Page 1

For U.S.A., Canada, Europe, U.K.,

Asia, China, Taiwan R.O.C., Korea

& Japan model

2

Ver. 2

SERVICE MANUAL

MODEL DN-S3500

TABLE TOP SINGLE CD PLAYER

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

Please refer to the

MODIFICATION NOTICE.

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0252V.02 DE/CDM 0511

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

DN-S3500

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…!マークで表示しています。

(2) 部品表…!マークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

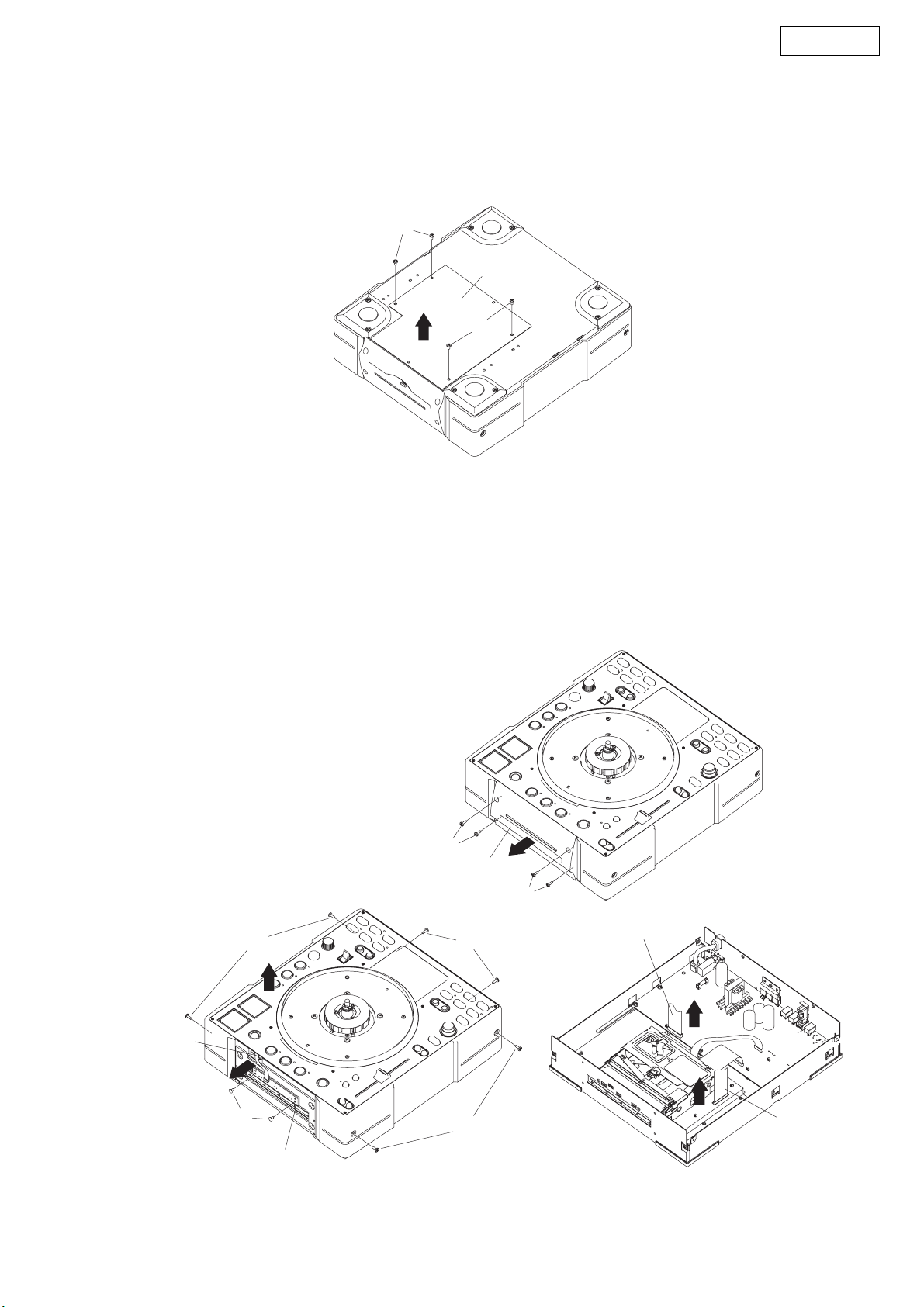

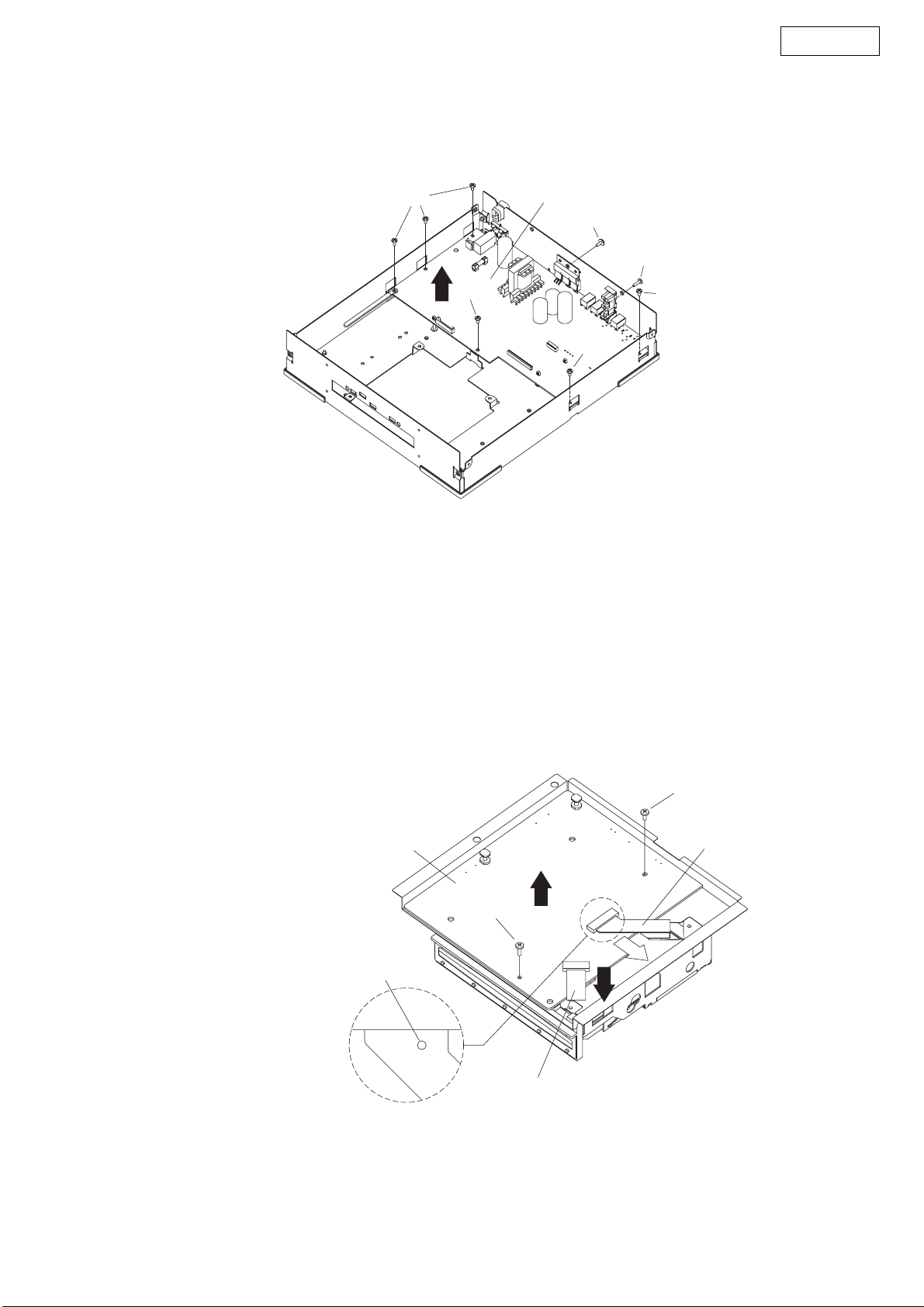

DISASSEMBLY

j

(Follow the procedure below in reverse order when reassembling.)

Note: First of all, remove the Platter. Refer to the Instruction Manuals.

1. Bottom Plate

(1) Remove 4 screws 70 and pull out Bottom Plate.

70

Bottom Plate

70

2. Top Cover unit

(1) Remove 4 screws 71.

(2) Detach FFC ESC.

(3) Remove 2 Push Rivets 31.

(4) Disconnect Connector to remove Eject LED unit.

(5) Remove 6 screws 71.

(6) Disconnect FFC Cable and Connector.

(7) Detach Top Cover unit.

DN-S3500

71

Front ESC

71

Connector

CW121

Connector

CX032

71

31

E

ect LED unit

71

71

Note:

z Do not pull out aslant to prevent FFC cable damage.

z Do not fail to pull AC cord from wall outlet before disconnect FFC Cable.

If AC cord is remained plugged into wall outlet, power is kept supplied in the unit, which may cause danger.

3

FFC Cable

CX251

Page 4

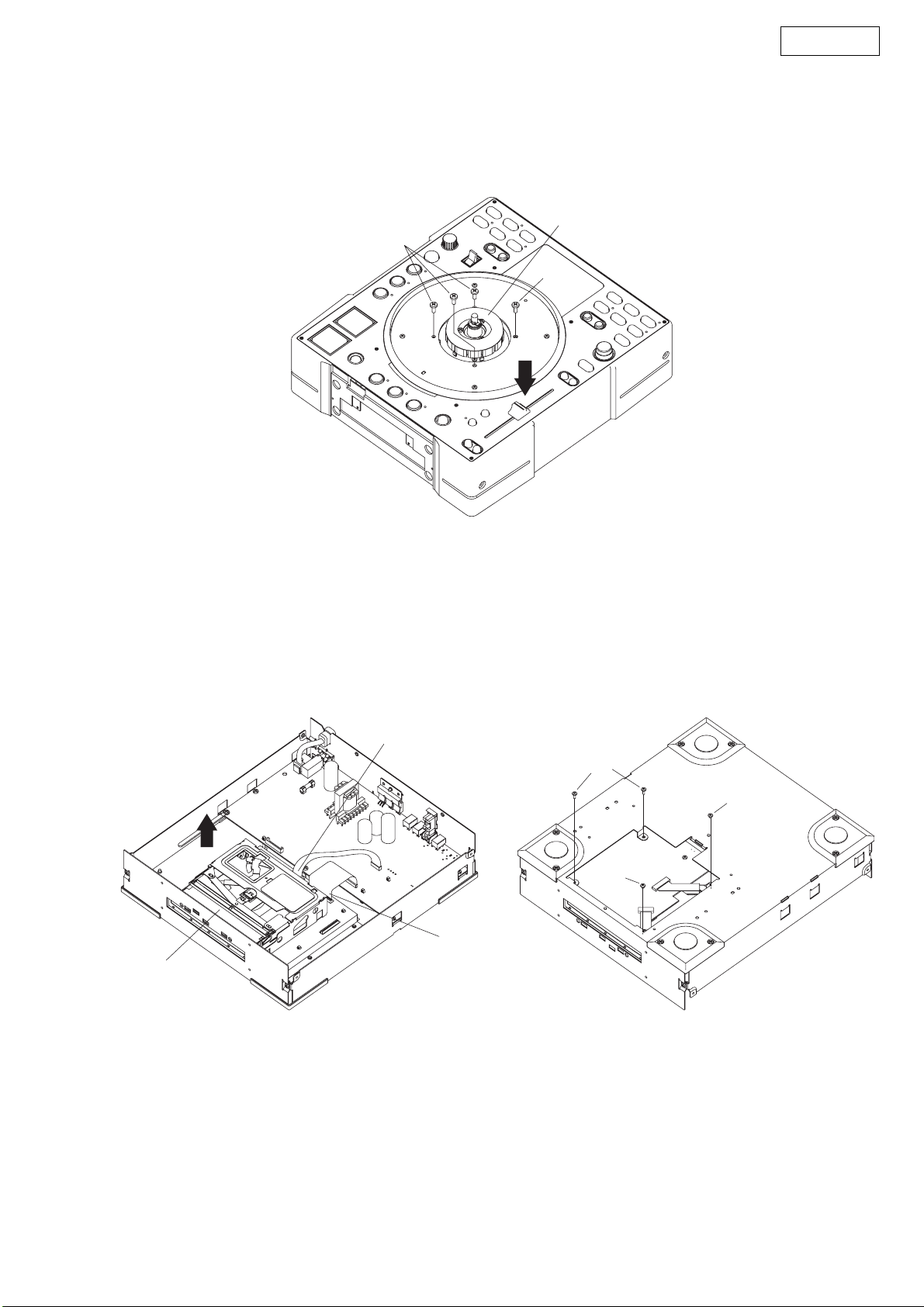

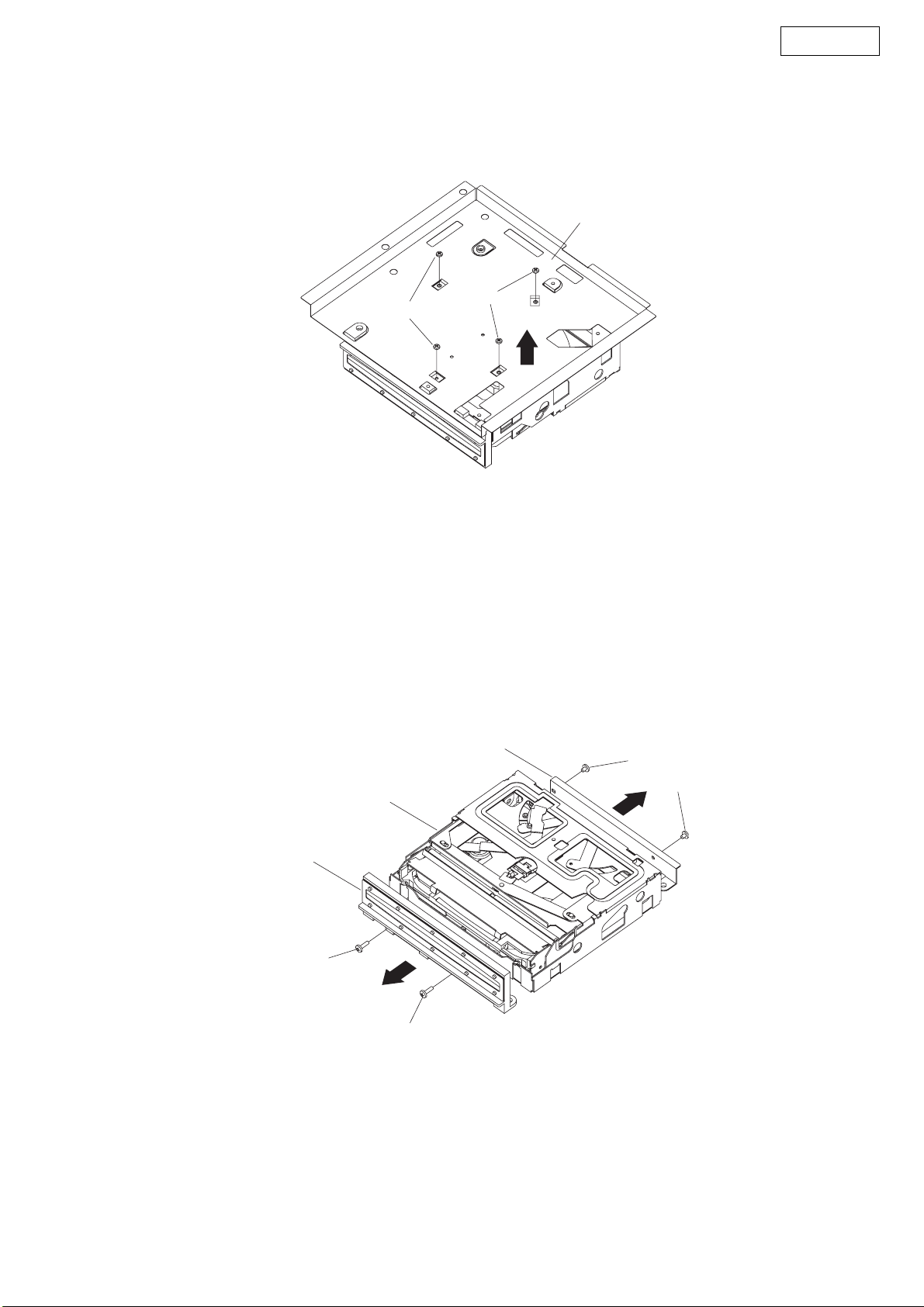

3. Motor unit

e

(1) Remove 4 screws 74.

