Page 1

Vista®

basic

Service

Manual

950971

Rev

A

(5/04)

Version

Software:

1.0

English

IFVA23002.......

Page 2

This

The

complete

the

foliowing

Service

Manual

Service

pages:

is

valid

Manual

for

contains

Voltages

Vistabasic

Vista

basic

Page

0-1

to

Page

1-1

to

Page

2-1

to

Page

3-1

to

Page

4-1

to

Page

5-1

to

Page

6-1

to

Page

7-1

to

Page

8-1

to

Page

9-1

to

Page

10-1

Page

A-1

to

100 V /

110 V /

120

V,

switchable:

....................................

.

Page

0-8

Page

1-12

Page

2-6

Page

3-12

Page

4-20

Page

5-2

Page

6-2

Page

7-2

Page

8-6

Page

9-2

to

Page

10-2

Page

A-4

637-102

637-202

Vista

basic

950971

Rev A (5/04)

Page 3

Table

of

Contents

Important

General

System

Information

Overview

Information

on

this

Manual

Service

Work

Technical

Current

Revision

Non-Liability

ISO

Repair

Spare

Setting

Technical

Entry

Ordering

Return

Service

Safety

Translation

Design

Operation

Function

Voltage

Signal

Mains

Battery

Alarm

Pump

Computer

Braun

Internal

Language

Accessories

Safety

Versions

Service

9000

ff/EN 46

and

by

Trained

Parts

Off

Training

for

the

of

of

Spare

Hotline

Officer

Supply

Table

Operation

Operation

Circuit

Unit

fluid

Assignment

Groups

Inspection

and

Spare

Flow

Interface

manager

Inspections

000

ff

only

Technicians

Test

Equipment

Product

Training

Parts

and

Parts

Chart

system

Test

(fm

Equipment

system)

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Software

Service

Ünit

Elements

Vista

basic

Program

950971

Rev A (5/04)

