Page 1

Aesculap Power Systems

microspeed® uni

Instructions for use

microspeed® uni motor system

Gebrauchsanweisung

microspeed® uni-Motorensystem

Mode d’emploi

¾ voir www.aesculap-extra.net

Instrucciones de manejo

¾ ver www.aesculap-extra.net

Istruzioni per l’uso

¾ vedere www.aesculap-extra.net

Instruções de utilização

¾ ver www.aesculap-extra.net

Gebruiksaanwijzing

¾ zie www.aesculap-extra.net

Bruksanvisning

¾ se www.aesculap-extra.net

Käyttöohjeet

¾ ks. www.aesculap-extra.net

Инструкция по примению

¾ смотри www.aesculap-extra.net

Page 2

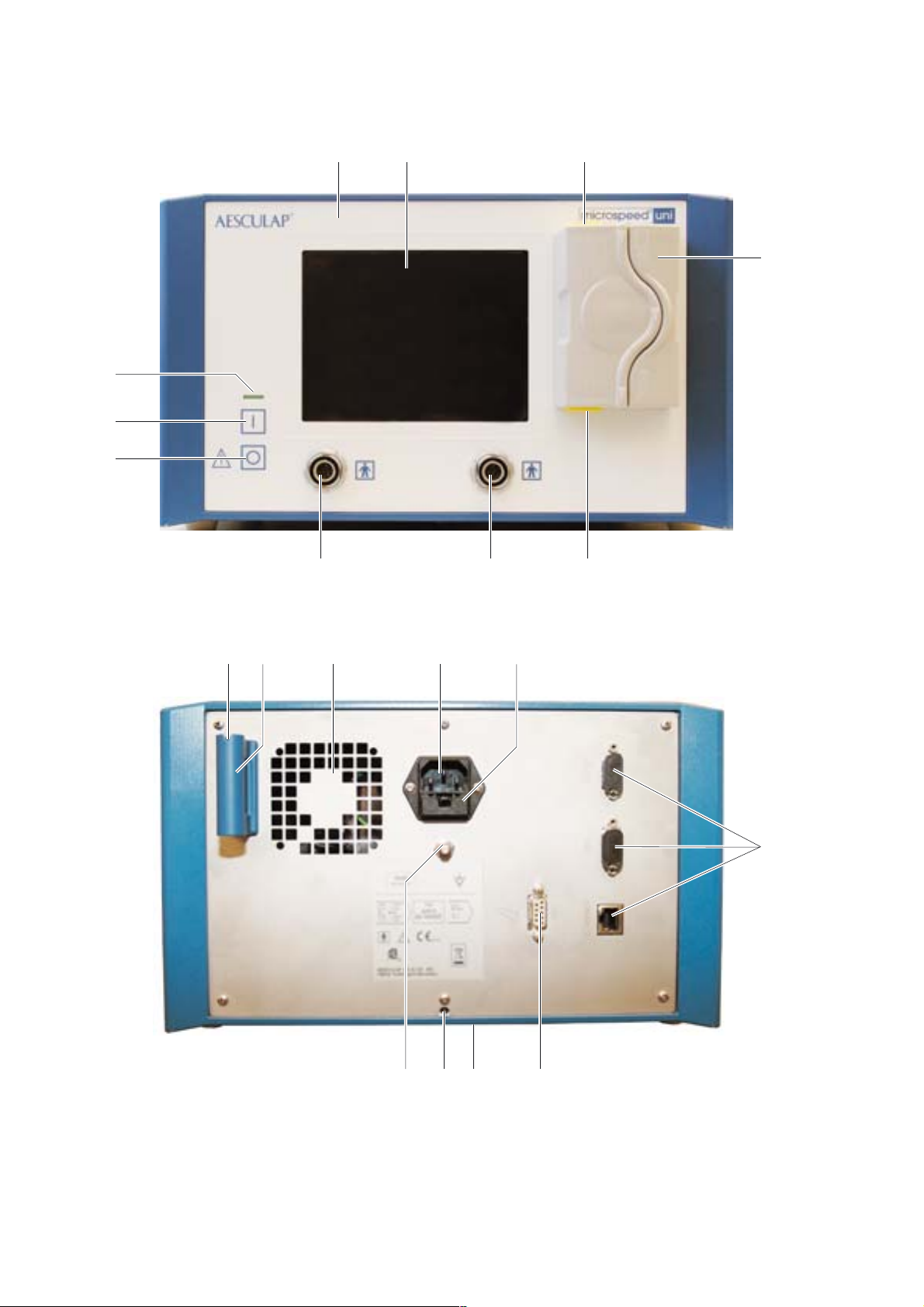

1 2

3

4

8

7

6

5 5

9 10 11 13

12

3

39

17 16 14

15

Page 3

18

18

22

20 19

21

25

29

26 30 28

27

23

24

31

28

33

34

35

32

36

3837

Page 4

Aesculap Power Systems

microspeed® uni motor system

Legend

Captions first foldout page: Control unit

1 microspeed® uni control unit with cooling unit GD670

2 Display and touch control field

3 Release buttons

4 Coolant pump

5 Motor connection sockets

6 Power OFF switch

7 Power ON switch

8 Power ON indicator

9 Bottle holder

10 Bottle holder mount

11 Ventilation grate

12 Power socket

13 Fuse holder

14 Connection socket for foot control

15 Stacking cones

16 Locking screw

17 Equipotentialization connector

39 Interfaces to be used by the manufacturer only

Captions second foldout page: Foot controls, motor cables, motors

18 Foot control function button

19 Right pedal

20 Left pedal

21 microspeed® uni foot control, two pedals, GD671

22 Motor direction switch

23 Pedal

24 microspeed® uni foot control, one pedal, GD668

25 Motor release switch

26 Hand control function button

27 microspeed® uni motor cable with hand control GD673

28 Release key

29 Lever

30 Motor release switch

31 microspeed® uni motor cable for foot control GD672

32 Motors with motor-side plug connection

33 microspeed® uni mini pistol handpiece GD684

34 Upper trigger

35 Lower trigger

36 Suction control lever

37 microspeed® uni shaver handpiece GD682

38 Tube olive

Contents

1. Safe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Components necessary for using the product . . . . . . . . . . . . . . . 4

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.1 Control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.2 Control and display interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.3 Control fields on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.4 Motor control fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.5 Pump control field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.6 Instruction menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.7 Motor recognition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.8 Automatic saving of device settings . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.9 Overload cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.10 Coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.11 Motor cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.12 Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.13 Foot control devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.1 Symbols on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.2 Symbols on foot control, motor cable and motor . . . . . . . . . . . 12

2.5.3 Symbols in display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Preparation and setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 Mounting the control unit on the mobile stand . . . . . . . . . . . . 15

3.1.2 Dismounting the control unit from the mobile stand . . . . . . . . 15

3.1.3 Mains power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Working with the microspeed® uni motor system . . . . . . . . . . . 16

4.1 System set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.1 Connecting the accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.2 Connecting the foot control to the control unit . . . . . . . . . . . . 16

4.1.3 Connecting the tubing set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.4 Connecting the motor cable to the control unit . . . . . . . . . . . . 17

4.1.5 Connecting a motor (GD674, GD676, GD677, GD678

and GD679) to the motor cable. . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.6 Switching on the control unit/Automatic self-test . . . . . . . . . . 18

4.1.7 Connecting handpieces/attachments/blades . . . . . . . . . . . . . . . 18

4.2 Function checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Safe operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.1 Setting up and operating the motors GD674, GD676,

GD677, GD678 and GD679 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.2 Setting up and operating

the microspeed® uni shaver handpiece GD682 . . . . . . . . . . . . . 26

4.3.3 Setting up and operating

the microspeed® uni mini pistol handpiece GD684. . . . . . . . . . 28

4.4 Settings in the Instruction menu . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4.1 Submenu information on the error conditions

shown on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.2 Submenu Device-specific settings . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.3 Submenu Motor (type)-specific settings . . . . . . . . . . . . . . . . . . 35

2

Page 5

5. Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1 Processing the microspeed® uni control unit with

cooling unit GD670 and

microspeed® uni foot control devices GD668/GD671 . . . . . . . . 38

5.1.1 Cleaning/Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1.2 Manual cleaning/disinfecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.3 Control, care and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.4 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Processing the microspeed® uni motors GD674, GD676,

GD677, GD678, GD679 and motor cables GD672 and GD673 . 39

5.2.1 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.2 Cleaning/Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.3 Mechanical cleaning/disinfecting . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.4 Manual cleaning/disinfecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5 Control, care and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.6 Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.7 Sterilization method and parameters . . . . . . . . . . . . . . . . . . . . . 41

5.2.8 Sterilization for the US market . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.9 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3 Processing the microspeed® uni shaver handpiece GD682 . . . . 41

5.3.1 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3.2 Mechanical cleaning/disinfecting . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3.3 Manual cleaning/disinfecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.4 Control, care and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.5 Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.6 Sterilization method and parameters . . . . . . . . . . . . . . . . . . . . . 42

5.3.7 Sterilization for the US market . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.8 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4 Processing

the microspeed® uni mini pistol handpiece GD684 . . . . . . . . . . 43

5.4.1 Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.2 Cleaning/Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.3 Mechanical cleaning/disinfecting . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.4 Manual cleaning/disinfecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.5 Control, care and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.6 Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.7 Sterilization method and parameters . . . . . . . . . . . . . . . . . . . . . 44

5.4.8 Sterilization for the US market . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.9 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4.10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7. Troubleshooting list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1 Malfunctions with error numbers . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2 Other malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3 Fuse change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8. Technical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9. Accessories/Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.1 microspeed® uni motors, motor cables and

foot control devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.2 Cooling unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.3 Other components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.4 Power cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.5 Maintenance, processing and service . . . . . . . . . . . . . . . . . . . . . 50

9.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10. Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10.1 Classification acc. to directive 93/42/EEC . . . . . . . . . . . . . . . . . 50

10.2 microspeed® uni control unit with cooling unit GD670 . . . . . . 51

10.2.1 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.3 Low-speed motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.3.1 Low-speed motors with micro-Line coupling. . . . . . . . . . . . . . . 51

10.3.2 Low-speed motor with mini-Line coupling . . . . . . . . . . . . . . . . 52

10.4 High-speed motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.4.1 High-speed motors with Hi-Line coupling . . . . . . . . . . . . . . . . . 52

10.5 microspeed® uni shaver handpiece GD682. . . . . . . . . . . . . . . . . 52

10.6 microspeed® uni mini pistol handpiece GD684 . . . . . . . . . . . . . 53

11. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

12. Distributor in the US/Contact in Canada

for product information and complaints . . . . . . . . . . . . . . . . . . 53

1. Safe handling

CAUTION

Federal law restricts this device to sale by or on order of a physician!

