Denon DN-T645, DN-T625 Service Manual

For U.S.A., Canada & Europe model

SERVICE MANUAL

MODEL

CD/CASSETTE COMBI-DECK

(This illustration shows the DN-T645 model.)

DN-T645/625

1 Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X-0159 NC 0210

DN-T645/625

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either

side of the power cord is less than 460 kohms, the unit is defective.

2

2

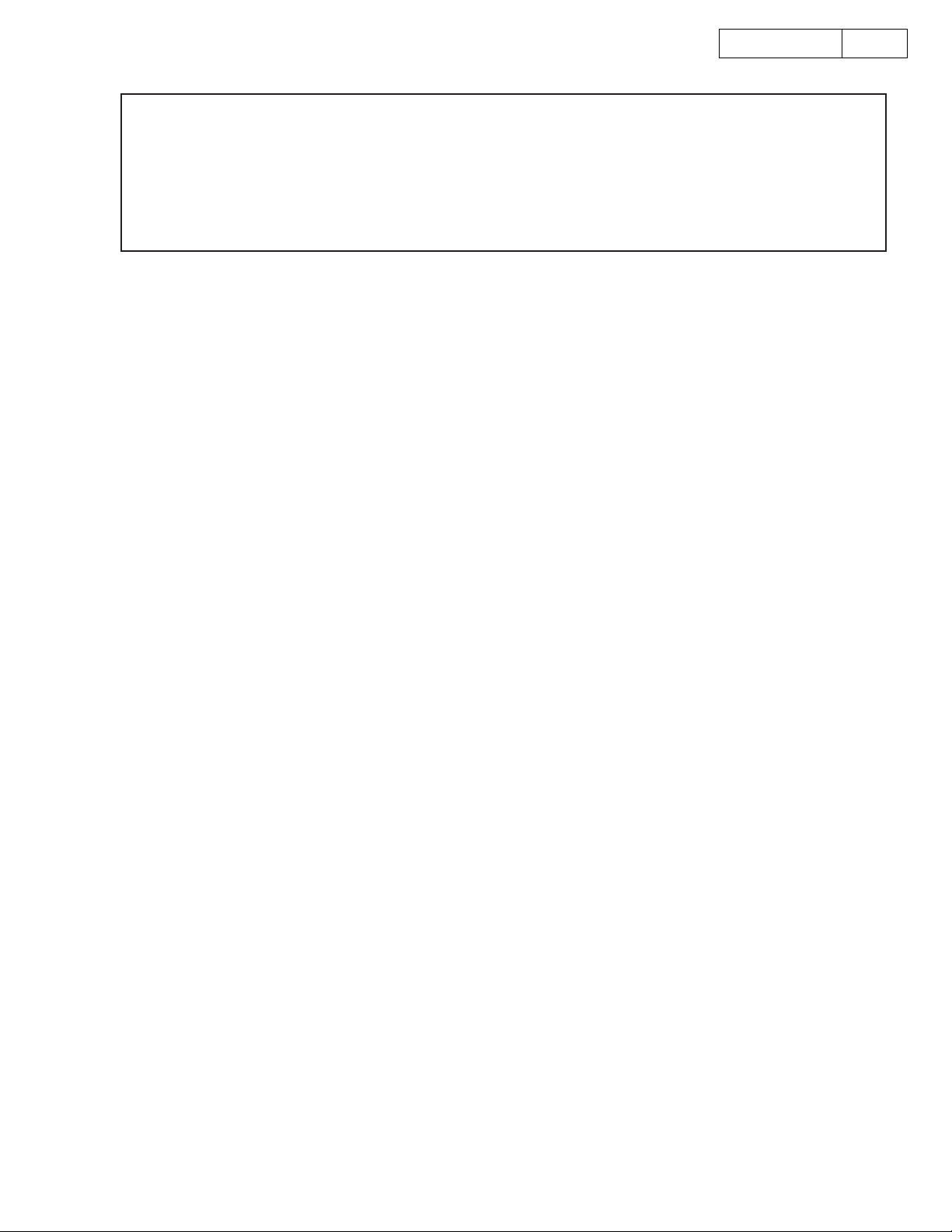

DISASSEMBLY

(To reassemble, reverse disassembly)

1. TOP COVER

(1) Remove 6 screws on both sides, and 3 screws on the rear panel.

(2) Pull the Top Cover as shown by the arrow direction.

DN-T645/625

3

2. FRONT PANEL

(1) Turn the unit power on, and open Tray of the CD Mecha.

(2) Remove the Loader panel, and switch off the power after closing the Tray.

(3) Remove 2 screws at the top, and 3 screws at the bottom.

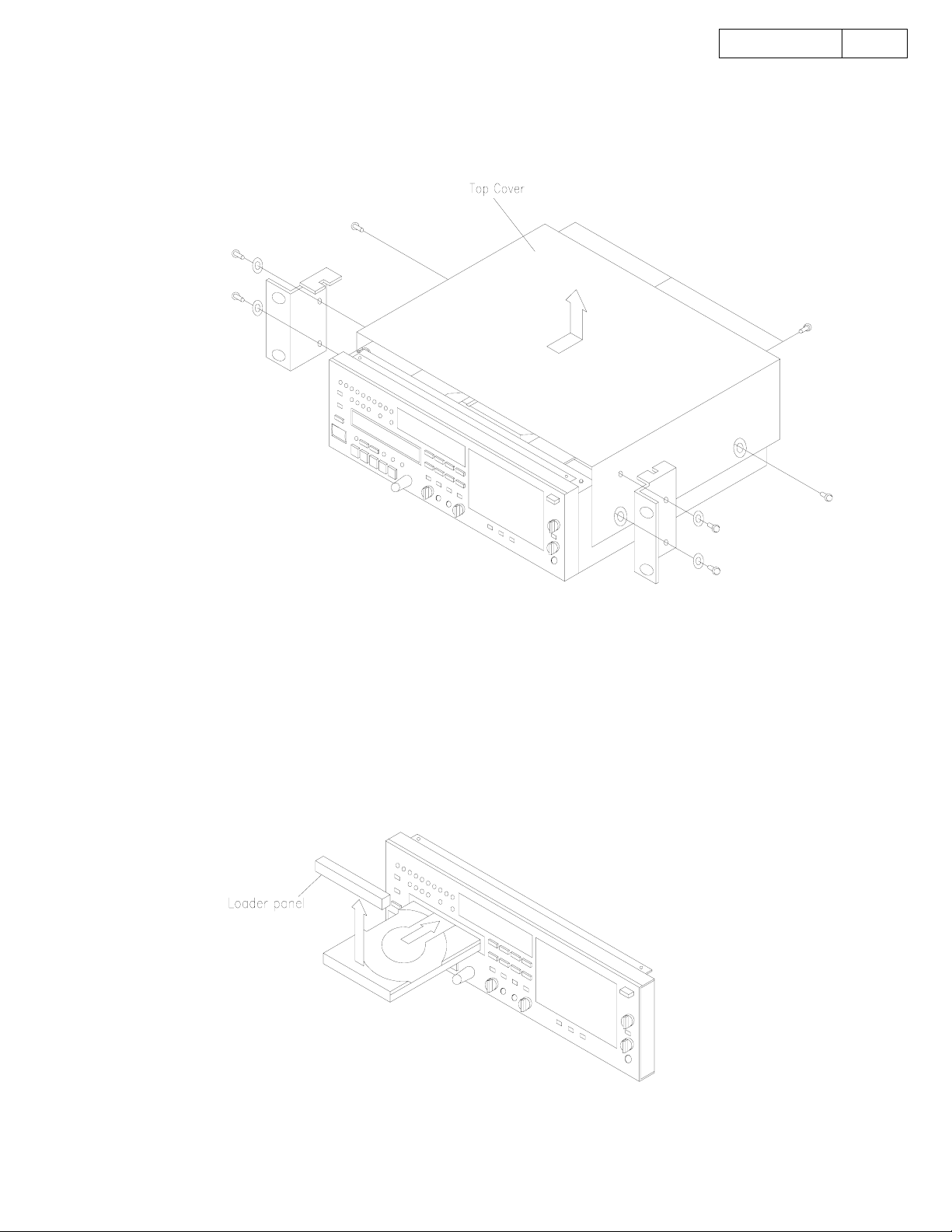

(4) Remove 2 screws to free Earth Wire.

(5) Remove the screw to free FFC.

(6) Cut the Clamp band.

(7) Disconnect 2 wire and 6 connectors from the Front Panel, then detach the Front Panel to the arrow direction about 50mm.

(8) Disconnect 2 connectors and the FFC from the Front Panel, then detach the Front Panel to the arrow direction.

3

DN-T645/625

4

Method of opening the Tray when the power would not be turned on in trouble.

(1) Please be sure to unplug the cord.

(2) Push the lever indicated in the circled figure below with small bar like a pencil or a ball pointed pen, through the square

opening on the left side of the main chassis.

(3) Push the Tray out to the direction indicated in the figure below.

(4) Detach the Loader Panel by lifting up to the direction indicated bellow.

4

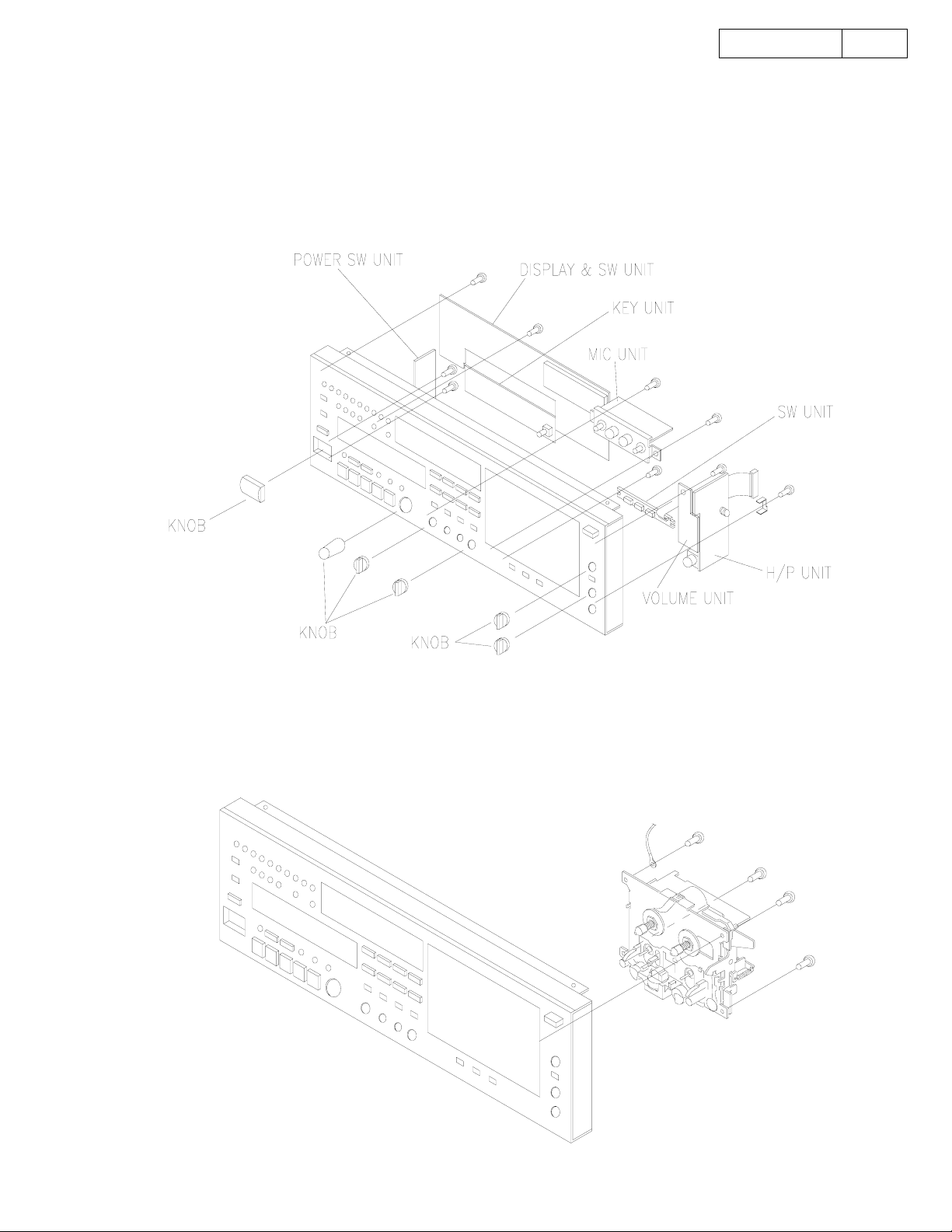

3. DISPLAY & SW UNIT / KEY UNIT / SW UNIT / MIC UNIT /

H/P UNIT / VOLUME UNIT / POWER SW UNIT

(1) Pull out 6 knobs on the front.

(2) Remove 15 screws and 6 screws on the DISPLAY & KEY UNIT.

(3) Remove 2 screw on the MIC UNIT.

(4) Remove the screws on the SW UNIT.

(5) Remove 2 screws on the H/P UNIT & VOLUME UNIT.

(6) remove 2 screws on the POWER SW UNIT.

DN-T645/625

5

4. CASSETTE MECHA

(1) Press Eject button and unlock cassette Door.

(2) Remove 4 screws on the Cassette Mecha.

(3) Detach the Cassette Mecha.

5

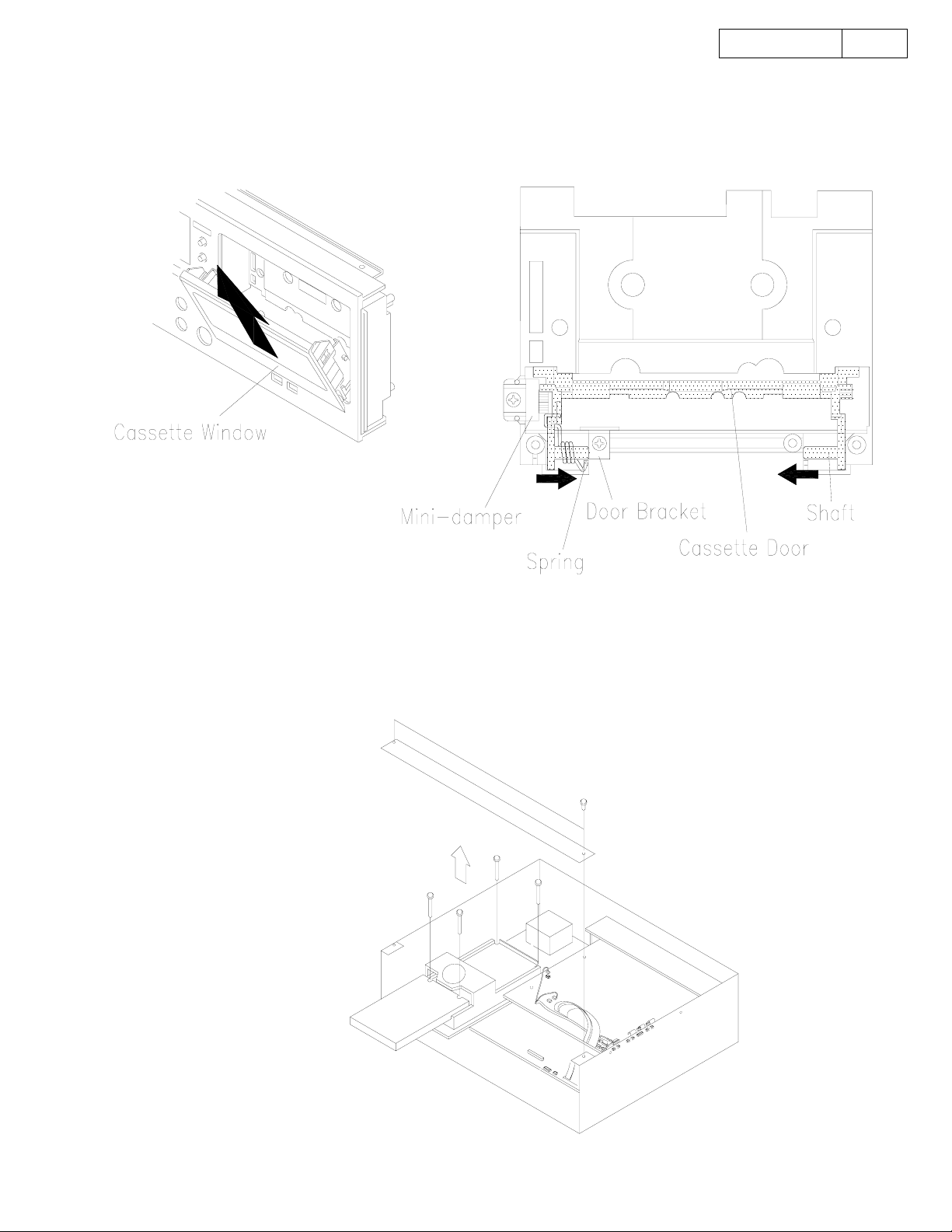

5. CASSETTE DOOR

(1) Take off the Cassette Window on the front.

