Carrier 42VMC14-H, 42VMC24-H, 38VMC18A-H, 42VMC18A-H, 38QG24-H Service And Maintenance Manual

...

03502566

SERVICE & MAINTENANCE MANUAL

Revision : (0) - 2009

Specifications are subject to change without notice according to Carrier Policy of continuous development.

TABLE OF CONTENTS

PAGE NO.

1. Precautions for Service & Maintenance 1

2. Split System Description 2

3. Unit Model Designation 3

4. Unit Models & Part Numbers 3

5. Options 4

6. System Operating Limits 5

7. System Safety Protections 5

8. Wiring Diagrams 6

9. Field Electrical Connections Matching 7

10. Refrigeration Cycle – 53QG Series 8

11. Replacing Batteries of Remote Control 10

12. Emergency Operation of Air-Conditioner 11

13. Standard and Optional Air Filters 12

14. Air Filter Cleaning 13

15. Indoor Unit Cleaning 14

16.

Considerations After Operational Season and Before Long

Shutdown Period Of Air Conditioner

14

17. Periodical Checks 15

18. Self Diagnostic Function For Malfunction Detection 16

19. Trouble Shooting 17

1

1. PRECAUTIONS FOR SERVICE AND MAINTENANCE

SAFETY CONSIDERATIONS

• Installation of air conditioning equipment can be hazardous due to system pressures and

electrical components.

• The installation of the air conditioner must be done by Carrier or one of Carrier authorized

dealers.

WARNING

• This installation manual describes the installation procedures of Carrier split room air

conditioner consisting of an outdoor unit and an indoor unit manufactured by Carrier.

What is not covered in Carrier warranty?

1- Failure due to wrong electrical connections between the electrical power supply and

circuit breaker of air conditioner leading to fire due to short-circuiting. As these electrical

connections are owner’s responsibility.

2- Failure due to Misuse, Abusing, overloading, negligence of air filters cleaning and

negligence of instructions included in the owner’s manual.

3- Failure due to Accident / Weather Natural catastrophe, accident due to bad weather

(Hail Storm, Sand Storm, lightning, Flooding, Acid Rain and Air Borne fallout, etc).

4- Failure due to damages during transport done through the owner.

5- Failure due to any modifications in the product done through the owner and not done by

Carrier or one of Carrier authorized dealers.

6- Failure due to Installation done through the owner and not done by Carrier or one of

Carrier authorized dealers.

7- Failure due to Service and Maintenance done through the owner and not done by Carrier

or one of Carrier authorized dealers.

8- Failure due to repair by using non-genuine Carrier Parts, or substituting other than

Carrier parts done through the owner and not done by Carrier or one of Carrier

authorized dealers.

9- Product normal sound ( refrigerant – moving parts )

10- Inconvenience or commercial loss is not covered.

The decision of Carrier in ascertaining the same will be final. Any such repairs will be carried -

out at the expense of the owner ( purchaser ).

!

2

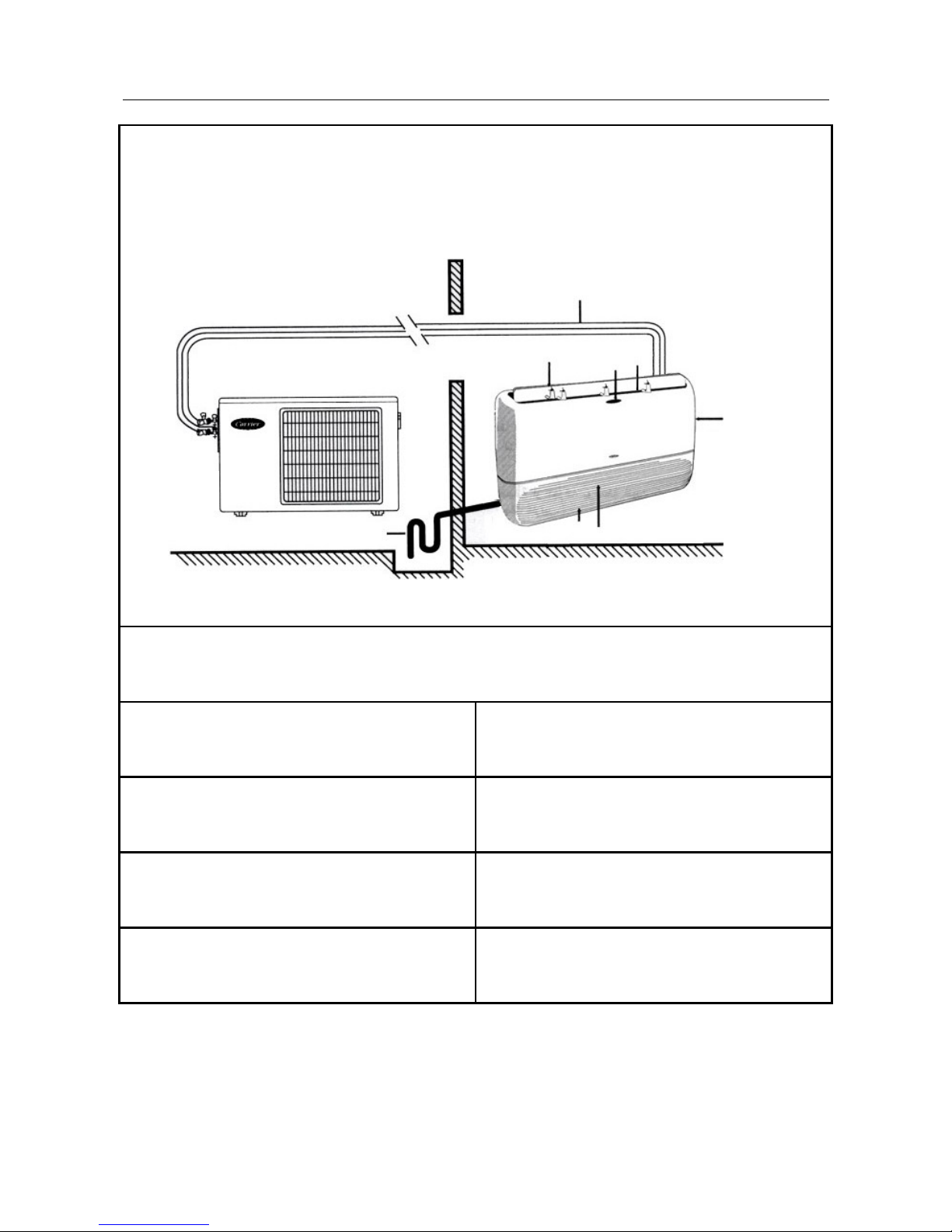

Outdoor Unit

2. SPLIT SYSTEM DESCRIPTION

1: Remote control signal receiver.

2: Operating status leds. 6: Supply air outlet.

3: Supply air flap. 7: Characteristics nameplate.

