Brother CM650W, CM350R, CM550DX, CM350, CM350H Quick Reference

...

EN Quick Reference Guide

Refer to the Operation Manual (PDF version on the CD or printed version) for detailed instructions. |

,03257$17 |

Be sure to first read the “Important Safety Instructions” in the Product Safety Guide. |

|

*In addition, the Operation Manual can be downloaded from the Brother Solutions Center (http://support.brother.com).

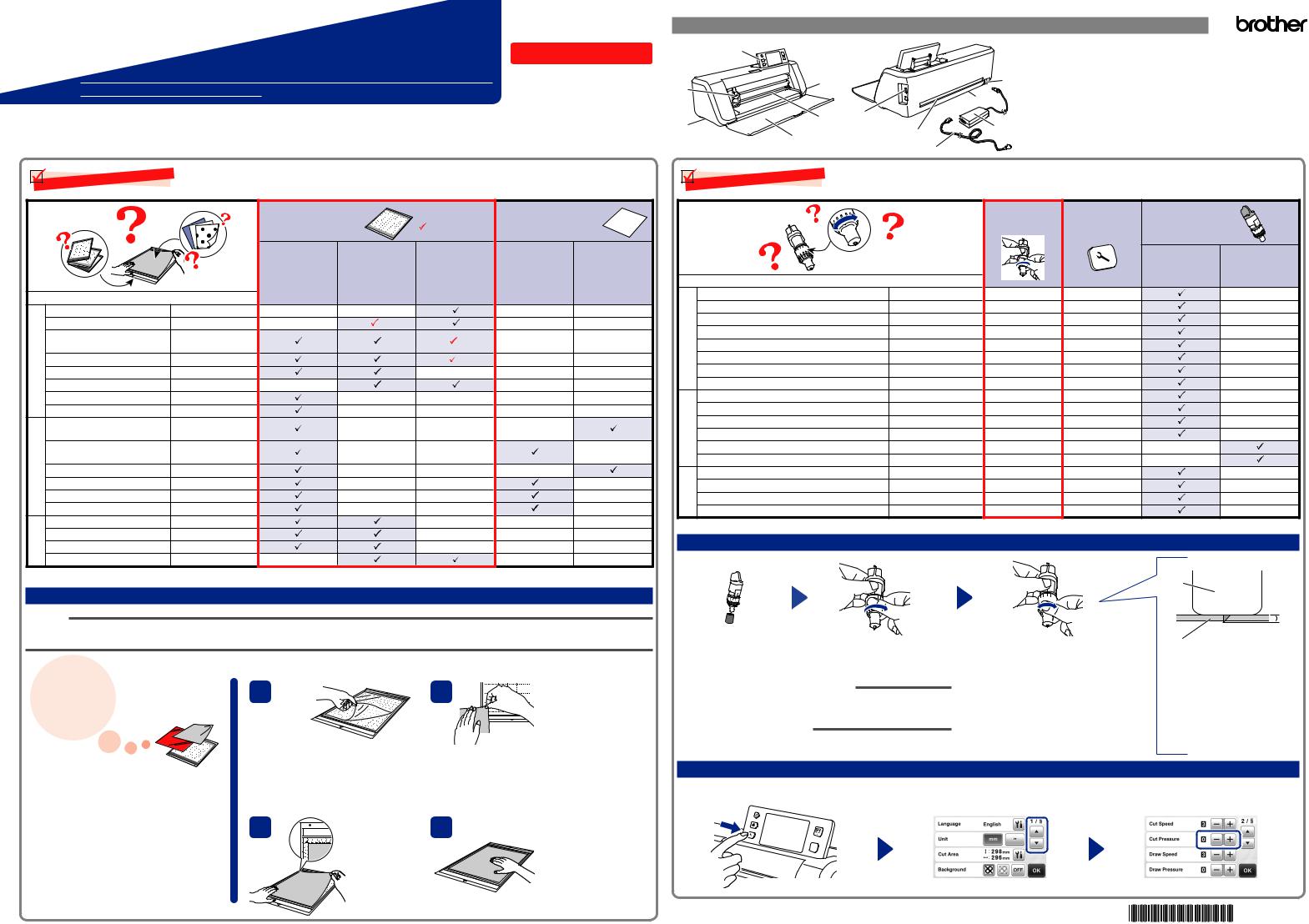

●●Use a blade and mat combination appropriate for the material to be cut, as indicated in the following table.

