Page 1

Horizon

Nxt®

Service

Manual

HORIZON

Modular

Service

Infusion

B.

Braun

June

950500

Nxt®

System

Manual

2000

Rev

E

‘950500

Rev E (06/00)

Page 2

Page 3

Horizon

Nxt®

Service

Manual

АН

rights

transmitted

including

photocopying

retrieval

reserved.

in

any

system,

except

Copyright

Printed

Copyright

No

part

form

or

by

and

recording,

as

may

Act

or

in

the

United

1997

of

this

any

means,

be

expressly

in

writing

States

by

book

or

B.

by

by

of

Braun

may

be

reproduced

electronic

any

or

information

permitted

B.

Braun

America.

or

mechanical,

storage

by

the

and

1976

ii

950500

Rev E (06/00)

Page 4

Page 5

Horizon

Nxt®

Service

Manual

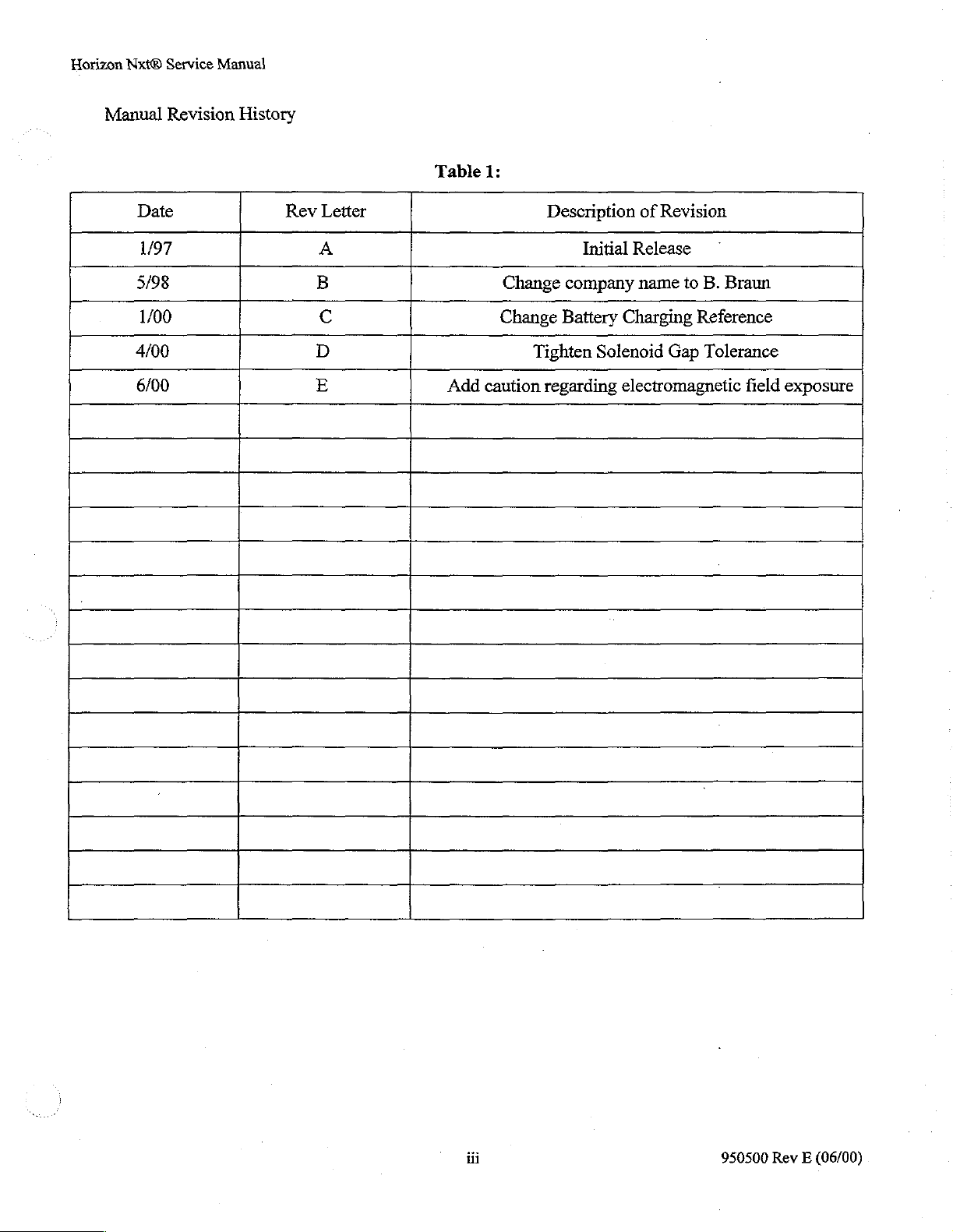

Manual

Date

1/97

5/98

1/00

4/00

6/00

Revision

History

Rev

Letter

A

B

C

D

E

Table

Add

1:

Description

Change

Change

Tighten

caution

regarding

Initial

company

Battery

Solenoid

of

Revision

Release

name

to

B.

Braun

Charging

electromagnetic

Reference

Gap

Tolerance

field

exposure

iii

950500

Rev E (06/00)

Page 6

Page 7

Horizon

Nxt®

Service

‘CONTENTS

Manual

CHAPTER

CHAPTER

CHAPTER

1.0

2.0

3.0

INTRODUCTION

¡NINAS

1.2

WARRANTY

1.3

INTENDED

AAA

....

USE...

DESCRIPTION

2.1

VISUAL

2.2

SPECIFICATIONS

RECOMMENDED

3.1

RECEIVING

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.2

CHECK-INPROCEDURE.......................

INDICATORS

ii

RECEIVING

NOTICES

Damaged

Goods

Late

Expedited

Receiving

Goods

Received

Shipments.........

Shipments

Inspection

AND

CONTROLS

PROCEDURE

ooo

eee.

in

Error................

in

eee

ner

eee

eee

iii

one

eee

nee

me

1-1

„12

sknrns

1-2

2-1

2-5

3-1

3-1

3-1

CHAPTER

4.0

3.3

MECHANICAL

3.3.1

3.3.2

3.3.3

3.3.4

3.4

MAIN

3.5

DEFAULT

3.6

SIMULATED

3.6.1

3.7

VOLUME

3.7.1

3.8

ELECTRICAL

3.8.1

THEORY

4.1

GENERAL

INSPECTION

Door

Alignment

Inspection...

PoleClamplnspection............................

Switch

Gasket

BATTERY

Test

Test

Test

Inspection

and

SOFTWARE

USE

Procedure:

DELIVERY

Procedure:

SAFETY

Procedure:

OF

OPERATION,

DESIGN

Hardware

CHECK

SETTINGS

AND

Simulated

ACCURACY

Volumetric….….......................

CHECK

Electrical

FEATURES

sens

Inspection...........

AND

CHARGING

irene

PERFORMANCE

Use

CHECK.....................

iii

GENERAL

een

sr.

iii

.........................

eee

DESCRIPTION

3-3

3-3

3-3

3-3

„3-3

3-3

3-3

3-4

3-4

4.1.1

Patient

:

Safety...

iv

ドー

トー

トー

に

950500

Rev E (06/00)

Page 8

Horizon

Nxt®

Service

Manual

CHAPTER

5.0

4.1.2

4.1.3

4.2

FUNCTIONAL

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

THEORY

Si

POWERSUPPLYBOARDASSY.........................................

5.1.1

3.1.2 5 VoltSuppliy.................

5.2

LEDDISPLAYBOARDASSY.............................

5.2.1

(5.2.2

5.2.3

Ease

of

Operation

Upgradabjlity

.es

DESCRIPTION

Case

Power

Main

Half

Door/Bezel

Main

OF

16

Volt

Door

LED

Key

Panel

Bottom

Supply

Battery

Board...

OPERATION,

Processor

Displays

............

uen,

Supply

Interface

and

Repair

rennes

Mechanism.

DETAILED

Assy.

A

DESCRIPTIONS

ーー

emen

ue

aa

a

amma

..

.

5-1

.

5-2

・

5-3

5.2.4

5.2.5

5.2.6

5.3

PRESSURE

5.3.1

5.3.2

5.4

MECHANISM

5.5

MANBOARDASSY......................

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

A

5.5.8

5.5.9

LCD

LCD

LCD

Contrast

Backight

Module

Voltage....

Sopply

Assÿ..…..

