keys

o Function of displays

o Mains failure alarm

o Data storage with mains failure alarm

• No error messages

4.8 Keypad

4.8.1 General information

The keypad contains:

- 5 touch-sensitive keys

-6 LEDs

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 58 of 115

Page 59

4.8.2 Keypad 2M 20 885

Layout:

L5

S1 S2 S3 S4 S5

S1

1

S2

2

S3

3

S4

4

S5

5

125

L1

L2

L3

L4

L6

11

12

L3

14

15

16

L1

L2

9

17

18

L5

L6

L4

22

23

Components and function:

ComponentFunction

S1

Touch-sensitive key ">37°C/<35°C" read in by display

PCB

S2 Touch-sensitive key "negative setpoint" read in by

display PCB

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 59 of 115

Page 60

S3 Touch-sensitive key "positive setpoint" read in by display

PCB

S4 Touch-sensitive key "horn off" read in by display PCB

S5 Touch-sensitive key "check" read in by display PCB

Component Function

L1 LED "40°C", red, actuated by display PCB

L2

LED "±1°C", red, actuated by display PCB

L3 LED "Inop.", red, actuated by controller PCB

L4 LED "power failure", red, actuated by power PCB

L5

LED ">37°C/<35°C", yellow, actuated by display PCB

L6 LED "horn off", yellow, actuated by display PCB

The keypad cannot be repaired.

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 60 of 115

Page 61

4.8.3 Testing of keypad

4.8.3.1 Testing of keys in situ

Following successful switch-on test, every pressing of a key is indicated by the

service LEDs on the controller PCB. Important: a jumper on the controller PCB

X12 in position 1-2 (call-up of DS mode without keys) is classed as pressing of a

key (see also 4.3.3).

F2 F1

Keyboard

EPROM

PCB Controller

4 Service-LEDs

PCB Display

4 Service-LEDs on Controller PCB

during switch-on test after swich-on test

EPROM defective

RAM defective

PCB Display INOP

Processor ok

V1 V2 V3 V4

no key pressed = V1 to V3 off

1 key pressed = 1 LED flashes

2 keys pressed = 2 LEDs flash

3 keys pressed = 3 LEDs flash

Processor ok

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 61 of 115

Page 62

4.8.3.2 Testing keys with keypad removed

The keys can be ohmically checked at the keypad connector (see layout under

4.8.2).

Switch condition, key Resistance

Key not pressed

Key pressed

R = ∞

R ≤ 100 ohms

4.8.3.3 Testing LEDs in situ

Prerequisite: Key "check" and display PCB OK, see 4.8.3.1.

Press "check" key during operation:

⇒ All LEDs and (horn) are actuated for 1 second; "88.8" appears on the

7-segment displays.

Possible faults:

Display Possible faults

LEDs "40°C", "±1°C", ">37°C/<35°C"

and "horn off " defective (off or flash),

7-segment displays not OK

LED "40°C", "±1°C", ">37°C/<35°C"

and "horn off" off, 7-segment displays

OK

One - three of LEDs "40°C", "±1°C",

">37°C/<35°C" or "horn off" off, 7segment displays OK

LED "horn off" off, horn on - Keypad defective (LED defective

LED "horn off" and horn off - Power PCB defective

LED "Inop." off - Keypad defective (LED defective

- Display PCB defective

- Display PCB defective (actuation of

LEDs)

- Keypad defective (cable break in

joint GND of these LEDs )

- Keypad defective (LED(s) defective

or cable break)

or cable break)

- Actuation transistor on power PCB

defective

or cable break)

- Controller PCB defective (actuation)

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 62 of 115

Page 63

4.8.3.3 Testing LEDs with keypad removed

- Electronics assembly is ready for operation, however cable connection

between display PCB and keypad detached.

- Testing is performed by supplying current from test points 2 "+ 5 V digital"

and 1 "GNDD" on power PCB to contacts of LEDs at keypad connector (see

4.8.2 Layout). Caution: Only current from these test points is permitted since

the test point is safeguarded by a 14 Kohm resistor.

F2

Fus es

F1

Test points

24 V AC

EPR OM

R0

F2

1

GND digital

+ 5 V digital

4 Serv ice-LEDs

9 V AC

Fus es

F1

Test points

1

PCB Controller

PCB Displ ay

F1 = Fuse for 24 V AC - Voltage

F2 = Fuse for 5 V - Voltages

PCB Power

Batt.-Volt.

- Each LED is to be checked individually. The LEDs only light very dimly on

account of the low current; the room may have to be darkened. "+" is fed in

in each case at the anodes of the LEDs (pins 14, 15, 16, 17, 18 or 22).

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 63 of 115

Page 64

4.8.4 Replacement in repair situation

The following spare part is available for repairs:

- Keypad 2M 20 885

4.8.5 Testing after replacement

The following tests are to be performed after replacing the keypad:

- Visual checks

o Keypad and connecting cable correctly installed

- Electrical safety check

- Functional check:

Test duration at least 20 minutes.

o Function of keys

o Function of display elements

o Mains failure alarm

o Data storage with mains failure alarm

o No error messages

4.9 Mains input

4.9.1 General information

The mains-input assembly features the following functions:

- Power cord connector

- Accommodation of both mains fuses

- Mains filter

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 64 of 115

Page 65

4.9.2 Replacement in repair situation

The following spare parts are available for repairs:

- Mains filter (mains input) 18 18 384

o 220/240V units:

2 x fuse DIN 41662, T800mA 18 15 075

o 100/127V units:

2 x fuse DIN 41662, T1.6A 18 15 105

- Euro power cord 2M 21 220

4.9.3 Testing after replacement

The following tests are to be performed after replacing the mains input:

- Visual checks

o Connecting cable correctly installed

- Electrical safety check:

- Functional check (Test duration at least 20 minutes)

o Function of keys

o Function of display elements

o Mains failure alarm

o Data storage with mains failure alarm

o No error messages

6132.200 Babytherm 8000 Repair Instructions 04.01 Page 65 of 115

Page 66

4.10 Heating and sensor adapters

4.10.1 General

The heating and sensor adapters are the two cable connections between the

PCBs and the cover of the mattress heating control.

The adapters differ depending on class type B or BF.

4.10.2 Differences between class type B and BF

Type B Type BF

Wiring harness

Heating adapter 2M 21 096

3-pin adapter cable without ferrite

between heating connection on

housing cover and power PCB.

Wiring harness

Sensor adapter 2M 21 094

Wiring harness with ferrite 18 31 577

between sensor connection on

housing cover and controller PCB.

This cable can also be used in type

BF.

Wiring harness

Heating adapter 2M 21 507

2-pin adapter cable with ferrite

between heating connection on

housing cover (2-pin) and power PCB

(3-pin).

Wiring harness

Sensor adapter 2M 21 508

Wiring harness without ferrite

between sensor connection on

housing cover and controller PCB