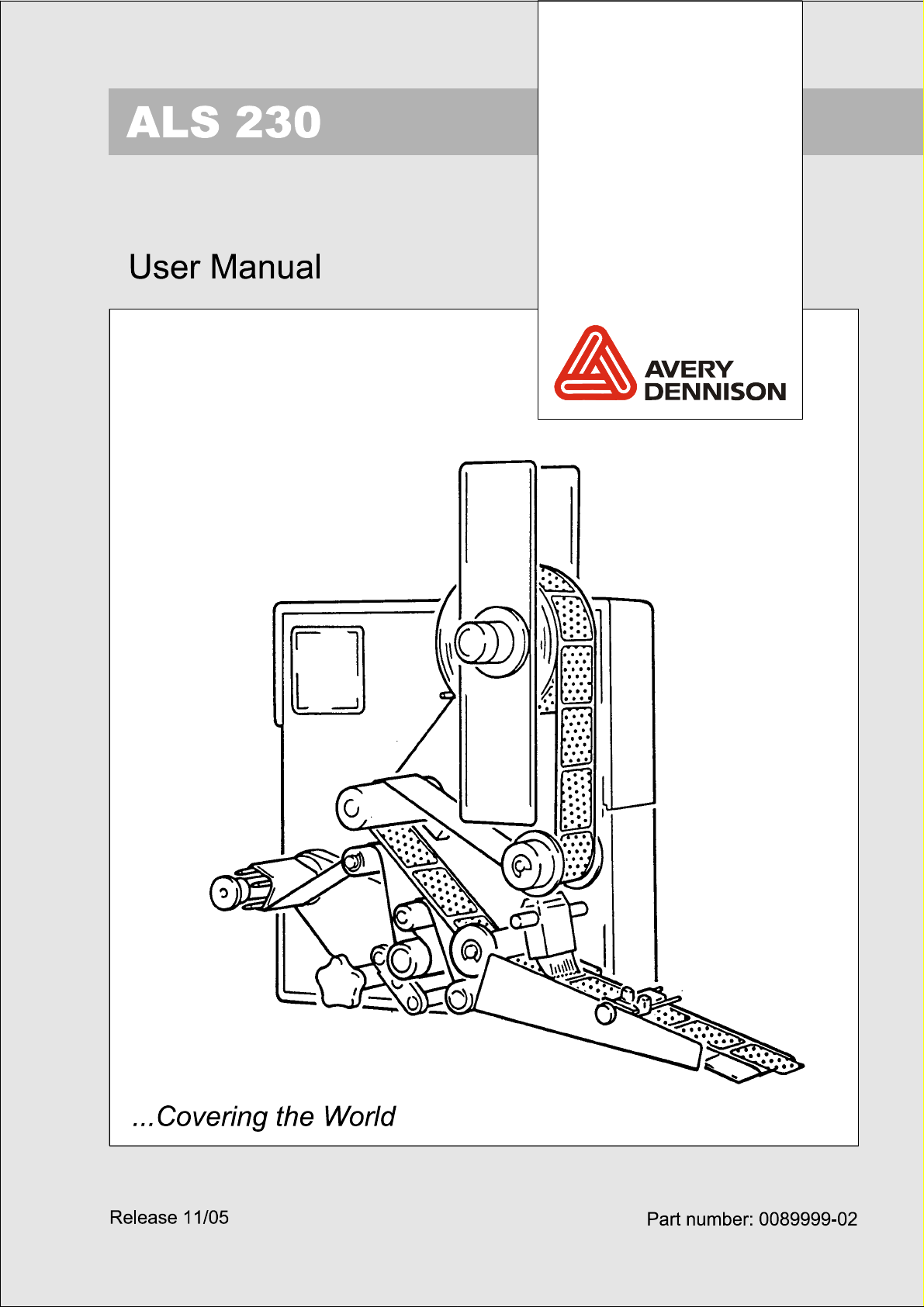

Avery ALS 230 User Manual

Operators Manual

ALS 230

Release 11/05 Page i Contents

Contents

1. Important Notes........................................................................................................4

1.1 Overview.......................................................................................................................................4

1.1.1 Manufacturer......................................................................................................................4

1.1.2 Copyright............................................................................................................................ 4

1.2 Safety............................................................................................................................................ 5

1.2.1 General Safety Notes ........................................................................................................ 5

1.2.2 Warning Notes in the Text .................................................................................................5

1.2.3 Operator’s duty of care...................................................................................................... 6

1.2.4 Concrete security regulations and symbols used..............................................................7

1.2.5 Security measures during normal operation...................................................................... 8

1.2.6 Security measures during maintenance and repairs......................................................... 8

1.2.7 Work on the electrical equipment...................................................................................... 9

1.2.8 Work on pneumatic equipment..........................................................................................9

1.2.9 Observe environmental regulations................................................................................... 9

2. Description .............................................................................................................11

2.1 Mechanics ..................................................................................................................................11

2.2 Operator panel............................................................................................................................13

2.3 Plug board ..................................................................................................................................15

2.4 Electronic....................................................................................................................................15

3. Preparing the machine...........................................................................................17

1.1 Installation.................................................................................................................................... 17

1.1.1 Unpacking of the unit......................................................................................................... 17

1.1.2 Connection of the machine................................................................................................ 17

1.1.3 General setting.................................................................................................................. 17

1.2 Prepare dispensing ......................................................................................................................18

1.2.1 Insert material....................................................................................................................18

1.2.2 Define label data................................................................................................................18

3.1.1 Capacitive label sensor....................................................................................................19

3.2 Label guide................................................................................................................................. 20

3.3 Adjust dispense function............................................................................................................. 21

3.3.1 Stop position.................................................................................................................... 21

3.3.2 Fixed dispensing speed................................................................................................... 21

3.3.3 Automatic dispensing speed (APSF)............................................................................... 22

3.3.4 Label position on the product........................................................................................... 22

3.3.5 Product data bank............................................................................................................22

Operators Manual

ALS 230

Release 11/05 Page ii Contents

4. Operation ...............................................................................................................23

4.1 Safety recommendation..............................................................................................................23

4.2 Inserting label material................................................................................................................24

4.3 Initialise new label material.........................................................................................................25

4.4 Control of dispense unit ..............................................................................................................26

4.4.1 Dispenser Menu selection................................................................................................26

4.4.2 Missing label function and web breaks ............................................................................26

4.4.3 Display and data input......................................................................................................26

4.5 Maintenance ...............................................................................................................................30

5. Menu structure....................................................................................................... 31

5.1 Standard menu ...........................................................................................................................33

5.2 Extended standard menu............................................................................................................35

5.3 Product menu..............................................................................................................................41

6. Configuration..........................................................................................................43

6.1 Handling the menu......................................................................................................................44

6.2 Menu functions............................................................................................................................45

7. Serial interface....................................................................................................... 51

7.1 Data of the serial interface..........................................................................................................51

7.2 Interface commands ...................................................................................................................52

Bit definition in error flag.............................................................................................................54

Bit definition in warning flag........................................................................................................54

8. Connections and signals........................................................................................55

8.1 Output signals.............................................................................................................................55

8.1.1 Error and warning output..................................................................................................55

8.1.2 Printer output....................................................................................................................55

8.1.3 OD-Control output............................................................................................................55

8.1.4 Ready output....................................................................................................................55

8.2 Applicator modes ........................................................................................................................56

8.2.1 Signals for direct dispense...............................................................................................56

8.2.2 Control signals for the ASA applicator .............................................................................57

8.2.3 Signals for the EP applicator............................................................................................58

8.2.4 Applicator connector ........................................................................................................59

8.3 Input signals................................................................................................................................60

8.3.1 Product sensor.................................................................................................................61

