DELTA VFD-B User Manual

230V Series |

460V Series |

||

0.75 |

37KW |

0.75 |

75KW |

1.0 |

50HP |

1.0 |

100HP |

|

|

|

|

VFD-B Series

VFD-B Series

Preface

Thank you for choosing DELTA’s high-performance VFD-B Series. VFD-B Series are manufactured by adopting high-quality components, material and incorporating the latest microprocessor technology available.

Getting Started

This manual will be helpful in the installation, parameter setting, troubleshooting, and daily maintenance of the AC motor drives. To guarantee safe operation of the equipment, read the following safety guidelines before connecting power to the AC drives. Keep this operating manual handy and distribute to all users for reference.

!

! WARNING

WARNING

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Always read this manual thoroughly before using VFD-B series AC Motor Drives.

DANGER! AC input power must be disconnected before any maintenance. Do not connect or disconnect wires and connectors while power is applied to the circuit. Maintenance must be performed by qualified technicians.

CAUTION! There are highly sensitive MOS components on the printed circuit boards. These components are especially sensitive to static electricity. To avoid damage to these components, do not touch these components or the circuit boards with metal objects or your bare hands.

DANGER! A charge may still remain in the DC-link capacitor with hazardous voltages even if the power has been turned off. To avoid personal injury, please ensure that power has turned off before operating AC drive and wait ten minutes for capacitors to discharge to safe voltage levels.

CAUTION! Ground the VFD-B using the ground terminal. The grounding method must comply with the laws of the country where the AC drive is to be installed. Refer to

Basic Wiring Diagram.

DANGER! The AC drive may be destroyed beyond repair if incorrect cables are connected to the input/output terminals. Never connect the AC drive output terminals

U/T1, V/T2, and W/T3 directly to the AC main circuit power supply.

CAUTION! The final enclosures of the AC drive must comply with EN50178. (Live parts shall be arranged in enclosures or located behind barriers that meet at least the requirements of the Protective Type IP20. The top surface of the enclosures or barrier that is easily accessible shall meet at least the requirements of the Protective Type

IP40). (VFD-B series corresponds with this regulation.)

CAUTION! Heat sink may heat up over 70oC (158oF), during the operation. Do not touch the heat sink.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

VFD-B Series

VFD-B Series

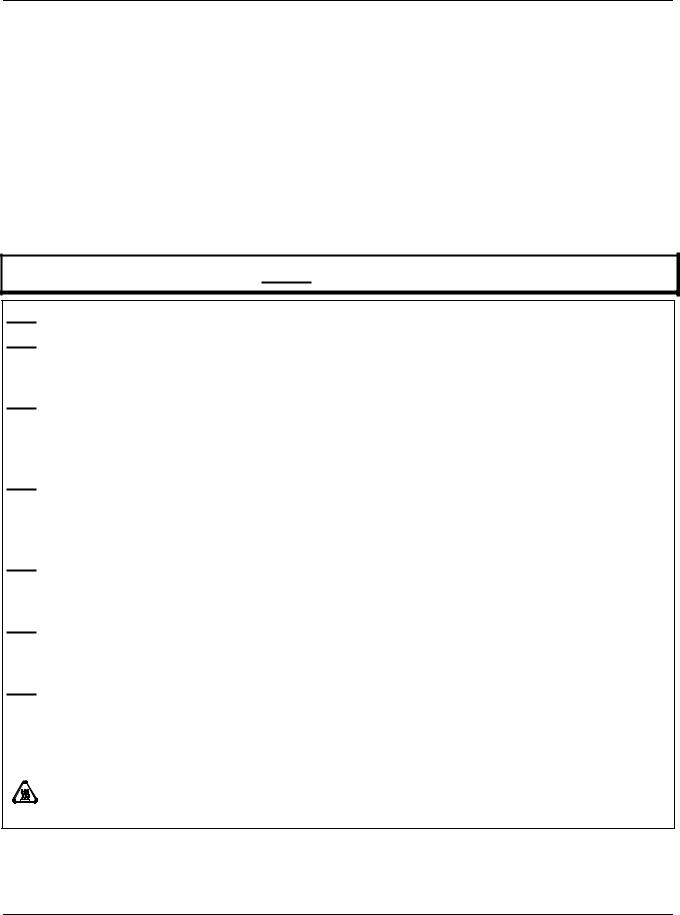

TABLE OF CONTENTS

CHAPTER 1 RECEIVING AND INSPECTIONS |

|

|

|

1.1 |

Nameplate Information ....................................................................... |

1 |

- 1 |

1.2 |

Model Explanation .............................................................................. |

1 |

- 1 |

1.3 |

Serial Number Explanation................................................................. |

1 |

- 2 |

CHAPTER 2 STORAGE AND INSTALLATION |

|

|

|

2.1 |

Storage ............................................................................................... |

2 |

- 1 |

2.2 |

Installation .......................................................................................... |

2 |

- 2 |

CHAPTER 3 WIRING |

|

|

|

3.1 |

Basic Wiring Diagram ......................................................................... |

3 |

- 2 |

3.2 |

External Wiring ................................................................................... |

3 |

- 6 |

3.3 Terminal Explanation .......................................................................... |

3 |

- 7 |

|

3.4 |

Control Terminal Explanation.............................................................. |

3 |

- 7 |

3.5 |

Main Circuit Wiring ............................................................................ |

3 |

- 9 |

3.6 |

Wiring Notes ....................................................................................... |

3-16 |

|

3.7 |

Motor Operation Precautions.............................................................. |

3-17 |

|

CHAPTER 4 DIGITAL KEYPAD OPERATION |

|

|

|

4.1 |

Description of the Digital Keypad VFD-PU01 ..................................... |

4 |

- 2 |

4.2 |

Operation steps of the Digital Keypad VFD-PU01.............................. |

4 |

- 4 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

VFD-B Series

VFD-B Series

CHAPTER 5 DESCRIPTION OF PARAMETER SETTINGS |

|

|

Group 0: User Parameters ....................................................................... |

5 |

- 1 |

Group 1: Basic Parameters ...................................................................... |

5 |

- 5 |

Group 2: Operating Method Parameters .................................................. |

5-11 |

|

Group 3: Output Function Parameters ..................................................... |

5-17 |

|

Group 4: Input Function Parameters ........................................................ |

5-22 |

|

Group 5:Multi-step Speed and PLC (Process Logic Control) Parameter . 5-32

Group 6: Protection Parameters............................................................... |

5-38 |

Group 7: Motor Parameters...................................................................... |

5-44 |

Group 8: Special Parameters ................................................................... |

5-47 |

Group 9: Communication Parameters ...................................................... |

5-54 |

Group 10: PID Control Parameters .......................................................... |

5-69 |

Group 11: Fan and Pump Control Parameters ......................................... |

5-74 |

CHAPTER 6 MAINTENANCE AND INSPECTIONS |

|

|

|

6.1 |

Periodic Inspection ............................................................................. |

6 |

- 1 |

6.2 |

Periodic Maintenance ......................................................................... |

6 |

- 1 |

CHAPTER 7 TROUBLESHOOTING AND FAULT INFORMATION........... |

7 - 1 |

CHAPTER 8 SUMMARY OF PARAMETER SETTINGS ............................ |

8 - 1 |

APPENDIX A SPECIFICATIONS ............................................................... |

A - 1 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

VFD-B Series

VFD-B Series

APPENDIX B ACCESSORIES |

|

|

B.1 |

Non-fused Circuit Breaker and Fuse Specification Chart................... |

B - 1 |

B.2 |

Braking Resistors & Braking Units ..................................................... |

B - 3 |

B.3 AMD-EMI Filter Cross Reference....................................................... |

B - 7 |

|

B.4 |

PG Cards ........................................................................................... |

B-16 |

B.5 |

Remote Controller RC-01................................................................... |

B-22 |

B.6 |

Remote Panel Adapter ....................................................................... |

B-23 |

B.7 |

Zero Phase Reactor ........................................................................... |

B-24 |

APPENDIX C DIMENSIONS....................................................................... |

C - 1 |

APPENDIX D EC DECELERATION OF CONFORMITY............................. |

D - 1 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

VFD-B Series

VFD-B Series

CHAPTER 1 RECEIVING AND INSPECTION

1

This VFD-B AC drive has gone through rigorous quality control tests at the factory before shipment. After receiving the AC drive, please check for the following:

Receiving

Check to make sure that the package includes an AC drive, the User Manual, dust covers and rubber bushings.

