Page 1

Robert Bosch Power Tools GmbH

1 609 92A 4R8

70538 Stuttgart

GERMANY

www.bosch-pt.com

GLM Professional

1 609 92A 4R8 (2019.02) O / 70

100 | 100+R 60

en Original instructions

zh 正本使用说明书

zh 原始使用說明書

ko 사용 설명서 원본

th หนังสือคู่มือการใช้งานฉบับ

ต้นแบบ

id Petunjuk-Petunjuk untuk Penggun-

aan Orisinal

vi Bản gốc hướng dẫn sử dụng

Page 2

2 |

English . . .. .. .. .. .. . .. .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. Page 8

中文 . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 页 17

繁體中文. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. . 頁 25

한국어 .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 페이지 32

ไทย. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. . หน้า 41

Bahasa Indonesia. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. Halaman 51

Tiếng Việt . .. .. .. .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. .. Trang 60

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 3

GLM 250 VF

P

rofessiona

l

GLM 1

0

0

GLM 100

(j)(i)

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(1)

(2)

(3)

(9)

(13)

(15)

(16)

(14)

(17)

(21)

(20)

(22)

(18)

(19)

(8)

(7)

(6)

(5)

(4)

(10)

(11)

(12)

(23)

| 3

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 4

4 |

min

max

1

X

1

1

X

2

1

2

1

XX

1

A

B C

D

E

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 5

| 5

180º 90º 180º

1

2

3

A

B

3

B

2

B

1

F

H

G

I

(24)

(24)

(25)

(3)

(2)

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 6

180º

1

90º

180º

90º

J

K

I

6 |

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 7

1 608 M00 05B

0 601 079 000

2 607 001 391

BT 150

0 601 096 B00

(24)

(26) (27) (28)

| 7

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 8

8 | English

Laser Radiation

Do not stare into beam

Class 2 laser product

English

Safety instructions

All instructions must be

read and observed in order

for the measuring tool to

function safely. The safe-

guards integrated into the

measuring tool may be compromised if the measuring

tool is not used in accordance with these instructions.

Never make warning signs on the measuring tool unrecognisable. SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE AND INCLUDE THEM WITH THE MEASURING

TOOL WHEN TRANSFERRING IT TO A THIRD PARTY.

u Warning! If operating or adjustment devices other

than those specified here are used or other procedures are carried out, this can lead to dangerous exposure to radiation.

The measuring tool is delivered with a warning label

(marked in the illustration of the measuring tool on the

graphics page with number (20)).

u If the text on the warning label is not in your native

language, cover it with the label supplied, which is in

your language, before initial commissioning.

Do not direct the laser beam at persons or

animals and do not look directly into the

laser beam or at its reflection. Doing so

could lead to blindless, or could cause acci-

dents or damage to the eyes.

u If laser radiation hits your eye, you must close your

eyes and immediately turn your head away from the

beam.

u Do not make any modifications to the laser equip-

ment.

u Do not use the laser goggles as protective goggles.

The laser goggles make the laser beam easier to see; they

do not protect you against laser radiation.

u Do not use the laser goggles as sunglasses or while

driving. The laser goggles do not provide full UV protection and impair your ability to see colours.

u Have the measuring tool serviced only by a qualified

specialist using only original replacement parts. This

will ensure that the safety of the measuring tool is maintained.

u Do not let children use the laser measuring tool unsu-

pervised. They could accidentally dazzle someone.

u Do not use the measuring tool in explosive atmo-

spheres which contain flammable liquids, gases or

dust. Sparks may be produced inside the measuring tool,

which can ignite dust or fumes.

Protect the measuring tool against heat,

e.g. including prolonged sun exposure, fire,

water, and moisture. Danger of explosion.

u The battery may give off fumes if it becomes damaged

or is used incorrectly. Ensure the area is well ventilated and seek medical attention should you experience any adverse effects. The fumes may irritate the

respiratory system.

Product Description and Specifications

Intended Use

The measuring tool is intended for measuring distances,

lengths, heights, clearances and inclines, and for calculating

areas and volumes.

The measuring tool is suitable for indoor and outdoor use.

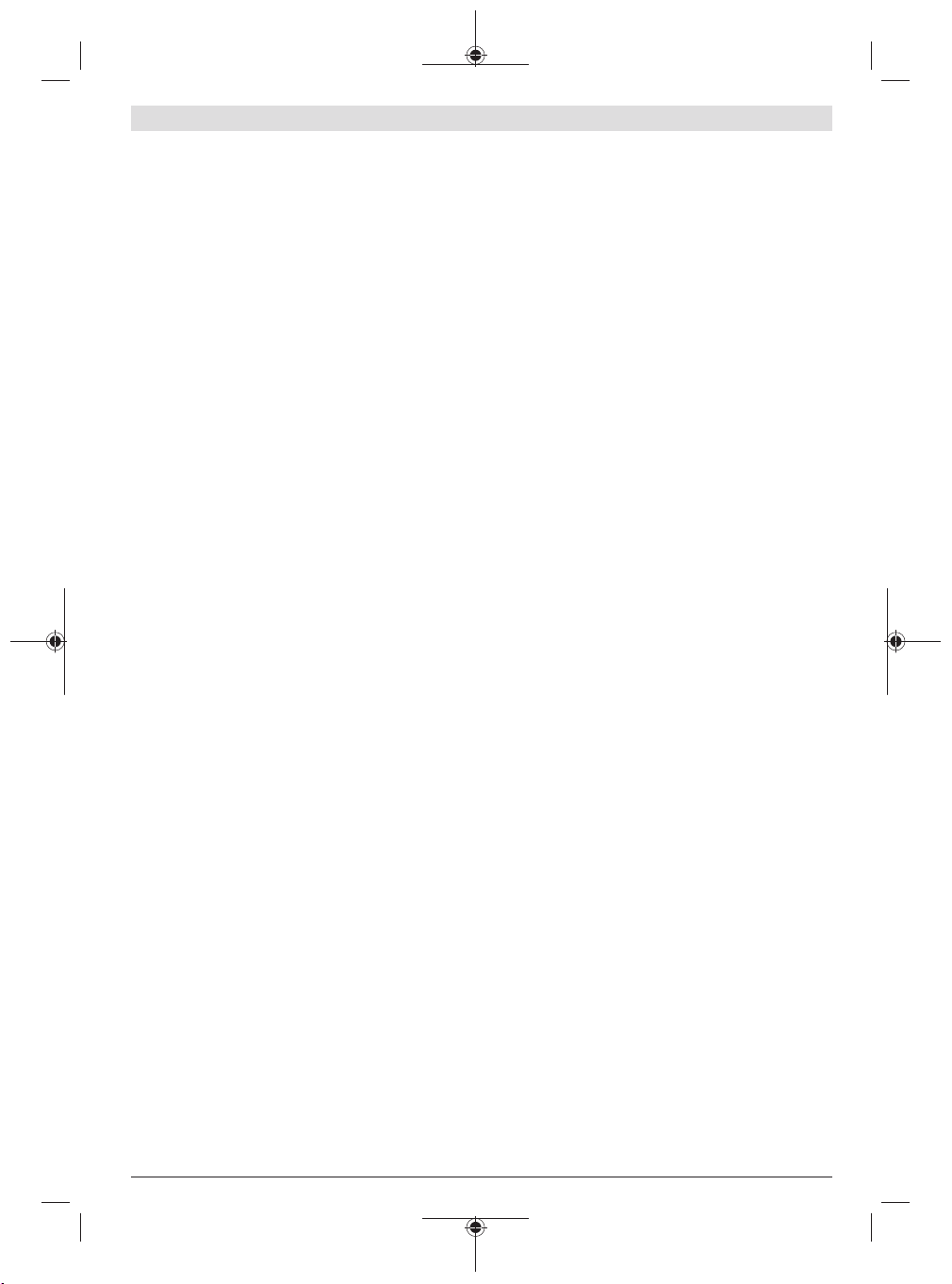

Product features

The numbering of the product features refers to the diagram

of the measuring tool on the graphics page.

Display

(1)

Measuring button

(2)

Button for grade measurement/calibration

(3)

Button for changing function/basic settings

(4)

Minus button

(5)

Button for results/timer function

(6)

Button for list of measured values/saving constant

(7)

Button for memory deletion/switching on or off

(8)

Measuring pin

(9)

Reference level selection button

(10)

Plus button

(11)

Button for distance, area and volume measurement

(12)

Charging socket cover

(13)

Socket for charging connector

(14)

Carrying strap lug

(15)

Laser beam output

(16)

Reception lens

(17)

Serial number

(18)

1/4" thread

(19)

Laser warning label

(20)

Charging connector

(21)

A)

A)

A)

A)

A)

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 9

English | 9

1

1

2

1

Micro USB cable

(22)

Protective bag

(23)

Measuring rail

(24)

Locking lever for measuring bar

(25)

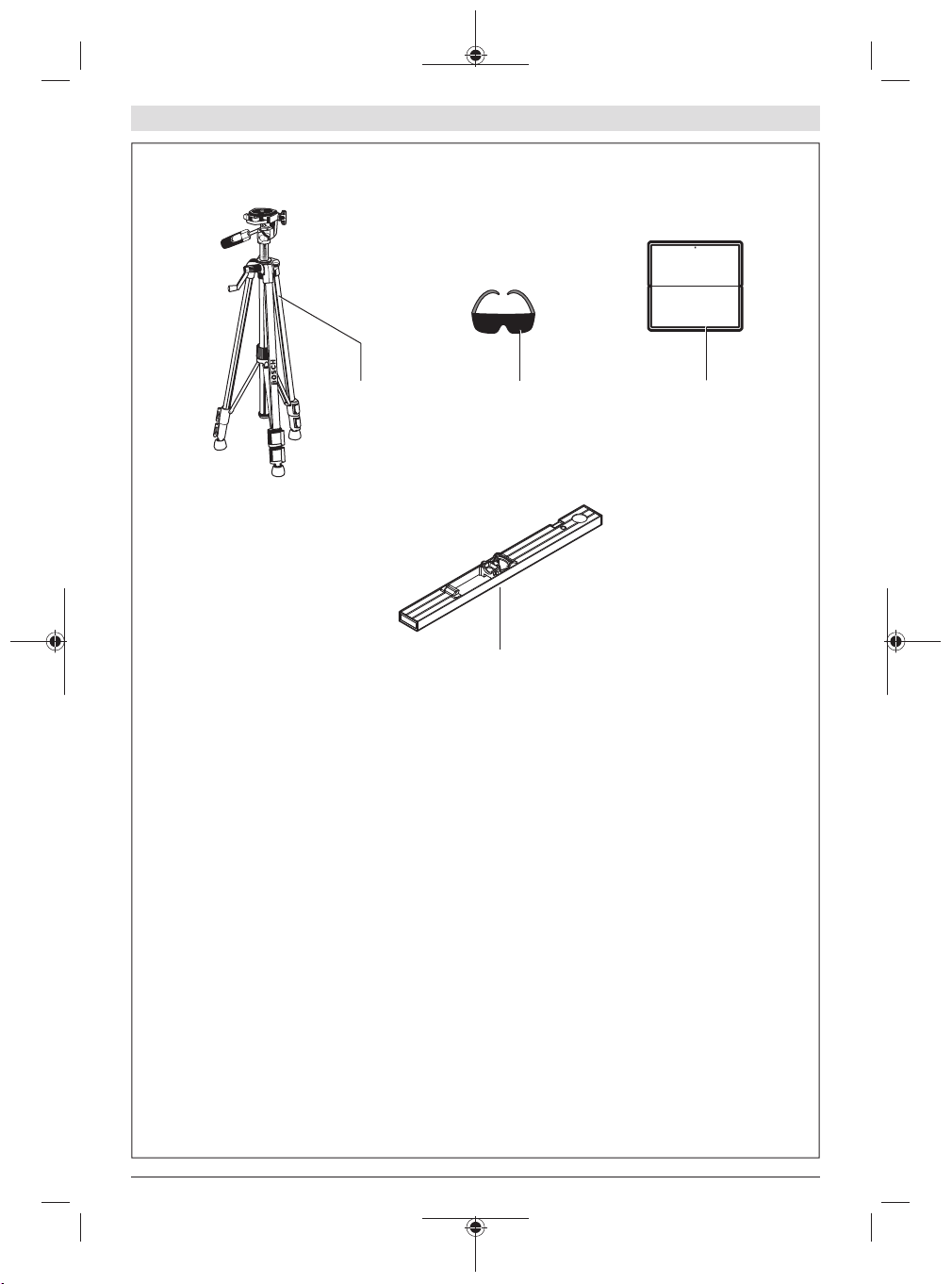

Tripod

(26)

Laser viewing glasses

(27)

Laser target plate

(28)

A)

Press and hold a button to activate its additional function.

B)

Accessories shown or described are not included with the

product as standard.

B)

B)

B)

B)

B)

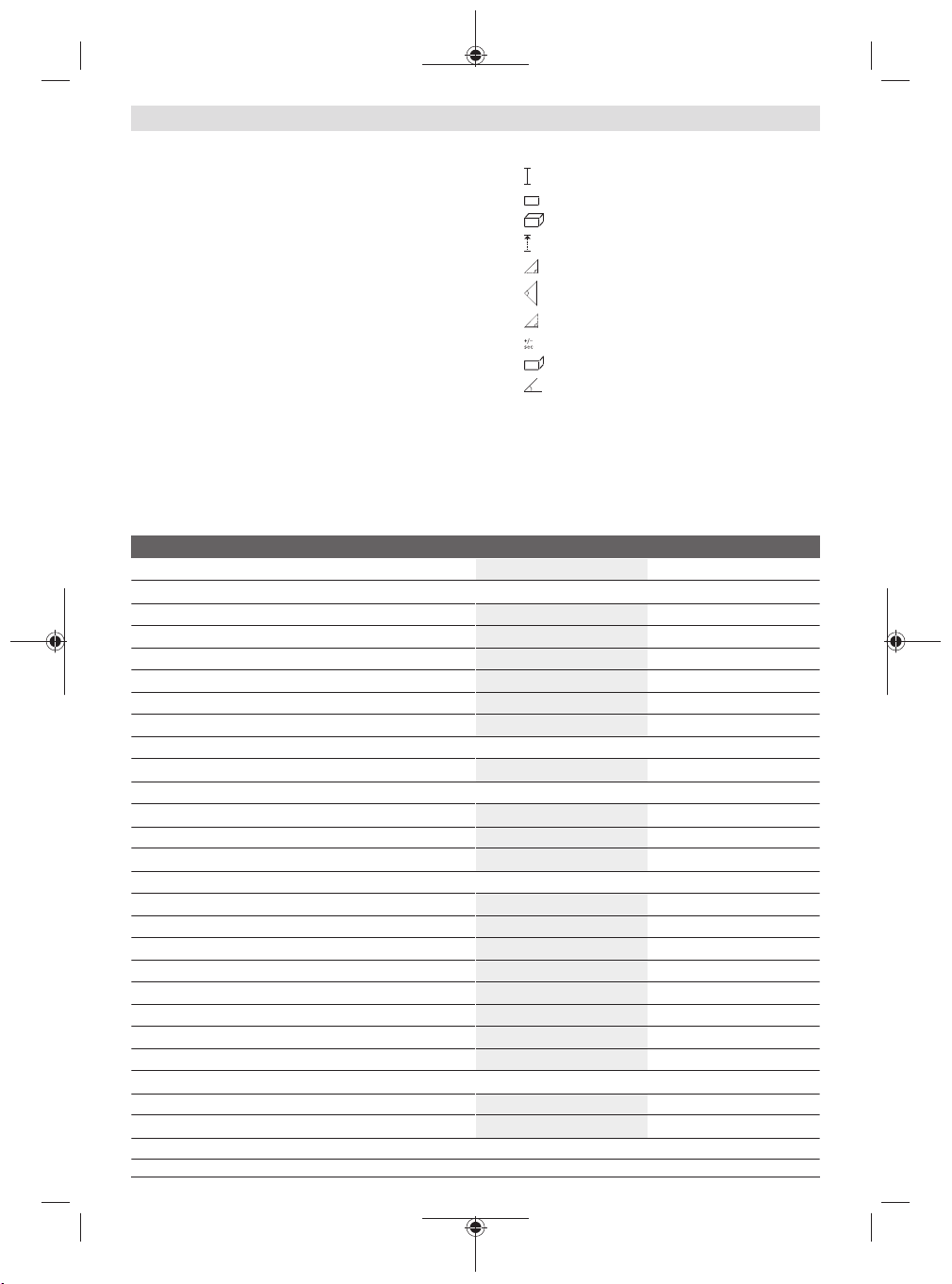

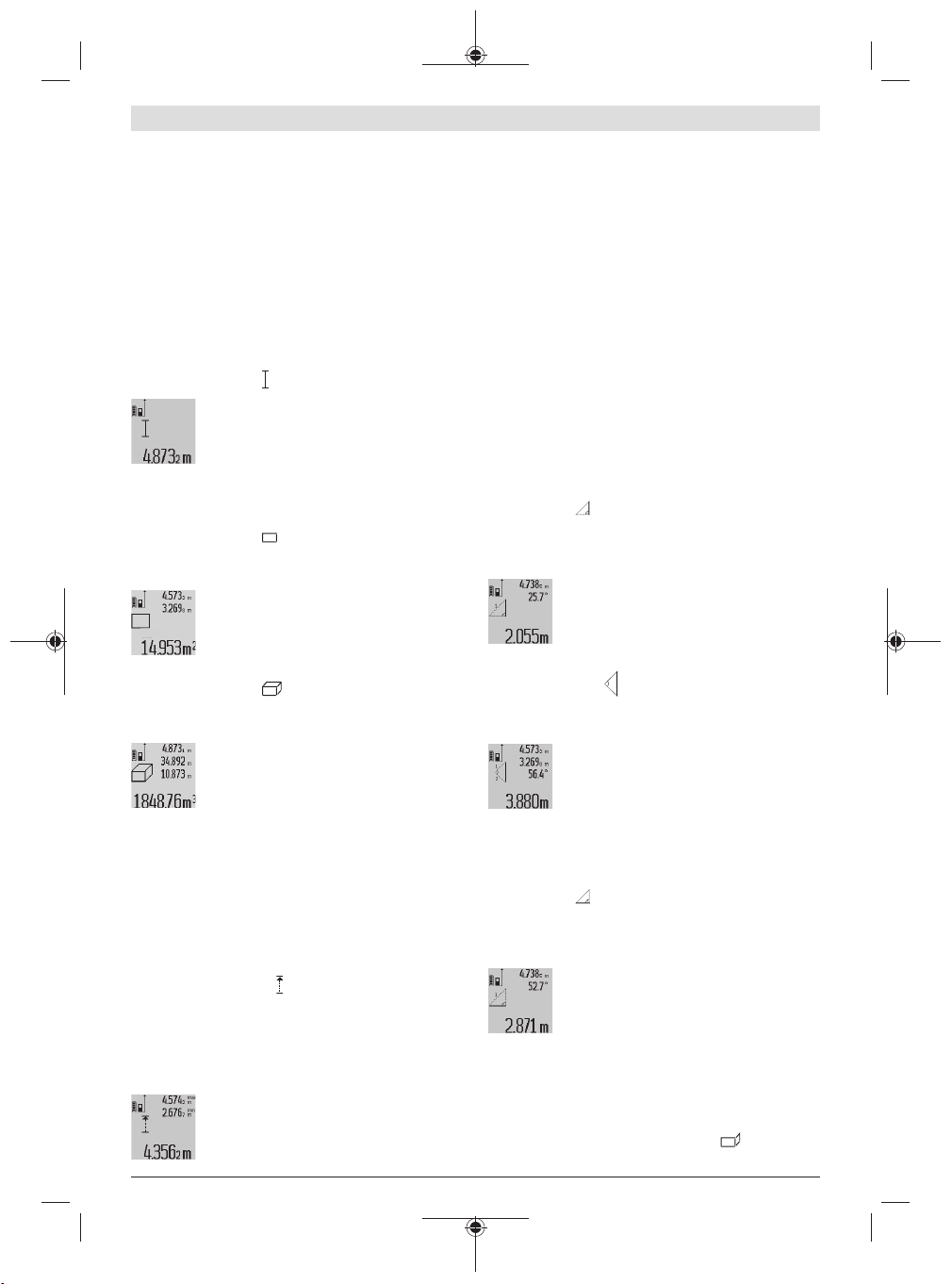

Display elements

Measured value lines

(a)