(2) Detach Motor unit (FG3500).

74

DN-S3500

Motor unit

(FG3500)

74

4. Mecha unit

(1) Remove 2 screws 63 and 2 screws 64.

(2) Disconnect FFC cable and Connector.

(3) Detach Mecha Unit.

Mecha unit

Connector

CX061

64

63

63

FFC Cabl

CX361

Note:

z Do not pull out aslant to prevent FFC cable damage.

z Do not fail to pull AC cord from wall outlet before disconnect FFC cable.

If AC cord is remained plugged into wall outlet, power is kept supplied in the unit, which may cause danger.

4

Page 5

5. Power P.W.B.

(1) Remove 6 screws 69, a screws 72 and a screws 73.

(2) Detach Power P.W.B.

DN-S3500

69

69

Power P.W.B.

73

72

69

69

6. Main P.W.B.

(1) Short-circuit the short land above.

(2) Remove a screws 65 and a screws 66.

(3) Disconnect FFC Cable and FPC Cable.

(4) Detach Main P.W.B.

Main P.W.B.

Short land for laser diode

65

FPC Cable

66

Note:

z Do not pull out aslant to prevent FFC cable damage.

FFC Cable

5

Page 6

7. Shield Plate (E3 Model only)

(1) Remove 4 screws 60.

(2) Detach Shield Plate.

DN-S3500

Shield Plate

60

8. CD Mecha

(1) Remove 2 screws 63 and pull out Main Pwb Bracket.

(2) Remove 2 screws 64 and pull out Disc Guide.

Main Pwb Bracket

CD Mecha

60

63

63

Disc Guide

64

64

6

Page 7

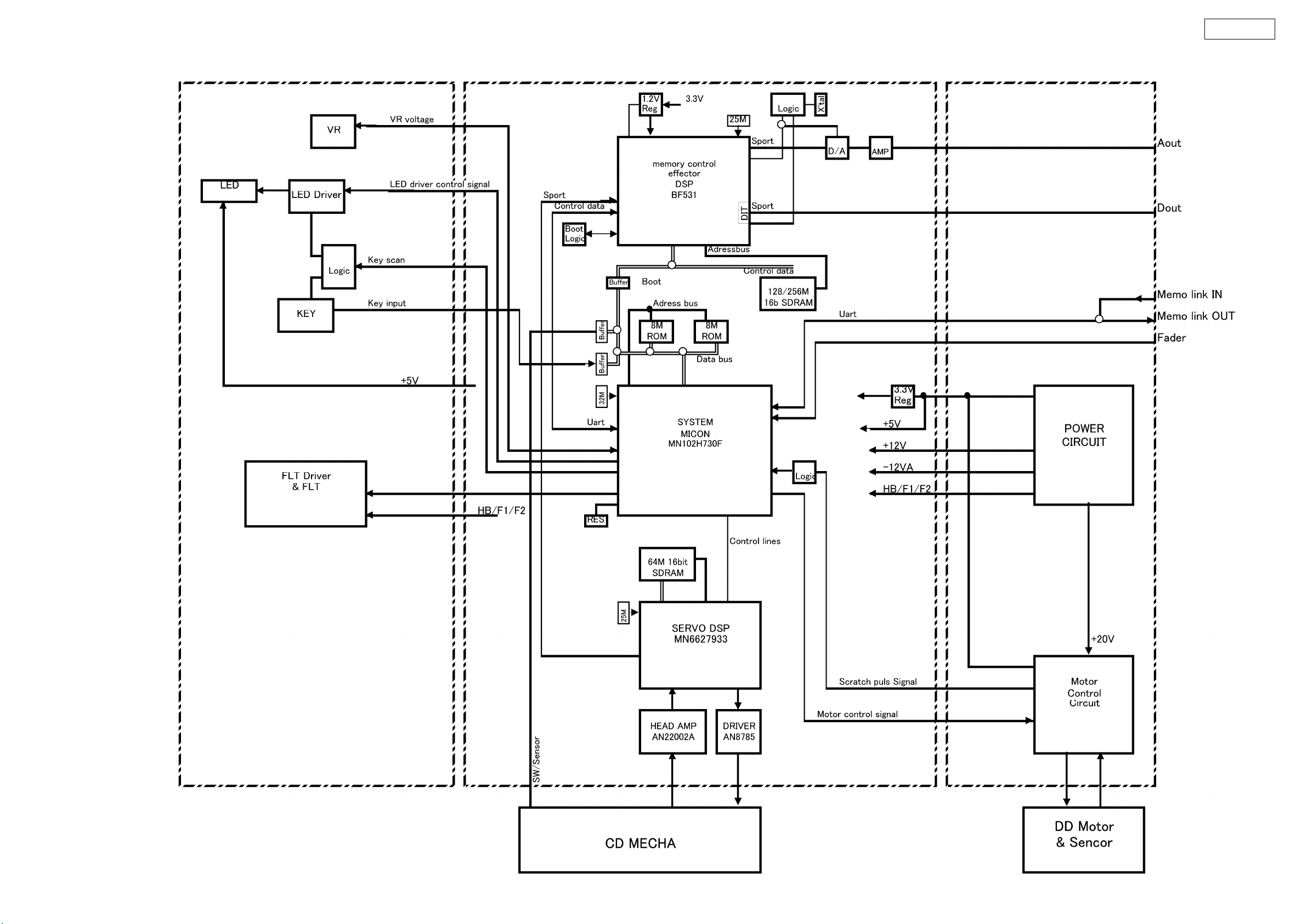

BLOCK DIAGRAM

DN-S3500

7

Page 8

DN-S3500

CONFIRMING THE SERVO

What is Service Program

Service program is a special program intended for confirming servo functions etc.

Required Measuring Implement

Reference disc (TCD784 or CO-74176)

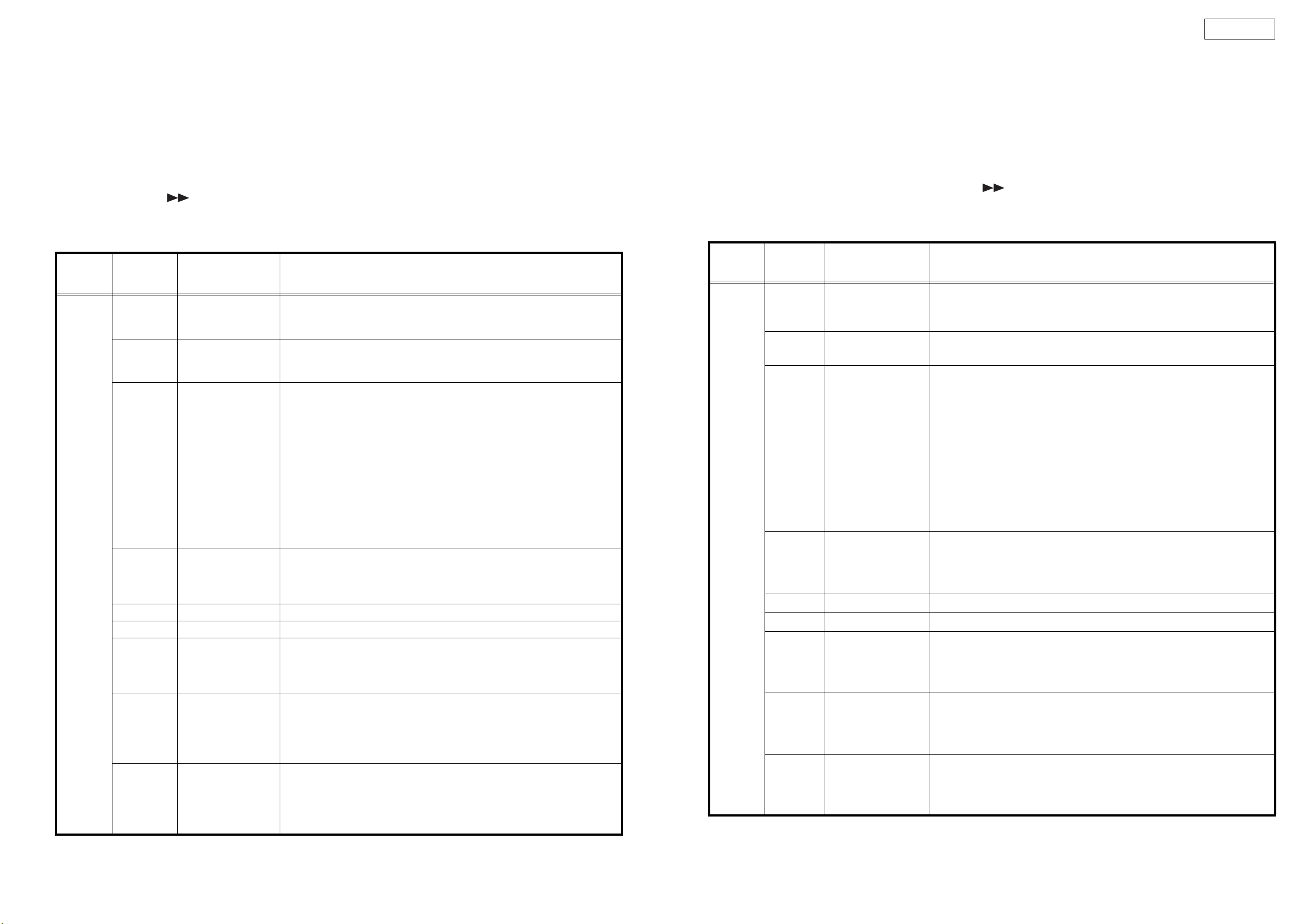

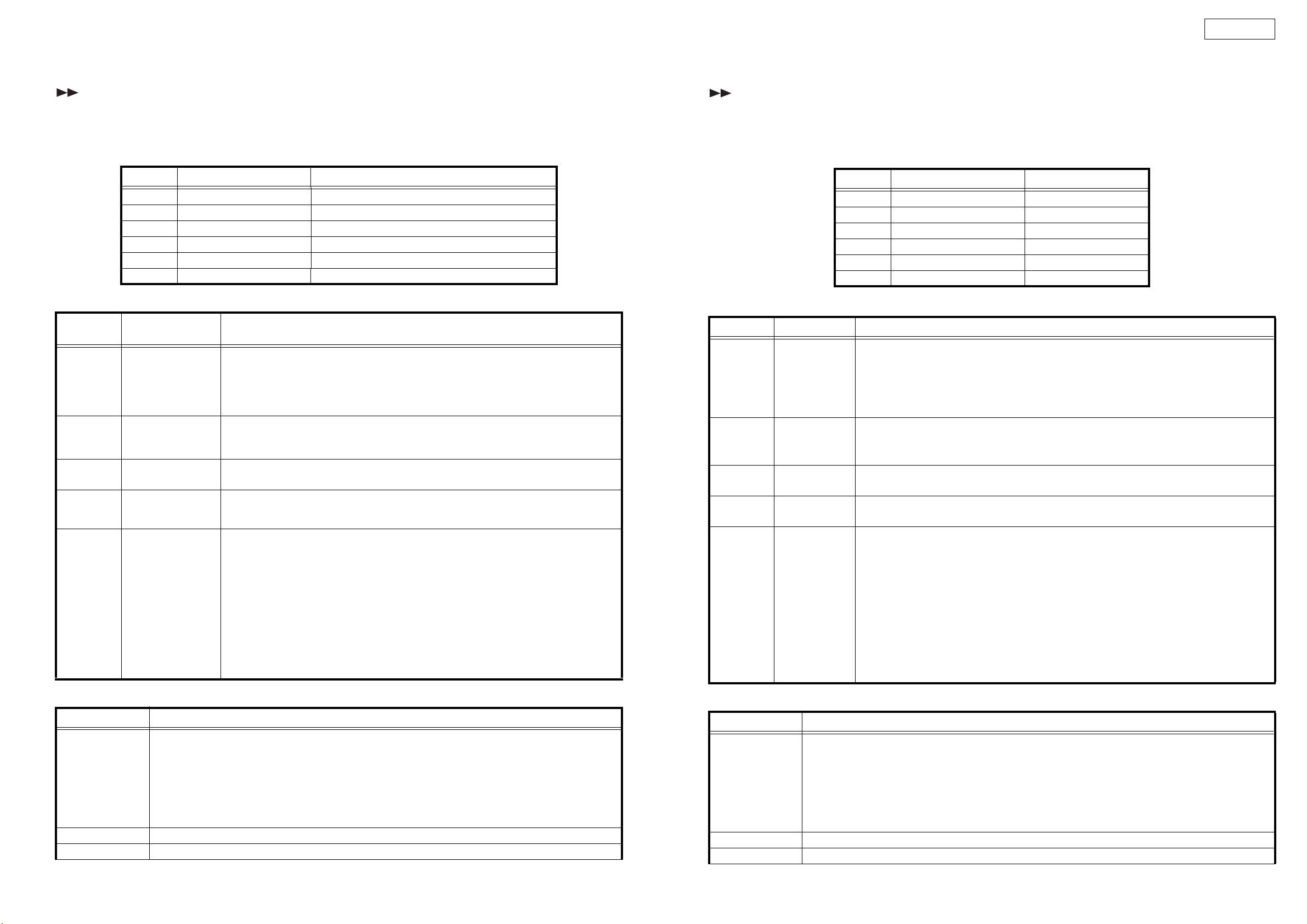

1. Contents of Service Program

Turn on the power while pressing both B button and the PARAMETER knob to set the service mode of DN-S3500. The various

check items can be selected with the PARAMETER knob, the various test items can be selected with the A, SAMP, EXIT/RELOOP,

(SAMP.)EXIT/RELOOP, and BEND buttons. Press either the PARAMETER knob or PLAY/PAUSE button to start the check

or test and display the result.

To eject the disc, press the DISC EJECT button.

To cancel the service mode, turn the power off.

PAR A ME T ER

knob

Process No.

(TRACK

Indication)

01

02

03

04 "Fo_Gain"

05 "Tr_Gain" Select the tracking gain. Default : 2. The operation is the same as for the Fo Gain.

06 "Block_Err" The block error rate is displayed.

07 "PU._Clean"

08

09

Function

(Character-display)

µcom Version check

(Version No.)

"TR_Signal"

"HF_Signal"

Automatic Servo

Adjustment call

(Servo Data)

Error Code Check

(Error Data)

Total Running Time

(Total Time)

Contents

A PARAMETER knob is pushed and a version is checked.

1. System µcom version No. : "System_XXXX"

2. DSP soft version No. : "Dsp_XXXX"

Press the PARAMETER knob to turn the tracking servo off.

When the tracking servo is off, press the PARAMETER knob to turn the tracking

servo on.

Press the PARAMETER knob to start automatic servo adjustment. When the

adjustment is completed, the adjustment data is displayed. The data can be

selected by turning the EFFECTS knob.

1. Disc check, CD/CD-RW

2. Focus gain data

3. Focus balance data

4. Focus offset data

5. Tracking gain data

6. Tracking balance data

7. Tracking offset data

8. S curve maximum

9. S curve minimum

Select the focus gain. Default : 7. Select the data with the scratch disc, then press

the PARAMETER knob to enter it. The higher the value, the higher the gain, while

the lower the value, the lower the gain.

* Do not change this without instruction from engineering.

When the PARAMETER knob is pressed, the pickup moves towards the outer

edge of the disc. The pickup lens becomes visible through the slit in the CD mechanism plate. The lens can be cleaned using a cotton swab, etc.

(Perform this operation with the top panel/cover removed and the disc ejected.)

During normal operation, the error code for the error that occurred is displayed.

Turn the EFFECTS knob to select up to 10 sets of error data stored in the memory. (See the error code table for a description of the error codes.)

・Press the PARAMETER knob to set the error data clear mode. ("Error Clear?" is

displayed.) Press the PARAMETER knob again to clear all the error data.

The total operating time of the spindle motor is displayed. A total of 65,535 hours

can be counted, in units of hours.

NOTE: If the power is turned off after 59 minutes or less, that hour is not counted.

・Press the PARAMETER knob to set the total time clear mode. ("Time Clear?" is

displayed.) Press the PARAMETER knob again to clear the total time.