4: Air return grille. 8: Inter connecting tubing.

5: Air filter ( behind return grille ). 9: Condensate drain line.

Floor/Wall/Ceiling Split System

53VMC14-18-24

4

6

3

Indoor Unit

3

3. UNIT MODEL DESIGNATION

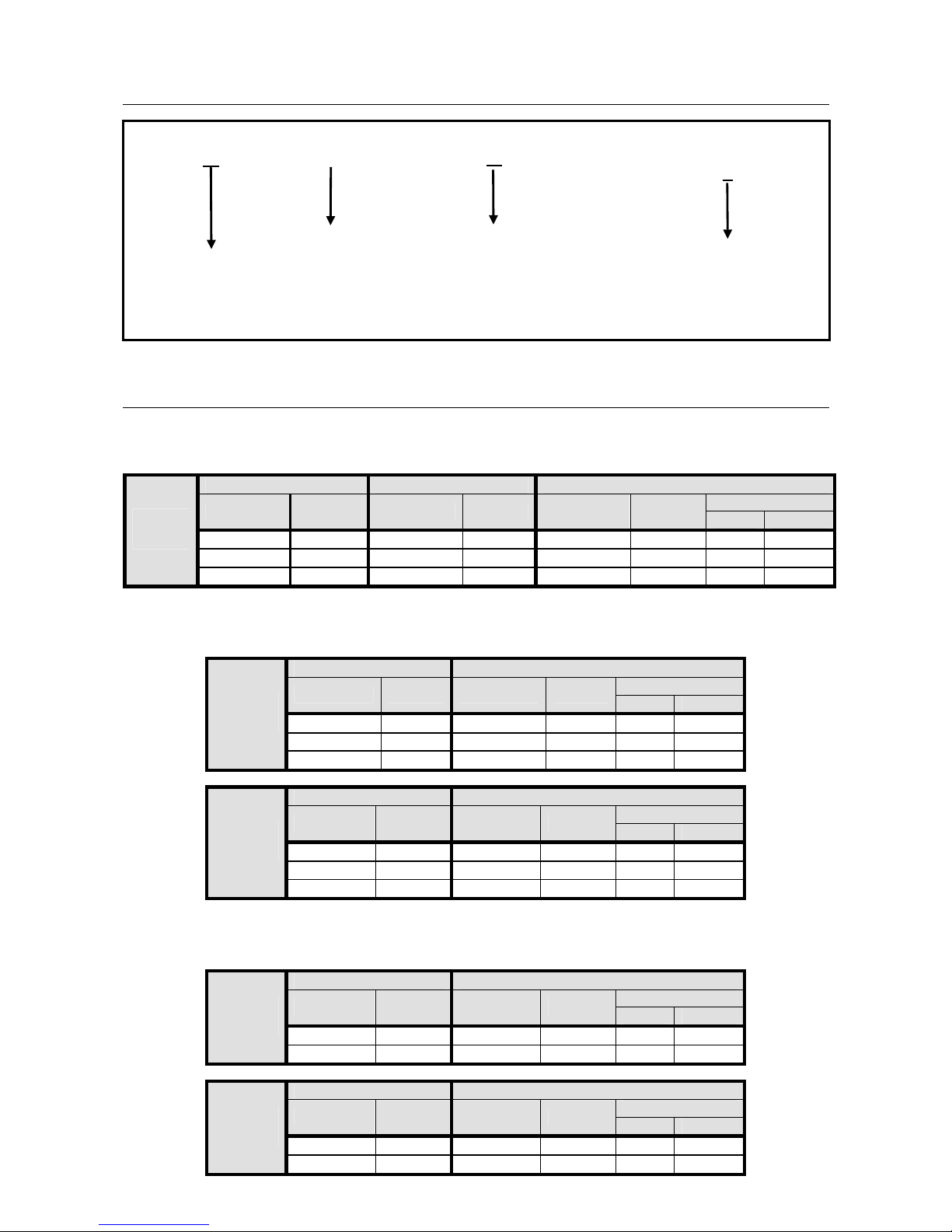

4. UNIT MODELS & PART NUMBERS

SPLIT SYSTEMS FOR LOCAL MARKET

System Indoor Unit Outdoor Unit

Compressor

Model P/N Model P/N Model P/N

Type Supplier

53VMC14-H

46303279 42VMC14-H 46303290 38VMC14-H

46303278 Rotary LG

53VMC18A-H

46303118 42VMC18A-H 46303276 38VMC18A-H 46303117 Rotary Hitachi

HEAT

PUMP

53VMC24-H

46303359 42VMC24-H 46303292 38QG24-H

46302128 Rotary LG

SPLIT SYSTEMS FOR MILD AMBIENT EXPORT MARKETS

Indoor Unit Outdoor Unit

Compressor

Model P/N Model P/N

Type Supplier

42VMC14-H

46303221 38QG15-H

46303300 Rotary Mitsushita

42VMC18A-H

46303533 38VMC18A-H 46303534 Rotary Hitachi

HEAT

PUMP

42VMC24-H

46303233 38QG24-H

46303644 Rotary LG

Indoor Unit Outdoor Unit

Compressor

Model P/N Model P/N

Type Supplier

42VMC14-C

46303293 38QG15-C

46302110 Rotary Mitsushita

42VMC18-C

46303294 38QG18-C

46303517 Rotary Mitsushita

COOL

ONLY

42VMC24-C

46303295 38QG24-C

46303365 Rotary Mitsushita

SPLIT SYSTEM FOR HIGH AMBIENT EXPORT MARKETS

Indoor Unit Outdoor Unit

Compressor

Model P/N Model P/N

Type Supplier

42VMC18-H

46303219 38QG18-H

46303516 Rotary Mitsushita

HEAT

PUMP

42VMC24-H

46303220 38QG24-H

46303363 Rotary Mitsushita

Indoor Unit Outdoor Unit

Compressor

Model P/N Model P/N

Type Supplier

42VMC18-C

46303294 38QG18-C

46303517 Rotary Mitsushita

COOL

ONLY

42VMC24-C

46303295 38QG24-C

46303365 Rotary Mitsushita

VMC

QG

42 = Indoor Unit

38 =Outdoor Unit

18

System

Cooling Capacity

At ISO Conditions

14 = 14,000 Btu/hr

18 = 18,000 Btu/hr

24 = 24,000 Btu/hr

Unit Family

H

C

Unit Type

H = Heat Pump

C = Cool Only

42

38

4

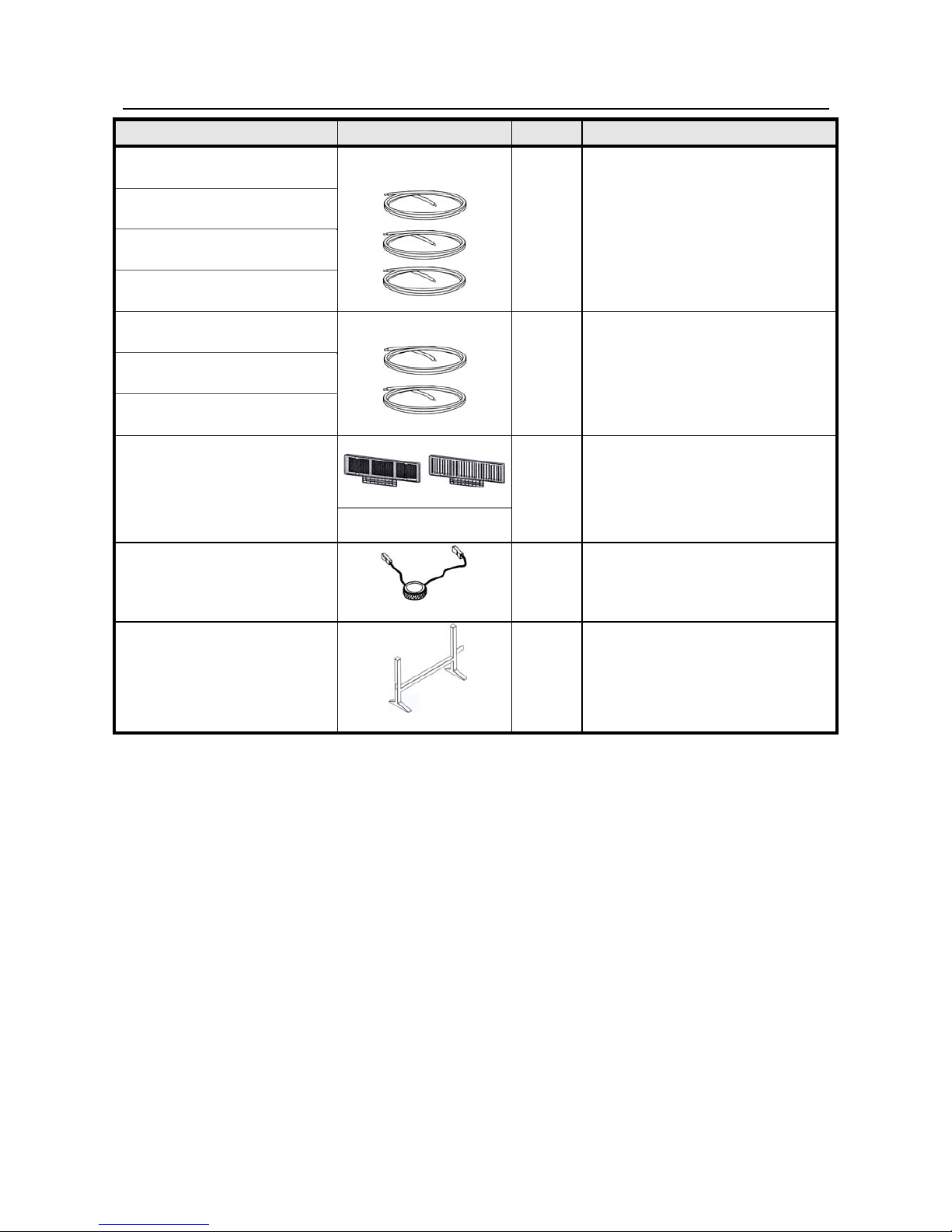

5. OPTIONS

DESCREPTION CONFIGURATION QTY USAGE

Electrical Cables Set

for Heat Pump System

Main Power cable

Outdoor Unit–Circuit Breaker

Power cable

Outdoor Unit – Indoor Unit

Control & Defrost cable

Outdoor Unit–Circuit Breaker

P/N : 02500894

Set of 3

To electrically connect between

circuit breaker, outdoor and

indoor units

Electrical Cables Set

for Cool Only System

Main Power cable

Outdoor Unit – Indoor Unit

Power & Control cable

Outdoor Unit – Indoor Unit

P/N : 02500893

Set of 2

To electrically connect between

circuit breaker, outdoor and

indoor units

Optional set of air filters

(Carbon air filter + Photocatalytic air filter)

P/N : 02802563

( for 42VMC14-18-24 )

Set of 2

To eliminate odor and cigarette

smoke in the room air

respectively.