Software

Approved

Error

Software

Structure

Additional

Start / Quit

Unit

History

Test

Unit

Calibration

Mains

Battery

Door

Pump

Pump

Update

Software

Messages

Default

of

the

Functions

Inserted

the

Data

Data

Madifications

Fuses

Lock

Cover

Housing

Versions

and

Alarms

Values

Service

Service

Plug

Service

Program

with

Program

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page 4

Table

of

Contents

Checks

Maintenance

Technical

Procedurat

Test

Spare

after

Equipment

Parts

Repair

Safety

Inspection

Instructions

and

List

for

Special

TSI

Inspection

Tools

Housing

Controller

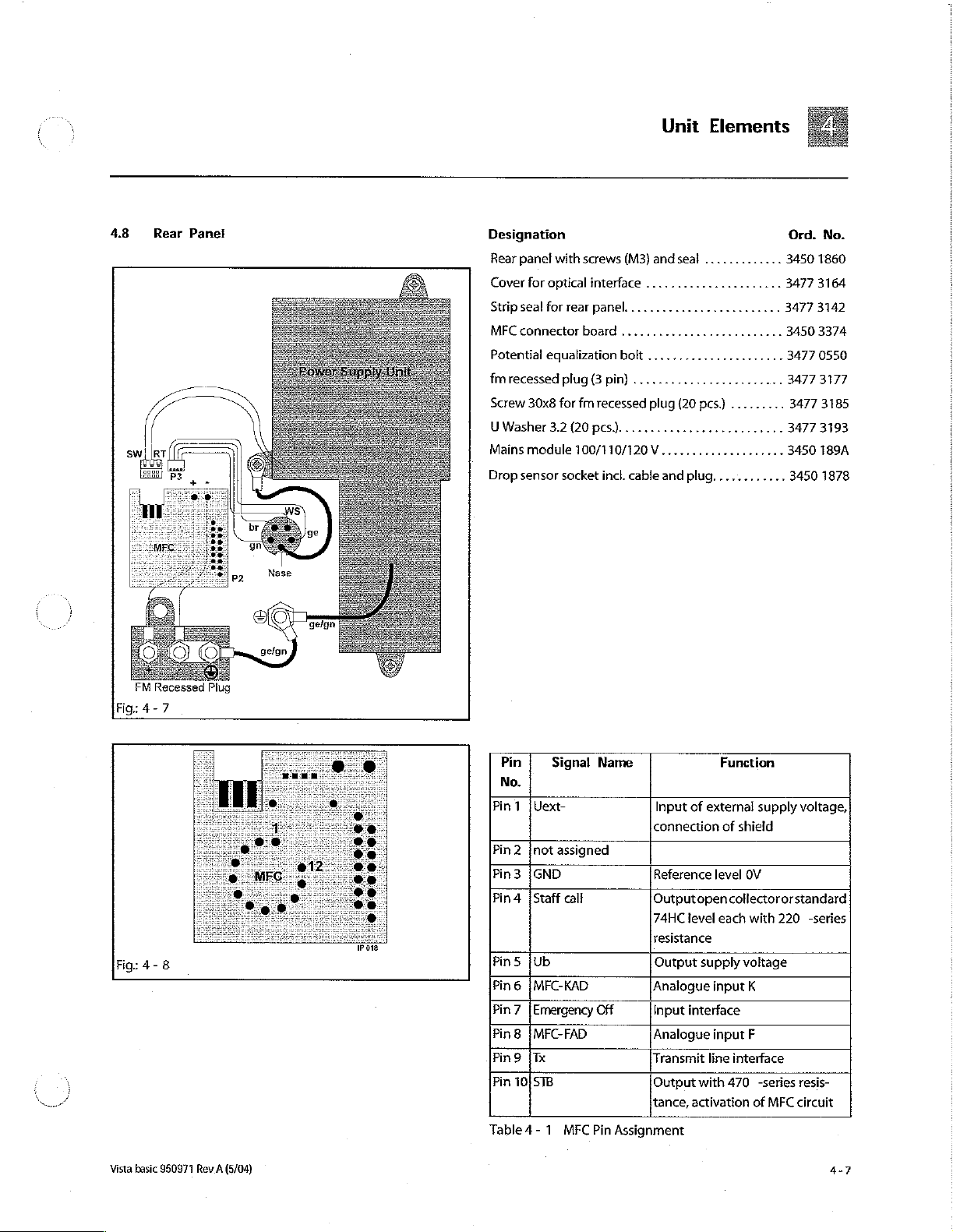

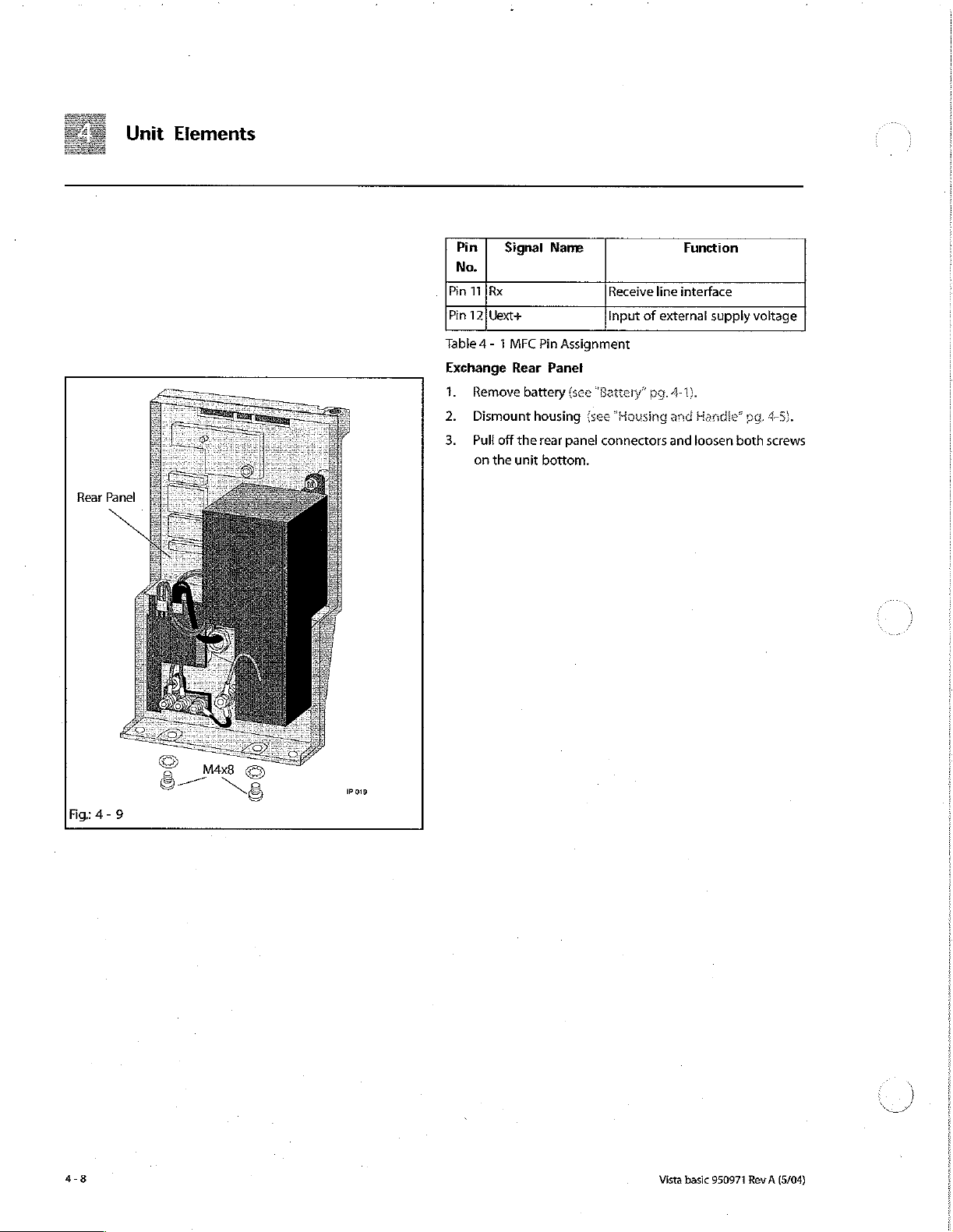

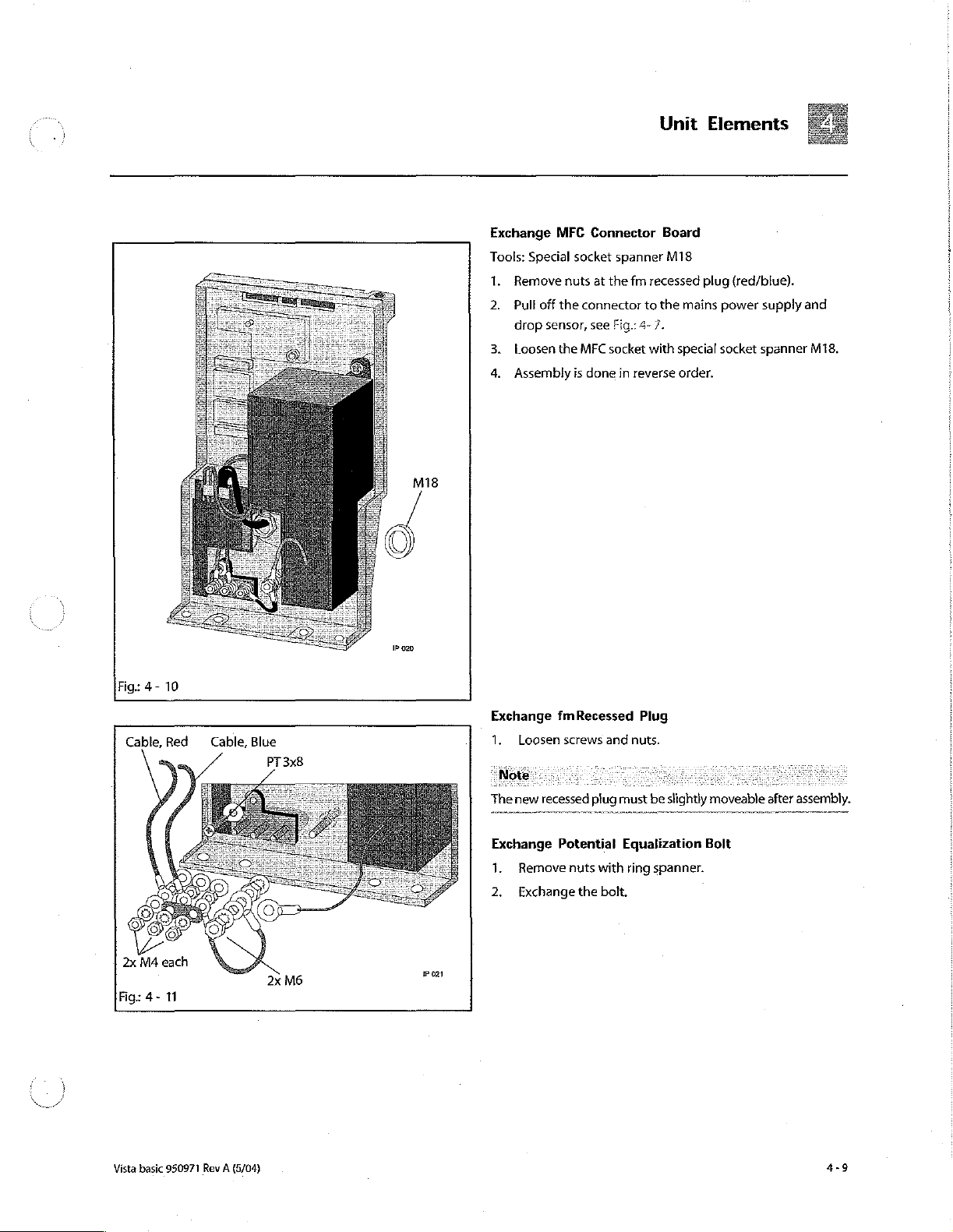

Rear

Front

Pump

Occlusion

Air

Operating

Barcode

Frame

1.

2.

3.

4.

Test

Unit

„Colours

Miscellaneous

Software

and

Handle

Board

Panel

Panel

Unit

Sensor

Sensor

Unit

Label

with

Seal

Visual

Inspection

Electrical

Functional

Pump

Safety

per

IEOEN60

Inspection

Unit

Inspection

Equipment

Elements

Update Page

Inspection

601-1

and

Special

as

Tools

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

4-5

4-6

4-7

4-10

4-

12

4-14

4-17

4-18

4-19

4-19

5-1

6-1

7-1

8-1

8-1

8-2

8-3

9-1

10-1

10-2

10-2

10-2

n

)

-

Appendix

0-4

ESD

Recommendations

Workstation

Revision

Current

Order

Service-

Documentation

Information

Form Page

Vista

basic

Page

Page

Page

Page

950971

A-1

A-1

A-2

A-2

A-2

Rev A (5/04)

Page 5

Important

The

following

notes

should

Information

be

observed:

on

this

Manual

Service

Technical

Current

Work

Versions

Safety

Inspections

The present

this

Service

- © have

- © areinctuded

- © possess

-

B.

Braun

spections,

version

-

-

-

This

was

must

the

manual

manual

does

tasks

may

received

Braun

the

and

fulfil

the

personal

also

or to

of

the

manual,

the

TS!

requires

served

the

manuais

depending

called

up

which

case

of

an

service

connector

manual

written.

index

always

number

version

Technical

be

recommends

is

for

your

not

authorize

only

be

executed

appropriate

in

the

revision

necessary

perform

are a reference

on

inappropriate

expected.

test

requirements

training

at

least

as:

that

the

the

unit

type,

may

leadto a dangerous

may

be

corresponds

changes,

The

on the

title

information

the

training

service

equipment

the

instructions

for

operation.

necessary.

especially

state

page.

only.

performance

by

persons,

on

(training

on

the

steps

indicated

in

measurements

the

service

Furthermore, a special

to

the

state

software

of

the

revision

The

possession

of

service

who

the

system

and

mechanical

and

knowledge).

technical

in

the

manuals

program

unit

conditionin

when

modifications

is

indicated

from

safety

the

current

are

must

the

manual

of

work,

B.

aids,

in-

ob-

be

the

by

Revision

Service

Non-Liability

Vista

basic

950971

Rev A (5/04)

The

possession

sion

in

the

service

after:

-

technical

- © a

written

(incurred

B.

Braun

juries

to

-

the

use

respondtothe

vice

-

the

service

-

technicians

course

of

this

manual

revision

Melsungen

persons,

tasks

non-inclusion

service.

training

order

placed

costs),

property

of a wrong

revision

who

for

the

specific

by

AG

manual,

of

have

B.

with

does

damages

state

the

not

does

You

Braun

not

service

B,

not

automatically

will

be

included

Melsungen

the

sales

department

assume

any

or

other

damages

or a manual

for

maintenance,

participated

Braun

which

technician

in a technical

unit.

mean

inclu-

in

the

revision

or

of

B.

Braun

responsibility

caused

does

repair,

and

in

the

for

not

revision

training

in-

by:

cor-

ser-

Page 6

Z

ISO

Important

9000

ff/EN

46

Information

000

ff

on

this

Manual

B.

Braun

001.

46

The

Vista

IEC/EN60601-

cording

is

certified

This

certification

basic

complies

2-24

to

the

EC

in

accordance

also

with

standards

directive

with

includes

the

IEC/EN60601-1

and

is

certified

93/42/EC.

DIN

ISO

9001

maintenance

and

with

the

and

and

CE

DIN

EN

service.

label

ac-

Repair

by

Trained

Spare

Parts

Setting

and

Inspection

Technicians

and

Off

Test

only

Equipment

Training

manual

structions

must

An

"Checks

Only

tamper

completely.

instructions,

The

test

works

Additional

may

does

on

be

observed.

electrical

after

use

original

with

inspection

equipment.

of

B.

Braun.

notes

Gives

additional

steps.

Is

system

E

used

for

working

or to a connected

only

be

performed

not

authorize

electrostatic

check

must

be

Repair”

bg.

spare

assembly

The

personnel

groups

spare

parts

Original

test

Further

and

warnings

or

special

steps

which

by

B.

the

performance

sensitive

performed

5-1).

parts

from

which

required

is

responsible

equipment

information

are

notes

on

may

device.

Braun.

The

of

components

following each

the

manufacturer.

can

only

are

listed

'

for

the

can

be

is

available

set

off

as

information

FES

result

in

damage

possession

repairs.

The

(ESD

standards)

repair

Do

be

exchanged

in

the

repair

calibration

calibrated

upon

request.

follows:

and

working

to

the

of

the

in-

(see

not

of

the

at

the

unit,

IS

USED

INJURY.

FOR

WORKING

STEPS

WHICH

MAY

Vista

RESULTIN

basic

950971

PERSONAL

Rev A (5/04)

Page 7

General

Information

Technical

Entry

for

Ordering

Return

Technical

Training

the

of

of

Spare

Service

Product

Spare

Parts

Support

Training

Parts

and

Test

Equipment

B.

Braun

Medical

1601

Wallace

Carrollton,

Responsibility

B.

Braun

Only

B.

1

800

B.

1601

Carrollton,

Carrollton,

Tel: 1 800

via

Braun

627-PUMP

Braun

Wallace

Texas

Medical

the

responsible

Medical

Medical

Texas

Texas

241-2243

Inc.

Drive,

75006

Inc.,

Inc.

(7867)

Inc.

Drive,

75006

75006

Suite

150

Service

representative

Suite

150

Tel.:

Fax:

1

800

972

241-2243

245-1612

Vista

basic

950971

Rev A (5/04)

Page 8

For

your

General

notes:

Information

0-8

-

Vista

basic

950971

Rev A (5/04)

Page 9

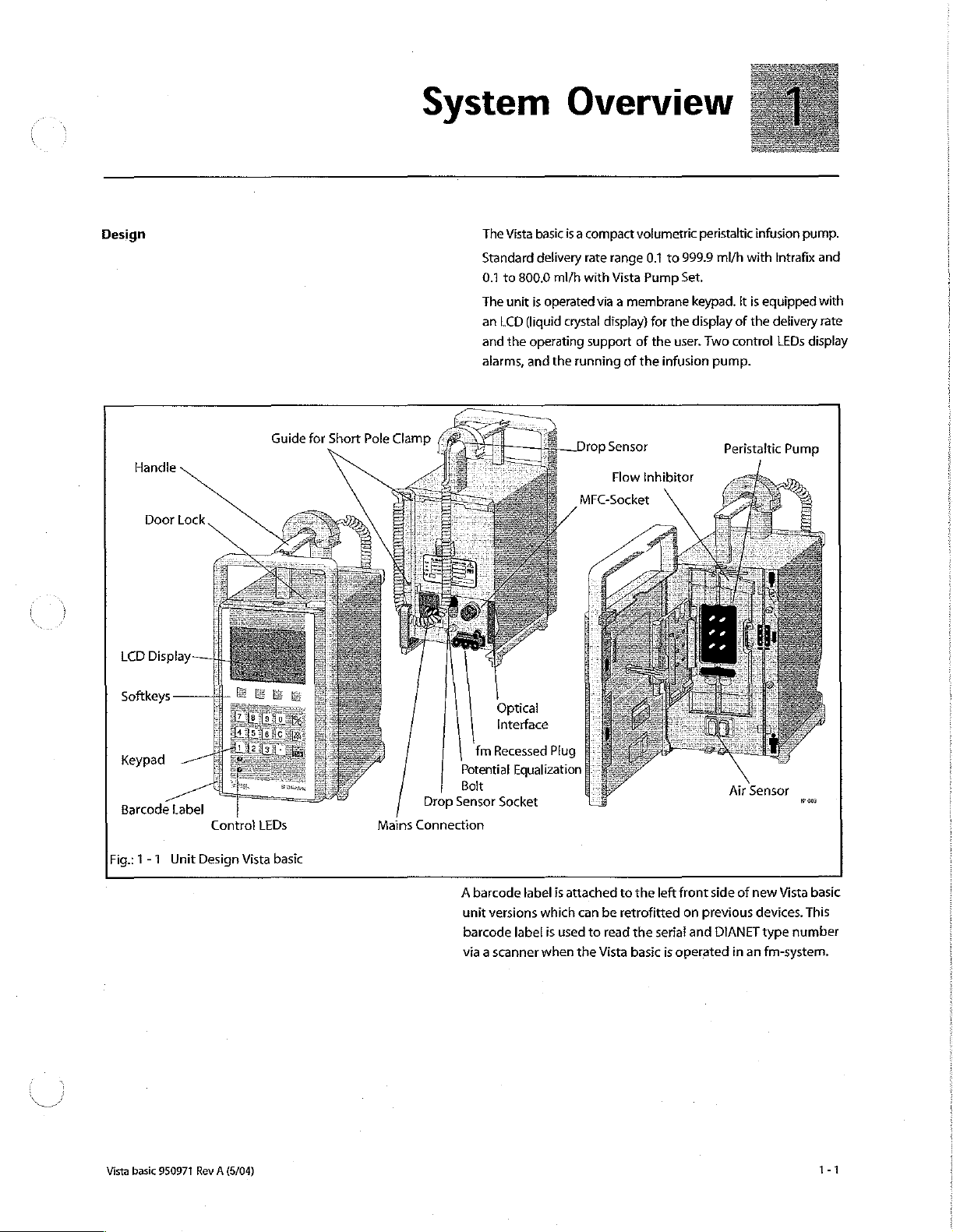

System

Overview

Design

LCD

Handle

Door

Display

Lock

Guide

for

Short

Pole

Clamp

The

Vista

Standard

0.1

to

800.0

The

unit

is

an

LCD

(liquid

and

the

operating

alarms,

and

basic

is a compact

delivery

ml/h

with

operated

crystal

the

running

Drop

MFC-Socket

volumetric

rate

range

0.1

Vista

Pump

via a membrane

display)

support

of

of

Sensor

Flow

the

Inhibitor

to

999.9

Set.

keypad.

for

the

display

the

user.

infusion

na

peristaltic

Two

infusion

ml/h

with

It

is

of

the

control

pump.

ete

Peristaitic

pump.

