Page 1

BROOKFIELD SPIRAL ADAPTER

SPECIALISTS IN THE

MEASUREMENT AND

CONTROL OF VISCOSITY

T

EL

800-628-8139 or 508-946-6200 FAX 508-946-6262

www.brookfieldengineering.com

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346-1031 USA

Operating Instructions

Manual No. M93-270-D0812

Brookeld Engineering Labs., Inc. Page 1 Manual No. M93-270-D0812

Page 2

Page 3

TABLE OF CONTENTS

I. Introduction ...................................................................................................................................5

II. Components ...................................................................................................................................6

III. Specications for Test Set Up ...................................................................................................7

IV. Installation ......................................................................................................................................8

V. Operation ..................................................................................................................................... 10

V.1 Theory ......................................................................................................................................................... 10

V.2 Test Procedure .......................................................................................................................................... 10

V.3 Data Gathering ........................................................................................................................................ 11

V.4 Application Examples - Solder Paste ............................................................................................... 12

V.5 Cleaning the Spiral Adapter ................................................................................................................ 12

Appendix A - Spiral Spindle Factors for Torque Measurements .................................................................. 13

Appendix B - Online Help and Additional Resources ..................................................................................... 14

Appendix C - Warranty Repair and Service ......................................................................................................... 15

Page 4

Page 5

I. INTRODUCTION

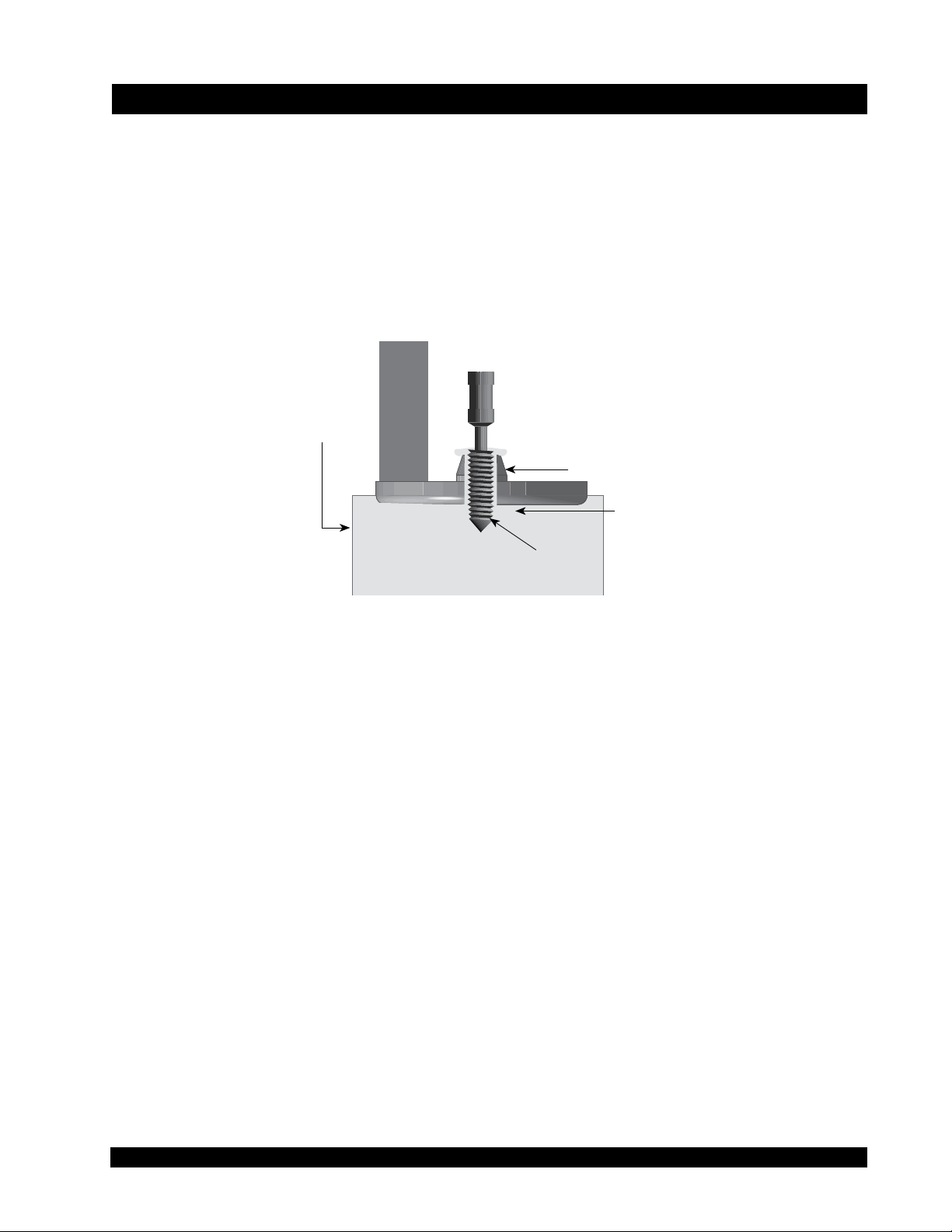

Sample

Material

Paste

Container

Spiral

Chamber

Spiral

Spindle

When used with any Brookeld Viscometer/Rheometer, the Spiral Adapter can measure uid viscosity

at various shear rates. Viscosity is a measure of a uid’s resistance to ow. You will nd a detailed

description of the mathematics of viscosity in the Brookeld publication “More Solutions to Sticky

Problems”, a copy of which was included with your Viscometer/Rheometer and is also available as a

pdf le on the Brookeld website.

The Spiral Adapter has an inner, threaded spindle surrounded by a concentric outer cylinder, as shown in

