Page 1

DuMaster D-480

Operation Manual

11593626C en

Page 2

Imprint

ProductIdentification:

Operation Manual (original) DuMaster

D-480 11593626Cen

Publicationdate:

06.2016

BÜCHILabortechnikAG

Meierseggstrasse40

Postfach

CH9230Flawil1

EMail:quality@buchi.com

BUCHIreservestherighttomakechangestothemanualasdeemednecessaryinthelightofexperi

ence;especiallyinrespecttostructure,illustrationsandtechnicaldetail.

Thismanualiscopyright.Informationfromitmaynotbereproduced,distributed,orusedforcompetitive

purposes,normadeavailabletothirdparties.Themanufactureofanycomponentwiththeaidofthis

manualwithoutpriorwrittenagreementisalsoprohibited.

Page 3

Copyright Note 3

Copyright ©BÜCHI Labortechnik AG

All rights reserved

®

Windows

, Windows XP® und Windows 7® are trademarks of Microsoft Corporation.

MS-Excel® und MS-Access® are trademarks of Microsoft Corporation.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 4

Page 5

Contents 5

Contents

CHAPTER 1 General 13

About this document .................................................................................................................................... 14

Display conventions .................................................................................................................................... 15

General information on the operating instructions ....................................................................................... 15

CHAPTER 2 Basic security settings 17

Working with the operating instructions ....................................................................................................... 18

Representation of safety instructions .......................................................................................................... 18

Instructions for disposal of consumables ..................................................................................................... 18

Intended use of the instrument .................................................................................................................... 19

Warning: residual risks ................................................................................................................................ 19

Safety devices in the analyzer ..................................................................................................................... 20

Warning signs on the analyzer .................................................................................................................... 22

Warning: changes to the instrument ............................................................................................................ 23

Warning: unsuitable spare parts and consumables ..................................................................................... 23

Required user knowledge and skills ............................................................................................................ 23

Required personal safety equipment ........................................................................................................... 24

Warning notes during operation .................................................................................................................. 24

CHAPTER 3 Product description 31

Analytical characteristics and technical specifications ................................................................................. 32

Analytical characteristics .................................................................................................................. 33

Technical specifications ................................................................................................................... 33

Instrument design ........................................................................................................................................ 35

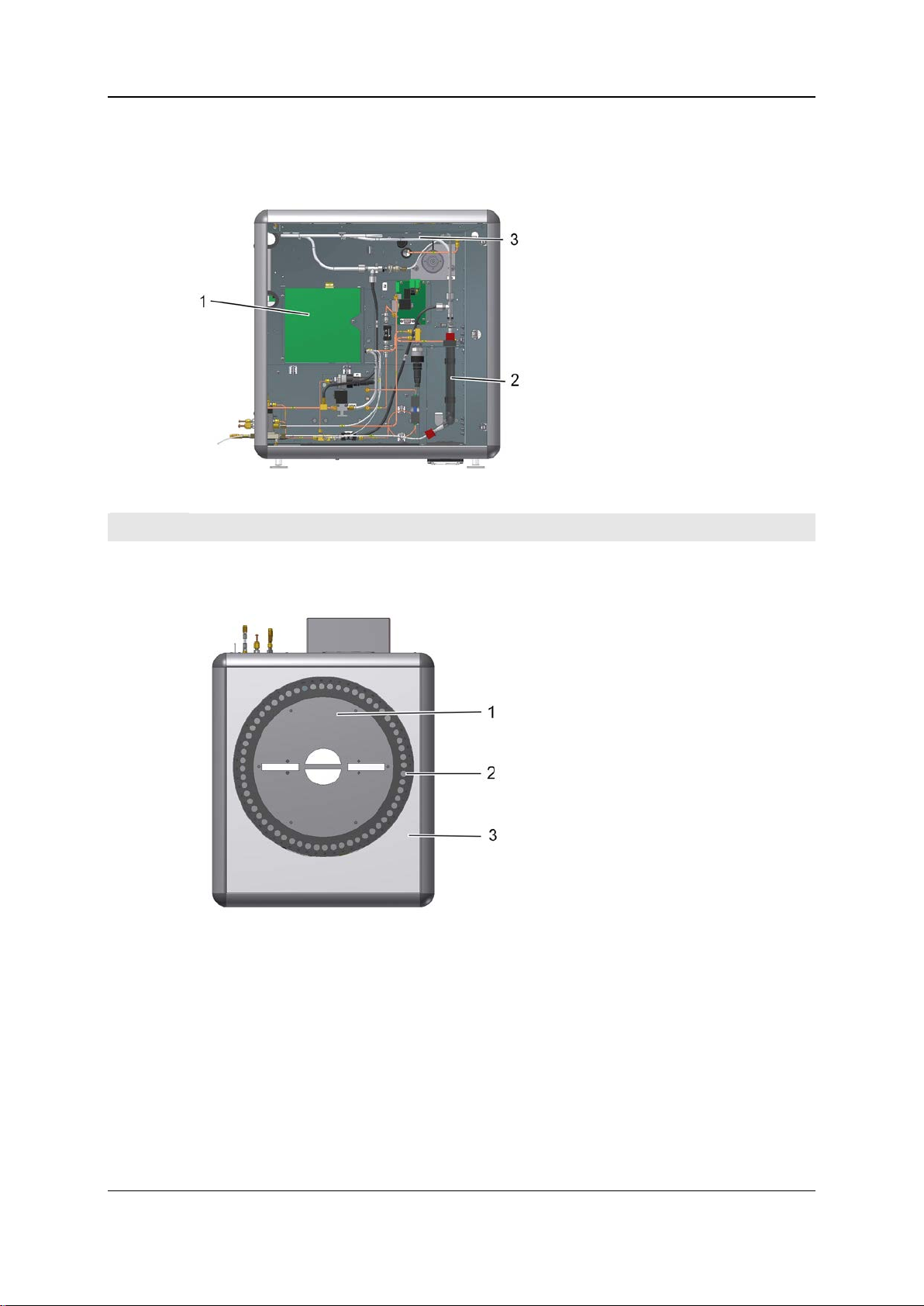

Front view ........................................................................................................................................ 36

Rear view ......................................................................................................................................... 37

Right side view ................................................................................................................................. 37