8.3.2 OD Control sensor ...........................................................................................................62

8.3.3 APSF sensor....................................................................................................................63

8.3.4 Control signals .................................................................................................................64

Operators Manual

ALS 230

Release 11/05 Page iii Contents

8.4 EMI ............................................................................................................................................. 66

8.5 Electronic diagrams.................................................................................................................... 67

9. Errors and warnings...............................................................................................71

9.1 Dispenser error messages .........................................................................................................71

9.2 Dispenser warnings....................................................................................................................73

10. Technical Specification...........................................................................................75

10.1 Technical Information.................................................................................................................75

10.2 Application specification.............................................................................................................76

10.3 APSF- Sensor Specification (Optional function) ........................................................................ 76

10.4 Performance............................................................................................................................... 77

10.4.1 Labels per minute in relation to different label pitches.................................................... 77

10.4.2 Dispensing speed reached while dispensing certain label length...................................78

11. Adjustment.............................................................................................................81

12. Index ......................................................................................................................83

Operators Manual

ALS 230

Release 11/05 Page 4 Important Notes

1. Important Notes

1.1 Overview

The AVERY ALS 230 is a fully automatic labeller. Handling is very easy and can be learned

with a minimum of training. For operation, only a few adjustments are necessary. The machine

is controlled by a microprocessor and because of its programmable functions, it can be used in

many applications.

Except for cleaning the rollers and the label sensor there is no periodical maintenance

necessary. This manual should help you to operate the ALS 230. In chapter 2 the machine is

described and many expressions are explained. For normal operating chapters 3 and 4 are

important. All other chapters give additional details of the machine.

For technical questions, particularly in case of problems, your local service organisation will be

pleased to help you.

Note: This manual applies to ALS 230s equipped with a software version from 5.x

onwards.

1.1.1 Manufacturer

This machine was built by:

AVERY Maschinen GmbH

Ohmstraße 3

85386 Eching

Germany

Tel. 08165-(0)925-0

FAX 08165-(0)-3143

1.1.2 Copyright

© 2005 Avery Maschinen GmbH. All rights reserved. No part of this work covered by Avery 's

copyright may be reproduced or copied in any form or by any means (graphic, electronic or

mechanical, including photocopying, recording, recording taping, or information and retrieval

systems) without the written permission of Avery Maschinen GmbH. Avery also reserves all

other rights, including the right to make changes or corrections at any time without notice.

Avery make no representation or warranties about the accuracy, currency, completeness or

suitability of the information provided herein and will not be held liable for any use of this

information for any purpose. It is provided "as is" without express or implied warranty.

AVERY and all other related brands and product names are trademarks of Avery Dennison

Corporation. No licence to use or reproduce any of these trademarks or other trademarks of

Operators Manual

ALS 230

Release 11/05 Page 5 Important Notes

Avery Dennison Corporation is given or implied. All other brand and product names are the

trademark of their respective owners.

1.2 Safety

1.2.1 General Safety Notes

In order to avoid any risk of injury due to squeezing between the fixed dispensing edge and the

passing product, it may be necessary to add a protection cover in front of the dispensing edge.

The necessity for this has to be decided on case by case.

See also regulation EN 292 and 294.

1.2.2 Warning Notes in the Text

In this description, two types of notes can be found:

y Warning note – indicates a possible risque of injury for the user. Ignoring the warning can

lead to injuries or material damages.

Example:

CAUTION! - The machine is connected to mains. Only authorised

personnel may open the cover. Operation without this cover is not

allowed.

y Special advice regarding the carrying out – please notice!

Example:

Note: Please take note of the given notes and advices. They serve your safety

as well as the preservation of value of the machine.

Operators Manual

ALS 230

Release 11/05 Page 6 Important Notes

1.2.3 Operator’s duty of care

The machine was designed and constructed taking into account a

hazard analysis and after careful selection of the harmonised

standards to be observed, as well as other technical specifications.

Thus, it corresponds to the state of the art and allows the highest

possible degree of safety during operation.

The safety of the machine, however, can only be put into operating

practice if all measures required for the safety are taken. It falls within

the operator‘s duty of care to plan these measures and to verify their

implementation.

Above all, the operator must make sure that

• the machine is only used in accordance with its purpose (cf. the

section “Use in accordance with the purpose” in the chapter

“Specification”)