PTC starting device for

38QG15-18-24

P/N : 02501579

1

To start the compressor in

outdoor unit at low voltage down

187V

Floor support for indoor units

42VMC14-18-24

P/N : 46300822

1

To mount the indoor unit on the

floor in case of impossibility of

mounting the unit on the wall

5

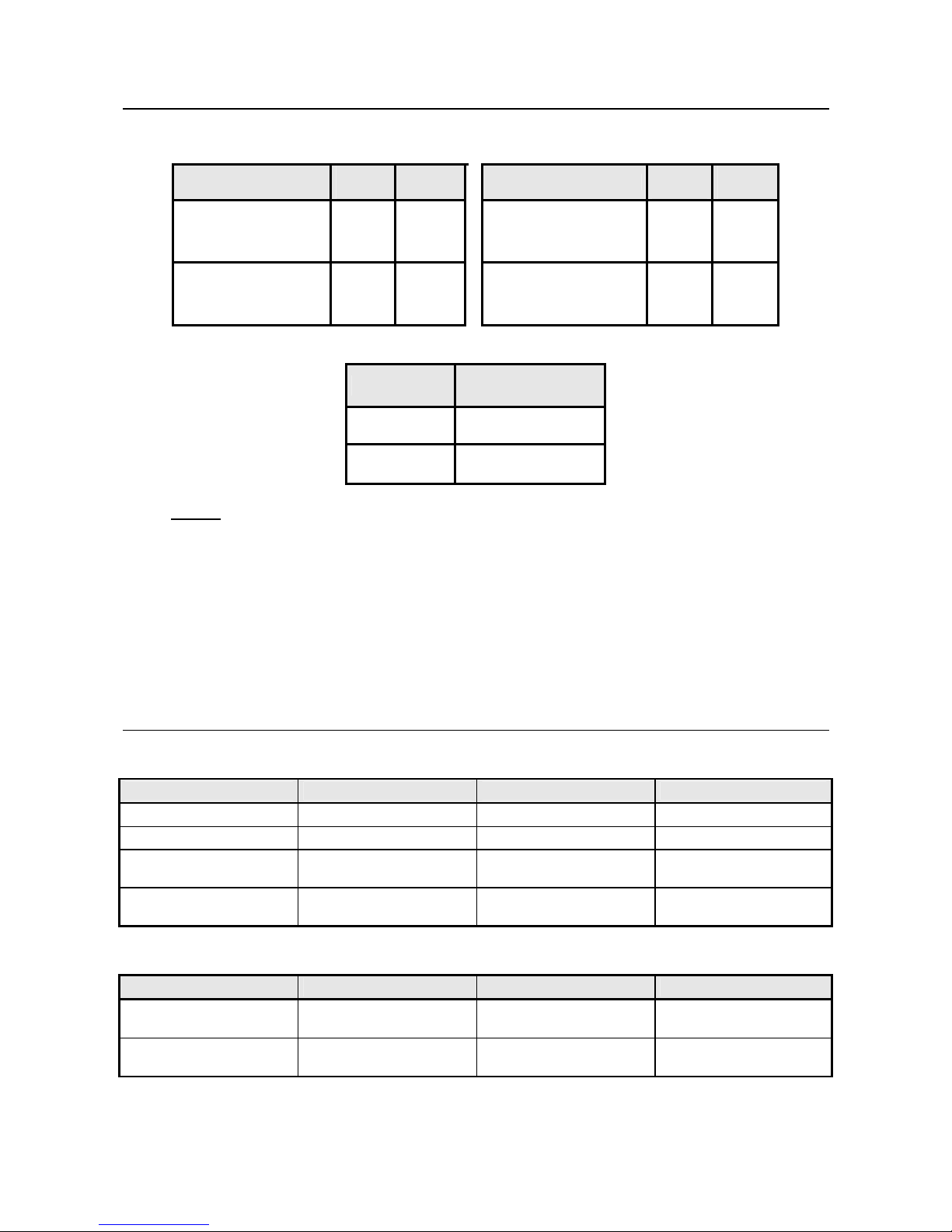

6. SYSTEM OPERATING LIMITS *

COOLING

HEATING

Difference

Dry Bulb

Temp. C°

Wet Bulb

Temp. C°

Difference

Dry Bulb

Temp. C°

Wet Bulb

Temp. C°

Indoor temperature

Maximum

Minimum

32

21

23

15

Indoor temperature

Maximum

27

-

Outdoor temperature

Maximum

Minimum

55

20

-

-

Outdoor temperature

Maximum

21

-

MAIN POWER SUPPLY

Difference

Nominal

200-240V/1PH/50HZ

Min. Voltage 187

Max. Voltage 264

NOTES:

* When the unit is operated above or below these limits for a long time, system diagnostics may detect

a malfunction and the unit will not operate properly.

** During heat pump operation the system will undergo several defrost cycles to remove ice that might

collect on the outdoor unit in very low ambient temperature.

After completion of defrosts cycle, the system will normally operate.