Left side view ................................................................................................................................... 38

Top view ........................................................................................................................................... 39

Peripherals and their function .......................................................................................................... 40

CHAPTER 4 Understanding the instrument and planning its use 41

Layout and mode of functioning .................................................................................................................. 42

Functional units ................................................................................................................................ 43

The thermal conductivity detector (TCD) .......................................................................................... 45

Processes in the instrument during a measurement ................................................................................... 46

Sample insertion and initiation of measurement .............................................................................. 47

Substance digestion and preparation of the reaction gas mixture .................................................... 47

Detection of measuring components and evaluation of the measuring signal .................................. 48

Formulas for determining element concentration of analysis samples (Solids) ................................ 48

Basic facts about working with the instrument ............................................................................................. 49

Instrument equipment ...................................................................................................................... 50

Background knowledge required for calibration ............................................................................... 51

Calibration curve calculation method criteria .................................................................................... 52

Calibration formulae ......................................................................................................................... 54

Routine measuring work .................................................................................................................. 55

Formulae for blank value determination and compensation ............................................................. 56

Formula for determining the daily factor ........................................................................................... 57

Understanding the operating software ......................................................................................................... 58

Basic functions of the operating software ......................................................................................... 59

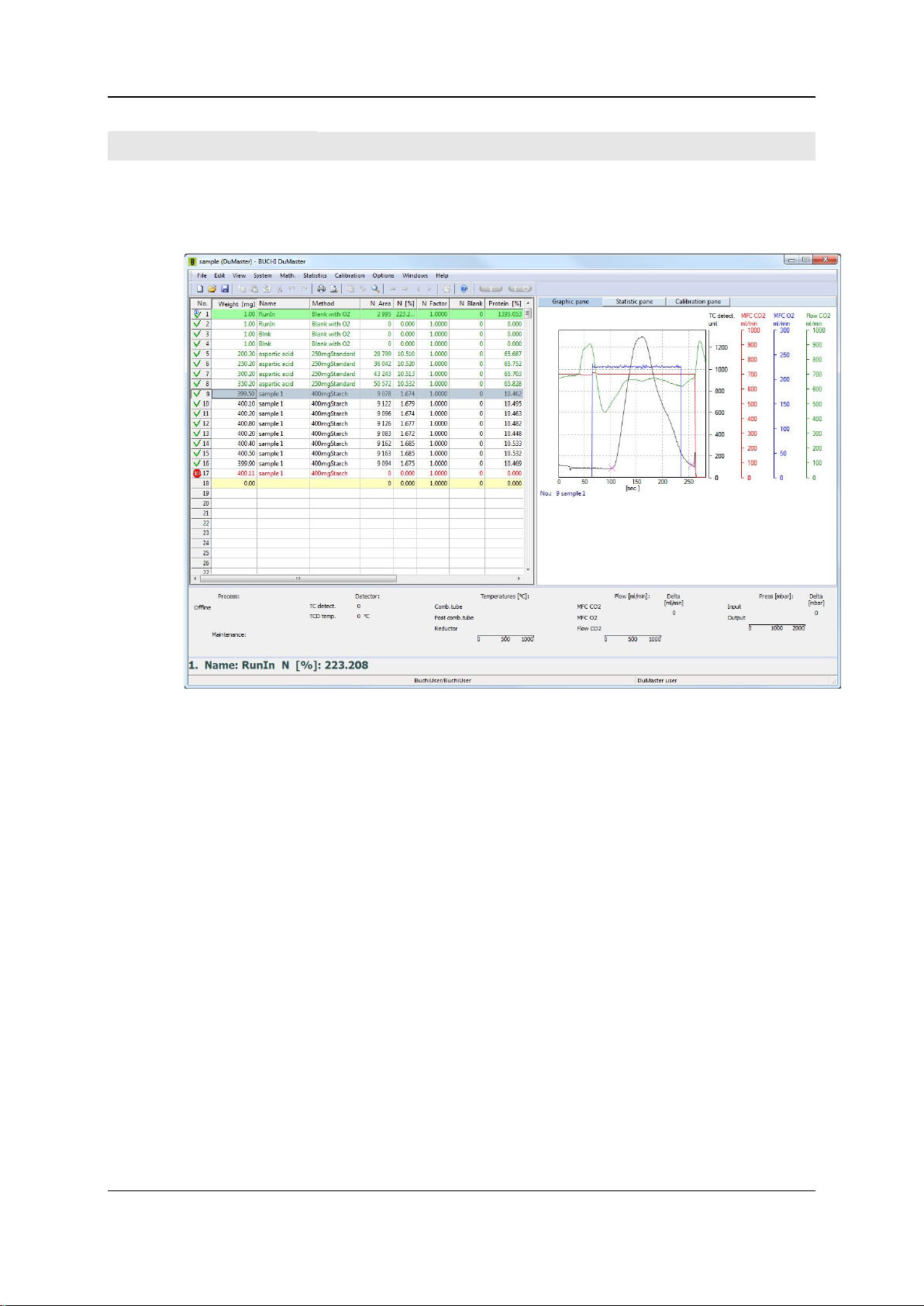

Software user interface .................................................................................................................... 60

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 6

Contents 6

Sample view ..................................................................................................................................... 61

Combi view ...................................................................................................................................... 63

Status view ....................................................................................................................................... 66

Right mouse button function ............................................................................................................ 67

Data administration and data security ......................................................................................................... 69

Laboratory information and management system (LIMS) ................................................................ 70

Conditions for operating the LIMS .................................................................................................... 70

21 CFR Part 11 functionality ............................................................................................................ 71

Versioning ........................................................................................................................................ 72

Linking the analyzer and software .................................................................................................... 72

CHAPTER 5 Work performed by the system administrator 73

Installing and updating the software ............................................................................................................ 74

Configure analyzer ...................................................................................................................................... 75

What can you modify in the configuration? ...................................................................................... 76

Defining logon timeout ..................................................................................................................... 76

Creating new sections ...................................................................................................................... 77

Defining LIMS export settings ..................................................................................................................... 78

LIMS export settings ........................................................................................................................ 79

Setting up user administration ..................................................................................................................... 80

User administration .......................................................................................................................... 81

Recommendations for user administration ....................................................................................... 81