サービスモード

サービスモードについて

サービスモードは、サーボ状態などを確認するための特別なプログラムです。

確認に必要な測定器具

リファレンスディスク:TCD784、CO-74176

1. サービスプログラムの内容

DN-S3500 は B ボタンとパラメータノブを両方押しながら、電源を投入するとサービスモードになります。パラメータノブで各チェック項目が、A ボタン、

SAMP ボタン、EXIT/RELOOP ボタン、(SAMP.)EXIT/RELOOP ボタン、 ボタンまたは BEND ボタンで各テスト項目が選択できます。

パラメータノブを押すか、PLAY/PAUSE ボタンを押すと各項目のチェック、テストを開始し、その結果を表示します。

ディスクをイジェクトするには、DISCEJECT ボタンを押します。

サービスモードをキャンセルするには、電源を切ってください。

パラメータノブ

チェック項No.

( トラック番号 )

01

02

03

04 "FoGain"

05 "TrGain" トラッキングゲインを選択します。デフォルト -2.操作方法は FoGain と同じ。

06 "BlockErr" ブロックエラーレートが表示されます。

07 "PU.Clean"

08

09

マイコンバージョンチェツク

VersionNo

"TRSignal"

"HFSignal"

サーボ自動調整値

読み出し

(ServoData)

エラーコードチェック

(ErrorData)

トータルランニングタイム

(TotalTime)

機能

キャラクター表示

内容

パラメータノブを押して、バージョンをチェックします。

1.システムマイコンバージョン No.:"SystemXXXX"

2.DSP ソフトバージョン No.:"DspXXXX"

パラメータノブを押すとトラッキングサーボを off します。

トラッキングサーボ off のとき、パラメータノブを押すとトラッキングサーボを on します。

パラメータノブを押すとサーボ自動調整を開始します。調整が終了すると、調整データ表示

します。データはエフェクトノブを回すことで選択できます。

1.ディスクチェック、CD/CD-RW

2.フォーカスゲインデータ

3.フォーカスバランスデータ

4.フォーカスオフセットデータ

5.トラッキングゲインデータ

6.トラッキングバランスデータ

7.トラッキングオフセットデータ

8.S カーブ最大値

9.S カーブ最小値

フォーカスゲインを選択します。デフォルト -7。スクラッチディスクでデータを選択し、パラメータノブを押

すと確定されます。数値が大きくなるとゲインが高くなり、数値が小さくなるとゲイン

が低くなります。

*設計からの指示がない限り変更しないで下さい。

パラメータノブを押すとピックアップがディスク外周方向へ移動します。CD メカ板金の隙間から

ピックアップのレンズが見えるようになります。綿棒等でレンズをクリーニングすることができ

ます。

( トップパネル / カバーを外し、ディスクをイジェクトした状態で実施下さい )

通常動作時、発生したエラーのエラーコードが表示されます。エフェクトノブを回すと、最大 10

個まで、記憶されたエラーデータが選択できます。( エラーコードはエラーコード表を参照下さい。)

・パラメータノブを押すと、エラーデータ消去モードになります。(ErrorClear?が表示されま

す ) 再度、パラメータノブを押すと、全てのエラーデータが消去されます。

スピンドルモータのトータル動作時間を表示します。1 時間単位で 65535 時間まで計測でき

ます。注意 )59 分以下で電源を切るとカウントされません。

・パラメータノブを押すと、トータル時間消去モードになります。(TimeClear?が表示されま

す ) 再度、パラメータノブを押すと、トータル時間が消去されます。

8

Page 9

DN-S3500

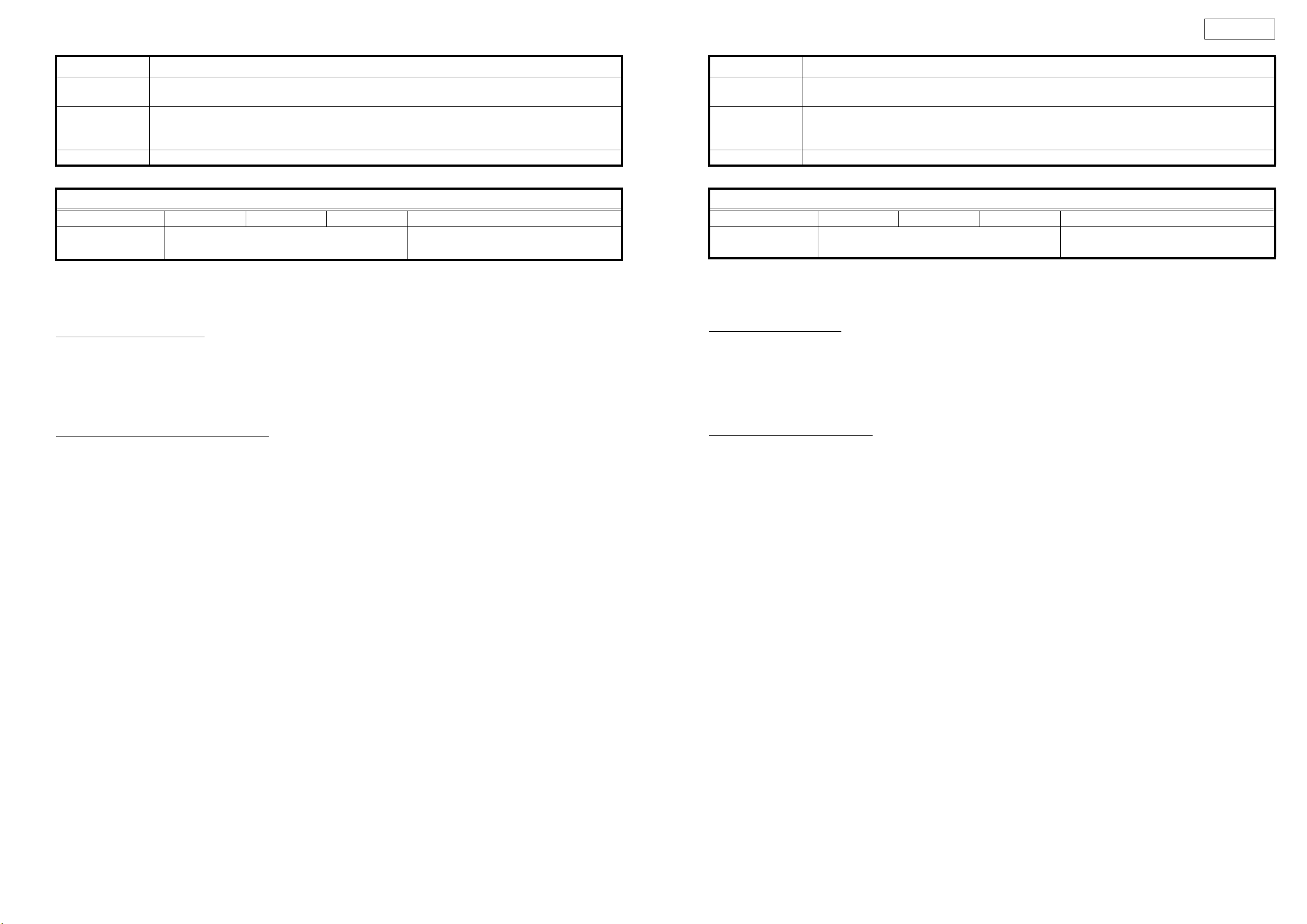

BEND+ button FLT all light check performed while button pressed.

-

BEND

button FLT all off check performed while button pressed.

button Disc eject status set while button pressed.

The disc loading/eject roller turns. The dirt can be cleaned off the roller by gently pressing a cotton swab with

propyl alcohol"

, against the roller.

(Perform this operation with the top panel/cover removed and the disc ejected.)

Servo automatic adjustment read-out value

Adjustment Item Adjustment Value indication at character portions.

1 Focus Gain 0408 ~ 3248

2 Focus Balance -50 ~ +50

3 Focus Offset -005 ~ +005

4 Tracking Gain 0392 ~ 1569

5 Tracking Balance -025 ~ +025

6 Tracking Offset -005 ~ +005

2. TEST MODE

A button

A2 button

SAMP button

(SAMP.)EXIT

/RELOOP

button

EXIT/

RELOOP

button

Function

(Character-display)

Heat Run Test

H/R1 Normal

Chucking Test

H/R2 Tray

Platter rotation speed

check

Platter rotation speed

fine adjustment

System check

Sys. Check

Press button A1, then press the PLAY/PAUSE button to start the test.

The disc is ejected, loaded and played repeatedly.

For discs containing 20 tracks or less, all the tracks are played.

For discs containing 21 tracks or more, only the first and last tracks on the disc are played.

If an error occurs, the error code is displayed and the stop mode is set.

Press button A2, then press the PLAY/PAUSE button to start the test.

The disc load/eject, servo input and TOC reading operations are performed repeatedly.

If an error occurs, the error code is displayed and the stop mode is set.

Press button SAMP, then press the PLAY/PAUSE button. The platter starts to rotate and

revolution number is displayed.

Press the (SAMP.)EXIT/RELOOP button, then press the PLAY/PAUSE button. The Platter starts

to rotate and revolution number is displayed. The rotation speed can be adjusted to turn the

parameter knob.

Press button EXIT/RELOOP, then press the PLAY/PAUSE button to start the system check.

Once the check is completed, the results are displayed.

1. The system µcom and DSP communications are checked.

2. Reading and writing SDRAM of DSP are checked.

3. Reading and writing SDRAM of servo DSP are checked.

4. Communications between the system µcom and servo DSP are checked.

5. The CD drive operation is checked. (Inner edge switch detection is performed.)

6. The CD drive operation is checked. (Disc detection is performed.)

Once all the checks are completed, the results are displayed on the character display. The

numbers of the checks in items 1 to 6 above that were OK are displayed. If one of the checks

was not OK, the number of that item is not displayed.

Contents

3. Error Code Table (Appears only at Heat Run and Chucking Test function)

Error Code Contents

Automatic Adjustment Error

E1 00

E1 01

E1 03

E1 04

E1 05

E1 06

E2 02 Servo down during automatic Adjustment

E3 00 Unable to read TOC

Unable to detect disk

Unable to adjust tracking offset

Unable to adjust focus fine gain

Unable to actuate focus

Unable to actuate tracking

Unable to adjust tracking fine gain

"Iso-

BEND+ボタン ボタンを押している間、FLT の全点灯チェックを行います。

-

BEND

ボタン ボタンを押している間、FLT の全消灯チェックを行います。

ボタン ボタンを押している間、ディスクをイジェクト状態にします。

ディスクローディング / イジェクト用のローラーが回転しますので、イソプロピルアルコールを付けた綿棒をローラーに軽く押し当てることに

より、ローラーの汚れを落とすことができます。

( トップパネル / カバーを外し、ディスクをイジェクトした状態で実施下さい )

サーボ自動調整読み出し値

サーボ調整項目 調整 OK 範囲

1 フォーカスゲイン 0408 〜 3248

2 フォーカスバランス -50 〜 +50

3 フォーカスオフセット -005 〜 +005

4 トラッキングゲイン 0392 〜 1569

5 トラッキングバランス -025 〜 +025

6 トラッキングオフセット -005 〜 +005

2. テストモード

機能キャラクター表示 内容

A1 ボタンを押し、PLAY/PAUSE ボタンを押すとテストを開始します。

ディスクの出し入れと、再生を繰り返します。

20 トラック以下のディスクのときは、全てのトラックを再生します。

21 トラック以上のディスクのときは、ディスク先頭トラックと最終トラックのみ再生します。エラーが発生すると、エラーコード

を表示して停止します。

A2 ボタンを押し、PLAY/PAUSE ボタンを押すとテストを開始します。

ディスクの出し入れと、サーボ投入、TOC の読み込みを繰り返します。

エラーが発生すると、エラーコードを表示して停止します。

SAMP ボタンを押し、PLAY/PAUSE ボタンを押すとプラッターが回転し、プラッターの回転数を表示します。

(SAMP.)EXIT/RELOOP ボタンを押し、PLAY/PAUSE ボタンを押すと、プラッターが回転し、プラッターの回転速度

を表示します。パラメータノブを回すと調整することができます。

EXIT/RELOOP ボタンを押し、PLAY/PAUSE ボタンを押すとシステムチェックを開始し、チェック終了後、その結果を表

示します。

1.システムマイコンと DSP の通信チェツクを行います。

2.DSP の SDRAM のリード / ライトチェツクを行います。

3.サーボ DSP の SDRAM のリード / ライトチェツクを行います。

4.システムマイコンとサーボ DSP の通信チェツクを行います。

5.CD ドライブの動作チェックを行います。( 内周 SW の検出をおこないます。)

6.CD ドライブの動作チェックを行います。( ディスク検出をおこないます。)

全てのチェックが終了すると、キャラクター表示に結果を表示します。1 〜 6 項目のチェックが OK の時は、OK になっ

た項目の番号が表示されます。NG の項目が合った場合、NG になった項目の番号が表示されません。

Aボタン

A2 ボタン

SAMP ボタン

(SAMP.)EXIT/

RELOOP ボタン

EXIT/RELOOP

ボタン

ヒートランテスト

H/R1Normal

チャッキングテスト

H/R2Load

プラッター回転速度

チェック

プラッター回転速度

微調整

システムチェック

Sys.Check

3. エラーコードテーブル ( ヒートランテスト、及び、チャッキングテストのとき表示されます )

エラーコード 内容

サーボ自動調整エラー

E100

E101

E103

E104

E105

E106

E202 サーボ自動調整中サーボが外れた。

E300 TOC が規定時間内に読めない。

ディスクが検出できない。

トラッキングオフセットが調整できない。

フォーカスゲインが調整できない。

フォーカスサーボが入らない。

トラッキングサーボが入らない。

トラッキングゲインが調整できない。

9

Page 10

DN-S3500

Error Code Contents

E4 00

E4 01

E5 00

E5 01

E5 02

E8 00 Track jumping was happened during memory of data. And unable to memorize data continuously.

TR MIN SEC FRAM CHARACTER

displays the track No. in

which error occurred.

Unable to close the disc holder in the regular time

Unable to open the disc holder in the regular time

The inner SW dose not turn on

Slider error

The inner SW dose not turn off

Error Indication

Displays the time at which error occurred.

H ****Operation count

E ****Error code

4. µcom update

The system µcom and DSP can be updated from a disc.

The µcom should be updated to the latest version, when GU-3689(MAIN PWB UNIT) or IC102(Flash ROM) is replaced.

(1) Creating the update disc

Use the procedure described below to create the disc for updating the system microprocessor and DSP.

① Store the update file on a CD-R or CD-RW disc in ISO9660 Mode 1 format, then finalize the disc.

・Write the distributed update files using the "DISC AT ONCE" CD writing software and finalize.

・Do not record any other software or data on the disc containing the update software.

・Do not change the file names - use the file names as distributed.

エラーコード 内容

E400

E401

E500

E501

E502

E800 メモリにデータ記憶中トラック飛びが発生し、規定のリトライを実施したが、連続でデータ記憶出来なかった。

トラック 分 秒 フレーム キャラクター

エラーが発生したトラック番号 エラーが発生した時間 (A タイム ) H ****動作回数

ディスクが規定時間内にローディングできない。

ディスクが規定時間内にイジェクトできない。

内周 SWON しない

スライドエラー

内周 SWOFF しない

エラー表示

E ****エラーコード

4. マイコンアップデート

DN-S3500 は、ディスクから、システムマイコン、DSP のアップデートを行うことができます。

GU-3689( メイン基板ユニット ) 又は、IC102 を交換した時は、最新バージョンにアップデートしてください。

(1) アップデートディスクの作成

システムマイコン、DSP のアップデート用ディスクディスクを下記に従い作成する。

① アップデート用のファイルを、CD-R、又は CD-RW ディスクに ISO9660,MODE1 のフォーマットで記録し、ファイナライズする。

・配布されたアップデートファイルを、CD ライティングソフトで DISCATONCE で書き込みしファイナライズする。

・アップデート用ソフト以外のソフトやデータを同一ディスク内に記録しないこと。

・ファイル名は、配布されたときのファイル名をそのまま使用すること。

(2) Updating the system µcom and DSP

① Turn on the power and load the disc created in (1) above.

When the update disc is detected, "Version Up" is displayed. And "xxxx → yyyyy" and "Push Play!" are displayed by turns.

xxxx : Old Version No., yyyy : New Version No.

② Press the PLAY/PAUSE button. "NowLoading" is displayed and the updating procedure starts.

As updating proceeds, the playback position indicator lights in order from left to right.

NOTE: In some extremely rare cases, the updating procedure is not completed. If the updating procedure has not finished after

three minutes, there could be a problem. Turn off the power and repeat the operation from step (2) ① .

