Avery SNAP Sonic Knife User Manual

Users Manual

Sonic Knife, 1000w

With AVERY DENNISON 500™

AVERY DENNISON

Manual Edition 2.1

2 February 2011

Manual Part Number 571392

This page intentionally left blank

Contents |

|

Warranty Information |

5 |

Limited Warranty....................................................................................................................... |

5 |

Operation |

7 |

Theory of Operation................................................................................................................... |

7 |

Safety Issues / Warnings............................................................................................................ |

7 |

Unpacking and Re-Packing Instructions.................................................................................... |

8 |

Location of Sonic Knife............................................................................................................. |

9 |

Unit Specification ...................................................................................................................... |

9 |

Ultra Sonic Power Supply........................................................................................................ |

10 |

Connecting The Power Supply................................................................................................. |

11 |

Operating The Power Supply................................................................................................... |

12 |

Installation |

14 |

Attaching Sonic Knife – AVERY DENNISON 500................................................................ |

14 |

Attaching Sonic Knife – Stacker.............................................................................................. |

15 |

Cable Connections to 500 Printer ............................................................................................ |

16 |

Connecting the Sonic Knife to the Printer and Ultrasonic Power Supply................................ |

17 |

Ultra Sonic Horn "Stack"......................................................................................................... |

17 |

Loading the Machine ............................................................................................................... |

18 |

Machine Maintenance |

19 |

Replacing the Knife Blade....................................................................................................... |

19 |

Leveling the Knife Blade......................................................................................................... |

20 |

Knife Pressure Adjust .............................................................................................................. |

21 |

Proximity Switch Adjustment .................................................................................................. |

23 |

Horn Replacement / Adjustment.............................................................................................. |

24 |

Exit Conveyor.......................................................................................................................... |

25 |

Machine Maintenance.............................................................................................................. |

26 |

Cleaning Infeed Rollers ........................................................................................................... |

27 |

................................................................................................................................................. |

27 |

Knife Spring Replacement....................................................................................................... |

28 |

Troubleshooting....................................................................................................................... |

31 |

Appendix A |

32 |

Manufactures of Hearing Protectors ........................................................................................ |

32 |

Appendix B |

33 |

Label / Machine Speed ............................................................................................................ |

33 |

Installation Instructions for Stacker Option 580028 |

34 |

Installation Procedure .............................................................................................................. |

34 |

Users Manual Sonic Knife w/500 |

• 3 |

Electrical Schematic |

36 |

115V / 230V Schematic........................................................................................................... |

37 |

500 Downstacker Schematic.................................................................................................... |

38 |

Assembly Drawings Mechanical |

39 |

Cover Assembly....................................................................................................................... |

40 |

Machine Parts List ................................................................................................................... |

41 |

Drive Assembly........................................................................................................................ |

42 |

Cut Assembly........................................................................................................................... |

44 |

Cut Assembly Parts List........................................................................................................... |

45 |

Infeed Conveyor Assembly...................................................................................................... |

46 |

Infeed Conveyor Assembly Parts List...................................................................................... |

47 |

H Frame Assembly................................................................................................................... |

48 |

H Frame Assembly Parts List................................................................................................... |

49 |

Sonic Knife for AVERY DENNISON 500 Assembly ............................................................. |

50 |

Sonic Knife for AVERY DENNISON 500 Parts List.............................................................. |

51 |

Exit Conveyor Assembly.......................................................................................................... |

52 |

Exit Conveyor Parts List.......................................................................................................... |

53 |

Users Manual Sonic Knife w/500 |

• 4 |

Warranty Information

Warranty Policy

Avery Dennison Retail Information Systems, In-Plant Printing Solutions provides the following warranty policy.

Scope

Warranties against defects from workmanship for equipment and parts manufactured and sold from Sayre, PA. Includes time and material except as otherwise noted below.

Time

−New equipment and parts: 6 months

−Refurbished equipment and parts: 90 days

−Warranty period starts when equipment ships from selling location.

General Conditions

Avery Dennison extends warranty coverage under the following conditions.

−Equipment and parts will perform within published specifications. Promised or implied statements by any Avery Dennison employee or representative will not be deemed to vary the terms of the warranty.