Intrafix

equipped

delivery

LEDs

Pump

and

with

rate

display

Softkeys

Keypad

Barcode

Fig.:

1-1

Label

Unit

Design

Control

LEDs

Vista

basic

Mains

Potential

D

Sol

Top

sensor

Connection

A

unit

barcode

via a scanner

Optical

Interface

fm

Recessed

Equalization

sock

Socket

barcode

versions

label

P

lug

label

which

is

when

is

attached

can

used

to

the

to

the

be

retrofitted

read

the

Vista

basic

left

front

on

serial

and

is

operated

Air

side

of

previous

DIANET

in

Sensor

new

Vista

devices.

type

number

an

fm-system.

won

basic

This

Vista

basic

950971

Rev A (5/04)

Page 10

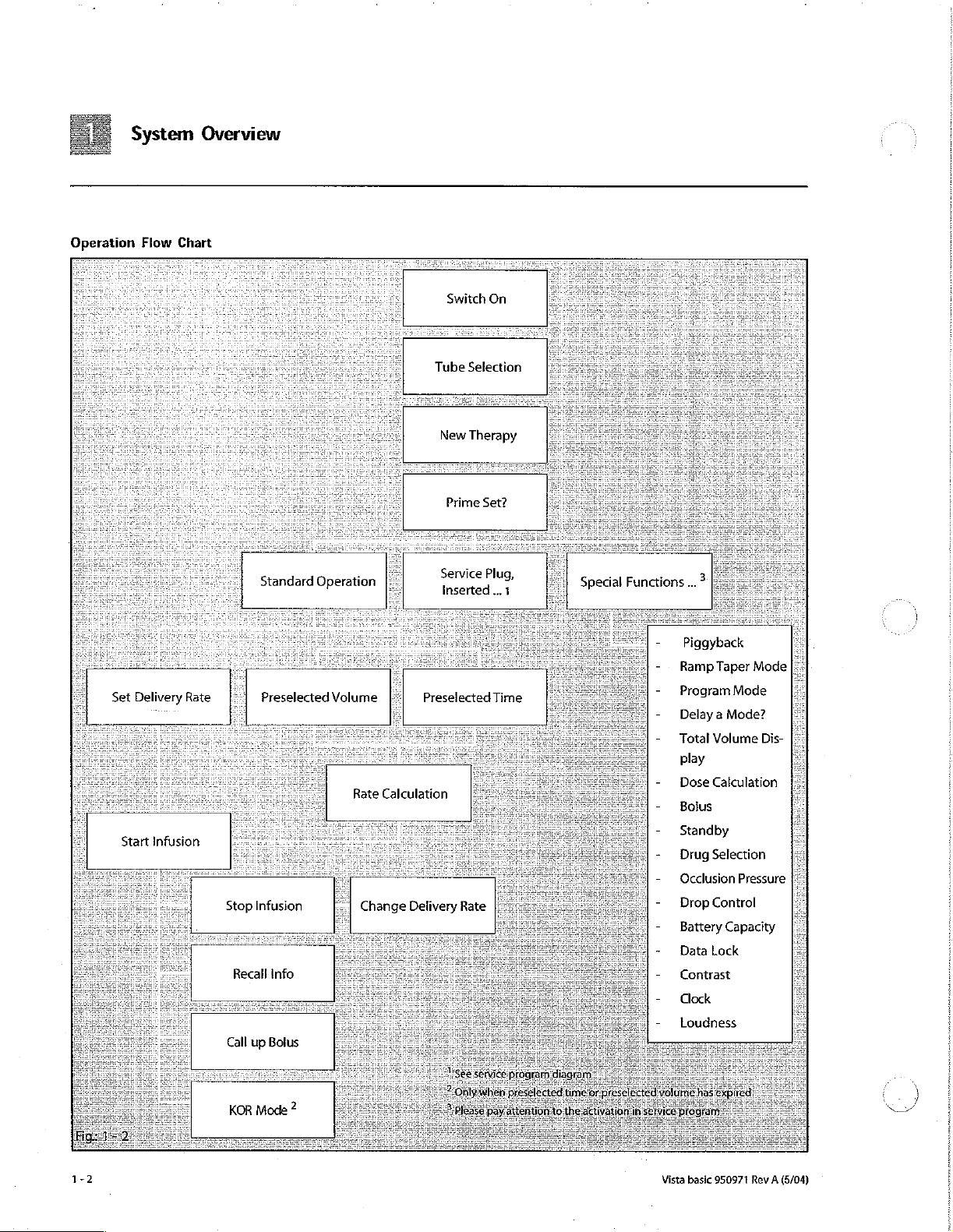

System

Overview

Operation

Flow

Chart

Standard

Operation

Switch

Tube

Selection

New

Therapy

Prime

Service

Inserted

On

Set?

Plug,

...

+

Special

Functions...

3

Piggyback

Ramp

Taper

Mode

Set

Start

Delivery

infusion

Rate

‘|

Stop

Recall

Call

KOR

up Bolus

Preselected

Infusion

info

Mode

2

Volume

Rate

:

Change

||

Preselected

Calculation

.

Delivery

Ses

Rate

Time

Program

Delay à Mode?

Total

play

Dose

Bolus

Standby

Drug

Occlusion

Drop

Battery

Data Lock

Contrast

Clock

Loudness

Mode

Volume

Calculation

Selection

Pressure

Control

Capacity

Dis-

|:

トーン

a

1-2

Vista

basic

950971

Rev A (5/04)

Page 11

System

See

Instructions

for

Use

for

detailed

Overview

information.

M

Vista

basic

950971

Rev A (5/04)

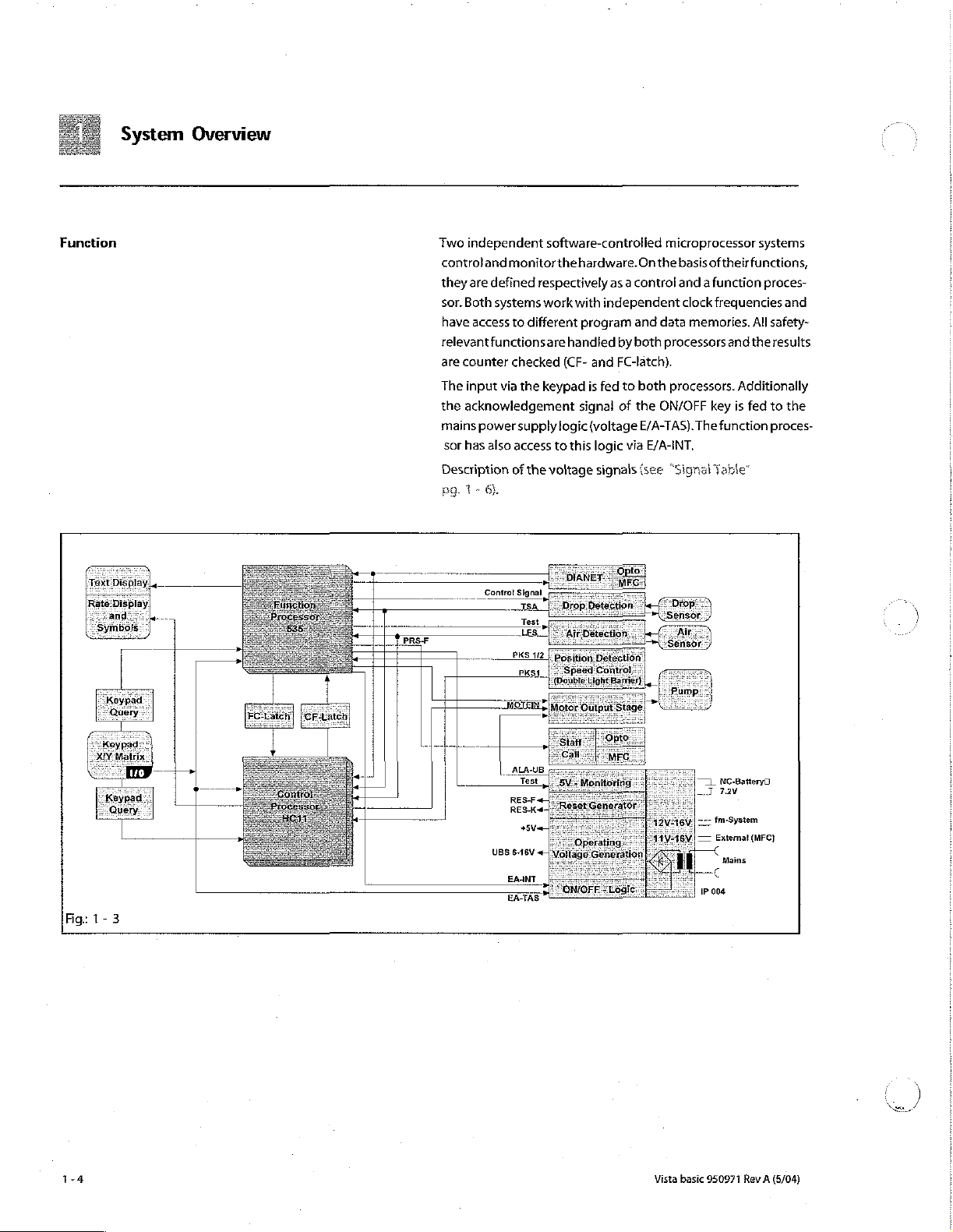

Page 12

System

Overview

Function

Two

independent

control

and

they

are

defined

sor.

Both

systems

have

access

relevant

functions

are

counter

The

input

the

acknowledgement

mains

power

sor

has

also

Description

29.

1-5).

