Page 1

Installation and Operating instruction

C9900-G072 and C9900-G073

Push-button extension for 10.1-inch "Economy" built-in Panell

Version:

Date:

1.0

26.04.2019

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

2 Transport and unpacking..........................................................................................................................7

2.1 Transport ...........................................................................................................................................7

2.2 Unpacking..........................................................................................................................................7

3 Product description...................................................................................................................................8

3.1 Product overview ...............................................................................................................................8

3.2 Options ............................................................................................................................................10

3.3 Intended use....................................................................................................................................11

3.4 Accessing the connections ..............................................................................................................11

3.4.1 C9900-G072 connections ................................................................................................ 11

3.4.2 C9900-G073 connections ................................................................................................ 14

3.5 Accessories .....................................................................................................................................16

3.5.1 Push-button caps and labels ........................................................................................... 16

4 Mounting...................................................................................................................................................17

4.1 Installing the labels ..........................................................................................................................17

4.2 Installing the Wago picoMax® connector system............................................................................18

5 Operation..................................................................................................................................................19

5.1 Switching the Control Panel on and off ...........................................................................................19

5.1.1 Switching on .................................................................................................................... 19

5.1.2 Shutting down and switching off ...................................................................................... 19

5.2 Operation.........................................................................................................................................19

5.3 Maintenance ....................................................................................................................................19

5.3.1 Cleaning........................................................................................................................... 19

5.3.2 Maintenance .................................................................................................................... 19

5.3.3 Emergency procedures.................................................................................................... 20

5.3.4 Decommissioning ............................................................................................................ 20

6 TwinCAT System Manager......................................................................................................................21

7 Dimensional drawing...............................................................................................................................23

7.1 Dimensional drawing CP6x00 with C9900-G072 or C9900-G073...................................................23

8 Technical data..........................................................................................................................................25

9 Support and Service................................................................................................................................26

10 Approvals for USA and Canada .............................................................................................................27

10.1 FCC approvals for the United States of America.............................................................................27

10.2 FCC approvals for Canada..............................................................................................................27

C9900-G072 and C9900-G073 3

Version: 1.0

Page 4

Table of contents

Version: 1.0

C9900-G072 and C9900-G0734

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT P®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

C9900-G072 and C9900-G073 5

Version: 1.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life and health of

persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to persons.

NOTE

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or

equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

Version: 1.0

C9900-G072 and C9900-G0736

Page 7

Transport and unpacking

2 Transport and unpacking

2.1 Transport

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport the device must therefore be protected from mechanical stress. Therefore, please use the original

packaging.

NOTE

Risk of damage to the device

If the device is transported in cold weather or is exposed to extreme variations in temperature, make sure that moisture (condensation) does not form on or inside the device.

2.2 Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

If you notice any shipping damage or inconsistencies between the contents and your order, you should notify

Beckhoff Service.

C9900-G072 and C9900-G073 7

Version: 1.0

Page 8

Product description

3 Product description

3.1 Product overview

CP6x00

The C9900-G07x push-button extensions add an emergency stop button and three illuminated push-buttons

to the "Economy" built-in Panel PCs and Control Panels.

The push-button extension can be ordered ex factory for all Control Panels and Panel PCs of the "Economy"

family in size 10.1 inch (CP6600, CP6700 and CP6900).

C9900-G072 (USB version)

The actuation of the emergency stop and other push-buttons is transferred to the controller via USB and can

be read with TwinCAT. Optionally, customers may use the signals for additional purposes.

• The emergency stop button S1 has two NC contacts and one NO contact. The signal of the NO contact

is transferred to the controller. The two NC contacts can be used by the customer.

• The push-buttons S2 (green) and S4 (blue) each actuate two NO contacts, of which one is relayed to

the controller and one is available as a potential-free contact for use by the customer.

• The push-button S3 (red) actuates an NC contact and an NO contact. The NO contact is relayed to the

controller, the NC contact is available as a potential-free contact for use by the customer.

• The indicator lamps are only controlled via USB.

• All terminal strips are pluggable.

C9900-G073 (hard-wired version)

The actuation of the emergency stop and push-buttons is only queried via the terminal strip.

• The emergency stop button S1 actuates two NC contacts.

• The push-buttons S2 (green) and S4 (blue) each actuate two NO contacts.

• The push-button S3 (red) actuates two NC contacts.