(2) Remove the screw to detach the Mini-damper.

(3) Remove the screw to detach the Door Bracket.

(4) With pushing the shaft in the arrow directions, no spring side first, detach the Cassette Door.

DN-T645/625

6

6. CD MECHA

(1) Remove 2 screws, then detach the FRONT BRIDGE.

(2) Remove 4 screws.

(3) Pull out the CD Mecha in the arrow direction.

6

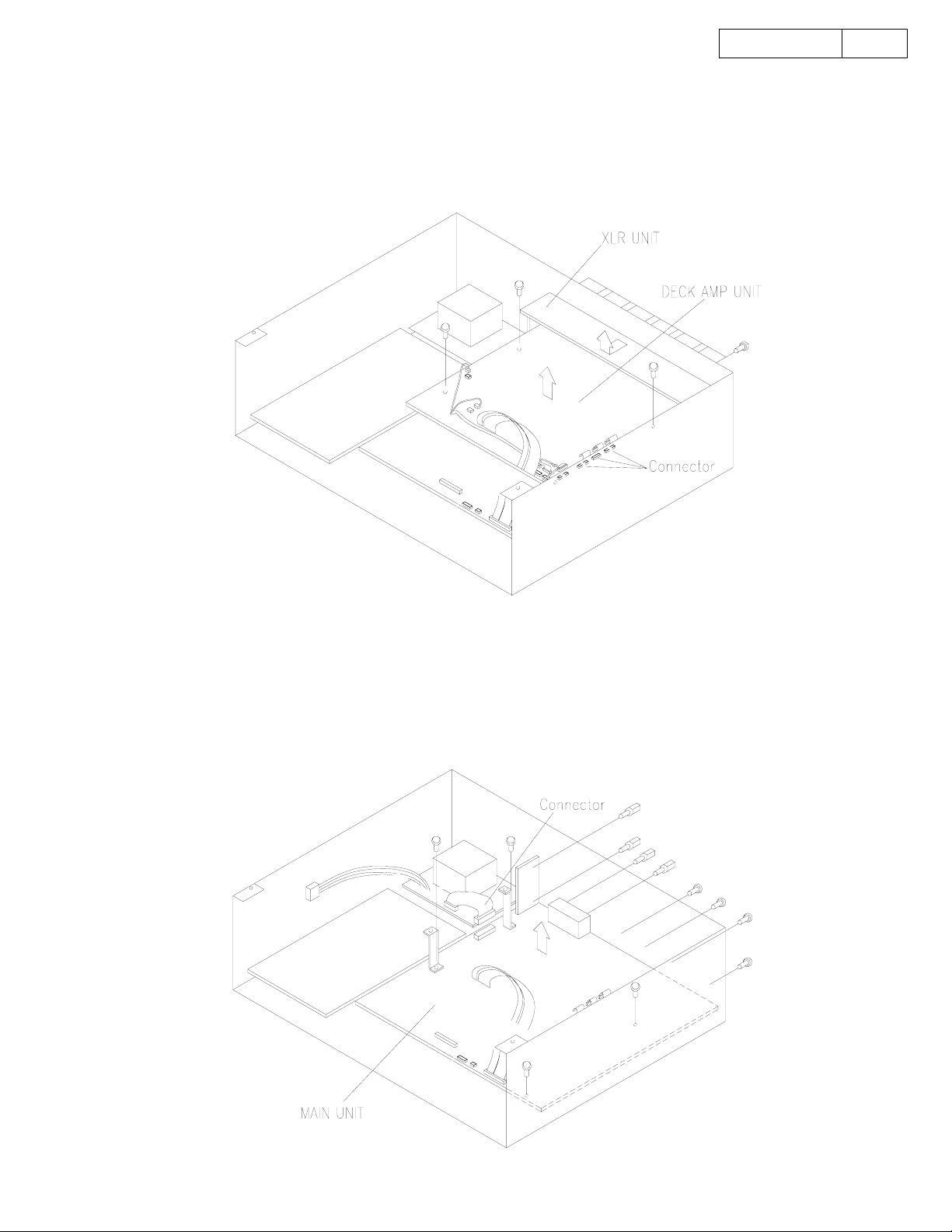

7. XLR UNIT / DECK AMP UNIT

(1) Disconnect the connectors from the DECK AMP UNIT.

(2) Disconnect the FFC and 2 connectors from the MAIN UNIT.

(3) Remove 12 screw, then detach the XLR UNIT to the arrow direction.

(4) Remove 3 screws, then detach the DECK AMP UNIT to the arrow direction.

DN-T645/625

7

8. MAIN UNIT / 25P DSUB UNIT

(1) Disconnect the connectors from the TRANS UNIT.

(2) Remove 8 screws.

(3) Remove 4 hexagon screws, then detach the MAIN UNIT and 25P DSUB UNIT to the arrow direction.

7

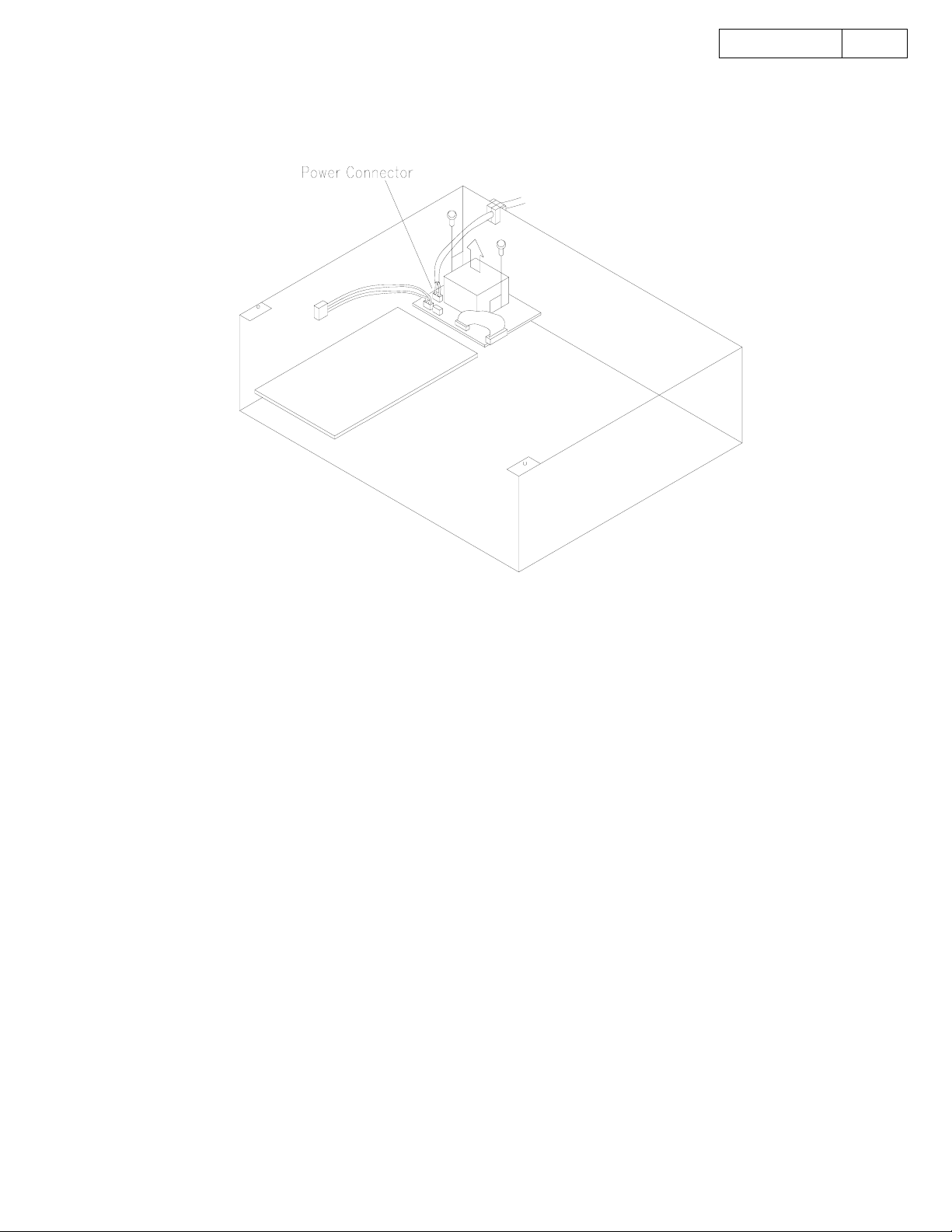

9. TRANS UNIT

(1) Disconnect the power connector.

(2) Remove 4 screws, then detach the TRANS UNIT to the arrow direction.

DN-T645/625

8

8

SERVICE PROGRAM

Required Measuring Implement

z Reference disc (TCD784 or CO-74176)

1. What is Service Program

Service program is a special program intended for confirming servo functions etc.

2. µcom Version Check

z Refer to "Preset Functions and Operations" of the instruction manual.

z You can check the µcom version.

3. Error Data Check

z Switch on the power while pushing the 7 button and 8 button at the same time.

z After actuating the error data check program, press the CD's >> or << button to display the logging error codes

in the occurred order.

XX Err**

Err**: error code (Refer to the "Error Code Table")

z 10 error logs are memorized at maximum. Item 1 is newest data. Item 10 is oldest data. Item 2 is the 9th old data.

z Pressing the 0/CLEAR button enters to data erase mode. ("Err Clear?" is displayed.)

If the 0/CLEAR button is pressed again, the memorized error data are cleared.

z To stop the Error Data check mode, please turn off the POWER switch.

NOTE:

4. Total Running Time

z Switch on the power while pushing the 9 button and 0/CLEAR button at the same time.

Total time span of CD that counted by the hour is displayed.

CD XXXXh

z Press the CD's >> or << button to change the display between CD and DECK.

DEC XXXXh

NOTE:

z Pressing the 0/CLEAR button enters to data erase mode. ("Time Clear?" is displayed.)

If the 0/CLEAR button is pressed again, the memorized time data are cleared.

z To stop the Total Running Time check mode, please turn off the POWER switch.

NOTE:

5. B.E.R. Checks and Automatic Servo Adjustment Call

z Switch on the power while pushing the 5 button and 6 button at the same time.

And Loading a disc by OPEN/CLOSE button.

(1)Block Error Rate

Press the PLAY/PAUSE button. B.E.R. is displayed.

01Tr **m XXXX

You can select the track by the select knob.

(2)Tracking balance and Focus balance data

Press the 2 button. Tracking balance and Focus balance data is displayed.

2 ±XXX±@@@

@@@: Focus balance

(3)Focus gain data

Press the 3 button. Focus gain data is displayed.

3 XXXX

(4)Tracking gain data

Press the 4 button. Tracking gain data is displayed.

4 XXXX

(5)Tracking offset and Focus offset data

Press the 5 button. Tracking offset and Focus offset data is displayed.

5 ±XXX±@@@

@@@: Focus offset

(6)Press the 1 button to select the Block Error Rate data.

(7)To stop the B.E.R. Check and Automatic Servo Adjustment Call mode,

please turn off the POWER switch.

XX: occurred order

When the service is finished, delete the error logs.

Time is counted if powered down first 30 minutes.

When the replacing the associated parts, delete the ranning time.

XXXX: Block Error Rate

XXX: Tracking balance

XXXX: Focus gain

XXXX: Tracking gain

XXX: Tracking offset

9DN-T645/625

No. botton Adjustment Item Adjustment Value indicator

2

3 Focus Gain 0576 ~ 2304

4 Tracking Gain 0392 ~ 1569

5

Tracking Balance -025 ~ +025

Focus Balance -030 ~ +030

Tracking Offset -005 ~ +005

Focus Offset -005 ~ +005

9

6. Test Mode (Heat Run mode)

z Switch on the power while pushing the 3 button and 4 button at the same time.

"

000TroHR0000

(1)Hold the disc by the edges and place it on the disc tray.

(2)Starting with the OPEN/CLOSE button, it repeats open/close of the tray and playback.

***TrxHRXXXX

x : o, c, s, t, r, and p

XXXX: Cycle quantity

All tracks are played back if the track count is less than 20.

Only the first and last tracks are played back if the tracks are more than 21.

When any errors, it stops and indicates error code (Refer to the Error Code Table).

(3)To stop the Test mode, please turn off the POWER switch.

" is displayed. And the tray is opened.