−Equipment and parts must be installed and operated according to recommended procedures and operating conditions.

−Consumable elements are not covered. Consumable elements are those that show normal wear from typical equipment usage including, without limitation, printheads, knives, rollers in contact with the web, and sonic units. Avery Dennison reserves the right to determine which elements are defined as “consumable.”

−No customer maintenance may be performed except as directed by qualified Avery Dennison personnel.

−Equipment and parts damaged by negligence or abuse are not covered.

−Avery Dennison US reserves the right in its sole discretion to incorporate any modifications or improvements in the machine system and machine specifications which it considers necessary but does not assume any obligation to make said changes in equipment previously sold.

Equipment Purchased In US and Shipped In US

−Avery Dennison US covers warranty for equipment and parts installed and operated in the Americas (United States, Canada, Mexico, Central America, Caribbean Region, and South America excluding Brazil).

−Outside the US, the local Avery Dennison office is responsible for equipment and parts warranty. Customers must ensure coverage during machine purchase.

Users Manual Sonic Knife w/500 |

Warranty Information • 5 |

−Equipment purchased and exported to regions outside local Avery Dennison office coverage are not covered by warranty. The purchasing agent must acquire a service contract from the Avery Dennison office where the equipment or parts are operated to ensure machine coverage. For example, if an agent purchases a printer in the US, exports to Brazil, and then needs warranty coverage, Avery Dennison Brazil has no obligation to provide warranty coverage. The agent must purchase services from Avery Dennison Brazil.

THE WARRANTIES PROVIDED HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY OR PERFORMANCE, WHETHER EXPRESS OR IMPLIED. EXCEPT THE WARRANTY OF TITLE, IN NO EVENT SHALL AVERY DENNISON BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF AVERY DENNISON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Service

When ordering machines and supplies in the U.S.A., reference all correspondence to the address below.

AVERY DENNISON Corporation

One Wilcox Street

Sayre, PA 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For spare parts, requests for service or technical support, contact

AVERY DENNISON Corporation

One Wilcox Street

Sayre, PA 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For parts and service in other countries, please contact your local AVERY

DENNISON supplier.

.

Users Manual Sonic Knife w/500 |

Warranty Information • 6 |

Operation

Theory of Operation

The Sonic Knife was designed to work in-line with a variety of AVERY DENNISON printers to cut and stack pre-printed Polyester tapes using Ultra-sonic vibrations to produce a fray resistant label. This provides the label with a cut edge that is as soft and smooth as the original label tape.

Safety Issues / Warnings

This machine has some pinch points and warm surfaces. All of these areas have been well guarded and it is recommended that the safety features of this machine are never altered or defeated.

Since ultrasonics is high frequency sound, some noise will be produced as it makes its cut. It is recommended that people in the immediate area wear ear protection. (See appendix “A” for a list of manufacturers of hearing protection.)

Warning:

High voltage is present in the power supply. Never attempt to operate the unit with the cover off.

To prevent the possibility of electrical shock, make sure the power supply is properly grounded.

Keep hands from under horn. High pressure and vibrations can cause injury to hands and fingers.

Ultrasonic vibrations may be within the audible frequency range when cutting. If this occurs, use ear protection to prevent possible injury.

Do not allow the ultrasonically activated horn to touch a metal base or metal fixture.

Do not press the “TEST” switch when the stack assembly is removed from the equipment.