Controt

software-controlled

monitor

via

respectively

work

to

different

are

checked

the

keypad

supply

access

of

the

voltage

Signal

Test

the

(CF-

logic

to

hardware.

with

independent

program

handled

and

is

fed

signal

(voltage

this

logic

signals

microprocessor

On

the

as a control

and

data

by

both

processors

FC-latch).

to

both

processors.

of

the

ON/OFF

E/A-TAS).

via

E/A-INT,

(see

“Sign:

basis

of

their

and a function

clock

frequencies

memories,

and

Additionally

key

is

The

function

ile

systems

functions,

proces-

and

All

safety-

the results

fed

to

the

proces-

Fig:

1-3

1-4

UBS

+5V

6-16V

EAANT

EA-TAS

71

=]

ーー-

一

—

IP

Vista basic

NC-BatteryD

TN

fm-System

Емета

Mains

004

950971

Rev A (5/04)

(МЕС)

Page 13

System

Overview

Voltage

Supply

The

voltage

FM

plug

(14 V connection

MFC

connector

ternal

7.2 V NiCD

versions:

voltage

Avoltage

tification.

unit

MFC

the

OFF switch

+5V

nel

monitors

checked

stepper

The

of

switching

on

The

ply

delay

tor

The

when

alarm

is

ON/OFF

test

is

ing

230

has a tolerance

of

This

supply.

or

FM

internal

supplies

microprocessor

the

during

motor

transistor

an

alarm

function

test.

circuit

voltages

switch:

V10b.

alarm

logic

the

buzzer

activated

key.

of

the

performed,

pulses

supply

is

generated

(11

to

16

V)

battery.

V,

220 / 230 / 240 V and

of + 10%

11

Vto

18

Vis

voltage

is

fed

This

is

also

valid

plug.

The

FET

V10

voltage

supply.

for

the

operating

the

complete

system. A window

+5V

for

undervoltage

switch-

on.

and

the

UMOT,

V47

switches

the

motor

is

of

the

has

two

separate

UBA

and UBB. The

off. A follow-up

(operating voltage

unit

is

running

and

drive

are

and

the

voltage

The

alarm

latch

voltage

monitoring,

The

voltage

fed

to

the

logic.

either

to

the

fluid

manager

and

as

an

The

mains

module

to — 15

available

electronics

The

switched

transistor

also

supply

The

to

the

battery

for

an

external

switches

The

transistor

voltages

or

operating

the

stepper

the

operating

assembly

ON/OFF

charging

UBB)

and

activates

driven

supply

is

is

reset

motor

is

maintained

alarm

after

off

is

switched

circuit

directly

from

mains,

via

the

system),

internal

supply

is

100 / 110 / 120

%.

transformation

charge

12 V supply

between

VIOb

UBS,

UMOT

including

comparator

overvoltage.

voltage

motor

voltage

by

V47.

checked

groups

with

circuit

has a retriggerable

circuit

is

an RS

the

by

UBB.

The

simultaneously. A function

and

latch

is

also

or

via

via

the

available

the

during

drives

alarm

on

by

in

V.

The

and

circuit

and

from

the

external

works

as

an

and

+5V.

double

constantly

The

function

UBS

supplies

drive.

UMOT.

In

Additionally

the

switch-

separate

the

transis-

latch.

This

circuit.

ON/OFF

by

pressing

alarm

activation

cyclic

self-hold-

activated.

the

in-

three

rated

rec-

the

the

and

ON/

The

chan-

is

the

case

the

sup-

is

set

The

circuit

the

Vista

basic

950971

Rev A (5/04)

1-5

Page 14

MAINS:

+

MFC

11-16\

_

fm-System

+

1246V

System

Overview

Switching

Current

Source

Battery:

6x1,

2V

+8V

Fig:

1-4

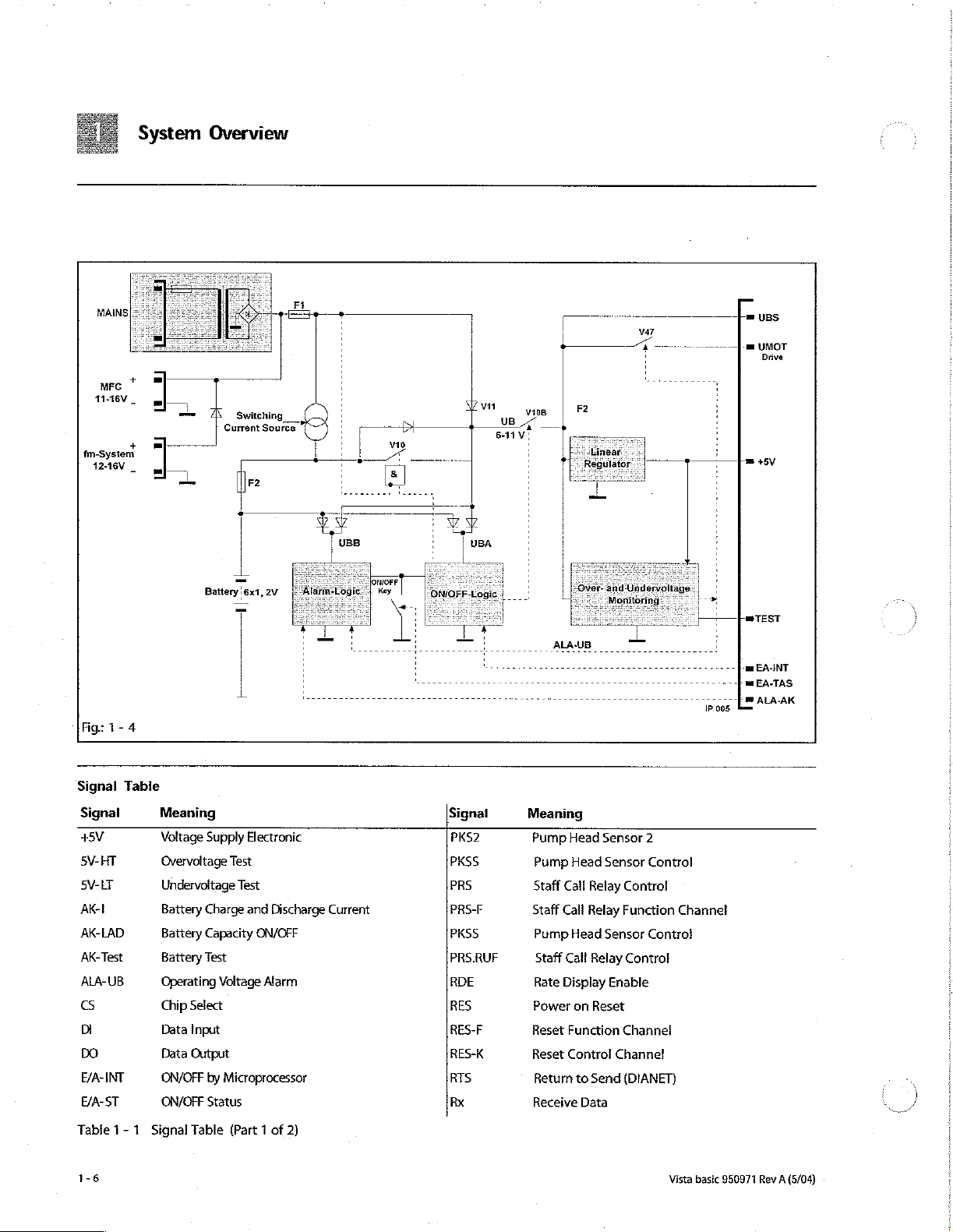

Signal

Table

Signal

+5V

5V-HT

5V-LT

AKI

AK-LAD

AK-Test

ALA-UB

G

Di

DO

E/A-INT

E/A-ST

Table 1 - 1 Signal

Meaning

Voltage

Overvoltage

Undervoltage

Battery

Battery

Battery

Operating

Chip

Data

Data

ON/OFF

ON/OFF

T

Supply

Test

Charge

Capacity

Test

Voltage

Select

Input

Output

by

Microprocessor

Status

Table

(Part 1 of

Electronic

Test

and

Discharge

ON/OFF

Alarm

Signai

PKS2

PKSS

PRS

Current

2)

PRS-F

PKSS

PRS.RUF

RDE

RES

RES-F

RES-K

RTS

Rx

Meaning

Pump

Head

Pump

Staff

Call

Staff

Cali

Pump

Staff

Cali

Rate

Display

Power

Reset

Function

Reset

Control

Return

Receive

Head

Relay

Relay

Head

Relay

on

Reset

to

Send

Data

Sensor

Sensor

Control

Function

Sensor

Control

Enable

Channel

Channel

(DIANET)

2

Control

Channel

Control

TEST

-

Pan

EASINT

mi

EA-TAS

τον 8 ALA-AK

IP

005

1-6

Vista

basic

950971

Rev A (5/04)

Page 15

System

Overview

Signal

E/A-TAS

EDB

FMC-F

FMCK

UEXFN

UEXT-P

UFM-P

LFCL

LFDA

LFS

LFSEL

LFT

MISO

MOSI

MOTEIN

MS

P-ENA

PHO

PH1

PH2

PH3

PKS

PKS1

Table

1 - 1

Meaning

ON/OFF

Electronic

FM

Connection

FM

Connection

External

External

External

Air

Sensor

Air

Sensor

Air

Sensor

Air

Sensor

Air

Sensor

Serial

Data

Serial

Data

Motor ON

Motor

Control

Port

Enable

Phase

0

Phase

1

Phase

2

Phase

3

Pump

Cover

Pump

Head

Signal

Table

Key

Occlusion

Function

Control

12V

Supply

12V

Supply

12V

Supply

Clock

Data

Signal

Selection

Reset

Output

Input

Sensor

Sensor

(Part 2 of

Pressure

Channel

Channel

(-)

(+)

(FM)

Interface

Interface

1

2)

Signal

SCK

TD-AO

TD-A1

TD-A2

TD-A3

TD-E

TD-RAW

TD4

TDS

τος

TD7

TSA

TSCL

TSE

TSR

TSS

Tx

UBA,

UBS

UBS-M

UMOT

UMOT-M

URTC

UBB

Meaning

Serial

Data

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Text

Display

Drop

Sensor

Drop Sensor

Drop Sensor

Drop Sensor

Drop

Sensor

Transmit

Supply

Voltage

Switched

UBS

Measurement

Supply

Voltage

UMOT

Measurement

Supply

Voltage

Lock

Address

Address

Address

Address

Enable

Read/Write

Data

4

Data

5

Data

6

Data

7

Output

Clock

Receiver

Regulation

Control

Data

for

Operating

of

Motor

Clock

0

1

2

3

Alarm,

Voltage

Line

Drive

Line

Module

On/Off

UB

Logic,

RTC

Mains

Vista

basic

Operation

950971

Rev A (5/04)

When

the

unit

is

switched

microprocessor

on

for

connected

the

recognizes a sufficient

to

duration

mains

of

the

the

unit

switch-

off

mains

supply

delay

voltage

voltage

time.

for

lf

is

the

the

charging,thevoltagesupplyismaintained.Inthiscaseonlyabat-

terybalanceiscarried

tual

battery

displayed

key

triggered

20

ing.

ON/OFF

In

switch-on

is

pressed

and

seconds

If

the

key,

mains

operation

in

the

the

Vista

the

test.

out,

capacity

LCD.

