Page 1

Installation and Operating Manual for

C9900-G0xx

Push-Button Extension for Multi-Touch Control Panel

- CP2xxx

- CP39xx

Version: 1.2

Date: 2014-12-12

Page 2

Page 3

Table of contents

Table of contents

1 Foreword 3

1.1 Notes on the documentation 3

1.1.1 Disclaimer 3

1.1.2 Brands 3

1.1.3 Patents 3

1.1.4 Copyright 3

1.1.5 Delivery state 3

1.1.6 Delivery conditions 3

1.2 Description of safety symbols 4

1.3 Basic safety measures 5

1.4 Operator's obligation to exercise diligence 6

1.4.1 National regulations 6

1.4.2 Procedure in the event of a fault 6

1.4.3 Operator requirements 6

2 Product description 7

2.1 Product overview 7

2.2 Intended use 8

2.3 Accessing the connections 8

2.3.1 CP2xxx 8

2.3.2 CP39xx without mounting arm adapter 9

2.3.3 CP39xx with mounting arm adapter 10

2.4 Connections 11

2.4.1 Description of the PCBs 11

2.4.2 Configuration 14

2.4.3 Toggle switch 15

2.5 Wiring of the connection strips 15

2.6 Inserting self-printed labels 16

3 Special instructions for the TwinCAT System Manager 17

3.1 From TwinCAT 2.11 build 2245 18

4 Installation 19

4.1 Transport and unpacking 19

4.1.1 Transport 19

4.1.2 Unpacking 19

4.2 Connecting the push-button extension 20

4.2.1 Connecting cables 20

5 Operation 21

C9900-G0xx 1

Page 4

Table of contents

5.1 Maintenance 21

5.1.1 Cleaning 21

5.1.2 Maintenance 21

5.2 Emergency procedures 21

5.3 Decommissioning 21

5.3.1 Disposal 21

6 Technical data 22

7 Appendix 23

7.1 Service and support 23

7.1.1 Beckhoff's branch offices and representatives 23

7.2 Headquarters 23

7.2.1 Beckhoff Service 23

7.2.2 Beckhoff Support 23

7.3 PCBs used in keyboard extensions 24

7.4 Circuit diagrams 25

7.4.1 Circuit diagram for emergency off PCB 25

7.4.2 Circuit diagram for three-button PCB 26

7.4.3 Circuit diagram for four-button PCB 27

7.5 FCC certifications for the United States of America 28

7.6 FCC certifications for Canada 28

2 C9900-G0xx

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation technology

familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components. The responsible staff must ensure that the application or use of the products

described satisfy all the safety requirements, including all the relevant laws, regulations, guidelines and

standards.

1.1.1 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under

development. For this reason, the documentation may not always have been fully checked for

consistency with the performance data, standards or other characteristics described. If it should contain

technical or editorial errors, we reserve the right to make changes at any time and without notice. No

claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

1.1.2 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to

an infringement of the rights of the respective trademark owner.

1.1.3 Patents

The EtherCAT technology is patent protected, in particular by the following applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications and

registrations in various other countries.

The TwinCAT technology is patent protected, in particular by the following applications and patents:

EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.1.4 Copyright

©

Beckhoff Automation GmbH.

The copying, distribution and utilization of this document as well as the communication of its contents to

others without express authorization is prohibited. Offenders shall be held liable for damages. All rights

conferred by patent grant or registration of a utility model or registered design are reserved.

1.1.5 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

1.1.6 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

C9900-G0xx 3

Page 6

Foreword

1.2 Description of safety symbols

The following safety symbols are used in these operating instructions. They are intended to alert the

reader to the associated safety instructions.

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers

DANGER

WARNING

CAUTION

the life and health of persons.

Caution - Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life

and health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries

to persons.

Damage to the environment or devices

Attention

Note

Failure to follow the instructions associated with this symbol can lead to damage to the

environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

4 C9900-G0xx

Page 7

Foreword

1.3 Basic safety measures

Before the Industrial PC is switched off, software that is running must be properly closed. Otherwise data

can get lost.

Switch off system components and disconnect the Control Panel from the

system

Attention

Disconnect the Control Panel by releasing the connectors at the back. System components that have

been switched off must be secured against being switched on again.

Attention

Before opening the housing, and whenever the control panel is not being used for

control purposes (such as during functional checks after a repair), all parts of the

equipment must first be switched off, after which the control panel is to be

disconnected from the equipment.