Inspect the unit to insure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part number of your order.

1.1 Nameplate Information: Example for 1HP/0.75kW 3-phase 230V AC drive

AC Drive Model |

|

MODE |

|

|

|

|

: VFD007B23A |

||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

Input Spec. |

|

|

INPUT |

|

|

|

|

: 3PH 200-240V 50/60Hz 6.0A |

|||||||||||||||||||||||||||||||||

Output Spec. |

|

OUTPUT |

|

|

|

|

: 3PH 0-240V 5.0A 1.9kVA 1HP |

||||||||||||||||||||||||||||||||||

|

Freq. Range : 0.1~400Hz |

||||||||||||||||||||||||||||||||||||||||

Output Frequency Range |

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

ENCLOSURE: TYPE 1 |

|||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||

Enclosure type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Serial Number & Bar Code |

|

|

|

|

|

|

|

|

|

007B23A0T0220001 |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

1.2 Model Explanation:

VFD 007 B 23 A |

|

|

||||||

|

|

|

|

|

|

Version Type |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Input Voltage |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

21:Single phase 230V 23:Three phase 230V |

||

|

|

|

|

|

|

43:Three phase 460V |

||

|

|

|

|

|

|

B Series |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Applicable motor capacity |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

007: 1 HP(0.7kW) |

150: 20HP(15kW) |

|

Series Name |

||||||||

|

|

|||||||

|

|

|

|

|

|

022: 3 HP(2.2kW) |

220: 30 HP(22kW) |

|

|

|

|

|

|

|

037: 5 HP(3.7kW) |

300: 40HP(30kW) |

|

|

|

|

|

|

|

055: 7.5HP(5.5kW) |

370: 50 HP(37kW) |

|

|

|

|

|

|

|

075: 10 HP(7.5kW) |

450: 60HP(45kW) |

|

|

|

|

|

|

|

110: 15 HP(11kW) |

550: 75HP(55kW) |

|

750: 100HP(75kW)

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

1-1 |

VFD-B Series

VFD-B Series

1.3 Series Number Explanation:

1

007B23A0 T 3 01

|

|

Production number |

|

|

|

||

|

|

Production week |

|

|

|

Production year 2003 |

|

|

|

Production factory |

|

230V 3-phase 1HP(0.75kW) |

(Taoyuan) |

||

Model |

|||

|

|

||

If there is any nameplate information not corresponding to your purchase order or any problem, please contact your distributor.

1-2 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

CHAPTER 2 STORAGE AND INSTALLATION |

|

||

2.1 Storage |

|

|

|

|

2 |

||

The AC drive should be kept in the shipping carton before installation. In order to retain the |

|||

|

|||

warranty coverage, the AC drive should be stored properly when it is not to be used for an |

|

||

|

|||

extended period of time. |

|

||

Ambient Conditions: |

|

||

Operation |

Air Temperature: -10oC to +40oC (14oF to 104oF) (UL & cUL); |

|

|

+50oC (122oF) without dust cover. |

|

||

|

|

||

|

Atmosphere pressure: 86 to 106 kPa |

|

|

|

Installation Site Altitude: below 1000m |

|

|

|

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz |

|

|

|

Maximum 5.88 m/s2 (0.6G) at 20Hz to 50Hz |

|

|

Storage |

Temperature: -20oC to +60oC (-4oF to 140oF) |

|

|

Relative Humidity: Less than 90%, no condensation allowed |

|

||

|

|

||

|

Atmosphere pressure: 86 to 106 kPa |

|

|

Transportation |

Temperature: -20oC to +60oC (-4oF to 140oF) |

|

|

Relative Humidity: Less than 90%, no condensation allowed |

|

||

|

|

||

|

Atmosphere pressure: 86 to 106 kPa |

|

|

|

Vibration: Maximum 9.80 m/s2 (1G) at less than 20Hz, Maximum 5.88 |

|

|

|

m/s2 (0.6G) at 20Hz to 50Hz |

|

|

Pollution Degree 2: good for a factory type environment.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

2-1 |

VFD-B Series

VFD-B Series

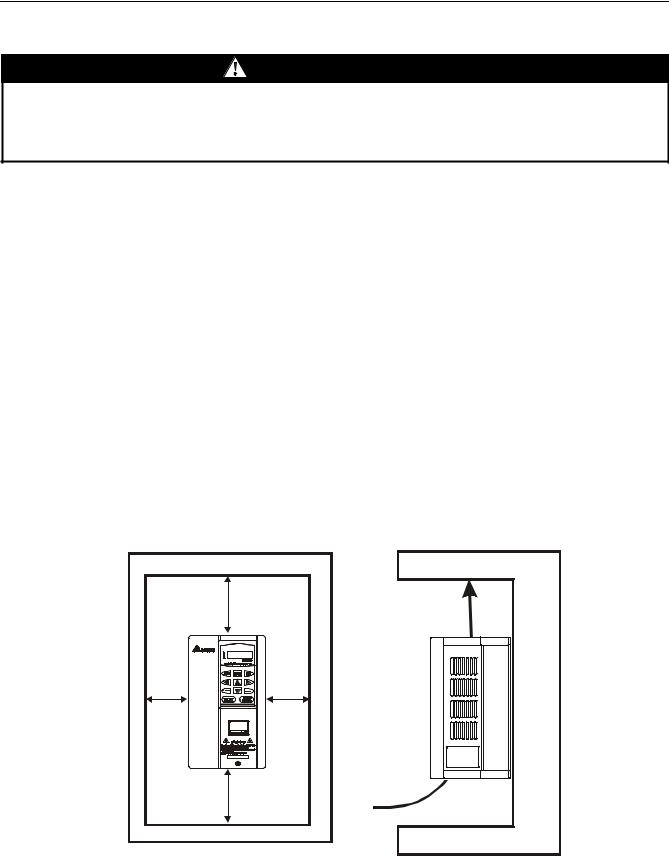

2.2 Installation

CAUTION

The control, power supply and motor leads must be laid separately. They must not be fed through the same cable conduit / trunking.

High voltage insulation test equipment must not be used on cables connected to the drive.

Improper installation of the AC drive will greatly reduce its life. Be sure to observe the following precautions when selecting a mounting location.

Failure to observe these precautions may void the warranty!

Do not mount the AC drive near heat-radiating elements or in direct sunlight.

Do not install the AC drive in a place subjected to high temperature, high humidity, excessive vibration, corrosive gases or liquids, or airborne dust or metallic particles.

Mount the AC drive vertically and do not restrict the air flow to the heat sink fins.

The AC drive generates heat.

120mm

50mm

FWD

REV

Allow sufficient space around the unit for heat dissipation.

Air Flow

PROG

DATA

50mm

120mm

2-2 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

CHAPTER 3 WIRING

DANGER

Hazardous Voltage

Before accessing the AC drive:

Disconnect all power to the AC drive. 3 Wait five minutes for DC bus capacitors discharge.

Any electrical or mechanical modification to this equipment without prior written consent of Delta Electronics, Inc. will void all warranties and may result in a safety hazard in addition to voiding the UL listing.