Risk of death by electric shock!

¾ The user must not open the control unit under any

DANGER

Note

For handling and operating the products that are used with the

microspeed® uni motor system, always observe the instructions for use of

the respective products. The present instructions for use only describe the

handling and operation of the “microspeed® uni motor system”.

¾ Prior to use, check for proper condition and functioning of the product.

¾ Observe “Notes on Electromagnetic Compatibility (EMC)”, see

TA022130.

¾ To avoid damaging the product through improper setup or operation

and mitigating the warranty and liability on the part of the product’s

manufacturer:

– Use the product only according to these instructions for use.

– Follow the safety instructions and maintenance advisories.

– Only combine Aesculap products with each other.

¾ Ensure that the products and accessories are operated and used only

by persons with the requisite training, knowledge or experience.

¾ Keep the instructions accessible for the O.R. personnel.

¾ Always adhere to applicable standards.

¾ Verify that the electrical installations in the room in which the

equipment is to be used conform to IEC standards.

¾ Unplug the device by pulling on the plug, and never on the power cord.

¾ Do not use the control unit and motors in explosion hazard areas.

¾ Prior to use, carry out sterile processing of motor(s), motor cable,

tubing, handpiece(s) and tools.

¾ Operate the handpieces only at the recommended motor speeds.

circumstances.

¾ Connect product only to mains with protective circuit.

3

Page 6

Aesculap Power Systems

microspeed® uni motor system

2. Product description

2.1 System components

Designation Art. no.

microspeed® uni control unit with cooling unit GD670

Bottle holder GD412804

Instructions for use TA022089

Notes on Electromagnetic Compatibility (EMC) TA022130

2.2 Components necessary for using the product

• microspeed® uni control unit with cooling unit GD670

• Power cord

• Motor

• Motor cable

(when using a motor with a motor-side plug connection)

• Foot control

(when using a motor cable without hand control, or the shaver

handpiece)

• Bottle holder

(when using the coolant pump)

•Tubing set

(when using the coolant pump)

• Surgical suction device

(when using the shaver handpiece)

2.3 Intended use

The microspeed® uni motor system is a universal system with respect to

its range of applications and to the system composition and its variety of

uses.

The microspeed® uni motor system is used in orthopedics/traumatology,

neurosurgery, spine surgery, hand/foot surgery, ENT/OMF surgery, plastic

surgery and arthroscopy.

The microspeed® uni motor system can be operated as complete from the

sterile area, either through foot control or through hand control.

2.4 Mode of operation

The microspeed® uni motor system comprises the following components:

• Control unit with coolant pump, for universal application

• Two motor cables (with or without hand control)

• Various motors with different coupling types

• Pistol handpiece

• Shaver handpiece

• Two foot control devices

2.4.1 Control unit

Control unit 1 has been designed for a mains voltage rating of 100 V to

240 V/50 Hz to 60 Hz. The mains voltage is transformed so that the motors

run at safety low voltage.

Control unit 1 is equipped with two motor connection sockets 5 for

connecting two (different) motors, and with one foot control connection

socket 14 (on rear panel).

The following devices can be connected to control unit 1 at the same time:

•Two motors and

• One foot control (GD668 or GD671).

Note

Do not connect two shaver handpieces GD682 at the same time.

Only one motor can be activated at any one time.

Motors with motor-side plug connection (GD674, GD676, GD677, GD678

and GD679) can be operated either through hand control (motor cable

GD673) or foot control GD668 or GD671 (with motor cable GD672).

Note

When two motors without hand control are connected to the control unit

(motor cable GD672), a motor can only be activated if the motor release

switch of the motor that is to be activated is in the “ON” position while the

other motor is locked (motor release switch in “OFF” position).

2.4.2 Control and display interface

Display 2 shows the present device status (operating and error conditions)

at all times. The display is divided into motor control field(s) and a pump

control field. The device parameter settings can be changed by pressing

the control keys.

For information on all the symbols used in the motor and pump control

fields, see chapter Symbols in display.

Control key “Instruction menu” calls up the Instruction menu.

4

Page 7

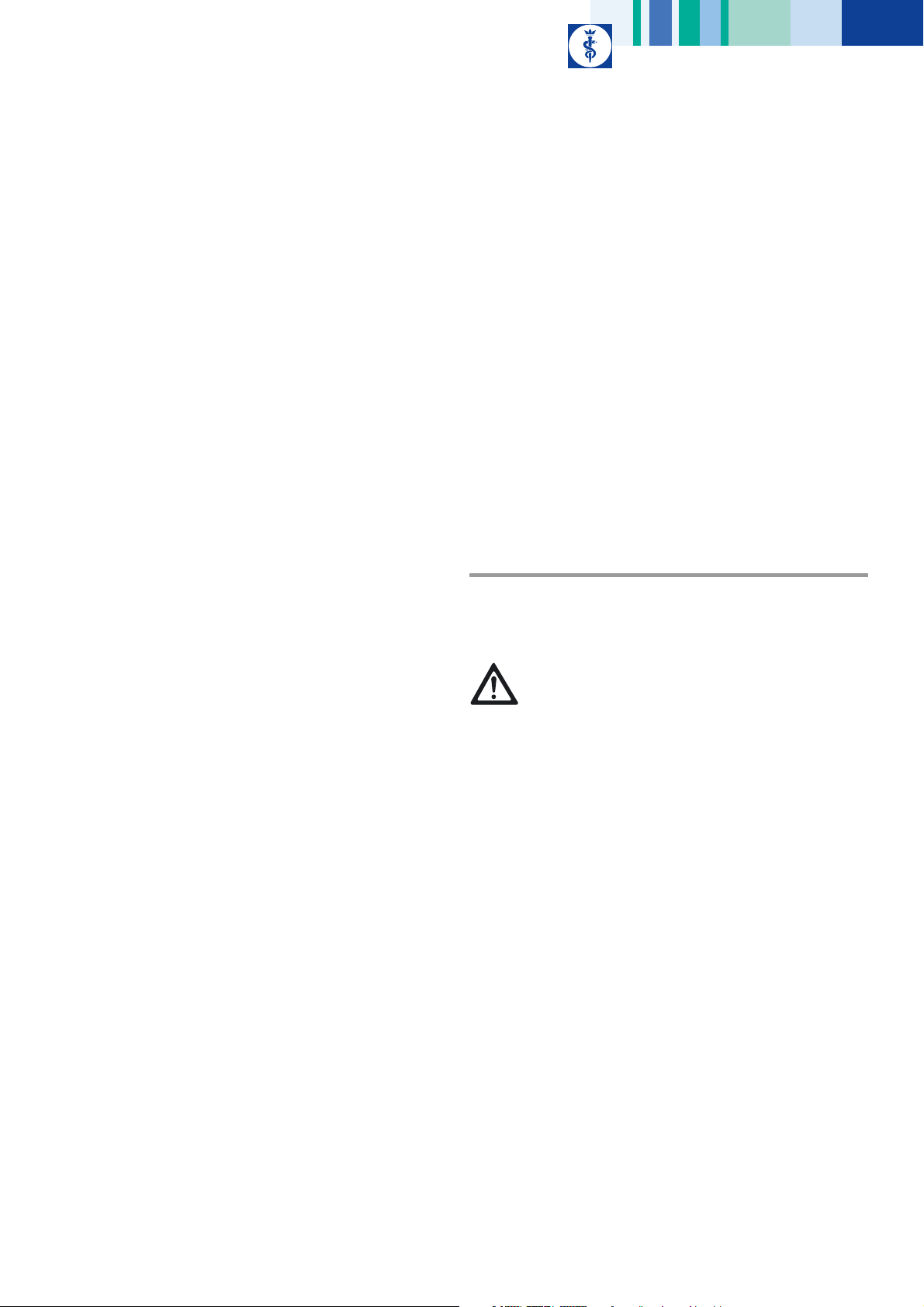

2.4.3 Control fields on the display

A B

2.4.4 Motor control fields

A

B

C

D

E

F

G

H

I

C

Fig. 1

Legend

A Motor control field(s)

B Pump control field

C Instruction menu

The display is divided into three different control fields, which are

described in the following chapters.

Fig. 2

Legend

A Status display and control key for releasing (symbol highlighted by

green background)/locking the pump

B Activation mode indicator: hand control or foot control

C Present motor speed range upper limit setting

D Qualitative display of the actual motor speed

E Control keys for increasing or reducing the motor speed range upper

limit

F Motor direction indicator

G Operating mode selected for the connected motor type, e.g. saw

program for motors GD678 and GD679

H Connected motor type

I Maximum selectable motor speed range upper limit for the connected

motor type or with the selected operating mode, respectively

Each motor connected to control unit 1 has a motor control field assigned

to it.

Two motor control fields are opened in display 2 only if two motors 32 are

actually connected to control unit 1.

Only one motor control field will be opened if only one motor is connected.

The control fields are visually identified as belonging to the respective

motor connection sockets 5.

5

Page 8

Aesculap Power Systems

A

C

microspeed® uni motor system

A motor control field is displayed as an active control field when the motor

assigned to the motor control field:

• is operated

• was the last motor operated.

The symbol of the connected motor type is highlighted by a green

background whenever a motor control field is released for operation.