(b) "ERROR" indicator

Result line

(c)

Digital spirit level/position of measured value list

(d)

entry

Indicator for measured value list

(e)

Measuring functions

(f)

Length measurement

Area measurement

Volume measurement

Continuous measurement

Indirect height measurement

Double indirect height measurement

Indirect length measurement

Timer function

Wall area measurement

Grade measurement

Battery charge indicator

(g)

Laser switched on

(h)

Reference level of measurement

(i)

Temperature warning

(j)

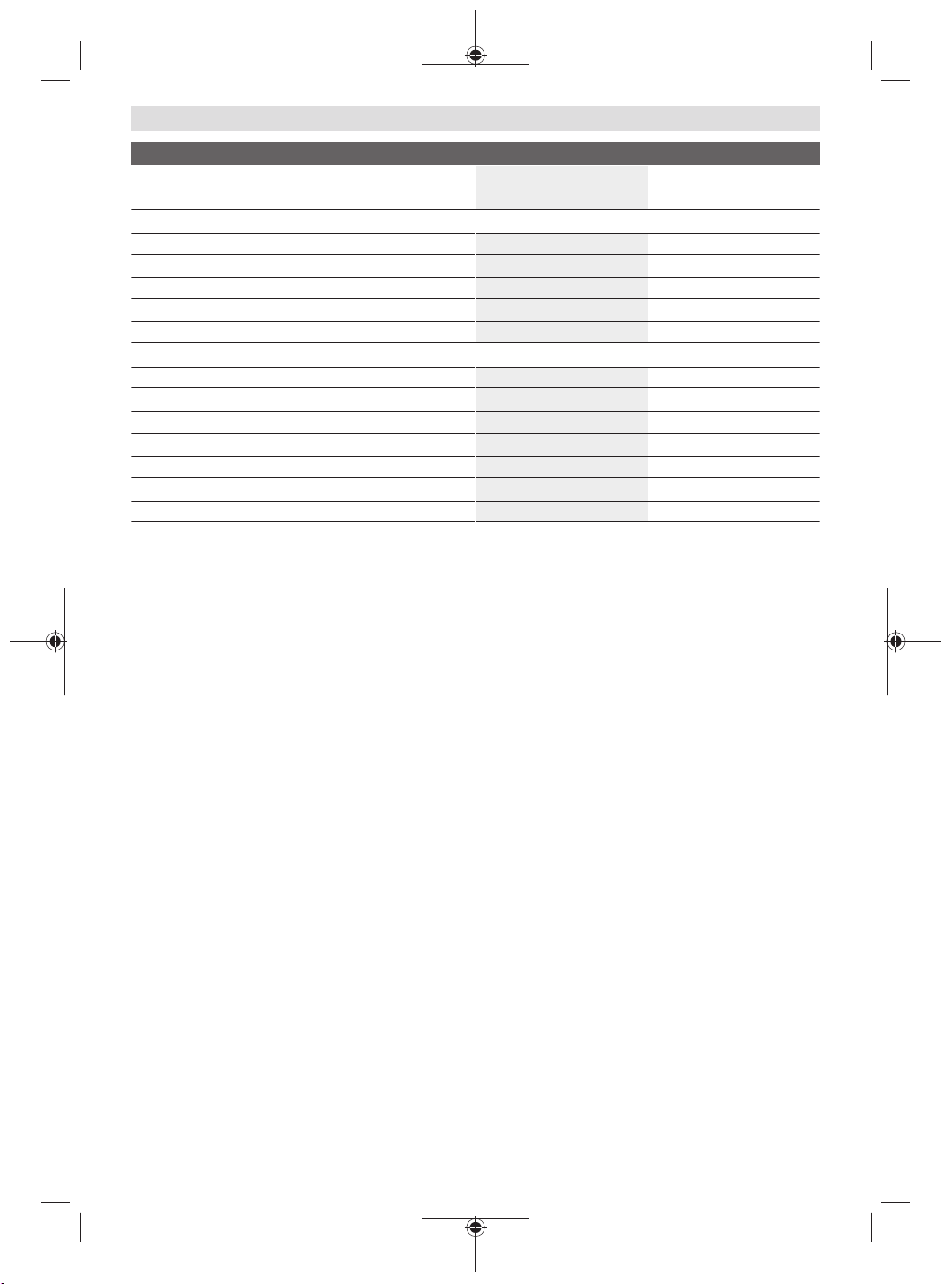

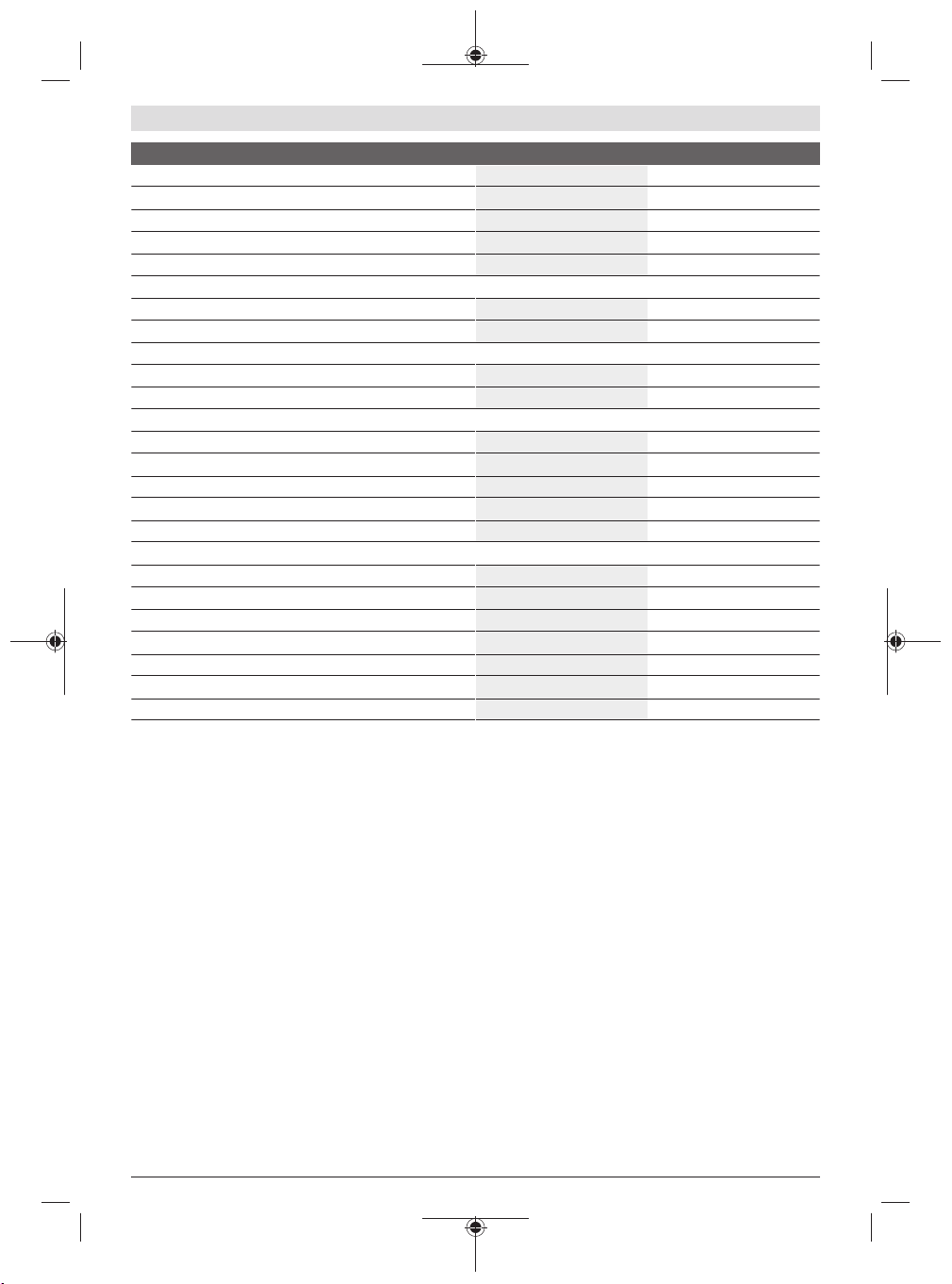

Technical data

Digital laser measure GLM 100 GLM 100+R 60

Article number

Distance measurement

Measuring range (maximum) 100m

Measuring range (typical) 0.05–80m

Measuring range (typical, unfavourable conditions) 35m

Measuring accuracy (typical) ± 1.5mm

Measuring accuracy (typical, unfavourable conditions) ±2.5mm

Smallest display unit 0.1mm 0.1mm

Indirect distance measurement and level

Measuring range -60° to +60° -60° to +60°

Grade measurement

Measuring range 0°–360° (4 x 90°)

Measuring accuracy (typical) 0.2°E)

Smallest display unit 0.1° 0.1°

General

Operating temperature -10°C to +50°C

Storage temperature -20°C to +50°C -20°C to +50°C

Permitted charging temperature range +5°C to +40°C +5°C to +40°C

Relative air humidity max. 90% 90%

Max. altitude 2000m 2000m

Pollution degree according to IEC61010-1 2

Laser class 2 2

Laser type 635 nm, < 1mW 635 nm, < 1mW

Laser beam diameter (at 25°C) approx.

– 10m distance 6mm

– 80m distance 48mm

Adjustment accuracy of the laser to the housing approx.

3 601 K72 P.. 3 601 K72 P..

A)

B)

C)

B)

C)

D)

F)

G)

H)

F)

F)

0°–360° (4 x 90°)

100m

0.05–80m

35m

± 1.5mm

±2.5mm

±0.2°E)

-10°C to +50°C

6mm

48mm

A)

B)

C)

B)

C)

D)

F)

G)

H)

2

F)

F)

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 10

10 | English

Digital laser measure GLM 100 GLM 100+R 60

– Vertical ±2mm/m

– Horizontal ±10mm/m

I)

I)

±2mm/m

±10mm/m

Automatic switch-off after approx.

– Laser 20s 20s

– Measuring tool (without measurement) 5min 5min

Weight according to EPTA-Procedure 01:2014 0.14kg 0.14kg

Dimensions 51 x 111 x 30mm 51 x 111 x 30mm

Protection rating IP 54 (dust and splash-proof) IP 54 (dust and splash-proof)

Measuring rail

Article number –

3 601 K79 000

Dimensions – 58 x 610 x 30mm

Battery Li-ion Li-ion

Rated voltage 3.7V 3.7V

Capacity 1.25Ah 1.25Ah

Number of battery cells 1 1

Individual measurements per battery charge approx. 25000

A) For distances greater than 80m, we recommend using a retroreflective target plate (accessory).

B) For measurements from the front edge of the measuring tool, 100% reflectivity of the target (e.g. a white wall), weak backlighting and 25°C

operating temperature. In addition, a deviation influence of ± 0.05mm/m needs to be taken into account.

C) For measurements from the rear edge of the measuring tool, 10–100 % reflectivity of the target, strong backlighting and 25°C operating

temperature. In addition, a deviation influence of ± 0.29mm/m needs to be taken into account.

D) For measurements that use the back of the device as a reference, the max. measuring range amounts to ± 60°

E)

After calibration in accordance with figure H. Additional pitch error of ± 0.01°/degree up to 45°.

F) The width of the laser line depends on the surface characteristics and on the ambient conditions.

G) In continuous measurement mode, the max. operating temperature is +40 °C.

H) Only non-conductive deposits occur, whereby occasional temporary conductivity caused by condensation is expected.

I) At 25°C

J) For a new and charged battery without display illumination and sound.

The serial number (18) on the type plate is used to clearly identify your measuring tool.

J)

25000

I)

I)

J)

Assembly

Battery charging

The battery can be charged from a USB port or USB power

supply (min. 500mA) by using the micro USB cable.

Recommendations for optimal handling of the battery

Only store the battery in the permitted temperature range

(see "Technical data"). Do not leave the battery in your car in

the summer, for example.

A significantly reduced operating time after charging indicates that the battery has deteriorated and must be replaced.

Follow the instructions on correct disposal.

do not leave it in a car for extended periods of time. In

case of large variations in temperature, allow the measuring tool to adjust to the ambient temperature before putting it into operation. The precision of the measuring tool

may be compromised if exposed to extreme temperatures or variations in temperature.

u Avoid substantial knocks to the measuring tool and

avoid dropping it. Always carry out an accuracy check

before continuing work if the measuring tool has been

subjected to severe external influences (see "Checking

accuracy and calibrating the grade measurement (see figureH)", page14) and (see "Accuracy check of the distance measurement", page14).

Switching on/off

Operation

Start-Up

u Protect the measuring tool from moisture and direct

sunlight.

u Do not expose the measuring tool to any extreme tem-

u Never leave the measuring tool unattended when

switched on, and ensure the measuring tool is

switched off after use. Others may be dazzled by the

laser beam.

The following options are available for switching on the

measuring tool:

peratures or variations in temperature. For example,

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 11

English | 11

– Pressing the on/off button (8): The measuring tool is

switched on in the length measurement function. The

laser is not switched on.

– Pressing the measuring button (2): Measuring tool and

laser are switched on. The measuring tool will be in the

length measurement function. When the measuring tool is

inserted in the measuring rail (24), the grade measurement function is activated.

u Do not direct the laser beam at persons or animals and

do not stare into the laser beam yourself (even from a

distance).

To switch off the measuring tool, press and hold the on/off

button (8).

If no button on the measuring tool is pressed for approx. five

minutes, then the measuring tool will automatically switch itself off to preserve battery life.

If the angle has not been changed for approx. five minutes

while the measuring tool is in the "grade measurement" operating mode, the tool will automatically switch itself off to preserve battery life.

All saved values are retained when the tool is automatically

switched off.

Measuring process

After the measuring tool has been switched on by pressing

the measuring button (2), the tool is always in the length

measurement function by default, or in the grade measurement function if the tool has been inserted into the measuring rail (24). Other measuring functions can be switched to

by pressing the respective function button (see "Measuring

functions", page12).

Once the measuring tool has been switched on, the rear

edge of the measuring tool is selected as the reference level

for measurement. You can change the reference level by

pressing the reference level selection button(10) (see "Selecting the reference level (see figureA)", page11).

Apply the measuring tool with the selected reference level to

the point at which you want to start the measurement (e.g.

wall).

To switch on the laser beam, briefly press the measuring button (2).

u Do not direct the laser beam at persons or animals and

do not stare into the laser beam yourself (even from a

distance).

Aim the laser beam at the target surface. To initiate the

measurement, briefly press the measuring button (2) again.

While the laser beam is continuously switched on, measurement will begin after the first press of the measuring button

(2). In the continuous measurement function, measurement

begins as soon as the function is activated.

The measured value typically appears within 0.5 seconds

and no later than 4 seconds. The duration of the measurement depends on the distance, the lighting conditions and

the reflective properties of the target surface. The end of the

measurement is indicated by an audio signal. Upon completion of the measurement, the laser beam is automatically

switched off.

If no measurement has been performed within approx.

20seconds of aim being taken, the laser beam is switched

off automatically to preserve battery life.