7. SYSTEM SAFETY PROTECTION

7-1 FOR HEAT PUMP SYSTEM

PROTECTION TYPE PROTECTION EFFECT OPERATION MODE WHEN ON

Cold draft prevention Indoor fan off Heating mode During unit operation

Defrost cycle Indoor fan off Heating mode During unit operation

Indoor coil

Freeze protection

Compressor off Cooling mode During unit operation

Against frequent

Compressor cycling

Compressor

Time delay

Cooling or heating

modes

At unit start-up or change

of operating mode

7-2 FOR COOL ONLY SYSTEM

PROTECTION TYPE PROTECTION EFFECT OPERATION MODE WHEN ON

Indoor coil

Freeze protection

Compressor off Cooling mode During unit operation

Against frequent

Compressor cycling

Compressor

Time delay

Cooling mode

At unit start-up or change

of operating mode

6

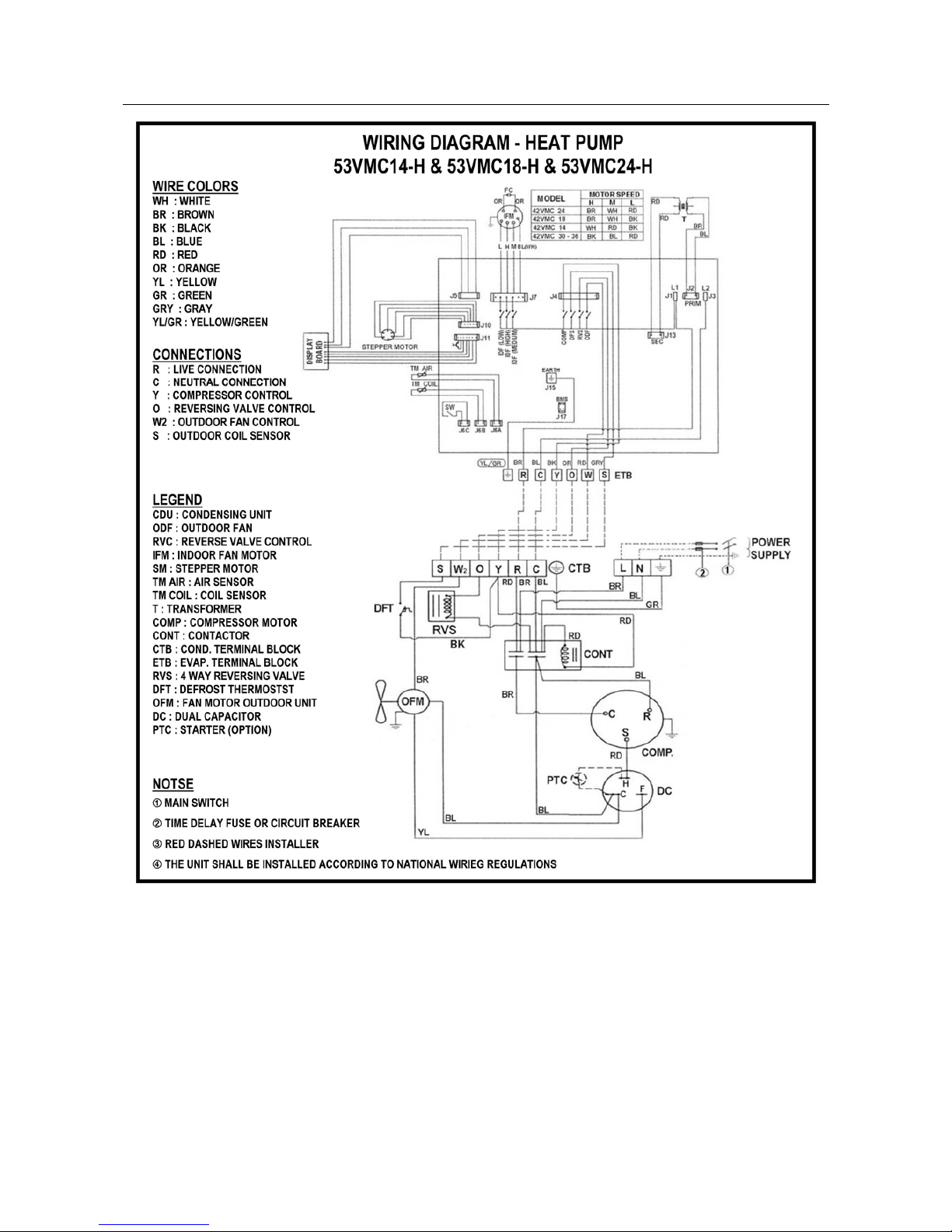

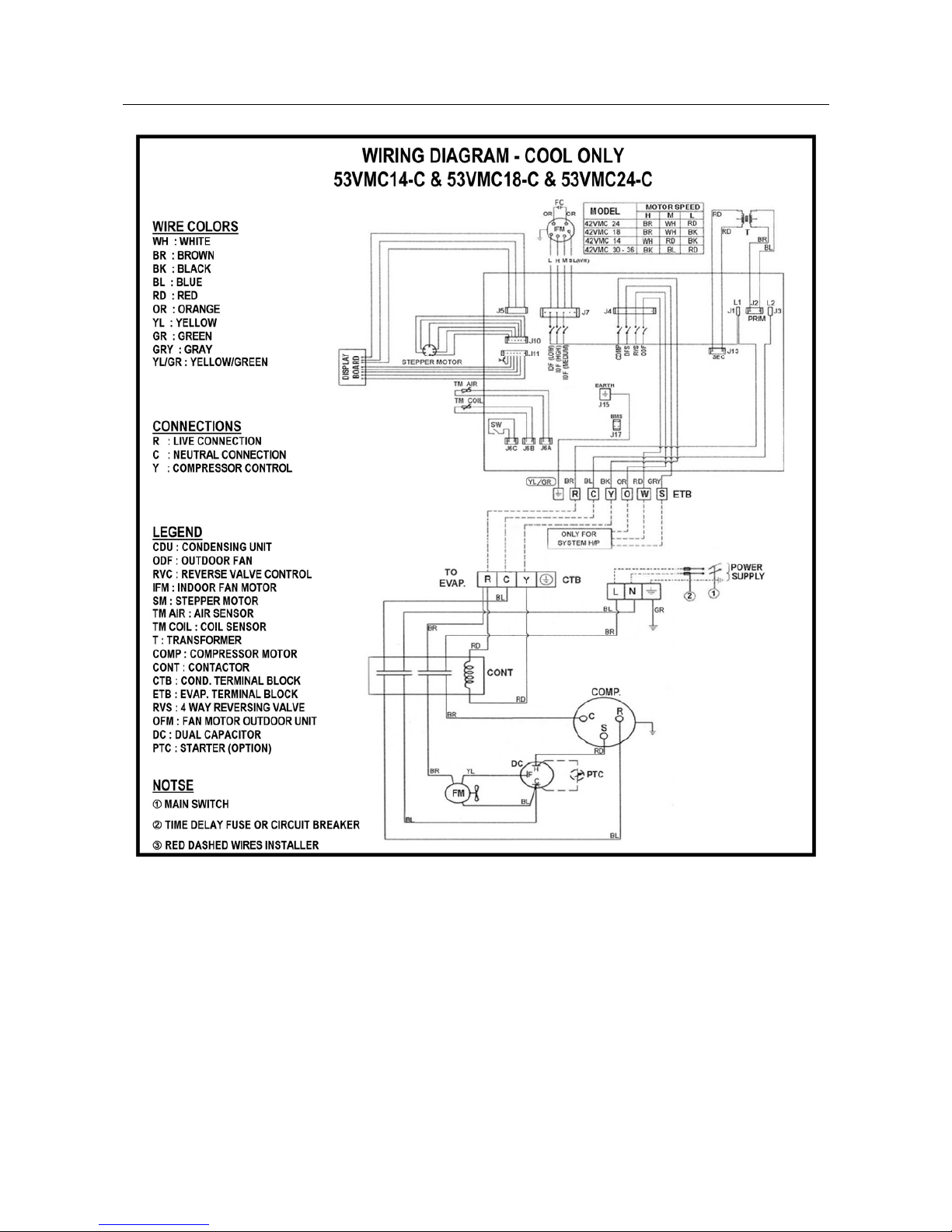

8. WIRING DIAGRAMS

7

WIRING DIAGRAMS (Cont.)

8

LEGEND

Earth

L Live power supply.

N Neutral power supply.

R Live connection indoor/outdoor unit.

C Neutral connection indoor/outdoor unit.

Y Compressor control.

O Reversing valve control.

W2 Outdoor fan motor control.

S Outdoor coil sensor.

LEGEND

Earth

L Live power supply.

N Neutral power supply.

R Live connection indoor/outdoor unit.

C Neutral connection indoor/outdoor unit.

Y

Compressor control.