Depending on the problem that occurred, it may happen that no other operations can be performed. If this happens, GU-

3689 IC102 must be replaced. Software must be pre-recorded on the IC102. (When ordering the IC102, order the more

recent system microprocessor version number (GEN number).)

③ When updating is completed, "Complete!" is displayed and the disc is ejected.

ADJUSTMENT

* When the motor (FG-3500) is replaced, platter rotation speed adjustment is necessary.

(1) Start the Platter Rotation Speed Fine Adjust mode in the test mode. (Refer to page 9)

The actual revolution number is indicated on the lower part of the Character display. (Standard is 33rpm)

The difference from the standard revolution number is indicated on the upper part of the Character display.

(2) Turn the parameter knob. And the "D_**"(left side) of the lower part of the Character display is set to "D_77".

Then check the difference from the standard revolution number.

-

a) The difference from the standard number is

・Turn the parameter knob to set "-2%". And push the parameter knob to complete the adjustment.

b) The difference from the standard number is outside of

・Start the platter revolution check mode in the test mode. (Refer to page 9)

Present revolution number is indicated on the lower part of character display. (Standard is 33rpm)

Difference from the standard revolution number is indicated on the upper part of character display.

・Make adjustment by turning VR701 on the power unit GU-3690 so that difference from the standard revolution number

indicated on the upper part of character display becomes

5% ~ +1% :

-

5% ~ +1% :

-

2%.

(2) システムマイコン、DSP のアップデート

① 電源を投入し、(1) で作成したディスクをローディングします

アップデート用ディスクが検出されると、"VersionUp" と表示し、"xxxx → yyyy"、"PushPlay!" の交互表示になります。

xxxx:旧バージョン No.、yyyy:新バージョン No.

② PLAY/PAUSE ボタンを押すと、"NowLoading" を表示しアップデートを開始します。

アップデートの進行に合わせ、再生位置表示が左から右へ順に点灯します。

注意 ) 大変希ではありますが、アップデート中に、アップデート未終了の異常状態が発生することがあります。アップデートを開始し3分

を経過しても終了しない場合も、異常が発生したと考えられますので、電源を切って、再度、(2) ①から同一の操作を

行って下さい。

発生した異常状況により、以後の全ての動作が出来なくなることがあります。その場合、GU-3689IC102 の交換が必要

になります。IC102 は、予め、ソフトウエアを書き込みする必要があります。(IC102 を発注の際は、最新のシステム

マイコンバージョン No(GENNo) で発注願います。)

③ アップデートが終了すると、"Complete!" を表示しディスクがイジェクトされます。

調整

*モータユニット(FG-3500) を交換した時は、プラッターの回転速度の調整が必要です。

(1) テストモードのプラッター回転速度微調整モードをスタートさせる。(9 ページ参照 )

キャラクター表示部下段の右側に現在の回転数が表示されます。( 基準は、33rpm です。)

キャラクター表示部上段に基準回転数との差が表示されます。

(2) パラメータノブを回し、キャラクター表示下段左側の D** を D77 に設定します。

その時、基準回転数との差を確認します。

-

a) 基準回転数との差が

・パラメータノブを回して、基準回転数との差が

が確定します。

b) 基準回転数との差が

・テストモードのプラッター回転数チェックモードをスタートさせる。(9 ページ参照 )

キャラクター表示部下段に現在の回転数が表示されます。( 基準は 33rpm です。)

キャラクター表示部上段に基準回転数との差が表示されます。

・電源ユニット GU-3690 の VR701 を回し、キャラクター表示部上段に表示されている基準回転数との差が

ます。

5%〜+1% の場合:

-

2%になるように調整する。そして、パラメータノブを押すと、回転速度の調整

-

5%〜+1% の範囲から外れる場合:

-

2% になる様に調整し

10

Page 11

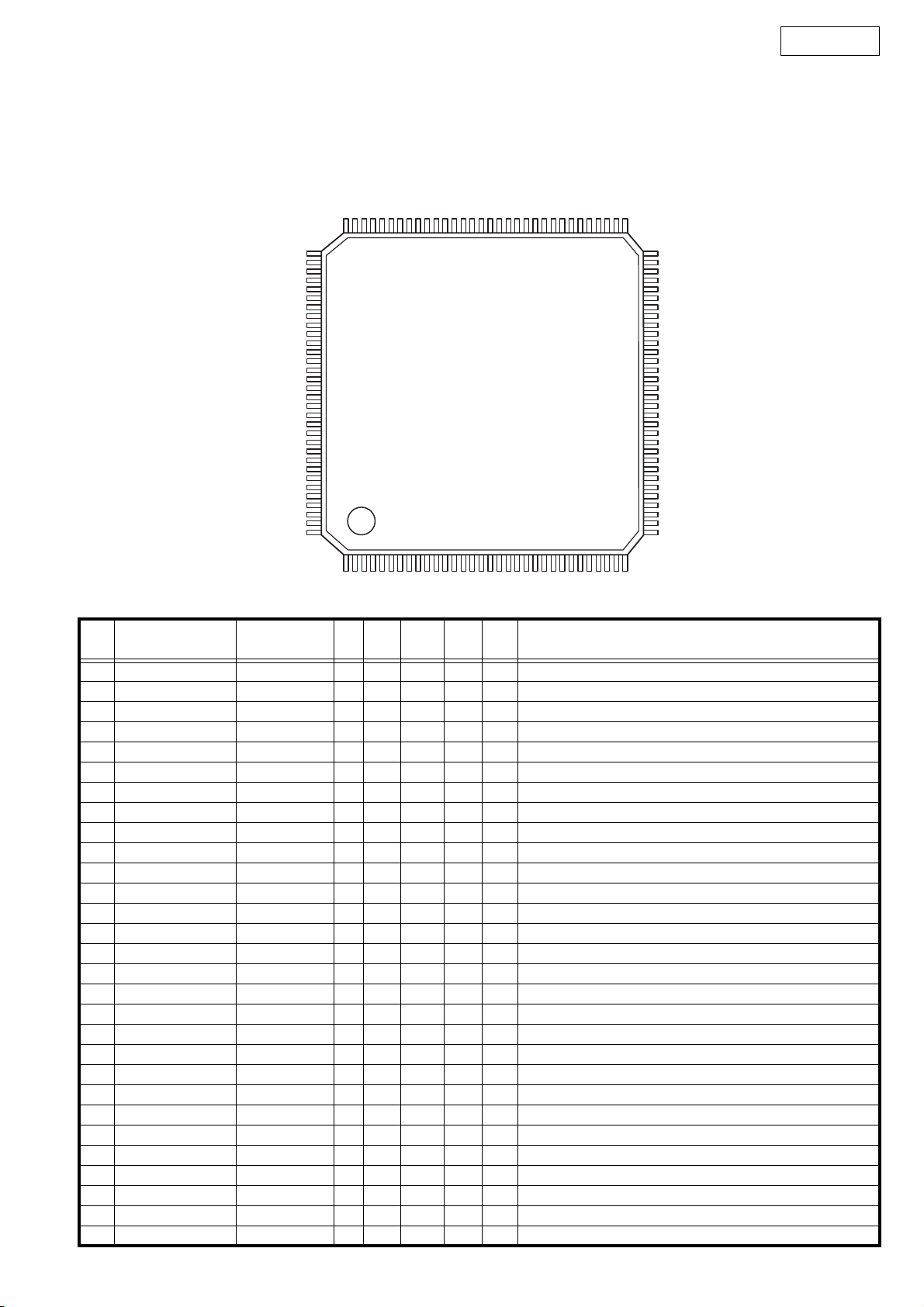

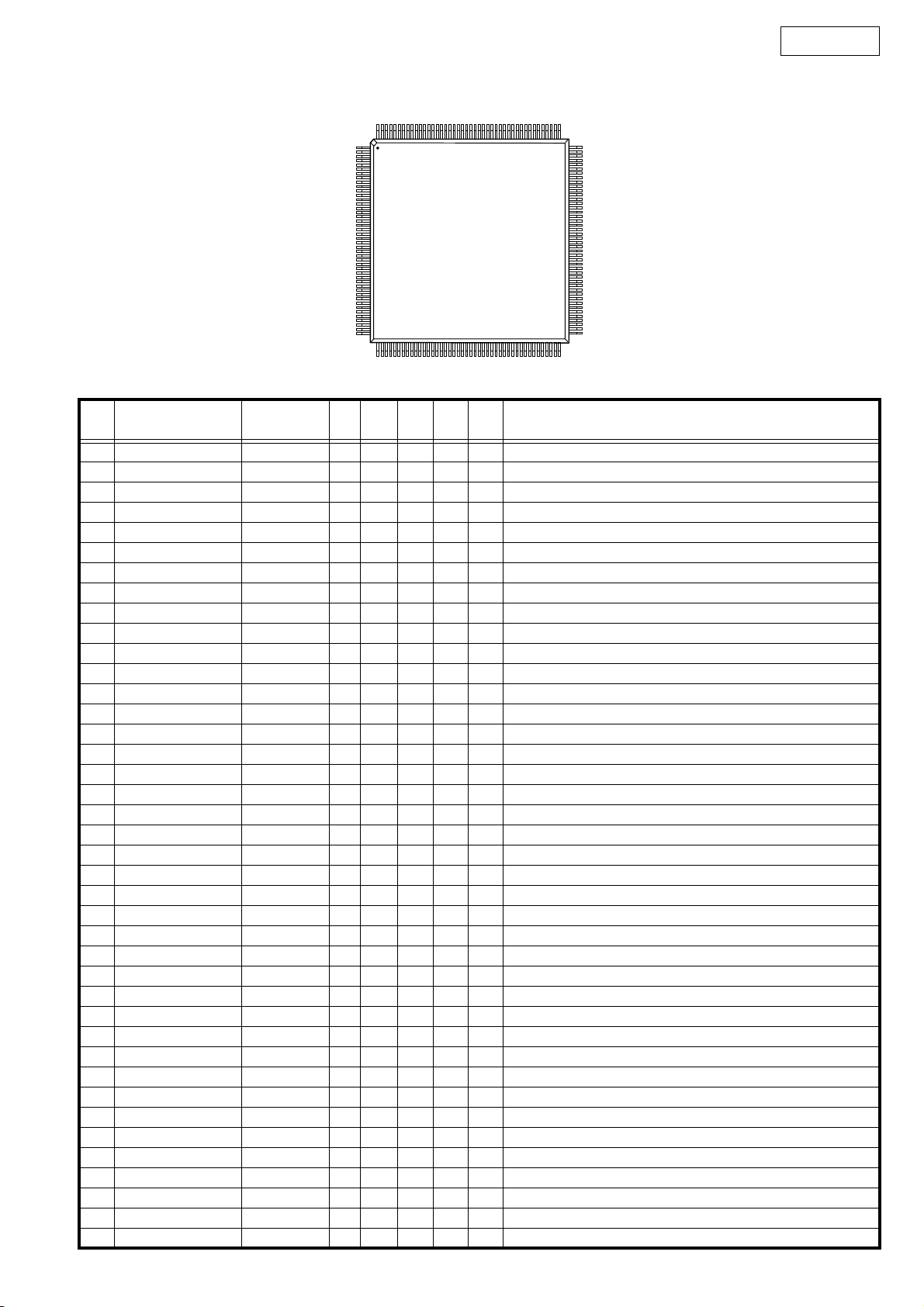

SEMICONDUCTORS /半導体一覧表

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

主な半導体を記載しています。汎用の半導体は記載を省略しています。

1. IC’s

MN102H730F (IC101)

96 65

97 64

TOP VIEW

DN-S3500

128 33

1

32

MN102H730F Terminal Function

Pin

No.

1 CS0_ CS0_ O - Pu - - External memory chip select 0 (FrashROM CS)

2 CS1_ CS1_ O - Pu - - External memory chip select 1 (Frashrom for memo)

3 D00 DQ0 I/O - - - - External memory data in/out 0, DSP interface 0

4 D01 DQ1 I/O - - - - External memory data in/out 1, DSP interface 1

5 D02 DQ2 I/O - - - - External memory data in/out 2, DSP interface 2

6 D03 DQ3 I/O - - - - External memory data in/out 3, DSP interface 3

7 VDD VDD - - - - - Power (+3.3V)

8 VSS VSS - - - - - GND

9 D04 DQ4 I/O - - - - External memory data in/out 4, DSP interface 4

10 D05 DQ5 I/O - - - - External memory data in/out 5, DSP interface 5

11 D06 DQ6 I/O - - - - External memory data in/out 6, DSP interface 6

12 D07 DQ7 I/O - - - - External memory data in/out 7, DSP interface 7

13 D08 DQ8 I/O - - - - External memory data in/out 8, DSP interface 8

14 D09 DQ9 I/O - - - - External memory data in/out 9, DSP interface 9

15 D10 DQ10 I/O - - - - External memory data in/out 10, DSP interface 10

16 PD0,DMAACK1_ MUTE_ O - Pd L L Mute signal (L:mute)

17 PD1,DMAREQ1_ DSPF3 O - - L - FLAG3 for DSP

18 D11 DQ11 I/O - - - - External memory data in/out 11, DSP interface 11

19 D12 DQ12 I/O - - - - External memory data in/out 12, DSP interface 12

20 D13 DQ13 I/O - - - - External memory data in/out 13, DSP interface 13

21 D14 DQ14 I/O - - - - External memory data in/out 14, DSP interface 14

22 D15 DQ15 I/O - - - - External memory data in/out 15, DSP interface 15

23 WORD WORD I - - Data bus width select (H:16bit width), GND fixed

24 VDD VDD - - - - - Power (+3.3V)

25 MODE MODE I - - L L Processor mode, GND fixed

26 PC3 APOWER O - Pd L L Analog out power ON/OFF (L: Power OFF)

27 XI XI I - - - - Oscillation input terninal

28 XO XO O - - - - Oscillation output terninal

29 VDD VDD - - - - - Power (+3.3V)

Pin Name Symbol I/O DET Ext Ini Res Function

11

Page 12

DN-S3500

Pin

No.

30 OSCI OSCI I - - - - Oscillation input terninal 32.0MHz

31 OSCO OSCO O - - - - Oscillation output terninal

32 VSS VSS - - - - - GND

33 P57,BOSC DR_/W O - - H - DN7000X: DSP interface send/receive select signal

34 PC5,NMI_ NMI I - - - - Connect to power

35 RST_ RST_ I - - - - Micro-processor RESET

36 PC0 FPLAY1 I - (Pu) H H MAIN fader start PLAY input

37 P76 FCUE1 I - (Pu) H H MAIN fader start CUE input

38 P60,IRQ0 DTIME I - iPu H -

39 P61,IRQ1 BLKCK I - iPu - - Sub-code clock interrupt

40 P62,IRQ2,TM10IOA TABLE I - (Pu) - - Pulse width measure input for turntable

41 P63,IRQ3,TM10IOB DBCLK I - - - - Pulse width measure clock input (5.6MHz) for DISC

42 P64,IRQ4 DTIMES I - iPu H - X2;clock interrupt input for sampler play/X1

43 P65,IRQ5,TM12IOA DISCA I - - - - Pulse width measure input for scratch DISC

44 P66,IRQ6 DISCDIR I - (Pu) - - Scratch DISC turn direction detect interrupt input

45 P67,IRQ7 DQSY I - iPu - - CD-TEXT DQSY interrupt

46 P70,TM13IOB DISCPA I - (Pu) H H Pulse A count input for scratch DISC

47 P71 ML O - iPu - - D/A interface latch 2 lines common

48 PD2,DMAACK0_ CHGOFT O - - L - Off track signal (transistor drive)

49 PD3,TM3IO DISCPA_ I - - - - Pulse A inverse count input for scratch DISC

50 VDD VDD - - - - - Power (+3.3V)

51 P77 DSTBY_ O - Pd L L Driver standby signal Çk: standby

52 P72,TM14IOB DISCPB I - - - - Pulse B count input for scratch DISC

53 P73,TM11I0B DISCINT I - (Pu) - - DISC rotation start interrupt input

54 P74 MLD O - - H - Servo DSP interface latch

55 P75§TM12IOB DBCLK I - - - - Pulse width measure clock input (5.6MHz) for DISC

56 PA0,SBI0 STAT I - iPu - - Servo DSP interface receive (clock synchronous)

57 PA1,SBO0 MDAT O - - H - Servo DSP interface send (clock synchronous)

58 PA2,SBT0 MCLK O - - H - Servo DSP interface clock (clock synchronous)

59 PA3,SBI1 RXDM I - (Pu) - - Interface receive with Memo link SET (asynchronous)

60 PA4,SBO1 TXDM O - Pu H H Interface receive with Memo link SET (asynchronous)

61 PA5,SBT1 NRES_ O - Pd L L Peripheral IC reset signal

62 PB0,SBI2 DSPRXD I - Pu - H DSP interface receive (asynchronous)

63 PB1,SBO2 DSPTXD O - Pu H H DSP interface send (asynchronous)

64 PB2,SBT2 FLCS_ O - - H - FLT driver enable signal

65 PB3,SBI3 FLRES_ O - Pd L L FLT driver reset signal

66 PB4,SBO3 PDATA O - - H - FLT driver data, and LED driver data (clock synchronous)

67 PB5,SBT3 FLCLK O - - H - FLT driver data send clock (clock synchronous)

68 VDD VDD - - - - - Power (+3.3V)

69 VSS VSS - - - - - GND

70 AVSS AVSS - - - - - Analog standard GND for AD conversion

71 Vref- Vref- - - - - - Analog standard voltage for AD conversion

72 P80 O - Pd L L Not used

73 P81 O - - H - Not used

74 P82 O - - H - Not used

75 P83 SEL_A O - - L - Key scan out select signal A

76 P84 SEL_B O - - L - Key scan out select signal B

77 P85 SEL_C O - - L - Key scan out select signal C

78 P86,AD06 PITCH I - - - - Slide VR data input for pitch

79 P87,AD07 PITCHC I - - - - Slide VR center value data input for pitch

80 PD4 SEL_D O - Pu H H Key scan out select signal D

81 PD5 I - Pu (H) H Not used

82 P90 I - Pu (H) H Not used

83 P91 MSTART O - Pd L L MOTOR START/STOP H: MOTOR START

84 P92 MDIR O - - H - MOTOR turn direction select H: forward

Pin Name Symbol I/O DET Ext Ini Res Function

X2;clock interrupt in for play/X1;LRCK :used for time code make

out when MP3 play

12

Page 13

DN-S3500

Pin

No.