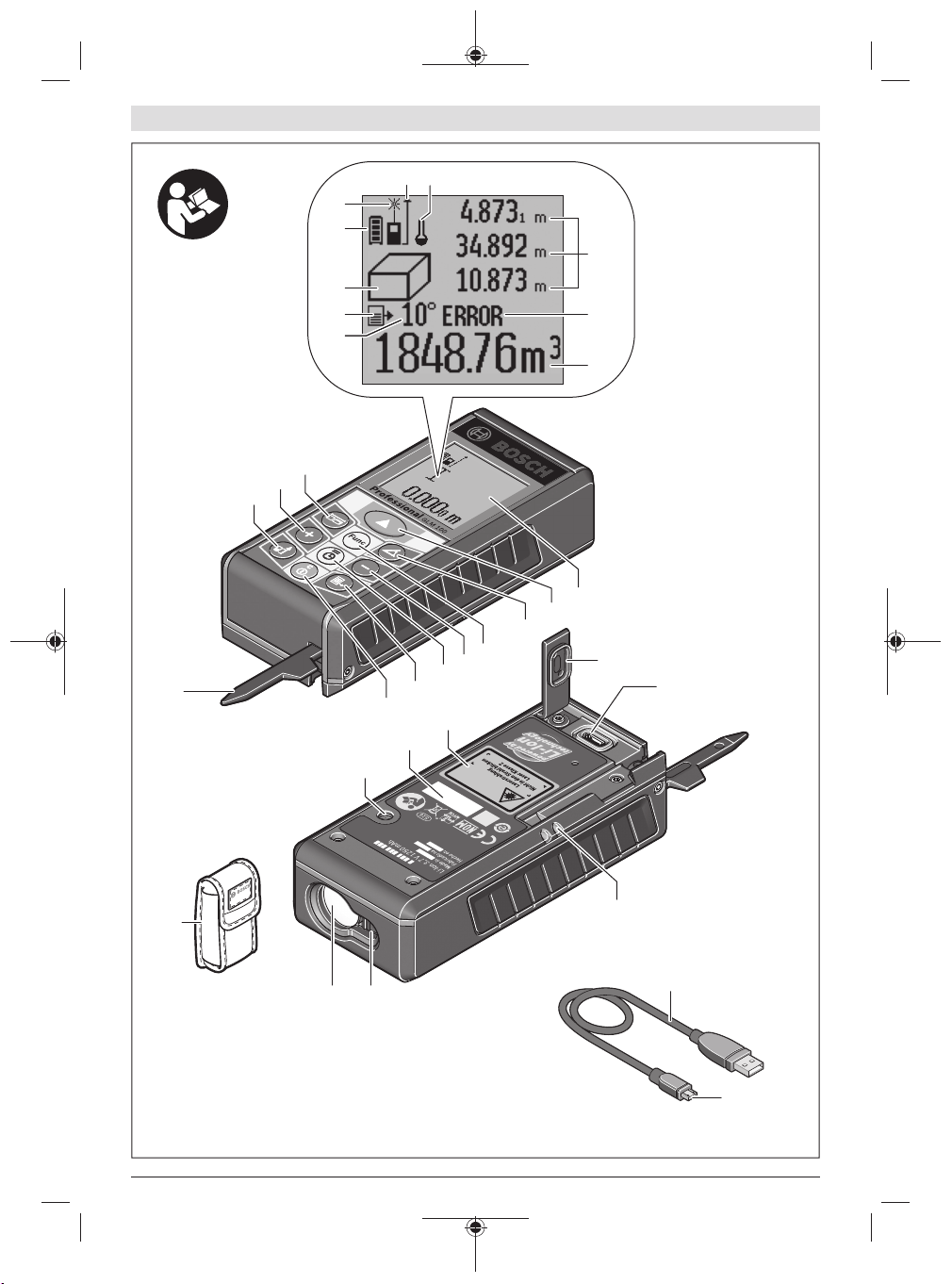

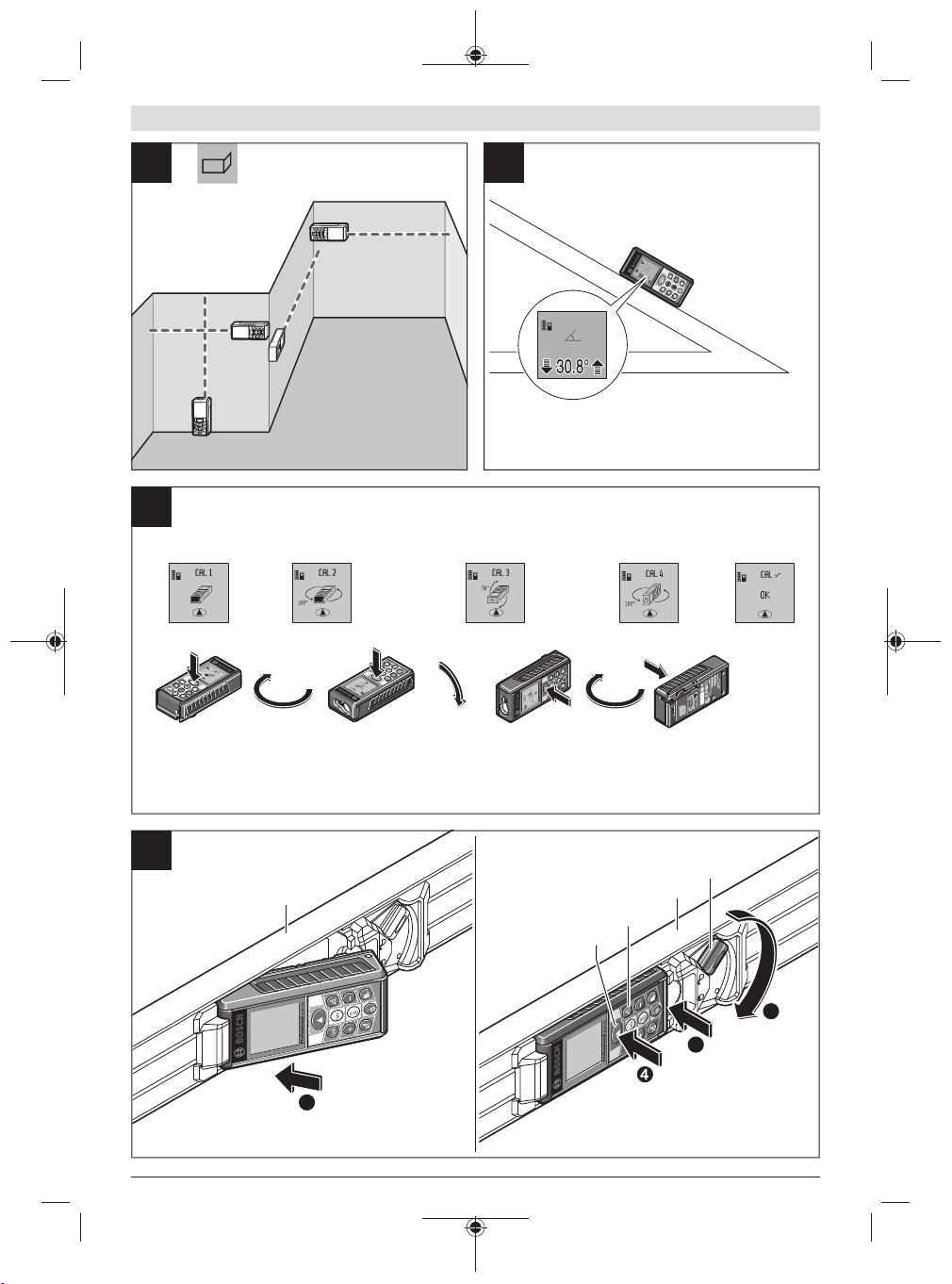

Selecting the reference level (see figureA)

You can choose between four different reference levels for

the measurement:

– The rear edge of the measuring tool or the front edge of

the measuring pin (9) when it has been folded out by 90°

(e.g. when applying the tool to outer corners)

– The tip of the measuring pin (9) when it has been folded

180° (e.g. when measuring from a corner)

– The front edge of the measuring tool (e.g. when measur-

ing from a table edge)

– The centre of the thread (19) (e.g. for tripod measure-

ments)

To select the reference level, press the button (10) until the

required reference level is shown on the display. The rear

edge of the measuring tool is pre-set as the reference level

every time the measuring tool is switched on.

It is not possible to make a retrospective alteration to the reference level for measurements that have already been taken

(e.g. when displaying measured values in the measured

value list).

Basic settings menu

To enter the basic settings menu, press and hold the button

for basic settings (4).

Briefly press the basic settings button (4) to select the individual menu items.

Press the minus button (5) or the plus button (11) to select

the setting within the menu items.

To exit the basic settings menu, press the measuring button

(2).

Basic settings

Audio signals On

Off

Display illumination On

Off

Automatically

on/off

Digital spirit level On

Off

Display rotation On

Off

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 12

12 | English

Basic settings

Continuous laser beam On

Off

Unit of distance (depending

m, ft, inch, etc.

on country version)

Unit for angle °, %, mm/m,

inch/ft

All basic settings except for the continuous laser beam setting are saved when switching off the tool.

Continuous laser beam

u Do not direct the laser beam at persons or animals and

do not stare into the laser beam yourself (even from a

distance).

In this setting, the laser beam remains switched on even

between measurements; measurement simply requires one

brief press of the measuring button (2).

Measuring functions

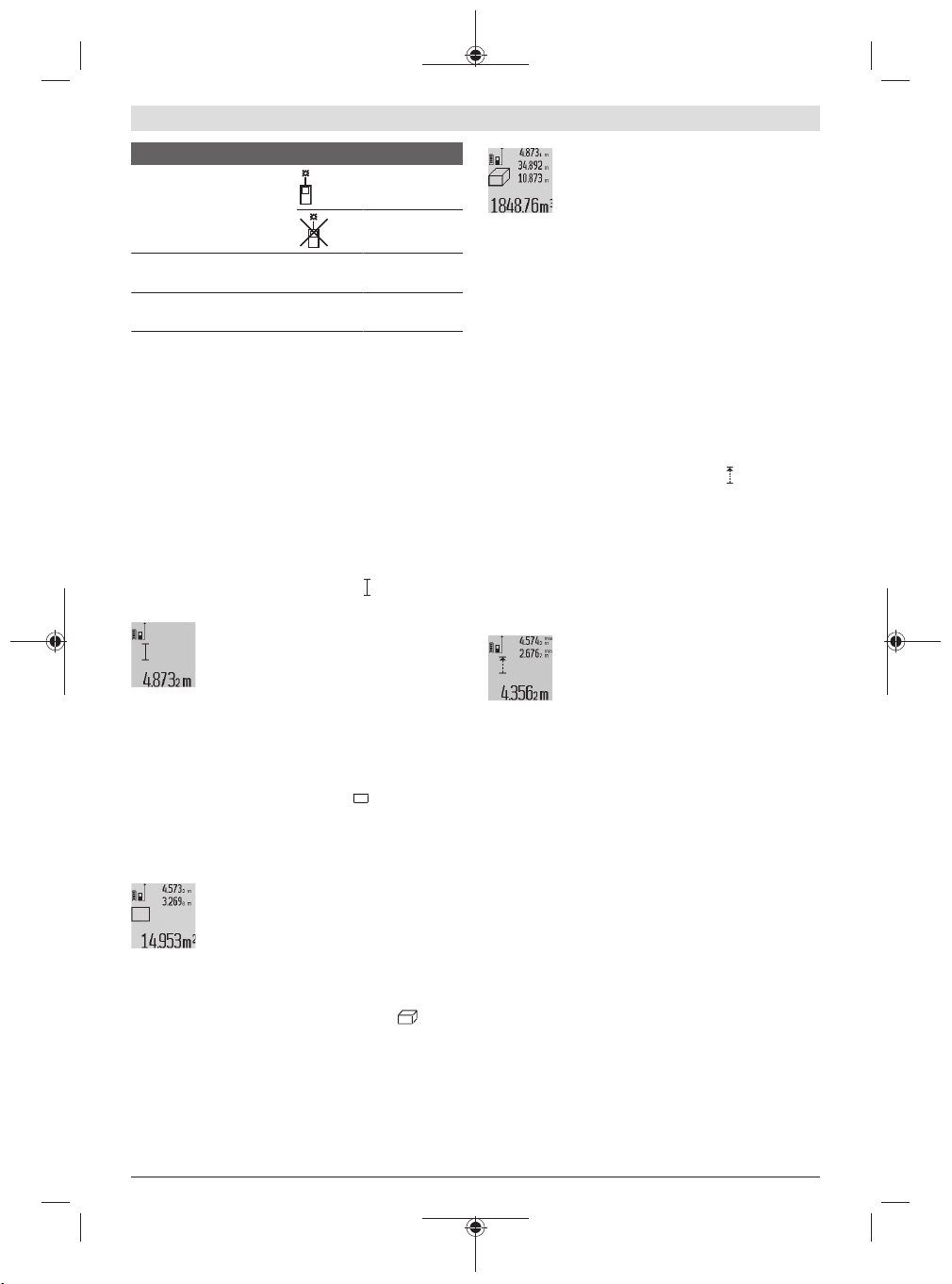

Simple length measurement

For length measurements, repeatedly press the button (12)

until the indicator for length measurement appears on the

display.

Briefly press the measuring button (2) once to

switch on the laser and once to measure.

The measured value is displayed in the result

line (c).

For multiple consecutive length measurements, the results

of the last measurements are shown in the measured value

lines (a).

Area measurement

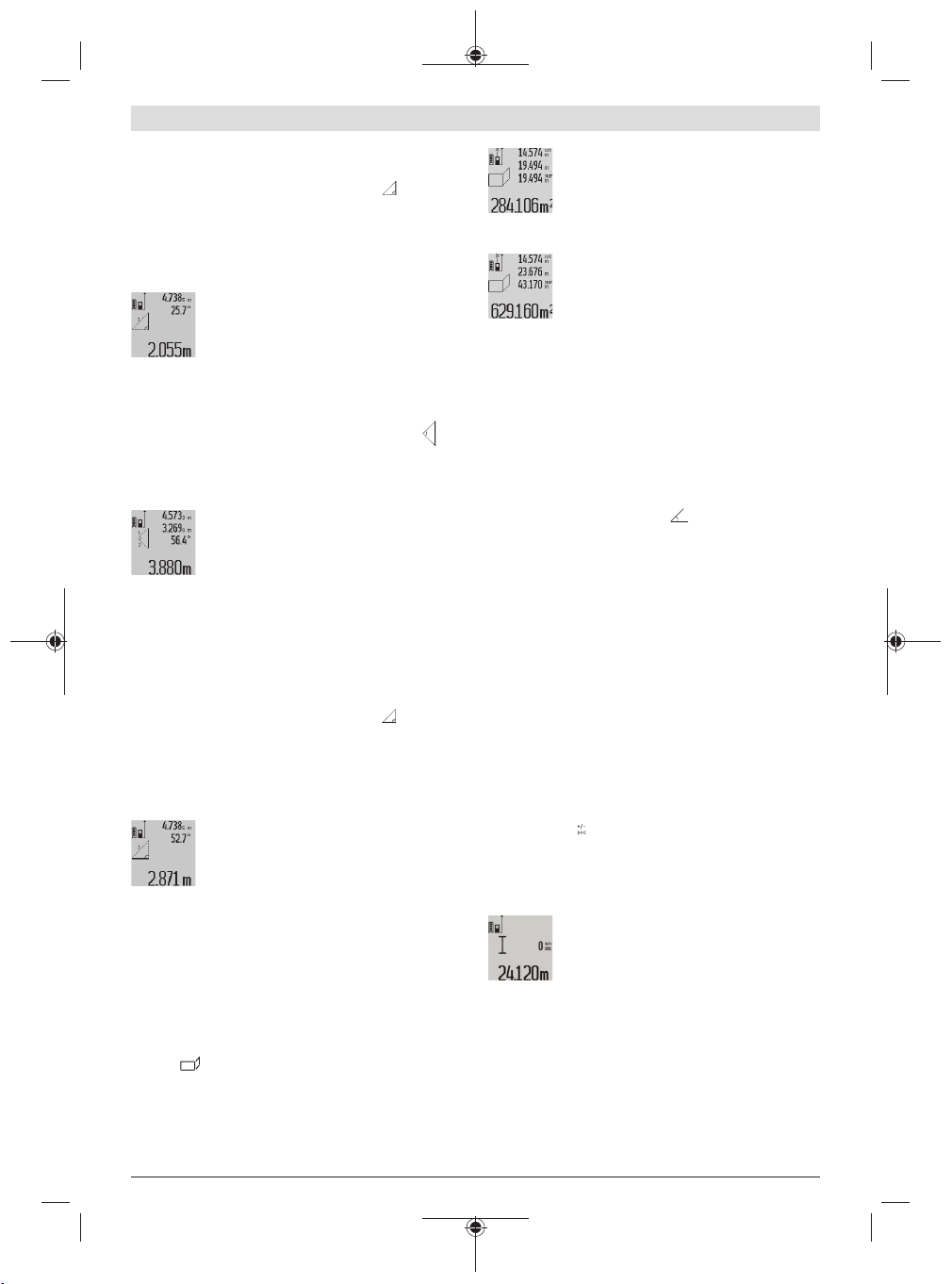

For area measurements, repeatedly press the button (12)

until the indicator for area measurement appears on the

display.

Then measure the width and length one after the other as

with a length measurement. The laser beam remains

switched on between the two measurements.

Once the second measurement has been completed, the area is automatically calculated and

displayed in the result line (c). The individual

measured values can be found in the measured

value lines (a).

Volume measurement

For volume measurements, repeatedly press the button

(12) until the indicator for volume measurement ap-

pears on the display.

Then measure the width, length and depth one after the

other as with a length measurement. The laser beam remains

switched on between the three measurements.

Once the third measurement has been completed, the volume is automatically calculated

and displayed in the result line (c). The individual measured values can be found in the

measured value lines (a).

Values over 999,999m3 cannot be displayed; "ERROR" will

instead appear on the display. Divide the volume to be measured into individual measurements, the resulting values of

which you can calculate separately and then combine into an

overall total.

