Delonghi DE 906 GWF User Manual

INSTALLATION and SERVICE INSTRUCTIONS

USE and CARE INSTRUCTIONS

DE 906 GWF

DUAL FUEL COOKER

distributed by

DèLonghi

Pty Ltd

Dear Customer,

Thank you for having purchased and given your preference to our product.

The safety precautions and recommendations reported below are for your own safety and that of others. They will also provide a means by which to make full use of the features offered by your appliance.

Please keep this booklet in a safe place. It may be useful in future, either to yourself or to others in the event that doubts should arise relating to its operation.

This appliance must be used only for the task it has explicitly been designed for, that is for cooking foodstuffs. Any other form of usage is to be considered as inappropriate and therefore dangerous.

The manufacturer declines all responsibility in the event of damage caused by improper, incorrect or illogical use of the appliance or be faulty installation.

Important:

This appliance is designed and manufactured solely for the cooking of domestic (household) food and is not suitable for any non domestic application and therefore should not be used in a commercial environment.

The appliance guarantee will be void if the appliance is used within a non domestic environment i.e. a semi commercial, commercial or communal environment.

PRODUCT LABEL

2

USING THE OVEN FOR THE FIRST TIME

You are advised to carry out the following operations:

■Furnish the interior of the oven.

■Switch the empty oven ON at maximum temperature for about two hours to eliminate traces of grease and smell from the components.

■Disconnect the appliance from the electric power supply and clean the interior of the oven with a cloth soaked in water and neutral detergent and dry thoroughly.

IMPORTANT PRECAUTIONS AND RECOMMENDATIONS FOR USE OF ELECTRICAL APPLIANCES

Use of any electrical appliance implies the necessity to follow a series of fundamental rules. In particular:

■Never touch the appliance with wet hands or feet;

■do not operate the appliance barefooted;

■The appliance is not intended for use by young children or infirm persons without supervision

■Young children should be supervised to ensure they do not play with the appliance

The manufacturer cannot be held responsible for any damages caused by improper, incorrect or illogical use of the appliance.

This cooker has been designed and constructed in accordance with the following codes and specifications:

AGA101 (AS 4551) Approval Requirements for Domestic Gas cooking appliances

AS/NZS 60335-1 General Requirements for Domestic electrical appliances

AS/NZS 60335-2-6 Particular Requirements for Domestic electrical cooking appliances

AS/NSZ 1044 Electromagnetic Compatibility Requirements.

3

IMPORTANT PRECAUTIONS AND RECOMMENDATIONS

After having unpacked the appliance, check to ensure that it is not damaged.

In case of doubt, do not use it and consult your supplier or a professionally qualified technician. Packing elements (i.e. plastic bags, polystyrene foam, nails, packing straps, etc.) should not be left around within easy reach of children, as these may cause serious injuries.

■Do not attempt to modify the technical characteristics of the appliance as this may become dangerous to use.

■Do not carry out cleaning or maintenance operations on the appliance without having previously disconnected it from the electric power supply.

■After use, ensure that the knobs are in the off position.

■The appliance is not intended for use by young children or infirm persons unless they have been adequately supervised by a responsible person to ensure that they can use the appliance safely.

■During and after use of the appliance, certain parts will become very hot. Do not touch hot parts. Care should be taken to avoid touching heating elements inside the oven.

■Keep children away from the appliance when it is in use.

■Young children should be supervised to ensure that they do not play with the appliance.

■Some appliances are supplied with a protective film on steel and aluminium parts. This film must be removed before using the appliance.

■Make sure that electrical cables connecting other appliances in the proximity of the cooker cannot come into contact with the hob or become entrapped in the oven door.

■Do not line the oven walls with aluminium foil. Do not place baking trays or the drip tray on the base of the oven chamber.

■WARNING When correctly installed, your product meets all safety requirements laid down for this type of product category. However special care should be taken around the rear or the underneath of the appliance as these areas are not designed or intended to be touched and may contain sharp or rough edges, that may cause injury.