2.4.5 Pump control field

Fig. 3

Legend

A Status indicator symbol of coolant pump 4. The symbol is highlighted

by a green background while the pump is active. The pump can only

be activated if it has been released for operation and if the motor is

active.

B Control keys for increasing or reducing the delivery rate

C Display of selected dosage

The preset dose level C applies to the motor whose settings are displayed

in the (white background) motor control field.

2.4.6 Instruction menu

Note

The Instruction menu can only be called up at the control unit.

This control key is pressed to call up the Instruction menu. In the

Instruction menu, information about the error conditions output to the

display and device settings such as the user language and the volume of

the acoustic alarm/notification signal can be changed.

Motor-type specific adjustments and settings can be carried out here, too:

• Slow-down and speed-up ramps for each motor type

• Oscillating or tapping mode (for pistol handpiece GD684)

• Oscillation frequency and speed-up ramp in oscillating mode (in

Shaving mode of operation of shaver handpiece GD682)

• Reset: to restore the factory settings

B

2.4.7 Motor recognition

Control unit 1 recognizes the motor type connected to one of the motor

connection sockets 5 of control unit 1 and displays the type in the

respective motor control field of display 2. The most recent settings for this

motor type at the same motor connection socket are shown on display 2.

B

The settings can be changed within the motor-specific setting ranges,

either on the display or through hand or foot control (in the Device

settings menu), see chapter Technical specifications.

The motor control field of the most recently activated motor is always

brightly highlighted, whereas the motor control field of the motor that is

not the one that was most recently activated or locked is displayed with

a gray background. When only one motor is connected to control unit 1,

the corresponding control field is highlighted, if this motor is not locked.

Saw program (only for low-speed motors GD678 and GD679)

In this program the maximum motor speed is limited to 16,000 1/min. The

settings most recently used with the saw program (motor speed range

upper limit, dose level for coolant pump 4) are recalled automatically.

2.4.8 Automatic saving of device settings

The most recent settings for this motor type at this motor connection

socket (speed range upper limit, delivery rate, etc.), are called up

automatically as soon as the same motor type is recognized again as

connected at the same motor connection socket of control unit 1 after a

motor change.

Note

After each device start-up both the coolant pump and motor type-specific

special functions such as the saw program (for GD678 and GD679) or the

oscillating or tapping mode (for GD684) are always inactive (even if they

had been released or activated before). All parameters are reset when the

operating key "Factory setting" in the Instruction menu is pressed.

6

Page 9

2.4.9 Overload cut-out

To protect the connected motors against thermal destruction, the system

features a separate motor temperature monitoring device. For this

purpose, a temperature module is integrated in the device.

•1st Level:

As soon as the temperature module indicates a motor temperature

above 75 °C and below 90 °C, an acoustic warning is sounded and the

message “Temp. Motor” flashes on the display. Any further overload

causes control unit 1 to switch to level 2.

• 2nd Level:

As soon as a motor temperature in excess of 90 °C is detected, the

motor is switched off and the message “Error 7 – Motor overheated” is

shown on display 2.

After a cooling-down period the motor can be activated again.

Alternatively, the temperature module is reset, and work can be continued

as soon as the overheated motor has been replaced. We recommend

keeping a replacement motor on standby.

2.4.10 Coolant pump

Note

The coolant pump only works when a motor is running!

At power-on of the control unit, coolant pump 4 is always deactivated

(even if it had been released for operation at an earlier time).

The microspeed® uni control unit 1 is fitted with a coolant pump 4. This

coolant pump serves exclusively for cooling or irrigating the tools. The

delivery rate at the highest dose level is approx. 80 ml per minute. The

coolant pump can be activated either in the respective motor control field

or through the appropriate hand or foot control device. The delivery rate

can be selected via the pump control field or through the Device settings

menu, see chapter Submenu Device-specific settings.

Exception: When using pistol handpiece GD684, the pump can be

activated, and the delivery rate can be changed, only via the appropriate

control fields on the control unit.

Any one of 21 dosage settings can be selected. At dosage settings 1 to 5,

coolant pump 4 operates in intermittent mode. The pump can be switched

on and off, and the delivery rate can be changed, even while the motor is

active. Once the motor was active for more than two seconds, a special

drive control prevents further coolant from dripping out.

2.4.11 Motor cable

Risk of injury due to uncontrolled movement of skin

abrading handpiece GB280 in conjunction with a motor

WARNING

Note

A motor cable is needed to connect motors (with motor-side plug

connection) GD674, GD676, GD677, GD678 and GD679 to the control unit.

The microspeed® uni motor system comprises one motor cable for foot

control (GD672) and one motor cable with hand control (GD673). Both

motor cables can be used in connection with all motors with a motor-side

plug connection. Either of the two motor cables can be connected at any

of the two motor connection sockets 5.

Notes

The choice of motor cable depends on the application and which handpiece

is to be used.

For using saws GB128R, GB129, GB130R and motor cable with hand

control GD673, we recommend guiding the saw with both hands for

optimal handling. If single-handed saw guidance is required, use motor

cable GD672 with a foot control device.

cable with hand control GD673!

¾ Use skin abrading handpiece GB280 only with motor

cable GD672 and foot control.

7

Page 10

Aesculap Power Systems

microspeed® uni motor system

microspeed® uni motor cable for foot control GD672

30

Fig. 4

Legend

30 Motor release switch

Note

This motor cable can only be used in connection with a foot control.

The motor coupled to this motor cable can only be activated if motor

release switch 30 is in the “ON” position. When two motor cables GD672

are used at the same time, a motor can be activated only if it has been

released (motor release switch 30 in position "ON") while the other motor

is deactivated (motor release switch 30 in position "OFF").

microspeed® uni motor cable with hand control GD673

2629 25

Fig. 5

Legend

25 Motor release switch:

Position "ON": Motor released for operation

Position "OFF": Motor locked against operation

26 Hand control function button:

Short actuation: Switching on/off the coolant pump

Pressing for more than three seconds (with the motor inactive):

Change to Device settings menu, siehe Kapitel Changing the settings

in the Device settings menu through hand control

29 Lever:

Actuator for motor speed setting

Note

This motor cable can not be used in connection with a foot control.

The motor coupled to this motor cable can only be activated if the motor

release switch is in its “ON” position.

8

Page 11

2.4.12 Motors

Motors with motor-side plug connection

Note

A motor cable GD672 or GD673 is required for connecting motors with

motor-side plug connection to the control unit!

Depending on the field of application, there are five different motor types

available, with the three Aesculap standard coupling systems Hi-Line,

micro-Line (Intra coupling system to DIN 13940/ISO 3964) and mini-Line.

Each motor can be operated in right or left (clockwise or

counterclockwise) rotation mode. When a motor is running in leftrotation mode, control unit 1 issues an acoustic signal.

For the performance data and parameters to be set for the individual

motor types, see chapter Technical specifications.

Motor types GD678 and GD679 offer the option to select a saw program.

In this program the maximum motor speed is limited to 16,000 1/min.

Motors with fixed motor cable GD682 and GD684

Note

The motors are directly connected to the control unit. An additional motor

cable is not required!

For the performance data and parameters to be set for the individual motor

types, see chapter Technical specifications.

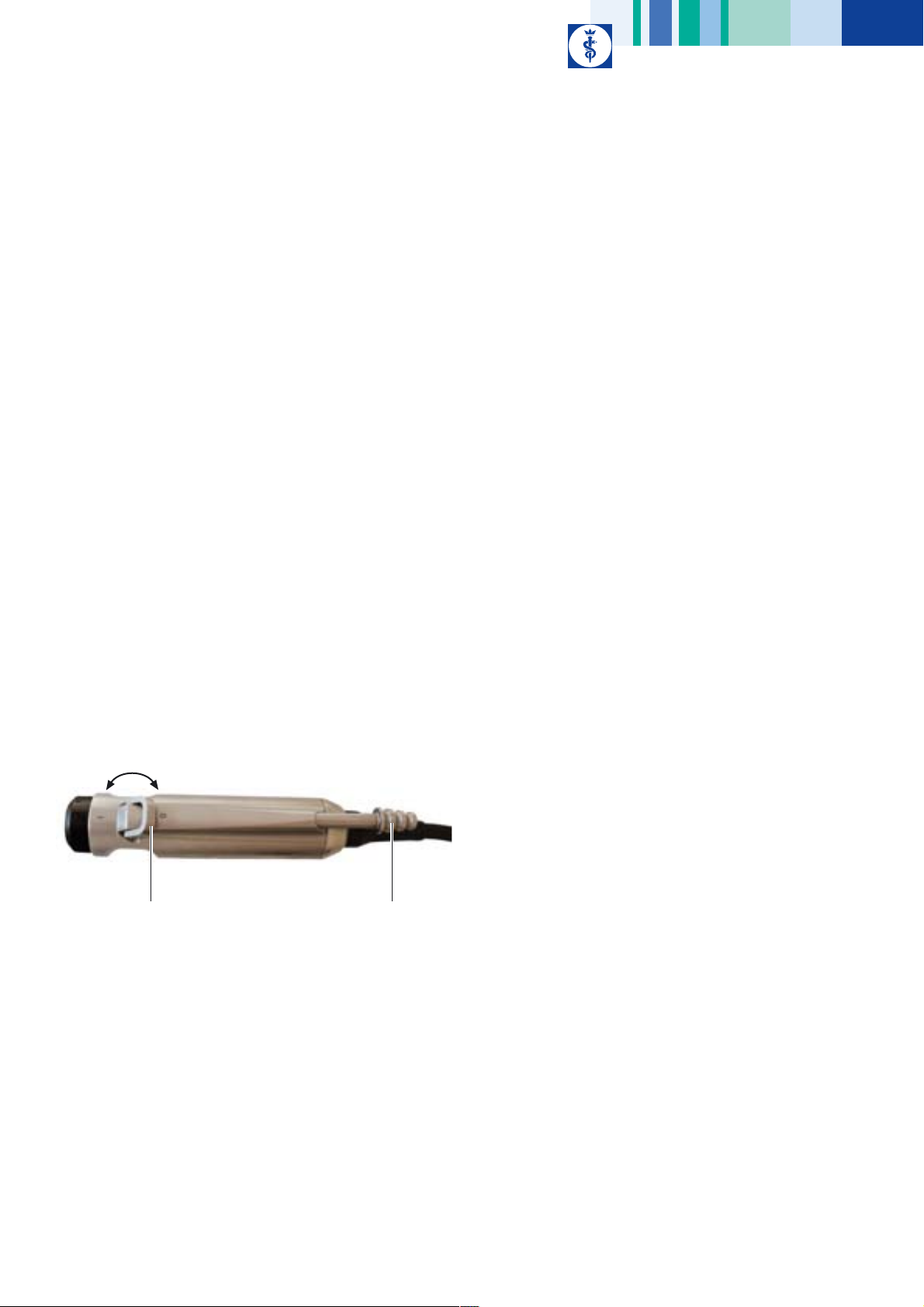

microspeed® uni shaver handpiece GD682

Notes

Always observe the instructions for use of blades TA011579.

