Page 1

360INFUSER™

SERVICE

MANUAL

B

BRAUN

8874

Rev C (10/03)

Page 2

8874

Rev C (10/03)

Page 3

360INFUSER™

>

THIS

MANUAL

OR

MACHINE-READABLE

©

2003

B.

‘WORKING

B-D

AND

TOGETHER

PLASTIPAK

BRAUN

MAY

NOT,

MEDICAL

FOR

ARE

IN

WHOLE

FORM

WITHOUT

INC.

EXCELLENCE

REGISTERED

SERVICE

OR

IN

PART,

PRIOR

ALL

RIGHTS

IN

SAFETY,

TRADEMARKS

BE

COPIED,

AND

OF

PHOTOCOPIED,

360INFUSER

BECTON

WRITTEN CONSENT

RESERVED.

MANUAL

REPRODUCED, TRANSLATED,

OF

B.

BRAUN

ARE

TRADEMARKS

DICKINSON

MEDICAL

OF

INC.

B.

BRAUN

OR

CONVERTED

MEDICAL

INC.

TO

AND

ANY

ELECTRONIC

ITS

AFFILIATES.

B

BRAUN

Page 4

8874

Rev C (10/03)

Page 5

TABLE

OF

CONTENTS

LK

2.0

RECEIVING

TABLE

Si

eg

1.1Disclaimers.....................................

1.2

1.3

1.4

1.5

1.6

1.7

2.1

2.2

2.3

24

e V reina

Intended

Pump

1.3.1

1.3.2

1.3.3

Theory

Specifications.......

Trackind

Service & Performance

Introduction

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

Receivinginspeciion........................................

Operating

Displays

Use

of

Service

Safety

Warnihgs...............

Cautions.....................................

Attentions.....

of

PROCEDURE

Notices...

Damaged

Goods

Late

Expedited

iii

Operation

cnonnncncaoncnronnnananncanencnnnnnrnnn

ice

Goods...

Received

Shipments............

Shipments

Procedure..

and

Alarms

OF

Manual.

eee

eee

Information...

in

Error.

CONTENTS

:

eee

rn

sern

ron

ee

ss

ran

orar

1

eee

orar

eee eee

ememeeemenenn

ii

아아

1

„3

...4

4

ER

SES

4

6

9

anna

11

...

11

nenene

11

…

11

a

3.0

SIMULATED

3.1

4.0

CLEANING & DISINFECTING..

5.0

TROUBLESHOOTING

5.1

6.0

REMOVAL

6.1

6.2

8874

Rev C (10/03)

USE

Inspection

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

6.2.1

6.2.2

6.23

6.2.4

Equipment

Unit

Infusion

DOcclusion

Time

General

AND

INSTALLATION

Sub

Assembly

Assembly

Front

Split

Curtains.......................

RearCaseAssembly..............................

AND

Procedure

Initialization

Test...

Troubleshooting

Repair

Case

Ring

PERFORMANCE

.........................

Required

Test.............

Complete

TeSt

PROCEDURES...

and

Repair

Instructions................

Assembly

and

Retainer....................................

CHECKS

...........

Tone

Test.

000000000

ον

Guide...

Service

.pe

i

οκοωο

εκτ

Kits.

nenene

νοκ

iii

rei

renerne

nene

nenene

eee

neem

ee

een

ean

„17

…

…

…

renerne

een

…

… 35

… 35

… 38

… 39

17

17

17

18

18

20

23

25

30

40

Page 6

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

7.0

CALIBRATION

7.1

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

6.2.10

6.2.11

6.2.12

6.2.13

6.2.14

6.2.15

6.2.16

6.2.17

7.1.1

7.1.2

7.1.3

7.1.4

Battery

Wired

Instruction

PC

EPROM..........

Microprocessor.

LCD.....................

LCD

Crystal

Buzzer..............

Motor

Clamp

PusherBlock..........................................

PROCEDURES

Alignment

Equipment

Initial

Home

Occlusion

DoOT

in

Battery

Board........

Terminal.......

Label.................

Display

With

Block.....

Test

Setup

Position

Driver.

.................

Gear..

sinon

Procedures

Required.....

.................

Alignment

Adjustment......................

..

n

8874

Rev C (10/03)

Page 7

INTRODUCTION

CHAPTER

1.0

INTRODUCTION

IN

THIS

CHAPTER

*

The

intended

*

This

manual

troubleshooting,

It

is

suggested

material

ensure

delivery

components

any

liability

Do

not

permanently

equipment

is

carefully

that

the

of

spare

accepts

associated

use

the

damage

in

question.

designed

and

that

360infuser

pump

About

*

Of

+

How

modular

before

to

become

parts

responsibility

in

the

the

warnings,

to

contact

to

help

repair

attempting

familiar

will

for

the

360infuser,

with

the

the

presence

pump.

use

of

important

cautions,

B.

the

biomedical

of

the

any

with

perform

device

For

dependably

for

the

incurred

of

strong

further

YOU

WILL

this

service

features

Braun

of

and

disclaimers

Customer

engineer

B.Braun

360infuser

maintenance

the

unit.

This

and

the

party

performing

performance

at

the

electromagnetic

information,

LEARN:

manual.

the

360infuser

related

Service

perform

Syringe

or

repair

will

help

accurately

the

of

the

device

time

of

the

fields.

consult

pumps.

to

the

use

and

Technical

routine

functions,

avoid

repair

the

maintenance,

Pump.

review

possible

at

all

times.

installation

and,

in

and

The

field

manufacturer

of

this

manual.

Support.

basic

this

damage

By accepting

of

said

addition,

in

the

accepts

future.

may

of

the

and

To

facilitate

user-replaceable

Problems

engineer,

Services

1.1

DISCLAIMERS

Due

service

qualified

course.

not

microprocessor

devices,

which

8874

Rev C (10/03)

maintenance

parts

and/or

but

at

to

repairs

should

1-800-627-PUMP

the

critical

on

this

product

biomedical

Repairs

be

attempted

testing,

have

not

and

repair,

(see

Chapter

not

covered

be

referred

to

(1-800-627-7867).

nature

should

by

controlled

static

specifically

of

be

performed

repair

not

other

than

control

product

professional

be

attempted

electronics,

been

B.Braun

6).

in

this

our

Technical

performance,

only

qualified

and

soldering

identified

has

designed

manual

who

without a current

personnel

digital

Service

by

an

has

and

should

not

Department

B.Braun

authorized

attended

that

analog

techniques.

in

this

Service

the

360infuser

be

attempted

recommends

B.Braun

the

B.Braun

Service

are

knowledgeable

circuitry,

Repairs

should

Manual.

to

include

by

the

at

B.Braun

that

Service

service

Manual.

electromechanical

Repairs

not

specific

biomedical

Technical

all

required

Center

training

in

the

areas

be

attempted

Page 1 of

or

a

should

of

70

Page 8

360INFUSER

E + WARNING:

2/

component

undergo

calibrations

patient

360infuser

patient

cause

(©

CAUTION:

7.

unless

soldering

consent

Representative.