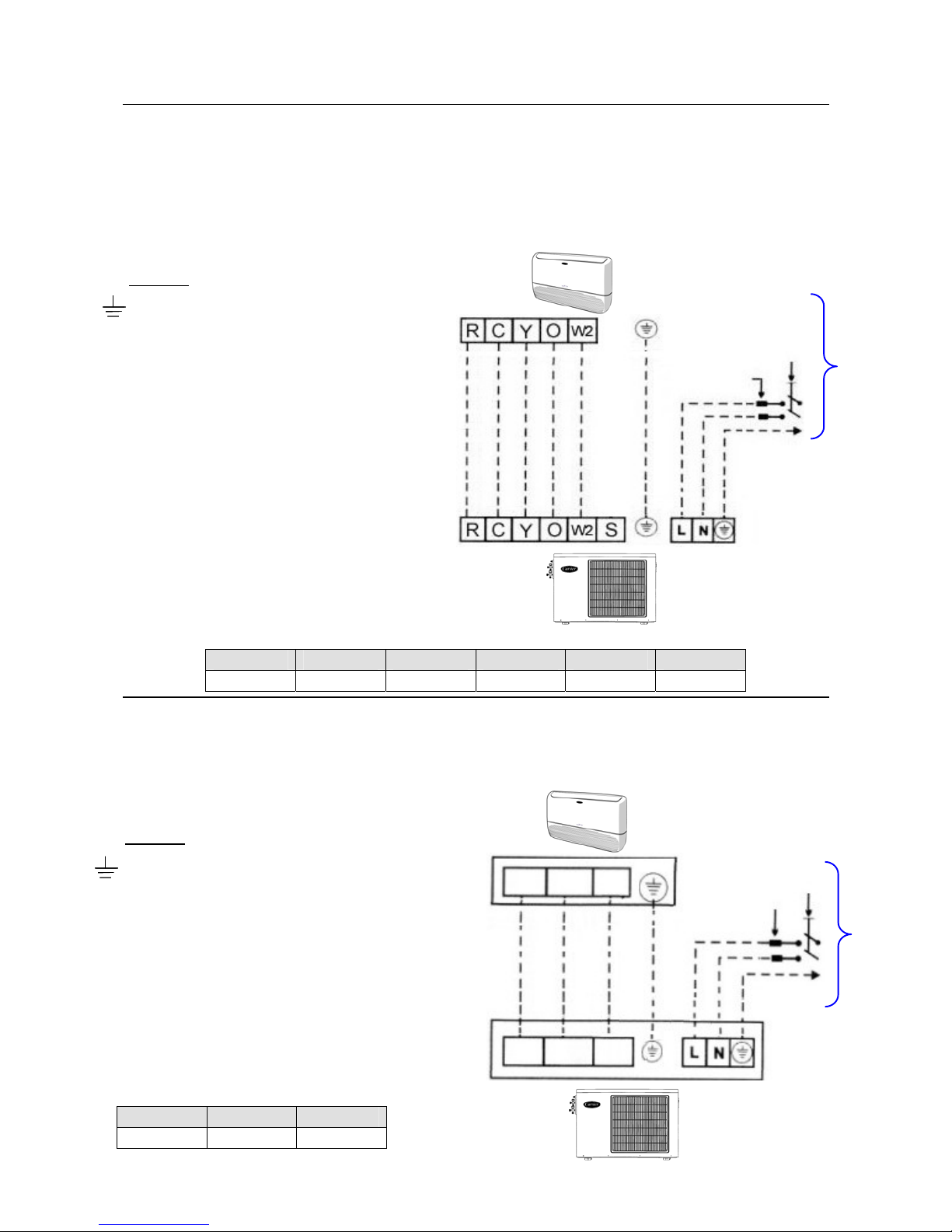

9. FIELD ELECTRICAL CONNECTIONS MATCHING

- Connect the power supply to the outdoor unit and then get the power required for the indoor unit from the outdoor unit.

- Refer to wiring diagrams and stickers-caution sticked inside the outdoor & indoor units.