Users Manual Sonic Knife w/500 |

Operation • 7 |

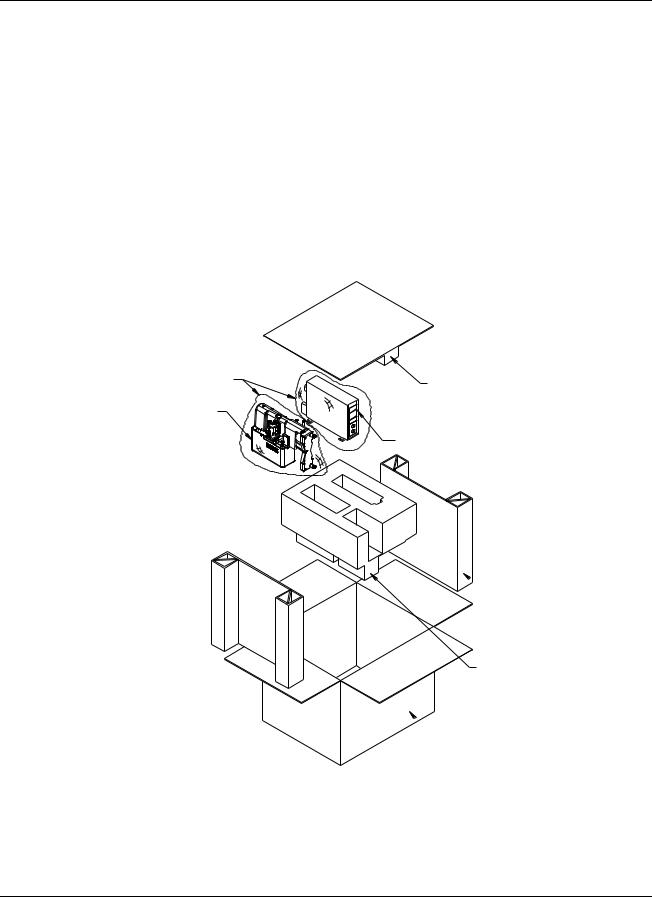

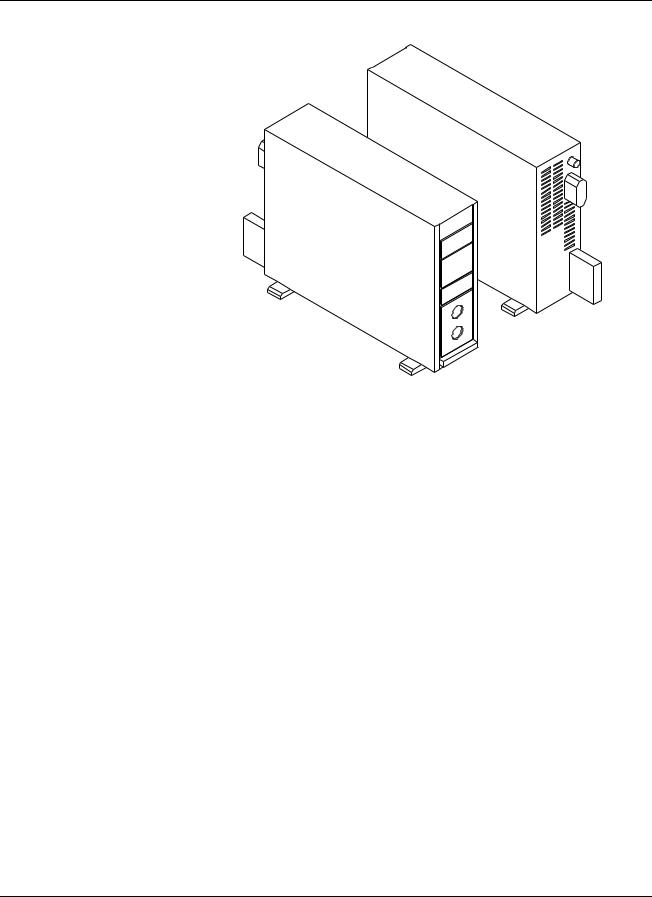

Unpacking and Re-Packing Instructions

Unpacking

1:Remove binding straps from the carton and discard.

2:Break tape seal and open carton.

3:Remove Top Foam and set aside.

4:Lift Sonic Knife and Sonic power supply directly up, out of the foam pocket.

5:Remove Poly Bags.

6:Set the Sonic Knife on its back cover (the same position as it sits in the carton).

7:Remove the tool bag, machine manual and power cord.

POLY BAG |

TOP FOAM |

|

|

SONIC KNIFE |

|

|

SONIC POWER SUPPLY |

SIDE FILLER SUPPORT

SIDE FILLER SUPPORT

BOTTOM FOAM

CARTON

CARTON

Repacking

Follow procedure in reverse order. It is not required to band the package if straps are not available.

Users Manual Sonic Knife w/500 |

Operation • 8 |

Location of Sonic Knife

The Sonic Knife weighs approximately 25 Lbs. (12Kg). A table of sufficient quality and strength should be used to support the sonic knife once it is mounted to a suitable printer.