• The indicator lamps can be controlled via the terminal strip. In this case, an additional 24 VDC power

supply is required at terminal strips X3.1 and X3.2.

• All terminal strips are pluggable.

Version: 1.0

C9900-G072 and C9900-G0738

Page 9

Product description

By default, the push-buttons are delivered with green, red and blue push-button caps. Other push-button cap

color options are available for retrofitting (see chapter Accessories [

A label sheet with 54 pre-punched button labels is available under order code C9900-Z260. Installation is

explained in chapter Installing the labels [

}17].

}16]).

C9900-G072 and C9900-G073 9

Version: 1.0

Page 10

Product description

3.2 Options

Options Description

C9900-G072 Push-button extension for CP6x00 with horizontal 10.1-inch display

• push-button extension on the bottom side

• 3 push-button keys with signal lamp, type RAFI RAFIX 22FS+, round, 30 mm

• 1 emergency stop button, type RAFI RAFIX 22FS+

• Labels for push-button caps for individual marking of each push-button can be ordered

as an option.

• The emergency stop key is wired with two normally-closed contacts, the red

illuminated key with one normally-closed contact and the remaining illuminated keys

with one normally-open contact each to a terminal row.

• Additionally, all push-buttons are queried with a normally-open contact via USB.

• The LEDs of the illuminated keys are only controlled via USB.

C9900-G073 Push-button extension for CP6x00 with horizontal 10.1-inch display

• push-button extension on the bottom side

• 3 push-button keys with signal lamp, type RAFI RAFIX 22FS+, round, 30 mm

• 1 emergency stop button, type RAFI RAFIX 22FS+

• Labels for push-button caps for individual marking of each push-button can be ordered

as an option.

• The emergency stop key and the red illuminated key are wired with two normallyclosed contacts each. The remaining illuminated keys are wired with two normallyopen contacts each to a terminal row.

• All LEDs of the illuminated keys are wired to a terminal row.

Version: 1.0

C9900-G072 and C9900-G07310

Page 11

Product description

X2 (Wago 6-

pin)

X1 (Wago 4-

pin)

3.3 Intended use

The C9900-G0xx built-in Panels with push-button extension are designed for industrial use in machine and

plant engineering applications. The push-button extension is located below the touchscreen.

NOTE

Risk of explosion

The built-in Panels must not be used in potentially explosive atmospheres.

3.4 Accessing the connections

The connections of the push-button extension for use by the customer are located at the bottom of the

housing.

3.4.1 C9900-G072 connections

C9900-G072 and C9900-G073 11

Version: 1.0

Page 12

Product description

3.4.1.1 C9900-G072 circuit diagram

Fig.1: C9900-G072

Version: 1.0

C9900-G072 and C9900-G07312

Page 13

Product description

3.4.1.2 Description of the C9900-G072 connections

Connection strip Terminal point Description

X1 1 X1.1 NO contact emergency stop

2 X1.2 NO contact emergency stop

3 X1.3 NO contact emergency stop

4 X1.4 NO contact emergency stop

Connection strip Terminal point Description

X2 1 X2.1 NO contact S4 blue

2 X2.2 NO contact S4 blue

3 X2.3 NC contact S3 red

4 X2.4 NC contact S3 red

5 X2.5 NO contact S2 green

6 X2.6 NO contact S2 green

NOTE

Electrical characteristic values of the operating elements

The electrical characteristic values of the emergency stop and push-button contacts must

not be exceeded. (see chapter Technical data [

}25]

