Page 1

aprilia part# 8202099

First edition: november 1997

structions required for normal use and maintenance of

your vehicle.

For controls and check-ups that cannot be carried out

easily with the standard equipment supplied, we advise

you to consult our Dealers who can assure you of quick

and careful servicing.

To keep your aprilia vehicle always in perfect operating

conditions, we advise you to insist on Original Spares

and to have repairs carried out only by aprilia Authorized Outlets and Official Dealers.

When ordering spare parts from the Dealer, always

quote the spares code which is stamped on a sticker

placed under the saddle.

It is a good idea to make a note of the identification code

in the space provided in this manual, so that you will always have a record of it even if the identification sticker

comes off

.

Reprint:

Produced and printed by:

editing division

Soave (VERONA) - Italy

Tel. +39 - 045 76 11 911

Fax +39 - 045 76 12 241

E-mail: customer@stp.it

www.stp.it

On behalf of:

aprilia s.p.a.

via G. Galilei, 1 - 30033 Noale (VE) - Italy

Tel. +39 - 041 58 29 111

Fax +39 - 041 44 10 54

www.aprilia.com

This manual contains all the main information and the in-

aprilia CODICE RICAMBI spare parts code number

ABCDE

N°

IUKA PSFB D F E

GR NL CH DK J SGP PL IL ROK

MAL RCH BM USA

All information is purely indicative and may be subject to

variation without notice

I.M.

.

1

Page 2

Carefully observe the instructions preceded by the following warning signs:

Safety norms and regulations to protect the

driver and other people from severe injuries

or grave risks

a

Indications to make the operations easier.

c

Technical information.

In this manual the various versions are indicated by the

following symbols:

catalytic version

2

Italy version

I

United Kingdom version

U

Austria version

A

Portugal version

P

Finland version

"

Belgium version

B

Germany version

D

France version

F

Spain version

E

Greece version

G

Holland version

O

2

.

Switzerland version

C

Denmark version

Japan version

J

Singapore version

S

Poland version

V

Israel version

%

South Korea version

K

Malaysia version

M

Chile version

R

Bermuda version

Q

United States of America version

-

#/.4%.43

page

Catalitic silencer

Technical data .............................................................3

Identification data ........................................................5

Controls arangement .....................................................6

Instructions for use .....................................................9

Maintenance instructions .........................................15

Periodic maintenance chart .....................................26

Lubricant chart ..........................................................27

Wiring diagram ..........................................................28

#!4!,94)#3),%.#%2

Avoid parking the vehicle catalytic version

near dry brush wood or in places easily ac-

a

becomes extremely hot during use; be very careful

and avoid any kind of contact before it has completely cooled down.

The catalytic Amico 50 is fitted with a silencer with metal

catalytic converter of the "platinum-rhodium bivalent"

type. This device provides for the oxidation of the CO

(carbon monoxide) and of the HC (unburned hydrocarbons) contained in the exhaust gases, changing them

into carbon dioxide and steam, respectively.

Due to the catalytic reaction, the high temperature

reached by the exhaust gases makes for the burning of

the oil particles, thus keeping the silencer clean and

eliminating the exhaust fumes.

cessible to children, as the catalytic silencer

.....................................................2

2

2

Page 3

To have the catalytic converter function correctly and for

long and to reduce possible problems regarding the soiling of the thermal unit and of the exhaust, it is necessary

to avoid covering long distances with the engine running

at constantly low rpm.

It is sufficient to alternate these periods with periods in

which the engine runs at relatively high rpm, even if only

for a few seconds, but rather frequently.

What has been stated above assumes particular importance for the cold starting of the engine: in this case, in

order to reach a rpm regime sufficient to enable the

"priming" of the catalytic reaction, just make sure that the

temperature of the thermal unit has reached at least

50°C, which generally occurs a few seconds after starting the engine.

Do not use leaded petrol, since it causes the

destruction of the catalytic converter.

a

4%#(.)#!,$!4!

-/4/2

Model ................................................................... aprilia

.....................................2-stroke single-cylinder

Type

Cylinder .............................................................cast iron

Bore / stroke ...................................... 40 mm e 39,2 mm

Compression ratio ................................................... 13:1

Displacement ...................................................... 49 cm³

Starting ................................................................electric

Gearbox ..........................................automatic converter

Transmission oil capacity................................... 110 cm³

42!.3-)33)/.

Primary ............................................................... “V'' belt

Secondary ............................................... reduction gear

Variator ....................................................................3YJ

)'.)4)/.

Typ ..................................................................electronic

Spark advance .........................14° at 5000 rpm 1,4 mm

Spark plug ................................................ NGK BR7 HS

#!2"52%44/2

Model ............... Dell’Orto PHBN 12 (TEI KEI TK12Y12)

with lamellar inlet

with belt drive

before T.D.C.

3

Page 4

&5%,3500,9

Fuel .................... premium grade petrol (4 Stars U)

according to the DIN 51 600

standard, min. O.N. 98 (N.O.R.M.)

and 88 (N.O.M.M.)

2 ........................... unleaded petrol according

Fuel

to the DIN 51 607 standard,

min. O.N. 95 (N.O.R.M.)

and 85 (N.O.M.M.)