Do not exchange any parts when under power

When components are being fitted or removed, the supply voltage must be switched

off.

Assembly work can cause damage:

if metal objects such as screws or tools fall onto operating circuit boards.

if cables are connected or disconnected during operation.

C9900-G0xx 5

Page 8

Foreword

1.4 Operator's obligation to exercise diligence

The operator must ensure that

the products are only used as intended (see Product description chapter);

the products are only operated in sound condition and functioning properly.

the products are operated only by suitably qualified and authorized personnel.

the personnel is instructed regularly about relevant occupational safety and environmental

protection aspects, and is familiar with the operating instructions and in particular the safety

instructions contained herein.

the instruction manual is in good condition and complete, and always available for reference at

the location where the products are used.

1.4.1 National regulations

Depending on the type of machine and plant in which the product is used, national regulations governing

the controllers of such machines will apply, and must be observed by the operator. These regulations

cover, amongst other things, the intervals between inspections of the controller. The operator must initiate

such inspections in good time.

1.4.2 Procedure in the event of a fault

In the event of product malfunctions please contact Headquarters

Beckhoff Automation GmbH

Eiserstraße 5

33415 Verl

Germany

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.de

Beckhoff Service.

1.4.3 Operator requirements

All users of the product must have read the operating instructions and be aware of all the functions they

can access.

6 C9900-G0xx

Page 9

Product description

2 Product description

2.1 Product overview

Fig. 1: CP3918 with push-button extension C9900-G025 (one emergency stop button, ten illuminated

push buttons)

The optional C990-G0xx push-button extensions for the Control Panels CP2xxx and CP39xx from

Beckhoff Automation provide additional input options. Push-button extensions that match the design of

the Control Panels enable application-specific use of electromechanical buttons. Selection and key

switches can also be integrated. The push-button extension is located below the touchscreen. The

number of buttons that can be added depends on the display size.

The actuation of the emergency stop and other buttons is transferred to the controller via USB and can be

read with TwinCAT. Optionally, customers may use the signals for additional purposes. The emergency

stop has two N/C contacts and one N/O contact. The signal of the N/O contact is transferred to the

controller. The two N/C contacts can be used by the customer. One button actuates two N/O contacts,

one of which is available as a potential-free contact for use by the customer. The indicator lamps are

controlled via USB.

By default the first button is supplied with a green cap, the second with a red cap, and the other buttons

with white caps (see Fig. 1). Other button cap color options are available for retrofitting:

C9900-Z255: 5 button caps (blue)

C9900-Z256: 5 button caps (yellow)

C9900-Z257: 5 button caps (green)

C9900-Z258: 5 button caps (red)

C9900-Z259: 5 button caps (white)

A label sheet with 54 pre-punched button labels is available under order code C9900-Z260. Application of

the labels is explained in section 2.6.

Custom adaptations are possible on request.

C9900-G0xx 7

Page 10

Product description

2.2 Intended use

The multi-touch Control Panels CP2xxx and CP39xx with push-button extension C9900-G0xx are

designed for industrial machine and systems engineering applications. The push-button extension is

located below the touchscreen.

Risk of explosion!

The Control Panels must not be used in potentially explosive atmospheres.

DANGER

2.3 Accessing the connections

The push-button extension connections for use by the customer are located at the rear of the housing. To

access the connections remove the cover panel at the rear. The exact procedure depends on the housing

type and mounting arm.

2.3.1 CP2xxx

Release the M3 screws around the perimeter of the button cover (see Fig. 2) and remove the cover. The

number of screws may vary, depending on the display size. The potential-free contacts are now

accessible. The cabling can be fed out of the housing via the M20 cable gland shown in Fig. 2. Attach the

button cover and secure it with the screws.

Fig. 2: CP2924-0000-G007 with or without button cover

8 C9900-G0xx

Page 11

Product description

2.3.2 CP39xx without mounting arm adapter

Release the M3 screws around the perimeter of the button cover (see Fig. 3) and remove the cover. The

number of screws may vary, depending on the display size. The potential-free contacts are now

accessible. The cabling can be fed out of the housing via the M20 cable gland. Attach the button cover

and secure it with the screws.