• the machine is only operated in faultless serviceable condition

and that especially the safety devices are regularly checked with

respect to their serviceability

• the required personal protective clothing and equipment for

operating, maintenance and repair personnel are available and

are being used

• a legible and complete copy of the operating instructions is always

available at the place of operation of the machine

• only personnel which is qualified and authorised for it will operate,

service, and repair the machine

• this personnel is instructed in all relevant issues of occupational

safety and environmental protection on a regular basis and is

familiar with the operating instructions and especially the safety

instructions contained therein

• all safety and warning instructions on the machine itself are not

removed and are legible

Operators Manual

ALS 230

Release 11/05 Page 7 Important Notes

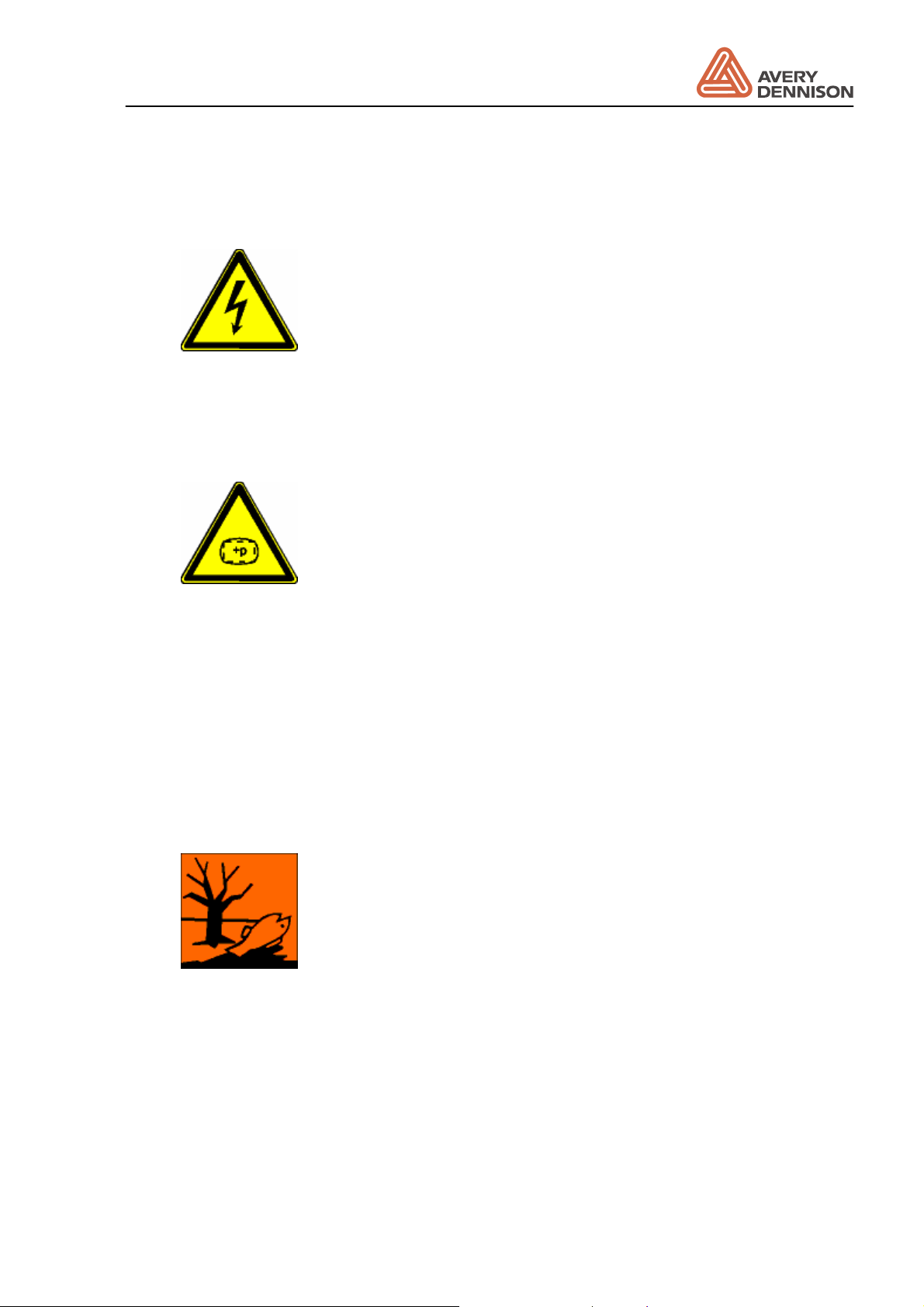

1.2.4 Concrete security regulations and symbols used

In the following operating instructions, concrete security regulations are indicated in order to

point out the remaining risks which cannot be avoided when operating the machine. These

remaining risks include danger to

• Persons

• Product and machine

• Environment

The symbols used in the operating instructions are above all intended to point out the security

regulations!

This symbol indicates that especially danger to persons has to be

expected.

(Lethal danger, danger of injury)

This symbol indicates that especially danger to the machine, material,

and the environment has to be expected.

The most important aim of the security regulations is to avoid injuries to a person.

• Whenever there is a warning triangle with the caption “Danger” in front of a security

regulation, dangers to the machine, materials, and the environment are not excluded.

• Whenever there is a warning triangle with the caption “Warning” in front of a security

regulation, a danger to persons, however, must not be expected.

The symbol used in each case, however, cannot replace the text of the security instruction.

Thus, it is necessary to always read the text completely!

This symbol does not indicate security regulations, but provides

information for a better understanding of the machine’s operations.

Operators Manual

ALS 230

Release 11/05 Page 8 Important Notes

1.2.5 Security measures during normal operation

The machine may only be operated by trained and authorised

persons who are familiar with the operating instructions and are able

to work in accordance with it!

• Before starting the machine, check and make sure that

• only authorised personnel is staying in the operating area of the

machine

• Nobody can get hurt when the machine is started!

• Before every production start-up, the machine must be checked

for visible damage and it must be made sure that it is only

operated in faultless working condition! Any defects found must

be immediately reported to the supervisor!

Before every production start-up, all materials/objects that are not

necessary for production must be removed from the operating area of

the machine!

Before every production start-up, it must be checked and made sure

that all safety devices function in a correct manner!

1.2.6 Security measures during maintenance and repairs

Inspection and maintenance periods laid down in the operating

instructions must be observed!

Observe maintenance and repair instructions in these operating

instructions, which refer to individual components!

Before performing maintenance and repair work, the access to the

operating area of the machine must be prohibited for unauthorised

personnel! Post or put up a sign, which indicates the maintenance, or

repair work!

Before performing maintenance and repair work, turn off the main

switch for the electric power supply and secure it with a padlock!. The

key to this padlock must be in the hands of the person who performs

the maintenance or repair work!

When exchanging heavy machine parts, use only suitable and

faultless load suspension devices and stopping devices!

Operators Manual

ALS 230

Release 11/05 Page 9 Important Notes

1.2.7 Work on the electrical equipment

Repair work on the electrical equipment of the machine may only be

performed by a trained electrician!

Electrical equipment must be checked on a regular basis!

Loose connections must be fixed again!

Exchange damaged lines/cables immediately!

Always keep the switch cabinet closed! Access is only allowed to

authorised personnel with keys/tools!

Never wash down switch cabinets and other housings of electrical

equipment with a water hose for cleaning!

1.2.8 Work on pneumatic equipment

Maintenance and repair work on pneumatic equipment may only be

performed by specially trained personnel!

Before starting maintenance and repair work, depressurise the

pneumatic equipment of the machine!

By way of precautionary maintenance, exchange hose pipes on a

regular basis, even if there is no damage to be detected!

(Observe the manufacturers’ instructions!)

Before setting into operation after maintenance or repair works

• check if loosened screwed connections are tight

• make sure that removed coverings are re-installed

After termination of maintenance and repair work and before re-

starting the production, make sure that

• all materials, tools, and other equipment required for maintenance

and repair work are removed from the operating area of the plant

• all safety devices of the plant function in a faultless manner!

1.2.9 Observe environmental regulations

During any and all work on and with the machine, the statutory duties

concerning prevention of waste and the proper waste

disposal/recycling regulations must be observed.

Especially in the case of installation, repair and maintenance work,

substances which are hazardous for the water, such as detergents

containing dissolvents, may not pollute the soil or get into the sewage

system!

These substances must be stored, transported, collected, and

disposed of in appropriate containers!

Operators Manual

ALS 230

Release 11/05 Page 11 Description

2. Description

CAUTION! - The machine is connected to mains. Only authorised

personnel may open the cover. Operation without this cover is not

allowed.

This chapter explains the structure and the function of the labeller. The expressions used are

explained here.

