Page 1

Operating-Instructions

INFUSOMAT?®

Il

Page 2

Contents

Operating

Description

instructions

INFUSOMAT

©

II

Short

operating

Operating

Faults

Maintenance,

Techničal

Ordering

Accessories

instructions

Cleaning,

data

data

and

instructions

and

spare

parts

Renair

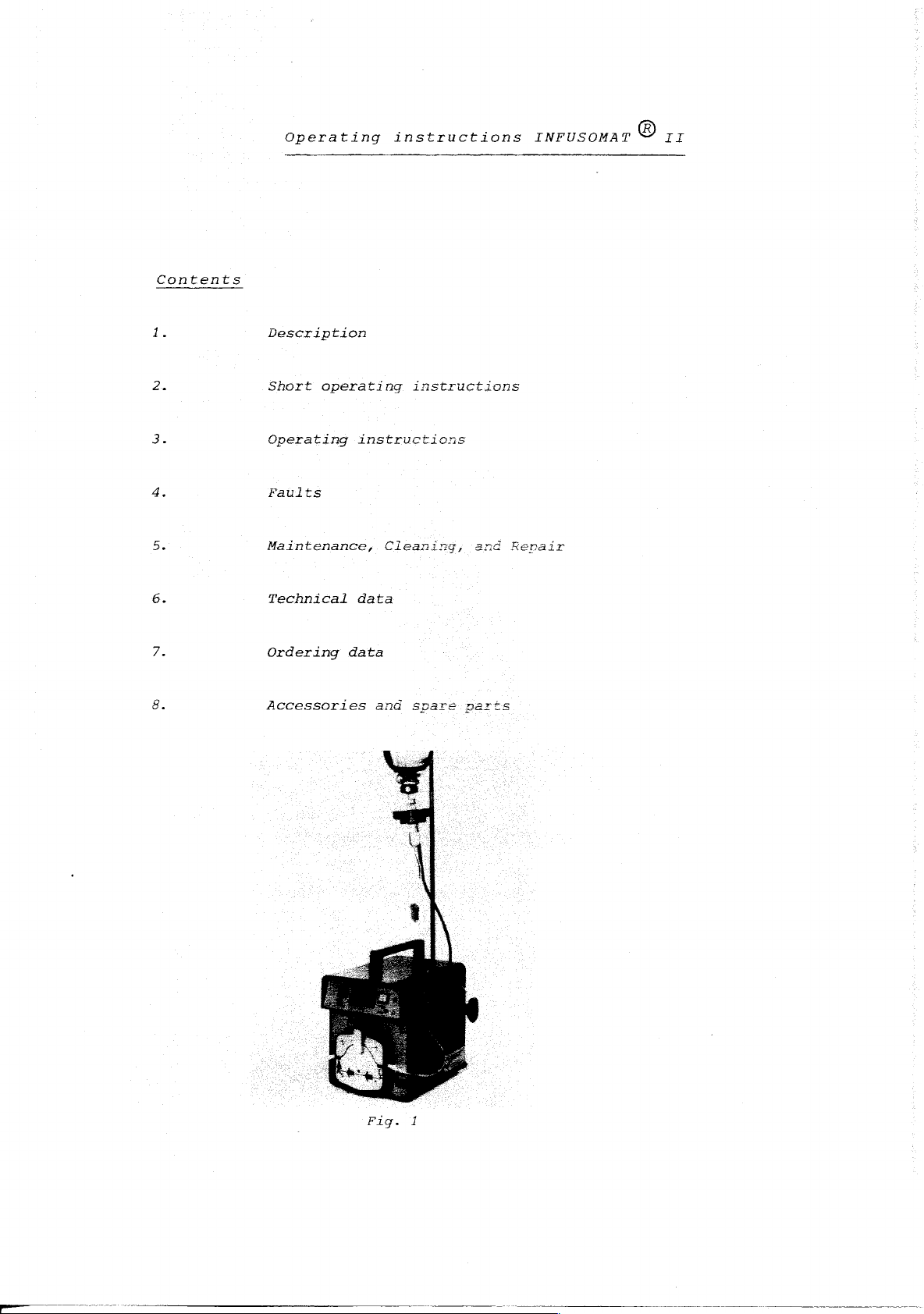

Fig.

1

Page 3

Description

Application

For

the

and

medicaments

-

for

intravenous

-

for

the

addition

-

for

infusing

-

for

the

1

ml/h

-

for

rapid

999

ml/h

-

for

keeping

periods

f

QI

bh

ty

he

ee

M

Reliability

ranges

precise

intravenous

to

slow

onwards

administration

uick

and

HQ

Ft

herapeutic

in

application

with

decisive

long

administration

an

infusion

precise

administration

the

infusion

accurate

development

service:

term

solution

amounts

of

|

rate

adaption

of

highly

advantages...

infusion

of

liquid

of

smali

large

constant

of

effective

of

liquid

liquid

the

medicaments

at

constant

volumina

volumina

over

prolonged

infusion

solutions

after

speed

up

time

»

from

to

to

The

INFUSOMAT

test

of

safety

1

carries

means

equipment.

and

and

it

safety

Reliability

- a liguid

the

blood

- a liquid

liquid

volume.