Granting authorizations .................................................................................................................... 81

Defining interfaces ....................................................................................................................................... 83

Defining the analyzer / PC interface ................................................................................................. 84

Defining the LIMS / PC interface ...................................................................................................... 84

Defining the balance / PC interface .................................................................................................. 85

Editing analysis data ................................................................................................................................... 86

When does it make sense to edit analysis data? ............................................................................. 87

Limits for modifying analysis data .................................................................................................... 87

Consequences of modifying analysis data ....................................................................................... 87

Performing checks ....................................................................................................................................... 88

Checking documents for authenticity ............................................................................................... 89

Signing documents........................................................................................................................... 89

Viewing the logbook ......................................................................................................................... 90

Working with the database .......................................................................................................................... 91

Database .......................................................................................................................................... 92

Administrative work on the database ............................................................................................... 92

Defining the autoexport directory ..................................................................................................... 93

Database backup ............................................................................................................................. 93

Starting the database backup .......................................................................................................... 94

Reorganize database ....................................................................................................................... 94

Reloading an old database file ......................................................................................................... 95

Ways of optimizing the use of the analyzer ................................................................................................. 96

Optimizing basic instrument settings ................................................................................................ 97

Optimizing sample data editing ........................................................................................................ 97

"Balance" weighing data input program ........................................................................................... 98

Optimizing data evaluation ............................................................................................................... 99

Performing other administrator tasks ......................................................................................................... 100

Modifying the registration ............................................................................................................... 101

Printer setup ................................................................................................................................... 101

CHAPTER 6 Starting up and shutting down the instrument 103

Setting up and starting up the instrument .................................................................................................. 104

Rules for first-time start-up ............................................................................................................. 105

Instructions for operating the furnace ............................................................................................. 105

Installation site requirements ......................................................................................................... 105

Gases and chemicals to be provided ............................................................................................. 106

Start-up .......................................................................................................................................... 107

Connecting peripherals .................................................................................................................. 108

Connecting supply lines and waste gas lines ................................................................................. 109

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 7

Contents 7

Removing the transport protection ................................................................................................. 110

Switching on ................................................................................................................................... 112

Default instrument settings ............................................................................................................. 112

Heating up the furnace ................................................................................................................... 113

Shutting down the instrument .................................................................................................................... 114

Shutting the instrument down for short measuring breaks (standby) ............................................. 115

Shutting the instrument down for long measuring breaks (switching off) ....................................... 115

CHAPTER 7 Using the instrument 117

Measurement settings ............................................................................................................................... 118

Defining keywords for blank and conditioning samples .................................................................. 119

Viewing list of defined factor, monitor and standard samples ........................................................ 119

Defining custom standard substances ........................................................................................... 119

Defining standard substances as factor and monitor samples ....................................................... 120

Defining standard substances as calibration samples.................................................................... 120

Specifying the computation method for blank value and daily factor .............................................. 121

Enabling/disabling acoustic signals ................................................................................................ 121

Configuring error handling .............................................................................................................. 122

Preparing samples .................................................................................................................................... 123

Sample preparation instructions ..................................................................................................... 124

Determining sample weight ............................................................................................................ 124

Showing or hiding the weight window ............................................................................................ 125

Packing samples ............................................................................................................................ 125

Preparing measurement work ................................................................................................................... 127

Software usage rules ..................................................................................................................... 128

Starting the operating software ...................................................................................................... 128

Showing or hiding the toolbar ......................................................................................................... 128

Waking up the instrument .............................................................................................................. 128

Viewing method settings ................................................................................................................ 129

Defining custom methods ............................................................................................................... 129

Defining the Kjeldahl factor ............................................................................................................ 130

Copy methods ................................................................................................................................ 130

Settings for sample input ................................................................................................................ 131

Importing weighing data ................................................................................................................. 131

Prioritizing urgent samples ............................................................................................................. 132

Optimizing sleep and wake-up behavior ........................................................................................ 132

Performing measurement work ................................................................................................................. 134

Values for oxygen dosing ............................................................................................................... 135

Performing measurements ............................................................................................................. 136

Performing routine measuring work ............................................................................................... 138

Checklist for blank value / conditioning and daily factor measurements ........................................ 139

Checklist for real sample measurement ......................................................................................... 140

Types of blank value determination and their settings ................................................................... 141

Determining blank values ............................................................................................................... 141

Determining the daily factor ........................................................................................................... 142

Stopping continuous analysis ......................................................................................................... 144

Preparing measuring data for evaluation ................................................................................................... 146

Configuring the sample view .......................................................................................................... 147

Determine measuring units and number of decimal places. ........................................................... 147

Saving the sample view ................................................................................................................. 148

Loading a sample view ................................................................................................................... 148

Configure statistics view ................................................................................................................. 148

Generating statistical data .............................................................................................................. 148

Formulae for generating statistical data ......................................................................................... 149

Manual peak integration ................................................................................................................. 150

Configuring the graph view ............................................................................................................ 154

Setting the size of the graph .......................................................................................................... 154

Configure report ............................................................................................................................. 155

Display print preview ...................................................................................................................... 155

Data backup and printing ............................................................................................................... 156

Overview of export and import file formats ..................................................................................... 157

Exporting analysis data to MS Excel and viewing .......................................................................... 157

Exporting LIMS data....................................................................................................................... 158

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 8

Contents 8

Working with documents ........................................................................................................................... 159

Creating new documents ............................................................................................................... 160

Editing documents.......................................................................................................................... 160

Deleting documents ....................................................................................................................... 161

Finding documents ......................................................................................................................... 161

Copying documents via the clipboard ............................................................................................ 162

Importing documents ...................................................................................................................... 163

Signing documents......................................................................................................................... 163

Checking documents for authenticity ............................................................................................. 164

CHAPTER 8 Maintaining the instrument 165

Important information about maintenance ................................................................................................. 166

Maintenance work to be performed by the customer ..................................................................... 167

Viewing the status of maintenance intervals .................................................................................. 168

Defining maintenance intervals in the software .............................................................................. 168

Installing used tubes ...................................................................................................................... 169

Preparing and following up maintenance work ............................................................................... 169

Conditioning newly installed tubes ................................................................................................. 170