Fuel tank capacity ................................................... 7,5 L

Mixer oil tank capacity ............................................. 1,3

of wich 2 L reserve

&2!-%

Type ...................... split single beam tubular steel frame

3530%.3)/.3

Front .......................................... fork with articulated rod

Rear ...............................hydraulic monoshock absorber

"2!+%3

Front ....................................................... disc Ø 155 mm

Rear .......................................shoe brake Ø 110x25 mm

with hydraulic control

with mechanical control

492%3

– Front ........................................................ 100/90×10”

Inflation pressure ............................170 kPa (1,7 bar)

– Rear ......................................................... 100/90×10”

Inflation pressure ............................190 kPa (1,9 bar)

with passenger.................................210 kPa (2,1 bar)

2)-3

Front ................................................ 2,50×10” light alloy

Rear ................................................. 2,50×10” light alloy

L

%,%#42)#3934%-

Front lights .......................................................12V 15W

Front lights

Front parking light

(not provided in the

Rear light/stop light ......................................12V 5/21 W

Turn indicators .................................................12V 10W

Dash board light ................. 5×12V 2W (warning lights);

Light for tool case/helmet case .......................12V 1,2W

Battery ..............................................................12V 4Ah

Fuse......................................................................... 7,5A

C............................................12V 35/35W

O versions).....................12V 3 W

3×12V 1,2W - 1×12V 2W

$)-%.3)/.3

Length ..............................................................1780 mm

Width ............................................ 690 mm (handle bar)

Height ................1060 mm (handle bar); 760 mm (seat)

Centre to centre distance ................................1240 mm

Weight without fuel and oil .....................................71 kg

4

Page 5

)$%.4)&)#!4)/. $! 4!

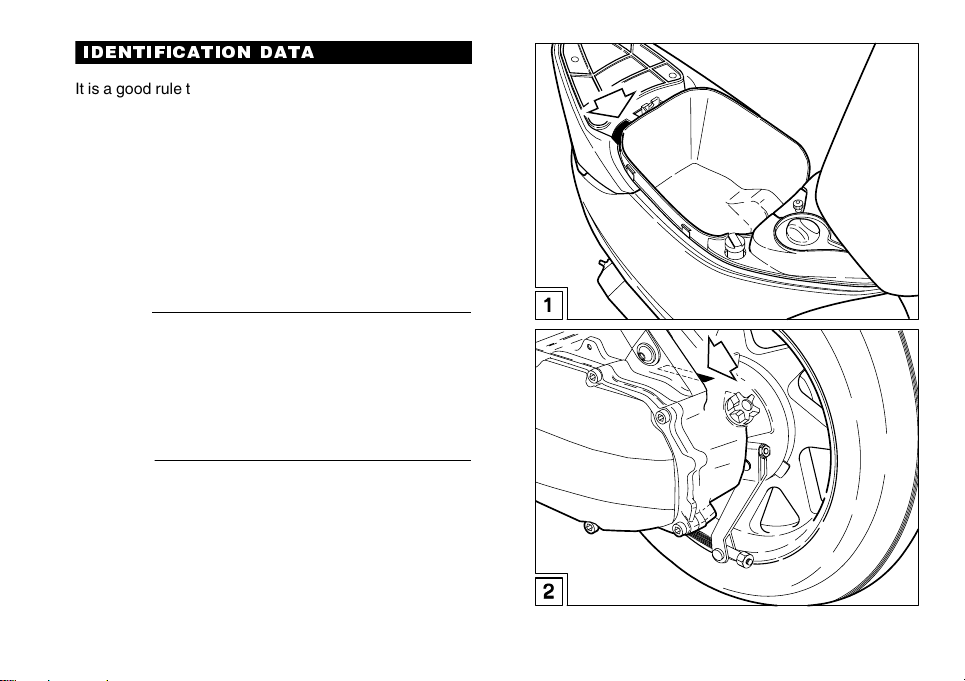

It is a good rule to write down the frame and engine numbers in the space provided in this manual.

Do not al ter the identification numbers if you

c

ministrative sanctions.

FRAME NUMBER (Fig. 1)

The frame number is stamped on the frame. To be able

to read it, it is necessary to raise the saddle (1).

Frame no.

ENGINE NUMBER (Fig. 2)

The engine number is stamped on the lower support of

the rear shock absorber.

Engine no.