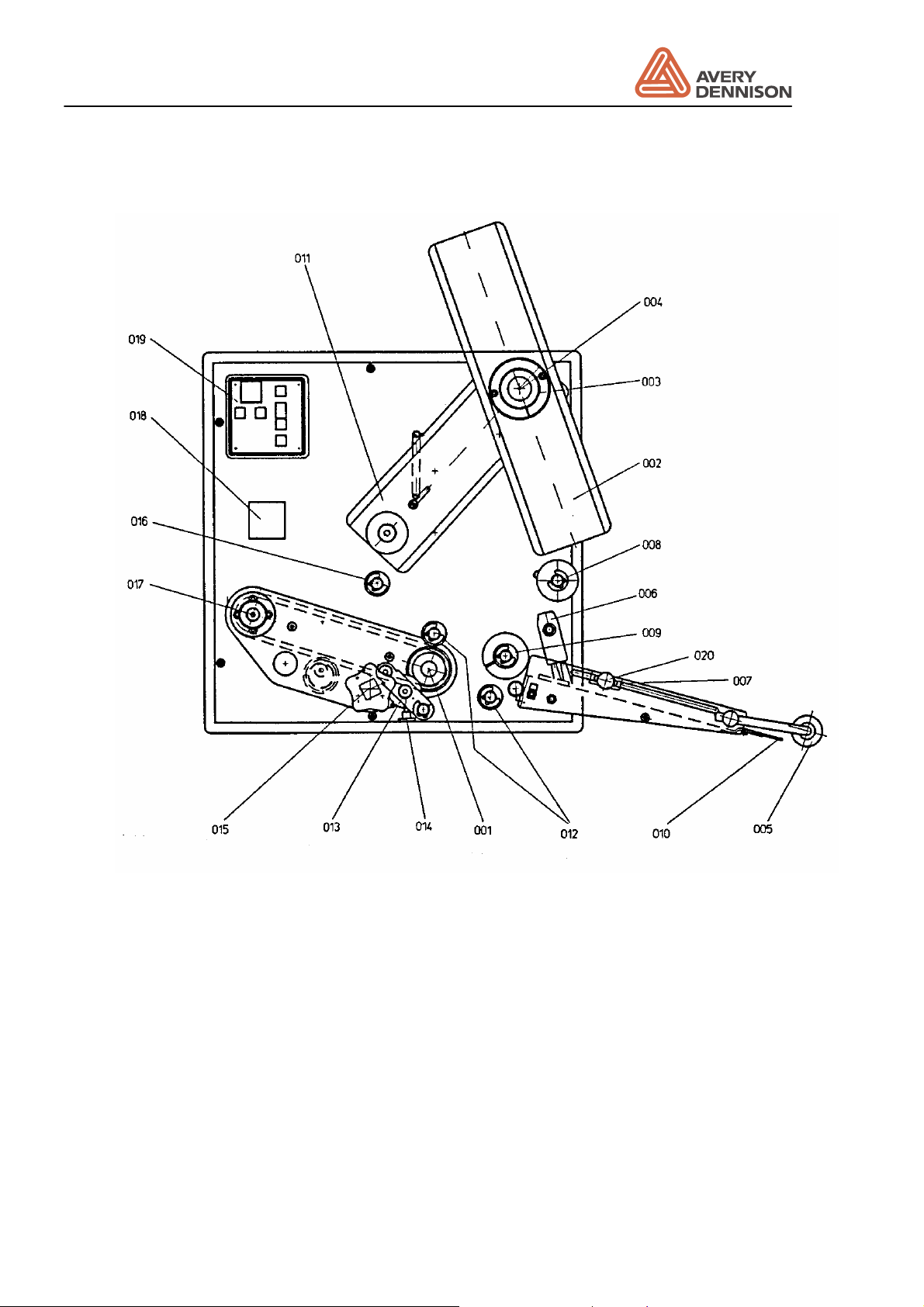

2.1 Mechanics

The machine is available in a right- or a left-hand version. The expression right or left is related

to the direction of product transport. In the following, a right hand machine is explained. For the

left-hand version all explanations have to be mirrored. The dispensing mechanics of the

machine are shown below.

The label material is unwound from roller (003). The maximum diameter of the label roll is 300

mm. The maximum width is 100 mm. The material roll is guided by two removable plate’s (002).

The guide plate in front has to be pressed against the label roll. Behind the cap (004) of unwind

mandrel (003) an adjustment screw for the brake is located. The unwind brake avoids after run

of the label roll when the label drive stops.

Note: For labels longer than 100 mm and in "side labelling applications" it is

recommended to use the optional available kit dancer arm controlled unwind brake

.

This device avoids uncontrolled after run of label material. The brake should not be

fixed too tight, otherwise the motor may stall or the material web gets broken.

The dancer arm (011) keeps the material tight and the acceleration forces low. The deviator

roller (008) makes sure that the material is guided correctly. The material is guided to the

dispensing edge via the deviator roller (009).

The brush (006) keeps the material tight without disturbing the movement. At the dispensing

edge (010) the label sensor (007) is mounted. The label sensor detects the gaps between

labels. The label sensor comprises of a light source and a light receiver. The sensitivity can be

adjusted by the operators panel.

Operators Manual

ALS 230

Release 11/05 Page 12 Description

Figure 1 Dispensing mechanics

At the dispensing edge (010) the label is separated from the backing paper. By means of a soft

(005) roller the label is applied on to the product.

Roller (012) makes sure that the material is always guided properly around the dispensing

edge. Drive roller (001) keeps the transport speed of the material constant.

Deviator rollers (012) guide the backing material around the drive roller (001). The pressure

mechanics (013) press the backing paper against the drive roller (001).

With the handle (015) you may open and close the pressure mechanics (013) . When inserting

the material the pressure roller has to be opened.

Operators Manual

ALS 230

Release 11/05 Page 13 Description

Dispensing is only possible when the handle (015) is in the closed position. Via the deviator

roller (016) the backing paper is guided to the rewind mandrel (017). The cone between the 4

pins can be pulled out to allow the reward backing paper to be removed.

Except for the drive roller (001) and the material brush (006) the labeller has no wearing parts.

The operator panel (019) is described in the next chapter.

A threading diagram is affixed to the front of the machine, which shows how the label material

should be threaded through the machine.

Screw (014) secures the position of the pressure roller (013) in a lateral direction. In order to

achieve a reliable run of the label web position, adjust the roller to the centre of the label web.

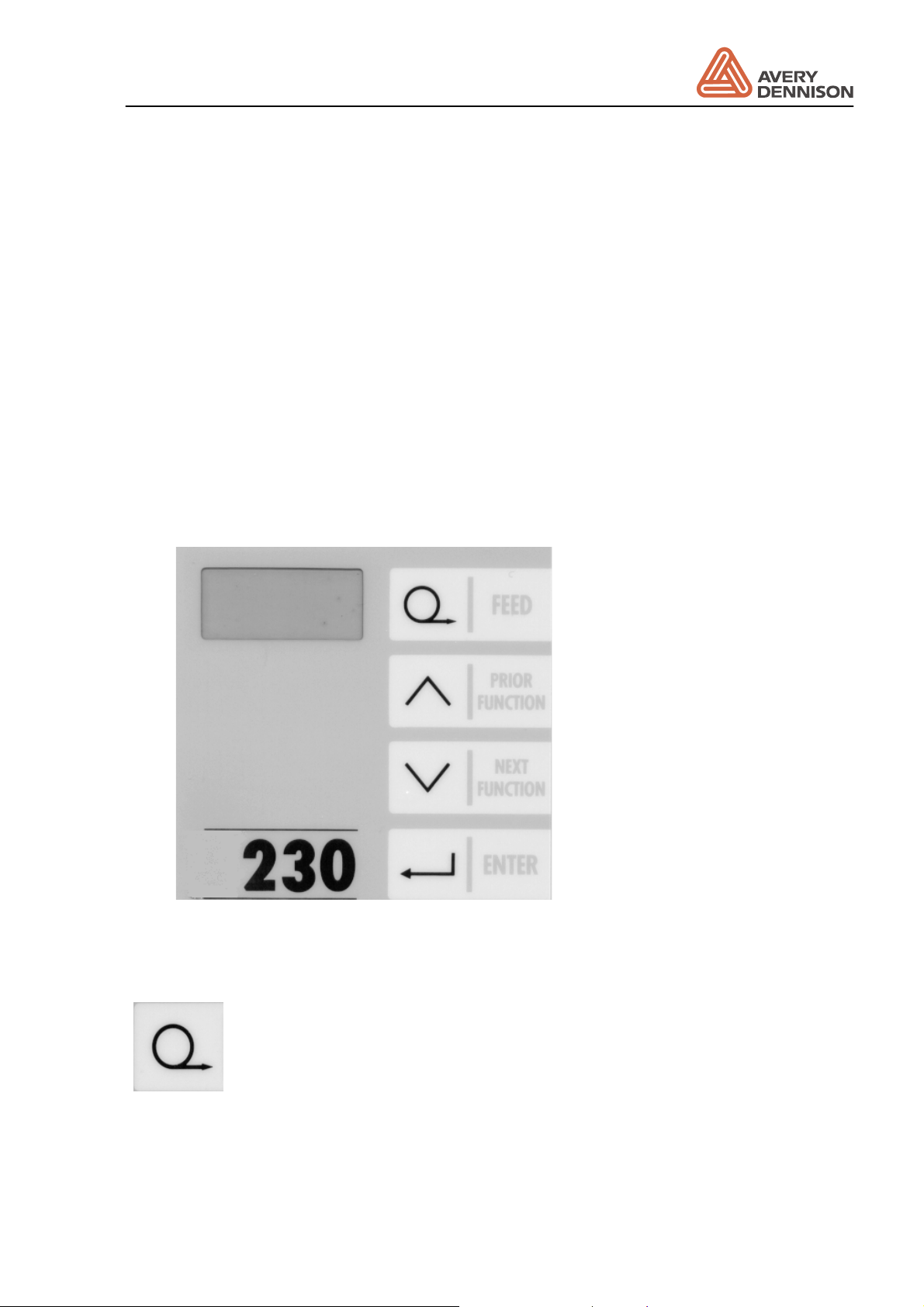

2.2 Operator panel

The operator panel (Figure 2) of the 230 is shown below, it has a 4 digit LED display and 4

membrane keys.