***: Track No.

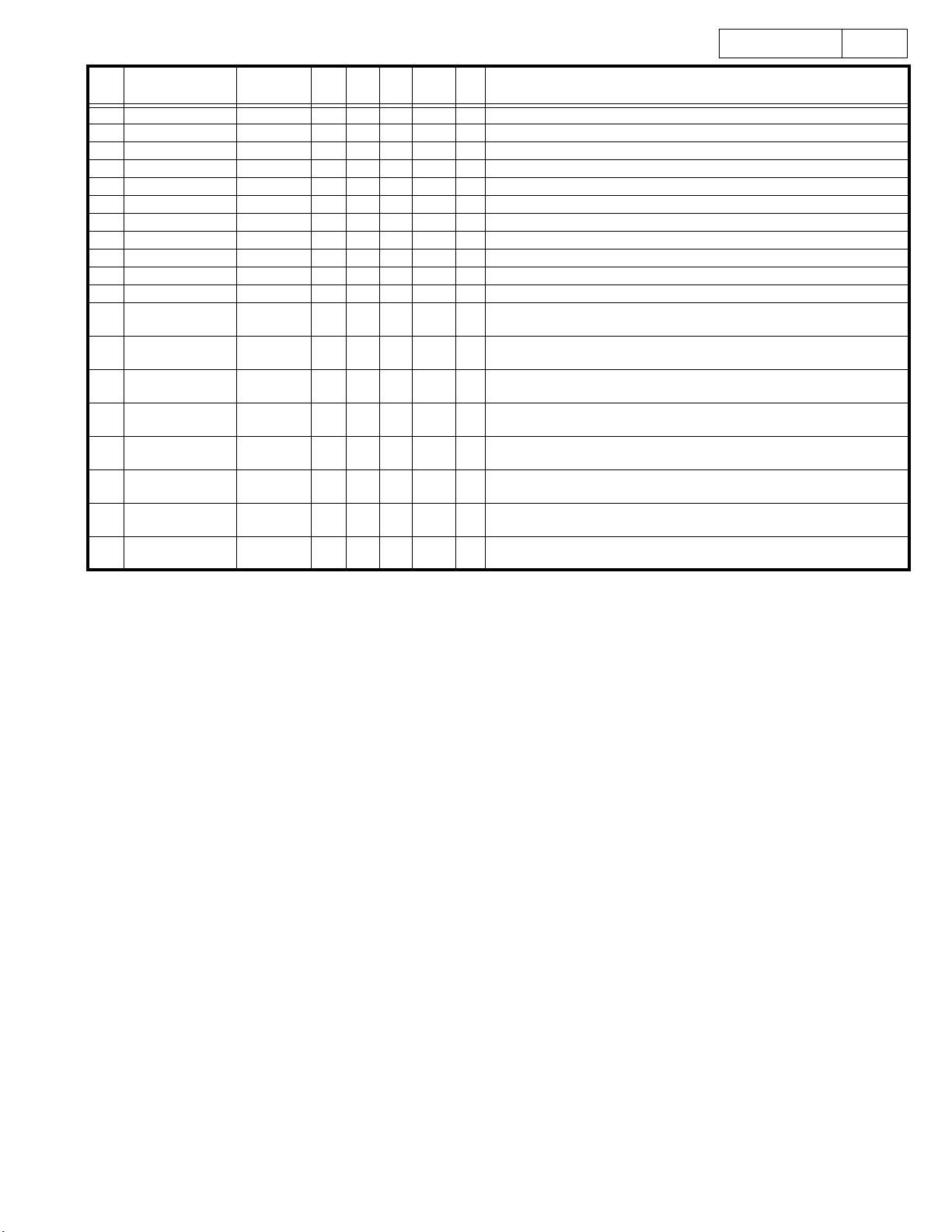

7. Error Code Table

Error Code CONTENTS

Error 01 Unable to close the loader tray in the regulation time.

Error 02 Unable to open the loader tray in the regulation time.

Error 03 Inner circle switch ON error even if the time is over.

Error 04 Inner circle switch OFF error even if the time is over.

Error 05 The focus offset adjustment result is outside the regulation range.

Error 06 Unable to adjust the focus offset in the regulation time.

Error 07 The tracking offset adjustment result is outside the regulation range.

Error 08 Unable to adjust the tracking offset in the regulation time.

Error 09 The FE peak is outside the regulation range.

Error 0A The FE peak is outside the regulation range.

Error 0B Unable to adjust the focus rough gain in the regulation time.

Error 0C The focus rough gain is outside the regulation range.

Error 0D Unable to actuate focus in the regulation time.

Error 0E Unable to actuate tracking in the regulation time.

Error 0F Unable to adjust the tracking rough gain in the regulation time.

Error 10 The tracking rough gain is outside the regulation range.

Error 11 Unable to adjust the tracking balance in the regulation time.

Error 12 The tracking balance adjustment result is outside the regulation range.

Error 13 Focus servo down during automatic adjustment.

Error 14 Focus servo down during automatic adjustment.

Error 15 Unable to adjust the focus balance in the regulation time.

Error 16 The focus balance adjustment result is outside the regulation range.

Error 17 Track servo down during automatic adjustment.

Error 18 Unable to adjust the focus fine gain in the regulation time.

Error 19 The focus fine gain is outside the regulation range.

Error 1A Unable to adjust the tracking fine gain in the regulation time.

Error 1B The tracking fine gain is outside the regulation range.

Error 1C Unable to adjust automatically in the regulation time.

Error 1D Unable to read the subcode Q in the regulation time.

Error 1E Unable to read the TOC in the regulation time.

Error 1F Focus servo down during search (over the regulation time).

Error 20 Track servo down during search (over the regulation time).

Error 2116 Servo error during search.

Error 2103 Search error (over the regulation time).

Error 22 Discontinuity occurred, during write to the DRAM.

Error 23 The error which cannot be corrected to the read data.

Error 24 Unable to do the level detect.

Error 25 Unable to join data in the regulation time.

Error 26 The error rate when recording on the memory is over the regulation value.

Error 27 The subcode jump more than regulation.

10DN-T645/625

10

µCOM VERSION UPGRADE

System µcom can be upgraded in the following manner.

Version Upgrade Method

1.Record the version upgrade software on a CD-R or CD-RW disc,

only as one file with the format ISO9660 Mode-1.

The file name of the supplied version upgrade software should be used as is and this disc needs

to finalize.

2.Hold the disc by the edges and place it on the disc tray.

3.Press the OPEN/CLOSE button to start the version upgrade.

"

Version Up

xxxx : current version

XXXX : upgrade version

4.Press the PLAY/PAUSE button.

"

Now Writing

XXX : count up from 000 to129

5.When the version upgrade is finished, "

6.Turn off the power once and turn on again.

Press the OPEN/CLOSE button and remove the disc.

NOTE:

"→"

Push Play!

" → "

Writing-XXX

When the power is turned off before "

" "

xxxx->XXXX

" are displayed.

Complete!

" are displayed.

" is indicated.

Complete!

" is displayed,

version is not written correctly.

µcom

11DN-T645/625

11

ADJUSTMENT

ADJUSTING AND CHECKING THE

MECHANISM SECTION

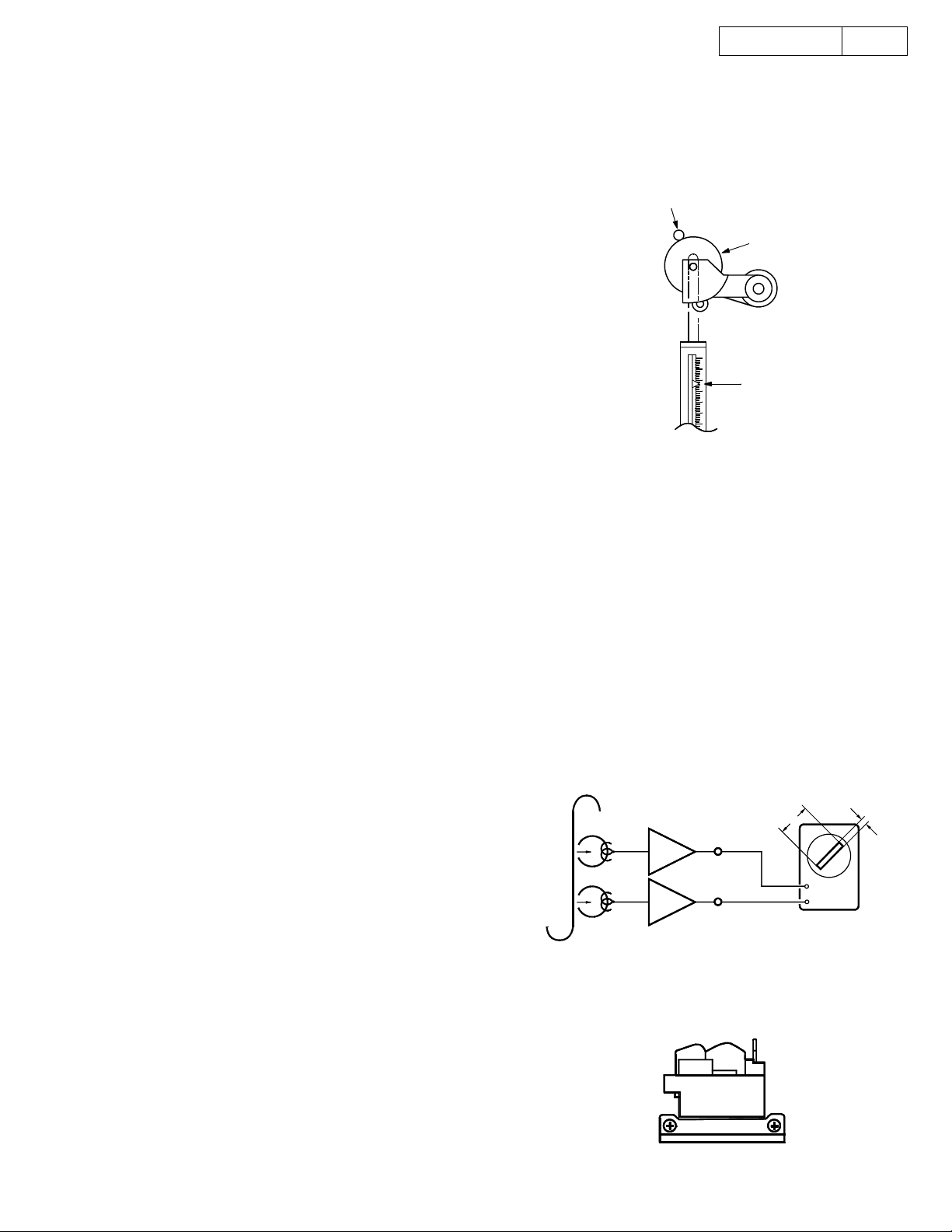

1. Replacing Pinch Roller

Before replacing the pinch roller, clean the tape contact

surface of the pinch roller and the capstan shaft.

Most causes of poor tape transport can be traced to dirty

pinch roller and capstan shaft.

Removing the pinch roller

Remove the clips that press the pinch roller and pull the

pinch roller forward remove it.

After replacing, run a padles C-90 tape to check for tape

curls at the tape guide section of the head.

12DN-T645/625

Capstan shaft

Pinch roller

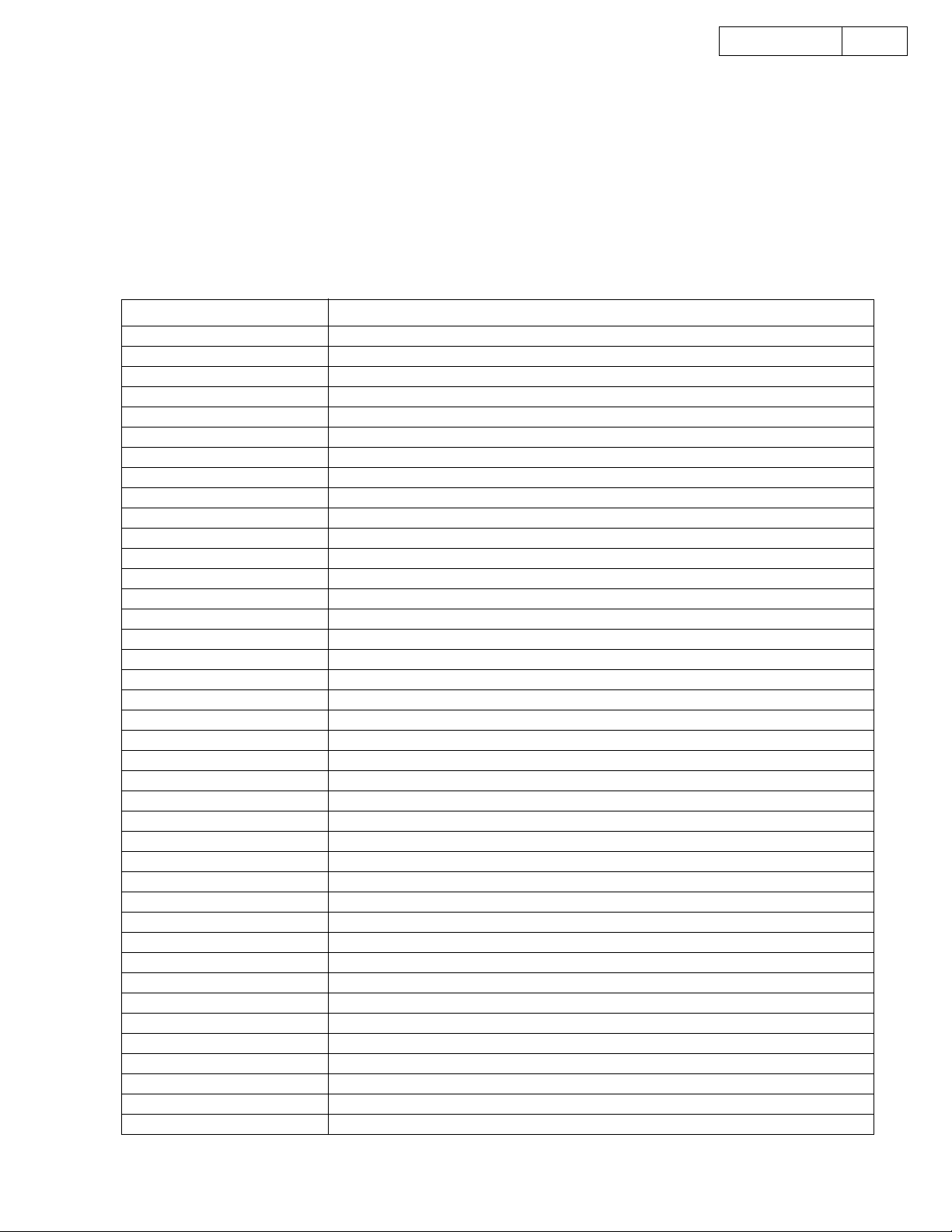

2. Checking the pressure Force of the Pinch

Roller

In the playback mode, hook a spring weight onto the

bracket at the center of the pinch roller. After separating

the pinch roller from the capstan shaft allow the pinch roller

to contact the capstan shaft again. Check to make sure

the spring weight reads between 250 ~ 350g when the

pinch roller starts to rotate.

Replace the pinch roller when it does not conform to the

standard specification values.

3. Replacing the Head Ass'y

(1) Removing the head Ass'y

1. Remove the head base mounting screws.

2. Remove the head base from the lead holder and

the wire connectors.

(2) Head Ass'y Installation

1. Assembly is the reverse of disassembly.

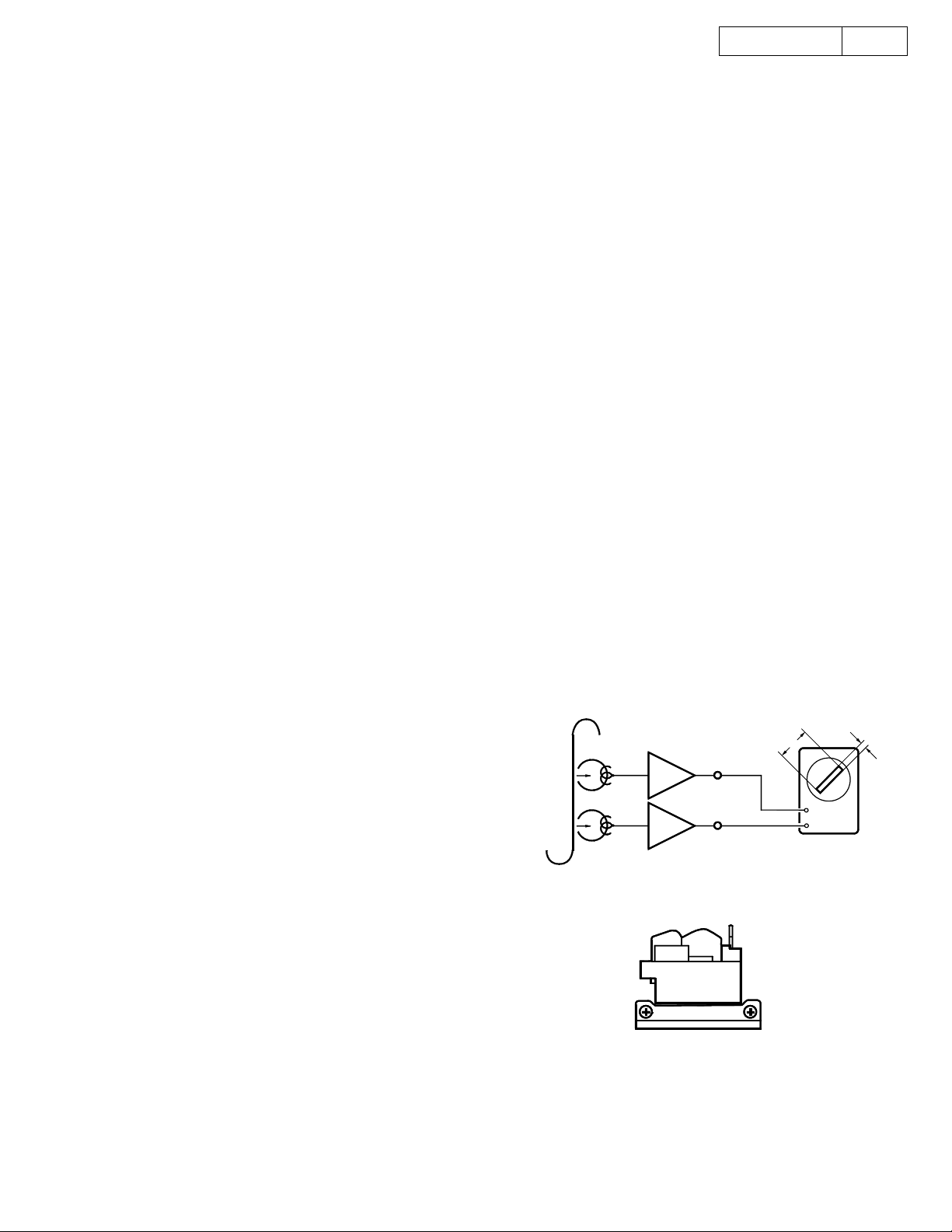

4. Adjusting the R/P HEAD

Azimuth adjustments

Set test tape A-BEX TCC-153 so that the A surface faces

forward, and adjust accordingly.