The

for

at

least 2 seconds.

the

alarm

unit

is

switched

basic

is

internal

the

Therefor

becauseakeywasnotpressed.

and

the

unit

is

latch

is

reset

off,

switched

mains

voltage

battery

function

the

charge

battery

switched

off

operating

off

Thereby

with a delay.

because

and

in

mains

is

still

is

discharge

the

checked

when

the

operation

present.

hours

the

self-

holding

After

pulses

during

current

Theac-

ON/OFF

another

are

miss-

with

is

mea-

1-7

are

is

the

the

Page 16

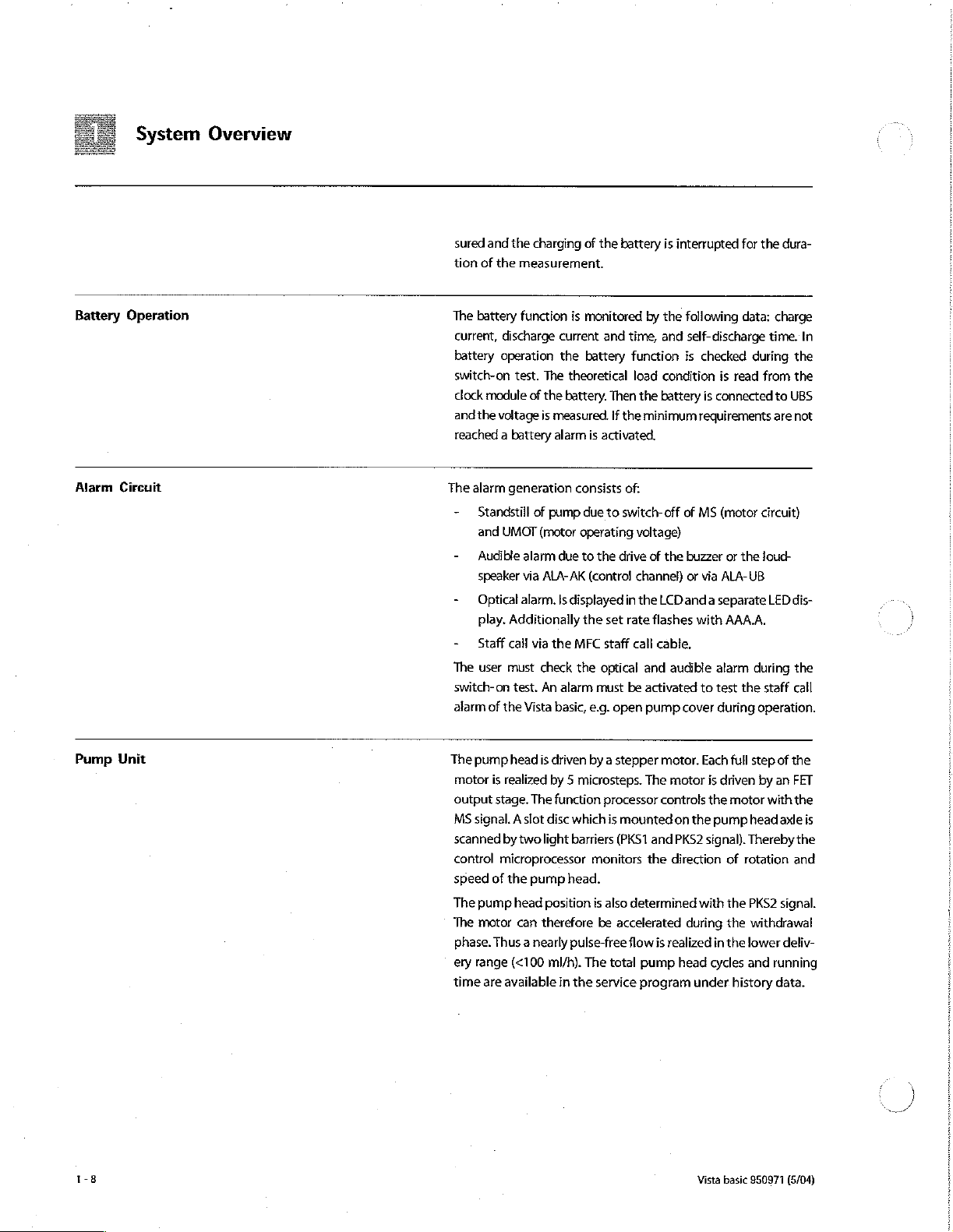

Battery

Alarm

System

Operation

Circuit

Overview

sured

and

the

charging

tion

of

the

measurement.

The

battery

function

current,

battery

switch-on

clock

and

discharge

operation

module

the

voltage

test.

of

is

reached a battery

The

alarm

generation

-

Standstill

and

-

Audible

speaker

-

Optical

play.

-

Staff

The

user

switch-on

alarm

of

UMOT

(motor

alarm

via

alarm.

Additionally

call

via

must

check

test.

An

of

the

Vista

of

is

monitored

current

the

battery

The

theoretical

the

battery.

measured.

alarm

is

consists

pump

due

operating

due

to

ALA-

AK

(control

Is

displayed

the

the

MFC

the

alarm

basic,

e.g.

the

battery

by

and

time,

function

load

Then

the

If

the

minimum

activated.

of:

to

switch-

voltage}

the

drive

of

channel)

in

the

set

rate

flashes

staff

call

optical

and

must

be

activated

open

pump

is

interrupted

the

following

and

self-discharge

is

checked

condition

battery

is

requirements

off

of

MS

the

buzzer

or

via

LCD

and a separate

with

cable.

audible

to

cover

for

the

data:

during

is

read

from

connected

(motor

circuit}

or

the

ou

ALA-

UB

AAA.A.

alarm

during

test

the

staff

during

operation.

dura-

charge

time.

the

the

to

UBS

are not

中

LED

dis-

the

call

In

Pump

Unit

The

pump

motor

output

MS

signal. A slot

scanned

control

speed

of

The

pump

The

motor

phase.

ery

range

time

are

head

is

driven

is

realized

by 5 microsteps. The

stage.

The

function

disc

by

two

light

microprocessor

the

pump

head.

head

position

can

therefore

Thus a nearly

(<100

available

pulse-free

ml/h).

in

by a stepper

processor

which

is

mounted

barriers

(PKS1

monitors

is

also

be

accelerated

The

total

the

service

motor.

motor

controls

on

and

PKS2

the

direction

determined

flow

is

realized

pump

head

program

Each

is

the

the

pump

signal).

with

during

in

cycles

under

Vista

full

driven

motor

head

Thereby

of

rotation

the

PKS2

the

withdrawal

the

lower

and

history

basic

950971

step

by

with

running

of

the

an

FET

the

axle

is

the

and

signal.

deliv-

data.

(5/04)

Page 17

System

Overview

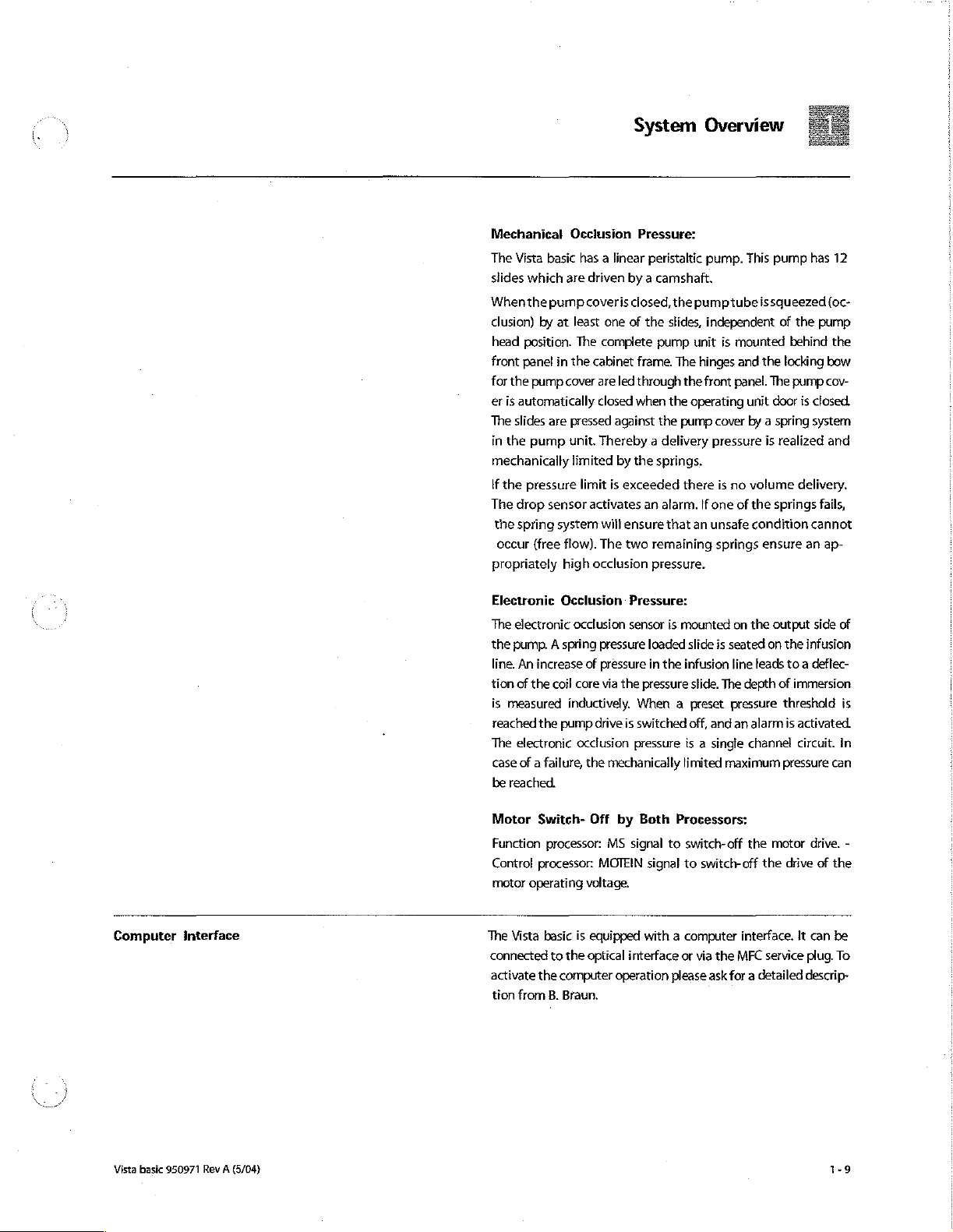

Mechanical

The

Vista

basic

slides

which

are

When

the pump

clusion)

head

front

for

er

The

in

by

at

position.

panel

in

the

pump

cover

is

automatically

slides

are

the

pump

mechanically

If

the

pressure

The

drop

sensor

the

spring

system

occur

(free

flow).

propriately

Electronic

The

electronic

the

pump. A spring

line.

tion

is

measured

reached

The

case

be

reached.

high

Occlusion:

An increase

of

the

coil

inductively.

the

pump

electronic

of a failure,

Occlusion

has a

driven

coveris

least

The

the

pressed

unit.

limited

limit

activates

Pressure:

linear

by a camshaft.

closed,

one

of

the

complete

cabinet

frame.

are

led

through

closed

when

against

Thereby a delivery

by

the

is

exceeded

an

will

ensure

The two

occlusion

Pressure:

occlusion

sensor

pressure

of

pressure

core

via

the

pressure

When a preset

drive

is

switched

occlusion

the

pressure

mechanically

peristaltic

pump

the

pump

slides,

unit

pump.

independent

The hinges and

the

front

the

operating

the

pump

springs.

there

alarm.