Fig. 3: CP3919-0000-G026 with or without button cover

C9900-G0xx 9

Page 12

Product description

②

②

2.3.3 CP39xx with mounting arm adapter

For Control Panels with mounting arm adapter (C9900-M752 and C9900-M753), release the M3 screws

(labelled 1 in Fig. 4) around the perimeter of the button cover and release it. Release the screws labelled

2 in Fig. 4 and remove the cover. Then remove the cover panel (3). The cover panel can easily be

levered off with a suitable tool to enable access to the connections. The potential-free contacts are now

accessible. The cabling can be guided into the mounting arm adapter through the cable channel and M20

gland shown in Fig. 5. Re-assemble the button cover and the cover panel in reverse order.

③

①

Fig. 4: CP3919-0000-G023-M752

Fig. 5: CP3919-0000-G023-M752 without button cover and cover panel

10 C9900-G0xx

Page 13

Product description

2.4 Connections

2.4.1 Description of the PCBs

This section describes and explains the PCBs for the buttons and their connections. Each PCB has

connection strips to enable customers to use the buttons and the emergency stop. The pin assignment of

the connection strips is shown on each PCB. The circuit diagrams for each of the three PCBs used can

be found in the annex under section 7.4. The connector designations (CONxxx) used in this description

refer to these circuit diagrams.