Only use Aesculap blades.

Shaver handpiece GD682 can only be used with foot control GD671 and a

surgical suction device (e.g. GF200 or GF210).

Shaver handpiece GD682 can be used if:

• a motor with motor cable GD673 is connected at the second motor

connection socket, or

• a pistol handpiece GD684 is connected at the second motor connection

socket, or

• a motor with motor cable GD672 is connected at the second motor

connection socket and the motor release switch of that cable is in its

“OFF” position, or

• only one shaver handpiece GD682 is connected to control unit 1.

There are two types of blades available for shaver handpiece GD682:

reamer and shaver blades.

Control unit 1 recognizes whether the coupled blade is a reamer or a

shaver blade. The respective mode of operation (reaming or shaving) is

indicated on the display.

An acoustic signal is issued whenever a blade of a different type is

inserted. At the same time the respective symbol is displayed in the

appropriate control field.

With a reamer blade inserted, left-rotation and right-rotation modes are

avilable, but not the oscillating mode. The maximum speed is limited to

8,000 1/min. The symbol for the "Reaming" operating mode is displayed in

the control field.

With a shaver blade inserted, right-rotation and left-rotation operating

modes are available. The maximum speed is limited to 5,000 1/min. The

symbol for the "Shaving" operating mode is displayed in the control field.

36 38

Fig. 6

Legend

36 Suction control lever:

Lever for continuous regulation of the suction power

38 Tube olive:

Connection to the surgical suction device via a suction tube

9

Page 12

Aesculap Power Systems

microspeed® uni motor system

microspeed® uni mini pistol handpiece GD684

34

35

Fig. 7

Legend

34 Upper trigger

35 Lower trigger

Note

The pistol handpiece can be locked against inadvertent actuation by gently

pressing and turning the upper trigger by 90°.

The pistol handpiece cannot be used with foot control.

Pistol handpiece GD684 is fitted with the Aesculap mini-Line coupling

system.

A protective sleeve is supplied with the handpiece. This sleeve serves to

protect against injury and damage when inserting Kirschner wires.

There are two operating modes of pistol handpiece GD684:

• Standard operation

• Oscillating or tapping mode

If control unit 1 recognizes a pistol handpiece GD684 connected, the

pistol handpiece will operate in the Standard mode (factory setting). The

device parameter settings (speed range upper limit, delivery rate, pump

status) can be changed only via the touch control field of control unit 1.

Oscillating or tapping mode can be selected via the Instruction menu. The

symbol for “Oscillating or tapping mode” is displayed in the respective

motor control field. Oscillating or tapping mode is activated though the

upper trigger. An acoustic notification signal is sounded and “Oscillating

or tapping mode active” flashes in the respective motor control field. In

this mode of operation, the speed range upper limit cannot be changed via

the touch control field on control unit 1.

The oscillating or tapping mode can be deactivated again by pressing the

upper trigger. After each power-up of the control unit and connection of

the pistol handpiece, oscillating or tapping mode is always deactivated

and needs to be activated anew via the pistol handpice. The preselected

setting in the Instruction menu is saved and remains in memory even

through subsequent system restarts.

Standard operation:

Right and left rotation mode (when in left-rotation mode, control unit 1

issues an acoustic signal).

Motor direction switch/trigger for left rotation 34, see Fig. 7:

• Pressing lower trigger 35 while holding down upper trigger 34 makes

the pistol handpiece operate in left-rotation mode.

• The motor direction is changed by pressing trigger 34 with trigger 35

already actuated.

Motor speed control trigger 35:

• Actuator for motor speed setting (motor speed proportional to

actuator travel).

• If only trigger 35 is pressed, the pistol operates in right rotation mode.

Oscillating or tapping mode:

Activating or deactivating the operating mode, see Fig. 7:

• This mode of operation is activated (and deactivated) by pressing and

holding upper trigger 34 for three seconds.

Working in “Oscillating or tapping mode”:

• The pistol handpiece is operated in tapping mode by pressing lower

trigger 35 within the first half of the total trigger travel. The motor

speed is proportional to the actual trigger travel.

Tapping mode means: Clockwise rotation by a certain angle (forward step)

followed by counterclockwise rotation (backward step) by a smaller angle.

• The pistol handpiece is operated in oscillating mode by pressing lower

trigger 35 within the second half of the total trigger travel. The motor

speed is proportional to the actual trigger travel.

Oscillating mode means: Clockwise rotation by a certain angle followed by

counterclockwise rotation by the same angle.

The pistol handpiece is operated in left-rotation mode by pressing lower

trigger 35 at the same time as upper trigger 34.

10

Page 13

2.4.13 Foot control devices

Notes

The microspeed® uni motor system includes two different foot controls

(GD668 and GD671).

Only one foot control can be connected to control unit GD670 at any time.

microspeed® uni foot control, one pedal, GD668

microspeed® uni foot control, two pedals, GD671

18

18

22

23

Fig. 8

Legend

18 Foot control function button:

Short actuation: Switching on/off the coolant pump

Actuation for more than three seconds (with the motor inactive):

Changing to Device settings menu, see chapter Changing the settings

in the Device settings menu through the foot control

22 Motor direction switch:

Selection of right or left rotation

23 Pedal:

Actuator for motor speed setting

20

Fig. 9

19

Legend

18 Foot control function button:

Short actuation: Switching on/off the coolant pump

Actuation for more than three seconds (with the motor inactive):

Change to Device settings menu, see chapter Changing the settings in

the Device settings menu through the foot control.

19 Right pedal:

Actuator for motor speed setting in right rotation

20 Left pedal:

Actuator for motor speed setting in left rotation

11

Page 14

Aesculap Power Systems

microspeed® uni motor system

2.5 Symbols

2.5.1 Symbols on the control unit

Adhere to instructions for use

Type BF application component

Input from irrigation bottle (coolant pump)

Outlet to handpiece (coolant pump)

Pumping direction (coolant pump)

Equipotentialization connector

Fuse

2.5.2 Symbols on foot control, motor cable and motor

Foot control function button

(Foot control GD668, GD671, motor cable GD673)

Motor direction switch

Selection of left or right rotation

(Foot control GD668)

Pedal for left/right rotation

(according to the motor direction set through the motor

direction switch, foot control GD668)

Pedal for right rotation

(Foot control GD671)

Pedal for left rotation

(Foot control GD671)

Oscillating operation when both pedals are pressed

(only allowed in "Shaving" mode in conjunction with

shaver handpiece GD682 , foot control GD671)

Class AP anesthetic test

(EN 60601-1)

(Foot controls GD668 and GD671)

Enclosure protection type to DIN EN 60529

IPX8

(Foot controls GD668 and GD671)

Alternating current

Foot control

Marking of electric and electronic devices according to

directive 2002/96/EC (WEEE), see chapter Disposal.

Release

(Motors GD674, GD682 and GD684)

Motor speed control

(Motor GD684)

Right/left rotation switch

(Motor GD684)

Oscillating or tapping mode:

(Motor GD684)

Protection against inadvertent activation

(Motor GD684)