If

that

an

unsafe

remaining

pressure.

is

mounted

loaded

slide

in

the

infusion

slide.

off,

and

is a single

limited

This

tube

is

mounted

panel.

unit

cover

by a spring

pressure

is

no

volume

one

of

the

condition

springs

on

the

is

seated

line

The

depth

pressure

an

alarmis

channel

maximum

pump

is

squeezed

of

the

The

door

is

realized

springs

ensure

output

on

leads

of

has

12

(oc-

the

pump

behind

the

locking

bow

pump

cov-

is

closed.

system

and

delivery.

fails,

cannot

an ap-

side

of

the

infusion

to a deflec-

immersion

threshold

activated.

circuit.

pressure

can

is

In

Computer

Vista

basic

interface

950971

Rev A (5/04)

Motor

Function

Control

motor

operating

The

Vista

connected

activate

tion

from

Switch-

Off

processor:

processor:

basic

to

the

B.

MOTEIN

voltage.

is

equipped

the

optical

computer

Braun.

by

Both

MS

signal

signal

with a computer

interface

operation

Processors:

to

switch-off

to

switch-off

or

via

the

please

ask

the

motor

the

drive

interface.

MFC

for a detailed

It

service

plug.

descrip-

drive.

-

of

the

can

be

To

Page 18

E. | System

managersystem

fluid

Braun

Internal

Assignment

Overview

system)

(fm

Vista

The

in

ed

(fm

tem

system,

the

Mains

nected.

puter

basic

intensive

an

system).

supply

Thereby

system

be

can

care

is

It

and

data

data

levels

are

operated

integrated

acquisition

as

e.g.

unit,

communication

possible.

stand-alone

a

Braun

B.

the

simply

by

and

transmission

unit

fluid

snapping

are

automatically

to

integrat-

or

manager

unit

the

higher

sys-

into

con-

com

Fig:

1-5

1-10

Vista

basic

950971

Rev

(5/04)

A

Page 19

System

Overview

Language

Accessories

Groups

A:

German,

B:

English,

C:

English,

D:

English,

E:

English,

F:

English,

General

Designation

Universal

Drop

Short

Power

Universal

Pole

English,

French,

French,

French,

French,

French,

adapter

sensor,

Stand

Cord

Clamp

Clamp

French,

Spanish,

Spanish,

Spanish,

Spanish,

Spanish,

for

drop

complete

.........

(Hospital

(rotating}

Grade)

Spanish

Portuguese

Portuguese

Portuguese

Portuguese

Portuguese

sensor.

.

.....................

..........................,

.871

3450

3450

3450

3450 9054

Ord.

No.

1747

578A

5873

5458

Vista

basic

950971

Rev A (5/04)

1

Page 20

System

Overview

1-12

Vista

basic

950971

Rev A (5/04)

Page 21

Software

Software

Approved

Update

Software

Versions

Designation

MFCinterface

The

higher

level,

e.g.

When

the

are

changed,

struct

coding,

FVA23002

software

the

e.g.

line

digit

too.

user

IFVA

always

and

Note

Mark

the

unit after

ware

version

Only

update

order

All

units

and

basic

“Note

Software

Observethenotes

IFVA23002

-

Basic

IFVB23003

must

from

(e.g.

neverupdate

used

in

setup

updates

software

one

to

replaces

replaces

group

changes

Therefore

is

on

having

old

avoidoperator

exchang

the

be

clearly

to

new

from

ward

should

unit

cover

updated

0

must

be

reported

ofthe

update

the

lower

digit

IFVA23001.

(IFVA23002)

users

must

be

the

instructions

page

of

the

the

software!

E

recognizable.

software

versions,

IFVA23002

have

the

mistakes.

to

same

to

B.

Braun

programandthe

Ord.

No.

cece

eee

871

1661

for

the

revision

the

unit

functions

informed

for use — software

instructions

(e.g.

for

use.)

in-

=

The

new

soft-

never

in

reverse

IFVA230011).

software

for

supplements!

status

registration.

Vista

basic

950971

Rev A (5/04)

Page 22

Error

Software

Messages

7

Segment

and

Alarms

Display

Alarms

textfield

displayed

shoot

unit

sidered,

not

listed,

Detected

Alarms”

ber

is

displayed

of

the

function

ofthe

LCD.

inthe 7 segmentdisplay.

malfunctions.

unit

malfunctions

can

be

unit

alarms

in

the

selected

processor

Alarms

displayed,

are

language.

in

the

text

ofthecontrol

As

net

with

or

displayed

field,

80c535

are

displayed

processor

The

alarmshelptotrouble-

all

malfunctions

different

there

messages,

may

be

in

the

text

Additionally

no

field

the

in

68HC

can

be

con-

which

message.

as

“Unit

error

num-

the

11

are

are

so

BN

Fig:

2-2

Text

100

101

102

103

104

105

106

107

108

109

110

111

112

113

116

117

118

119

120

Field

Description

defective

UMOT

UMOT

UMOT

UMOT

ON/OFF

defective

defective

defective

different

different

different

defective

testbit!=0

defective

defective

reset

defective

defective

BEE

Text

Field

RAM

cannot

still

switched

still

switched

still

switched

key

air

program

program

number

keypad

program

program

out

program

program

during

program

program

Te

memory

be

switched

on

on

on

pressed

sensor

(calibration

memory

flow

of

gaps

versions

flow

of

switch-on

memory - text

memory - text

active

operation

memory

memory

HL

despite

despite

despite

longer

pump

between

on

overvoltage

MOTEIN=0

undervoltage

than

14

value?)

head

cycles

80c838

between

test

does

transit

tube

parameters

sec

and

80c535

not

time

ROM-test

68hc11

and

match

68hc11

with

program

Table 2 -

2-2

1

Vista basic

950971

Rev A (5/04)

Page 23

Software

7

Segment

ΕΕΟΙ

FFO2

FFO3

FF04

FF05

FF06

FF07

FFO8

FFO9

FF10

FF12

FF14

FF16

FF17

Display

dummy

battery

defective

defective

defective

calibration

pump

failure / inaccuracy

failure

reset

no

defective

defective

defective

Description

for

test

not

present / missing

RAM

memory

program

program

data

head

cycle

100msec

during

active

dynamic

pressure

temperature

membrane

program

battery

memory - ROM

memory - ROM

error

from

EEPROM

not

plausible

of

system

clock

system

clock

operation

sensor

signal

sensor

keypad

memory

tube

current

test

error

test

error

(EDB)

parameters

Control

FFxx

is

displayedin

is

the

error

1

2

Microprocessor

the 7 segment

code.

68hc11

display

with

flashing

dots.

FFxx

ューー

Table 2 -

2

Vista

basic

950971

Rev A (5/04)

2-3

Page 24

Software

2-4

Vista

basic

950971

Rev A (5/04)

Page 25

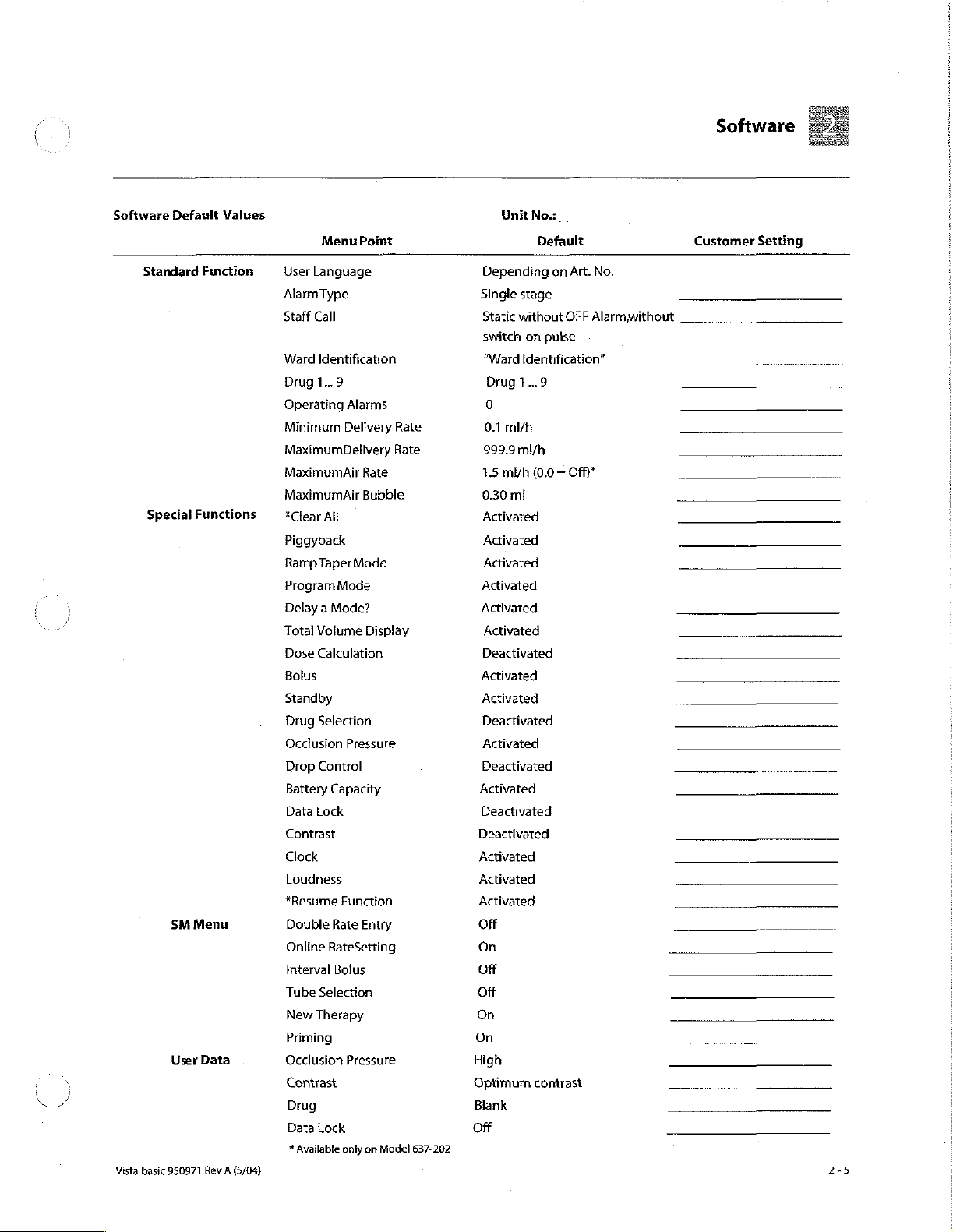

Software

Software

Standard

Special

Vista

basic

Default

Functions

SM

Menu

User

950971

Values

Finction

Data

Rev A (5/04)

Menu

Point

User

Language

AlarmType

Staff

Call

Ward

Identification

Drug

1..9

Operating

Minimum

MaximumDelivery

MaximumAir

MaximumAir

*Clear

Alarms

Delivery

Rate

Bubble

All

Piggyback

Ramp

Taper

Mode

Program

Mode

Delay a Mode?