&

CAUTION:

7

and

has

B.Braun

to

SYRINGE

care.

use

bodily

personnel

will

void

been

test

complete

PUMP™

If

the

product

or

assembly

and

pass

all

and/or

All

final

must

be

with an

harm

Rework

of

have

techniques

has

been

obtained

Failure

Individual

any and

obiained

recommends

circuit

SERVICE

is

partially

has

been

performance

tests

as

outlined

performance

performed

exception

and

will

void

multi-layer

attended

for

this

type

from

to

do

component

all

warranties

from

an

authorized

board

replacement

function

MANUAL

or

completely

replaced

checks

in

this

testing

with

syringes

for

sterility

all

warranties.

boards

and

passed

of

board

an

authorized

so

will

void

replacement

unless

B.Braun

to

factory

disassembled,

or

repaired,

and

the

appropriate

manual

and

that

only.

should

an

and

prior

calibration

are

Failure

not

be

accredited

express

B.Braun

all

warranties.

is

not

recommended

express

written

Represeniative.

as

it

may

specifications.

the

unit

to

use

of

the

acceptable

to

do

so

attempted

course

written

consent

not

be

possible

or

must

for

for

may

a

in

By

performing

acknowledge

harmless

including

repairs.

You

also

dental

rized

and

experience

beyond

B.Braun

additional

accepts

ing

the

The

information

Page 2 of

any

repairs

and

agree

that

from

and

against

attorney's

understand

or

consequential

or

unauthorized

fees,

that

repair

of

personnel

loss,

B.Braun's.control,

neither

no

warranty

70

assumes,

liability

financial

or

period.

contained

responsibility

obligations

with

or

B.Braun

any

and

directly

neither

or

B.Braun

damage,

of

this

performing

directly

nor

authorizes

for

in

this

manual

without

all

use

and

its

damages,

indirectly

nor

or

expense

device

affect

in

any

since

repairs,

the

any

connection

institution's

is

current

of

this

manual

distributors

liabilities,

arising

its

distributors

directly

the

as

device

other

shall

out

of

or

quality

well

as

other

and

the

person

with

to

repair

authorized

as

of

the

as a reference,

be

indemnified

actions

of

results

or

causes

or

resulting

shall

be

liable

indirectly

repair,

arising

and

factors

obtained from

assume

of

date

for

this

device.

or

unauthorized

of

issue.

you

and held

of

action,

from

such

for

any

from

the

knowledge

relating

it,

8874

to

any

other

B.Braun

repair

Rev C (10/03)

hereby

inci-

autho-

matters

its

use.

or

dur-

Page 9

1.2

INTENDED

This

manual

troubleshooting

performed

each

service

recommended.

the

training

institution

is

intended

and

by a qualified

professional

Please

classes

until a service

ATTENTION:

B.Braun.

in

maintaining

contained

than

for

component

herein

trade

secrets,

USE

to

repair

biomedical

contact

and

fee

professional

This

This

herein

the

maintenance

parts.

may

subject

OF

SERVICE

be

used

by a qualified

of

the

referenced

service

be

certified

B.Braun,

structure.

manual

by

B.Braun

contains

information

and

servicing

may

be

Any

unauthorized

the

user

copyright,

MANUAL

equipment.

professional.

B.Braun

Inc.

Technical

withholds

has

been

certified

information

is

provided

the

360infuser.

duplicated

and

servicing

to

substantial

and

patents.

biomedical

Repair

Although

prior

to

servicing

Service

the

right

by

B.Braun.

and

solely

for

None

or

used

in-any

of

the

use

of

the

liability

INTRODUCTION

service

for

pumps

information

professional

of

the

device

it

is

not

the

360infuser,

additional

to

sell

parts

data

proprietary

technical

of

the

information

manner

or

their

for

infringement

personnel

for

should

mandatory

only

it

information

to

any

to

other

contained

of

the

be

that

is

on

This

Service

Please

syringe

Additionally,

described

refer

pump.

below.

Manual

to

the

throughout

ATTENTION:

topic

NOTE:

this

IS

CAUTIONS

“4

recommendations

the

patient.

is

Methods

in

this

This

manual.

or

organized

of

Use

this

manual

This

icon

manual.

icon

will

provide

WARNINGS:

in

into

seven

section

are

will

provide

This

order

Chapters

of

the

Operator's.Guide

icons

which

additional

additional

icon

will

to

prevent

as

outlined

identify

supplemental

information

information

provide

accident

safety

or

in

the

Contents.

for

the

intended

for a given

for a given

injury

to

the

use

of

information

topic

user

as

in

or

this

8874

Rev C (10/03)

Page 3 of

70

Page 10

360INFUSER

1.3

PUMP

SYRINGE

SAFETY

PUMP™

SERVICE

MANUAL

1.3.1

Warnings

© . WARNING:

X/

cleaning.

“ai,

WARNING:

2.

component

undergo

calibrations

patient

360infuser

patient

cause

© „ WARNING:

^

cleaning.

To

If

the

or

and

and/or

care.

must

use

with an

bodily

To

avoid

electrical

product

assembly

pass

ail

tests

All

final

be

performed

exception

harm

and

avoid

electrical

shock,

is

partially

has

been

performance

as

outlined

performance

with

for

will

void

all

shock,

tum

the

pump

or

completely

replaced

checks

in

testing

this

and

and

manual

syringes

sterility.only.

disassembled,

or

repaired,

the

calibration

that

are-acceptable

Failure

warranties.

turn

the

pump

off

before

the

unit

appropriate

prior

to

use

of

the

to

do

so

off

before

or

must

for

for

may

a

1.3.2

my

Cautions

CAUTION:

unless

soldering

consent

Rework

personnel

techniques

has

been

Represeniative.

CAUTION:

and

has

B.Braun

to

test

Individual

will

void

been

obtained

recommends

complete

any

of

multi-layer

have

attended

for

obtained

Failure

component

and

all

from

board

circuit

function

boards

and

this

type

of

from

an

to

do

so

will

replacement

warranties

an

authorized

replacement

to

factory

should

passed

board

an

and

authorized

void

all

warranties.

is

unless

express

B.Braun

as

it

specifications.

not

be

attempted

accredited

express

course

written

B.Braun

not

recommended

written

consent

Representative.

may

not

be

possible

in

Page 4 of

70

8874

Rev C (10/03)

Page 11

INTRODUCTION

“i,

CAUTION:

1,

Attention

to

needed,

©

CAUTION:

‘autoclave

©

CAUTION:

By

solutions

abrasive

©

CAUTION:

Sy

Autoclaving

press

If

during

LED

the

Stop

remove

To

or

To

containing

cleaners

the

flashes.

Infusion

the

avoid

mechanical

immerse

avoid

mechanical

on

syringe

glutaraldehyde,

Sterilization

is

not

recommended.

infusion

To

deactivate

button,

the

pump

the

instrument.

of

the

an

from

or

in

damage,

pump

occlusion

the

occlusion

unlock

the

the

pusher.

electronic

any

fluids

DO

ammonium

using

ethylene

alarm

syringe

damage,

or

cleaning

NOT

chlorides

oxide

appears,

alarm,

head

DO

NOT

solutions.

use

acetone,

(EtO)

the

you

and,

or

red

have

if

steam

gas

or

L

CAUTION:

©

Caution:

4”

provided

attached

©

CAUTION:

Sy

Compressing

©

CAUTION:

7

the

Do

not

When

and

take

to

the

Do

not

the

Federal

order

of a physician.

clean

the

reattaching

care

not

J1

connector

compress

spring

(U.S.A.)

will

pump

the

back

to

bend

or

the

spring

affect

law

restricts

using

any

the

high-pressure

case,

use

or

crimp

other

when

the

wires.

tightening

occlusion

this

device

devices.

the

three

ribbon

pressure

to

sale

screws

cable

the

set

readings.

by

screw.

or

on

8874

Rev C (10/03)

Page 5 of

70

Page 12

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

1.3.3

Attentions

ATTENTION:

/ ! \

use.

Ί

ATTENTION: A new

ATTENTION:

the

studs

ATTENTION:

EPROMs.

ATTENTION:

connector.