The Sonic Knife should be located in an area that the ultrasonic noise emitted from the cutting operation will not affect others. AVERY DENNISON has taken many steps to keep the Sonic Knife noise to the lowest level. The Sonic Knife is not recommended for an office environment.

The power source of the Sonic Knife should be a dedicated line. The first sign that the Sonic Knife is not being supplied with sufficient power is the ultrasonics will stop cutting, but the rest of the Sonic Knife will appear fully functional.

Unit Specification

Label Size |

Max: - 2.00" (51mm) web x up to 8" (203 mm) feed |

|||

|

Min: - 5/8" (16mm) web x 1.2" (30.5mm) feed – Also listed in Appendix B |

|||

|

|

|

|

|

|

|

Print Speed |

Minimum Length |

|

|

|

|

|

|

|

|

3 IPS |

1.2” (30.5 mm) |

|

|

|

|

|

|

|

|

4 IPS |

1.6” (40.7mm) |

|

|

|

|

|

|

|

|

4.5 IPS |

1.8” (45.8mm) |

|

|

|

|

|

|

|

|

5 IPS |

2” (50.8mm) |

|

|

|

|

|

|

|

|

6 IPS |

2.4” (61mm) |

|

|

|

|

|

|

|

|

7 IPS |

2.8” (71.2mm) |

|

|

|

|

|

|

Justification |

Material must be centered over ultrasonic horn. |

|||

|

|

|||

Sense Mark |

The sense mark is not required – does not register to a sense mark – The printer controls the cut position |

|||

|

|

|||

Speed |

Controlled by speed of printer – See chart in Appendix B. |

|||

|

|

|||

Stock |

Polyester woven edge fabric and AVERY DENNISON So-Soft® Products |

|||

|

|

|

|

|

Interface |

Cabling to printers and to Sonics |

|

|

|

|

|

|||

Dimensions |

16.0" (406mm) high x 5 1/2" (138mm) wide x 14" (356mm) deep |

|||

|

|

|

|

|

Weight |

25 Lbs. (12Kg). |

|

|

|

|

|

|

||

Electrical |

90-132 / 180-265 VAC 50-60Hz 10/5Amp |

- factory set |

||

|

|

|

|

|

Temperature |

41°F (5°C) to 104°F (40°C) |

|

|

|

|

|

|

|

|

Humidity |

5% to 90% non-condensing |

|

|

|

|

|

|

|

|

Options |

- Flag cutting – (Controlled by printer) |

|

|

|

|

- Spare Parts Kit not required |

|

|

|

|

- International Hardware Kit |

|

|

|

|

|

|

|

|

The Sonic Knife is a modular design, which can be added to the AVERY DENNISON fabric printers - including the 500, 545, 636, 656 and 676 thermal transfer printers.

Users Manual Sonic Knife w/500 |

Operation • 9 |

Ultra Sonic Power Supply

Caution

Only qualified technicians should service the power supply.

The ultrasonic attachment is made up of several components. They are the power supply, the horn assembly and the connecting cable. In addition there is a knife assembly with a changeable tool steel blade.

The power supply should be located next to the Sonic Knife. This unit generates electrical pulses at 35 KHz to the converter. The power supply must be turned on and off separately from the main printer. The power supply contains no ON/OFF switch. Power on/off is accomplished by either plugging/unplugging the power supply. The front display has several setting adjustments and status indicators.

LINE CORD

Connects the power supply to line power.

Fuse

Refer to the nameplate on the ultrasonic power supply for replacement fuse information.

RF Cable to Sonic Converter

Interface cable from the power supply to the converter.

Users Manual Sonic Knife w/500 |

Operation • 10 |

Custom Trigger

The interface cable from the Sonic Knife is used to turn the Sonics off and on. The sonic unit is on all the time the stacker is running.

Air Cooling

The Sonic Horn does not require special cooling. However, to maintain optimum efficiency, keep the horn stack area and the back cover cooling vents free from debris and clutter.