Figure 1. This combination causes the sample to be continuously pumped up through the gap between

the rotating spindle and the outer cylinder. The material reaches a steady state of ow during which

viscosity is measured.

Figure 1

The principle of viscosity measurement is to drive the spiral spindle (which is immersed in the test

uid) through a calibrated spring in the Viscometer/Rheometer. The viscous drag of the uid against

the spindle is measured by the spring deection.

The measuring range of the Spiral Adapter [in centipoise (cP) or milliPascal seconds (mPa•s)] is

determined by the rotational speed of the spindle, the length and effective diameter of the spindle, the

length and diameter of the chamber the spindle is rotating in, and the full scale torque of the viscometer’s

calibrated spring.

Brookeld Engineering Labs., Inc. Page 5 Manual No. M93-270-D0812

Page 6

II. COMPONENTS

The following components are included in the Spiral Adapter Accessory (part number SAA):

Item Part Number

Two (2) Spindles of identical design SA-70

One (1) Chamber SA-1Y

One (1) Assembly Clamp SA-5Y

One (1) Carrying Case SA-8

One (1) Cleaning Brush SA-4

One (1) Operator Manual M93-270

Please check to be sure that you have received all components, and that there is no damage. If any

parts are missing, please notify Brookeld Engineering or your local Brookeld agent immediately.

Any shipping damage must be reported to the carrier.

SPECIFICATIONS FOR TEST SET UP

Brookeld Engineering Labs., Inc. Page 6 Manual No. M93-270-D0812

Page 7

III. SPECIFICATIONS FOR TEST SET UP

The Spiral Adapter can be used with any Brookeld Viscometer/Rheometer. Selection of the appropriate

Viscometer/Rheometer depends upon the viscosity range of the sample uid over the shear rates at

which it will be tested.

There are four basic spring torque series offered by Brookeld as shown in Table 1. The higher the

torque range, the higher the viscosity measurement range. The corresponding ranges for viscosity

measurement when the spiral spindle is rotating at 1.0 RPM are also shown. Lower spindle speeds are

possible, but the pumping action within the spiral chamber may not be sufcient to provide meaningful

viscosity data.

Spring Torque Spiral Adapter

Viscosity Range

Brookeld

Viscometer/Rheometer

Series Designation

LV 673.7 0.0673 1.0 x 10

RV 7,187.0 0.7187 1.1 x 10

HA 14,374.0 1.4374 2.2 x 10

HB 57,496.0 5.7496 9.0 x 10

dyne-cm milli Newton-m minimum maximum

at 1.0 RPM

cP (mPa·s)

4

5

5

5

1.0 x 10

1.1 x 10

2.2 x 10

9.0 x 10

5

6

6

6

Table 1

Table 2 provides general information on Brookeld Viscometers/Rheometers and the type of data that

can be generated when using the Spiral Adapter.

Measurement accuracy for any viscosity value obtained during a test is ± 2.0% of the full scale viscosity

range (i.e. at 100% torque) for the specic rotational speed in use. See Appendix A for the necessary

information to determine full scale range.