(Depending on your machine model, additional purchases may be required.) In addition, adjust the blade extension and cutting pressure.

|

Mat Selection |

●●This table provides general guidelines. Before making your project, test attaching the same material. |

|

||||

|

|

|

|

Mat |

* When cutting |

Sheet for fabric cutting |

|

|

|

|

|

|

smooth paper |

|

|

|

|

|

Standard mat |

Middle tack |

|

Iron-on fabric |

|

|

|

|

Low tack adhesive |

appliqué contact |

High tack adhesive |

||

|

|

|

(purple and |

adhesive mat |

|||

|

|

|

mat (turquoise) |

sheet (white |

fabric support sheet |

||

|

|

|

turquoise) |

(pink and turquoise) |

|||

|

|

|

|

backing) |

|

||

|

Material and its thickness |

|

|

|

|

||

|

|

|

|

|

|

||

|

Printer paper |

80 g/m² (0.1 mm) |

X |

* |

|

|

|

|

Scrapbook paper (thin) |

120 g/m² (0.15 mm) |

|

|

|

|

|

|

Scrapbook paper |

200 g/m² (0.25 mm) |

|

|

* |

|

|

Paper |

(medium-thick) |

|

|

|

|

||

|

|

|

* |

|

|

||

Cardstock (thin) |

200 g/m² (0.25 mm) |

|

|

|

|

||

|

|

|

|

|

|||

|

Cardstock (medium-thick) |

280 g/m² (0.35 mm) |

|

|

|

|

|

|

Vellum, tracing paper |

0.07 mm |

|

|

|

|

|

|

Poster board (thin) |

280 g/m² (0.35 mm) |

|

|

|

|

|

|

Poster board (thick) |

400 g/m² (0.5 mm) |

|

|

|

|

|

|

Thin cotton fabric |

0.25 mm |

|

|

|

|

|

|

(for quilt piece) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fabric |

Thin cotton fabric |

0.25 mm |

|

|

|

|

|

(except for quilt piece) |

|

|

|

|

|

||

|

|

|

|

|

|

||

Flannel (for quilt piece) |

0.6 mm |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Flannel (except for quilt piece) |

0.6 mm |

|

|

|

|

|

|

Felt |

1 mm |

|

|

|

|

|

|

Denim 14 oz |

0.75 mm |

|

|

|

|

|

Others |

Plastic sheet (PP) |

0.2 mm |

|

|

|

|

|

Vinyl |

0.2 mm |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Magnet |

0.3 mm |

|

|

|

|

|

|

Sticker or seal |

0.2 mm |

|

|

|

|

|

Attaching the Material to the Mat

Note

●●Craft paper or fabric covered with decorative layer (that can easily separate) such as lamé or foil is not recommended. If such media is used or tested it is recommended to clean the scanner glass at the bottom of the machine after every use.

With Fabric

After referring to the table above, use a sheet for fabric cutting.

Refer to the instrucitons included with the above sheet for details.

Iron-on fabric appliqué contact sheet:

●●Reinforces the fabric so that various patterns can be cut out.

●●Original texture may change because it remains attached to the back of fabric.

*For use with the standard mat. Do not place fabric backed with iron-on contact sheet directly onto a mat with high tack fabric support sheet.

High tack adhesive fabric support sheet:

●●By attaching this adhesive sheet to the standard mat, the adhesive strength of the mat is increased.

●●Depending on the shape, the pattern may not be cleanly cut.

With Paper

1

Peel off the protective sheet.

*Do not discard the protective sheet peeled off the mat.

*In order to maintain the adhesive strength, attach the protective sheet to the adhesive side of the mat after use.

3 |

Attach the material |

|

to the mat’s |

|

adhesive side. |

2 |

Before attaching the |

|

material to the mat, use a |

|

corner of the adhesive side |

|

of the mat to test attaching |

|

it. |

* Use the low tack adhesive mat with copy paper and |

|

smooth paper. |

|

Since the standard mat has a high adhesive strength, materials may remain stuck to the mat, causing the mat to become unusable.

4 |

Firmly attach all of the |

|

material to the mat. |

* Make sure that there are no wrinkles and no part can curl off.