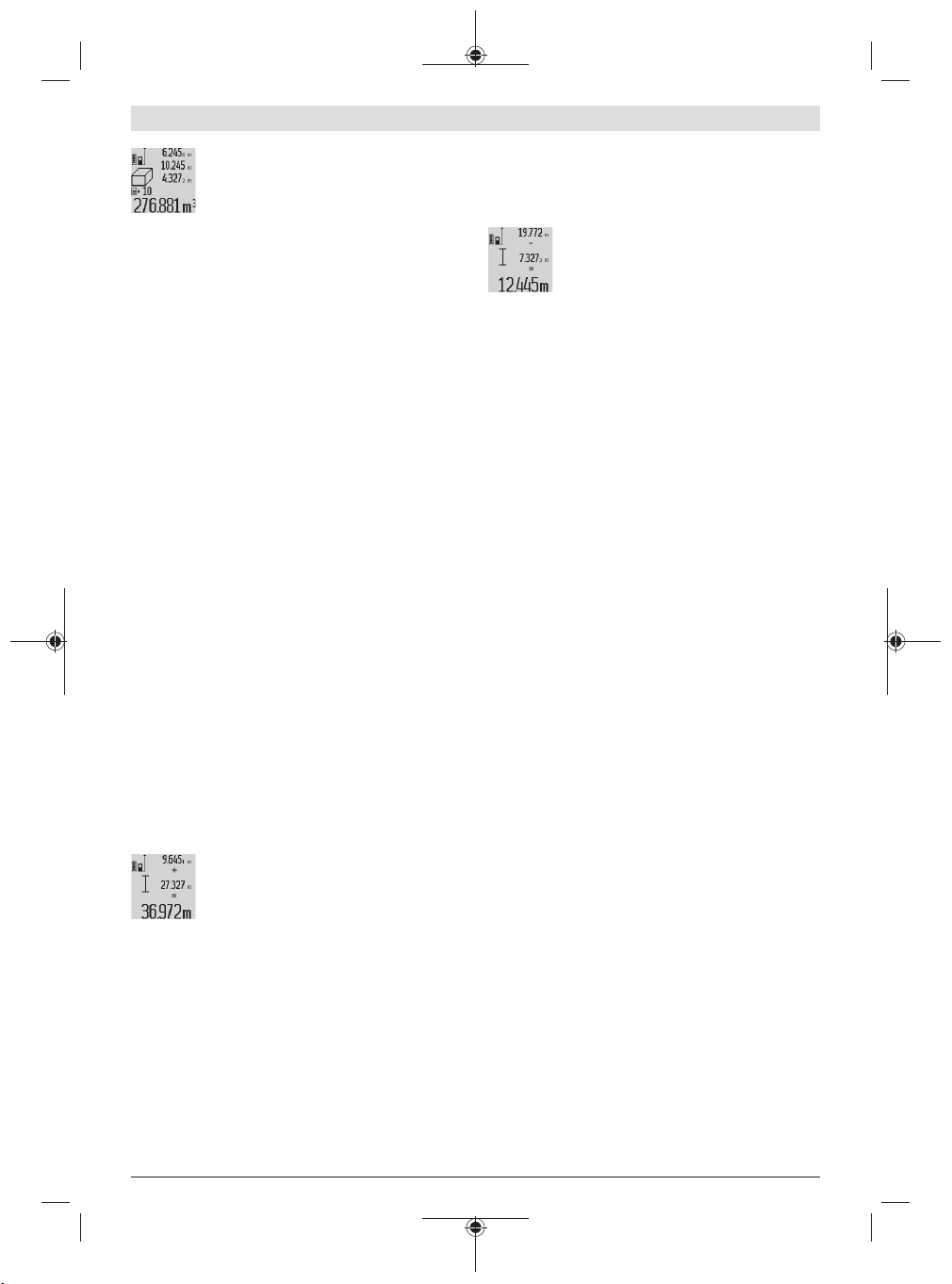

Continuous measurement and minimum/maximum

measurement (see figureB)

In continuous measurement mode, the measuring tool can

be moved relative to the target, during which the measured

value will be updated every half a second. You can, for example, move a desired distance away from a wall while reading off the current distance at all times.

For continuous measurements, repeatedly press the button

for changing function (4) until the indicator for continuous

measurement appears on the display. To start the continuous measurement, press the measuring button (2).

The minimum measurement is used to determine the

shortest distance from a fixed reference point. For example,

it can help in determining verticals or horizontals.

The maximum measurement is used to determine the

greatest distance from a fixed reference point. For example,

it can help in determining diagonals.

The current measured value is shown in the

result line (c). The maximum ("max") and minimum ("min") measured value appear in the

measured value lines (a). It is then always

overwritten if the current length measurement

value is smaller or larger than the previous minimum or maximum value.

Press the memory deletion button (8) to erase the previous

minimum or maximum values.

Press the measuring button (2) to end the continuous measurement. The last measured value is displayed in the result

line (c). Pressing the measuring button (2) again starts a

new continuous measurement.

Continuous measurement automatically switches off after

fiveminutes. The last measured value remains displayed in

the result line (c).

Indirect distance measurement

The indirect distance measurement is used to determine distances that cannot be measured directly, due to an obstacle

that would impede the path beam or the absence of a target

surface that could serve as a reflector. This measuring procedure can only be employed vertically. Any horizontal deviation will lead to measurement errors.

The laser beam remains switched on between the individual

measurements.

For indirect length measurements, three measuring modes

are available. Each measuring mode can be used for determining different distances.

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 13

English | 13

1

2

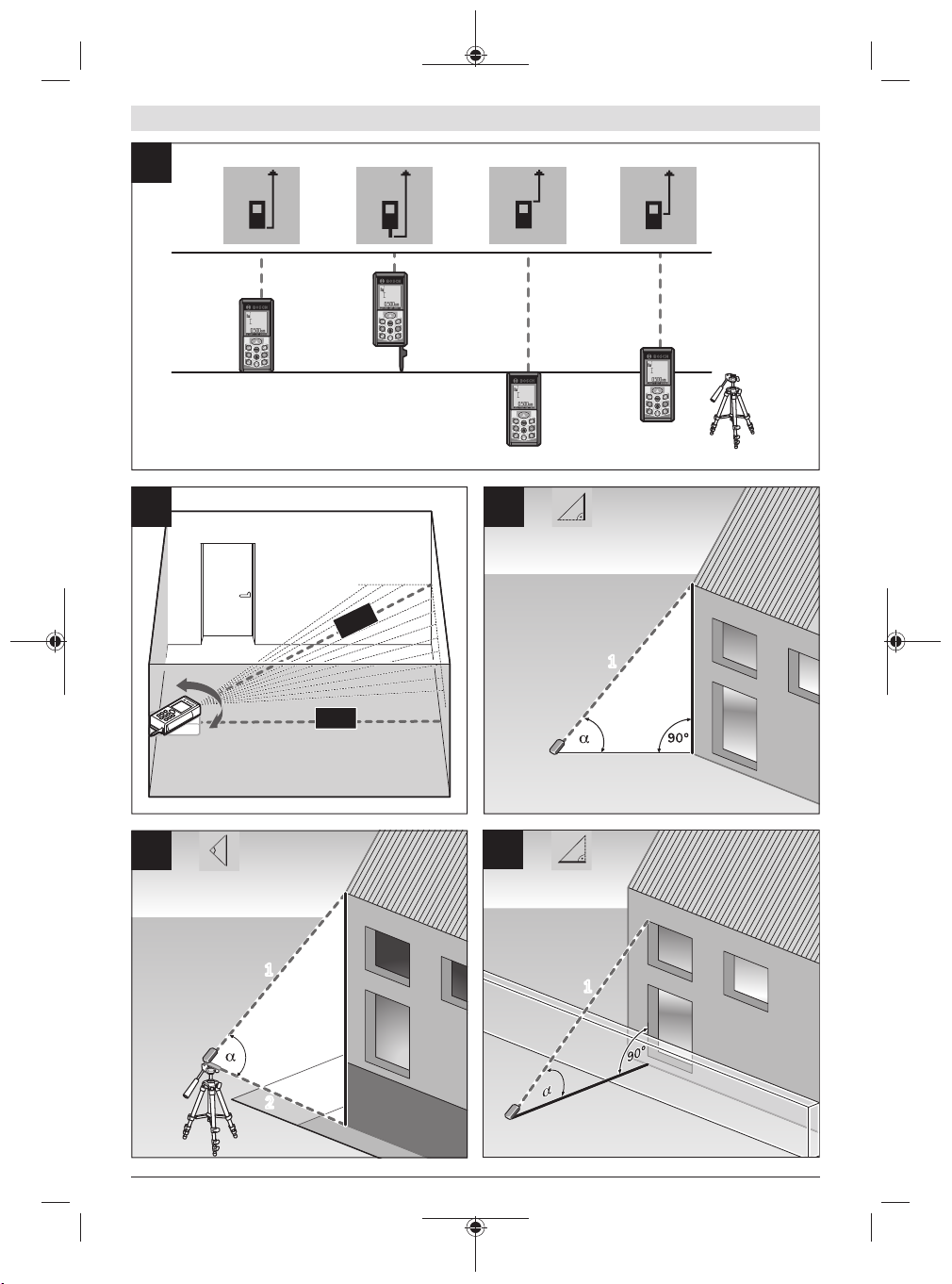

a) Indirect height measurement (see figureC)

Repeatedly press the button for changing function (4) until

the indicator for indirect height measurement 1 appears on

the display.

Ensure that the measuring tool is at the same height as the

lower measuring point. Then tilt the measuring tool around

the reference level and measure distance (1) as for a length

measurement.

Once the measurement is complete, the result

for the required distance "X" is displayed in

the result line (c). The measured values for distance "1" and angle "α" can be found in the

measured value lines (a).

b) Double indirect height measurement (see figureD)

Repeatedly press the button for changing function (4) until

the indicator for double indirect height measurement

ap-

pears on the display.

Measure distances "1" and "2" in succession as for a length

measurement.

Once the measurement is complete, the result

for the required distance "X" is displayed in

the result line (c). The measured values for distances "1" and "2" and angle "α" can be found

in the measured value lines (a).

Ensure that the reference level for the measurement (e.g.

the rear edge of the measuring tool) remains in exactly the

same place for all the individual measurements in a single

measuring process.

a) Indirect length measurement (see figureE)

Repeatedly press the button for changing function (4) until

the indicator for indirect length measurement 1 appears on

the display.

Ensure that the measuring tool is at the same height as the

required measuring point. Then tilt the measuring tool

around the reference level and measure distance "1" as for a

length measurement.

Once the measurement is complete, the result

for the required distance "X" is displayed in

the result line (c). The measured values for distance "1" and angle "α" can be found in the

measured value lines (a).

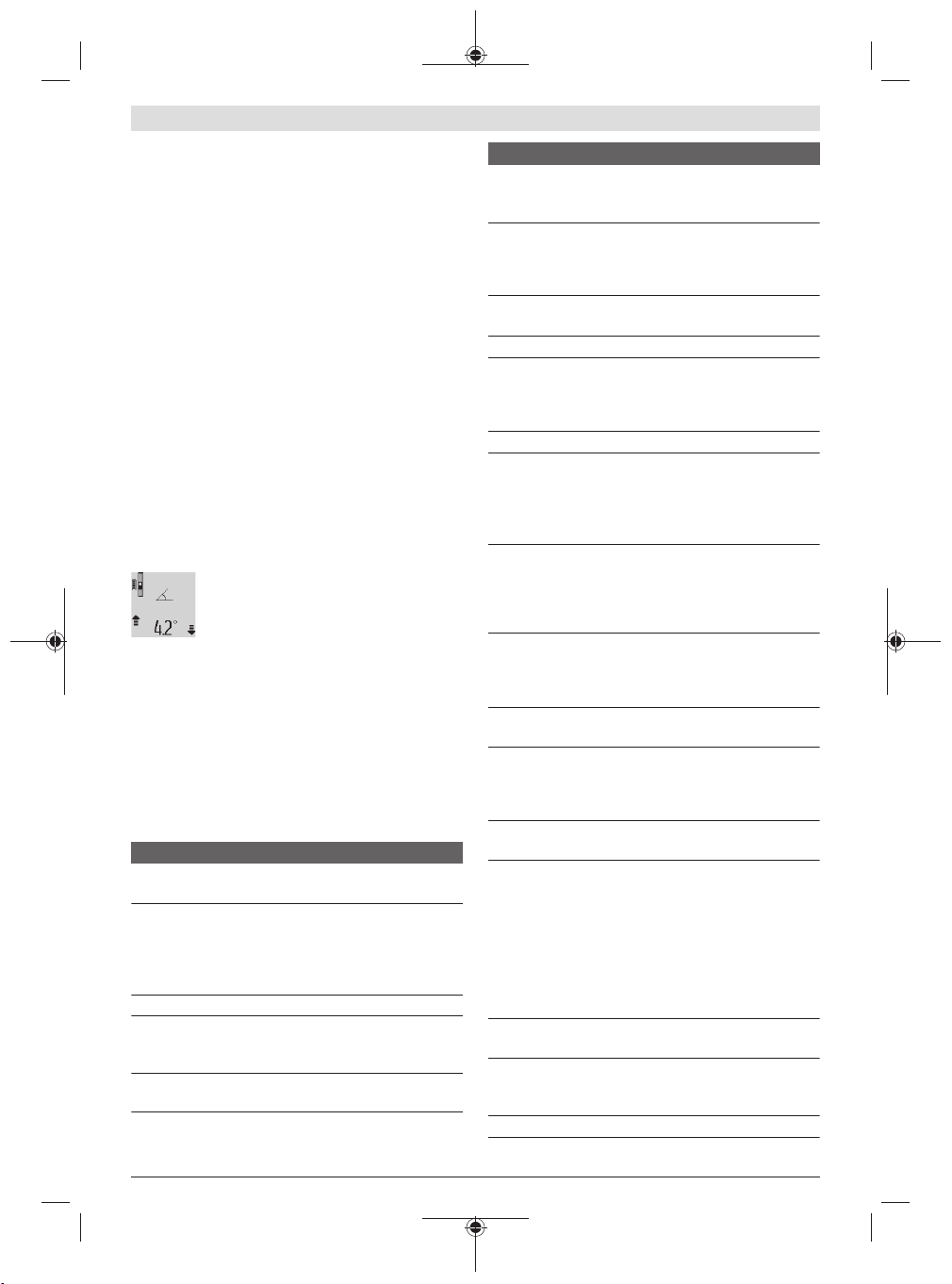

Wall area measurement (see figureF)

The wall area measurement is used to determine the sum of

multiple individual areas with a common height.

In the illustrated example, the total area of several walls that

have the same ceiling height A but different lengths B is to

be determined.

For wall area measurements, repeatedly press the button for

changing function (4) until the indicator for wall area measurement appears on the display.

Measure the ceiling height A as with a length measurement.

The measured value ("cst") is displayed in the top measured

value line (a). The laser remains switched on.

Then measure the length B1 of the first wall.

The area is automatically calculated and dis-

played in the result line (c). The last measured

value for length can be found in the middle

measured value line.(a). The laser remains

switched on.

Now measure the length B2 of the second wall.

The individual measured value displayed in the

middle measured value line (a) is added to the

length B1. The sum of the two lengths ("sum",

displayed in the bottom measured value line

(a)) is multiplied by the saved height A. The total area value

is displayed in the result line (c).

You can measure any number of lengths Bx, which will be

automatically added and multiplied by the height A.

The requirement for a correct area calculation is that the first

measured length (for example the ceiling height A) is

identical for all sub-areas.

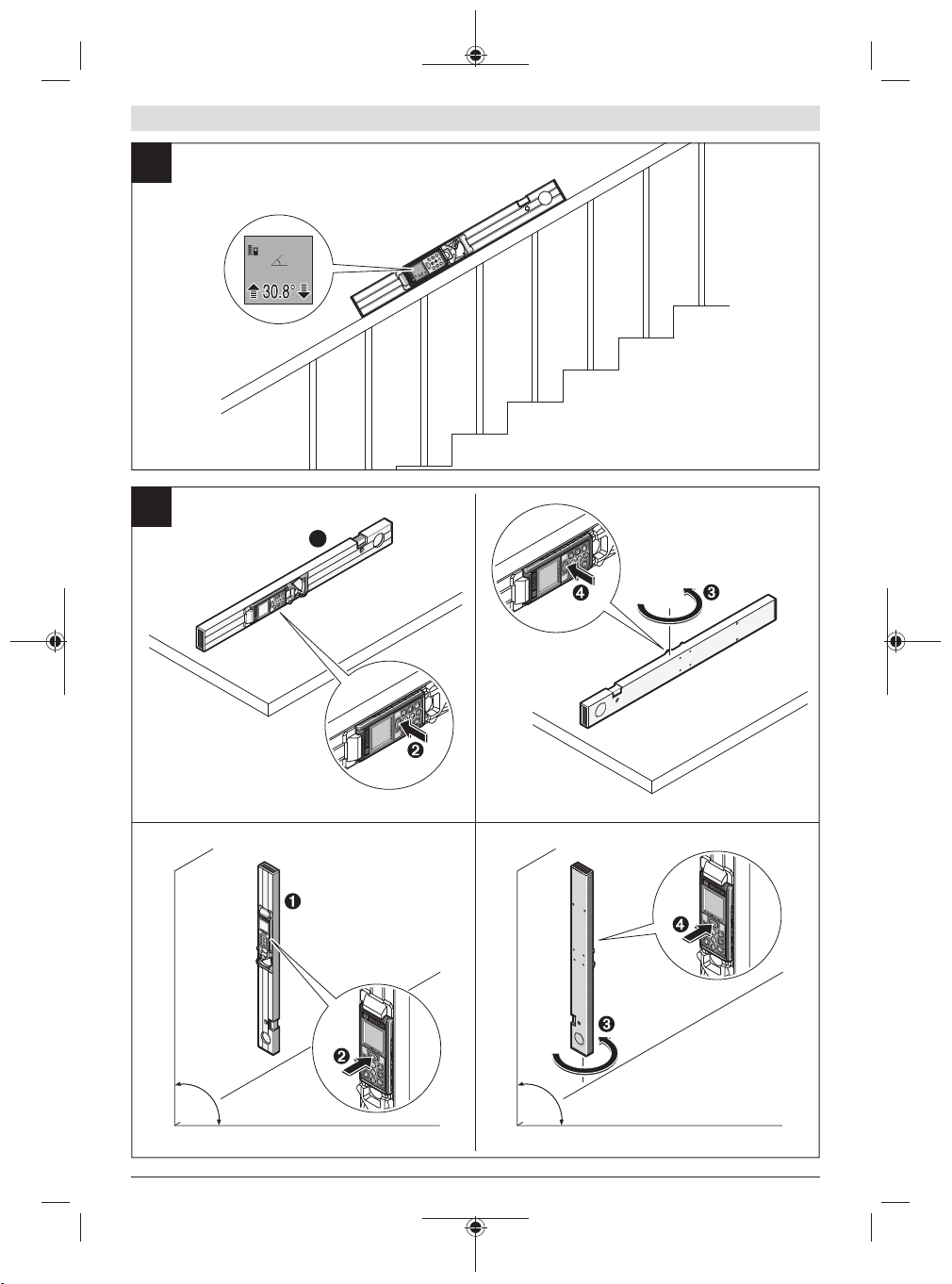

Grade measurement (see figureG)

Press the button for grade measurement (3) to bring up the

indicator for grade measurement on the display. The rear

of the measuring tool serves as the reference level. Press the

button for grade measurement (3) again to use the sides of

the measuring tool as a reference level and rotate the display

view by 90°.