■Fire risk! Do not store flammable material in the oven and in the storage compartment.

■Always use oven gloves when removing the shelves and food trays from the oven whilst hot.

■Do not hang towels, dishcloths or other items on the appliance or its handle – as this could be a fire hazard.

■Clean the oven regularly and do not allow fat or oils to build up in the oven base or tray. Remove spillages as soon as they occur.

■Do not stand on the open oven door.

■Always stand back from the appliance when opening the oven door to allow steam and hot air to escape before removing the food.

■This appliance is for domestic use only.

■Safe food handling: leave food in the oven for as short a time as possible before and after cooking. This is to avoid contamination by organisms which may cause food poisoning. Take particular care during warmer weather.

■The manufacturer declines all liability for injury to persons or damage to property caused by incorrect or improper use of the appliance.

■WARNING: Taking care NOT to lift the oven by the door handle.

■IMPORTANT NOTE: This appliance shall not be used as a space heater, especially if installed in marine craft or caravans.

4

INSTALLATION

CAUTION:

■This appliance must be installed in accordance with these installation instructions.

■This appliance shall only be serviced by authorized personnel.

■This appliance is to be installed only by an authorised person.

■Incorrect installation, for which the manufacturer accepts no responsibility, may cause personal injury of damage.

■Always disconnect the cooker from mains power supply before carrying out any maintenance operations or repairs.

■In the room where the cooker is installed, there must be enough air to allow the gas to burn correctly, according to the current local regulations.

ELECTRICAL REQUIREMENTS

■The appliance must be connected to the mains checking that the voltage corresponds to the value given in the rating plate and that the electrical cable sections can withstand the load specified on the plate.

■The plug must be connected to an earthed socket in compliance with safety standards.

■If the appliance is supplied without plug, fit a standard plug which is suitable for the power consumed by the appliance.

■The appliance must be connected directly to the mains placing a two pole switch with minimum opening between the contacts of 3 mm between the appliance and the mains.

■The power supply cable must not touch the hot parts and must be positioned so that it does not exceed 50°C above ambient.

■Once the appliance has been installed, the switch or socket must always be accessible.

■If the supply cord is damaged it must be replaced by the manufacturer or it’s Service Agent or a similarly qualified person in order to avoid a hazard.

WARNING: This cooker must be connected to electrical supply using V105 insulated cable.

N.B. The connection of the appliance to earth is mandatory.

If the installation requires alterations to the domestic electrical system call a qualified electrician.

He should also check that the socket cable section is suitable for the power drawn by the appliance.

Appliance power rating:

230 V~ 3345 W (14.5 A)

240 V~ 3640 W (15.1 A)

Replacing the power cord must be done by a qualified electrician in accordance with the instructions supplied by the manufacturer and in compliance with established electrical regulations.

5

CLEARANCES

Installation clearances and protection of combustible surfaces shall comply with the current local regulations eg. AG 601 (AS 5601) Gas Installations code.

Installation shall comply with the dimension in Fig. 1a bearing in mind that.

Overhead Clearances

In no case shall the clearances between the highest part of the cooker be less than 600 mm or for an overhead exhaust fan 750 mm. AII other downward facing combustible surfaces less than 600 mm above the cooker surface shall be protected for the full width of the cooking surface in accordance with the standards noted above. In no case shall the clearance be less than 450 mm.

Rear and Side Clearances

Where the dimensions from the periphery of the nearest burner to any vertical combustible surface is less than 200 mm the surface shall be protected in accordance with the standards to a height of not less than 150 mm above the cooking surface for the full width or depth of the cooking surface.

Where the dimensions from the periphery of the nearest burner to any horizontal combustible surface is less than 200 mm, the horizontal surface shall be greater than 10 mm below the surface of the hob, or the horizontal surface requirement above.

Protection of combustible surfaces.

The standards above specify that where required protection shall ensure that the surface temperature of the combustible surface does not exceed 65°C above room temperature.