(1) Playback FWD. Turn the azimuth adjustment nut so

that the Lissajous waveform (A) is at maximum scale

and the Lissajous waveform (B) is at minimum scale.

(2) Playback REV. Turn the azimuth adjustment nut in

the same manner as (1), above.

(3) Make further adjustments to (1) and (2), above.

(4) Apply torsion locks to the adjusted nuts.

Note: Only the azimuth adjustment is necessary; no height

and tilt angle adjustments are required.

A-BEX TCC-153

PB Amp

L

R

LINE OUT

250 ~ 350g

A

B

V

H

12

R/P Head

FWD REV

13DN-T645/625

5. Checking the Take-up Torque

Load the cassette type torque meter

FWD side .........SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure that the average torque meter reading

is within 30 ~ 70g-cm during playback. If it is not within

this range, check the voltage (approx. 4V) of the reel motor.

After the verification, replace the reel motor if there is no

problem with the voltage value.

6. Checking the FF and REW Torques

Load the cassette type torque meter (SONY TW2231).

Check to make sure the torque meter indicates within

90 ~ 180g-cm at the end of FF and REW.

7. Checking the Back Tension Torque During

Record/Playback

Load the cassette type torque meter

FWD side .........SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure the torque meter reads between

2 ~ 6g-cm during playback and that there is no unevenness.

8. Checking the FF and REW Times

Load a C-60 cassette tape (TDK AC-514); check to make

sure the tape is fast forwarded or rewound within 85 ~

115 seconds. If it is not within this range, check sections 5

and 7.

9. Checking the Operation of the Erase

Prevention, Metal and Chrome Switch

Confirm that the sensor arm properly detecting the tape

type detection holes on the cassette housing.

Caution on adjusting

(1) Before adjusting, clean the head surface, capstan and

the pinch roller with a gauze or cotton swab moistened

with alcohol.

(2) Demagnetize the R/P HEAD and the E HEAD with a

head eraser.

(3) Completely demagnetize the adjustment screwdriver.

(4) Unless instructed otherwise, set the various controls

as follows:

INPUT volume ....................... maximum

DOLBY NR button ................. OFF

TAPE SPEED ....................... Center click position

PHONES SELECT ................ TAPE/MIX

INPUT SELECT .................... LINE

1. Tape Transport Check

Load the transport check cassette. In the operational mode,

illuminate the fixing guides of the R/P HEAD with a lamp

and check to make sure the tape edge does not come in

contact with the tape guide section.

The tape transport is the most important element in

determining the performance of a cassette deck.

Avoid moving the various adjustment screws, nuts, etc.,

as much as possible. Refer to the pages on "Adjusting

and Cheking the Mechanism Section" when replacing or

adjusting the R/P HEAD.

2. Adjusting the Azimuth

(1) After completing the tape transport check, load the

test tape (A-BEX TCC-153).

(2) Playback (both FWD side and REV side) the test tape;

adjust the azimuth screw so that section A of the

Lissajous waveform is maximum and section B is

minimum.

ADJUSTING THE ELECTRICAL SECTIONS

Measuring instruments necessary for

adjustments

(1) Audio signal generator

(2) Variable resistance attenuator

(3) Electronic voltmeter

(4) Oscilloscope

(5) Frequency counter

(6) Adjustment screwdriver.

(7) Trap coil adjustment square stick

(8) Test tapes (SONY TY-224)

(A-BEX TCC-130, TCC-153, TCC-262B/162B)

(TDK AC-514)

(9) Transport Check cassette tape (A-BEX TCC-902)

A-BEX TCC-153

FWD REV

PB Amp

L

R

LINE OUT

R/P Head

A

V

H

B

13

3. Checking and Adjusting the Tape Speed

(1) Connect the frequency counter to the LINE OUT

terminal and load test tape (SONY TY-224).

(2) Load cassette tapes and playback test tape.

(3) At about halfway through the tape, where the tape

transport is stable, adjust the VR-502.

14DN-T645/625

F. Counter

PB Amp

LINE OUT

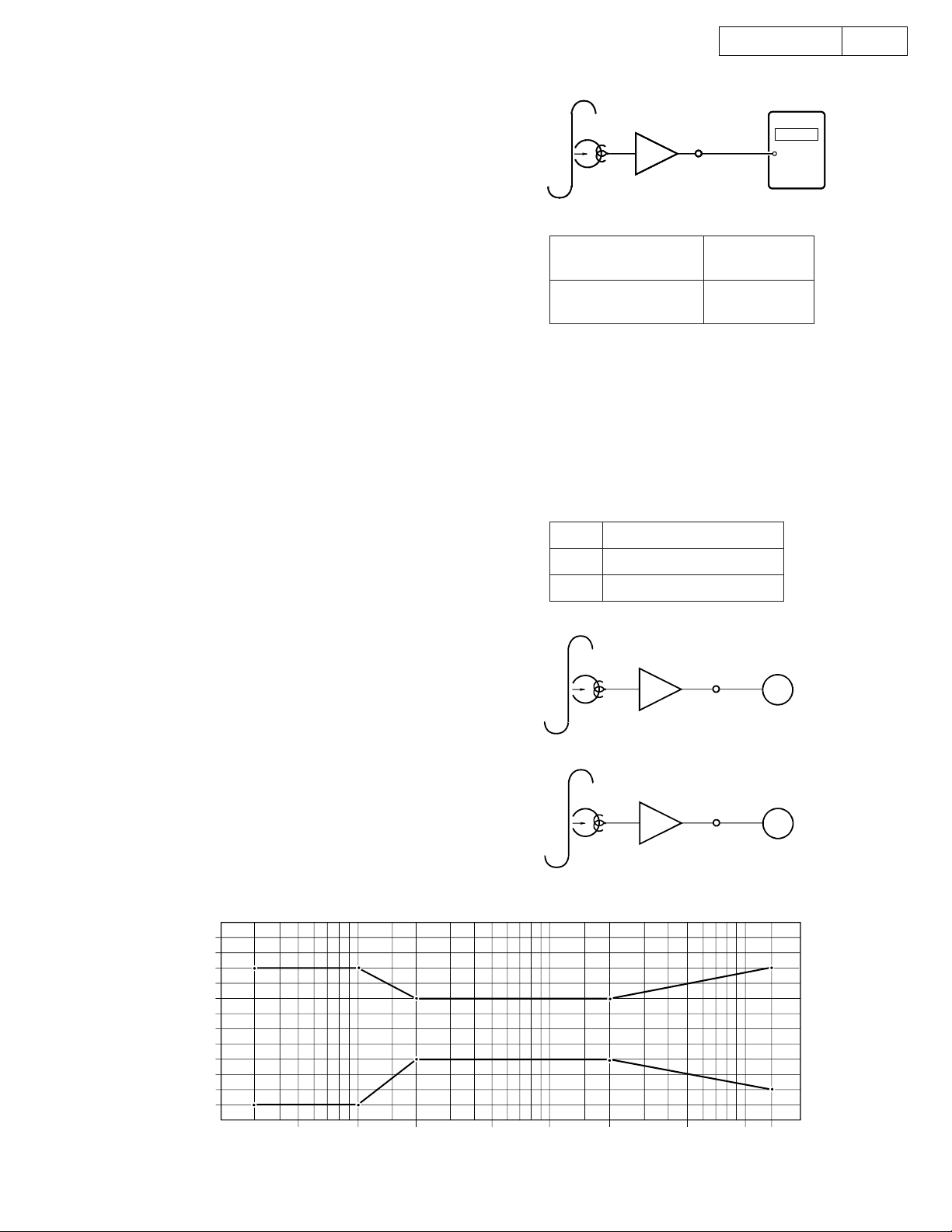

4. Playback System Adjustment

(1) Playback level

Playback a test tape for Dolby standard level (A-BEX

TCC-130). Adjust (Lch) and (Rch) so that the LINE

OUT terminal level is at 0 dB (775 mV).

(2) Verifying playback frequency characteristics

Playback the test tape (A-BEX TCC-262B/162B) and

verify that the frequency characteristics conform to

the specified standard.

Note: Before checking the playback frequency response,

first adjust the azimuth using the 8 kHz signal at the

beginning of the test tape (A-BEX TCC-262B). Also,

after checking the playback frequency, make sure

to readjust the azimuth with the test tape (A-BEX

TCC-153) and then lock the adjustment screw.

SONY TY-224

Adjusting volume

number

VR-502

Playback Level

L/R

Adjusting volume number

L

R

A-BEX TCC-130

F. counter

(Hz)

3005±5

VR-301

VR-302

PB Amp

LINE OUT

V.V

(db)

PB Amp

LINE OUT

A-BEX TCC-262B/162B

V.V

Playback frequency characteristics

+6

+

5

4

+

+3

+2

1

+

0

1

−

−2

3

−

−4

−5

6

−

20

10050

200

500

1 k

2 k

5 k

10 k 12 k

20 k (Hz)

Tape: A-BEX TCC-262B/162B

14

15DN-T645/625

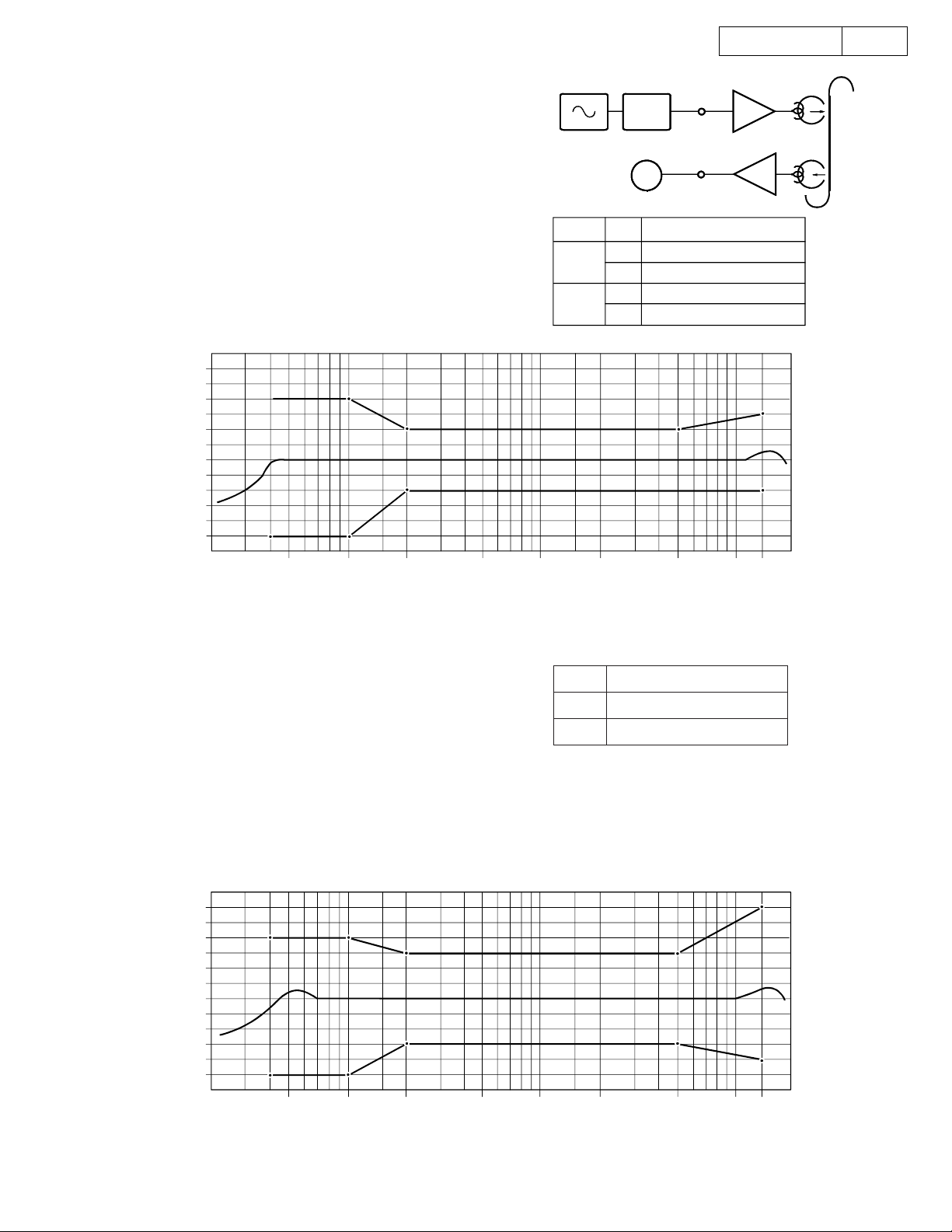

5. Recording System Adjustment

5-1. Adjusting recording/playback comprehensive

frequency characteristics.

(1) Load a test tape TDK AC-514.

Record with a -20 dB 1 kHz input level signal into

the LINE IN terminal and playback.

(2) Make a sample recording using a 12 kHz input

signal and playback this recording. Adjust (left

channel) and (right channel) so that they conform

to the following specified characteristics.

(db)

+6

+5

+

4

+

3

2

+

+1

0

−1

−2

−3

−4

5

−

−

6

20

Record/Playback Overall Frequency Response

10050

200

500

Frequency Responce

L/R

DN-T

645

DN-T

625

1 k

L VR-551

R

L

R

2 k

Tape

Dolby NR

Level

REC Amp

LINE IN

ATT

LINE OUT

V.V

PB Amp

Adjusting volume number

VR-552

VR-582

VR-581

5 k

: AC-514

: Off

: −20 dB From Dolby Level

10 k 12 k

20 k (Hz)

5-2. Recording/Playback Level Adjustment

(1) Load the test tape TDK AC-514. Make a sample

recording with the 1 kHz (-20 dB) signal and play

this section back.

