Page 1

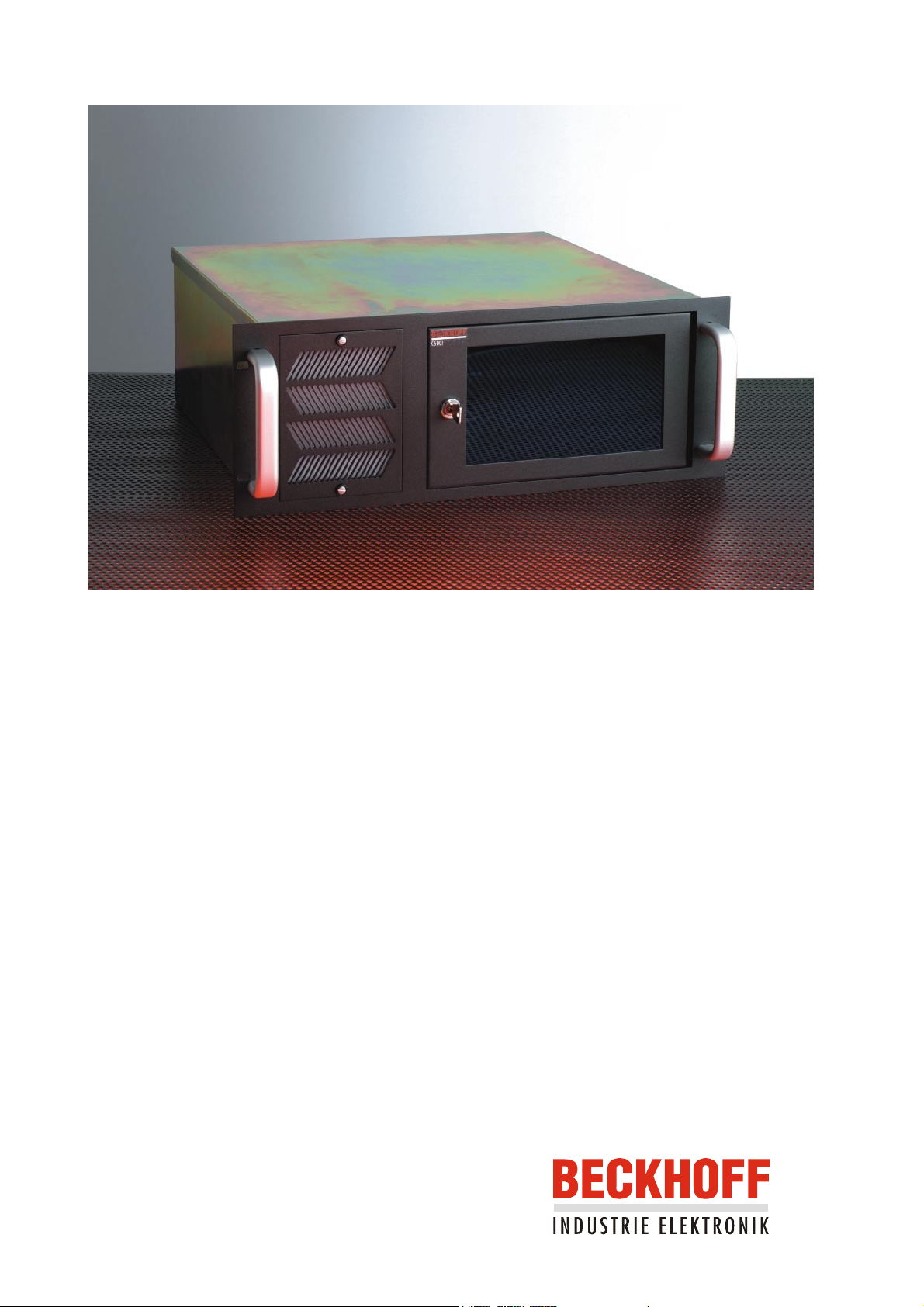

Beckhoff Industrial PC C5002

Operating Instructions

Version: 1.0

Last change: 05.06.2000

Page 2

Page 3

Table of contents

Safety instructions 3

The operator’s duties 3

The user’s duties 4

Appropriate Use 4

Connections 5

Power supply 5

Serial interfaces 6

Parallel interface 6

PS/2 Connections 6

USB Interfaces 6

Video connection 6

Additional plug-in cards (optional) 6

Operation of the Industrial PC 7

Servicing and maintenance 8

Changing the Air Filter 8

Cleaning 8

Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

Table of contents 2

Disposal 9

Faults 9

C5002

Page 4

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

Operating Instructions Slide-in PC C5002 3

Industrial PC C5002 Operating Instructions

Safety instructions

Only switch the PC off after

closing the software

Switch off all parts of the

equipment, then uncouple

the field bus

Do not open the power

supply unit while voltage is

applied

Do not exchange any parts

when under power

Before the Industrial PC is switched off, software that is running must

be properly closed.