Figure 2 Operator panel

The 4 membrane keys have following functions:

FEED: By pressing this key one label will be dispensed. When the machine

displays INIT pressing this key will start initialisation of the machine. An

initialisation has to be made each time a new material is used. If the FEED key is

pressed and held as the machine is turned on then the machine carries out an

automatic initialisation of the label parameters "CONT" and "LPIT".

Operators Manual

ALS 230

Release 11/05 Page 14 Description

PRIOR: This key moves up the menu (prior function) or increases the value of a

parameter. If the up arrow key is pressed and held as the machine is turned on

the product menu is selected.

NEXT: This key moves down the menu (next function) or decreases the value of

a parameter. If the down arrow key is pressed and held as the machine is turned

on the standard menu is selected.

ENTER: This key is used to enter or exit a menu point or to cancel a warning or

error message.

When the keys have different meanings, it will be explained in the relevant menu description.

Operators Manual

ALS 230

Release 11/05 Page 15 Description

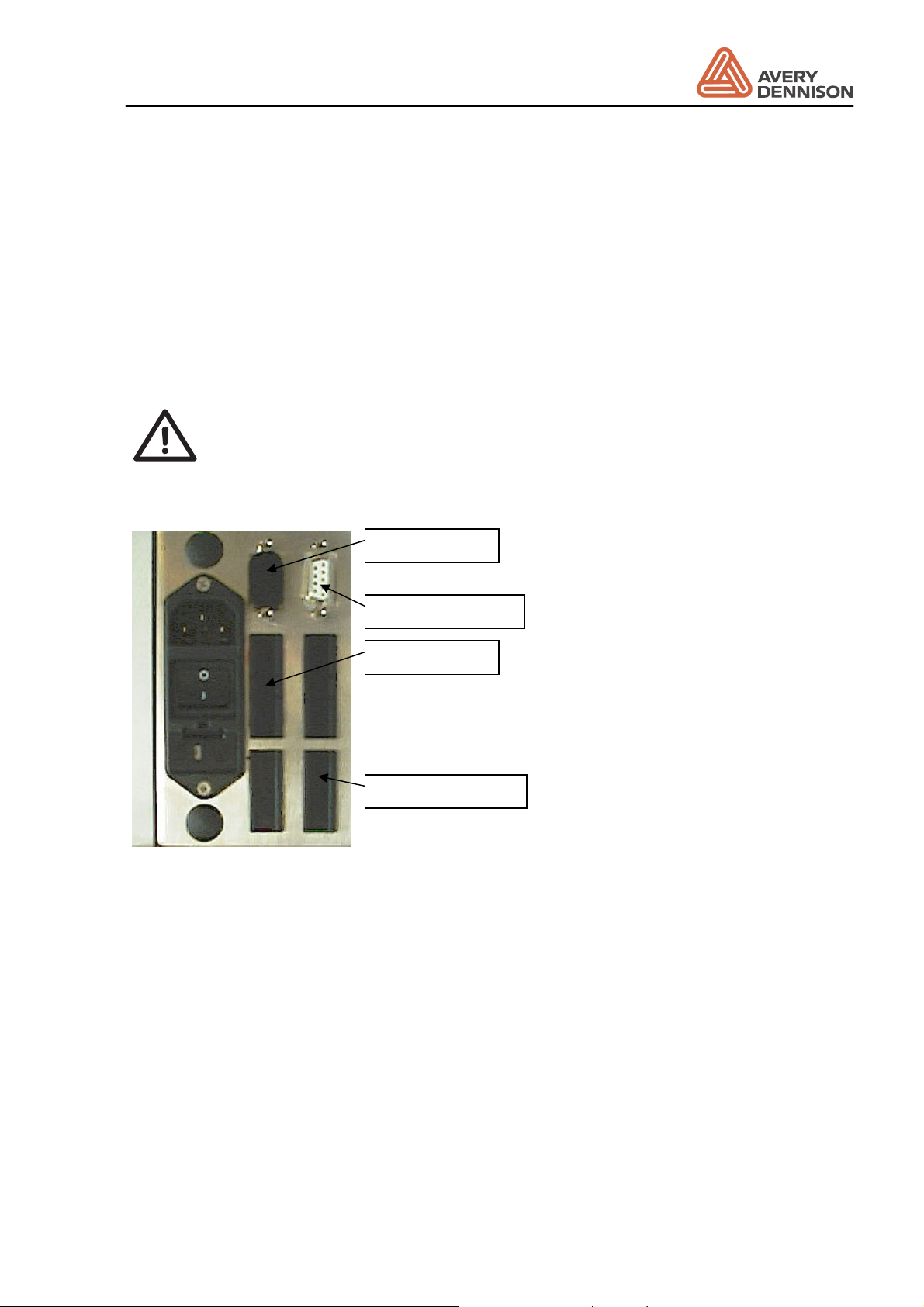

2.3 Plug board

The plug board is shown in Figure 3. Beside the mains switch and the mains cable socket there

are some more holes for optional functions. Standard execution in this machine is one I/O plug

prepared for the product sensor. The connection of the other plugs is described in chapter

Connections.

If you use the optional connections, it is strongly recommended to do this by means of the

optional available SUB-D connectors. This ensures best EMI stability of the machine.

CAUTION! - The fuse holder setting you have to select according to your local

main voltage (100, 120, 200 or 230 V). You carry this out by taking off the fuse

holder and position the fuse holder insert accordingly.

Figure 3 Plug board

2.4 Electronic

As standard the complete electronic is integrated in the machine. For special requirements

(water protection e.g.) a machine version the electronic is housed in a separate cabinet is

available.

Product sensor

APSF-Sensor

Applicator

PLC control

Operators Manual

ALS 230

Release 11/05 Page 16 Description

Operators Manual

ALS 230

Release 11/05 Page 17 Preparing the machine

3. Preparing the machine

In this chapter you will learn how to install and adjust the labeller. After this step has been

completed you will be ready to learn how the labeller's parameters can be adjusted to suit your

particular production requirements.

1.1 Installation

1.1.1 Unpacking of the unit

• For removing the unit off the box, don’t hold the machine on the dispensing edge to prevent

disadjustment off the machine.

• For mounting the machine, a complete system of holding tools is available. Ask your

representative.

• Take care that the machine is safe and stable mounted.

• There are rotating parts on the machine. Do the necessary actions to prevent that anybody

can be caught from these parts.

1.1.2 Connection of the machine

Before connecting the machine to the mains, check the correct setting of the line voltage. For

the connection of sensor, applicators e.g. see the chapter connections. Fix all cables to prevent

accidents and damaging of cables. Have also a look to the EMI chapter for proper machine

operation.

For checking of correct operation of sensors, applicators use the check functions SCHK, I_CH

and O_CH.

1.1.3 General setting

Normally the setting is done, but before operation check and note the general dispenser

configuration: dispenser direction, machine type, applicator mode, and APSF function.

Operators Manual

ALS 230

Release 11/05 Page 18 Preparing the machine

1.2 Prepare dispensing

1.2.1 Insert material

Insert your label material in the machine to follow the instructions in the chapter Operation /

Threading.

1.2.2 Define label data

For correct dispenser operation, you have to tell the machine the length of the label and adjust

the label sensor. Normally this is done automatically. For this follow the instructions in chapter

Operation / Initialise material.

There are some reasons the automatic initialisation is not possible:

1. Using another then the standard optical label sensor

2. Label material with a low contrast ratio between label and backing paper

3. Labels with holes inside the label

In this case, you have to set one or both of the parameter manually.