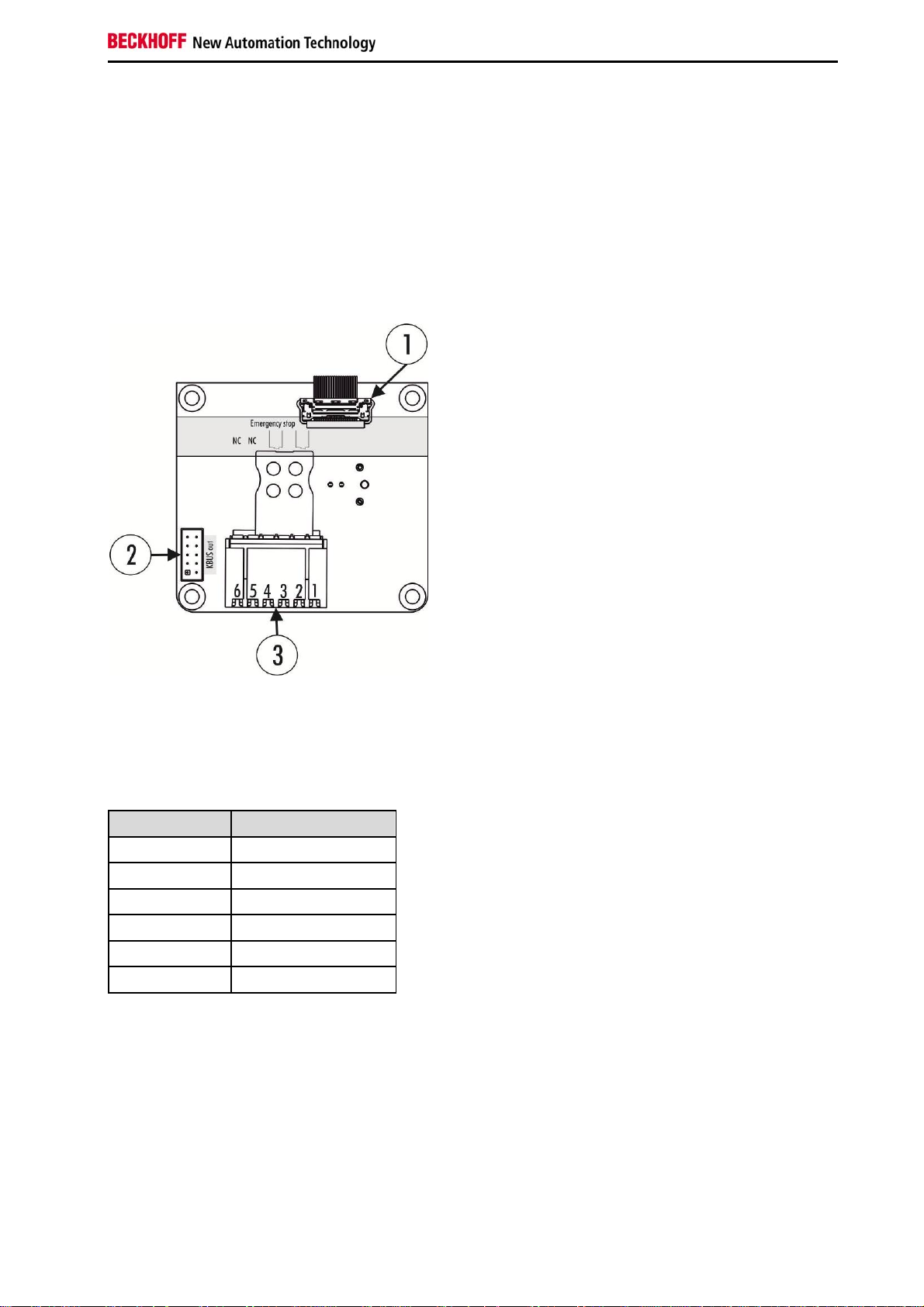

Emergency stop PCB

Fig. 6: Emergency stop PCB

The emergency stop PCB has a USB (1, CON500) and a K-bus interface (2, CON400). Both interfaces

are used for signal transfer and are assigned ex factory. A further connection strip (3, CON402) is

available for customer use via the two additional N/C contacts of the emergency stop. The connection

strip assignment is shown in Table 1.

Terminal point Description

1 Input N/C contact 1

2 Output N/C contact 1

3 Input N/C contact 2

4 Output N/C contact 2

5 Not used

6 Not used

Table 1: Pin assignment for emergency stop PCB

C9900-G0xx 11

Page 14

Product description

Three-button PCB

Fig. 7: Three-button PCB

The three-button PCB has two K-bus interfaces (1, CON400 & CON401), which are assigned ex factory.

The outer connection strips (2, CON600 & CON601) are used for power supply for the indicator lamps,

connection strip 4 is available for customer use. The bridges between the button PCBs are assigned ex

factory. The power supply has to be provided by the customer. One of the two N/O contacts of each

button is available for customer use via a connection strip (3, CON603). At a further connection strip (4,

CON602) three digital inputs are available for customer use, which are transferred via the K-bus. The 24

V supply has to be provided by the customer. The PCB also features a DIP switch (5, SW600), which is

explained in section 2.5.

The pin assignments for connection strips 2, 3 and 4 are listed in Table 2.

Connection

strip

1

Terminal

point

1 24 V DC

2 0 V

Description

1 Input N/O contact 1

2 Output N/O contact 1

3

3 Input N/O contact 2

4 Output N/O contact 2

5 Input N/O contact 3

6 Output N/O contact 3

1 24 V output

2 Digital input 1

4

3 24 V output

4 Digital input 2

5 24 V output

6 Digital input 3

Table 2: Pin assignment for three-button PCB

12 C9900-G0xx

Page 15

Product description

Four-button PCB

Fig. 8: Four-button PCB

The four-button PCB also has two K-bus interfaces (1, CON400 & CON401), which are assigned ex

factory. The outer connection strips (2, CON600 & CON601) are used for power supply for the indicator

lamps, connection strip 4 is available for customer use. The bridges between the button PCBs are

assigned ex factory. The power supply has to be provided by the customer. One of the two N/O contacts

of each button is available for customer use via a connection strip (3, CON603). At a further connection

strip (4, CON604) four digital inputs are available for customer use, which are transferred via the K-bus.

The 24 V supply has to be provided by the customer. The PCB also features a DIP switch (5, SW600),

which is explained in section 2.5.

The pin assignments for connection strips 2, 3 and 4 are listed in Table 3.

Connection

strip

1

Terminal

point

1 24 V DC

2 0 V

Description

1 Input N/O contact 1

2 Output N/O contact 1

3 Input N/O contact 2

3

4 Output N/O contact 2

5 Input N/O contact 3

6 Output N/O contact 3

7 Input N/O contact 4

8 Output N/O contact 4

1 24 V output

2 Digital input 1

3 24 V output

4 Digital input 2

4

5 24 V output

6 Digital input 3

7 24 V output

8 Digital input 4

Table 3: Pin assignment for four-button PCB

C9900-G0xx 13

Page 16

Product description

2.4.2 Configuration

Each configuration features an emergency stop PCB, which contains the USB K-bus coupler. The

remainder of the configuration of the three- and four-button PCBs depends on the display size. Some

examples are shown in Table 4 examples below. A detailed list of combinations can be found in the

annex in section 7.3.

Designation

C9900-G022 4 Horizontal ● - ●

C9900-G023 7 Horizontal ● ● ●

C9900-G024 8 Horizontal ● - ●●

C9900-G027 13 Horizontal ● ●●● ●

Table 4: Button PCB combinations

Fig. 9 shows a possible configuration and the factory state, using the CP2924-0000-G007 as an example.