12

Page 15

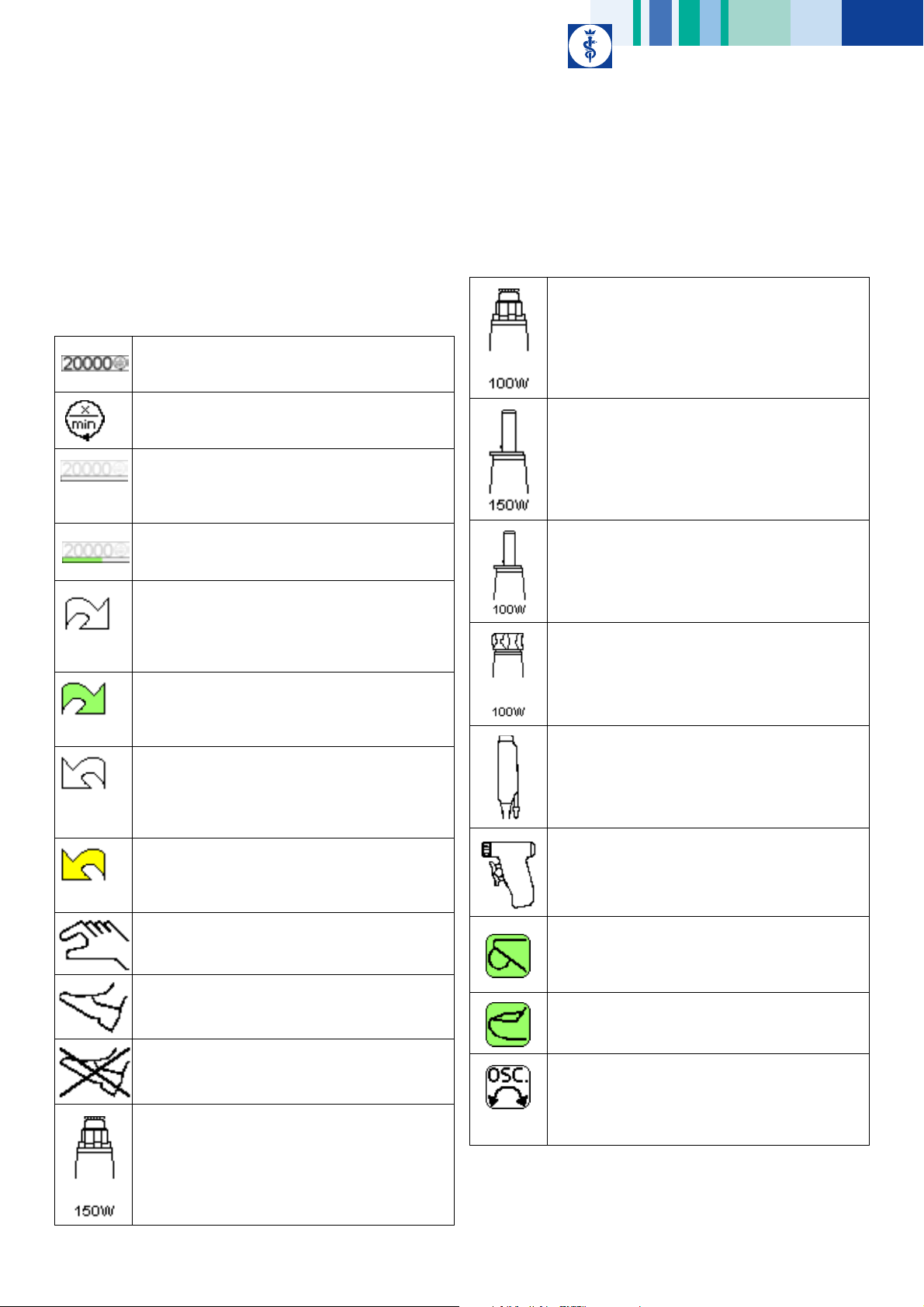

2.5.3 Symbols in display

Display symbols in the motor control fields

(Set) motor speed range upper limit

(example: 20,000 1/min)

GD677 microspeed® uni Hi 100 motor (high-speed motor;

100 W; coupling system: Hi-Line (XS) connected

If the motor can be activated (is released), the symbol is

highlighted by a green background

Motor speed in 1/min

Qualitative display of the actual motor speed (for shaver

handpiece GD682: actual tool speed)

Symbol displayed on gray background in motor control

field if the respective motor is not activated

Qualitative display of the actual motor speed (for shaver

handpiece GD682: actual tool speed);

active while motor is operated

Motor direction indicator for right rotation

when the motor is inactive or when right rotation was

not selected through foot control GD668;

in an inactive motor control field, this symbol is displayed

on a gray background

Motor direction indicator for right rotation

active when the motor is operated or in standby, provided

this motor direction was selected and foot control GD668

is connected to the control unit

Motor direction indicator for left rotation

when the motor is inactive or when left rotation was not

selected through foot control GD668;

in an inactive motor control field, this symbol is displayed

on a gray background

Motor direction indicator for left rotation

active when the motor is operated or in standby, provided

this motor direction was selected and foot control GD668

is connected to the control unit

Hand control

active if connected hand control is recognized

Foot control

active if connected foot control is recognized and at least

one motor is not operated through a hand control device

No response when foot control is pressed down

active if neither a foot control nor a hand control device

is recognized as connected

GD676 microspeed® uni Hi 150 motor (high-speed motor;

150 W; coupling system: Hi-Line (XS) connected

If the motor can be activated (is released), the symbol is

highlighted by a green background

GD678 microspeed® uni micro 150 motor (low-speed

motor; 150 W; coupling system: micro-Line)

If the motor can be activated (is released), the symbol is

highlighted by a green background

GD679 microspeed® uni micro 100 motor (low-speed

motor; 100 W; coupling system: micro-Line)

If the motor can be activated (is released), the symbol is

highlighted by a green background

GD674 microspeed® uni mini 100 motor (low-speed

motor; 100 W; coupling system: mini-Line) connected

If the motor can be activated (is released), the symbol is

highlighted by a green background

GD682 microspeed® uni shaver handpiece connected

If the motor can be activated (is released), the symbol is

highlighted by a green background

GD684 microspeed® uni mini pistol handpiece (coupling

system: mini-Line) connected

If the motor can be activated (is released), the symbol is

highlighted by a green background

Operating mode "Reaming"

(only in connection with shaver handpiece GD682, if no

shaver tip is recognized)

Operating mode "Shaving"

(only in connection with shaver handpiece GD682, if a

shaver tip is recognized)

Oscillating or tapping mode (only in connection with

pistol handpiece GD684)

Displayed when oscillating or tapping mode was released

in the instruction menu, but not activated through the

pistol handpiece

13

Page 16

Aesculap Power Systems

microspeed® uni motor system

Oscillating or tapping mode active:

(only in connection with pistol handpiece GD684)

Displayed when oscillating or tapping mode was released

in the Instruction menu and is activated through the

pistol handpiece (by holding down the upper trigger for

three seconds)

Display/Control key symbols in the motor control fields Display symbols in the pump control field

Increasing the motor speed range upper limit

Reducing the motor speed range upper limit

Status indicator/control key of the saw program

This symbol indicates that the saw program, which can

only be selected in connection with motors GD678 and

GD679, is inactive

Status indicator/control key of the saw program

This symbol indicates that the saw program, which can

only be selected in connection with motors GD678 and

GD679, is active

Motor direction indicator when left rotation was not

selected, and control key for selecting left rotation

The control key symbol is only displayed, and a motor

direction can only be selected if hand control GD673 is

connected

Motor direction indicator when left rotation was

selected, and control key for selecting left rotation

The control key symbol is only displayed, and a motor

direction can only be selected if hand control GD673 is

connected

Motor direction indicator when right rotation was not

selected, and control key for selecting right rotation

The control key symbol is only displayed, and a motor

direction can only be selected if hand control GD673 is

connected

Motor direction indicator when right rotation was

selected, and control key for selecting right rotation

The control key symbol is only displayed, and a motor

direction can only be selected if hand control GD673 is

connected

"Pump OFF" indicator and control key for activating the

pump

The symbol is displayed in the respective motor control

field

Control key symbols in the pump control field

Control key symbols within the display

"Pump ON" indicator and control key for activating the

pump

Active when, in connection with the selected motor, the

pump is switched on via the function button (hand or

foot control) or by actuating this field. The symbol is

displayed in the respective motor control field.

"Pump inactive" indicator

Symbol as displayed with the motor inactive, i.e. when

the pump has not been activated in the pump control

field

"Pump active" indicator

is active when the pump released in connection with the

selected and activated motor is activated

Display of selected dosage

is always active

Increasing the delivery rate

Reducing the delivery rate

Selecting the secondary control level

Instruction menu,

can only be activated when no motor is active

14

Page 17

3. Preparation and setup

Non-compliance with these rules will result in complete exclusion of any

responsibility and liability on the part of Aesculap.

¾ Observe the following regulations when setting up and operating the

product:

– the national regulations for installation and operation

– national regulations on fire and explosion protection.

– operating advisories acc. to IEC-/VDE regulations.

The following advice is given on the basis of the presently applicable

IEC-/VDE regulations:

Fire and explosion hazard!

¾ Do not use the control unit and motors in explosion

WARNING

The foot control circuit is ignition-safe and approved for operation in

medical environments acc. to IEC 601/VDE 0750.

3.1 Preparation

Note

The control unit can be mounted on an Aesculap mobile stand for

microspeed® uni (adjustable height) GA411 or on an Aesculap mobile stand

for surgical devices GD416M.

Other Aesculap devices must not be stacked on top of the control unit.

3.1.1 Mounting the control unit on the mobile stand

Note

Follow the instructions for use of the mobile stand.

hazard areas.

Legend

A Device support

15 Stacking cones

16 Locking screw

Only one device may be mounted on the mobile stand at any time, always

taking into consideration the stability of the mobile stand.

¾ Remove the caps from stacking cones 15.

¾ Remove the device feet, using a screwdriver.

¾ Move stacking cones 15 to the correct mounting positions by turning

locking screw 16 counterclockwise as far as it will go, using a

screwdriver.

¾ Position the device on the mobile stand in such a way that front edge

sits flush with device support A and stacking cones 15 sit in the

corresponding holes in device support A.

¾ Secure the device by turning locking screw 16 clockwise as far as it

will go.

¾ Gently lift the device to check if it is securely attached to device

support A.

The device is now mounted on the mobile stand.

3.1.2 Dismounting the control unit from the mobile stand

¾ Use a screwdriver to turn locking screw 16 counterclockwise as far as

it will go.

¾ Lift off the device.

¾ Reattach the device feet either by hand or with a screwdriver.

The device is now dismounted from the mobile stand.

3.1.3 Mains power connection

The voltage of the mains power must correspond to the voltage indicated

on the type plate of the device.

¾ Plug in the power cord at power cord socket 12.

¾ Plug in the mains plug at the building mains power socket.

Fig. 10

16 15 A

15

Page 18

Aesculap Power Systems

microspeed® uni motor system

4. Working with the microspeed® uni

motor system

Risk of infection and contamination!

¾ Prior to first operation, carry out sterile processing of

WARNING

WARNING

4.1 System set-up

4.1.1 Connecting the accessories

Note

Follow the instructions for use of individual accessories!

Note

micro-Line drill pistol (GB200) and arthroscopy handpiece (GB801) must

not be used with this product.

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically designed

for the intended application and do not compromise the performance and

safety characteristics of the products.

Depending on the motor type, all handpieces and tools of this range can

be coupled through the three Aesculap standard coupling systems Hi-Line

(or Hi-Line XS), micro-Line (handpieces for drilling, reaming, sawing and

shaping, with Intra coupling system acc. to DIN 13940/ISO 3964) and

mini-Line.

For other accessories, see chapter Accessories/Spare parts and brochure

no. O22711, Aesculap Power Systems.

the motors, motor cable, tubing, handpiece and tools.