(2) Adjust (Lch) and (Rch) so that the output from

LINE OUT terminal is the same as the output at

recording monitoring time.

5-3. Dolby C recording and playback comprehensive

frequency characteristics verification

(1) Set the Dolby NR switch at "C" position.

(2) Use a test tape TDK AC-514 and record and

playback as in item 5-1 to verity that they satisfy

the characteristics standards.

Dolby C Record/Playback Overall Frequency Response

(db)

6

+

+5

4

+

+3

2

+

+

1

0

−1

−

2

3

−

−4

5

−

−6

20

10050

200

500

R/P Level Adjustment

L/R

Adjusting volume number

L

R

1 k

2 k

Tape

Dolby NR

Level

VR-303

VR-304

5 k

: AC-514

: On C

: −20 dB From Dolby Level

10 k 12 k

20 k (Hz)

15

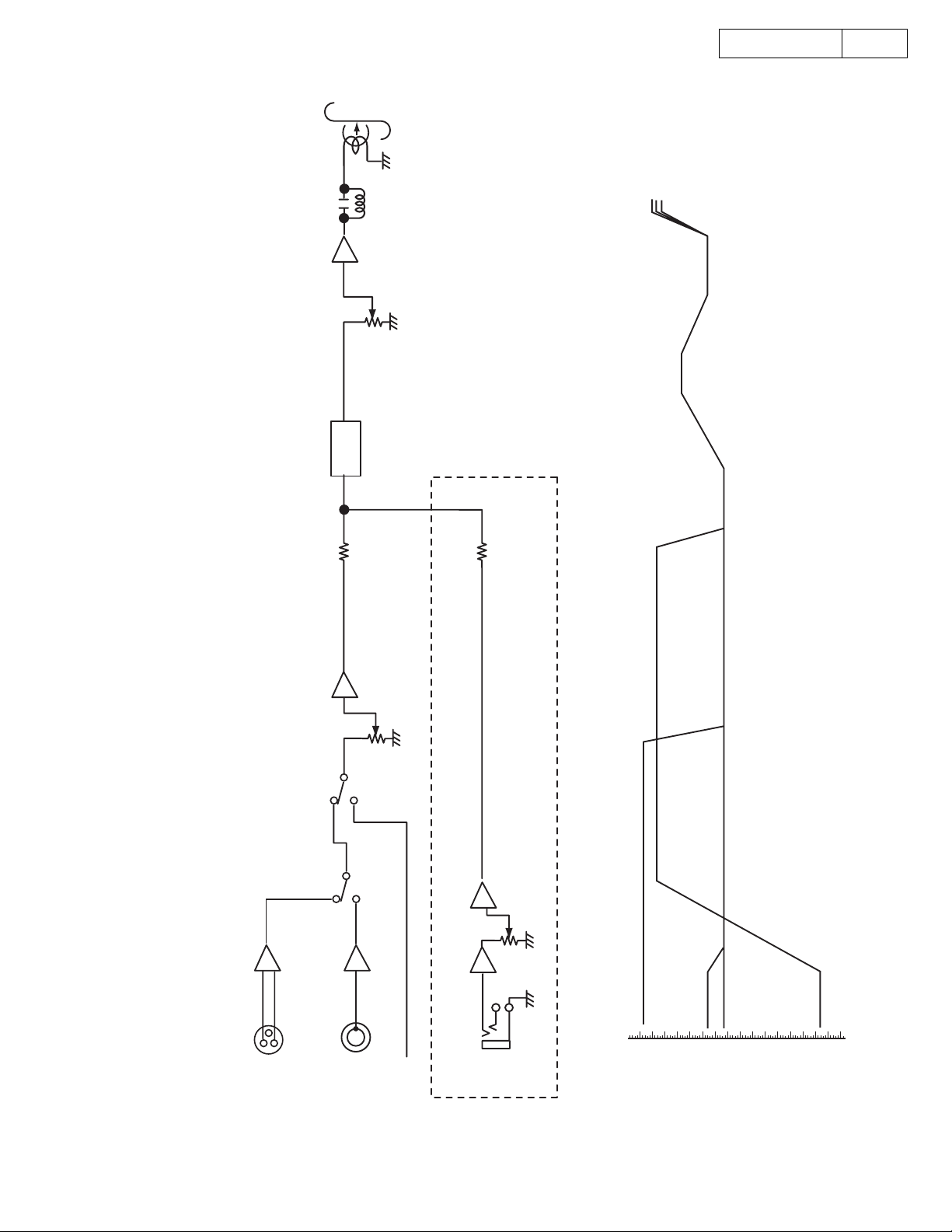

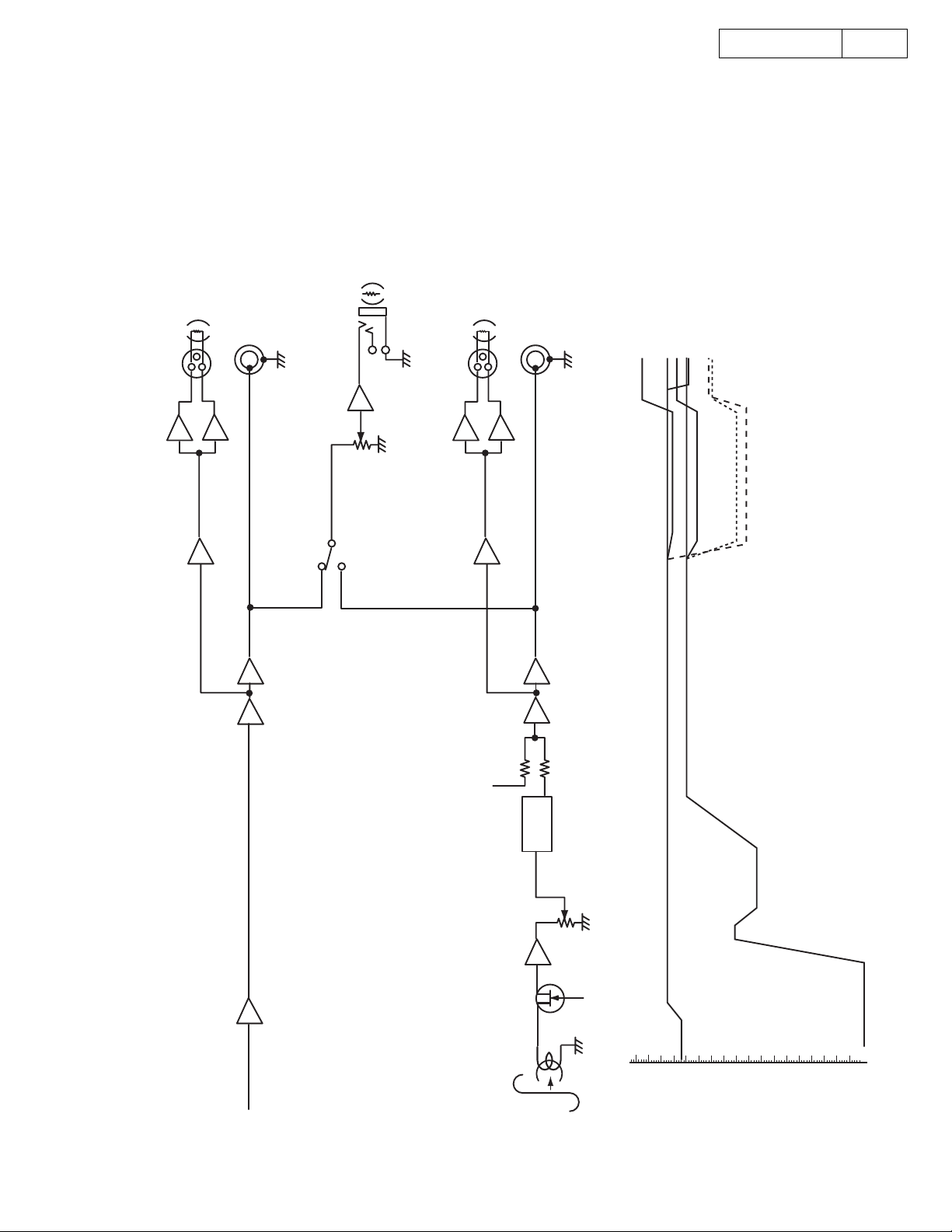

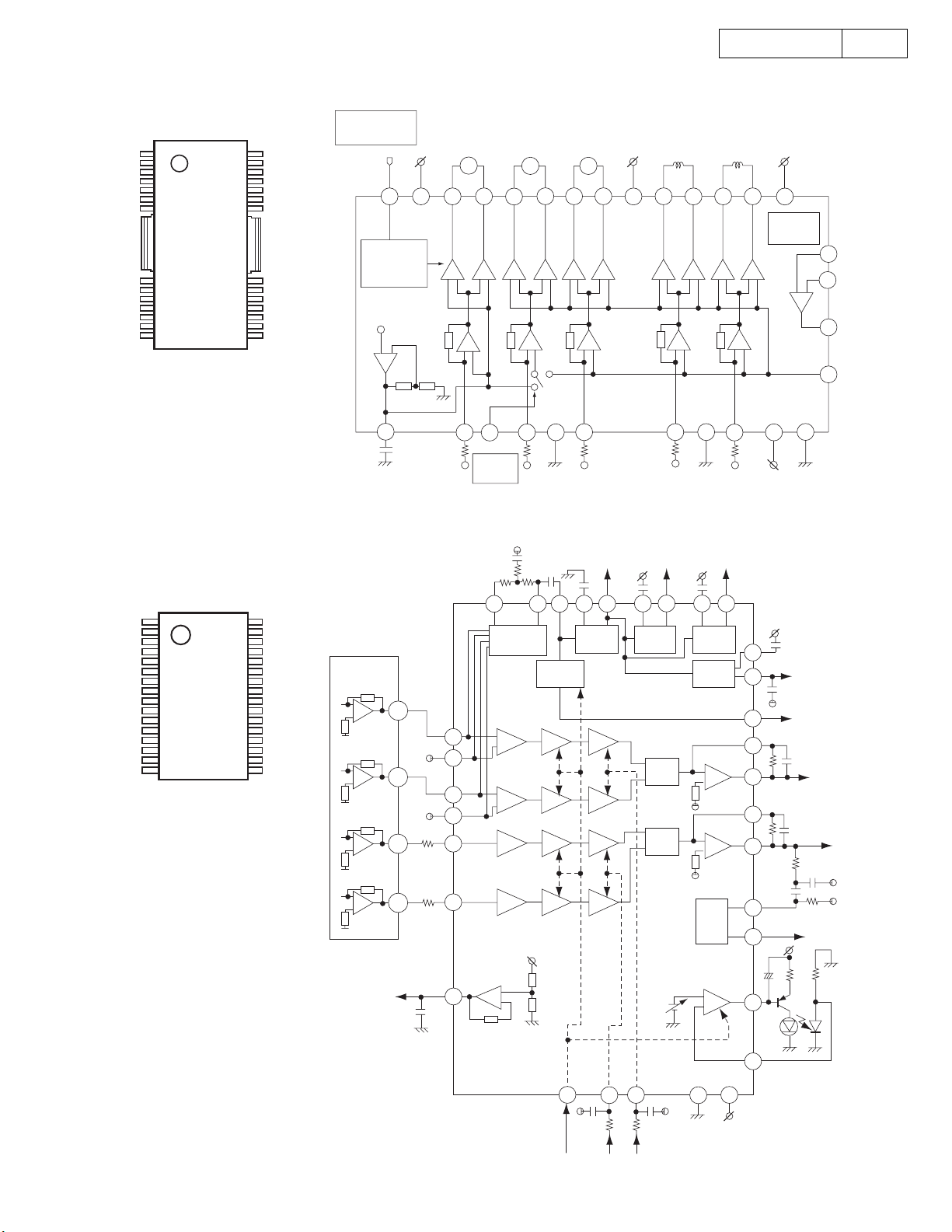

LEVEL DIAGRAMS (1/2)

1(7)

-1dB (NORMAL)

+2.5dB (METAL)

+1dB (CHROME)

DN-T645/625

16

IC304

IC601

IC302

HA12170

16(15)

30(1)

1(7)

VR303(304)

-19dB

+8.2dB

# A : VR621 ADJUST

# A

Not used for Model DN-T625

LEVEL DIAGRAM

1(7)

IC801

ACD 780 (Option)

XLR

RECORDING SYSTEM

INPUT FREQUENCY 400Hz

IC309

RCA

VR621

7(1)

LINE IN

(CD)

IC-651(652) IC-653

16

7

MIC

7(1)

(CD) +8dB

(dBV)

+2.5dB

0dB

RCA -24dB

XLR -17.5dB

-10dB

-20dB

-30dB

-40dB

0dB=0.775V

-50dB

MIC MODE=REC

MIC AGC=OFF

MIC -62dB

-70dB

-60dB

LEVEL DIAGRAMS (2/2)

LOAD

600 ohm

XLR

LINE OUT

RCA

LOAD

33 ohm

IC602

HEADPHONE

1(7)

LOAD

600 ohm

XLR

RCA

LINE OUT

0dB (RCA)(TAPE)

-1dB (HEADPHONE)(CD)

+4dB (XLR)(TAPE)

+18dB (XLR)(CD)

+8dB (RCA)(CD)

DN-T645/625

-9dB (HEADPHONE)(TAPE)

-10dB (XLR)(CD/TAPE:MONORAL RCH)

17

IC804(805)

IC317

1(7)

IC315

IC314

1(7)

1(7)

IC601(603)

IC319

1(7)

IC322

IC321

1(7)

1(7)

IC302

HA12170

28(3)

22(9)

VR301(302)

-28dB

0dB=0.775V

PLAYBACK SYSTEM

IC207

CD

1(7)

IC301

NJM2068

TR301(302)

TAPE

TCC-130 DOLBY B-TYPE

17

7(1)

3(5)

(dBV)