Otherwise it is possible that data on the hard disk is lost. Please read the

section on “Switching off”.

Before opening the housing of the PC, and whenever the PC is being

used for purposes other than plant control, such as during functional

tests following repair, all parts of the equipment must first be

switched off, after which the Industrial PC can be uncoupled from the

plant.

Pulling out the field bus connection plug uncouples the PC.

Items of equipment that have been switched off must be secured

against being switched on again.

The Industrial PC’s power supply unit must be supplied with

230 V / 115 V AC.

The supply voltage must be switched off before the power supply unit

housing is opened.

When components are being fitted or removed, the supply voltage

must be switched off.

National regulations

depending on the

machine type

Test regulations

Only trained personnel may

open the PC’s

Software knowledge

Fitting work on the PC can result in damage:

if metal objects such as screws or tools fall onto operating circuit

boards.

if connecting cables internal to the PC are removed or inserted

during operation.

if plug-in cards are removed or inserted when the PC is switched

on.

The operator’s duties

Depending on the type of machine and plant in which the Industrial PC is

being used, there will be national regulations for the control of such

machines and plant that the operator must observe. These regulations

cover, amongst other things, the intervals between inspections of the

controller.

The operator must initiate such inspections in good time.

The operator is responsible for ensuring that only trained electrical staff

opens the housing of the Industrial PC.

Every user must be familiar with any of the functions of the software

installed on the PC that he can reach.

Make operating instructions

accessible

The contents of these operating instructions must be known by every user

of the Industrial PC and by every fitter who installs, removes or opens the

device.

C5002

Page 5

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

4 Operating Instructions Slide-in PC C5002

Procedure in the event of a

fault

In the event of a fault in the Industrial PC, appropriate measures can be

determined with the aid of the list in the “Faults” section.

The BECKHOFF Service number:

for Germany: 05246/963-460

international: 0049-5246/963-460

The user’s duties

Read the operating

instructions

Software knowledge Every user must be familiar with any of the functions of the software

Every user of the Industrial PC must have read these operating

instructions.

installed on the PC that he can reach.

Appropriate Use

The C5002 Industrial Computer is intended for fitting into 19 inch racks for

industrial application in machine and plant control engineering. A complete

IBM compatible PC with a standard ATX motherboard, hard disk and floppy

drive is built into a 7-slot plug-in unit.

Do not use the PC in areas

of explosive hazard

The Industrial PC may not be used in areas of explosive hazard.

The following technical data must be observed during operation:

Environmental conditions Ambient temperature: 0 to 55 °C

Atmospheric humidity: Maximum 95 %, non-condensing

Shock resistance Housing & chassis: Vibrations 5 G at 10..55 Hz

Impact resistance 30 G

Disk drive: Vibrations 0.5 G at 5..500 Hz

Impact resistance 5 G

Hard disk: Vibrations 0.5 G at 17..500 Hz

Impact resistance 10 G

Protection type: IP60

Power supply

230/115 V AC mains power

supply unit

Compatibility Resistance to interference: according to EN 50082-2

Transport and storage

Supply voltage: Switchable between

115 V 60 Hz

230 V 50 Hz

Max. power consumption: 64 W for the basic version

The same values for atmospheric humidity and shock resistance are to be

observed during transport and storage as in operation. The shock

resistance during transport can be improved by means of suitably packing

the Industrial PC. The ambient temperature during storage and transport

must be between –20 °C and +60 °C.

C5002

Page 6

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

Operating Instructions Slide-in PC C5002 5

Connections

Rear view of the basic

version of the C5002

Industrial PC

Mains power supply unit

Power supply

The C5002 Industrial PC has a standard ATX 230/115 V 50/60 Hz power

supply.

Power supply plug On/off switch

Current loading capacity

230 V power supply unit

Mains power supply

voltage switch

Output voltages of the

115/230 V power supply unit maximum

+3,3 V

+12 V

-12 V

Current loading

+5 V

-5 V

22 A

0,3 A

14 A

8 A

0,8 A

C5002

Page 7

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

6 Operating Instructions Slide-in PC C5002

Setting the mains voltage

Changing from 230 V to

115 V

RS 232

COM1 - COM2

Mains voltages of 230 V 50 Hz or 115 V 60 Hz may be set. In order to do

this the slide switch (see photos below) is moved to the appropriate

position with the aid of a small screwdriver. The voltage that has been set

can be read.

Changing from 115 V to

230 V

Serial interfaces

The basic version of the C5002 Industrial PC has two serial interfaces,

COM1 and COM2, using the type RS 232, which are brought to a 9 pin

SUB-D pin connector.