¾ Make certain that the packaging of sterile products is

undamaged.

Risk of injury caused by inadvertent activation of the

motor!

¾ Secure motors that are not actively operated against

inadvertent activation through foot or hand control.

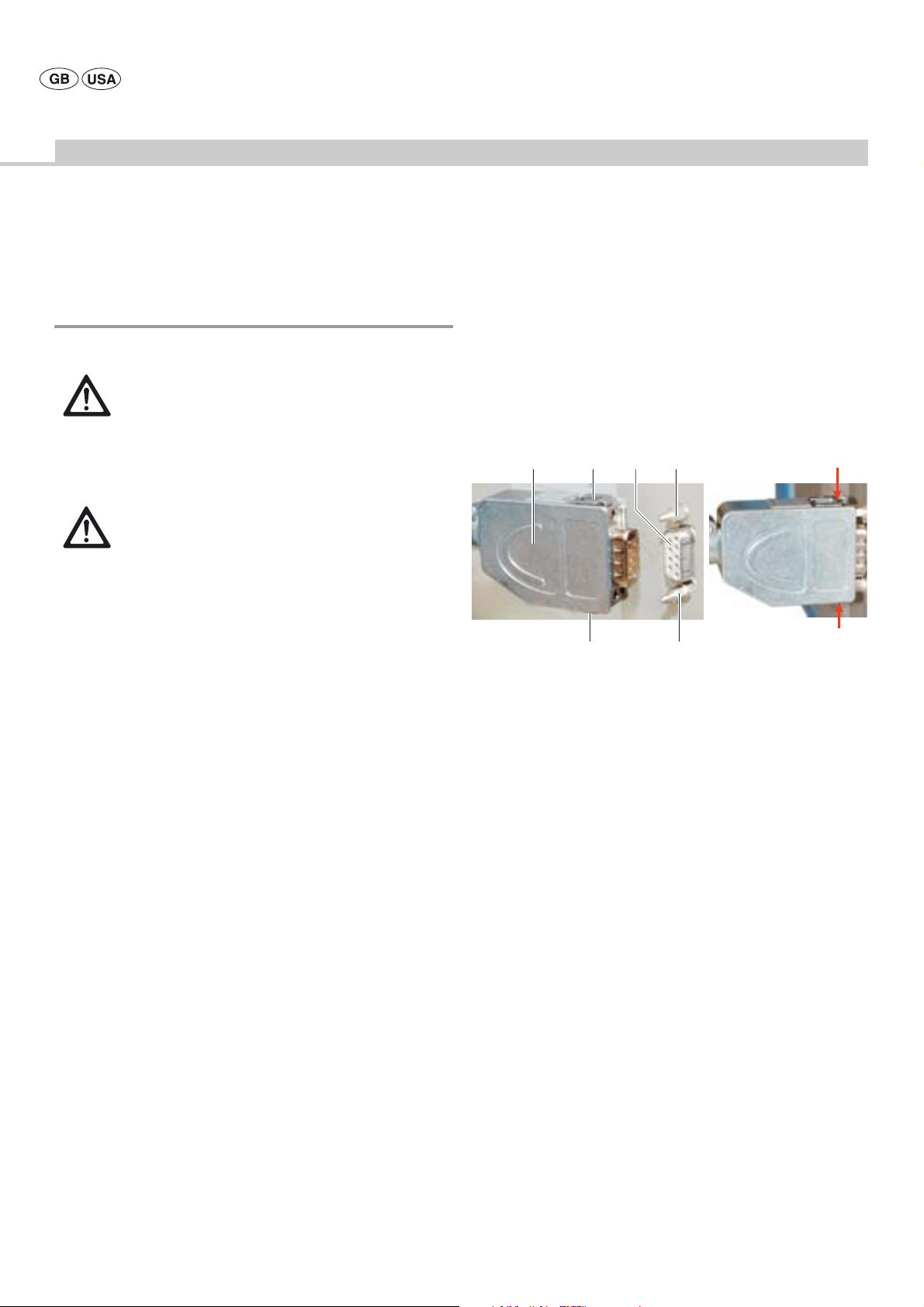

4.1.2 Connecting the foot control to the control unit

Note

Only necessary when using motor cable for foot control GD672 or shaver

handpiece GD682.

The foot control can not be used in combination with motor cable with

hand control GD673 and/or pistol handpiece GD684.

A

Fig. 11

C

C

B14

B

D

D

Legend

A Foot control connector

B Locking pins

C Locking clips

D Arrows

14 Connection socket for foot control

¾ To connect the foot control connector A to control unit 1:

Fully plug in the foot control connector A at the connection socket for

foot control 14 (in rear panel of the unit).

Locking clips C audibly engage in locking pins B, see Fig. 11.

¾ To disconnect the foot control device from control unit 1:

Simultaneously compress locking clips C (see arrows D) and unplug

connector A.

16

Page 19

4.1.3 Connecting the tubing set

Note

The tubing set is sterile! Sterile separation is carried out at the tubing.

¾ Insert bottle holder 9 for the sterile fluid bottle into bottle holder

mount 10.

¾ Insert the spike into the sterile fluid bottle.

¾ Mount the sterile fluid bottle at bottle holder 9.

3

B

4

4.1.4 Connecting the motor cable to the control unit

Note

The motor cable and the motor are sterile! Sterile separation is carried out

at the motor cable.

A

5

AA

DD

C B

Fig. 13

B

3

Fig. 12

Legend

A Arrows

B Arrows

3 Release buttons

4 Coolant pump

¾ To open coolant pump 4: Simultaneously press release buttons 3.

¾ Insert tubing: Insert the pump tube with the tube nipple into the recess

(arrows B).

¾ Close coolant pump 4: Push together the pump housing until it clicks

into position (arrows A). When doing this, ensure that the pump

enclosure is completely closed, both at the inlet (from the irrigation

bottle) and at he outlet (to the handpiece).

Legend

A Mark (motor connection socket)

B Plug

C Mark (plug)

D Arrows

5 Motor connection socket

Damage to, or destruction of, the motor cable caused by

pulling the cable!

CAUTION

¾ To connect plug B: Align plug B in such a way that mark C on the plug

¾ Fully insert plug B in the motor connection socket.

¾ To disconnect plug B: Hold plug B in the marked places (arrows D) and

¾ Always pull at the plug, never at the cable.

is aligned with mark A on motor connection socket 5.

unplug it from motor connection socket 5.

17

Page 20

Aesculap Power Systems

microspeed® uni motor system

4.1.5 Connecting a motor (GD674, GD676, GD677, GD678

and GD679) to the motor cable

32

B 28

Fig. 14

28

A

C

C

Legend

A Mark on motor cable

B Mark on motor

C Arrows

28 Release key (x2)

32 Motor

¾ To couple motor 32: Install motor 32 on the motor cable, making

certain that mark B on the motor is aligned with mark A on the motor

cable.

Motor 32 will audibly engage in its proper position.

¾ To uncouple motor 32: Compress both release keys 28 at the points

indicated by arrows C. (The motor will be pushed away slightly from

the motor cable.)

This completes the uncoupling of motor 32.

4.1.7 Connecting handpieces/attachments/blades

Risk of injury due to uncontrolled movement of skin

abrading handpiece GB280 in connection with motor cable

WARNING

WARNING

WARNING

CAUTION

Note

For using saws GB128R, GB129, GB130R and motor cable with hand

control GD673, we recommend guiding the saw with both hands for

optimal handling. If single-handed saw handling is required, use motor

cable GD672 with a foot control.

with hand control GD673!

¾ Use skin abrading handpiece GB280 only with motor

cable GD672 and foot control.

Risk of injury and material damage due to inappropriate use

of handpieces or attachments!

¾ Always follow the safety advice and information given in

the instructions for use of the handpieces and

attachments.

¾ Do not exceed the specified maximum motor speed.

Risk of injury caused by loose milling heads when operating

high-speed motors in left rotation mode!

¾ Do not use screw-coupled milling heads.

Damage to motor and handpiece!

¾ Couple/uncouple handpieces only with the motor

inactive.

4.1.6 Switching on the control unit/Automatic self-test

¾ Switch on control unit 1 at mains power ON switch 7.

Power ON indicator 8 will be illuminated.

Control unit 1 always performs a self-test when the unit is switched on.

During this test the microspeed® uni start picture is displayed.

If any malfunction is detected, an error message will be displayed, see

chapter Malfunctions with error numbers.

18

Page 21

Connecting micro-Line handpieces to low-speed motors GD678 and

GD679

Connecting Hi-Line handpieces to high-speed motors GD676 and

GD677

A 32

B

C

Fig. 15

Legend

A Handpiece

B Catch

C Centering lug

32 Motor

¾ To couple handpiece A:

Install handpiece A on centering lug C.

Handpiece A engages in its proper position.

¾ Pull at motor 32 to check that the handpiece is securely coupled.

¾ To uncouple handpiece A:

press catch B and remove handpiece A.

DB 32CA

Fig. 16

Legend

A Handpiece

B Threaded ring

C Recess

D Lugs

32 Motor

Symbol “Handpiece release”

Symbol “Handpiece locking”

Handpiece A can be coupled to motor 32 in different positions.

Coupling:

¾ To release handpiece A: Turn threaded ring B in the direction indicated

by the arrow in symbol “Handpiece release” as far as it will go.

¾ To couple handpiece A: Install handpiece A at the desired position on

motor 32, making certain that lugs D of motor 32 engage in recesses C

at handpiece A.

¾ Lock handpiece A: Turn threaded ring B in the direction indicated by

the arrow in symbol "Handpiece locking" as far as it will go (to prevent

loosening of the handpiece due to vibrations during operation).

Uncoupling:

¾ To uncouple the handpiece: Turn threaded ring B in the direction

indicated by the arrow in symbol “Handpiece release” as far as it will

go and detach handpiece A.