- a dynamic

showing

construction

reliability

the

TUV-Rhineland

conforms

The

INFUSOMAT

controls

is

maintained

control

vessels.

control

delivered

cyclic

a

possible

II

is a fault proof

and

design

in

medicinal

label

with

the

by

the

system

system

falis

self-control

which

which

short

fault

unit

by

the

TÜV

use.

and

the

law

and

regulations

я

II

is

urdergoing

TÜV-organisation.

by:

prevents

signals

of

or

exceeds

of

the

electronic

of

electronic

with

,

Therefore

VDE

label

regular

pumping

an

alarm

parts.

an

additional

concernin

for

of

if

the

preselected

this

which

technical

quality

air

the

circuit,

unit

into

Page 4

-

-

the

tubing

the

design

system

ability

of

to

the

closed

signal

pump

head,

when

a

malfunction

the

which

rotor

always

stops.

through

keeps

a

the

built-in

alarm

-

the

and

Short

Connect

of

drip

close

Press

Important!

only

Original

Melsungen

For

reasons

should

system

ability

to

bridge

operating

infusion

chamber

roller

monitor

AG

be

used

as

to

eliminate

short

instructions

tubing

up to

clamp,

part

INPUSOMAT

are

of

maintaining

with

well

to

and

in

be

every

as a staff

normal

interruptions

to

solution

2/3,

vent

connect

the

clip

Ď

rnfusion

used

(See

sterility

new

bottle.

call

frequency

tubing

system

provided

tubings

ordering

system.

in

the

bottle,

system,

to

at

а

new

fluctuations

power

fill

connect

patient.

side

of

the

data).

infusion

supplu.

lower

of

pump

B.

part

cannula,

housing.

Braun

set

M

ho

Ra

Lai

Na

iba

Fit

silicone

Important!

Attention

Fix

drop

Open

roller

tubing

should

detector

clamp

part into

be

paid

to

drop

completely.

to

the

chamber.

the

pump

pump

direction!

head.

Page 5

Select

infusion

rate.

Switch

lamp

M

Push

start

Infusion

€

To

Hints

This

have

Βάσος

creased

on

go

starter

lamp

stop

for

unit

been

transfusions

INFUSOMAT

on).

goes

begins.

NFUSOMAT

the

INFUSOMAT

with

utilisation

is

to

isolated

danger

button

on).

the

not

be

of

II

(red

ーー

CR)

““

IT

to

©

mains

to

be

used

used

in

according

are

not

haemolysis!

(green

pilot

staff

Ir

it

switch.

medicinal

recommended

pilot

lamp

call

is

sufficient

where

there

to

VDE-reguiation

lamp

goes

off,

system

is a risk

and dry

because

and red

yellow

.

if

existing.

to

switch

rooms

0107.

of

pilot

,

of

oniy

an

>

off

RE

which

in-

Operating

10

to

40

mm

instructions

dia.

ー

Compare

The

-

bud

à

Page 6

When

using

stand

as

Attention!

When

an

for

accessory.

using

the

INPUSOMAT

suspension

an

infusion

of

®

the

stand

ТТ

as a bench

solution

with

bottle

three

unit,

legs

is

the

a

small

available

zwrusomar

one

of

should

Electrical

The

inpusomar®

of

the

via a special

hints.

The

INFUSOMAT

source

further

Venting

a)

©

the

be

used.

cable

of

12 V (e.g.Accu

details

the

Connect

and

venting

fill

lower

11

should

legs.

connection:

тт

supplied.

cable

©

77

see

tube

drip

If

system:

ciosed.

part

be

possible

is

connected

supplied.

can

6.

chamber

of

fastened

only

Connection

be

used

by

means

technical

to

solution

By

squeezing

it

up.to

See

with

to

to

technical

data.

2/3

to

the

upright

stands

the

the

an

with

mains

staff

external

of a socket

bottle

flexible

(see

fig.

five

supply

data

with

above

iegs

by

call

system

for

low-voltage

at

the

roller

drip

chamber,

4/5).

means

is

installation

rear.