Number of

Keys

Alignment

Emergency stop

PCB

…

Three-button

PCB

Four-button

PCB

Fig. 9: Rear view of CP2924-0000-G007

USB input

The USB input is located on the emergency stop PCB. The push-button extension is controlled via the

USB port of the CP39xx/CP2xxx. The USB input is pre-wired in the factory.

K-bus

The conversion from USB to K-bus takes place on the emergency stop PCB. The button PCBs are

connected via the K-bus interface of the emergency stop PCB. Each button PCB has a K-bus input and a

K-bus output. The last button PCB is terminated with a jumper at the K-bus output. The K-bus wiring of

the PCBs is done in the factory.

Power supply

The button PCBs are supplied via the voltage input of the first button PCB, from where the power supply

is looped to the next button PCB with a connecting cable, and so on. The connecting cables are provided

ex factory. The wiring of the voltage input is done by the customer.

Connector strips

On the PCBs connection strips are available so that the signals can be used for additional purposes. The

wiring is done by the customer.

14 C9900-G0xx

Page 17

Product description

2.4.3 Toggle switch

An application example for the connection strips is the use of a toggle switch. If a toggle switch is installed

instead of a button, which is to be queried electronically in two positions, the potential-free contact of the

button (see item 3 in Fig. 7 & Fig. 8) can be used for this purpose. The N/O contact can be read-in with

the aid of the additional digital input (see item 4 in Fig. 7 & Fig. 8).

2.5 Wiring of the connection strips

Releasing the spring contact strip

The connection strip can be wired in unconnected or connected state. To release the spring contact strip

from the pin contact strip, use a suitable tool, for example a screwdriver, to guide the locking device in the

direction of the connection strip. The spring contact strip can be removed from the handle plate while the

locking device is held in this position.

Fig. 10: Releasing the spring contact strip

Wiring

The cables are connected as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square

opening above the connection strip.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire safely and

permanently.

DIP switch

The dip switch can be used to loop the 24 V supply of the PCB (see item 2 in Fig. 7 & Fig. 8) directly via

the second N/O contact of a button. In this way the cabling effort at the pin contact strip (see item 3 in

Fig. 7 & Fig. 8) can be reduced.

Example:

Button 2 needs to switch 24 V. Turn the DIP switch to position 2. If button 2 is now actuated, 24 V is

applied to contact 4 on the connector strip.

C9900-G0xx 15

Page 18

Product description

2.6 Inserting self-printed labels

The blank label sheets for the push buttons of the push-button extension offered under order code

C9900-Z260 can be printed with a conventional office printer and then inserted in the push-button

extension.

Fig. 11: Releasing the button cap and inserting the label

First remove the button caps of the buttons that are to be labelled. Use a suitable tool, for example a

screwdriver, to lever off the button caps and remove them. Then remove the labels from the sheet and

place them in button caps. The labels have tabs to aid alignment. Then place the button cap with the label

on the button and push it in.

Fig. 12: Replacing the button caps

16 C9900-G0xx

Page 19

Special instructions for the TwinCAT System Manager

3 Special instructions for the TwinCAT System

Manager

The push-button extension can be integrated via the search

function in the System Manager. The PCBs in use are shown

as terminals in the System Manager (see Fig. 10).

KL1002 stands for the emergency off PCB. Channel 1 is the

N/O contact actuated by the emergency stop. Channel 2 is

not used.

The terminals following the KL1002 represent the button

PCBs used in the configuration. The number of displayed

inputs and outputs is independent of the number of buttons

on a PCB.

For a three-button PCB the inputs “Button 1” to “Button 3”

correspond to the N/O contacts that are actuated by the

respective buttons. The inputs “Button 4” to “Button 6”

correspond to the digital inputs that are allocated for

customer use. “Button 7” and “Button 8” are not used. The

outputs “LED 1” to “LED 3” are connected to the indicator

lamps. “LED 4” to “LED 8” are not used.

For a four-button PCB the inputs “Button 1” to “Button 4”

correspond to the N/O contacts that are actuated by the

respective buttons. “Button 5” to “Button 8” correspond to the

digital inputs that are allocated for use by the customer. “LED

1” to “LED 4” are connected to the indicator lamps. “LED 5” to

“LED 8” are not used.