TRANSDUCER

Pressure

Offset,

Transducer

Gain,

and

INTERFACE

Management

Door

Interface

LCD

Interface

IR

Link...

Pump

Processor

Interprocessor

Processor...

Bus

emmek

usines

Communications

CA

Transfer

Temperature

Valve

Controller

Solenoid

ner

...

Circuits...

Output

Circuits...

BOARD

...

Driver

eee

ASSY

Bus...

000”

eee

ns

.

ii

ecran

ii

.

.

λος

う

.5.10

πω

5.5.12

External

Power

Sensor

μμ

Control

Interface

μῥὕϱϱϱϱϱ.

Circuits

v

rire

nie

950500

Rev

(06/00)

E

Page 9

Horizon

Nxt®

Service

Manual

CHAPTER

6.0

5.6

5.7

、

CLEANING

6.1

5.5.13

5.5.14

5.5.15

5.5.16

5.5.17

5.3.18

5.5.19

AIR-IN-LINE

SYSTEM

5.7.1

5.7.2

5.7.3

5.7.4

5.7.5

Voltage

Pressure

Variable

Variable

Time

Audible

References...

Signal

Level

Gain

Of

Day...

Alarms

Overvoltage

BOARD

OPERATION

Power-up........

Hold

State

Run

State

Operation

Keep

Vein

Alarm

State

AND

RECOMMENDATIONS

ieri

Circuits...

Shifter

su

Amplifier...................

rennes

зеленеет

Detection

ASSY.

Circuit...

..........

rien

Operatton

iii

se

Open

State

Operation

....

Operation

DISINFECTING

iii

”

.Ne

ieri

eira

5-16

5-16

5-16

5-16

5-16

emeernne

5-17

5-17

5-18

5-18

e

5-18

5-19

5-20

522

5-22

6-1

CHAPTER

7.0

PREVENTATIVE

7.1

PREVENTATIVE

7.2

EQUIPMENT

7.2.1

Hand

7.2.2

Test

7.23

7.2.4

73

PROCEDURES

7.3.1

7.3.2

7.3.3

7.3.4

7.3.5

7.4

PROCEDURES

Consumables...

Spare

Mechanical

Main

Simulated

Volume

Electrical

MAINTENANCE

MAINTENANCE

REQUIRED

Too!s

iii

Equipment

sise

Parts...

NOT

(6

MONTH)

Inspection...

Battery

Use

Delivery

Safety

REQUIRING

(12

MONTH)

inner

and

Materials..............

REOUIRING

Capacity

and

Performance

Accuracy

Check

AND

PROCEDURES

CASE

DISASSEMBLY

(optional)...

Check

.............

ss

CASE

DISASSEMBLY

REPAIR

ire

seo

on

ena e vena

rei

...................

7-1

7-2

7-2

7-2

7-3

eee

vete

nav

73

0

7-3

rici

7-3

7-4

ui

7-5

7-5

75

REPAR...........................

7.5.1

7.6

DISASSEMBLY

7.6.1

Biomed

Case

Halves

Menu

AND

insu

Oti

c.oocococacicnncannnnnioncannncconacnononacoraracnon

REASSEMBLY

vi

enano

7-8

INSTRUCTIONS...........

©

950500

7-10

7-10

Rev E (06/00)

Page 10

Horizon

Nxt®

Service

Manual

CHAPTER

8.0

7.6.2

7.6.3

7.6.4

7.6.5

7.6.6

7.6.7

7.6.8

769

76.10

7.6.11

7.6.12

7.6.13

7.1

CALIBRATION,

7.7.1

7.7.2

PARTS

Pole

Clamp

Management

Main

Board

Мана

ВаЧету...............

PoWer

Cooling

Petal

Cover

HalfDoor/BezelAâssembiy.............................................

sn

and

ere

ereta

SupPPHy

Fan

.ee

and

ins

Pump

Main

Processor

Speaker..

EPROMS

and

Fuses........

아 아

„72

7-14

아아

CosmeticBezel.............................................................

LED

Display/LCD

LCD

PCB...

Door

Lever...

ADJUSTMENTS,

Elecironic............................

Mechanical

LISTS,

SCHEMATICS,

Controller

eee

AND

AND

PCBS

SPECIFIC

DRAWINGS

ee

TESTS

7-23

ei

7-24

ーー

7-25

......7-26

CHAPTER

CHAPTER

APPENDIX

APPENDIX

APPENDIX

9.0

10.0

A:

B:

C:

NINA

8.2

ELECTRICAL

SERVICE

9.1

CONTACT

AND

MONITOR

10.1

DESCRTPTTON

10.2

INSTALLATION

10.2.1

10.22

10.2.3

10.3

STORAGE

10.4

TROUBLESHOOTING..................

System

DockingSetUp........................

Disconnecting

Abbreviations

Troubleshooting

Operation

Log.................

COMPONENTS

PERFORMANCE

INFORMATION..

DOCKING

eee

eee

Requirements.

Monitor

AND

MAINTENANCE

and

Symbols.…..................................

Guide

AND

ee

Docking

SCHEMATICS

een

.ee

rss

8-1

..................

mmeeesimsemenen

8-1

9-1

..

10-2

10-2

ee

ooo

eee

anne

10-3

A-1

vii

950500

Rev E (06/00)

Page 11

Horizon

1.0

Nxt®

INTRODUCTION

11

DISCLAIMER

Due

uct

be

sional

current

edgeable

ical

not

specifically

Service

to

Manual

the

criticality

performed

who

has

Service

in

the

devices,

testing,

of

product

only

by

attended

the

Manual.

areas

of

microprocessor

static

been

identified

performance,

an

authorized

B.

Braun

Repairs

should

control

in

B.

service

controlled

and

soldering

this

Service

Braun

not

be

B.

Braun

recommends

Service

training

course.

attempted

electronics,

techniques.

Manual.

Center

Repairs

by

other

digital

Repairs

that

all

required

or a qualified

should

than

qualified

and

should

biomedical

not

analog

not

be

service

repair

be

attempted

personnel

circuitry,

that

electromechan-

attempted

on

this

profes-

without

are

knowl-

which

prod-

a

have

WARNING:

CAUTION:

CAUTION:

CAUTION:

Ifthe

product

replaced

Section

3.7

the

an

exception

warranties

Rework

passed

ten

so

will

individual

ties

sentative.

complete

Do

manently

ment

or

repaired,

3.6

of

and

3.8

Horizon

and

of

multi-layer

an

accredited

consent

has

void

component

unless

express

B.

circuit

not

use

the

damage

in

question.

is

partially

the

this

manual

prior

to

use

Nxt

for

pump

set

must

sterility

liabilities.

boards should

course

been

obtained

all

warranties.

replacement

written

Braun

recommends

function

pump

the

in

pump.

or

completely

unit

must

and

the

for

patient

be

performed

only.

in

soldering

from

consent

to

factory

the

presence

For

disassembled,

undergo

appropriate

care.

and

pass

calibrations

All

final

with a set

Failure

has

board

to

not

be

techniques

an

authorized

is

not

recommended

been

replacement

do

so

attempted

obtained

specifications.

of

strong

further

information

electromagnetic

or a component

all

performance

and

performance

that

is

acceptable

may

cause

bodily

unless

for

this

B.

Braun

from

as

consult

personnel

type

Representative.

and

will

an

authorized

it

may

the

or

assembly

checks

or

tests

outlined

testing

and

for

harm

calibration

patient

and

have

of

board

and

void

any

and

B.

not

be

possible

fields.

The

field

manufacturer

has

outlined

in

Sections

use

will

void

attended

express

Failure

Braun

all

warran-

to

test

to

Repre-

may

of

the

equip-

been

in

of

with

all

and

writ-

do

per-

By

performing

agree

that

B.

Braun

all

damages,

out of

You

or

also

auential

this

device

as

well

results

B.

Braun

or

responsibility

institution’s

liabilities,

resulting

understand

loss,

damage,

since

as

other

obtained

from

neither

authorized

any

repairs

and

its

actions

from

such

that

or

the

guality

factors

relating

its

assumes,

in

connection

or

with

or

without

distributors

or

causes

repairs.

neither

expense

of

repair,

to

B.

Braun

directly

matters

use.

nor

authorizes

with

repair

unauthorized

use

shall

of

action,

nor

or

and

the

beyond

any other

of

repair

of

this

manual

be

indemnified

including

its

distributors

indirectly

knowledge

arising

B.