Performing the calibration ......................................................................................................................... 173

Viewing list of defined factor, monitor and standard samples ........................................................ 174

Defining standard substances ........................................................................................................ 174

Viewing calibration coefficients ...................................................................................................... 175

Optimizing instrument condition for calibration ............................................................................... 175

Performing the calibration .............................................................................................................. 175

Assessing the calibration curves .................................................................................................... 179

Calibration tables....................................................................................................................................... 182

Calibration table for nitrogen calibration ......................................................................................... 183

Replacing the ash crucible ........................................................................................................................ 184

Purpose and frequency of crucible replacement ............................................................................ 185

Removing the ash crucible ............................................................................................................. 185

Installing the ash crucible ............................................................................................................... 188

Refill the Regainer ..................................................................................................................................... 190

Purpose and frequency of refilling of the Regainer ........................................................................ 191

Refill the Regainer.......................................................................................................................... 191

Replacing sealing elements ...................................................................................................................... 194

When to replace sealing elements ................................................................................................. 195

Removing sealing elements from grooves ..................................................................................... 196

Ball valve maintenance ............................................................................................................................. 197

Removing and dismantling the ball valve ....................................................................................... 198

Cleaning, assembling and installing the ball valve. ........................................................................ 202

Maintaining the Ni flap and the O2 lance ................................................................................................... 206

Purpose and frequency of maintaining the Ni flap and O2 lance ................................................... 207

Removing and cleaning the Ni flap ................................................................................................ 207

Installing the Ni flap ........................................................................................................................ 209

Removing, cleaning and re-installing the O2 lance ........................................................................ 211

Removing, cleaning and installing the quartz glass bridge ........................................................................ 213

Removing the quartz glass bridge .................................................................................................. 214

Cleaning and installing the quartz glass bridge .............................................................................. 214

Removing, cleaning and installing the carousel ........................................................................................ 217

Removing, cleaning and installing the carousel ............................................................................. 218

Emptying and filling reaction tubes ............................................................................................................ 220

Emptying reaction tubes ................................................................................................................. 221

Filling the combustion tube ............................................................................................................ 221

Filling the post combustion tube ..................................................................................................... 223

Reductor replacing ......................................................................................................................... 224

Removing/installing and conditioning the reaction tubes ........................................................................... 225

Removing the reaction tubes from the furnace .............................................................................. 226

Installing reaction tubes in the furnace and conditioning ................................................................ 228

Filling, removing and installing the absorption and drying tubes ............................................................... 232

Filling the drying tubes ................................................................................................................... 233

Removing and installing the drying tubes ....................................................................................... 235

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 9

Contents 9

CHAPTER 9 Repairing the instrument 237

Interpreting PC error messages ................................................................................................................ 238

Performing a system test ........................................................................................................................... 239

Performing a leak test ............................................................................................................................... 240

Leak test procedure ................................................................................................................................... 241

Replacing fuses ......................................................................................................................................... 241

What to do after a computer crash ............................................................................................................ 245

Reacting to a power failure ........................................................................................................................ 245

Stopping continuous analysis .................................................................................................................... 248

Re-weighing after sample loss .................................................................................................................. 248

Changing the position of the carousel ....................................................................................................... 249

Export analysis data for support ................................................................................................................ 249

CHAPTER 10 Menu and dialog descriptions 251

Dialog descriptions key ............................................................................................................................. 252

File menu .................................................................................................................................................. 253

File > New (Command) .................................................................................................................. 254

Select document name (Dialog) ..................................................................................................... 254

Select version (Dialog) ................................................................................................................... 256

Save file as (Dialog) ....................................................................................................................... 257

File > Delete (Command) ............................................................................................................... 258

Comment modification (Dialog) ...................................................................................................... 258

Sign (Dialog) .................................................................................................................................. 259

Verify digital signature (Dialog) ...................................................................................................... 259

Export to LIMS (Dialog) .................................................................................................................. 260

Export peak graphics (Dialog) ........................................................................................................ 261

Configure report (Dialog) ................................................................................................................ 261

Print (Dialog) .................................................................................................................................. 263

Print preview (Dialog) ..................................................................................................................... 264

Printer setup (Dialog) ..................................................................................................................... 265

Open (Dialog) ................................................................................................................................. 266

Load balance file (Dialog) .............................................................................................................. 267

Configure backup (Dialog) ............................................................................................................. 267

Clean database (Dialog) ................................................................................................................ 269

Restore database (Dialog) ............................................................................................................. 269

Log in as (Dialog) ........................................................................................................................... 270

File > Logoff (Command) ............................................................................................................... 271

File > Exit (Command) ................................................................................................................... 271

File > Export/Import > Create Excel sheet (Command).................................................................. 271

Edit menu .................................................................................................................................................. 272

Edit > Undo (Command) ................................................................................................................ 273

Edit > Redo (Command) ................................................................................................................ 273

Edit > Cut (Command) ................................................................................................................... 273

Edit > Copy (Command) ................................................................................................................ 273

Edit > Paste (Command) ................................................................................................................ 274

Edit > Insert line (Command) ......................................................................................................... 274

Edit > Delete line (Command) ........................................................................................................ 274

Swap samples (Dialog) .................................................................................................................. 275

Edit > Modify (Command) .............................................................................................................. 275

Set stop tag (Dialog) ...................................................................................................................... 276

Select current sample (Dialog) ....................................................................................................... 276

Set current weighed sample (Dialog) ............................................................................................. 277

View menu ................................................................................................................................................ 278

View > Toggle (Command) ............................................................................................................ 279

Zoom in/out (Dialog) ....................................................................................................................... 279

Configure sample view (Dialog) ..................................................................................................... 279

Save sample pane (Dialog) ............................................................................................................ 280

Load sample pane (Dialog) ............................................................................................................ 281

Delete sample pane (Dialog) .......................................................................................................... 281

View > Gridview > Auto align (Command) ..................................................................................... 282

Configure graph view (Dialog) ........................................................................................................ 282

View > Graphic > Auto align (Command) ....................................................................................... 283

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 10

Contents 10

Configure statistics view (Dialog) ................................................................................................... 283

View > Statistic > Auto align (Command) ....................................................................................... 284

Select columns (Dialog) ................................................................................................................. 284