+20dB

+8dB

+10dB

+2dB

0dB

-10dB

-19dB

-20dB

-30dB

-40dB

-50dB

-60dB

-71dB

-70dB

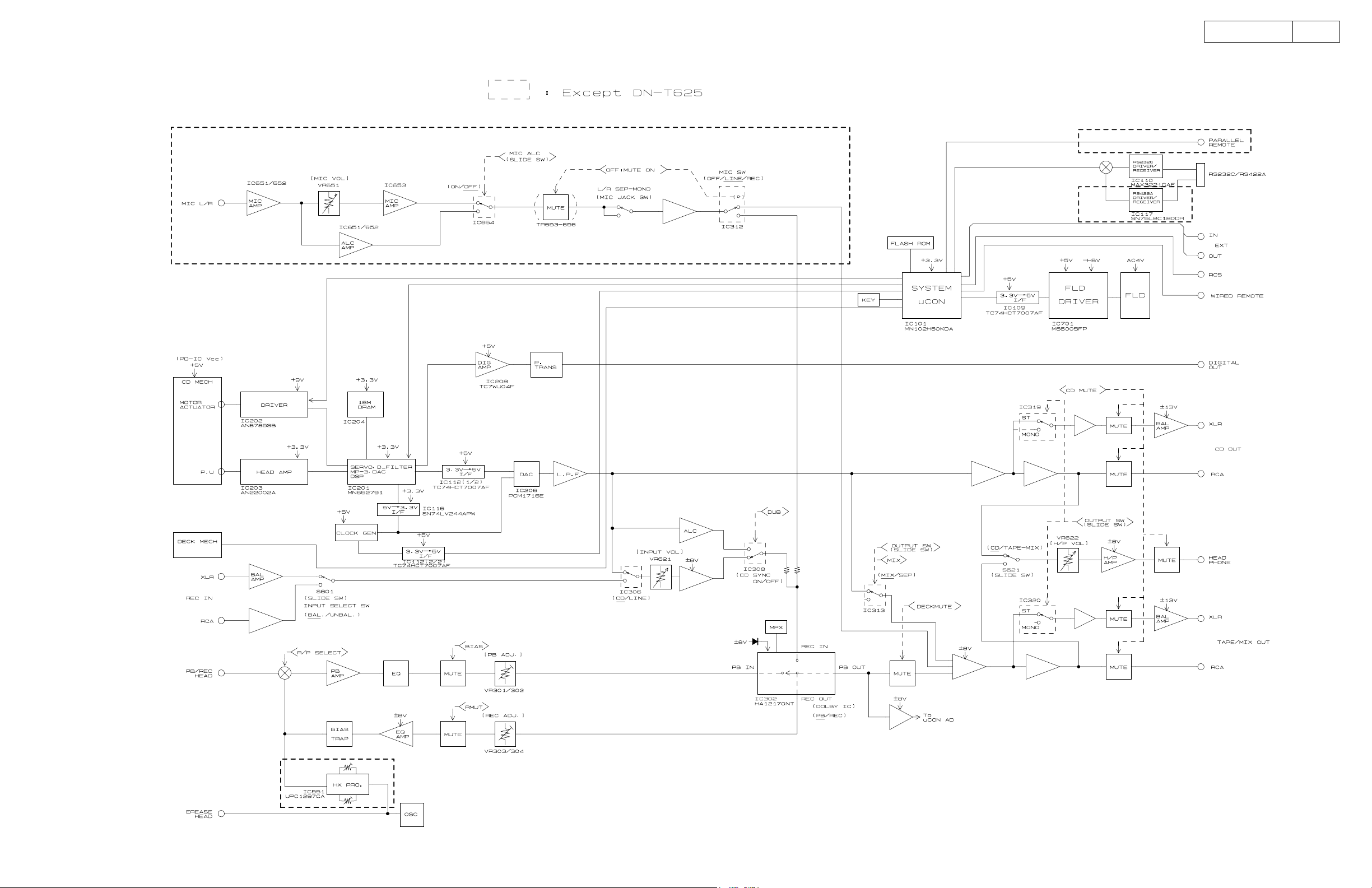

BLOCK DIAGRAM

DN-T645/625

18

18

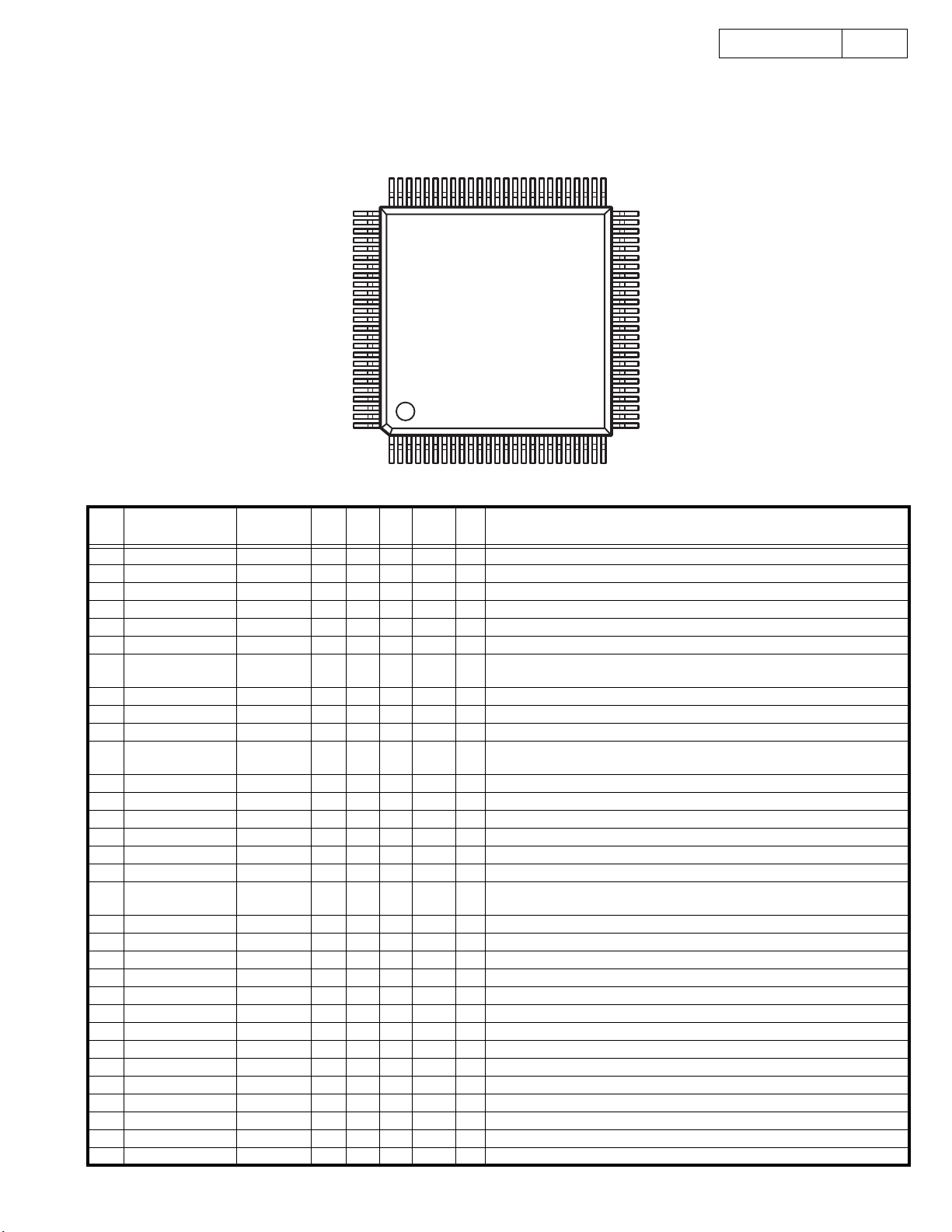

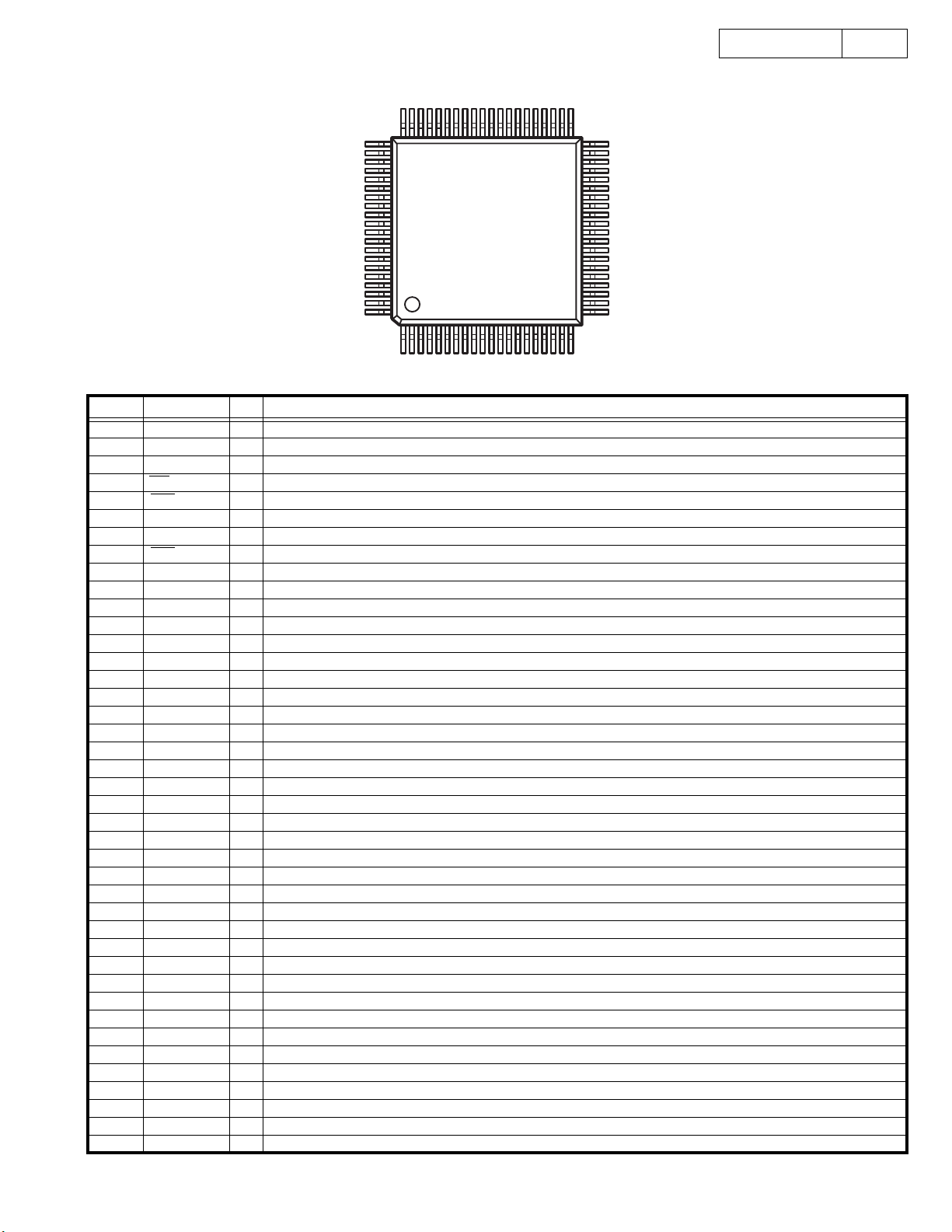

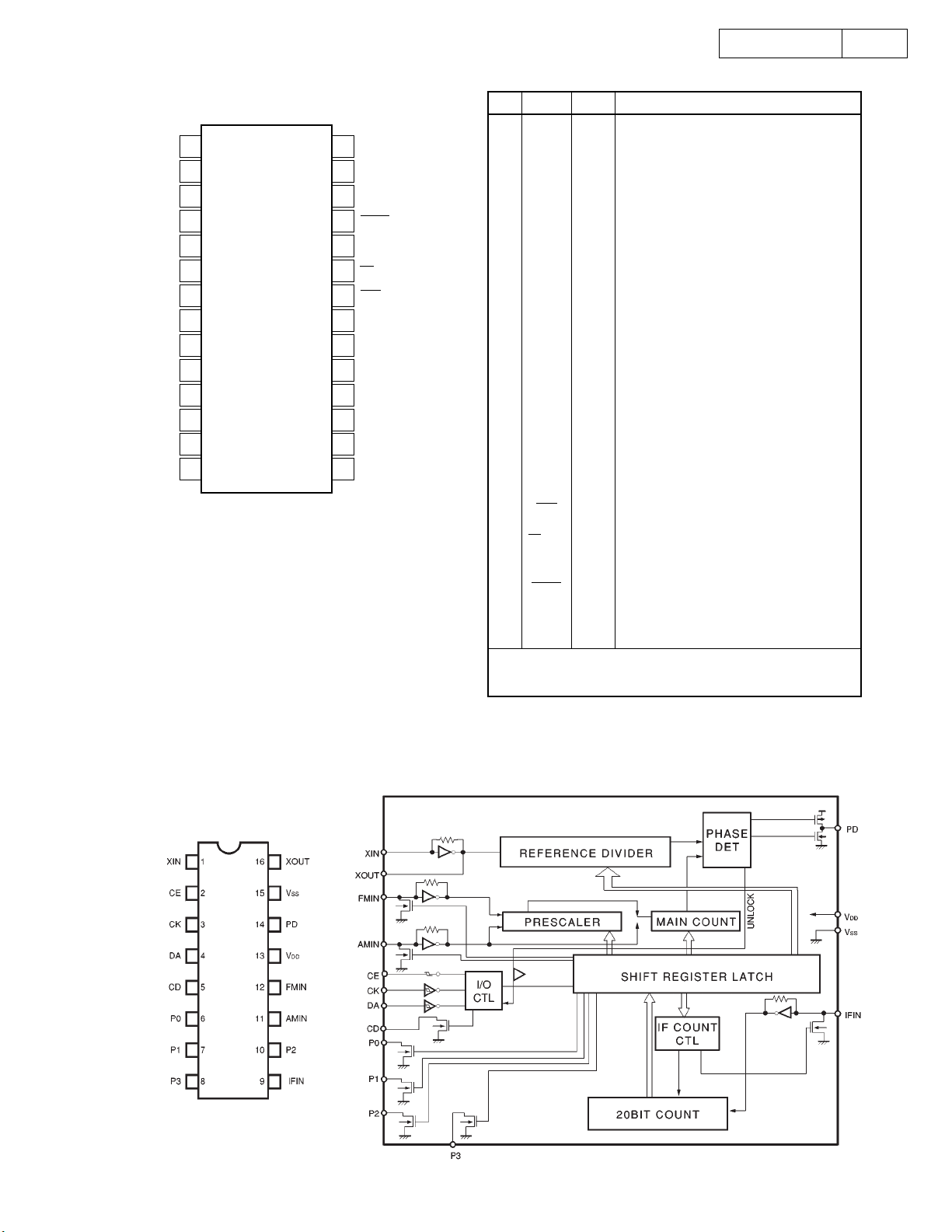

SEMICONDUCTORS

IC’s

MN102H60KDA

(IC101)

DN-T645/625

19

75

76

100

1

51

50

26

25

MN102H60KDA Terminal Function

Pin

No.