Refer

It

or

For

Some

is

very

case

all

to

Operator’s

syringe

important

halves

old

revisions,

devices

should

when

may

Guide

to

closing

for

be

used

avoid

the

B.Braun

require

complete

for

each

pinching

unit.

should

to

desolder

.

directions

test.

any

remove

34

u

wires

the

pins

for

between

obsolete

of

LCD

VAN

ZN

ATTENTION:

there

is a jumper

the

display

ATTENTION:

chassis.

in

place,

location.

ATTENTION:

off

In

discard

Cut

with a pair

If

the

driver

Some

this

case,

off

If

you

of

PC

board

wire

from

U5.

units

remove

the

buzzer,

one

of

the

can

not

pliers.

displays

pin 0 of

may

new

remove

have

the

screw

and

install

buzzer's

part

the

the

the

number

LCD

buzzer

holding

the

new

mounting

.035"

set

PD-7790,

connector

mounted

the

damaged

buzzer

arms

screw,

ensure

to

pin

to

the

in

the

for

fit.

pry the

32

of

buzzer

same

gear

Page 6 of

70

8874

Rev C (10/03)

Page 13

A

1.4

THEORY

The

360infuser

to

administer

and

is

capable

The

unit's

indicator

battery

completed,

of

the

lights

voltage

LCD.

ATTENTION:

B.Braun.

in

maintaining

contained

than

for

component

herein

trade

secrets,

is a microprocessor

This

This

herein

the

parts.

may

subject

OF

OPERATION

intermittent

of

delivery

Power

the

On

button

are

sequentially

is

read

(internal

unit

automatically

manual

information

and

servicing

may

be

maintenance

Any

unauthorized

the

user

copyright,

controlled,

infusions.

times

The

ranging

activates

activated

to

the

presets

contains information

is

provided

the

duplicated

and

servicing

to

substantial

and

patents.

pump

from

an

automatic

as

are

unit,

not

the

timer

solely

360infuser.

or

used

of

the

use

of

the

liability

battery

accepts

10

the

displayed).

syringe

to

60

system

LCD

at

30

operated,

minutes.

check.

bars,

When

minutes,

for

None

in

INTRODUCTION

and

data

proprietary

technical

of

the

any

manner

pumps

information

sizes

the

or

for

infringement

portable

ranging

During

buzzer

this

system

displaying

to

personnel

information

other

their

contained

of

syringe

this

tone

from

self-

sounds,

check

the

first

pump

3cc

test,

has

used

to

60ce,

all

and

been

12

the

bars

After a syringe

proper

determines

determines

infusion

has

The

the

displacement

established

automatically

timer

reset

have

infusion

the

the

has

been

been

detected

occlusion

syringe

clamp

in

off.

When

ali

variables

to

remove

mechanism

resulting

the

interrupt

has

been

speed

and

syringe

period

diameter,

and

completed,

and

the

against

from

product

the

the

infusion

used

to

the

syringe

placed

in

the

pump

occlusion

width

the

Stop

is

contained

an

internal

the

specification,

infusion,

is

calculate

from

pressure.

the

pusher

of

motor

Stop

Infusion

Infusion

spring.

pressure

activate

restarted,

the

the

pusher

and

To

block

impulses

button

button

within

has

the

The

on

the

spring.

the

Occlusion

an

audible

the

unit

infusion

parameters

to

reset

the

time

has

perform

these

position,

to

govern

has

been

been

pressed.

syringe

clamp

occlusion

If

the

Alarm

alarm,

will

ignore

the

occlusion

been

set,

calculations,

and

the

clamp

the

plunger

pressed,

and

operates

wiper

constantly

displacement

is

activated.

and

turn

the

initial

(except

occlusion

pressure

the

unit

calculates

the

unit

block

position,

speed

until the

or

an

alarm

condition

by

depressing

monitors

exceeds

The

both

the

calculations,

the

unit will

motor

and

pressure).

to

zero.

the

first

then

the

value

and

the

will

You

8874

Rev C (10/03)

Page 7 of

70

Page 14

360INFUSER

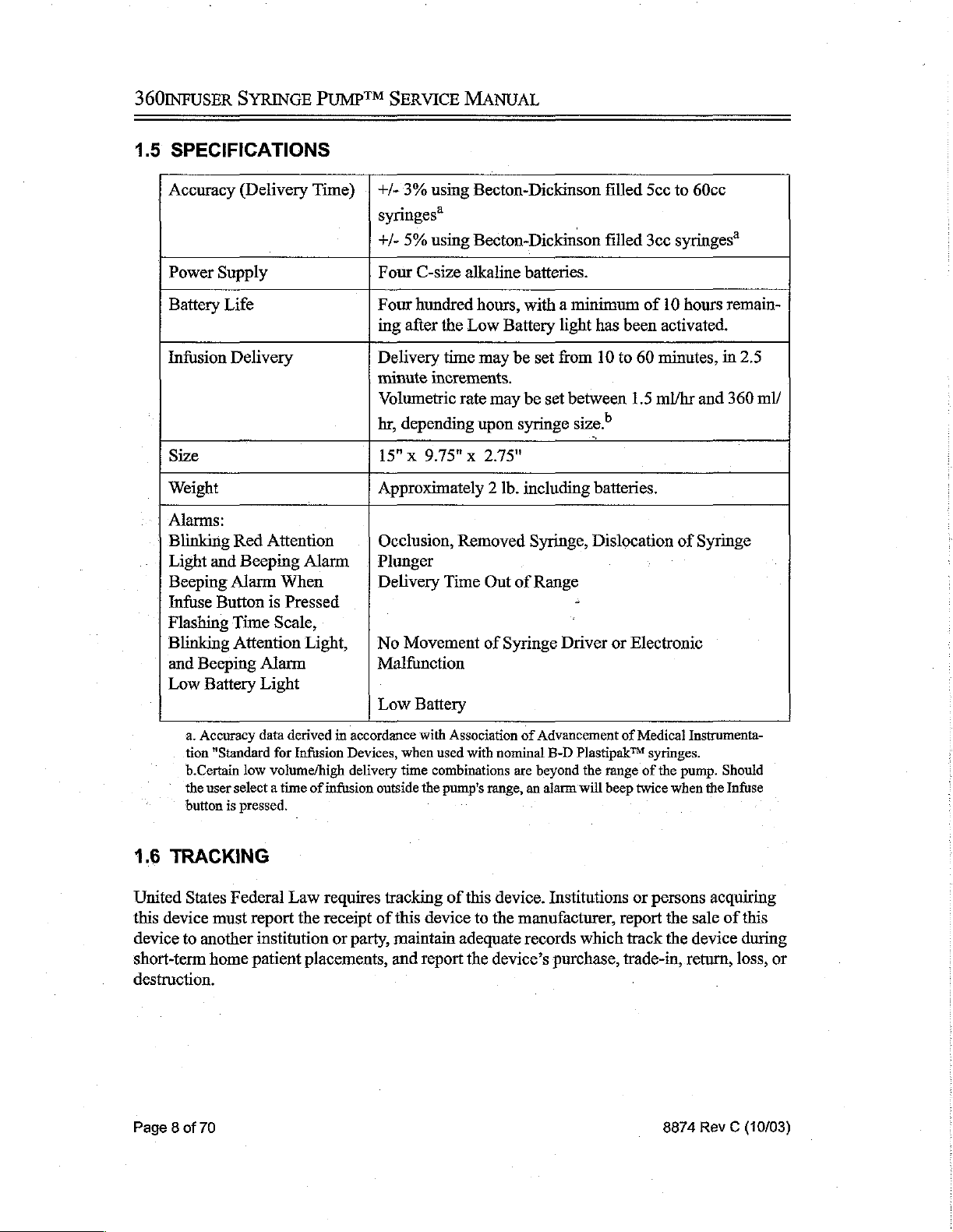

1.5

SPECIFICATIONS

Accuracy

Power

Battery

Infusion

Size

Weight

Alarms:

Blinking

Light

Beeping

Infuse

Flashing

Blinking Attention

and

Low

Supply

Life

Delivery

Red

and

Alarm

Button

Time

Beeping

Battery

a.