Braun's

person

this

device.

during

1-1

the

as

reference,

and

held

attorney’s

shall

from

and

experience

control,

to

assume

B.

Braun

warranty

you

harmless

fees,

be

liable

authorized

of

personnel

directly

for

it,

any

accepts

no

period.

hereby

from

and

directly

for

any

incidental

or

unauthorized

affect

financial

other

or

950500

the

acknowledge

against

or

indirectly

or

repair

performing

device

and

additional

obligations

Rev E (06/00)

and

any

and

arising

conse-

of

repairs,

the

liability

for

any

Page 12

Horizon

1.2

Nxt®

Service

The

information

WARRANTY

B.

Braun

fusion

ship

for a period

to

meet

B.

Braun’s

modification,

In

this

be

returned

B.

Braun

lieu of

operation

fitness,

beyond

shall

not

from

the

rizes

any

this

device.

has

been:

hereby

Pump.

these

option,

case,

to

will

and

excludes

of

since

B.

Braun’s

be

liable

use

other

Manual

When

standards

or

an

estimate

B.

be

law

handling,

of

this

person

This

contained

warrants

in

that

properly

of

one

year

after

within

will

be

replaced

abnormal

Braun

at

the

or

otherwise

control, directly

for

device

warranty

conditions

will

be

properly

purchaser’s

all

other

storage,

any

incidental

other

to

assume

will

this

manual

reasonable

used

and

maintained,

the

date

this

one

year

without

of

operation,

submitted

packaged,

risk.

The

warranties

including,

and

than

for

not

not

but

cleaning

affect

or

consequential

replacement

it,

another

apply

is

current

care

has

of

shipment.

period

charge.

before

work

postage

foregoing

expressly

not

limited

of

these

these

devices

or

to

any

Horizon

as

of

the

date

been

used

in

it

shall

be

free

Any

Horizon

will

be

repaired

Ifthe

defect

repairs

will

is

started,

prepaid.

Loss

be

express warranty,

set

forth

herein,

to,

any

implied

devices,

and

loss,

of

all

or

additional

as

the

damage

part

of

liability

Nxt

Infusion

of

issue.

the

manufacture

from

defects

Nxt

after

has

been

billed

at

if

requested.

or

damage

whether

warranties

well

as

results

obtained

or

expense,

it.

B.

Braun

or

responsibility

Pump

of

each

in

material

Infusion

Pump

examination

caused

B.Braun’s

as

factors

by

misuse,

then

The

defective

in

return

conditioned

expressed

of

merchantability

relating

from

their

directly

neither

or

component

or

assumes,

Horizon

and

that

by

B.Braun , or,

Nxt

workman-

is

found

unauthorized

current charges.

device should

shipment

and

to

indirectly

in

connection

to

limited,

or

implied

other

matters

use.

B.

nor

thereof

Braun

arising

autho-

which

In-

not

at

is

in

by

or

with

This

warranty

by,

any

1.3

INTENDED

This

manual

and

repair

medical

B.

Braun

institution

tomer

maintains

B.

Braun.

NOTE:

¢

Repaired

*

Altered

*

Subjected

*

Used

Manual

extends

other

person.

USE

is

of

the

service

prior

upon

Service

the

(see

right

by

anyone

in

any

way

to

misuse,

in

any

manner

and/or

intended

referenced

Service

only

to

to

be

equipment.

professional.

to

servicing

the

expiration

Chapter

to

This

manual

vided

Pump.

other

unauthorized

ability

the

9)

withhold

contains

solely

than

None

for

for

of

use

for

infringement

other

than

that,

in

B.

negligent

not

according

Manual.

the

first

purchaser

used

by a gualified

Although

Horizon

of

the

standard

for

additional

the

purchase

information

technical

the

information

the

maintenance

of

the

information

authorized

Braun’s

handling,

to

the

or

Repair

it

Nxt

is

not

Pump,

of

mandatory

Horizon

information

of

parts

personnel

contained

and

of

trade

secrets,

B.

Braun

judgement,

or

accident;

affects

instructions

lessee

biomedical

the

and

device

service

should

that

it

is

recommended,

Nxt

Infusion

on

the

until a service

]

and

data

proprietary

in

maintaining

herein

servicing

of

contained

copyright,

trained

technician

its

furnished

does

not

extend

professional

only

each

service

and

Pump

training

classes

professional

to

and

servicing

may

be

the

pumps

herein

may

and

patents.

or

stability

be

or

by

B.

Braun

to,

and

performed

professional

will

be

warranty.

and

has

B.

Braun

the

duplicated

or

their

subject

the

repair

reliability;

.

for

facility;

in

the

Operation

may

not

be

the

troubleshooting

by a qualified

be

certified

made

available

Please

fee

structure.

been

This

Horizon

or

used

component

user

contact

certified

information

Nxt

in

any

parts.

to

substantial

]

enforced

bio-

by

to

your

Cus-

B.

Braun

by

is

pro-

Infusion

manner

Any

li-

1-2 950500

Rev E (06/00)

Page 13

Horizon

Nxt®

Service

This

Service

Operation

Operation

Manual

Manual

Manual

Manual

is

organized

is

included

for

the

into

at

the

intended

use

end

ten

chapters

of

this

of

this

as

outlined

manual

infusion

for

pump.

in

easy

reference.

the

Table

Please

of

Contents. A Horizon

refer

to

Chapter 1 of

Nxt

the

1-3

950500

Rev E (06/00)

Page 14

Horizon

2.0

ПЕ

Nxt®

Service

DESCRIPTION

2.1

VISUAL

Manual

INDICATORS

AND

CONTROLS

—S

TE

PIGGYBACK

Figure

1.

PRIMARY

2.

Primary

3.

POWER

4.

AC

5.

Battery

6.

HOLD

POWER

PAPA

2-1:

Rate

Key

Use

Indicator

Use

Indicator

[ac + ar

RATE

ML/HR

VOLUME

180]

Front

View

Indicator

Display

Indicator

Key

ROLES

TO

BE

DELIVERED

RN

2500

AE

DV

PIGGYBACK

7.

RUN

8.

ALARM

9.

Primary

10.

PRIMARY

11.

PIGGYBACK

12.

Door

AA

Z

=”

Indicator

Indicator

Volume

RUN

Lever

つぐ

Display

Key

RUN

の

Key

τς

em

2-1

950500

Rev E (06/00)