9-1 CONNECTING ELECTRICAL WIRING FOR HEAT PUMP SYSTEM

Sizes of electrical wires connecting outdoor and indoor units

R C Y O W2 S

1 mm

2

1 mm

2

1 mm2 1 mm2 1 mm2 1 mm2

9-2 CONNECTING ELECTRICAL WIRING FOR COOL ONLY SYSTEM

Sizes of electrical wires connecting

outdoor and indoor units

R C Y

1 mm

2

1 mm

2

1 mm2

200 - 240V ~ 50Hz

Circuit

Breake

r

Main

Switch

RCY

RCY

200 - 240V ~ 50Hz

Circuit

Breake

r

Main

Switch

Indoor Unit

Outdoor

Unit

Outdoor

Unit

Indoor Unit

9

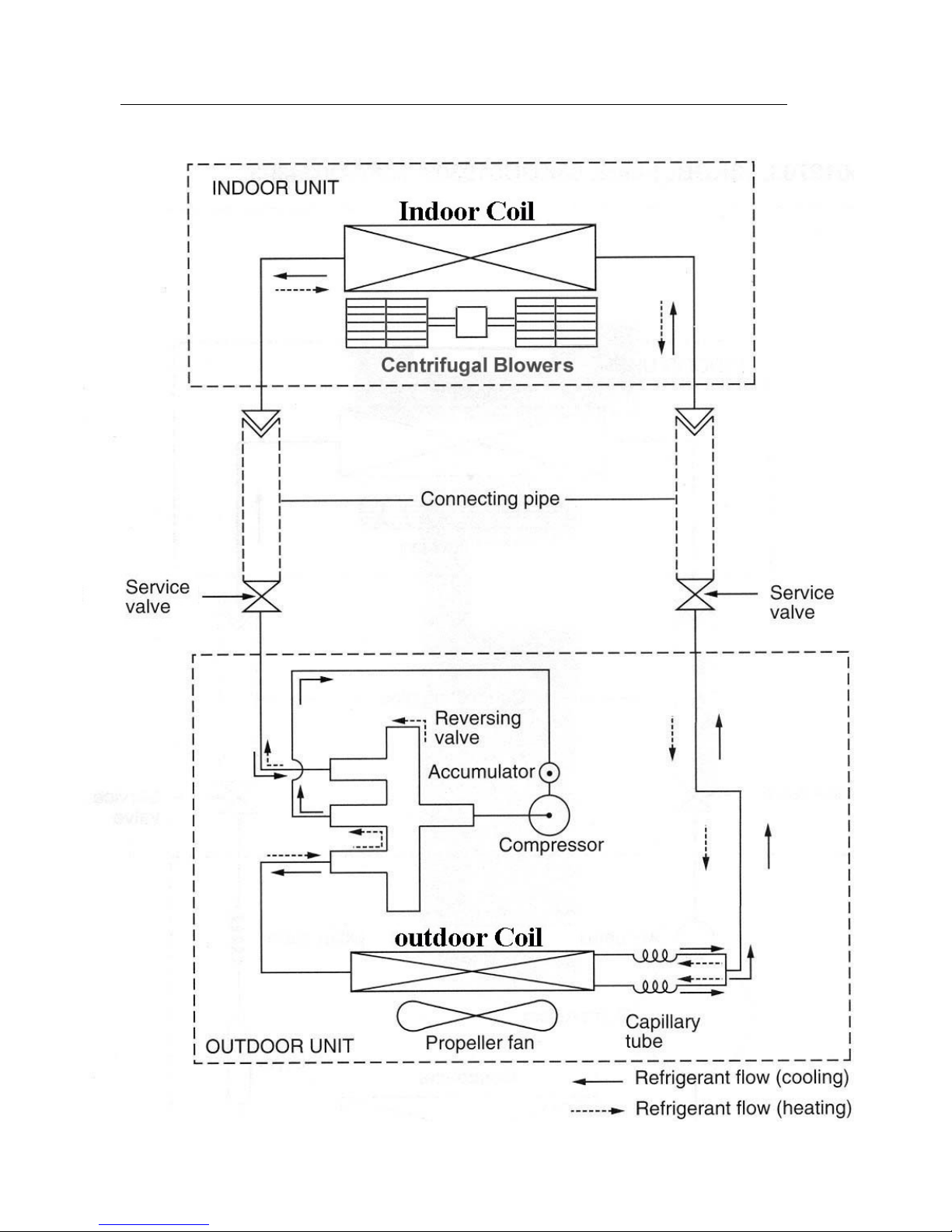

11. REFRIGERATION CYCLE – 53VMC SERIES

HEAT PUMP SYSTEM

10

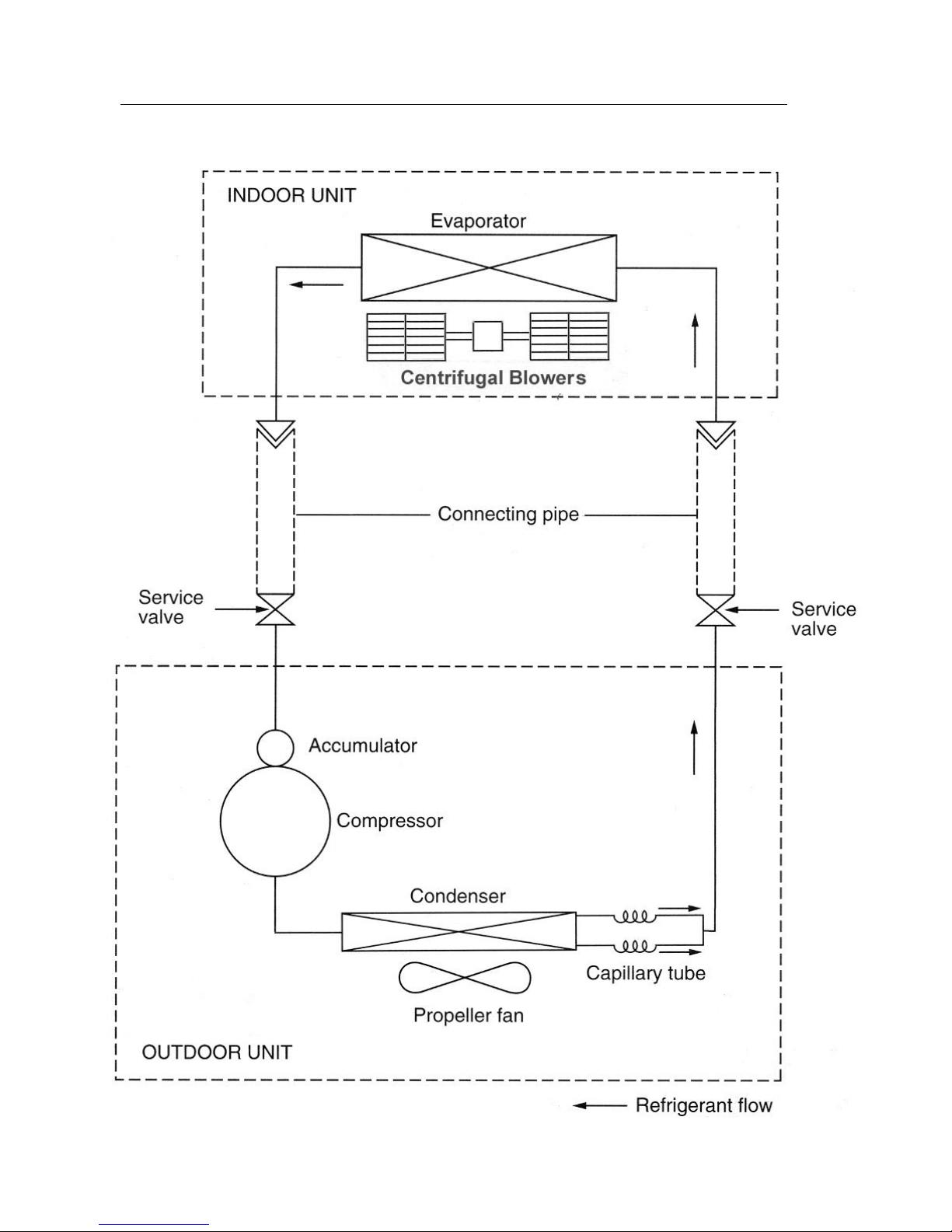

REFRIGERATION CYCLE – 53VMC SERIES (Cont.)

COOL ONLY SYSTEM

11

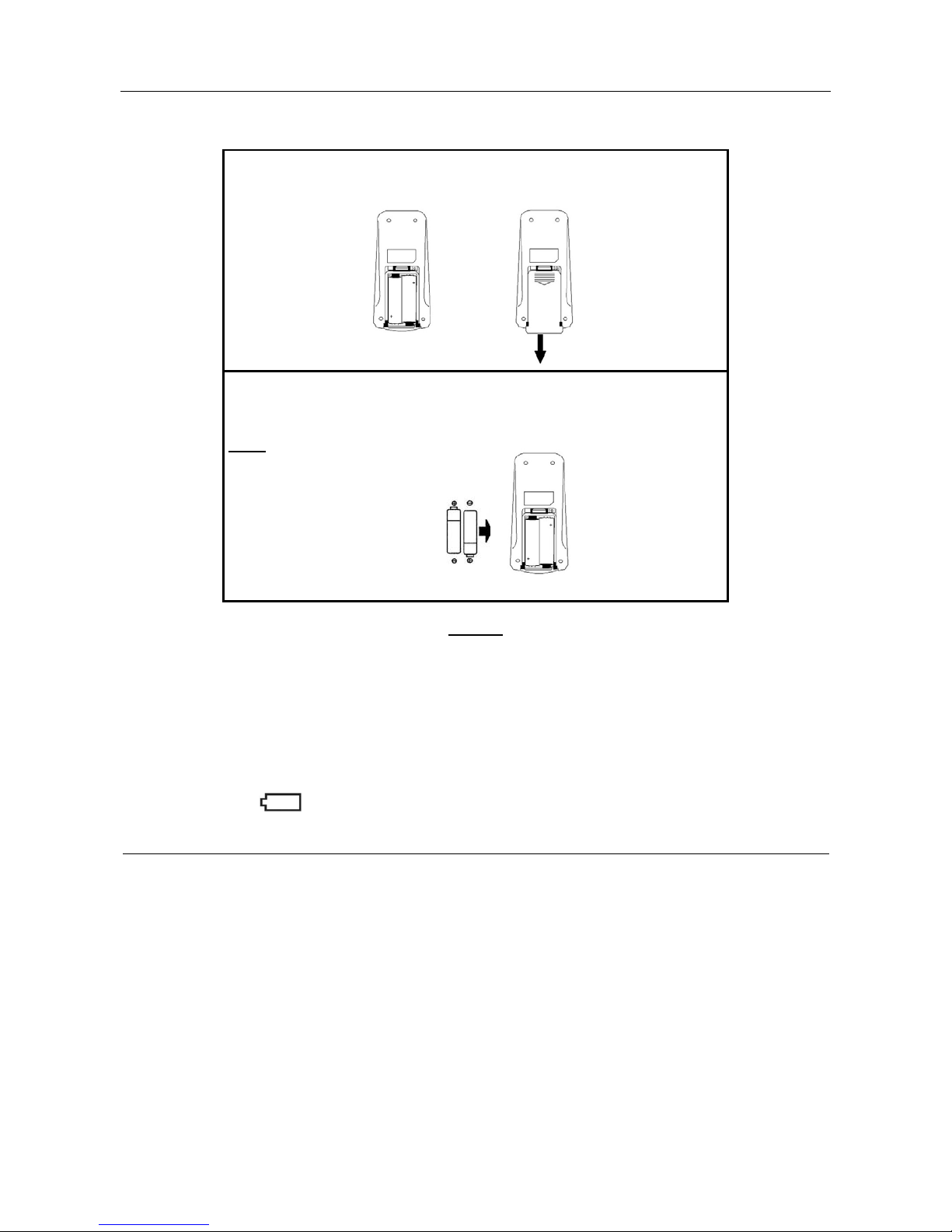

12. REPLACING BATTERIES OF REMOTE CONTROL Model 42QG&42VMC 14-18-24

12-1 HOW TO INSERT BATTERIES:

(a) Remove the cover of battery compartment at the back of the remote

control by pressing the tab toward inside, in the direction of the

arrow.