1 P60, WAIT, SBT2 PCDMUTE O - Pd L L Mute for CD

2 P61, _RE _RD O - - Hi-Z - Read signal

3 P62, _WEL _WEL O - - Hi-Z - Write signal

4 P63, _WE, _WEH PEXTIN I - - Hi-Z - EXT.IN signal

5 _CS0,TM13OA _CS0 O - - Hi-Z - Chip select signal (MASK ROM operation : Input port)

6 _CS1, TM13OB _CS1 O - - Hi-Z - Chip select signal (IN/OUT)

7 _CS2, TM14OA _CS2 O - - Hi-Z - Chip select signal (Normal operation : Input port, MASK ROM operation

8 _CS3, TM14OB _CS3 O - - Hi-Z - Deck (Input/Output)

9 P54, _BREQ PEXTOUT O - - Hi-Z H EXT.OUT signal

10 P55, _BRACK PRMTOUT O - - Hi-Z H Remote output signal

11 P56, ALE, _ALE,

12 P57,_WORD _WORD I - H H H Data bit bus width select 'H': 8bit

13 P20,A00,SBT2 A00 A/O - - Unfix - Address bus

14 P21,A01,SBI2 A01 A/O - - Unfix - Address bus

15 P22,A02,SBO2 A02 A/O - - Unfix - Address bus

16 P23,A03 A03 A/O - - Unfix - Address bus

17 Vdd Vdd - - - - - Power supply (+3.3V)

18 BOSC,BIBT1,

19 Vss Vss - - - - - GND(0V)

20 XI,PB1 PCE O - - Hi-Z L Chip select 'L': MN662791 / 'H': BU2618

21 XO XO - - - - - Not used. OPEN

22 Vdd Vdd - - - - - Power supply (+3.3V)

23 OSCI OSCI I - - - 24 OSCO OSCO O - - - - OSCI output

25 MODE MODE I - L L L Mode select 'L': Processor mode

26 P24,A04,TM15IA A04 A/O - - Unfix - Address bus

27 P25,A05 A05 A/O - - Unfix - Address bus

28 P26,A06 A06 A/O - - Unfix - Address bus

29 P27,A07 A07 A/O - - Unfix - Address bus

30 P30,A08,_KI0 A08 A/O - - Unfix - Address bus

31 P31,A09,_KI1 A09 A/O - - Unfix - Address bus

32 P32,A10,_KI2 A10 A/O - - Unfix - Address bus

Pin Name Symbol I/O Det Ext Res Ini Function

: F.ROM Chip select)

PMON2 I - - Hi-Z - Monitor signal 2

_BSTRE, TM15IA

PIRINH O - - Hi-Z L Infrared remote 'L': Enable / 'H': Inhibit

BIBT2,PB0

19

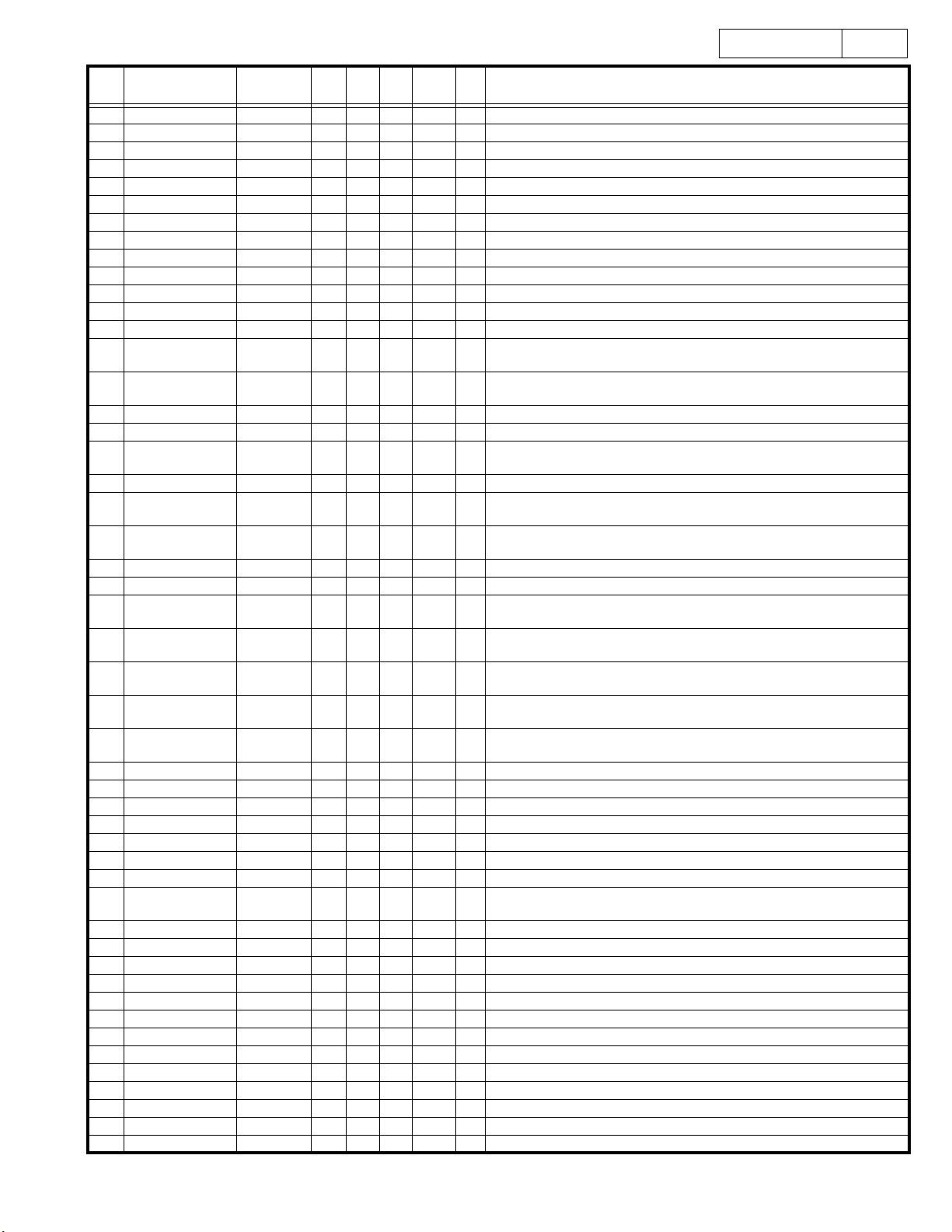

DN-T645/625

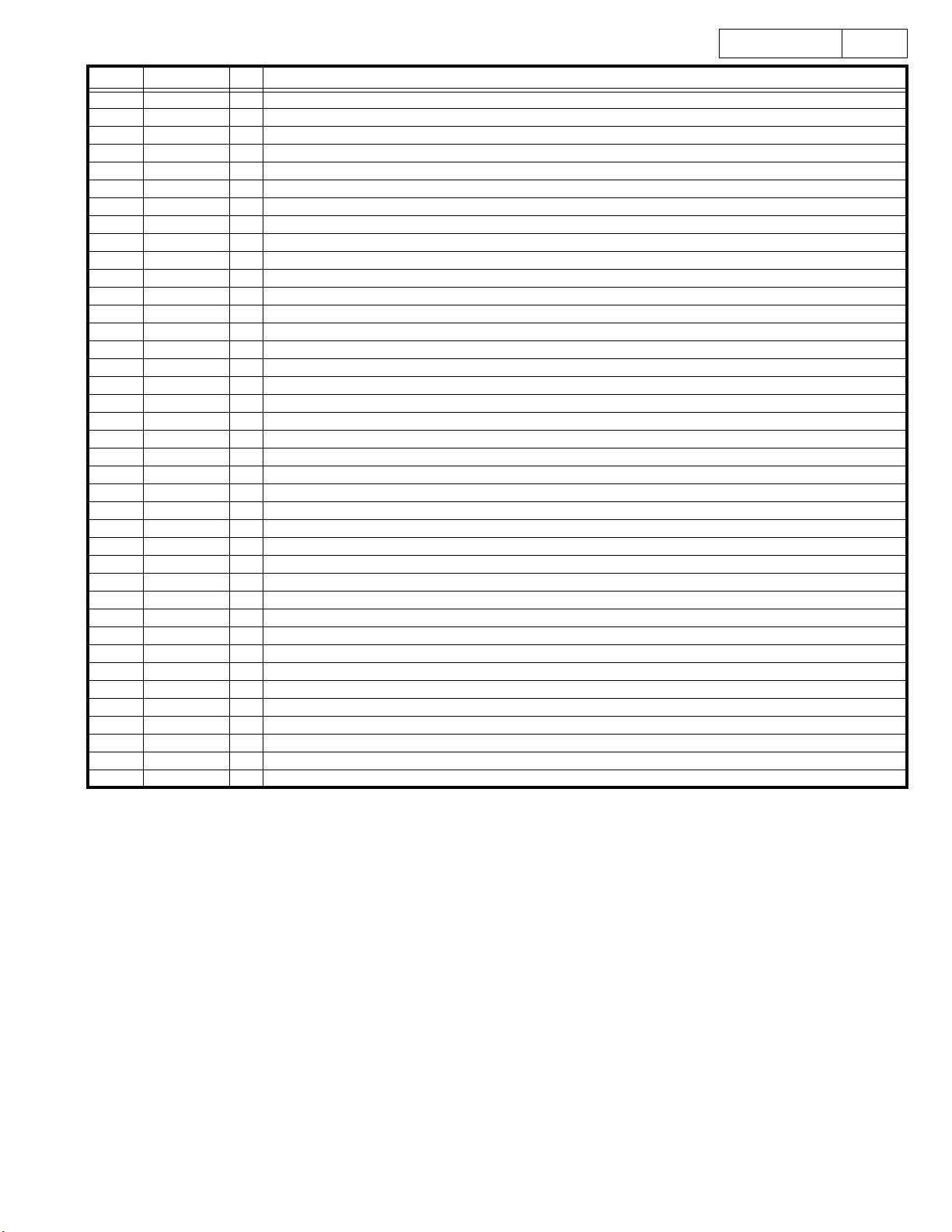

20

Pin

No.

33 P33,A11,_KI3 A11 A/O - - Unfix - Address bus

34 AVDD AVDD - - - - - Analog power supply terminal

35 P34,A12,_KI4 A12 A/O - - Unfix - Address bus

36 P35,A13,_KI5 A13 A/O - - Unfix - Address bus

37 P36,A14,_KI6 A14 A/O - - Unfix - Address bus

38 P37,A15,_KI7 A15 A/O - - Unfix - Address bus

39 P40,A16 A16 A/O - - Unfix - Address bus

40 P41,A17 A17 A/O - - Unfix - Address bus

41 P42,A18 A18 A/O - - Unfix - Address bus

42 P43,A19 A19 A/O - - Unfix - Address bus

43 Vref- Vref- - - - - - Standard analog power supply

44 P44,AN4,A20 PPARA1 I Lv - Unfix - Parallel input 1 (Use A/D converter)

45 P45,AN5,A21 PPARA2 I Lv - Unfix - Parallel input 2 (Use A/D converter)

46 P46,AN6,STOP,

47 P47,AN7,WDOUT,

48 P80,TM14OA PSCL O - - Hi-Z H Not used.

49 P81,TM14OB PDUB O - - Hi-Z H Dubbing signal 'L': Dubbing

50 P82,TM0IO,SBI2,

51 P83,TM4IO,SBI3 RxD I - - Hi-Z - Serial port (9600bps by xxMHz)

52 P84,TM7IO,SBO3,

53 P85,TM9IOA,SBO2,

54 Vref+ Vref+ - - - - - Standard analog power supply

55 P86,TM9IOB,SBI4 PFLCS O - - Hi-Z H To FL driver CS

56 P87,TM9IC,SBO4,

57 P90,TM8IOA,BIBT1,

58 P91,TM10IOA,BIBT2,

59 P92,TM10IOB,

60 P93,TM10IC,

61 Vss Vss - - - - - GND (0V)

62 P94,AN0 PADINL I Lv Pd L - Use A/D converter

63 P95,AN1 PADINR I Lv Pd L - Use A/D converter

64 P96,AN2 PREMO1 I Lv - Hi-Z - Use A/D converter

65 P97,AN3 PREMO2 I Lv - Hi-Z - Use A/D converter

66 Vdd Vdd - - - - - Power supply (+3.3V)

67 P70,SBT0,_RAS PMCLK O - - Hi-Z H DSP interface Clock (clock synchronous formula)

68 P71,SBI0,_CAS,

69 P72,SBO0,_UCAS PMDAT O - - Hi-Z H DSP interface Transmission (clock synchronous formula)

70 P73,SBT1,DUMX PTXTCLK O - - Hi-Z H Use during CD-TEXT data read (clock synchronous formula)

71 P74,SBI1 PTXTD I - - Hi-Z - Use during CD-TEXT data read (clock synchronous formula)

72 P75,SBO1 PMLD O - - Hi-Z H DSP interface latch

73 TEST1 TEST1 I - Pu - - Pull up 33 - 50K

74 TEST2 TEST2 I - Pu - - Pull up 33 - 50K

75 _NMI _NMI I Lv - Hi-Z - Need pull up

76 PA0,_IRQ0 PBLKCK I Ed - Hi-Z - Sub code clock interruption

77 PA1,_IRQ1 PDQSY I Ed - Hi-Z - CD-TEXT DQSY Interruption

78 PA2,_IRQ2 PPLS I Ed - Hi-Z - Count by DOWN EDGE. One rotation by three counts.

79 PA3,_IRQ3 PREMOTE I Ed - Hi-Z - RC-5/Infrared remote signal input

80 PA4,_IRQ4,TM15IB PCHGOFT O - Pu H L Off track signal

81 PA5,ADSEP ADSEP I - H H H 'H': Address data separation mode / 'L': Address data common mode

Pin Name Symbol I/O Det Ext Res Ini Function

PPARA3 I Lv - Hi-Z - Parallel input 3 (Use A/D converter)

A22

PSDA I/O - - Hi-Z - Not used.

A23

PMON1 I - - Hi-Z - Monitor signal 1

SBT3,SCL3

TxD O - - Hi-Z H Serial port (9600bps by xxMHz)

SDA3

PFLCLK O - - Hi-Z H To FL driver SCK

SBT4,SCL4

PFLSD O - - Hi-Z H To FL driver SDATA

SDA4

PBIAS O - Pd L L Bias signal 'H': BIAS ON

_DMAREQ1

PRMUTE O - Pu H H Rec mute change signal 'H': MUTE ON

_DMAACK1

PLRCK I Ed - Hi-Z - LRCK : Use for time code creation during MP3 playback.

_DMAREQ0

PNRST O - Pd L L Round IC reset signal

_DMAACK0

PSTAT I - - Hi-Z - DSP interface Reception (clock synchronous formula)

_LCAS

20

DN-T645/625

21

Pin

No.

82 _RST _RESET I Lv - L - Reset signal 'L': RESET

83 Vdd Vdd - - - - - Power supply (+3.3V)

84 P00,D00,AD00 D00 D/O - - Hi-Z - Data bus

85 P01,D01,AD01 D01 D/O - - Hi-Z - Data bus

86 P02,D02,AD02 D02 D/O - - Hi-Z - Data bus

87 P03,D03,AD03 D03 D/O - - Hi-Z - Data bus

88 P04,D04,AD04 D04 D/O - - Hi-Z - Data bus

89 P05,D05,AD05 D05 D/O - - Hi-Z - Data bus

90 P06,D06,AD06 D06 D/O - - Hi-Z - Data bus

91 P07,D07,AD07 D07 D/O - - Hi-Z - Data bus

92 Vss Vss - - - - - GND(0V)

93 P010,D08,AD08,

94 P011,D09,AD09,T

95 P012,D10,AD10,

96 P013,D11,AD11,T

97 P014,D12,AD12,

98 P015,D13,AD13,

99 P016,D14,AD14,

100 P017,D15,AD15,

Pin Name Symbol I/O Det Ext Res Ini Function

TM8IOB

M8IC

TM11IOA

M11IOB

TM11IC

TM12IOA

TM12IOB

TM12IC

PMIX O - Pd L L Deck line out 'H': Mix out of CD+DECK

PPOFF I - - H - 'L': Power failure detection

PDECKMUTO - Pd L L Deck line mute 'L': MUTE ON

POPEN I - - Hi-Z - OPEN switch

PCLOSE I - - Hi-Z - CLOSE switch

PLOAD O - - Hi-Z H OPEN/CLOSE signal (PWM out put) (During Pnrst='L', out put

PWM(50%))

O- -Hi-ZH

PINSW I - - Hi-Z - Inner circle SW

21

MN6627911AC

(IC201)