C9900-G072 and C9900-G073 13

Version: 1.0

Page 14

Product description

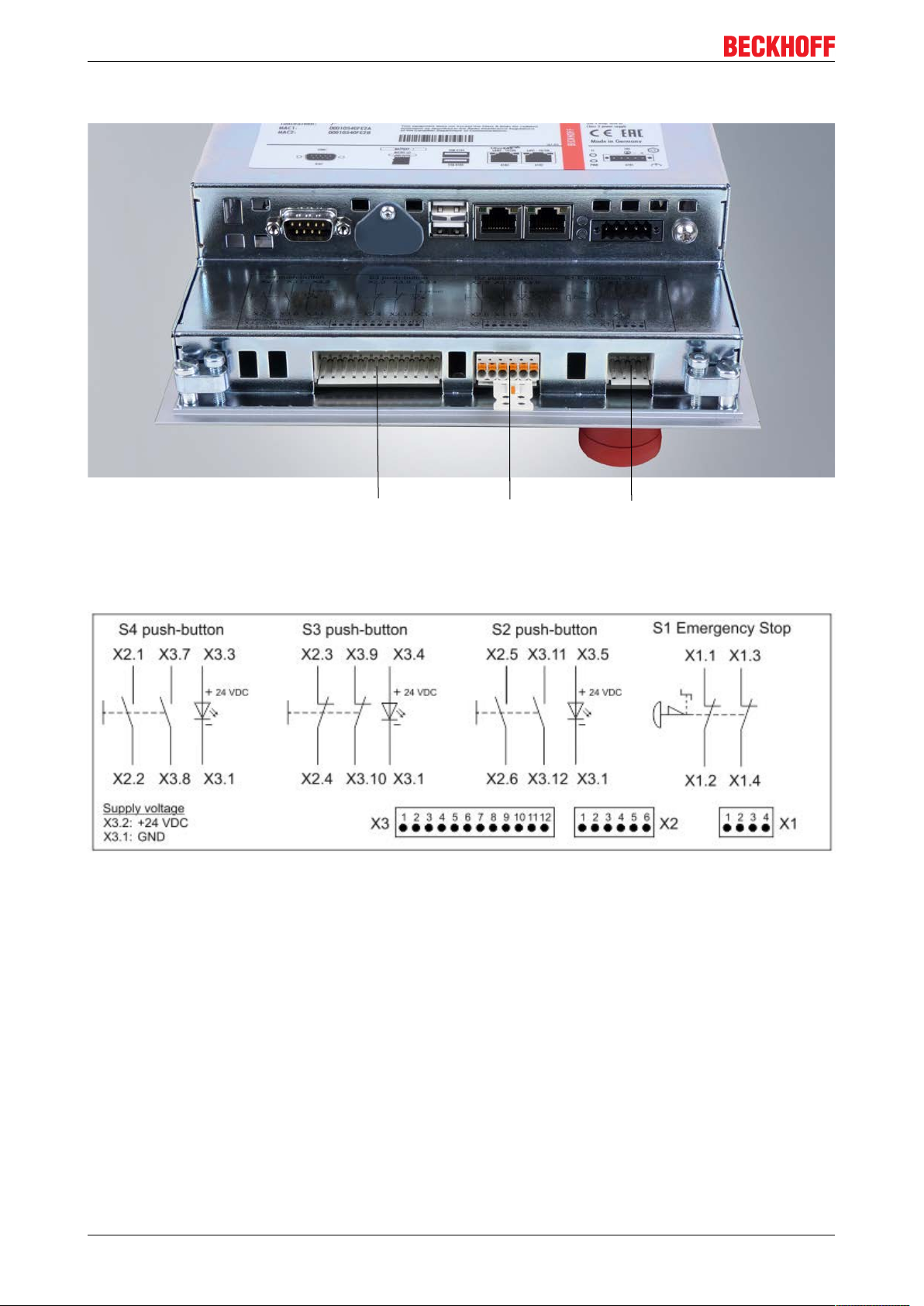

X3 (Wago 12-

pin)

X2 (Wago 6-pin)

X1 (Wago 4-pin)

3.4.2 C9900-G073 connections

3.4.2.1 C9900-G073 circuit diagram

Fig.2: C9900-G073

Version: 1.0

C9900-G072 and C9900-G07314

Page 15

Product description

3.4.2.2 Description of the C9900-G073 connections

Connection strip Terminal point Description

X1 1 X1.1 NO contact emergency stop

2 X1.2 NO contact emergency stop

3 X1.3 NO contact emergency stop

4 X1.4 NO contact emergency stop

Connection strip Terminal point Description

X2 1 X2.1 NO contact S4 blue

2 X2.2 NO contact S4 blue

3 X2.3 NC contact S3 red

4 X2.4 NC contact S3 red

5 X2.5 NO contact S2 green

6 X2.6 NO contact S2 green

Connection strip Terminal point Description

X3 1 GND Supply Power

2 +24 V

3 X3.3 + 24 V LED blue

4 X3.4 + 24 V LED red

5 X3.5 + 24 V LED green

6 N.C.

7 X3.7 NO contact S4 blue

8 X3.8 NO contact S4 blue

9 X3.9 NC contact S3 red

10 X3.10 NC contact S3 red

11 X3.11 NO contact S2 green

12 X3.12 NO contact S2 green

Supply Power

DC

NOTE

Electrical characteristic values of the operating elements

The electrical characteristic values of the emergency stop and push-button contacts must

not be exceeded. (see chapter Technical data

C9900-G072 and C9900-G073 15

Version: 1.0

Page 16

Product description

3.5 Accessories

3.5.1 Push-button caps and labels

Options Description

C9900-Z255 Push-button cap (blue) for individual application to a C9900-G0xx push-button extension,

type Rafi FS+, diameter: 22.3 mm, 5 pcs.