do not want to incur severe penal and ad-

5

Page 6

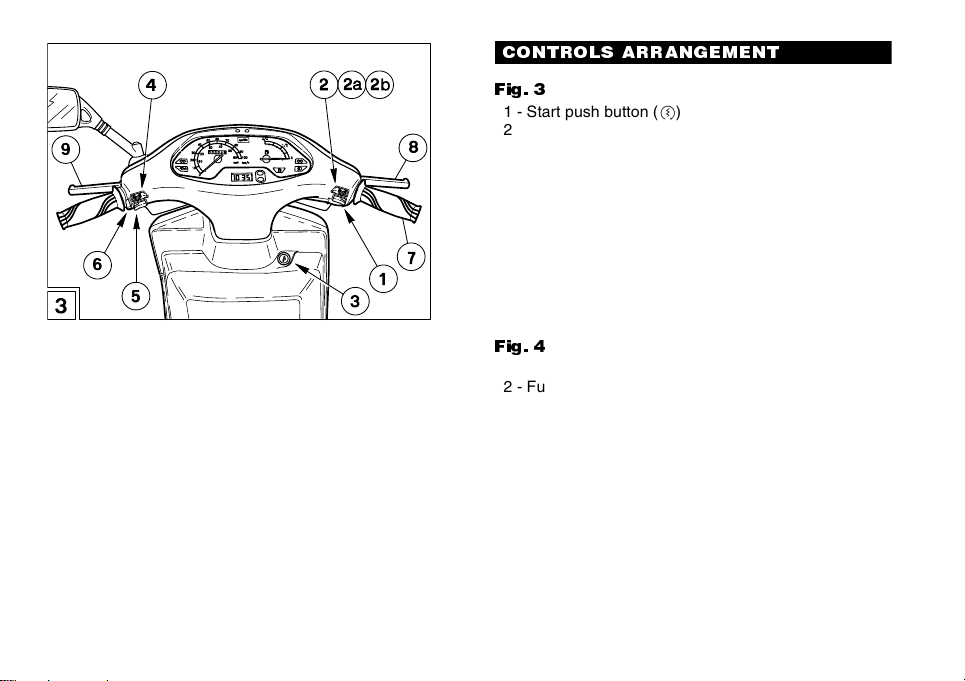

#/.42/,3 !22 !.'%-%.4

&IG

1 - Start push button (r)

2 - Lights switch (

2a - Lights switch (

2b - Lights switch (a - b - •)

3 - Ignition block/steering lock switch (n - m - s)

4 - Turn indicators switch (

5 - Horn push button (

6 - Cold start lever (

7 - Thraottle grip

8 - Front brake lever

9 - Rear brake lever

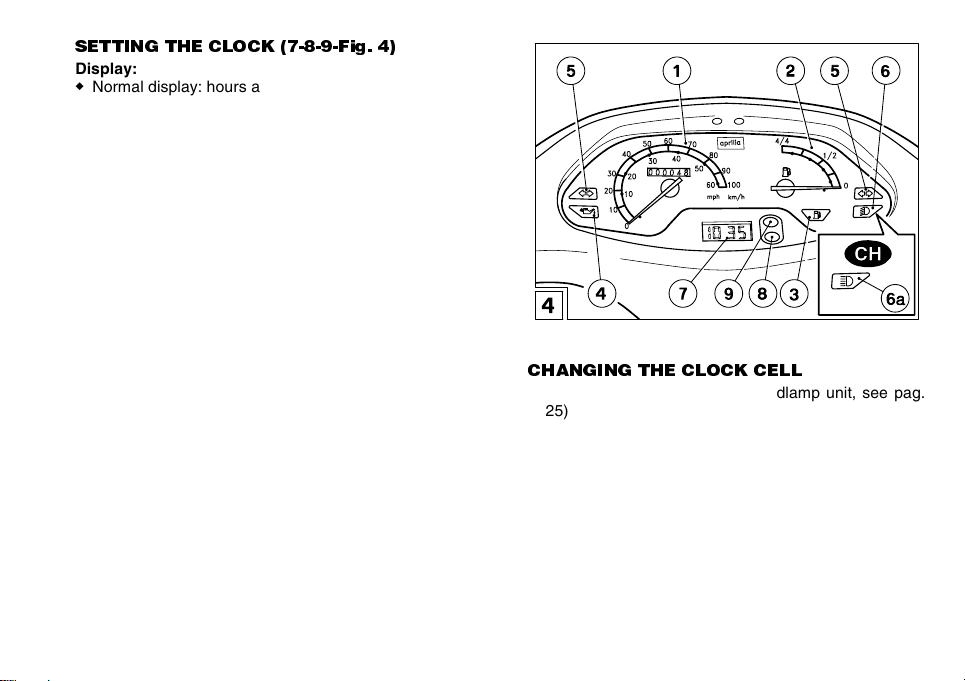

&IG

1 - Speedometer / Odometer

2 - Fuel level indicator (

3 - Fuel reserve warning light (

4 - Mixer oil reserve warning light (

5 - Turn indicators warning light (

6 - Low beam warning light (

6a - High beam warning light (

7 - Digital clock

8/9 - Clock adjustment and functions selection push

buttons

Remember: 1 mile = 1.6 km

c

b - p - •)

b - •)

O

C

c)

f)

e)

g)

g)

b)

a)

1 km = 0.625 miles

j)

c)

C

6

Page 7

3%44).'4(%#,/#+&IG

Display:

◆

Normal display: hours and minutes.

◆

Date display: press (9) once to display the month and

date.

◆

Seconds display: press (9) twice to display the sec-

onds.

Setting

◆

Press (8) once, the date and time will be displayed alternately.

◆

Month: press (8) again and the month will appear on

the right (the rest disappears), press (9) to obtain the

desired month.

◆

Date: press (8) again and the date will appear on the

right. Press (9) to obtain the desired date.

◆

Hours: press (8) again and the hour will appear on the

left with the letter “A” or “P” (“A” = a.m., “P” = p.m.).

Press (9) to obtain the desired hour.

◆

Minutes: press (8) again and the minutes will appear

on the right of the display.

Press (9) to obtain the desired minutes

◆

The clock is now set.

Press (8) again to return to normal operation.

#(!.').'4(%#,/#+#%,,

◆

Remove the front grille and headlamp unit, see pag.

25).

◆

Remove the clock support from the rear of dashboard,

acting on the snapcouplings.

◆

Extract the clock and change the cell.

7

Page 8

&IG

1 - Fuel tank plug

2 - Mixer oil tank plug

3 - Tool case/helmet case

&IG

1 - Central stand

2 - Starter pedal

3 - Case

4 - Case lock

5 - Seat lock

6 - Carrier/handle

,/#+3

The key provided starts the engine, operates the steering lock (3-Fig. 3), the luggage case lock (4-Fig. 6) and

the saddle lock (5-Fig. 6).