Since it is not directly apparent from the diagram which PCB

is at which location, section 7.3 of the annex contains an

overview of PCB combinations for different devices. Please

note that in cases where three- and four-button PCBs are

combined, the three-button PCBs are always listed first.

Fig. 13: Push-button extension in the System

Manager

C9900-G0xx 17

Page 20

Special instructions for the TwinCAT System Manager

3.1 From TwinCAT 2.11 build 2245

Build 2245 was added as a new option in the TwinCAT System Manager. KL1002 and CPx9xx-8

terminals found via the search function can be changed via the function “Change to compatible type”. The

display of the inputs and outputs then matches the actual inputs and outputs.

Fig. 14: Change to compatible types

Right-click on the terminal to be changed and select the option “Change to Compatible Type…”. The next

field then shows all compatible types. Table 5 shows the type to be selected. Once the change has been

implemented, only the inputs and outputs that can actually be used are shown.

Found terminal Compatible type Hardware

KL1002 CPx9xx-E-Stop Emergency stop PCB

CPx9xx-8 CPx9xx-3-2 Three-button PCB

CPx9xx-8 CPx9xx-4-2 Four-button PCB

Table 5: Found terminals and compatible types

Please refer to the table in annex 7.3 regarding the hardware present in your device.

18 C9900-G0xx

Page 21

Installation

4 Installation

4.1 Transport and unpacking

The specified storage conditions must be adhered to (see "Technical data").

4.1.1 Transport

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts.

During transport the device must therefore be protected from mechanical stress. Therefore, please use

the original packaging.

Risk of damage to the device

If the device is transported in cold weather or is exposed to extreme variations in

Attention

The device should be left to adapt to room temperature slowly before it is commissioned. Should

condensation occur, a delay time of approximately 12 hours must be allowed before the unit is switched

on.

temperature, make sure that moisture (condensation) does not form on or inside the

device.

4.1.2 Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

If you notice any shipping damage or inconsistencies between the contents and your order, you should

notify Beckhoff Service.

C9900-G0xx 19

Page 22

Installation

4.2 Connecting the push-button extension

The power supply plug must be withdrawn

Please read the documentation for the external devices prior to connecting them.

Attention

4.2.1 Connecting cables

The connections are located at the rear of the push-button extension and are documented in section

Connections.

When connecting cables, please adhere to the following order:

Disconnect all components from the power supply.

Connect all cables to the push-button extension and the devices to be connected.

Ensure that all screw connections between connectors and sockets are tight!

Do not connect or disconnect the cables during a thunderstorm!

When disconnecting a plug connector, always handle it at the plug. Do not pull the cable!

Reconnect all devices to the power supply.

20 C9900-G0xx

Page 23

Operation

5 Operation

5.1 Maintenance

5.1.1 Cleaning

Disconnect the power supply

Switch off the device and all connected components, and disconnect the device from

DANGER

The device can be cleaned with a damp, soft cloth. Do not use any aggressive cleaning materials,

thinners, scouring material or hard objects that could cause scratches.

5.1.2 Maintenance

The push-button extension is maintenance-free.

5.2 Emergency procedures

the power supply.

In the event of a fire use powder or nitrogen to extinguish.

5.3 Decommissioning

5.3.1 Disposal

Observe national electronics scrap regulations

When disposing of the device follow the national electronic waste regulations.

Note

In order to dispose of the device, it must be removed and fully dismantled.

Housing components (polycarbonate, polyamide (PA6.6)) are suitable for plastic recycling.

Metal parts can be sent for metal recycling.

Electronic parts such as disk drives and circuit boards must be disposed of in accordance with

national electronics scrap regulations.

C9900-G0xx 21

Page 24

Technical data

6 Technical data

Risk of explosion!

The push-button extension must not be used in potentially explosive atmospheres!

DANGER

Product designation C9900-G0xx

Supply voltage 24 V

Min. operating voltage AC/DC 5 V

Max. operating voltage AC/DC 35 V

Min. operating current AC/DC 1 mA

Max. operating current AC/DC 100 mA

Switching capacity max. 250 mW

UL compliance

(in preparation)

Use a class 2 power supply, or

Protection via a 4 A fuse, according to UL 60950.2

Interface USB 2.0 interface

Protection class Front IP65, rear IP65

Shock resistance

(sinusoidal vibration)

EN 60068-2-6: 10 to 58 Hz: 0.035 mm

58 to 500 Hz: 0.5 G (~ 5 m/ s²)

Shock resistance (shock) EN 60068-2-27: 5 G (~ 50 m/ s²), duration: 30 ms

EMC - interference immunity According to EN 61000-6-2

EMC interference emission According to EN 61000-6-4

Permitted ambient temperature 0 to +55°C (operation); CP3919/ CP3924: 0 to +50 °C (operation)

-25 to +65 °C (transport/storage)

Permissible relative humidity Maximum 95%, without condensation

Transport and storage The same values for atmospheric humidity and shock resistance are

to be observed during transport and storage as in operation. Suitable

packaging of the Control Panel can improve the resistance to impact

during transport.