Short Circuit Withstand:

The rated voltage must be equal to or less than 240V (460V model is 480Volts) and the current must be equal to or less than 5000A RMS. (the model of 40HP or above is 10000A RMS)

General Wiring Information

Applicable Codes

All VFD-B AC drives except 015B21A, 015B23A and 075B23B are Underwriters Laboratories, Inc. (UL) and Canadian Underwriters Laboratories (cUL) listed, and therefore comply with the requirements of the National Electrical Code (NEC) and the Canadian Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the instructions provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL and cUL requirements. Refer to the technical data label affixed to the AC drive and the motor nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for each B-Series part number. These fuses (or equivalent) must be used on all installations where compliance with U.L. standards is a required.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-1 |

VFD-B Series

3.1 Basic Wiring Diagram

Users must connect wires according to the following circuit diagram shown below. Do not plug a Modem or telephone line to the RS-485 communication port, permanent damage may result. Terminals 1 & 2 are the power sources only for the optional copy keypad and should not be used while using RS-485 communication.

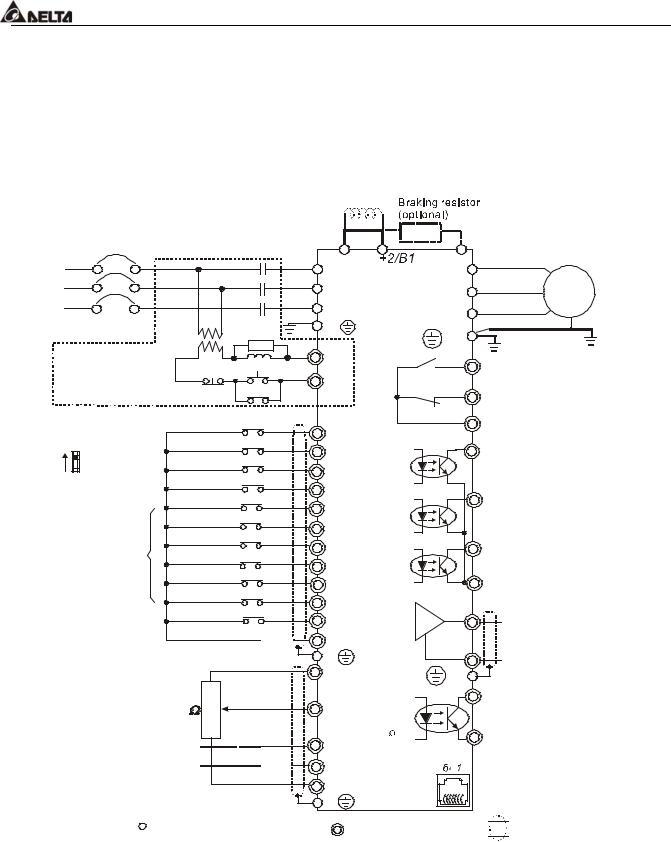

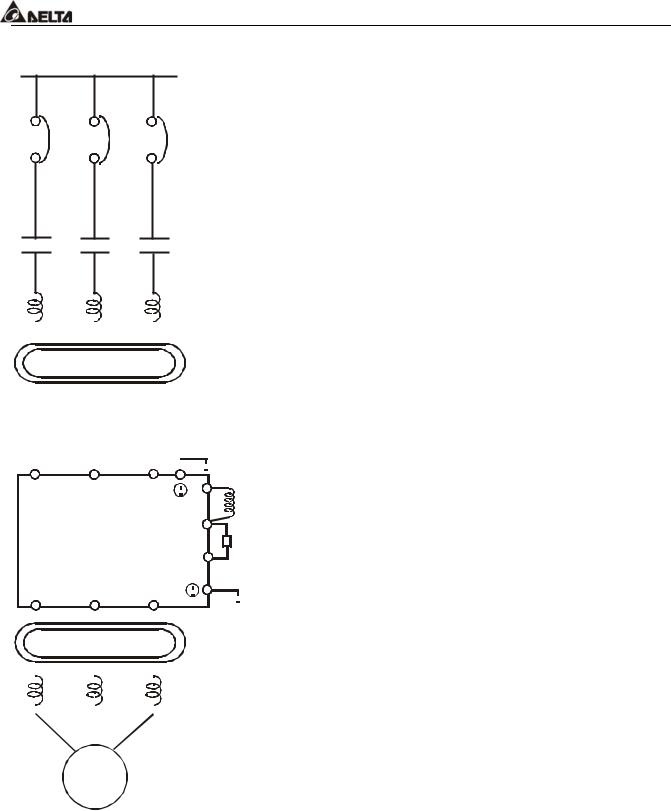

Figure 1 for models of VFD-B Series |

|

|

|

|||||

VFD007B21A/23A/43A, VFD015B21A/21B/23A/23B/43A |

|

|

||||||

VFD022B23B/43B |

|

|

|

DC choke |

|

|

||

|

|

|

|

(optional) |

|

|

||

Fuse/NFB(None Fuse Breaker) |

Jumper |

|

|

|||||

|

+1 |

B2 |

Motor |

|||||

R(L1) |

|

|

|

|

||||

|

|

|

|

R(L1) |

U(T1) |

IM |

||

S(L2) |

|

|

|

|

S(L2) |

V(T2) |

||

T(L3) |

|

|

|

|

T(L3) |

W(T3) |

3~ |

|

|

|

|

|

|

E |

E |

|

|

|

|

|

|

SA |

|

|

||

Recommended Circuit |

|

|

RB |

RA |

|

|||

|

|

MC |

|

|||||

when power supply |

|

|

|

|

RC |

|

|

|

is turned OFF by a |

OFF |

|

ON |

RB |

Please refer to “Control |

|||

fault output |

|

|

||||||

|

|

|

|

MC |

+24V |

RC |

Terminal Explanation”. |

|

Factory Default: |

FWD/STOP |

|

|

|

||||

|

|

FWD |

|

|

||||

SINK Mode |

REV/STOP |

|

|

MO1 |

|

|||

Sink |

|

|

REV |

Factory default: |

||||

Sw1 |

JOG |

|

|

|

|

|||

|

|

|

JOG |

|

indicates during operation |

|||

Source |

E.F. |

|

|

|

|

48V50mA |

||

Please refer to Figure 4 |

|

|

|

EF |

MO2 |

|

||

|

|

|

|

Factory default: |

||||

for wiring of SINK |

Multi-step 1 |

|

MI1 |

|

||||

mode and SOURCE |

Multi-step 2 |

|

|

Freq. Setting Indication |

||||

mode. |

|

MI2 |

MO3 |

48V50mA |

||||

Factory |

Multi-step 3 |

|

MI3 |

Factory default: |

||||

Multi-step 4 |

|

|||||||

default |

|

MI4 |

|

Low-voltage Indication |

||||

|

RESET |

|

|

MI5 |

|

48V50mA |

||

|

|

|

MCM |

Multi-function |

||||

|

Accel/Decel prohibit |

|||||||

|

MI6 |

Photocoulper Output |

||||||

|

Counter |

|

|

AFM |

Analog Multi-function Output |

|||

|

|

|

TRG |

|||||

|

Digital Signal Common |

DCM |

|

Terminal |

||||

* Don't apply the mains voltage directly |

ACM |

Factory default: Analog freq. |

||||||

E |

/ current meter 0~10VDC/2mA |

|||||||

to above terminals. |

|

|

|

|

||||

|

|

|

+10V |

E |

Analog Signal common |

|||

|

|

|

|

|

|

|||

|

|

3 |

|

|

Power supply |

DFM |

Digital Frequency Output |

|

|

|

|

|

+10V 20mA |

||||

|

|

|

|

|

Terminal |

|||

|

5K |

2 |

|

|

AVI |

|

||

|

|

|

|

Factory default: 1:1 |

||||

|

|

1 |

|

|

Master Frequency |

Duty=50% |

||

|

|

4~20mA |

0 to 10V 47K |

|

Digital Signal Common |

|||

|

|

|

|

|||||

|

|

-10~+10V |

ACI |

DCM RS-485 |

||||

|

|

AUI |

||||||

|

|

|

|

|

|

Serial interface |

||

|

Analog Signal Common |

ACM |

|

1: EV 2: GND 3: SG- |

||||

|

E |

|

4: SG+ 5:NC |

|||||

|

|

|

|

|

|

6: for communication |

||

Main circuit (power) terminals |

Control circuit terminals |

Shielded leads & Cable |

||||||

3-2 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

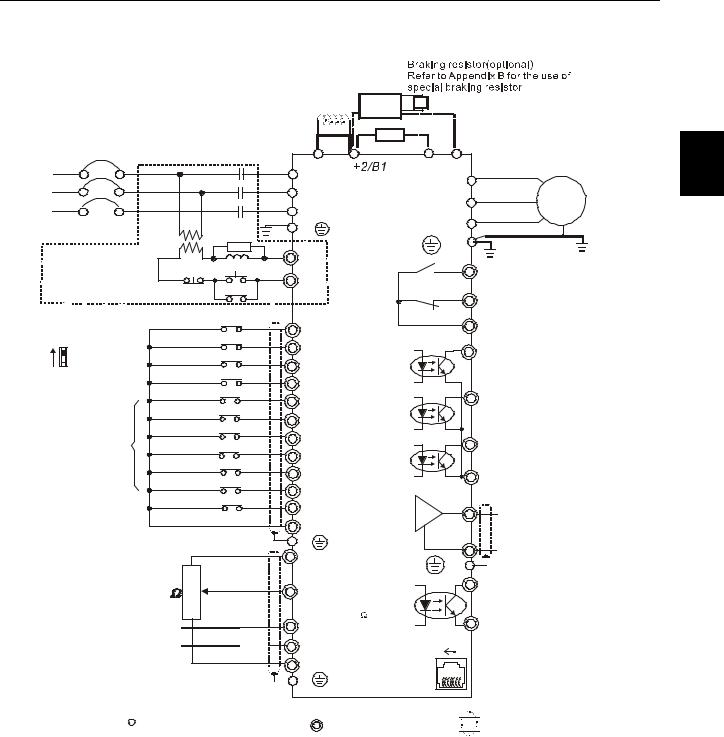

Figure 2 for models of VFD-B Series 3-15 HP

VFD022B21A, VFD037B23A/43A, VFD055B23A/43A, VFD075B23A/43A, VFD110B23A/43A

* Three phase input power may apply to single phase drives.