To operate the steering lock, turn the han-

c

and turn it to “

dlebars to the left, press the key, pull it up

s” position, then extract the key.

8

Page 9

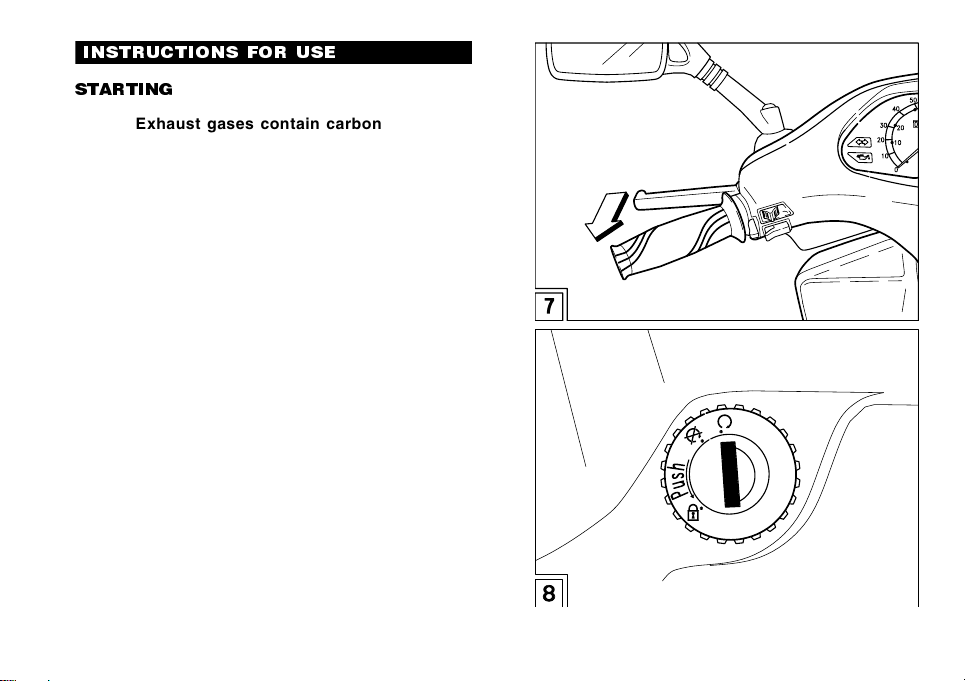

).3425#4)/.3&/253%

34!24).'

Exhaust gases contain carbon monoxide,

which is extremely noxious if inhaled.

Avoid starting the vehicle in closed or badly-

a

ventilated rooms.

The non-observance of this warning may cause loss

of consciousness or even lead to death by asphyxia.

Do not get on the vehicle for the starting.

Electric starting

◆

Position the vehicle on the stand.

◆

Lock at least one wheel, by pulling a brake lever (Fig.

7). If this operation is not carried out, the start relay receives no current and therefore the engine does not

start.

◆

Turn the ignition switch (Fig. 8) to position "n".

9

Page 10

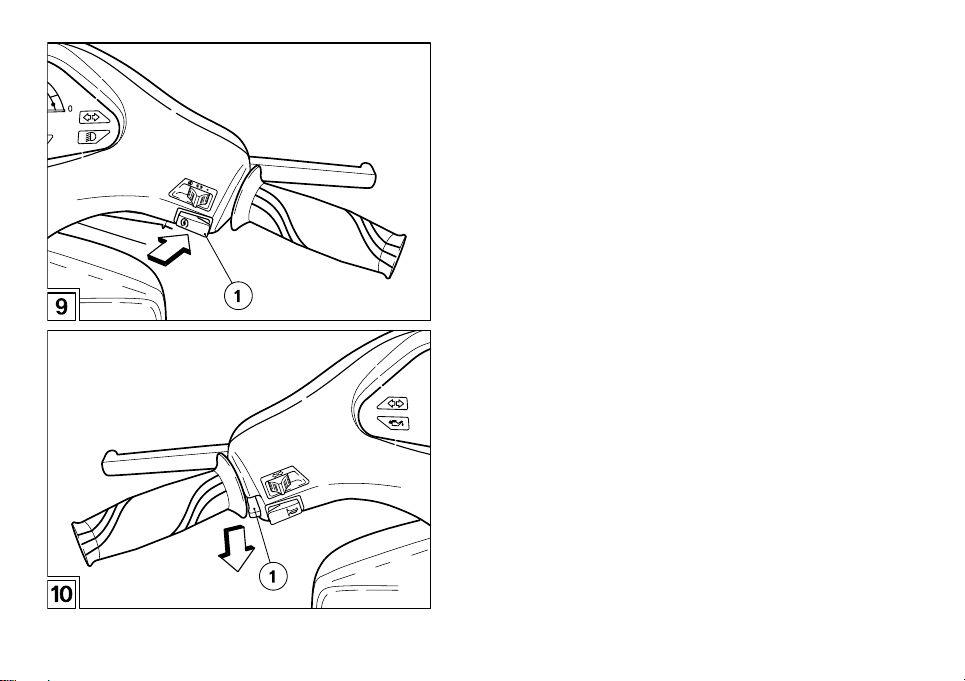

◆

Press the start push button “r” (1-Fig. 9) without accelerating, then release it as soon as the engine starts.