Page 15

Horizon

Nxt®

Service

Manual

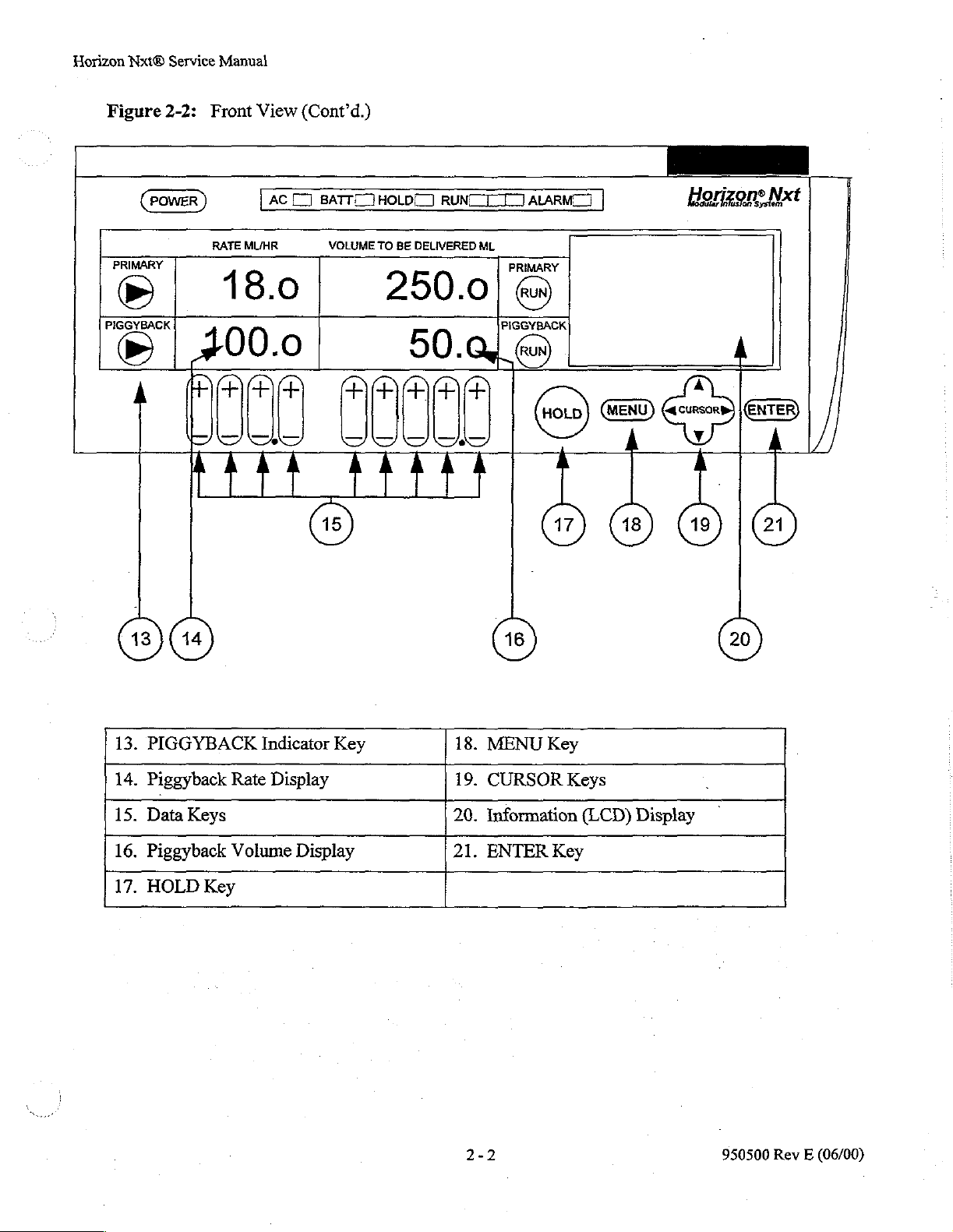

Figure

PRIMARY

Φ

"=="

2-2:

Front

View

(Cont'd.)

POWER

RATE

|

LAC

CI

MUHR

18.0

BATTET

VOLUME

400.0

1000

Minis

€

HOLD]

TO

BE

DELIVERED

oe

RUNC

ALARM]

ML

PRIMARY

|

==

cet

dde

Horizons

Nxt

13.

PIGGYBACK

14.

Piggyback

15.

Data

16.

Piggyback

17.

HOLD

Rate

Keys

Volume

Key

Indicator

Display

Key

Display

18.

MENU

19.

CURSOR

20.

Information

21.

ENTER

Key

Key

Keys

(LCD)

Display

2-2

950500

Rev E (06/00)

Page 16

Horizon

Nxt®

Service

Manual

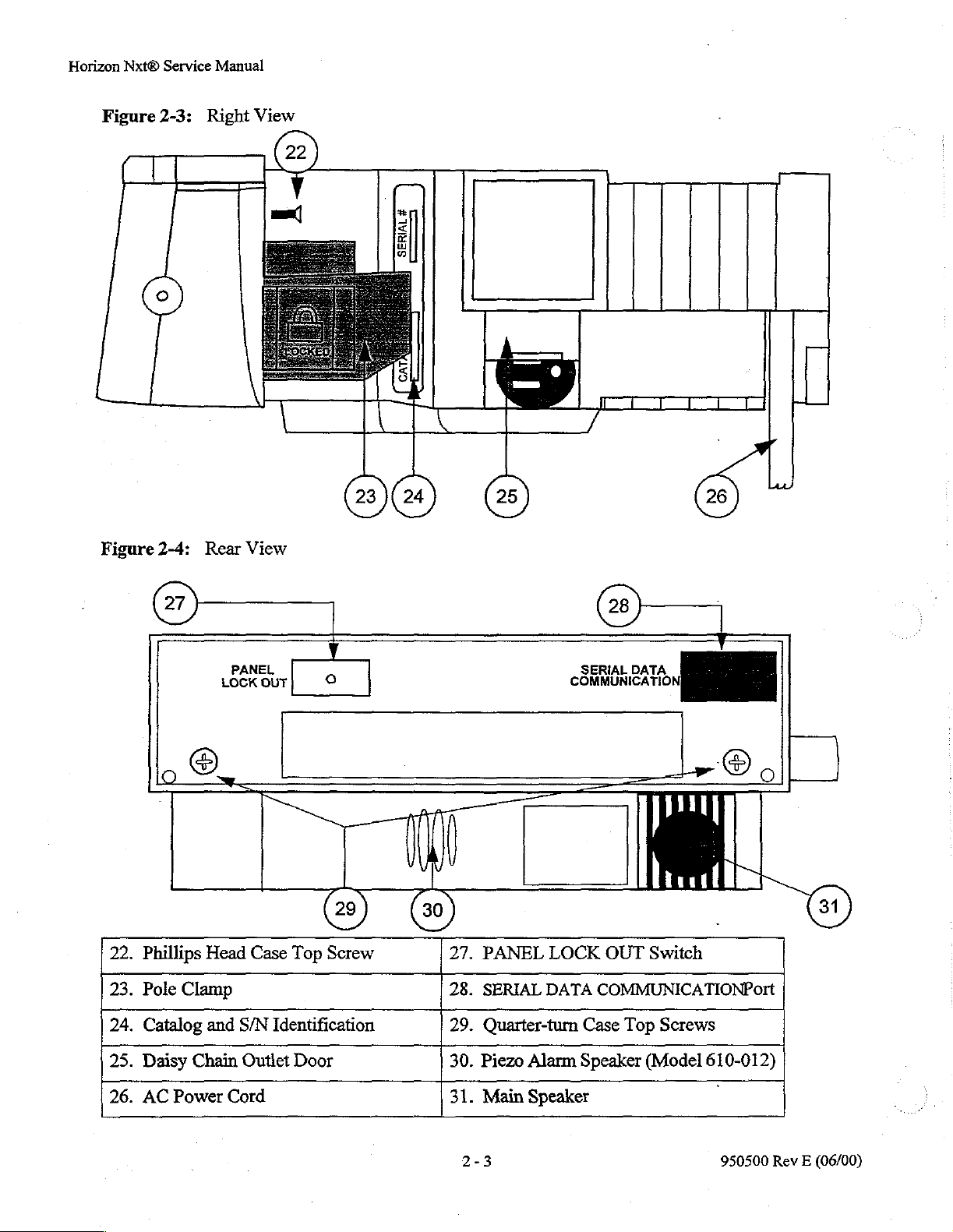

Figure

1

Figure

2-3:

2-4:

Right

Rear

View

View

ma

#

SERIAL

===

CAT

COMO

X

У

©

(2

„©

22.

Phillips

23.

Pole

24.

Catalog

25.

Daisy

26.

AC

Power

一

LOCK

+.

Head

Clamp

and

Chain

一

一

OUT

PANEL

Case

Top

S/N

Identification

Outlet

Cord

Door

o

Screw

SERIAL

COMMUNICATION

DATA

r

Bo

|

|

|

27.

PANEL

28.

SERIAL

29.

Quarter-turn Case

30.

Piezo

31.

Main

Alarm

Speaker

LOCK

DATA

OUT

Switch

COMMUNICATIONPort

Top

Screws

Speaker

(Model

610-012)

2-3

950500

Rev E (06/00)

Page 17

Horizon

Nxt®

Service

Manual

Figure

2 3

2-5:

Front

View,

4

Door

Open

1.

Cassette

2.

Inlet

3.

Refill

4.

Transfer

5.

Petal

6.

Restriction/Outlet

Alignment

Valve

Piston

Valve

Module

Pins

Cover

Valve

7.

Air-In-Line

8.

Anti-Freeflow

9.

Pressure

10.

Tube

Pusher

11.