Column properties (Dialog) ............................................................................................................ 284

Weighing window (Dialog) .............................................................................................................. 285

System menu ............................................................................................................................................ 287

System > Auto run (Command) ...................................................................................................... 288

System > Single run (Command) ................................................................................................... 288

System > Stop (Command) ............................................................................................................ 288

System > Auto zero (Command) .................................................................................................... 289

Furnace switch off/on (Dialog) ....................................................................................................... 289

Initialize the instrument (Dialog) ..................................................................................................... 289

System > Wake up (Command) ..................................................................................................... 290

Feeding (Dialog)............................................................................................................................. 290

Adjust carousel position (Dialog) .................................................................................................... 290

Math menu ................................................................................................................................................ 292

Math > Blank values > Calculate (Command) ................................................................................ 293

Blank values (Dialog) ..................................................................................................................... 293

Math. > Factor (Command) ............................................................................................................ 294

Define type of peak (Dialog) ........................................................................................................... 294

Define peak start / end (Dialog) ..................................................................................................... 294

Area assignment (Dialog) ............................................................................................................... 295

Standard samples display (Dialog)................................................................................................. 296

Math. > Recalculate (Command) ................................................................................................... 297

Statistics menu .......................................................................................................................................... 298

Statistics > Via names (Command) ................................................................................................ 299

Statistics > Group (Command) ....................................................................................................... 299

Statistics > Sort group (Command) ................................................................................................ 299

Statistics > Delete group (Command) ............................................................................................ 299

Statistics > Clear statistic (Command) ........................................................................................... 299

Statistics > Include/Exclude sample (Command) ........................................................................... 300

Statistics > Include/Exclude value (Command) .............................................................................. 300

Statistics > Create Excel sheet (Command)................................................................................... 300

Calibration menu ....................................................................................................................................... 301

Calibration coefficients (Dialog) ..................................................................................................... 302

Configure calibration (Dialog) ......................................................................................................... 303

Specify lower and upper calibration range (Dialog) ........................................................................ 304

Calibration > Next sample (Command) .......................................................................................... 305

Calibration > Previous sample (Command).................................................................................... 305

Calibration > Next (Command) ....................................................................................................... 305

Calibration > Previous (Command) ................................................................................................ 305

Options menu ............................................................................................................................................ 306

Maintenance intervals (Dialog) ....................................................................................................... 307

Replace part (Dialog) ..................................................................................................................... 308

Adjust carousel (Dialog) ................................................................................................................. 309

Leak test (Dialog) ........................................................................................................................... 310

Leak test: Test phases (Dialog) ..................................................................................................... 311

System test (Dialog) ....................................................................................................................... 312

Error buffer (Dialog) ....................................................................................................................... 314

Error display (Dialog) ..................................................................................................................... 314

Options > Diagnostics > Baseline recording (Command) ............................................................... 315

Input options (Dialog) ..................................................................................................................... 315

Standard samples (Dialog) ............................................................................................................. 316

Keywords (Dialog) .......................................................................................................................... 317

Acoustic signals (Dialog) ................................................................................................................ 318

Configure Calculations (Dialog) ..................................................................................................... 318

LIMS settings (Dialog) .................................................................................................................... 319

Method (Dialog) ............................................................................................................................. 322

Monthly logbook (Dialog) ............................................................................................................... 323

Select period (Dialog) ..................................................................................................................... 324

Device configuration (Dialog) ......................................................................................................... 325

Error handling (Dialog) ................................................................................................................... 328

Sleep / wake-up function (Dialog) .................................................................................................. 329

Configure key value (Dialog) .......................................................................................................... 330

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 11

Contents 11

Windows menu .......................................................................................................................................... 332

Windows > Toolbar / Run-Bar (Command) .................................................................................... 333

Toolbar ........................................................................................................................................... 333

Windows > Recent sample (Command) ......................................................................................... 334

Windows > Status view (Command) .............................................................................................. 334

Windows > Default layout (Command) ........................................................................................... 334

Help menu ................................................................................................................................................. 335

Help > Content (Command) ........................................................................................................... 336

Help > Find (Command) ................................................................................................................. 336

Help > BÜCHI Labortechnik AG on the WEB (Command) ............................................................. 336

Product registration (Dialog) .......................................................................................................... 336

Help > About... (Command) ........................................................................................................... 337

CHAPTER 11 Appendix 339

Revision history ......................................................................................................................................... 340

Warranty .................................................................................................................................................... 341

Warranty of the overall instrument ................................................................................................. 342

Warranty on the furnace ................................................................................................................. 342

Accessories, spare parts and consumables .............................................................................................. 343

Smallest workable unit ................................................................................................................... 344

Required accessories ..................................................................................................................... 345

Optional accessories ...................................................................................................................... 346

Declaration of conformity ........................................................................................................................... 347

Declaration of conformity ............................................................................................................... 348

Index 349

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 12

Page 13

General information on the operating instructions .........................................................................15

CHAPTER 1

General

Purpose

This chapter contains general topics of the document.

In this chapter

About this document ......................................................................................................................14

Display conventions .......................................................................................................................15

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 14

1 - General 14

About this document

Status of the operating instructions

The status of the operating instructions is: 16.10.2014.

Identification number

The operating instructions identification number is: 11593627.

Validity

The operating instructions are valid for all instruments as from serial number: 16144001.

Analyzer

The operating instructions describe the basis type of the instrument D-480.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 15

1 - General 15

Display conventions

Formatting convention

Type of information

Denote amongst others the names of dialogs in the software, e. g.

Before you start using this guide, it is important to understand the terms and typographical

conventions used in the documentation. The following kinds of formatting in the text identify special

information.

Triangular bullet () Step by step procedure. You can follow these instructions to

Special bold Items you must select, such as menu options (e. g. File > New),

Italics

CAPITALS Names of keys on the keyboard, for example, SHIFT, CTRL, or

KEY+KEY Key combinations for which the user must press and hold down

"Quotation marks"

{Symbolic name} Denotes a symbolic name, e. g. {Element} stands for the

complete a specific task.

command buttons (e. g. Cancel), or common accentuation.

Used to emphasize the importance of an item or for variable

expressions such as parameters.

ALT.

one key and then press another, for example, CTRL+P, or

ALT+F4.

the "Replace part" dialog.

corresponding name of an element.