For

clamp

b)

c)

d)

Open

Open

Close

bubbles.

vent:

roller

roller

cone

clamp

(see

clamp

and

and

fig.

vent

4/4).

check

system

system

as

far

for

as

to

possible

the

cannula.

air

Page 7

Placing

a)

b)

the

Press

the

Place

that

and

pump

tube

monitor

pump

silicone

the

guide

head.

system:

housing.

tubing

rollers,

part

tubing

is

into

the

part

positioned

and

the

clip

in

guide

pump

in

provided

head

the

middle

grooves

at

the

correctly,

of

the

at

bothe

side

ensuring

pressure

sides

of

of

the

Attention!

Pay

heed

c)

Close

a

いっ

n

Pay

attached

in a vertical

Selection

Fry

ixing

The

To

open

flow

cone

pump

drip

heed

prevent

the

detector

drip

to

pump

roller

into

tubing

head.

drip

to

the

unneccessary

detector

position.

of

infusions

pump

head

clamp

the

drip

part

detector

is

marking

direction

completely.

chamber.

has

not

fixed

"oben"

fault

should

rate

to

and

at

If

been

positioned

the

white

and

signals,

be

connected

starting

front

No

infusion

this

"top"

of

pump

is

the

ring

of

respectively

the

drip

to

the

unit,

head!

solution

case,

correctly

the

chamber

the

solution

the

drip

must

in

(see

with

sili-

the

chamber.

fig.4/2).

the

bottle

o

Mens

The

desired

the

pre-selector

When

pressing

on

(green

volume

pilot

the

in

switch

lamp

is

the

selected

range

goes

"Netz"

on).

by

means

from 1 ...

("Mains"),

of

999

the

the

thumb

ml/h.

unit

wheels

is

of

switched

Page 8

At

on

the

and

same time

the

built-in

the

red

alarm

pilot

lamp

system starts

for

faults

to

function

goes

after

When

pressing

(The

yellow

fault

during

cable

Important!

Don't

reasons

switched

plug

for

INFUSOMAT

To

put

To

put

the

mains

approx.

pilot

signal

preparation

has

to

start

the

off

the

©

unit

unit

switch.

5

seconds.

the

is to

be

disconnected

unit

built-in

(switch

staff

IT.

out

of

out

of

button

lamp

be

procedure,

with

alarm

at

call

service.

service

"Start",

goes

on;

transmitted

the

pump

system

the

rear

system

it

the

for

head

is

is

the

fault

to

the

plug

a.

short

open.

(buzzer)

panel)

connected

sufficient

inrusomar D 11

signals

of

only

staff

the

period.

For

can

when

to

to

go

out).

call

call

safety

be

the

switch

system

system

the

starts.

If

no

off

If

the

The

of

the

mains

drip

the

unit

detector

pump

piug

is

(see

to

be

Should

can

fig.

out

of

be

disconnected:

be

clipped

3).

service

to

for

the

longer

support

periods,

on

the

handle

Page 9

- 8

2

Fig.

2/1

Pump

2/2

Closure

2/3

Mains

2/4

Preselector

2/5

Start-Stop-button

Fault

2/6

head

switch

signal

pilot

lamp

Clamping

Socket

staff

Switch

built-in

Socket

Socket

Support

for

call

for

for

for

for

device

connection.

system

shut-off

buzzer

low-voltage

mains

drop

of

supply

detector

to

input

Vent

opening

Drip

detector

Clamp

Drip

chamber

Liquid

level

Page 10

Faults

Principly

every fault

the

staff

accoustical

the

staff

Fault

Fault

Pilot

supply

glow

Red

giows

alarm

pilot

+

accoustical

finding

lamp

does

continuousiy

signal

the

through

cali

signal

call

power

not

lamp

rueusomar®

the

built-in

system,

system

table

if

can

only

is

Possible

Power

connected

Infusion

Drop

detector

connected,

connected.

supply

connected correctly

rr

sounds

connected

be

cause

bottle

or

buzzer

shut

cord

not

not

not

an

to

off

not

empty

operi

alarm

as

it.

if

signal

well

The

the

as

built-in

plug

Remedy

Connect

Connect

Connect

with

through

for

it

new

correctly

bottle

Red

piloť

biinks

lamp

Fiow

direction

tubing

Defective

Drop

Defect

system

detector

in

monitoring

the

unit

incorrect

infusion

soiled

the

self-

system

of

tubing

of

Locate

tubing

Place

tubing

correctly

Change

tubing

Clean

a)

Get

before

b)

If

during

infusion,

infusion,

repair

afterwards.

silicone

part

infusion

unit

use

carried

system

repaired

complete

and

have

out

Page 11

-

10

-

Maintenance,

Maintenance

Besides

no

The

occasional

maintenance.

usual

cleaning

infection

make.

sure

the

unit.