Spring

2-4

10

Detector

Socket

Transducer

(Free

Flow

Prevention)

950500

Rev E (06/00)

Page 18

Horizon

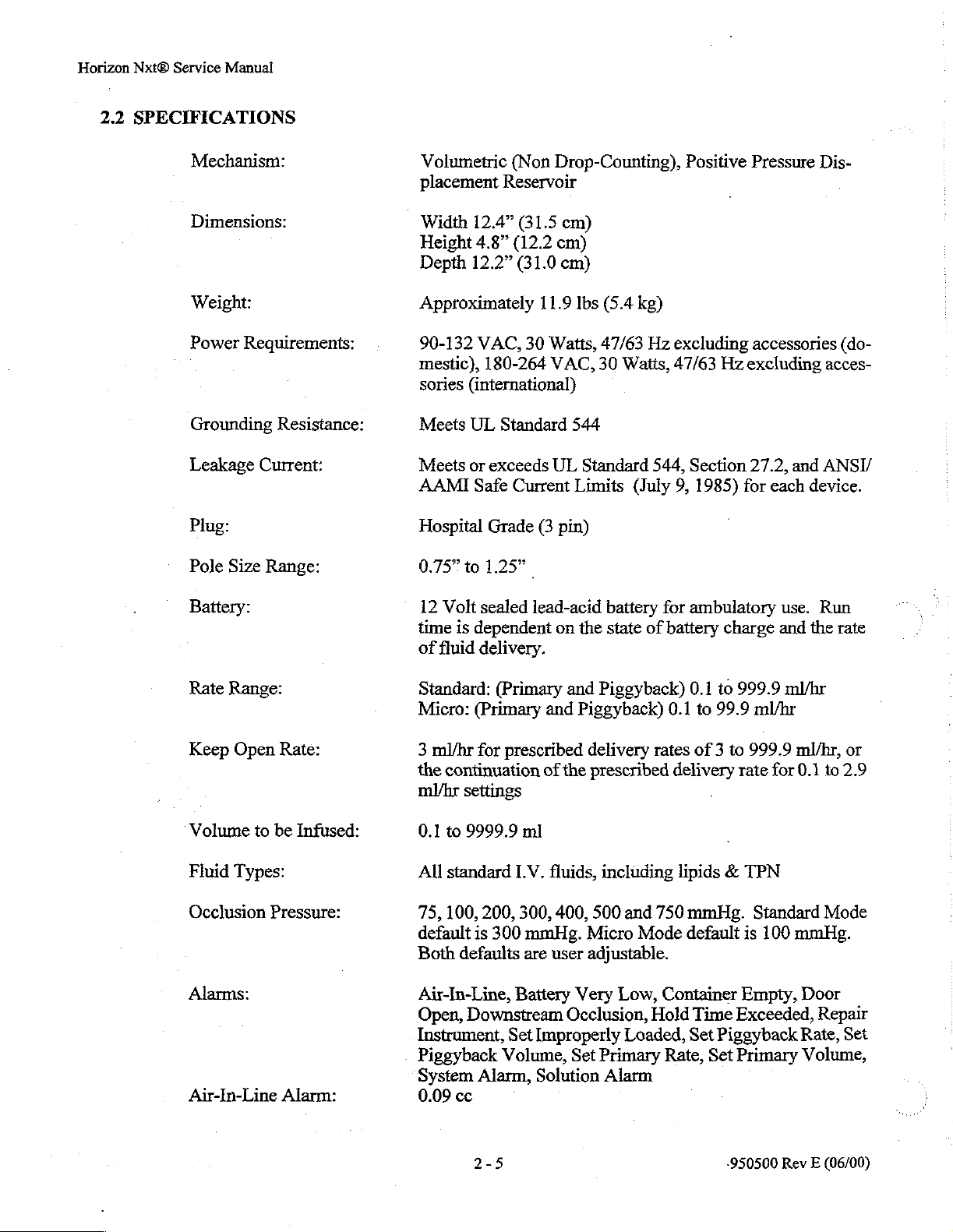

2.2

Nxt®

Service

Manual

SPECIFICATIONS

Mechanism:

Dimensions:

Weight:

Power

Grounding

Leakage

Plug:

Pole

Battery:

Requirements:

Resistance:

Current:

Size

Range:

Volumetric

placement

Width

Height

Depth

Approximately

90-132

mestic),

sories

Meets

Meets

AAMI

Hospital

0.75”

to

12

Volt

time

is

of

fluid

(Non

Reservoir

12.4"

(31.5

4.8"

(12.2

12.2”

(31.0

VAC,

180-264

(international)

UL

Standard

or

exceeds

Safe

Current

Grade

1.25”

sealed

dependent

delivery.

Drop-Counting),

cm)

cm)

cm)

11.9

lbs

(5.4

30

Watts,

VAC,

UL

(3

lead-acid

544

Standard

Limits

pin)

on

the

47/63

30

Watts,

battery

state

kg)

Hz

544,

(July

for

of

battery

Positive

excluding

47/63

Hz

Section

9,

1985)

ambulatory

for

excluding

charge

Pressure

accessories

27.2,

each

and

use.

and

Dis-

acces-

ANSI/

device.

Run

the

(do-

rate

Rate

Range:

Keep

Open

Volume

Fluid

Occlusion

Alarms:

Air-In-Line

to

be

Types:

Pressure:

Rate:

Infused:

Alarm:

Standard:

Micro:

3

ml/hr

the

continuation

ml/br

0.1

to

All

standard

75,

100,

default

Both

Air-In-Line,

Open,

Instrument,

Piggyback

System

0.09

(Primary

(Primary

for

prescribed

settings

9999.9

ml

IV.

200,

300,

is

300

mmHg.

defaults

are

Battery

Downstream

Set

Volume,

Alarm,

cc

and

Piggyback)

and

Piggyback)

delivery

of

the

prescribed

fluids,

400,

including

500

and

Micro

user

adjustable.

Very

Low,

Occlusion,

Improperly

Set

Solution

Loaded,

Primary

Alarm

0.1

0.1

rates

of 3 to

delivery

lipids € TPN

750

mmHg.

Mode

default

Container

Hold

Time

Set

Rate,

to

999.9

to

99.9

ml/hr

999.9

rate

-

Standard

is

Empty,

Exceeded,

Piggyback

Set

Primary

ml/hr

for

100

ml/hr,

0.1

to

or

2.9

Mode

mmHg.

Door

Repair

Rate,

Set

Volume,

2-5

«950500

Rev E (06/00)

Page 19

Horizon

Nxt®

Service

Hold

Manual

Time

Exceeded:

Activated

tivated

if

the

after

three

door

minutes

of

the

pump

without

is

open)

user

interaction

(deac-

Memory:

Permanent

the

Data

Retention

the

Biomed

data

retention

Defaults

Options.

after

the

have

pump

been

is

turned

otherwise

off,

unless

selected

in

2-6

950500

Rev E (06/00)

Page 20

Horizon

3.0

Nxt®

RECOMMENDED

3.1

RECEIVING

New

tion

numbers,

of

box

Service

Device

will

be

or

failure.

Manual

RECEIVING

NOTICES

Notice:

replaced

preventative

Any

only

maintenance

new

if

the

device

device

tags.

PROCEDURE

that

does

not

is

not altered,

Ifa

device

meet

i.e.

is

factory

hospital

used

specifications

identification

on a patient,

during

markings,

it

will

not

be

in-coming

asset

inspec-

control

considered

an

out

WARNING:

3.1.1

Damaged

Upon

should

age

company.

mediately,

happy

and

forwarded

request

tation

3.1.2

Goods

_

Ifthe

replaced

Section

3.7

and

Horizon

tion

ties.

Goods

receipt,

not

be

or

loss

noted

If

and

to

issue a credit

the

carrier’s

to

must

be

company

Received

product

for

count

is

or

repaired,

3.6

of

this

3.8

prior

Nxt

must

set

sterility

and

accepted.

on

the

damage

request

is

that

for

freight

the

Carrollton,

accompanied

has

properly

in

Error

partially

manual

to

inspect

or

the

unit

and

use

for

be

performed

only.

Failure

your

patient

Identify any

customer’s

discovered

inspection

the

loss

bill

indicating

Texas

copy

after

or

damage,

office

by a delivery

noted

such

completely

must

the

disassembled,

undergo

appropriate

care.

with a set

to

do

so

freight

items

be

before

that

are

of

the

delivery

receipt

made

of

and

and

the

item and

(see

Chapter

receipt

damage

and

pass

calibrations

All

final

performance

that

is

acceptable

may

cause

the

carrier

damaged

document

shipment,

an

inspection

file a claim

quantity

9),

and

or

an

inspection

or

loss.

or a component

all

performance

and/or

testing

for

bodily

or lost,

notify

with

damaged

received

harm

departs.

report

the

Damaged

and

have

by

an

the

transportation

rendered.

carrier,

or

within

agent

report

or

assembly

checks

tests

outlined

and

patient

and

use

will

the

of

providing

not

received

ten

upon

which

has

been

outlined

in

Sections

calibration

with

void

of

an

excep-

all

warran-

merchandise

extent

the

of

the

dam-

transportation

company

B.