General inform ati on on the op er ati ng ins tr uc t ions

Pictures

The instruments of BÜCHI Labortechnik AG underlie a permanent development and adjustment

regarding the optimum parameter settings. This may lead to deviations in terms of picture display of

the manual and the current instrument status which are not relevant for the understanding of the

instrument operation.

The valid numbers of the parameter settings and/or variables can be found in the current text part.

Therefore, numbers in the pictures of software dialogs are mainly replaced by spaces or only reflect

examples. They do not reflect the proper, recommended set values.

Reading aids

Subheadings are displayed in the left margin as reading aids. They sum up the content of the

particular section and are useful for quick navigation.

Index

An index is given at the end of the operating instructions that helps you locate certain topics more

easily. Index entries always refer to the first page of the section in which the index term is found.

Therefore, don't be confused if the index term does not appear on the first page but rather on one of

the following pages.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 16

Page 17

Warning notes during operation ....................................................................................................24

CHAPTER 2

Basic security settings

Target group

Personnel working with the instrument.

Purpose

This section describes basic safety rules required to avoid risks for the user of the analyzer.

In this chapter

Working with the operating instructions .........................................................................................18

Representation of safety instructions .............................................................................................18

Instructions for disposal of consumables .......................................................................................18

Intended use of the instrument ......................................................................................................19

Warning: residual risks ..................................................................................................................19

Safety devices in the analyzer .......................................................................................................20

Warning signs on the analyzer ......................................................................................................22

Warning: changes to the instrument ..............................................................................................23

Warning: unsuitable spare parts and consumables .......................................................................23

Required user knowledge and skills ..............................................................................................23

Required personal safety equipment .............................................................................................24

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 18

2 - Basic security settings 18

Working with the operating instructions

Risk level

Consequences

Probability

Operating the analyzer

Read the operating instructions thoroughly before performing work with the analyzer.

Storing the operating instructions

Store the operating instructions carefully and make sure the instructions are accessible for all relevant

personnel.

Passing on the operating instructions

If you pass on the analyzer, always pass on the operating instructions, too.

Representation of safety instructions

Safety signs

This is a safety sign. Instructions with this sign contain warnings about risks of injury and even death.

These instructions must always be observed in order to avoid risks.

Risk levels

The safety instructions are categorized according to the following risk levels:

Risk

Warning

Caution

Death / serious injury (irreversible) high

Death / serious injury (irreversible) medium

Minor injury (reversible) medium

Caution

Damage to property possibly

Instructions for disposal of consumables

Rules

Observe the following rules for disposal of consumables:

Dispose of the consumables according to the relevant disposal categories.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 19

2 - Basic security settings 19

Read the instructions on the individual chemicals in the safety data sheets. The risk notes for

individual chemicals can be found in the R-Phrases. Safety advice can be found in the SPhrases.

Intended use of the instrument

Intended use

This section describes what the instrument is suitable for and what substances may be analyzed with

it.

Description of the instrument

The elementary analyzer is an instrument for fully automatic and quantitative analysis of the element

N.

Suitable analysis samples

Only samples that can be decomposed in a controlled manner under the method-dependent

combustion conditions are suitable for analysis.

Advice on difficult applications

You have the following ways of getting advice on difficult applications:

You will find useful tips in the "Application notes" on the provided CD.

You will find also the "Application notes" section on the www.buchi.com website.

Warning: residual risks

Hot components inside the instrument

During operation, the furnaces inside the instrument heat certain components to very high

temperatures. Even after switching off the instrument, these components stay hot for long periods of

time that you can suffer serious burns if working inappropriately inside the instrument.

Observe the relevant instructions exactly in order to avoid burns.

Live components inside the instrument

There are live parts (up to 230V) inside the instrument. When you are working on the electrical

components, you may suffer electrocution if you do not work properly. Never bring liquids or leak-test

spray in the vicinity of live components.

Observe the relevant instructions exactly in order to avoid injuries caused by electrocution.

Unsuitable consumables and spare parts

If you use consumables and spare parts of an unsuitable type and quality, you risk:

Injuries to the operating personnel

Damages to the instrument

Distortion of analysis results

loss of warranty.

Only use original spare parts and original consumables that you have purchased from BÜCHI

Labortechnik AG or authorized dealers.

Samples with potential risks

Samples to be analyzed may pose the following risks:

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 20

2 - Basic security settings 20

Contact with the substances may lead to chemical burns or poisoning.

Combustion analysis of larger quantities of the substance may lead to explosions.

These sample substances include:

Aggressive chemicals such as acids or alkaline solutions

Organic solvents

Explosives

Substances that develop toxic or explosive gas mixtures

You are obliged to protect yourself prior to contact with hazardous substances and to reduce the

quantity of the substance to a safe amount.

You are also obliged to observe the safety instructions of the chemical manufacturer on the label of

the bottle or in the safety data sheets. The safety data sheets contain risk information about a

chemical in the R-Phrases and safety information in the S-Phrases.

Safety devices in the analyzer

Note

The analyzer may only be operated if all of the safety devices indicated in this section are in place

and in working order.

Gas supply

Gas supply is only possible if the mains switch is switched on and the software is running.

Temperature monitoring

A temperature limiter automatically switches off the instrument in the event of excess temperature

inside the instrument. All heating is monitored by an integrated microprocessor controller. All furnaces

are automatically shut down in the event of the following malfunctions:

The heating fails to reach setpoint temperature within the set time.

A thermocouple is defective or displays an illegal value.

The set threshold temperature is exceeded.