10

Avoid pressing the start push button "

(3) when the engine is running: this may

damage the starter.

a

When the start push button "

stroke oil reserve warning light "

With the engine in running condition, when the start

push button "

warning light "

cur, top up the 2 stroke oil tank

◆

If the starting is carried out with cold engine, rotate the

cold start lever "

◆

Do not accelerate and pull the brake levers at the

same time until you move off.

◆

Warm the engine up before leaving.

◆

Once the engine has warmed up, rotate the cold start

lever "

r" is released, the 2 stroke oil reserve

j" must go out; if this does not oc-

e" (1-Fig. 10) downwards.

e" (1-Fig. 10) upwards.

r" is pressed, the 2

j" comes on.

.

r"

Page 11

+)#+34!24

For the kick start, proceed as follows:

◆

Position the vehicle on the centre stand.

◆

Move to the left side of the vehicle.

◆

To avoid losing control of the vehicle during the starting, lock both wheels by putting on the brake levers

(Fig. 7).

◆

Turn the ignition switch (Fig. 8) to position "n".

Do not push down the kick starter with the

a

◆

engine on.

Push down the kick starter with your right foot, releasing it immediately.

If necessary, repeat the operation until the engine

starts.

34!24).'

!&4%2!,/.'0%2)/$/&).!#4)6)49

After a long period of inactivity, proceed as follows:

◆

Move the ignition switch (Fig. 8) to position "n".

◆

Make the starter run for about 10 seconds, in order to

ensure the filling up of the float chamber.

To start the engine:

◆

Rotate the cold start lever "e" (1-Fig. 10) downwards.

◆

Slightly open the throttle, then carry out the electric

starting procedure (or KICK START).

11

Page 12

$%0!2452%!.$$2)6%

Release the throttle grip (Pos. A - Fig. 11), put on the

rear brake, then move the vehicle down the stand.

Get on the vehicle, keeping at least one foot on the

ground in order not to lose balance.

Properly adjust the inclination of the rearview mirrors.

a

To leave, release the brake lever and accelerate by gently rotating the throttle grip (Pos. B - Fig. 11); the vehicle

will start moving.

Avoid opening and closing the throttle grip

repeatedly and continuously, so that you do

not accidentally lose control of the vehicle.

a

If you have to brake, close the throttle and put on

both brakes in order to obtain uniform deceleration,

properly exerting pressure on the braking parts.

By putting on the front brake only or the rear brake

only, you reduce the braking force considerably,

thus running the risk of locking one wheel and consequently losing grip.

Before beginning to turn, slow down or brake driving at moderate and constant speed or accelerating

slightly; avoid braking at the last moment: it would

be very easy to skid.

12

Page 13

If the brakes are operated continuously on

downhill stretches, the friction surfaces can

a

cy. Never drive with the engine off!

In case of wet ground or scarce wheel grip (snow,

ice, mud, etc.), drive slowly, avoiding sudden brakings or manoeuvres that could make you lose grip

and fall down.

Pay the utmost attention to any obstacle or variation

of the ground.

Uneven roads, rails, manhole covers, indications

painted on the road surface, building site metal

plates become rather slippery by rain. For this reason all these obstacles have to be carefully avoided,

driving smoothly and bending the vehicle as little as

possible.

Always use the turn indicators timely when you intend to change lane or direction, avoiding sharp and

dangerous movements.

overheat, thus reducing the braking efficien-

25..).').

After the first 500 kilometres, carry out the

checking operations indicated in the column

"After running-in" of the PERIODIC MAINTE-

a

NANCE CHART, see p. 26, in order to avoid hurting

yourself or other people and/or damaging the vehicle.

The running-in of the engine is primary to ensure its correct functioning and its correct functioning.

If possible, drive on hilly roads and/or roads with many

bends, so that the engine, the suspensions and the

brakes undergo a more effective running-in.

For the first 500 km, keep to the following indications:

0-300 km

Do not keep the throttle grip open more than one half for

long stretches.

300-500 km

Do not keep the throttle grip open more than threefourths for long stretches.

Remember: 1 mile = 1.6 km

c

1 km = 0.625 miles

13

Page 14

34/00).'!.$0!2+).'&IG

◆

Release the throttle grip and stop the vehicle by

putting on the brakes.

◆

Move the ignition switch to position "m".

14

c

automatic closing system.

0/3)4)/.).'4(%6%()#,%

/.4(%34!.$&IG

lay it on the ground.

Make sure that the vehicle and especially its red-hot

parts do not represent a danger for persons and

children.

Do not leave the vehicle unattended when the engine is on or the key is inserted into the ignition

switch.

Do not sit on the vehicle when the stand is down.

Seize the vehicle using the rear grab rail and at the

same time push the stand lever downwards (see figure).

Make sure that the vehicle is resting firmly.

It is not necessary to close the fuel tap when

the engine is off, since it is equipped with an

Park the vehicle on firm and flat ground, to

prevent it from falling down.

Neither lean the vehicle against walls, nor

a

Page 15

-!).4%.!.#% ). 3425#4)/.3

&2/.4"2!+%&IG

This vehicle is provided with front hydraulic disc brake.

When the disc pads wear out, the level of the fluid decreases to automatically compensate for their wear.

Periodically check the brake fluid level in the tank and

the wear of the pads, see p. 18 (CHECKING THE PAD

WEAR).

2%!2$25-"2!+%

The brakes are the parts that most ensure

your safety and for this reason they must always be perfectly working.

a

ADJUSTING THE BRAKE

◆

Measure the distance covered by the lever (9-Fig. 3)

before the brake starts it braking action.