85 P93 DSPRES_ O - Pd L L DSP RESET signal L: RESET

86 Vref+ Vref+ - - - - - Analog standard voltage +3.3V for AD conversion

87 AVDD AVDD - - - - - Power (+3.3V)

88 P94,DAC0 MSPD1 O - - - - MOTOR turn speed output D/A1

89 P95,DAC1 MSPD2 O - - - - MOTOR turn speed output D/A2(RESERVE)

90 P96,DAC2 MBRK O - - - - MOTOR BRAKE ON: H

91 P97,DAC3 LOAD O - - - - Disc loading, eject signal (D/A)

92 PC6,BREQ_ BREQ_ I - Pu - H Bus request signal

93 PC7,BRACK_ BRACK_ O - Pu H H Bus request accept signal

94 WEL_ WE_ O - Pu - H External memory write enable (lower 8bit)

95 P51 BOOT_ O - Pu H H DSP boot start signal L: START

96 RE_ RE_ O - Pu - H External memory read enable

97 CS2_ CS2_ O - Pu - H External memory chip select 2 (DSP Latch buffer interface)

98 VDD VDD - - - - - Power (+3.3V)

99 VSS VSS - - - - - GND

100 P54,BSTRE DACK_ I - Pu H H Not used

101 P55,WR_ DREQ_ O - Pu H H Not used

102 CS3_ CS3_ O - Pu - H Extended port chip select

103 A00 A00 O - - - - External memory address bus 0 (not used when 16bit bus select)

104 A01 A01 O - - - - External memory address bus 1

105 A02 A02 O - - - - External memory address bus 2

106 A03 A03 O - - - - External memory address bus 3

107 A04 A04 O - - - - External memory address bus 4

108 A05 A05 O - - - - External memory address bus 5

109 A06 A06 O - - - - External memory address bus 6

110 A07 A07 O - - - - External memory address bus 7

111 A08 A08 O - - - - External memory address bus 8

112 PD6 DSPF1 O - - L - FLAG1 for DSP

113 PD7,TM7IO DISCPB_ I - iPu - - Pulse B inverse count input for scratch DISC

114 A09 A09 O - - - - External memory address bus 9

115 A10 A10 O - - - - External memory address bus 10

116 A11 A11 O - - - - External memory address bus 11

117 A12 A12 O - - - - External memory address bus 12

118 A13 A13 O - - - - External memory address bus 13

119 VDD VDD - - - - - Power (+3.3V)

120 PC4 DSPF2 O - - L - FLAG2 for DSP

121 A14 A14 O - - - - External memory address bus 14

122 A15 A15 O - - - - External memory address bus 15

123 A16 A16 O - - - - External memory address bus 16

124 A17 A17 O - - - - External memory address bus 17

125 A18 A18 O - - - - External memory address bus 18

126 A19 A19 O - Pd - - External memory address bus 19

127 A20 A20 O - - - - External memory address bus 20

128 A21 A21 O - - - - External memory address bus 21

Pin Name Symbol I/O DET Ext Ini Res Function

13

Page 14

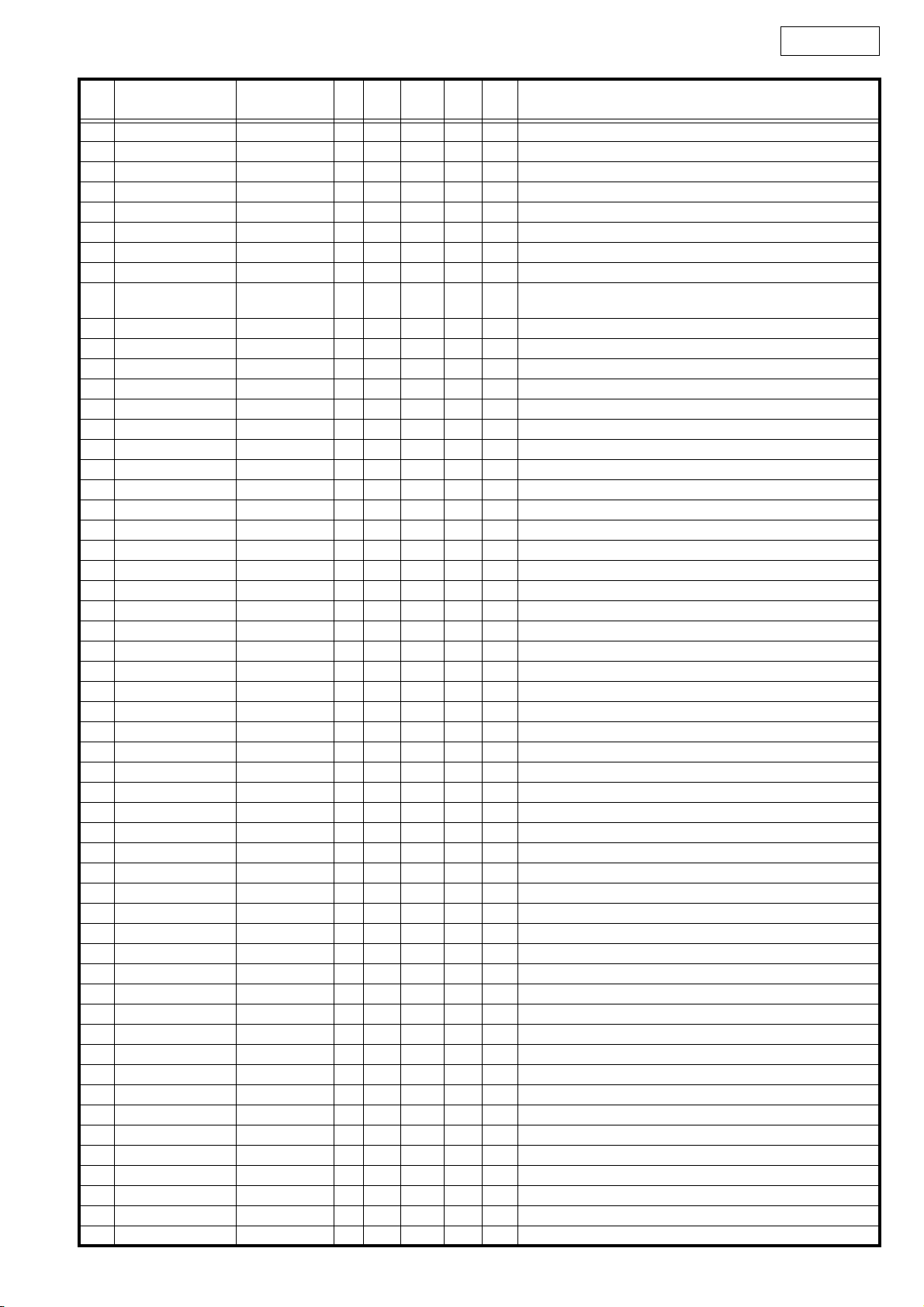

ADSP-BF531 (IC401)

DN-S3500

176

1

PIN 1

TOP VIEW

44

45

133

88

132

89

ADSP-BF531 Terminal Function

Pin

No.

1 GND GND - - - - - GND

2 GND GND - - - - - GND

3 GND GND - - - - - GND

4 VROUT2 O - - - - External FET drive output 2

5 VROUT1 VROUT1 O - - - - External FET drive output 1

6 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

7 GND GND - - - - - GND

8 GND GND - - - - - GND

9 GND GND - - - - - GND

10 CLKIN CLKIN I - - - - Clock input 25MHz oscillation

11 XTAL XTAL O - - - - Cristal oscillator terminal

12 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

13 _RESET _RESET I - - - - Reset signal input

14 NMI NMI I - - - - Mask disable interrupt

15 GND GND - - - - - GND

16 RTXO O - - - - RTC cristal oscillator output

17 RTXI I - - L L RTC cristal oscillator input

18 VDDRTC VDDRTC I - - - - Real time clock power (+3.3V)

19 GND GND - - - - - GND

20 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

21 PPI_CLK I - - L L PPI clock

22 PPI0 O - - L - PPI data 0

23 PPI1 O - - L - PPI data 1

24 PPI2 O - - L - PPI data 2

25 VDDINT VDDINT I - - - - Internal power (+1.2V)

26 PPI3 O - - L - PPI data 3

27 PF15 O - - L - Programmable flag pin 15

28 PF14 O - - L - Programmable flag pin 14

29 PF13 O - - L - Programmable flag pin 13

30 GND GND - - - - - GND

31 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

32 PF12 I - Pu H H Not used

33 PF11 I - - L - Not used

34 PF10 O - Pu H H Not used

35 PF9 I - Pu H H Not used

36 PF8 DSPF5 O - - L - (RESERVE)

37 PF7 O - - L - Not used

38 PF6 DTIMES O - - L - Playback clock output for SAMPLER

39 GND GND - - - - - GND

40 GND GND - - - - - GND

Pin Name Symbol I/O DET Ext Ini Res Function

14

Page 15

DN-S3500

Pin

No.

41 GND GND - - - - - GND

42 GND GND - - - - - GND

43 GND GND - - - - - GND

44 GND GND - - - - - GND

45 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

46 PF5 DSPF3 O - - L - Programmable flag pin5 Inter micro processor pin3 (RESERVE)

47 PF4 DSPF2 O - - L - Programmable flag pin4 Inter micro processor pin2 (RESERVE)

48 PF3 DSPF1 O - - L - Programmable flag pin3 Inter micro processor pin1 (RESERVE)

49 PF2 DSPF0 O - - L - Programmable flag pin2 Inter micro processor pin0 (RESERVE)

50 PF1 DTIME O - - L - Programmable flag pin1 Clock output for playback

51 PF0 BTEND O - Pd L L Programmable flag pin0 'H' when all boot completed

52 VDDINT VDDINT I - - - - Internal power (+1.2V)

53 SCK O - - L - Master slave clock

54 MISO O - - L - Master input slave output

55 MOSI O - - L - Master output slave input

56 GND GND - - - - - GND

57 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

58 DT1SEC O - - - - Not used

59 DT1PRI DDATA1 O - - - - Main digital out data send 0 (serial port OUT 1)

60 TFS1 DLRCK I - IPu - H Digital out send frame synchro (LRCK) signal (serial port OUT 1)

61 TSCLK1 DBCK I - - - - Digital out send frame synchro (BCK) signal (serial port OUT 1)

62 DR1SEC I - - L L Playback data receive 1

63 DR1PRI I - - - - Not used

64 RFS1 O - - - - Not used

65 RSCLK1 O - IPu - H Not used

66 VDDINT VDDINT I - - - - Internal power (+1.2V)

67 DT0SEC ADATA2 O - - - - Not used

68 DT0PRI ADATA1 O - - - - Main analog playback data send 0 (serial port OUT 0)

69 TFS0 ALRCK I - IPu - H

70 GND GND - - - - - GND

71 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

72 TSCLK0 ABCK I - - - -

73 DR0SEC I - - L L Playback data receive 1

74 DR0PRI SRDATA I - - - - Playback data receive 0 (serial port IN 0)

75 RFS0 LRCK I - - - - Receive frame synchro (LRCK) signal (serial port IN 0)

76 RSCLK0 BCLK I - IPu - H Receive frame synchro (BCK) signal (serial port IN 0)

77 TMR2 O - - L - Timer 2

78 TMR1 O - - L - Timer 1

79 TMR0 O - - L - Timer 0

80 VDDINT VDDINT I - - - - Internal power (+1.2V)

81 TX TX O - Pu H - UART send

82 RX RX I - Pu - H UART receive

83 _EMU _EMU O - - - - Emulation status

84 _TRST _TRST I - Pd - L Test reset (JTAG)

85 TMS TMS I - Pu - H Test mode select (JTAG)

86 TDI TDI I - Pu - H Test data input (JTAG)

87 TD0 TD0 O - - - - Test data output (JTAG)

88 GND GND - - - - - GND

89 GND GND - - - - - GND

90 GND GND - - - - - GND

91 GND GND - - - - - GND

92 GND GND - - - - - GND

93 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

94 TCK TCK I - Pu - H Test clock (JTAG)

95 BMODE1 BMODE1 I - - - - Boot mode strap 1

Pin Name Symbol I/O DET Ext Ini Res Function

Analog playback send frame synchro (LRCK) signal (serial port OUT 0)

Analog playback send frame synchro (BCK) signal (serial port OUT 0)

15

Page 16

DN-S3500

Pin

No.

96 BMODE0 BMODE0 I - - - - Boot mode strap 0

97 GND GND - - - - - GND

98 DATA15 D15 I/O - - - - External bus data 15

99 DATA14 D14 I/O - - - - External bus data 14

100 DATA13 D13 I/O - - - - External bus data 13

101 DATA12 D12 I/O - - - - External bus data 12

102 DATA11 D11 I/O - - - - External bus data 11

103 DATA10 D10 I/O - - - - External bus data 10

104 DATA9 D9 I/O - - - - External bus data 9

105 DATA8 D8 I/O - - - - External bus data 8

106 GND GND - - - - - GND

107 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

108 DATA7 D7 I/O - - - - External bus data 7

109 DATA6 D6 I/O - - - - External bus data 6

110 DATA5 D5 I/O - - - - External bus data 5

111 VDDINT VDDINT I - - - - Internal power (+1.2V)

112 DATA4 D4 I/O - - - - External bus data 4

113 DATA3 D3 I/O - - - - External bus data 3

114 DATA2 D2 I/O - - - - External bus data 2

115 DATA1 D1 I/O - - - - External bus data 1

116 DATA0 D0 I/O - - - - External bus data 0

117 GND GND - - - - - GND

118 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

119 _BG O - - - - Bus accept signal

120 _BGH O - - - - Bus accept wait signal

121 ADDR19 BA1 I/O - - - - External bus address 19

122 ADDR18 BA0/ADDR18 I/O - - - - External bus address 18

123 ADDR17 ADDR17 I/O - - - - External bus address 17

124 ADDR16 ADDR16 I/O - - - - External bus address 16

125 ADDR15 ADDR15 I/O - - - - External bus address 15

126 ADDR14 ADDR14 I/O - - - - External bus address 14

127 ADDR13 ADDR13 I/O - - - - External bus address 13

128 GND GND - - - - - GND

129 GND GND - - - - - GND

130 GND GND - - - - - GND

131 GND GND - - - - - GND

132 GND GND - - - - - GND

133 GND GND - - - - - GND

134 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

135 ADDR12 ADDR12 I/O - - - - External bus address 12

136 ADDR11 ADDR11 I/O - - - - External bus address 11

137 ADDR10 ADDR10 I/O - - - - External bus address 10 (SDRAM connects with SDA10)

138 ADDR9 ADDR9 I/O - - - - External bus address 9

139 ADDR8 ADDR8 I/O - - - - External bus address 8

140 ADDR7 ADDR7 I/O - - - - External bus address 7

141 ADDR6 ADDR6 I/O - - - - External bus address 6

142 ADDR5 ADDR5 I/O - - - - External bus address 5

143 VDDINT VDDINT I - - - - Internal power (+1.2V)

144 GND GND - - - - - GND

145 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

146 ADDR4 ADDR4 I/O - - - - External bus address 4

147 ADDR3 ADDR3 I/O - - - - External bus address 3

148 ADDR2 ADDR2 I/O - - - - External bus address 2

149 ADDR1 ADDR1 I/O - - - - External bus address 1

150 _ABE1 SDQM1 I/O - - - - SDRAM data mask 1

Pin Name Symbol I/O DET Ext Ini Res Function

16

Page 17

DN-S3500

Pin

No.