Accuracy

tion

"Standard

b.Certain low

the

user

select a time

button

is

SYRINGE

(Delivery

Attention

Beeping

When

is

Pressed

Scale,

Alarm

Light

data

derived

for

Infusion

volume/high

pressed.

PUMP™

Time) | +/-

Alarm | Plunger

Light, | No

in

of

infusion

SERVICE

3%

syringes*

+/-

5%

Four

C-size

Four

hundred

ing

after

Delivery

minute

Volumetric

hr,

depending

15"x

9.75" x 2.75"

Approximately 2 Ib.

Occlusion,

Delivery

Movement

Malfunction

Low

accordance

Devices,

delivery

Battery

with

when

time

outside

the

MANUAL

using

Becton-Dickinson

using

Becton-Dickinson

alkaline

hours,

the

Low

Battery

time

may

be

increments.

rate

may

upon

syringe

Removed

Time

Out

of

of

Syringe

Association

used

with

nominal

combinations

pump's

are

range,

filled

filled

batteries.

with a minimum

light

has

set

from

10

to

be

set

between

size?

|

including

Syringe,

Range

of

Advancement

beyond

an

alarm

batteries.

Dislocation

+

‘

Driver

B-D Plastipak™

the

will

or

of

range

beep

5cc

to

60cc

3cc

syringes*

of

10

hours

been

activated.

60

minutes,

1.5

ml/hr

of

Syringe

Electronic

Medical

twice

Instrumenta-

syringes.

of

the

pump.

when

remain-

in

and

Should

the

Infuse

2.5

360

ml/

1.6

TRACKING

United

this

device

short-term

destruction.

Page 8 of

States

device

to

another

70

Federal

must

home

Law

requires

report

the

receipt

institution

patient

or

placements,

tracking

of

this

device

party,

maintain adequate

and

report

of

this

device.

to

the

the

device’s

Institutions

manufacturer,

records

which

purchase,

or

persons

report

the

track

the

trade-in,

8874

acquiring

sale

of

this

device

return,

during

loss,

Rev C (10/03)

or

Page 15

1.7

SERVICE

Ifthe

pump

manual,

and

fails

to

the

cause

&

PERFORMANCE

respond

to

cannot

the

operating

be

determined,

INFORMATION

or

troubleshooting

discontinue

using

INTRODUCTION

procedures

the

pump.

listed

in

this

Service

contacting:

Product

With

a

and

occurred,

Should

(preferably

manufacturer

while

Authorization

contact

Number.

and

product

compiaints

each

complaint,

description

volume,

they

of

the

and

it

be

necessary

in

are

Customer

the

difficulty

type

any

other

the

original

cannot

in

transit.

to

return

Service

performance

B.

1601

Carrollton,

Attn.:

(800)

(800)

may

be sent

please

include

experienced,

of

I.V.

fluid

information

to

return

packing),

assume

any

products

at

the

information

Braun

Medical

Wallace

Texas

Drive,

Manager

627-PUMP

627-7867

to

the

Manager

the

serial

information

in

use,

the

alarms

which

the

pump

and

responsibility

must

above

to

ship

be

received

phone

might

the

it

may

be

obtained

Inc.

Suite

150

75006

of

Service

of

Quality

number

or

lot

regarding

displayed

aid

in

the

manufacturer,

prepaid

for

number

to

the

loss

or

from

B.Braun

for a Returned

from

the

Assurance

number

at

investigation

the

the

at

of

time

time

carefully

above

address.

damage

・

to

returned

prior

Goods

to

manufacturer

the

above

address.

the

product

setting,

the

of

pack

shipment.

syringe

difficulty

the

complaint.

the

pump

The

instruments

Authorization

by

involved,

size

Please

With

each

question

*

opump's

* - description

+ © initial

*

type

*

amount

noticed

・

alarms

*

catalog

8874

Rev C (10/03)

or

serial

of

volume

of

fluid

of

time

displayed

and

lot

complaint,

number

the

difficulty

to

be

infused

between

at

the

time

number

of

please

the

include

experienced

start

the

difficulty

the

set(s)

of

the

infusion

in

use.

the:

occurred

and

the

time

the

difficulty

was

Page 9 of

70

Page 16

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

.

This

page

intentionally

left

blank.

Page

10

of

70

8874

Rev C (10/03)

Page 17

RECEIVING

PROCEDURE

CHAPTER

RECEIVING

IN

*

*

*

+

2.14

INTRODUCTION

211

If

been

appropriate

All

acceptable

cause

Notices

the

product

replaced

final

bodily

is

partially

or

calibrations

performance

for

patient

harm

2.0

PROCEDURE

THIS

CHAPTER

How

to

properly

How

to

perform a receiving

What

procedures

Ofthe

repaired,

testing

use

and

system

or

completely

the

and/or

with

will

void

unit

tests

of

an

YOU

receive

to

follow

displays

disassembled,

must

undergo

as

outlined

the

360infuser

exception

all

warranties.

WILL

in a pump.

inspection.

when

and

alarms

and

in

must

for

syringe

LEARN:

checking

and

their

or a component

pass

all

this

manual

be

performed

sterility

in a pump.

indications

or

performance

prior

to

use

with a syringe

only.

Failure

assembly

checks

for

and

patient

that

to

do

so

has

the

care.

is

may

2.1.2

Upon

chandise

extent

agent

notify

an

age,

indicating

Carrollton,

must

portation

2.1.3

Items

Service

ordered

Damaged

receipt,

should

of

the

of

the

the

transportation

inspection

and

file a claim

the

Texas

be

accompanied

company

Goods

ordered

is

notified

in

error

Goods

count and

not

damage

transportation

inspect

be

accepted.

or

loss

company.

company

report

rendered.

with

the

item

and

quantity

office

(see

by a delivery

has

properly

Received

or

shipped

(see

must

in

in

Section

be

returned

your

Identify

noted

on

immediately,

B.Braun

carrier,

damaged

Section

noted

Error

error

may

1.7),

freight

freight

before

any

the

customer's copy

If

damage

will

be

providing

or

not

1.7),

and

receipt

such

be

and

or

damage

returned

the

products

prepaid

the

items

that

is

discovered

and request

happy

to

your

request

received

received

an

within

inspection

or

loss.

to

the

are

by.

the

carrier

are

damaged

of

that

departs.

the

delivery

after

receipt

inspection

issue a credit

and

the

are

promptly

ten

days.

report

upon

warehouse

returned

provided

within

customer.

Damaged

or

lost,

and

document

of

shipment,

be

for

the

loss

carrier's

freight

forwarded

The

claim request

which

Customer

14

days.

mer-

have

made

or

to

the

trans-

Items

the

by

an

and

dam-

bill

the

8874

Rev C (10/03)

Page

11

of

70

Page 18

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

Credit

*

»

+

*

Certain

*

*

Except

tomer.

2.1.4

B.Braun

cause

acts

tial

tials,

will

Proper

Products

Products

Merchandise

products

Products

Products

in

Late

beyond

of

God,

shortages,

equipment,

be

issued

authorization

are

in

the

are

current

has

are

which

whose

the

case

of a B.