Braun

days.

will

your

reque

are

promptly

The

the

transpor-

claim

in

the

im-

be

Items

notified

be

Credit

ordered

returned

will

1.

Proper authorization

2.

Products

3.

Products

4.

Merchandise

Certain

1.

2.

products

Products

Products

(see

Chapter

freight

be

or

shipped

issued

are

in

are

current

has

are

which

whose

in

9),

and

prepaid

for

by

all

has

the

original

inventory

been

shipped

not

eligible

have

been

labels

or

error

may

the

products

the

customer.

returns

been

for

obtained

undamaged

items.

and

for

used.

seals

have

be

returned

are

goods

billed

return

for

been

3-1

to

returned

received

(see

Chapier

cases,

suitable

to

the

credit.

tampered

the

warehouse

within

in

error

9).

for

customer

These

with

are:

or

provided

14

days.

Items

provided:

immediate

by

B.

Braun.

removed.

Customer

ordered

resale.

950500

Service

in

error

is

must

Rev E (06/00)

Page 21

Horizon

Nxt®

Service

Manual

3.1.3

3.1.4

3.1.5

Except

Late

B.

yond

acts

strike,

Expedited

When

by

in

the

Shipments

Braun

shall

its

or

of

government,

labor

expedited

the

customer,

Receiving

Each

Horizon

ment.

therefore,

your

There

the

(customer)

case

of a B.

be

excused

its

suppliers’

acts

trouble,

Shipments

sabotage

transportation,

an

additional

Inspection

Nxt

Infusion

is,

however,

following

policy,

Braun

from

or

of

error,

any

delay

subcontractors’

purchase

or

priorities

delay

specialized

charge

Pump

the

possibility

inspection

refer

to

the

to

is

factory

is

recommended.

section

items

must

in,

or

control,

or

in

obtaining

services,

cover

the

inspected

of

in-transit

in

this

be

returned

impossibility

freight

of

including,

allocations,

labor,

or

alternate

premium

and

damage

If

functional

chapter

raw

materials,

expense

tested

which

titled

prepaid

performance

but

not

limited

material

shortages,

equipment,

transportation

will

be

added

prior

to

its

final

may

or

may

testing

“CHECK-IN

is

required

PROCEDURE.”

by

the

customer.

due

to

any

cause

to:

acts

of

God,

fire,

flood,

or

transportation.

modes

packaging

to

not

upon

are

specified

the

invoice.

and

be

obvious;

receipt

be-

war,

ship-

by

3.2

CHECK-IN

Prior

manual.

(RMA#).

Before

1.

age.

opening

If

damage

until a representative

for

shipping

to

the

company

.

Remove

Www

Carefully

ping

damage.

.

Make

A

aligned

un

.

Make

.

Check

.

Inspect

.

Make

01d

erwise

manufacturer

sure

sure

sure

damage

is

responsible

the

pump

inspect

the

with

the

there

the

Pole

the

power

the

damaged.

PROCEDURE

to

use,

it

is

recommended

If

the

pump

See

Chapter 9 for

fails

the

shipping

is

present,

of

after

unless

from

the

pump

door

of

the

bezel.

are

no

visible

Clamp

petal

for

cord

for

module

that

to

operate,

information

container,

notify

the

the

the

shipping

shipping

specifically

for

the

repair.

the

shipping

for

dents,

pump

opens

dents,

ease

of

operation.

nicks

or

cover,

the

contact

valve

pump

B.

on

contacting

inspect

freight

carrier

company

container

authorized

carton.

scratches,

and

closes

tears

or

scratches

cuts,

and

the

tips

be

checked-in

Braun

for a Returned

the

it

carefully

immediately,

is

present.

is

opened).

to

do

missing

easily,

plug

for

and

pressure

according

company.

to

assure

(It

is

Do

so

by

the

parts,

or

without

on

the

pump

bent

or

transducer

to

Sections

Materials

the

absence

and

wait

to

difficult

not

to

return

company,

any

other

obvious

binding,

and

membrane

insecure

prongs.

cover

3.3

Authorization

of

obvious

open

the

place

responsibility

damaged

whether

that

panel.

are

not

through

container

equipment

or

not

signs

of

it

is

properly

torn

or

3.8

of

Number

dam-

the

ship-

oth-

this

Each

may

used

pump

have

caused

by

qualified

has

been inspected

some

misalignment.

service

and

personnel

tested

prior

Therefore,

in

the

initial

to

shipment;

the

and

3-2

however,

procedures

routine

outlined

checks

in-transit

in

this

of

the

Horizon

handling

chapter

Nxt

950500

are

Infusion

or

repair

intended

Pump.

Rev E (06/00)

work

to

be

Page 22

Horizon

3.3

Nxt®

Service

Manual

MECHANICAL

INSPECTION

3.3.1

3.3.2

See

Table

3.3.3

See

Table

3.3.4

Door

Alignment

1.

Make

aligned

2.

The

Pole

Clamp

3-2, # 1.

Switch

3-2, # 2.

Gasket

1.

All

2.

Petal

3.

The

marks.

All

No

Tube

No

Inspect

none

sure

the

with

the

gap

on

each

Inspection

Inspection

and

Hardware

gaskets

module

cover

screws

cracks

pusher

cracks

on

are

in

the

and

cover

the

are

is

the

power

Inspection

door

of

the

bezel.

side

and

The

Inspection

seals

are

securely

and

valve

pressure

tight

and

secure.

present

intact

case

cord

in

the

and

securely

or

handle

for

pump

along

opens

door

the

latch

top

attached.

tips

are

transducer

bezel

or

shall

inner

mounted.

exist.

nicks

or

cuts.

and

closes

allows

of

the

in

place

not

door

Inspect

easily,

the

door

door

and

have

face.

the

without

to

close

is

symmetrical.

in

good

condition.

any

rips,

tears,

plug

for

bent

binding,

and

completely.

punctures

or

insecure

that

it

is

properly

or

indentation

prongs.

3.4

MAIN

All

pump

the

Allow

the

whenever

12

3.5

DEFAULT

A

by

BATTERY

rechargeable

is

no

exception.

battery

battery

be

at

least

in a fully

fully

24

possible.

Horizon®

and/or

SOFTWARE

1.

Set

all

pumps.

2.

Verify

list

of

all

the

contacting

Technical

CHECK

batteries

Therefore,

charged

hours

to

charged

When

Horizon

defaults

Refer

to

that

the

options

in

Support

AND

CHARGING

automatically

it

is

suggested

by

connecting

fully

charge

the

condition,

charging

Nxts

multiple

may

SETTINGS

according

the

pump’s

the

PC

Docking

calendar

Menu

to

your

System,

Services

discharge

that

the

power

battery

the

pump

devices

be

Daisy

Chained

individual

Operation

and

clock

and

the

at

(800)

3-3

when

not

in

before

cord

from a fully

should

attempting

of

the

be

plugged

in a storage

together

institution’s

Manual,

are

set

appropriately.

submenus

627-7867.

use.

The

rechargeable

to

pump

to a hospital

discharged

into a hospital

facility,

for

outlet

needs.

Part

No.

950441,

in

which

they

use

the

pump

grade

condition.

grade

not

in

the

conservation

Use

PC

Docking

for

can

be

battery

In

used

in

for

the

first

electrical

order

outlet.

to

maintain

electrical

vicinity

instructions.

placed,

950500

of

patients,

purposes.

to

program

is

available

Rev E (06/00)

this

time,

outlet

the

Page 23

Horizon

3.6

Nxt®

Service

SIMULATED

Manual

USE

AND

PERFORMANCE

CHECK

Action

.

Unlock

lever

turn.

down

holding

the

case.

supported

press

ver

the

Press

Equipment

1.

Horizon®

2.

Container

3.

Needle

4.

LV.

5.

AC

3.6.1

Table

pole

1/4

pump

Test

3-2:

the

Pole

clockwise

Attach

on

Release

down

the

the

the

unlocked

the

lever

is

seated

the

by

the

on

turn

counterclockwise

to

lock

Power

Required:

Pump

with

and

pole

or

power

Procedure:

Simulated

Clamp

toward

pump

down,

in

Pole

I.V.

the

the

Key

by

the

to

Pole

position

the

V-block

Clamp.

pole,

pump.

Pole

to

turn

source

LV.

Set

suitable

3ml

Syringe

equivalent

Simulated

Use

Initial

rotating

front

an

LV.