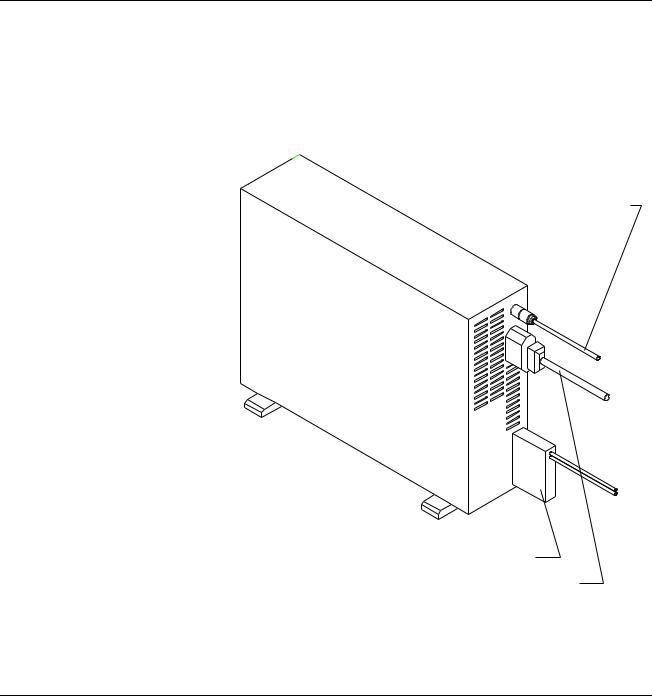

Connecting The Power Supply

Connections

Connect the 37-pin Connector and the Coaxial Converter Cable from Sonic Knife as shown in the illustration below. Secure AC outlet cord to suitable outlet. NOTE: There is no AC power switch on the Power Supply. It will be on whenever the power cable is plugged in.

COAXIAL CONVERTER

CABLE

37 PIN CONNECTOR

AC POWER CABLE

Users Manual Sonic Knife w/500 |

Operation • 11 |

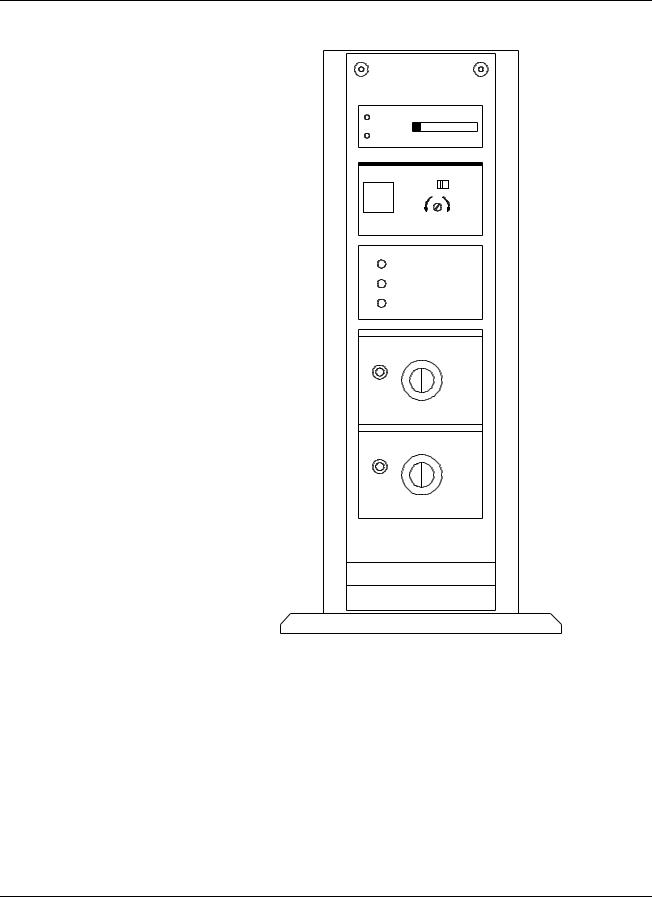

Operating The Power Supply

TELESONIC |

|||

ULTRASONICS |

|||

TEST |

2 |

10 |

20 |

LOAD |

10 |

50 |

100 |

|

AUTO |

MAIN |

|

TEST |

|

|

|

|

TUNING |

||

|

OVERLOAD |

||

|

OVERTEMP |

||

|

POWER |

|

|

CUTTING-CONTROL |

|||

|

1 |

|

|

|

0 |

1 |

|

|

|

2 |

|

|

|

3 |

|

100 |

10 |

4 |

|

9 8 7 6 5 |

|

||

|

MS |

|

|

|

US-TIME |

|

|

|

100 |

|

|

|

0 |

1 |

|

|

|

2 |

|

|

|

3 |

|

200 |

10 |

4 |

|

9 8 7 6 5 |

|

||

|

MS |

|

|

SG3510 CT |

|||

The Ultrasonic Power Supply is pre-programmed for the correct settings at the factory. The following instructions describe how to check and change these settings.