Printer

LPT1

PS/2

USB1 – USB2

Video

Type plate

Parallel interface

The parallel interface corresponds to the Centronics standard, and is

addressed by the software as LPT1.

PS/2 Connections

The upper PS/2 connector allows a PS/2 mouse to be used, while a PC

keyboard can be connected to the lower PS/2 connector.

USB Interfaces

Both USB interfaces provide for the connection of any peripheral devices

with USB connections.

Video connection

A 15-pin SUB-D socket allows a VGA monitor to be

connected.

Additional plug-in cards (optional)

There is a type plate on the rear of the PC which provides information

about the hardware configuration of the PC at the time it was supplied.

C5002

Page 8

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

Operating and LED's

behind the front cover

Operating Instructions Slide-in PC C5002 7

Operation of the Industrial PC

The front of the PC has a lockable front cover, behind which operating

elements and LED's are located. There is a number on the lock.

If the key is lost, the number on the lock can be used to order a

replacement.

Reset key

LED's

Keyboard switch

Switching on

Reset key

Switching off

KeyLock

LED's

On/off switch

The Industrial PC has its own ON switch (see photo above), although this

can optionally be configured to have no function.

At the top left behind the front panel there is a reset button with which the

system can be re-booted (see photo above).

Control software such as is typically used on Industrial PCs permits various

users to be given different rights. A user who may not close the software

must also be unable to switch the Industrial PC off, since data can be lost

from the hard disk by switching off while the software is running.

If the Industrial PC is switched off while the software is writing a file to the

hard disk, this data can be damaged. Control software generally writes files

such as logs to the disk of its own accord at intervals of just a few seconds,

which means that the probability of damage is quite high if the computer is

switched off while the software is running.

A keyboard switch above the mains switch allows a connected PC

keyboard to be switched off.

There are two LED's behind the front cover. The yellow LED indicates hard

disk activity, while the green LED indicates that the power is switched on.

Disk drive

C5002

Page 9

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

8 Operating Instructions Slide-in PC C5002

Servicing and maintenance

Changing the Air Filter

The PC has an air filter that must be changed at regular intervals. The

Usable life

filter's usable life depends on the number of operating hours and on the

amount of dust in the surrounding air.

If it is not possible to determine the need to change the filter with a visual

check, then if the air is very dusty the filter must be changed once a month.

Caution

Item number

View of the fan cover

If a necessary filter change is omitted components within the computer can

be damaged or destroyed through overheating.

The ordering/item number for replacement filters is: C9900-Z210

Fast closing

screws

Fan cover

Filter changing procedure

Caution!

First switch the Industrial

PC off

Follow these instructions when changing the air filter:

1. First use a screwdriver to turn one of the fast closing screws (see

photo above) 90 degrees in any direction.

2. Hold the fan cover in place while you do the same with the second

screw. Failure to follow this procedure can result in injury to persons or

damage to objects situated underneath the PC or to the cover itself as

it falls.

3. The fan cover is not fixed to the housing in any other way, and can be

drawn forwards to remove it.

4. The dust filter can easily be pulled out and exchanged.

5. Return the filter cover to its original position on the housing.

6. Press and turn both the fast-closing screws 90 degrees in any direction

with a screwdriver.

Cleaning

The front of the Industrial PC can be cleaned with a soft, damp cloth. Do

not use any aggressive cleaning materials, thinners, scouring material or

hard objects that could cause scratches. The Industrial PC must be

switched off for cleaning.

C5002

Page 10

INDUSTRIE ELEKTRONIK Eiserstraße 5 / D-33415 Verl / Phone 05246/963-0 / Fax 05246/963-149

Operating Instructions Slide-in PC C5002 9

Disposal

Remove the Industrial PC

and dismantle it Observe

national electronics scrap

regulations

In order to dispose of the device, it must be removed and fully dismantled.

The housing can be sent for metal recycling. Electronic parts such as disk

drives and circuit boards must be disposed of in accordance with national

electronics scrap regulations.

Faults

Quote the project number If servicing is required, please quote the project number of your PC.

fault Cause Procedure

No function after the Industrial PC

has been switched on

The Industrial PC does not boot

fully

No power supply. 1. Measure voltage at

connection, check plug

wiring.

2. Call Beckhoff Service.

Floppy disk in drive.

Hard disk damaged (e.g. by

switching off while software

running).

Remove floppy disk and

press any key

Call Beckhoff Service.

Incorrect setup.

Other cause.

Computer boots, software starts,

but control does not operate

correctly

Error during floppy disk access Faulty floppy disk.

Cause of the fault is either in the

software or in parts of the plant

outside the Industrial PC.

Faulty disk drive.

Check the set-up. If

necessary, call the Beckhoff

service department

Call Beckhoff Service.

Call the manufacturer of the

machine or the software.

Check disk in another PC.

Call Beckhoff Service.

C5002

Loading...

Loading...