Shipments

shall

be

excused

its

or

its

war,

acts

fire,

flood,

or

transportation.

for

ail

returns

has

been

original

inventory

been

shipped

not

eligible

have been

labels

or

seals

Braun

from

suppliers'

of

government,

strike,

for

goods

obtained

undamaged

items,

for

and

billed

return

and

used.

have

been

error,

items

any

delay,

or

subcontractors’

acts

labor

trouble,

received

(refer

to

Section

cases,

suitable

to

the

customer

for

credit.

These

tampered

must

be

returned

or

impossibility

control,

of

purchase

sabotage

in

error

provided:

1.7),

for

immediate

by

are:

with

or

removed.

freight

of

performance,

including,

priorities

or

delay

or

in

resale,

B.

Braun.

prepaid

due

but

not

allocations,

obtaining

by

the

to

any

limited

raw

mate-

labor,

mate-

cus-

to:

2.1.5

When

Expedited

expedited

specified

added

to

2.2

RECEIVING

Each

360infuser

There

is,

however,

therefore,

receipt

by

the

your

Checks."

1.

Before

obvious

open

to

return

the

opening

the

place

damaged

company,

Carefully

case

the

Shipments

transportation,

by

the

customer,

the

invoice.

INSPECTION

is

factory

the

following

(customer)

the

damage.

container

responsibility

equipment

whether

remove

pump

ever

tested

possibility

inspection

policy,

shipping

If

damage

until a representative

for

or

the

pump

has

to

specialized

an

additional

and

of

in-transit

is

refer

container,

is

present,

shipping

to

the

not

the

company

from

be

shipped

services,

charge

inspected

to

prior

damage

recommended.

to

Chapter

inspect

notify

of

damage

manufacturer

the

shipping

for

3.0

it

the

the

shipping

after

unless

is

responsible

carton.

repair.

or

alternate

cover

the

premium

to

its

final

packaging

which

If

carefully

freight carrier

may

functional

"Simulated

to

assure

company

the

shipping

container

specifically

for

the

Retain

the

transportation

expense

and

or

may

not

be

testing

is

required

Use

and

Performance

the

absence

immediately,

is

present.

is

opened).

authorized

repair.

packaging

modes

will

be

shipment.

obvious;

upon

of

and

wait

(It

is

difficult

Do

to

do

so

materials

in

are

to

not

by

Page

12

of

70

8874

Rev C (10/03)

Page 19

RECEIVING

PROCEDURE

Carefully

of

shipping

Make

5.

Make

Check

2.3

OPERATING

Refer

to

1.

Press

displaying

completed,

Move

away

Insert

positioned

Once

Pusher

rim

inspect

damage

sure

the

sure

there

the

pole

the

360infuser

the

360infuser

all

the

the

Pusher

from

the

the

filied

in

again,

Block

is

positioned

the

pusher

are

no

clamp

PROCEDURE

Operator's

24

LCD

time

scale

Block

unit,

then

syringe

the

clamp

pressing

down

until

between

pump

block

visible

for

ease

Power

time

is

to

the

slide

in

the

notch.

on

the

it

the

for

dents,

of

the

dents,

of

Guide

On

bars

automatically

top

the

Syringe

Pusher

catches

plunger

scratches,

pump

tears

operation.

for

button.

and

all 4 LEDs,

of

the

The

unit

entire

Clamp,

Block

the

rim

lock

slides

up

or

scratches

complete

system

set

at

by

pulling

Pusher

Block

making

and

pulling

of

the

notch

missing

and

down

on

operation

will

perform

one

at a time.

30

minutes.

the

upwards.

sure

the

syringe

and

the

parts,

or

any

easily.

the

pump

instructions.

an

When

Plunger

the

rim

Plunger

plunger.

syringe

driver

other

obvious

membrane

electronic

this

test

Lock

as

far

of

the

syringe

Lock

back,

Make

sure

notch.

signs

panel.

self-test,

has

been

as

possible

barrel

is

slide

the

the

plunger

Set

the

delivery

indicates

If

an

upon

+

the

audible

the

pump

For

units

bell

symbol

Tone

button

determine

Infusion

light

stays

end

of

begun,

button,

*

Forunits

button,

bell

symbol's

not.

+

For

units

Alarm

activation.

time

using

established

tone

at

the

version):

with

the

in

the

(these

if

the

audible

Complete

on

as

long

the

infusion

press

the

Stop

and

finally,

with

the

press

the

Infusion

appearance

with

no

bell

Tone

Off

button

the

Increase

delivery

end

of

the

Infusion

LCD,

versions

Complete

press

alarm

Tone

(On)

as

the

has

been

Infusion

press

the

bell

symbol

Complete

in

symbol

to

disable

or

Decrease

time

throughout

infusion

Tone

the

Infusion

operate

button

activated.

Infuse

identically)

had

been

button

and,

is

pressed,

button,

button

in

the

display and

To

then

Tone

the

display

in

the

display

all

audible

buttons.

the

is

desired,

On

or

Infusion

Complete

before

selected

ifa

after the

beep

then

activate

press

(to

continue

the

(On)

button.

indicates

and

the

alarms

The

infusion.

perform

the

Complete

Tone

On

the

infusion

infusion

sounds

the

this

the

whether

Alarm

and

audible

alarm

Infusion

the

infusion).

Infusion

The

presence

this

Tone

for

one

top

bar

following

Tone

or

Infusion

begins.

begins,

the

Infusion

alarm

after the

Complete

Complete

or

alarm

Off

minute

after

on

the

screen

(depending

without

Complete

To

press

Complete

signalling

infusion

Tone

(On)

Tone

(On)

absence

is

activated

button,

press

their

the

the

has

of

or

the

the

the

8874

Rev C (10/03)

Page

13

of

70

Page 20

360INFUSER SYRINGE

7.

To

begin

infusion, press

light

and

the

top

bar

8.

9.

10.

down,

The

An

Stop

without

To

press

ing

Infusion

infusion

Infusion

as,

’

reset

the

the

one

bar

below

Complete

may

button.

altering

the

CAUTION:

Attention

to

press

the

needed,

the

remove

delivery

appropriate

Infuse

button.

be

If

LED

PUMP™

the

for

the

the

top

light

stopped

The

Stop

original

during

the

flashes.

Stop

Infusion

the

time

after the

Increase

SERVICE

Infuse

time

that

bar

will

will

blink

at

any

Infusion

time

setting.

infusion

To

syringe

or

Decrease

MANUAL

button.

has

During

been

disappear

when

time

by

pressing

button

an

occlusion

deactivate

button,

infusion

from

unlock

the

has

Time

set

will

every

the

infusion

allows

the

pusher.

begun,

Set

the

infusion,

both

flash.

2.5

minutes.

has

either

the

the

operator

alarm

occlusion

the

syringe

press

button.

the

green

As

been

completed.

Power

to

appears,

alarm,

head

the

Stop

Restart

Infuse

the

time

Off

button

resume

the red

you

and,

Infusion

the

infusion

indicator

scale

or

the

have

if

button,

by

counts

the

infusion

then

press-

Page

14

of

70

This

space

intentionaily

left

blank.

8874

Rev C (10/03)

Page 21

2.4

DISPLAYS

AND

ALARMS

RECEIVING

PROCEDURE

Blinking

Blinking

Beeping

Yellow

Green

Indicates

an

Red

Indicates

plunger

Driver

an

has

stops,

Alarm

Indicates

properly

Low

the

placed.

Battery

Attention

Indicates a minimum

activated).