61

60

41

40

DN-T645/625

22

80

1

20

MN6627911AC Terminal Function

Pin No. Pin Name I/O Function

1 DRVDD I Power supply for DRAM interface (Pin No.2 - 18, 80)

2 D0 I/O Data I/O signal 0 for DRAM

3 D1 I/O Data I/O signal 1 for DRAM

4 WE O Write enable signal for DRAM

5 RAS O RAS control signal for DRAM

6 D2 I/O Data I/O signal 2 for DRAM

7 D3 I/O Data I/O signal 3 for DRAM

8 CAS O CAS control signal 0 for DRAM

9 A10 O Address signal 10 for DRAM

10 A8 O Address signal 8 for DRAM

11 A7 O Address signal 7 for DRAM

12 A6 O Address signal 6 for DRAM

13 A5 O Address signal 5 for DRAM

14 A4 O Address signal 4 for DRAM

15 A9 O Address signal 9 for DRAM

16 A0 O Address signal 0 for DRAM

17 A1 O Address signal 1 for DRAM

18 A2 O Address signal 2 for DRAM

19 A3 O Address signal 3 for DRAM

20 DVSS2 I GND for digital

21 DVDD2 I Power supply for digital

22 SPOUT O Spindle motor drive signal

23 TRVP O Traverse drive signal

24 TRVM O Not used

25 TRP O Tracking drive

26 GCNTL O Gain control signal for CD-RW

27 FOP O Focus drive

28 CHGICO O EQ select signal

29 IOVDD1 I Power supply for IO

30 TBAL O Tracking balance adjust

31 FBAL O Focus balance adjust

32 FE I Focus error signal (Analog input)

33 TE I Tracking error signal (Analog input)

34 RFENV I RF envelope signal (Analog input)

35 OFT I Off track signal H : OFF TRACK

36 NRFDET I RF detect signal H : DETECT

37 BDO I Drop out signal H : DROP OUT

38 LDON O Laser ON signal H : ON

39 ARF I RF signal

40 IREF I Standard current input terminal

41 ADPVCC I Voltage for power supply monitor

21

22

Pin No. Pin Name I/O Function

42 DSLF O Loop filter for DSL

43 RFSW I Loop filter for DSL

44 PLLF O Loop filter for PLL

45 PLLFO O Loop filter for PLL

46 AVDD2 I Power supply for analog (DSL, PLL, AD)

47 AVSS2 I GND for analog (DSL, PLL, AD)

48 OUTL O Not used

49 AVSS1 I GND for analog (Audio output)

50 OUTR O Not used

51 AVDD1 I Power supply for analog (Audio output)

52 DVSS3 I GND for digital

53 DVDD3 I Power supply for digital

54 TMOD2 I Test terminal L : Normal

55 MON2 O Serial monitor signal 2

56 BCLK O Bit clock for serial data

57 SRDATA O Serial data signal

58 LRCK O L, R discernment signal

59 IOVDD2 I Power supply for IO

60 TX O Digital audio interface signal

61 MCLK I ucon command clock signal

62 MDATA I ucon command data signal

63 MLD I ucon command load signal L : LOAD

64 BLKCK O Sub code block clock signal (f=75Hz : Normal speed playback)

65 PWMSEL I PWM output mode select L : Direct H : 3 values

66 SMCK O Not used

67 SBCK I Not used

68 STAT O Status signal

69 NRST I Reset L : RESET

70 SPPOL O Not used

71 PMCK O Not used

72 DQSY O Pack signal for CD TEXT data

73 TXTD O CD TEXT data signal

74 TXTCK O Ext. clock signal input for CD TEXT resister

75 NTEST I Test terminal H : Normal

76 X2 O Not used

77 X1 I 16.9344MHz input terminal

78 DVSS1 I GND for digital

79 DVDD1 I Power supply for digital

80 MON1 O Serial monitor signal

DN-T645/625

23

23

AN8785SB

(IC202)

DN-T645/625

24

1

7

8

14 15

AN22002A

(IC203)

L: All mute

Hiz: ch2,4 ON

H: Active

28

22

21

Standby

16

Standby

Band-gap

Vcc/Vref

Reser Circuit

1.25V

+

-

7

IN2+

0.1µ

(2.5V)

PVcc2

10

[ Loading ]

D2+

D2-

M

12 11

-

+

-

+

9

ch.4 SW

H:2.5V

L or

IN2-

HIZ

-

+

8

:Vref

[ Traverse ]

D4-

18

-+-

21

IN4

[ Others ]

D4+

[ Spindle ]

D3-

D3+

PVcc3

[ Focus ]

D1-

D1+

[ Tracking ]

D5-

D5+

PVcc1

MM

17

14

13

-+-

+

-

+

switch

15

PGnd2

20

IN3

CAGC

+

-

+

ARF

19

CBD0

1

28

-+-+-

-

+

23 27

IN1

PGnd1

C0FTR

BD0

26

+

0FTR

IN5

25

24

Protection

Circuit

4

IN-

-

+

-

+

22

2

SVcc

+

-

SGnd-Fin

5

IN+

3

OUT

6

Vref

RFN

1

16

32

A

+

C

-

+

A

B

+

17

D

-

+

F

-

+

E

-

+

32

C

31

B

30

D

29

27

E

F

28

VREF

17

5

4

RFOUT

RF_EQ

NRFDET

AMP GCA BCA

AMP GCA BCA

GCA

AMP

AMP

GCA

+

-

8

6

7

RFIN

AGC BD0 0FTR

BCA

BCA

12

SUB

SUB

13

3TENV

-

+

-

+

14

9

CEA

10

3TOUT

15

NRFDET

FEN

22

23

FEOUT

TEN

21

20

TEOUT

TEBPF

11

19

VDET

-

+

LD

VDET

18

2

24

PD

1

TBAL

GCTL

24

26

FBAL

25

3

16

VCCGND

PCM 1716E (IC206)

1

LRCIN

2

DIN

3

BCKIN

4

CLKO

5

XTI

6

XTO

7

DGND

8

V

DD

9

VCC2R

EXTR

NC

V

OUT

AGND1

10

11

12

13

R

14

AGND2R

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/IIS

MC/DM1

MD/DM0

MUTE

MODE

CS/IWO

RST

ZERO

V

2L

CC

AGND2L

EXTL

NC

V

L

OUT

V

1

CC

DN-T645/625

PIN NAME I/O DESCRIPTION

1 LRCIN IN Left and Right Clock Input. This clock is equal to

the sampling rate - f

2 DIN IN Serial Audio Data Input

3 BCKIN IN Bit Clock Input for Serial Audio Data.

4 CLKO OUT Buffered Output of Oscillator. Equivalent to

System Clock.

5 XTI IN Oscillator Input (External Clock Input)

6 XTO OUT Oscillator Output

7 DGND

8V

9V

CC

10 AGND2R

-

Digital Ground

-

DD

2R

Digital Power +5V

-

Analog Power +5V

-

Analog Ground

11 EXTR OUT Rch, Common Pin of Analog Output Amp

-

12 NC

13 V

OUT

14 AGND1

15 V

16 V

CC

OUT

1

17 NC

R OUT Rch, Analog Voltage Output of Audio Signal

L OUT Lch, Analog Voltage Output of Audio Signal

No Connection

-

Analog Ground

-

Analog Power +5V

-

No Connection

18 EXTL OUT Lch, Common Pin of Analog Output Amp

-

19 AGND2L

20 V

2L

CC

Analog Ground

-

Analog Power +5V

21 ZERO OUT Zero Data Flag

22 RST IN Reset. When this pin is low, the DF and

modulators are held in reset.

23 CS/IWO IN Chip Select/Input Format Selection. When this

pin is low, the Mode Control is effective.

24 MODE IN

Mode Control Select. (H: Software, L: Hardware)

25 MUTE IN Mute Control

26 MD/DM0 IN Mode Control, DATA/De-emphasis Selection 1

27 MC/DM1 IN Mode Control, BCK/De-emphasis Selection 2

28 ML/I2S IN Mode Control, WDCK/Input Format Selection

NOTES: (1) Pins 1, 2, 3; Schmitt Trigger input. (2) Pins 22, 24, 25, 26, 27,

28; Schmitt Trigger input with pull-up resister. (3) Pin 23; Schmitt Trigger

input with pull-down resister.

(1)

.

S

(1)

(1)

(2)

(3)

25

(2)

(2)

(2)

(2)

BU2618FV (IC113)

25

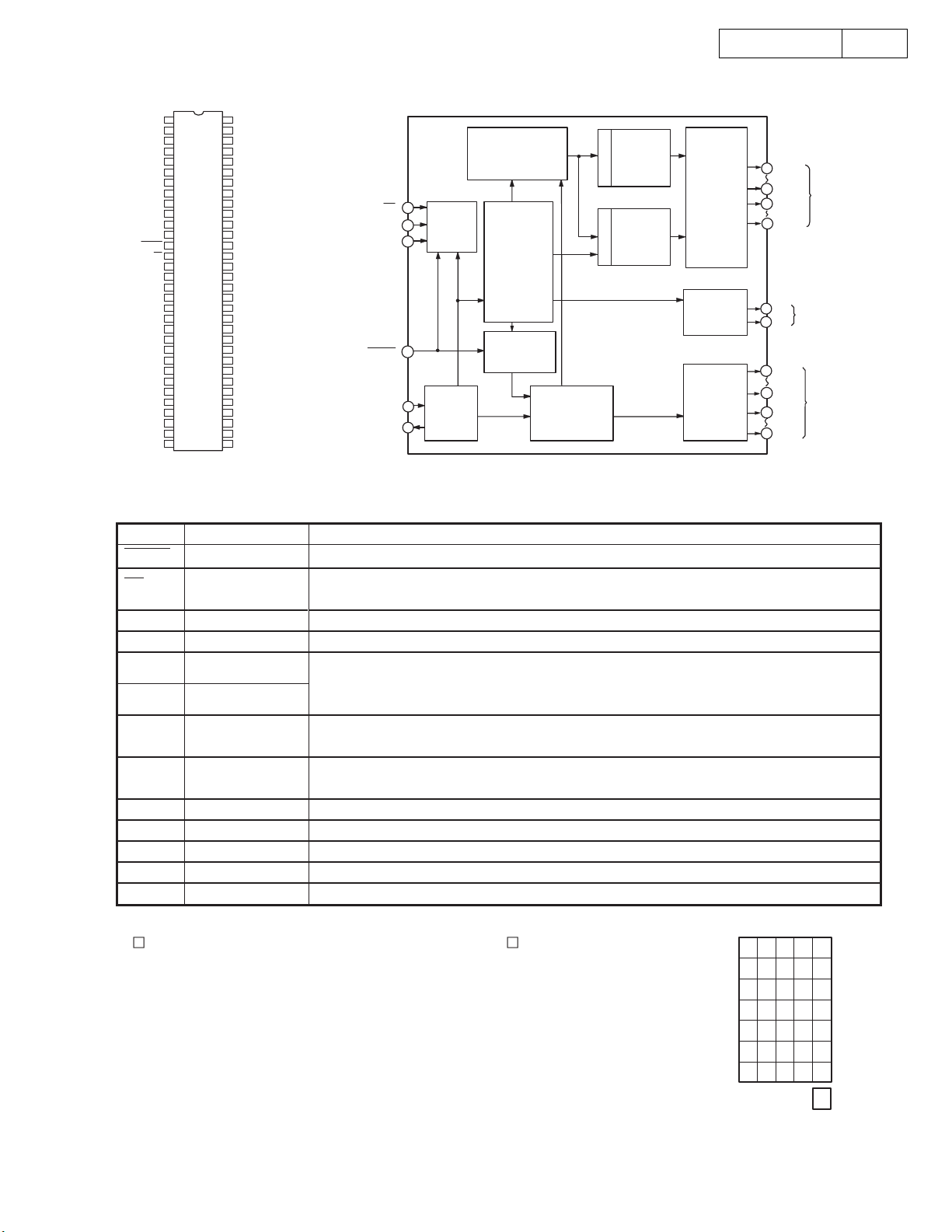

M66005FP (IC701)

D I G

1 1

1

2

D I G

1 0

3

D I G

0 9

D I G

0 8

4

D I G

0 7

5

D I G

0 6

6

D I G

0 5

7

D I G

0 4

8

9

D I G

0 3

D I G

0 2

1 0

D I G

0 1

1 1

D I G

0 0

1 2

1 3

R E S E T

C S

1 4

1 5

S C K

S D A T A

1 6

P I

1 7

P O

1 8

1 9

V c c 1

2 0

X

o u t

2 1

X

i n

2 2

V s s

S E G

2 3

3 5

2 4

S E G

3 4

S E G

3 3

2 5

S E G

3 2

2 6

S E G

3 1

2 7

2 8

S E G

3 0

S E G

2 9

2 9

S E G

2 8

3 0

S E G

2 7

3 1

V p S E G

3 2

D I G

6 4

6 3

D I G

6 2

D I G

D I G

6 1

6 0

V c c 2

5 9

S E G

S E G

5 8

S E G

5 7

5 6

S E G

5 5

S E G

5 4

S E G

5 3

S E G

5 2

S E G

5 1

S E G

5 0

S E G

4 9

S E G

4 8

S E G

4 7

S E G

4 6

S E G

4 5

S E G

S E G

4 4

4 3

S E G

4 2

S E G

4 1

S E G

S E G

4 0

3 9

S E G

3 8

S E G

S E G

3 7

S E G

3 6

3 5

S E G

3 4

S E G

3 3

1 2

1 3

1 4

1 5

0 0

0 1

0 2

0 3

0 4

0 5

0 6

0 7

0 8

0 9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

2 4

2 5

2 6

C h i p S e l e c t I n p u t

S h i f t C l o c k I n p u t

S e r i a l D a t a I n p u t

R e s e t I n p u t

C l o c k I n p u t

C l o c k O u t p u t

S C K

S D A T A

R E S E T

X O U T

DN-T645/625

D i s p l a y C o d e R e g i s t e r

( 8 - b i t x 1 6 )

c o d e

1 4

C S

S e r i a l

1 5

R e c e p t i o n

C i r c u i t

1 6

1 3

C l o c k

2 1

X I N

2 0

G e n e r a t i o n

C i r c u i t

w r i t e

C o d e /

C o m m a n d

C o n t r o l C i r c u i t

D i s p l a y C o n t r o l

R e g i s t e r

R A M

w r i t e

c o d e s e l e c t

D i s p l a y C o n t r o l l e r

C G R O M

( 3 5 - b i t x 1 6 0 )

D e c o d e rD e c o d e r

C G R O M

( 3 5 - b i t x 1 6 )

S e g m e n t

O u t p u t

C i r c u i t

O u t p u t P o r t

( 2 - b i t )

D i g i t O u t p u t

C i r c u i t

S E G

0 0

5 9

2 6

S E G

3 3

3 1

2 3

1 8

1 7

1 2

1

6 4

6 1

S E G

S E G

P 0

P 1

D I G

D I G

D I G

D I G

2 7

3 5

O u t p u t P o r t

0 0

1 1

D i g i t O u t p u t

1 2

1 5

S e g m e n t

O u t p u t

26

M66005FP Terminal Function

Symbol Name Function

RESET Reset Input

CS Chip Select Input

SCK Shift Clock Input

SDATA Serial Data Input

X

IN

OUT

X

DIG 00~

DIG 15

SEG 00~

SEG 35

Clock Input

Clock Output

Digit Output

Segment Output

P0, P1

V

CC1

V

CC2

Vss

Vp

(Forwarding connection of segment output terminal.)

in the right figure indicates 1 dot of segment, the figure in shows the segment output

terminal number (00~35) to be connected.

Initialzes internal state of M66005.

Able to communicate with MCU in "L" mode.

Command from MCU will be disregareded in "H" mode.

Shifts input data at rise from "L" to "H".

Inputs character code or command data needed to display from MSB.

Sets oscillation frquency by connecting external resistor and capacitor (maximum

oscillation frequency fosc (max)=1MHz). Also feasible to apply external clock. In this case,

inject external clock to Xin terminal and open Xout terminal.

Connect to digit terminal of VFD. DIG00~DIG15 correspond to the 1st figure to 16th figure

respectively.

Connect to segment terminal of VFD. For corresponding SEG00~SEG35 to segment

terminal of VFD, refer to the figure right.

Output port (static operation).

Positive power supply terminal for internal logic.

Positive power supply terminal for high tension output port.

GND terminal.

Negative power supply terminal for VFD drive.

00 01 02 03 04

05 06 07 08 09

10 11 12 13 14

15 16 17 18 19

20 21 22 23 24

25 26 27 28 29

30 31 32 33 34

26

35

Loading...

Loading...