19

Page 22

Aesculap Power Systems

microspeed® uni motor system

Connecting Hi-Line XS handpieces to high-speed motors GD676 and

GD677

CB 32A

Fig. 17

Legend

A Handpiece

B Threaded ring

C Handpiece coupling

32 Motor

Symbol “Handpiece release”

Symbol “Handpiece locking”

Coupling:

¾ Turn threaded ring B of handpiece A in the direction indicated by the

arrow in symbol “Handpiece release” as far as it will go.

¾ Install handpiece A on handpiece coupling C of motor 32 in such a way

that the pin on the handpiece engages in one of the notches of the

handpiece coupling.

¾ Turn threaded ring B in the direction indicated by the arrow in symbol

“Handpiece locking” as far as it will go.

¾ Make certain that threaded ring B is tightened to its limit stop to

prevent it from coming loose due to vibrations during operation.

Uncoupling:

¾ Turn threaded ring B in the direction indicated by the arrow in symbol

“Handpiece release” as far as it will go.

¾ Detach handpiece A from motor 32.

Connecting mini-Line attachments to microspeed® uni mini 100

motor GD674 and microspeed® uni mini pistol handpiece GD684

A B C

Fig. 18

Legend

A mini-Line attachment

B Tension ring

C Motor drive

Coupling:

¾ Turn tension ring B on motor C in the “open” direction as indicated by

the arrow, as far as it will go.

¾ Push the coupling of mini-Line attachment A into tension ring B at

motor C as far as it will go.

¾ Turn tension ring B on motor C against the “open” direction as

indicated by the arrow, as far as it will go.

Uncoupling:

¾ Turn tension ring B on motor C in the “open” direction as indicated by

the arrow, as far as it will go.

¾ Retract mini-Line attachment out of tension ring B at motor C.

¾ If tension ring B on the coupling cannot be loosened by hand, use the

auxiliary wrench of motor C.

20

Page 23

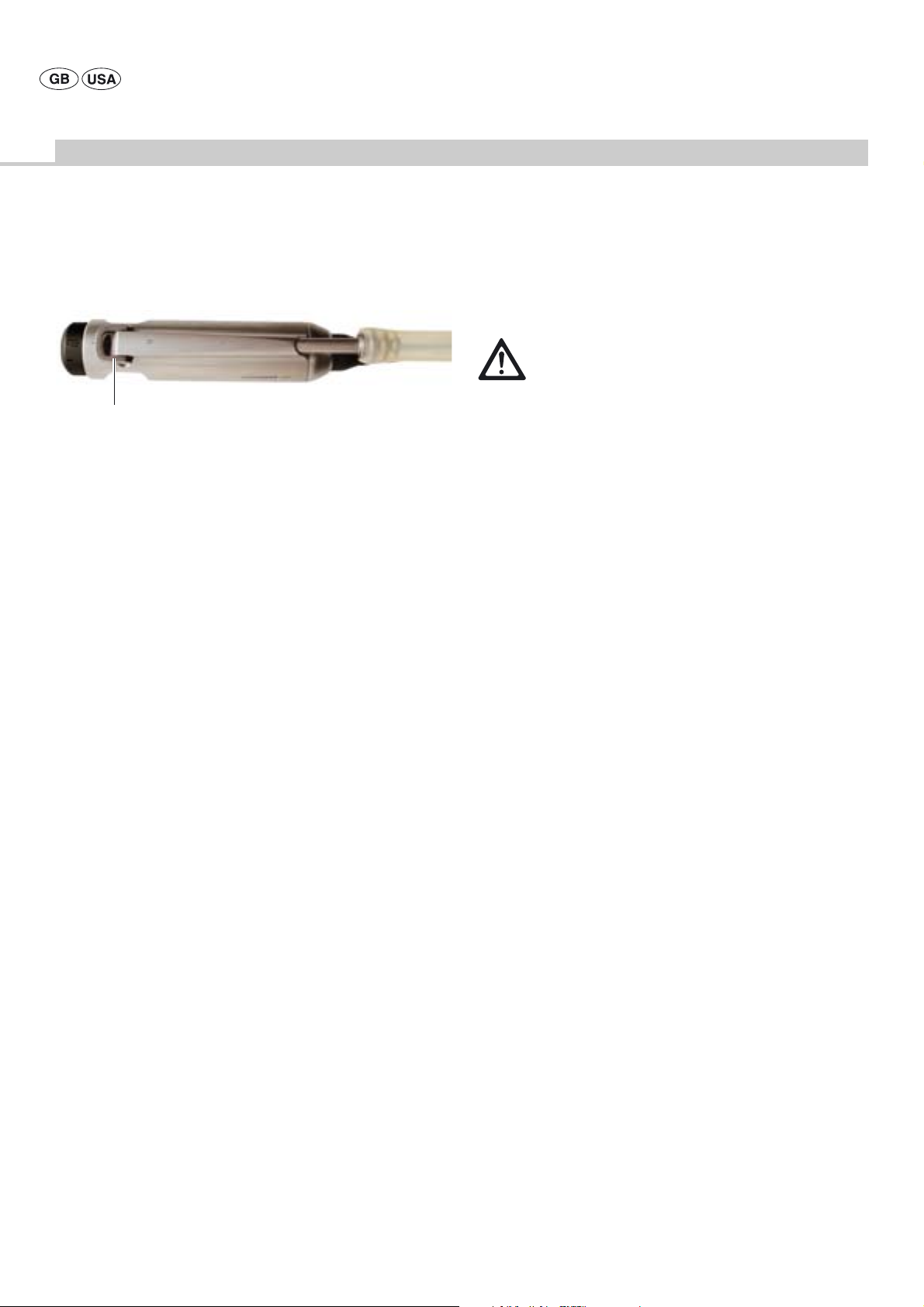

Connecting protective sleeve GD684225 to microspeed® uni mini

pistol handpiece GD684

Coupling the blades to shaver handpiece GD682

33

Fig. 19

A

Legend

A Protective sleeve GD684225

33 Pistol handpiece

Coupling:

¾ Slide protective sleeve A onto pistol handpiece 33 so that it clicks into

position.

Uncoupling:

¾ Retract protective sleeve A from pistol handpiece 33.

Risk of injury and material damage due to inappropriate use

of the blades!

WARNING

Note

Only use Aesculap blades.

Coupling a blade to the shaver handpiece

¾ Always follow the safety advice and information given in

the respective instructions for use.

E

D

C

B

A

37

F

Fig. 20

Legend

A Blade

B Cap

C Fixation nose

D Coupling

E Unlocking sleeve

F Groove

37 Shaver handpiece

Blade A can be mounted on shaver handpiece 37 in four different

positions.

¾ Hold blade A at cap B and push it into the blade adapter of the

handpiece as far as it will go, making certain that fixation nose C sits

in groove F of the motor.

The blade window is aligned with fixation nose C.

¾ Check the firm seating of blade A by pulling blade A.

21

Page 24

Aesculap Power Systems

microspeed® uni motor system

Uncoupling a blade from the shaver handpiece

A

E

B

Fig. 21

¾ Pull back unlocking sleeve E at the handpiece in the direction of the

arrow; remove blade A, holding it at cap B.

Connecting a suction tube to shaver handpiece GD682

A3736 38

4.2 Function checks

¾ Prior to each use, inspect the entire unit for functionality and proper

condition.

¾ Verify that all components to be used function properly and are

properly connected.

The connected motor type must be indicated in the appropriate motor

control field on the display.

¾ Set the motor release switch to its "ON" position, if necessary.

The motor to be used is released.

¾ Actuate the foot or hand control down to the limit stop.

The motor starts and reaches the maximum speed indicated in the

motor control field in display 2.

The motor audibly runs smoothly and at a constant speed.

The qualitative display of the actual motor speed in the motor control

field is fully illuminated.

¾ Enable coolant pump 4 in the respective motor control field or via the

function key of the foot or hand control device.

Coolant pump 4 is started by activating the motor.

Once the motor was active for more than two seconds, a special drive

control prevents further coolant from dripping out.

Fig. 22

Legend

A Suction tube

36 Suction control lever

37 Shaver handpiece

38 Tube olive

¾ To connect suction tube A to shaver handpiece 37: Push suction

tube A (GF572 or GF573) of the surgical suction device over tube

olive 38.

22

Page 25

4.3 Safe operation

Risk of injury caused by inadvertent activation of the

motor!

WARNING

WARNING

WARNING

¾ Secure any motors that are not actively operated

against inadvertent activation through foot or hand

control.

Risk of burns to patient and user, due to hot motor/hot

handpiece/hot tool!

¾ Put down the hot motor/hot handpiece/hot tool beyond

reach of the patient.

Risk of injury and material damage due to inappropriate use

of handpieces or motors!

¾ Always follow the safety advice and information given in

the instructions for use of the handpieces and motors.

¾ Do not exceed the specified maximum motor speed.

Changing the settings in the Device settings menu on the control unit

Fig. 23

Risk of injury caused by loose milling heads when operating

high-speed motors in left rotation mode!

WARNING

¾ Do not use screw-coupled milling heads.

4.3.1 Setting up and operating the motors GD674, GD676,

GD677, GD678 and GD679

Note

The instruction menu allows changing motor type-specific settings (run-

down and run-up ramp), see chapter Instruction menu.

A motor can be operated and settings can be changed only if:

•a motor 32 is connected at control unit 1

• the motor control field is not locked, meaning

– when using the motor cable for foot control GD672, the motor

release switch is in its "ON" position

– when using the motor cable for foot control GD672, a foot control

device is connected at control unit 1

• any motor connected to the other motor connection socket is inactive.

The following settings cannot be changed while motor 32 is running:

• Motor direction (of rotation)

• Motor speed range upper limit

• Operating mode

All settings for the respective motor type and motor connection socket are

saved on exit from the settings mode.

Selecting the motor speed range upper limit

The set motor speed upper limit is indicated in the respective motor

control field in display 2 and can be adjusted via the touch control keys.

Note

The setting range and the step width for the speed range upper limit depend

on which motor was selected, see chapter Technical specifications.

¾ To increase the motor speed range upper limit: press key to increase the

motor speed range upper limit.