* For the single phase application, the AC input line can

be connected to any two of the three input terminals R,S,T

VFDB BR

|

|

|

|

DC chock |

|

|

|

|

|

|

|

|

|

|

(optional) |

BR |

|

|

|

|

|

Fuse/NFB(None Fuse Breaker) |

Jumper |

|

|

|

|

3 |

||||

|

+1 |

B2 -(minus sign) |

|

|||||||

R(L1) |

|

|

|

|

Motor |

|||||

|

|

|

|

R(L1) |

U(T1) |

|

IM |

|

||

S(L2) |

|

|

|

|

S(L2) |

|

|

|||

|

|

|

|

V(T2) |

|

|

|

|||

T(L3) |

|

|

|

|

T(L3) |

|

|

3~ |

|

|

|

|

|

|

W(T3) |

|

|

|

|||

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

Recommended Circuit |

|

|

SA |

RB |

|

|

|

|

||

|

|

MC |

RA |

|

|

|

||||

when power supply |

|

|

|

RC |

|

|

|

|||

is turned OFF by a |

OFF |

|

ON |

|

|

|

|

|

||

fault output |

|

|

RB |

Please refer to “Control |

|

|||||

|

|

|

|

MC |

|

|

||||

Factory Default: |

|

|

|

|

+24V |

RC |

Terminal Explanation”. |

|

||

FWD/STOP |

|

|

|

|

|

|||||

|

|

FWD |

|

|

|

|||||

SINK Mode |

REV/STOP |

|

|

MO1 |

|

|

|

|

||

Sink |

|

|

REV |

|

Factory default: |

|

||||

Sw1 |

JOG |

|

|

|

|

|

||||

|

|

|

JOG |

|

|

indicates during operation |

|

|||

Source |

E.F. |

|

|

|

|

|

|

|||

Please refer to Figure 4 |

|

|

|

EF |

MO2 |

|

48V50mA |

|

|

|

|

|

|

|

|

|

|

|

|||

for wiring of SINK |

Multi-step 1 |

|

MI1 |

|

Factory default: |

|

||||

mode and SOURCE |

|

|

|

|

|

|

|

|||

Multi-step 2 |

|

|

|

|

Freq. Setting Indication |

|

||||

mode. |

|

MI2 |

|

|

|

|||||

|

|

|

48V50mA |

|

|

|||||

Multi-step 3 |

|

|

|

|

|

|||||

Factory |

|

MI3 |

MO3 |

|

Factory default: |

|

||||

Multi-step 4 |

|

|

|

|||||||

default |

|

MI4 |

|

|

Low-voltage Indication |

|

||||

RESET |

|

|

|

|

|

|||||

|

|

|

MI5 |

|

|

48V50mA |

|

|

||

|

Accel/Decel prohibit |

MCM |

Multi-function |

|

|

|||||

|

|

|

|

|

MI6 |

Photocoulper Output |

|

|||

|

Counter |

|

|

AFM |

|

|

|

|||

|

|

|

TRG |

Analog Multi-function Output |

|

|||||

|

Digital Signal Common |

|

|

|

||||||

|

DCM |

|

|

Terminal |

|

|

||||

* Don't apply the mains voltage directly |

ACM |

Factory default: Analog freq. |

|

|||||||

E |

|

|||||||||

/ current meter 0~10VDC/2mA |

|

|||||||||

to above terminals. |

|

|

|

|

||||||

|

|

|

+10V |

E |

|

Analog Signal common |

|

|||

|

|

|

|

|

|

|

||||

|

|

3 |

|

|

Power supply |

|

Digital Frequency Output |

|

||

|

|

|

|

|

+10V 20mA |

DFM |

|

|||

|

5K |

2 |

|

|

AVI |

|

|

Terminal |

|

|

|

|

|

|

|

Factory default: 1:1 |

|

||||

|

|

|

|

|

Master Frequency |

|

|

|||

|

|

1 |

|

|

|

Duty=50% |

|

|

||

|

|

4~20mA |

0 to 10V 47K |

|

|

|

|

|||

|

|

|

|

|

Digital Signal Common |

|

||||

|

|

-10~+10V |

ACI |

DCM |

|

|||||

|

|

AUI |

RS-485 |

|

|

|||||

|

|

|

|

|

6 |

1 |

|

|

||

|

|

|

|

|

ACM |

Serial interface |

|

|

||

|

Analog Signal Common |

|

|

1: EV 2: GND 3: SG- |

|

|||||

|

E |

|

|

4: SG+ 5:NC |

|

|

||||

|

|

|

|

|

|

|

6: for communication |

|

||

|

|

|

|

|

|

|

|

|

||

Main circuit (power) terminals |

Control circuit terminals |

|

Shielded leads & Cable |

|

||||||

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-3 |

VFD-B Series

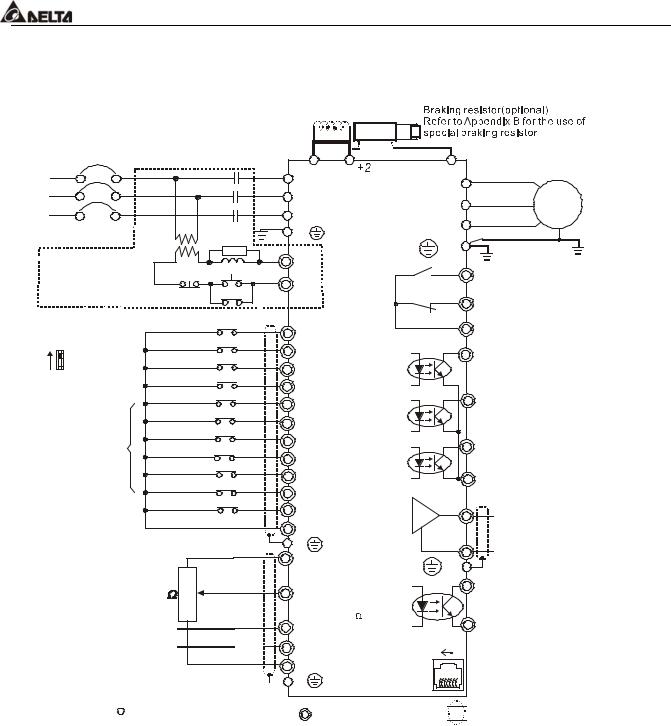

Figure 3 for models of VFD-B Series 20 HP and above

VFD150B23A/43A, VFD185B23A/43A, VFD220B23A/43A, VFD300B23A/43A,

VFD370B23A/43A, VFD450B43A, VFD550B43A, VFD750B43A