Red

Infusion

Signals

Infusion

Provides

Complete

the

Complete

an

Infuse

Light

infusion

occlusion

been

moved

and

the

When

set

delivery

Light

Infuse

Complete

end

of

the

Tone

audible

is

in

progress.

Light

and

in

the

up

or

Stop

Infusion

Button

time

of

10

hours

the

infusion

Light

infusion.

signal

at

Beeping

IV

set,

down

is

out

the

end

the

syringe

during

button

is

Pressed

of

range

remains

in

progress

of

the

Alarm

has

an

infusion.

must

be

for

the

in

the

battery

and replace

infusion.

been

removed,

In

pressed

syringe

(after

the

a

|

or

these

instances,

to

deactivate

size,

or

the

light

batteries.

the

the

has

syringe

the

Syringe

the

alarm.

syringe

first

is

not

been

Flashing

Indicates

units,

was

infusing.

Time

no

this

Scale,

movement

may

indicate

The

Blinking

of

the

that

unit

should

This

Attention

Syringe

the

syringe

be

sent

to

space

intentionally

Light,

Driver

and

or

was

removed

Biomedical

Beeping

an

electronic

from

Engineering.

left

blank.

Alarm

malfunction.

the

clamp

while

In

certain

the

unit

8874

Rev C (10/03)

Page

15

of

70

Page 22

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

This

page

intentionally

left

blank.

|

Page

16

of

70

8874

Rev C (10/03)

Page 23

SIMULATED

USE

AND

PERFORMANCE

CHECKS

CHAPTER

SIMULATED

3.1

INSPECTION

The

following

unit's

case.

diagnostic

3.1.1

*。 . Stopwatch

*

Pressure

*

Syringes

*

B.Braun

«

Three

inspection

This

procedure

procedure

Equipment

least 1 second).

meter

(Becton

Cat.

way

3.0

USE

IN

THIS

CHAPTER

*

What

equipment

Performance

+

How

to

PROCEDURE

procedure

may

and

at

the

Required

(the

longest

(0-50

Dickinson

No

V6512

stopcock

AND

Checks.

perform

permits

be

used

completion

test

will

psig

minimum

Plastipak™

Extension

with

luer

PERFORMANCE

YOU

WILL

is

required

the

Simulated

testing

for

periodic

of

every

be

approximately 1 hour.

range,

Set (60

fittings.

LEARN:

to

perform

Use

of

the

inspection.

repair.

with

3cc, Sec,

inch

the

Simulated

and

Performance

360infuser

It

should

Record

0.1

10cc,

microbore

all

Resolution

psig

resolution).

20cc, 30cc,

tubing

CHECKS

Use

Checks.

without

be

data

for

and

set).

and

opening

performed

this

should

the

section.

be

60cc).

as

at

a

3.1.2

1.

Install

2.

Press

3.

Press

4.

Press

+

*

8874

Rev C (10/03)

Unit

batteries.

Power

Power

*

Beep

*

Each

minutes.

*

Each

*

The

*

On

bell

Infuse

Observe

Unit does

Initialization

Do

not

Off

button.

On

button.

is

activated

segment

LED

LCD

bar

some

units,

symbol,

button

double

not

once.

of

LCD

flashes

graph

the

instructions

with

beep.

infuse.

Test

piace a syringe

Observe

bar

in

order

indicates

bell

graph

from

symbol

the

30

appears

pertaining

no

syringe

in

the

following

is

activated

bottom

to

minutes.

within

to

its

in

place.

clamp.

sequence

except

top.

the

ZERO

function

appear

of

for

one

events:

indicating

bar.

(If

on

the

the

unit

rear

ZERO

has

case

Page

the

label.)

17

of

70

Page 24

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

3.1.3

1.

Place

Infusion

*

*

.

Press

+

*

*

3.

Press

*

3.1.4

^

See

Figure

Infusion

an

Observe

On

some

Infuse

Observe

Observe

LCD

Power

Observe

Occlusion

Complete

unfilled

Complete

single

units,

button.

single

green

display

Off

button.

all

displays

Test

10cc

Tone

beep.

observe

beep.

Infuse

activated.

ATTENTION: A new

3-1

for

pressure

Tone

syringe

(On)

bell

LED

and

lights

syringe

meter

Test

in

the

clamp,

button

(if

symbol

blinking.

turn

should

set

up

description.

set

the

time

applicable).

disappears

off.

be

used

in

for

to

ZERO

each

+

30

minutes,

bar.

test.

and

press

the

1.

Place a 3cc

pusher

Do

not

.

Press

.

Set

the

Connect

Extension

.

Advance

the

3-way

meter

.

Close

.

Press

.

When

syringe

block.

push

down

Power

the

Infuse button.

On

delivery

the

pressure

Set

(Cat.

the

pusher

valve

(to

zero

vent

the

system

*

the

Attention

*

the

alarm

*

the

motor

button.

time

(all

the

system).

valve

detects

beeps,

stops

filled

with

on

the

for

10

meter

No

V6512).

toward

air

is

out

and

zero-out

an

LED

and

running.

3.0

cc

syringe

using

minutes.

to

the

syringe

the

clamp

of

the

system)

the

occlusion:

flashes,

of

water

into

position

pusher

block; a loose

through a 3-way

until 2 or 3 drops

and

zero

relative

meter.

in

the

stopcock

of

water

pressure

clamp

mounting

and a B.Braun

appear

is

block

and

is

desired.

at

the

end

applied

to

of

the

Page

18

of

70

8874

Rev C (10/03)

Page 25

SIMULATED

USE

AND

PERFORMANCE

CHECKS

9.

10.

11.

These

Press

ing

reads

events

Power

Repeat

Attention

between

Press

Power

ol

ии

щен

1-9

ЕГЕРЕЕЕЕ!

should

Off

button.

using

LED,

5.0

Off

occur

60cc

syringe

multiple

and

button

when

beeps,

13.2

psig.

and

disconnect

the

pressure

filled

with

and

60

cc

unit

shutdown)

the

unit

reading

of

water.

from

the

Syringe

is

between

The

should

test

20.0

and

occlusion

occur

apparatus.

alarms

when

46.8

(blink-

the

meter

psig.