Certifications CE, UL in preparation

(20,4 – 28,8 VDC)

DC

section 2.5, table 2C

22 C9900-G0xx

Page 25

Appendix

7 Appendix

7.1 Service and support

Beckhoff and their partners around the world offer comprehensive service and support, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

7.1.1 Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

7.2 Headquarters

Beckhoff Automation GmbH

Eiserstraße 5

33415 Verl

Germany

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.de

7.2.1 Beckhoff Service

The Beckhoff Service Centre supports you in all matters of after-sales service:

on-site service

repair service

spare parts service

hotline service

Hotline: + 49 (0) 5246/963-460

Fax: + 49 (0) 5246/963-479

E-mail: service@beckhoff.com

If servicing is required, please quote the project number of your Industrial PC.

7.2.2 Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

world-wide support

design, programming and commissioning of complex automation systems

and extensive training program for Beckhoff system components

Hotline: + 49 (0) 5246/963-157

Fax: + 49 (0) 5246/963-9157

E-mail: support@beckhoff.com

C9900-G0xx 23

Page 26

Appendix

7.3 PCBs used in keyboard extensions

Designation Diagonal

Number of

Keys

Emergency

stop PCB

Three-button

PCB Four-button PCB

C9900-G002 12 inch 4 ● - ●

C9900-G003 15 inch 7 ● ● ●

C9900-G004 15,6 inch 8 ● - ●●

C9900-G005 18,5 inch 10 ● ●● ●

C9900-G006 19 inch 9 ● ●●● -

C9900-G007 24 inch 13 ● ●●● ●

CP2xxx, horizontal

C9900-G008 21,5 inch 12 ● - ●●●

C9900-G012 12 inch 3 ● ● -

C9900-G013 15 inch 4 ● - ●

C9900-G014 15,6 inch 4 ● - ●

C9900-G015 18,5 inch 4 ● - ●

C9900-G016 19 inch 7 ● ● ●

CP2xxx, vertical

C9900-G017 24 inch 6 ● ●● -

C9900-G018 21,5 inch 6 ● ●● -

C9900-G022 12 inch 4 ● - ●

C9900-G023 15 inch 7 ● ● ●

C9900-G024 15,6 inch 8 ● - ●●

C9900-G025 18,5 inch 10 ● ●● ●

C9900-G026 19 inch 9 ● ●●● -

C9900-G027 24 inch 13 ● ●●● ●

CP39xx, horizontal

C9900-G028 21,5 inch 12 ● - ●●●

C9900-G032 12 inch 3 ● ● -

C9900-G033 15 inch 4 ● - ●

C9900-G034 15,6 inch 4 ● - ●

C9900-G035 18,5 inch 4 ● - ●

C9900-G036 19 inch 7 ● ● ●

CP39xx, vertical

C9900-G037 24 inch 6 ● ●● -

C9900-G038 21,5 inch 6 ● ●● -

24 C9900-G0xx

Page 27

Appendix

7.4 Circuit diagrams

This section shows the circuit diagrams for the PCBs used in the C9900-G0xx push-button extensions.

Additional information can be found the PCBs above (section 2.4.1).