Important:

Before

connect

seconds

cleaning

the

for

cleaning,

and

commercial

the

unit.

spray

no

liquid

unit

evaporation

cleaning

cleaning

For

"ue

sepr

enters

or

disinfecting

from

warranty

cleaning

disinfecting

Dr.

the

the

mains

of

the

the

INFUSOMAT

agents

When

controls

it is

supply.

disinfecting

are

we

cleaning

imperative

Ď

11

suitable

recommend

or

or

the

Wait

at

agent

needs

for

our

dis-

disinfecting

interior

to

dis-

least

before

of

10

5.3.

Starting

Repair

According

must

either

rised

Warranty

For

every

the

of

dealer

unit.

the

INFUSOMAT

to

VDE-regulations

be

carried

only.

INFUSOMAT

©

IT

0750,

out

in

R

Ö

77

we

,

give

our

repair

works

a

warranty

or

of

by

the

for

an

unit

autho-

12

months,

Page 12

-

ll

-

valid

or

from

exchange

construction,

becomes

altered

invalid

any

seal has

-

rectifying

improper

We

reserve

prior

notice.

date

of

parts,

been

handling,

the

of

faulty

assembly,

if

broken.

faults

right

invoice.

parts

the

user

or

carried

Not

caused

or

normal

for

or

material.

included

by

changes

This

caused

or

out

wrong

warranty

by

other

repairs

in

wear.

in

covers

faults

The

warranty

persons

or

the

warranty

manipulations,

instruction

in

have

when

repairs

the

are:

without

Page 13

-

12

-

Technical

Power

Power

Low

Interference

Switch-on

supply

consumption

voltage

Permissible

Permissible

temperature

Tolerance

Automatic

if

rpm

deviates

Fastening

Finish

Dimensions

Weight

Data

connection

protection

time

humidity

ambient

in

rpm

alarm

triggered

possibilities

WxHxD

220

У

(+10%,

.

O.1

A

(100

12 V =

safe

supply

N

100

30

+10

È

2

È

On

from

dark

160 x 260 x 280

approx.

(minimum

galvanic

reguired.

(according

%

...

75

...

ae

5

SS

infusion

10

to

green

5.3

%

40°

mA)

stand

40

RAL

kg

-15%)

to

C

mm

50/60

11.5;maximum

separation

Consumption

VDE

0875)

or

dia.

6010

mm

bed

Hz

from

frame:

15V)

mains

1

A

Staff

Ordering

Cat.

870

602/6

cail

No.

Data

system

rnrusonar

Infusion

volume

999

ml/h,

50/60

O

pump

selectable

for

Hz

:

max.

rr

for

connection

24 V / 1 A / 24

continuous

between

1.

to

infusion,

ml/h

220

W

and

7,

Page 14

Accessories

NO.:

Cat.

and

Spare

parts

870

870

870

870

190/3

195/4

260/8

265/9

rwrusomar®

flexible

liquid

58

362,

drop

filter

sterile

disposable,

patient

Standard

INFUSOMAT

flexible

liquid

58

disposable,

patient

Standard

inrusomar®

flexible

filter

pyrogen-free

from

Rekord-Lok-cone.

Standard

INFUSOMAT

flexible

filter

1.50

pack

© - tubing

drop

filter

362,

sterile

1.50

pack

drop

after

INFUSOMAT ® to

pack

© - tubing

drop

after

pyrogen-free

from

INFUSOMAT ® to

Luer-Lok-cone.

Standard

pack

-

tubing

chamber,

according

and

length

m,

Rekord-Lok-cone.

100

pcs.

chamber,

according

and

length

m,

Luer-Lok-cone.

100

pcs.

-

tubing

chamber,

DIN

58

packed,

100

pcs.

chamber,

DIN

58

packed,

100

pes.

N,

complete,

roller

to

pyrogen-free

from

INFUSOMAT

N,

complete,

roller

to

pyrogen-free

from

INFUSOMAT

U,

complete

roller

362;

sterile

disposable;

patient

U,

complete

roller

362;

sterile

disposable;

patient

clamp

DIN

clamp

DIN

clamp

2.00

clamp

2.00

with

and

regulations

packed,

À

to

with

and

reguiations

packed,

R

to

with

and

and

length

m;

with

with

and

and

length

m;

with

171/7

870

750/4

872

760/0

872

3317301/0

870

170/9

Small

for

BRAUNOSTAT

5

for

stand

fastening

feet,

connection

BRAUNOSTAT

5

feet,

board.

Lamp

for

Cable

for

for

solution

to

the

"S",

safety

with

socket

of 3 infusion

"N",

safety

for 1 infusion

power

staff

supply

call

bottle,

INFUSOMAT É II

infusion

board

infusion

pump,

and

system,

with

operation

stand

3

pumps.

stand

without

complete

sockets

socket

(750

with

with

with

510/8)

plug

Loading...

Loading...