Activate the extended standard menu to do the settings by:

y Pressing both keys NEXT and PRIOR simultaneously

Display: CODE

y Password CODE entering:

1 time pressing the key PRIOR FUNCTION

2 times pressing the key NEXT FUNCTION

3 times pressing the key ENTER

Display: LPIT

y Setting the label length

Enter the LPIT function by pressing ENTER. Measure the distance from one label edge to

the edge of the next label. Enter the value in mm by using the function keys. Press ENTER

to leave the function. See also the information below.

y Change the setting of the label sensor

If another label sensor then the Wenglor type will be used, call the CONT function and set

the value to any manual value (e.g. M006.).

If the contrast ratio is low, follow the instructions to adjust manually contrast.

y To store the setting permanent leaves the menu with the QUIT function. If you power off the

machine without quit all modification are lost.

y By pressing the key FEED one label can be dispensed if you are in the parameter selection.

Operators Manual

ALS 230

Release 11/05 Page 19 Preparing the machine

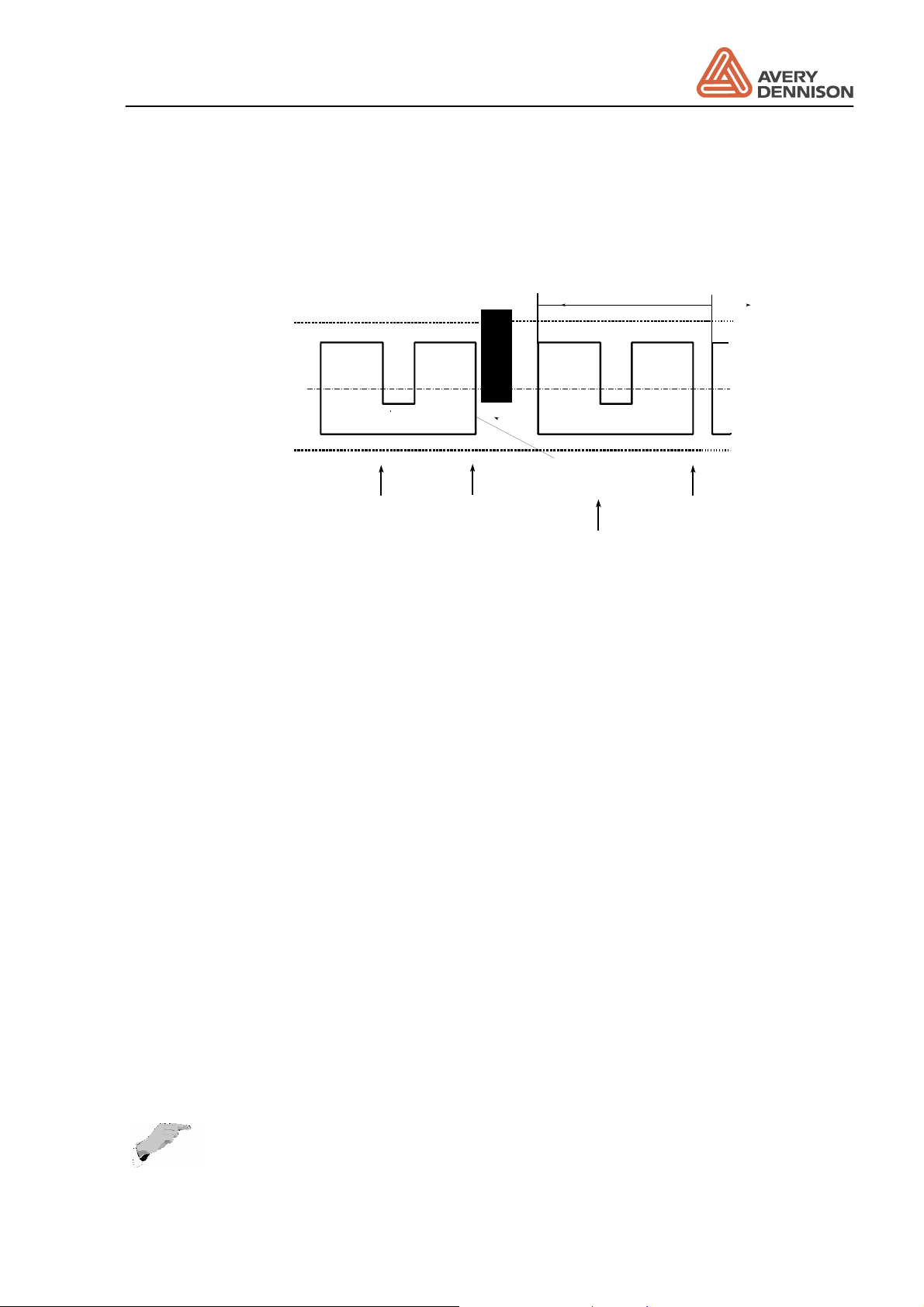

Setting LPIT manually

To initialise labels with cut outs such as the one shown below - the "LPIT" parameter should be

used to enter the label pitch of the label web.

Sensor signals

Label sensor

LPIT

real leading

edge of label

Figure 4 Definition of LPIT

All other label edges seen by the label sensor will be ignored until the distance adjusted in the

"LPIT" parameter has been fed through the label sensor.

Manual adjustment of the CONT parameter

y Remove a label from the backing paper and slide it inside the sensor.

y Reduce the value with the PRIOR key until the LED switched on.

y Press the key NEXT until the LED switched off. If there are marks an the backing paper do

the measurement on this position.

y Note the value GAP xxx

y Slide the backing paper including label inside the sensor. Use the lightest position on the

label for the adjustment.

y Increase with the NEXT key the value until LED lights again. Note the second value GAP

yyy

y Calculate the contrast value by the formula (xxx + yyy) / 2 and set it.

y Manual adjustment is completed.

With a difference of less than 20 an operation with this kind of sensor is not possible

(sometimes two or more labels are dispensed).