If the cooker is located on a pedestal it is necessary to provide safety measures to prevent falling out.

6

Figure 1a

750 mm |

|

450 mm |

|

|

|

|

|

m |

m |

500 m |

50 m |

Cooker overall dimensions [mm]

• height: min 900 - max 925

• width: 900

• depth: 600

GAS AND ELECTRIC CONNECTION

|

Dotted line |

|

Figure 1b |

showing the |

|

position of the |

||

|

||

|

cooker when |

|

|

installed |

Area for GAS and ELECTRIC connection

max 290 mm

7

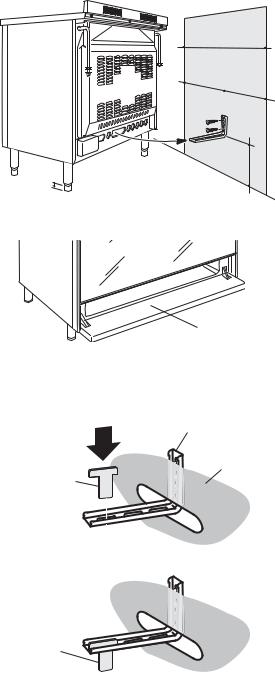

FITTING THE ADJUSTABLE FEET

The adjustable feet must be fitted to the base of the cooker before use.

Rest the rear of the cooker an a piece of the polystyrene packaging exposing the base for the fitting of the feet.

Fit the 4 legs by screwing them tight into the support base as shown in figure 3.

Figure 2 |

Figure 3 |

LEVELLING THE COOKER

The cooker may be levelled by screwing the lower ends of the feet IN or OUT (fig. 4).

Figure 4

8

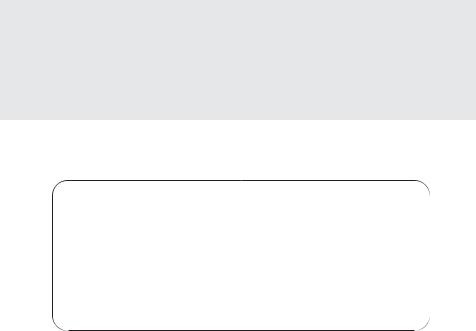

MOVING THE COOKER

WARNING

When raising cooker to upright position always ensure two people carry out this manoeuvre to prevent damage to the adjustable feet (fig. 5).

Figure 5

WARNING

Be carefull: do not lift the cooker by the door handle when raising to the upright position (fig. 6).

Figure 6

WARNING

When moving cooker to its final position DO NOT DRAG (fig. 7).

Lift feet clear of floor (fig. 5).

Figure 7

9

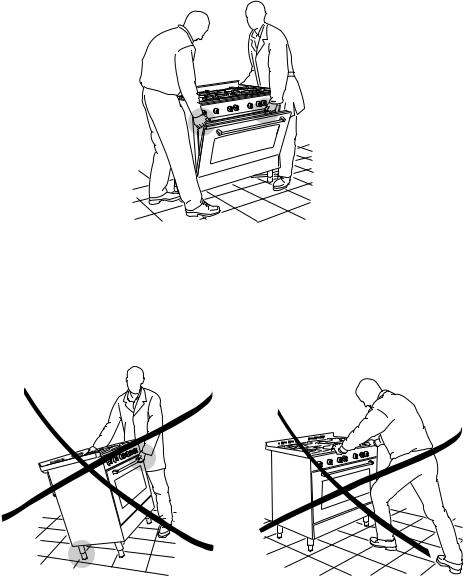

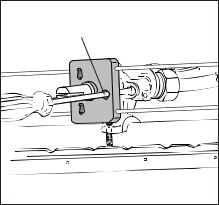

ANTI-TILT BRACKET

Important!

To restrain the appliance and prevent it tipping accidentally, fit a bracket to its rear to fix it securely to the wall. Make sure you also fit the supplied lock pin to the anti-tilt bracket.