151 _ABE0 SDQM0 I/O - - - - SDRAM data mask 0

152 _AWE _AWE O - - H H Asynchro memory write enable

153 _ARE _ARE O - - H H Asynchro memory read enable

154 _AOE O - - - - Asynchro memory output enable

155 GND GND - - - - - GND

156 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

157 VDDINT VDDINT I - - - - Internal power (+1.2V)

158 _AMS3 O - - - - Asynchro memory bank select 3

159 _AMS2 O - - - - Asynchro memory bank select 2

160 _AMS1 _AMS1 O - - - - Asynchro memory bank select 1

161 _AMS0 _AMS0 O - - - - Asynchro memory bank select 0

162 ARDY I - - - L Bus wait ready signal

163 _BR I - - - H Bus request signal

164 SA10 SA10 I/O - - - - Synchro memory A10

165 _SWE _SWE O - - - - Synchro memory write enable signal

166 _SCAS _SCAS O - - - - Synchro memory column address strobe signal

167 _SRAS _SRAS O - - - - Synchro memory row address strobe signal

168 VDDINT VDDINT I - - - - Internal power (+1.2V)

169 CLKOUT CLKOUT I/O - - - - Synchro memory clock output

170 GND GND - - - - - GND

171 VDDEXT VDDEXT I - - - - I/O power (+3.3V)

172 _SMS _SMS O - - - - Synchro memory bank select signal

173 SCKE SCKE O - - - - Synchro memory clock enable signal

174 GND GND - - - - - GND

175 GND GND - - - - - GND

176 GND GND - - - - - GND

Pin Name Symbol I/O DET Ext Ini Res Function

17

Page 18

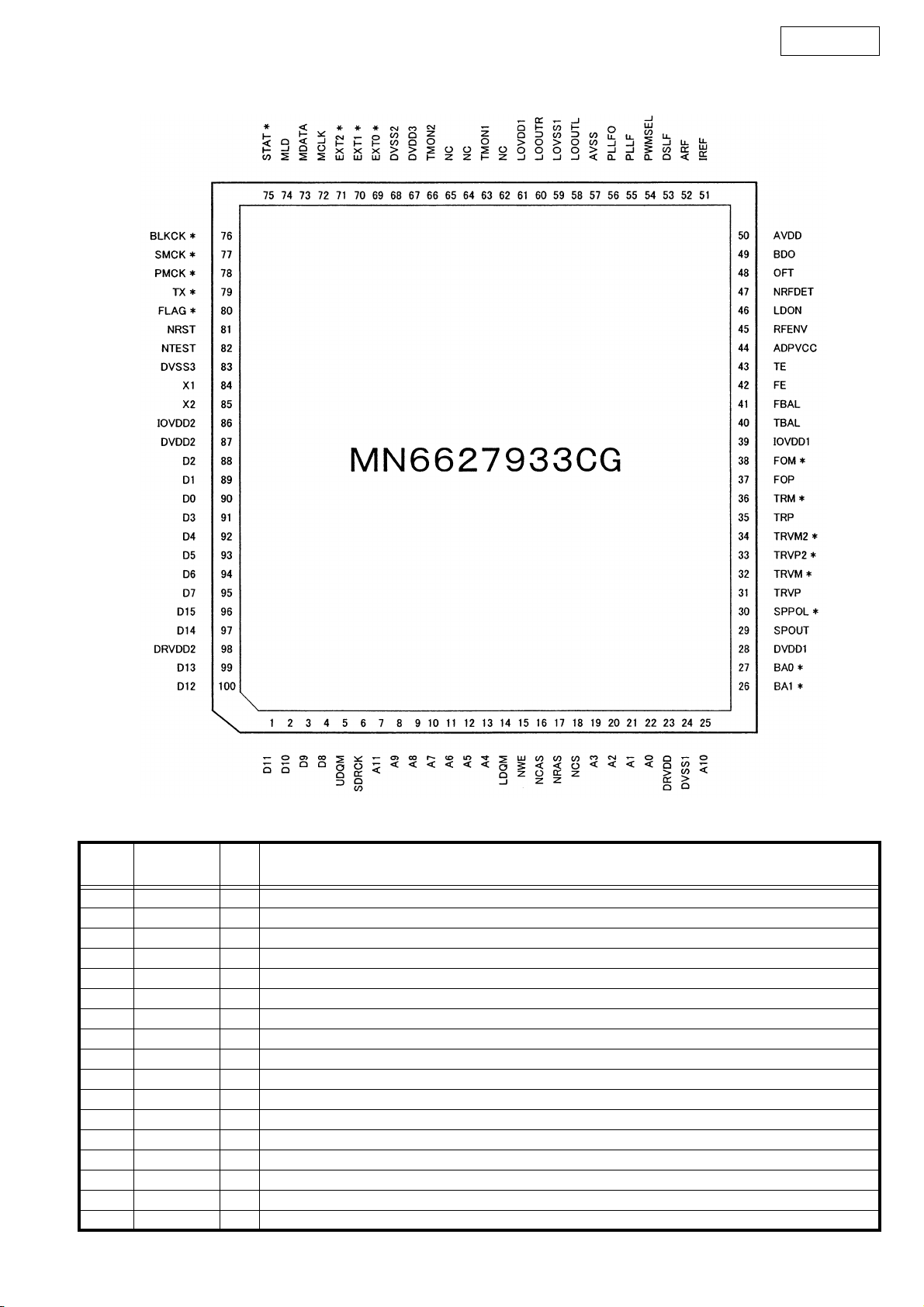

MN6627933 (IC201)

DN-S3500

MN6627933 Terminal Function

Pin

No.

Pin Name I/O Function

1 D11 I/O SDRAM data signal I/O 11

2 D10 I/O SDRAM data signal I/O 10

3 D9 I/O SDRAM data signal I/O 9

4 D8 I/O SDRAM data signal I/O 8

5 UDQM O SDRAM higher rank byte data mask signal output

6 SDRCK O SDRAM clock signal output

7 A11 O SDRAM address signal output 11

8 A9 O SDRAM address signal output 9

9 A8 O SDRAM address signal output 8

10 A7 O SDRAM address signal output 7

11 A6 O SDRAM address signal output 6

12 A5 O SDRAM address signal output 5

13 A4 O SDRAM address signal output 4

14 LDQM O SDRAM lower rank byte data mask signal output

15 NEW O SDRAM write enable signal output

16 NCAS O SDRAM CAS control signal output

17 NRAS O SDRAM RAS control signal output

18

Page 19

DN-S3500

Pin

No.

Pin Name I/O Function

18 NCS O SDRAM chip select signal output

19 A3 O SDRAM address signal output 3

20 A2 O SDRAM address signal output 2

21 A1 O SDRAM address signal output 1

22 A0 O SDRAM address signal output 0

23 DRVDD1 I Power supply 1 for SDRAM interface I/O

24 DVSS1 I GND 1 for digital circuits

25 A10 O SDRAM address signal output 10

26 *BA1 O SDRAM bank selection signal output 1

27 *BA0 O SDRAM bank selection signal output 0

28 DVDD1 I Power supply 1 for inside digital circuits

29 SPOUT O Spindle drive signal output (absolute value)

30 *SPPOL O Spindle drive signal output (polarity)

31 TRVP O Traverse drive signal output (positive polarity)

32 *TRVM O Traverse drive signal output (negative polarity)

33 *TRVP2 O Traverse drive signal output 2 (positive polarity)

34 *TRVM2 O Traverse drive signal output 2 (negative polarity)

35 TRP O Tracking drive signal output (positive polarity)

36 *TRM O Tracking drive signal output (negative polarity)

37 FOP O Focus drive signal output (positive polarity)

38 *FOM O Focus drive signal output (negative polarity)

39 IOVDD1 I Power supply 1 for digital I/O

40 TBAL O Tracking balance adjustment signal output

41 FBAL O Focus balance adjustment signal output

42 FE I Focus error signal input

43 TE I Tracking error signal input

44 ADPVCC I Voltage input for supply voltage monitor

45 RFENV I RF envelope signal input

46 LDON O Laser ON signal output

47 NRFDET I RF detect signal input

48 OFT I Off-track signal input

49 BDO I Dropout signal input

50 AVDD I Power supply 1 for analog circuits

51 IREF I Analog reference current input

52 ARF I RF signal input

53 DSLF O DSL loop filter

54 PWMSEL I PWM output mode selection input L: Direct H: 3-state

55 PLLF O PLL loop filter (phase comparison output)

56 PLLFO O PLL loop filter (speed comparison output)

57 AVSS I GND 1 for analog circuits

58 LOOUTL O L-ch audio signal output for lineout output

59 LOVSS1 I GND for lineout output

60 LOOUTR O R-ch audio signal output for lineout output

61 LOVDD1 I Power supply for lineout output

62 N.C. -

63 TMON1 O Test monitor output 1

64 N.C. -

65 N.C. -

66 TMON2 O Test monitor output 2

67 DVDD3 I Power supply 3 for digital circuits

68 DVSS2 I GND 2 for digital circuits

69 *EXT0 I/O Expansion I/O port 0

70 *EXT1 I/O Expansion I/O port 1

71 *EXT2 I/O Expansion I/O port 2

72 MCLK I µcom command clock signal input

19

Page 20

DN-S3500

Pin

No.

100 D12 I/O SDRAM data signal I/O 12

Pin Name I/O Function

73 MDATA I µcom command data signal input

74 MLD I µcom command load signal input

75 *STAT O Status signal output

76 *BLKCK O Subcode block clock signal output

77 *SMCK O 4.2336MHz/8.4672MHz clock signal output

78 *PMCK O 88.2kHz clock signal output

79 *TX O Digital audio interface signal output

80 *FLAG O Flag signal output

81 NRST I LSI reset signal input

82 NTEST I Test mode setup input

83 DVSS3 I GND 3 for digital circuits

84 X1 I Crystal oscillator circuit input

85 X2 O Crystal oscillator circuit output

86 IOVDD2 I Power supply 2 for digital I/O

87 DVDD2 I Power supply 2 for inside digital circuits

88 D2 I/O SDRAM data signal I/O 2

89 D1 I/O SDRAM data signal I/O 1

90 D0 I/O SDRAM data signal I/O 0

91 D3 I/O SDRAM data signal I/O 3

92 D4 I/O SDRAM data signal I/O 4

93 D5 I/O SDRAM data signal I/O 5

94 D6 I/O SDRAM data signal I/O 6

95 D7 I/O SDRAM data signal I/O 7

96 D15 I/O SDRAM data signal I/O 15

97 D14 I/O SDRAM data signal I/O 14

98 DRVDD2 I Power supply 2 for SDRAM interface I/O

99 D13 I/O SDRAM data signal I/O 13

Note) Pins marked with an asterisk can be switched to different signals by using microcontroller commands.

20

Page 21

AN8785SB (IC202)

DN-S3500

1

7

8

14 15

AN22002A (IC203)

L: All mute

Hiz: ch2,4 ON

H: Active

28

22

21

Standby

16

Standby

Band-gap

Vcc/Vref

Reser Circuit

1.25V

+

-

7

IN2+

0.1µ

PVcc2

(2.5V)

10

[ Loading ]

D2+

D2-

M

12 11

-

+

-

+

9

ch.4 SW

H:2.5V

Lor

IN2-

HIZ

-

+

8

[ Traverse ]

D4-

18

-+-

:Vref

IN4

21

-

D4+

17

+

switch

+

15

PGnd2

[ Others ]

[ Spindle ]

D3-

MM

14

-+-

-

+

20

IN3

D3+

13

[ Focus ]

PVcc3

D1-

1

19

+

-+-+-

23 27

IN1

[ Tracking ]

D5-

D5+

IN5

PVcc1

25

24

Protection

Circuit

4

IN-

-

+

-

+

22

2

SVcc

+

-

SGnd-Fin

5

IN+

3

OUT

6

Vref

D1+

26

28

+

-

+

PGnd1

CAGC

RFN

1

16

32

A

+

C

-

+

A

B

+

17

D

-

+

F

-

+

E

-

+

32

C

31

B

30

D

29

27

E

F

28

VREF

17

5

4

RFOUT

RF_EQ

AMP GCA BCA

AMP GCA BCA

AMP

AMP

+

-

6

RFIN

NRFDET

GCA

GCA

7

CBD0

ARF

11

8

AGC BD0 0FTR

BCA

BCA

BD0

12

SUB

SUB

C0FTR

13

3TENV

VDET

+

-

+

-

+

-

0FTR

14

LD

9

10

15

22

23

21

20

19

18

2

CEA

NRFDET

FEN

FEOUT

TEN

TEOUT

TEBPF

VDET

3TOUT

21

PD

1

TBAL

GCTL

24

26

FBAL

25

3

16

VCCGND

Page 22

PCM1748 (IC106)

DN-S3500

BCK

DATA

LRCK

DGND

V

OUT

V

OUT

BCK

LRCK

DATA

ML

1

2

3

4

5

V

DD

6

V

CC

7

L

8

R

PCM1748

Serial

Input

I/F

16

SCK

15

ML

14

MC

13

MD

12

ZEROL/NA

11

ZEROR/ZEROA

10

V

COM

9

AGND

8x

Oversampling

Digital Filter

with

Function

Controller

Enhanced

Multi-Level

Delta-Sigma

Modulator

DAC

Output Amp and

Low-Pass Filter

V

L

OUT

V

COM

Function

MC

MD

SCK

Control

I/F

System Clock

Manager

GP1A038RBK (IC915,916)

1

2

3

6

System Clock

ZEROL

Zero Detect

ZEROR

DAC

Output Amp and

Low-Pass Filter

Power Supply

DD

V

DGND

CC

V

AGND

V

R

OUT

54

22

Page 23

64M SDRAM (IC210)

128M SDRAM (IC402)

154

TOP VIEW

27 28

DN-S3500

Pin Assignment

22, 23~26, A0~A11 Address Multiplexed pins for row and column address.

29~35 Row address: A0~A11. Column address: A0~A8.

20, 21 BS0, Bank Select Select bank to activate during row address latch time, or bank to

2, 4, 5, 7, 8, DQ0~ Data Input/Output Multiplexed pins for data output and input.

10,11, 13, 42, DQ15

44,45, 47, 48,

50, 51, 53

19 CS# Chip Select Disable or enable the command decoder. When command decoder is

18 RAS# Row Address Strobe Command input. When sampled at the rising edge of the clock,

17 CAS#

16 WE# Write Enable Referred to RAS#

15, 39 UDQM/ input/output mask The output buffer is placed at Hi-A (with latency of 2) when DQM is

38 CLK Clock Inputs System clock used to sample inputs on the rising edge of clock.

37 CKE Clock Enable CKE controls the clock activation and deactivation. When CKE is low,

1, 14, 27 Vcc Power (+3.3V) Power for input buffers and logic circuit inside DRAM.

28, 41, 54 Vss Ground Ground for input buffers and logic circuit inside DRAM.

3, 9, 43, 49 VccQ

6, 12, 46, 52 VssQ Ground for I/O buffer Separated ground from Vss, used for output buffers to improve noise.

36, 40 NC No Connection No Connection

Pin Name

BS1 read/write during address latch time.

LDQM sampled high in read cycle. In write cycle, sampling DQM high will

Function

Column Address Strobe

Power (+3.3V) for I/O buffer

disabled, new command is ignored and previous operation continues.

RAS#, CAS# and WE# define the operation to be executed.

Referred to RAS#

block the write operation with zero latency.

Power Down mode, Suspend mode, or Self Refresh mode is entered.

Separated power from Vcc, used for output buffers to improve noise.

DescriptionPin No.