Model Dial DV-E DV-I Series DV-II Series DV-III Series

Speeds 8 18 18 54 2,600

-1

Shear Rate 0.677 sec

per RPM

Signal Options

Torque

Viscosity

Temperature

No

No

No

No

No

No

Yes

No

*

Yes

Yes

Yes

Yes

Yes

Yes

Software No No No Yes Yes

Temperature

Probe

No * Yes

Table 2

Note: At speeds of 1 RPM and lower, additional time may be required to allow for

complete deection of the torque sensor.

* Available as option when ordering instrument.

Brookeld Engineering Labs., Inc. Page 7 Manual No. M93-270-D0812

Page 8

IV. INSTALLATION

Viscometer

Pivot Cup

Pointer Shaft

Clamp

Chamber

Spindle Nut

Spindle

Install the spiral spindle by lifting and holding the pointer shaft of the Viscometer/Rheometer while

screwing the spindle onto it. The threads are left-hand so the spindle must be turned to the left. Gently

lift the chamber over the spindle up against the pivot cup until it rests over the locating shoulder.

While holding the chamber in place, fasten the assembly clamp onto the pivot cup, thereby securing

the chamber in place. The thread in this case is right hand.

See Figure 2 which shows an assembly schematic for the Spiral Adapter.

Figure 2

Turn on the Viscometer/Rheometer and rotate the spindle at various speeds. Observe the spiral spindle

to make sure there is no interference with steady and even rotation. If the spindle does not run “true”,

then inspect the spindle and Viscometer/Rheometer shaft for straightness. Rotate the Viscometer/

Rheometer shaft without the spindle and conrm that the rotation is steady and even.

Notify Brookeld or your authorized Brookeld agent if you experience any difculty in performing

the above procedure.

The spiral spindle code number is 70. If you have a Brookeld digital viscometer or rheometer, which

does not contain this number, you must do the following:

Brookeld Engineering Labs., Inc. Page 8 Manual No. M93-270-D0812

Page 9

• For DV-I and Dial Viscometers, use the torque reading and manually convert to a viscosity

value using the table in Appendix A.

• For DV-II Viscometers, use the spindle 99 entry. Enter the following values:

SMC (Spindle Multiplier Constant) = 105

SRC (Shear Rate Constant) = .677

Note: Customers who use the Brookeld Spiral Adapter may need to have their Brookeld Viscometer/

Rheometer serviced before using this accessory device. All Brookeld digital viscometers/

rheometers with serial number lower than 24250 may not have proper alignment between

bearings and pivot cup. The same applies to all Brookeld dial viscometers.

This does not present any problem for normal Brookeld Viscometer/Rheometer use. However,

it may result in erroneous data when using the Spiral Adapter. For this reason, please return

your Brookeld Viscometer/Rheometer to Brookeld for servicing before using it with the

Spiral Adapter.

Brookeld Engineering Labs., Inc. Page 9 Manual No. M93-270-D0812

Page 10

V. OPERATION

V.1 Theory

The Spiral Adapter has an inner, threaded spindle surrounded by a concentric outer cylinder, as

shown previously in Figure 1. This combination causes the sample to be continuously pumped

up through the gap between the rotating spindle and the outer cylinder. The material reaches a

steady state of ow during which viscosity is measured.

At its various rotating speeds, the Brookeld Viscometer/Rheometer with the Spiral Adapter

provides viscosity data at different shear rates. The resulting rheogram from an up/down speed

ramp supplies important information on the pseudoplastic and thixotropic behavior of the test

material which may correlate with actual use in a process. In addition, the measurement method

may be less sensitive to sample handling and minor material variations than other viscosity

measuring methods.

V.2 Test Procedure

Ensure that the test material has been prepared properly in accordance with your prescribed

procedure. Lower the Spiral Adapter into the test uid as shown in Figure 1.

Start the Viscometer/Rheometer and allow it to run at high speed for quick ooding of the

chamber. This speed will vary with the nature of the test uid, but will typically be between 20

and 60 RPM for 2 to 10 minutes. The speed and time of the ood cycle may be an important

part of the test procedure. This is because the uid in the chamber will experience a shear

history before the start of the test.

When the chamber is ooded, you will observe test uid covering the top of the spindle. Stop

the Viscometer/Rheometer and allow a settling period per your dened procedure. Run the

viscosity test and record the data. An example of a test procedure is as follows:

Speed Duration

50 RPM 6 min.

0 RPM 2 min.

5 RPM 1 min.

10 RPM 1 min.

15 RPM 1 min.

20 RPM 1 min.

30 RPM 1 min.

A strip chart recorder can be used with digital Brookeld Viscometers/Rheometers during the

above procedure. An example of data output is shown in Figure 3.