Total

Dose

Bolus

Volume

Calculation

Display

Standby

Drug

Selection

Occlusion

Drop

Battery

Data

Contrast

Pressure

Control

Capacity

Lock

Clock

Loudness

*Resume

Double

Online

Interval

Tube

New

Priming

Occlusion

Contrast

Drug

Data

*

Rate

RateSetting

Bolus

Selection

Therapy

Lock

Available

Function

Entry

Pressure

only on

Rate

Rate

Model

637-202

Unit

Depending

Single

stage

Static

without

switch-on

"Ward

Identification”

Drug

1...9

0

0.1

ml/h

999.9

ml/h

1.5

mi/h

0.30

ml

Activated

Activated

Activated

Activated

Activated

Activated

Deactivated

Activated

Activated

Deactivated

Activated

Deactivated

Activated

Deactivated

Deactivated

Activated

Activated

Activated

Off

On

Off

Off

On

On

High

Optimum

Blank

Off

No.:

Default

on

Art.

OFF

Alarmwithout

pulse

(0.0 = Off)"

contrast

No.

Customer

Setting

Page 26

Software

Calibration

Unit

Specific

Data

Data

Standby

Drop

Control

Alarm

Tone

Dianet

Mode

Bolus Key

Bolus

Rate

Air

Sensor

Tube

group!

(dependent

Air

Sensor

Intrafix

(dependent

Scale

Factor

(dependent

Occlusion

Occlusion

History

Function

DIANET

Type

No.

Unit

Operating

Battery

Hours

Number

Menu

Point

Time

Display

Calibration

on

Calibration

Air P or

Vista

on

on

tube)

Level,

Low

Level,

High

No.

Hours

of

Pump

Head

Value

tube)

tube}

Value

Pump

Cycles

Set

24h

00min

Off

Stage

7

60sec

On

999.9

mi/h

130

mV

130

mV

50

(Intrafix

6

(no

PSI)

12

(no

PSi)

Activated

Depending

Depending

Depending

Depending

Depending

Default

Air P or

on

unit

on

unit

on

unit

on

unit

on

unit

Vista

Pump

Set)

Must

Must

Customer

not

be

changed

not

be

changed

Setting

Vista

basic

950971

<

Rev A (5/04)

Page 27

Service

Program

Structure

Standard

of

(see

operating

flow

diagram}

the

Service

Operation

Program

Group:

Unit

Software

Ward

Tube

Serial

DIANET

Data

Version

100.0

Drug

110.0

identification

120.0

Type

130.0

Number

140.0

Type

No.

150.0

Group:

History

Operating

Battery

Pump

Alarms

Service

Tube

New

Prime

Data

200.0

Op.

210.0

Head

Cycles

220.0

230.0

Plug,

Inserted

Type

Selection

Therapy

Set?

Hours

Hours

Special

(see

flow

Service

Activated

|

Occlusion

Temperature

Functions

operating

diagram)

Program

Group:

Test

Air

Sensor

300.0

310.0

320.0

Sensor

Sensor

Unit

É

Е

Service

Special

Group:

Modification

Language

400.0

User

Language

410.0

Alarm

Tone

420.0

Staff

Call

430.0

Function

440.0

Menu

450.0

Delivery

Rate

460.0

Air

Alarm

470.0

È

Calibration

Occlusion

500.0

Scale

Factor

5100

Air

Sensor

520.0

Occlusion

540.0

Pump

Data

550.0

History

560.0

Sensor

Level

Vista

basic

950971

Rev A (5/04)

Dianet

Display

480

Priming

490.0

Mode

Volume

Page 28

Service

Program

Additional

inserted

Functions

Service

Plug

with

Software

1.

Insert

2.

Switch

(for

max.

3.

The

software

inthe

4.

The

unit

5.

**

appears

Two

LEDs

-

green = Power

-

red

=Alarm

The

following

-

The

operating

-

All

special

-

The

special

battery

-

The

battery

and

the

not

reached

pacity.

-

The

tube

Version

service

plug

on

unit

15

s).

version

LCD.

is

switched

in

the

are

integrated

conditions

functions

functions

capacity

capacity

actual

”?”

type

andUser

into

the

and

keep

and

on

when

LCD

if

in

supply

active

are

alarms

are

are

are

has

key

display

capacity.

will

be

displayed

will

be

displayed

Languages

MFC

socket

the

ON/OFF

user

languages

the

ON/OFF

the

service plug

the

service

active:

muted.

accessible

slightly

for 0 min/32

If

switches

the

maximum

in

modified.

before

at

the

rear

button

are

button

is

inserted,

plug:

(including

(Example:

min

presetting).

between

battery

the

new

the

tube

selection

of

the

unit.

pressed

displayed

is

released.

the

disabled).

the

nominal

capacity

nominal

menu.

SM

is

ca-

i

)

i

Disabling

The

electronic

the

mechanical

1.

Select

2.

Then

select

3.

Return

A

too

low

Alarm”

with

The

display

indicates

the

Occlusion

pressure

occlusion

“Occlusion

“mechanical”.

to

the

main

pump

speed

underlined

"Pressure

that

no

tube

Sensor

monitoring

pressure.

Pressure”

menu

Alarm”

has

with

with

is

indicated

stars.

with

been

can

be

the

SM

END.

in

the

display

underlined

inserted.

Vista

basic

deactivated

key.

by

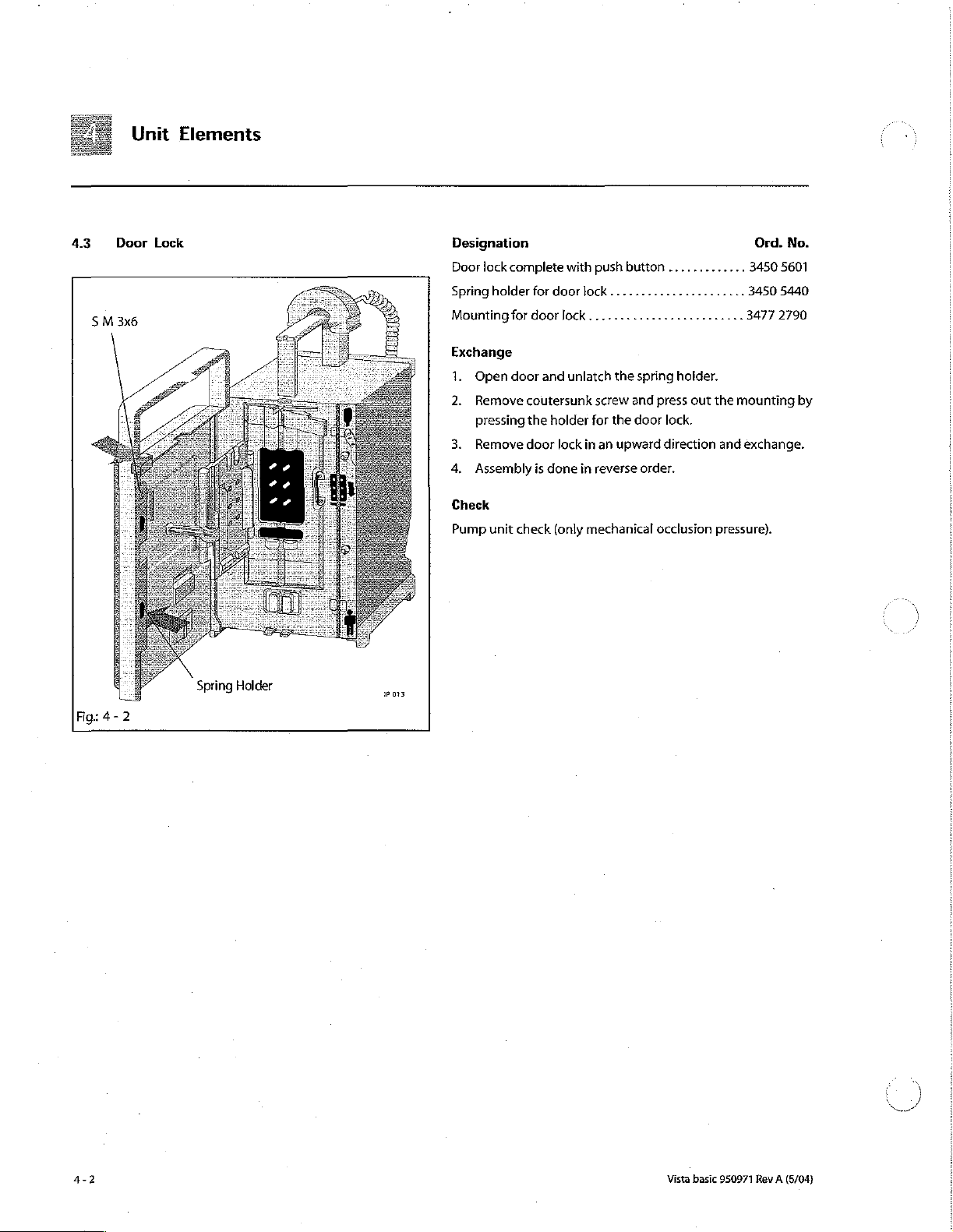

"Pressure

questions

950971

Rev A (5/04)

to

check

marks

Page 29

Service

Program

Start

/Quit

the

Service

Fig:

3-2

i

ο

Fig:

3-

à

3

Program

πες

à à à

Activate

1.

2.

12007

FUNCTION

:

FE

16008

the

Insert

service

- * appears

Select

"Service

program

plays

END

GR+

FU+

OK

is

the

code

Jumps

Selects

Selects

activated

Activates

necessary

with

Service

plug

into

in

the

display.

Program”

activated

number

to

group

function

대

NEXT

Program

the

MFC

with

the

red

of

the

the

initial

group

the

selected

skips

to

socket

the

SM

alarm

LED

selected

function

in

the

function

the

sub-functions

at

the

key.

When

flashes.

group

or

Quit

the

1.

2.

Press

END

vated:

Y/N

terminates

Press

Switch

Service

END

in

the

“Save

Changes?

to

jump

off

the

Infusomat P and

Program

main

menu - À

the

service

to

the

data

Yes / No”.

program.

last

function.

remove

storage

service

rear

of

the

the

service

The

LED

and

function.

if

query

is

acti-

plug.

unit.

dis-

Unit

Vista

Data

basic

950971

Rev A (5/04)

Disconnect

ter

termination

the

unit

Software

1.

2.

3.

can

Select

The

current

-

User

-

Language

-

Service

-

Service

-

Tube

Return

the

Vista

basic

of

the

service

be

switched

Version

sub-functions

software

program

type

to

version

with

text

program

language

version

the

initial

version

with

function

from

mains

for

at

least

program

on

again.

with

version

with

version..Further

text

NEXT.

is

date

version

with

(memory

displayed

languages

END.

30

seconds

is

deleted).

Function

in

the

LCD:

with

af-

Then

100.6

(+).

3-3

Page 30

Service

Program

Drug

Name

Memory

1.

2.

3.

4.

Ward

Enter

display

1.

2.

3.

009

for

maximum 9 drugs

Display

the

stored

Delete

displayed

Press

YES

to

modify a drug

Move

cursor

to

Select

new

character

Repeat

the

procedure

Return

to

the

Identification

and

display

of a ward

if

the

unit

is

Delete

displayed

ifications:

Move

cursor

to

Select

new

character

Repeat

the

procedure

Return

to

the

drug

names

entry with CLR.

character

from

for

initial

function

specific

connected

entry

with

character

from

for

initial

function

and

20

with

name:

with

NEXT.

line 3 with

each

character.

with

unit

identification.

to

mains

CLR.