The Main Parts

a |

|

|

|

|

|

|

b |

c |

|

|

|

h 1Operation Panel |

7Slot |

|

|

k |

|

2Carriage |

8DC Power Jack |

|

|

|

|

|

3Handles |

9AC Adapter |

|

|

|

|

|

|

||

|

d |

f |

|

|

4Feed Slot |

0AC Power Cord |

|

|

|

|

5Front Tray Cover |

AScanner Glass (Bottom of |

|

c |

|

|

|

i |

||

|

g |

|

6USB port (for a USB flash drive) |

Machine) |

||

e |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

j |

|

|

|

Blade (Holder) |

|

●●This table provides general guidelines. Before making your project, perform trial cutting with the same material. |

||||

|

|

|

|

Blade scale |

Cut pressure |

Cutting blade |

||

|

|

|

|

setting |

setting |

|||

|

|

|

|

|

|

Standard cut blade |

Deep cut blade |

|

|

Material and its thickness |

|

|

|

(turquoise) |

(purple) |

||

|

|

|

|

|

|

|||

|

Printer paper |

|

80 g/m² (0.1 mm) |

3 |

-1 |

|

|

|

|

Scrapbook paper (thin) |

|

120 g/m² (0.15 mm) |

3.5 |

0 |

|

|

|

Paper |

Scrapbook paper (medium-thick) |

|

200 g/m² (0.25 mm) |

4 |

0 |

|

|

|

Cardstock (thin) |

|

200 g/m² (0.25 mm) |

4 |

0 |

|

|

||

Cardstock (medium-thick) |

|

280 g/m² (0.35 mm) |

5 |

0 |

|

|

||

|

Vellum, tracing paper |

|

0.07 mm |

3 |

0 |

|

|

|

|

Poster board (thin) |

|

280 g/m² (0.35 mm) |

5.5 |

0 |

|

|

|

|

Poster board (thick) |

|

400 g/m² (0.5 mm) |

7.5 |

4 |

|

|

|

|

Thin cotton fabric (for quilt piece) |

0.25 mm |

4 |

4 |

|

|

||

Fabric |

Thin cotton fabric (except for quilt piece) |

0.25 mm |

4 |

4 |

|

|

||

Flannel (except for quilt piece) |

0.6 mm |

6.5 |

4 |

|

|

|||

|

Flannel (for quilt piece) |

|

0.6 mm |

6.5 |

4 |

|

|

|

|

Felt |

|

1 mm |

5 |

5 |

|

|

|

|

Denim 14 oz |

|

0.75 mm |

5.5 |

6 |

|

|

|

Others |

Plastic sheet (PP) |

|

0.2 mm |

4 |

0 |

|

|

|

Vinyl |

|

0.2 mm |

4 |

0 |

|

|

||

|

|

|

|

|||||

|

Magnet |

|

0.3 mm |

5.5 |

0 |

|

|

|

|

Sticker or seal |

|

0.2 mm |

4 |

0 |

|

|

|

Adjusting the Blade Extension |

|

|

|

|

|

|||

|

|

|

|

|

|

a |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

c |

|

Remove the protective cap. |

Fully turn the cap to the right to |

After referring to the table above, set the |

b |

|

||||

|

|

|||||||

* After use, be sure to |

extend the blade tip to its maximum. |

blade extension to the indicated setting. |

1End of holder cap |

|||||

retract the blade into the |

|

|

* If the material is not cut cleanly, even |

2Material that will be cut |

||||

holder and attach the |

Note |

|

after adjusting the setting, increase the |

3Length of blade tip |

||||

protective cap. |

|

setting in increments of 0.5. If material |

||||||

●●After adjusting the blade extension, |

* The blade can cut even |

|||||||

|

|

is cut after increasing the setting by |

||||||

|

|

perform trial cutting (Refer to the |

though it only slightly extends |

|||||

|

|

more than 0.5, too much of the blade |

||||||

|

|

back of this sheet). |

|

from the holder. |

||||

|

|

|

may be extended, causing it to break. |

|||||

|

|

|

|

If too much of the blade |

||||

|

|

|

|

If the blade breaks, it may no longer be |

||||

|

|

|

|

extends, it may break. |

||||

|

|

|

|

able to cut. |

|

|||

|

|

|

|

|

|

|

||

Adjusting the Cut Pressure

* If the material is not cut cleanly, even after adjusting the blade extension, add more cutting pressure.

;*1

Loading...

Loading...