Clamp

use one

Rotate

Clamp.

on

the

of

the

pole

lever.

the

pump

of

the

With

the

hand

the

towards

the

pump.

fluid

in

it

Use

Checkout

Pole

Clamp

pump

by

instrument

Pole

the

1/4

pressing

While

such

pump

now

to

lightly

Clamp

back

Observation

1.

that

le-

of

Verify

onto

Note:

The

HOLD

To

Be

LCD

the

Pole

the

pole.

As

the

open

er,

the

pump

mounted

speaker

will

will

LEDs

Delivered

illuminate

Clamp

on

will

mechanism

Pole

Clamp

will

become

the

I.V.

sound a tone.

illuminate.

columns

and

lever

more

pole.

The

The

Rate

will

display

display:

tightens

is

snugged

securely

BATT

and

and

Volume

values,

firmly

tight-

the

and

Total

Occlusion

Note:

Ifno keys

ly

30

seconds,

the

Primary

is

not

active.

3

min.,

“HOLd”

ume

To

Be

and

the

alarm

Load

the

then

close

Infused = 0.0

Limit = 300

have

been

pressed

“HOLd”

or

Piggyback

If

no

keys

will

flash

Delivered

will

sound.

Set

the

Door.

mmHg

for

will

be

channel,

have

been

in

the

column

950500

ml

approximate-

displayed

whichever

pressed

Primary

of

the

Rev E (06/00)

in

Vol-

LED’s

for

Page 24

Horizon

Nxt®

Service

Manual

3.

4.

5.

Table

Individually

each

DATA

GYBACK

the

Piggyback

values

Enter a Primary

10.

Press

to

Press

the

3-2:

Simulated

press

Key

to

INDICATOR

Rate

zero.

rate

the

PRIMARY

MENU

Key,

and

hold

verify

and

of

900

then

Use

Initial

the + and - portion

operation.

Key

and

Volume

and a Primary

RUN

Key.

the

repeat.

To

HOLD

Checkout

Press

Be

Delivered

Key.

of

the

PIG-

Return

volume

of

3.

Key

clicks

dible

tone

Rate

and

Delivered

decremented

attempt

0.0

ml.

Note:

4.

The

audible

proximately

LED

will

ume

To

HELP”.

5.

The

LCD

are

heard

will

sound

the

thousands

are

advanced

past

0.

is

made

to

set

Whichever

INDICATOR

TOR,

the

respective

brighter,

dimmer.

illuminate.

Be

Delivered

The

Then

Check

will

while

alarm

will

once

every

LCD

will

CLOSE

open

Placement

Secure

(picture)...

display:

as

the

as

the

column

past 9 or

This

same

the

rate

key

is

or

PIGGYBACK

the

begin

three

The

LEDs

column

display:

ROLLER

door.

Flow

Сатр-у

LEDs

depressed,

sequence.

hundreds

of

the

Volume

if

any

tone

will

or

volume

display

other

to

seconds.

will

will

display

sound

in

the

flash

CLAMP

of

column

PRIMARY

and

The

Primary

An

a.

of

the

To

Be

column

sound

less

INDICA-

illuminate

becomes

“SEE

is

if

than

repeat

ALARM

ap-

Vol-

an

6.

Press

the

MENU

CURSOR

ed.

Press

CURSOR

lighted.

7.

Cursor

Key

the

Key

Press

left

and

Key

until

ENTER

until

the

ENTER

right.

followed

“Alternate

“Set

Key.

LCD

Key.

by

the

Menu”

Press

the

Contrast”

down

arrow

is

highlight-

down

arrow

is

high-

Load

and

then

Total

Occlusion

Flow

6.

The

LCD

will

Adjust

this

Then

7.

The

contrast

high

present

cursor

message

press Enter

changes

again.

and

The

not

Infused = 0.0

Limit = 300

Clamp

display:

< —

is

clear.

from

backlight

erratic

the

Set

close

the

Position

EXIT

until

key.

high

to

intensity

or

flickering.

Door.

ml

mmHg

HELP

low

and

should

950500

back

to

be

Rev E (06/00)

Page 25

Horizon

Nxt®

Service

Manual

©.

Press

9.

Open

10.

Spike

the

the

instruction

11.Press

Piggyback

¿2.Close

press

Table

the

ENTER

the

door.

the

set

with

set

before

cassette

into

the

PIGGYBACK

the

clamp

the

PRIMARY

3-2:

fluid

container

fluid.

closing

the

label

rate

Simulated

Key.

Make

pump

inside

and

volume

downstream

Use

with

sure

the

roller

mechanism

the

Indicator

RUN

Initial

the

all

air

clamp.

door.

of

0.0.

from

Key.

Checkout

I.V.

set,

and

is

removed

Load

according

Close

Key

and

the

cassette

the

prime

from

the

to

the

door.

enter

and

a

8.

The

LCD

9.The

only

display

onds,

after

play

“HOLd”.

Time

Exceeded

10.

The

Rate

display

ing

11.

The

PIGGYBACK

PRIMARY

12.

The

with a complete

should

sage

those

the

door.

LCD

“Total

of

will

display:

and

then

Total

Occlusion

Flow

Clamp

change

which

and

Volume.

Occlusion

will

sound

“OCCL.”

the

Opening

alarm.

Volume

values

The

LCD

Set

Total

Flow

Clamp

drop

LEDs

LEDs

Infused

occlusion

associated

Load

the

Set

close

Infused = 0.0

Limit = 300

PIGGYBACK

To

that

the

Then

Infused = 0.0

Limit = 300

the

will

will

become

=”

value

the

Position

will

occur

the

door

Be

Delivered

were

present

will

illuminate

Rate

&

Press

Position

last

line

of

illuminate.

dim.

should

and

an

with a flashing

Door.

mi

mmHg

HELP

after

several

LEDs

disables

columns

prior

and

RUN.

mí

mmHg

HELP

text.

The

The

stop

increasing

audible

LED

sec-

will

dis-

the

Hold

will

to

open-

display:

row

of

row

of

alarm

mes-

13.

Press

the

HOLD

clamp.

and

Clamp

press

the

PRIMARY

Key

the

and

tubing

open

the

upstream

RUN

Key.

downstream

of

the

pump

Note:

Note:

13.

Note:

The

amount

how

far

downstream

sion

limit

The

Occlusion

crease

fect

exceed

The

“Total

with a complete

should

sage

The

how

limit

of

Infused

sound

of

“SOLU.”

amount

far

setting

to

400

tubing

399.9

upstream

of

time

setting

associated

as

Limit

mmHg

flow

resistance

ml/hr.

=”

value

occlusion

of

time

the

as

well

will

vary

depending

the

clamp

well

as

will

to

compensate

should

and

with a flashing

will

vary

clamp

as

the

is,

the

the

infusion

automatically

as

infusion

stop

increasing

an

audible

depending

is,

the

occlusion

infusion

950500

Rev E (06/00)

upon

occlu-

rate.

in-

for

the

rates

alarm

LED

upon

rate.

ef-

mes-

Page 26

Horizon

Nxt®

Service

Manual

14.

15.

16.

Table

Press

the

tubing.

the

“Y”

the

pump.

When

Press

the

pump

such

upwards,

the

3-2:

Simulated

HOLD

Inject

site

an

of

Press

air

bubble

that

toward

MENU

the

Key

air

tubing

the

the

distal

the

Key.

Use

and

unclamp

bubble

PRIMARY

reaches

ceiling.

of

on

the

the

(delivery

Initial

the

at

least

upstream

RUN

pump,

end)

Checkout

upstream

0.9

ml

side

Key.

tilt

the

is

pointing

into

of

14.

The

15.

The

the

LEDs

flash

16.

The

tinguish.

LCD

cassette

ized,

The

LEDs

LCD

luminate.

will

will

Occlusion

alarm

air-in-line

in

the

“Air.”

alarm

The

will

chambers

HOLD

begin

display:

will

The

Press

will

display:

LED

to

Time

Left = 0

Total

Volume

Infused = 1.8

sound

detector.

RUN

The

LCD

Air

To

Silence

MENU

Press

silence.

HOLD

will

be

filled

will

extinguish.

illuminate

Limit = 400

as

the

The

LEDs

To

Be

will

In

HOLD.

The

LED

sequentially.

hr 0 min

air

bubble

ALARM

will

extinguish.

Delivered

display:

Line

Alarm

for

help,

ALARM

will

illuminate.

and

ml

mmHg

column

or

LED

pressur-...!

The

RU?