¾ To reduce the motor speed range upper limit: press key to reduce the

motor speed range upper limit.

Selecting the saw program (only for motors GD678 and GD679)

This key can only be activated when no motor is active.

The saw program is activated and deactivated via the control key in the

respective motor control field.

The same control key also serves as a status indicator:

• The symbol displayed on a white background means that the saw

program is not active.

• The symbol displayed on a green background means that the saw

program is active, with a maximum setting of 16,000 1/min for the

motor speed range upper limit.

The settings most recently used with the saw program (motor speed range

upper limit, dose level for coolant pump 4) are recalled automatically.

23

Page 26

Aesculap Power Systems

microspeed® uni motor system

Setting the coolant pump delivery rate

Coolant pump 4 is activated and deactivated via the control key in the

respective motor control field.

The same control key also serves as a status indicator:

• The symbol displayed on a white background means that the pump is

switched off.

• The symbol displayed on a green background means that the pump is

switched on.

¾ To increase the delivery rate: press the key to increase the delivery rate

in the pump control field.

¾ To reduce the delivery rate: press the key to reduce the delivery rate in

the pump control field.

Changing the settings in the Device settings menu through the foot

control

¾ Press and hold down foot control function button 18 for three seconds.

Control unit 1 switches to the settings mode.

Motor 32 and coolant pump 4 are disabled.

Saw program selection (only for motors GD678 and GD679)

Notes

These motors support an additional saw program. The maximum motor

speed and the coolant delivery rate are changed in the same way as for

motor types GD674, GD676 and GD677.

In the saw program, the maximum motor speed is limited to 16,000 1/min.

The settings that were used most recently with or without the saw program

are recalled and displayed automatically.

The indicator/control key for the saw program flashes in the respective

motor control field.

The saw program is activated or deactivated by pressing the respective

pedal of foot control 21/24:

• Symbol on white background: program deactivated

• Symbol on green background: program activated

¾ To switch from parameter saw program to parameter motor speed

range upper limit: briefly press foot control function button18.

Changing the motor speed range upper limit

The motor speed range upper limit display for the motor is flashing in the

motor control field.

¾ To increase the motor speed range upper limit:

– press right pedal 19 when using foot control GD671.

– for foot control GD668, set motor direction switch 22 to right

rotation and press the pedal.

If the motor speed range upper limit is reached and the pedal is still

held down, the display switches to the minimum setting for the motor

speed range upper limit before rising according to the technical

specifications of the respective motor type.

¾ To reduce the motor speed range upper limit:

– press left pedal 20 when using foot control GD671.

– for foot control GD668, set motor direction switch 22 to left

rotation and press the pedal.

If the minimum possible setting for the motor speed range upper limit

is reached and the pedal is still held down, the display switches to the

maximum setting for the motor speed range upper limit before being

reduced according to the technical specifications of the respective

motor type.

¾ To switch from parameter motor speed range upper limit to parameter

coolant pump 4: briefly press foot control function button 18.

Setting the coolant pump delivery rate

The display for the selected dosage is flashing in the pump control field.

¾ To increase the delivery rate:

– press right pedal 19 when using foot control GD671.

– for foot control GD668, set motor direction switch 22 to right

rotation and press the pedal.

If the maximum dosage is reached while the pedal is still held down,

the display switches to the minimum dosage setting and then increases

according to the preselected dosage.

¾ To reduce the delivery rate:

– press left pedal 20 when using foot control GD671.

– for foot control GD668, set motor direction switch 22 to left

rotation and press the pedal.

If the minimum dosage is reached and the pedal still held down, the

display switches to the maximum dosage setting before falling back to

the preselected dosage.

Exiting the settings mode

¾ Press and hold down foot control function button 18 for three seconds.

The settings mode is quitted automatically if no button or pedal is

pressed within five seconds.

Changing the settings in the Device settings menu through hand

control

¾ Press and hold down hand control function button 26 for three

seconds.

Control unit 1 switches to the settings mode.

Motor 32 and coolant pump 4 are disabled.

24

Page 27

Selecting the saw program (only for motors GD678 and GD679)

Notes

These motors support an additional saw program. The maximum motor

speed and the coolant delivery rate are changed in the same way as for

motor types GD674, GD676 and GD677.

In the saw program, the maximum motor speed is limited to 16,000 1/min.

The settings that were used most recently with or without the saw program

are recalled and displayed automatically.

The indicator/control key for the saw program flashes in the respective

motor control field.

The saw program is activated and deactivated through lever 29:

• Symbol on white background: program deactivated

• Symbol on green background: program activated

¾ To switch from parameter saw program to parameter motor speed

range upper limit: briefly press hand control function button 26.

Activating a motor through foot control

To activate right rotation:

– press right pedal 19 when using foot control GD671.

– when using foot control GD668, set motor direction switch 22 to

right rotation and press pedal 23.

The motor direction indicator for right rotation is illuminated in the motor

control field and motor 32 runs clockwise.

To activate left rotation:

– press left pedal 20 when using foot control GD671.

– For foot control GD668, set motor direction switch 22 to left

rotation and press pedal 23.

The motor direction indicator for left rotation is illuminated in the motor

control field and motor 32 runs counterclockwise.

Control unit 1 issues an acoustic signal.

¾ To switch on/off coolant pump 4:

briefly press foot control function button 18.

Changing the motor speed range upper limit

The motor speed range upper limit display for the motor is flashing in the

motor control field.

¾ To increase/reduce the motor speed range upper limit: actuate lever 29.

If the motor sped upper limit is reached while lever 29 is still being

actuated, the display switches to the minimum setting for the motor

speed upper limit before rising according to the technical

specifications of the respective motor type.

¾ To switch from parameter motor speed range upper limit to parameter

coolant pump: briefly press hand control function button 26.

Setting the coolant pump delivery rate

The display for the selected dosage is flashing in the pump control field.

¾ To increase or decrease the delivery rate: Actuate the lever until the

required delivery rate is displayed.

As soon as the maximum delivery rate is reached, the lowest rate will

be displayed again.

¾ To switch from parameter coolant pump to parameter motor direction:

briefly press hand control function button 26.

Setting the motor direction

The most recently set motor direction flashes in the motor control field.

¾ Actuate lever 29 until the indicator for the required motor direction

lights up.

Activating a motor with a handpiece

The selected motor direction is displayed in the motor control field.

¾ Actuate lever 29.

Motor 32 runs in the direction indicated in the motor control field.

¾ To switch on/off coolant pump 4: briefly press hand control function

button 26.

Exiting the settings mode

¾ Press and hold down hand control function button 26 for three

seconds.

The settings mode is automatically exited if no key or control element

is actuated within five seconds.

25

Page 28

Aesculap Power Systems

microspeed® uni motor system

4.3.2 Setting up and operating the microspeed® uni shaver

handpiece GD682

Risk of injury caused by inadvertent activation of the

motor!

WARNING

WARNING

Note

Shaver handpiece GD682 can only be used with foot control GD671 and a

surgical suction device (e.g. GF200 or GF210).

The instruction menu allows changing motor type-specific settings (slow-

down and speed-up ramps and oscillation frequency, speed-up ramp for

Shaving mode), see chapter Instruction menu.

Parameter settings can only be changed if:

• a motor with motor cable GD673 is connected at the second motor

• a pistol handpiece GD684 is connected at the second motor connection

• a motor with motor cable GD672 is connected at the second motor

• only one shaver handpiece GD682 is connected at the control unit and

• a foot control device is connected to the control unit.

The following settings cannot be changed while shaver handpiece GD682

is running:

• Motor direction (of rotation)

• Motor speed range upper limit

• Operating mode

All settings will be saved on exit from the settings mode.

Operating modes

There are two types of blades for shaver handpiece GD682:

• Reamer blades

• Shaver blades

Control unit 1 recognizes whether the coupled blade is a reamer or a

shaver blade. The respective mode of operation (reaming or shaving) is

indicated on the display.

An acoustic signal is issued whenever a blade of a different type is

inserted, and the respective symbol is displayed in the appropriate motor

control field.

¾ Secure any motors that are not actively operated

against inadvertent activation through foot or hand

control.

Risk of injury and material damage due to inappropriate use

of the blades!

¾ Always follow the safety advice and information given in

instructions for use TA011579.

¾ Do not exceed the specified maximum motor speed.

connection socket without being active, or

socket without being active, or

connection socket and the motor release switch is in its “OFF” position,

or

With a reamer blade coupled, the motor can be operated in right or left

rotation, but not in oscillating mode. The maximum speed is limited to

8,000 1/min. The symbol for the "Reaming" operating mode is displayed in

the control field.

With a shaver blade coupled, the motor can be operated in right or left

rotation as well as in oscillating mode. The maximum speed is limited to

5,000 1/min. The symbol for the "Shaving" operating mode is displayed in

the control field.

Changing the settings in the Device settings menu on the control unit

Notes

For shaver handpiece GD682, the tool speed is indicated in the display.

The setting range and the step width for the speed range upper limit depend

on which operating mode (cutting or shaving) is selected, see chapter

Technical specifications.

Selecting the motor speed range upper limit

The set motor speed upper limit is indicated in the respective motor

control field in display 2 and can be adjusted via the touch control keys.

¾ To increase the motor speed range upper limit: press key to increase the

motor speed range upper limit.

¾ To reduce the motor speed range upper limit: press key to reduce the

motor speed range upper limit.

Setting the coolant pump delivery rate

Note

The coolant pump serves exclusively for cooling or irrigating the tools. The

delivery rate at the highest dose level is approx. 80 ml per minute.

Coolant pump 4 is activated and deactivated via the control key in the

respective motor control field.

The same control key also serves as a status indicator:

• The symbol displayed on a white background means that the pump is

switched off.

• The symbol displayed on a green background means that the pump is

switched on.

¾ To increase the delivery rate: press the key to increase the delivery rate

in the pump control field.

¾ To reduce the delivery rate: press the key to reduce the delivery rate in

the pump control field.

Changing the settings in the Device settings menu through foot

control GD671