Brookeld Engineering Labs., Inc. Page 10 Manual No. M93-270-D0812

Page 11

30

20

15

10

30405060

20

5

10

Tim

%

Figure 3

V.3 Data Gathering

Brookeld offers applications software for comprehensive data gathering with any IBM compatible

PC.

Brookeld software will capture and display the following data in tabular and/or graphical

format when used with the appropriate Brookeld Viscometer.

- Viscosity in centipoise (cP) or milliPascal seconds (mPa•s)

- % scale (Brookeld units)

- RPM

- Shear rate (sec-1)

- Shear stress (dynes/cm2 or N/m2)

- Temperature (°F or °C)

The data from a Brookeld dial reading, DV-E or DV-I+ (or DV-I) Viscometer can be manually

entered into one of our software applications.

In addition, the Brookeld Strip Chart Recorder (Model 1201) can be used to obtain a permanent

record of the Viscometer/Rheometer torque signal output, as shown in Figure 3. The Model

1202 can be used to record a second parameter, such as temperature, at the same time.

Contact Brookeld or an authorized dealer for more details on the appropriate software to use

with your viscometer/rheometer.

Brookeld Engineering Labs., Inc. Page 11 Manual No. M93-270-D0812

Page 12

V.4 Application Example - Solder Paste

Applying solder paste is a printing operation that shears the materials as the paste “rolls” on

the stencil surface. Solder paste typically shows pseudoplastic behavior (exponential decrease

in viscosity with increasing shear rate) as shown in Figure 4.

6

LOG VISCOSITY (cP)

10

10

Slope of Line =

Shear Sensitivity Factor

5

1

10 100

LOG RPM

VISCOSITY (cP)

7 x 10

6 x 10

5 x 10

4 x 10

5

5

5

5

05

10 15

20 25 30 35

RPM

40

45

50

55

Figure 4 Figure 5

A plot of viscosity vs. RPM on a log/log scale approximates a straight line as shown in Figure 5.

The slope of the line provides information about the shear thinning of the paste. The absolute

value of the slope is called the “shear sensitivity factor”. Experimental correlations of these

slope values to actual printing properties allow the user to establish acceptable ranges of the

shear sensitivity factor.

The plots shown in Figures 4 and 5 can be generated easily when using Brookeld application

software. There is a math model (IPC Paste Analysis) included in the software which converts

viscosity vs. RPM data (Figure 4) into a log/log plot (Figure 5) and automatically computes

the “shear sensitivity factor.”

V.5 Cleaning the Spiral Adapter

Support the chamber and remove the clamp. Carefully lower the chamber off the spindle. Soak

in appropriate solvent. Remove spindle by lifting the lower shaft and holding it rm. Turn

the spindle nut to the right (counter-clockwise) to remove. Clean by wiping and soaking in

appropriate solvent. A soft brush is provided to aid in cleaning the threads. This brush should

also be cleaned in solvent.

Brookeld Engineering Labs., Inc. Page 12 Manual No. M93-270-D0812

Page 13

APPENDIX A - Spiral Spindle Factors for Torque (% Scale) Measurements

Table A-1 applies to Brookeld Viscometer models with series designation LV, RV, HA, and HB.

The procedure for converting a torque value (% scale) into a viscosity value (cP) is accomplished

by multiplying the appropriate factor shown in Table A-1 by the torque reading on your Brookeld

Viscometer.

Spindle

Spiral Spindle Factors

Speeds

(RPM)

LV RV HA HB

0.3 3,280.0 35,000 70,000 280,000

0.5 1,968.0 21,000 42,000 168,000

0.6 1,640.0 17,500 35,000 140,000

1.0 984.0 10,500 21,000 84,000

1.5 656.0 7,000 14,000 56,000

2.0 492.0 5,250 10,500 42,000

2.5 394.0 4,200 8,400 33,600

3.0 328.0 3,500 7,000 28,000

4.0 246.0 2,625 5,250 21,000

5.0 197.0 2,100 4,200 16,800

6.0 164.0 1,750 3,500 14,000

10.0 98.4 1,050 2,100 8,400

12.0 82.0 875 1,750 7,000

20.0 49.2 525 1,050 4,200

30.0 32.8 350 700 2,800

50.0 19.7 210 420 1,680

60.0 16.4 175 350 1,400

100.0 9.8 105 210 840

Table A-1

The full scale viscosity measurement range (in cP or mPa•s) for any given speed is obtained by multiplying

the corresponding spiral spindle factor in the above table by 100.