DC chock |

|

(optional) |

VFDB |

Jumper |

|

Fuse/NFB(None Fuse Breaker) |

|

R(L1) |

|

|

|

|

+1 |

-(minus sign) |

Motor |

||

|

|

|

|

R(L1) |

U(T1) |

IM |

|||

S(L2) |

|

|

|

|

S(L2) |

||||

|

|

|

|

V(T2) |

|

||||

T(L3) |

|

|

|

|

T(L3) |

|

3~ |

||

|

|

|

|

W(T3) |

|

||||

|

|

|

|

|

E |

|

|

||

|

|

|

|

|

E |

|

|

||

Recommended Circuit |

|

|

SA |

|

|

|

|||

|

|

RB |

|

|

|

||||

|

|

MC |

RA |

|

|||||

when power supply |

|

|

|

RC |

|

||||

is turned OFF by a |

OFF |

|

ON |

|

|

|

|||

fault output |

|

|

RB |

Please refer to “Control |

|||||

|

|

|

|

MC |

|

||||

|

|

|

|

|

+24V |

RC |

Terminal Explanation”. |

||

Factory Default: |

FWD/STOP |

|

|

|

|||||

|

|

FWD |

|

||||||

SINK Mode |

REV/STOP |

|

|

MO1 |

|

|

|||

Sink |

|

|

REV |

|

Factory default: |

||||

Sw1 |

JOG |

|

|

|

|

||||

|

|

|

JOG |

|

|

indicates during operation |

|||

Source |

|

|

|

|

|

||||

E.F. |

|

|

|

EF |

|

|

48V50mA |

||

Please refer to Figure 4 |

|

|

|

MO2 |

|

|

|||

|

|

|

|

|

|

||||

for wiring of SINK |

Multi-step 1 |

|

MI1 |

|

Factory default: |

||||

|

|

|

|||||||

mode and SOURCE |

Multi-step 2 |

|

|

|

|

Freq. Setting Indication |

|||

mode. |

|

MI2 |

|

|

48V50mA |

||||

Multi-step 3 |

|

|

|

||||||

Factory |

|

MI3 |

MO3 |

|

Factory default: |

||||

Multi-step 4 |

|

|

|||||||

default |

|

MI4 |

|

|

Low-voltage Indication |

||||

RESET |

|

|

|

|

|||||

|

|

|

MI5 |

|

|

48V50mA |

|||

|

Accel/Decel prohibit |

MCM |

Multi-function |

||||||

|

MI6 |

Photocoulper Output |

|||||||

|

|

|

|

|

|||||

|

Counter |

|

|

AFM |

|

||||

|

|

|

TRG |

Analog Multi-function Output |

|||||

|

Digital Signal Common |

|

|

||||||

|

DCM |

|

|

Terminal |

|||||

* Don't apply the mains voltage directly |

ACM |

Factory default: Analog freq. |

|||||||

E |

|||||||||

/ current meter 0~10VDC/2mA |

|||||||||

to above terminals. |

|

|

|

+10V |

E |

|

Analog Signal common |

||

|

|

|

|

|

|

||||

|

|

3 |

|

|

Power supply |

|

Digital Frequency Output |

||

|

|

|

|

|

+10V 20mA |

DFM |

|||

|

5K |

2 |

|

|

AVI |

|

|

Terminal |

|

|

|

|

|

|

Factory default: 1:1 |

||||

|

|

|

|

|

Master Frequency |

|

|

||

|

|

1 |

|

|

|

|

Duty=50% |

||

|

|

4~20mA |

0 to 10V 47K |

|

|

||||

|

|

|

|

|

Digital Signal Common |

||||

|

|

-10~+10V |

ACI |

DCM |

|||||

|

|

AUI |

RS-485 |

||||||

|

|

|

|

|

6 |

1 |

|||

|

|

|

|

|

ACM |

Serial interface |

|||

|

Analog Signal Common |

|

|

1: EV 2: GND 3: SG- |

|||||

|

E |

|

|

4: SG+ 5:NC |

|||||

|

|

|

|

|

|

|

6: for communication |

||

|

|

|

|

|

|

|

|

||

Main circuit (power) terminals |

Control circuit terminals |

|

Shielded leads & Cable |

||||||

3-4 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

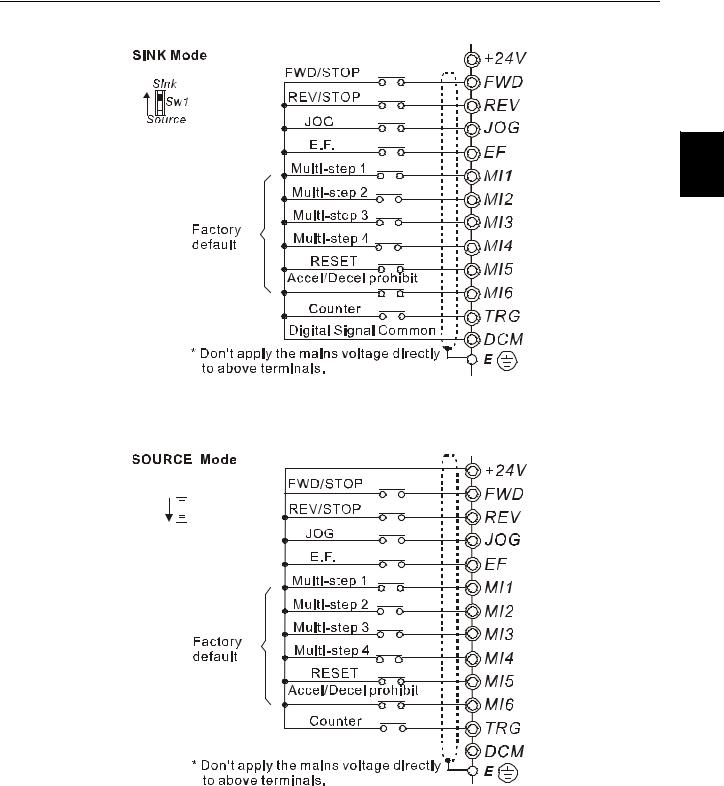

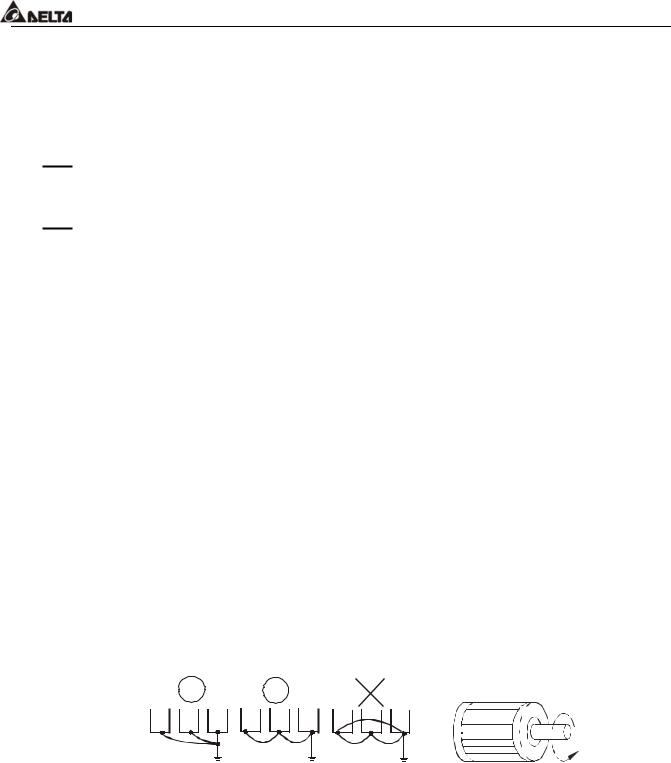

Figure 4 Wiring for SINK mode and SOURCE mode

3

Sink

Sw1

Sw1

Source

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-5 |

VFD-B Series

3.2 External Wiring

Power Supply

FUSE/NFB

Magnetic contactor

|

|

|

|

|

Input AC |

|

|

|

|

|||||||||||||

|

|

|

|

|

Line Reactor |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zero-phase |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reactor |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EMI Filter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R/L1 |