Press

with

NEXT.

line 3 with <<

each

character.

with

Function

characters

the

NEXT

<<

or

END.

Function

and

switched

YES

to

or

END.

110.0

per

name.

key.

>>.

120.0

Permanent

off.

enter

mod-

>>.

Tube

This

function

Serial

The

displayed

the

unit

1.

YES

2.

YES

3.

Return

DIANET

The

displayed

the

unit

1.

YES

2.

YES

3.

Return

Type

Number

type

activates

stores

to

Type

type

activates

stores

to

is

for

serial

plate,

the

the

the

initial

Number

serial

plate,

the

the

the

initial

future

number

as

this

entry

changed

function

number

as

this

entry

changed

function

extensions.

must

correspond

number

number

mode.

or

new

must

mode.

or

new

is

used

Enter

number.

with

correspond

is

used

Enter

number.

with

in

via

END.

in

via

END.

with

the

the

Function

with

the

the

Function

Function

the

number

interface

numeric

the

number

interface

numeric

130.0

140.0

on

mode.

keypad.

150.0

on

mode.

keypad.

Vista

basic

950971

Rev A (5/04)

Page 31

Service

Program

History

Data

Operating

1.

2.

Battery

1.

2.

Pump

Display

1.

2.

Operating

The

They

be

1.

set

PEN

Hour

OK

activates

Return

Operating

OK

activates

Return

Head

of

OK

activates

Return

last

20

aredisplayedas

from 0 to

OK

activates

Display

Delete

Return

the

to

the

the

to

the

Cycles

the

pump

the

to

the

Alarms

operating

1.

the

operating

the

operating

to

the

Counter

display.

initial

function

Hours

display.

initial

function

head

display.

initial

function

alarms

16

bit

alarm

alarms

initial

function

cycles

can

binary

codes

display.

-01 to

alarms

with

END.

with

END.

(delivered

with

be

with

with

volume).

END.

recalled.

andeach

-20

with

CLR.

END.

Function

Function

Function

Function

bit

positioncan

the

(+)

and

200.0

210.0

220.0

230.0

(-)

key.

Vista

basic

950971

Rev A (5/04)

Page 32

Service

Program

Test

.

Air

Sensor

After

exchange

See

TSI-List

inspection

1.

Press

measurement

(The

test

2.

Insert

permissible

3.

Insert

minimum

4.

Return

Pressure

Test

Eguipment

2.2

mm

template

{see

“Test

Push

Press

ウー

Open

の

Note

お

Insert

pu

The

new

be

15

7.

Return

If

the

15

to

must

be

pg.

4-14}.

check

for

permissible

TSF

pg.

72-15.

OK.

The

received

value,

value

with

an

infusion

air

value.

an

infusion

permissible

to

the

initial

Sensor

Eguinmentand

in

the

bottom

OK

twice.

unit

door.

the

measurement

the

2.2

mm

measurement

to

25

digits

to

the

initial

25

digits

mechanically

the

function

signal

NEXT

line

filled

line

filled

water

function

slide

template

higher

function

are

not

aligned

of

the

air

check

values

(see

amplitude

is

not

with

with

value.

with

Special

of

the

value

and

value

than

with

reached,

is

displayed

important).

air

and

check

fluid

and

END.

Tools”

finger

pump.

(actual

value).

close

the

will

be

displayed.

the

first

value.

END.

the

pressure

isee"OcclusionSensor“

Function

sensor.

schnical

as

the

maximum

check

the

Function

po.

9-1)

unit

door.

It

sensor

300.0

Safety

a

310.0

must

unit

:

İ

|

3-6

Temperature

Display

of

the

tions

are

possible,

1.

OK

activates

2.

Return

to

Sensor

measured

the

the

display.

the

initial

temperature

display

is

function

only

with

of

both

for

internal

END.

Vista

basic

Function

processors.

use.

950971

Rev

320.0

Devia-

A

(5/04)

Page 33

Unit

Modifications

Service

English

1.

2.

3.

4

User

Four

(depending

1.

2.

4.

Language

or

OK

activates

Select

Acknowledge

Return

Language

user

OK

activates

Select

The

language

Acknowledge

Return

German

the

language

with

to

the

initial

languages

on

software).

the

language

no.

with

to

the

initial

Service

can

be

function.

with

YES.

function

per

language

function.

with

and

YES.

function

selected.

NEXT.

with

NEXT.

text

version

with

Program

END,

group

are

are

END.

Function

Function

available

displayed.

400.0

410.0

Alarm

Tone

Different

-

-

The

-

- © the

1.

PEN

alarm

Single

A"10

minutes

In

this

mode

of

10minutes.

activation

the

staff

Vista

M007100000F04).

OK

activates

Select

Acknowledge

Return

stage

of

call

basic

alarm

to

the

modes

off

the

audible

the

10

is

connected

has

the

tone

with

initial

can

be

selected:

alarm”

can

alarm

minutes

and

an

attention

function.

with

NEXT.

YES.

function

be

off

with

is

alarm

Function

selected.

activated

is

only

label

(label

END.

420.0

with a delay

permissible,

drawing

no.

if:

Vista

basic

950971

Rev A (5/04)

3-7

Page 34

3

|

Service

UNIT

OFF

Optical?

Alarm

Alarm

ON

FERE

Alarm

DEF:

+ に i

AudibleO

Alarm

‘ures

Alarm

Fig:

on

SESE

OFF.

3-6

a

и

Program

UNIT

ON

Operating

Alarm

Off

Alarm,

Staff

Cal!

Select

first,

whether

NO).

The

switch-on

ferent

staff

„UNIT

OFF

Zinet

“START

ade

oo

-

-

-

For

An

additional

mode

1.

2.

3.

4.

call

Dynamic

Dynamic

Static

without

further

details

to

test

OKactivates

Select

staff

Acknowledge

Return

to

the

pulse

modes

with

OFF

without

OFF

see

switch-on

the

staff

the

function.

call

type

with

the

initial

switch-on

is

used

can

be

Alarm

OFF

Alarm

Alarm

staff

call

pulse

(YES/NO)

call

unit.

with

NEXT.

YES.

function

pulse

to

test

selected

line

in

with

END.

Function 430.0

shall

be

the

staff

with

the

the

instructions

can

be

activated

activated

call

NEXT

line.

key:

for

for

(YES/

Dif-

each

use.

Special

Special

are

tions

in

Special

Functions

functions

then

available

will

not

standard

functions

can

be

on

the

be

displayed.

operation,

to

be

activated

user

interface.

The

SM

if

all

special

selected,

in

the

Deactivated

softkey

functions

see

Fig:

service

will

not

are

1-4.

Function

program,

440.0

which

special

func-

be

displayed

deactivated.

-

1.

OK

activates

Select

special

Activate / deactivate

た の »

Return

to

the

the

function.

functions

the

main

menu

with

NEXT.

respective

with

END.

Vista

function

basic

950971

with

YES/NO,

Rev A (5/04)

Se

Page 35

Service

Program

Menu

The

availability

-

Double

-

Online

-

Interval

-

Tube

1.

OK

2.

Activate / deactivate

3.

Acknowledge

4

Return

Delivery

The

maximum

of

adjustment

1.

OK

Select

Acknowledge

Enter

SSN

Acknowledge

Return

Ou

of

rate

entry

rate

entry

bolus

selection

activates

to

the

Rate

and

of

activates

the

the

min./max.

value

with a numeric

to

the

menus

the

function.

with

YES.

main

menu

minimum

the

delivery

function.

with

YES.

with OK.

initial

on

the

the

decimal

with

delivery

rate:

delivery

key.

function

user

interface

function

END.

0.1

rate

with

rates

to

999.9

with

END.

Function

can

be

with

Function

can

be

set.

ml/h

NEXT.

450.0

set.

NEXT.

460.0

Range

Vista

basic

950971

Rev A (5/04)

Air

Alarm

The

air

sensor

air

alarm)

ble}

can

Setting

range

Setting

range

1.

OK

activates

본

Select

Acknowledge

の

まお

Enter

Acknowledge

の の

Return

and

be

adjusted.

air

value

to

sensitivity

of

air

air

rate

the

of

the

the

maximum

rate:

0.5

to

3.5

bubble:

the

0.01

function.

(mi/h)

or

with

YES.

air

with a numeric

with OK.

initial

function

air

air

bubble

ml/h

to

0.3

bubble

key.

with

rate

ml/h

(ml)

END.

Function

alarm

in

ml

with

in

ml/h

(single

NEXT.

470.0

{total

bub-

Page 36

Service

Program

Calibration

Dianet

When

Mode

is

The

be

Priming

All

If

performed

Occlusion

Measurement

sensor,

pg.

1.

2.

3.

4,

5.

6.

7.

It

Mode

operated

(CA,

CC,

displayed

duration

set

safety-relevant

these

414).

Press

Press

Open

Check

(briefly

played

Wait

change

must

Acknowledge

Return

is

not

by:

between 0 and

Volume

parameters

with

Sensor

Ord.

No.:

the

the

the

the

operate

measurement

until

any

be

to

allowed

Display

with

DianetStar

CD)

with

“###CA01###".

of

the

display

255

parameters

are

calibrated

and

setting

3452

0619.

OK

key

twice.

Align

key.

unit

door

occlusion

the

the

displayed

more

(+/-

between

the

250

the

entry with

initial

to

enter

the

address

01,

e.g.

after

the

last

seconds.

are

set

changed, a new

test

equipment.

of

the

zero

Calibration

and

remove

sensor

for

cleanliness and

sensor

and

check

value

changes).

measurement

one

digit).

and 400

function

the

zero

digits.

YES.

with

point

Function

respective

mode

CA and

data

transmission

Function

by

the

calibration

Function

value

"3"

(see

“Occlusion

tube.

whether

value

The

measurement

END.

value

via

480.0

DianetStar-

address

can

490.0

manufacturer.

must

500.0

of

the

occlusion

Sansor*

function

the

dis-

does

not

value

the

keypad.

01

be

A

/

3-10

Scale

Factor

The

scale

factor

for

each

tube

ification

duces

1

2

3

4.

5.

6.

of

the

Press

Select

"Yes"

The

value

Acknowledge

Return

can

be

type.

Every

the

delivery

pump

speed,

the

OK

key

the

tube

activates

to

can

the

the

be

the

initial

set

in

the

digit

step

rate.

An

and a decrease

twice

to

activate

type

with

the

function

changed

entry with

with

function

limits

between

is

equivalent

increase

for

with END.

increases

NEXT

the

the

OK.

Vista

of

the

key.

selected

entry

Function

40

and

to a 0.5 % mod-

the

scale

the

function.

tube

keypad.

basic

950971

510.0

99

digits

factor

pump

speed.

type.

Rev A (5/04)

re-

Page 37

Service

7.

Quit

the

service

8.

Switch

curacy”

KH

necessary

Air

Sensor

Alignment

{see

“Air

“Not

The

value

Press

>

Press

WN

The

value

Acknowledge

ES

M

AIR

SENSOR

Return

NPD

Quit

onunit

pg.

or

check

Sensor”

is

dependent

OK

twice

OK

again

can

to

the

the

service

program

and

8-4},

repeat

of

pg.

4-17).

and

to

be

changed

the

IS

SET

initial

program

and

check

the

delivery

the

delivery

the

air

sensor

on

the