Press the measuring button (2) to fix the measured value

and transfer it to the measured value memory. Press the

measuring button (2) again to continue the measurement.

If the display flashes during measurement, the measuring

tool has been tipped too heavily to the side.

If the "digital spirit level" function is activated in the basic

settings, the grade value is also displayed in the other measuring functions in line (d) of the display (1).

Timer function

The timer function is useful when the measuring tool should

be kept stationary during measurement, for example.

Press and hold the button for the timer function (6) to bring

up the indicator on the display.

The time period between triggering the timer and starting

measurement is displayed in the measured value line (a).

The time period can be set between 1–60 seconds by pressing the plus button (11) or minus button (5).

The measurement is made automatically after

the set time period has expired.

The timer function can also be used for dis-

tance measurements within other measuring

functions (e.g. area measurement). It is not possible to add

or subtract measuring results or carry out continuous measurement.

List of the last measured values

The measuring tool stores the last 20 measured values and

their calculations and displays them in reverse order (with

the most recent measured value displayed first).

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 14

14 | English

To retrieve the saved measurements, press the

button (7). The result of the last measurement

appears on the display, along with the indicator for the measured values list (e) and with

storage space for the numbering of the dis-

played measurements.

If no further measurements are saved upon pressing the but-

ton (7) again, the measuring tool switches back to the last

measuring function. Press one of the buttons for the measuring functions to exit the list of measured values.

To permanently save the currently displayed measured

length value as a constant, press and hold the button for the

list of measured values (7) until "CST" is shown on the display. An entry in the list of measured values cannot be retrospectively saved as a constant.

To use a measured length value in a measuring function (e.g.

area measurement), press the button for the list of measured values (7), select the desired entry and confirm it by

pressing the results button (6).

Deleting measured values

Briefly pressing the button (8) will delete the last measured

value in all measuring functions. Repeatedly pressing the

button briefly will delete the individual measured values in

reverse order.

To delete the currently displayed entry in the list of measured values, briefly press the button (8). To delete the complete list of measured values and the constant "CST", press

and hold the measured value list button (7) and at the same

time briefly press the button (8).

In the wall area measurement function, a brief first press of

the button (8) will delete the last individual measured value;

a second press will delete all lengths BX; a third will delete

the ceiling height A.

Adding measured values

To add measured values together, first perform any measurement or select an entry from the list of measured values.

Next, press the plus button (11). "+" will appear on the display as confirmation. Then perform a second measurement

or select another entry from the measured value list.

Press the results button (6) to retrieve the sum

of both measurements. The calculation is

shown in the measured value lines (a) and the

sum is displayed in the result line (c).

When the sum has been calculated, you can add more measured values or measured value list entries to this result if you

press the plus button (11) before each measurement. Press

the results button (6) to end the addition.

Information on addition:

– Mixtures of length, area and volume values cannot be ad-

ded together. For example, if a length value and an area

value are added together, "ERROR" will appear briefly on

the display when the results button (6) is pressed. The

measuring tool will then switch back to the most recently

active measuring function.

– The result of a measurement (e.g. volume value) is always

added; for continuous measurements, the measured

value displayed in the result line (c) is added. It is not

possible to add individual measured values from the

measured value lines (a).

Subtracting measured values

To subtract measured values, press the minus

button (5); "-" will appear on the display as

confirmation. The subsequent steps are the

same as for the "Adding measured values" sec-

tion.

Practical advice

General advice

The reception lens (17) and the laser beam output (16)

must not be covered during the measuring process.

The measuring tool must not be moved during a measurement (with the exception of the continuous measurement

and grade measurement functions). For this reason, place

the measuring tool against or on a firm surface whenever

possible.

Influences on the measuring range

The measuring range depends on the lighting conditions and

the reflective properties of the target surface. For better visibility of the laser beam when working outdoors and in bright

sunlight, use the laser viewing glasses (27) (accessory) and

the laser target plate (28) (accessory) or shade the target

area.

Influences on the measurement result

Due to physical effects, the possibility of inaccurate measurements when measuring various surfaces cannot be excluded. These include:

– Transparent surfaces (e.g. glass, water)

– Reflective surfaces (e.g. polished metal, glass)

– Porous surfaces (e.g. insulating materials)

– Structured surfaces (e.g. roughcast, natural stone).

If necessary, use the laser target plate (28) (accessory) on

these surfaces.

Inaccurate measurements are also possible where the laser

is pointed at target surfaces diagonally.

Layers of air at different temperatures and indirectly re-

ceived reflections can also influence the measured value.

Checking accuracy and calibrating the grade

measurement (see figureH)

Regularly check the accuracy of the grade measurement.

This is accomplished by means of a reverse measurement.

To do this, lay the measuring tool on a table and measure the

inclination. Turn the measuring tool by 180° and measure

the inclination again. The difference between the displayed

values must not exceed 0.3°.

In case of greater deviation, the measuring tool must be recalibrated. To do this, press and hold the grade measurement button (3). Follow the directions on the display.

Accuracy check of the distance measurement

You can check the accuracy of the measuring tool as follows:

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 15

English | 15

– Choose a measuring section of approx. 1–10 m in length

that is permanently unchanged, the exact length of which

is known to you (e.g. room width, door opening). The

measuring section must be indoors, and the target surface of the measurement must be smooth and reflect

well.

– Measure the section ten times in succession.

The deviation between the individual measurements and the

mean value must not exceed ± 2mm. Record the measurements in order to be able to compare the accuracy later on.

Working with the tripod (accessory)

The use of a tripod is particularly necessary for larger distances. Place the measuring tool with the 1/4" thread (19)

on the quick-release plate of the tripod (26) or a conventional camera tripod. Tighten it using the locking screw of the

quick-release plate.

Set the reference level for measurements with a tripod by

pressing the button (10) accordingly (thread reference

level).

Working with the measuring rail (see figuresI–K)

The measuring rail (24) can be used for a more exact grade

measurement result. Distance measurements are not possible with the measuring rail.

Insert the measuring tool into the measuring

rail (24) as shown and lock the measuring tool

in place with the locking lever (25). Press the

measuring button (2) to activate the "measuring rail" operating mode.

Regularly check the accuracy of the grade measurement by

means of a reverse measurement or the levels on the measuring rail.

In case of greater deviation, the measuring tool must be recalibrated. To do this, press and hold the grade measurement button (3). Follow the directions on the display.

To end the "measuring rail" operating mode, switch off the

measuring tool and remove it from the measuring rail.

Errors – Causes and Corrective Measures

Cause Corrective measures

Temperature warning flashes, measurement not possible

The measuring tool is outside

the operating temperature of

-10 °C to +50 °C (in the continuous measurement function, up to +40 °C).

Display shows "ERROR"

Addition/subtraction of

measured values with different units of measurement.

Angle between laser beam

and target is too acute.

Target surface is too reflective (e.g. mirror) or not re-

Wait until the measuring tool

has reached operating temperature.

Only add/subtract measured

values with the same units of

measurement.

Increase the angle between

the laser beam and the target

Use the laser target plate

(28).

Cause Corrective measures

flective enough (e.g. black

material), or ambient light is

too bright.

The laser beam output (16)

and/or reception lens (17)

are fogged up (e.g. due to a

rapid temperature change).

Calculated value is larger

than 999,999m/m2/m3.

Display shows "> 60°" or "< -60°"

The grade measuring range

for the measuring function or

reference level has been exceeded.

Display shows "CAL" and "ERROR"

The calibration of the grade

measurement has not been

carried out in the right order

or has not been carried out in

the correct positions.

The surfaces used for calibration were not precisely horizontal or vertical.

The measuring tool has

moved or tilted when the

button was pressed.

Battery charge indicator (g), temperature warning (j)

and "ERROR" shown in the display

The temperature of the

measuring tool is outside the

permissible charging temperature range.

Battery charge indicator (g) and "ERROR" shown in the

display

The battery charging voltage

is not correct.

Battery charge indicator (g) and clock symbol (f) shown

in the display

Charging time significantly

extended due to the charging

current being too low.

Measurement result implausible

Wipe the laser beam output

(16) and/or reception lens

(17) dry with a soft cloth.

Divide the calculation into intermediate steps.

Perform the measurements

within the specified angle

range.

Repeat the calibration according to the instructions

that appear on the display

and in the manual.

Repeat the calibration on a

horizontal or vertical surface

and check the surfaces beforehand if necessary using a

spirit level.

Repeat the calibration and

hold the measuring tool still

against the surface when

pressing the button.

Wait until the charging temperature range has been

reached.

Check whether the connection has been established

correctly and that the micro

USB cable is working properly. If the device symbol

flashes, the battery is defective and must be replaced by

the Bosch after-sales service.

Only use the original Bosch

micro USB cable.

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 16

16 | English

Cause Corrective measures

Target surface reflection not

distinct (e.g. water, glass).

Laser beam output (16) and/

or reception lens (17) are

covered.

An incorrect reference level

has been set.

Obstruction in the path of the

laser beam.

The indicator remains unchanged or the measuring tool

reacts unexpectedly when a button is pressed.

Software error. Press the measuring button

The measuring tool monitors correct functioning in every measurement. If a defect is detected, the display will indicate only the symbol

shown opposite. In this case, or if the above-

mentioned corrective measures cannot rectify

an error, submit the measuring tool to the Bosch after-sales

service via your dealer.

Cover the target surface.

Keep the laser beam output

(16) and/or reception lens

(17) clear.

Select a reference level that

is appropriate for the measurement.

The laser point must be fully

on the target surface.

(2) and the button for

memory deletion/switching

on or off (8) to reset the software.

Maintenance and Service

Maintenance and Cleaning

Only store and transport the measuring tool in the protective

bag provided.

Keep the measuring tool clean at all times.

Never immerse the measuring tool in water or other liquids.

Wipe off any dirt using a damp, soft cloth. Do not use any de-

tergents or solvents.

Take particular care of the reception lens (17), which must

be handled with the same level of care you would give to a

pair of glasses or a camera lens.

If the measuring tool needs to be repaired, send it off in the

protective bag (23).

After-Sales Service and Application Service

Our after-sales service responds to your questions concerning maintenance and repair of your product as well as spare

parts. You can find explosion drawings and information on

spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you

with any questions about our products and their accessories.

In all correspondence and spare parts orders, please always

include the 10‑digit article number given on the nameplate

of the product.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham Uxbridge

UB 9 5HJ

At www.bosch-pt.co.uk you can order spare parts or arrange

the collection of a product in need of servicing or repair.

Tel. Service: (0344) 7360109

E-Mail: boschservicecentre@bosch.com

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: (01) 4666700

Fax: (01) 4666888

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch-pt.com.au

www.bosch-pt.co.nz

Republic of South Africa

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: (031) 7012120

Fax: (031) 7012446

E-mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: (021) 5512577

Fax: (021) 5513223

E-mail: bsc@zsd.co.za

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 17

Bosch Headquarters

Laser Radiation

Do not stare into beam

Class 2 laser product

Midrand, Gauteng

Tel.: (011) 6519600

Fax: (011) 6519880

E-mail: rbsa-hq.pts@za.bosch.com

Disposal

Measuring tools, rechargeable/non-rechargeable

batteries, accessories and packaging should be

sorted for environmental-friendly recycling.

Do not dispose of the measuring tools or rechargeable/non-rechargeable batteries with

household waste.

Batteries:

u Integrated batteries may only be removed for disposal

by qualified personnel. Opening the housing shell can

destroy the measuring tool.

Discharge the battery completely. Unscrew all screws on the

housing and open the housing shell. Disconnect the connections at the battery and take out the battery.

Do not dispose of the batteries by throwing them out with

household waste, on a fire or into water. After running down

their charge (where possible), batteries should be collected

and recycled or disposed of in an environmentally friendly

manner.

中文

安全规章

必须阅读并注意所有说

明,从而安全可靠地操作

测量仪。如果不按照给出

的说明使用测量仪,可能

会影响集成在测量仪中的

保护功能。测量仪上的警戒牌应保持清晰可读的状

态。请妥善保存本说明书,并在转交测量仪时将本

说明书一起移交。

u 小心 – 如果使用了与此处指定的操作或校准设备

不同的设备,或执行了不同的过程方法,可能会

导致危险的光束泄露。

交付的测量仪带有一块警戒牌(在图形页的测量仪

示意图中用编号(20)标记)。

中文 | 17

u 如果警戒牌的文字并非贵国语言,使用仪器之

前,先把附带的以贵国语言书写的的贴纸贴在警

戒牌上。

不得将激光束指向人或动物,请勿直视

激光束或反射的激光束。 可能会致人炫

目、引发事故或损伤眼睛。

u 如果激光束射向眼部,必须有意识地闭眼,立即

从光束位置将头移开。

u 请不要对激光装置进行任何更改。

u 激光视镜不得用作护目镜。激光视镜用于更好地

识别激光束;然而对激光束并没有防护作用。

u 激光视镜不得用作太阳镜或在道路交通中使用。

激光视镜并不能完全防护紫外线,还会干扰对色

彩的感知。

u 仅允许由具备资质的专业人员使用原装备件修理

测量仪。如此才能够确保测量仪的安全性能。

u 不得让儿童在无人看管的情况下使用激光测量

仪。可能意外地让人炫目

u 请勿在有易燃液体、气体或粉尘的潜在爆炸性环

境中使用测量仪。测量仪器内可能产生火花并点

燃粉尘和气体。

保护测量工具 免受高温(例如长期日

照)、火焰、水和湿气的侵害。 有爆炸

的危险。

u 如果充电电池损坏或者未按照规定使用,充电电

池中会散发出有毒蒸汽。 工作场所必须保持空气

流通,如果身体有任何不适必须马上就医。 蒸汽

会刺激呼吸道。

产品和性能说明

按照规定使用

本测量仪用于测量距离、长度、高度、间距和倾角

以及用于计算面积和体积。

本测量仪适合在室内和室外使用。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

插图上的机件

机件的编号和仪器详解图上的编号一致。

(1) 显示屏

(2) 测量按键

(3) 倾斜度测量/校准按键

(4) 功能转换/基本设置按键

A)

A)

Page 18

18 | 中文

1

1

2

1

(5) 减号键

(6) 结果/计时器功能按键

(7) 测量值列表/常数存储按键

(8) 存储器删除按键/开关键

A)

A)

(9) 止动销

(10) 选择基准面

(11) 加号键

(12) 长度、面积和体积测量按键

(13) 充电插座的盖子

(14) 充电插头的插口

(15) 拎环固定座

(16) 激光束出口

(17) 接收透镜

(18) 序列号

(19) 1/4英寸螺纹

(20) 激光警戒牌

(21) 充电插头

(22) Micro USB电缆

(23) 保护袋

(24) 测量轨

(25) 测量轨锁定杆

(26) 三脚架

(27) 激光护目镜

B)

B)

B)

B)

(28) 激光靶

A)

A) 按住按键以调用扩展功能。

B) 图表或说明上提到的附件,并不包含在基本的供货范围

中。

B)

显示元件

(a) 测量值行

(b) 错误显示“Error”

(c) 测量结果行

(d) 数字水准仪/测量值列表条目的位置

(e) 测量值列表指示器

(f) 测量功能

长度测量

面积测量

体积测量

持续测量

间接高度测量

双重间接高度测量

间接长度测量

计时器功能

墙壁面积测量

倾斜度测量

(g) 充电电池电量指示灯

(h) 激光已接通

(i) 测量的基准面

(j) 温度警告

技术参数

数字式激光测距仪

物品代码

距离测量

测量范围(最大)

测量范围(一般)

测量范围(一般,不利的条件)

测量精度(一般)

测量精度(一般,不利的条件)

最小显示单位

间接距离测量和水准仪

测量范围

倾斜度测量

测量范围

0度–360度(4x90度)D)0度–360度(4x90度)

测量精度(一般)

最小显示单位

常规

工作温度

仓储温度

许可的充电温度范围

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

–10摄氏度至+50摄氏度 G)–10摄氏度至+50摄氏度

–20摄氏度至+50摄氏度 –20摄氏度至+50摄氏度

+5摄氏度至+40摄氏度 +5摄氏度至+40摄氏度

GLM 100 GLM 100+R 60

3 601 K72 P.. 3 601 K72 P..