To fit the anti-tilt bracket:

1.After you have located where the cooker is to be positioned, mark on the wall the place where the two screws of the anti-tilt bracket have to be fitted. Please follow the indications given in Fig. 8a.

2.Drill two 8 mm diameter holes in the wall and insert the plastic plugs supplied.

Important!

Before drilling the holes, check that you will not damage any pipes or electrical wires.

3.Loosely attach the anti-tilt bracket with the two screws supplied.

4.Move the cooker to the wall and adjust the height of the anti-tilt bracket so that it can engage in the slot on the cooker’s back, as shown in Fig. 8a.

5.Tighten the screws attaching the anti-tilt bracket.

6.Push the cooker against the wall so that the anti-tilt bracket is fully inserted in the slot on the cooker’s back.

7.Access the bracket and fit the lock pin:

•Open the pivoting panel (Fig. 8b).

•Fit the lock pin through the bracket, as shown (Fig. 8c).

•Close the pivoting panel.

900 mm

|

|

|

450 |

450 |

|

|

|

|

|

|

|

0 |

min 220 |

max245 |

|

|

+ 25

Figure 8a Fitting the anti-tilt bracket

Pivoting panel

Figure 8b Opening the pivoting panel

Anti-tilt bracket attached on the

rear wall

1

Cooker’s back

Lock pin

Slot on the  cooker’s back

cooker’s back

2

Lock pin correctly fitted

Figure 8c Fitting the lock pin through the bracket

10

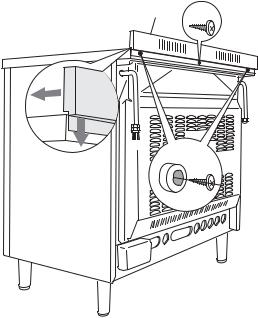

BACKGUARD

Before installing the cooker, assemble the backguard C (fig. 9).

■The backguard C can be found packed at the rear of the cooker.

■Before assembling remove any protective film/adhesive tape.

■Remove the two spacers A and the screw B from the rear of the cooktop.

■Assemble the backguard as shown in figure 9 and fix it by screwing the central screw B and the spacers A.

Figure 9

C

C B

A

11

GAS SUPPLY:

■The connection must be executed by an authorised person according to the relevant standards.

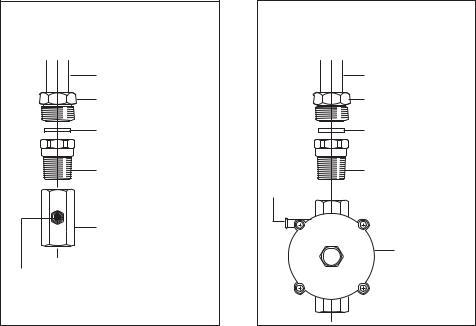

■Before connecting the appliance to the gas main, mount the brass conical adaptor onto the gas inlet pipe, upon which the gasket has been placed (figures 10-11).

Conical adaptor and gasket are supplied with the appliance (packed with conversion kit for use with Natural gas or ULPG).

■This appliance is suitable for use with Natural Gas or ULPG. (Check the “gas type” sticker attached to the appliance).

■For Natural Gas models the gas supply is connected to the pressure regulator which is supplied with the appliance (fig. 11). Adjust the regulator to obtain a test point pressure of 1 kPa with the two semi-rapid (SR) burners operating at the maximum.

■For ULPG models the gas supply is connected to the test point adaptor which is supplied with the appliance (fig. 10) and ensure that the supply pressure is regulated to 2.75 kPa.

■The connection must be made at the rear of appliance (left or right); the pipe do not cross the cooker.

■The inlet not used must be closed off with the cap and sealing gasket supplied.