The idle stroke at the end of the brake lever must be

about 5 ÷ 10 mm.

◆

Adjust the clearance by acting on the adjuster

(1-Fig. 15).

◆

Put on the brake (9-Fig. 3) repeatedly and make sure

that the wheel turns freely after the brake has been released.

◆

Check the braking efficiency.

For any doubt regarding the perfect functioning of the braking system and in case

you are not able to carry out the usual

a

checking operations, contact your

Dealer.

APRILIA

Official

15

Page 16

$)3-!.4,).'4(%&2/.47(%%,

&IG

◆

Remove the two plastic elements (1) protecting the

stem.

◆

Unscrew the two screws (2) and remove the brake

caliper.

◆

Unscrew the nut (3).

Coppia di serraggio: 50 Nm (5 kgm).

◆

Slide the pin nut (5).

◆

Remove the wheel.

Upon reassembly position the odometer ca-

c

ble (4) correctly.

!$*534).'4(%!##%,%2!4)/.'2)0

&IG

Adjust the play on the accelerator via the appropriate

tightener on the carburettor.

To access the carburattor:

◆

Remove the screw (1).

◆

Pull the tool-helmet, compartment after disconnecting

the compart- ment lighting cable.

16

Page 17

2%-/6).'4(%2%!27(%%,&IG

Before carrying out the following operations, let the engine and the silencer cool

down until they reach room temperature, in

a

order to avoid burns.

◆

Position the vehicle on the centre stand.

◆

Unscrew and remove the two screws (1) and (2).

◆

Slacken the two screws that hold the exhaust silencer

to the cylinder (access through the battery compartment)

◆

Remove the silencer (4).

Upon reassembly, change the exhaust man-

c

ifold-silencer seal.

◆

Put on the rear brake (9 - Fig. 3) to lock the wheel.

◆

Unscrew and remove the wheel nut (3) and the washer.

Upon reassembly, change the wheel nut

c

(special type).

Wheel nut driving torque: 110 Nm (11 kgm).

◆

Withdraw the wheel.

17

Page 18

#(%#+).'4(%3(/%7%!2&IG

Check the wear of the rear brake shoes after the first

500 km and successively every 4000 km.

Remember: 1 mile = 1.6 km

c

To check the wear of the rear brake shoes, proceed as

follows:

◆

Remove the rear wheel, see p. 17 (REMOVING THE

REAR WHEEL).

◆

To check the thickness of the friction material, which

must never be less than 1 mm (Fig. 19).

1 km = 0.625 miles

If the minimum allowed limit has been

reached, if you notice any irregularity in the

operation or if any part is damaged, contact

a

your

APRILIA

changing the brake shoes.

#(%#+).'4(%"2!+%0!$7%!2

Check the brake pad wear after the first 500 km and successively every 2000 km.

c

The wear of the brake pads depends on the use, on the

kind of drive and on the road. The wear will be greater

when the vehicle is driven on dirty or wet roads.

To carry out a rapid checking of the wear of the front

pads, proceed as follows:

◆

Position the vehicle on the centre stand.

◆

Remove the brake caliper cover.

◆

Carry out a visual checking of the friction material

thickness by looking between the brake caliper and

the pads.

If the thickness of the friction material (even of one pad

only) has reduced to about 1 mm, replace both pads.

c

Official Dealer, who will provide for

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

Have the pads changed by your

cial Dealer.

APRILIA

Offi-

18

Page 19

'2%!3).'4(%2%!2"2!+%#!-0).

&IG

c

this operation must be carried out more frequently.

◆

◆

bruise your hands and fingers.

◆

◆

◆

the pin seat with grease.

Grease the rear brake cam pin every 4000

km. If the vehicle is used on dusty roads,

Remember: 1 mile = 1.6 km

c

Disassemble the rear wheel, see p. 17 (REMOVING

THE REAR WHEEL (Fig. 18)).

Unscrew and remove the adjuster (1-Fig. 15).

Do not dirt the shoes and the friction material with grease, to avoid compromising the

braking efficiency of the vehicle.

a

This operation may be difficult because the

springs resist considerably to the removal

of the shoes. Be careful not to crush or

a

Grasp the inner edge of the two friction elements (1)

at its centre and, pulling toward yourself, shake the

two shoes, thus releasing them.

Loosen the nut (2) and remove the pin lever (3).

Withdraw the cam pin (4).

Moderately grease only the central part of

the pin.

Avoid dirting the cam or the areas around

a

1 km = 0.625 miles

◆

Grease the central part of the pin by using grease for

kinematic motions, see p. 27 (LUBRICANT CHART).

Upon reassembly:

Neither strike, nor force the cam pin (4) with

hammers or others tools, in order not to

damage the two O-rings.

a

◆

Manually insert the cam pin (4), rotating and pushing it

slightly.

Make sure that the springs are correctly

coupled.

a

19

Page 20

2%-/6).'!.$#,%!.).'

4(%!)2&),4%2

Remember: 1 mile = 1.6 km

c

Check the conditions of the air cleaner and clean it

monthly or every 4000 km, depending on the conditions

in which the vehicle is used.

If the vehicle is used on dusty or wet roads, the cleaning

operations and any replacement should be carried out

more frequently.

◆

Position the vehicle on the stand.

◆

To remove the left side panel of the vehicle.

◆

Unscrew the four screws.

◆

Remove the filter case cover and extract the filtering

element.