BU2090F (IC602,632,662) TPC6103 (IC410) TOP247YN (IC901)

654

Control Circuit

12-Bit Shift Register

Latch

Output Buffer

(Open Drain)

7Q3

8Q4

16 VDD1Vss

15 Q112DATA

14 Q103CLOCK

13 Q94Q0

12 Q85Q1

11 Q76Q2

10 Q6

Q5

9

123

1C2L3X4S5F7

D

NJM2626 (IC708) EW-510 (IC751-753)

FR

Vref

H1

H2

H3

1

2

3

4

5

16

15

14

13

12

VCC

UH

VH

WH

UL

1 Vcc

REG.

3 Output

OSC

Verr

GND

6

7

8

11

10

VL

Vcc

123

Gnd

Output

WL

9

llimit

2 Gnd

23

Page 24

2. FL DISPLAY 16-MT-82GINK (FL601)

144

Pin Connection

DN-S3500

24

Page 25

PRINTED WIRING BOARDS

GU-3689 MAIN P.W.B. UNIT

DN-S3500

25

COMPONENT SIDE

Page 26

DN-S3500

26

FOIL SIDE

Page 27

GU-3690 POWER P.W.B. UNIT

DN-S3500

27

COMPONENT SIDE

Page 28

DN-S3500

28

FOIL SIDE

Page 29

GU-3691 PANEL P.W.B. UNIT

DN-S3500

29

COMPONENT SIDE

Page 30

DN-S3500

30

FOIL SIDE

Page 31

GU-3717 PANEL P.W.B. UNIT

DN-S3500

COMPONENT SIDE FOIL SIDE

31

Page 32

DN-S3500

NOTE FOR PARTS LIST

• Part indicated with the mark "nsp" are not always in stock and possibly to

take a long period of time for supplying, or in some case supplying of part

may be refused.

• When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-

supplying.

• Ordering part without stating its part number can not be supplied.

• Part indicated with the mark " ★ " is not illustrated in the exploded view.

• Not including Carbon Film Resister ±5%, 1/4W Type in the P.W.Board

parts list. (Refer to the Schematic Diagram for those parts.)

• Not including Carbon Chip Resister 1/16W Type in the P.W.Board parts

list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol ! have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

] Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

部品表について

1.nsp 印の部品は常時在庫していませんので供給に長時間を要すること

があります。

場合によっては、供給をお断りすることがあります。

2.部品を発注する際は特に数字の " 1 " と英字の "I" との区別をはっき

り記入してください。

3.部品番号を表示していない部品は供給できません。

4.!印の部品は安全上重要な部品です。交換するときは、安全および性

能維持のため必ず指定の部品をご使用ください。

5.★印のついている部品は分解図中には記載していません。

6.カーボン抵抗器± 5%、1/4W 型は記載していません。定数は回路図を

参照願います。

7.カーボンチップ抵抗器 1/16W 型は記載していません。定数は回路図を

参照願います。

8.部品表の抵抗器、コンデンサの品名記号の読み方は表を参照してくだ

さい。

RN 14K 2E 182 G FR

RD : 2B : 1/8 W F : ±1% P :

RC : 2E : 1/4 W G : ±2% NL :

RS : 2H : 1/2 W J : ±5% NB :

RW : 3A : 1 W K : ±10% FR :

RN : 3D : 2 W M : ±20% F :

RK : 3F : 3 W

∗

18 2

1R 2

3H : 5 W

1800

Ö

2

1.2

Ö

1

2 R

=1.8k

0

ll

l Capacitors

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR : Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL par t

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

] Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

] Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

2-digit effective number.

2-digit effective number.

requency

CE 04W 1H 2R2 M BP

CE : 0J : 6.3 V F : ±1% HS :

CA : 1A : 10 V G : ±2% BP :

CS : 1C : 16 V J : ±5% HR :

CQ : 1E : 25 V K : ±10% DL :

CK : 1V : 35 V M : ±20% HF :

CC : 1H : 50 V Z : +80% U : UL

CP : 2A : 100 V −20% C : CSA

CM : 2B : 125 V P : +100% W : UL-CSA

CF : 2C : 160 V − 0% F :

CH : 2D : 200 V C : ±0.25pF

2E : 250 V D : ±0.5pF

2H : 500 V = :

2J : 630 V

∗

22 2

22 2

2200µF

Ö

2

µ

F

2200pF=0.0022µF

Ö

(0 2 )

2

p

F

0

0

2R 2

22 1

Ö

1

2 R

µ

F

Ö

(0 0 1 )

2

p

F

AC

2.2µF

220pF

0

32

Page 33

DN-S3500

PARTS LIST OF P.W.B. UNIT

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3: U.S.A. & Canada model E2: Europe model

JP: Japan model

GU-3689 MAIN P.W.B. UNIT ASS'Y

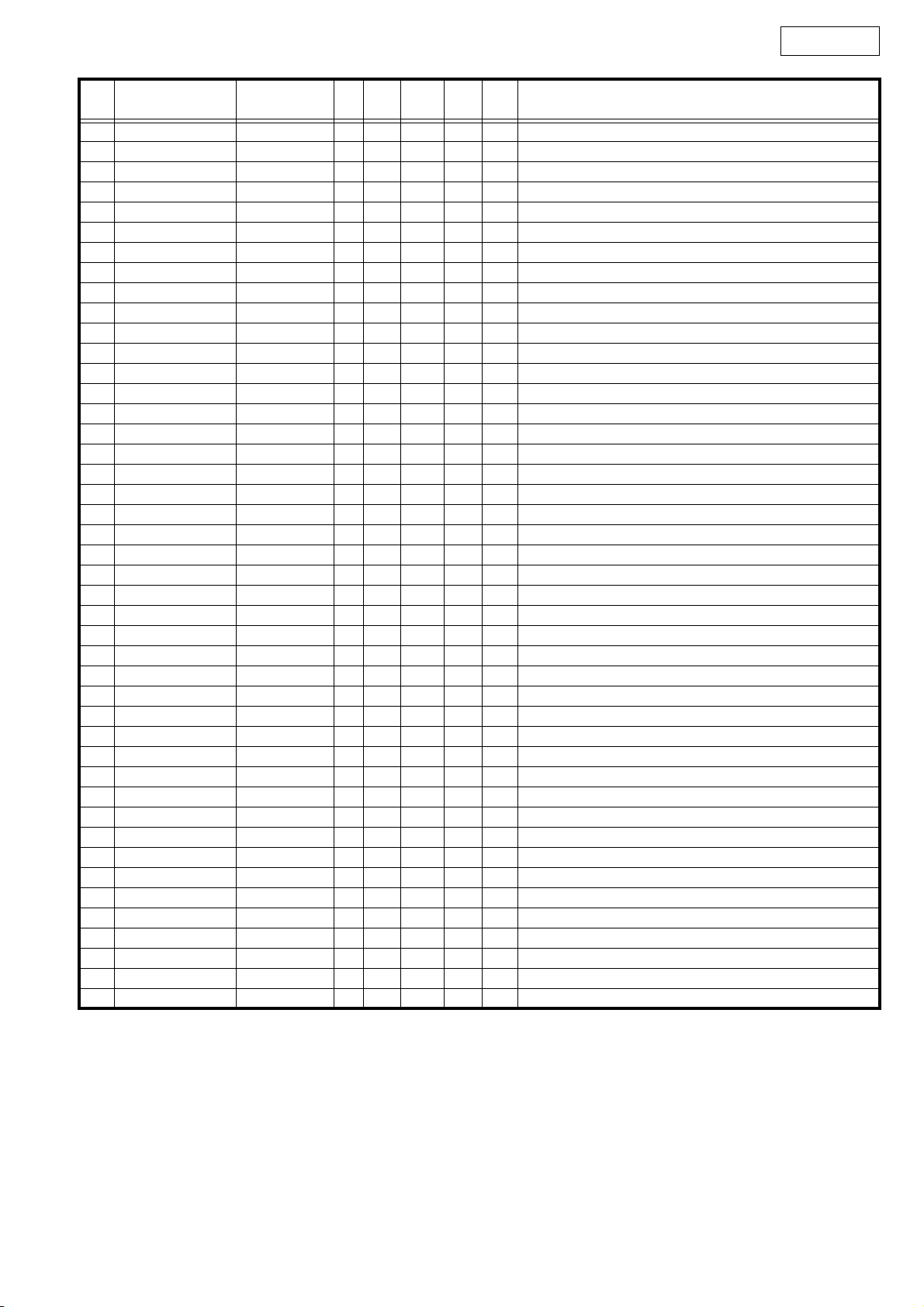

Ref. No. nsp Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC101 00D 262 3044 001 MN102H730F

IC102 00D GEN 8017 SYSTEM ROM SUB ASSY 8M FLASH MEMORY(70N)

IC103 00D 262 3082 911 BD4745G

IC104 00D 262 1953 903 TC7WU04F +C

IC105 00D 262 3305 902 SN74LV393APW

IC106 00D 262 3166 905 PCM1748E(TAPE) +C

IC107 00D 262 2640 901 SN74LV245APW-EL2

IC108 00D 262 3305 902 SN74LV393APW

IC109 00D 262 2517 908 SN74LV08APW-EL2 +REF

IC110 00D 263 1079 903 BA033FP +C

IC111 00D 262 3513 008 8M FLASH MEMORY(90N)

IC113 00D 262 2948 904 SN74LV86APW +REF

IC201 00D 262 3398 003 MN6627933

IC202 00D 262 3159 909 AN8785SB

IC203 00D 262 3160 901 AN22002A

IC207 00D 263 0615 902 BA15218F-DXE2 +C

IC210 00D 262 3401 000 64M SDRAM(TSOP)

IC401 00D 262 3399 002 ADSP-BF531(LQFP)

IC402 00D 262 3407 004 128M SDRAM(TSOP)PBF

IC403,404 00D 262 2640 901 SN74LV245APW-EL2

IC405 00D 262 2959 906 SN74LV244APW +REF

IC406 00D 262 2640 901 SN74LV245APW-EL2

IC408 00D 262 2518 907 SN74LV74APW-EL2 +C

IC409 00D 262 2516 909 SN74LV32APW-EL2 +C

IC410 00D 262 3400 904 TPC6103

TR201 00D 272 0125 904 2SB709A +C

TR202,203 00D 269 0082 902 DTC114EKT96 +C

TR301 00D 269 0082 902 DTC114EKT96 +C

TR302 00D 269 0083 901 DTA114EKT96 +C

TR303 00D 273 0437 909 2SC2411K-T146 +C

TR304 00D 271 0260 905 2SA1036KT146(S/R) +C

D101 00D 276 0559 909 DAP202KT146 +C

D401 00D 276 0559 909 DAP202KT146 +C

D402 00D 276 0750 902 RB521S-30TE61 +REF

CAPACITORS GROUP

C101 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C102 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C104-107 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C108 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C109 nsp 00D 257 0506 951 CC73CH1H101JT +1608

C110-113 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C114 nsp 00D 257 0506 951 CC73CH1H101JT +1608

33

Page 34

DN-S3500

Ref. No. nsp Part No. Part Name Remarks Q'ty New

C115 nsp 00D 257 0509 929 CK73B1H102KT +1608

C116 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C117 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C118,119 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C120 nsp 00D 257 0503 967 CC73CH1H150JT +1608

C121 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C122 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C123 nsp 00D 257 0509 929 CK73B1H102KT +1608

C124 nsp 00D 257 0506 951 CC73CH1H101JT +1608

C125 nsp 00D 257 0503 967 CC73CH1H150JT +1608

C126 nsp 00D 257 0516 954 CK73B1E104KT +1608

C127 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C128 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C129 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C130,131 nsp 00D 257 0516 954 CK73B1E104KT +1608

C132 00D 257 4012 904 CE67C1C100MT (RV2B55 +REF

C133 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C134,135 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C136 00D 257 4012 933 CE67C1C101MT (RV2) +REF

C137,138 nsp 00D 257 0504 940 CC73CH1H330JT +1608

C148-152 nsp 00D 257 0509 929 CK73B1H102KT +1608

C153,154 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C155 nsp 00D 257 0509 929 CK73B1H102KT +1608

C156 nsp 00D 257 0516 954 CK73B1E104KT +1608

C157 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C158 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C159 nsp 00D 257 0516 954 CK73B1E104KT +1608

C201 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C202 nsp 00D 257 0509 929 CK73B1H102KT +1608

C203 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C204 nsp 00D 257 0509 929 CK73B1H102KT +1608

C205 nsp 00D 257 0516 909 CK73B1E223KT +1608

C206 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C208 00D 254 4655 922 CE67C0J470MT (RV2) +REF

C211,212 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C213 nsp 00D 257 0509 929 CK73B1H102KT +1608

C214 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C216 nsp 00D 257 0510 950 CK73B1H682KT +1608

C217-220 nsp 00D 257 0509 990 CK73B1H222KT +1608

C222,223 nsp 00D 257 0516 909 CK73B1E223KT +1608

C224 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C227 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C228 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C229 nsp 00D 257 0504 937 CC73CH1H300JT +1608

C231,232 00D 254 4655 922 CE67C0J470MT (RV2) +REF

C233 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C234 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C237 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C238 nsp 00D 257 0501 914 CK73B1H123KT +1608

C239 nsp 00D 257 0510 947 CK73B1H562KT +1608

C240 nsp 00D 257 0516 909 CK73B1E223KT +1608

C241 nsp 00D 257 0501 927 CK73B1H153KT +1608

C242 nsp 00D 257 0506 919 CC73CH1H680JT +1608

C243 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C244 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C245 nsp 00D 257 0507 950 CC73CH1H271JT +1608

34

Page 35

DN-S3500

Ref. No. nsp Part No. Part Name Remarks Q'ty New

C246 nsp 00D 257 0506 993 CC73CH1H151JT +1608

C250 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C251 00D 254 4661 929 CE67C1H4R7MT (RV2) +REF

C252 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C253 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C254 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C255 nsp 00D 257 0520 911 CK73B1A224KT +1608

C256 nsp 00D 257 0520 908 CK73B1A154KT +1608

C257 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C261,262 00D 257 4012 904 CE67C1C100MT (RV2B55 +REF

C263,264 nsp 00D 257 0510 918 CK73B1H332KT +1608

C265,266 nsp 00D 257 0506 935 CC73CH1H820JT +1608

C267,268 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C274 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C280 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C281 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C282 00D 254 4658 916 CE67C1E100MT (RV2)

C283-285 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C291,292 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C293 00D 257 4012 933 CE67C1C101MT (RV2) +REF

C295 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C298 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C301 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C302,303 00D 254 4660 946 CE67C1H010MT (RV2B55 +REF

C304,305 nsp 00D 257 0509 929 CK73B1H102KT +1608

C306 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C307 nsp 00D 257 0509 929 CK73B1H102KT +1608

C401 nsp 00D 257 0509 929 CK73B1H102KT +1608

C402-406 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C407 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C408-412 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C413 nsp 00D 257 0509 929 CK73B1H102KT +1608

C414 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C415-419 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C420 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C421,422 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C423 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C424-429 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C431 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C432 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C433-438 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C439 00D 257 4011 905 CE67C0J101MT (RV2) +REF

C440-443 nsp 00D 257 0512 903 CK73F1E104ZT +1608

OTHERS PARTS GROUP

CX061 nsp 00D 205 1072 946 6P PH CON.BASE +REF

CX121 00D 205 1314 934 12P FFC BASE(9616S)Y

CX181 00D 205 1314 947 18P FFC BASE(9616S)Y

CX251 00D 205 1313 906 25P FFC.BASE(9610SCA +REF

CX361 00D 205 1367 907 28P FFC BASE(FMN BT)

FB101 nsp 00D 235 0158 901 CHIP BEADS(18PG121) +1608

FB103-116 nsp 00D 235 0130 903 CHIP EMIFIL(11A121) +1608

FB118,119 nsp 00D 235 0130 903 CHIP EMIFIL(11A121) +1608

FB201-204 nsp 00D 235 0106 908 CHIP EMIFIL (21A05) +C

35

Page 36

DN-S3500

Ref. No. nsp Part No. Part Name Remarks Q'ty New

FB401 nsp 00D 235 0158 901 CHIP BEADS(18PG121) +1608

X101 00D 399 1029 906 CSACW32M0X51-R0

X102 00D 399 1031 907 XTAL(11.2896M/SMT)