S/L2 |

T/L3 |

|

|

|

|

|

|

|

|

|

DC |

||||||||||

|

|

|

|

|||||||||||||||||||

|

|

|

|

+1 |

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Choke |

||

|

|

|

|

|

+2/B1 |

|

Braking |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

B2 |

|

Resistor |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

U/T1 |

V/T2 |

W/T3 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zero-phase |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reactor |

||||||||

|

|

|

|

|

Output AC |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

Line Reactor |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor

Items |

Explanations |

|

Power |

Please follow the specific power |

|

supply requirement shown in |

||

supply |

||

APPENDIX-A. |

||

|

||

|

There may be inrush current during |

|

Fuse/NFB |

power up. Please check the chart of |

|

(Optional) |

APPENDIX B and select the correct |

|

fuse with rated current. NFB is |

||

|

optional. |

|

|

|

|

Magnetic |

Please do not use a Magnetic |

|

contactor as the I/O switch of the AC |

||

contactor |

||

(Optional) |

drive, this will reduce the operating |

|

life cycle of the AC drive. |

||

|

||

|

|

|

|

In order to improve the input power |

|

|

factor, reduces harmonics and |

|

|

protection from AC line |

|

Input AC |

disturbances. (Surge, switching |

|

Line |

spike, power flick, etc.) AC line |

|

Reactor |

reactor should be installed when the |

|

(Optional) |

power supply capacity is 500kVA or |

|

|

more and exceeds 6 times of the |

|

|

inverter capacity, or the wiring |

|

|

distance within 10m. |

|

Zero-phase |

Zero phase reactors are used to |

|

reduce radio noise specify when the |

||

Reactor |

audio equipments installed near the |

|

(Ferrite |

inverter. Good effective for noise |

|

Core |

reduction on both the input and |

|

Common |

output sides. Attenuation quality is |

|

Choke) |

good in a wide range from AM band |

|

(Optional) |

to 10Mhz. Appendix B for specifies |

|

|

zero phase reactors. (RF220X00A) |

|

EMI filter |

To reduce the electromagnetic |

|

interference. Please refer to |

||

(Optional) |

||

Appendix B for detail. |

||

Braking |

Used to reduce stopping time of the |

|

motor. Please refer to the chart on |

||

Resistor |

||

Appendix B for specific Braking |

||

(Optional) |

||

Resistors. |

||

|

|

|

Output AC |

Motor surge voltage amplitudes |

|

Line |

depending on the motor cable |

|

Reactor |

length. For long motor cable |

|

(Optional) |

application, it is necessary installed |

|

|

on the inverter output side. |

3-6 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

3.3 Terminal Explanations

|

Terminal Symbol |

|

Explanation of Terminal Function |

|

|

|

|||||||

|

R/L1, S/L2, T/L3 |

|

AC line input terminals |

|

|

|

|||||||

|

U/T1, V/T2, W/T3 |

|

AC drive output terminals motor connections |

|

|

|

|||||||

|

+1,+2 |

|

|

Connections for DC Link Reactor (optional) |

|

|

|

||||||

|

|

|

|

|

3 |

||||||||

|

+2/B1~B2 |

|

Connections for Braking Resistor (optional) |

|

|

||||||||

|

+2 ~ -(minus sign) |

|

Connections for External Braking Unit (VFDB series) |

|

|

|

|||||||

|

|

|

|

||||||||||

|

+2/B1~ -(minus sign) |

|

|

|

|||||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

Earth Ground |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.4 Control Terminals Explanations |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

Terminal Symbols |

|

Terminal Functions |

Factory Settings |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

FWD |

Forward-Stop command |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

REV |

Reverse-Stop command |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

JOG |

Jog command |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

EF |

External fault |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

TRG |

External counter input |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

MI1 |

Multi-function Input 1 |

|

|

|

|

|||||||

|

MI2 |

Multi-function Input 2 |

|

|

|

|

|||||||

|

MI3 |

Multi-function Input 3 |

Refer to Pr.04-04 to Pr.04-09 |

|

|

||||||||

|

MI4 |

Multi-function Input 4 |

Multi-function Input Terminals |

|

|

||||||||

|

MI5 |

Multi-function Input 5 |

|

|

|

|

|||||||

|

MI6 |

Multi-function Input 6 |

|

|

|

|

|||||||

|

DFM |

Digital Frequency Meter |

Factory setting 1:1 |

|

|

||||||||

|

(Open Collector Output) |

(Maximum 48VDC, 50mA) |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

+24V |

DC Voltage Source |

(+24V, 20mA), used for source mode. |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCM |

Digital Signal Common |

Used as common for digital inputs |

|

|

||||||||

|

and used for sink mode. |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-7 |

VFD-B Series

Terminal Symbols |

Terminal Functions |

Factory Settings |

|

|

|

|

|

RA |

Multi-function Relay output |

Resistor Load |

|

(N.O.) a |

5A(N.O.)/3A(N.C.) 240VAC |

||

|

|||

|

Multi-function Relay output |

||

RB |

5A(N.O.)/3A(N.C.) 24VDC |

||

(N.C.) b |

|||

|

Inductive Load |

||

|

|

||

RC |

Multi-function Relay common |

1.5A(N.O.)/0.5A(N.C.) 240VAC |

|

1.5A(N.O.)/0.5A(N.C.) 24VDC |

|||

|

|

||

|

|

Refer to Pr.03-01 to Pr.03-03 |

|

MO1 |

Multi-function output 1 |

|

|

(Photocoupler) |

|

||

|

|

||

MO2 |

Multi-function output 2 |

Maximum 48VDC, 50mA |

|

(Photocoupler) |

Refer to Pr.03-01 to Pr.03-03 |

||

|

|||

MO3 |

Multi-function output 3 |

|

|

(Photocoupler) |

|

||

|

|

||

MCM |

Multi-function output common |

Maximum 48VDC, 50mA |

|

|

|

|

|

+10V |

Potentiometer output power |

+10V 20mA |

|

source |

|||

|

|

||

AVI |

Analog voltage Input |

0 to +10V |

|

|

|

|

|

ACI |

Analog current Input |

4 to 20mA |

|

|

|

|

|

AUI |

Auxiliary analog voltage input |

-10 to +10V |

|

|

|

|

|

AFM |

Analog output meter |

0 to 10V, 2mA |

|

|

|

|

|

ACM |

Analog control signal |

|

|

(common) |

|

||

|

|

* Control signal wiring size: 18 AWG (0.75 mm2).