OOo

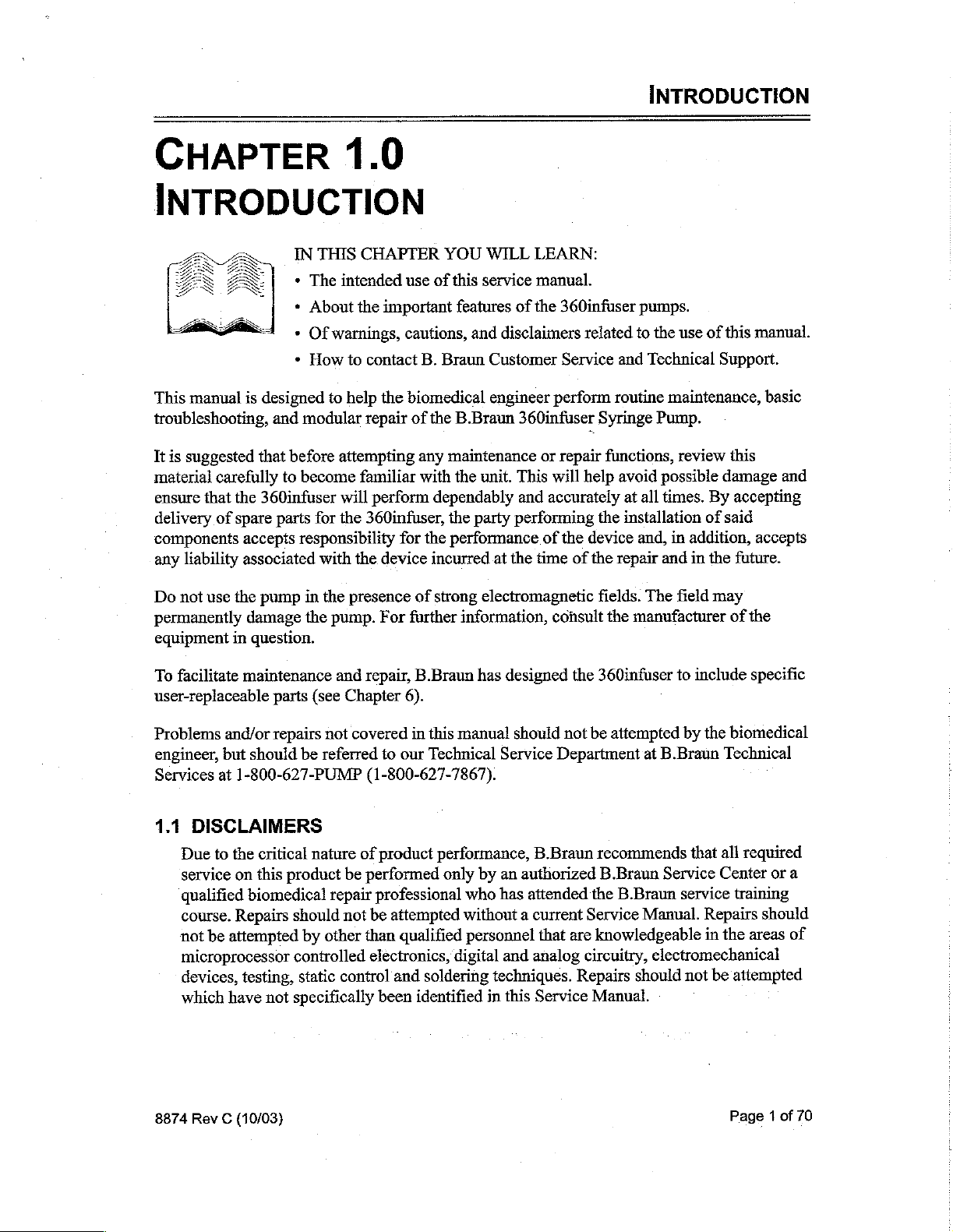

Figure

3-1:Occlusion

<

O

J]

Test,

——

———

Pressure

V6512

Three-Way

Microbore

Transducer

Transducer

Pressure

Meter

Stopcock

Electrical

Meter

Setup

Tubing

Cord

8874

Rev C (10/03)

Page

19

of

70

Page 26

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

3.1.5

Time

Test

3.1.5.1

1.

Insert

clamp.

2.

Press

>

Set

Observe

decrease.

Set

P

Press

MH

Observe

NO

At

Complete

and

part

8.

Press

3.1.5.2

High

Speed

an

empty

Power

delivery

the

the

stopwatch

Infuse

flashing

the

moment

alarm)

10

minutes

of

the

syringe

Power

Low

Speed

60

cc

On

button.

interval

LCD

button

to

bar

to

zero.

and

green

when

the

stopwatch

18

seconds.

tip

Off

button.

syringe

10

minutes

graph

decrease

start

the

LED

the

syringe

as

an

indicator

with

plunger

by

stopwatch

and

downward

bottoms

should

Look

pressing

with one

read

for

the

of

the

extended

at

the

motion

out

between 9 minutes

stopper

syringe

Time

beep

same

(do not

pressing

bottoming

to

60

Set

Down

for

every

time.

of

plunger.

wait

cc

against

into

the

syringe

button.

incremental

for

an

Infusion

42

seconds

the

angled

out.

1.

Insert a new,

clamp.

2.

Press

3.

Set

delivery

*

Observe

increase.

4.

Set

the

5.

Press

6.

Observe

7.

At

the

Complete

and

61

part of

8.

Press

Power

Infuse

On

intervai

the

stopwatch

button

the

flashing

moment

alarm)

minutes

the

syringe

Power

Off

empty

button.

LCD

to

when

the

48

tip

button.

5cc

syringe

to

60

minutes

bar

graph

zero.

and

start

green

LED

the

syringe

stopwatch

seconds.

as

an

indicator

with

by

increase

the

stopwatch

and

bottoms

should

Look

for

plunger

pressing

one

extended

beep

at

the

downward

out

read

between

the

stopper

of

the

syringe

Time

for

every

same

motion

(do

not

pressing

bottoming

to 5 cc

Set

Up

incremental

time.

of

plunger.

wait

58

minutes

into

the

button.

for

an

Infusion

12

against

the

out.

syringe

seconds

angled

Page

20

of

70

8874

Rev C (10/03)