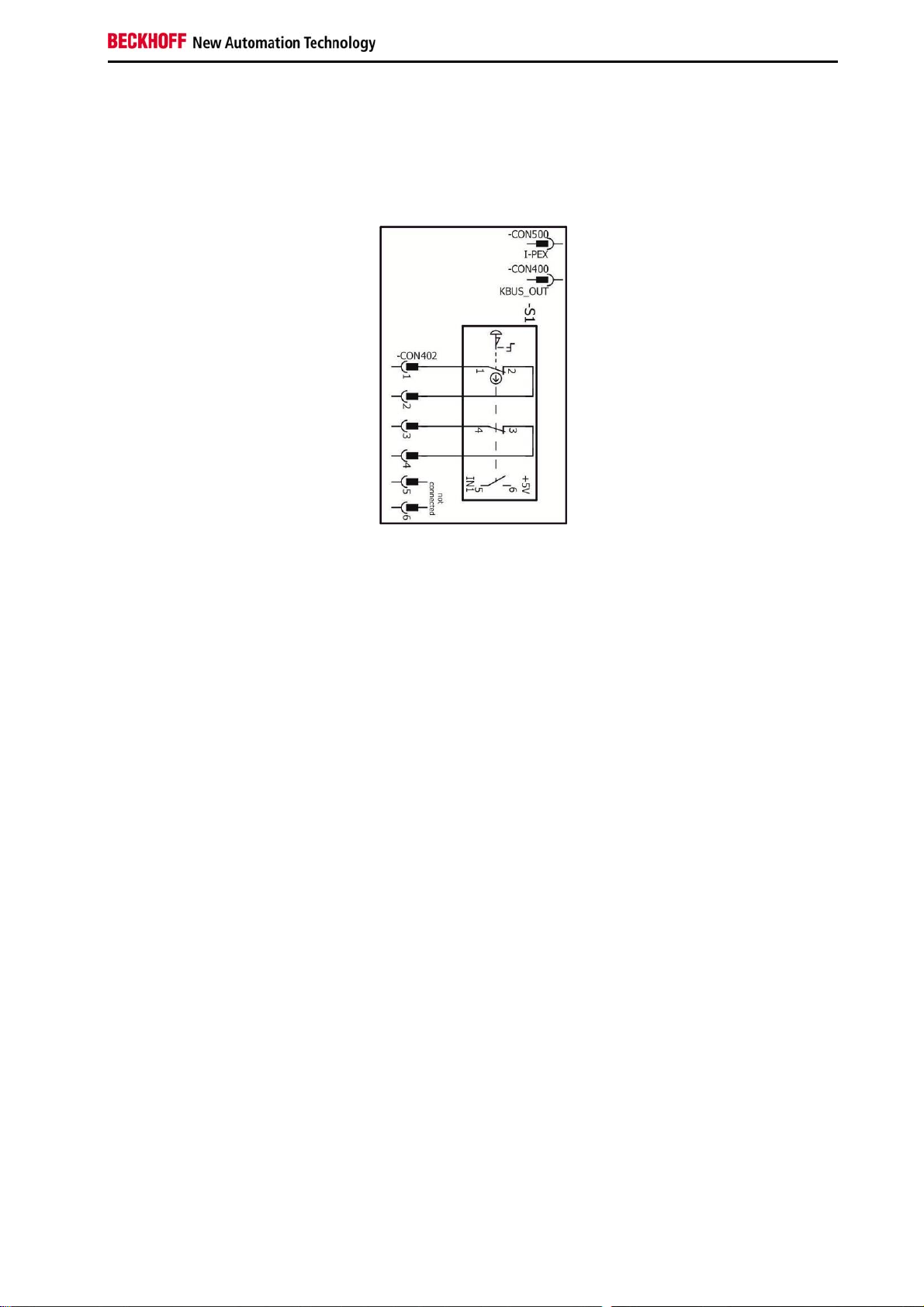

7.4.1 Circuit diagram for emergency off PCB

C9900-G0xx 25

Page 28

Appendix

7.4.2 Circuit diagram for three-button PCB

26 C9900-G0xx

Page 29

Appendix

7.4.3 Circuit diagram for four-button PCB

C9900-G0xx 27

Page 30

Appendix

Approvals for USA and Canada

7.5 FCC certifications for the United States of America

FCC: Federal Communications Commission Radio Frequency Interference Statement

This device was tested and complies with the limits for a digital device of class A, according part 15 of the

FCC regulations. These limits are designed to provide adequate protection against adverse interference,

if the device is used in a commercial environment. This device generates, uses and may emit radio

frequency energy and may cause adverse interference with radio communications, if it is not installed and

used in accordance with the operating instructions. If this device is used in a residential area it is likely to

cause adverse interference, in which case the user must take appropriate countermeasures in order to

eliminate the interference at his own expense.

Technical modifications

Technical modifications of the device may void the FCC certification.

Note

7.6 FCC certifications for Canada

FCC: Canadian Notice

This device does not exceed the class A limits for radiation, as specified by the Radio Interference

Regulations of the Canadian Department of Communications.

28 C9900-G0xx

Loading...

Loading...