The’

passes

LED

into

will

The

will

will

The

il-

ex-

17.

Open

the

door

and

flush

form

the

Volumetric

3.7.1.

10.0

Enter a Primary

ml.

Press

the

RUN

the

Test

as

Volume

Key.

air

in

the

tubing.

described

to

be

Delivered

in

Section

-

Air

in

downstream

-

Tubing

inserted

Detector.

Per-

of

17.

Press

Atthe

Vein

RUN

end

Open

improperly

in

Air-In-Line

Press

of

infusion,

mode.

HOLD

tubing

or

the

pump

will

go

into

Keep

950500

Rev E (06/00)

Page 27

Horizon

Nxt®

Service

Manual

19.

20.

21.

22.

Table

.

Wait

Open

Press

Press

“Clear

Press

3-2:

until

the

door.

the

HOLD

the

MENU

Total

the

ENTER

Simulated Use

the

infusion

Key.

Key.

Infused.”

Key.

Initial

is

complete.

Press

the

Checkout

ENTER

Key

to

18.

An

tion.

ume

flashing.

19.

The

nate.

umn

20.

The

minate. The

Volume

play;

21.

The

22.

The

alarm sounds,

The

primary

to

be

delivered

The

KVO:

Occlusion

alarm

will

The

LEDs

will

flash

alarm

will

to

be

PRIMARY

Time

Total

Occlusion

LCD

will

The

LCD

will

indicating a KVO

rate

LCD

PRIMARY

Total

sound.

in

“door.”

silence.

Primary

Delivered

Left= 0 hr

Infused=

display:

present

of

10.00

zeroed.

display:

will

be

3.0

ml/hr

will

be

0.0,

each

will

display:

COMPLETE

Infused = 10.0

Limit = 300

The

Alarm

the

Volume

The

rate

will

of

0.o.

COMPLETE

Limit = 300

Total

mi

Is

this

YES

mmHg

LED

to

be

HOLD

display 900 and

The

Отт

10.0

mmHg

Infused

will

be

OK?

NO

state

of

and

the

will

be

mi

will

illumi-

Delivered

LED

will

LCD

will

ml

opera-

vol-

col-

illu-

a

dis-

Press

the

23.

a

POWER

Key

to

turn

the

pump

off.

PRIMARY

Time

Total

Occlusion

23.

The

LED’s

will

display

the

power

lit

while

supply.

3-8

in

“----”

down

the

the

pump

COMPLETE

Left=

Infused = 0.0

Volume

until

cycle.

is

Ohr

Limit = 300

to

be

the

device

The

AC

plugged

into

Omin

ml

mmfig

delivered

has

completed

LED

will

an

AC

950500

Rev E (06/00)

column

remain

power

Page 28

‘Horizon

3.7

Nxt®

Service

VOLUME

Manual

DELIVERY

ACCURACY

Equipment

3.7.1

Table

Volume

10

3-3:

mi

Required:

1.

Distilled

2.

Horizon®

3.

Electronic

4.

Needle

Test

Procedure:

1.

Connect

2.

Attach

3.

Completely

clamp

4.

Insert

pump.

5.

Close

6.

Open

Volumetric

water

Pump

Balance

or

dispenser

the

the

needle

prime

on

the

the

cassette

the

door

all

clamps

Rate

120

in

an

I.V.

or

tip

Volumetric

fluid

delivery

to

the

the

set.

into

and

press

and

Test

Values

mi/br

J.V.

fluid

Set

Precision

with a Luer

set

delivery

set

with

the

pump

the

POWER

enter:

container

Collection

lock

to

the

fluid

end

of

fluid

so

all

according

Key

Pressure

300

mmHg

Vessel

type

connector.

container.

the

I.V.

Set.

the

air

is

to

the

instructions

to

turn

expelled

on

from

the

pump.

Acceptable

9.5 - 10.5

the

set,

inside

the

ml

and

door

Limit

then

of

the

close

the

Horizon

roller

Nxt

Note:

Note:

.

Place

lection

.

Press

eo

ら

When

\

sure

10.

Zero

pump

turn

the

collection

vessel.

the

RUN

Key.

the

pump

the

actual

volume

1ml=1cc=1¢

the

reading

with

additional

the

pump

Tf

using

adaptive

in

section

cause

transitions

tem

first

equipment

LV.

different,

to

other

energy

5.5.7.2

the

motor

dynamics

few

delivery

pumps

typically

vessel

goes

into

delivered

of

on

the

I.V.

an

authorized

accuracy

processing

“Motor

energy

from

the

and

rate)

cycles

will

supply

which

employ

on

the

the

Keep

distilled

balance.

fluid

delivery

B.

test

methods,

Controllers.”

to

rise

Hold

state

momentary

after

you

with

this

all

that

is

balance,

Vein

Open

is

between

water

at

If

the

actual

sets.

Braun

Service

in

used

to

conserve

and

fall

to

the

Run

pauses

the

RUN

written

type

of

required

3-9

zero

the

reading,

mode,

the

acceptable

room

temperature

values

If

the

values

Center.

addition

to

battery

This

dynamic

at

the

beginning

state).

of

the

Key

is

pressed.

instructions

energy

is

that

processing.

you

allow

and

press

the

limits

are

not

remain

the

above,

power

processing

This

results

motor

for

5-10

suspend

HOLD

(70°

within

and

of

an

as

the

listed

infusion

in

the

Key

in

the

F)

the

specifications,

outside

be

sure

the

to

reduce

of

resistance

several

energy

is

Manufacturers

use

of

their

equipment

While

milliliters

volumetric

of

needle

immediately.

over

above

the

Make

table.

test

specifications,

compensate

noise

(each

time

(varies

changed

of

biomedical

for

as

described

to

flow

the

pump

with

the

during

when

testing

analyzers

fluid

to

bleed

950500

Rev E (06/00)

cv.

the

re-

the

will

sys-

the

test

ar,

fro

.

Page 29

Horizon

3.8

Nxt®

Service

ELECTRICAL

Manual

the

system

Contact

procedures

SAFETY

prior

to

starting

the

manufacturer

are

used.

CHECK

the

timer(s)

of

you

or

counter(s). A 3-way

volumetric

analyzer

to

ensure

stopcock

proper

is

software

very

useful

and

testing

here.

Equipment

1.

2.

3.8.1

Note:

Test

에

DWN

Required:

Medical

AC

power

Procedure:

.

Plug

the

.

Make

.

Plug

the

.

Attach

Chain

If

ther

stainless

you

Set the

Set

the

Press

Press

IEC

the

601-1

LIA

equipment

source

Electrical

analyzer

sure

the

pump

the

probe

outlet

using a manual

the

may

into

analyzer

into

to a single

on

the

metal

steel

need

grounding

polarity

the

POWER

Chassis

to

Leakage

specifications

electrical

an

AC

is

functioning

the

AC

outlet

lead

side

of

the

probe

frame

door

selection

latch.

to

scratch

of

the

to

“Normal.”

Key

to

turn

button

as

indicated

safety

analyzer

outlet.

of

the

and

touch

pump

for

Being

and

‘No

your

power

scrape

Ground.”

on

the

and

or

stainless

pump.

make

below.

properly,

according

analyzer.

it

to

the

any

protruding

resistance

supply,

the

checks,

located next

steel,

probe

sure

the

to

aluminum

metal

you

the

door

on

the

latch.

reading

your

institution’s

plate

which

component.

will

need

to

the

Daisy

latch

makes

does

not

exceed

protocol.

supports

to

make

Chain

for a difficult

contact

outlet,

the

UL

the

Daisy

with

or

contact;

544

the

or

the

ei-

Note:

Note:

9.

10.

11.

12.

13.

14.

As

of

the

date

544 and

Chain

chassis

The

IEC

feature

leakage

number

601-1

of

it

Set

the

polarity

Press

the

the

TEC

Press

the

Set

the

Set the

Press

the

or

the

IEC

As

601-1

polarity

grounding

of

to

“Reverse.”

Chassis

Leakage

specifications.

HOLD

Key.

to

Ground

601-1

the

date

with a non-detachable

this

manual

is

on

the

current

pumps

Horizon

was

100

microamps

Nxt

is

cumulative.

interconnected

button

again.

“Off.”

selection

Wire

switch

Resistance

specification.

this

manual

was

power

cord

3-10

written,

the

for

(plugging

Therefore,

at

any

Make

to

“Ground.”

button.

written,

for

Make

the

UL

AC

leakage

patient

one