3-8 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

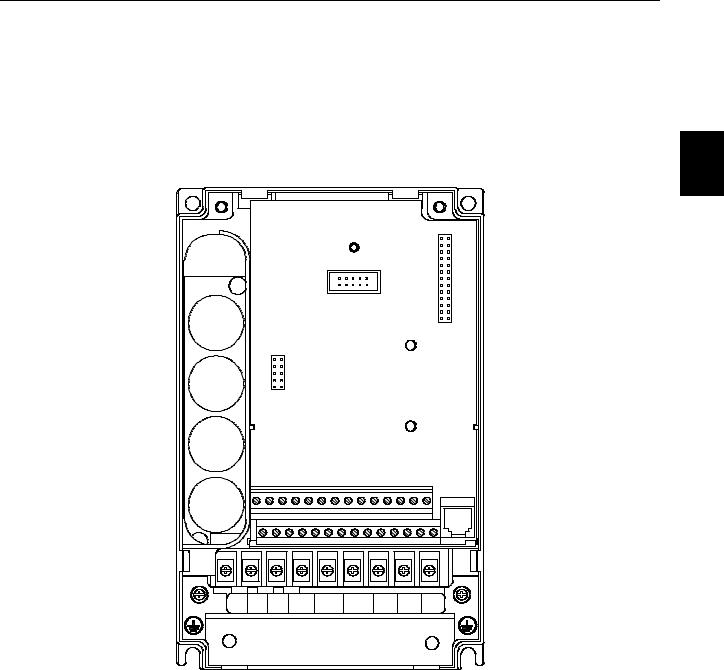

3.5 Main Circuit Wiring

1HP to 3HP (VFD007B23A, VFD007B43A, VFD007B21A, VFD015B21A, |

||||||

VFD015B23A, VFD015B43A, VFD015B21B, VFD015B23B, |

||||||

VFD022B23B, VFD022B43B) |

|

|

|

|||

|

|

|

|

|

|

3 |

R |

S |

T |

+2 |

U |

V |

W |

/L1 |

/L2 |

/L3 +1 |

/B1 B2 |

/T1 |

/T2 |

/T3 |

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 10-18 AWG stranded wire, 12-18 AWG solid wire

Wire Type: Copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-9 |

VFD-B Series

3HP to 5HP (VFD022B21A, VFD037B23A, VFD037B43A)

+1

+1  +2

+2 B1

B1 -

-  B2

B2

U/T1

U/T1  V/T2

V/T2  W/T3

W/T3

Screw Torque : 18Kgf-cm

Wire Gauge : 18~10AWG

R/L1

R/L1 S/L2

S/L2 T/L3

T/L3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

]Torque: 18 kgf-cm (15.6 in-lbf) Wire Gauge: 10-18 AWG

Wire Type: Stranded copper only, 75°C

3-10 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

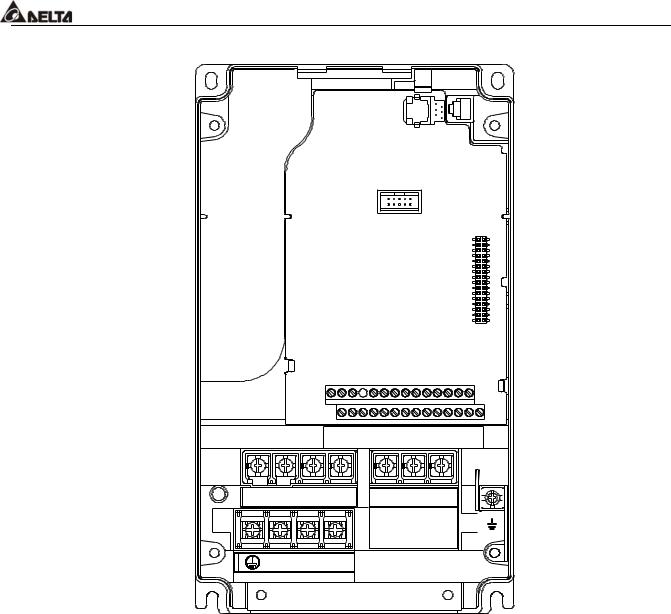

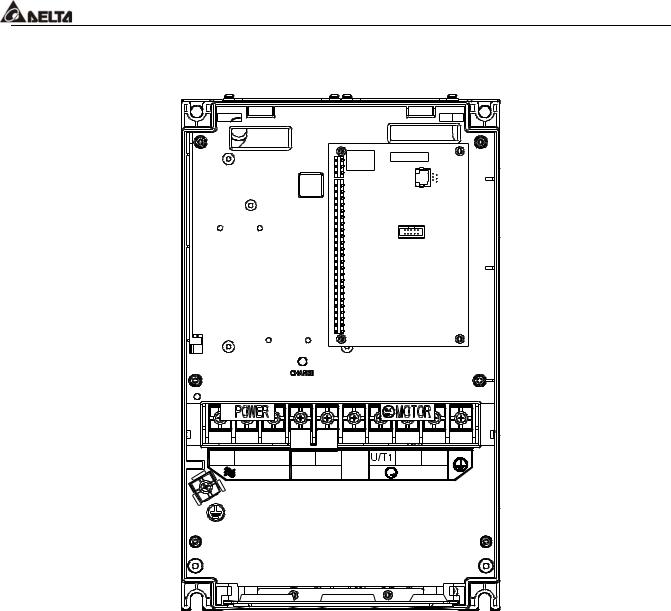

7.5 HP to 15 HP (VFD055B23A, VFD055B43A, VFD075B23A, VFD075B43A, VFD110B23A, VFD110B43A)

3

POWER |

3 MOTOR |

|

IM |

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 30Kgf-cm (26 in-lbf) Wire: 8-12 AWG

Wire Type: Stranded Copper only, 75°C

NOTE: If wiring of the terminal utilizes the wire with a 6AWG-diameter, it is thus necessary to use the Recognized Ring Terminal to conduct a proper wiring.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-11 |

VFD-B Series

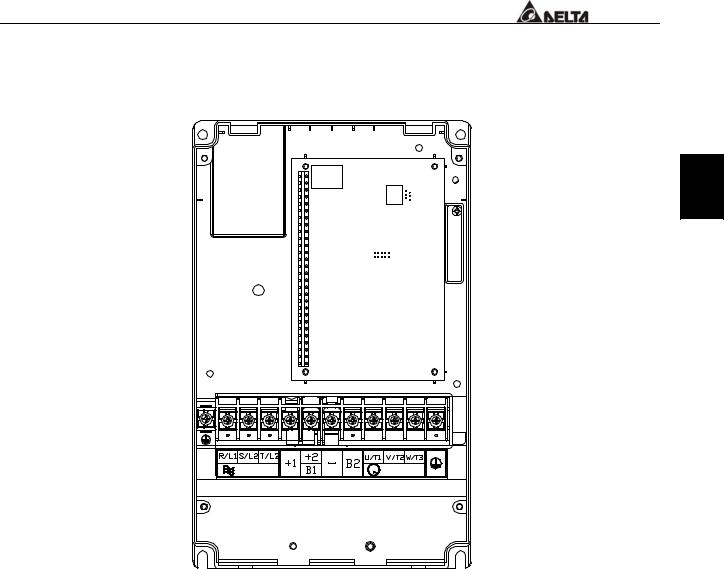

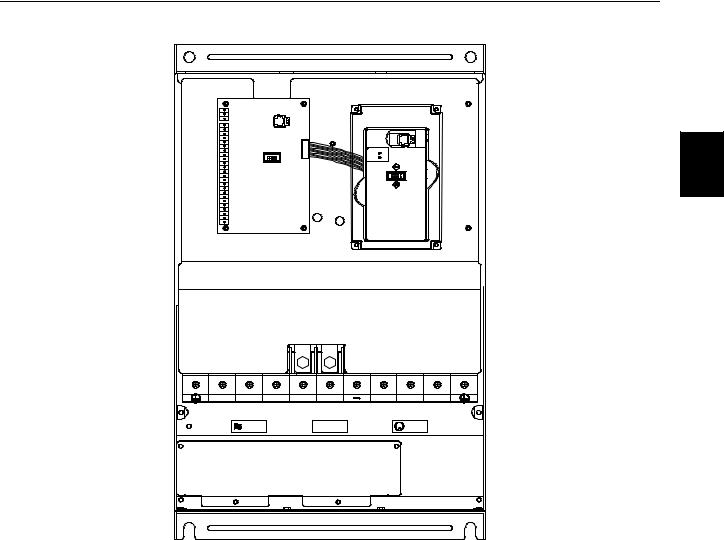

20 HP to 30 HP (VFD150B23A, VFD150B43A, VFD185B23A, VFD185B43A, VFD220B23A, VFD220B43A)

R/L1 S/L2 T/L3 |

+1 |

+2 |

- |

|

V/T2 W/T3 |

POWER |

DC(+) |

DC( - ) |

IM |

MOTOR |

|

3 |

|||||

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 30Kgf-cm (26 in-lbf)

Wire: 2-8 AWG

Wire Type: Stranded Copper only, 75°C

NOTE: If wiring of the terminal utilizes the wire with a 1AWG-diameter, it is thus necessary to use the Recognized Ring Terminal to conduct a proper wiring.