Instrument casing

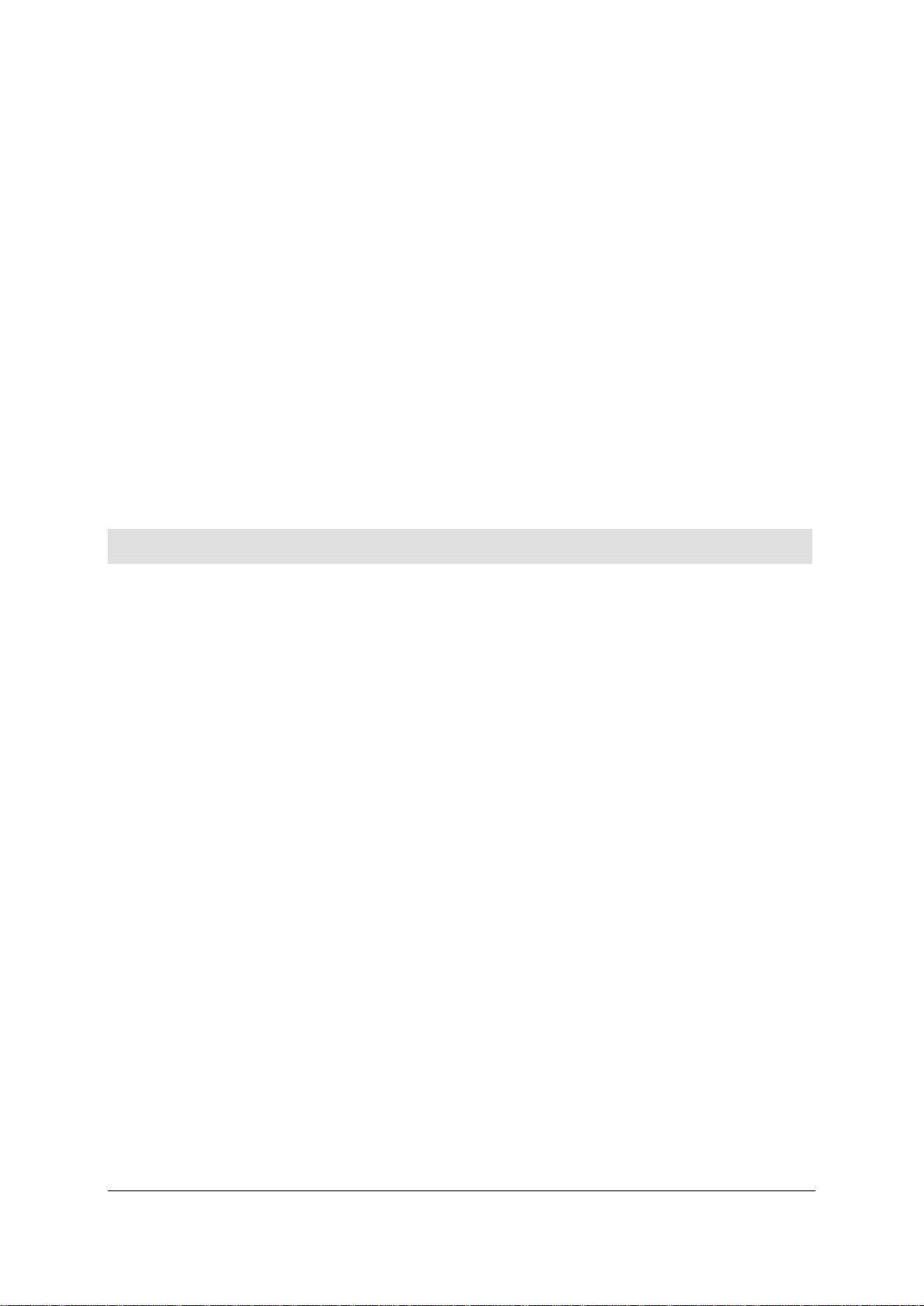

The instrument casing comprises the following, as seen from the top left in the picture:

Right side door

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 21

2 - Basic security settings 21

Front door

Left side door

Rear wall

Instrument cover.

The casing separates hot, live parts from the surroundings.

Protective earth conductor

The electrical components of the analyzer are grounded by a protective earth conductor:

The first protective earth conductor is located on the rear wall of the analyzer.

The second protective earth conductor is located outside the cover of the electrical area (arrow).

The third protective earth conductor is located intside the cover of the electrical area (arrow).

If the protective earth conductor connections need to be detached, they must be re-connected

correctly when re-assembling.

Waste gas lines

The operator is obliged to connect waste gas lines if the national limits for toxic gases in workplace air

are exceeded. The waste gas lines must discharge into the open or into an exhaust hood. The end of

the waste gas lines must discharge into the open at a location protected from the wind as pressure

fluctuations, e.g. caused by wind, cause detector instabilities.

In addition, the installation room should be well ventilated.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 22

2 - Basic security settings 22

Warning signs on the analyzer

Warning sign

Meaning

Warning sign furnace

The following picture shows the warning sign on the furnace heat protection cladding:

Warning sign electrical area

The following picture shows the warning sign on the electrical section cover:

Meaning of the warning signs

The following table explains the meaning of the warning signs:

Warning: hot surfaces

Electric current hazard

Note

You are obliged to keep the warning signs on the instrument complete and in a legible condition.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 23

2 - Basic security settings 23

Warning: changes to the instrument

Section

Required knowledge and skills

Safe instrument

The analyzer is designed and delivered in such a way to ensure safe working if you observe the

instructions in the operating instructions.

Warning: Changes to the instrument

If you make any changes to the instrument, you risk rendering the instrument unsafe.

The consequences would be:

Injuries to the operating personnel

Damages to the instrument

loss of warranty.

Therefore, never make any unauthorized additions/conversions to the instrument.

Warning: unsuitable spare parts and consumables

Warning

If you use spare parts and consumables of an unsuitable type and quality, you risk:

Injuries to the operating personnel

damage to the instrument

Distortion of analysis results

Loss of warranty.

Only use original spare parts and original consumables that you have purchased from BÜCHI

Labortechnik AG or authorized dealers.

Required user knowledge and skills

Knowledge and skills

Depending on the specific task, the user must have different knowledge and skills. The following table

indicates which sections of the operating instructions require what knowledge and skills:

Work performed by the system

administrator

Starting up or shutting down the

instrument

Using the instrument Personnel with basic knowledge of chemistry and

Maintaining the instrument Personnel authorized by BÜCHI.

Repairing the instrument Personnel authorized by BÜCHI and having undergone

Personnel with good knowledge of the operating system

and administrative settings.

Personnel authorized by BÜCHI and having undergone

training.

experience with laboratory work (e.g. laboratory worker).

training.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 24

2 - Basic security settings 24

Required personal safety equipment

Protective glasses

You require protective glasses for many activities. Make sure that protective glasses are always

available nearby the analyzer.