A)

100米

0.05-80米

35米

±1.5毫米

±2.5毫米

B)

C)

B)

C)

100米

0.05-80米

35米

±1.5毫米

±2.5毫米

0.1毫米 0.1毫米

–60度至+60度 –60度至+60度

F)

0.2度 E)

±0.2度 E)

0.1度 0.1度

A)

B)

C)

B)

C)

D)

F)

G)

Page 19

中文 | 19

数字式激光测距仪

最大相对空气湿度

基准高度以上的最大使用高度

脏污程度符合IEC61010-1

激光等级

激光种类

635纳米,< 1毫瓦 635纳米,< 1毫瓦

GLM 100 GLM 100+R 60

90 % 90 %

2000米 2000米

H)

2

2 2

激光束直径(在25摄氏度时)约

– 距离10米远

– 距离80米远

6毫米

48毫米

F)

F)

6毫米

48毫米

针对机壳的激光调节精度约

– 垂直

– 水平

±2毫米/米

±10毫米/米

I)

I)

±2毫米/米

±10毫米/米

自动断开时间约

– 激光

– 测量仪(不测量)

重量符合EPTA-Procedure 01:2014

尺寸

防护类型

51 x 111 x 30毫米 51 x 111 x 30毫米

IP 54(防尘、防溅) IP 54(防尘、防溅)

20秒 20秒

5分 5分

0.14千克 0.14千克

测量轨

物品代码

尺寸

充电电池

额定电压

电量

1.25安培小时 1.25安培小时

充电电池单元数量

每次充电后的单次测量数约

A) 对于大于80米的距离我们推荐使用回射的目标激光靶(附件)。

B) 在从测量仪的前缘起测量、目标有100%的反射能力(例如涂刷的白色墙壁)、背景照明暗且工作温度为25摄氏度时。

此外要考虑±0.05毫米/米的影响。

C) 在从测量仪的后缘起测量、目标有10 –100%的反射能力、背景照明亮且工作温度为25摄氏度时。此外要考虑±0.29毫

米/米的影响。

D) 如果以设备背面为基准测量,则最大测量范围为±60度

E) 按照图示H校准后。额外的螺距误差±0.01度/至45度。

F) 激光线的宽度取决于表面特性和环境条件。

G) 在持续测量功能中,最大工作温度为+40摄氏度。

H) 仅出现非导电性污染,不过有时会因凝结而暂时具备导电性。

I) 在25摄氏度时

J) 针对新的和已充满电的充电电池,在未使用显示屏照明和声音信号的情况下。

型号铭牌上的序列号(18)是测量仪唯一的识别码。

–

3 601 K79 000

– 58 x 610 x 30毫米

锂离子 锂离子

3.7伏 3.7伏

1 1

J)

25000

25000

H)

2

F)

F)

I)

I)

J)

安装

为充电电池充电

可以通过USB接口或USB电源(最小500毫安)用

Micro USB电缆给充电电池充电。

如何正确地使用充电电池

充电电池只能存放在允许的温度范围内,参见“技术

参数”。夏天不得将充电电池搁置在汽车中。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

充电后如果充电电池的使用时间明显缩短,代表充

电电池已经损坏,必须更换新的充电电池。

请注意有关废弃处理的规定。

工作

投入使用

u 不可以让湿气渗入仪器中,也不可以让阳光直接

照射在仪器上。

Page 20

20 | 中文

u 请勿在极端温度或温度波动较大的情况下使用测

量仪。比如请勿将测量仪长时间放在汽车内。温

度波动较大的情况下,使用测量仪之前先使其温

度稳定下来。在极端温度或温度波动较大的情况

下,测量仪的精度可能会受到影响。

u 避免让测量仪发生剧烈碰撞或使其掉落。 测量仪

受到强烈的外部影响后,在继续工作前务必进行

一次精度检查 (参见 “倾斜度测量的精度检查和校

准(参见插图H)”, 页23)和(参见 “距离测量精

度检查”, 页23)。

接通/关闭

u 测量仪接通后应有人看管,使用后应关闭。激光

可能会让旁人炫目。

可采用以下方式接通测量仪:

– 按压开关键(8):测量仪接通并且处于长度测量功

能中。激光器不接通。

– 按下测量按键(2):测量仪和激光器被接通。测量

仪处于长度测量功能中。对于安装在测量轨(24)

上的测量仪,倾斜度测量功能已激活。

u 不得将激光束对准人或动物,也请勿直视激光

束,即使和激光束相距甚远也不可以做上述动

作。

如要关闭测量仪,长按开关键(8)。

如果在约5分钟的时间内没有按下测量仪上的任何按

键,测量仪便会自动关闭,以保护充电电池。

如果在运行模式“倾斜度测量”中,角度约5分钟不变

化,测量仪便会自动关闭,以保护充电电池。

在自动关机后,所有储存的测量值被保留。

测量过程

按下测量按键(2)接通测量仪后,如果测量仪是安装

在测量轨(24)上,便会始终处于长度测量或倾斜度

测量模式下。可以按下相应的功能键调到其他测量

功能 (参见 “测量功能”, 页21)。

开机后的测量基准面已选为测量仪的后缘。按下基

准面按键(10),可更改基准面 (参见 “选择基准面

(参见插图A)”, 页20)。

将测量仪的所选基准面置于所需的测量起始点上

(如墙壁)。

如要接通激光束,请短促按压测量按键(2)。

u 不得将激光束对准人或动物,也请勿直视激光

束,即使和激光束相距甚远也不可以做上述动

作。

将激光束瞄准目标面。启动测量时,请再次短促按

压测量按键(2)。

如永久性激光束已接通,则第一次按下测量按键(2)

后便会开始测量。如果选择持续测量功能,只要一

启动这个功能便可以进行测量。

测量值通常在0.5秒最晚4秒后出现。测量时长取决

于距离、照明条件和目标面的反射特性。在测量结

束后,将发出一个信号音。测量结束后,激光束自

动关闭。

如果在激活后约20秒后未进行测量,激光束便会自

动关闭,以保护充电电池。

选择基准面(参见插图A)

测量时可以选择四个不同基准面:

– 测量仪的后缘或翻开90度后的止动销(9)的前缘

(例如在靠到外角上时),

– 翻转180度后的止动销(9)的尖部(例如用于从角

落测量),

– 测量仪的前缘(例如在从台面棱边开始测量

时),

– 螺纹(19)的中心(例如用三脚架测量时)。

选择基准面时应反复按压按键(10),直到显示屏上

显示出所需的基准面。每次接通测量仪后,测量仪

的后缘都已预设为基准面。

无法在完成测量后再对基准面进行事后更改(例如

在测量值已显示在测量值列表中时)。

“基本设置”菜单

如要进入“基本设置”菜单,请按住基本设置按键

(4)。

短促按下基本设置按键(4),可以选择各个菜单项。

按下减号键(5)或加号键(11),可以在菜单项内部选

择设置。

如要退出“基本设置”菜单,请按下测量按键(2)。

基本设置

信号音 接通

关闭

显示屏照明 接通

关闭

自动

接通/关闭

数字水准仪 接通

关闭

显示屏旋转 接通

关闭

永久性激光束 接通

关闭

距离的单位(视国别而

定)

角度的单位 度、%、毫米/

米、英尺、英

寸等

米、英寸/英尺

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 21

除了“永久性激光束”设置外,其他所有基本设置在

1

2

关机后都将被保留。

永久性激光束

u 不得将激光束对准人或动物,也请勿直视激光

束,即使和激光束相距甚远也不可以做上述动

作。

采用该设置时,激光束在两次测量之间时仍保持接

通状态,仅需短促按压一次测量按键(2)就可测量。

测量功能

单一长度测量

进行长度测量时,反复按压按键(12),直到显示屏

上出现长度测量显示 。

如要接通激光并进行测量,请分别短促

按压测量按键(2)一次。

在结果行(c)中显示测量值。

如果先后进行多次长度测量,最后几次

测量的结果会显示在测量值行(a)中。

面积测量

进行面积测量时,反复按压按键(12),直到显示屏

上出现面积测量显示 。

然后像长度测量一样依次测量宽度和长度。在两次

测量之间激光束保持接通。

两次测量结束后会自动计算出面积,并

显示在结果行(c)中。各个测量值位于测

量值行(a)中。

体积测量

进行体积测量时,反复按压按键(12),直到显示屏

上出现体积测量显示 。

然后像测量长度一样依次测量宽度、长度和深度。

在三次测量之间激光束保持接通。

三次测量结束后会自动计算出体积,并

显示在结果行(c)中。各个测量值位于测

量值行(a)中。

大于999999立方米的数值无法显示,

在显示屏上将显示“ERROR”。您可以把要测量的体

积分割成数个单一测量,分别计算其数值,然后再

累加。

持续测量/最小/最大测量(参见插图B)

持续测量时,测量仪可相对于目标进行运动,同

时,测量值每0.5秒更新一次。例如,您可以从一堵

墙出发,移动所需的距离,这样将随时可以读取当

前的距离。

进行持续测量时,按下功能转换按键(4),直到显示

屏上出现持续测量显示 。按下测量按键(2),开始

持续测量。

最小测量功能用于确定到固定基准点的最近距离。

这有助于例如确定垂直或水平位置。

最大测量功能用于确定到固定基准点的最远距离。

这有助于例如确定对角线。

在结果行(c)中显示当前测量值。在测量

值行(a)中显示最大(“max”)和最小

(“min”)测量值。如果新测得的长度

中文 | 21

小于或大于以前的最小值或最大值,旧的储存值便

会被新的测量值取代。

按下存储器删除按键(8),此前的最小值或最大值将

被删除。

按下测量按键(2),可退出持续测量。在结果行(c)

中显示最后一个测量值。再次按下测量按键(2),将

再次启动持续测量。

持续测量在5分钟后自动关闭。在结果行(c)中仍显

示最后一个测量值。

间接距离测量

间接距离测量用于确定无法直接测量的距离,例如

有障碍物阻挡了光路或者没有目标表面可以充当反

射体时。该测量方法只适用于垂直方向。任何水平

方向的偏差都会导致测量错误。

在各个单一测量之间激光保持接通。

间接距离测量有三种测量功能可用,通过这些相应

的功能可以确定不同的线段。

a) 间接高度测量(参见插图C)

反复按压功能转换按键(4),直到显示屏上出现间接

高度测量显示1。

请确保测量仪处在与下部测量点相同的高度上。然

后使测量仪绕基准面倾斜,与长度测量时一样测量

线段(1)。

测量完成后,在结果行(c)中显示所求线

段“X”的结果。线段“1”和角度“α”的测

量值位于测量值行(a)中。

b) 双重间接高度测量(参见插图D)

反复按压功能转换按键(4),直到显示屏上出现双重

间接高度测量显示

。

像长度测量一样,以这样的顺序测量线

段“1”和“2”。

测量完成后,在结果行(c)中显示所求线

段“X”的结果。线段“1”“2”和角度“α”的

测量值位于测量值行(a)中。

请注意,测量的基准面(例如测量仪的

后缘)在同个测量过程中的所有单一测量时应处于

完全相同的位置。

c) 间接长度测量(参见插图E)

反复按压功能转换按键(4),直到显示屏上出现间接

长度测量显示1。

请确保测量仪处在与找寻的测量点相同的高度上。

然后使测量仪绕基准面倾斜,与长度测量时一样测

量线段“1”。

测量完成后,在结果行(c)中显示所求线

段“X”的结果。线段“1”和角度“α”的测

量值位于测量值行(a)中。

墙壁面积测量(参见插图F)

墙壁面积测量是用来计算高度相同的数个单一墙面

的总面积。

在图示的例子中要测定空间高度A相同但长度B不同

的多个墙面的总面积。

进行墙壁面积测量时,反复按压功能转换按键(4),

直到显示屏上出现墙壁面积测量显示 。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 22

22 | 中文

像长度测量一样测量空间高度A。测量值(“cst”)

在上部的测量值行(a)中显示。激光保持接通状态。

然后测量第一堵墙的长度B1。面积自动

计算出来并在结果行(c)中显示。最后一

个长度测量值位于中间的测量值行(a)

中。激光保持接通状态。

现在测量第二堵墙的长度B2。中间测量

值行(a)中显示的测量值被加到长度B

上。两个长度的总和(“sum”,显示在

1

下部的测量值行(a)中)被乘以存储的高

度A。总面积值在结果行(c)中显示。

您可以测量任意多个其它长度Bx,它们将自动相

加,然后乘以高度A。

间接面积计算的前提条件是,第一个测得的长度

(在本例中是空间高度A)对于所有子面积都相同。

倾斜度测量(参见插图G)

按下倾斜度测量按键(3),会在显示屏上出现倾斜度

测量显示 。测量仪的背面被当作基准面。再次按

下倾斜度测量按键(3),会把测量仪的侧面用作基准

面,并且显示屏视图旋转90度显示。

按下测量按键(2),可固定测量值并将其接收到测量

值存储器中。再次按下测量按键(2),将继续测量。

测量过程中如果显示开始闪烁,说明测量仪过度侧

向侧倾。

如果在基本设置中开启了功能“数字水准仪”,在其

他测量功能中,倾斜度值也会显示在显示屏(1)的

(d)行中。 计时器功能

计时器功能有助于防止测量仪在测量过程中发生移

动。

如要启用计时器功能,按住按键(6),直到显示屏上

出现显示 。

在测量值行(a)中显示从触发到测量的时间段。该时

间段可通过按下加号键(11)或减号键(5)在1秒到60

秒之间进行调整。

设置的时间段过去后将自动进行测量。

计时器功能也可在进行距离测量时而在

其他测量功能内(例如面积测量)使

用。但是该功能无法用在累加和减除测

量结果以及持续测量时。

最近的测量值列表

测量仪存储最近20个测量值及其计算结果,并按相

反的顺序显示它们(首先显示倒数第一个测量

值)。

如要调出所保存的测量结果,按下按键

(7)。在显示屏上出现最近一次测量的结

果,此外还显示测量值列表指示器(e)以

及所显示的多个测量编号的存储位置。

如果再次按下按键(7)后没有更多测量结果被保存,

测量仪则切换回到前一项测量功能。要离开测量值

列表,请按压任意测量功能按键。

为了将当前显示的长度测量值作为常数长期保存,

按住测量值列表按键(7),直到显示屏上显

示“CST”。无法在事后将一个测量值列表条目作为

常数保存。

要将一个长度测量值用在一项测量功能(如面积测

量)中,按下测量值列表按键(7),选择所需的条目

并按下结果按键(6)进行确认。

删除测量值

通过短促按压按键(8)可以在所有测量功能中删除倒

数第一个单个测量值。多次短促按压按键,可按相

反的顺序删除单个测量值。

如要删除当前显示的测量值列表条目,短促按压按

键(8)。如要删除整个测量值列表和常数“CST”,按

住测量值列表按键(7)并同时短促按压按键(8)。

在墙壁面积测量功能中,第一次短促按压按键(8)时

将删除倒数第一个单个测量值,在第二次按压时将

删除所有长度Bx,在第三次按压时将删除空间高度

A。 测量值相加

要累加测量值,首先进行一次任意测量或者从测量

值列表中选择一个条目。然后按压加号键(11)。在

显示屏上出现“+”,用于进行确认。然后再进行另一

次测量或者从测量值列表中选择另一个测量值。

按下结果按键(6),以查询两个测量结果

之和。计算显示在测量值行(a)中,总和

显示在结果行(c)中。

如果在测量前分别按下加号键(11),便

会在计算了总和之后,在这个结果之上再加上其他

测量值或测量值列表条目。按下结果按键(6)将结束

累加过程。

有关累加功能的指示:

– 长度、面积和体积值不能混合相加。例如,如果

将一个长度值和一个面积值相加,在按下结果按

键(6)后将在显示屏上短暂显示“ERROR”。然后

测量仪切换回上一个测量功能。

– 可以累加相应的测量结果(如体积值),对于持

续测量则加上结果行(c)中所显示的测量值。无法

将测量值行(a)中的单个测量值相加。

测量值相减

如要将测量值相减,按下减号键(5),显

示屏上出现“–”,用于进行确认。后续操

作类似于“测量值相加”。

工作提示

一般性指示 测量时,不得遮挡接收镜头(17)和激光束出口

(16)。

进行测量时不得移动测量仪(使用持续测量功能和

测量倾斜度时例外)。因此将测量仪尽可能放在固

定的止挡面或支承面上。

影响测量范围的因素

测量范围取决于照明条件和目标面的反射特性。在

室外以及外来光线过强时,为了更好地看清激光

束,可使用激光护目镜(27)(附件)和激光靶(28)

(附件),或遮暗目标面。

影响测量结果的因素

基于物理原理,无法避免在不同的表面上进行测量

时产生的误差。例如:

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 23

– 透明表面(例如玻璃、水),

– 反光表面(例如抛光金属、玻璃),

– 多孔表面(例如绝缘材料),

– 有纹路的表面(例如粗糙的灰泥墙、天然石)。

必要时,在这些表面上使用激光靶(28)(附件)。

如果未正确地瞄准好目标点,也可能产生误测。

此外有温差的空气层和间接的反射都可能影响测量

值。

倾斜度测量的精度检查和校准(参见插图H)

定期检查倾斜度测量的精度。这可通过包络测量进

行。为此将测量仪置于一个桌面上并测量倾斜度。

将测量仪旋转180度,然后再次测量倾斜度。显示值

之差最大允许为0.3度。

如果有更大的偏差,必须重新校准测量仪。为此需

按住倾斜度测量按键(3)。请遵照显示屏上的指示操

作。

距离测量精度检查

您可以按照如下方式检查测量仪的精度:

– 选择一个您确切知道的一直不变的测量距离,大

约1至10米(例如房间宽度、门洞)。测量段必

须位在室内,测量的目标表面平整且反射性良

好。

– 依次测量该距离10次。

单次测量与平均值之间的偏差最大允许为±2毫米。

记录测量情况,以便以后能对精度进行比较。

使用三脚架(附件)工作

如果距离较远,特别有必要使用三脚架。将测量仪

用1/4英寸螺纹(19)安装到三脚架(26)或市售摄影三

脚架的快拆板上。用快拆板的固定螺丝拧紧。

按下按键(10),对用三脚架进行测量的基准面进行

相应调节(基准面螺纹)。

使用测量轨工作(参见插图I–K)

可以使用测量轨(24),以便在倾斜度测量时获得更

精确的结果。无法利用测量轨进行距离测量。

如图所示,将测量仪装入到测量轨

(24),然后用锁定杆(25)锁定测量仪。

按下测量按键(2),激活运行模式“测量

轨”。

请定期通过包络测量或测量轨上的水准仪检查倾斜

度测量的准确度。

如果有更大的偏差,必须重新校准测量仪。为此需

按住倾斜度测量按键(3)。请遵照显示屏上的指示操

作。

如要退出运行模式“测量轨”,关闭测量仪,然后将

其从测量轨中取出。

故障 – 原因和补救措施

原因 补救方法

温度警告灯闪烁,无法测量

测量仪的温度超出–10摄

氏度至+50摄氏度的工作

温度(在持续测量功能中

停下工作,等待测量仪的

温度回到工作温度范围

内。

中文 | 23

原因 补救方法

最高工作温度为+40摄氏

度)。

显示屏上显示“Error”

不同测量单位的测量值相

加/相减。

激光和目标之间的角度太

狭小。

目标表面反射过强(例如

镜子)或过弱(例如黑色

材料)或环境光线过强。

激光束出口(16)或接收

镜头(17)蒙上雾气(例

如因温度快速变化)。

计算值大于999 999米/

平方米/立方米。

显示屏上显示“>60度”或“<–60度”

超出了该测量功能或该基

准面的倾斜度测量范围。

显示屏上显示“CAL”和显示“ERROR”

倾斜度测量的校准未以正

确的顺序或未在正确的位

置上进行。

进行校准时使用的平面未

正确地位在水平或垂直的

位置。

按下按键时移动了或翻倒

了测量仪。

充电电池电量指示灯(g)、温度警告(j)和显示屏上

显示“ERROR”

测量仪的温度在许可的充

电温度范围之外

充电电池电量指示灯(g)和显示屏上显示“ERROR”

充电电池的充电电压不正确检查插头是否正确连接,

充电电池电量指示灯(g)和显示屏上的时钟图标(f)

充电时间明显延长,因为

充电电流太弱。

测量结果不可信

目标表面反射不清晰(例

如水、玻璃)。

激光束出口(16)或接收

镜头(17)被遮挡。

设置了错误的基准面 选择适合测量功能的基准

激光束路线中有障碍物 激光点必须完全在目标表

只有相同测量单位的测量

值才能相加/相减。

加大激光和目标之间的角

度

使用激光靶(28)(附

件)

用柔软的布擦干激光束出

口(16)或接收镜头(17)

将计算分割成多个中间步

骤

在各个指定的角度范围内

进行测量。

根据显示屏和使用说明书

上的指示重复校准过程。

在水平或垂直的平面上重

复校准工作,必要时事先

使用水平仪检查该平面。

重复校准工作,按压按键

时确保测量仪在其平面上

不会移动。

等待回到充电温度范围

内。

Micro USB电缆是否功

能正常。如果仪器符号开

始闪烁,代表充电电池损

坏,必须由博世的客服中

心更换。

只能使用博世原装Micro

USB电缆。

盖住目标

保持激光束出口(16)或

接收镜头(17)不被遮挡

面。

面上。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 24

24 | 中文

原因 补救方法

按压按键,显示保持不变或测量仪意外响应

软件错误 同时按下测量按键(2)和

存储器删除按键/开关键

(8),将软件复位。

每次测量时,测量仪都会监控功能是否

正常。如果发现故障,则显示屏只显示

旁边的图标。在这种情况下或者如果上

述补救措施无法排除故障,请将测量仪

通过经销商交给博世客户服务部。

维修和服务

维护和清洁

使用附带的保护套储存和携带仪器。

测量仪器必须随时保持清洁。

不可以把仪器放入水或其它的液体中。

使用潮湿,柔软的布擦除仪器上的污垢。切勿使用

任何清洁剂或溶剂。

必须特别小心地维护接收镜头(17)、处理目镜或摄

像机透镜。

需要修理时,请将测量仪装入保护袋(23)邮寄。

客户服务和应用咨询

本公司顾客服务处负责回答有关本公司产品的修

理,维护和备件的问题。备件的展开图纸和信息也

可查看:www.bosch-pt.com

博世应用咨询团队乐于就我们的产品及其附件问题

提供帮助。

如需查询和订购备件,请务必提供产品型号铭牌上

的10位数货号。

中国大陆

博世电动工具(中国)

有限公司,中国浙江省杭州市

滨江区滨康路567号

102/1F服务中心

邮政编码:310052

电话:(0571)8887 5566 / 5588

传真:(0571)8887 6688 x 5566# / 5588#

电邮:bsc.hz@cn.bosch.com

中华人民共和国

中国大陆

博世电动工具(中国)有限公司

博世服务中心

中国浙江省杭州市

滨江区

滨康路567号,

310052

电话:(0571)8887 5566 / 5588

传真:(0571)8887 6688 x 5566# / 5588#

电子邮件:bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

处理废弃物

应对测量仪、蓄电池/电池、附件和包装进

行环保的回收利用。

请勿将测量仪和电池/蓄电池扔到生活垃圾

里!

充电电池/蓄电池:

u 要进行废物处理,只能由专业人员取下内置充电

电池。打开壳体可能毁坏测量仪。

将充电电池完全放电。拧出仪器壳上所有的螺丝,

然后打开壳盖。断开充电电池上的所有连接,取出

充电电池。

不要将充电电池/蓄电池丢入生活垃圾、火中或水

中。可能的话,必须先让充电电池/蓄电池放电,然

后再收集、回收或者以符合环保的方式处理。

产品中有害物质的名称及含量

部件名称 有害物质

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr+6)

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

外壳的金属部分 X O O O O O

外壳的非金属部分 (包

O O O O O O

括玻璃)

组合印刷电路板 X O O O O O

A)

附件

X O O O O O

碱性电池系统 O O O O O O

充电电池系统

B)

X O O O O O

键盘 O O O O O O

C)

显示器

激光模块

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

D)

X O O O O O

X O O O O O

Page 25

繁體中文 | 25

Laser Radiation

Do not stare into beam

Class 2 laser product

部件名称 有害物质

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr+6)

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

内部连接电缆 O O O O O O

A) 适用于采用附件的产品

B) 适用于采用充电电池电供的产品

C) 适用于采用显示器的产品

D) 适用于采用激光模块的产品

本表是按照SJ/T 11364的规定編制

O: 表示该有害物质在该部件所有物质材料中的含量均在GB/

T26572 规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一物质材料中的含量超

出GB/T26572 规定的限量要求,且目前业界没有成熟的替代

方案,符合欧盟RoHS 指令环保要求。

产品环保使用期限内的使用条件参见产品说明书。

眩光,進而引發意外事故或使眼睛受到傷害。

u 萬一雷射光不小心掃向眼睛,應立刻閉上眼睛並

立刻將頭轉離光束範圍。

u 請勿對本雷射裝備進行任何改造。

u 請勿將雷射眼鏡當作護目鏡使用。雷射眼鏡是用

來讓您看清楚雷射光束:但它對於雷射光照射並

沒有保護作用。

u 請勿將雷射眼鏡當作護目鏡使用,或在道路上行

進間使用。雷射眼鏡無法完全阻隔紫外線,而且

繁體中文

還會降低您對於色差的感知能力。

u 本測量工具僅可交由合格的專業技師以原廠替換

零件進行維修。如此才能夠確保本測量工具的安

安全注意事項

為確保能夠安全地使用本

測量工具,您必須完整詳

讀本說明書並確實遵照其

內容。若未依照現有之說

明內容使用測量工具,測

量工具內部所設置的防護措施可能無法發揮應有功

效。謹慎對待測量工具上的警告標示,絕對不可讓

它模糊不清而無法辨識。請妥善保存說明書,將測

量工具轉交給他人時應一併附上本說明書。

u 小心-若是使用非此處指明的操作設備或校正設

備,或是未遵照說明的操作方式,可能使您暴露

於危險的雷射光照射環境之下。

全性能。

u 不可放任兒童在無人監督之下使用本雷射測量工

具。他們可能會不小心對他人眼睛產生眩光

u 請不要在存有易燃液體、氣體或粉塵等易爆環境

下操作本測量工具。測量工具內部產生的火花會

點燃粉塵或氣體。

保護測量工具免受高溫(例如長期日

照)、火焰、水和濕氣的侵害。有爆炸

的危險。

u 如果充電電池損壞了,或者未按照規定使用充電

電池,充電電池中會散發出有毒蒸氣。工作場所

必須保持空氣流通,如果身體有任何不適必須馬

上就醫。充電電池散發的蒸氣會刺激呼吸道。

本測量工具出貨時皆有附掛警示牌(即測量工具詳

解圖中的編號 (20))。

產品和規格

u 警示牌上的內容若不是以貴國語言書寫,則請於

第一次使用前將隨附的當地語言說明貼紙貼覆於

其上。

請勿將雷射光束對準人員或動物,您本

人亦不可直視雷射光束或使雷射光束反

射。因為這樣做可能會對他人眼睛產生

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

依規定使用機器

該測量工具是用來測量距離、長度、高度、間距、

傾角,並具有計算面積及體積之功能。

本測量工具可同時適用於室內及戶外應用。

插圖上的機件

機件的編號和儀器詳解圖上的編號一致。

(1) 螢幕

(2) 測量按鈕

(3) 傾角測量/校正按鈕

(4) 功能切換/基本設定按鈕

(5) 減號按鈕

(6) 測量結果/定時功能按鈕

(7) 測量值清單/常數儲存功能按鈕

(8) 記憶刪除按鈕/電源按鈕

(9) 止動銷

A)

A)

A)

A)

A)

Page 26

26 | 繁體中文

1

1

2

1

(10) 基準點選擇按鈕

(11) 加號按鈕

(12) 長度、面積和體積測量按鈕

(13) 充電插座的護蓋

(14) 充電插頭的插座

(15) 腕帶繫座

(16) 雷射光束出口

(17) 接收點

(18) 序號

(19) 1/4" 螺紋孔

(20) 雷射警示牌

(21) 充電插頭

(22) Micro USB 傳輸線

(23) 保護套袋

(24) 測量軌道

(25) 測量軌道的鎖止扳桿

(26) 三腳架

(27) 雷射辨識鏡

(28) 雷射標靶

A) 按鈕放住不放即可開啟進階功能。

B) 圖文中提到的配件,並不包含在基本的供貨範圍中。

B)

B)

B)

B)

B)

指示器元件

技術性數據

數位雷射測距儀

產品機號

距離測量

測量範圍(最大值)

測量範圍(標準值)

測量範圍(標準值,在不利條件下)

測量準確度(標準值)

測量準確度(標準值,在不利條件下)

最小顯示單位

間接距離測量和水平儀

測量範圍

傾角測量

測量範圍

測量準確度(標準值)

最小顯示單位

一般資訊

操作溫度

儲藏溫度範圍

容許的充電溫度範圍

空氣相對濕度最大值

從基準點高度算起的最大可測量高度

依照 IEC61010-1,污染等級為

(a) 測量值顯示列

(b) 錯誤指示器「ERROR」

(c) 測量結果顯示列

(d) 數位水平儀/測量值清單項目編號

(e) 測量值清單指示器

(f) 測量功能

長度測量

面積測量

體積測量

連續測量

間接高度測量

雙重間接高度測量

間接長度測量

定時功能

牆壁面積測量

傾角測量

(g) 充電電池的電量指示器

(h) 雷射已啟動

(i) 測量基準點

(j) 溫度警示燈

GLM 100 GLM 100+R 60

3 601 K72 P.. 3 601 K72 P..

A)

100m

35m

±1.5 mm

±2.5 mm

B)

C)

B)

C)

0.05–80m

0.1 mm 0.1 mm

–60° – +60° –60° – +60°

0.2°

D)

E)F)

0°–360°(4x90°)

0°–360°(4x90°)

0.1° 0.1°

–10 °C ...+50°C

G)

–10 °C ...+50°C

–20 °C ...+50 °C –20 °C ...+50 °C

+5 °C...+40 °C +5 °C...+40 °C

90 % 90 %

2000 m 2000 m

H)

2

100m

0.05–80m

35m

±1.5 mm

±2.5 mm

±0.2°

A)

B)

C)

B)

C)

D)

E)F)

G)

H)

2

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 27

繁體中文 | 27

數位雷射測距儀

雷射等級

雷射種類

GLM 100 GLM 100+R 60

2 2

635 nm,< 1mW 635 nm,< 1mW

雷射光束直徑(當 25 °C 時)約略值

– 距離為 10 m

– 距離為 80 m

6 mm

48 mm

F)

F)

6 mm

48 mm

針對機殼的雷射調整準確度,約略值

– 垂直

– 水平

±10 mm/m

±2 mm/m

I)

I)

±2 mm/m

±10 mm/m

自動關機的執行時間點,約略值

– 雷射

– 測量工具(未進行測量)

重量符合 EPTA-Procedure 01:2014

尺寸

防護等級

51 x 111 x 30 mm 51 x 111 x 30 mm

IP 54(防塵防潑濺) IP 54(防塵防潑濺)

20 秒 20 秒

5 分鐘 5 分鐘

0.14 kg 0.14 kg

測量軌道

產品機號

尺寸

充電電池

額定電壓

容量

充電電池數量

充電電池充飽電後可執行的單一測量次數,約略值

A) 距離超過 80m 時,建議使用反光標靶牌(配件)。

B) 以測量工具前緣為測量起點、目標物的反射率達 100 %(例如白漆牆)、背景照明微弱、操作溫度為 25 °C。應額外再

將影響系數 ±0.05 mm/m 列入計算。

C) 以測量工具後緣為測量起點、目標物的反射率為 10–100%、背景照明光線強、操作溫度為 25°C。應額外再將影響系

數 ±0.29 mm/m 列入計算。

D) 以裝置背面為基準點進行測量時,最大值測量範圍是 ±60°

E) 依照圖 H 完成校正。45° 以下必須另外加上每度 ±0.01° 的螺距誤差。

F) 雷射標線的線寬取決於表面特性與環境條件。

G) 使用連續測量功能時的操作溫度最高為 +40 °C。

H) 只產生非傳導性污染,但應預期偶爾因水氣凝結而導致暫時性導電。

I) 在 25 °C 環境下

J) 使用滿電量的全新充電電池、關閉螢幕照明和音效。

從產品銘牌的序號 (18) 即可確定您的測量工具機型。

–

3 601 K79 000

– 58 x 610 x 30 mm

鋰離子 鋰離子

3.7 V 3.7 V

1.25 Ah 1.25 Ah

1 1

J)

25000

25000

F)

F)

I)

I)

J)

安裝

為充電電池進行充電

您可使用 Micro USB 線透過 USB 連接埠或 USB

電源轉接器(500mA 以上)為充電電池進行充

電。

如何正確地使用充電電池

充電電池必須存放在容許溫度範圍的環境中,請參

考「技術性數據」。夏天不可以把充電電池擱置在

汽車中。

充電後如果充電電池的使用時間明顯縮短,代表充

電電池已經損壞,必須更換新的充電電池。

請您遵照廢棄物處理相關指示。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

操作

操作機器

u 不可以讓濕氣滲入儀器中,也不可以讓陽光直接

照射在儀器上。

u 勿讓測量工具暴露於極端溫度或溫度劇烈變化的

環境。例如請勿將它長時間放在車內。測量工具

歷經較大溫度起伏時,請先讓它回溫後再使用。

如果儀器曝露在極端溫度下或溫差較大的環境

中,會影響儀器的測量準確度。

u 測量工具須避免猛力碰撞或翻倒。測量工具遭受

外力衝擊後,一律必須先檢查其精準度,確認後

才能繼續使用(參見 「檢查傾角測量準確度及進

Page 28

28 | 繁體中文

行相關校正(請參考圖 H)」, 頁31)與(參見

「檢查距離測量準確度」, 頁31)。

啟動/關閉

u 不可放任啟動的測量工具無人看管,使用完畢後

請關閉測量工具電源。雷射可能會對旁人的眼睛

產生眩光。

您可透過以下方式啟動測量工具:

– 按一下開關按鈕 (8):測量工具隨即開機,並進入

長度測量功能。此時雷射光並不會開啟。

– 按一下測量按鈕 (2):測量工具和雷射隨即啟動。

此時儀器是處於「長度測量」操作模式。測量工

具若是安裝在測量軌道 (24) 中,則傾角測量功能

啟用。

u 雷射光束不可以對準人或動物,操作人本身也不

要直視光束,即使和光束相距甚遠也不可以做上

述動作。

若要將測量工具關機,請長按開關按鈕 (8)。

若持續約 5 分鐘未按壓測量工具上的任何按鈕,則

測量工具將自動關機以節省電池電力。

在「傾角測量」操作模式下時,只要角度未改變的

時間已達約 5 分鐘之久,測量工具將自動關機以節

省電池電力。

已儲存的測量值會在自動關機之後全數保留下來。

測量流程

測量工具安裝在測量軌道 (24) 上時,按一下測量按

鈕 (2) 啟動後測量工具將一律進入長度測量功能或傾

角測量功能。按一下對應的功能按鈕即可換至其他

測量功能 (參見 「測量功能」, 頁29)。

啟動後,測量工具後緣即被選取做為測量基準點。

按一下基準點按鈕 (10) 即可變更此基準點(參見

「選擇基準點(請參考圖 A)」, 頁28)。

將測量工具選定的基準點置於所需的測量起點上

(例如:牆壁)。

短按一下測量按鈕 (2) 以便啟動雷射光束。

u 雷射光束不可以對準人或動物,操作人本身也不

要直視光束,即使和光束相距甚遠也不可以做上

述動作。

將雷射光束對準目標物表面。再次短按一下測量按

鈕 (2) 即可開始測量。

雷射光束若已是常亮狀態,則第一次按下測量按鈕

(2) 後就會開始測量。如果選擇連續測量功能,只要

一啟動這個功能便可立刻進行測量。

原則上 0.5 秒鐘內會出現測量值,最晚 4 秒。測量

時間取決於距離、光線情況和目標物表面的反射特

性。測量結束時,會發出一個聲音訊號提醒您。完

成測量後,雷射光束將自動關閉。

瞄準後若 20 秒內未進行測量,將自動關閉雷射光

束,以節省充電電池的電力。

選擇基準點(請參考圖 A)