C9900-Z256 Push-button cap (yellow) for individual application to a C9900-G0xx push-button

extension, type Rafi FS+, diameter: 22.3 mm, 5 pcs.

C9900-Z257 Push-button cap (green) for individual application to a C9900-G0xx push-button

extension, type Rafi FS+, diameter: 22.3 mm, 5 pcs.

C9900-Z258 Push-button cap (red) for individual application to a C9900-G0xx push-button extension,

type Rafi FS+, diameter: 22.3 mm, 5 pcs.

C9900-Z259 Push-button cap (clear) for individual application to a C9900-G0xx push-button

extension, type Rafi FS+, diameter: 22.3 mm, 5 pcs.

C9900-Z260 Transparent film for individual labeling of a C9900-G0xx- push-button extension, type

Rafi FS+, diameter: 22.3 mm, 1 sheet DIN A4, 54 pcs.

Version: 1.0

C9900-G072 and C9900-G07316

Page 17

Mounting

4 Mounting

4.1 Installing the labels

The blank label sheets for the push-buttons of the push-button extension offered under order code C9900Z260 can be printed with a conventional office printer and then inserted in the push-button extension.

C9900-G072 and C9900-G073 17

Version: 1.0

Page 18

Mounting

1

2

4.2 Installing the Wago picoMax® connector system

Plugged connection consists of male connector and

female connector with grip plate and release slide

Disconnect the plug connection with the release

slide.

1. Open the locking device (latch) by pushing down

the release slide on the grip plate.

2. Pull out the female connector with the grip plate

from the male connector.

Version: 1.0

C9900-G072 and C9900-G07318

Page 19

Operation

5 Operation

5.1 Switching the Control Panel on and off

5.1.1 Switching on

The Control Panel does not have its own mains switch. On switching on the power supply the Control Panel

will also be switched on.

5.1.2 Shutting down and switching off

Control software such as is typically used on Industrial PCs permits various users to be given different rights.

A user who is not permitted to close software may also not switch the Industrial PC off, as data can be lost

from the data storage device by switching off while software is running.

NOTE

First shut down, then switch off!

If the Industrial PC is switched off while the software is writing a file to the data storage device, this file will

be destroyed. Control software usually writes data to the data storage device automatically at intervals of a

few seconds, for which reason there is a very high probability of causing damage by switching off while

software is running.

NOTE

Switching off the Industrial PC

Once you have shut down the Industrial PC, you must switch it off for at least 10 seconds in order to be

able to restart it! After switching on the power supply again the Industrial PC starts automatically.

5.2 Operation

The Control Panel is operated via the touch screen.

NOTE

Damage to the touch screen

The touch screen may only be operated with your finger or the touch screen pen. The operator may wear

gloves but there must be no hard particles such as metal shavings, glass splinters embedded in the glove.

.

5.3 Maintenance

5.3.1 Cleaning

The device can be cleaned with a damp, soft cloth. Do not use any aggressive cleaning materials, thinners,

scouring material or hard objects that could cause scratches.

5.3.2 Maintenance

The Control Panel needs no maintenance.

C9900-G072 and C9900-G073 19

Version: 1.0

Page 20

Operation

5.3.3 Emergency procedures

In case of fire, the Control Panel should be extinguished with powder or nitrogen.

5.3.4 Decommissioning

5.3.4.1 Disposal

Observe national electronics scrap regulations

When disposing of the device follow the national electronic scrap regulations.

In order to dispose of the device, it must be removed and fully dismantled.

• Housing components (polycarbonate, polyamide (PA6.6)) are suitable for plastic recycling.

• Metal parts can be sent for metal recycling.

• Electronic parts such as disk drives and circuit boards must be disposed of in accordance with national

electronics scrap regulations.

Version: 1.0

C9900-G072 and C9900-G07320

Page 21

TwinCAT System Manager

6 TwinCAT System Manager

Before the push-button extension can be put into operation, it must first be configured in the TwinCAT

System Manager.