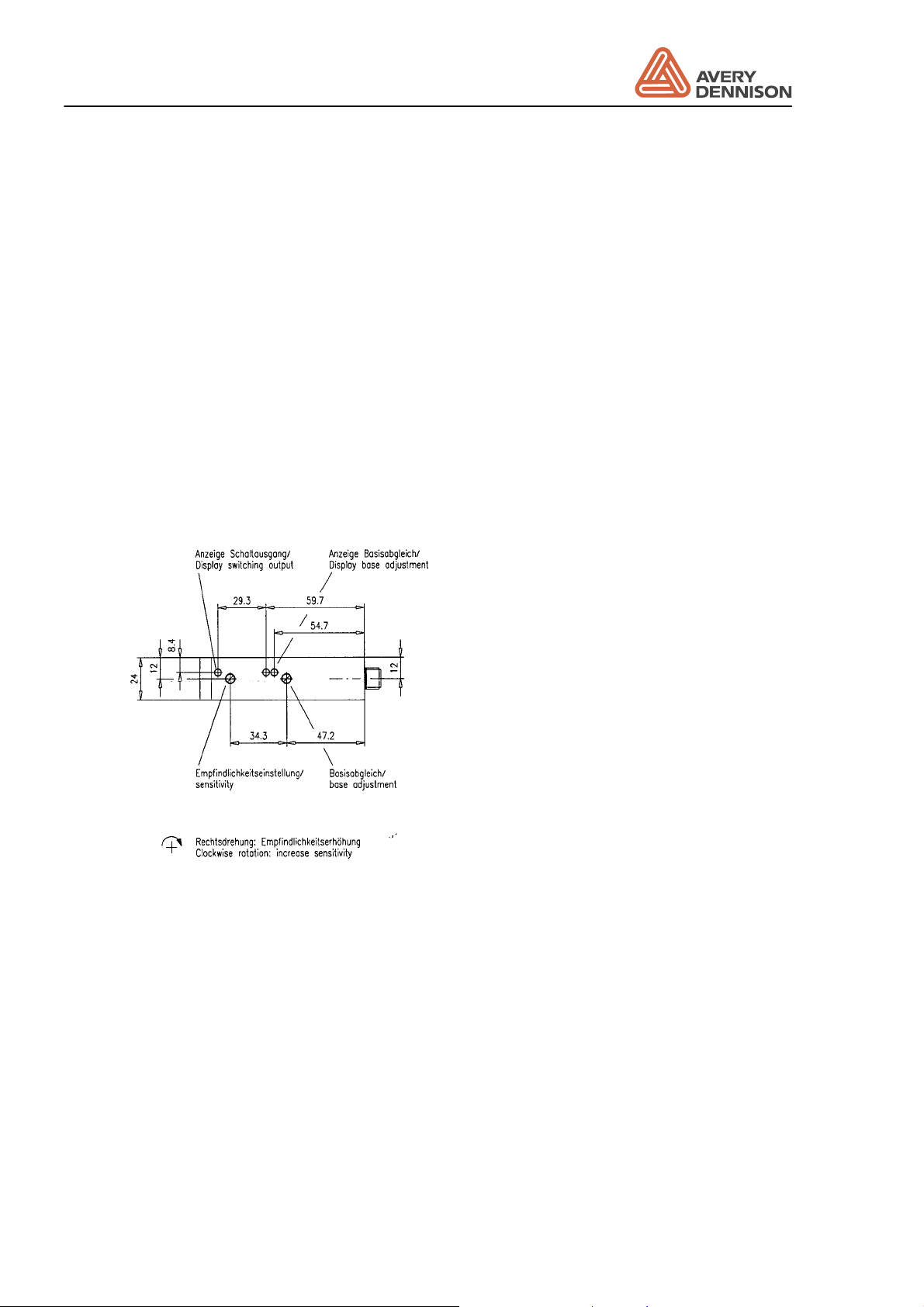

3.1.1 Capacitive label sensor

For transparent labels the standard photo label sensor doesn’t work. In this case, use a

mechanic or a capacitive label sensor.

Note: For correct automatic initialisation, the CONT parameter has to be set to a

manual value, if you using not the standard photo sensor.

Operators Manual

ALS 230

Release 11/05 Page 20 Preparing the machine

A mechanical sensor is limited in the speed. The bounce at the label edges produces wrong

signals.

There is optional a capacitive label sensor available (Leuze GK14/24L).

Adjustment of the sensor is carried out as follows (Figure 5):

1. Set sensitivity to maximum by turning the Potentiometer clockwise. Then rotate ½ turn

anticlockwise.

2. Remove label material out of sensor.

3. Perform base adjustment, that both LED “base adjustment” have the same brightness.

4. Put label with backing paper inside the sensor. Doing this, the LED “switch output” and the

left LED “base adjustment” are switched off. With backing paper only in the sensor both

LED are switched on. If the LED are lightning with label inside the sensor, increase

sensitivity in ¼ turn steps by rotating the sensitivity clockwise.

5. Check the adjustment over the complete length of label.

Carry out the above adjustment after mounting, cleaning or increasing sensitivity.

Figure 5 Capacitive sensor

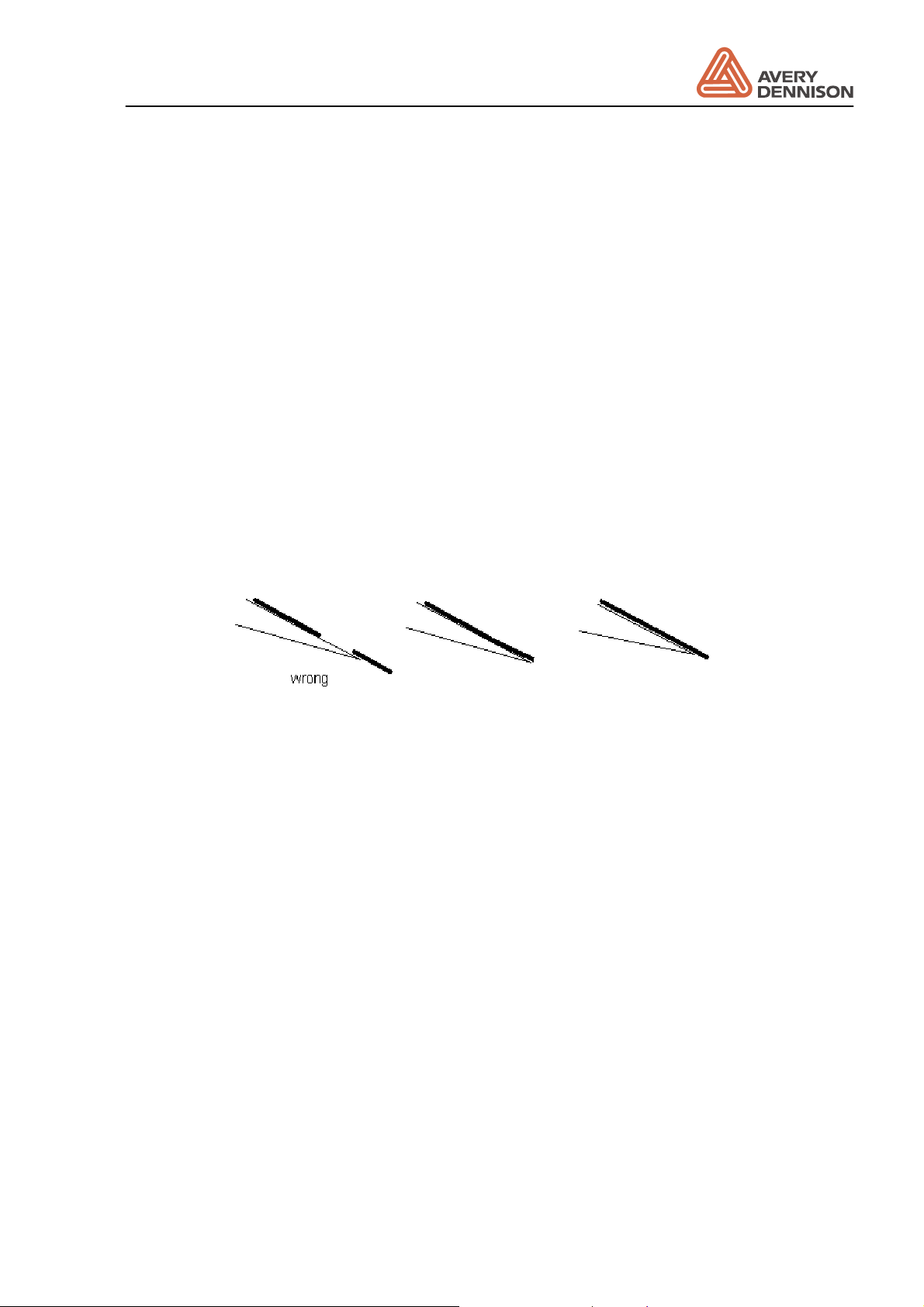

3.2 Label guide

On some of the axles, they’re guiding clamps. Adjust the clamps near the machine so all have

the same distance to the front plate (31.5mm). The outer clamps should be mounted that the

guide but not bend the label material.

The front of the V-dispensing edge has a rot, which can be adjusted for straighten the material

guiding. Spend several labels by pressing the dispenser FEED key. If the material guiding is

running out of the guiding way, adjust the rot by loosing two screws at the dispensing edge.