◆

To clean the filtering element use clean, non-inflammable solvents or solvents with high volatility point,

then let it dry thoroughly.

◆

Apply a filter oil or a thick oil (SAE 80W-90) on the

whole surface of the filtering element, then squeeze it

to eliminate the oil in excess.

The filter must be well impregnated, though

c

not dripping.

1 km = 0.625 miles

30!2+0,5'&IG

Periodically remove the spark plug and clean it carefully,

removing carbon deposits; change it if necessary.

To remove and clean the spark plug:

◆

Remove the engine compartment cover.

◆

Take off the spark plug cap.

◆

Remove all the dirt from the base of the spark plug,

then unscrew it with the spanner you will find in the

tool kit and extract it from its seat, taking care that neither dust nor other substances enter the cylinder.

◆

Make sure that there are neither carbon deposits, nor

corrosion marks on the electrode and on the central

porcelain part; if necessary, clean them with the special cleaners for spark plugs, with an iron wire and/ or

a metal brush.

◆

Energetically blow some air, in order to prevent the removed residues from getting into the engine.

If the spark plug has crackings on the insulating material, corroded electrodes or excessive deposits, it

must be changed.

20

Page 21

◆

Check the spark plug gap with a thickness gauge.

The gap must be 0,5

carefully bending the earth electrode.

◆

Make sure that the washer is in good conditions.

◆

With the washer on, screw the spark plug by hand in

order not to damage the thread.

◆

Tighten the spark plug by means of the spanner you

will find in the tool kit, giving it half a turn to compress

the washer.

◆

Position the spark plug cap.

◆

Put back the engine compartment cover.

÷ 0,6 mm; if necessary adjust it,

The spark plug must be well tightened,

otherwise the engine may overheat and

a

be seriously damaged.

Change the spark plug every 8000 km.

Use the recommended type of spark plug only,

see p. 3 (TECHNICAL DATA), in order not to

compromise the life and performance of the

engine.

21

Page 22

22

"!44%29&IG

Remember: 1 mile = 1.6 km

c

Check the electrolyte level and the tightening of the terminals after the first 500 km and successively every

4000 km or 8 months

The electrolyte in the battery is toxic and

caustic and if it gets in contact with the skin

it can cause burns, since it contains sulphu-

a

ric acid.

Wear protection clothes, a face mask and/or goggles

during maintenance operations.

In case of contact with the skin, rinse with plenty of

water.

In case of contact with the eyes, rinse with plenty of

water for 15 minutes, then consult an oculist without

delay.

If the electrolyte is accidentally swallowed, drink a

lot of water or milk, then continue drinking milk of

magnesia or vegetable oil and consult a doctor without delay.

The battery gives off explosive gases; keep it away

from flames, sparks, cigarettes and any other

source of heat.

During the recharging or the use, make sure that the

room is properly ventilated and avoid inhaling the

gases released during the recharging.

1 km = 0.625 miles

.

Page 23

Never invert the connection of the battery

cables.

Do not incline the vehicle too much, in order

a

to avoid dangerous leaks of the battery fluid.

KEEP AWAY FROM CHILDREN

Connect and disconnect the battery with the

ignition switch in position “

Connect first the positive cable (+) and then

a

the negative cable (–).

Disconnect following the reverse order.

To check the battery (1), remove the engine compartment cover.

Make sure that the fluid level is included between the

two "MIN" and "MAX" notches stamped on the battery

side.

If necessary, top up by adding distilled water.

To recharge, disconnect the cables, extract the battery

from its container and remove the element plugs.

A recharge with an amperage equal to 1/10th of the battery capacity is recommended.

After the recharging operation, check the electrolyte level again and if necessary top up with distilled water.

Tighten the element plugs.

Always connect the battery breather pipe, to

prevent the sulphuric acid vapours from

corroding the electric system, painted parts,

a

rubber elements or gaskets when they exit the

breather pipe itself.

m”.

,/.').!#4)6)49/&4(%"!44%29

If the vehicle remains unused for a long period, remove

the battery and place it in a cool and dry place.

Recharge it completely, by using a trickle charge.

If the battery remains on the vehicle, disconnect the cables from the terminals.

It is important to check the charge periodically (about

once a month), during the winter or when the vehicle remains unused, in order to prevent the deterioration of the

battery.

23

Page 24

#(!.').'4(%&53%&IG

Do not repair faulty fuses.

Never use fuses different from the recommended ones.

a

The use of unsuitable fuses may cause damages to

the electric system or, in case of short circuit, even a

fire.

If an electric component fails to work, the fuse must be

checked (2).

In this case it must be changed with another with the

same amp value.

If the fuse cuts out again there is probably a short circuit

in the electric system and it is advisable to consult an

aprilia Official dealer.

!$*534).'4(%(%!$,!-0"%!-

&IG

The headlamp beam may be adjusted by turning the

screw provided with a screwdriver (1).

24

Page 25

#(!.').'4(%"5,"3).4(%

(%!$,!-0!.$&2/.4$)2%#4)/.

).$)#!4/23&IG

By slackening the two screws (2-3-Fig. 23) the two side

covers of the direction indicators may be removed and

the headlamp reflector unit released.

Access is thus obtained to the two bulbs of the direction

indicators.

The front grille and headlamp unit must be dismantled so

as to change the headlamp bulbs.

Access to the bulbs may be gained from behind the reflectors.

To remove them unscrew the 2 central screws (4-Fig.