Page 27

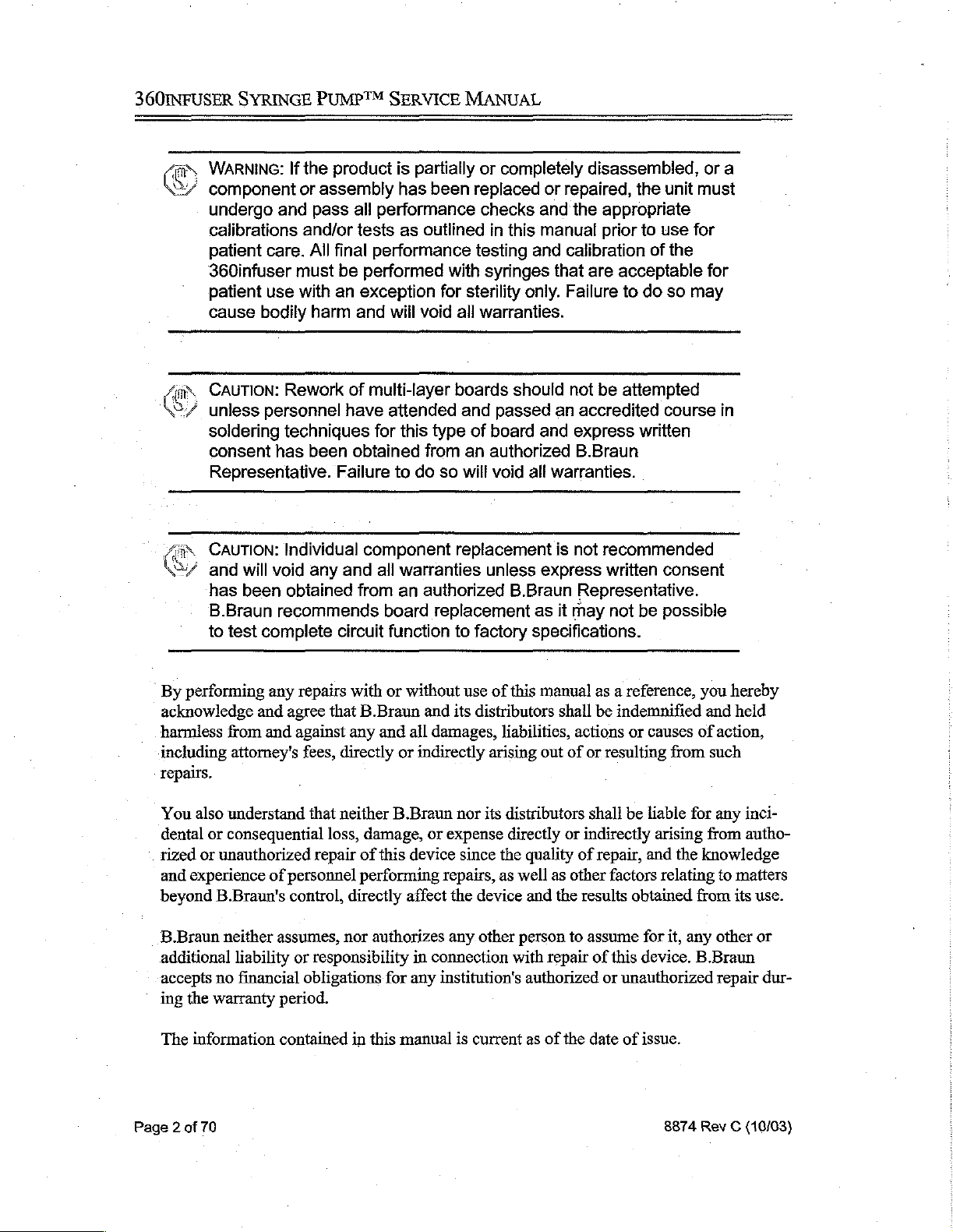

Serial

Number

Tested

Dept./Location

Date

Test

Unit

Infusion

Occlusion - 3

Occlusion - 60

High

Low

By

Initialization

Complete

Speed

Speed

(time

(time

SIMULATED

Tone

сс

ce

test)

test)

Data

mins

mins

Sheet

Pass

USE AND

for

Testing

psi

psi

secs

(9min,42secs

secs

(58min,12secs

PERFORMANCE

360infuser

Fail

(20.0

to

46.8

psi)

(5.0

to

13.2

psi)

to

10min,18secs)

to

61min,48secs)

CHECKS

Comments:

8874

Rev C (10/03)

Page

21

of

70

Page 28

360INFUSER

SYRINGE

PUMP™

This

SERVICE

page

intentionally

MANUAL

left

blank.

Page

22

of

70

8874

Rev C (10/03)

Page 29

CLEANING

&

DISINFECTING

CHAPTER

CLEANING

WW

i

}

Clean

the

pump

following

Once

lint-free

with a soft,

Please

further

recommended

*

Household

+ © Isopropyl

*

Warm

the

infusion

cloth

refer

information.

ZEN

WARNING:

Sy

cleaning.

&

NN

Ml)

Én

)

with a swab

Alcohol

Soapy

pump

to

remove

lint-free

to

the

hospital's

4.0

DISINFECTING

IN

THIS

CHAPTER

+

Recommended

or

soft,

solutions:

Bleach

Water

is

all

cloth.

To

avoid

and

90%

cleaned,

wipe

remaining

housekeeping,

electrical

YOU

cleaning

lint-free

Water

the

cloth

entire

WILL

solutions

LEARN:

and

dampened

pump

twice with

cleaner/disinfectant.

central

shock,

service,

turn

the

procedures.

(not

saturated)

fresh

Thoroughly

or

infection

pump

off

before

with

water

dry

the

control

department

any

of

the

using a soft,

instrument

for

Ge.

CAUTION:

2

autoclave

|

¿Py

CAUTION:

‘©

solutions

abrasive

“ip,

CAUTION:

ペン

Autoclaving

8874

Rev C (10/03)

To

avoid

mechanical

or

immerse

To

avoid

containing

cleaners

Sterilization

is

not

the

mechanical

glutaraldehyde,

on

the

of

recommended.

or

electronic

pump

in

any

damage,

instrument.

the

pump

using

damage,

fluids

or

DO

NOT

ammonium

ethylene

DO

cleaning

use

acetone,

chlorides

oxide (EtO)

NOT

steam

solutions.

or

gas

or

Page

23

of

70

Page 30

360INFUSER

©

SYRINGE

CAUTION:

Do

PUMP™

not

clean

SERVICE

the

pump

MANUAL

using

high-pressure

devices.

This

space

intentionally

left

blank.

Page

24

of

70

8874

Rev C (10/03)

Page 31

TROUBLESHOOTING

CHAPTER

5.0

TROUBLESHOOTING

IN

THIS

CHAPTER

*

The

main

assemblies

*

This

chapter

configuration

designed

has

been

for

replacement

provides

of

to

aid the

identified,

General

detailed

the

360infuser.

bioengineer

Chapter 6 of

and

repair.

troubleshooting

information

The

General

in

pinpointing

this

manual

YOU

WILL

of

the

procedures.

regarding

Troubleshooting

problems

provides

LEARN:

pump

the

information

and

their

location.

mechanical

Guide

and

their

sources.

on

and

electrical

detailed

ordering

in

Once

and

Section

the

5.1

problem

procedures

is

8874.

Rev C (10/03)

Page

25

of

70

Page 32

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

=

5

à

$ a

2

|

o 2

= =

을

È

o

m

3

8

©

B

a

=

8

=

&

g

a

동

5

B E E

¿sz

=

$

E

=

8

о

5

> 5

>

2

E

2

2

=

= 3

5

2

ош

&

Ec

$

5

을

3

o

Assembly

Block

Pusher

@

>

6

©

№

N

N

N

à

>

~

N

NÍ

NN

AN

>

5

Е

È

<

= κ

e

Page

2

3

=

S

8

26

of

70

o

x

8

>

Е

5

<

2

9

a

5 5

5

o

Figure

\

\

à

5-1:

Exploded

View

8 a

a

3

>

E

6

=

5

©

8874

Rev C (10/03)

Page 33

TROUBLESHOOTING

Pin

on

PC

Board

Pin

14

to

Pin

25

Pin

30

Pin

31

Pin

32

Pin

33

Pin2

Pin3

[Pin

35

Pin

36

Pin

37

Pin

38

¡Pin6

Pin

7

Pin

27

Pin

28

Wire

Color

Ribbon

Cable

White/Blue

White/Yellow

White/Green

White/Red

Red

Black

_¡Green

Yellow

Orange

Brown

Red

Red/Black

Orange

White

KEY

|

Connector

Jt

J2

i

"JE

JB

Controls

Switch

Panel

Clamp

Block

Power

Resistor

Strip

Meter

Alarm

Figure

5-2:

PC

Board

8874

Rev C (10/03)

Page

27

of

70

Page 34

360INFUSER

SYRINGE

PUMP™

SERVICE

MANUAL

Figure

5-3:

Electrical

Schematic

Page

28

of

70

8874

Rev C (10/03)

Page 35

360

Infusion

Component

Controller

Side

install

Insulated

(From

to

Pin

TROUBLESHOOTING

cp

Connector - Back

Jumper

Pin

Marked 0 of

32

of

U5)

Wire

LCD

as

Shown

Connector

Side

Figure

Revision - Compoment

Infusion

Controller

LCD

Side

Path

Copper

Cut

in

Location

Shown

Side

of

Figure

5-4:

Board

LCD

install

Wire

Infusion

LCD

Controller

Insulated

in

Location

5-5:

Infusion

Controller,

Jumper

as

Shown

Controller,

Component

LCD

Side

Side

From

Pin 35

of

Socket

8874

Rev C (10/03)

Page

29

of

70

Page 36

360INFUSER

5.1

GENERAL

Problem

On

key

LCD

indicators

sound

Not

ali

One

or

function

LCD

timer

to

30

minutes

Displays

LCD

time

accordance

Tone

does

infusion

No

tone

is

pressed

Multiple

is

pressed

Alarm

starting

sounds

is

pressed,

LCD

indicators

more

LED

does

are

erratic

display

with

not

is

sounded

tones

an

infusion

SYRINGE

TROUBLESHOOTING

light,

not

at

end

Time

sound

sound

within a few

PUMP™

but

nothing

but

tones

light

indicators

automatically

of

system

does

not

move

Set

keys

at

the

end