Protective gloves

BÜCHI two kinds of protective gloves with the instrument:

The protective leather gloves for protection against cuts on broken glass from cold quartz

components.

The heat protection gloves for protection against burns on hot components.

Always keep the protective gloves nearby the analyzer. Replace the protective gloves immediately if

required.

Laboratory clothing

For work on and with the instrument you need:

Sturdy shoes

Cotton apron

Hair tie to tie back long hair

Obedience of general rules for safe work in the laboratory

Warning notes during operation

Note

Always pay attention to careful handling when working with the instrument, especially for modifications,

maintenance and repairing works. The following notes have to be strictly observed when performing the

corresponding works.

Replacing the ash crucible/finger

Please observe the following instructions:

Warning

Hot instrument parts and hot ash particles!

Risk of burning due to hot instrument parts.

When replacing:

Wear protective glasses.

Wear the enclosed heat protection gloves.

Place the hot instrument tubes in a tube rack on a level, non-combustible

surface.

Protect the hot instrument parts from unauthorized access.

Never leave the instrument unattended when the furnace has been pulled

out.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 25

2 - Basic security settings 25

Warning

Damaged base panel

Please observe the following instruction:

Caution

Gas pressure

Please observe the following instruction:

Warning

Gas pressure and caustic substances in the instrument

Consumables may escape under pressure and cause chemical burns. Before

performing the work:

Shut off the gas supply. To do so, execute the Options > Maintenance >

Replace parts command.

Damaged base panel!

Damage to the base panel will impair proper functioning of the carousel.

Before starting maintenance work, always remove all samples from the carousel.

When dismantling and cleaning the carousel:

Never use pointed objects to dismantle the carousel.

Never use sharp or aggressive cleaners.

Gas pressure and caustic substances in the instrument

Consumables may escape under pressure and cause chemical burns. Before

performing the work:

Shut off the gas supply. To do so, execute the Options > Maintenance >

Replace parts command.

Hot instrument parts

Please observe the following instruction:

Warning

Hot instrument parts!

Risk of burning due to hot instrument parts. Before performing the work:

Allow the furnace to cool down

Disconnect the power supply plug

Cleaning and installing/removing the quartz glass bridge

Please observe the following instruction:

Warning

Sharp pieces of broken glass!

When cold quartz or glass components break there is a risk of cut injuries.

Wear the enclosed protective leather gloves and protective glasses when

handling cold quartz and glass parts.

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Page 26

2 - Basic security settings 26

Removing reaction tubes

side the instrument there is a risk of burning as many parts of the

Please observe the following instructions:

Warning

Warning

Filling reaction tubes

Please observe the following instructions:

Warning

Caution

Hot reaction tubes!

Risk of burning due to hot instrument parts.

When replacing the reaction tubes:

Wear protective glasses.

Wear the enclosed heat protection gloves.

Place the hot tubes in a tube rack on a level, non-combustible surface.

Protect the hot tubes from unauthorized access.

Never leave the instrument unattended when the furnace has been pulled

out.

Gas pressure and caustic substances in the instrument

Consumables may escape under pressure and cause chemical burns. Before

performing the work:

Shut off the gas supply. To do so, execute the Options > Maintenance >

Replace parts command.

Sharp pieces of broken glass!

When cold quartz or glass components break there is a risk of cut injuries.

Wear the enclosed protective leather gloves and protective glasses when

handling cold quartz and glass parts.

Cutting sealing elements apart/out (o-rings, quad rings, half shells, ferrules).

When cutting sealing elements apart/out with a knife you may damage sealing

surfaces.

Never remove sealing elements with a knife but rather with tweezers.

Installing and conditioning the reaction tubes

Please observe the following instructions:

Warning

Caution

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Hot components in the instrument

When working in

instrument are hot.

When working inside the instrument always wear protective glasses and the

enclosed heat protection gloves.

Overheating if tube fillings are not appropriate for the operating mode!

Overheated tube fillings melt, run into the furnace area and destroy the furnace.

Make sure that the tube fillings correspond to the selected operating mode.

Page 27

2 - Basic security settings 27

Emptying reaction tubes

A lack of ventilation leads to overheating of the analyzer. Before you switch off the

til the temperature displayed is less than 55

Please observe the following instruction:

Warning

Warning

Replacing fuses

Please observe the following instructions:

Risk

Risk

Caution

Sharp pieces of broken glass!

When cold quartz or glass components break there is a risk of cut injuries.

Wear the enclosed protective leather gloves and protective glasses when

handling cold quartz and glass parts.

Harmful substances when glass is broken!

When filled quartz or glass components break there is a risk that harmful

substances may be released.

Wear a dust mask when handling cold quartz and glass parts.

Live parts!

When replacing fuses there is a risk of electrocution.

Before replacing fuses:

Allow the furnace to cool down.

Disconnect the power supply plug.

High voltage!

Using the wrong fuses can pose a risk of electrocution or fire.

Only use fuses matching the indicated type and the indicated voltage on the fuse

holder.

Lack of ventilation of the analyzer!

instrument:

Switch off the furnace. To do so, execute the following command: System >

Furnace

Allow the furnace to cool down un

°C.

Filling the drying tube

Please observe the following instructions:

Warning

Warning

Operating instructions DuMaster D-480 ©BÜCHI Labortechnik AG

Caustic substance Sicapent® (phosphorus pentoxide)!

Danger of chemical burns when handling Sicapent®.

Wear protective glasses and the enclosed protective leather gloves.

Sharp pieces of broken glass!

When cold quartz or glass components break there is a risk of cut injuries.

Wear the enclosed protective leather gloves and protective glasses when

handling cold quartz and glass parts.

Page 28

2 - Basic security settings 28

Installing/removing the drying tube

Improper changes impair proper operation of the system and may destroy system

Please observe the following instructions:

Caution

Warning

Lack of ventilation of the analyzer!

A lack of ventilation leads to component overheating

Do not open the front door too long when the furnaces are hot and the furnace is

not pulled out. Otherwise the ventilation will not work properly.

Caustic substance Sicapent® (phosphorus pentoxide)!

Danger of chemical burns when handling Sicapent®.

Wear protective glasses and the enclosed protective leather gloves.

Overheating of tube fillings