24) the 2 screws at the side (1-2-Fig. 24), the screw at

the front (4-Fig. 23) and release the 8 clips (3-Fig. 24).

Proceed with care.

Do not damage the tangs and/or their seats.

Handle the painted components with care

a

and avoid scraping or damaging them.

Upon reassembly, correctly position the

c

base (5) of the rear mirror.

#(!.').'4(%"5,"3).4(%2%!2,!-0

!.$2%!2$)2%#4)/.).$)#!4/23

&IG

Unscrew the two screws (1).

In this way the 3 transparent covers (2-3) are removed

and the bulbs are accessible.

25

Page 26

0%2)/$)#-!).4%.!.#%#(!24

Cheking operations

Clean and check spark plug ★★

Clean air filter

Check and adjust idling ★★

Check fuel pipes

Check drive oil level change

Check the mixer oil check every 500 km

Check op. mix pump and air bleeding

Check op. brakes and shoe wear

Greasing the rear brake cam pin

Checking the brake pad wear

Brake liquid periodically check change every year

Check driving belt wear

Check wheel bearings

Check adjustment of steering bearings

Check battery electrolyte level ★

Check tyre wear

Check tyre pressure every month

Check wheel alignment

Check tightness of nuts and bolts

Check rear shock absorber ★

Checking moving parts on front suspension

Cleaning scale from exhaust terminal ★

If the conditions of use are particularly severe, more frequent maintenance is advised.

After running in 500 km Every 4000 km Every 8000 km Notes

★

★

★

★★

★★

★

★

★

★★

★

★★

★

★★

★

every 2000 km

★

change every

12000 km or 2 years

26

Page 27

,5"2)#!.4#(!24

Transmission oil (recommended): 0 F.C., SAE 75W - 90.

As an alternative to the recommended oil, it is possible to use high-quality oils with characteristics in compliance with or

superior to the A.P.I. GL4 specifications.

Mixer oil (recommended):

Use high-quality oils with characteristics in compliance with or superior to the ISO-L-ETC++, A.P.I. TC++ specifications.

Fork oil (recommended):

If you need an oil with intermediate characteristics in comparison with the two recommended products, these can be

mixed as indicated below:

SAE 10W

SAE 15W

Bearings and other lubrication points (recommended):

As an alternative to the recommended product, use high-quality grease for rolling bearings, working temperature range

-30°C…+140°C, dripping point 150°C…230°C, high protection against corrosion, good to water and oxidation resistance.

Protection of the battery poles: neutral grease or vaseline.

Spray grease for chains (recommended):

Brake fluid (recommended):

F.A. 5W 67% of the volume, + 0 F.A. 20W 33% of the volume.

0

F.A. 5W 33% of the volume, + 0 F.A. 20W 67% of the volume.

0

Use new brake fluid only.

GREEN HIT.

0

F.A. 5W or 0 F.A. 20W fork oil.

0

CHAIN SPRAY.

0

F.F., DOT 5 (DOT 4 compatible).

0

AUTOGREASE MP.

0

a

Engine coolant (recommended):

Use only antifreeze and anticorrosive without nitrite, ensuring protection at -35°C at least.

a

ECOBLU -40°C.

0

27

Page 28

7)2).'$)!'2!-!-)#/

28

Page 29

7)2).'$)!'2!-+%9!-)#/

1) Generator

2) CDI

3) Spark plug

4) H.T. coil

5) Voltage regulator

6) Battery

7) Starter

8) Start relay

9) Front stoplight switch

10) Rear stoplight switch

11) Mixer oil reserve switch

13) Fuel level sensor

14) Right rear turn indicator

15) Rear light

16) Left rear turn indicator

17) Dip switch

18) Turn indicator switch

19) Ignition switch

20) Control diode

21) Crash helmet compartment light

22) Blinking

23) Dashboard

24) Turn indicator warning light

25) Mixer oil reserve warning light

26) Dashboard light

27) Fuel level indicator

28) Low fuel warning light

29) Low beam warning light

30) Crash helmet compartment light switch

31) Front right turn indicator

32) Front left turn indicator

33) Front parking light

(not provided in the

34) Low beam

35) Horn

36) Pick up

37) Fuse

38) Multiple connectors

39) START push button

40) Horn push button

42) Low/High beam

#!",%#/,/523

Ar Orange

Az Light blue

B Blue

Bl White

G Yellow

Gr Gray

M Brown

N Black

R Red

V Green

Vi Violet

O version)

29

Page 30

)MPORTERS

APRILIA MOTO U.K. LTD.

DUNRAGIT

STRANRAER

WIGTOWNSHIRE DG9 8PN

SCOTLAND (UK)

TEL. (1581) 400660

FAX (1581) 400661

IDEAL MOTOR SPORT PTE LTD.

18, HOWARD ROAD

1336 SINGAPORE (SGP)

TEL. 2820082

FAX 2821012

AVIRAM & GOLDMAN IMPORT & MARKETING CO. LTD.

21, TUSHIA STREET

61572 TEL-AVIV

P.O. BOX 57266

ISRAEL (IL)

TEL. (3) 5623951

FAX (3) 5623950

!3+&/2'%.5).%30!2%0!243/.,9

30

Page 31

./4%

31

Page 32

32

aprilia s.p.a. wishes to thank its customers for the purchase of this vehicle.

- Do not dispose of oil, fuel or polluting substances and components in the environment.

- Do not keep the engine running if it isn’t necessary.

- Avoid troublesome noises.

- Respect nature.

Loading...

Loading...