Brookeld Engineering Labs., Inc. Page 13 Manual No. M93-270-D0812

Page 14

APPENDIX B - Online Help and Additional Resources

www.brookeldengineering.com**

The Brookeld website is a good resource for additional and self-help whenever you need it. Our

website offers a selection of “how-to” videos, application notes, conversion tables, instructional manuals,

material safety data sheets, calibration templates and other technical resources.

http://www.youtube.com/user/BrookeldEng

Brookeld has its own YouTube channel. Videos posted to our website can be found here as well as

other “home-made” videos made by our own technical sales group.

Viscosityjournal.com

Brookeld is involved with a satellite website that should be your rst stop in viscosity research. This

site serves as a library of interviews with experts in the viscosity eld as well as Brookeld technical

articles and conversion charts. Registration is required, so that you can be notied of upcoming

interviews and events, however, this information will not be shared with other vendors, institutions, etc..

Article Reprints

- Available in Print Only

- Brookeld has an extensive library of published articles relating to viscosity, texture and

powder testing. Due to copyright restrictions, these articles cannot be emailed. Please request

your hardcopy of articles by calling our customer service department directly or by emailing:

marketing@brookeldengineering.com

- Available Online

- Brookeld has a growing number of published articles that can be downloaded directly from

the Brookeld website. These articles can be found on our main site by following this path:

http://www.brookeldengineering.com/support/documentation/article reprints

More Solutions to Sticky Problems

Learn more about viscosity and rheology with our most popular publication. This informative booklet will

provide you with measurement techniques, advice and much more. It’s a must-have for any Brookeld

Viscometer or Rheometer operator. More Solutions is avaiable in print and also as a downloadable pdf

on the Brookeld website by following this path:

http://www.brookeldengineering.com/support/documentation

Training/Courses

Whether it is instrument-specic courses, training to help you better prepare for auditing concerns, or

just a better understanding of your methods, who better to learn from than the worldwide leaders of

viscosity measuring equipment? Visit our Services section on our website to learn more about training.

** Downloads will require you to register your name, company and email address. We respect your

privacy and will not share this information outside of Brookeld.

Brookeld Engineering Labs., Inc. Page 14 Manual No. M93-270-D0812

Page 15

APPENDIX C - Warranty Repair and Service

The Brookeld Spiral Adapter is guaranteed for one year from date of purchase against defects in materials

and workmanship. The Spiral Adapter must be returned to Brookeld Engineering Laboratories, Inc.

or the Brookeld dealer from whom it was purchased for no charge warranty service. Transportation

is at the purchaser’s expense. The Spiral Adapter should be shipped together with all components

originally provided with the system. If returning to Brookeld please contact us for a return authorization

number prior to shipping.

For repair or service in the United States return to:

Brookeld Engineering Laboratories, Inc.

11 Commerce Boulevard

Middleboro, MA 02346 U.S.A.

Telephone: (508) 946-6200 FAX: (508) 923-5009

www.brookeldengineering.com

For repair or service outside the United States consult Brookeld Engineering Laboratories, Inc. or the

dealer from whom you purchased the instrument.

For repair or service in the United Kingdom return to:

Brookeld Viscometers Limited

1 Whitehall Estate

Flex Meadow, Pinnacles West

Harlow, Essex CM19 5TJ, United Kingdom

Telephone: (44) 27/945 1774 FAX: (44) 27/945 1775

www.brookeld.co.uk

For repair or service in Germany return to:

Brookeld Engineering Laboratories Vertriebs GmbH

Hauptstrasse 18

D-73547 Lorch, Germany

Telephone: (49) 7172/927100 FAX: (49) 7172/927105

www.brookeld-gmbh.de

For repair or service in China return to:

Guangzhou Brookeld Viscometers and Texture Instruments Service Company Ltd.

Room C1, 5/F, Tianxing Building East Tower, No. 21, Zhongshan Yi Road, Yuexiu District

Guangzhou, 510600, P. R. China

Telephone: (86) 20/3760-0548 FAX: (86) 20/3760-0548

www.brookeld.com.cn

On-site service at your facility is also available from Brookeld. Please contact our Service

Department in the United States, United Kingdom, Germany or China for details.

Brookeld Engineering Labs., Inc. Page 15 Manual No. M93-270-D0812

Loading...

Loading...