3-12 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

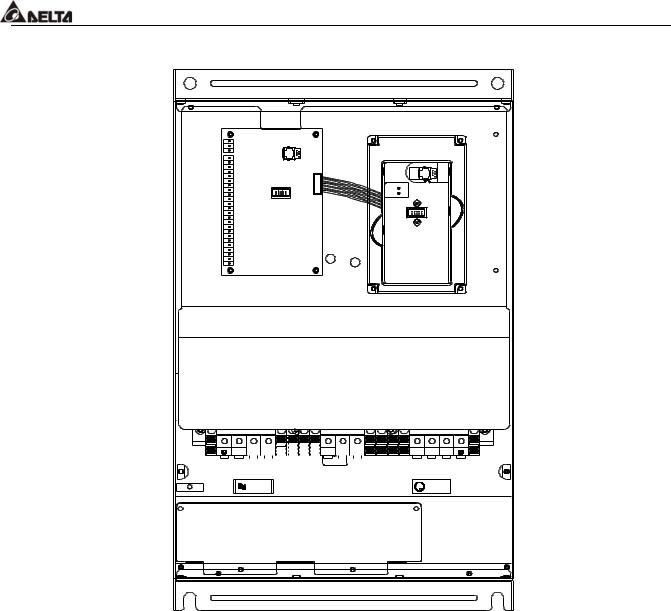

40 HP to 50 HP 230V (VFD300B23A, VFD370B23A)

POWER |

3 |

ALARM |

CHARGE

R/L1 S/L2 T/L3 |

+1 +2 |

U/T1 V/T2 W/T3 |

|

POWER |

Screw Torque: |

IM |

MOTOR |

200kgf-cm (173in-lbf) |

3 |

||

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 200kgf-cm (173 in-lbf)

Wire Gauge: 2/0 - 3/0 AWG

Wire Type: Stranded copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-13 |

VFD-B Series

40 HP to 60 HP 460V (VFD300B43A, VFD370B43A, VFD450B43A)

POWER

ALARM

CHARGE

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R/L1 S/L2 T/L3 |

|

|

|

|

|

|

|

+1 +2 - |

|

||||||||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER

POWER

U/T1 V/T2 |

2/T3 |

IM MOTOR

3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 58.7kgf-cm (50.9 in-lbf) max.

Wire Gauge: 2-4AWG

Wire Type: Stranded copper only, 75°C

3-14 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

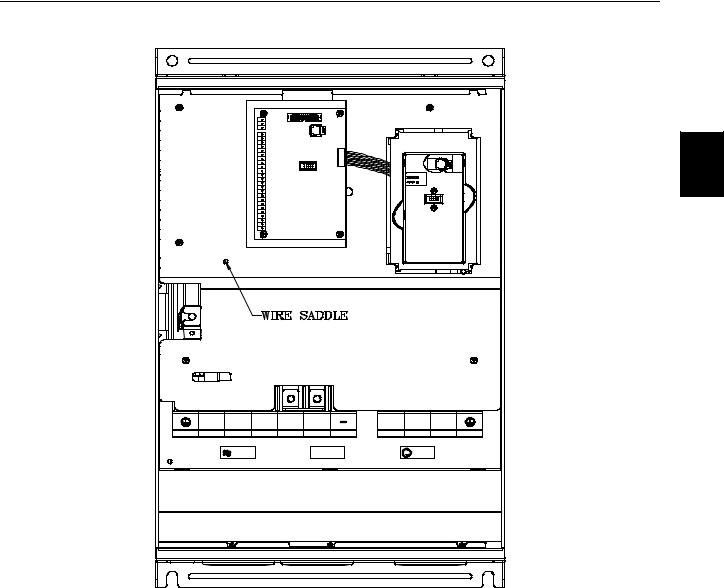

75-100 HP 460V (VFD550B43A, VFD750B43A)

|

|

|

|

3 |

R/L1 S/L2 T/L3 |

+1 |

+2 |

U/T1 V/T2 W/T3 |

|

POWER |

|

Screw Torque: |

IM |

MOTOR |

|

200kgf-cm (173in-lbf) |

3 |

||

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG

Power Terminal

Torque: 200 kgf-cm (173 in-lbf)

Wire Gauge: 2/0-3/0 AWG

Wire Type: Stranded copper only, 75°C

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-15 |

VFD-B Series

3.6 Wiring Notes: PLEASE READ PRIOR TO INSTALLATION.

1.There are corresponding ring terminals which will be included with each unit (20-30HP), and please use the proper crimping tool by KST INC. P/N: KST-HDC38A for securing the conductor.

2. !

! CAUTION: Do not connect the AC power to the U/T1, V/T2, W/T3 terminals, as it will damage the AC drive.

CAUTION: Do not connect the AC power to the U/T1, V/T2, W/T3 terminals, as it will damage the AC drive.

3. !

! WARNING: Ensure all screws are tightened to the proper torque rating.

WARNING: Ensure all screws are tightened to the proper torque rating.

4.During installation, follow all local electrical, construction, and safety codes for the country the drive is to be installed in.

5.Ensure that the appropriate protective devices (circuit breaker or fuses) are connected between the power supply and AC drive.

6.Make sure that the leads are connected correctly and the AC drive is properly grounded. (Ground resistance should not exceed 0.1Ω .)

7.Use ground leads that comply with AWG/MCM standards and keep them as short as possible.

8.Multiple VFD-B units can be installed in one location. All the units should be grounded directly to a common ground terminal. The VFD-B ground terminals may also be connected in parallel, as shown in the figure below. Ensure there are no ground loops.

Forward running

9.When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor terminals U/T1, V/T2, and W/T3, respectively, the motor will rotate counterclockwise (as viewed from the shaft ends of the motor) when a forward operation command is received. To reverse the direction of motor rotation, switch over any of the two motor leads.

3-16 |

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

VFD-B Series

VFD-B Series

10.Make sure that the power source is capable of supplying the correct voltage and required current to the AC drive.

11.Do not attach or remove wiring when power is applied to the AC drive.

12.Do not monitor the signals on the circuit board while the AC drive is in operation.

3

13.For the single-phase rated AC drives, the AC power can be connected to any two of the three input terminals R/L1, S/L2, T/L3. Note: This drive is not intended for the use with single-phase motors.

14.Route the power and control wires separately, or at 90°angle to each other.

15.If a filter is required for reducing EMI (Electro Magnetic Interference), install it as close as possible to AC drive. EMI can also be reduced by lowering the Carrier Frequency.

16.If the AC drive is installed in the place where a load reactor is needed, install the filter close to U/T1, V/T2, W/T3, side of AC drive. Do not use a Capacitor or L-C Filter (Inductance-Capacitance) or R-C Filter (Resistance-Capacitance), unless approved by Delta.

17.When using a GFCI (Ground Fault Circuit Interrupt), select current sensor with sensitivity of 200mA, and not less than 0.1-second detection to avoid nuisance tripping.

3.7 Motor Operation Precautions

1.When using the AC drive to operate a standard 3-phase induction motor, notice that the energy loss is greater than for an inverter duty motor.

2.Avoid running a standard induction motor at low speed. Under these conditions, the motor temperature may rise above the motor rating due to limited airflow produced by the motor’s fan.

3.When the standard motor operates at low speed, the output load must be decreased.

4.If 100% output torque is desired at low speed, it may be necessary to use a special “inverter-duty” rated motor.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED |

3-17 |

Loading...

Loading...