X201 00D 399 0978 906 CSTCG25M0V53-R0

X401 00D 399 0978 906 CSTCG25M0V53-R0

-RADIATOR

36

Page 37

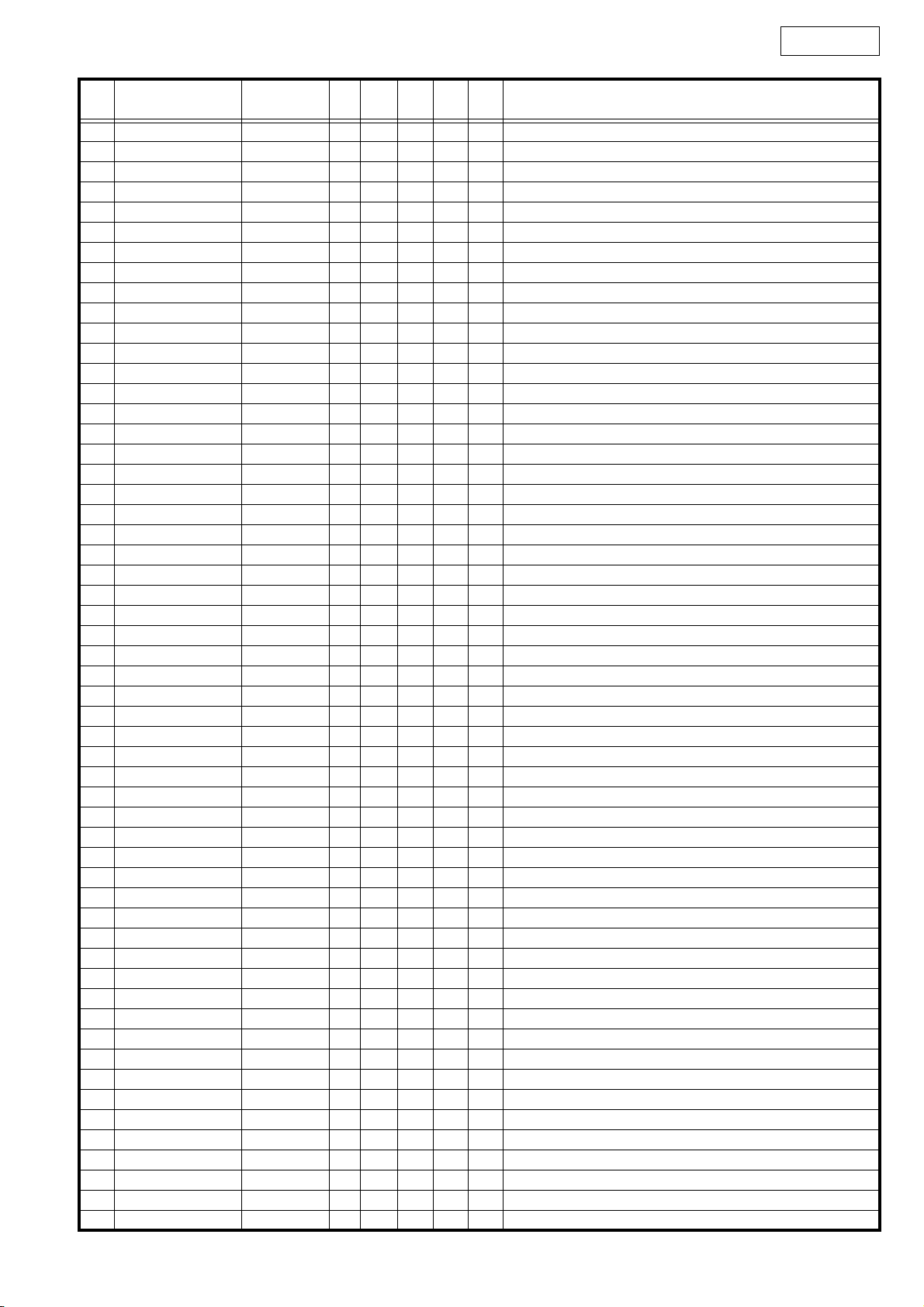

GU-3690/36902 POWER P.W.B. UNIT ASS'Y

Ref. No. nsp Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC701 00D 262 3531 909 SN74HCT14PW

IC702 00D 262 1346 905 TC74HC08AF(TP1) +C

IC703,704 00D 263 0845 905 NJM3404AM-TE1

IC705 00D 262 1875 900 BU4066BCF-T1 +C

IC706 00D 263 0845 905 NJM3404AM-TE1

IC707 00D 262 3530 900 TC74HC86AF

IC708 00D 262 3532 908 NJM2626

IC802 00D 262 1953 903 TC7WU04F +C

IC901 00D 265 0126 002 TOP247YN

IC902 00D 262 3047 008 PC123Y22

IC903 00D 263 0809 006 NJM7805FA(S)

IC913 00D 263 0810 008 NJM7808FA(S)

IC914 00D 263 1206 912 TA76432F

TR701,702 00D 269 0082 902 DTC114EKT96 +C

TR703 00D 275 0113 902 2SJ377(SMT)

TR704 00D 275 0114 901 2SK2231(SMT)

TR705 00D 275 0113 902 2SJ377(SMT)

TR706 00D 275 0114 901 2SK2231(SMT)

TR707 00D 275 0113 902 2SJ377(SMT)

TR708 00D 275 0114 901 2SK2231(SMT)

TR709-712 00D 269 0082 902 DTC114EKT96 +C

TR805 00D 273 0460 905 KTC2875B-RTK +C

TR806 00D 273 0426 907 2SC2412KLNT146 +C

TR807,808 00D 273 0460 905 KTC2875B-RTK +C

TR809 00D 269 0082 902 DTC114EKT96 +C

TR810 00D 269 0083 901 DTA114EKT96 +C

TR811-813 00D 269 0082 902 DTC114EKT96 +C

TR901 00D 271 0308 906 2SA933ASTPS

TR902 00D 274 0158 016 2SD1763A(E)

DN-S3500

D701 00D 276 0787 001 RN2Z

D803 00D 276 0559 909 DAP202KT146 +C

D804 00D 276 0560 901 DAN202KT146 +C

D805 00D 276 0717 903 1SS355 TE-17 +C

D806 00D 276 0559 909 DAP202KT146 +C

D807 00D 276 0560 901 DAN202KT146 +C

D901-904 00D 276 0729 904 EM01AT (V1)

D905,906 00D 276 0813 001 AP01C

D908 00D 276 0401 905 1SS133T77 (TAPE)

D909 00D 276 0757 002 FML-G12S

D910 00D 276 0832 008 FMX-G22S

D912-914 00D 276 0730 906 AG01ZT (V1)

ZD902 00D 276 0762 945 MTZJ36B T77

ZD903 00D 276 0831 902 0ZDZ2.4-Z

TH901 00D 279 0044 002 NTH11D8R0LA

RESISTORS GROUP

R744 00D 244 2043 982 RS14B3AR22JNBST(S)

R901 00D 244 2675 729 RS14B3D224JNBF (ERG)

VR701 00D 211 6132 983 V06PB104T

37

Page 38

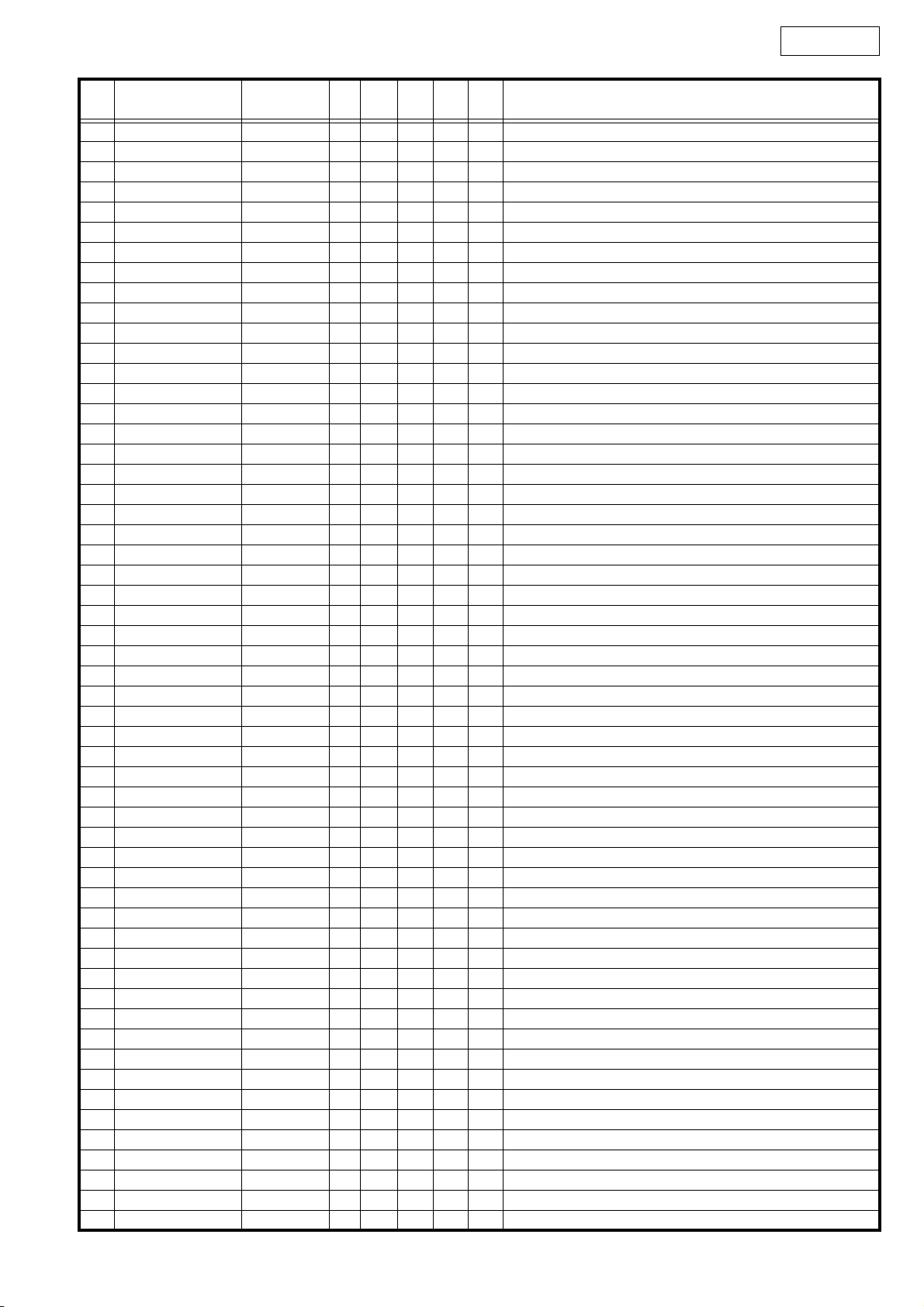

Ref. No. nsp Part No. Part Name Remarks Q'ty New

CAPACITORS GROUP

C701 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C702 nsp 00D 257 0506 951 CC73CH1H101JT +1608

C703 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C704 nsp 00D 257 0516 954 CK73B1E104KT +1608

C705 nsp 00D 257 0516 941 CK73B1E473KT +1608

C706 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C707 nsp 00D 257 0516 941 CK73B1E473KT +1608

C708 nsp 00D 257 0501 901 CK73B1H103KT (1608) +1608

C709 nsp 00D 257 0520 911 CK73B1A224KT +1608

C710,711 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C712 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C713 nsp 00D 257 0501 901 CK73B1H103KT (1608) +1608

C714 00D 254 4524 943 CE04W1H010MT SMG/RE3

C715 nsp 00D 257 0509 990 CK73B1H222KT +1608

C716 00D 254 4522 783 CE04W1V471MC SMG/RE3

C717 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C718-721 nsp 00D 257 0501 901 CK73B1H103KT (1608) +1608

C722-725 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C726 00D 254 4524 943 CE04W1H010MT SMG/RE3

C727 00D 254 4528 729 CE04W2A101MC SMG/RE3

C728,729 nsp 00D 257 0516 954 CK73B1E104KT +1608

C730 00D 254 4524 972 CE04W1H4R7MT SMG/RE3

C819 nsp 00D 257 0509 929 CK73B1H102KT +1608

C820 nsp 00D 257 0501 901 CK73B1H103KT (1608) +1608

C821 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C822 00D 254 4536 928 CE04W1A101MT SMG/RE3

C824 00D 254 4524 943 CE04W1H010MT SMG/RE3

C825,826 00D 254 4538 900 CE04W1C100MT SMG/RE3

C827,828 nsp 00D 257 0509 929 CK73B1H102KT +1608

C829,830 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C831 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C832 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C833 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C834 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C835 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C836 nsp 00D 257 0511 904 CK73F1H103ZT +1608

C838 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C839,840 nsp 00D 257 0507 934 CC73CH1H221JT +1608

C841 nsp 00D 257 0508 917 CC73CH1H471JT +1608

C842,843 nsp 00D 257 0507 934 CC73CH1H221JT +1608

! C901 00D 253 8022 707 CK45F2EAC103MC

C902 00D 256 8038 004 CF99--2EAC104M

C903 00D 253 8029 713 CK45F2EAC471KC(KX)

C904 00D 254 4588 714 CE04W2D221MC(KMG) for E3, JP

C904 00D 254 4589 713 CE04W2G101MC(KMG) for E2

C905,906 00D 253 8029 713 CK45F2EAC471KC(KX)

C907 00D 257 3013 933 CF73=1H104JT(ECHUC9) +C

C909 00D 256 8038 004 CF99--2EAC104M

C910 00D 254 4525 913 CE04W1H470MT SMG/RE3

C911 00D 253 8029 713 CK45F2EAC471KC(KX)

C912 00D 257 3013 933 CF73=1H104JT(ECHUC9) +C

C913 00D 254 4525 913 CE04W1H470MT SMG/RE3

C914 00D 254 4756 902 CE04W1H101MT HB5(KY) for E3, JP

C914 00D 254 4708 905 CE04W1E221MT HB5(KY) for E2

C915 00D 254 4756 902 CE04W1H101MT HB5(KY)

DN-S3500

2

2

38

Page 39

DN-S3500

Ref. No. nsp Part No. Part Name Remarks Q'ty New

C916 00D 253 8029 713 CK45F2EAC471KC(KX)

C918 00D 254 4710 906 CE04W1C331MT HB5(KY)

C919 00D 254 4758 706 CE04W1V272MCL35(KY)

C923 00D 254 4525 913 CE04W1H470MT SMG/RE3

C925,926 00D 254 4757 707 CE04W1E272MCL25(KY)

C927 00D 254 4541 942 CE04W1E101MT SMG/RE3

C931 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C934,935 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C937 00D 254 4538 939 CE04W1C470MT SMG/RE3

C940,941 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C942 00D 254 4541 942 CE04W1E101MT SMG/RE3

C943 00D 254 4525 913 CE04W1H470MT SMG/RE3

C944 00D 254 4541 942 CE04W1E101MT SMG/RE3

C945,946 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C948-950 nsp 00D 257 0512 903 CK73F1E104ZT +1608

C951 00D 254 4756 902 CE04W1H101MT HB5(KY) for E3, JP

C951 00D 254 4708 905 CE04W1E221MT HB5(KY) for E2

2

OTHERS PARTS GROUP

CW121 nsp 00D 205 0375 026 12P CONN.BASE(KR-PH)

CX021 nsp 00D 205 0581 001 2P VH CONNECTOR BASE

CY061 nsp 00D 204 0579 023 6P PH-SAN CON.CORD

CY361 00D 205 1100 041 28P FFC BASE (P=1)

! F901 00D 206 1089 000 FUSE (ET0.8A) for E3, JP

! F901 00D 206 1089 013 FUSE(ET1.25A) for E2

FB801,802 nsp 00D 235 0130 903 CHIP EMIFIL(11A121) +1608

FF901 nsp 00D 202 0040 909 FUSE CLIP(TAPE)

FH901 nsp 00D 202 0040 909 FUSE CLIP(TAPE)

JK802 00D 204 8664 011 3P PIN JACK

JK804-806 00D 204 8416 007 MINI JACK

L901 00D 235 0157 009 PLA10AN7720R7D2B

L907 00D 235 0159 007 PLH10AN3711ROP2B

! S901 00D 212 1176 015 POWER SWITCH(TV-5)

2

! T901 00D 233 0699 008 SW TRANSFORMER

-RADIATOR

nsp 00D 471 3304 015 3X8 CBS-Z

nsp 00D GEN 8038 FUSE LABEL SUB ASSY for F901, for E2

39

Page 40

GU-3691 PANEL P.W.B. UNIT ASS'Y

Ref. No. nsp Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC602 00D 262 2745 903 BU2090F(E2) +C

IC603 00D 262 2514 901 SN74LV138APW-EL2 +C