IMPORTANT: FOR PROPER OPERATION, USE THE FACTORY SETTINGS

AT ALL TIMES. CHANGING THESE SETTINGS MAY RENDER THE

SONIC KNIFE INOPERABLE, REDUCE THE QUALITY OF THE CUT

AND/OR REDUCE THE RELIABILITY OF THE SONIC KNIFE.

Users Manual Sonic Knife w/500 |

Operation • 12 |

Settings

The Power Supply is set properly at the factory. Any changes to the factory setting may result in improper operation. If necessary, the factory settings may be restored as follows:

AUTO/MAN switch |

AUTO |

CUTTING CONTROL |

0 |

US-TIME |

0 |

Users Manual Sonic Knife w/500 |

Operation • 13 |

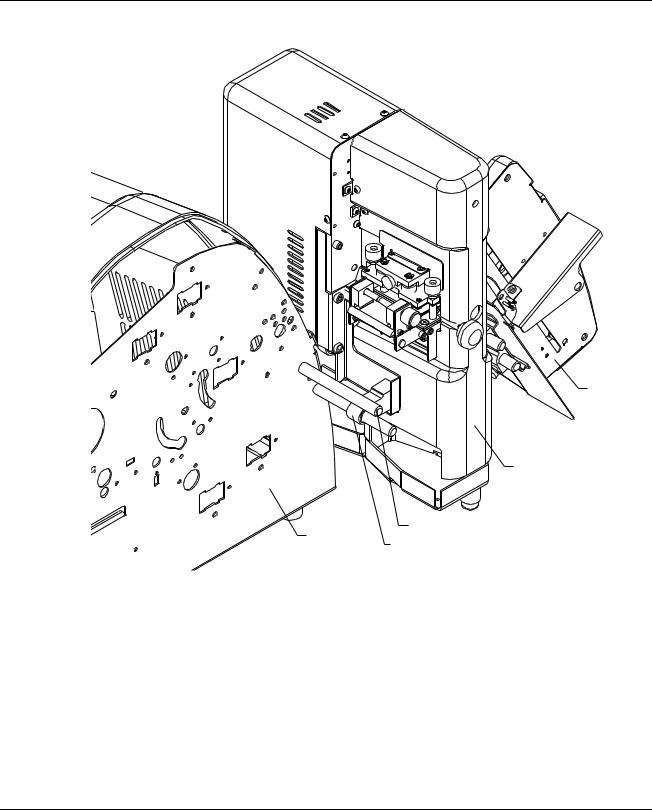

Installation

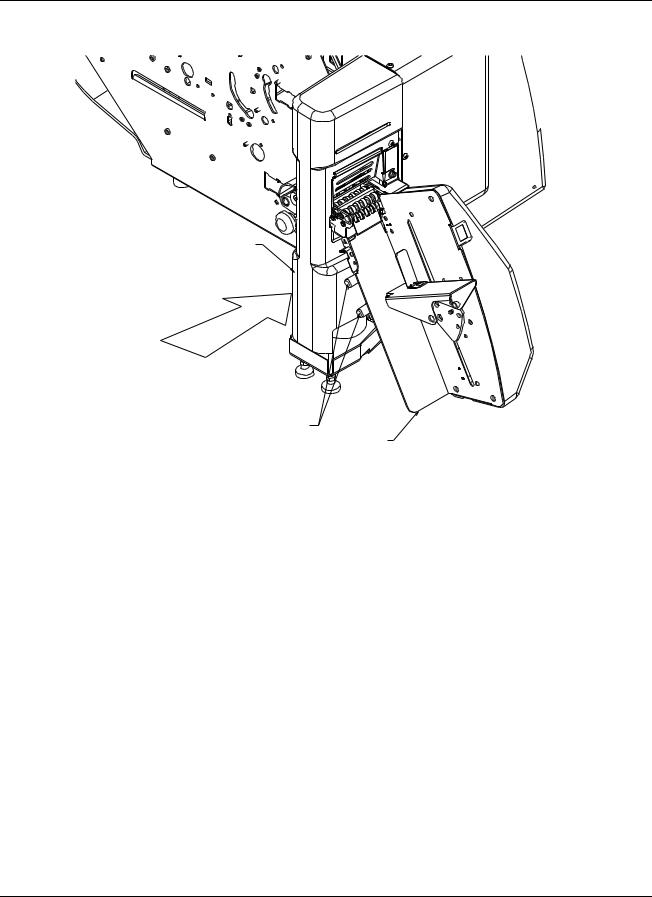

Attaching Sonic Knife – AVERY DENNISON 500

STACKER

SONIC KNIFE

PAXAR 500

PAXAR 500

POST BRACKET

FIGURE 1