共有四個不同的測量基準點供您選擇:

– 測量工具後緣或止動銷 (9) 旋轉 90° 後翻出的前

緣(例如:置於外角上時)、

– 旋轉 180° 後翻出的止動銷尖端 (9)(例如:從角

落測量)、

– 測量工具前緣(例如:以桌緣做為測量起點)、

– 螺紋孔中心點 (19)(例如:使用三腳架進行測

量)。

若要選擇基準點,請反覆按壓按鈕 (10),直到螢幕

上出現您想要使用的基準點。開機時,基準點預設

為測量工具後緣。

已完成的測量無法後續變更基準點(例如:出現在

測量值清單中的測量值)。

「基本設定」功能表

若要進入「基本設定」功能表,請按住基本設定按

鈕 (4) 不放。

短按一下基本設定按鈕 (4),即可選擇個別功能表項

目。

按一下減號按鈕 (5) 或加號按鈕 (11),即可選擇功能

表項目裡面的設定。

若要離開「基本設定」功能表,請按一下測量按鈕

(2)。

基本設定

聲音訊號 開啟

關閉

螢幕照明 開啟

關閉

自動

開啟/關閉

數位水平儀 開啟

關閉

螢幕旋轉 開啟

關閉

雷射光束常亮 開啟

關閉

距離的單位(視國別而

定)

角度的單位 °、%、mm/

關機時將保留除了「雷射光束常亮」設定以外的所

有基本設定。

m、ft、

inch、…

m、inch/ft

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 29

雷射光束常亮

1

2

u 雷射光束不可以對準人或動物,操作人本身也不

要直視光束,即使和光束相距甚遠也不可以做上

述動作。

若是選用此項設定,則在兩次測量的間隔時間裡雷

射光束也會保持開啟,您只需短按一次測量按鈕 (2)

即可進行測量。

測量功能

單一長度測量

若要進行長度測量,請反覆按壓按鈕 (12),直到螢

幕上出現長度測量符號 。

按一下測量按鈕 (2) 將啟動雷射,再按

一下即開始測量。

測量值將出現在測量結果顯示列 (c)。

連續進行多次長度測量時,最新的測量

結果將出現在測量值顯示列 (a) 中。

面積測量

若要進行面積測量,請反覆按壓按鈕 (12),直到螢

幕上出現面積測量符號 。

接著按照進行長度測量之方式,測量寬度、長度即

可。進行這兩次測量之間,雷射光束將保持開啟。

完成第二次測量後,將自動計算出面積

並於測量結果顯示列 (c) 中顯示該值。測

量值顯示列 (a) 中將詳列出每一個測量

值。

體積測量

若要進行體積測量,請反覆按壓按鈕 (12),直到螢

幕上出現體積測量符號 。

接著按照進行長度測量之方式,測量寬度、長度及

深度即可。進行這三次測量之間,雷射光束將保持

開啟。

完成第三次測量後,將自動計算出體積

並於測量結果顯示列 (c) 中顯示該值。測

量值顯示列 (a) 中將詳列出每一個測量

值。

無法顯示大於 999 999 m3 的數值,螢幕上將出現

「ERROR」。您可以把待測量的面積分割成數個單一

測量。分別計算各單一測量的體積,然後再累加各

個體積。

連續測量/最小值測量/最大值測量(請參考圖 B)

進行連續測量時,可針對目標物讓測量工具進行相

對移動,期間系統將每 0.5 秒左右更新一次測量

值。舉例來說,您可從某一個牆面離開,直到相隔

所需距離為止,而且您可隨時看到當下的實際距

離。

若要進行連續測量,請按一下功能切換按鈕 (4),直

到螢幕上出現連續測量符號 。按一下測量按鈕 (2)

即可開始連續測量。

使用最小值測量功能可以找出距離基準點最近的位

置。舉例來說,它可幫助您找出垂直位置或水平位

置。

繁體中文 | 29

使用最大值測量功能可以找出距離基準點最遠的位

置。舉例來說,它可幫助您找出對角線位置。

當下的實際測量值將顯示於測量結果顯

示列 (c) 中。最大值測量值(「max」)

及最小值測量值(「min」)則是位於測

量值顯示列 (a)。如果新測得的長度小於

目前的最小值或大於目前的最大值,舊

的儲存值便會被新的測量值取代。

按一下記憶刪除按鈕 (8) 即可刪除目前的最小值或最

大值。

按一下測量按鈕 (2) 即可結束連續測量。新測得的測

量值將顯示於測量結果顯示列 (c) 中。若再按一下測

量按鈕 (2),連續測量將重頭開始。

連續測量功能將於 5 分鐘後自動關閉。新測得的測

量值仍將顯示於測量結果顯示列 (c) 中。

間接長度測量

無法進行直接測量時(例如有障礙物會阻擋雷射,

或者沒有目標物可充當反射體時),則必須以間接

的方式測量。此一測量方式僅適用於垂直方向。任

何水平方向的偏差都會導致誤測。

雷射將在各次單一測量之間的空檔保持開啟。

間接距離測量共分為三種測量功能供您選用,它們

分別可用來量測不同類型的距離。

a)間接高度測量(請參考圖 C)

反覆按壓功能切換按鈕 (4),直到螢幕上出現間接高

度測量符號 1。

請注意:測量工具應位於與下方測量點一致的高度

上。接著將測量工具沿基準點側傾,依照進行長度

測量之方式來測量 (1) 線段。

完成測量後,測量結果顯示列 (c) 中顯示

的測量結果即為您想要確認的「X」線

段。「1」線段及「α」角的測量值則是

位於測量值顯示列 (a) 中。

b)雙重間接高度測量(請參考圖 D)

反覆按壓功能切換按鈕 (4),直到螢幕上出現雙重間

接高度測量符號

。

依照進行長度測量之方式依序測量線段 「1」 和

「2」。

完成測量後,測量結果顯示列 (c) 中顯示

的測量結果即為您想要確認的「X」線

段。「1」線段、「2」線段及「α」角

的測量值則是位於測量值顯示列 (a) 中。

請注意:在同一個測量流程中進行每一次測量時,

測量基準點(例如:測量工具後緣)都必須精準地

保持在同一位置上。

c)間接長度測量(請參考圖 E)

反覆按壓功能切換按鈕 (4),直到螢幕上出現間接長

度測量符號 1。

注意,測量儀器必須與您想要確認的測量點位在同

一高度上。接著將測量工具沿基準點側傾,依照進

行長度測量之方式來測量「1」線段。

Bosch Power Tools 1 609 92A 4R8 | (13.02.2019)

Page 30

30 | 繁體中文

完成測量後,測量結果顯示列 (c) 中顯示

的測量結果即為您想要確認的「X」線

段。「1」線段及「α」角的測量值則是

位於測量值顯示列 (a) 中。

牆壁面積測量(請參考圖 F)

牆壁面積測量是用來計算相同高度之數個單一牆面

的總面積。

插圖範例中所測量的是:空間高度 A 相同但長度不

同 B 之多個牆面加總起來的總面積。

若要進行牆壁面積測量,請反覆按壓功能切換按鈕

(4),直到螢幕上出現牆壁面積測量符號 。

依照進行長度測量之方式來測量空間高度 A。測量

值(「cst」)將顯示於上方測量值顯示列 (a)。雷射

功能將保持開啟。

隨後請測量第一面牆的長度 B1。將自動

計算出面積並於測量結果顯示列 (c) 中顯

示該值。新測得的長度測量值位於中間

測量值顯示列 (a)。雷射功能將保持開

啟。

現在請您測量第二面牆的長度 B2。中間

測量值顯示列 (a) 所顯示的單次測量值將

累加到長度 B1 中。兩個長度的總和(即

「sum」,顯示於下方測量值顯示列

(a))再乘以之前儲存的高度 A。所得的總面積值將

顯示於測量結果顯示列 (c) 中。

您可以繼續測量任意多個長度 BX,系統會自動相加

這些值後再乘以高度 A。

為求正確計算面積,其前提是:所有區塊面積的第

一個測量長度要一致(在本範例中即為空間高度

A)。

傾角測量(請參考圖 G)

按一下傾角測量按鈕 (3),螢幕上隨即出現傾角測量

符號 。目前是以測量工具背面做為基準點。再按

一下傾角測量按鈕 (3),即改以測量工具側面做為基

準點,而且螢幕畫面將旋轉 90°。

按一下測量按鈕 (2),以便鎖定並記憶測量值。再按

一下測量按鈕 (2) 即可繼續測量。

測量中途如果此符號開始閃爍,代表測量儀器過度

側傾。

如果基本設定中的「數位水平儀」功能為啟用狀

態,即便是在使用其他測量功能時,也可以從螢幕

(1) 的顯示列 (d) 中看見此一傾角值。

定時功能

舉例來說,定時功能可幫助您:避免在進行測量期

間移動測量工具。

若要使用定時功能,請按住按鈕 (6) 不放,直到螢幕

上出現符號 。

測量值顯示列 (a) 中將顯示:觸發後到真正開始執行

測量之間的這段間隔時間。按一下加號按鈕 (11) 或

減號按鈕 (5),即可在 1 秒至 60 秒之間調整此一間

隔時間。

到了設定的時間儀器便會自動測量。

在其他測量功能(例如:面積測量)底

下進行距離測量時也可以使用定時功

能。但是測量結果相加、相減以及連續測量時無法

使用該功能。

最新測量值清單

測量工具會儲存最後的 20 個測量值及其算式。顯示

是採取回溯方式(即最後一筆測量值最先顯示)。

按一下按鈕 (7) 即可叫出已儲存的測量

內容。螢幕上將顯示上一次測量的測量

結果,同時還會有代表測量值清單的指

示器 (e) 以及所顯示之測量內容的記憶編

號。

若已沒有其他儲存的測量內容,那麼再按一下按鈕

(7) 時測量工具將跳回之前使用的測量功能。只要按

下任一測量功能按鈕,就可離開測量值清單。

若要將目前顯示的長度測量值儲存起來做為常數,

請按住測量值清單按鈕 (7) 不放,直到螢幕上出現

「CST」。測量值清單中的項目無法後續再將它儲存

為常數。

若要使用某一測量功能(例如:面積測量)中的特

定長度測量值,請按一下測量值清單按鈕 (7),選取

您想要使用的那筆記錄,然後再按一下測量結果按

鈕 (6) 確認。

刪除測量值

在所有測量功能中短按一下按鈕 (8),即可刪除您新

測得的最後一筆測量值。多次短按該按鈕,即能反

序刪除各測量值。

若要刪除測量值清單中目前顯示的記錄,請短按一

下按鈕 (8)。若要刪除整個測量值清單及「CST」常

數,請按住測量值清單按鈕 (7) 不放,並同時再短按

一下按鈕 (8)。

使用牆壁面積測量功能時,第一次短按一下按鈕 (8)

可刪除最後一筆測量值,第二次按一下時即刪除所

有長度值 BX,第三次按一下時則會刪除空間高度

A。

測量值相加

若要累加測量值,請先隨意執行一次測量,或是直

接從測量值清單中挑選一筆記錄。接著按一下加號

按鈕 (11)。螢幕上隨即出現「+」,以示確認。然後

再進行另一次測量或者從測量值清單中挑選另一個

測量值。

按一下測量結果按鈕 (6) 即可查看這兩

次測量的加總。測量值顯示列 (a) 中將顯

示算式,總和則是位於測量結果顯示列

(c)。

算出加總值後,只要在進行測量前按一下加號按鈕

(11),就可繼續在此值中累加其他測量值或測量值清

單中的記錄。按一下測量結果按鈕 (6) 即可停止累

加。

關於相加功能的注意事項:

– 長度值、面積值和體積值不可以混合相加。舉例

來說,如果將長度和值面積值相加,那麼按一下

測量結果按鈕 (6) 時「ERROR」將短暫出現在螢幕

上。然後測量儀器便會跳回上一個測量功能。

– 系統會累加每一次的測量結果(例如:體積

值),進行連續測量時則是累加測量結果顯示列

1 609 92A 4R8 | (13.02.2019) Bosch Power Tools

Page 31

(c) 中所顯示的測量值。系統無法累加測量值顯示

列 (a) 中的單次測量值。

刪除測量值

若想要將測量值相減,請按一下減號按

鈕 (5),於是螢幕上隨即出現「–」,以

示確認。後續步驟請比照「測量值相

加」。

作業注意事項

一般注意事項

測量時,接收點 (17)、雷射光束出口 (16) 上不得有

遮蓋物。

進行測量時不可移動測量儀器(使用連續測量功能

和傾角測量功能時例外)。因此,請將測量工具儘

可能放置在固定的擋塊或托架平面上。

影響測量範圍的因素

測量範圍取決於光線情況和目標物表面的反射特

性。當您在戶外或者在日照強烈的環境中進行測量

時,佩戴雷射辨識鏡 (27)(配件)並使用雷射標靶

(28)(配件)或者遮暗目標物表面,皆可提高雷射光

束的能見度。

影響測量結果的因素

由於物理作用之故,無法排除在不同種型表面上進

行測量時出現誤測的狀況。表面的類型可分為:

– 透明表面(例如玻璃、水)

– 反射表面(例如拋光金屬、玻璃)

– 多孔狀表面(例如具有阻隔特性的材料)

– 結構性表面(例如毛胚、天然石材)。

必要時請將雷射標靶 (28)(配件)放到表面上。

如果未正確地瞄準好目標物表面,也可能會出現誤

測。

此外有溫差的空氣層和間接的反射都可能影響測量

值。

檢查傾角測量準確度及進行相關校正(請參考圖 H)

請定期檢查傾角測量準確度。其做法是執行一次反

轉測量。請將測量工具放到桌上,然後進行傾角測

量。將測量工具旋轉 180°,然後再測量一次傾角。

顯示值最多可相差 0.3°。

如果差距超出規定則必須重新校正測量儀器。若要

這樣做,請按住傾角測量按鈕 (3) 不放即可。並遵照

螢幕上的指示。

檢查距離測量準確度

您可按以下方式檢查測量工具的準確度:

– 選擇一個您本人非常熟悉且長度不會改變的測量

線段,線段長度大概介於 1 到 10 公尺之間(例

如房間的寬度、門口等)。測量線段必須位於室

內。測量目標的表面必須是光滑且具備良好的反

射性。

– 連續測量該線段 10 次。

每一次的測量結果最多只能與平均值相差 ±2 mm。

要做好測量記錄,以便日後充當檢查儀器精確度的

根據。

繁體中文 | 31

使用三腳架(配件)進行測量

當測量目標位於遠處時,必須使用三腳架。請利用

1/4" 螺紋孔 (19) 將測量工具安裝到三腳架 (26) 或一

般市售相機三腳架的快拆座上。或者您也可以使用

一般市面上的照相機三腳架。

請按一下按鈕 (10) 以便配合情況改設為使用三腳架

時的測量基準點(螺紋孔基準點)。

使用測量軌道進行測量(請參考圖 I–K)

進行傾角測量時若想要得到更精準的測量結果,您

可使用測量軌道 (24)。使用測量軌道時無法進行距

離測量。

請按照圖示將測量工具嵌進測量軌道

(24),然後利用鎖止扳桿 (25) 將測量工

具鎖定。按一下測量按鈕 (2),以便啟用

「測量軌道」操作模式。

請藉由執行反轉測量或是測量軌道上的水平儀,定

期檢查傾角測量準確度。

如果差距超出規定則必須重新校正測量儀器。若要

這樣做,請按住傾角測量按鈕 (3) 不放即可。並遵照

螢幕上的指示。

若要結束「測量軌道」操作模式,請將測量工具關

機並將它從測量軌道中取出。

故障-原因和補救方法

原因 補救措施

溫度警示燈閃爍時,無法進行測量

測量工具已超出 –10 °C

至 +50 °C 的操作溫度之

外(使用連續測量功能時

須在 +40 °C 以下)。

螢幕上出現「Error」

相加/相減不同測量單位

的測量值

雷射與目標物之間的夾角

太小。

目標物表面的反射性太強

(例如鏡子)或太弱(例

如黑色材料),或是環境

光線過強。

雷射光束出口 (16) 或接

收點 (17) 起霧(例如因

溫度變化過快)。

算出的數值大於 999

999 m/m2/m3。

螢幕上出現「>60°」或「<–60°」

超出測量功能或基準點的

傾角測量範圍。

螢幕上出現「CAL」和「ERROR」

未按照正確順序或未在正

確位置上進行傾角測量的

校正作業。

停下工作靜待測量工具的

溫度回到操作溫度範圍。

只能相加/相減相同測量

單位的測量值

加大雷射與目標物之間的

夾角

請使用雷射標靶 (28)(配

件)

請用軟布擦乾雷射光束出

口 (16) 或接收點 (17)

進行測量時把待計算的長

度再細分成多段

在各個指定的角度範圍內

進行測量。

根據螢幕和使用說明書上

的指示再做一次校正。