Proceed as follows:

1. Click at the top in the menu on File > New > Project and create a new TwinCAT XAE Project.

2. In the tree view on the left, click on I/O and then right-click on Device.

3. In the context menu click on Scan.

The New I/O Devices window appears. All available devices are displayed.

4. Select the devices you want to use and confirm the selection with OK.

5. Confirm the request with Yes, in order to look for boxes.

6. Confirm the request whether to enable FreeRun with Yes.

ð The device is inserted as a box in the tree view and displayed with the respective inputs and outputs

(e.g. Term 2 to 5). Label the inputs and outputs (Term 2 to 5) as follows.

C9900-G072 and C9900-G073 21

Version: 1.0

Page 22

TwinCAT System Manager

Term label after activating FreeRun Term label after processing

Version: 1.0

C9900-G072 and C9900-G07322

Page 23

Dimensional drawing

7 Dimensional drawing

7.1 Dimensional drawing CP6x00 with C9900-G072 or C9900-G073

Fig.3: External dimension

C9900-G072 and C9900-G073 23

Version: 1.0

Page 24

Dimensional drawing

Fig.4: Installation dimension

Version: 1.0

C9900-G072 and C9900-G07324

Page 25

Technical data

8 Technical data

NOTE

Risk of explosion!

The built-in Panels with push-button extension must not be used in potentially explosive atmospheres!

Properties Description

Supply voltage

Only for C9900-G073

Characteristic values emergency stop and push-buttons

Max. operating voltage AC/DC 35V

Max. operating current AC/DC 100 mA

Switching capacity max. 250 mW

Characteristic values Wago picoMax® connectors

Connection technology Cage Clamp

Conductor cross-section Solid wire 0.2 - 1.5 mm²

Conductor cross-section Stranded wire 0.2 - 1.5 mm²

Conductor cross-section Stranded wire 0.25 - 0.75 mm²

Conductor cross-section Stranded wire 0.25 - 1.5 mm²

Conductor (AWG) 24 - 14

Strip length 8 - 9 mm / 0.31 - 0.35 in

Properties of the push-button extension

Protection class Front IP54, rear IP20

Shock resistance

(sinusoidal vibration)

Shock resistance

(Shock)

EMC - interference immunity conforms to EN 61000-6-2

EMC interference emission conforms to EN 61000-6-4

Permissible ambient temperature 0 °C to + 55 °C (operation)

Permissible maximum air humidity Maximum 95%, no condensation

Transport and storage The same values for air humidity and shock

Certification CE

24V

(with ferrule with plastic collar)

(with ferrule without plastic collar)

EN 60068-2-6: 10 to 58 Hz: 0.035 mm 58 to

500 Hz: 0.5 G (~ 5 m/ s2)

EN 60068-2-27: 5 G (~ 50 m/s2 ), duration: 30 ms

-25°C to +65°C (transport / storage)

resistance are to be observed during transport and

storage as in operation. The vibration resistance

during transport can be improved by suitable

packaging of the Panels.

(20.4– 28.8VDC)

DC

C9900-G072 and C9900-G073 25

Version: 1.0

Page 26

Support and Service

9 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone: +49(0)5246/963-0

Fax: +49(0)5246/963-198

e-mail: info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

on Beckhoff

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: +49(0)5246/963-157

Fax: +49(0)5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: +49(0)5246/963-460

Fax: +49(0)5246/963-479

e-mail: service@beckhoff.com

Version: 1.0

C9900-G072 and C9900-G07326

Page 27

Approvals for USA and Canada

10 Approvals for USA and Canada

10.1 FCC approvals for the United States of America

FCC: Federal Communications Commission Radio Frequency Interference Statement

This device was tested and complies with the limits for a digital device of class A, according part 15 of the

FCC regulations. These limits are designed to provide adequate protection against adverse interference, if

the device is used in a commercial environment. This device generates, uses and may emit radio frequency

energy and may cause adverse interference with radio communications, if it is not installed and used in

accordance with the operating instructions. If this device is used in a residential area it is likely to cause

adverse interference, in which case the user must take appropriate countermeasures in order to eliminate

the interference at his own expense.

Technical modifications

Technical modifications of the device may void the FCC approval.

10.2 FCC approvals for Canada

FCC: Canadian Notice

C9900-G072 and C9900-G073 27

Version: 1.0

Loading...

Loading...