There are two exit posts on the AVERY DENNISON 500. To attach Sonic Knife to the AVERY DENNISON 500, slide the Sonic Knife onto the bottom post, using the post bracket. Adjust the Sonic Knife forward/backward so the web coming from the printer is centered on the horn face. Connect cables per electrical schematic.

Users Manual Sonic Knife w/500 |

Installation • 14 |

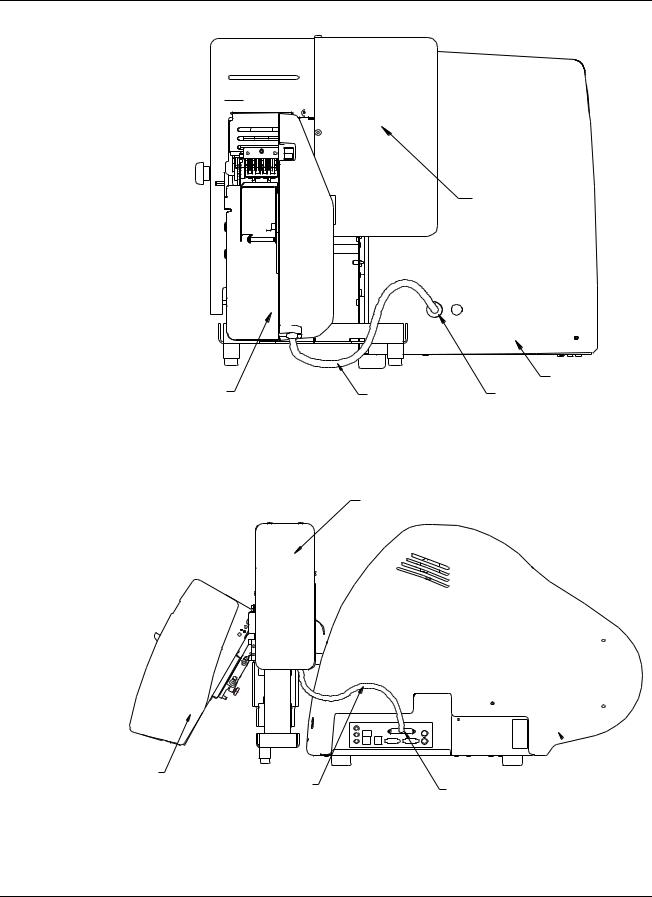

Attaching Sonic Knife – Stacker

SONIC KNIFE

POST

STACKER

FIGURE 2

There are two posts on the outfeed end of the Sonic Knife. Slide the stacker onto the posts. Adjust the stacker backward/forward and will pivot so the cut labels stack uniformly. Connect cable per electrical schematic.

Users Manual Sonic Knife w/500 |

Installation • 15 |

Cable Connections to 500 Printer

SONIC KNIFE

|

|

PAXAR 500 |

STACKER |

STACKER CABLE |

CONNECTOR LOCATION |

|

FIGURE 3

SONIC KNIFE

PAXAR 500

PAXAR 500

STACKER

PRINTER CABLE |

CONNECTOR LOCATION |

|

FIGURE 4

Users Manual Sonic Knife w/500 |

Installation • 16 |

Loading...

Loading...