Operators Manual

ALS 230

Release 11/05 Page 21 Preparing the machine

With a L-dispensing the adjustment is done by move the tail sheaves behind the dispensing

edge.

3.3 Adjust dispense function

For an operation without any trouble and high label accuracy, tree adjustments are required:

• Label position on the dispensing edge: stop position

• Dispense speed

• Label position on the product

The adjustment should be done in the same order, because parameter like the stop position

depends on the setting of the stop position and the dispensing speed.

3.3.1 Stop position

The first step is to adjust the stop position. This is the basic adjustment of the dispense

process. Also in case of problems with the machine check if the stop position is okay.

Figure 6 Stop position

The stop position should be adjusted so that the label stops at the dispensing edge up to 3 mm

behind.

For a correct operation of the automatic label compensation, they will compensate a missing

label on the web, first the distance between label sensor and dispensing edge has to be

defined. Do this by calling the DIST function in the configuration menu. Check the setting by

removing a label before the label sensor from the web. Give a start signal to the machine by

triggering the start sensor (not the FEED key) and see if the compensation is done on the right

position. Do the fine adjustment with the STOD function.

3.3.2 Fixed dispensing speed

The second step is to adjust the dispense speed. If an APSF sensor is used see 3.3.3.

If an applicator is used, then the dispense speed has no influence to the dispense process.

Continue with 3.3.4.

Set POS to the distance between start sensor and dispensing edge. If installed remove the

roller to press the label onto the product. Now try to dispenser one product. If the label has

wrinkles reduce the speed VELO. If the product peels out the label, so the stop position of the

next label is different to the last position increase the speed. Normally your dispense speed

should be a little bit higher than your product speed.

Operators Manual

ALS 230

Release 11/05 Page 22 Preparing the machine

3.3.3 Automatic dispensing speed (APSF)

With a connected rotary encoder, the dispensing speed follows the measured product speed.

To adjust the speed use the EGRA function located in the extended standard menu. The

measured speed will be displayed in the VELO function. Do the adjustment in the same way

described for fixed speed.

3.3.4 Label position on the product

At least adjust the position of the label on the product with the POS function or with the STAD

function, if an applicator is in use.

3.3.5 Product data bank

Save your setting in one of the product data banks. If different products and / or labels are in

use up to nine different combinations could be stored. Define and store the different product

data. The select the product data bank mode by holding the PRIOR key during power on.

Switch back to normal mode by holding the NEXT key.

Operators Manual

ALS 230

Release 11/05 Page 23 Operation

4. Operation

This chapter describes the operation of the machine.

4.1 Safety recommendation

CAUTION!

y Before connections to the mains check the correct voltage selection.

y Use only original spare parts for service.

y Open of the cover is only allowed authorised personal.

y Handling of the machine is permitted only trained personal.

y Be careful on operation, fingers, hair, clothes, jewellery, etc. may be caught

by and get into rotating axles.

Operators Manual

ALS 230

Release 11/05 Page 24 Operation

4.2 Inserting label material

Attention:

• Before threading the new material, the waste paper should be removed.

CAUTION! - Isertion/exchange of material should be carried out only by

especially instructed personal.

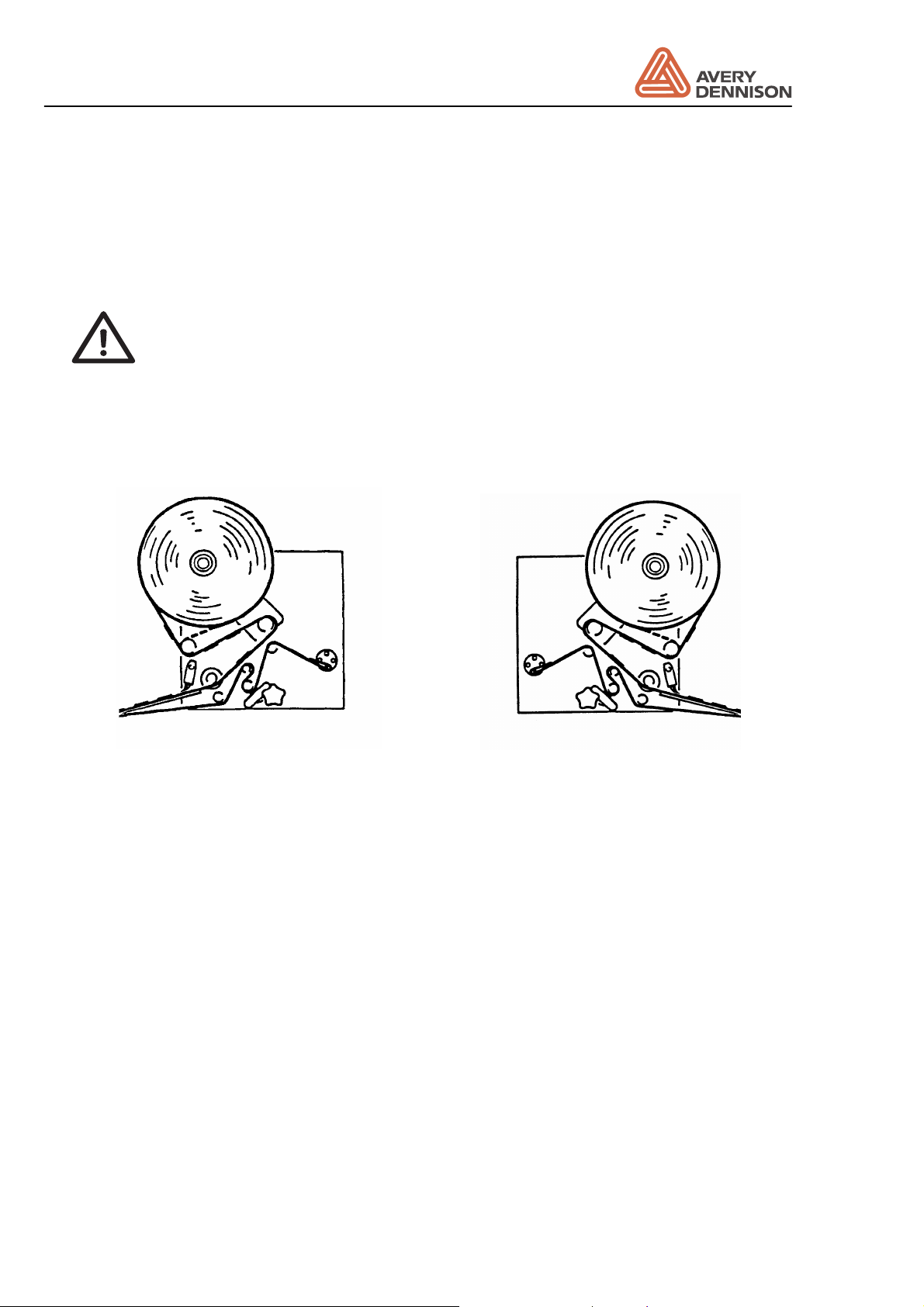

Threading of the label material is shown down below on the threading diagrams for the

right-hand and the left-hand version.

left hand version right hand version

Figure 7 Threading diagram

y Hang document material in reel holder in a way to ensure unwinding that label in the printer

section is on the top. Put outer guide disk onto mandrel. The two guide plates keep the label

roll reliably in position on the unwind mandrel.

y Guide material around the dancer arm.

y Labels behind the dispensing edge should be removed. The material brush has to be

positioned in a way, that the material is kept tight. From time to time, it is recommended to

reverse the mounting of the brush while you are loading a new label roll.

y Adjust the pressure roller before the rewind, so that it is right in the middle of the material.

Close the pressure roll and turn the roll 2 or 3 times, so that the material is threaded. Check

that the material is guided straight.

y Check correct position of the label sensor.

Loading...

Loading...