(b) Mount the two-battery size AAA 1.5 Volt supplied with the remote

control. Then close the cover of the battery component.

Note:

During mounting of batteries

check battery symbols (+, -)

indicated in batteries

compartment.

NOTES:

1. The remote control uses two alkaline batteries (1.5V, LRO03x2).

2. Do not use used batteries or batteries of different types, as this may cause the air conditioner to

malfunction.

3. Batteries should only be changed after turning OFF the air conditioner.

4. The average battery life during normal use is approximately one year.

5. When the symbol appears in the display of the remote control, this indicates that the batteries are

exhausted and required to be replaced.

WHEN DIRECTING THE TRANSMITTER OF WIRELESS REMOTE CONTROL TO THE RECEIVER

OF INDOOR UNIT FROM A CERTAIN LOCATION, CHECK THE FOLLOWING POINTS:

1- Avoid direct sunlight on the receiver of indoor unit, which may interfere with good signal reception

2- No obstructions such as curtains or plants should be between the remote control and the receiver of

indoor unit.

3- The maximum operating range for the remote control is approximately 5 meters.

4- The remote control must be directed toward the receiver of indoor unit when pressing the buttons of the

desired functions. An acoustical acknowledgement sound (beep) will indicate that signal has been received.

12

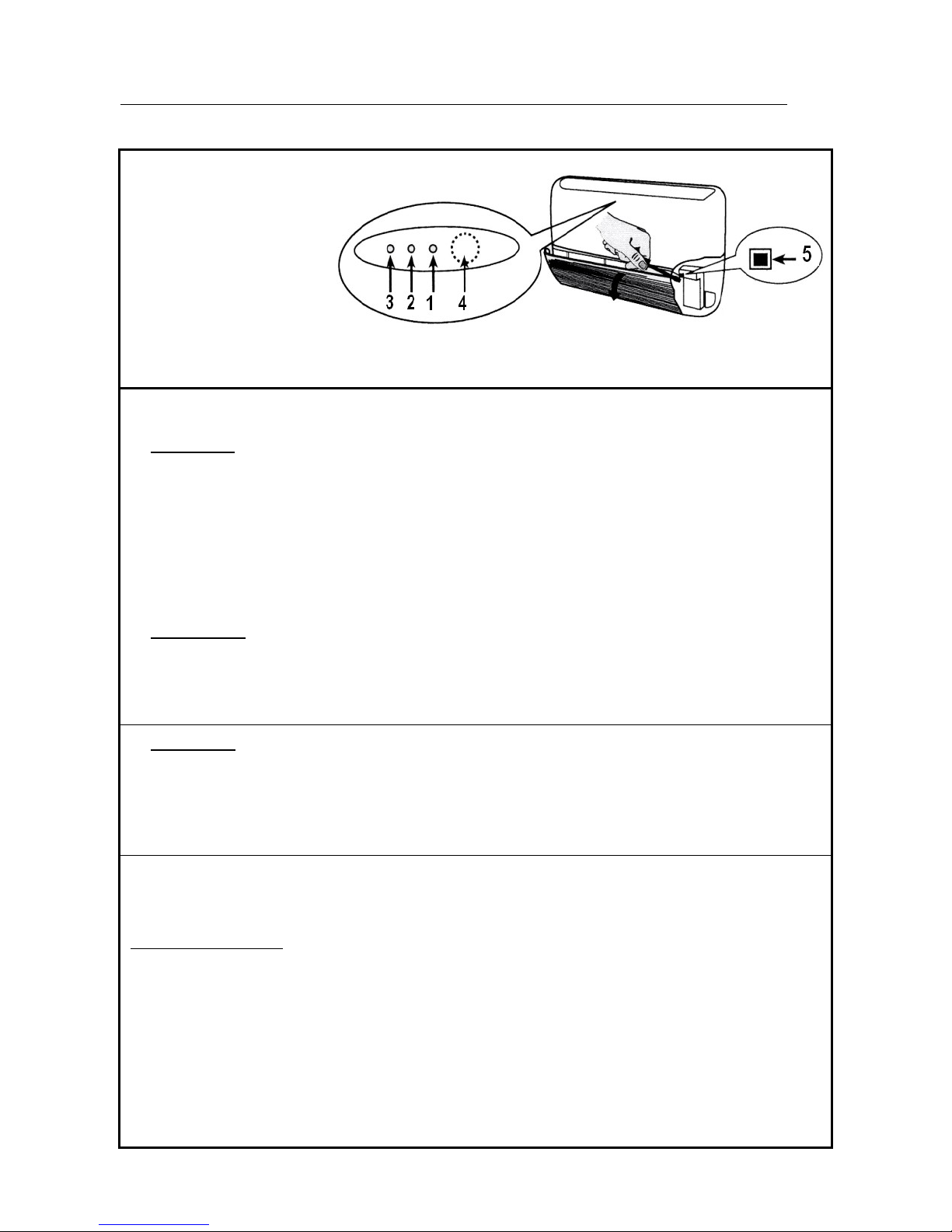

13. EMERGENCY OPERATION OF AIR-CONDITIONER

INDOOR UNITS 42VMC14-18-24-30-36 SERIES

Indoor unit LED’s

• GREEN LED (1) shows the following conditions :

- Fault codes (diagnostic);

- During normal operation, the LED is lit.

Once a failure occurs, the LED flashes at intervals of 0.5 seconds. The fault code is deduced from

the number of times the LED flashes. Between one flash cycle and the next a pause of 5 seconds

elapses.

If the timer mode is active and the unit is immediately restarted after a stop, this LED flashes until a

new signal is sent to the indoor unit.

• YELLOW LED (2) shows the operation in timer mode.

During this operation in this operating mode, the LED is lit .

If the time mode is active and the unit is immediately restarted after a stop, this LED flashes until a

new signal is sent to the indoor unit.

• RED LED (3) gives the following information:

- During normal operation, the LED is OFF;

- During defrost the LED is lit;

- During the test for wired connection, the LED

flashes at 1- second intervals.

Button (5) : “EMERGENCY”

Can be used when the remote control is lost or inoperative.

Use a screwdriver to press the push-button.

Emergency operation:

When the unit is in the OFF mode and the emergency is pressed for 5 seconds, the system will

operate as follows:

- Automatic mode.

- Temperature preset to 22ºC.

- Automatic fan speed.

- Louvers set automatically according to operating mode.

- Timer Functions are inactive.

When a signal is received by the remote control, system operates accordingly.

1 : Green Led

2 : Yellow Led

3 : Red Led

4 : Remote control

signal receiver

5 : “Emergency” button

Loading...

Loading...