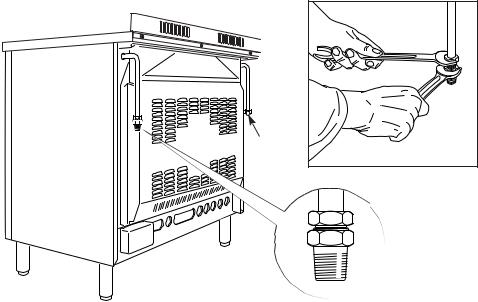

■IMPORTANT: Use two spanners to tighten or loosen the connecting pipe (fig. 13)

Figure 10 Figure 11

Gas connection for |

|

Gas connection for |

ULPG |

|

NATURAL GAS |

Gas inlet pipe |

|

Gas inlet pipe |

Nipple |

|

Nipple |

Gasket |

|

Gasket |

Brass conical adaptor |

Test |

Brass conical adaptor |

(Thread tight: use |

point |

(Thread tight: use |

suitable seal) |

|

suitable seal) |

Test point adaptor |

|

|

|

|

Gas regulator |

Test point

12

1.After connecting the gas supply, check the piping and connections for leaks using a soap and water solution. The presence of bubbles indicates a leak, tighten or replace connections as appropriate.

Warning: Do not use any naked flame to check for leaks.

2.Adjust the test point pressure or supply pressure to the value which is appropriate for the gas type.

3.The operation of the appliance must be tested when installation is completed.

4.Turn on the appliance gas controls and light each burner individually and in combination. Check for a well defined blue flame without any yellow tipping. If any abnormality is evident then check that the burner cap is located properly and the injector nipple is aligned correctly.

5.Check the minimum burner setting by quickly rotating the gas control knob from the maximum to the minimum position, the flame must not go out. If adjustment is required carry out the “minimum burner setting adjustment" procedure described

6.If satisfacfory performance cannot be obtained, the installer shall check the installation and notify the local gas supply authority for a gas supply problem, or if it is an appliance problem, our Customer Service Centre should be called to obtain the nearest authorized Delonghi Service Agent.

WARNING, This appliance IS NOT SUITABLE for installation with a hose assembly.

Figure 12 |

|

|

|

Figure 13 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plug

13

CONVERSION PROCEDURE (to convert to Natural gas or to ULPG)

REPLACING THE INJECTORS

This appliance is suitable for use with Natural gas or ULPG (check the “gas type” sticker attached to the appliance). A label stating the type of gas used after replacing the injectors must be attached at the rear of the appliance, in proximity of the gas inlet connection. The nominal gas consumption and injector size details are provided in table at page 16.

To replace the injectors proceed as follows:

■Remove pan supports and burners from the cooktop.

■Using a spanner, remove the injector J (figs. 14a, 14b) and replace it with one according to the gas type (see following tables - page 16).

■Affix to the rear of the appliance, in proximity of the gas inlet connections, the warning label (supplied with the conversion kit) stating that the cooker has been converted for use with ULPG / Natural gas.

IMPORTANT

■If the cooker is suitable for use with Natural gas and must be converted for use with ULPG, before connecting to gas main remove the appliance gas regulator and replace with test point adaptor (see figs. 10-11)

■If the cooker is suitable for use with ULPG and must be converted for use with Natural gas, before connecting to the gas main remove the appliance test point adaptor and replace with gas regulator (see figs. 10-11).

NOTE:

Gas regulator and test point adaptor are supplied with the appliance (packed with conversion kit)

The burners are designed so that regulation of primary air is not required.

Figure 14a |

Figure 14b |

J

J

14

MINIMUM BURNER SETTING ADJUSTMENT

Check whether the flame spreads to all burner ports when the burner is lit with the gas tap set to the minimum position. If some ports do not light, increase the minimum gas rate setting.

Check whether the burner remains lit even when the gas tap is turned quickly from the maximum to the minimum position. If the burner does not remain lit, increase the minimum gas rate setting.

The procedure for adjusting the minimum gas rate setting is described below.

■Turn on the burner

■Turn the tap to the MINIMUM position

■Take off the knob

■With a small flat screwdriver turn the screw “F” (fig. 15) to the correct regulation.

Normally for ULPG, the regulation screw is tightened up.

Figure 15

F |

15

Loading...

Loading...